Page 1

Quin Systems Limited

Q-drive Servo Amplifier

Installation & Users Manual

Issue 1.5

June 1996

(MAN430)

Page 2

Copyright Notice

Copyright 1996 Quin Systems Limited. All rights reserved.

Reproduction of this document, in part or whole, by any means, without the

prior written consent of Quin Systems Limited is strictly prohibited.

Software Version

This manual reflects the following software versions.

• QDRIVE.EXE version 2.0 or high er.

Important Notice

Quin Systems reserves the right to make changes without notice in the

products described in this document in order to improve design or performance

and for further product development. Examples given are for illustration only,

and no responsibility is assumed for th eir suitability in particular applications.

Although every attempt has been made to ensure the accuracy of the

information in this document, Quin Systems assu mes no liability for inadvertent

errors.

Suggestions for improvements in either the products or the documentation are

welcome.

Relevant Directives

This product is designed to be incorporated into a system for the control of

machinery, and needs external equipment to enable it to fulfil this function. It

must not be relied upon to provide safety-critical features such as guarding or

emergency-stop functions. It must not be put into service until the machinery

into which it is incorporated h as been declare d in conformi ty with the Machi nery

Directive 89/392/EEC and/or its relevant amendments.

The installation instructions in this manual should be followed in constructing a

system which meets requirements.

The product has been tested in typical configurations, and meets the EMC

Directive 89/336/EEC When used with the recommended mains filter.

This product as normally supplied has mains level voltages accessible to touch,

and requires t o be mounte d within a su itable cabine t to meet a ny required IP

rating to BSEN 60529.

Page 3

Issue 1.5 Q-Drive Installation Manual

Table of Contents

List of Figures iii

List of Tables iv

1. Introduction 1

1.1 Q-Drive Characteristics 2

1.2 EMC Compliance 3

2. Unpacking and Inspection 5

3. Drive Specifications 7

3.1 Mechanical specification 7

3.2 Environmental specification 7

3.3 Power supply specification 7

3.4 Electrical Specification 8

3.4.1 General data for all types 8

3.4.2 Drive Performance Specification 9

3.4.3 Analogue readings on the motherboard 9

3.5 Mounting Details 10

3.6 Relevant Directives 11

4. Connections 13

4.1 General 13

4.1.1 Wiring and connectors 14

4.1.2 Cable lengths and cross-sections 14

4.2 Low Voltage Connections 15

4.2.1 P2 Upper: R esolver 15

4.2.2 P2 Lower: Encoder 16

4.2.3 P4 RS422 Out / RS232 18

4.2.4 P3 RS422 In 18

4.2.5 P10, P11 & P12 19

4.3 High Voltage Connections 20

4.3.1 P7, Three Phase In 20

4.3.2 P8, Earth Terminals 20

4.3.3 P9, Motor 20

4.3.4 Wago Spring Terminals 21

5. Electrical Installation 23

5.1 General 23

5.2 Mains supply 24

5.3 Auxiliary Supply 25

5.4 Earth connections 26

5.5 Connecting the motor to the drive 27

5.6 Connecting the drive to the controller 28

6. Safety - Using Guards and Limits 29

6.1 Choosing a motor 30

6.2 Mounting the motor 32

6.3 Connecting the motor to the load 32

Copyright © 1996 Quin Systems Ltd. Page i

Page 4

Q-Drive Installation Manual Issue 1.5

7. Drive Parameters 33

7.1 Serial Link 33

7.2 Getting Around the Configuration Program 33

7.3 Page 0 Parameters 36

7.4 Page 1 Parameters 37

7.5 Page 2 Parameters 39

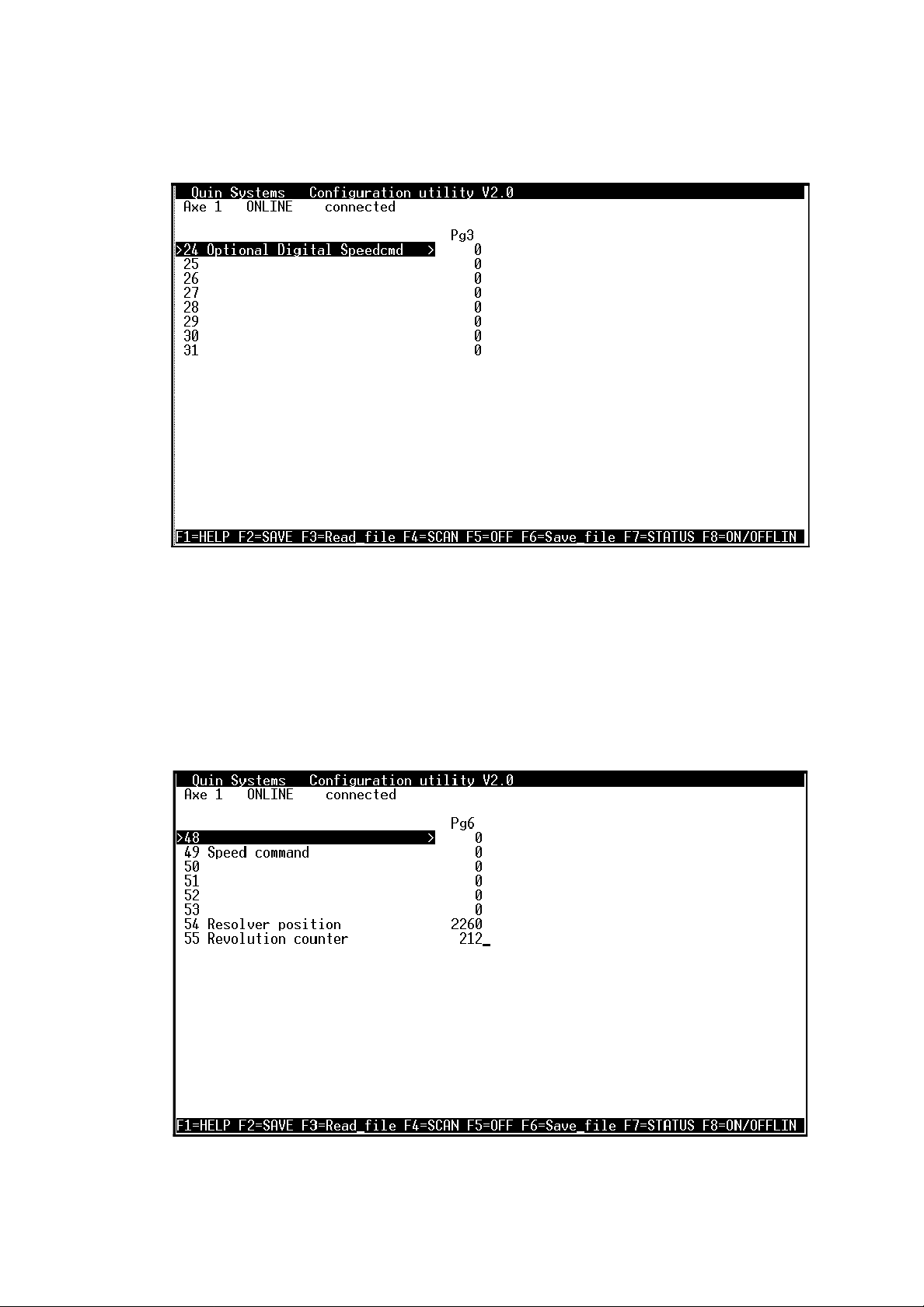

7.6 Page 3 parameters 41

7.7 Page 6 parameters 41

7.8 Page 8 parameters 42

7.9 Page 9 parameters 43

7.10 Status & Alarm page 44

8. Switching On 47

8.1 Switching the Servo-Amplifier On Without a Motor 47

8.2 Checking LEDS and 7 segment display 47

8.3 7 segment display on the front panel 48

8.3.1 Checking the electrical rotation sense of the resolver 49

8.4 Determining the motor phases 50

8.5 Switch the Servo Amplifier on with a Motor and Optimization 51

8.5.1 Preparation before switching the mains voltage on 51

8.5.2 Switching the mains voltage on 51

8.6 Compensating the speed controller 52

8.6.1 Offset and speed compensation 52

8.7 Trouble Shooting 54

9. Testing the System 55

9.1 General 55

9.2 Serial port 55

9.3 Resolver Interface 55

9.4 Encoder Simulator 56

10. Configurations 57

10.1 General 57

10.2 Resolver Ratio 57

10.3 Amplifier Configuration 58

10.4 Servo-amplifier fuses 58

10.5 Backplane configuration 60

10.6 Backplane Fuse 62

11. Options List 63

Page ii Copyright © 1996 Quin Systems Ltd.

