Page 1

INSTRUCTIONS FOR ASSEMBLING

AD

11/15/12 - Frame Press Instructions.cdr REV 12

Your "Q.V .P." frame press is unique in that it has

a 6" or 24” high top. This special Gusset box top

gives over twice the height of conventional frame

presses. This means pressing more flat panels at

one time or large curved pieces can be pressed in

place. In addition, unlike others, it is made with

one piece of material with only 8" or 24”of seam

at each corner . This means less chance of failure

due to seam delamination.

Y our Frame Press Includes:

Lifters

VCA6F (VAKuum Connector

THE VAKUUM FRAME PRESS

Polyurethane 6" or 24” top

Aluminum side frames, with adhesive

tape applied.

Corner Brackets

Foam Gasket Material

Instructions

Bleeder V alve

Hinges

T oggle Clamps and screws

Assembly)

IMPORTANT: Your table top must be flat and nonporous or the frame will leak. Unlike a vacuum bag

that only has one or two short sides to seal, the frame

press has a long linear perimeter that must be sealed.

Do not be concerned if your vacuum pump cycles on

and off more often than when using a vacuum bag.

Building the T able Top

A Smooth, FLAT NONPOROUS TABLE TOP IS

ESSENTIAL IN GETTING A GOOD VACUUM

SEAL. You must spend the time to get it flat for

trouble free frame pressing.

The table top should be made from 3/4" or thicker

MDF, plywood or particle board. A single sheet is

best, however, you can splice 2 sheets together for the

larger press. Once the table top is cut to size apply a

single sheet of SMOOTH

plastic laminate to the top (NON MATTE FINISH).

This will make the top nonporous which is very

important. If you need to have a joint, apply a bead of

Silicone II to the joint and push the second piece into

the joint and wipe leaving a slight crown. A slight

hump of silicone where the gasket material touches

the seam is a better seal than a slight valley below the

gasket.

The frame should take about 1 to 2 hours to

assemble depending on its size. Building the

table can take a day or two.. The following chart

is used to size your table top.

Frame Size

I.D.

25” x 25”

54” x 54”

54” x 54”

54” x 102”

54” x 126”

54” x 126”

66” x 102”

66” x 126”

66” x 126”

If you have a special size frame press, add 2.5"

to the inside length and width to determine the

table top size.

T able Top Size

O.D.

27.5” x 27.5”

56.5” x 56.5”

56.5” x 56.5”

56.5” x 104.5”

56.5” x 128.5”

56.5” x 128.5”

68.5” x 104.5”

68.5” x 128.5”

68.5” x 128.5”

CALL 1-800-547-5484 TODAY!

