The Labels You Want When You Need Them.

®

USER

GUIDE

• Fast print speed,

up to 305 mm/s

• Excellent print

quality up to 1600 dpi

• High-yield, vivid inks

• Complete with color

labeling software

QuickLabel.com

Part Number: 22834649-EN-E

QL-800 User Guide

Part Number 22834649-EN-E

Revision 1.2

11/2015

QuickLabel Systems, An AstroNova™ Division

World Headquarters

600 East Greenwich Ave., West Warwick, RI 02893

Tel: +1 (401) 828-4000 Fax: +1 (401) 822-2430

E-mail: info@QuickLabel.com

www.QuickLabel.com

Technical Support

Tel: +1 (401) 828-4000

E-mail: support@QuickLabel.com

www.QuickLabel.com/support/

© 2015 Astro-Med, Inc. All Rights Reserved

This manual is copyrighted with all rights reserved. No part of this manual may be

reproduced, transmitted, transcribe d, stored in a retrieval system, or translated into any

language in any form by any means without written permission of QuickLabel Systems.

Trademarks

QL-800® and Custom QuickLabel Omni® are registered trademarks of Astr o-Med, Inc.

Adobe®, Photoshop®, and Illustrator® are registered trademarks of Adobe Systems,

Inc.

Corel® is a registered trademark of Corel Corporation.

Microsoft® Windows® XP, Windows® Vista®, Windows® 7, and Windows® 8 are

registered trademarks of Microsoft Corporation.

QL-800 Limited Warranty

QuickLabel Systems, An AstroNova Division, warrants all components of this pro duct,

except wear parts and consumables, against defects in materials or workmanship for

a period of one (1) year from the date of original purchase. Wear parts include the

transport unit, maintenance roller, maintenance cartridge, cutter blades and the like.

Consumables include ink cartridges and labels, which are covered under a separate

warranty. If the customer discovers a defect, this defect must be reported promptly to

QuickLabel Systems or an authorized QuickLabel dealer. QuickLabe l Systems will, at

its option, repair the printer or repair or replace its defective component(s) at no

additional charge. Repair parts and replacement parts will be furnished on an

exchange basis and will be either reconditioned or new. The customer is responsible

for freight to return the printer or component to our factory or authorized service center.

We will ship the repaired or replaced printer or component back to you via standard

ground freight service. All replaced parts become the property of QuickLabel System s.

Travel, freight and other expenses related to warranty repairs are not covered.

In the first year of product ownership, you may be covered by a separate Customer

Support Agreement purchased from or issued by QuickLabel or an authorized

QuickLabel dealer. In such a case, you would be entitled to an on-site installation

and/or training visit. Otherwise, Customer Support Agreements and renewals are

available for purchase and provide on-site support.

This warranty is void if the product has been damaged by accident, abuse, neglect or

misapplication or by the use of incompatible consumables or parts, or if the product has

been improperly installed, or if the product has been modified without the express

written permission of QuickLabel Systems. QuickLabel is not responsib le for products

lost or damaged in transit.

QuickLabel makes no warranty, either express or implied, with respect to this product's

merchantability or fitness for a particular purpose. In no event shall QuickLabel be held

liable for any direct, indirect, special, incidental, or consequential damages, whether

based on a contract, tort, or any other legal theory and whether advised of the

possibility of such damages.

Ink Limited Warranty

This warranty covers QuickLabel QL-800 ink cartridge sold by QuickLabel Systems.

Each QL-800 ink cartridge is warranted to be free from defects in materials and

workmanship for up to 12 months from the date of manufacture if in original u nopened

packaging, or up to 3 months after installation, wh ic he ve r oc cu rs first. This warranty

applies only to the ink cartridges as used in the QuickLabel QL-800 printing system.

If the customer suspects a defect in a QL-800 ink cartridge, the customer must notify

QuickLabel or an authorized QuickLabel dealer within the warranty period. Upon return

of the ink cartridge and QuickLabel's verification of the defect, QuickLabel will, at its

option, either:

1. Replace the defective ink cartridge; or,

2. If the customer has used the ink, pro-rate the price of a new ink based upon the

estimated life remaining for the ink, as reported by the QL-800 system. The QL-800

provides the estimated life remaining, and QuickLabel may obtain this information from

the system remotely or request the customer to furnish this information.

This warranty does not cover QL-800 ink cartridges that have been emptied, refilled,

remanufactured, modified, refurbished, misused, or tampered with, or that have

expired, or when used to print on label or tag media that is not compatible with the

QL-800.

This warranty is void if the QL-800 ink cartridge has been damaged by accident, abuse,

neglect or misapplication, if the product has been improperly installed or maintained, if

the product has been used outside of its environmental specifications, or if the product

has been modified without the express written permission of QuickLabel.

QuickLabel makes no warranty, either express or implied, with respect to this product's

merchantability or fitness for a particular purpose. In no event shall QuickLabel be held

liable for any direct, indirect, special, incidental, or consequential damages, whether

based on a contract, tort, or any other legal theory and whether advised of the

possibility of such damages.

Printhead Limited Warranty

QuickLabel Systems warrants the printhead from the date of purchase for a period of

90 days or for 250,000 inches of printing, whichever comes first, contingent upon the

use of QuickLabel ink and labels. The QL-800 printhead is calibrated for use with

QuickLabel ink and labels and performs optimally only when used with these materials.

This specific printhead warranty does not apply to printheads damaged by accident,

abuse, neglect, misapplication or the like. This warranty is void if the product has b een

damaged by accident, abuse, neglect or misapplication, or if the product has been

improperly installed, or if the product has been modified without th e express written

permission of QuickLabel Systems.

ICC Profile

ICC Profile Powered by X-Rite Incorporated

Obtaining Service

To obtain warranted service, please contac t QuickLabel Technical Support through

one of the Factory Sales and Service Centers.

Contact Information for Factory Sales and Service

QuickLabel USA and World Headquarters

600 East Greenwich Avenue

West Warwick, RI 02893 USA

Tel: +1 (401) 828-4000

Fax: +1 (401) 822-2430

Web Site: www.QuickLabel.com

Sales E-mail: info@QuickLabel.com

Technical Support E-mail: support@QuickLabel.com

QuickLabel Deutschland

Astro-Med GmbH, Senefelderstraße 1/ T6 D-63110 Rodgau

Tel. +49 (0) 6106-28368-20

Fax: +49 (0) 6106-771121

Web Site: www.QuickLabel.de

Sales E-mail: info@QuickLabel.de

Technical Support E-mail: support@QuickLabel.de

Ownership Information

Congratulations and thank you for your business. Your purchase of a QuickLabel digital

label printer is an investment in production flexibility and packaging efficiency. Please

record the model number and serial number of your product.

Contents

Chapter: 1 Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

About the QL-800 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Installation and Setup Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Unpacking the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Checking the Included Parts . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Before Installing the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Choosing an Installation Location . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Connecting the Power Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Switching the Printer On and Off . . . . . . . . . . . . . . . . . . . . . . . . 9

Installing the Printer Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installing the Printer Driver (USB) . . . . . . . . . . . . . . . . . . . . . . . . 9

Resolving Windows 7 and Windows 8 USB Installation Issues . . . . . . . . . 11

Installing the Printer Driver (Network) . . . . . . . . . . . . . . . . . . . . . . 12

Using the After Shipping Wizard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Readying the Maintenance Roller . . . . . . . . . . . . . . . . . . . . . . . . 14

Installing Ink Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Installing the Printhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Loading and Unloading Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Loading Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Unloading Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

QuickLabel Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

QL-800 Label Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

QuickLabel BPO Blanket Purchase Order Program . . . . . . . . . . . . . . 24

Media Specialists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Chapter: 2 QL-800 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Printer Part Names and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Back View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Operation Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Color Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Color and Computers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Color Profiling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Display Profiling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

QuickLabel QL-800 Color Profiles . . . . . . . . . . . . . . . . . . . . . . . . 30

A Profile for Each Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Chapter: 3 Designing and Printing Labels . . . . . . . . . . . . . . . . . . . . .31

Designing Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Choosing Design Software . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Disabling Anti-aliasing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Planning Full-Bleed and Non-Bleed Labels . . . . . . . . . . . . . . . . . . . 31

Setting up the Label Design Software . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Setting up Labels in Custom QuickLabel Omni . . . . . . . . . . . . . . . . . 32

QL-800 User Guide i

Contents

Setting up Labels in Third-Party Design Applications . . . . . . . . . . . . . . 32

Setting up the Printer Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Setting up General Options . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Setting up a Custom Label Size . . . . . . . . . . . . . . . . . . . . . . . . . 35

Setting up Media Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Using Service Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Saving and Recalling Driver Settings . . . . . . . . . . . . . . . . . . . . . . 40

