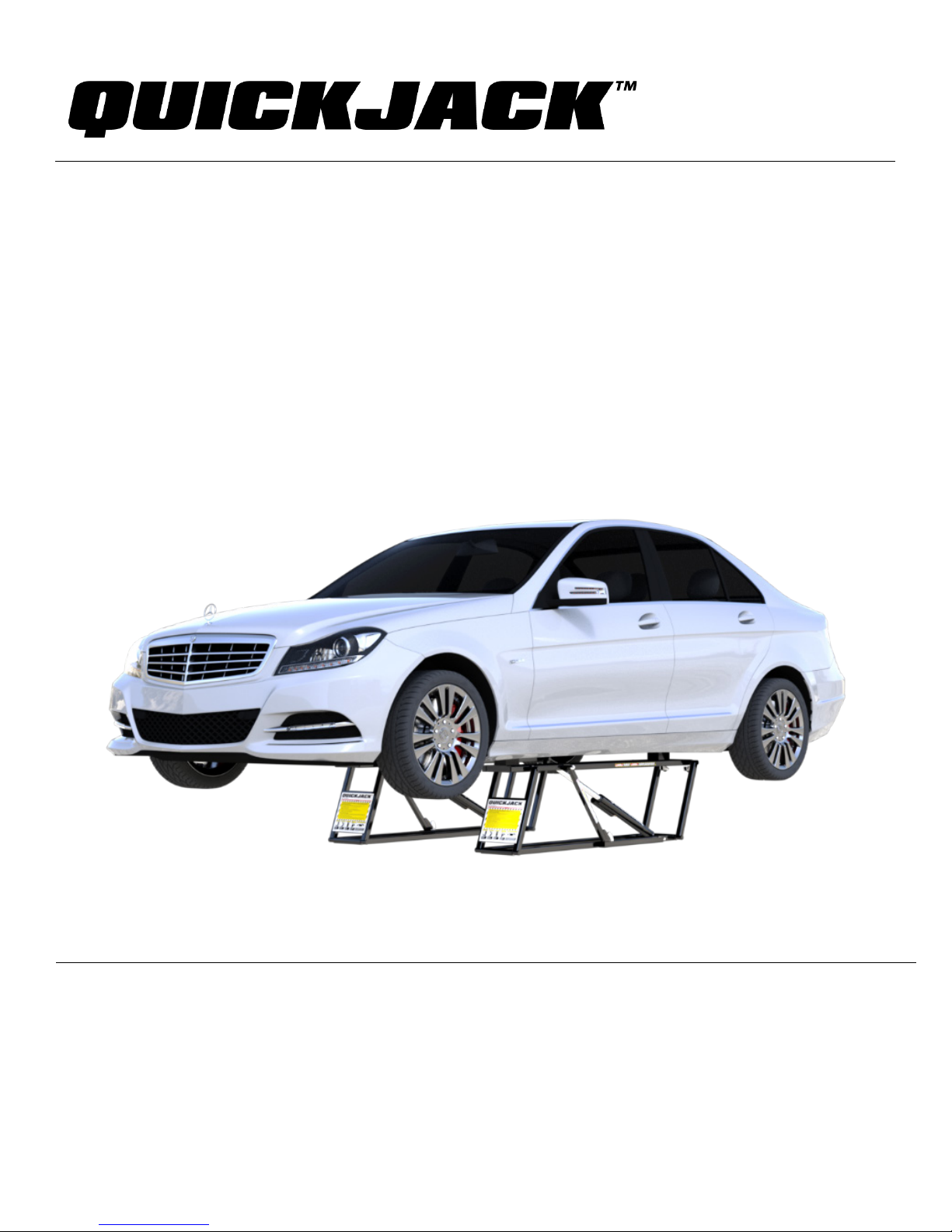

QuickJack BL-3500SLX, BL-5000SLX, BL-5000EXT, BL-6000XLT, BL-7000SLX Setup And Operation Manual

...Page 1

1645 Lemonwood Dr.

Santa Paula, CA, 93060 USA

Toll Free: (888) 262-3880

Tel: (805) 421-5114

quickjack.com

QuickJack™ Portable Car Jack

Setup and Operation Manual

Manual P/N 5900959 — Manual Revision J1 — Released December 2018

Models:

• BL-3500SLX

• BL-5000SLX

• BL-7000SLX

BL-6000XLT

BL-5000EXT

BL-7000EXT

Visit http://www.quickjack.com/setup.html for a video demonstration of QuickJack setup.

QuickJack is designed and engineered by BendPak Inc. in Southern California, USA. Made in China.

IMPORTANT SAFETY INSTRUCTIONS, SAVE THESE INSTRUCTIONS!

⚠ DANGER

Read the

servicing, or maintaining this lift. Failure to follow the instructions and

safety precautions in this manual can result in serious injury or death.

Make sure all other operators also read this manual. Keep the manual

near the product for future reference. By proceeding with setup and

operation, you agree you fully understand the contents of this manual.

entire

contents of this manual

before

installing, operating,

Page 2

Manual. QuickJack™ Portable Car Jack, Setup and Operation Manual, P/N 5900959, Manual Revision J1,

• Only use this product if it can be used safely!

Released December 2018.

Copyright. Copyright © 2018 by BendPak Inc. All rights reserved. You may make copies of this document if you

agree that: you will give full attribution to BendPak Inc., you will not make changes to the content, you do not gain

any rights to this content, and you will not use the copies for commercial purposes.

Trademarks. BendPak and the BendPak logo are registered trademarks of BendPak Inc. QuickJack and

JackPak are trademarks of BendPak Inc. All other company, product, and service names are used for

identification only. All trademarks and registered trademarks are the property of their respective owners.

Limitations. Every effort has been made to ensure complete and accurate instructions are included in this

manual. However, product updates, revisions, and/or changes may have occurred since this manual was

published. BendPak reserves the right to change any information in this manual without incurring any obligation for

equipment previously or subsequently sold. BendPak is not responsible for typographical errors in this manual.

Warranty. The QuickJack warranty is more than a commitment to you: it is also a commitment to the value of

your new product. For full warranty details and to register your new QuickJack product, contact your nearest

QuickJack dealer or visit quickjack.com/warranty.

Safety. Your new product was designed and manufactured with safety in mind. Your safety also depends on

proper training and thoughtful operation. Do not set up, operate, maintain, or repair the unit without reading and

understanding this manual and the labels on the unit.