Page 5

Issue 1.5 Q-Drive Installation Manual

List of Figures

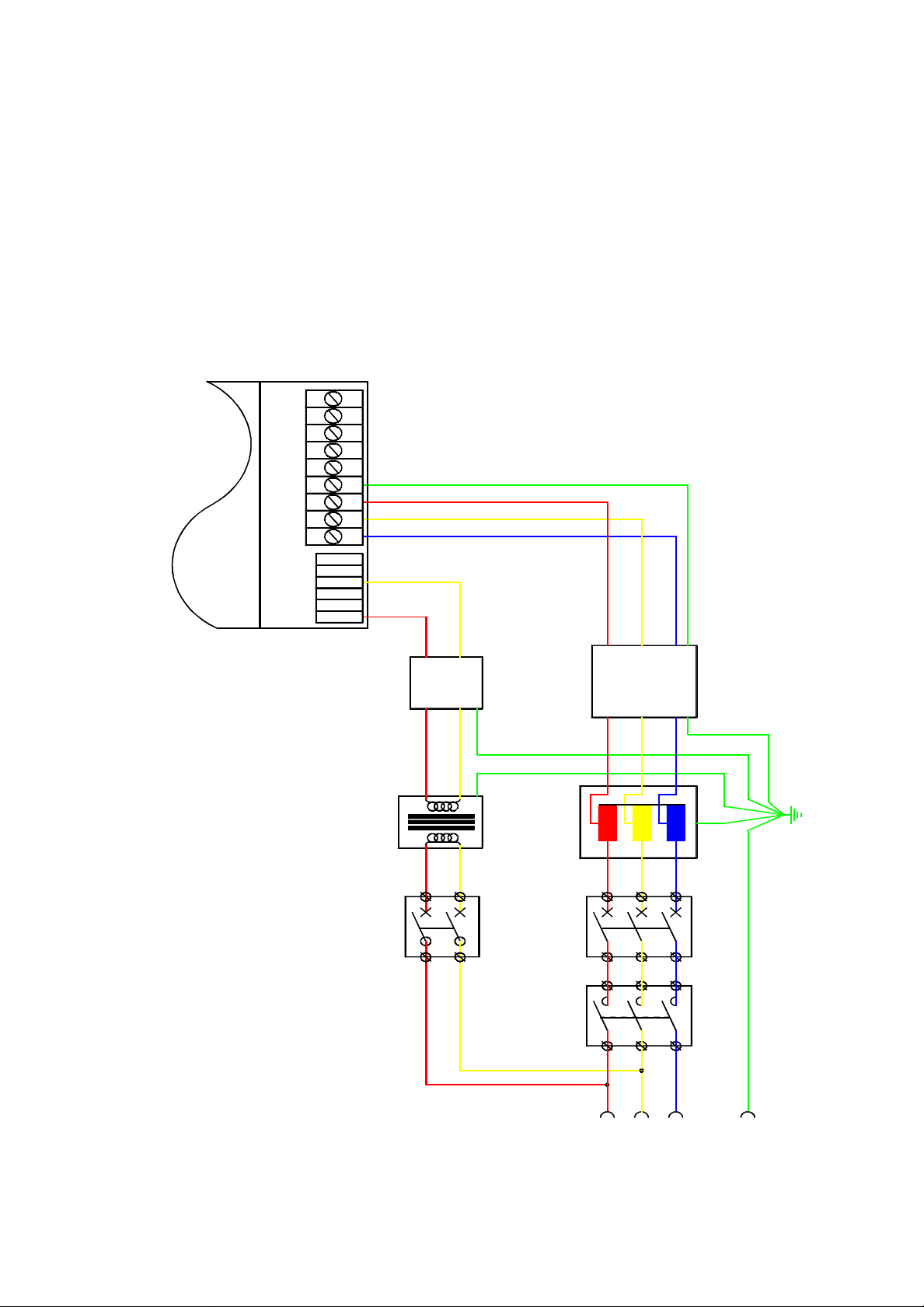

Figure 1: EMC filtering 3

Figure 2: Fixing centres for the Q-Drive. 10

Figure 3: Connections 13

Figure 4: P2 Upper: resolver connector 16

Figure 5: P2 Lower: encoder connector 17

Figure 6: P10, P11, P12: discrete signals 19

Figure 7: P7, P8, P9: power connectors 20

Figure 8: Wago spring terminals 21

Figure 9: General installation arrangement 23

Figure 10: Auxiliary supply connection 25

Figure 11: System earthing 26

Figure 12: Q-Drive.exe: password entry page 34

Figure 13: Q-Drive.exe: scanning for active drives 35

Figure 14: Q-Drive.exe: page 0 parameters. 36

Figure 15: Q-Drive.exe: page 1 parameters 37

Figure 16: Q-Drive.exe: page 2 parameters 39

Figure 17: Q-Drive.exe: page 3 parameters 41

Figure 18: Q-Drive.exe: page 6 parameters 41

Figure 19: Q-Drive.exe: page 8 parameters 42

Figure 20: Q-Drive.exe: page 9 parameters 43

Figure 21: Q-Drive.exe: status display 44

Figure 22: Seven segment display codes 48

Figure 23: Electrical rotation sense of the resolver 49

Figure 24: Backplane configuration 61

Figure 25: Backplane fuse 62

Figure 26: Drive amplifier jumper & fuse locations 64

Figure 27: Complete wiring plan 65

Copyright © 1996 Quin Systems Ltd. Page iii

Page 6

Q-Drive Installation Manual Issue 1.5

List of Tables

Table 1: Drive Data 9

Table 2: Test Points 9

Table 3: Cable Sizes 14

Table 4: P2 Upper, Resolver Input Connections 15

Table 5: P2 Lower, Encoder Output Connections 17

Table 6: P4 RS422 Out / RS232 Connections 18

Table 7: P3 to P4 RS422 Daisy Chain Connections 18

Table 8: P10, P11, P12 Connections 19

Table 9: Motor Phase Determination 50

Table 10: Q-Drive Trouble Shooting 54

Table 11: Amplifier Configuration 58

Table 12: Amplifier Fuses 58

Table 13: Backplane configuration Jumpers 60

Page iv Copyright © 1996 Quin Systems Ltd.

Page 7

Issue 1.5 Q-Drive Installation Manual

1. Introduction

This document is the Installation Manual for the Q-Drive s ervo amplifier, a me mber of

the Quin Systems Ltd. digital Programmable Transmission System (PTS) range.

The Q-Drive series of servo-amplifiers are intended to control 3 phase AC servomotors with electronic commutation and resolver feedback, up to a maximum rating of

18 Amps, 6.8kW continuous.

Such servo-motors are generally ca lled AC Brushless, but to avoid any confusion,

motors which can be used with the Q-Dri ve series servo-amplifiers should have the

following characteristics:

• Rotor constructed with permanent magnets a rranged in 1, 2, 3, 4, 5 or 6 po le

pairs, without commutator or slip rings.

• Stator constructed with 3 windings connected in star or delta.

• Electronic commutation is effected by means of a resolver (motors with Hall

effect sensors or tachogenerators are not suitable).

Note:

Servo-amplifiers which deliver a 3 phase sinusoidal supply are usually called

AC Brushless. The name DC Brushless is reserved for servo-amplifiers whose

output supply is trapezoidal.

PLEASE READ THIS MANUAL BEFORE INSTALLATION.

It is very important that the guidelines for installation are observed, otherwise damage

to the system or to the machine may occur. Quin Systems Limited accept no liability

for damage or costs arising from incorrect or inadequate installation of the systems, or

from incorrect programming of the system for the required application. Digital control

systems are not simple, but can be used successfully to control industrial machinery and

provide great improvements in reliability, performance and flexibility.

Copyright © 1996 Quin Systems Ltd. Page 1

Page 8

Q-Drive Installation Manual Issue 1.5

1.1 Q-Drive Characteristics

The main characteristics of the Q-Drive servo-amplifiers are as follows:

• Digital servo-amplifier with analogue speed command +/- 10V, for Brushless

motor with resolver.

• Utilises a 16 bit DSP (Digital Signal Processor)

• Compact unit for connection to 3 phase power supply with built-in braking

module.

• Double Eurocard Format using Surface Mount Technology (SMD).

• Completely programmable by a multi-drop RS422 or direct RS 232 serial link.

• Sinusoidal current output assures smooth torque and optimum performance at

low speed.

• Power and command circuits are optically isolated from each other.

• Protections and ruggedness for use in severe conditions.

• Easy to use external connections including two part connectors for resolver

input and encoder output.

• Simulated incremental encoder output with adjustable resolution to 1024 ppr

and adjustable marker pulse. Differential line driver outputs.

• 7 segment status indicator for diagnostic display.

• Short-circuit protected output stage.

• I2t protection.

• Detection of resolver fault, motor overheating.

• Velocity or current regulation.

• Auxiliary voltages are produced within the drive, no external power supply

required.

• Drive can be enabled using an optional opto-coupled input or using a volt free

contact.

• Motor connections are constantly monitored.

Page 2 Copyright © 1996 Quin Systems Ltd.

Page 9

Issue 1.5 Q-Drive Installation Manual

1.2 EMC Compliance

The Q-Drive amplifier has been tested to and complies with BSEN 50081-1 and BSEN

50081-2 for radiated emissions. The Q-Drive also complies with mains borne

interference tests when used with a suitable three phase filter and when both the Q Drive and the filter are securely mounted and earth bonded to a conductive panel. If the

auxiliary supply is used then this too must be filtered. Both filters must provide at least

55dB attenuation at 1MHz. The cable between the filters and the Q-Drive should

preferably be screened and be kept as short as possible. Figure 1. below shows a typical

arrangement between the filter and Q-Drive,

U

V

W

E

E

E

R

S

T

Q-Drive

S'

R'

transformer

1 ø isolating

B

C

2 ø M

1 ø line

filter

uto3 ø A

transformer

B

C

3 ø M

Drive

Contactor

3 ø line

filter

R

T

S

E

Figure 1. EMC filtering

Copyright © 1996 Quin Systems Ltd. Page 3

Page 10

Q-Drive Installation Manual Issue 1.5

This Page is intentionally Left Blank

Page 4 Copyright © 1996 Quin Systems Ltd.