Printing Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Using the Status Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Viewing the Printer Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Viewing the Job Status and Cancelling Jobs . . . . . . . . . . . . . . . . . . 44

Viewing Ink and Consumable Levels . . . . . . . . . . . . . . . . . . . . . . 44

Chapter: 4 QL-800 Maintenance Utility . . . . . . . . . . . . . . . . . . . . . . .47

About the Maintenance Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Printer Information Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Viewing Printer Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Upgrading the Printer and Print Module Firmware . . . . . . . . . . . . . . . 48

Setting the Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Print Settings Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Setting the Vertical Baseline . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Setting the Horizontal Baseline . . . . . . . . . . . . . . . . . . . . . . . . . 50

Setting the Cut/Stop Position . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Cleaning Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Setting up Auto-Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Cleaning Printheads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Preparing for Moving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Preparing for Shipping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

System Logs Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Viewing the Error History . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Saving Log Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Parts Replacement Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Replacing the Printhead Assembly . . . . . . . . . . . . . . . . . . . . . . . 57

Replacing the Cutter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Replacing the Aerosol Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Replacing the Maintenance Cartridge . . . . . . . . . . . . . . . . . . . . . . 58

Replacing the Maintenance Roller . . . . . . . . . . . . . . . . . . . . . . . 59

Advanced Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Chapter: 5 Printer Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Replacing Ink Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Cleaning the Printer Exterior . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Cleaning the Input Pinch Rollers . . . . . . . . . . . . . . . . . . . . . . . . 63

Cleaning the Maintenance Tray Area . . . . . . . . . . . . . . . . . . . . . . 64

Cleaning the Transport Belts . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Chapter: 6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Removing a Media Jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

ii QL-800 User Guide

Contents

Chapter: 7 Safety Warnings and Precautions . . . . . . . . . . . . . . . . . . .79

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Power Supply and Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

General Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Moving the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Ink Cartridge and the Maintenance Cartridge . . . . . . . . . . . . . . . . . . . . . . 82

Chapter: 8 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Printer Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Label Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

QL-800 User Guide iii

Contents

iv QL-800 User Guide

1

About the QL-800

When you start printing your own labels in your office or factory with the QL-800 from

QuickLabel Systems, you'll stop production delays and reduce excess inventory. You

will achieve flexibility and cost-savings because you are digitally printing the right label

for the right customer in the right quantity, just-in-time.

Getting Started

As a true digital printer, the QL-800 easily prints labels with any text, barcode, or

graphics in affordable small batches, perfect for labeling multiple different products or

labeling for different wholesale customers. The QL-800 is the best too l for customizing

your product labels in affordable small quantities.

• Fast print speed, up to 305 mm/s

• Excellent print quality up to 1600 dpi

• High-yield, vivid inks

• Complete with color labeling software

QL-800 User Guide 1

Getting Started

The QL-800 is designed with all the power of a high-end digital label printing press, but

it's sold at just a fraction of the price and fits on your desk or table top. The QL-800 is a

versatile, in-house digital color label printer that prints both labels in a range of widths

at high speeds, and in high-quality.

The QL-800 makes great-looking labels that perform well even in challenging

conditions. Your products will look appealing and professional, with bright, vivid inks

that reproduce a wide gamut of colors. Genuine QL-800 inks are available in large

capacity, high-yield separate cyan, magenta, yellow, and black (CMYK) cartridges.

Installation and Setup Overview

Refer to the installation and setup summary for an outline of the required steps.

1 Unpack the printer. See “Unpacking the Printer” on page 3.

2 Ensure all parts are included. See “Checking the Included Parts” on page 6.

3 Before installing the printer, select an appropriate location and ensure system

requirements are met.

• See “Choosing an Installation Location” on page 6.

• See “Installation Precautions” on page 7.

• See “System Requirements” on page 8.

4 Connect the power cable to the printer. See “Connecting the Power Cable” on page

8.

5 Switch the printer power on. See “Switching the Printer On and Off” on page 9.

6 Install the printer driver.

• See “Installing the Printer Driver (USB)” on page 9.

• See “Installing the Printer Driver (Network)” on page 12.

7 Use the After Shipping wizard in the QL-800 Maintenance Utility. See “Using the

After Shipping Wizard” on page 14. This wizard will guide you through the following

actions.

• Foam support block removal - See “Readying the Maintenance Roller” on page

14.

• Ink cartridge installation - See “Installing Ink Cartridges” on page 15.

• Printhead installation - See “Installing the Printhead” on page 16.

8 Load media. See “Loading Media” on page 21.

2 QL-800 User Guide

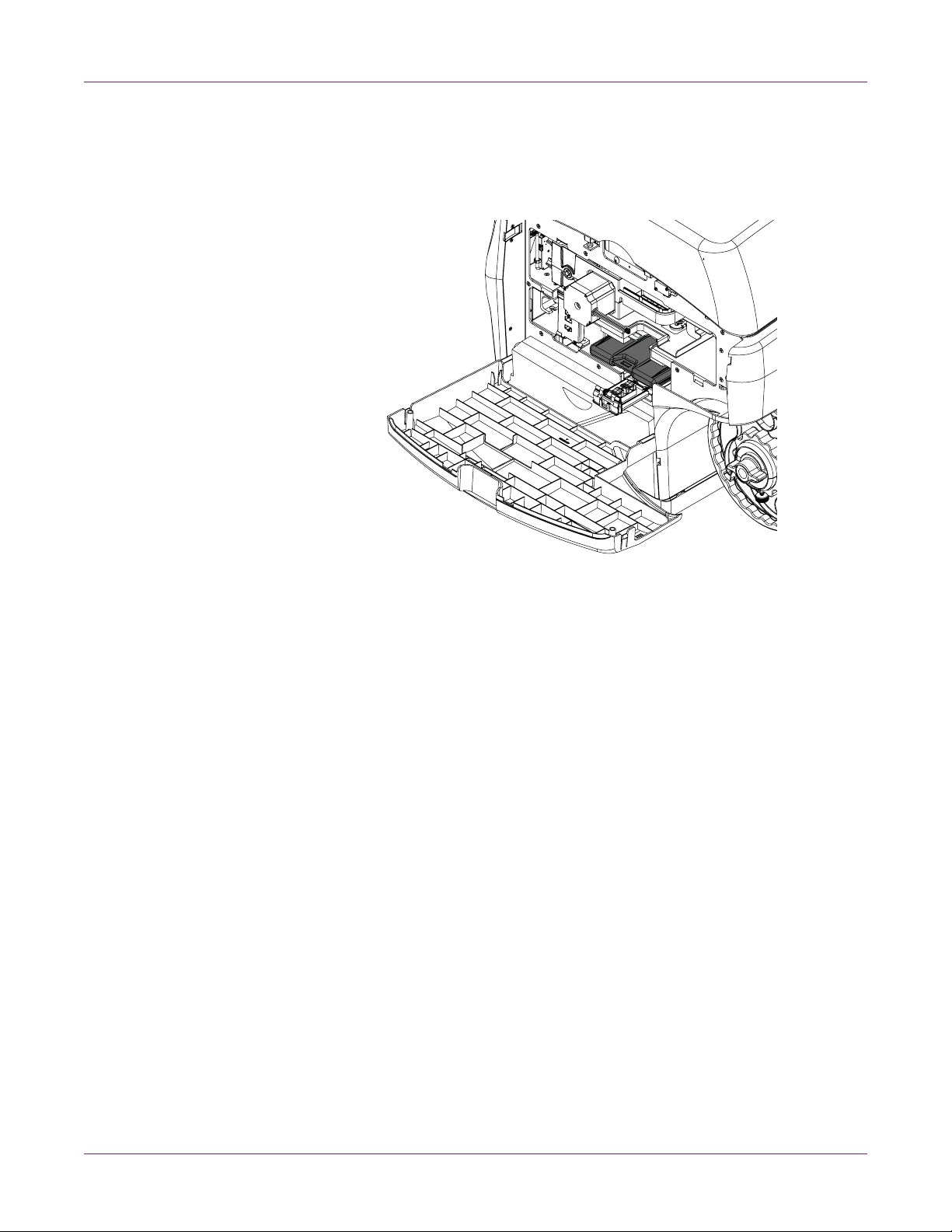

Unpacking the Printer

The printer is secured using packing tape and cushioning materials to protect it against

vibrations and shock during transportation. Use the following pro cedure to unpack the

printer. Keep the packing materials for future transportation.

1 Remove the accessory box and packing materials from the shipping carton.

Getting Started

QL-800 User Guide 3

Getting Started

2 Lift the printer out of the shipping carton.

The printer weighs about 70 pounds (31.75 kilograms). Two persons standing at

the front and back of the printer respectively must lift the printer by the indicated lift

points.