Owner Responsibility. In order to maintain your product properly and to ensure operator safety, it is the

responsibility of the product owner to read and follow these instructions:

• Follow all setup, operation, and maintenance instructions.

• Make sure product setup conforms to all applicable local, state, and federal codes, rules, and regulations,

such as state and federal OSHA regulations and electrical codes.

• Consult a qualified person or organization to address any special regional structural and/or seismic

requirements specified by any other agencies and/or codes such as the Uniform Building Code (UBC) and/or

International Building Code (IBC).

• Read and follow all safety instructions. Keep them readily available for operators.

• Make sure all operators are properly trained, know how to safely operate the unit, and are properly supervised.

• Do not operate the product until you are certain that all parts are in place and operating correctly.

• Carefully inspect the product on a regular basis and perform all maintenance as required.

• Service and maintain the unit only with approved replacement parts.

• Keep all instructions permanently with the product and make sure all labels are clean and visible.

Unit Information. Enter the Model Number, Serial

Number, and the Date of Manufacture from the label

on your unit. This information is required for part or

warranty issues.

Model:

Serial:

Date of Manufacture:

Page 3

Table of Contents

Introduction 3 Operation 34

Shipping 5 Maintenance 47

Safety 5 Troubleshooting 49

Components 8 Wiring Diagrams 52

Accessories 10 Labels 53

Specifications 11 Parts Sheets 56

FAQ 13 ALI Store 76

Setup Checklist 14 Maintenance Log 77

Setup 15 CE Documentation 78

Introduction

This manual covers all models of the QuickJack portable car jack, which makes Vehicle maintenance

in your garage or at the track fast and easy.

QuickJack models include:

• BL-3500SLX: Raises Vehicles up to 3,500 lbs. on a frame of 62.5"

• BL-5000SLX: Raises Vehicles up to 5,000 lbs. on a frame of 69"

• BL-7000SLX: Raises Vehicles up to 7,000 lbs. on a frame of 69"

• BL-5000EXT: Raises Vehicles up to 5,000 lbs. on an extended frame of 75"

• BL-7000EXT: Raises Vehicles up to 7,000 lbs. on an extended frame of 76.25"

• BL-6000XLT: Raises Vehicles up to 6,000 lbs. on an extremely long frame of 86.5"

All models are CE certified. This manual is mandatory reading for all QuickJack users, including anyone

who sets it up, operates it, maintains it, or repairs it.

⚠ DANGER Be very careful when setting up, operating, maintaining, or repairing your unit;

failure to do so could result in property damage, product damage, injury, or (in very

rare cases) death. Make sure only authorized personnel operate the unit. All repairs

must be performed by an authorized technician. Do not make modifications to the

unit; this voids the warranty and increases the chances of injury or property

damage. Make sure to read and follow the instructions on the labels on the unit.

Keep this manual on or near your QuickJack so that anyone who uses or services it can read it.

For technical support, visit quickjack.com/support or email QuickJack Technical Support at

support@quickjack.com. You can also request parts (be sure to have the serial and model

numbers of your unit available).

QuickJack™ Portable Car Jack 3 P/N 5900959 — Rev. J1 — Dec. 2018

Page 4

IMPORTANT!

LEASE READ

P

Only raise your QuickJack Frames

with a Vehicle on them!

The QuickJack is designed and engineered to be used with the weight of a Vehicle on it. You

should only raise the QuickJack Frames with the weight of a Vehicle on them, even the very

first time you use them. There is simply no reason to raise your QuickJack Frames unless

there’s a Vehicle on them.

Why are we telling you to do it this way? Because your QuickJack Frames may occasionally

become stuck up in the air if you raise them without the weight of a Vehicle. There is nothing

wrong with them if this happens, and the issue can be quickly and easily fixed, it’s just that

they are designed and engineered to work with the weight of a Vehicle.

QuickJack Frames with a Vehicle on them.

Only raise your

And since we have your attention…

Do

not

remove your Vehicle’s tires then lower the QuickJack to the ground.

The QuickJack requires space between the ground and your Vehicle to build up enough force

to raise a Vehicle. It cannot raise a full load from a completely flat starting position.

Do

Not

Do

This is not a problem in normal operation, as the Vehicles you want to raise are being held well

above the ground by their tires. The problem generally happens when people lower the

QuickJack to a completely flat position with the Vehicle’s tires removed.

What do you do if either of these problems happens to you? Refer to Troubleshooting.

This!

QuickJack™ Portable Car Jack 4 P/N 5900959 — Rev. J1 — Dec. 2018

Page 5

To protect yourself, do not sign the bill of lading until

you have inspected the

shipment.

Shipping

Your QuickJack was carefully checked before shipping. Nevertheless, you should thoroughly inspect

the shipment

When you sign the bill of lading, it tells the carrier that the items on the invoice were received in good

condition.

shipment until the carrier makes a notation on the bill of lading that lists the missing and/or damaged

goods.

If you discover missing or damaged goods

lading, notify the carrier at once and request the carrier to make an inspection. If the carrier will not

make an inspection, prepare a signed statement to the effect that you have notified the carrier (on a

specific date) and that the carrier has failed to comply with your request.

It is difficult to collect for loss or damage after you have given the carrier a signed bill of lading. If this

happens to you, file a claim with the carrier promptly. Support your claim with copies of the bill of

lading, freight bill, invoice, and photographs, if available. Our willingness to assist in helping you

process your claim does not make us responsible for collection of claims or replacement of lost or

damaged materials.

before

If any of the items listed on the bill of lading are missing or are damaged, do not accept the

you sign to acknowledge that you received it.

after

you receive the shipment and have signed the bill of

after

Safety

Refer to ANSI/ALI ALIS Standard (R2015) Safety Requirements for Installation and Service of

Automotive Lifts for more information about safely installing your QuickJack.

Important Safety Instructions

When using your garage equipment, basic safety precautions should always be followed, including:

1. Read all instructions.

2. Do not touch hot parts; you could be burned. Always use care with the equipment.

3. Do not operate equipment with a damaged cord or if the equipment has been dropped or

4. Do not let a cord hang over the edge of a table, bench, or counter or come in contact with hot

5. If an extension cord is necessary, a cord with a current rating equal to or greater than that of the

6. Always unplug equipment from electrical outlet when not in use. Never use the cord to pull the plug

7. Let equipment cool completely before putting away. Loop cord loosely around equipment when

damaged — until it has been examined by a qualified service person.

manifolds or moving fan blades.

equipment should be used. Cords rated for less current than the equipment may overheat. Care

should be taken to arrange the cord so that it will not be tripped over or pulled.

from the outlet. Grasp plug and pull to disconnect.

storing.

