Page 1 of 79

2nd Version

TABLE OF CONTENTS

INTRODUCTION 3

CUSTOMER SERVICE 4

FEATURES 5

FRE-ASSEMBLY INFORMATION 6

REQUIRED TOOLS 7

HARDWARE & OPTIONAL ACCESSORIES 8

OTHER HARDWARE & OPTIONAL ACCESSORIES 9

OTHER REQUIREMENTS 12

PART LIST 13

SECTION 1: UPPER FRAMES 14

SECTION 2: LOWER FRAMES 28

SECTION 3: LANDING GEAR ASSEMBLY 40

SECTION 4: DRIVING SYSTEM 42

SECTION 5: TAIL ASSEMBLY 44

SECTION 6: CONTROL SYSTEMS 50

SECTION 7: ROTOR HEAD 53

SECTION 8: LINKAGE RODS AND SETTINGS 56

FRE-LIGHT CHECKS 72

WARNINGS 73

ADJUSTMENTS 74

HOW TO HOVER 75

HOW TO FLY FORWARD 77

AFTER FLIGHT CHECKS 78

WHAT IF THE HELICOPTER CRASHED 78

SPECIFICTION 79

Page 2 of 79

INTRODUCTION

Congratulation and thank you for the purchase of great product! It is our sole desire for

you to enjoy the quality workmanship and performance of any of our Nitro powered

helicopters. We believe we have the latest designs and technology incorporated into our

model helicopters. Our CNC parts are produced using the best high density materials &

anodized using material hardening finishes with the tightest of tolerances. Our new

helicopters feature the latest advances in R/C helicopter design. The simple and

mechanically superior EMS design (also known as CCPM) ensures a helicopter that will

be more responsive and more stable than any other R/C helicopter you have ever

flown. Three servos are attached directly to the Swashplate to ensure precise control.

This kit features all metal construction, and a carbon or composite frames are standard.

Along with great products, our staffs are RC guys that fly and have hands on experience

with total manufacturing & testing of our helicopters. In addition, we stand behind all our

products 100% with satisfaction guaranteed. Our kits will be shipped 100% complete

and we can assure you that once you fly your helicopter you will love it.

The QUICK 50

We believe you hold in your hands one of the best helicopters manufactured in the world

today. The Quick 50 is one of the famous versions of our Big Nitro Quick line. It is

a bigger, stronger frames, yet powerful machine. This baby delivers amazing power

smoothly throughout the entire range of its nitro motor. It functions so responsive and

stable. The Quick 50 Pro version features a fully machined head, metal

grips, dual bearing tail rotor, carbon fiber frames, carbon rudder push rod, and carbon

fiber boom supports. The Big Quick 50 Sport version features a G10

fiberglass frame, machined metal head, molded plastic grips, carbon boom supports,

carbon rudder push rod, and dual bearing tail rotor. Our helicopters are carefully

designed and tested, and manufactured of the highest quality materials available.

In a short time, you can be flying.

We ask that you please read the entire manual before starting the construction of the

Quick 50, and if you have any questions our technical support staff can be reached

at

(610) 282-4811 M-F 9-6, S 9-4 Eastern time,

or by email at

For the latest information and updates, please visit our website at

chuck@quickworldwide.com.

Page 3 of 79

www.quickworldwide.com

CUSTOMER SERVICE

Quickworldwide

201 South 3

rd. St. & 309 N.

Coopersburg, PA 18036

Phone: (610)-282-4811

Fax: (610)-282-4816

Office Hours:

Mon – Fri: 8:30 – 6:00

Sat: 8:30 – 1:30

(Eastern Daylight Time)

Technical Support Personnel:

Chuck – chuck@quickworldwide.com

Jon –

Websites:

http://www.hhiheli.com

http://www.quickheli.com

http://www.giantscaleplanes.com

E-mail:

hhi@fast.net

jon@quickworldwide.com

Page 4 of 79

FEATURES

1. Frame Construction: Quick 50 frames are made of the highest Quality Black G-10

Frames or Carbon Fiber. These frames are not only rigid but will provide excellent

vibration absorption.

2. One-Way Hex Start Shaft System: The one-way bearing allows the engine to

continue to run after the starter motor has been stopped.

3. Constant Tail Rotor Drive System: The constant tail system will provide full tail

authority during engine off maneuvers.

4. Belt driven Tail: Belt Driven tail is not only a reliable way to drive a tail, but is also

very smooth and low maintenance.

5. High Quality Ball Bearings: Quick 50 offers ball bearings on all moving parts.

6. EMS Collective System: The EMS Collective design allows ease of setup with fewer

moving parts. EMS constitutes overall design simplicity and represents the future of

helicopter technology.

7. Heavy-Duty Clutch System: Based on the same design as our famous heavy-duty

clutch upgrade that fits most popular machines, this clutch will give many years of

problem free operation.

8. Control Linkages: The control linkages that are provided with the Quick Learner Kit

are high quality 2.3mm stainless steel rods and the rod ends are made of a high quality

Delrin.

9. Single Blade Axle Design: The single blade axle design is simple very responsive

system, with very consistent flight characteristics.

10. Advanced Airfoil Fly-bar Paddles: These paddles will provide the best both kind of

flight characteristics for both 3D & Sport flying. Not only do they provide smooth forward

flight, they also provide quick response upon demand.

11. Rearward facing Engine Design: This design provides quick access to the glow

plug and is advantageous for easy engine removal.

Page 5 of 79

PRE-ASSEMBLY INFORMATION

Warning

The radio-controlled model helicopter contained in this kit is not a toy.

Rather, it is a sophisticated piece of equipment. This product is not recommended for

use by children without adult supervision. Radio controlled models such as this are

capable of causing both property damage and/or bodily harm to both the

operator/assembler and spectators if not properly assembled and operated. Hobbies &

Helis assumes no liability for damage that could occur from the mis-assembly and/or

use/misuse of this product.

Academy of Model Aeronautics

We strongly encourage all prospective and current R/C aircraft pilots to join the

Academy of Model Aeronautics. The AMA is a non-profit organization that provides

services to model aircraft pilots. As an AMA member, you will receive a monthly

magazine entitled Model Aviation, as well as a liability insurance plan to cover against

possible accident or injury. All AMA charter aircraft clubs require individuals to hold a

current AMA sporting license prior to the operation of their model. For further information,

please contact AMA at:

Academy of Model Aeronautics

5161 East Memorial Drive

Muncie, IN 47302-9252

USA

Phone: (317) 287-1256

www.modelaircraft.org

Before you begin

Quick Helicopter kits are packaged with care and attention to detail. We recommend

when you are ready to begin building this model that you examine the kit carefully,

inspect the contents of each package, and read and understand these instructions

thoroughly before starting assembly. It is suggested that you purchase a parts box for

the small fasteners and hardware, or use small bowls or other containers.