Or visit our site at www.qualityvak.com

TABLE TOP

BOX FRAME

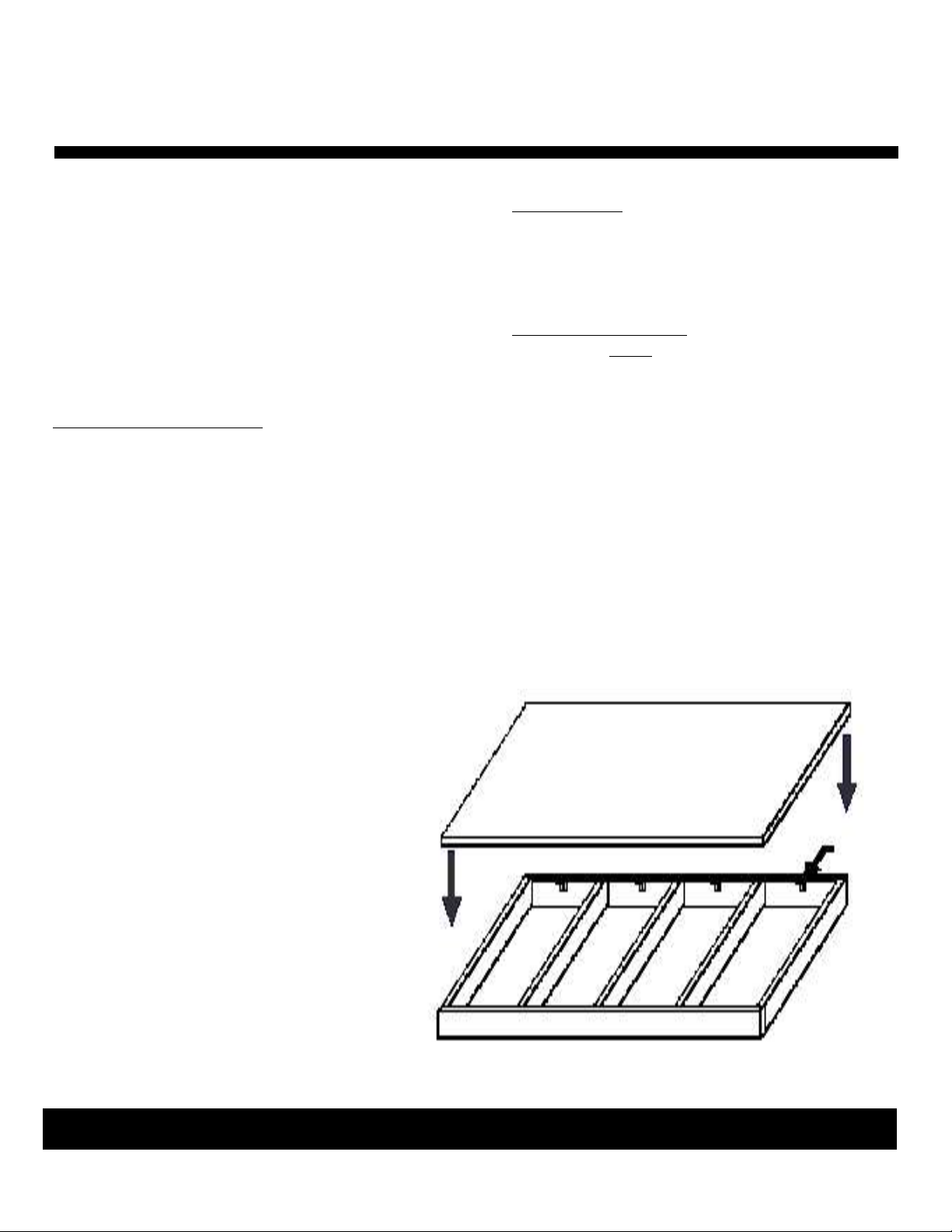

DRAWING A

Quality VAKuum Products, Inc.

BRACKETS

OVER

74 Apsley St. - Hudson, MA 01749

Tel: 978-562-4680 - Fax: 978-562-4681

Page 2

INSTRUCTIONS FOR ASSEMBLING

THE VAKUUM FRAME PRESS

7/11/12 - Frame Press Instructions.cdr Page 2

The key to the top laying flat is the box frame that

supports the top. Straight, dry 2"X6"‘s are

recommended. Joint the edges if necessary to make

them straight. Make the box as shown in DRAWING

A. Use brackets or cleats to hold the table top to the

frame box. Use short screws to attach the brackets to

the underside of the tabletop. Do not puncture the top

surface with a screw as it will cause a leak. This method

is used as it allows for shimming the tabletop to assure

flatness. Level the top with shims if necessary. This is

the most important step in building the table. If it’ s not

flat, you could have leakage. Also, if it’s cupped, you

could press a curve into your piece. Once the tabletop is

completed, it can be used to assemble the frame press.

Applying the SMOOTH Laminate

If you can, purchase a sheet of laminate that will cover

the table in one piece. If you have a seam, apply a bead

of silicone II along the joint and push the second piece

into it, thus filling the seam. Remove the excess. It’s

best to leave a slight crown at the joint rather than a

slight depression. Where the gasket material comes

down on the seal, it will seal better on a slight crown

rather than into a depression.

Assembling the Frame Press

Lay the aluminum frame pieces on the table and

assemble the joints. Place the steel corner brackets

inside the aluminum frame. Slide each joint together.

Screw the frame to the connectors with the 1/4-20

phillips head screws using the pre-drilled holes.

Assembling the T op to the Frame:

To assemble the Gusset Top to the frame, elevate the

frame 6" or more off the table with blocks with the

bottom side (tape) up. This allows you to drop the T op

inside the frame. Hold the top in place with several

spring clamps. The Top will fit inside the frame. The

2 1/2" flange from the Top should sit on the frame

without any bunching or ripples along the frame.

The top is slightly smaller than the frame to eliminate

the possibilities of wrinkles or bunching of the material.