8. To reduce the risk of fire, do not operate equipment in the vicinity of open containers of flammable

liquids (gasoline).

9. Adequate ventilation should be provided when working on operating internal combustion engines.

QuickJack™ Portable Car Jack 5 P/N 5900959 — Rev. J1 — Dec. 2018

Page 6

10. Keep hair, loose clothing, fingers, and all parts of your body away from moving parts.

11. To reduce the risk of electric shock, do not use on wet surfaces or expose to rain.

12. Use only as described in this manual. Use only manufacturer’s recommended attachments.

13. Always wear safety glasses. Everyday glasses only have impact resistant lenses, they are not

safety glasses.

14. To reduce the risk of injury, close supervision is necessary when this product will be used around

children.

15. To reduce the risk of injury, never overload the drawers or shelves. Refer to loading instructions.

16. To reduce the risk of electric shock or fire, never overload receptacles. Refer to markings for the

proper load on receptacles.

Save these instructions!

QuickJack Safety Information

Please note the following:

• The product is a portable car jack. Use it only for its intended purpose.

• Read this manual thoroughly before installing, operating, servicing, or maintaining your QuickJack.

• The product should only be operated by authorized personnel.

• Do not make any modifications to the product.

• Never exceed the rated capacity of the jack.

• Make sure all operators read and understand this Setup and Operation Manual. Keep the manual

near the device at all times.

• Floor surface must be dry, flat, and have a minimum compressive strength of 500 PSI.

• Avoid using an extension cord; they can overheat. If you must use an extension cord, make sure it

is No. 14 AWG minimum.

• Make a visual inspection of the product before using it

parts. Do not use the product if you find any of these issues. Instead, stop using it, then contact

QuickJack at quickjack.com/support or support@quickjack.com.

• Make a

severely worn electrical cables, Hydraulic Hoses, decals, or warning labels. Do not use the product

until damaged or worn items have been replaced.

• Take care locating the electrical cable and Hydraulic Hoses; you do not want them driven over or

stepped on.

• Always wear heavy-duty footwear and safety glasses.

• While handling a Hydraulic Cylinder or a Hydraulic Hose, also wear gloves. In rare cases, a needlelike stream of hydraulic fluid (even at low pressure) can penetrate fingers, hands, or arms; such a

puncture can feel like a bite, electric shock, or a prick. While it may seem like a minor issue, any

amount of Hydraulic Fluid injected into the human body is a serious issue. Anyone suffering such a

puncture wound should be

extent of the injury. Explain the circumstances of the injury to the attending physician, including

what kind of Hydraulic Fluid was involved. Do not assume a puncture wound that could have been

caused by Hydraulic Fluid is a minor issue; it could be life threatening.

thorough

each time

inspection of the product at least once a year. Replace any damaged or

immediately

taken to a hospital emergency room to determine the

. Check for damage or missing

QuickJack™ Portable Car Jack 6 P/N 5900959 — Rev. J1 — Dec. 2018

Page 7

• Remove all jewelry while working with the product. Dangling jewelry can get caught in moving

parts; metal jewelry can conduct electricity. Avoid wearing loose-fitting clothing.

• Clear the area if a Vehicle is in danger of falling off the jack.

Make sure both Lock Bars are engaged before nearing an elevated Vehicle.

•

• Do not work under an elevated Vehicle unless properly rated Vehicle Jack Stands are used and

placed under the factory-approved Lifting Points.

Symbols

Following are the symbols used in this manual:

⚠ DANGER Calls attention to an immediate hazard that

⚠ WARNING Calls attention to a hazard or unsafe practice that

personal injury.

will

result in death or severe injury.

could

result in death or severe

⚠ CAUTION Calls attention to a hazard or unsafe practice that could result in minor personal

injury, product, or property damage.

Tip Calls attention to information that can help you use your QuickJack better.

Liability Information

BendPak assumes no liability for damages resulting from:

• Use of the equipment for purposes other than those described in this manual.

• Modifications to the equipment without prior, written permission from BendPak.

• Damage to the equipment from external influences.

• Incorrect operation of the equipment.