Page 6 of 79

REQUIRED TOOLS

Page 7 of 79

HARDWARE & OPTIONAL ACCESSORIES

GLUES AND THREAD LOCK COMPOUNDS

RADIO MOUNTING ACCESSORIES

Page 8 of 79

ENGINES, GLOW PLUGS, AND EXHAUST SYSTEM

ENGINES: we recommend OS50SX but others may work

GLOW PLUGS: OS # 8…OSMG2691

One-Piece Muffler

FUEL SYSTEM

Two-Piece Muffler

OTHER HARDWARE & OPTIONAL ACCESSORIES

3MM FLYBAR STIFFENERS

HHI 402

Page 9 of 79

60 SIZE SKID STOPS

HHI 200 AVAILABLE IN COLORS

LANDING GEAR DAMPENERS

W

W

W

W

HHI2004

SERVO

ARM SET

SERVO FIXING PLATES

ITH

ITHOUT

ITH

ITHOUT

• Transmits force of fastener to

plastic instead of rubber

HHI 1205 SERVO MOUNT KIT

• Includes hardware and fixing

plates to mount 5 servos

Page 10 of 79

W

W

ITH

ITHOUT

BASE LOAD ANTENNA

HHI 53**

AVAILABLE IN BLUE, GOLD,

PURPLE

AND IN 40, 50, AND 72 MHz

FINISHING CAPS

• Adds color and style

• Distributes force across larger surface area

3mm 4mm

(20 pcs in a package) (8 pcs in a package)

BLACK HHIM11100B --BLUE HHIM11103 HHIM11108

GOLD HHIM11101 HHIM11106

GREEN HHIM11100G --PURPLE HHIM11100 HHIM11105

RED HHIM11100R --SILVER HHIM11100 HHIM11107

Page 11 of 79

OTHER REQUIREMENTS

Radios:

Any radio that supports EMS/CCPM Mixing will work fine. Hobbies & Helis & its

distributors carry various lines of helicopter radios.

Note: Please consult the instruction for your Gyro for setting the overall travel

and limits to ensure proper operation and travel of Tail Pitch Slider.

Servos:

Any sport servo will offer acceptable performance. However, because servos

operate all critical functions of the helicopter, they can be the single most

important component that contributes to proper function of the helicopter. Due to

the nature of EMS collective, we suggest the use of digital servos to enhance

and ensure matched servo timing without servo interaction

Locktite Warning (CRITICAL):

.

This is a general warning about the use of Locktite and its

importance. Locktite must be used anywhere that a metal

fastener i.e. (M2, M3, M4 Cap Head Bolts, Set Screws etc.) is

threaded into a metal part i.e. (Bearing Blocks, Cross-members,

etc.). Failure to use Locktite can result in loosening of critical

operating components, loss of control of the model, and can

lead to a crash.

Page 12 of 79

PART LIST

• In your kit, parts are bagged according to each major assembly and are labeled “Bag

1, Bag 2, etc.” You will note that the heading for each assembly indicates which bag

correlates with each assembly.

• For a good installation, only open up the bag that you need for particular assembly.

• Please check the parts in that bag against the parts list shown for each assembly as

well as each subassembly to make sure there are no missing parts.

• Small parts such as nuts and bolts can be put into containers or trays to prevent

losing parts.

• Part No. with ***** means that part is not included in the kit.

• The colors of drawings in this manual may look different from the parts you have in

the kit.

No. Bag No. Description Quantity Check

1 Bag 1 For Upper Frame Assembly 1

2 Bag 2 For Lower Frame Assembly 1

3 Bag 3 Landing Gear 1

4 Bag 4 Driving System 1

5 Bag 5 For Tail Assembly 1

6 Bag 6 Control System 1

7 Bag 7 Head Rotor 1

8 Bag 8 Linkage 1

9 Frame Frame 1

10 HB Hardware Bag 1

Canopy

Carbon Push Rod

11

Loose in Box

Tail Gear Belt

Tail Boom

Flybar

Decal Sheet

Instruction CD

1

1

1

1

1

1

1

Page 13 of 79

SECTION 1: UPPER FRAMES Bag 1

• In your kit, parts are bagged according to each major assembly and are labeled “Bag

1, Bag 2, etc.” You will note that the heading for each assembly indicates which bag

correlates with each assembly.

• For a good installation, only open up the bag that you need for particular assembly.

• Please check the parts in that bag against the parts list shown for each assembly as

well as each subassembly to make sure there are no missing parts.

• Small parts such as nuts and bolts can be put into containers or trays to prevent

losing parts.

• No. with ***** means that part is not included in the kit.

• Colors of the parts in the drawings may look differently from ones in the kit.

1-1 ELEVATOR SHAFT BEARINGS

No. Bag# Description Qty

1 Frame Upper Frame (from Frame Bag) 2

2 1 5X10X4Flanged Bearing 2

Note: The holes on the frames are designed for “push-fit” feature. Sometime you may

have to sand them a little bit before pushing the bearings in. The bearing flange mates

Page 14 of 79

against the inside of the frame.

Page 15 of 79

1-2 LEFT AILERON & RUDDER SERVO SUBASSEMBLY

No. Bag# Description Qty

1 Step

2***** Servo 2

3 HB M2.5x14 Cap Head Bolt 8

4 HB M2.5 Locknut 8

***** Part No. with ***** means that part is not included in the kit.

Note: If the servos come with anti-vibrating rubber, insert them on the servos first. We

recommend using the servo fixing plates to protect and get the best performance from

the servos. Please see “Hardware & Optional Accessories” for more details.

L. Upper Frame Subassembly 1

Page 16 of 79

1-3 RIGHT AILERON & ELEVATOR SERVO SUBASSEMBLY

No. Bag# Description Qty

1 Step 1-1 R. Upper Frame Subassembly 1

2 Servo 2

3 HB M2.5x14 Cap Head Bolt 8

4 HB M2.5 Locknut 8

1-4 INNER ELEVATOR CONTROL ARM SUBASSEMBLY

No. Bag # Description Qty

1 1 Inner Elevator Control Arm 1

2 1 Elevator Control Shaft 1

3 HB M3x5 Set Screw 1

4 HB M3x7 Pivot Ball Stud 1

Note: Remember to apply Locktite for Set Screw

and Pivot Ball Stud (see Locktite Warning on

page 11)

Page 17 of 79

1-5 TAIL TRANSMISSION SUBASSEMBLY

No Bag# Description Qty

1 1 Counter Gear 1

2 1 Counter Gear Shaft 1

3 1 Counter Gear Lock Pin 1

4 1 M4 E-clip 2

5 1 Counter Gear Bearing Block 2

6 1 Pulley Gear Plate 1

7 1 Pulley Gear Block Pin 1

8 1 Pulley Gear 1

9 ***** JP Weld glue 1

-Install Counter Gear to Counter Gear Shaft using Counter

Gear Lock Pin (No. 3) and M4 E-clip to secure it. Apply JP

Weld glue around the pin.

-Put Counter Gear Bearing Block (the lower) in with the

Flange facing up

-Install Counter Gear Bearing Block (the upper) with the

Flange facing up

-Install Pulley Gear Plate (No. 6)

-Insert Pulley Gear Lock Pin (No. 7). Apply JP Weld glue

around the pin

-Install Pulley Gear and retain with M4 E-clip

Page 18 of 79

1-6 UPPER FRAME INSTALLATION

1-6-a ELEVATOR CONTROL ARM-RIGHT SIDE

No. Bag# Description Qty

1 Step 1-3 R. A&E Arm Subassembly 1

2 Step 1-4 Inner El. Ctrl. Arm Subassembly 1

3 1 Outer Elevator Control Arm 1

4 HB M3x5 Set Screw 1

5 HB M3x4 Pivot Ball Stud 5

6 HB M3x5x3 Spacer 1

7 1 Right Aileron Control Lever 1

8 HB M3x12 Cap Head Bolt 1

Note: The Inner Elevator Control Arm (belongs to Inner Elevator Control Arm Sub

assembly) should be next to the upper right frame.

Note: The Elevator Control Shaft is designed to fit tight in the bearings. Sometime, you

might have to sand it a little to get it go into the bearings.

Page 19 of 79

1-6-b ANTI-ROTATION GUIDE ASSEMBLY (SPORT MODEL)

No. Bag# Description Qty

1 Step 1-6-a Right Upper Frame (up to step 1-6-a) 1

2 1 Washout Anti-Rot. Guide 1

3 HB M3x5x3 Spacer 2

4 HB M3x45 Cap Head Bolt 2

Note: The Elevator Control Shaft is designed to fit tight in the bearings. Sometime, you

might have to sand it a little to get it go into the bearings.