Hold each corner with a spring clamp and make sure the

top is centered.

Note: If you didn't install the frame press when

received, you should re-etch the bag top if it's more than

one week after shipping date as per the packing slip..

Etch the bag flange (the side that will stick to the tape

on the aluminum frame) with PVC pipe cleaner.

Etching will give better adhesion.

Remove about 12" of the backing material from the tape

from the center of one end only. Press the flange in place

as you continue removing the backing from the tape. DO

NOT PRESS THE FLANGE WITH MUCH FORCE

A T THIS TIME. You may have to pull up the flange if

you did not center the top correctly . Do the same for the

other end. The long lengths should be ripple free,

remove the backing material and press the long length in

place. Again starting in the center and working toward

the end. At this point you have the bottom stuck in place.

Once the top is stuck in place, take a dowel or hard roller

and roll around the frame to press the top in place. If you

make a mistake in a short length, you can pull the top and

reset it. Now remove the paper from the side of the frame

and roll the remainder of the flange to the side. Trim

excess.

Applying the Foam Gasket T ape:

Apply the foam gasket tape, to the poly top, around the

outside edge of the bottom of the frame . Drawing B.

Remove about 12 - 18" of backing and start in the center

of the front side and work your way around the frame.

Make a smooth curve at the corners as in Drawing B.

When you come around to the beginning, run the tape to

the inside of the Foam Gasket tape just applied, thus

making the two rows parallel and tight to each other. This

will give you a long joint that will be vacuum tight.

CALL 1-800-547-5484 TODAY!

Or visit our site at www.qualityvak.com

Quality VAKuum Products, Inc.

74 Apsley St. - Hudson, MA 01749

Tel: 978-562-4680 - Fax: 978-562-4681

Page 3

INSTRUCTIONS FOR ASSEMBLING

THE VAKUUM FRAME PRESS

7/11/12 - Frame Press Instructions.cdr Page 3

Making the Baseboard

Y ou must make a baseboard or platen for inside the frame.

It is similar to the baseboard used in a vacuum bag with

saw kerfs 1/8 - 3/16' deep, every 6 to 10" in both

directions. This helps improve the seal and cuts down on

leakage problems. The baseboard dimensions should be

6" less than the inside of the frame, thus giving a

minimum 3" space Around the frame. Since it lays flat

on the tabletop, it can be anywhere from 3/8" to 3/4"

thick. You must round all the edges to eliminate all

sharp corners. Do not screw the Baseboard to your

table top, it will cause leaks, use contact cement or just

let it lay in place.

NOTE: The 3" gap between the baseboard and the

inside of the frame, helps improve the vacuum seal.

Also make sure you push the bag flat on the table

around the perimeter of the baseboard when you are

pulling vacuum. This will improve the seal and prevent

the bag from pulling off the frame.