QuickJack™ Portable Car Jack 7 P/N 5900959 — Rev. J1 — Dec. 2018

Page 8

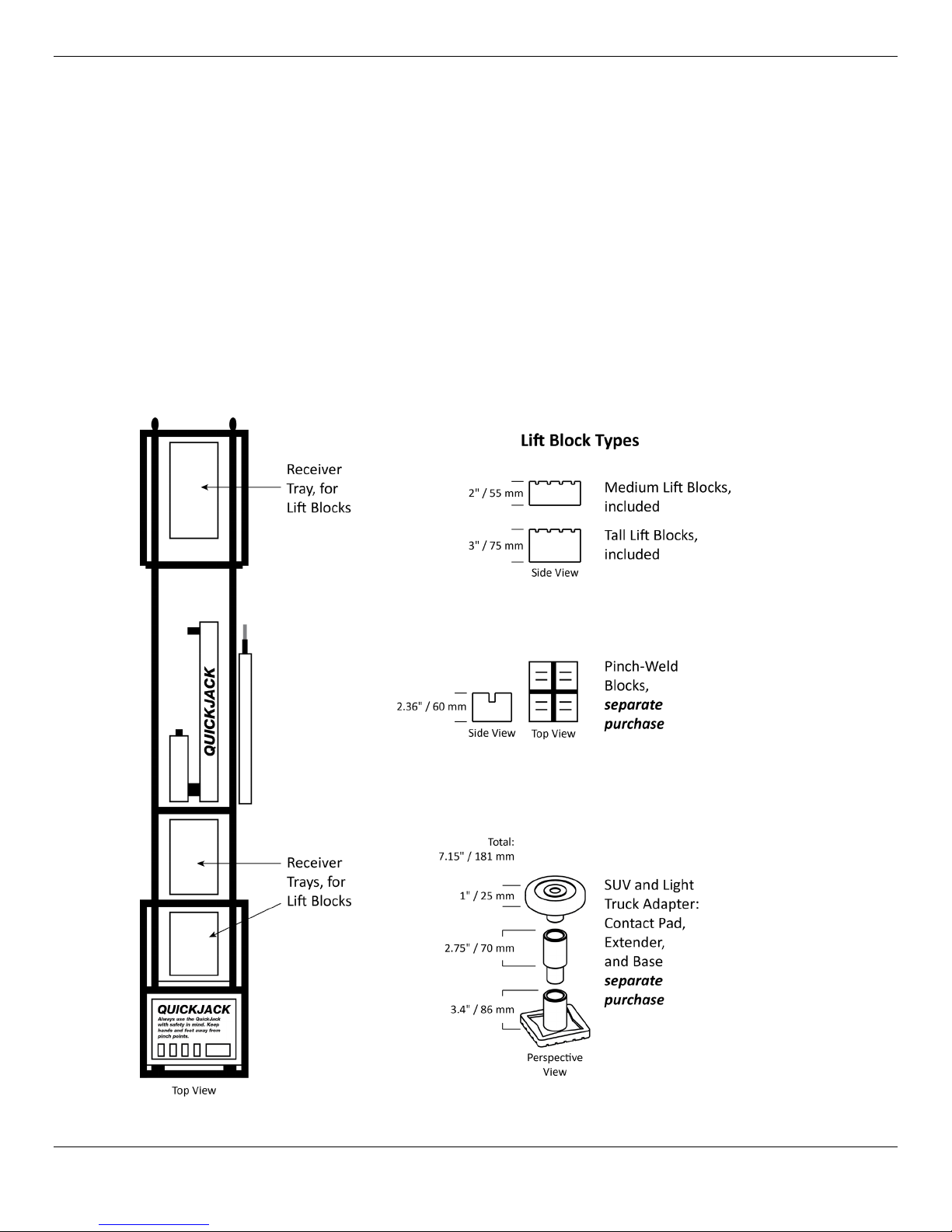

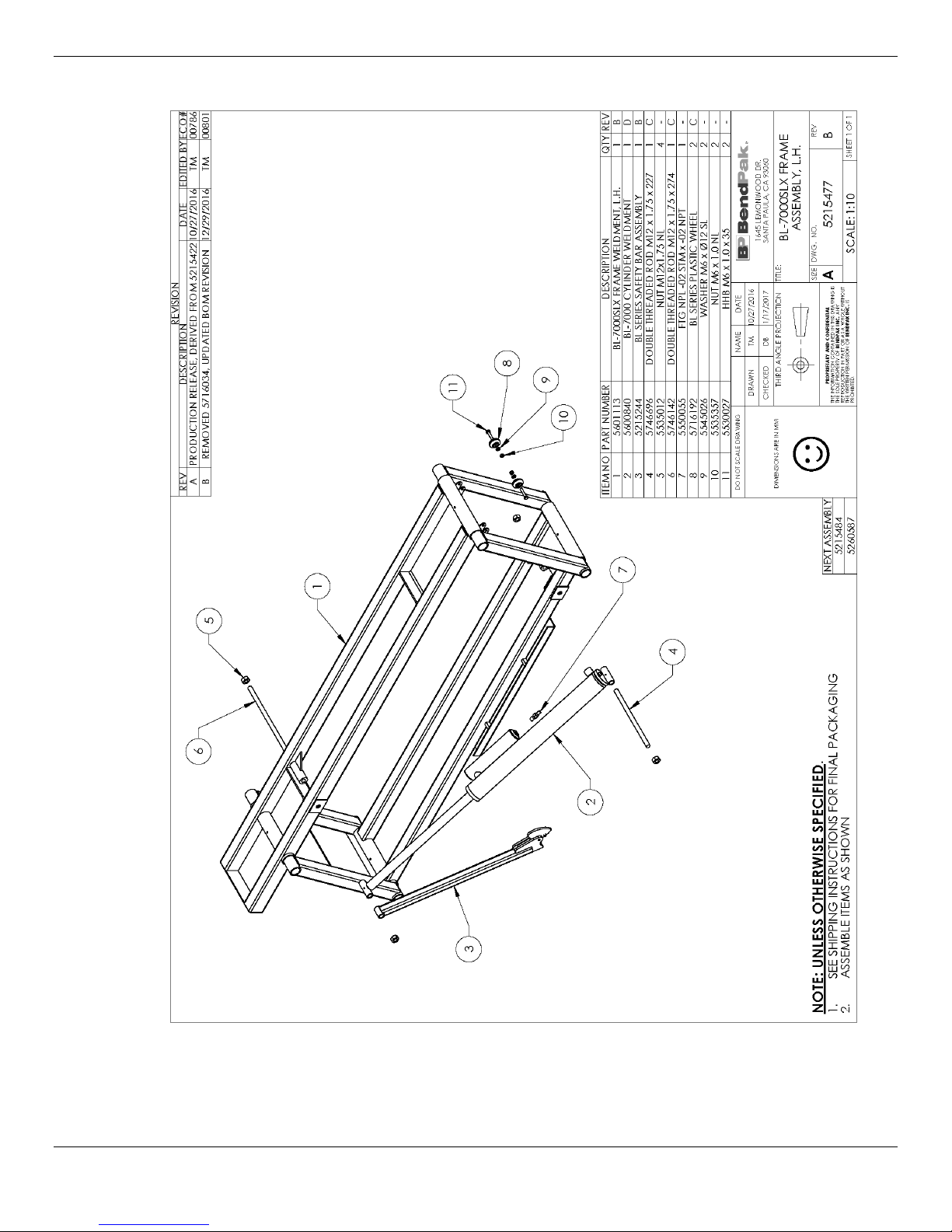

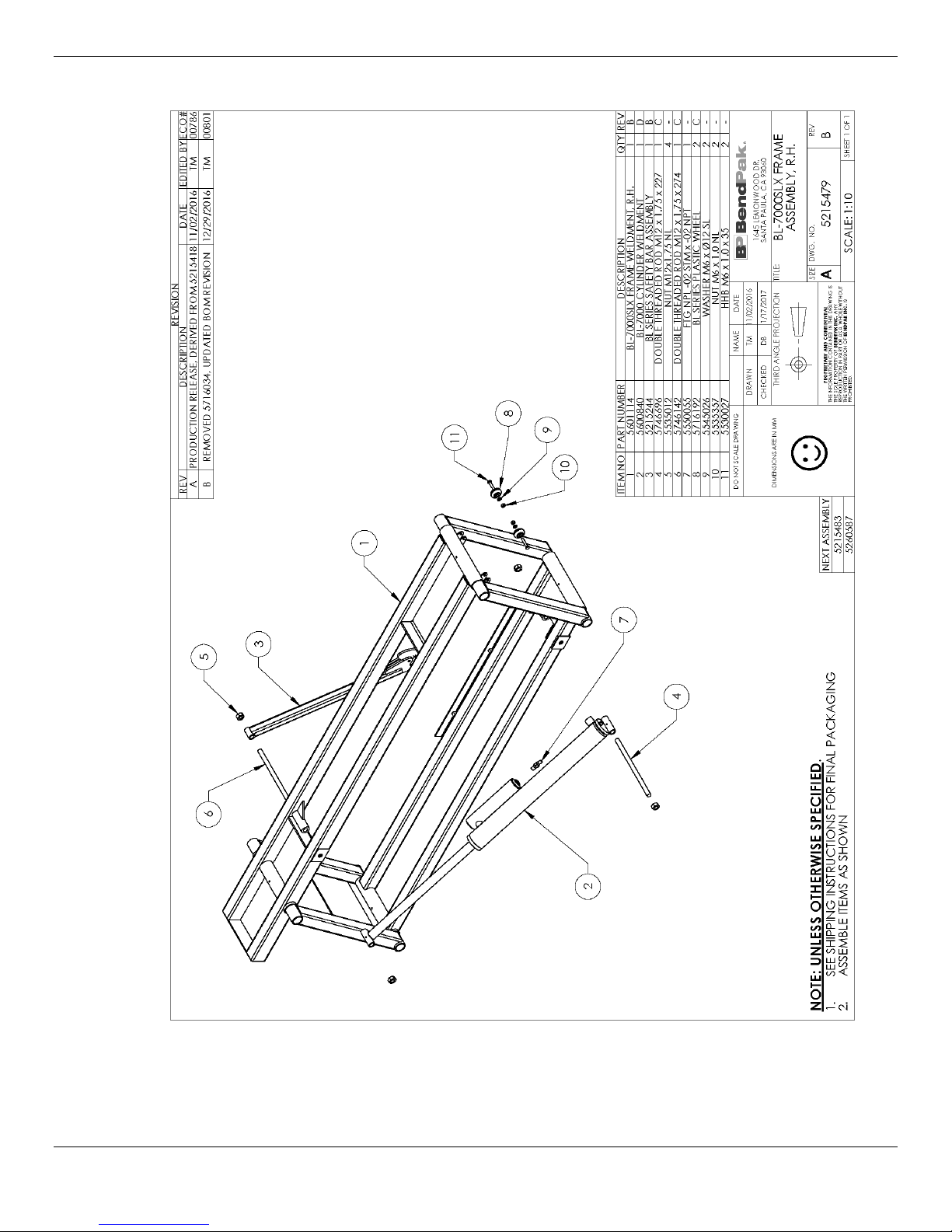

Components

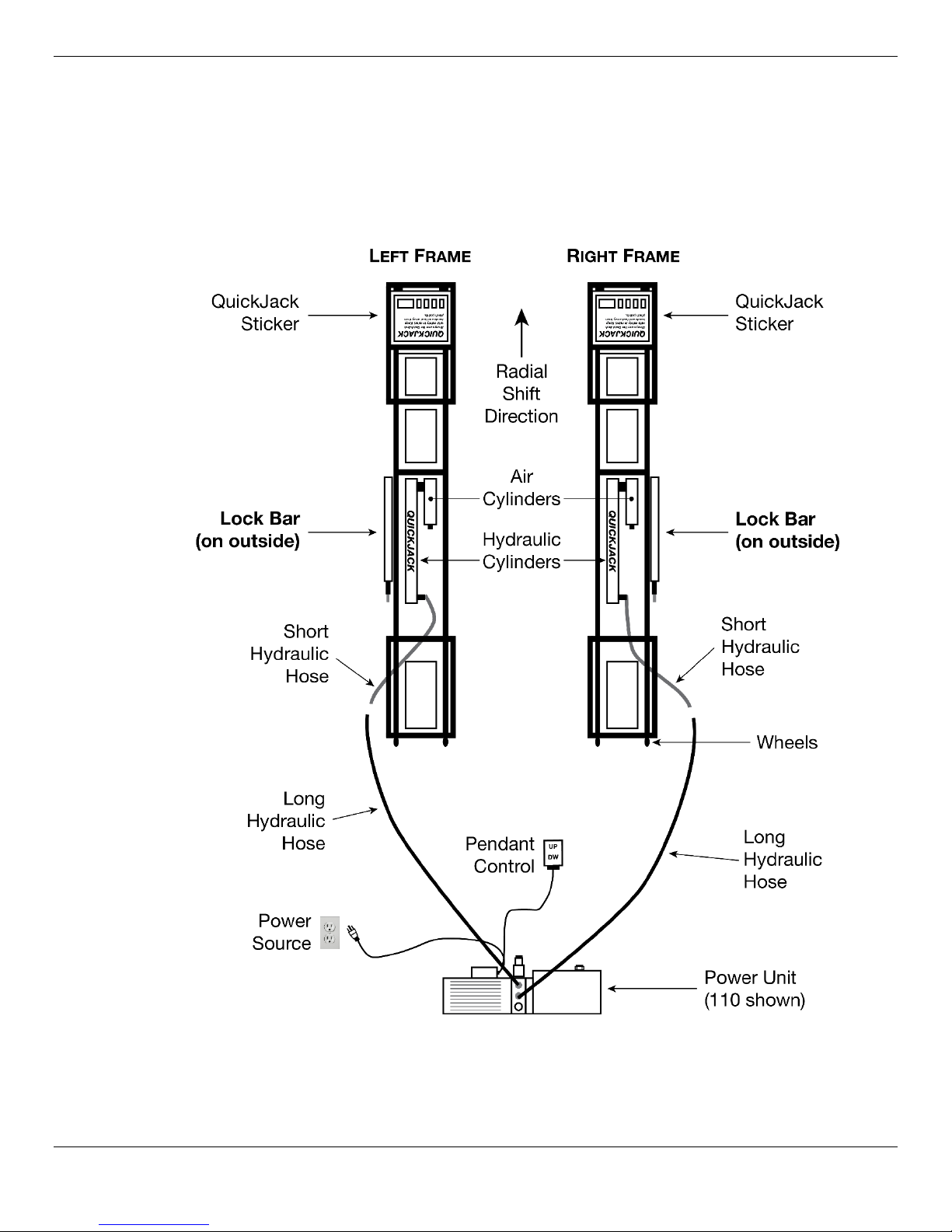

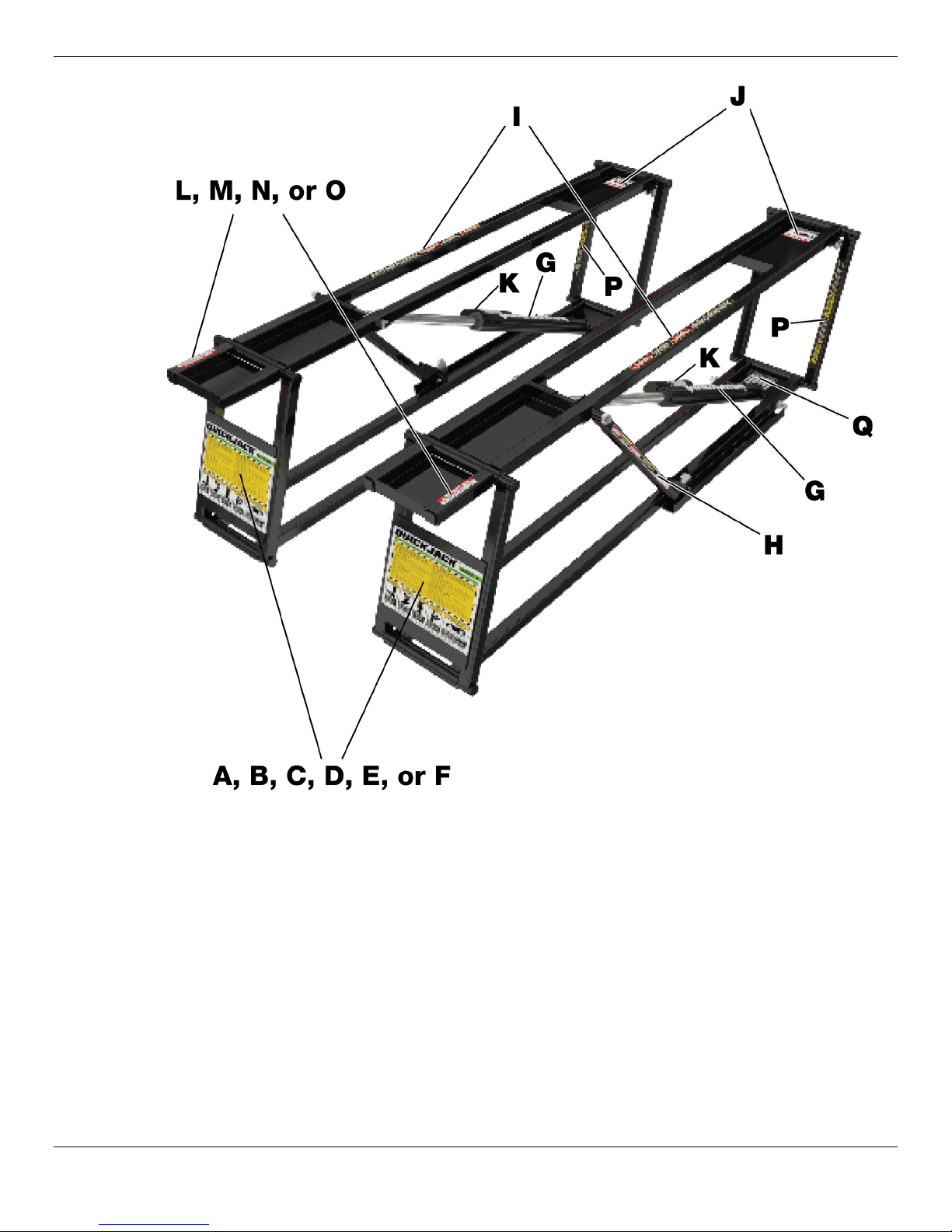

QuickJack components include:

• Two QuickJack Frames. The Frames, working together, raise and lower Vehicles.

The two Frames are

outside when you orient the Frames.

Your QuickJack has a left Frame and a right Frame. If you put your QuickJack Frames next to each

other with both Lock Bars on the outside and the end with the sticker away from you, then the

Frame on the left is the “left” Frame and the Frame on the right is the “right” Frame.

These are the orientations noted on the boxes the QuickJack Frames are shipped in and they are

also shown in the drawing in Unpacking.

• Eight rubber Lift Blocks. Four are medium height (2 inches) and four are tall (3 inches high).

The Lift Blocks can be placed in different locations in the Receiver Trays, allowing you to hit the

factory-recommended Lifting Points on a wide variety of Vehicles. Always use Lift Blocks; do not