Lift the front of the printer by the recessed handle. Lift th e rear of the printer by th e

flat area of the purple frame above the mandrel.

Caution: Do not lift the printer by the mandrel.

3 Place the printer on a horizontal table.

4 QL-800 User Guide

Getting Started

4 Remove all pieces of packing tape. This clear filament tape is used to secure the

doors and covers in place.

There is also tape holding the maintenance cartridge in place. Open the main si de

door and lower side door to access and remove this tape.

5 With the main side door open, remove the yellow transport unit shipping lock by

rotating it counterclockwise and then pulling it straight out.

Note: The printer will function with the transport shipping lock installed. However,

the transport unit cannot be removed while the lock is installed.

QL-800 User Guide 5

Getting Started

6 Close all covers and doors.

Checking the Included Parts

Check to make sure the following items are included with the printer.

• Power cable

• USB cable

• Printhead

• Four ink cartridges (one for each color)

• Installation CD

Before Installing the Printer

Choosing an Installation Location

The installation environment must be as described in this section.

• The printer power cord must be able to connect to an outlet (100V - 240V AC). This

outlet must be easily accessible.

• Avoid installing the printer near a faucet, water heater, humidifier, or refrigerator.

• Ensure the environment temperature is within 41 to 95 degrees Fahrenheit (5 to 35

degrees Celsius). For optimal print quality, an environment temperatu re of

approximately 73 degrees Fahrenheit (23 degrees Celsius) is recommended.

• Ensure the environment humidity is withi n 20% to 80% (non-condensing) relative

humidity. For optimal print quality, a relative humidity of approximately 60% is

recommended.

• Avoid placing the printer in areas exposed to high temperature and humidity,

extremely low temperature, severe temperature changes, or direct sunlight.

Especially, avoid placing the printer near fire, outdoors, in distribution warehouses,

or in refrigerated areas.

• Avoid installing the printer in areas subject to dust.

• The room must be properly ventilated.

• No printer feet should float. The printer must be held level constantly.

• When placing the printer on a desk, table, or other similar surface, it must be sturdy

and stable enough to support the weight of the printer. The table must be rated for

a minimum of 100 pounds.

6 QL-800 User Guide

Getting Started

8 inches

203 mm

15 inches

381 mm

17.75 inches

451 mm

8 inches

203 mm

• The minimum space required for installation and maintenance is shown below.

Installation Precautions

When installing the printer, observe the following precautions.

• Imaging faults can result from dew condensation that occurs when the printer is

moved from a cold place to a warm place. Leave the unpacked printer as is for at

least two hours before installing it.

• The printer weighs about 70 pounds (31.75 kilograms). Two persons standing at

the front and back of the printer respectively must lift the printer by the indicated lift

points.

Lift the front of the printer by the recessed handle. Lift th e rear of the printer by th e

flat area of the purple frame above the mandrel.

Caution: Do not lift the printer by the mandrel.

QL-800 User Guide 7

Getting Started

1

2

System Requirements

• 32-bit or 64-bit Microsoft® Windows® XP, Windows Vista®, Windows 7, or

Windows 8

• Microsoft .NET Framework 3.5 SP1

• 350 MB free hard drive space

• CD/DVD drive

• One available USB 2.0 port for USB installation or network connectivity for network

installation

Connecting the Power Cable

1 Connect the power cable to the printer power inlet (1).

2 Connect the power cable to the outlet.

3 Move the power inlet switch (2) to the on position.

Related Topics:

- Switching the Printer On and Off on page 9

8 QL-800 User Guide

Getting Started

Switching the Printer On and Off

After you have connected the power cable and plugged it into an outlet, use the

following instructions to turn the printer power on/off.

Note: The power cable connects to a power inlet on the rear of the printer. This inlet

has a power switch. Ensure the power inlet switch is switched to the on position.

1 If the printer power is off, press and release the power key to turn the power on.

The printer will begin the power-up process, and the green LED will flash

momentarily. When the green LED stops flashing and remains on, the printer will

be ready to use.

2 If the printer power is on, press and hold the power key to turn the powe r off.

Related Topics:

- Connecting the Power Cable on page 8

Installing the Printer Driver

Installing the Printer Driver (USB)

Use the following instructions to install the printer via USB 2.0 on Windows XP,

Windows Vista, Windows 7, or Windows 8.

Note: When the Windows logo testing, publisher verification, or digital signing warning

messages appear, choose to continue the installation. These messages indicate that

the driver has not been “logo tested” by Microsoft. However, it has been tested

thoroughly by QuickLabel Systems, and will not cause any of the problems listed in

these messages.

1 Ensure the QL-800 is powered on but not connected to your computer via the USB

cable.

2 Power on your computer and insert the QL-800 Installer CD in the CD drive. The

Installer CD wizard will open. Choose Next.

Note: If the autorun program does not start automatically, use Windows Explorer

to launch the “Setup.exe” file located in the root level of the CD.

QL-800 User Guide 9

Getting Started

3 Use the driver installation wizard to install the driver. Refer to the following

information during this process.

• Choose the USB connection method when prompted.

• Select an installation location for the QL-800 Maintenance Utility when

prompted.

Choose Finish in the installation wizard after successfully installing the QL-800

Maintenance Utility and driver.

4 When prompted, connect the smaller end of the USB cable to the QL-800 USB type

B port.

Connect the larger end of the USB cable to an available USB 2.0 port on your

computer.

5 Once the USB connection is made, the Windows Found New Hardware Wizard will

start. This wizard will guide you through rest of the installation process. Refer to the

following general guidelines when using this wizard.

• If you are prompted to connect to Windows Update to search for software,

choose no.

• Choose to install the software automatically when you are presented with this

option.

• If the Windows logo testing or publisher verification warning messages appear,

choose to continue the installation.

10 QL-800 User Guide

Getting Started

Resolving Windows 7 and Windows 8 USB Installation Issues

When you install the printer driver via USB, you first run the installation wizard and then

connect the printer to your PC via the USB cable.

If you connected the USB cable before running the installation wizard, Windows 7 and

Windows 8 will not recognize the printer correctly. In this case, the QL-800 will be listed

as an Unspecified item in the Devices and Printers window.

Use the following procedure to correct this issue. This procedure assumes you have

already installed the printer driver.

Note: This procedure requires administrator level access in Windows.

1 Open the Devices and Printers window in Windows 7 or Windows 8.

2 Right-click the QuickLabel QL-800 in the Unspecified list. Then choose

Properties. The QuickLabel QL-800 Properties window will open. Choose the

Hardware tab.

QL-800 User Guide 11

Getting Started

3 Select QuickLabel Systems QuickLabel QL-800 and choose Properties. The

Properties window will open. Choose the General tab.

4 Choose Change Settings. Then choose the Driver tab.

5 Choose Update Driver. When you are prompted, select the Search automatically

for updated driver software option. Windows will locate the driver on your system

and create a printer item.

Installing the Printer Driver (Network)

Use the following instructions to install the printer via a network connectio n on Windows

XP, Windows Vista, Windows 7, or Windows 8.

For detailed information about the topic of networking, refer to documentation

applicable to your network environment and/or contact your network administrator.

Note: When the Windows logo testing, publisher verification, or digital signing warning

messages appear, choose to continue the installation. These messages indicate that

the driver has not been “logo tested” by Microsoft. However, it has been tested

12 QL-800 User Guide

Getting Started

thoroughly by QuickLabel Systems, and will not cause any of the problems listed in

these messages.

1 Ensure the printer is powered on and connected to the network via a LAN cable.

2 Power on your computer and insert the QL-800 Installer CD in the CD drive. The

Installer CD wizard will open. Choose Next.

Note: If the autorun program does not start automatically, use Windows Explorer

to launch the “Setup.exe” file located in the root level of the CD.

3 Use the driver installation wizard to install the driver. Refer to the following

information during this process.

• Choose the Ethernet connection method when prompted.

• Allow the installer to access the network if prompted.

• Choose the QL-800 printer in the printer list when prompted. Alternately, you

can choose to find a specific printer by IP address or MAC address.

• Configure the printer for DHCP or a static IP address.

Ensure the printer has been in the “Ready” state fo r at least 30 seconds before

attempting to connect via DHCP or static IP address. Additionally, if you

change the selection from static IP address to DHCP, wait at least 30 seconds

before proceeding to allow the printer to establish DHCP communication.

• Select an installation location for the QL-800 Maintenance Utility when

prompted.

Choose Finish in the installation wizard after successfully installing the QL-800

Maintenance Utility and driver.

QL-800 User Guide 13

Getting Started

Using the After Shipping Wizard

After installing the driver, the QL-800 Maintenance Utility will be available for use. You

will use the After Shipping wizard in this utility to ready the maintenance roller, install

ink cartridges, and install the printhead.