Page 11

Issue 1.5 Q-Drive Installation Manual

2. Unpacking and Inspection

Inspect the packaging for external signs of damage if possible before signing the

delivery receipt, as this may indicate that the goods have been mishandled in transit.

When unpacking the Q-drive , keep all the packaging materials if possible. If it is

necessary to ship th e Q-drive to another site, or to return it for service, the original

packing can be reused.

Inspect the Q-drive carefully when it is unpacked. Check for any loose parts, any circuit

boards loose in their card guides, cables not connected, or any bending of the case or

chassis.

If any defect or damage is suspected, do not connect powe r to the system

the carrier immediately, and contact your sales of fice or the Quin Systems Service

Department:

Quin Systems Limited

Service Department

Oaklands Business Centre

Oaklands Park

Wokingham

Berkshire RG11 2FD

England

Telephone Wokingham (01734) 771077

Fax (01734) 776728

. Notify

Copyright © 1996 Quin Systems Ltd. Page 5

Page 12

Q-Drive Installation Manual Issue 1.5

This Page is intentionally Left Blank

Page 6 Copyright © 1996 Quin Systems Ltd.

Page 13

Issue 1.5 Q-Drive Installation Manual

3. Drive Specifications

This section gives the overall specifications of the drive, including mechanical details

and environmental requirements.

3.1 Mechanical specification

The dimensions of the Q-Drive are as follows:

Height 400 mm

Width 115 mm

Depth 290mm

Weight 4 kg

IP Rating IP20

The drive is designed to be mounted wit h the circuit board vertical, to allow cooling air

circulation by convection. There should be at least 100mm clearance above and below

the unit to allow free air flow. If the unit cannot be mounted with the drive vertical, then

a fan must be fitted to blow air through the unit. The 18 amp model has built in fans for

forced cooling, the fans are optional on other models.

3.2 Environmental specification

Temperature: operating 0°C to 60°C

full power 0°C to 45°C

storage -20°C to 70°C

Relative humidity: 20 to 80% non-condensing

The drive may be operated at higher ambient temperatures, but will require additional

cooling such as forced air ventilation in order to do so. The drive is normally supplied

in a case or chassis with ventilation holes top and bottom, and therefore is not protected

against dust, particle s, or liquids. If necessary, the unit can be supplied in a suitable

sealed cabinet. Please contact your sales office or Quin Systems directly for further

details.

3.3 Power supply specification

Supply voltage 3 x 220V AC +/- 15%

Supply frequency 45 to 65 Hz

An additional single phase 230V AC supply is required to keep the resolver interface

powered when the main three phase supply to the drive is interrupted, i.e. during an Estop situation. If this auxiliary supply is fitted it is very impo rtant to ensure that the

correct phases are used, this is explained further in section 5.3 on page 25.

Copyright © 1996 Quin Systems Ltd. Page 7

Page 14

Q-Drive Installation Manual Issue 1.5

3.4 Electrical Specification

3.4.1 General data for all types

Supply voltage 3 x 220V AC +/- 15%

Supply frequency 45 to 65 Hz

Operating temperature range 0 to 60° C

Operating temperature range at full power 0 to 45° C

(from 45°C, reduce output current by 2%/°C to 60°C)

Storage temperature range -20 °C to + 70 °C

PWM chopper frequency 9.99 kHz

Differential input reference +/- 10V

Speed control range 1/5000

Bandwidth:

speed loop 300 Hz

current loop 2 kHz

Rated power dissipation during braking

with standard resistance 125W

Max. output to motor 3 x 210 V, 0 to 500 Hz

Incremental encoder: output 5V

“low speed” settings available 128, 256, 512, 1024 ppr

“high speed” settings available 128, 256, 512 ppr

Theoretical max. speed for motor with resolver:

“low speed” up to 3500 rpm

“high speed” up to 6000 rpm

Switching threshold of brake module 385 V DC

Over voltage trip threshold 415 V DC

Voltage drop trip threshold 180 V DC

RS 232/RS422 serial link

baud rate

Standard: 9600 Bd

Configured by solder bridge: 19200 Bd

transmission Full duplex

format 1 Start bit

8 Data bit

no parity

1 Stop bit

RTS/DTR controls RS232 transmission flow

Page 8 Copyright © 1996 Quin Systems Ltd.

Page 15

Issue 1.5 Q-Drive Installation Manual

3.4.2 Drive Performance Specification

Servo-amplifier type

Rated rms current Amps 5,9 10,0 18,7

Rated peak current Amps 8,3 14,2 26,4

Max. rms current Amps 11,8 20,1 37,3

Max. peak current

Rated power (kW) 2,1 3,6 6,8

Max. power (kW) 4,3 7,3 13,6

:

Amps 16,7 28,4 52,8

Table 1: Drive Data

PQD506 PQD510 PQD518

Note:

I

= I

rms

P =1.73 x I

- in star V

I

rms phase

- in delta V

peak

rms phase

= I

/ 1.41

x V

rms

= 210V / 1.73

rms

rms phase

or P= 3 x I

rms

= 210V

rms phase

x V

rms phase

I

rms phase

Example: Type PQD506 I

P

max

P

rated

= I

rms

/ 1.73

rms max

= 11.8 A

= 1.73 x 11.8 x 210 = 4.3 kW

= 1.73 x 5.9 x 210 = 2.1 kW

rms rated

= 5.9 A

3.4.3 Analogue readings on the motherboard

The Q-Dri ve mo therboard contains several meas urement points which permit an

analogue reading of the three signals shown in Table 2-

Measurement

point

Current Instanta neo us Cur rent 10V corresponds to the ma x. current o f

Command Internal command voltage V

Speed Motor speed +/- 10V corresponds to the max. speed

Description Scaling

the unit

command

of 6000 rpm

= V

ext. cmd

Table 2: Test Points

The location of the measurement points is shown in Figure 24. on page 61

Copyright © 1996 Quin Systems Ltd. Page 9

Page 16

Q-Drive Installation Manual Issue 1.5

3.5 Mounting Details

The Q-Drive has mounting holes on the rear plate for fixing to an electrical panel inside

a cabinet. The unit is fixed with four M5 bolts using the fixing centres as shown in

Figure 2. below.

115.5m m

95.5m m

Braking

Over Current

4 off fixing holes

M5 Clearance.

m

385.0mm400.0m

Figure 2. Fixing centres for the Q-Drive.

Page 10 Copyright © 1996 Quin Systems Ltd.

Page 17

Issue 1.5 Q-Drive Installation Manual

3.6 Relevant Directives

This product is designed to be incorporated into a system for the control of

machinery, and needs external equipment to enable it to fulfil this function. It

must not be relied upon to provide safety-critical features such as guarding or

emergency-stop functions. It must not be put into service until the machinery

into which it is incorporated h as been declare d in conformi ty with the Machi nery

Directive 89/392/EEC and/or its relevant amendments.

The installation instructions in this manual should be followed in constructing a

system which meets requirements.

The product has been tested in typical configurations, and meets the EMC

Directive 89/336/EEC when used with the recommended mains filter.

This product as normally supplied has mains level voltages accessible to touch,

and requires t o be mounte d within a su itable cabine t to meet a ny required IP

rating to BSEN 60529.

Copyright © 1996 Quin System s Ltd. Page 11

Page 18

Q-Drive Installation Manual Issue 1.5

This Page is intentionally Left Blank

Page 12 Copyright © 1996 Quin Systems Ltd.

Page 19

Issue 1.5 Q-Drive Installation Manual

4. Connections

4.1 General

High and low voltage cable connections ha ve been segregated in the Q-drive. The

positions of the various connectors are shown in Figure 3.

P11

P12

P10

RESOLVER

P2 Upper

SW1

J4 J3

ENCODER

J1J2

P4

RS422/232

P2 Lower

P3

RS422

Fan

SUPPLY

T S R

P7

S'

R'

S'

Figure 3. Connections

R'

Copyright © 1996 Quin Systems Ltd. Page 13

Fan

P7

P8

EARTH

P8 P9

P9

MOTOR

W U V

Page 20

Q-Drive Installation Manual Issue 1.5

4.1.1 Wiring and connectors

The wiring of the Q-Drive series of servo-amplifiers must be carried out according to

the schematics in these instructions. Local wiring regulations must be observed.

Special attention should be paid with respect to wiring rules regarding ground, earth and

neutral.

The earth wire to the amplifier, motor and housing must be as short as possible and

connected to a common earth point.

The complete wiring plan is represented in on the next page.

4.1.2 Cable lengths and cross-sections

Quin Systems recommend that the following cable cross-sections are used:

Units PQD506 PQD510 PQD518

Supply voltage

Motor

Earth

Command signals

mm

mm

mm

mm

2

2

2

2

1.50 2.50 4.00

1.50 2.50 4.00

1.50 2.50 4.00

0.18 0.18 0.18

Table 3: Cable Sizes

Page 14 Copyright © 1996 Quin Systems Ltd.

Page 21

Issue 1.5 Q-Drive Installation Manual

4.2 Low Voltage Connections

Details of the low voltage connections which include the Encoder, Resolver, RS422/

RS232 and discrete signals, are described in the following sections.