Page 20 of 79

1-6-b ANTI-ROTATION GUIDE ASSEMBLY (PRO MODEL)

No. Bag# Description Qty

1 Step 1-6-a Right Upper Frame (up to step 1-6-a) 1

2 1 Washout Anti-Rot. Guide Base 1

3 Frame Washout Anti-Rot. Guide A 1

4 HB M3x5x3 Spacer 2

5 HB M3x10 Cap Head Bolt 2

6 HB M3x6 Cap Head Bolt 2

Page 21 of 79

1-6-c MAIN SHAFT BEARING BLOCKS

No. Bag# Description Qty

1 Step 1-6-c Right Upper Frame (up to step 1-6-b) 1

2 1 Main Shaft Bearing Block 2

3 HB M3x8 Cap Head Bolt 4

Note: For the Upper Bearing Block, the flange should face down. For the Lower one, the

flange should face up.

Page 22 of 79

1-6-d FRAME CROSS MEMBERS, PINION GEAR BEARING BLOCK &

TAIL TRANSMISSION

No. Bag# Description Qty

1 Step 1-6-c Right Upper Frame (up to step 1-6-c) 1

2 Step 1-5 Tail Transmission Subassembly 1

3 1 32mm Cross Member 4

4 1 Clutch Bearing Block 1

5 HB M3x8 Cap Head Bolt 12

6 Frame Bulkhead 1

7 1 28mm Cross Member 1

8 1 10mm Spacer 1

9 HB M3x18 Cap Head Bolt 1

10 HB M3x7 Flat Washer 6

Note:

For the Clutch Bearing Block, the side with the smaller bearing should be face up.

Use M3x7 Flat Washers when attaching the Clutch Bearing Block and Tail Transmission

Subassembly to the frame.

Page 23 of 79

1-6-e UPPER FRAME INSTALLATION

No. Bag# Description Qty No. Bag# Description Qty

1 Step 1-6-d Right Upper Frame (up to step 1-6-d) 1 8 HB M3 Locknut 2*

2 Step 1-2 Left Upper Frame Subassembly 1 9 HB M3x10 Cap Head Bolt 2**

3 HB M3x5x3 Spacer 2 10 1 28mm Cross Member 1

4 1 Left Aileron Control Lever 1 11 1 10mm Spacer 1

5 HB M3x4 Pivot Ball Stud 3 12 HB M3x18 Cap Head Bolt 1

6 HB M3x8 Cap Head Bolt 17 13 HB M3x7 Flat Washer 6

7 HB M3x12 Cap Head Bolt 1

*Note: Pro Version does not need these.

**Note: Sport Version does not need these.

Page 24 of 79

Attach the right side and left side together using M3x8 Cap Head Bolts. Remember to use M3x7

Flat Washers for attaching the Clutch Bearing Block and Tail Transmission Subassembly to the

frame. Note: The Elevator Control Shaft is designed to fit tight in the bearings. Sometime, you

might have to sand it a little to get it go into the bearings.

Note: The Elevator Control Shaft is designed to fit tight in the bearings. Sometime, you might

have to sand it a little to get it go into the bearings.

Page 25 of 79

1-7 CLUTCH BELL ASSEMBLY

No. Bag# Description Qty

1 1 Pinion Gear 1

2 1 Clutch Bell 1

3 1 Clutch Shoe Lining 1

4 HB M4x4 Set Screw 1

5 1 Start Coupler 1

6 1 Start Shaft 1

7***** Electric Tape 1

Install (1) Clutch Lining into (1) Clutch Bell. Note: The recommended adhesives for

installing the clutch lining are JB Weld or 10 Min + Epoxy. Prepare the clutch bell by

scuffing the interior with an x-acto blade or sand paper. Put the Clutch Lining in the

Clutch Bell and mark it for cutting (the length is around 134mm). Cut the Clutch Lining.

Apply the adhesive thin and even and finish the installation by inserting and finishing the

clutch lining.

Then insert the Clutch Shoe into the Clutch Bell. Clean up any excess adhesive. Let it sit

there until the adhesive dry out then take the Clutch Shoe and electric tape off. See the

label on the adhesive bottle for drying time.

Trick: Use electric tape wrap around the Clutch Shoe (in bag # 2) one time.

Page 26 of 79

Note: It is very important to use a Dialing Indicator to check the run out of the

Clutch Bell. The run out should be no more than 0.004 inch (0.10 mm).

Page 27 of 79

SECTION 2: LOWER FRAMES Bag 2

2-1 RADIO TRAY ASSEMBLY

No. Bag# Description Qty

1 Frame Front Lower Frame 2

2 Frame Radio Tray 1

3 2 Long Canopy Standoff 2

4 2 60mm Cross Member 1

5 HB M3x8 Cap Head Bolt 4

6 HB M3X10 Cap Head Bolt 4

7 HB M3x5x3 Spacer 4

8 2 M3x6x10 Spacer 2

9 HB M3x18 Cap Head Bolt 2

Page 28 of 79

2-2 FUEL TANK ASSEMBLY

No. Bag# Description Qty

1 Loose in box Tank Clunk 1

2***** 12 cm Hose 1

3 Loose in box Long Tube 2

4 Loose in box Tank Rubber Plug 1

5 Loose in box Short Tube 1

6 Loose in box Tank Fuel Plug Bottom Flange 1

7 Loose in box Tank Fuel Plug Top Flange 1

8 Loose in box M3x25 Cap Head Bolt 1

9 Loose in box Fuel Tank 1

• There are three (3) lines (Aluminum fuel tubing) that need to be constructed for

the tank assembly. Depending on the engine you use, you may need only two (2)

lines. One line is the fuel pick-up line and requires a length of silicon fuel tubing

running from end of alum. Tube to clunk – which should be centered in tank. The

other line is pressure-line, which should be bent to reach the top of the tank on

the inside. The third line will generally be plugged. Tighten rubber stopper screw

– but do not tighten much.

Page 29 of 79

• Insert the whole construction into the Fuel Tank. Continue tightening but do not

over tighten or you will ruin rubber stopper!

Page 30 of 79

2-3 FUEL TANK INSTALLATION

No. Bag# Description Qty

1 Step 2-1 Radio Tray Assembly 1

2 Step 2-2 Fuel Tank Assembly 1

3 2 Half Round Cross Member 1

4***** Double Side Tape 1

5 HB M3x8 Cap Head Bolt 2

Page 31 of 79

2-4 THROTTLE SERVO ASSEMBLY

No. Bag# Description Qty

1 Step 2-3 Fuel Tank Installation 1

2***** Servo 1

3 HB M2.5x14 Cap Head Bolt 4

4 HB M2.5 Locknut 4

Page 32 of 79

2-5 LOWER FRAME INSTALLATION

No. Bag# Description Qty

1 Step 1 Upper Frame Assembly 1

2 Step 2-4 Lower Frame Assembly 1

3 Frame Rear Frame 2

4 Frame Gyro Tray 1

5 2 One-piece Cross Member 2

6 2 32mm Cross Member 3

7 HB M3x20 Cap Head Bolt 6

8 HB M3x5x3 Spacer 4

9 HB M3x10 Cap Head Bolt 4

10 HB M3x8 Cap Head Bolt 4

Page 33 of 79

2-6 FRAME ANGLE & SHROUD ASSEMBLY

No. Bag# Description Qty

1 Loose in box Fan Shroud 1

2 2 M2.5x6 Self Taping Screw 4

3 Frame Frame Angle 2

4 2 60 mm Cross Member 1

5 HB M3x10 Cap Head Bolt 4

6 HB M3x8 Cap Head Bolt 4

7 HB M3 Locknut 4

Page 34 of 79

2-7 ENGINE ASSEMBLY

No. Bag# Description Qty

1***** Engine 1

2 2 Fan Hub 1

3 2 Cooling Fan 1

4 HB M3x6 Cap Head Bolt 6

5 2 Engine Hub Collect 1

6 HB M6 Nord-Loc Washer 2

7***** M6 Hex Nut 1

8 2 Clutch Shoe 1

9 2 Engine Mount 1

10 HB M3x10 Cap Head Bolt 4

Page 35 of 79

Page 36 of 79

Note: it is very important to use a Dialing Indicator to check the run out of the

Engine Assembly. Most of the vibration problems come from this. The run out

should be no more than 0.004 inch (0.10 mm).