1 Launch the QL-800 Maintenance Utility.

From the Windows Start Menu, choose Start > All Programs > QL-800 > QL-800

Maintenance Utility. A language and printer prompt will open.

Select a display language and the QL-800 printer you want to connect to. Choo se

OK.

2 Choose the Cleaning tab.

3 Choose After Shipping. Follow the on-screen instructions to complete this

procedure. This wizard will guide you through the following actions.

• Foam support block removal - See “Readying the Maintenance Roller” on page

14.

• Ink cartridge installation - See “Installing Ink Cartridges” on page 15.

• Printhead installation - See “Installing the Printhead” on page 16.

Readying the Maintenance Roller

A foam block is installed over the maintenance roller to protect it during shipping . Use

the following instructions to remove this foam block.

1 Open the top cover and cut the zip tie.

2 Remove the zip tie and foam support block from the printer.

14 QL-800 User Guide

Getting Started

Installing Ink Cartridges

Use the following instructions to install ink cartridges.

Warning: For safety, keep ink cartridges out of the reach of children. If ink is

accidentally ingested, contact a physician immediately.

1 Open the main side door.

2 Open both ink cartridge latches. Each latch can be opened by pressing the top of

the locking mechanism and pulling outward.

3 Slide in the ink cartridge, septum end first, label side up. Pus h the car tr idg e in all

the way.

You will feel slight resistance near the end of this process as the ink cartridge

engages the ink needles inside the printer. Repeat this step for each color.

QL-800 User Guide 15

Getting Started

Caution: There are sharp needles in the ink cartridge slot. Never put your fingers

in this area.

Note: The printer is designed so that ink cartridges cannot be inserted in the

wrong slots. Do not attempt to insert ink cartridges in the wrong slots.

4 Close the ink cartridge latches.

5 Close the main side door.

Installing the Printhead

Use the following instructions to install the printhead.

Caution: The printhead is sensitive to electrostatic discharge (ESD). Use ESD

protection when handling the printhead.

Caution: Do not touch the printhead cartridge ink couplings, nozzle surface, or the

electrical contacts when installing the printhead cartridge. Hold the printhead cartridge

ONLY by the handles.

Caution: To avoid dehydrating the printhead, do not remove the printhead from the

package until you are ready to use it.

Caution: Open the printhead packaging over an appropriate receptacle to safely

capture any excess shipping fluid.

1 Ensure the printer is powered on and ink cartridges have been installed.

16 QL-800 User Guide

2 Open the top cover.

3 Remove the fluidic cap protectors from the two fluidic couplings.

Getting Started

4 Open the end of the printhead package box and slide out the foil bag.

5 Inspect the integrity of the foil vacuum sealing. The foil bag should be formed tightly

to the contours of the printhead cartridge. If the foil is loose to any degr ee, then the

seal has been compromised.

Caution: If a poor seal is suspected, do not use that printhead. Report the issue

to Technical Support.

QL-800 User Guide 17

Getting Started

6 Carefully rip open the foil packaging at the notch. Use scissors if yo ur foil bag does

not have a notch or you are finding it difficult to tear the bag.

7 Remove the printhead from the foil bag.

Caution: Do not place the unprotected printhead cartridge on any surface prior to

installation in the printer. Protect the printhead cartridge at all times from

contamination by airborne contaminants such as dust or fibers.

8 Wipe any excess shipping fluid from the cartridge with a clean, lint-free cloth.

9 Remove the orange protective plastic cover from the printhead cartridge, holding

the printhead by the handle.

• Release the flaps covering the ink ports.

• Release the clip retaining the cover near the center of the printhead cartridge.

• Carefully remove the protective cover. Do not touch any of the fluid couplings

or nozzle plate after the orange cover is removed.

18 QL-800 User Guide

Getting Started

No less than 45°

10 Carefully remove the protective tape from the electrical contacts. While holding the

printhead cartridge by the handle with one hand, grasp the pull tab with the other

hand, and slowly peel back the plastic strip covering the electrical contacts.

Caution: Dispose of the removed strip immediately and do not allow the removed

strip to touch the electrical contacts.

11 Remove the protective strip from the printhead nozzles. While holding the

printhead cartridge by the handle with one hand, grasp the pull tab with the other

hand and slowly and carefully peel back the plastic strip to uncover the printhead

nozzles. Maintain an angle of no less than 45° with the printhead surface when

pulling on the strip.

Note: Dispose of the removed strip immediately and do not allow the removed

strip to contact the electrical contacts or the printhead nozzles.

12 Point the ink connections away from the front (that is, the label exit side) of the print

engine.

13 Align the printhead cartridge with the printhead slot.

QL-800 User Guide 19

Getting Started

14 Tilt the top of the printhead cartridge toward the back of th e printer, about 20º. Then

gently seat the back of the printhead cartridge into the print engine.

20°

15 When the back of the printhead is firmly seated, gently rotate the printhead

cartridge into position against the stops on the printhead connector board.

Caution: If the printhead will not rotate into position, do not force it. Reseat the

printhead and try again.

20 QL-800 User Guide

Getting Started

[1]

[2]

[4]

[3]

16 Slowly close the printhead latch. The fluidic couplings should advance and seal to

the printhead cartridge.

Caution: If the latch will not close, do not force it. Reseat the printhead and try

again.

17 Close the top cover.

Loading and Unloading Media

Loading Media

1 Turn the wing nut [1] on the end of the mandrel counterclockwise to loosen the

mandrel.

2 Orient the media roll [2] as illustrated and put it on the mandrel. Make sure the roll

contacts the inner flange [3].

QL-800 User Guide 21

Getting Started

[5]

[6]

[7]

3 Turn the wing nut [1] on the end of the mandrel clockwise un til you feel resistance.

This action secures the roll in place.

4 Put the outer flange [4] on the mandrel. Make sure the outer flange contacts the roll

[2].

5 Tighten the captive fastener on the outer flange [4] until you feel resistance. This

action secures the outer flange in place.

6 On the front of the printer, slide the media exit guide [5] all the way toward the

control panel. This guide will be adjusted later in the procedure.

7 Place the media near the entry slot and slide the adjustable media guide [6] to the

width of the media. The edges of the media should lightly contact the fixed media

guide [7] and adjustable media guide [6].

8 Slowly insert the media into the printer as illustrated until the media stops moving.

The printer will beep three times to indicate the media has been detected.

9 Release the media when the printer starts automatically feeding it into the printer.

The printer will feed media as needed and the media loading process will be

complete.

22 QL-800 User Guide

Getting Started

[1][2]

Note: If the automatic media feeding process fails, the media will be ejected back

out of the printer.

10 On the front of the printer, slide the media exit guide [5] so it lightly contacts the

edge of the media exiting the printer.

Unloading Media

1 Press and hold the back-feed key. The printer will back-feed media.

When the media has almost exited the back of the printer, back-feeding will stop

and the printer will beep once. This confirmation tone alerts you that media is about

to be unloaded.

2 To continue and unload media, press and hold the back-feed key again. Media will

back-feed fully out of the printer.

3 Loosen the captive fastener on the outer flange [1]. Then remove the flange from

the mandrel.

4 Turn the wing nut [2] on the end of the mandrel counterclockwise to loosen the

mandrel. Loosen the wing nut until the media roll moves freely.

5 Remove the media roll from the mandrel.

QL-800 User Guide 23

Getting Started

QuickLabel Services

QL-800 Label Materials

QuickLabel develops QL-800 label printing substrates. We sell cost-effective labels

that meet various end-use requirements, including industry and government regulatory

labeling standards.

QuickLabel BPO Blanket Purchase Order Program

As the manufacturer of the QL-800 and the supplies, QuickLabel has the advantage of

providing you with lower prices due to production efficiencies. QuickLabel's QL-800

BPO Program covers all of your requirements for printing supplies over a 12-month

period. You receive a discounted price for your annual commitment and regular

scheduled deliveries based on your production requirements. Customers wh o take

advantage of our BPO program receive maximum savings on all of their i nk and blank

label purchases!

Media Specialists

QuickLabel offers the services of our highly trained label experts to advise you on

choosing the right label material and on designing label files for custom and special

label shapes.

Your personal Media Specialist is available to:

• Provide a point of contact for ongoing development of label materials that may be

required for unique labeling applications

• Advise you on expected usage so you can plan purchasing and manage your

inventory levels

• Advise you on our convenient blanket orders, which automate shipment of your

supplies to your location on dates you specify in advance

• Take your orders for labels and new label shapes

• Take your orders for printer supplies

24 QL-800 User Guide

2

Printer Part Names and Functions

Front View

[1]

QL-800 Overview

[3]

[2]

[6]

# Part Description

1 Media Exit Slot Printed labels are ejected through this slot.

2 Operation Panel Use these keys to operate various printe r func -

tions.