4.2.1 P2 Upper: Resolver

The resolver interf ace uses the upper half of c onnector P2 and is wired as sh own in

Table 4: and Figure 4. . The external screen should be connected at both ends; motor

and amplifier. The overall screen must be connected at the amplifier end, pin 1 should

be used, and it should also be connected to the motor earth terminal at the motor end of

the cable. It is recommended that the three internal screens should be connected only at

the servo-amplifier end of the cable. They should be connected to pin 8 along with the

Ref. 2 connection. Pins 2 and 3 of the connector are used for the motor thermal overload

which can be either normally open or normally closed, or (if a thermal sensor is used)

have the following characteristics:

Contacts Open: >10kΩ

Contact closed <1kΩ

P2 Pin Number Function

1ScreenBraid J

2 Thermal Trip 1 White T

3 Thermal Trip 2 Brown S

4 Sin 2 Pink E

5Sin 1GreyC

6 Cos 2 Yellow P

7Cos 1GreenD

8Ref. 2Blue B

9Ref. 1Red A

Table 4: P2 Upper, Resolver Input Connections

Suggested Wire

Colour

SEM Motor

Resolver

connector

Copyright © 1996 Quin System s Ltd. Page 15

Page 22

Q-Drive Installation Manual Issue 1.5

1

2

3

4

5

6

7

8

Screen

White

Brown

Pink

Grey

Yellow

Green

Blue

Red

9

Heidenhain cable

type 200 775 02

Figure 4. P2 Upper: resolver connector

4.2.2 P2 Lower: Encoder

The Encoder output uses the lower half of connector P2 and is wired as shown in Table

5: and Figure 5. . The Q-Drive servo amplifier simulates an incremental encoder using

the positional information obtained from the resolver. The encoder resolution can be as

high as 1024 pulses per revolution (PPR) when the drive speed is limited to 3500 RPM.

If the drive is required to move the motor at higher speeds then the encoder resolution

drops to a maximum of 512 PPR. If the drive is set to 1024 PPR and 6000 RPM then an

incorrect encoder pulse train will be produced.

The cables used for the encoder signals should be high quality screened cables, using

individually screened twisted pairs, with an overall cable screen as well. The cable

screen should be connected directly to the main earth point, not via the control system

0V supply.

It is recommended that the maximum cable length for the enc oder output should not

exceed 25m, which should not be a problem as the Q-drive and control system can

usually be mounted within the same cabinet. If the machine installation requires a cable

longer than 25m, then it may be necessary to install an additional line driver unit to

boost the encoder signals.

Page 16 Copyright © 1996 Quin Systems Ltd.

Page 23

Issue 1.5 Q-Drive Installation Manual

Q-Drive Pin

Number.

1. A. 1. Pink.

2. /A. 6. Grey.

3. B. 2. Yellow.

4. /B. 7. Green.

5. Z. 3. Blue.

6. /Z. 8. Red.

7. Not Used. . .

8. 0V. 9. White.

9. Screen. 5. All screens.

Table 5: P2 Lower, Encoder Output Connections

Function.

PTS D-type Pin

no.

Suggested Wire

Colour.

1

2

3

4

5

6

7

Pink

Grey

Yellow

Green

Blue

Red

e

t

hi

W

Screen

Heidenhain cable

type 200 775 02

8

9

Figure 5. P2 Lower: encoder connector

Copyright © 1996 Quin System s Ltd. Page 17

Page 24

Q-Drive Installation Manual Issue 1.5

4.2.3 P4 RS422 Out / RS232

The socket P4 is used as the daisy chain OUT connector in an RS422 multi-drop drive

chain or the RS232 port in a single drive application. The RS232 option can only be

used if the drive has been setup for this format by Quin systems. The def ault

configuration is for RS422, the connections are shown below.

Pin Number. RS422 Function. RS232 Function.

1. Not Used. Not Used.

2. Tx. Tx.

3. Rx. Rx.

4. Not Used. Not Used.

5. Gnd. Gnd.

6. Not Used. Not Used.

7. /Tx. RTS.

8. /Rx. DTR.

9. Not Used. Not Used.

Table 6: P4 RS422 Out / RS232 Connections

4.2.4 P3 RS422 In

The plug P3 is used as the RS422 daisy chain IN connector in a multi -drop drive chain.

If the unit has been configured for RS232 then this connector has no function.As a

temporary measure, an RS232 device may connect to an RS422 drive (default linking)

with the connections shown.

P4 (OUT

Connector)

Pin Number.

1. Not Used. . 1.

2. Tx. . 2.

3. Rx. Gnd. 3.

RS422

Function.

RS232 (temporary

usage).

P3 (IN connector)

Pin Number.

4. Not Used. . 4.

5. Gnd. Gnd. 5.

6. Not Used. . 6.

7. /Tx. Tx. 7.

8. /Rx. Rx. 8.

9. Not Used. . 9.

Table 7: P3 to P4 RS422 Daisy Chain Connections

Page 18 Copyright © 1996 Quin Systems Ltd.

Page 25

Issue 1.5 Q-Drive Installation Manual

4.2.5 P10, P11 & P12

These connectors are used for interfacing all other low voltage signals to the drive and

are detailed below in Table 8: Figure 6. shows the pin 1 & 2 socket of connector P10,

Pin Number. Signal Name. Function.

P10.1. Earth. Command shield connection.

P10.2. Gnd. Drive internal Ground (not isolated).

P10.3. S+. Command signal +ve.

P10.4. S-. Command signal -ve.

P11.1. EXTILIM. External current limit,+10V

corresponds to max peak current.

P11.2. +12V Bat. External 12V battery +ve.

P11.3. RDY2. Volt free drive ready relay contact.

P11.4. RDY1. Volt free drive ready relay contact.

P12.1. -12V Bat. External 12V battery -ve.

P12.2. BGnd. External 12V battery Gnd.

P12.3. 024V. 0V for ENABLE signal.

P12.4. ENABLE. Drive enable signal from controller.

Table 8: P10, P11, P12 Connections

P11 & P12 already inserted into their respective mating half, whilst the pin 3 & 4

connectors are shown waiting to be inserted.

4

2

3

1

P

4

3

1

1

P

4

0

1

P

2

1

2

1

2

1

0

1

P

Figure 6. P10, P11, P12: discrete signals

Copyright © 1996 Quin System s Ltd. Page 19

Page 26

Q-Drive Installation Manual Issue 1.5

4.3 High Voltage Connections

4.3.1 P7, Three Phase In

P7 is a block of three high current scr ew terminals used to connec t the three pha se or

single phase supply to the Q-Drive. If a single phase supply is used then connections

‘R’ and ‘S’ should be use d. The individual phases ar e identified by markings o n the

circuit board just above the terminals.

4.3.2 P8, Earth Terminals

P8 is a block of three terminals, all connected to ground. These terminals should be used

to connect the earth wire from the three phase supply or transformer and an earth

connection to the motor. One of these terminals can also be used to connect an earth

bonding strap to the Q-Drive although there is an M4 stud just below these terminals

designed expressly for this purpose. All metal parts of the Q-Drive are bonded to this

stud and hence it is imperative that it is connected to ground. The earth terminals are

marked as ‘EARTH’ on the circuit board just above the terminals.

4.3.3 P9, Motor

P9 is used to connect the three phase output to the motor. As with P7 and P8 it uses high

current screw terminals, The output phases are marked just above the terminals and

should be connected to the corresponding phases at the motor.The standard connections

to an SEM motor plug are phase U to pin A, phase V to pin B, phase W to pin F, and

earth to pin E.

U

V

W

E

E

E

R

S

T

Figure 7. P7, P8, P9: power connectors

Page 20 Copyright © 1996 Quin Systems Ltd.

Page 27

Issue 1.5 Q-Drive Installation Manual

4.3.4 Wago Spring Terminals

A group of six Wago spring terminals are positioned to the left of the screw terminals.

These are used to connect the auxiliary supply and an external fan.The terminals

marked R‘ and S‘ are used to connect the single phase auxiliary supply to the Q-Drive.

This supply is required if the resolver position and encoder output signals are to be

maintained when the three phase supply is removed, i.e. during an emergency stop, it

does not supply power to the amplifier part of the drive. There are two terminals each

for R‘ and S‘. It is vitally important to ensure that the same phase is connected to R and

R‘ and similarly that the phase connected to S is the same as that connected to S‘. A

typical connection diagram is shown in Figure 10. on page 25 .

There are also a pair of terminals for the connection of an externally mounted fan, if one

is used. Fans can be fitted internally and if so then the internal power connector should

be used, leaving the external terminals free.

.

Figure 8. Wago spring terminals

Copyright © 1996 Quin System s Ltd. Page 21

Page 28

Q-Drive Installation Manual Issue 1.5

This page is intentionally left blank

Page 22 Copyright © 1996 Quin Systems Ltd.

