T12 S TC- O LED DIGITAL SOLDERI N G STATI O N

USERMANUAL

VE R:1. 4@ 20 17618

5

℃

1

5

2

%

3

℃

9

ERI NG STAT

ION

1 -

O

K

C

I

U

O

L

ED T

1

2 Q

T

0℃

0

3

:

SET

0

0

3

V

4

2

U

C

I

K

O HE

A

TING SO LD

QUICKO ELECTRONIC.,LT D

http:// www.quick ochin a.com

Conventional safety

Please use only the power adapter that is dedicated to the

product and is certified by the country / area.

Do not operate in a wet environment.

Do not operate in a flammable and explosive environment.

Please keep the surface of the product clean and dry.

To protect your family and friends for the safety, please power

off after use or leave, beware of fire.

When the host is starting up, the temperature of iron tip will

be reached 100℃ to 480 ℃, beware of scalds.

Do not be soaked in water or with wet hands to use the

soldering station, prevent leakage.

Operating environment

Operating environment

temperature

humidness

Requirements

Working condition:+0 to +50℃ ℃

Off working state:-20 to +60℃ ℃

Working condition:high temperature 40 -60 , 0%-60%RH℃ ℃

Working condition:low temperature 0 -40 , 10%-90%RH℃ ℃

Off working state:high temperature 40 -60 , 5%-60%RH℃ ℃

Off working state:low temperature 0 -40 , 5%-90%RH℃ ℃

Matters needing attention

When using the T12 iron tip please tighten the nut for soldering

head to avoid falling and damaging the iron tip.

The temperature will be reached above 350℃ of soldering

station is used for 40 minutes, and the temperature of the front

end of the handle will be reached 50℃ -60℃.

When the new T12 soldering iron tip is used for the first

time,Host will appear temperature jump and display ERROR,it

will become a normal phenomenon due to the heating of the

inner galvanic couple part of the iron tip. After repeated use

several times, the temperature will be stabled.

