Quincy 325 Parts Manual

QR-25® Series

Model 325

Parts Manual

Record of Change 106

This manual contains important safety information and must be carefully read in its entirety and understood prior to installation by all personnel who install, operate and/or maintain this product.

On-line product registration, parts ordering and warranty information is available at www.quincycompressor.com

Manual No. 50215-106

January 2014 Edition

Downloaded from www.Manualslib.com manuals search engine

INTRODUCTION

This manual provides information for the following QR-25 Series, Model 325 (Record of Change 106) compressor versions:

LControl Version L

head assembly with 1 unloader tower & a hydraulic unloader

LS |

Control Version LS |

|

head assembly with 2 unloader towers,a |

|

hydraulic unloader, & a pilot valve with |

|

a check valve assembly |

LVD Control Version LVD

head assembly with 2 unloader towers,a hydraulic unloader, & a pilot valve with a lockout & check valve

These compressors are aircooled, two stage, two cylinder, pressure lubricated compressors, with up to 200 PSI continuous pressure capability (201 to 500 PSI intermittant pressure capability with proper configuration; consult factory). The Model 325 has a 4.5" low pressure piston bore and a 2.5" high pressure piston bore and a 3" stroke and can be run at 400-900 RPM.

Available options included in this manual:

-high pressure rated cylinder and head -spin-on oil filter

-hooded air filter

-hooded air filter / silencer

ChaNges

since previous printing dated October 2006:

Control groups were redesigned.

TaBLe OF CONTeNTs |

|

Serial Number Identification.................................. |

2 |

Ordering Replacement Parts................................. |

2 |

Quin-Cip Lubricant................................................. |

2 |

Crankcase Lubricant Capacity.............................. |

2 |

Crankshaft Group................................................ |

3-4 |

Crankcase Group................................................. |

5-6 |

Bearing Carrier Groups |

|

with oil filter...................................................... |

7-8 |

less oil filter .................................................... |

9-10 |

Connecting Rod & Piston Groups |

|

High Pressure............................................... |

11-12 |

Low Pressure................................................ |

13-14 |

Cylinder & Head Groups |

|

Control Version L ......................................... |

15-16 |

Control Versions LS, LVD............................ |

17-18 |

Head Assemblies |

|

Control Version L ......................................... |

19-20 |

Control Versions LS, LVD............................ |

21-22 |

Control Groups |

|

Version L............................................................ |

23 |

Version LS.......................................................... |

24 |

Version LVD ....................................................... |

25 |

Pilot Valves............................................................ |

26 |

Differential Setting Charts................................... |

26 |

Suction Valve Unloader Assemblies................... |

27 |

Gasket Set............................................................. |

28 |

Kits......................................................................... |

28 |

Recommended Spare Parts................................. |

29 |

Decals.................................................................... |

29 |

Typical Unit Repair Parts List......................... |

30-32 |

QR 325 |

|

Quincy Compressor |

|

|

|

|

|

|

50215-106, January 2014 |

1 |

3501 Wismann Lane, Quincy IL - 62305-3116 |

Downloaded from www.Manualslib.com manuals search engine

mODeL & seRIaL NUmBeR

IDeNTIFICaTION Record

of

Change No.

Model & Serial Number

Identification Tag

The model & serial number tag is located on the handhole plate side of the crankcase. Fill in the numbers from your compressor's tag in the corresponding spaces provided here and reference this page when ordering replacement parts.

All replacement parts are to be ordered through an authorized Quincy distributor. Insist on genuine Quincy parts only! Failure to do so may void warranty.

QUIN-CIP LUBRICANT

Refer to the chart below to order Quin-Cip-D or QuinCip compressor lubricant from your local authorized Quincy distributor.

Quin-Cip-D Lubricant

(synthetic)

SAe 30 (ISO 100)

Quart |

115468Q |

Case (12 Qts.) |

115438C |

Quin-Cip Lubricant

SAe 10W (ISO 32)

Quart |

112541Q032 |

Case (12 Qts.) |

112541C032 |

SAe 20 (ISO 68) |

|

Quart |

112542Q068 |

Case (12 Qts.) |

112542C068 |

SAe 30 (ISO 100) |

|

Quart |

112543Q100 |

Case (12 Qts.) |

112543C100 |

ORDeRINg

RePLACemeNT PARTS

Prompt service can be rendered on repair parts orders if the following information is given:

Item 1) the model number, record of change number, & serial number.

