Quincy Lab 40AFE User Manual

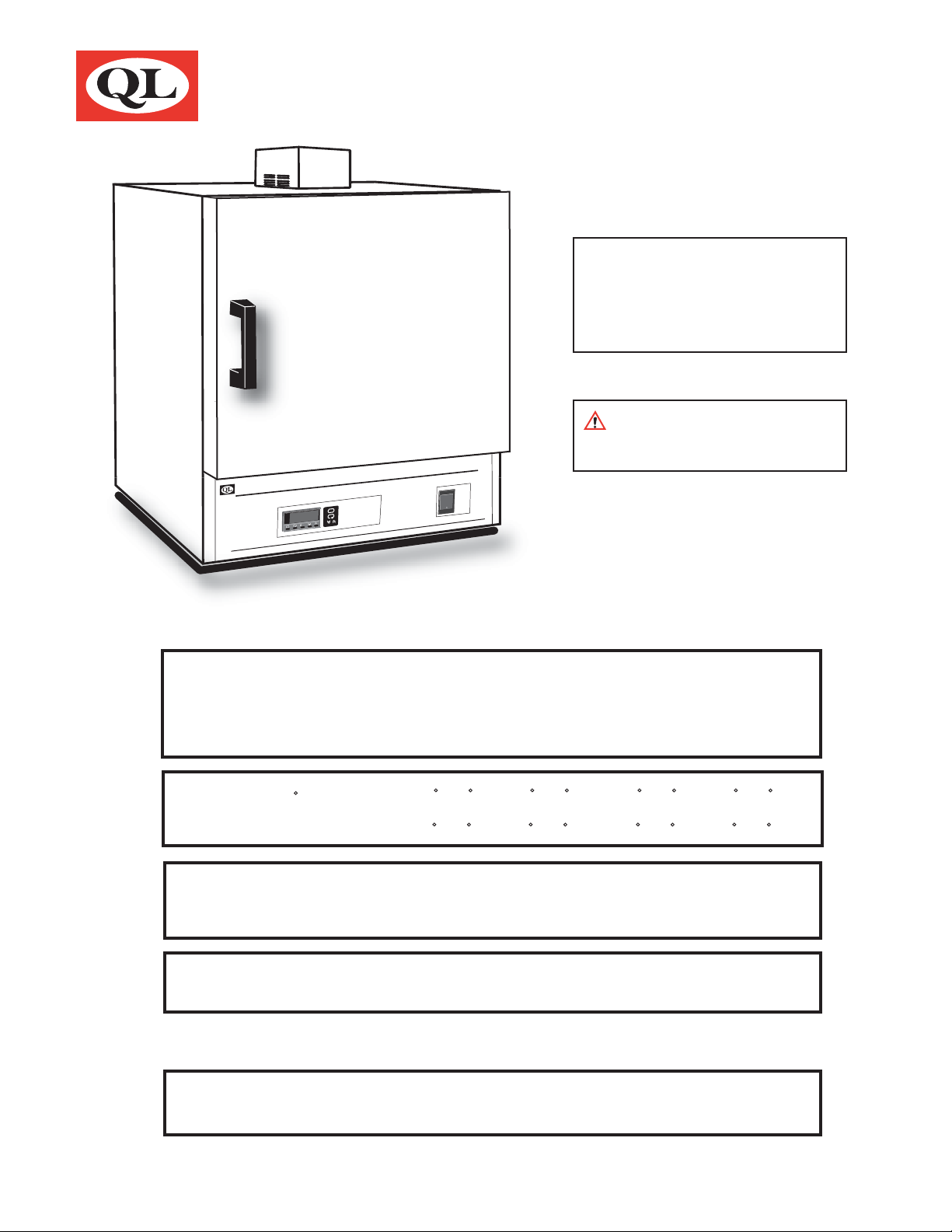

Model AFE Digital Series Lab Ovens

With Microprocessor Control & Digital Display

Quincy Lab, Inc.

Quincy Lab, Inc.

M

L

A

IT

IG

D

OPERATING MANUAL

Standard Contents

(1) AFE Series Lab Oven

(2) Adjustable chrome wire shelf

(4) Shelf brackets

Not For Use With Flammable

Solvents or Gases.