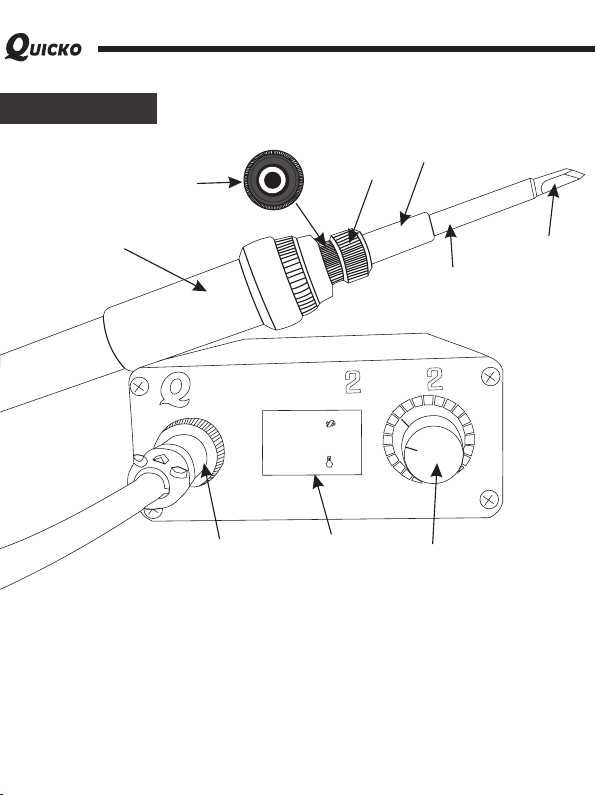

Parts list

②

④

③

①

1 -

S

IC

ET: 3

24V

30 0

KO H

T

℃

%

00

13

℃

25℃

EA

T

IN

G S

O

L

DE

⑦

O

CK

I

U

OLE

D T1

2 QU

⑥

1、T12- 9 0 7 H a n dle

2、So cket of iron ti p

3、Lo cking nut for i ro n tip

4、Lo ck tube for iro n ti p

5、He ad of iron tip

6、Avia ti on Plug of ha nd le

7、 O L ED te mperatu re d isplay

8、En coder

9、No zzle tip

95

RI

N

G ST

A

⑧

⑨

⑤

TI

O

N

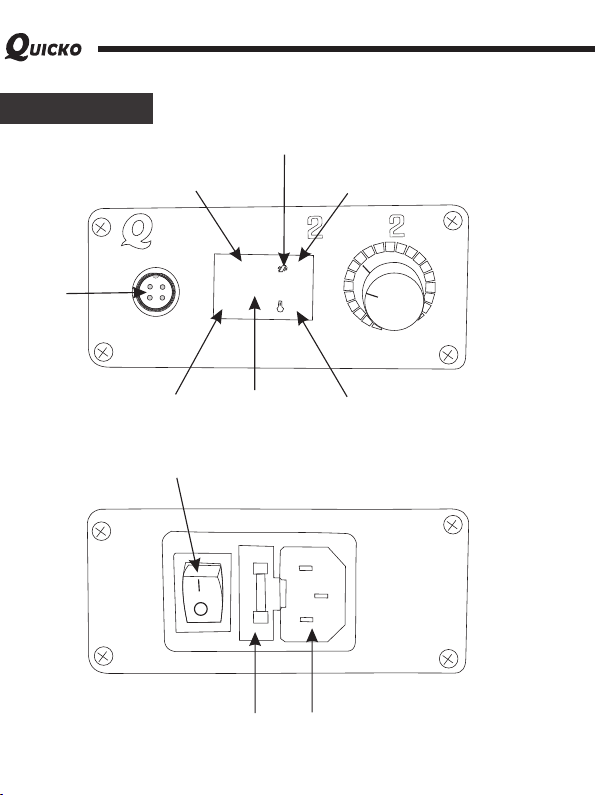

Parts list

The current set temperature

②

Vibration prompt

⑩

③

STC usage

Handle

interf ac e

①

Current voltage

O

K

C

I

U

OL

ED T1

2 Q

④

Current working

Switc h

⑦

Fuse

1 -

T

S

E

T

:3

00℃

1

3

00℃

2

4

V

2

UIC K

O HEAT

ING S

⑤

temperature

⑧

95

3%

5

℃

OL

D

E

R

I

N

G ST

AT

ION

⑥

Inside temperature of

Power c ord connector

⑨

Front

the machine

Back

Product parameter

Model number

Display

Handle interf ac e

Product weigh t

Dimension of ho st

Wire length of ha nd le

Application i ro n ti p

Tim e of m el t tin

Max power

Range tempera tu re

Voltage of power

Input voltage

T12 STC -9 52

OL E D

GX 12-4pi ns

Standard 510g

120*88*38mm

1.1m

T12 series

Work ing p arameter

<8S

108W

200-480℃

24V 4.5A

AC 100-240V

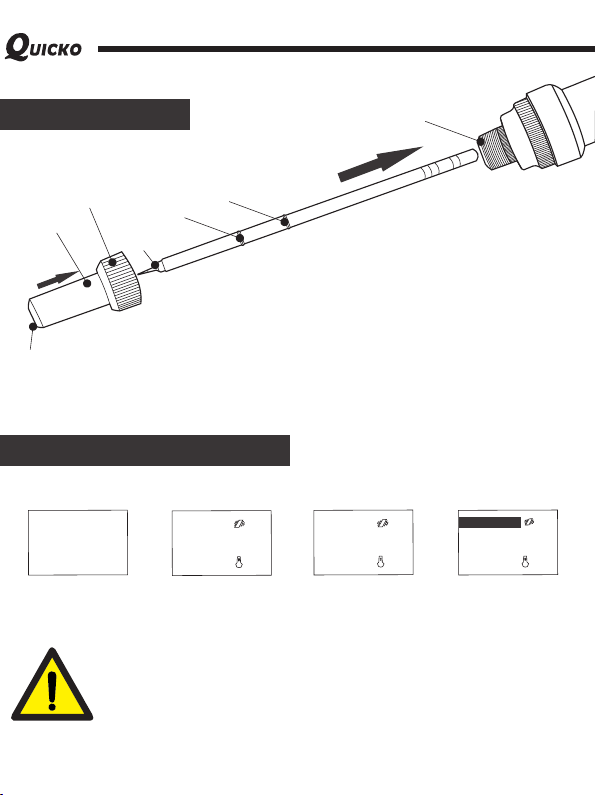

install iron tip

Socket of i ron tip

Locking nut

Tighten

sleeve

Head of nut

Note: Turn on the bu tt on , th e di sp la y sc reen shows E R ROR , in di ca ti ng t ha t th e iron

tip may not be well i ns ta ll ed , pl ea se t ry to install the iro n ti p ag ai n.