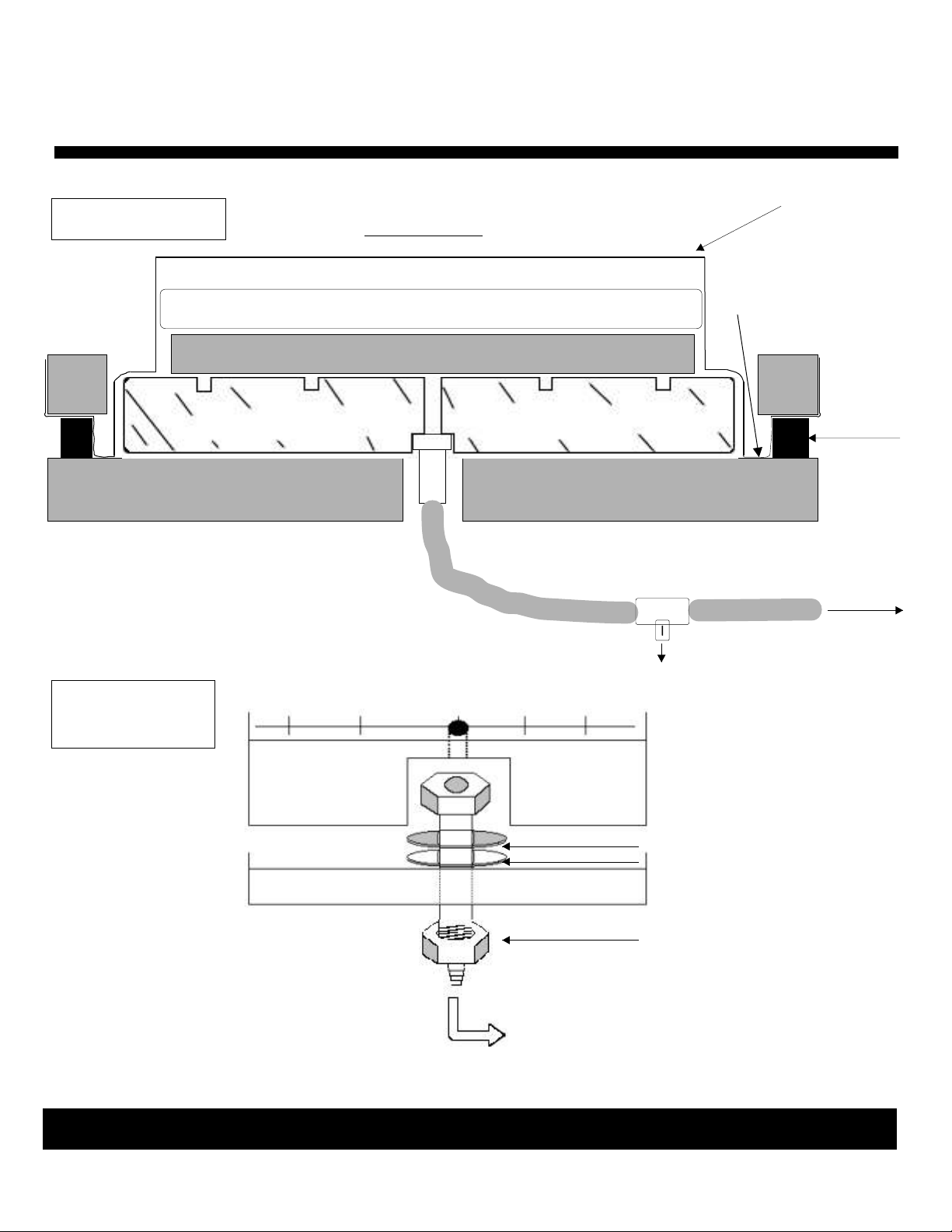

Installing the VCA6F:

You will need to install a VAKuum Connector

Assembly (VCA6F) into your table top as per Drawing

D. Drill a 3/4" hole (check the diameter of your

VCA6F) in your table where you wish to place the

VCA6F. The center of the VCA6F must be below an

intersection of the grid lines (saw kerfs) on your

baseboard.

Countersink a relief hole in the bottom of your

baseboard for the VCA6F bolt head and washers to fit

into. Depending on the thickness of your baseboard,

the top nut on the VCA6F may come completely

through the baseboard. The VCA6F must be slightly

below the baseboard. Also, never let the gusset top

cover the VCA6F as it can seal the vacuum hole.

Always have something on top of the VCA6F

(workpiece, piece of board with all edges rounded,

etc.).

If you use a thick baseboard, you will need to drill a 1/2"

hole through the baseboard that lines up with the

VCA6F. Your hole through the baseboard must be at

the intersection of a saw kerf (DRAWING D). If you

made a mistake and the VCA6F doesn't line up with a

grid line on the top of your baseboard, just cut another

grid line that connects to the existing grid and goes

across the hole.

At this point the Frame Press is ready to use. Use the

rubber snap clamps to hold the frame in place. If you

use mechanical clamps to hold the frame down, you can

have uneven pressure, this will cock the frame and

cause leakage. For those who are going to dedicate the

Frame Press to the table, attach the hinges.

Attaching the Hinges:

The bottom of the hinges have oval slots. The frame

must be able to be squashed down when under vacuum,

thus the bottom screws should be loose. Set the frame

in place on top of the table with hinges hanging down

over the back of the table. When the frame is locked in

place, the gap between the table top and the aluminum

frame should be about 3/16". Put the screws in at the

bottom of the slots, this allows the back of the press to

move down when vacuum is applied.