Page 29

Issue 1.5 Q-Drive Installation Manual

5. Electrical Installation

5.1 General

This section gives some guidelines for the electrical installation of the drive amplifier

system. The diagram below shows a typical installation, and is used to highlight

specific areas described in the following sections. Note that this is only a very

simplified sketch, not a full installation wiring diagram. Details such as isolators,

contactors and other switching arrangements are not shown but in most cases will be

used. Please refer to the motor and control manufacturer’s instructions for further

details on electrical installation

Control System

ø1

ø2

ø3

Neutral

Earth

8 8

8

8

8

1 ø

Isolating

Transformer

QUIN

Encoder cable

3 ø

Isolating

Transformer

Resolver cable

8

Q-Drive

Motor

Figure 9. General installation arrangement

Copyright © 1996 Quin Systems Ltd. Page 23

Page 30

Q-Drive Installation Manual Issue 1.5

5.2 Mains supply

The Q-Drive can be powered from one of four sources:-

• 220V three phase supply

• Isolating transformer

• Auto-transformer.

• Single phase supply

The drives are fitted with surge limiting devices which pre vent the bridge rectifier from

being damaged by high inrush currents.

If the drive is to operated directly from a 220V three phase or single phase supply then

a 4mH three phase choke should be installed between the supply and the drive.

The size of the mains tra nsformer is approximat ely calculated from the incoming power

per axis.

Mechanical power:

Motor Torque(Nm) Motor Speed(RPM)×

---------------------------------------------------------------------------------------------------- 9550

Mechanical Power(kW)=

The power of the transformer in kVA should be about equal to the mechanical power if

the motor efficiency is ignored.

Page 24 Copyright © 1996 Quin Systems Ltd.

Page 31

Issue 1.5 Q-Drive Installation Manual

5.3 Auxiliary Supply

A group of six Wago spring terminals are positioned to the left of the screw terminals.

The first four of these (from the left) are used to connect the auxiliary supply. The

terminals marked R‘ and S‘ are used to connect the auxiliary single phase supply to the

Q-Drive. This supply is needed if the resolver position and encoder output signals are

to be maintained during an emergency stop, i.e. when the three phase supply is

removed, it will not supply power to the amplifier p art of the drive. There are two

terminals each for R‘ and S‘. It is vitally important to ensure that the same phase is

connected to R and R‘ and similarly that the phase connected to S is the same as that

connected to S‘. A typical connection diagram is shown in Figure 10. below.

.

U

V

W

E

E

E

R

S

T

Q-Drive

S'

R'

transformer

1 ø isolating

B

C

2 ø M

1 ø line

filter

uto3 ø A

transformer

B

C

3 ø M

Drive

Contactor

3 ø line

filter

R

T

S

E

Figure 10. Auxiliary supply connection

Copyright © 1996 Quin Systems Ltd. Page 25

Page 32

Q-Drive Installation Manual Issue 1.5

5.4 Earth connections

Earthing is very important in any electrical installation. It is an essential safety measure

to prevent electric shock in case of any failure of the eq uipment, and is also used for

screening between different units. It provides a ground refer ence point for all units in

the system. Incorrect earth connection can result in erratic operation due to noise or

earth loops, or may prevent the system from operating a t all. These problems can be

avoided by careful arrangement of the earth connections, and by techniques such as

isolation.

Control System

8

8 888

Encoder cable

QUIN

Resolver cable

8

Q-Drive

ø1

ø2

ø3

Neutral

Earth

1 ø

Isolating

Transformer

3 ø

Isolating

Transformer

Figure 11. System earthing

Motor

• The earth connections from the isolation transf ormer or whatever source of

supply is used shoul d be made using a suitab le gauge of wire. The I EE 16th

edition wiring regulations (or appropriate local regulations) should be consulted

to determine an appropriate gauge of wire for the earth bonding straps. All the

earth connections should be connected together at one point, prefera bly on the

electronics cabinet chassis earth connection.

•Do

not

tie the earth wires together with any low voltage signal cables, or run

them close together in the same conduit or cable duct.

• All screened cables should have their screens connected directly to earth, not via

the system 0V power supply. This is very important, as otherwise noise and

transients picked up in the screen will pass through the system, instead of being

dissipated directly to earth

Page 26 Copyright © 1996 Quin Systems Ltd.

Page 33

Issue 1.5 Q-Drive Installation Manual

5.5 Connecting the motor to the drive

A typical brushless A.C. motor is connected with two cables; one carries the power to

the motor windings, and the other returns sign als from a position or speed feedback

device such as a resolver to the drive for positional speed sensing. The motor should be

connected using cables as specified by the manufacturer. These cables usually have a

strict specification with regard to size and length of motor connections.

In general though...

•Do

not

tie the motor cable and resolver cable together, or run them together in

the same conduit or cable duct. The motor cable can carry high currents in

normal operation, and the resolver cable carries low voltage signals back to the

drive. The correct performance and accuracy of the motor and drive depend on

the quality of the resolver signals.

• Do use a screened cable with individually screened twisted pairs for the resolver

signals from the motor to the drive. This prevents crosstalk and noise interfering

with the resolver signals, and gives the best performance.

• Recommended cable for motor drive power:

RS part number 379-198

Recommended cable for Resolver or Encoder:

Heidenhain cable part number 200-775-02

(Formerly part number 2449-5501)

Copyright © 1996 Quin System s Ltd. Page 27

Page 34

Q-Drive Installation Manual Issue 1.5

5.6 Connecting the drive to the controller

The drive is connected to a Quin motion controller using usually two multicore cables

and two discrete wire leads: one cable carries the analogue speed demand to the drive,

and the other returns the position feedback as processed in the drive. A pair of leads

connects the command to enable the drive

The analogue speed command uses a 2-core screened cable. The controller’s command

output for the chosen axis is connected to P10.3, with its 0 vol ts return to P 10.4 and the

screen of the cable to P10.1 - refer to table 8. A suitable scree ned cable is RS part

number 367-325.

The encoder simulation output of the drive is connected to a Quin controller as per table

5 and figure 5, using the appropriate axis socket. The chosen axis parameters are to be

set for Quadrature x 4 encoder, which is usually the default setting.

The axis enable relay output (“normally open” and “common” pins) is connected across

P12.3 and P12.4, as per table 8: by default, the drive sources the 24 volts which is

switched by the relay. If an external 24 volts is to be used (maybe to enable a quicker

safety stopping), enable the “valid” opto isolator by removing backplane J2 links 1-2

and 3-4, then wire as per the PTS or TRC Installation Manual “typical example”.

Page 28 Copyright © 1996 Quin Systems Ltd.

Page 35

Issue 1.5 Q-Drive Installation Manual

6. Safety - Using Guards and Limits

All machines should include comprehensive safety features. This is essential both for

normal safety considerations, and to comply with H ealth and Safety requirements. It

can also prevent any unwanted interference with the machine while it is running.

All moving machinery must be guarded so that it cannot be reached by anybody while

in motion. The guards should be fitted with guard switches or sensors, connected so as

to immediately cut power from the motors when any gu ard is opened. On some

machines, it may be useful to lock the guards closed by means of a solenoid to prevent

them from being opened while the machine is running. This allows the machine to

detect any attempt to open a guard and shut down the machine cleanly before unlocking

the guard and allowing it to open.

Motors which have constraints or limits on their range of motion should be fitted with

hard wired limit switches. These should cut power from the motors if any motor goes

outside its limits of travel. The machine must also have one or more locking em ergency

stop push-button switches, accessible from several positions around the machine.

Anyone operating or working on the machine must be able to instantly stop the machine

at any time by hitting an emergency stop switch.

There are no limit switches available on the Q-Drive but if the machine require s the use

of limit switches then they may be implemented using the digital i/o functio ns available

on the control system. If the control system is used to provide a limit switch function

then this should be backed up with an mechanical switch which should cut the power

to the Q-Drive.

Guards, emergency stop and limit switches may be connected into the control system

motor control systems, by using the digital input lines. However, the programmable

input functions on the control system should only be used in addition to the

conventional hard wired guard and limit switches, not to replace them. The digital

inputs can be used to trigger a smooth shutdown sequence, or to generate a limit switch

error and shut down immediately. The control system can then remove power from the

motors and drives if required, under software control, by using a digital output line to

switch the motor supply contactors.

switches MUST remove all electrical power fr om the motors and drives,

independently of any action of the control system.

control system, then again all power must be removed from the motors. This is easily

done by connecting the on board relay on each axis controller into the drive enable

function, or into the control circuit for the motor and drive main contactors.

Note that in most cases, it is not necessary to remove power from the control system,

only from all the high power equipment. If power to the control system and encoders

can be maintained even when the motors and drives are shut down, then the system does

not lose any position information. This can allow the machine to start up again much

more quickly than if the control system is powered off as well, since the machine does

not need to execute a complete initialisation before it can be restarted.

In all installations the limit switches and guard

If power is removed from the

Copyright © 1996 Quin Systems Ltd. Page 29

Page 36

Q-Drive Installation Manual Issue 1.5

2

6.1 Choosing a motor

The choice of motor for a particular application depends on several fac tors. Some of

these are given below.

• Maximum torque required.

• Continuous torque required (r.m.s.).

• Maximum motor shaft speed.

• Maximum acceleration rate.

The torque is the turning effort required from the motor in order to accelerate the

mechanical load or system at the desired rate. It is usually measured in Newton metres

(Nm), gram centimetres (gcm), pound feet (lb. ft ) or ounce inches (oz. in) . In order to

calculate the torque required from the motor, it is necessary to find out the following

information about the mechanical system.

• The reflected total inertia of the system or load, at the motor shaft.

• The reflected total friction of the load.

• The internal motor inertia and friction.

• The maximum acceleration rate of the motor.