3 Top Cover Open this cover to access the printhead.

4 Main Side Door Open this door to access the transport unit and

ink cartridges.

5 Lower Side Door Open this door to access the maintenance car-

tridge.

[4]

[5]

6 LED Indicators LEDs indicate the status of the printer.

QL-800 User Guide 25

QL-800 Overview

Back View

[1]

[2]

[3]

[4]

[5]

[6][7]

[8][9]

# Part Description

1 Media Entry Slot Media enters the printer through this slot.

2 Reserved This port is not used. Do not connect to this port.

3 USB Port Connect the USB cable here when using the USB

connection method.

4 LAN Port Connect the LAN cable here when using the LAN

connection method.

5 Power Inlet Connect the power cord here.

6 Inner Flange Position the media roll edge so it touches this

flange.

7 Mandrel Install the media roll on the mandrel.

8 Outer Flange Adjust this flange so it touches the media roll

edge opposite the inner flange.

9 Wing Nut Turn this nut to tighten or loosen the media roll

lock on the mandrel.

26 QL-800 User Guide

Operation Panel

[1] [2] [4]

[5]

[3]

QL-800 Overview

# Key Description

1 Power

2Feed

3 Pause/Resume

• If the printer power is off, press and release this

key to turn the power on.

• If the printer power is on, press and hold this

key to turn the power off.

• Press and release this key to recover from

some error conditions.

• Press and release the feed key to feed media

one label length.

• Press and hold the feed key to feed media until

you release the key.

• While printing, press and release this key to

pause the print job.

• While paused, press and release this key to

resume the print job.

• While paused, press and hold this key for

approximately three seconds to cancel the prin t

job.

QL-800 User Guide 27

QL-800 Overview

[1]

[2]

[3] [4] [5] [6] [7]

# Key Description

LED Indicators

4 Back-Feed

5 Cut If the printer is in the ready state, press and hold

• Press and release the back-feed key to

back-feed media one label length.

• Press and hold the back-feed key to back-feed

media until you release the key.

• To unload media, press and hold the back-feed

key until the printer beeps once. Press and hold

the back-feed key again to continue and unload

media.

this key for approximately one second to cut

media at the exit.

#LED Description

1 Power This green LED indicates the power status of the

printer.

• Off - Printer is off or in sleep mode.

• Flashing - Printer is initializing or busy.

• Solid - Printer is on and ready.

2 Error This red LED indicates when error conditions

occur.

28 QL-800 User Guide

QL-800 Overview

#LED Description

3 Cyan Ink These yellow LEDs indicate the status of each ink

cartridge.

4 Magenta Ink

5 Yellow Ink

6 Black Ink

7 Non-Ink Consumables This yellow LED indicates the status of the follow-

• Off - Ink cartridge has sufficient ink.

• Flashing - Ink cartridge is low.

• Solid - Ink cartridge is empty.

ing items.

• Printhead

• Cutter

• Aerosol Filter

• Maintenance Cartridge

• Maintenance Roller

The LED will illuminate based on remaining service life.

Color Basics

• Off - All items are above 20% service life

remaining.

• Flashing Slowly - One or more items are

below 20% service life remaining.

• Flashing - One or more items are below 10%

service life remaining.

• Solid - One or more items are at 0% service life

remaining.

Refer to the System Logs tab in the Maintenance

Utility to determine the affected items.

Color in design and printing is a sophisticated topic. At QuickLabel Systems, we have

worked to make using the QL-800 printer as easy as possible. We understand that your

goal is to design and print colorful, effective labels with consistency.

Color and Computers

While colors seem straightforward, describing colors using computers is not so simple.

Different display technologies can cause the same file to look different, and sometimes

different graphics programs or operating systems can display colors differently.

With printers there is frequently a difference between what is shown on a computer

screen and what comes out of the printer. The same file printed on printers using

different technologies may look very different as well.

QL-800 User Guide 29

QL-800 Overview

Color Profiling

These technical differences are universal, and as a result of them, software

developers, display manufacturers, and printer manufacturers have worked together to

develop a way to successfully describe and use color taking into consideration the

different technologies involved. This is called color profiling.

Color profiles have been developed to coordinate how each device displays or prints

that color. When using the proper profiles, color can be relatively consistent across

devices.

Color cannot be perfectly consistent because the huma n eye can see more colors th an

computer displays can show or printers can print. What’s more, the ranges of colors

available to displays and printers don’t completely overlap.

Profiles help out when these ranges don’t match; they help translate the differences to

create the widest and most accurate range of colors a device can display.

Display Profiling

There are devices that can help you develop profiles for your display to ensure that

what you see is close to what you are getting. Using QL-800 profiles will help with

consistency in printing, while using both QL-800 and display profiles will help with the

full design and printing process.

If color matching is important to you, you may consider profiling your computer display.

QuickLabel QL-800 Color Profiles

When printing, even the type of material printed on can chan ge the way colors appear.

QuickLabel Systems has created color profiles for the materials you will be using in

order to offer you the most accurate color reproduction possible.

A Profile for Each Device

The more of your devices that have profiles, the better. Since color is based on

technology, software, and the laws of physics, each device works with color differently.

In addition to your graphics program and the QL- 800 , you ma y be able to a dd profiles

for your display, your digital camera, and your scanner. This will help all of these

devices use color in a coordinated way. At minimum, to use color profiling, you need to

use a color profile for the QL-800.

30 QL-800 User Guide

3

Designing Labels

This section describes several factors you should consider before you start designing

labels.

Choosing Design Software

You can print to the QL-800 using any design software with printing function ality. There

are many graphic design software applications available, and the programs you choose

will depend on your desired workflow and design requirements.

Design software is available from QuickLab el Syst em s an d othe r so ftw ar e ven d or s.

• Custom QuickLabel Omni from QuickLabel Systems - This software product,

• Third Party Applications - There are a variety of graphic design programs

Designing and Printing Labels

developed by QuickLabel Systems, makes it easy to create barcodes and position

text and graphics on a label.

available from other software companies such as Adobe and Corel. Adobe

Photoshop, Illustrator, and similar professional image editing programs provide

advanced tools for creating your artwork.

A common scenario is to use a mixed approach to designing labels. For example, you

may want to edit a photographic element in Photoshop, create a logo in Illustra tor, and

then place both into a Custom QuickLabel Omni file for final layout and printing.

Disabling Anti-aliasing

Most graphic design software applications provide anti-aliasing features that result in

the appearance of smooth color transitions.

When designing labels that will be printed on the QL-800, do not use anti-aliasing. This

is especially important if you are printing text or barcode s. For example, an anti-aliased

barcode may not scan correctly due to the color transitions between lines.

For details about disabling anti-aliasing, refer to the user documentation for your

graphic design software

Planning Full-Bleed and Non-Bleed Labels

In full-bleed labels, color prints up to the edge of the label. With non-bleed labels, color

stops at a margin before the edge of the label.

Use the following guidelines when setting up a file for a full-bleed label.

• If you are using media with the matrix removed, you can print all the way to the

edge of die-cut labels, but doing so may cause a small amount of ink to deposit

onto the liner. In the event excess ink deposits on the liner, it will not dry and may

smear onto other surfaces, including hands and other printed labels.

QL-800 User Guide 31

Designing and Printing Labels

• The height and width of the label file “canvas” should be 0.04 to 0.08” (1-2 mm)

larger than the height and width of the physical label.

Excessive width and length will result in increased ink on the liner. You may need

to experiment to determine the optimal balance of bleed quality while minimizing

ink deposited on the liner. As a guideline, no more than 0.02” (0.5 mm) of ink should

be printed onto the liner.

• Design elements that will run to the edge of the label are the parts of the design

that will “bleed” across the edge. Your bleed will most commonly be a solid color,

pattern, or gradient background running off the edge of the label.

Use the following guidelines when setting up a file for a non-bleed label.

• The height and width of the label file “canvas” should be the same as the height

and width of the physical label.

• All design elements should be placed inside a 0.063” (1.5 mm) border of the

canvas. This will ensure such design elements never run to or over the edge of the

label.

Setting up the Label Design Software

This section describes how to set up your label design software to print on the QL-800.

Setting up Labels in Custom QuickLabel Omni

Custom QuickLabel Omni is a software application developed by QuickLabe l Systems

to access special features in our printers and allow customers to easily design and print

labels.

For detailed label setup and printing instructions, please refer to the Custom

QuickLabel Help.

Setting up Labels in Third-Party Design Applications

You can design and print label files exclusively within a third-party application such as

Adobe Photoshop or Illustrator. In this situation, use the following guidelines to en sure

best results.