Item 2) the exact part number needed. (Do not order by item numbers.)

Item 3) the exact quantity needed.

Item 4) the preferred type of transportation

CAUTION !

Refer to the Quincy QR-25 Series instruction manual for vital lubrication information.

CAUTION !

Follow all safety precautions outlined in the QR-25 Series instruction manual.

CRaNkCase LUBRICaNT

CAPACITy

Model |

Less Filter |

With Filter |

325 |

1 qt. & 16 oz. |

Add 10 oz. |

|

(1.42 lit.) |

(296 ml) |

WARNING !

Do not operate this compressor without a totally enclosed belt guard or any other required safety equipment.

DANGER !

Air used for breathing or food processing must meet OSHA 1910.134 or FDA21 CFR 178.3570 regualtions. Failure to do so may cause severe injury or death.

QR 325 |

|

Quincy Compressor |

|

|

|

|

|

|

50215-106, January 2014 |

2 |

3501 Wismann Lane, Quincy IL - 62305-3116 |

Downloaded from www.Manualslib.com manuals search engine

CRANKSHAFT GROUP 110238

1.3 1.4

1.1 |

1.6 |

3.1

1.3

2

1.2

1.5

3.2

3.4

3.3

3.3

QR 325 |

|

Quincy Compressor |

|

|

|

|

|

|

50215-106, January 2014 |

3 |

3501 Wismann Lane, Quincy IL - 62305-3116 |

Downloaded from www.Manualslib.com manuals search engine

|

|

|

CRANKSHAFT GROUP 110238 |

|

|

|

|

Item |

|

Part |

|

Number |

Qty. |

Number |

Description |

|

|

|

|

1 |

1 |

110217 |

crankshaft assembly |

1.1 |

1 |

110216 |

crankshaft (N.S.S.; order 110217) |

1.2 |

1 |

110234 |

orifice, 1/8 npt |

1.3 |

2 |

2755S |

pipe plug, 1/8 npt |

1.4 |

1 |

2585 |

bearing cone |

1.5 |

1 |

2788 |

bearing cone |

1.6 |

1 |

110705-F15 |

pin |

2 |

1 |

1466 |

key |

3 |

1 |

110472X |

sheave assembly |

3.1 |

1 |

4126R |

sheave, 16", 2 groove, B sect., ccw (N.S.S.; order 110472X) |

3.2 |

2 |

110983-N23 |

hex. screw, 1/2-13 unc x 3.50, grade 8 (@ 90 ft.-lbs.) |

3.3 |

2 |

116124-N02 |

square nut, 1/2-13 unc |

3.4 |

2 |

110428N050 |

flatwasher |

N.S.S. = Not Sold Separate

@ Indicates torque value in foot pounds (dry threads)

Note: For reversal of compressor rotation refer to QR-25 instruction manual.