• Any gear or pulley ratios in the mechanical system.

For example, consider a motor driving a load via a belt a nd pulleys. The total torque

required from the motor is given by:

2

D

1

T

------

ILI

D

+

2

2

D

dθ

M

t

d

1

------

F

+ +=

2

D

2

F

L

M

where T = total motor torque required

D1= diameter of motor pulley

D2= diameter of load pulley

I

= inertia of load

L

I

= inertia of motor

M

d θ

= acceleration at motor shaft

2

t

d

F

= friction torque of load

L

F

= friction of motor.

M

Page 30 Copyright © 1996 Quin Systems Ltd.

Page 37

Issue 1.5 Q-Drive Installation Manual

In most cases, the inertia and friction can be assumed constant, unless the system has a

changing load. In this case the maximum possible load should be used in the

calculations. The required velocity profile of the moto r should be sketched out by

plotting motor velocity against time. The slope of this gives the motor acceleration, and

thus the maximum required acceleration can be found from the steepest slope on the

graph. This acceleration value can then be substituted in the torque equation for a given

motor to see if the motor is powerful enough to do the job.

This can be repeated along the velocity-time plot for al l accelerations to give a graph of

torque against time. This can be used to find the average or r.m.s. continuous torque

required by the system. Servo motors are often specified with both a continuous and a

peak torque rating, and they should be chosen such that the torque requirement of the

machine is well within the capac ity of the motor. Care must al so be taken to ens ure that

the maximum speed of the motor is not exceeded.

Note that if too large a motor is selected, the motor inertia is higher than for a smaller

motor. This affects the maximum acceleration that the motor produces. It is not always

the largest or most powerful motor that accelerates the load at th e quickest rate . Also

note that maximum power transfer from the motor into the load is obtained if the motor

inertia and reflected load inertia are similar.

The ideal motor should have as high a torque to inertia ratio as possible. Pancake o r

printed armature motors are often used beca use they have low rotor inertias. This is also

another advantage of brushless motors, in that they have low rotor inertias because the

rotor often does not have any electrical windings but consists simply of a permanent

magnet on a shaft. Brushless motors also exh ibit better heat dissipation from their

wound stator.

Copyright © 1996 Quin System s Ltd. Page 31

Page 38

Q-Drive Installation Manual Issue 1.5

6.2 Mounting the motor

The motor must be mounted rigidly to the structure of the machine or to a solid floor.

If it is not mounted securely, it may vibrate or oscillate when the motor is powered up

and the position or velocity control loops closed. The motor exerts as much torque on

its mountings as it does on the lo ad. If the mountings are flexible, they ma y form a

resonant syst em, with the motor supplyi ng plenty of power to susta in severe

oscillations.

6.3 Connecting the motor to the load

The motor shaft must be connected se curely to the load. This may be by means of a

drive shaft, a toothed belt and pulleys, or by a gearbox. In all cases the coupling

between the motor and the load must be as stiff as possible, and must have minimum

backlash. At the same time, care must be taken to avo id adding any unnecessary friction

into the system, as this reduces the performance of the servo system.

A common problem when connecting the motor to its load is backlash. This is usually

found in gearboxes, where the input gear is allowed to move by a small amount between

the teeth of the output gear, while the output gear is stationary. A similar effect is seen

if the motor mountings are loose or sloppy, or if the coupling between motor and load

is too flexible. The effect of backlash is not just a loss of position accuracy, but may in

extreme cases result in a highly unstable system. All possible precautions must be taken

to minimise or eliminate backlash in the system.

Page 32 Copyright © 1996 Quin Systems Ltd.

Page 39

Issue 1.5 Q-Drive Installation Manual

7. Drive Parameters

7.1 Serial Link

The serial link is used to set or monitor drive parameters stored in non-volatile memory

using the configuration program.

This program allows the user to:

• set all user adjustable parameters

• monitor inputs and fault status

• In a multi drive configuration it is possible to acce ss all drives from a singl e PC

without having to transfer the serial cable from one drive to another.

With the serial link connected it is possible to monitor the position of the resolver (0-

1024) within one motor revolution.

Hardware:

A personal computer with either an RS422 adapter plus cable or an RS232 serial cable.

The choice depends upon how the drive has been configured.

7.2 Getting Around the Configuration Program

The program QDRIVE.EXE should be installed on an IBM compatible personal

computer (PC) and used to set the drive p arameters and monitor the servo-amplifier

status.

There are 80 parameters available on the Q-Drive that are divided up as detailed below.

On the following pages are descriptions of various parameter and their range of values;

parameters not described should not be changed.

0..10: Motor parameters

11..31: Installation parameters

32..43

44..59: Internal parameters (for testing)

60..63: Parameter protection bits

64..79: Status parameters, read only

Certain parameters only become active after they have been saved with the <F2>

function key. These are denoted by an <F2> symbol in their title

Copyright © 1996 Quin Systems Ltd. Page 33

Page 40

Q-Drive Installation Manual Issue 1.5

Run the configuration program by typing;

QDRIVE <Return>

The initial screen, shown below, appears asking for the password motor to be entered.

The program will allow changes to be made only if the password is correct, but will st ill

run if the password is incorrect to allow parameter monitoring only.

Figure 12. Q-Drive.exe: password entry page

The

QDRIVE.EXE

pr ogram presents the servo parameters using nine pa ges or screens.

The first three pages involve the setup of the servo-amplifier and the absolute position

of the resolver. The last page is used to monitor the inputs and alarm states. Only the

parameters on the first three pages can be modified through the computer program. In

order to change the parameters it is necessary to “Connect” to a pa rticular drive. This

is achieved in the following way.

1 Press the <F8> function key to put the program “On-Line”, the program will

immediately start trying to communicate with drive 1.

2 If drive 1 is not connected then press function key <F4> to scan fo r active

drives, Figure 13. on page 35 shows the program scanning for drives and

finding drive 1. When the active drive has been identified use the procedure

in steps 3 to 5 to connect to it.

3 To change to the required drive press and hold down the <Shift> key and

then press a function key from <F1> to <F10>, this will access drives 1

through to 10.

4 To access drives 11 to 15 press and hold down the <Ctrl> key and then

press a function key from <F1> to <F5>

5 When the desired drive has been selected, the message near the top of the

screen will show “ONLINE Connected”

Page 34 Copyright © 1996 Quin Systems Ltd.

Page 41

Issue 1.5 Q-Drive Installation Manual

Figure 13. Q-Drive.exe: scanning for active drives

Once a drive has been connected to it, it is possible to change the various pa rameters

available on each page. Moving around and selecting the parameters is done using the

following keys:

Change Pages:

The page displayed on the computer is changed by pressing the <TAB> key.

<Shift><Tab> will move backwards through the pages.

Select Parameters

The up/down arrow keys a re used to select the desired parameter on each page. The

selected parameter appears in reverse video, Figure 13. shows Proportional Gain as the

selected parameter.

Change Values:

The plus key <+> and the minus key <-> change the value of the selected parameter

displayed in reverse video. It is also possible to directly enter a value from the

keyboard, simply type in the new value and press the <Return> key.

Save Settings:

The <F2> key saves all settings to non-volatile (EEPROM) memory and in some cases

activates the changed value.

Read File:

A file containing preset drive parameters can be downloaded to the drive using the

<F3> key. Pressing this key will present the default drive parameter file name,

QDRIVE.CFG, this file name can be erased and replaced with another file name.

Copyright © 1996 Quin System s Ltd. Page 35

Page 42

Q-Drive Installation Manual Issue 1.5

Exit Program:

Press <ESC> to exit the program.

New Release:

For more information on new releases please look at the file README.TXT.

7.3 Page 0 Parameters

Figure 14. Q-Drive.exe: page 0 parameters.

0 Proportional Gain: (0..127)

1 Integral Gain: (0..127)

These two parameters determine the proportional and integral gain of the

servo velocity control loop. They are programmable from 0 to 127. Higher

values represent higher gains. The integral gain is cancelled for a value lower

or equal to 3.

2 Speed factor: (-127..+127)

This parameter sets the maximum speed and the direction of rotation of the

motor. This parameter is programmable from -127 to 127 corresponding to a

speed of -6000 rpm to +6000 rpm +/- 10%.

3 Maximum current: (0..127)

This parameter sets the peak current delivered to the motor. This parameter

is programmable from 0 to 127 (127 = maximum peak current of the

amplifier shown in Table 1: on page 9.

Page 36 Copyright © 1996 Quin Systems Ltd.

Page 43

Issue 1.5 Q-Drive Installation Manual

4 Nominal current: (10..64) <F2>

This parameter sets the con tinuous current delivered to the motor. This

parameter is programmable from 10 to 64

5 Pair of motor poles: (1..6)

This parameter sets the number of motor pole pairs for proper commutation.

This parameter is programmable from 1 to 6 (number of motor pole pairs).

6 Phase advance: (0..360)

This parameter is used to optimize the phase advance angle for each type of

motor. At max. speed (speed factor parameter = 127), this parameter can vary

the phase advance angle from 0 to 360 electrical degrees.

This parameter is programmable from 0 to 360° (typical value: 20).

7 Resolver Shift Angle: (-180..+180)

This parameter is used to set the resolver shift angle in software to

accommodate any resolver shift angle set by the motor manufacturer.

This parameter is programmable from -180 to +180 (electrical degrees).

