Page 1

M

INSTRUCTIONS FOR ASSEMBLING

VAKUUM B AGS WITHOUT BASEBOARDS

6/19/2000 - Bags Without Baseboards & Curve Info.cdr

When using a bag without a baseboard inside, you

need to make some changes to the setup.

VCA6

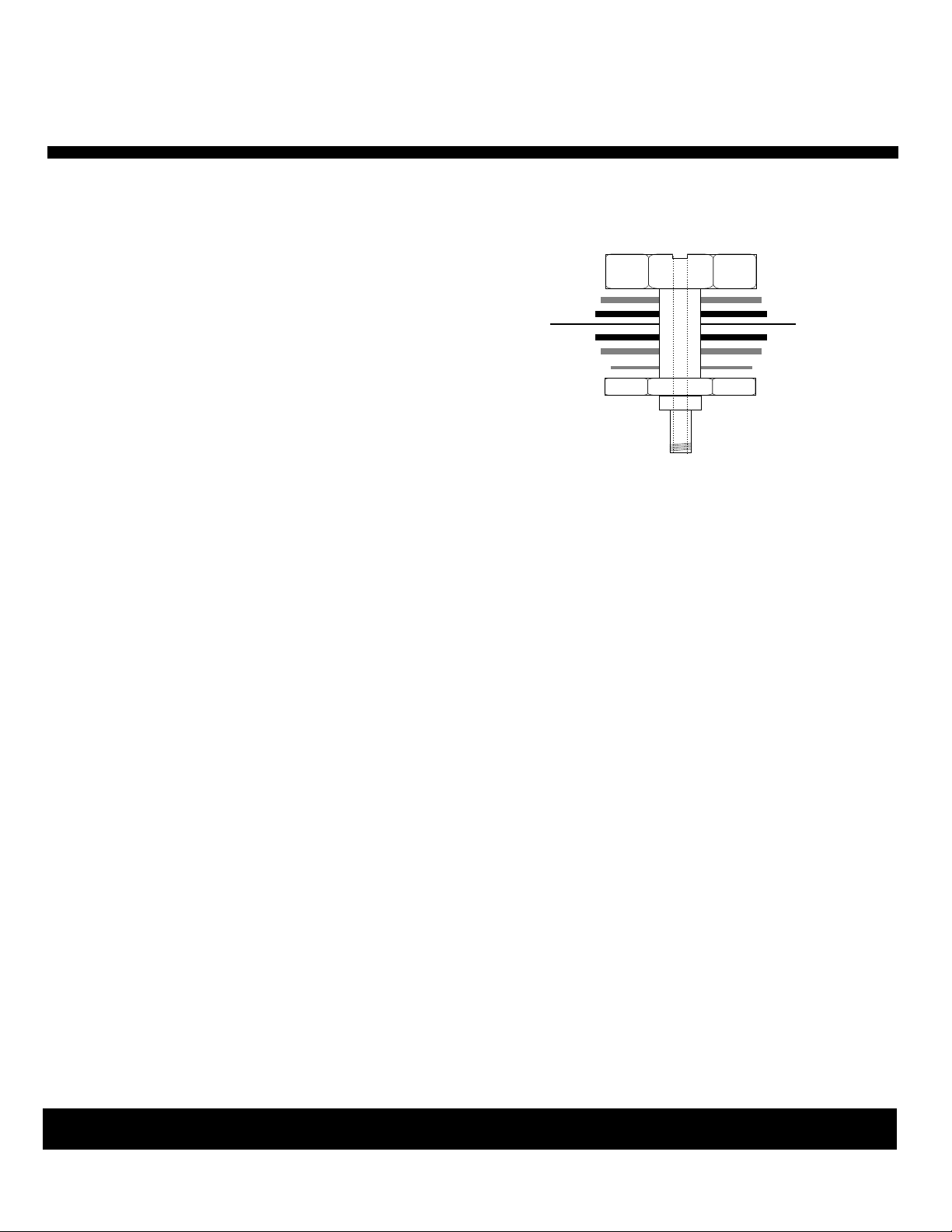

The V AKuum Bag Connector (VCA or VCA6) should

have an additional metal washer that goes inside the

bag as shown in Drawing A. If you do not have a

washer to fit the VCA(6), make one out of something

like Formica or a thin piece of wood. Make sure it

does not have any sharp edges!