The first screens

Tsui tip

The second step: Put the tube to the locking nut, let the nut and the tube

from the iron head nozzle tip into the iron tip, the nut head and the iron tip is

flat with first clamping, then tighten the nut, the installation is complete!

The second scre en s

The first step: remove the handle locking nut, insert the

iron tip to iron head socket, let the second clamping

and handle iron head socket is flat!

Description for display

1

℃

0

5

T:3

S

T12 S OLD ERI NG

IR ON STA TIO N

Initial state of

power off

Note: after confirming the installation of the components is right,

the new iron tip is inserted into the handle and the display screen will

be a flash or ERROR, and the host buzz is wrong. It’s normal. After

heating 5-20 minutes, it will return to normal gradually. Temperature

control range of mamin engine: 200 -480 .The common welding ℃ ℃

temperature is 300 -380 . In order to protect the working life of ℃ ℃

the soldering iron tip, it is recommended that the temperature do not

more than 380 !℃

℃

0

:30

T

SE

O

ERR

24V

Non plugged

iron tip

℃

00

℃

%

3

1

℃

25

3

0%

R

5℃

2

SET :

24

30 0

V

Normal

working state

BOO

30 0℃

25

V

24

One press

strong temperature

%

3

℃

Menu use

5

1 -9

D T12 Q

KO

C

ED T12 Q

S

ET

:30

0

℃

3

0

0℃

24

V

U

I

C

KO HE

MEN U

1.CAL IBRATI ON

2.AUT OSLEEP

3.AUT OPOWERO FF

UI

CKO HE

T

13%

25

ATI

NG S

1 -

T

A

T

I

N

G S

UICKO

MEN U

1.CAL IBRATI ON

2.AUT OSLEEP

OL

U

O

E

D T12 Q

C

I

L

ED T12 Q

KO

3.AUT OPOWERO FF

U

I

CKO H

E

MEN U

1.CAL IBRATI ON

2.AUT OSLEEP

3.AUT OPOWERO FF

UI

CKO HE

℃

OL

DE

R

IN

G ST

AT

I

ON

5

9

OLD

ERIN G S

T

A

TION

UICKO

O

LE

I

U

O

L

Enter the menu setting interface: under the normal working temperature interface, long

press the encoder button (about 3s). Enter the host setup mode! Exit menu settings

interface: at the menu setting interface, long press the encoder button (about 3s), exit the

host setup mode!

Setting menu:

Enter the function item: rotate the encoder to the corresponding function, and short press

the button to enter the function item.

Exit setting function item: after setting the corresponding parameters with the encoder rotary

knob, short press the button to confirm exit the function item.

1 -9

T

A

T

I

N

G SO

LDER I

1 -

T

A

T

I

N

G S

OLD

9

ERIN G S

NG ST

5

A

TI

ON

5

T

A

TION

Temperature calibration

UICKO

O

L

E

D T12 Q

MEN U

1.CAL IBRATI ON

2.AUT OSLEEP

3.AUT OPOWERO FF

UI

CKO H

E

1 -9

T

A

T

I

N

G S

OLD

ERIN G S

5

T

A

TI

ON

UICKO

O

L

E

D T12 Q

CURRE NT350℃

RATIO [100%]

UI

CKO H

E

A

1 -9

T

T

I

N

G S

OLD

ERIN G S

5

T

A

TI

ON

After selecting the temperature calibration function, short press the encoder to enter the

temperature calibration setting, the adjustable temperature ratio: 70%-130%, if there is no

professional measurement instrument, please set the ratio value to 100%.

Sleeping time

5

1 -9

D T12 Q

MEN U

1.CAL IBRATI ON

2.AUT OSLEEP

3.AUT OPOWERO FF

U

I

CKO H

E

T

A

T

I

N

G S

OLDE RI

N

G ST

A

TI

ON

UICKO

OL

E

D T12 Q

U

I

CKO H

AUTOSL EEP

[01mi n]

E

A

UICKO

OL

E

Choosing sleeping time feature, short press encoder, into the sleeping time setting, the

time setting range: 0-99 minutes, if you don't need the sleeping time function, the dormancy

feature can be set to OFF.

Default sleeping time for 1 minute, means after 1 minute the host and handle is stand still,

the soldering station will entry to dormant state, the temperature of soldering iron tip will drop

to 150℃, at this time when move handle or rotary encoder, the soldering station will rapidly

heat up the working temperature before Sleeping.