Note: You can also use third-party applications to design components of a label to be

imported into Custom QuickLabel Omni. In this situation, save or export graphic files in

a .BMP, .PCX, uncompressed .JPG, uncompressed .TIF, .GIF, .PNG, or .PDF format.

• Select a resolution of 600 pixels per inch - For raster -based design applications

such as Adobe Photoshop, choose a resolution of 600 pixels per inch. This will

provide sufficient image resolution to produce super ior print quality. This setting is

not used in vector-based design applications such as Adobe Illustrator.

32 QL-800 User Guide

Designing and Printing Labels

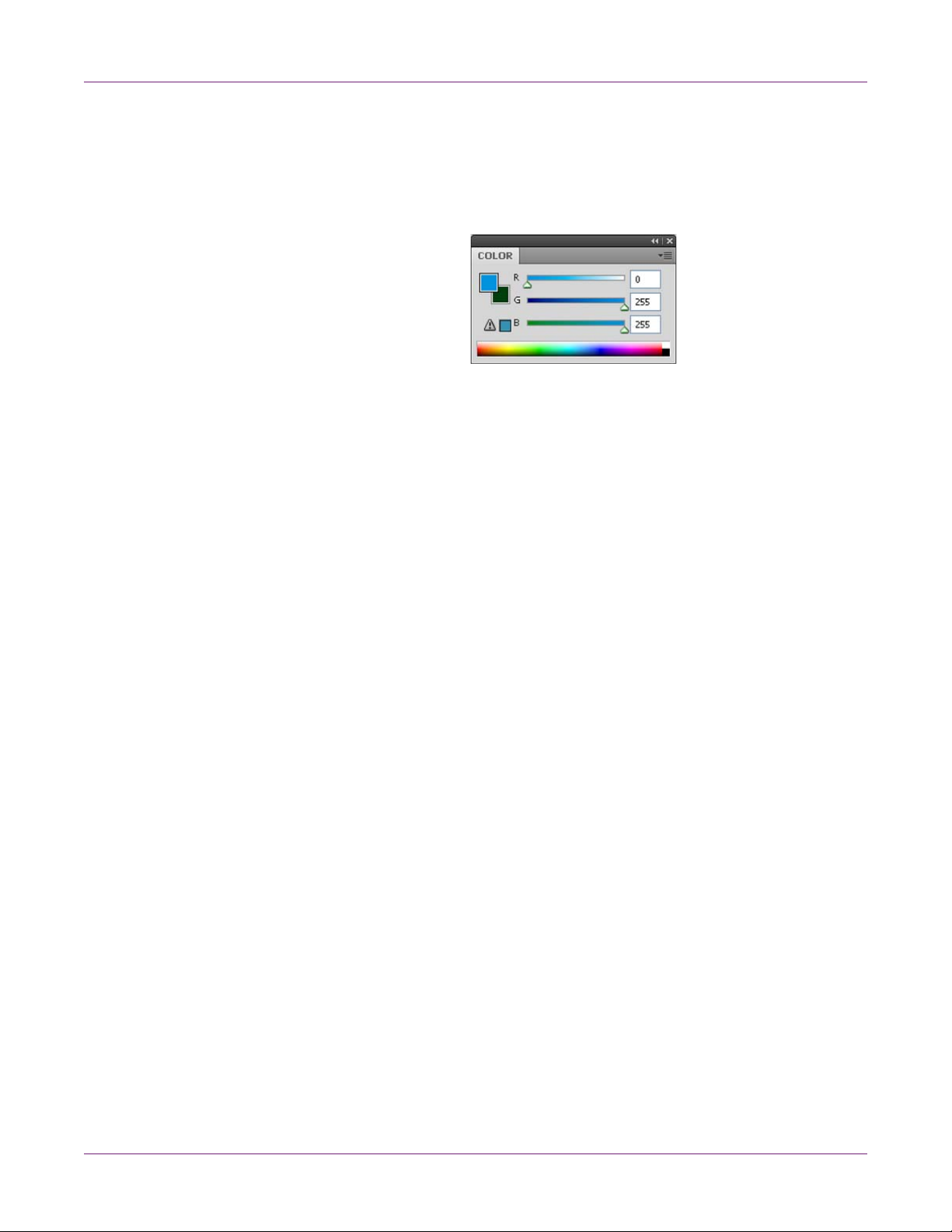

• Use in-gamut colors - When designing in color, ensure you use colors that are

within the printing gamut. Most design applications will indicate when a color is out

of gamut.

For example, in Adobe Photoshop and Illustrator, out-of-gamut colors are indicated

by an exclamation point icon in the Color palette.

Out-of-gamut colors cannot be accurately printed. There are often colors that can

be found to replace out-of-gamut colors.

• If the application supports color management, enable it - Professio nal design

applications support color management. This option is typically found in the

application’s print window.

Setting up the Printer Driver

Setting up General Options

Before you print using a third-party application, you will need to select the appropriate

general and label size options in the printer driver.

Note: Driver instructions apply only to printing via third party design applications. If you

are using Custom QuickLabel Omni, this process is not required.

1 Open the appropriate printer window based on your version of Windows.

• In Windows XP, choose Start > Printers and Faxes.

• In Windows Vista, choose Start > Control Panel > Printers.

• In Windows 7, choose Start > Devices and Printers.

• In Windows 8, access the Search option by pointing to the upper-right corner

of the screen. Search for “Control Panel” and click the Control Panel icon. In

the Control Panel window, click View Devices and Printers.

Right-click the printer icon and choose Printing Preferences. The QL-8 00 Driver

Printing Preferences window will open.

Note: You can also access the driver preferences via the application’s print dialog.

From the Print window in your software, select QuickLabel QL-800 from the printer

list and choose Properties or Setup (varies based on program).

QL-800 User Guide 33

Designing and Printing Labels

2 Choose the General tab.

3 If necessary, you can select a printing orientation. Orientation is often set within the

design application. However, if you cannot select an orientation in the design

application, choose from the following options:

• Portrait - Select this option if you want to print the label in a portrait orientation

on the label roll.

• Landscape - Select this option if you want to print the label in a landscape

orientation on the label roll.

4 If necessary, you can rotate the printed image 180 degrees by choosing Rotate

180°.

5 If necessary, you can print the image in a mirrored orientation by choosing Mirror

Image.

6 Select the page management options.

• Stitch - Choose this option to print with no gaps between labels. This option

should not be enabled when using gap media.

• Buffer - Choose this option to process print jobs completely before sending

them to the printer. This results in no pauses during printing.

• Mask Optimization - Choose this option to apply mask optimization. If you

observe image noise in printed labels, try turning off this option.

7 If necessary, you can select a printing quantity. Print copies are specified within the

application before printing. However, you can override that value here, or use this

setting if the application does not provide a setting.

34 QL-800 User Guide

Designing and Printing Labels

8 Select the type of material the label will be printed on.

9 Select a label size from the list.

Note: If necessary, you can set up a custom label size to meet your needs.

10 Select whether color or monochrome printing will be used.

• Color - Choose this option to print in full color.

• Composite Black - Choose this option to print in black using ink blended from

all ink cartridges.

• Black Only - Choose this option to print in black using only black ink.

11 Select a printing speed.

12 Choose OK.

Setting up a Custom Label Size

You can add and modify custom label sizes in the printer driver.

Note: Driver instructions apply only to printing via third party design applications. If you

are using Custom QuickLabel Omni, this process is not required.

1 Open the appropriate printer window based on your version of Windows.

• In Windows XP, choose Start > Printers and Faxes.

• In Windows Vista, choose Start > Control Panel > Printers.

• In Windows 7, choose Start > Devices and Printers.

• In Windows 8, access the Search option by pointing to the upper-right corner

of the screen. Search for “Control Panel” and click the Control Panel icon. In

the Control Panel window, click View Devices and Printers.

Right-click the printer icon and choose Printing Preferences. The QL-8 00 Driver

Printing Preferences window will open.

Note: You can also access the driver preferences via the application’s print dialog.

From the Print window in your software, select QuickLabel QL-800 from the printer

list and choose Properties or Setup (varies based on program).

QL-800 User Guide 35

Designing and Printing Labels

2 Choose the General tab.

3 Choose Manage Labels. The Custom Label Size window will open.

4 Enter or select a label name.

• To edit an existing label size profile, select the label name from the list.

• To create a new label size profile, enter a label name in the list.

5 Enter the height and width of your label. You can specify these measurements in

inches or millimeters.

6 Save the settings.

• If you edited an existing label size profile, choose Replace.

• If you created a new label size profile, choose Save.

36 QL-800 User Guide

Designing and Printing Labels

7 If necessary, you can delete a label size profile by selecting it from the list and then

choosing Delete.