Decide where you want the connector located.

Normally, 18“ in from the end is a good location for

long narrow bags. Remember, the connector must

butt up against your workpiece and not against the

opposite side of the bag. If it hits the opposite side of

the bag, the vacuum hole will seal itself off and you

will not get full vacuum in the bag.

METAL WASHER

BAG

METAL

WASHERS

RUBBER

WASHERS

Drawing A

For the VCA, cut a 5/8“ dia. hole or a 3/4” hole for the

VCA6 at the point you want the connector located. If

you put the hole in the wrong place, patch it using a

vinyl pool repair kit, but be careful not to glue the bag

together.

Push the connector through the bag so that the

rubber washer is against the bag. Place the other

rubber washer and metal washers over the connector

and snug the nut tight with a wrench. Do not over

tighten.

When using the bag without a baseboard, which has

grooves in it to allow the air to be evacuated through

the vacuum port, you need another method of

allowing the air to flow from one end of the bag to the

VCA(6). A good method is to wrap your workpiece in

nylon window screen material (see our video). The

connector then butts against the window screen

which allows the air to flow through the mesh.

It helps if you cut or file grooves into the top nut. This

allows the air to pass into the vacuum connector at a

faster rate.

NEW VAK-Net

A screen or net material is used inside a bag

without a baseboard in order to allow the air to be

evacuated from the back of the bag. The bag can

seal around the connector on a smooth surface

and seal itself off from the remainder of the bag.

We have recommended plastic window screen

and it can be used. This netting is easier to use

and remove.

The netting is expandable and can slide over a

jamb or stair stringer. If your part is too wide for

the net, just tape it to the top side (away from the

form) of your piece. Make sure that the VCA6

(VAKuum Bag Connector) touches the screen.

Always do a dry run the first time using V AK-Net.

CALL 1-800-547-5484 TODAY!

Or visit our site at www.qualityvak.com

Quality VAKuum Products, Inc.

74 Apsley St. - Hudson, MA 01749

Tel: 978-562-4680 - Fax: 978-562-4681

Page 2

TIPS WHEN PRESSING WITH FORMS

OUTSIDE THE VACUUM BAG.

Whether doing curved staircases or round top windows, the

laminates are glued up, taped, mesh is added and then put in

the bag. The bag is placed over the form and clamped to hold

it to the form. Vacuum is applied and squeezes with 1800

lbs./sq.ft. of even and uniform pressure.

Always do a dry run the first time trying something for

the first time or if you are resetting up the equipment.

Glue: For curved pieces we recommend our VAK-Bond

2000 for several reasons. It has 20 - 30 minutes of open time

and dries with a rigid glue line, thus eliminating or minimizing

spring back. A rigid glue line is developed due to the fact that

the glue cures by a chemical reaction. Most yellow and white

glues cure by the solvent migrating away from the glue joint.

Thus, if the solvent (usually water) comes in contact with the

joint, it softens and weakens. VAK-Bond 2000 has high

water and heat resistance.

After gluing and stacking the laminates, use fiberglass

reenforced tape to wrap them, however, reverse the tape.

The laminates need to slide as they are curved around the

form, thus, reversing the tape prevents sticking and they slide

freely while still being held in place by the tape. T o hold joint s

together, use one or two strips of the same tape across the

joint. Masking tape will break and not hold.

Wrap the laminates in a mesh (plastic window screen is OK).

It should cover at least the side where the VCA is located.

The mesh acts as channels for the air to get out of the far end

of the bag. If the head of the VCA hit s the outer laminate, and

not the mesh, it will seal itself off and the bag will not develop

the full 1800 lbs./sq.ft. of pressure. Apply some tape to hold

the mesh in place. Sometimes it helps if you draw a slight

vacuum on the bag before placing it on the form.

