Page 1

INSTRUCTIONS FOR Replacing a

AF

10/18/2012 r3 Replacing The Frame Press Top Instructions.cdr

Remove the old top by pulling it off the aluminum

frame. Clean the frame with acetone or PVC pipe

cleaner that does not leave a film.

NOTE: If you are just re-sticking the existing top

to the frame clean the old top with acetone/PVC

pipe cleaner being careful not to use an access,

as acetone and PVC pipe cleaner etches the poly

top. If an excess is used and puddles, it will soften

the poly .

Apply the High Tack thin Adhesive Tape to the

frame. This is a very aggressive tape. Hold the roll

in one hand after sticking it down at one end and

unroll the tape while guiding it in place along the

frame. Use your thumb on one side of the frame

and forefinger on the other to guide the tape.

Leave the paper on the top side for now. At the

end of a side, cut the tape flush with the end.

Frame Press Top

The top will fit inside the frame. The 2 1/2“ flange

from the T op should sit on the frame without any

bunching or ripples along the frame. The top is

slightly smaller than the frame to eliminate the

possibilities of wrinkle or bunching of the

material. Hold each corner with a spring clamp

and make sure the top is centered.

Remove about 12“ of the paper backing material

from the tape from the center of one end only.

Press the flange in place as you continue

removing the backing form the tape. DO NOT

PRESS THE FLANGE IN WITH MUCH FORCE AT

THIS TIME. You may have to pull up the flange if

you did not center correctly. Do the same for the

other end. The sides should be ripple free,

remove the backing material and press the sides

in place. Again st art at the center working toward

the end.

Start the next side by butting the tape at the

corner where you just finished the first strip. And

continue around until all four sides have been

taped. Now tape the outside of the frame as you

did the bottom. At this point you need to roll the

tape with a dowel or rounded piece of stock so

that it is firmly adhered to the frame and most of

the air bubbles have been removed. Air bubbles

can be removed by pushing them aside.

If you are applying a replacement top, it’s a good

idea to etch the flange with PVC pipe cleaner

(area that will stick to the frame). It was etched the

day it left the factory and should be etched again

if over 5 day has elapsed from shipping date. An

etched surface provides a better surface for the

adhesive to grab.

T o assemble the Gusset top to the frame, elevate

the frame off the table with blocks from the

bottom side (tape) up. This allows you to drop the

Top inside the frame. Hold the top in place with

several spring clamps.

Once the top is stuck in place, take a dowel or

hard roller and roll around the frame to press the

top in place. If you make a mistake in a short

length, you can pull the top and reset it.