Page 37 of 79

Note: Engine Mount may look differently from the one in the kit.

Page 38 of 79

2-8 ENGINE INSTALLATION

No. Bag# Description Qty

1 Step 2-7 Engine Assembly 1

2 Step 2-6 Assembly up to step 2-6 1

3 HB M3x10 Cap Head Bolt 4

4 HB M3 Flat Washer 4

Page 39 of 79

SECTION 3: LANDING GEAR Bag 3

No. Bag# Description Qty

1 Step 2 Assembly up to Section 2 1

2 3 Landing Gear Strut 2

3 3 Landing Gear Skid 2

4 3 Landing Gear End Cap 4

5

6

7

8***** CA Glue 1

• Drill 4 holes in the Landing Gear Struts with a 3mm drill bit with a spacing of 77mm

• Install the Landing Gear Skids into the Struts.

• Apply CA Glue into the Landing Gear End Cap then insert them into the Skids.

• Drill four 2.5mm holes into the little rounds on the ends of the Struts then secure

them with the four M2.5x6 Phillips Screws.

3

3

3

M2.5x6 Self Taping Screws 4

M3x14 Cap Head Bolt 4

M3 Locknut 4

• Install the Main Frames onto the Landing Gear Assembly and secure them with

four M3x14 Cap Head Bolts.

Note: It is recommended to use “Landing Gear Dampener” to reduce vibration. See

“Other Hardware & Optional Accessories” to make order. Landing Gear Dampener is

installed between the Landing Gear and the Landing Supports.

Page 40 of 79

Page 41 of 79

SECTION 4: DRIVING SYSTEM Bag 4

4-1 MAIN GEAR ASSEMBLY

No. Bag# Description Qty No. Bag# Description Qty

1 4

2 4 Upper Main Gear 97T 1 5 HB M3x6 Cap Head Bolt 4

3 3 Lower Main Gear Hub 1 6 HB M3x6 Philip Screw Flat Head 4

Lower Main Gear 88T 1 4 4 Auto-rotation Clutch 1

Note: The raised portion of For the Upper Main Gear should be face up.

Page 42 of 79

4-2 MAIN GEAR INSTALLATION

No. Bag# Description Qty No. Bag# Description Qty

1 Step 4-1

2 Step 3 Assembly up to step 3 1 6 HB M3 Locknut 1

3 3 Main Shaft 1 7 HB M3X5 Set Screw 4

4 3 Main Shaft Collar 1

• Slide the Main Gear Assembly in; install the Main Shaft down, then secure with one

M3x22 Cap Head Bolt and one M3 Locknut.

• Install the Main Shaft Collar on the Main Shaft then secure with four M3x5 Set

Screws. Be sure the ridge goes down.

Main Gear Assembly 1 5 HB M3x22 Cap Head Bolt 1

Page 43 of 79

SECTION 5: TAIL ASSEMBLY Bag 5

5-1 TAIL PULLEY GEAR ASSEMBLY

No. Bag# Description Qty

1 5

2 5 Tail Gear Lock Pin 1

3 5 Tail Pulley Gear 1

4 5 Tail Gear Side Plate 1

5 ***** JP Weld glue 1

Tail Output Shaft 1

Remember apply JP Weld glue around the pin.

Page 44 of 79

5-2 TAIL ROTOR ASSEMBLY

No Bag# Description Qty No. Bag# Description Qty

Frame Tail Case Side Plate 2 10 5 M2.3 Medium Ball Link 2

1

2 5 Tail Pitch Lever Mount 1 11

3 5 5X10X4Flange Bearing 2 12 5 Tail Pitch Control Lever 1

4 HB M2x6 Phillips Screw 2 13 HB M3x5x1 Spacer 1

5 In box Tail Boom (in Box) 1 14 HB M3x16 Cap Head Bolt 1

6 In box Timing Belt (in Box) 1 15 HB M3 Locknut 1

7 HB M3x6 Cap Head Bolt 6 16 Step 5-1 Tail Pulley Gear Assy 1

8

9 HB M3x4Pivot Ball Stud 2 18 HB M3x7 Flat Washer 1

5 Tail Case Cross Member 1

17 HB M2.5x6 Cap Head Bolt 1

5

First, to prevent the Boom End from

rotating, drill a 2.5mm hole on a side of the

Boom End, then secure with an M2.5x6

Cap Head Bolt.

Tail Pitch Slider 1

Install the Bearings into the Tail Case Side

Plates. The flanges should be inside.

Sometimes, the holes are too tight; you

have to sand them a little bit.

Note: Normally you just need one M3x5x1 Spacer between the Tail Pitch Control Lever

and Tail Pitch Lever Mount but you may need two of them in some cases (if you do not

have enough clearance for the lever.)

Page 45 of 79

Page 46 of 79

5-3 TAIL ROTOR INSTALLATION

No. Bag# Description Qty No. Bag# Description Qty

1 5 Dual Bearing Tail Rotor 1 9 5 Horizontal Fin Mount 1

2 HB M3x22 Cap Head Bolt 2 10 5 Vertical Fin Mount A 1

3 5 Tail Blade 2 11 5 Vertical Fin Mount B 1

4 5 Tail Blade Spacer 4 12 5 Horizontal Fin* 1

5 HB M2x8 Phillips Screw 2 13 5 Vertical Fin* 1

6 HB Shim Ball 2 14 HB M3 Locknut 4

7 HB M3x6 Cap Head Bolt 2 15 HB M3x30 Cap Head Bolt 2

8 HB M3x5 Set Screw 1 16 Step 5-2 Tail Rotor Assembly 1

• Carbon Fin Set is also available for option.

Page 47 of 79

After installing all the

parts as shown above,

slide this subassembly

on the output shaft then

secure it with one M3x5

Set Screw.

Wrap electric tape around the boom couple times where you are going to install the fin

mounts. Note: Fin set may look lightly differently from the one in the kit.

Page 48 of 79

5-4 TAIL INSTALLATION

No. Bag# Description Qt.

1

2 Step 5-3 Tail Assembly 1

3 In box Boom Support 2

4 5 Boom Support End 4

5 HB M3x12 Cap Head Bolt 2

6 HB M3x8 Cap Head Bolt 2

7 HB M3 Locknut 6

8 HB M3X45 Cap Head Bolt 4

9 5 Boom Holder 2

10***** CA Glue 1

• Note for installing the timing belt: Turn the Tail assembly so that the Tail Output Shaft

pointing upward put the belt onto the Transmission, then twist the Tail Assembly 90

to the right. Make sure the belt not too tight or loose. Tighten the four screws on the

boom holders.

• Measure the Boom Support carefully before cutting. It is a good idea if you install one

end of the rod first, then make the measure then cut it. Remember apply CA Glue for

the rods when installing into the Support Ends.