8 Choose OK.

Setting up Media Options

Before you print using a third-party application, you will need to select media options

for your label.

Note: Driver instructions apply only to printing via third party design applications. If you

are using Custom QuickLabel Omni, this process is not required.

1 Open the appropriate printer window based on your version of Windows.

• In Windows XP, choose Start > Printers and Faxes.

• In Windows Vista, choose Start > Control Panel > Printers.

• In Windows 7, choose Start > Devices and Printers.

• In Windows 8, access the Search option by pointing to the upper-right corner

of the screen. Search for “Control Panel” and click the Control Panel icon. In

the Control Panel window, click View Devices and Printers.

Right-click the printer icon and choose Printing Preferences. The QL-8 00 Driver

Printing Preferences window will open.

Note: You can also access the driver preferences via the application’s print dialog.

From the Print window in your software, select QuickLabel QL-800 from the printer

list and choose Properties or Setup (varies based on program).

2 Choose the Media tab.

QL-800 User Guide 37

Designing and Printing Labels

3 If necessary, use the offset options to adjust th e location of a printed image relative

to the registration marks on the media.

• Horizontal Offset - Negative values move the image left on the label. Positive

values move the image right on the label.

• Vertical Offset - Negative values move the image down on the label (out away

from the printer). Positive values move the image up on the label (in toward the

printer).

4 Select a sensor type.

• Gap - Choose this option if you are using gap media.

• Reflective - Choose this option if you are using reflective mark media.

• None - Choose this option if you are using media without gaps or reflective

marks (continuous media).

5 Select the cutter settings.

• Check the Cutter Enabled option to enable the auto-cutter.

•Use the Labels Between Cut field to indicate the number of labels to print

between each cut.

6 Choose OK.

38 QL-800 User Guide

Designing and Printing Labels

Using Service Options

You can clean the printheads, launch the status monitor, order supplies, and contact

technical support using the printer driver.

1 Open the appropriate printer window based on your version of Windows.

• In Windows XP, choose Start > Printers and Faxes.

• In Windows Vista, choose Start > Control Panel > Printers.

• In Windows 7, choose Start > Devices and Printers.

• In Windows 8, access the Search option by pointing to the upper-right corner

of the screen. Search for “Control Panel” and click the Control Panel icon. In

the Control Panel window, click View Devices and Printers.

Right-click the printer icon and choose Printing Preferences. The QL-8 00 Driver

Printing Preferences window will open.

Note: You can also access the driver preferences via the application’s print dialog.

From the Print window in your software, select QuickLabel QL-800 from the printer

list and choose Properties or Setup (varies based on program).

2 Choose the Services tab.

3 To clean the printheads, choose Clean Printheads. The QL-80 0 Maintenance

Utility will launch, providing access to the cleaning options.

4 To launch the status monitor, choose Launch Status Monitor.

5 Use the service links to order supplies or contact technical support.

QL-800 User Guide 39

Designing and Printing Labels

6 Choose OK.

Related Topics:

- Cleaning Printheads on page 53

Saving and Recalling Driver Settings

After setting up the driver, you can save the driver settings. It may be helpful to save

driver settings for each label you will be printing.

1 Open the appropriate printer window based on your version of Windows.

• In Windows XP, choose Start > Printers and Faxes.

• In Windows Vista, choose Start > Control Panel > Printers.

• In Windows 7, choose Start > Devices and Printers.

• In Windows 8, access the Search option by pointing to the upper-right corner

of the screen. Search for “Control Panel” and click the Control Panel icon. In

the Control Panel window, click View Devices and Printers.

Right-click the printer icon and choose Printing Preferences. The QL-8 00 Driver

Printing Preferences window will open.

Note: You can also access the driver preferences via the application’s print dialog.

From the Print window in your software, select QuickLabel QL-800 from the printer

list and choose Properties or Setup (varies based on program).

2 Choose the General or Media tab.

3 Enter or select a settings profile name in the My Print Settings area.

40 QL-800 User Guide

Printing Labels

Designing and Printing Labels

• To edit an existing settings profile, select the profile name from the list.

• To create a new settings profile, enter a profile name in the list.

4 Edit the driver settings as needed.

5 Save the settings.

• If you edited an existing settings profile, choose Replace.

• If you created a new settings profile, choose Save.

6 If necessary, you can delete a settings profile by selecting it from the list and then

choosing Delete.

7 Choose OK.

1 Ensure the label media has been loaded.

2 If you are printing from a third-party design app licat ion , en su re the prin te r dr iver

preferences are configured.

3 Open the label file using the appropriate software. Then choose to print the label,

and enter the number of copies you would like to print.

Note: If your software has a collate option, disable it before printing.

4 Print the labels. The Status Monitor will automatically open and display information

about printer and job status.

The job progress will be displayed in the Status Monitor.

If necessary, you can cancel the print job by choosing Cancel Job/Reset Error on

the Status Monitor.

QL-800 User Guide 41

Designing and Printing Labels

5 If necessary, you can pause, resume, and cancel print jobs from the operation

panel on the front of the printer.

• While printing, press and release the pause/resume key to pause the print job.

• While paused, press and release the pause/resume key to resume the print

job.

• While paused, press and hold the pause/resume key for approximately three

seconds to cancel the print job.

6 Receive the printed labels.

Note: Do not pull the printed labels in any direction as they exit the printer. Pulling

the labels may result in a media jam.

•If Cutter Enabled is checked in the printer driver Media tab, the printed labe ls

will automatically be cut at the end of the job.

•If Cutter Enabled is not checked in the printer driver Media tab, the printed

labels will not be cut at the end of the job. Instead, you can use the manual cut

feature by pressing and holding the cut key for approximately one second.

42 QL-800 User Guide

Using the Status Monitor

Viewing the Printer Status

1 Open the QL-800 Status Monitor. You can access the Status Monitor from the

Windows Start Menu, QL-800 Maintenance Utility, or the printer driver.

• From the Windows Start Menu, choose Start > All Programs > QL-800 >

QL-800 Status Monitor.

• In the QL-800 Maintenance Utility, choose Status Monitor.

• In the QL-800 printer driver, choose Launch Status Monitor from the

Services tab.

Designing and Printing Labels

2 You can view status information in the Printer Status area. This area will display

informational, error, and warning messages related to your printer’s cur rent status.

3 If necessary, you can initiate printhead cleaning if the printer is in the Ready,

Sleeping, or Paused modes.

Two cleaning options are available (light and heavy). Start with light cleaning and

then print a test label. If the issue is not resolved, repeat using the heavy cleaning

method.

If multiple heavy cleanings do not resolve the issue, contact Technical Support.

4 If necessary, you can view help topics by choosing Help > Help Topics.

QL-800 User Guide 43

Designing and Printing Labels

Viewing the Job Status and Cancelling Jobs

1 Open the QL-800 Status Monitor. You can access the Status Monitor from the

Windows Start Menu, QL-800 Maintenance Utility, or the printer driver.

• From the Windows Start Menu, choose Start > All Programs > QL-800 >

QL-800 Status Monitor.

• In the QL-800 Maintenance Utility, choose Status Monitor.

• In the QL-800 printer driver, choose Launch Status Monitor from the

Services tab.

2 You can view print job information in the Job Status area.

3 If necessary, you can cancel an in-progress job by choosing Cancel Job.

You can also use the printer operation panel to cancel a job. Wh ile printin g, press

and release the pause/resume key to pause the print job. Wh ile paused, press and

hold the pause/resume key for approximately thr ee seconds to cancel the print jo b.

Viewing Ink and Consumable Levels

1 Open the QL-800 Status Monitor. You can access the Status Monitor from the

Windows Start Menu, QL-800 Maintenance Utility, or the printer driver.

• From the Windows Start Menu, choose Start > All Programs > QL-800 >

QL-800 Status Monitor.

• In the QL-800 Maintenance Utility, choose Status Monitor.

44 QL-800 User Guide

Designing and Printing Labels

• In the QL-800 printer driver, choose Launch Status Monitor from the

Services tab.

2 You can view estimates of remaining ink percentages in the Ink Levels area.

3 You can view an estimate of the maintenance cartridge level percentage in the

Maintenance Cartridge Level area.

QL-800 User Guide 45

Designing and Printing Labels

46 QL-800 User Guide

QL-800 Maintenance Utility

4

About the Maintenance Utility

The QL-800 Maintenance Utility is installed during the driver installation process. The

utility allows you to view printer information and perform a variety of maintenance

functions.

Printer Information Tab

Use the Printer Information tab to view printer system information, upgrade printer

firmware, and set the clock.

Viewing Printer Information

1 Launch the QL-800 Maintenance Utility.

From the Windows Start Menu, choose Start > All Programs > QL-800 > QL-800

Maintenance Utility. A language and printer prompt will open.