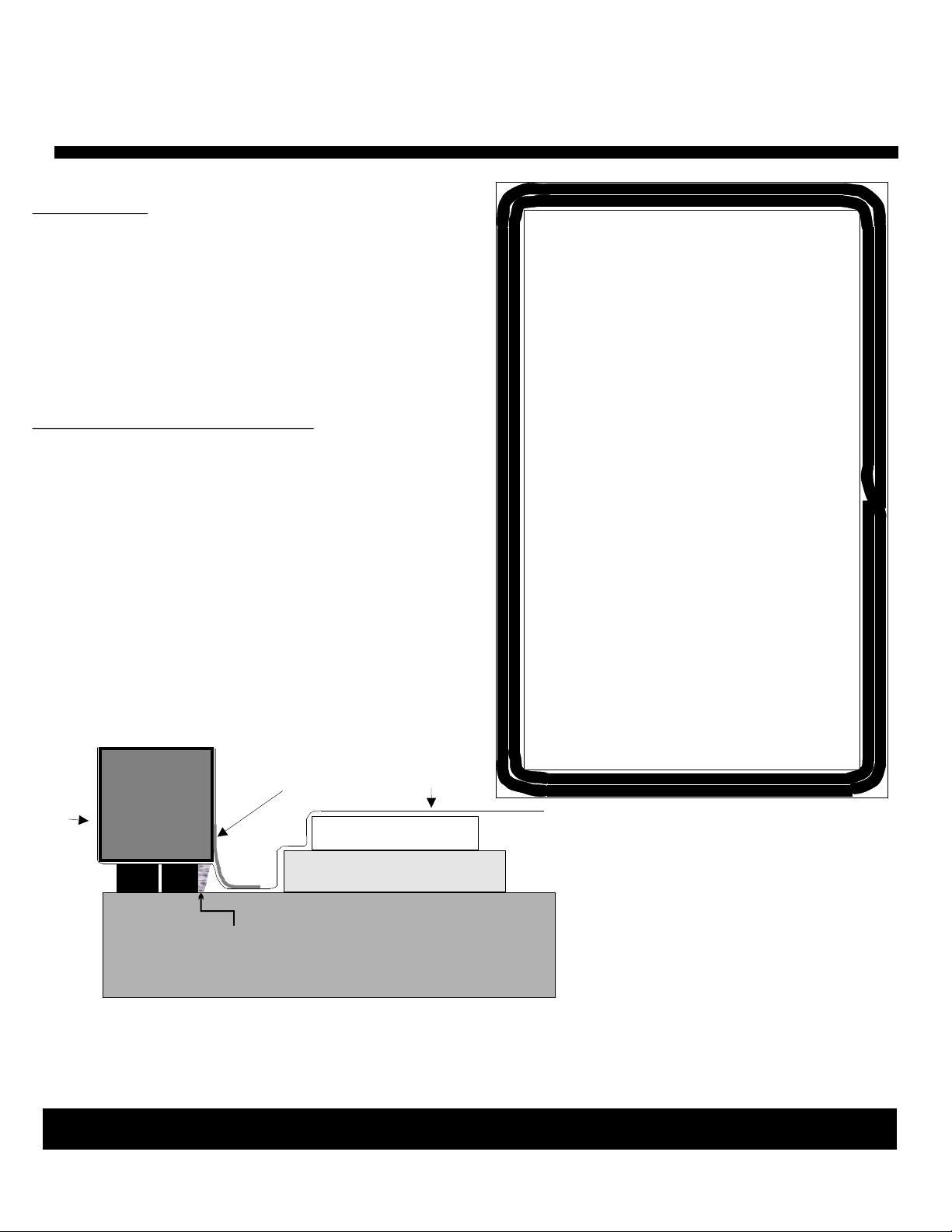

Applying the Foam Gasket T ape:

Apply the foam gasket tape around the outside

edge of the bottom of the frame . Drawing B.

Remove about 12 - 18" of backing and start in the

center of the front side and work your way around

the frame. Make a smooth curve at the corners

as in Drawing B. When you come around to the

beginning, run the tape to the inside of the

Foam Gasket tape just applied, thus making the

two rows parallel and tight to each other. This

will give you a long joint that will be vacuum tight.

Note: The second row of tape should go to the

inside corner, thus, place the first row

appropriately.

CALL 1-800-547-5484 TODAY!

Or visit our site at www.qualityvak.com

Quality VAKuum Products, Inc.

OVER

74 Apsley St. - Hudson, MA 01749

Tel: 978-562-4680 - Fax: 978-562-4681

Page 2

INSTRUCTIONS FOR ASSEMBLING

THE VAKUUM FRAME PRESS

Formica Top: It is very important that the Formica

finish be a smooth and not a matte finish.

If you made a table with a matte finish, wax the outer 3“

(around the baseboard) of our table top. This will do

two things, give a smother finish plus a better vacuum

seal and the wax makes it easier to remove glue squeeze

out from the table top.

A frame press (FP) has a very large area to

seal (up to 35') and it tends to cause the

pump to cycle on and off more often than a

bag. Under normal conditions a FP will

cycle every 3 to 5 minutes. Some have

achieved up to a 60 minute cycle by paying

close attention to details and adding a

vacuum tank.

Tips from an experienced user: To increase the

holding force of the high tack adhesive tape that holds

the top to the bottom of the frame, apply duct tape

around the inside of the frame and down on to the top.

This not only provides additional holding force but

most importantly also keeps sawdust from getting on to

the high tack tape. If the duct tape is not added, the high

tack adhesive tape will loose it’s adhesive quality and

will need to be replaced periodically depending on the

frequency of use and dust level in the shop.

Duct

Poly Top

Tape

Poly Top

You can improve the seal by applying a

small bead of Silicone II around the inside

edge of the gasket material. The key is not

to have it wider than 1/8” where it touches

your table top. If it's too wide, it can prevent

the gasket from compressing because the

silicone is much denser than the gasket

material. If this happens, the frame doesn't

compress evenly and you could be worse

off. Better to apply a smaller amount and

add more latter than to apply too much.

Also when applying the tape make sure to

butt the 2nd row against the 1st row. (The

gap in this drawing is only to show 2 rows.)

Drawing B

Gasket

BASE BOARD

Silicone II

TABLE TOP

CALL 1-800-547-5484 TODAY!

Or visit our site at www.qualityvak.com

Quality VAKuum Products, Inc.

Make sure you pat the poly top to the

table top between the frame and the

baseboard before pulling vacuum.

This is important to keep the top from

bending the frame in or pulling the top

off the frame when under vacuum.

You have 400 to 500 lbs of force per

linear foot pressing the poly top to the

table, thus, keeping it from pulling on

the aluminum frame.

74 Apsley St. - Hudson, MA 01749

Tel: 978-562-4680 - Fax: 978-562-4681

Loading...

Loading...