Step 4 Assembly up to step 4 1

o

Page 49 of 79

Note: Frames may look differently from the one in ki

SECTION 6: CONTROL SYSTEM Bag 6

6-1 SWASHPLATE ASSEMBLY

No. Bag# Description Qty

1 6 Swashplate Complete 1

2 HB M3x7Pivot Ball Stud 7

3 HB M3 x7 Flat Washer 4

4 HB M2X4 Phillips Screws 7

Note: There are two kinds of the Swashplate. One has little holes (maybe

7, 4, or 3 of them.) The other has no hole on it. Both work the same. If you

got the one with holes, just fill them in with Phillips Screws. If you got the

one with no hole, do not worry about Phillips Screws; the Swashplate still

works well.

Page 50 of 79

6-2 WASHOUT ASSEMBLY

No. Bag# Description Qty No. Bag# Description Qty

1 6

2

3

4

Washout Base 1 5

Washout Arm 2 6

6

Washout Link 2 7

6

Washout Link Pin 2 8

6

HB M3x5 Set Screw

M3x7Pivot Ball Stud 2

HB

M3x12 Cap Head Bolt 2

HB

M3X5X1 Spacer 2

HB

2

Note: There are some versions of the Washout Base (Item No. 1). All of them work the

same but they should be installed appropriately:

• If L1 is shorter or equal to L2, face A should go up.

• If L1 is longer than L2, face A should go down.

Page 51 of 79

6-3 CONTROL SYSTEM INSTALLATION

No. Bag# Description Qty

1 Sep 6-1

2

Step 6-2

3

Step 5

4 6 Swash Anti-rotation Pin 1

Swashplate Assembly 1

Washout Assembly 1

Assembly up to step 5 1

Note: the frame may look differently from the one in the kit.

Connect the Washout Links to the 3x7 Pivot Studs on the Washplate.

Page 52 of 79

SECTION 7: ROTOR HEAD Bag 7

7-1 MAIN ROTOR HUB ASSEMBLY

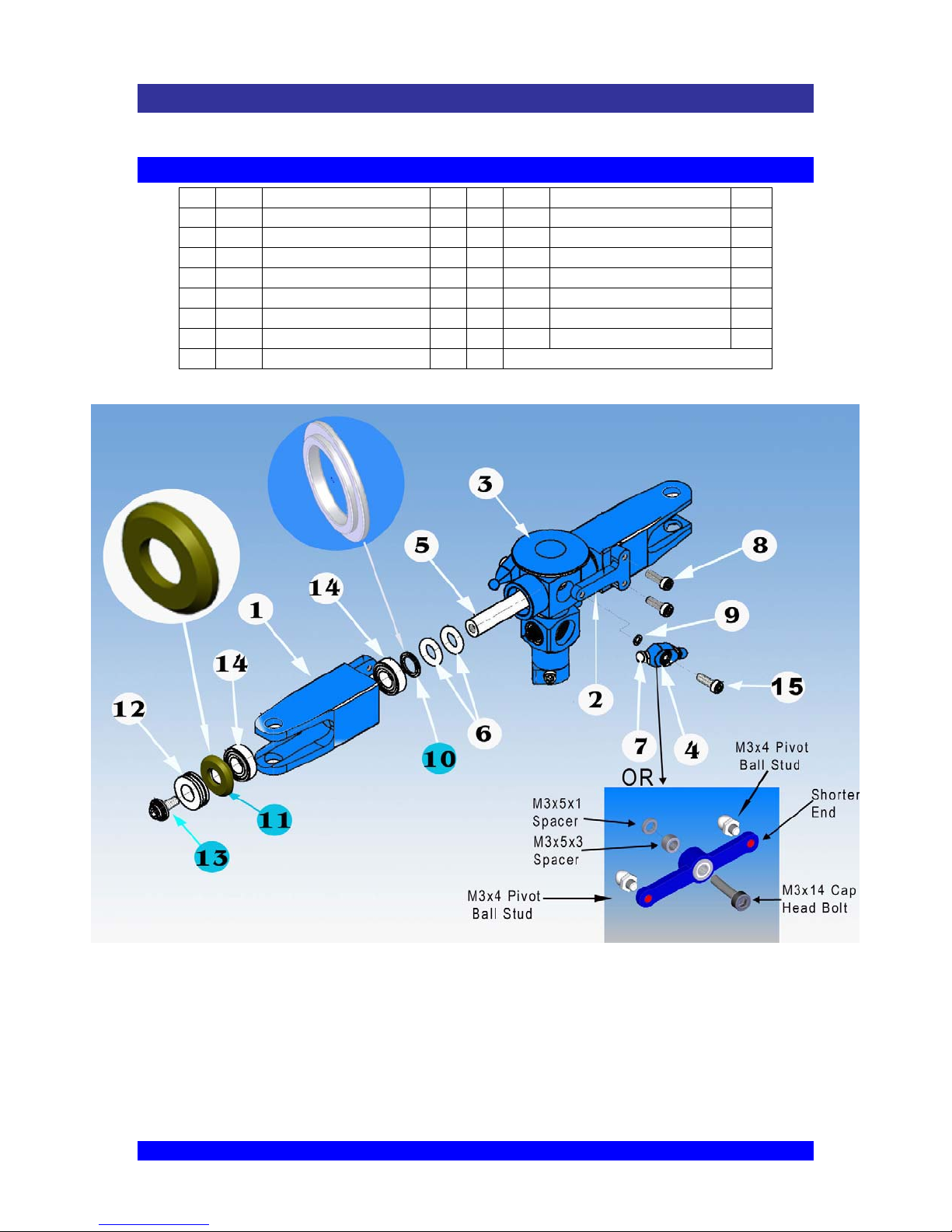

No. Bag# Description Qty No. Bag# Description Qty

1 7

2

3 7 Center Hub 1 11 7 Thrust Bearing Spacer 2

4

5 7 Head Spindle 1 13 7 M4 x8 Flange Cap Head Bolt 2

6 7 Dampener O-Ring 4

7

8

Main Blade Grip* 2 9

Pitch Arm** 2 10 7 Head Spindle Spacer 2

7

7 Hiller Arm

M3x7 Pivot Ball Stud(1) 2

HB

M3x10 Cap Head Bolt** 4 *Sport version: plastic

HB

**Sport version: Pitch Arms is built in the Main Blade Grips so there is no M3x10 Cap Head Bolts

(1) or four M3x4 Pivot Ball Stud; (2) or two M3x14 Cap Head Bolt

2 12 7 8x16x5 Thrust Bearing 2

14

15

M3X5X3 Spacer 2

HB

7 8x16x5 Regular Bearing 4

M3x12 Cap Head Bolt(2) 2

HB

Note: Some Center Hubs are designed for one O-ring each side. If this is your case, use

one O-ring each side. The beveled edge of the Thrust Bearing Spacer (No. 11) should

be face away from the Center Hub. The flanges of the bearings of the Hiller Arms should

face outside. Usually the Thrust Bearing has three parts: two race washers and caged

ball bearings. The caged ball bearings will be between two race washers. In some cases,

you may get different version of the Thrust Bearing: one race washer, one flat washer,

and caged ball bearings in your kit. That is fine; it still works the same. In this case, you

need to install the flat washer first (next to Thrust Bearing Spacer-No. 11), then the

caged ball bearings, the race washer goes last.