7.4 Page 1 Parameters

Figure 15. Q-Drive.exe: page 1 parameters

8 Motor thermostat normally, open: (0,1)

The servo-amplifier is set to suit the motor thermal switch type by selecting:

0: for motor thermal switch normally CLOSED (or for PTC)

1: for motor thermal switch normally OPEN (or for NTC)

Copyright © 1996 Quin System s Ltd. Page 37

Page 44

Q-Drive Installation Manual Issue 1.5

9 Speed Offset:(-127..+127)

The setting of the servo-amplifier speed offset is done with this parameter.

which is adjustable between -127 and +127.

10 Parameter not used

11 Not used on Qdrive

12 Direction Stop: (0..3)

This parameter is used to prevent the motor from turning in a particular

direction and is setup as follows.

0: Turns in both +ve and -ve directions

1: Only turns in a +ve direction

2: Only turns in a -ve direction

3: Will not turn in either direction

13 Relay, Alarm or Ready: (0,1)

This parameter is used to define the function of the on-board relay:

0: Relay is on when there are no alarms

1: Relay is on when the drive is enabled

14 Inverted display: (0,1)

The 7 segment display can be inverted if the drive is to be mounted upside

down.

1: Normal display

0: Inverted display

15 RS232, RS422 Address: (0..17)

This parameter is used to set the address to which the drive amplifier will

respond and whether the drive is using RS232 or RS422 commu nications.

For use with an RS422 interface the drive can be set to read the address from

the Q-Drive backplane or be set to address 1. For use with an RS232 interface

it can be set to read the address from the Q-Drive backplane or set to an

address in the range 1 to 15:

0: RS422 Read address from backplane

1..15: RS232 Address 1..15

16: RS232 Read address from backplane

17: RS422 Set to address 1

Page 38 Copyright © 1996 Quin Systems Ltd.

Page 45

Issue 1.5 Q-Drive Installation Manual

7.5 Page 2 Parameters

Figure 16. Q-Drive.exe: page 2 parameters

Speed/Resolution: (1,2)

16

<F2>

This parameter selects one of two maximum motor speeds in order to enable

the servo-amplifier for the appropriate encoder resolution range.

The limits are:

1: Max. speed = 3500 rpm Max. resolution = 1024 ppr

2: Max. speed = 6000 rpm Max. resolution = 512 ppr

NOTE.

The encoder simulation will not work if the encoder simulation is set

to 1024ppr and the maximum speed is set 6000rpm

Encoder Resolution: (1..1024)

17

<F2>

This parameter selects the number of pulses generated by the encoder

simulator and can be set anywhere in the range 1 to 1024.

Reference Marker Width: (0..2)

18

<F2>

This parameter selects the width of the simulated encoder marker pulse (Z

pulse) relative to the width of the A channel period. The following values are

available: 1/4 , 1/2 and 1 and are set up as follows

0: 1/4 pulse width

1: 1/2 pulse width

2: 1 pulse width

Reference shift: (-512..+512)

19

<F2>

This parameter is used to shift the simulated encoder reference marker pulse

by +/- 180° relative to the null position of the resolver. It is programmable

over a range of, 512 (-180°) to +512 (+180°).

Copyright © 1996 Quin Systems Ltd. Page 39

Page 46

Q-Drive Installation Manual Issue 1.5

20 Enable: Hard, Trig, Soft: (0..2) <F2>

This parameter defines the way in which the amplifier is enabled. The first

setting, “Hard”, means that the amplifier can only be enabled using the

external contacts availa ble at P12 pins 3and 4. The second setting, “Trig”,

means that the amplifier has to be hardware enabled as in setting 1 above and

then software enabled using the <F5> key. If at any time the ampl ifier

becomes disabled e.g. because of a motor fault then the <F5> key will no

longer work until the hardware enable has been reset, i.e. re moved and then

replaced. The third setting “Soft”, allows the amplifier to be enabled and

disabled using the <F5> key, the hardware enable needs to be set all of the

time for this function to work.

0: Hard

1: Trig

2: Soft

21 Software Watchdog: (0..65535)

The value set in the watchdog parameter determines the time in milli seconds

which the amplifier will wait after the QDRIVE.EXE goes off-line or is

disconnected before reporting error code 9 and disabling the motor. The

watchdog is only active when the drive is enabled. Setting this value to 0 will

disable the watchdog

22 Alarm Latch 2,7,2&7: (0..3) <F2>

This parameters determines how the amplifier treats the Over current (I2t)

and Under voltage alarms, i.e. whether or not they are latched.

0: Neither alarm latched

1: Over current alarm latched

2: Under voltage alarm latched

3: Both alarms latched

23 Optional Speed Module

Page 40 Copyright © 1996 Quin Systems Ltd.

Page 47

Issue 1.5 Q-Drive Installation Manual

7.6 Page 3 parameters

Figure 17. Q-Drive.exe: page 3 parameters

24 to 53: Not used

7.7 Page 6 parameters

Figure 18. Q-Drive.exe: page 6 parameters

Copyright © 1996 Quin Systems Ltd. Page 41

Page 48

Q-Drive Installation Manual Issue 1.5

The parameters on Page 6 are Read only and as such cannot be changed.

54 Resolver position

The resolver position is a 12 bit value of the current resolver position within

one rotation.

55 Revolution counter

The revolution counter is a 24 bit count of complete resolver revolutions.

This value can be used with the resolver position to effectively produce an

absolute encoder.

7.8 Page 8 parameters

Figure 19. Q-Drive.exe: page 8 parameters

The parameters on Page 8 are Read only and as such cannot be changed.

Page 42 Copyright © 1996 Quin Systems Ltd.

Page 49

Issue 1.5 Q-Drive Installation Manual

7.9 Page 9 parameters

Figure 20. Q-Drive.exe: page 9 parameters

Max Peak Current (0..127):

74

This parameter defines the maximum peak current that the drive will deliver

to the motor

75 Max Nominal Current (0..127):

This parameter defines the maximum nominal current that the amplifier will

deliver

76 Manufacturing week:

The week number in which the drive amplifier was manufactured.

77 Manufacturing year:

The year in which the drive amplifier was manufactured.

78 Hardware Version:

The hardware version number or revision number of the drive amplifier.

79 Firmware Version:

The firmware or EPROM revision number.

Copyright © 1996 Quin System s Ltd. Page 43

Page 50

Q-Drive Installation Manual Issue 1.5

7.10 Status & Alarm page

Figure 21. Q-Drive.exe: status display

Pressing function key <F7> from any of the nine pages will bring up the status page as

shown above. This page gives a continually updated display of all alarms and the

current status of the drive and is particularly useful whilst commissioning the drive.

Whilst this page is displayed it is possible to change from one drive to another to obtain

the new drive’s current status. If a non existent drive is selected, i.e. drive 6 in a 5 drive

system then the display will continue to show the previous drive’s val ues except for the

top line which will show

“Axe 6 ONLINE no connect”

i Earth Defect:-

If the optional Earth Fault module is fitted and the Q-Drive is supplied from

an Auto-transformer then this alarm indicates a problem with the amplifier

earthing

ii EEPROM Fault

The amplifier has been unable to read data from the EEPROM non-volatile

memory or the data is corrupt

iii Resolver Fault

The resolver or the connections to it are faulty and the system can no longer

read the resolver.

iv RDC Fault

The part of the system designed to convert the resolver signals into digital

signals is faulty.

Page 44 Copyright © 1996 Quin Systems Ltd.

Page 51

Issue 1.5 Q-Drive Installation Manual

v Battery Under voltage

The backup battery voltage is too low to reliably maintain the system in the

event of a power failure.

vi Software Watchdog

Software watchdog has tripped, this usually means that the processor has

stopped running or it is stuck in a perpetual loop.

vii End Switch 1

This alarm cannot occur in the Q-Drive as it does not support end switches.

viii Link Motor Fault

Failure in the wiring from the amplifier to the motor.

ix I2t reached

The amplifier has reached it’s power limit, if the control system is trying to

push the amplifier harder

x Torque Enable Input

This will show ON when the drive is enabled and OFF when the drive is

disabled.

xi Motor Thermostat

The thermostat built into the motor has tripped, the motor should be shut

down and allowed to cool.

xii Heatsink Thermostat

The amplifiers built-in heatsink has overheated, the amplifier should be

switched off and allowed to cool. The optional fans should be fitted into the

Q-Drive enclosure if the fault occurs on a regular basis.

xiii End Switch 2

This alarm can not occur in the Q-Drive as it does not support end switches

xiv Power Fault

The power amp section of the Q-Drive has developed a fault and can no

longer reliably drive the motor.

Copyright © 1996 Quin System s Ltd. Page 45

Page 52

Q-Drive Installation Manual Issue 1.5

This Page is intentionally Left Blank

Page 46 Copyright © 1996 Quin Systems Ltd.

Page 53

Issue 1.5 Q-Drive Installation Manual

8. Switching On

Preparation of AC Brushless servo motors and servo-amplifiers requires a little

more attention than that of DC servo-drives. We recommend that switching on

for the first time is done according to the following instructions.

8.1 Switching the Servo-Amplifier On Without a Motor

The first time the amplifier is switched on the enable contacts (connector P12 pins 3 and

4), should be open circuit. This will disable the power stages of the amplifie r. The

resolver should be connected to the servo-amplifier and some method o f reading the

encoder output, i.e. a Quin PTS system, should also be connected.