raise a Vehicle on just the QuickJack Frames.

Note: You can stack one medium and one tall block together, but not more than that.

If you have a Vehicle with a unibody/pinch-weld frame, QuickJack recommends ordering optional

Pinch-Weld Blocks, available on the QuickJack website. If you have an SUV or truck, there

is an SUV and Light Truck Adapter available for these Vehicles, also on the QuickJack website.

• One Power Unit (includes Pendant Control). Provides power to the QuickJack Frames. There

are four Power Units available: 110 VAC, 220/240 VAC, 12 VDC, and CE-approved 12 VDC. Note

that the Hydraulic Fluid reservoir of your Power Unit is shipped

fill it with approved fluid

• Two Short Hydraulic Hoses. Connect on one end to the Hydraulic Cylinder on each Frame

and on the other end to one of the Long Hydraulic Hoses. Note that the Short Hydraulic Hoses

must

be routed under the bottom of the Frame, never over the Frame.

• Two Long Hydraulic Hoses. Connect on one end to the Power Unit and on the other end to

one of the Short Hydraulic Hoses.

not

interchangeable. The Lock Bars, described below, must be on the

before

without

using your QuickJack.

Hydraulic Fluid; you

must

Tip To move your QuickJack components: disconnect the Long Hydraulic Hoses either

at the Power Unit or at the Short Hydraulic Hoses. This is easier than trying to move

the QuickJack with all components connected.

• Assembly Kit. Holds components used during setup. Refer to QuickJack Assembly Kit for

a list of all components in the Assembly Kit.

• Two Frame Positioning Handles. Used to easily move the QuickJack Frames, usually to

position the Frames under the Vehicle’s factory-recommended Lifting Points.

• Lock Bars. The two Lock Bars, one on each QuickJack Frame, hold the Frames in position when

they are raised—at either the First Locking Position or the Top Locking Position.

Only leave the QuickJack either fully lowered or engaged on one of the two locking positions.

Before using the QuickJack, check to make sure both Lock Bars are moving freely and are in their

tracks. If the Lock Bars get stuck in an up position or they come out of their tracks, the QuickJack

will not work correctly, which is a safety hazard.