Page 53 of 79

7-2 FLYBAR & SEESAW ASSEMBLY

No. Bag# Description Qty No. Bag# Description Qty

1 7

2

3

4

5

6 7 Fly-Bar Control Arm A 2 14

7 7 Fly-Bar Control Arm B 2 15

8 In 4mm Standard Flybar 1 16*****

Seesaw 1 9

Seesaw Collar 2 10

7

M3x8 Cap Head Bolt 4 11

HB

M3x7 Pivot Ball Stud 2 12

HB

M4x6x1 Spacer 4 13

HB

HB M3x5 Set Screw

7 4mm Fly-Bar Paddle

7 Short Ball End

Step 7-1

HB

7

7

Main Rotor Hub 1

M3x7 Flat Washer 2

2.3x10mm Linkage Rod 2

Washout Anti-rotation Pin 2

Epoxy Glue/JP Weld 1

Make sure to apply Epoxy Glue/JP Weld to the thread on Flybar when installing the Flybar

Paddle.

2

2

4

Note: The Center Hub and Flybar Control Arm shown may look differently from the ones

in the kit.

Page 54 of 79

7-3 ROTOR HEAD INSTALLATION

No. Bag# Description Qty

1 Step 7-2

2 Step 6-3

3

4

HB

HB

Install the Head Assembly into the Main Shaft, and then secure it by one M3x20 Cap

Head Bolt and one M3 Locknut.

Completed Rotor Head (step 7-2) 1

Helicopter (up to step 6-3) 1

M3x20 Cap Head Bolt 1

M3 Locknut 1

Page 55 of 79

SECTION 8: LINKAGE RODS & SETTINGS Bag 8

8-1 RUDDER PUSH ROD ASSEMBLY

No. Bag# Description Qty

In box Rudder Push Rod 1

1

2 8 Rudder Push Rod End 2

3* 8 Pushrod Guide Clamp-on 1

4** 8 Rudder Pushrod Guide 3

5** 8 Rudder Pushrod Guide Insert 3

6

7

8***** Servo Arm 1

9***** M3 Servo Phillips Screw 1

10

11*****

12*****

HB

HB

*Sport version does not use this part.

**Pro version does not use these parts.

Shim Ball 1

M2x8 Phillips Screw 1

2.3mm Long Ball End 2

8

CA Glue 1

Electric Tape 1

Note: Put electric tape around the Boom before installing the Rudder Push Guide in, so

you can remove them later.

Page 56 of 79

For the Pro Version, the diameter of the Pushrod Guide Clamp-on is a little bit bigger

than the diameter of the boom. Cut off 5-6 teeth of the clamp and wrap the Boom with a

couple of wraps of electrical tape to keep it from slipping.

The length of the Rudder Rod measured from center to center should be around 713 mm.

Page 57 of 79

8-2 LINKAGE ASSEMBLY

No. Bag# Description Qty

1 8

2

3

4

5

6

7

8

8

8

8

8

8

8

8

2.3 Long Ball End 28

2.3x25mm Rod 2

2.3x35mm Rod 3

2.3x40mm Rod 2

2.3x65mm Rod 2

2.3x80mm Rod 2

2.3x90mm Rod 1

2.3x100mm Rod 2

Coding the Rod Assembly:

All the Linkages should be assembled with dimensions measured center to center and

coded as following:

No. Code Rod Description Center to Center Qty

1

A

2

B

3

C

4

D

5

E

6

F

7

G

Note: Look close to a ball end; you will see one side is different from the other. One has a round

marked on it. The other is just plain. When installing a ball link into a pivot ball stud (or a shim

ball) the side with a round should face away from a ball stud (or shim ball.)

2.3x25mm Rod 51.5 mm 2

2.3x35mm Rod 64 mm 3

2.3x40mm Rod 66.5 mm 2

2.3x65mm Rod 94.5 mm 2

2.3x80mm Rod 110 mm 2

2.3x90mm Rod 124mm 1

2.3x100mm Rod 133 mm 2

Page 58 of 79

8-3 LINKAGE INSTALLATION

No. Code Center to Center Qty No. Bag# Description Qty

1

2

3

4

5

6

7

C

D

E

F

G

A

B

51.5 mm 2 8

64 mm 3 9*****

66.5 mm 2 10

94.5 mm 2 11

110 mm 2 12***** M3 Servo Phillips Screw 4

124mm 1 13***** Throttle Extension 1

133mm Rod 2 14***** M2.5x10 Cap Head Bolt 1

15***** Single Servo Arm 1

8-1

HB

HB

Helicopter (up to step 7) 1

Double Servo Arm 3

Shim Ball 8

M2x8 Phillips Screw 8

Page 59 of 79

Page 60 of 79

Note: the frame may look differently from the one in the kit.

Page 61 of 79

8-4 MUFFLER & HOSES ASSEMBLY

No. Bag# Description

1*****

2*****

3*****

4*****

Note: For some kinds of engines and mufflers, you may have to cut the frame angle to

make room for screws to fit. Although the drawings do not show the valves for hoses,

you need to put one somewhere between the fuel tank and the engine; the other for

refueling hose.

The frame may look differently from the one in the kit.