Consider using a female form when doing small radius

arches like window jambs. When the bag is bent around the

male side of the form,

be smooth, however,

ripples on the inside of the arch. On larger radii, this fraction

of an inch of ripple is normally not a problem. On a small

radius, this could be a problem, thus using the inside of the

form will solve this problem.

the bag on the topside of the arch will

notice that the bag will have small

Visit our web site www.qualityvak.com and

view the Q.V.P. Newsletter section to view

Techniques #1 for further instruction.

Page 3

BASIC VENEERING

5/4/98 - Basic Veneering Principles.cdr

PRINCIPLES

FLAT SURFACES

1. Start with cutting the substrate to the finished size.

Good substrate materials are; MDF , particle board or

plywood. If solid wood is to be used, a cross ply must be

applied and allowed to dry unless the panel is less than

1/4" thick.

2. Prepare a caul by rounding all edge that will be touched

by the VAK bag. The caul should be approximately 3/4"

larger than the substrate and made from 1/2 to 1" thick

melamine coated particle board. Any flat material can be

used, however, the coated stock has several advantages.

First, the coating makes it non-porous. With porous

material, the vacuum pulls the air from the pores over a

period of time, this has the effect of breaking the vacuum

prematurely. This causes the VAK Matic Controller to

cycle on and off more often. A coated caul can also be

lightly waxed, this helps keep the excess glue from

sticking.

3. The veneer should be matched and placed face down on

the caul. It should be about 1/4" larger than the substrate

so that it overhangs the substrate by at least 1/8" on all

sides. Tape the veneer to the substrate, however, make

sure that the tape will not touch the substrate when it is

placed on top of the veneer. Y ou do not want to trap t ape

under the veneer.

4. Glue one face of the substrate. Many use the regular

yellow glues unless the workpiece is going in a special

area where it sees some unusual conditions like excessive

heat (fireplace panels) or high moisture. Apply glue to the

top of the substrate and align the top caul, with its taped

veneer, on top of the substrate.

5. Tape the assembly together so it will not move when

placing it in the V AK Bag.

Top Caul

Substrate

Veneer

CURVED SURF ACES

1. Build your mold with the knowledge that it will see almost

1 Ton/sq.ft of pressing force. A weak mold will get

crushed. This is also true of curved furniture. Veneering a

hollow round base can be a problem unless the inside is

structurally sound.

2. Make the mold convexed whenever possible and do not

totally close it in. Leave the bottom open or cut some slot s

in the bottom so that air is not trapped inside.

3. Use the mold as the bottom caul and wax it as with a flat

caul. Tape the bottom veneer to the mold. Glue the

bending ply/substrate and place it over the veneer. The

number of bending plys glued at one time depends on the

size, thickness and stiffness of the ply . Glue several plys if

they are flexible enough to be bent in the bag. In some

cases, you will help the bag by pushing down on the

flexible top caul, as the bag is being evacuated. Once

evacuated, the bag will hold everything down.

4. Lay the top veneer on top of the glued substrate. Tape

the top caul to the assembly only at the points where it

meets the bottom assembly. If you tape it all the way

around, like with the flat panel, the inner plys may not slide

into their proper radius without causing a misalignment

problem.

5. Place a piece of plastic sheet over the top veneer and

tape in place. Place the top caul (bending ply) in position

and tape in place. Slide the completed assembly into the

bag. Start the VAK pump and hold the assembly down

while the reaches the desired vacuum level.

Notes:

A. Always try a dry run to make sure all the pieces fit to

gather and fit in the bag without problems. Go as far as to

pull the maximum vacuum with a new piece or shape.

B. Know your time limits for assembly, glue, and bag

evacuation so that you don't get caught short.

Bottom Caul

Base Board

CALL 1-800-547-5484 TODAY!

Or visit our site at www.qualityvak.com

Quality VAKuum Products, Inc.

OVER

74 Apsley St. - Hudson, MA 01749

Tel: 978-562-4680 - Fax: 978-562-4681

Page 4

ADDITIONAL VAKUUM BAG

VENEERING TIPS

4/7/98 - Electric Bag Instructions.cdr

Always dry test the system before trying something new

like a fast setting glue, a large item or a new form. This way

you can be sure that the work piece will fit in the bag and

you have sufficient time to do all that needs to be

accomplished in the time allowed.