Warning: Do not attach the hinge at a right angle to

the table top. The frame must be able to compress

the foam, therefore, it must free to float. If the

hinge is on top of the table, the hinge knuckle will

keep the foam from compressing and pr ovide a seal

T oggle Clamps:

The toggle clamps are to help create a seal until vacuum

pressure generates enough force to maintain its own

seal. See diagram on page 7 for placement. See

diagram E for installation.

CALL 1-800-547-5484 TODAY!

Or visit our site at www.qualityvak.com

Quality VAKuum Products, Inc.

74 Apsley St. - Hudson, MA 01749

Tel: 978-562-4680 - Fax: 978-562-4681

Page 4

INSTRUCTIONS FOR ASSEMBLING

THE VAKUUM FRAME PRESS

7/11/12 - Frame Press Instructions.cdr 9/16/06 Page 4

Center the top clip on the aluminum frame (drawing E)

and drill a 5/32 hole. Use the #10 metal screws to attach

the clip to the frame. Hang the toggle on the clip. The top

holes in the toggle plate should be about in the center of

the edge of the MDF table top. Screw in place with 4

wood screws. Adjust the U clamp so that the gasket

compresses slightly and provides a good initial seal to

draw vacuum. Do not over tighten as this could cause

compression set in the gasket material. Drawing E.

Bleeder V alve

Connect the VAKuum hose to the VCA6F , then connect

the bleeder valve (Drawing C). The other side of the

bleeder valve is connected to the VAKuum hose that

goes to your vacuum pump. Just open the bleeder valve

to allow air into the frame when you want to open the

frame.

Note: If your pump does not evacuate the Frame Press

fast enough, you can attach a VAK Pump to the bleeder

valve. The VAK-Pump would only be used during the

initial pump down then could be disconnected for other

uses in the shop

Checking For Leaks:

THERE ARE FOUR SOURCES OF LEAKAGE; THE

GASKET JOINT, THE GUSSET SEAMS, THE

JOINT ON EACH SIDE OF THE FOAM GASKET

TAPE (TO THE TABLE TOP AND THE TOP) and

THE T ABLE TOP/VCA6F.

Checking the Gusset Seam

With the frame down and under vacuum, put some

water inside the frame at each corner. Start at one

corner, if it leaks at the corner seam you will see the

water, in the form of droplets, move along the creases in

the bag and along the frame.

Checking the Foam T ape

Most causes of leakage will be at the interface of the

Foam Gasket tape and tabletop. If you can’t locate the

leak by listening, spray water at the Foam Gasket seam.

Go around the table and look inside the frame for water

bubbling in. If the leak is not at the butt joint, put a C

clamp where the leak is occurring.

CALL 1-800-547-5484 TODAY!

Don’t over tighten the clamp as it could cock the frame

and cause a leak elsewhere. The table may need

shimming as a permanent fix.

Another test is to walk around the frame and press on

the frame every foot or two. Many times you will find

the spot that is not sealing and you can add a snap clamp

or C clamp at this spot.

A frame press (FP) has a very large area to

seal (up to 35') and it tends to cause the

pump to cycle on and off more often than a

bag. Under normal conditions a FP will

cycle every 3 to 5 minutes. Some have

achieved up to a 60 minute cycle by paying

close attention to details and adding a

vacuum tank.

You can improve the seal by applying a

small bead of Silicone II around the inside

edge of the gasket material. The key is not

to have it wider than 1/8” where it touches

your table top. If it's too wide, it can prevent

the gasket from compressing because the

silicone is much denser than the gasket

material. If this happens, the frame doesn't

compress evenly and you could be worse

off. Better to apply a smaller amount and

add more latter than to apply too much.

Drawing G (Page 7)

Also when applying the tape make sure to

butt the 2nd row against the 1st row. (The

gap in this drawing is only to show 2 rows.)

Drawing B

Quality VAKuum Products, Inc.

74 Apsley St. - Hudson, MA 01749

Tel: 978-562-4680 - Fax: 978-562-4681

Page 5

INSTRUCTIONS FOR ASSEMBLING

THE VAKUUM FRAME PRESS

7/11/12 - Frame Press Instructions.cdr 9/16/06 Page 5

Drawing C

Frame Top

CAUL

1 1/4“

x

1 1/4“

Frame

WORK PIECE

BASE BOARD WITH SAW CUTS

Table Table

VCA6F

6“ or 24” High Gusset

Bag Top

Press

bag flat

on table

1 1/4“

x

1 1/4“

Frame

Foam Seal

To VACUUM PUMP

Drawing D

VCA6F or VCAF

Note: If the

threads on the

VCA(6) do not drop

below the table

bottom, remove

some material from

the bottom -NOT

the TOP of the

table.