Muffler 1

M3x35 Cap Head Bolt 2

Hose 3

M3 Locknut 2

Page 62 of 79

Page 63 of 79

8-5 MAIN BLADE INSTALLTION

No. Bag# Description Qty

1

2*****

3*****

4

5 8 M4 Locknut 2

Step 8-4

8

Helicopter (up to step 8-4) 1

Main Blade 2

Main Blade Spacer 4

M4x30 Cap Head Bolt 2

Page 64 of 79

8-6 RADIO SETUP

No. Bag# Description Qty

1

2

3

4

5 ***** Battery for Receiver 1

Step 8-5

*****

*****

*****

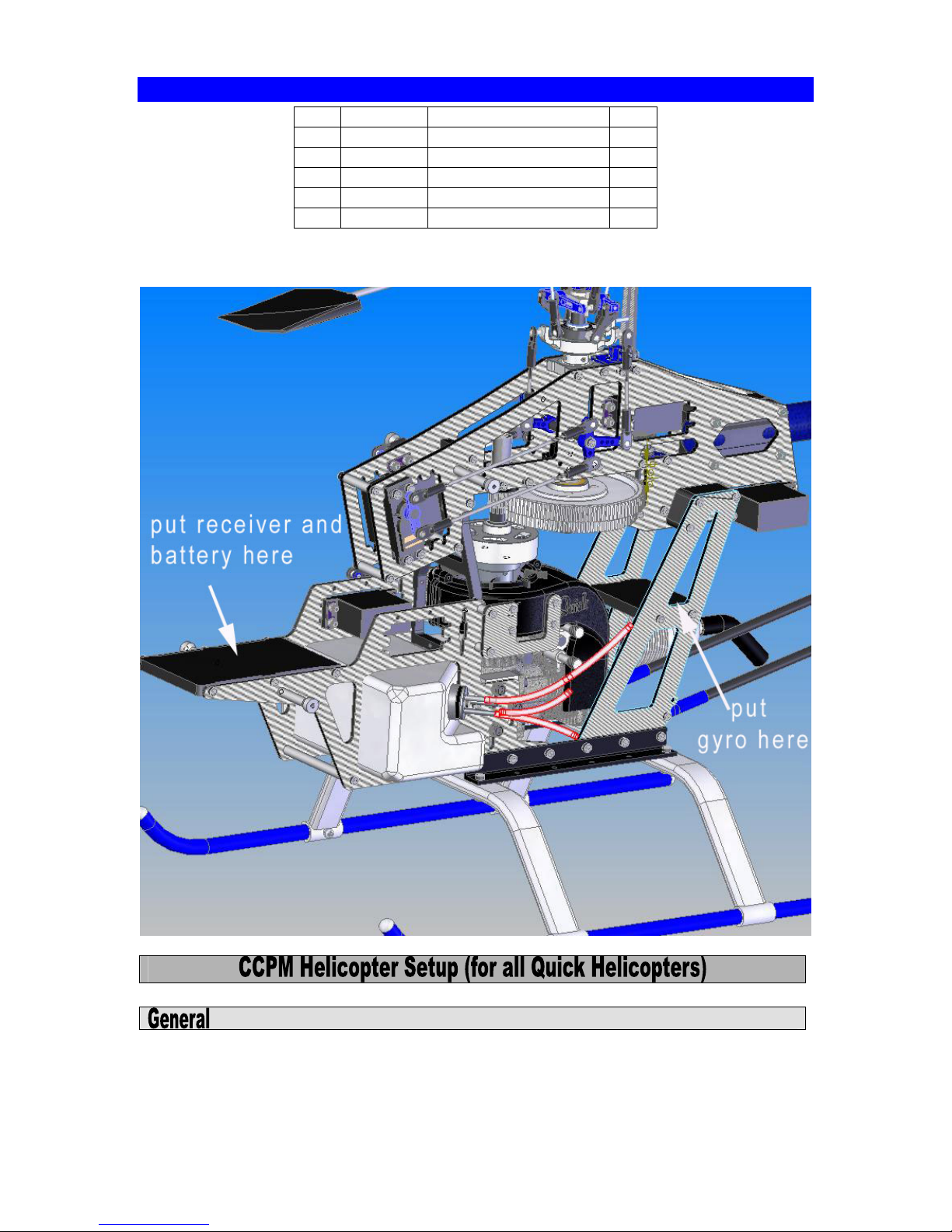

Before setting up the radio, you have to install the receiver, gyro, and batteries for your

helicopter. See your radio, receiver, and gyro manuals for how to hook up.

Helicopter (up to step 8-5) 1

Radio 1

Receiver 1

Gyro 1

Note: The frame may look differently from the one in the kit.

Instead of giving you the exact length of each linkage rod we will explain to you what you

are trying to achieve. This is the same for all Quick helicopters. Another thing worth

mentioning is that all controls on our helicopters are leading edge controlled. We have

three such controls on our helicopter and they are Main blades, Tail blade and flybar

control arms. For example the main blade pitch arms should be mounted so they are in

Page 65 of 79

front of the blades in the direction of travel, clockwise if you look at the helicopter from

above, see picture 4.

Your radio manual will be needed during this set up.

First, set your radio so that all travel values are at 100%. If you have a radio with Swash

Mixing set, ser those values to 50% (Aileron, Elevator, and Pitch.) Then use servo

reversing so that all servos are moving in the right direction. If Pitch operates reversed,

change the value in the Swash Mixing from + to -.

Step 1:First set your radio up so that all servos are moving in the right direction and

adjust all travel values to 100%. If you have a radio with Swash mixing values set those

to 50% (Pitch, Aileron and Elevator).

Now center both radio sticks (including “throttle”) and center all trim and sub-trim values.

When this is done turn your receiver pack on. Now mount the servo arms at a 90

towards the linkage rod. In our non push pull helis this will be horizontal. Use the

mounting position on the servo arm that will be closest to 90

100% correct. If they are visible off from the 90

o

position the use the sub-trim function in

o

, not all servos will line up

o

angle

your radio for fine tuning, do not use regular trim for this, see picture 1.

Now you have a good start and the rest of the setup will become easier.

Step 2:Connecting the Swashplate at the right distance. This is done by moving your

Pitch (throttle) stick all the way down, see picture 2. When the servos are in this position

adjust the length of the linkage rods so the Swashplate is located towards the bottom,

but still leaves enough room for left/right (aileron) and front/back (elevator) travel. During

such travel, portions of the Swashplate will move below the Swashplate position

archived during Pitch full down radio stick position. So make sure you leave enough

room for this extra travel, see picture 2 for recommended height. Also make sure that all

3 linkage rods between the servo arms and the Swashplate are the same, so the

Swashplate is level. It should not tilt in any direction; unless your right radio stick is

moved. If it lilts, and all linage rods are the same length, then go back to step one and

make sure your three servo arms have the same neutral position (horizontal on non

push pull helis).

Page 66 of 79

Picture 1, Swash center Picture 2, Swash Down

Step 3:Connecting the Washout assembly. Connect the fixed length plastic “A” arms to

the Swashplate, connect to the two longer pivot studs, if all four are the same length

then any two will do. The next step is to adjust the length of the linkage rod between the

Washout Arm and the Flybar connection point. Turn your radio and receiver back on and

center both sticks. Now adjust the length of the flybar linkage so the washout arms are

level (horizontal), see picture 1. Also make sure your flybar arms and flybar-paddles are

level (horizontal), when adjusting the linkage. After the length is adjusted make sure that

you have free travel in all directions and stick positions. When the Pitch stick is all the

way up it should look like picture 3. As you can see there is still plenty of room for aileron

and elevator travel. Now adjust the Washout Anti-rotation pin height so the pin is still in

the guide slot of the washout base during all travel positions. For the Left/Right Washout

Anti-rotation position, line the attachment point of the plastic washout “A” arm on the

Swashplate up with flybar linkage connection point. The imaginary line between these

points should be vertical.

Now you are almost done, only one set of links left, and the length of those links will be

depending on your desired setup whether it's Aerobatic or normal flying. Please refer to

the Pith travel setup table for this final link length.

Picture 3, Swash Up

Page 67 of 79

Picture 4, Head

Picture 5, Tail Center Picture 6, Tail Positive Thrust

Picture 7, Tail Negative Thrust Picture 8, Tail

Collective Position Normal Flying Aerobatic

Up (100%) +10o +10o

Center (50%) +5

Down (0%) -3o -10

Page 68 of 79

Pitch Travel Setup

o

+0o

o

Throttle Curve Setup

Electric

Flying

Collective Position

Normal

Flying

Fuel

Aerobatic

(non governor mode)

Normal

Up (100%) 100% 100% 85% 85%

Center (50%) 70% 60% 75% 75%

Down (0%) 10% 100% 0% 85%

Aerobatic

Page 69 of 79

First adjust the servo arm position like you did with the swash, make sure your trim and

sub-trim values are centered. Attach the servo arm so it's 90

(vertical). Now adjust your two plastic ball ends, for the push rod, so they are screwed on

about half way onto the threaded pushrod guide end piece. This will allow you have

maximum amount of adjustment available in both directions. Use the outer holes on the

tail blade grips for the ball link attachments. When this is done cut the carbon pushrod to

a length that will achieve about 3

o

of positive pith on your tail blades, when the servo is

in its neutral (vertical) position. Then glue the two end pieces on to the pushrod with CA

glue, don't forget to insert the pushrod guides first.

o

to the tail pushrod

When this is done you should have 3

o

of positive tail blade pitch. The tail should spin

counter clockwise looking at the right side of the helicopter with the nose to your right

and tail to your left. See pictures 5-8.

Note: Please consult the instruction for your Gyro for setting the overall travel and limits

to ensure proper operation and travel of Tail Pitch Slider.

The throttle cure will be affected by several conditions; some of them are, motor choice,

blades choice, elevation, temperature, helicopter weight and type of helicopter. So in

order to explain this I will explain what you are looking for. Your goal is to achieve a

constant head speed once the helicopter is airborne. If you ad pitch (climb) you need to

ad power (throttle) to compensate for the added resistance a higher blade pitch creates.

If during climb your head speed drops, then you need to add throttle to that particular

stick position, and reversed if you have an increase in rpm. If during max climb out you

experience an increase in head speed then you need to give the blades a higher pitch,

do not try to adjust the max climb rpm by reducing throttle. There are other ways of

achieving this by using cyclic mixing, however we will stay away from this for now.

Follow the pitch guidelines in the table above, and if you need more pitch at max power

because the rpm is increasing, then add pitch. 10

most setups, but a powerful motor or a light helicopter might need more. For rpm

adjustment during anything other than full stick deflection you should use the throttle.

o

is just a guideline and will work in

A short recap, adjust throttle to adjust rpm during anything other than full collective. At

full collective adjust the pitch. See the Throttle table for general setup.