QR 325 |

|

Quincy Compressor |

|

|

|

|

|

|

50215-106, January 2014 |

4 |

3501 Wismann Lane, Quincy IL - 62305-3116 |

Downloaded from www.Manualslib.com manuals search engine

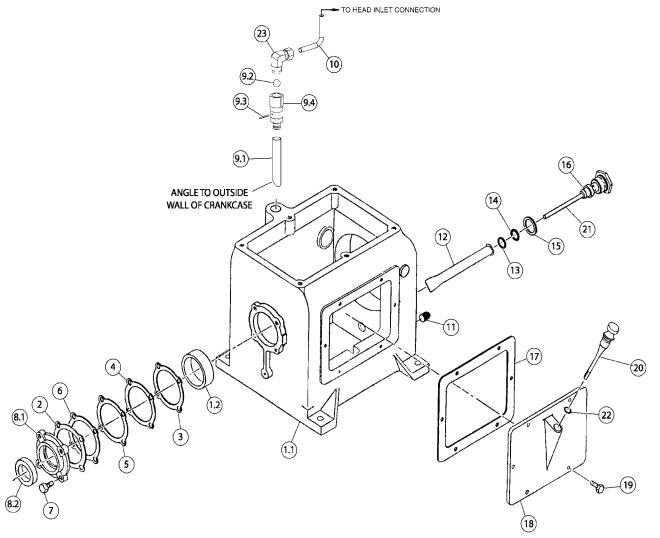

CRANKCASE GROUP 110237

QR 325 |

|

Quincy Compressor |

|

|

|

|

|

|

50215-106, January 2014 |

5 |

3501 Wismann Lane, Quincy IL - 62305-3116 |

Downloaded from www.Manualslib.com manuals search engine

|

|

|

|

CRANKCASE GROUP 110237 |

|

|

|

|

|

Item |

|

Part |

|

|

Number |

Qty. |

Number |

Description |

|

|

|

|

|

|

|

1 |

1 |

5503X003 |

crankcase assembly |

|

1.1 |

1 |

5503-003 |

crankcase |

|

1.2 |

1 |

2720 |

bearing cup |

|

2 |

* |

6294D |

bearing adj. shim, .002 steel |

|

3 |

* |

6294 |

bearing adj. shim, .005 steel |

|

4 |

* |

6294A |

bearing adj. shim, .007 steel |

|

5 |

* |

6294B |

bearing adj. shim, .020 steel |

|

6 |

* |

6294C |

bearing adj. shim, .005 paper |

|

7 |

4 |

123478-L10 |

hex. screw, 3/8-16 unc x .75, grade 5 (@ 30 ft.-lbs.) |

|

8 |

1 |

5506X1 |

bearing adjustment plate assembly |

|

8.1 |

1 |

5506 |

adjustment plate |

|

8.2 |

1 |

6316 |

oil seal |

|

9 |

1 |

112031X001 |

breather assembly |

|

9.1 |

1 |

112032-001 |

breather tube |

|

9.2 |

1 |

5783-002 |

breather ball |

|

9.3 |

1 |

110705-C11 |

roll pin, 3/32 x .81 |

|

9.4 |

1 |

112031-001 |

breather body |

|

10 |

3 ft. |

110515-031 |

copper tube, 5/16 o.d. |

|

11 |

1 |

1301 |

pipe plug, 3/8 npt |

|

12 |

1 |

6272 |

screen |

|

13 |

1 |

6313 |

gasket, inlet screw |

|

14 |

1 |

123157-116 |

"o"ring, 3/32 wide x .94 o.d. |

‡ |

15 |

1 |

6275 |

gasket, inlet screw |

16 |

1 |

6273 |

inlet screw |

|

|

17 |

1 |

1840 |

gasket, inspection plate |

|

18 |

1 |

2322-1 |

inspection plate, oil filler type |

|

19 |

6 |

123478-K12 |

hex. screw, 5/16-18 unc x 1.00, grade 5 (@ 12 ft.-lbs.) |

‡ |

20 |

1 |

110070-3 |

oil gauge |

21 |

1 |

8270 |

inlet tube |

|

|

22 |

1 |

123157-112 |

"o"ring, 3/32 wide x .69 o.d. |

|

23 |

1 |

110919-010 |

tube fitting, 5/16 tube x 3/8 npt, 90° |

|

|

|

|

Maintenance Parts |

|

8.2 |

1 |

6316 |

oil seal |

Parts for use with diester or phosphate ester synthetic based lubricants

10.1 |

1 |

22749-111 |

"o"ring, 3/32 wide x .62 o.d. |

14 |

1 |

22749-116 |

"o"ring, 3/32 wide x .94 o.d. |

22 |

1 |

22749-112 |

"o"ring, 3/32 wide x .69 o.d. |

* Quantity as required

@Indicates torque value (dry threads).

‡Assemble item 21 into item 16 with Loctite® 609.

