Page 1

INSTRUCTIONS FOR THE VM10FS & VM15FS

G

11/20/2006 - VM10FS Instructions.cdr

Place your two VCA6 connectors under the

bag wherever it is most convenient for you.

Congratulations, you have just purchased the finest system ever made for VAKuum Bag Veneering & VAKuum

Klamping. This system combines the best features of both applications into one complete system.

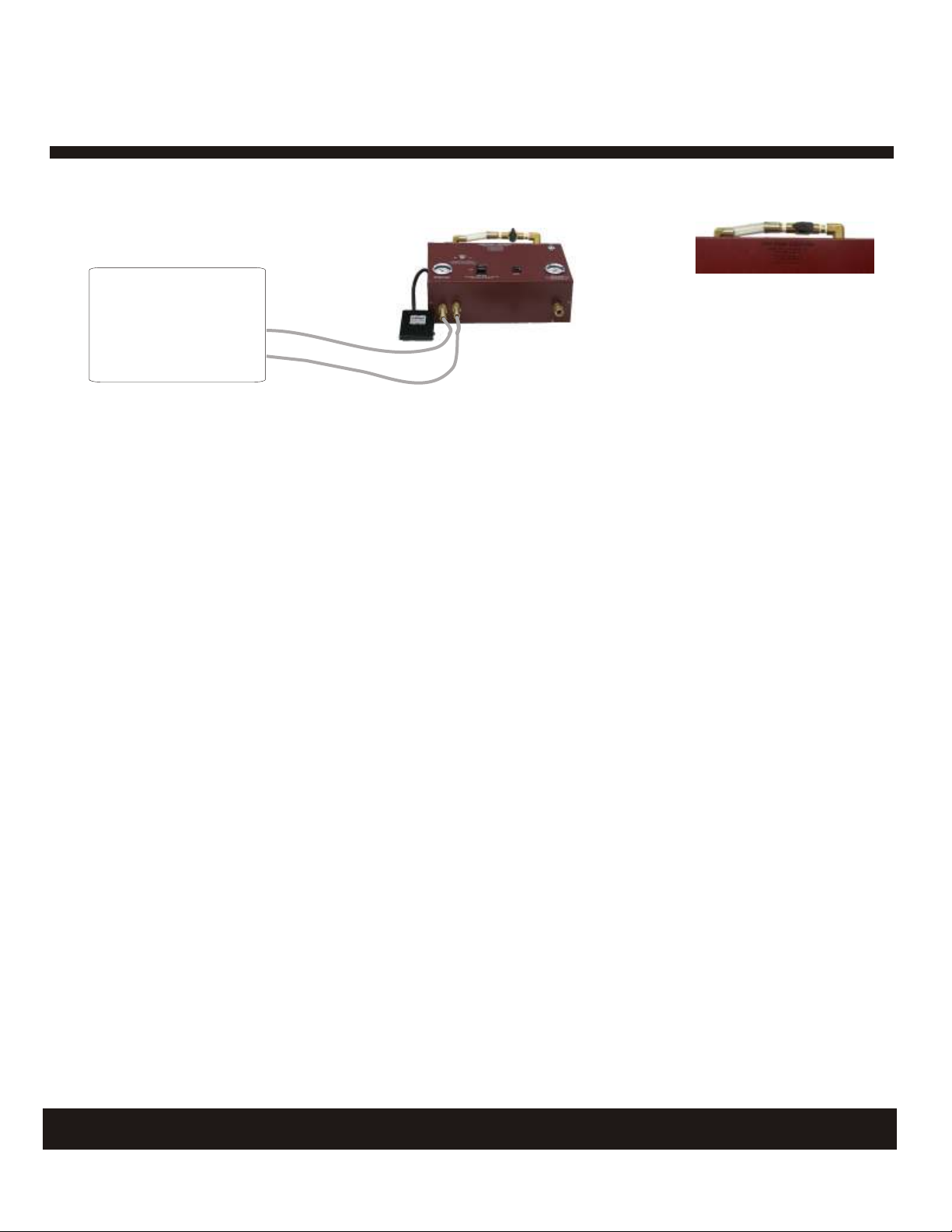

ALL-IN-ONE VAK-MATIC CONTROLLER

VAKuum Bag

or

Frame Press

Set up For

Veneering

Compressed Air

Line

V acuum Lines

Set up For

Klamping

Valve in rear of box.

Use the Y hose to connect the two vacuum barbs into one line for vacuum clamping.

The hand valve in the rear is to be closed when doing veneering. When working with vacuum jigs and fixtures,

turn the valve on (points to left) and turn the red rocker switch to VAK BAG, then step on the TOP of the foot

pedal. This will give vacuum to the jig, to release the part from the jig, step on the BOTTOM of the foot pedal.

ON/OFF SWITCH

Make sure that when you are clamping you have the red ON/OFF switch on “VAK-KLAMP.” Never have the

switch on “VAK-BAG” when you are clamping. Only use “VAK-BAG” when you are veneering.

TOGGLE SWITCH

When you are veneering, put the toggle switch to the ON position. This will make both pumps in the system

work together to evacuate the bag faster.

There are two venturi pumps inside your “VAK-MATIC” controller. When Klamping, you normally will need just

one venturi pump working. Therefore, you can put the toggle switch to the OFF position when you are

Klamping. This will reduce your compressed air usage, and make your system work more efficiently. When you

turn the toggle switch to OFF, you must use the tee and short hose set up to combine the two vacuum lines

intro one.

KEEP THE AIR PRESSURE BELOW 100PSI OR YOU WILL DAMAGE THE SOLENOID.

CALL 1-800-547-5484 TODAY!

Or visit our site at www.qualityvak.com

Quality VAKuum Products, Inc.

74 Apsley St. - Hudson, MA 01749

Tel: 978-562-4680 - Fax: 978-562-4681

Loading...

Loading...