You can set the sleeping time according as the usage scenario and working habit, it can

be extended the working life of the iron tip and protect your family and friends safe!

1 -9

T

T

I

N

G S

OLDE RI

5

NG S

T

A

TI

ON

Power off time

5

1 -9

D T12 Q

MEN U

1.CAL IBRATI ON

2.AUT OSLEEP

3.AUT OPOWERO FF

U

I

CKO H

E

T

A

T

I

N

G S

O

LDER I

NG S

T

A

TI

ON

1 -

T

O

K

C

I

U

AUTOPO WEROFF

[OFF]

O

L

ED T12 Q

UIC

KO HEATI

NG S

UICKO

AUTOPO WEROFF

[01mi n]

OL

E

D T12 Q

U

I

CKO H

E

A

95

OL

D

E

RIN

G S

TA

T

IO

N

UICKO

OL

E

Choosing power off time feature, short press encoder, into the power off time setting, the

time setting range: 0-99 minutes, if you don't need the power off time function, the power off

function can be set to OFF.

Default power off time for 1 minute, means after 1 minute the host and handle is stand

still, the soldering station will entry to power off time state, the temperature of soldering iron

tip will drop to indoor temperature (note: The temperature control range of the host is 200-

480℃, it will appear larger deviation when the temperature less than 100℃. Please

ignore it.). At this time when move handle or rotary encoder, the soldering station will

rapidly heat up the working temperature before power off.

You can set the power off time according as the usage scenario and working habit, it can

be extended the working life of the soldering iron tip!

1 -9

T

T

I

N

G S

O

LDER I

5

NG S

T

A

TI

ON

Strengthening time

5

1 -9

D T

1

2 QU

T

MEN U

4.BOO STDURAT ION

5.BOO STDEGRE E

6.WAK EUPMETH OD

I

C

KO H

E

AT

I

N

UICKO

BOOSTD URATIO N

[30S]

OL

E

D T

1

2 QU

I

C

KO H

E

G SO

LDE

R

I

NG STA

TI

O

N

AT

UICKO

OL

E

After choosing strengthen the time function, short press the encoder and enter the time

setting. The time setting range: 0-99 minutes.

The default time is 30 seconds, it can be set according as the actual needs, after setting,

short press the encoder to confirm and exit. When working normally, it takes a short time to

increase temperature welding the larger welding spot, it can be heated to the set

temperature rapidly after pressing the encoder. After 30 seconds, the host will

automatically return to original temperature. This can avoid soldering iron tip oxidation

when with high temperature to use!

1 -9

T

I

N

G SO

LDE

R

I

NG STA

5

TI

O

N

Strengthening temperature

95

1 -

T

O

K

C

I

U

MEN U

4.BOO STDURAT ION

5.BOO STDEGRE E

6.WAK EUPMETH OD

O

L

ED T12 Q

UICKO H EA

TI

NG S

OL

D

ERIN

G S

TA

T

IO

N

1 -

T

O

K

C

I

U

BOOSTD EGREE

[80℃]

O

L

ED T12 Q

UIC

KO HEATI

NG S

OL

D

E

RIN

After choosing strengthen the function of temperature, short press the encoder, enter

strengthening temperature setting, the temperature setting range: 10-80 ℃.

The default strengthen temperature is 30 ℃, it can be set according as actual needs,

after setting, short press the encoder to confirm and exit. When working normally, it takes a

short time to increase temperature welding the larger soldering spot, it can be heated to the

set temperature rapidly after pressing the encoder. After 30 seconds, the host will

automatically return to original temperature. This can avoid soldering iron tip oxidation

when with high temperature to use!

95

G S

O

K

C

I

U

BOOSTD EGREE

O

L

ED T12 Q

UICKO H EA

TA

T

IO

N

1 -

T

[50℃]

TI

95

NG S

OL

D

ERIN

G S

TA

T

IO

N

Wake-Up type

5

1 -9

D T

1

2 QU

T

MEN U

4.BOO STDURAT ION

5.BOO STDEGRE E

6.WAK EUPMETH OD

I

C

KO H

E

AT

I

N

UICKO

POWER OFFWAKE UP

ENCOD ER&HAN DLE

OL

E

D T

1

2 QU

I

C

KO H

E

G SO

LDE

R

I

NG STA

TI

O

N

95

1 -

T

O

K

C

I

U

POWER OFFWAKE UP

[ENCO DERONLY ]

O

L

ED T

1

2 QUIC

KO HEATI

NG SO

L

D

E

R

IN

G STA

T

IO

AT

N

UICKO

OL

E

After selecting the wake-up function, short press the encoder, enter setting of wake-up

type, the system provides two kinds of wake-up type: encoder together with handle or just

encoder. When choosing encoder + handle, the soldering station is automatic power off,

shaking handle or short press or rotary encoder, all can wake-up the host!