Select a display language and the QL-800 printer you want to connect to. Ch oose

OK.

QL-800 User Guide 47

QL-800 Maintenance Utility

2 Choose the Printer Information tab.

3 View the printer information.

• Printer - This section provides the serial number of the printer and the installed

firmware version number. It also provides the transport usage in inches.

• Print Module - This section provides the serial number o f the print module and

the installed firmware version.

• Ink Levels - This section provides the remaining ink percentages of ink

cartridges.

• Printhead - This section provides the remaining service life percentage of the

printhead. If print quality is acceptable, you can continue to use a printhead

past 100% of its service life.

This section also provides the serial number and number of inches printed with

the printhead.

• Parts Life - This section provides the remaining service life percentages of the

aerosol filter, maintenance roller, maintenance cartridge, and cutter.

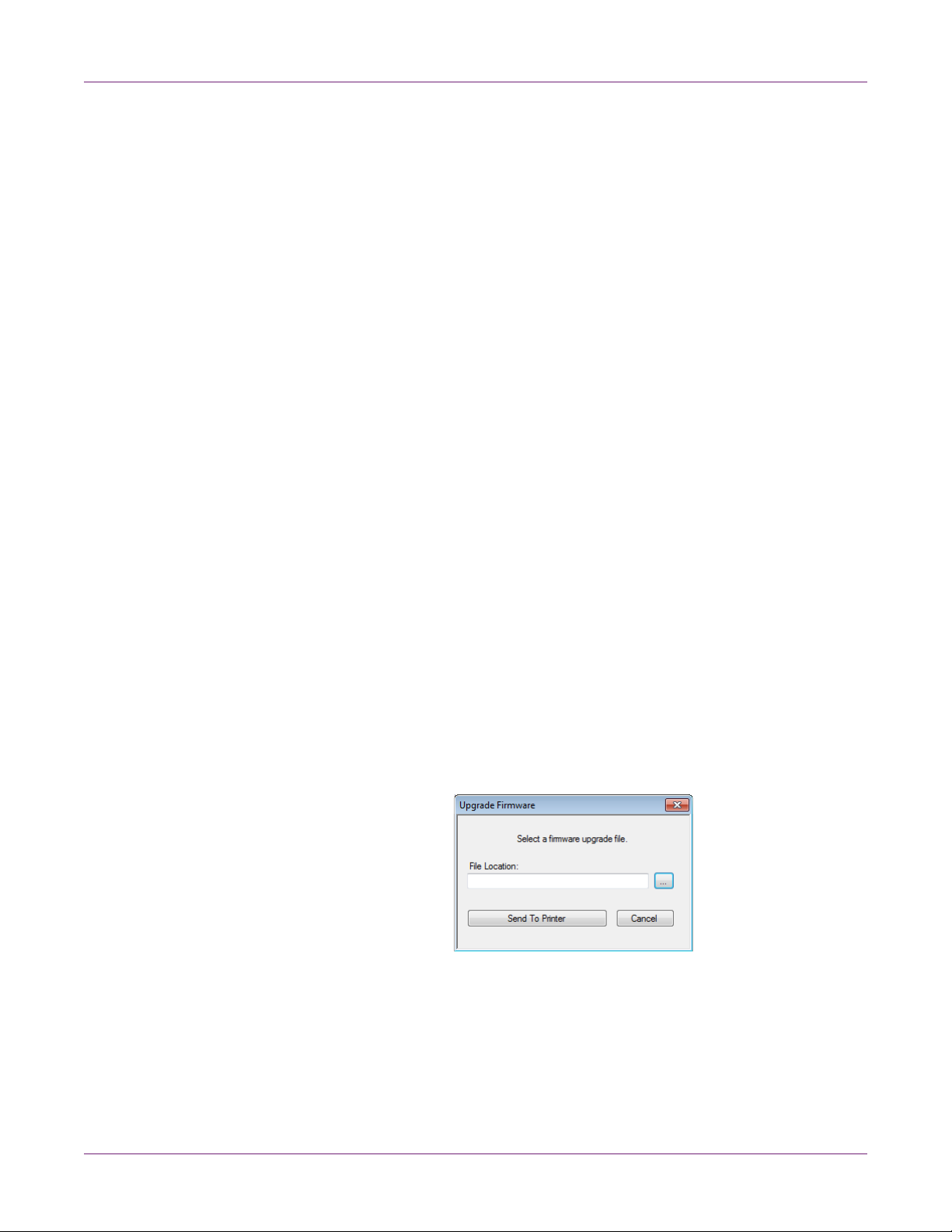

Upgrading the Printer and Print Module Firmware

1 Ensure the QL800_vX_X.upgrade file is accessible from your PC. The vX_X in the

file name indicates the firmware package version.

2 Launch the QL-800 Maintenance Utility.

From the Windows Start Menu, choose Start > All Programs > QL-800 > QL-800

Maintenance Utility. A language and printer prompt will open.

Select a display language and the QL-800 printer you want to connect to. Choo se

OK.

3 Choose the Printer Information tab.

4 Choose Upgrade Firmware. The Upgrade Firmware window will open.

5 Choose the ... button. Browse to the QL800_vX_X.upgrade file and choose Open.

6 Choose Send to Printer.

A progress indicator will be displayed and the firmware will be upgraded. When this

process is complete, proceed to the next step.

7 Power off the printer. On the rear of the printer, turn the power inlet switch off.

48 QL-800 User Guide

QL-800 Maintenance Utility

8 On the rear of the printer, turn the power inlet switch on. Power on the printer.

Setting the Clock

1 Launch the QL-800 Maintenance Utility.

From the Windows Start Menu, choose Start > All Programs > QL-800 > QL-800

Maintenance Utility. A language and printer prompt will open.

Select a display language and the QL-800 printer you want to connect to. Choo se

OK.

2 Choose the Printer Information tab.

3 To set the date/time controls to the current date/time as defined by your Windows

clock, choose Get Current Time.

4 To read the time from the printer's internal clock and set the date/time controls

accordingly, choose Read From Printer.

5 To set the printer’s internal clock, select a date/time with the controls and choose

Save to Printer.

Print Settings Tab

Use the Print Settings tab to adjust the vertical baseline, horizontal baseline, and

cut/stop position.

QL-800 User Guide 49

QL-800 Maintenance Utility

Setting the Vertical Baseline

If you send the same job to two or more QL-800 printers and notice that the image

prints in different locations, you can move the vertical baseline of a printer.

Note: Adjusting the baseline is needed only for synchronizing the output of two or

more printers. Baselines are adjusted at the factory and should be close from printer to

printer. If you are using one QL-800, baseline adjustment is not necessary.

1 Launch the QL-800 Maintenance Utility.

From the Windows Start Menu, choose Start > All Programs > QL-800 > QL-800

Maintenance Utility. A language and printer prompt will open.

Select a display language and the QL-800 printer you want to connect to. Choo se

OK.

2 Choose the Print Settings tab.

3 To read the vertical baseline value from the printer and set the Vertical Baseline

control accordingly, choose Read From Printer.

4 Enter a vertical baseline value.

In the following illustration, a label is exiting the printer. Note the positive and

negative adjustment directions.

5 To save the vertical baseline value, choose Save to Printer.

Setting the Horizontal Baseline

If you send the same job to two or more QL-800 printers and notice that the image

prints in different locations, you can move the horizontal baseline of a printer.

50 QL-800 User Guide

QL-800 Maintenance Utility

Note: Adjusting the baseline is needed only for synchronizing the output of two or

more printers. Baselines are adjusted at the factory and should be close from printer to

printer. If you are using one QL-800, baseline adjustment is not necessary.

1 Launch the QL-800 Maintenance Utility.

From the Windows Start Menu, choose Start > All Programs > QL-800 > QL-800

Maintenance Utility. A language and printer prompt will open.

Select a display language and the QL-800 printer you want to connect to. Choo se

OK.

2 Choose the Print Settings tab.

3 To read the horizontal baseline value from the printer and set the Horizontal

Baseline control accordingly, choose Read From Printer.

4 Enter a horizontal baseline value.

In the following illustration, a label is exiting the printer. Note the positive and

negative adjustment directions.

5 To save the horizontal baseline value, choose Save to Printer.

Setting the Cut/Stop Position

The cut/stop position setting adjusts the position at which media is fed after printing.

You can adjust the cut/stop position -20 to +20 mm.

1 Launch the QL-800 Maintenance Utility.

From the Windows Start Menu, choose Start > All Programs > QL-800 > QL-800

Maintenance Utility. A language and printer prompt will open.

Select a display language and the QL-800 printer you want to connect to. Choo se

OK.

QL-800 User Guide 51

QL-800 Maintenance Utility

Cleaning Tab