QR 325 |

|

Quincy Compressor |

|

|

|

|

|

|

50215-106, January 2014 |

6 |

3501 Wismann Lane, Quincy IL - 62305-3116 |

Downloaded from www.Manualslib.com manuals search engine

BEARING CARRIER GROUP 110816-001

(with oil filter)

1.12

|

|

1.11 |

|

1.14 |

|

|

|

|

|

|

|

|

1.13 |

1.1 |

|

|

|

|

|

|

|

|

|

1.15 |

|

|

|

|

1.2 |

4 |

|

|

|

2 |

|

|

|

1.4 |

|

|

|

|

1.6 |

1.3 |

|

|

|

|

|

|

|

1.7 |

|

1.16 |

|

|

|

1.5 |

|

|

|

|

|

|

|

1.8 |

|

|

3 |

|

|

|

|

|

6 |

5 |

|

|

|

|

|

|

|

1.10

1.171.9

QR 325 |

|

Quincy Compressor |

|

|

|

|

|

|

50215-106, January 2014 |

7 |

3501 Wismann Lane, Quincy IL - 62305-3116 |

Downloaded from www.Manualslib.com manuals search engine

|

|

|

|

BEARING CARRIER GROUP 110816-001 |

|

|

|

|

(with oil filter) |

|

|

|

|

|

Item |

|

Part |

|

|

Number |

Qty. |

Number |

Description |

|

|

|

|

|

|

1* |

|

1 |

110810-003 |

bearing carrier assembly (N.S.S.; order 110810X003) |

|

1.1 |

1 |

110810 |

bearing carrier (N.S.S.; order 110810X003) |

|

|

1 |

2523 |

bearing cup |

|

|

2 |

160005 |

bushing |

* |

1.2 |

1 |

123157-152 |

"o"ring, 3/32 wide x 3.44 o.d. |

* |

1.3 |

1 |

123157-112 |

"o"ring, 3/32 wide x .69 o.d. |

|

1.4 |

1 |

160002-002 |

driveshaft |

|

1.5 |

1 |

160075-001 |

driveshaft key |

|

1.6 |

1 |

160003 |

pump gerotor |

|

1.7 |

1 |

6285 |

retaining ring |

|

1.8 |

1 |

110813-001 |

oil pump housing |

§ |

1.9 |

6 |

123777-J12 |

hex. screw, 1/4-20 unc x 1.00, grade 5 (@ 6 ft.-lbs.) |

1.10 |

2 |

2719 |

pipe plug, 1/4 npt, hex socket |

|

|

1.11 |

1 |

5489 |

adjustment screw |

* |

1.12 |

1 |

123157-011 |

"o"ring, 1/16 wide x .44 o.d. |

|

1.13 |

1 |

124369-P02 |

jamnut, 9/16-18 unf |

|

1.14 |

1 |

1160 |

spring |

|

1.15 |

1 |

112857 |

needle valve |

|

1.16 |

2 |

6565 |

hole plug |

|

1.17 |

1 |

2755S |

pipe plug, 1/8 npt |

2 |

|

1 |

6312 |

gasket, bearing carrier |

3 |

|

6 |

123478-L12 |

hex. screw, 3/8-16 unc x 1.00, grade 5 (@ 30 ft.-lbs.) |

4§ |

|

1 |

110822 |

oil pressure gauge |

5 |

|

1 |

110825 |

stud |

6* |

|

|

|

Maintenance Parts |

|

1 |

110814-001 |

6 pack of oil filters |

|

|

|

|

160078 |

Oil Pump Repair Kit |

|

|

|

|

includes "o"rings, driveshaft, key, pump gerotor, & retaining ring |

|

|

|

110810X003 |

Replacement Bearing Carrier Assembly |

includes bearing carrier assy., oil filter, stud, & bearing carrier gasket

N.S.S. = Not Sold Separate

@ Indicates torque value (dry threads). Tighten multiple bolts, capscrews & hex nuts in a criss-cross or alternating pattern. Bring each fastener to the recommended torque specification in even increments.

* Can not be used with diester or phosphate ester synthetic lubricants. § Install with Teflon® tape.