Bleeder Valve Release

Grooved

Baseboard

Metal Washer

Rubber Washer

Table Top

Nut

To VACUUM PUMP

CALL 1-800-547-5484 TODAY!

Or visit our site at www.qualityvak.com

Quality VAKuum Products, Inc.

74 Apsley St. - Hudson, MA 01749

Tel: 978-562-4680 - Fax: 978-562-4681

Page 6

INSTRUCTIONS FOR ASSEMBLING

THE VAKUUM FRAME PRESS

7/11/12 - Frame Press Instructions.cdr Page 6

Top of aluminum frame

Drawing E

Frame Top

Foam Tape

Table

Drawing F

Allen Head Screw

& Spacer

Lifter

drill a 5/32 hole

Screws Provided by QVP

Wood Screws

Frame Top

Table

Back screw hole

in lifter

Foam Tape

CALL 1-800-547-5484 TODAY!

Or visit our site at www.qualityvak.com

Quality VAKuum Products, Inc.

6 1/2"

End of table top

74 Apsley St. - Hudson, MA 01749

Tel: 978-562-4680 - Fax: 978-562-4681

Page 7

INSTRUCTIONS FOR ASSEMBLING

THE VAKUUM FRAME PRESS

11/14/12 - Frame Press Instructions.cdr Page 7

WARNING: Do not overload the Frame Press or the

force of vacuum will pull the top off the frame or bend

the frame (this is better than ripping the poly top). This

is especially true with large curved work. Close the

frame over the workpiece and pat the plastic on the 3”

space between the frame and baseboard. This prevents

the frame from being pulled in. The plastic top should

go against the workpiece and the table top with no or

very little stretching.

Formica Top: It is very important that the Formica

finish be a smooth and not a matte finish.

Applying paste wax to the perimeter of the table and

gasket will do two things, give a smother finish plus a

better vacuum seal and the wax makes it easier to

remove glue squeeze out from the table top.

Tips from an experienced user: To increase the

holding force of the high tack adhesive tape that holds

the top to the bottom of the frame, apply duct tape

around the inside of the frame and down on to the top.

This not only provides additional holding force but

most importantly also keeps sawdust from getting on to

the high tack tape. If the duct tape is not added, the high

tack adhesive tape will loose it’s adhesive quality and

will need to be replaced periodically depending on the

frequency of use and dust level in the shop.

Duct

Toggle Clamps: Center the top clip on the aluminum

frame (drawing E) and drill a 5/32 hole. Use the #10 metal

screws to attach the clip to the frame. Hang the toggle on

the clip. The top holes in the toggle plate should be about in

the center of the edge of the MDF table top. Screw in place

with 4 wood screws. Adjust the U clamp so that the gasket

compresses slightly and provides a good initial seal to

draw vacuum. Do not over tighten as this could cause

compression set in the gasket material.

Toggle clamp diagram for frame presses 4 x 10 & 5 x 10

34.25” for a 68.5” side 28.25” for a 56.5” Side

Toggle clamp diagram for frame presses 4 x 8 & 5 x 8

34.25” for a 68.5” side 28.25” for a 56.5” Side

Hinges

Center of Rail

42” from end

7” from end

Hinges

Center of Rail

52.5”

Tape

7” from end

Note 1

Toggle clamp diagram for 54“ x 54” Frame Press

Hinges

BASE BOARD

Poly top

2 rows of gasket

material stuck to

poly top (no gap)

Silicone II

TABLE TOP

DRAWING G

Note 1: Press the top to the table top between the frame and baseboard prior to drawing vacuum. This prevents the frame from bending in.

CALL 1-800-547-5484 TODAY!

Quality VAKuum Products, Inc.

Or visit our site at www.qualityvak.com

74 Apsley St. - Hudson, MA 01749

Tel: 978-562-4680 - Fax: 978-562-4681

7” from end

Page 8

INSTRUCTIONS FOR ASSEMBLING

THE VAKUUM FRAME PRESS

7/11/12 - Frame Press Instructions.cdr Page 8

Adding a vacuum tank.