When choosing the encoder, the automatic shutdown state, short press or rotary encoder

can wake-up the host, but shaking handle cannot wake-up the host!

The default setting is: encoder + handle, which can be set according to actual needs.

1 -9

T

I

N

G SO

LDE

R

I

NG STA

5

TI

O

N

Buzzer switch

5

1 -9

T

O

UICK

MEN U

7.BUZ ZERSWIT CH

8.BAT TERYGUA RD

9.FIR MWARE

OL

E

D T

1

2 QU

I

C

KO H

EATI

NG SO

L

DE

R

I

NG STA

T

I

O

N

This version OLED controller integrates with a buzzer, and the sound prompts the host

state. The buzzer will beep when the host encounters an error or sets the appropriate

function.

UICK

OL

E

D T

1

O

2 QU

BUZZE RSWITCH

[ON]

I

C

KO H

EATI

1 -9

T

NG SO

L

DE

5

R

I

NG S

T

A

T

I

O

N

Battery guard

95

1 -

T

O

K

C

I

U

MEN U

7.BUZ ZERSWIT CH

8.BAT TERYGUA RD

9.FIR MWARE

OL

ED T

1

2 QU

IC

KO H

EATI

NG SO

L

DE

R

I

N

G STA

T

IO

N

According to the voltage environment of the host, built-in battery guard function of this

soldering station, and the default voltage is 12V. When the voltage is not stable, the power

supply will be supercharged according to the setting. Usually don't need to set it. The

setting range is 12V-24V.

O

K

C

I

U

BATTE RYPROTE CT

OL

ED T

1

2 QU

IC

KO H

AT[12 .0V]

EATI

1 -

T

NG SO

95

L

DE

R

I

N

G STA

T

IO

N

Version information

5

1 -9

D T

1

2 QU

T

MEN U

7.BUZ ZERSWIT CH

8.BAT TERYGUA RD

9.FIR MWARE

I

CKO H

E

A

T

I

N

G SO

LDER

I

NG ST

A

TI

ON

UICKO

OL

E

It shows the info rm at io n of t hi s ve rsion controller.

UICKO

OL

E

D T

1

2 QU

I

FIRMW ARE

[V1.4 @20170 618]

CKO H

E

A

1 -9

T

T

I

N

G SO

LDER

I

NG ST

5

A

TI

ON

Restore default

UICKO

OL

E

D T12 Q

MEN U

8.BAT TERYGUA RD

9.FIR MWARE

A.FAC TORYRES ET

U

I

CKO H

E

1 -9

T

A

T

I

N

G S

OLDE RI

5

NG S

T

A

TI

ON

UICKO

OL

E

D T12 Q

RESTO RESETTI NG

U

I

CKO H

[NO]

E

A

1 -9

T

T

I

N

G S

OLDE RI

5

NG S

T

A

TI

ON

Restore the parameters of the soldering station to the factory default. Note: please back-up

your usual important parameters before you restore factory Settings to prevent data loss.

For example: temperature calibration value, strengthening time and temperature, etc.

How to choose the iron tip

Note: Choosin g th e ri gh t ir on t ip c an m ake the work more effic ie nt .

Iron tips maintenance

1.Please put appropriate tin on the adhering head of iron tip Before powering off , and

please clean it before welding.

2.Do not allow the iron tip to stay at high temperature for a long time to avoid dry burning.

3.In welding, do not rub the soldering tip with too much pressure to friction the solder, which

will damage the iron head.

4.Never clean iron head with a rough material or file.

5.If the surface oxide and no absorb tin, as needed you can use 600 to 800 of emery cloth

friction it carefully and use isopropyl alcohol or equivalent solution to clean, heated to

200 immediately adhering tin to prevent sticking tin and then oxidation.℃

6.Do not use chlorine or high acid soldering flux. Only use of synthetic resin or activated

resin flux.