QR 325 |

|

Quincy Compressor |

|

|

|

|

|

|

50215-106, January 2014 |

8 |

3501 Wismann Lane, Quincy IL - 62305-3116 |

Downloaded from www.Manualslib.com manuals search engine

BEARING CARRIER GROUP 110816

(less oil filter)

1.12

|

|

1.11 |

|

1.14 |

|

|

|

|

|

|

|

|

1.13 |

1.1 |

|

|

|

|

|

|

|

|

|

1.15 |

|

|

|

|

1.2 |

4 |

|

|

|

2 |

|

|

|

1.4 |

|

|

|

|

|

|

|

|

|

1.6 |

1.3 |

|

|

|

|

|

|

|

1.7 |

|

1.16 |

|

|

|

1.5 |

|

|

|

|

|

|

|

1.8 |

|

|

3 |

|

|

|

|

1.10 1.9

1.10 1.9

QR 325 |

|

Quincy Compressor |

|

|

|

|

|

|

50215-106, January 2014 |

9 |

3501 Wismann Lane, Quincy IL - 62305-3116 |

Downloaded from www.Manualslib.com manuals search engine

|

|

|

|

BEARING CARRIER GROUP 110816 |

|

|

|

|

(less oil filter) |

|

|

|

|

|

Item |

|

Part |

|

|

Number |

Qty. |

Number |

Description |

|

|

|

|

|

|

1 |

|

1 |

110810-002 |

bearing carrier assembly (N.S.S.; order 110810X002) |

|

1.1 |

1 |

110810 |

bearing carrier (N.S.S.; order 110810X003) |

|

|

1 |

2523 |

bearing cup |

|

|

2 |

160005 |

bushing |

* |

1.2 |

1 |

123157-152 |

"o"ring, 3/32 wide x 3.44 o.d. |

* |

1.3 |

1 |

123157-112 |

"o"ring, 3/32 wide x .69 o.d. |

|

1.4 |

1 |

160002-002 |

driveshaft |

|

1.5 |

1 |

160075-001 |

driveshaft key |

|

1.6 |

1 |

160003 |

pump gerotor |

|

1.7 |

1 |

6285 |

retaining ring |

|

1.8 |

1 |

110813 |

housing |

|

1.9 |

6 |

123777-J12 |

hex. screw, 1/4-20 unc x 1.00, grade 5 (@ 6 ft.-lbs.) |

§ |

1.10 |

2 |

2719 |

pipe plug, 1/4 npt, hex socket |

|

1.11 |

1 |

5489 |

adjustment screw |

* |

1.12 |

1 |

123157-011 |

"o"ring, 1/16 wide x .44 o.d. |

|

1.13 |

1 |

124369-P02 |

jamnut, 9/16-18 unf |

|

1.14 |

1 |

1160 |

spring |

|

1.15 |

1 |

112857 |

needle valve |

|

1.16 |

2 |

6565 |

hole plug |

2 |

|

1 |

6312 |

gasket, bearing carrier |

3 |

|

6 |

123478-L12 |

hex. screw, 3/8-16 unc x 1.00, grade 5 (@ 30 ft.-lbs.) |

4§ |

|

1 |

110822 |

oil pressure gauge |

|

|

|

|

Maintenance Parts |

|

|

|

160078 |

Oil Pump Repair Kit |

|

|

|

|

includes "o"rings, driveshaft, key, & retaining ring |

|

|

|

110810X002 |

Replacement Bearing Carrier Assembly |

|

|

|

|

includes "o"rings, driveshaft, key, pump gerotor, & retaining ring |

|

|

|

Parts for use with diester or phosphate ester synthetic based lubricants |

|

|

1.2 |

1 |

22749-152 |

"o"ring, 3/32 wide x 3.44 o.d. |

|

1.3 |

1 |

22749-112 |

"o"ring, 3/32 wide x .69 o.d. |

|

1.12 |

1 |

22749-011 |

"o"ring, 1/16 wide x .44 o.d. |

|

|

|

160078-001 |

Oil Pump Repair Kit |

includes "o"rings, driveshaft, key, pump gerotor, & retaining ring

N.N.S. = Not Sold Separate

@ Indicates torque value (dry threads). Tighten multiple bolts, capscrews & hex nuts in a criss-cross or alternating pattern. Bring each fastener to the recommended torque specification in even increments.

§ Install with Teflon® tape.

QR 325 |

|

Quincy Compressor |

|

|

|

|

|

|

50215-106, January 2014 |

10 |

3501 Wismann Lane, Quincy IL - 62305-3116 |

Downloaded from www.Manualslib.com manuals search engine

Loading...

Loading...