QuickJack™ Portable Car Jack 8 P/N 5900959 — Rev. J1 — Dec. 2018

Page 9

• Hydraulic Cylinder and Air Cylinder. Each QuickJack Frame has one Hydraulic Cylinder and

one Air Cylinder. The Hydraulic Cylinder is welded to the Frame and the Air Cylinder is welded to

the Hydraulic Cylinder. The Hydraulic Cylinder receives Hydraulic Fluid from the Power Unit, which

is used to move the Frames up and down. The Air Cylinder acts like an air spring, which means

they assist in lowering the Frames. The Hydraulic Cylinders need Hydraulic Fluid to operate, the Air

Cylinders need to be pressurized from 40 to 50 PSI (2.75 to 3.4 BAR); do not exceed 50 PSI.

• Wheels. The two Wheels on the non-sticker end of each QuickJack Frame allow you to easily

move the Frame to a different location. Note that the Wheels and the weight of the Frame can

leave marks on some floors, so be careful using them.

• Handles. On the sticker end of each QuickJack Frame is an opening that can be used as a

Handle when you are moving the Frame. To pick up a Frame by its Handle, with one hand raise the

Frame just off the ground under the large yellow sticker, then put the other hand in the Handle and

continue to raise the Frame.

⚠ WARNING Be very careful when putting down the Frame; you do not want to crush your

fingers.

The following image shows the main components of a QuickJack.

Not all components shown. The Power Unit that came with your QuickJack may look slightly different,

but it will work the same.

QuickJack™ Portable Car Jack 9 P/N 5900959 — Rev. J1 — Dec. 2018

Page 10

Accessories

SUV and Light Truck Adapter Kit

The optional SUV and Light Truck Adapter Kit increases the service capability of your QuickJack by

providing stackable Lift Blocks that mount inside the Receiver Trays.

The Adapter Kit is available for Models BL-5000SLX/EXT and BL-7000SLX/EXT.

The Adapter Kit includes:

• Four low-profile, round Contact Pads

• Four Bases that accommodate the Contact Pads and the Extenders

• Four 3-inch Extenders that raise the Contact Pads

Visit the Accessories page of the QuickJack website for more information.

SLX Frame Extension Kit

The SLX Frame Extension Kit is a pair of QuickJack frame extenders that increase the lift-point spread

for BL-5000SLX and BL-7000SLX models by 6 inches, for a total lift point spread of 66 inches.

They fit snugly into your QuickJack with no setup required and can be easily taken off and put back

on, depending on what Vehicle you are raising.

Visit the Accessories page of the QuickJack website for more information.

Motorcycle Lift Adapter Kit

The Motorcycle Lift Adapter Kit lets you add a platform on top of your QuickJack Frames, converting it

into a motorcycle lift. This product is not CE certified.

The Adapter Kit includes a tread plate, heavy-duty tie-down rings, a support axle, a large clamp with

treaded-rubber padding, and an easy-to-use crank for wheel security.

Visit the Accessories page of the QuickJack website for more information.

Ranger RML-1100 Motorcycle Jack

The Ranger RML-1100 Motorcycle Jack is ideal for servicing motorcycles and ATVs up to 1,100

pounds / 499 kg. It is the perfect accessory for the QuickJack Motorcycle Lift Adapter Kit. This

product is not CE certified.

Visit the Accessories page of the QuickJack website for more information.

JackPak

The portable JackPak lets you add air to the Air Cylinders on each QuickJack Frame. It also includes

additional features for roadside assistance and emergencies.

Refer to jackpak.com for more information.