7.The working temperature of the soldering iron tip is about 300 to 380 , and the ℃ ℃

working temperature should not exceed 450 in a short time. Otherwise it will affect the ℃

working life of the soldering iron tip!

8.Different welding scenes should be selected with different soldering iron tip. Large

welding spot or aluminum base plates will need to be touched to large soldering iron tip

(such as C4). Small welding spot can be usedC1, JL02, ILS, etc.

9.The new soldering iron tip is used for the first time, the heat up may be slightly slower, and

it can melt tin 7 seconds after the normal use of 1-3 hours.

10.7 seconds of tin, only for solder wire with the high purity and low melting point, the higher

the lead tolerance, the speed of melt tin is slower, the higher the temperature will be

required. So we suggest to choose the high purity & low melting point solder wire from my

store.

保修服务

After-s ales se rvice

T12 soldering station host in non-human damage to provide 1 year free warranty

service. Warranty service, please contact the seller to buy! Iron head is a consumables, its

life and maintenance of the tip, the use of the number of the first use can not be returned or

replacement.

About Dis cardi ng

Do not discard in f am il y ga rb ag e!

Handling an d re cy cl in g: you ha ve to d ea l with the ir on corr ec tl y

according to lo ca l la ws a nd r eg ul at ions.

FA Q

FAQ:

1. Why the temperature of the new T12 solder tip is jump?

Because the inside heating core of the new T12 solder tip did not go through the high

temperature, so the first time to use will be a bit of temperature, generally without special

treatment, the normal use of 1-2 days after the basic will not bounce. Such as the need to

immediately effective, the general proposal to adjust the temperature to 380 -400 , side ℃ ℃

of the solder tip to the tip of tin, burning 5-10 minutes after the shutdown, until the solder tip of

the cooling and then re-boot! ( if 1 times no effect, then can be repeated 2-3 times). T12 is

pulsating temperature warming, even if the display temperature is flashing, the tip of the real

temperature is completely stable.

T12 jump temperature also are connected with the temperature control board of

procedures, power of electrostatic and if it connect the ground.

2. What the problem of attention when we use the T12 first time?

T12 tip heating speed is very fast, when the new solder tip connect the electricity, it must

be tinput immediately to the solder tip, for protection, due to heating up fast, just need 6-10

seconds, no have more time to you for preparetion.

so the important is prepare the items which will be welded, and finally boot power, and

each welding gap or the end, should be more on the tin to protect and then shutdown, so it

can avoid to tin the new sold tip is difficult, especially the T12 tip type of iron, such as T12-I /

T12-IL / T12-BL / T12-ILS and so on!

3.What are the precautions for using the T12 tip?

a. If can use low temperature, then do not high temperature: T12 is constant temperature

control, the general recommended working temperature control between 300 ~ 380 , ℃ ℃

higher than 380 damage the coating of solder tip and cut down the PTC life!℃

b. Do not dry: the first time to use solder tip, should be wrapped while heating a layer of

tin. If it's without work, at once shutdown!

c. Diligent to clean: before shutting down, use a wet sponge or detin the ball to remove the

tip of the oxidation of debris, on the tin after the shutdown power off!

d. Standard operation: Do not violent collision the solder tip, do not stamp the top of the

hard objects, but can not be used to hot plastic and other materials, specifically reminded

that friends like tin should avoid the iron and other hard metal knock tin, the heating core of

T12 is in the head of the solder tip, often percussion is a fatal damage to T12!

e. Less use of scaling powder: scaling powder can not be used, can be used as less as

possible! When scaling powder help make beautiful and reliable welding at the same time,

but also greatly speed up the consumption the coating of the solder tip, T12 heating core

high temperature position is very near of the Nozzle tip of the solder tip,Scaling powder in the

fear of threat to T12 head pressing parts.

4.How to do when T12 tip does not absorb tin?

T12 iron head does not absorb tin, generally there are two reasons:

A. The head of solder tip is severe oxidation can not absorb tin.

B. Temperature can not rise up then can not tin.

C. The head is oxidized and can not the tin, you can use the soldering iron to clean the ball

gently, then use the wet sponge rub and then heat the tin.

More FAQ please follow this link:http://www.quickochina.com/FAQ/

Your feedback will make us better!

Chinese websi te

Taobao

Aliexpress

Made in China

Quicko electronic co.,ltd TEL:08615992468682

Loading...

Loading...