The three-motor phases must not be connected to the servo-amplifier.

8.2 Checking LEDS and 7 segment display

LED

“OVER I”

This LED lights up during a short-circuit between two motor phases or a power stage

fault.

The state of the LED and the output stage inhibit are latched. To clear a latched fault it

is necessary to cycle the power. If the power is cycled, ensur e that at least 30 se conds

is allowed between switching off and switching back on. If this delay is shortened then

it is possible that the residual power in the smoothing capacitors will hold up the

amplifier control circuits and the alarm latch will not be cleared.

“Braking”

This LED lights up when the braking modul e operates. This is a non latching alarm and

it is quite normal to see this LED illuminate particularly under fast braking conditions

with a heavy load.

red LED normally off

yellow LED normally off

Copyright © 1996 Quin Systems Ltd. Page 47

Page 54

Q-Drive Installation Manual Issue 1.5

8.3 7 segment display on the front panel

This display shows the state of the servo-amplifier and motor. The alarm d has the

highest priority (following C, 7, 6, 5 etc.). If some alarms take place simultaneously,

only the one with the higher priority will be displayed. A alarm reset is only possible

by switching off the servo-amplifier supply.

Servo-amplifier powered on

and enable contact closed

Servo-amplifier powered on, enable

contact closed and motor at zero position

Servo-amplifier powered on

and enable contact open

Servo-amplifier powered on, enable

contact open and motor at zero position

Continuous current limit reached

Motor over temperature fault (alarm latched)

Amplifier heatsink over temperature fault.

Alarm latched

Resolver digital converter not functioning.

Alarm latched

Resolver feedback fault.

Alarm latched

Power amplifier section faulty.

Decimal point displayed with any other

display to show clockwise motor rotation.

Motor connection failure

Ground fault detected.

only if option fitted

Figure 22. Seven segment display codes

Page 48 Copyright © 1996 Quin Systems Ltd.

Page 55

Issue 1.5 Q-Drive Installation Manual

8.3.1 Checking the electrical rotation sense of the resolver

The decimal point of the 7 segment display lights up when the motor shaft is turned

clockwise.

Figure 23. Electrical rotation sense of the resolver

If the decimal point lights up during anti-clockwise rotation, connections to the upper

half of connector P2 pin 7 (COS1) and pin 6 (COS2) must be reversed.

Copyright © 1996 Quin System s Ltd. Page 49

Page 56

Q-Drive Installation Manual Issue 1.5

8.4 Determining the motor phases

This operation must only be done when the three-phase motor order is unknown (motor

prototype or no documentation).

It is necessary to have a DC supply of about 3A. and of sufficient voltage to move the

motor but not in excess of the motor rated voltage.

The procedure is as follows:

1 Define arbitrarily the Phase U as one of the 3 motor phases.

2 Connect U to

“+”

and a

2nd phase

motor to

“-”

of the DC supply.

3 Switch supply on. The shaft will move to a stable position.

4 Mark the new shaft position with a pencil, at top dead centre.

5 Disconnect the “-” of the supply from the

6 connect the “-” to the

3rd phase

motor. Observe the axis rotation direction.

2nd phase

of the motor and

7 Mark with a pencil the new shaft axis position.

With the help of the table below, determine the 2 unknown motor phases.

sense of axis rotation 2nd phase 3rd phase

clockwise

anti-clockwise

V W

W V

Table 9: Motor Phase Determination

Page 50 Copyright © 1996 Quin Systems Ltd.

Page 57

Issue 1.5 Q-Drive Installation Manual

8.5 Switch the Servo Amplifier on with a Motor and

Optimization

8.5.1 Preparation before switching the mains voltage on

a) Disconnect motor from the machine.

The 3 phases motor should be again connected to the servo-amplifier. Check

if the axis is stopped and release the motor brake.

b) Check the following connections:

• motor cable to the backplane

• resolver cable is plugged into P2 (Upper)

• control signals connected to P10 pins 3 and 4, +ve to pin 3, 0v to pin 4.

• enable contact connected to P12 pins 3 and 4.

c) Reduce the maximum current setting of the servo-amplifier us ing the Q-

DRIVE software. Save this value using the key

< F2 >

.

d) Set the proportional and integral gains to 25 and 10 respectively. Also set t he

resolver shift angle to 90 degrees. Save these values using

the < F2 > key

e) Open the enable contact connected on P12 pins 3and 4.

8.5.2 Switching the mains voltage on

a) Switch on the amplifier.

b) The 7 segment display should indicate “1”.

c) Set a positive speed voltage (about 1 V) to the servo-amplifier and close the

enable contact. The 7 segment display should now show “0”.

d) Increase the

max. current

parameter until the motor starts running.

If the motor doesn't turn or turns very slowly, check the sta te of the motor

brake if fitted.

e) Reverse the polarity of the speed command and check that the motor turns in

the reverse direction.

.

f) Set the

Save the

Copyright © 1996 Quin System s Ltd. Page 51

max. current

max. current

parameter to the initial state.

using the key <F2>.

Page 58

Q-Drive Installation Manual Issue 1.5

8.6 Compensating the speed controller

Optimizing the performance of the motor over the whole speed range can be achieved

by adjusting the drive amplifiers

Proportional Gain

Connect a Personal computer to the amplifier and run the QDRIVE.EXE configuration

program:

a) Set the value of both proportional (KP) and integral (KI) gain to a value of

10, this represents a very low gain setting.

b) Connect an oscilloscope between measuring points on J1, pins 9 and 10, pin

9 is signal and pin 10 is ground.

c) Switch on the servo-amplifier and close the enable contact.

d) Apply a low command speed voltage (<100 m V)

Integral Gain

and

parameters.

e) Increase the valu e of the

Integral Gain

parameter whilst ensuring that the

following factors are maintained:

i good static torque

i smooth shaft rotation

f) Apply a step function of 2 v olts to the command input and monitor the

response of the drive using an oscilloscope. One of the three following results

will occur:

i The signal shows several oscillations, this means the system is under

damped, in this case increase the

Proportional Gain

value

ii The motor is noisy, this means that the motor is over damped, in which

case decrease the

Proportional Gain

value

iii The signal shows only one small overshoot, this indicates critical

damping has been achieved and therefore the speed loop overshoot is

optimized

g) When the

f iii)

condition is achieved, save the gains obtained with key <F2>.

8.6.1 Offset and speed compensation Offset compensation

a)

The setting of the servo-amplifier speed offset is done with the

offset control

parameter in the QDRIVE.EXE software.

The setting of the offset can be done with or without the position controller.

If a position controller, such a Quin PTS unit, is used then all of the controller

gain parameters must be set to zero. Having set the controller gain parameters

to zero enable the controller output and adjust the servo-amplifier offset

compensation value until the motor stops moving. There will probably be a

range of values where the motor appears to be stationary, find the limits of

this range and set the value to the mid point. To set the offset value without a

controller attached then short out the command input terminals and adjust the

offset value. Again there will probably be a range of values which result in

Page 52 Copyright © 1996 Quin Systems Ltd.

Page 59

Issue 1.5 Q-Drive Installation Manual

the motor remaining stationary, find the limits of the range and set the value

to the mid point.

Press the < F2 > key to save this value.

b) Speed compensation

The Speed factor parameter allows adjustmen t of the motor speed from 6000 rpm to + 6000 rpm.

Press the <F2> key to save this value.

Copyright © 1996 Quin Systems Ltd. Page 53

Page 60

Q-Drive Installation Manual Issue 1.5

8.7 Trouble Shooting

The following table shows the most frequent troubles and their causes.

No Trouble Possible cause

1 LED “OVER I”

switched on

2 Display 2 limit of continuous current reached

3 Display 3 motor overloaded

4 Display 4 servo-amplifier overloaded

5 Display 5 resolver conversion circuit failure

6 Display 6 resolver failure - resolver wiring failure

7 Display 7 appears with OVER I LED

8 Display C motor connection failure

9 Display d detection of a motor ground defect (option) with

10 Motor doesn't turn. Display

shows 0 when speed

command is applied

short-circuit between 2 motor terminals

Resolver Shift Angle

-

- badly wired or loose connection of wires for motor

thermal switch

- cooling fan failure

Resolver Shift Angle

-

- brake fuse failure or missing

- appears in case of over-voltage or supply missing

auto-transformer

- max. current of servo-amplifier limited too low

- motor brake engaged

- speed reference short-circuited by

parameter incorrect

parameter incorrect

REF

Jumper

11 Motor rotation is not smooth

12 Motor turns in wrong

direction

Table 10: Q-Drive Trouble Shooting

Motor pole pairs

- Motor wiring on terminal U, V, W not in the correct

sequence

Command signal is wired incorrectly, Reverse

connections to PP10.3 and P10.4 and change the

setting of jumper J3.

parameter incorrect

Page 54 Copyright © 1996 Quin Systems Ltd.

Page 61

Issue 1.5 Q-Drive Installation Manual

9. Testing the System

9.1 General

This section describes some si mple test procedures for some parts of the Q-Driv e

systems. These do not comprise a full system test, but may be useful to verify the basic

operation of the system, the motor and the encoder.

All these tests require the use of a personal computer w ith a serial port, preferably

RS422. Most test can be carried out on the PC but additional test equipment may be