Model 30AFE Lab Oven

R

O

S

S

E

C

O

R

P

O

R

IC

W

M

C

U

N

A

M

OP

ST

E

N

U

T

N

O

R

M

O

Enter/Exit Menu

Menu Scroll

tpoint

crease Se

Increase/De

PF

C

G

5

E

)

S

S

E

R

P

(

POWER

Switch

opening

GCE SERIES

SPECIFICATIONS

INTERIOR DIMENSIONS

INCHES W x H x D

(CM) W x H x D

EXTERIOR DIMENSIONS

INCHES W x H x D

(CM) W x H x D

TEMPERATURE RANGE

Ambient + 25 F to: F / C

CONTROL STABILITY

Typically +/- F / C

STANDARD ELECTRICAL

VOLTS/AMPS

WATTS

PLUG/NEMA

WEIGHT (lbs)

SHIPPING

STAND ALONE

* Standard models voltage only, optional 220 voltage available. Check label on back of unit.

Common Unit Construction

12x8.63x10 13x11.63x13

30.5x22x25.4 33x29.5x33 45.7x50x35.545.7x37x30.5

14x20.5x12

35.5x52x30.5

MODEL

10AFE

450 /232

0.5 / 1.0

120/6.6*

800

5-15P*

44

38

MODEL

20AFE

MODEL

30AFE

15x24.5x15 20x28.5x14

38x61x38

450 /232

0.5 / 1.0

120/8.8*

1050

5-15P*

61

54

52x72.4x35.5

450 /232

0.5 / 1.0

120/12.5*

1500

5-15P*

78

70

MODEL

40AFE

18x19.63x1418x14.63x12

20x33.5x16

52x85x40.63

450 /232

0.5 / 1.0

120/12.5*

1500

5-15P*

94

85

Issue AFE 0415

Copyright Quincy Lab Inc. 2015

Exterior: Powder Coated Steel Interior: Aluminized Steel

Insulation: Fiberglass Motor: Sleeve Bearing, Thermally Protected

Thermo-control: PID Microprocessor Heater: Resistive-Tubular Incoloy

Quincy Lab Inc. 1925 N. Leamington Ave. Chicago, Illinois 1-800-482-HEAT (4328)

PAG E 1

Safety Precautions

The AFE Series lab ovens are not designed for use with any flammable solvents or gases or for

materials that may contain flammable solvents or gases. Use only a grounded outlet that is rated for

your model's electrical requirement. Oven exterior walls and doors may become hot to the touch

when operating at higher set temperatures. Do not leave the oven unattended during operation,

especially when processing materials that have flash point temperatures lower than the model oven's

maximum operating range. Do not modify the oven or control parameters to operate the oven above

the stated maximum operating temperature.

Set-up

Read Operating Instructions Thoroughly Prior to Operation

AB

Position unit in its ultimate operating location. Keep a

minimum of 2" of airspace around the unit and a minimum of

10" above the unit. Important: The exhaust ports should NOT

be used as chamber access for temperature-measuring

probes. Insertion of any such probe or device may damage

or unbalance the circulating fan blade at the top of the oven

chamber.

Install adjustable shelf by placing the ends of the wire shelf

bracket into the corresponding holes located on the inner

sides of the oven at the desired height. Push the ends of the

bracket into the holes until the first bends in the bracket are

against the wall, then rotate the bracket down. Place the

shelf on the brackets. (FIG 1)

FIG. 1

CD

Plug the unit into a grounded outlet for your unit's rated

voltage.

General Operation

The unit is ready for your immediate use. All control

parameters, calibration and tuning has been done at the

factory, no adjustments are necessary.

Push the illuminated power button. The fan motor will start.

All LED's on the temperature control will light up immediately

and display the current chamber temperature and the set

temperature.

Set temperature is constantly displayed in the lower righthand corner of the display. To change the set temperature,

simply press either the up arrow key or the down arrow key,

until desired set temperature is reached (FIG 2). The

temperature control is set at the factory to read in 1/10

degree F or Fahrenheit units.

To change temperature units or display resolution, see Menu

Level Functions (page 3).

Once the unit nears the desired temperature allow the unit to cycle for 20 minutes at set point before

temperature becomes fully stable. NOTE: Upon each initial powering-up, the control may typically

overshoot the set temp by 3 or 4 degrees especially if the temperature set point is close to the

operating ambient temperature. After equilibrium is achieved the control will hold set temperature

within 1 unit degree.

(PRESS)

FIG. 2

CMW

MANU

STOP

TUNE

OMRON

F

PF

E5GC

Enter/Exit Menu

Menu Scroll

Increase/Decrease Setpoint

Chamber Loading

Article processing times and temperature uniformity are largely dependent on load density and

positioning. Load the oven so that air circulation within the oven is not impaired. Here are some

general guidelines:

Continued on insert....

PAG E 2

Loading...

Loading...