Adding a vacuum tank will significantly increase the

time between cycles and you should consider this

option if you are experiencing cycle times of one to

two minutes. It is very simple to add. Since a

vacuumed down top has very little air space, just a

small amount of leakage will quickly fill this space

and cause the unit to cycle. It’ s a function of the size

of the tank. A 10 gallon tank or larger is suggested.

The tank can expand this space by anywhere from 5

to 10 times in size, thus, 5 to 10 times longer between

cycles.

The drawing shows how to include the tank into your

frame press set-up. It’s a very simple set up, if you

make it yourself, just make sure all your connections

are vacuum tight.

Once the tank is installed and the frame press is

pumped down to vacuum level, the time between

cycles will become longer . When ready to open the

press, shut off the valve to the tank then open the

bleeder valve. This will save the vacuum in the tank

and you will not have to pump it down every time

you press a new piece.

When ready to press again, close the lid, turn on the

pump and then open the valve to the tank.

Frame

Press

Tee

Valve

More than one tank can be added by connecting them

with a TEE.

Pump

Bleeder

V alve

T ANK

1

T ANK

2

T ANK

3

Page 9

BASIC VENEERING

PRINCIPLES

03/08/2007 r1 - Basic Veneering Principles.cdr

FLAT SURF ACES

1. You can either cut the substrate to finished size or

slightly oversized and trim later . Good substrate materials

are; MDF , p article board or plywood. If solid wood is to be

used, a cross ply must be applied and allowed to dry

unless the panel is less than 1/4" thick.

2. Prepare a caul by rounding all edge that will be touched

by the VAK bag. The caul should be approximately 1/2"

larger than the substrate and made from 1/2 to 1" thick

melamine coated particle board. If the caul has too much

of an overhang, it can bow up in the center and you will not

have a good pressing. Any flat material can be used,

however, the coated stock has the advantage of the glue

squeeze out not sticking.

3. Glue one face of the substrate and place the veneer on

the substrate. Do not glue the veneer . Use veneering tape

(not masking tape) to tape the veneer to the substrate on

opposite sides, not on all 4 sides (the veneer has to be able

to move when pressed). The veneer should be about 1/4"

larger than the substrate so that it overhangs the substrate

by approximately 1/8" on all sides, this allows for slight

movement and trimming later .

4. Place the caul on the veneer and tape it in place.

CURVED SURF ACES

1. Build your form with the knowledge that it will see almost

1 Ton/sq.ft. of pressing force. A weak mold will get

crushed. This is also true of curved furniture. Veneering a

hollow round base can be a problem unless the inside is

structurally sound. If you are veneering a curved piece of

finished furniture (like a juke box) that cannot be taken

apart, stuff it with bubble pack. Bubble pack can be stuffed

into every corner and is much better to use than a general

purpose inflatable bladder .

2. Make the mold convex whenever possible and do not

totally close it in. Leave the bottom open or cut some slots

in the bottom so that air is not trapped inside.

3. Assemble your veneer “sandwich” as per the flat panel

instructions. Place it on the form and slide it into the bag.

Hold the assembly on the form as the bag is being pumped

down. Once evacuated, the bag will hold everything

down.

4. Tape the top caul to the assembly only at the front and

bottom edge and not the side edges. If you tape sides, the

inner plies may not slide into their proper radius without

causing a misalignment problem.

5. Slide the whole assembly into the bag.

6. If you want to veneer both sides at the same time, flip the

assembly, at step 3, over and repeat for the second side.

Y ou may want to use a bottom caul for ease of handling. It

can be larger than the substrate since it will be laying flat on

the baseboard and will protect the veneer as you slide the

assembly into the bag.

Top Caul

Substrate

Bottom Caul

Veneer

Base Board

CALL 1-800-547-5484 TODAY!

Or visit our site at www.qualityvak.com

Notes:

A. Always try a dry run to make sure all the pieces fit to

gather and fit in the bag without problems. Go as far as to

pull the maximum vacuum with a new piece or shape.

B. Know your time limits for assembly, glue, and bag

evacuation so that you don't get caught short.

C. For guidelines on building a form go to

https://www.qualityvak.com/tech2.html.

OVER

Quality VAKuum Products, Inc.