These are guidelines and will get you going but might not be 100% accurate in regards to

all helicopters. Especially the throttle curve table should be considered as initial guidelines.

As mentioned before it's greatly affected by your equipment. As you become more familiar

and proficient with your helicopter you can change the pitch and throttle curves to your

flying style.

Page 70 of 79

8-7 CANOPY MOUNTING

No. Bag# Description Qty

1

2

In box

3 8 Canopy Grommet 4

4

HB

Helicopter 1

Canopy 1

M3x10 Cap Head Bolt 4

• Put the Canopy on the helicopter, mark the right

positions for 4 holes, and then drill four 5.5mm holes.

• Install the Canopy Grommets on the Canopy.

• Secure the Canopy by 4 M3x16 Cap Head Bolts.

Note: The frame may look differently from the one in the kit.

Page 71 of 79

PRE-FLIGHT CHECKS

• The rotor flybar and shaft must be straight.

• The flybar and control paddles must tilt in the proper direction and operates smoothly

throughout the whole range.

• Check the swashplate to make sure it move smoothly and clean.

• When control input are given to tilt the swashplate, make sure no control arms or

pushrods are binding.

• Check the two control paddles for level, parallel, and proper direction.

• Make sure the batteries are fully charged and the fuel tank is full.

• Make sure the radio and receiver are on and all controls operate properly before

flight.

• There should be no interference of radio signal in your flying zone. Range check the

radio.

• Always grab onto the helicopter main rotor head when turning on the helicopter.

These pictures illustrate how everything should be neatly wired up and strapped down

before your helicopters first flights.

Page 72 of 79

WARNINGS

• Do not operate helicopters in rainy, windy, or snowy condition.

•

Operate helicopter in a safe zone away from crowds, traffic, or distractions.

•

Use the proper batteries to prevent damage to the motor and equipment.

Make sure all the batteries are fully and properly charged and the fuel tank is full.

•

•

Make sure all the controls operate properly before flight.

•

The main and tail rotors blades operate at very high speed (rpm); therefore,

make sure nothing can come into contact with them while they are spinning.

•

Perform a range check on the radio before flying.

•

Make sure the transmitter and receiver are turned on before starting the engine

•

Keep a safe distance when operating a helicopter.

•

Do not fly for a long period of time. Take some rests during flights.

•

Motors are often very hot after operation. So be careful when handling or

touching them immediately after flying.

Page 73 of 79

ADJUSTMENTS

Tracking Adjustment: The tips of the main rotor blades should follow the same

path when they rotate. We call the main rotor blades are in track.

(a) Rev up the motor until the helicopter becomes light on its landing gear.

Raise throttle

gently and

gradually

(b) If the main rotor blades are in track, it’s good.

(c) If the blades are out of track, then adjust one of the pushrods that connect to the

main rotor blade pitch arm.

Out of track

Repeat steps (a) to (c) until the blades are in track.

Trimming: Most of new built helicopters are unstable. But if you trim your helicopter

properly, you will stop it from drifting away or yawing by itself quickly. Followings are

instructions for trimming your helicopter.

(a) If the helicopter nose starts to

compensate. If using a Heading Hold Gyro, do not adjust the trim lever on the radio.

yaw left or right, adjust the tail rotor push rod to

(b) If the helicopter rolls to left or right, then:

Page 74 of 79

•

Rolls to the left, move the

button to R

• Rolls to the right, move the

button to L

L R

(c) If the helicopter nose goes down or up, then:

• Goes up, move the stick

to U

• Goes down, move the

stick to D

U

D

HOW TO HOVER

Basic maneuver for a pilot is learning how to hover a helicopter. When the helicopter is

floating in a stationary position in the air, we call that hovering. Use the following

procedure to practice your hovering:

(a) Make sure everything is clear in the flying zone. Stand at least 30 feet (10 meters)

behind the helicopter.

(b) Check the main rotor fore/aft and left/right cyclic to make sure the main rotor is

following to your cyclic command before taking off. Make sure the helicopter nose

will swing in your desired directions by moving the tail rotor control stick.

(c) Now, increase the throttle/collective gently to lift the helicopter landing gear off the

ground to no more than 4 inches (10 cm). At the beginning, it is very difficult for the

pilot to keep the helicopter from moving. It will also be difficult to know if the

helicopter is in trim or not for a beginner. Keep going on the practice close to ground

you will develop your skills.

(d) Keep practicing lifting your helicopter no more than 8 inches (20cm) from the ground

until you feel comfortable with control commands. Once you can keep it at one place,

then it is time to slowly increase the height a few inches in each fight. Soon, you will

Page 75 of 79

be able to hover the helicopter confidently at a few feet high. Beginners should

always practice hovering close to ground since in an emergency situation; you can

drop the throttle and collective quickly without making any big damage.

4 ~ 8 inches

(e) Stand behind the helicopter so you can watch the nose of the helicopter. A left tail

rotor command will yaw the helicopter nose to the left, and a right command will yaw

to the right. Also, a left cyclic command will cause the helicopter to translate left.,

Start practice hovering while standing to either side of the model after you can

comfortably hover the helicopter at 3 feet (1m) high without drifting. Finally, you need

to learn hovering the model from any positions. When you can confidently hover a

helicopter at any altitude and at any position, you have mastered most of the

fundamental control movements of a helicopter.

Page 76 of 79

HOW TO FLY FORWARD

Once you have mastered hovering fight:

(a) Let’s begin the exercise of changing positions by practice moving the helicopter to

the left or right slowly from 60 inches (1.5 m) above the ground.

Hovering at 60 inches

(b) Once you have been comfortable with all the movements and controls in the

previous step, start using some tail rotor control to make the helicopter point slightly

to the left or right as you fly it to the left or right. Keep practicing the figure-eight path

as shown below, you will master all basic control movements of a helicopter.

Page 77 of 79

AFTER-FLIGHT CHECKS

After each flight, the helicopter should be thoroughly inspected:

(a) Unplug the batteries.

(b) Check every bolt, nut, and screw to make sure none has loosened due to vibration.

(c) Check every rotating and movable part like head rotor, swashplate, tail rotor, to ensure

they still move smoothly and properly.

(d) Check all movable parts, such as gears, ball links, belt, etc. for unusual wear.

(e) Clean up the helicopter then lubricate every moving part with oil to ensure a smooth

operation in the future.

(f) Keep the helicopter in a cool and dry place. Avoid storage under direct sun light or

near heat.

(g) Please replace any damaged parts if they are discovered during maintenance.

WHAT IF THE HELICOPTER CRASHED

Turn off everything and check the helicopter immediately. If any item is damaged,

replace the damaged parts to ensure safe operation. Do not try to glue any broken or

damaged plastic or carbon parts specially broken rotor blades. The followings are parts

that should be inspected right away:

• Main and tail rotor blades.

• Flybar, main shaft, head spindle, and tail output shaft.

• All the gears.

• Tail boom and supports for cracks.

• Vertical and horizontal fins.

• Frames.

• All pushrods.

• Servos, motor, and batteries.

Page 78 of 79

SPECIFICATIONS

Specification Quick 50

Blades Quick 580-600 mm

Length 1115 mm

Height 450 mm

Fully Equipped Weight ~ 7.5 lbs (3.40 kg)

Engine 50-70

Frame Thickness 2.0-2.2 mm

Spindle 8.0 mm

Main Shaft 10 mm

Canopy Fiberglass

Flying Aerobatic / 3D

Page 79 of 79

Loading...

Loading...