If the object in the bag is large, like hollow columns or a

box, you can use a shop vac to evacuate the bulk of the air .

A shop vac moves large volumes of air quickly, however , it

does not get a very high vacuum level needed to supply the

pressing force required for a good bond. Turn the VAK

Pump on, then insert the shop vac in the open end. It will

quickly pull the bag down and tight against the workpiece.

Remove the nozzle and close the bag, this will allow the

V AK Pump to finish the job.

A word of caution about continuously running a shop vac in

a closed system. Any electric motor needs an air flow to

cool it. If it is run continuously while attached to a closed

system, like the bag, the motor can burn out. Running it for

10 - 20 seconds to evacuate the bag is not a problem.

Any time a form is used inside the bag, make sure it is

strong enough to withstand the pressure of 1800 lbs/sq.ft.

Make a dry run!

Also, do not make a form or veneer a piece that has only 2

contact points with the baseboard. For example, think of

an inverted U shaped piece that is 2' wide, 5' across at the

base and 6 - 8" high at the top of the arch. If this were

placed on the baseboard and VAKuum applied, it would

snap most baseboards and possibly cause the bag to

implode (explosion pushes out, implosion pulls in). First,

all the pressure from the top area (2' X 5' = 10 sq ft X 1800

lbs/sq.ft. = 18000 pounds of force) is on the 2 contact

points. Since the base of the inverted U would have less

than 1 sq.ft of surface area to distribute the load, the 18000

lbs is distributed as 9000 lbs on two .5 sq.ft. areas. The

baseboard is seeing 1800 lbs/sq.ft on the underside and

since the top side is only supported by in two small .5 sq.ft.

areas (5' apart) it will snap most baseboards in the center .

Even if the baseboard was strong enough to withstand this

pressure, the bag would not. We have a situation where

the bag gets pushed in, under the arch, (roughly a 6" x 5'

area). The bag will stretch until it hits something or will

burst after a certain point. The open area must be blocked

to prevent the stretching. A strong form to fit under the arch

will not only prevent the bag from stretching but will also

support the arch and baseboard.

If for some reason you are not able to fully protect the bag

from sharp corners or excessive stretching, consider

purchasing an extra sheet of vinyl material and use it as a

protective layer. The double thickness will help extend the

life of the bag.

After the bag has been used and stretched, it will develop

pin holes which will cause leakage. Turn the bag over,

plug the hole and reinstall the VCA (VAKuum Connector

Assembly). The bottom side will be fresh and un-stretched

for the most part. With the top side now on the bottom, it

will be pressed against the bottom of the baseboard.

Since the bottom does not contain any saw cuts, the pin

holes will be sealed when pressed against the baseboard.

Excess glue must be cleaned from the bag as the hard glue

could puncture the bag. To make cleaning easier and to

add protection to the bag, order a length of vinyl material

and use it as a cover over the workpiece. The vinyl sheet

can be removed and easily cleaned. When used it will also

cover pin holes that have been created if the bag has been

overly stretched.

CAUTION: Some glues will stick to the bag: urea

formaldehyde, polyurathane and resorcinol are known to

stick to bags. Use wax paper or some material that will

isolate the bag from the glue.

Avoid, if possible, having the seam pulled tight against the

baseboard as shown below. This can be the cause of the

material ripping at the edge of the seam. This is

different than the seam delaminating. Leave some

space between the bag and the baseboard so that the bag

can flatten out against itself and not put any stress at the

edge of the seam.

Here it can rip due to stress.

Base Board

Seam

The bag flattens out against itself and does

not stress the edge of the seam.

Base Board

Always fully support the bag, do not set-up on saw

horses without complete support.

CALL 1-800-547-5484 TODAY!

Or visit our site at www.qualityvak.com

Quality VAKuum Products, Inc.

74 Apsley St. - Hudson, MA 01749

Tel: 978-562-4680 - Fax: 978-562-4681

Loading...

Loading...