74 Apsley St. - Hudson, MA 01749

Tel: 978-562-4680 - Fax: 978-562-4681

Page 10

ADDITIONAL VAKUUM BAG

03/08/2007 r1

VENEERING TIPS

Always dry test the system before trying something new

like a fast setting glue, a large item or a new form. This way

you can be sure that the work piece will fit in the bag and

you have sufficient time to do all that needs to be

accomplished in the time allowed.

If the object in the bag is large, like hollow columns or a

box, you can use a shop vac to evacuate the bulk of the air .

A shop vac moves large volumes of air quickly, however, it

does not get a very high vacuum level needed to supply the

pressing force required for a good bond. Turn the VAK

Pump on, then insert the shop vac in the open end. It will

quickly pull the bag down and tight against the workpiece.

Remove the nozzle and close the bag, this will allow the

V AK Pump to finish the job.

A word of caution about continuously running a shop vac in

a closed system. Any electric motor needs an air flow to

cool it. If it is run continuously while attached to a closed

system, like the bag, the motor can burn out. Running it for

10 - 20 seconds to evacuate the bag is not a problem.

Any time a form is used inside the bag, make sure it is

strong enough to withstand the pressure of 1800 lbs/sq.ft.

Make a dry run!

Also, do not make a form or veneer a piece that has only 2

contact points with the baseboard. For example, think of

an inverted U shaped piece that is 2' wide, 5' across at the

base and 6 - 8" high at the top of the arch. If this were

placed on the baseboard and VAKuum applied, it would

snap most baseboards and possibly cause the bag to

implode (explosion pushes out, implosion pulls in). First,

all the pressure from the top area (2' X 5' = 10 sq ft X 1800

lbs/sq.ft. = 18000 pounds of force) is on the 2 contact

points. Since the base of the inverted U would have less

than 1 sq.ft of surface area to distribute the load, the 18000

lbs is distributed as 9000 lbs on two .5 sq.ft. areas. The

baseboard is seeing 1800 lbs/sq.ft on the underside and

since the top side is only supported by in two small .5 sq.ft.

areas (5' apart) it will snap most baseboards in the center .

Even if the baseboard was strong enough to withstand this

pressure, the bag would not. We have a situation where

the bag gets pushed in, under the arch, (roughly a 6" x 5'

area). The bag will stretch until it hits something or will

burst after a certain point. The open area must be blocked

to prevent the stretching. A strong form to fit under the arch

will not only prevent the bag from stretching but will also

support the arch and baseboard.

If for some reason you are not able to fully protect the bag

from sharp corners or excessive stretching, consider

purchasing an extra sheet of vinyl material and use it as a

protective layer. The double thickness will help extend the

life of the bag.

After the bag has been used and stretched, it will develop

pin holes which will cause leakage. Turn the bag over,

plug the hole and reinstall the VCA (VAKuum Connector

Assembly). The bottom side will be fresh and un-stretched

for the most part. With the top side now on the bottom, it

will be pressed against the bottom of the baseboard.

Since the bottom does not contain any saw cuts, the pin

holes will be sealed when pressed against the baseboard.

Excess glue must be cleaned from the bag as the hard glue

could puncture the bag. To make cleaning easier and to

add protection to the bag, order a length of vinyl material

and use it as a cover over the workpiece. The vinyl sheet

can be removed and easily cleaned. When used it will also

cover pin holes that have been created if the bag has been

overly stretched.

CAUTION: Some glues will stick to the bag: polyurathane

and some epoxies are known to stick to bags. Use wax

paper or some material that will isolate the bag from the

glue.

Avoid, if possible, having the seam pulled tight against the

baseboard as shown below. This can be the cause of the

material ripping at the edge of the seam. This is

different than the seam delaminating. Leave some

space between the bag and the baseboard so that the bag

can flatten out against itself and not put any stress at the

edge of the seam.

Here it can rip due to stress.

Base Board

Seam

The bag flattens out against itself and does

not stress the edge of the seam.

Base Board

Always fully support the bag, do not set-up on saw

horses without complete support.

CALL 1-800-547-5484 TODAY!

Or visit our site at www.qualityvak.com

Quality VAKuum Products, Inc.

74 Apsley St. - Hudson, MA 01749

Tel: 978-562-4680 - Fax: 978-562-4681

Loading...

Loading...