QuickJack™ Portable Car Jack 10 P/N 5900959 — Rev. J1 — Dec. 2018

Page 11

Specifications

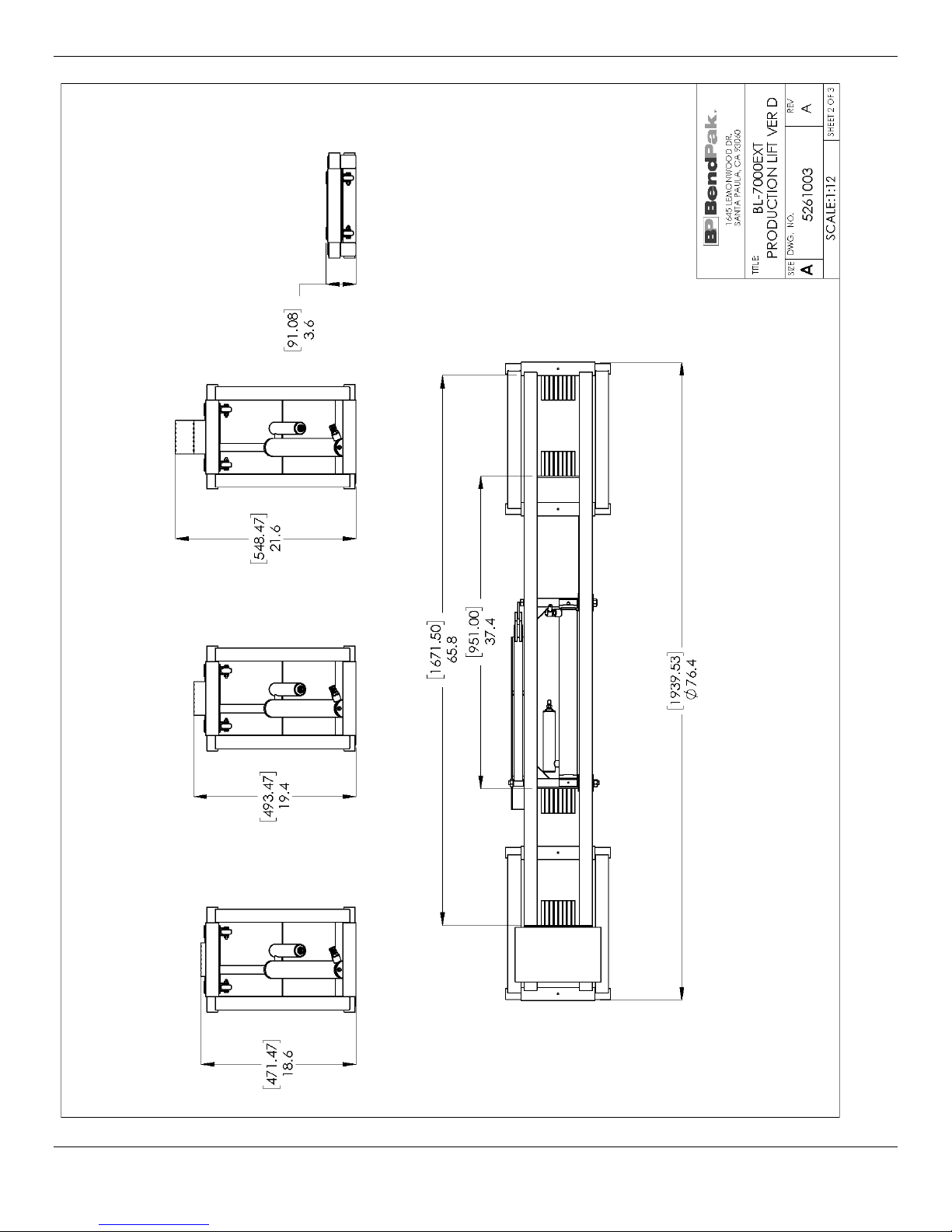

Model BL-3500SLX BL-5000SLX BL-7000SLX

Lifting capacity 3,500 lbs / 1,588 kg 5,000 lbs / 2,268 kg 7,000 lbs / 3,175

A Lowered height (frame only) 3" / 76 mm 3" / 76 mm 3.6" / 91 mm

B Height, frame only *

16.5" / 419 mm 17.6" / 447 mm 18.2" / 462 mm

C Height, 2" blocks 17" / 432 mm 18.4" / 467 mm 18.6" / 471 mm

D Height, 3" blocks 18.5" / 470 mm 19.2" / 487 mm 19.4" / 493 mm

E Height, stacked blocks 20" / 508 mm 21.3" / 542 mm 21.6" / 548 mm

F Frame width 10.6" / 268 mm 11" / 278 mm 12.5" / 318 mm

G Max lifting point spread 50.5" / 1,283 mm 60" / 1,524 mm 60" / 1,524 mm

H Min lifting point spread 26.7" / 678 mm 29.5" / 749 mm 29.5" / 749 mm

I Frame length 62" / 1,575 mm 70" / 1,778 mm 71" / 1,803 mm

Individual frame weight 60 lbs / 27 kg 76 lbs / 35 kg 96 lbs / 44 kg

Power unit weight (no fluid) 35 lbs / 16 kg 35 lbs / 16 kg 35 lbs / 16 kg

Power Unit PRV setting 1,980 PSI 1,980 PSI 1,980 PSI

Sound (when raising/lowering) <70 dBA <70 dBA <70 dBA

Maximum allowed wind speed

<60 mph / <96.5 kph <60 mph / <96.5 kph <60 mph / <96.5 kph

*

For reference purposes only;

Specifications are subject to change without notice.

QuickJack™ Portable Car Jack 11 P/N 5900959 — Rev. J1 — Dec. 2018

do not

raise a Vehicle without Lift Blocks.

Page 12

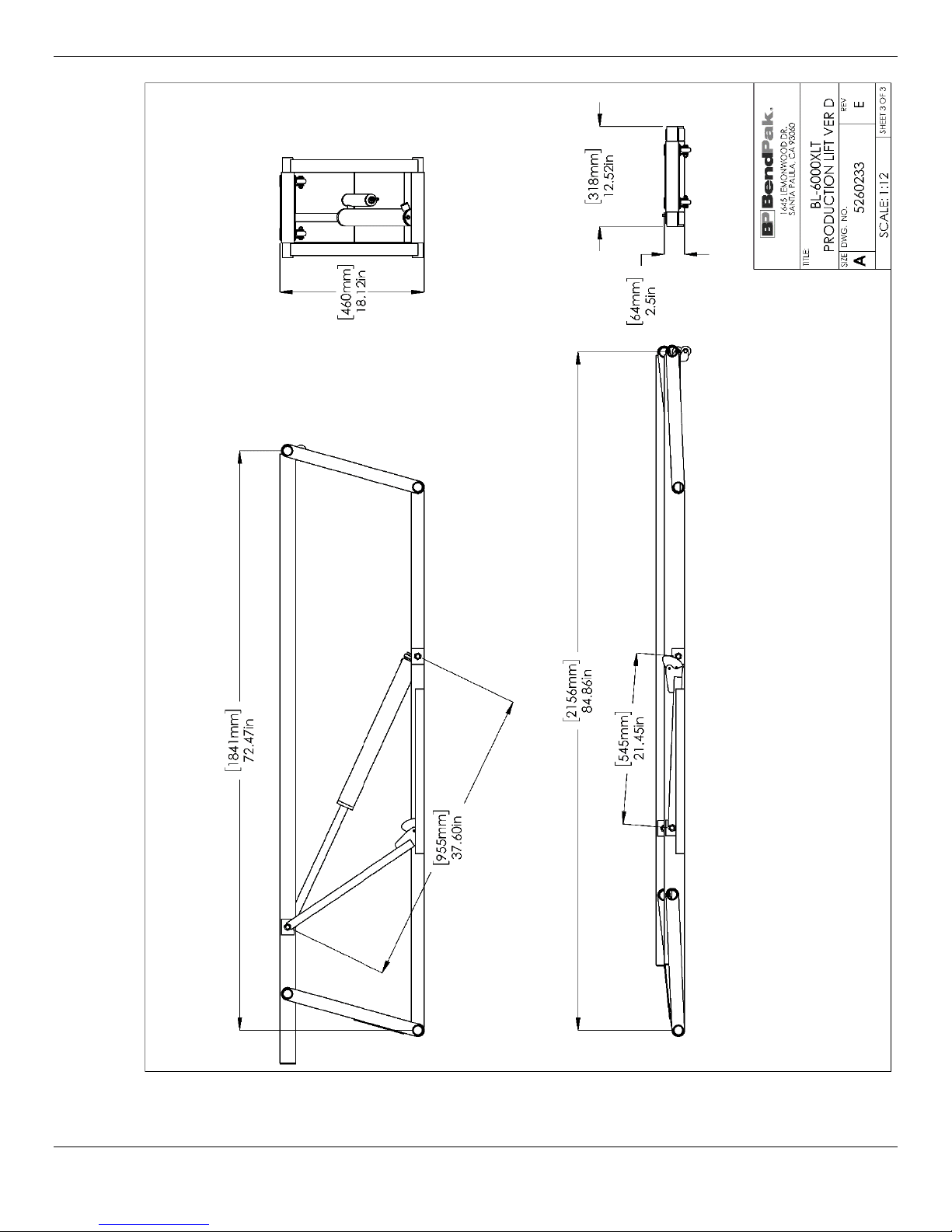

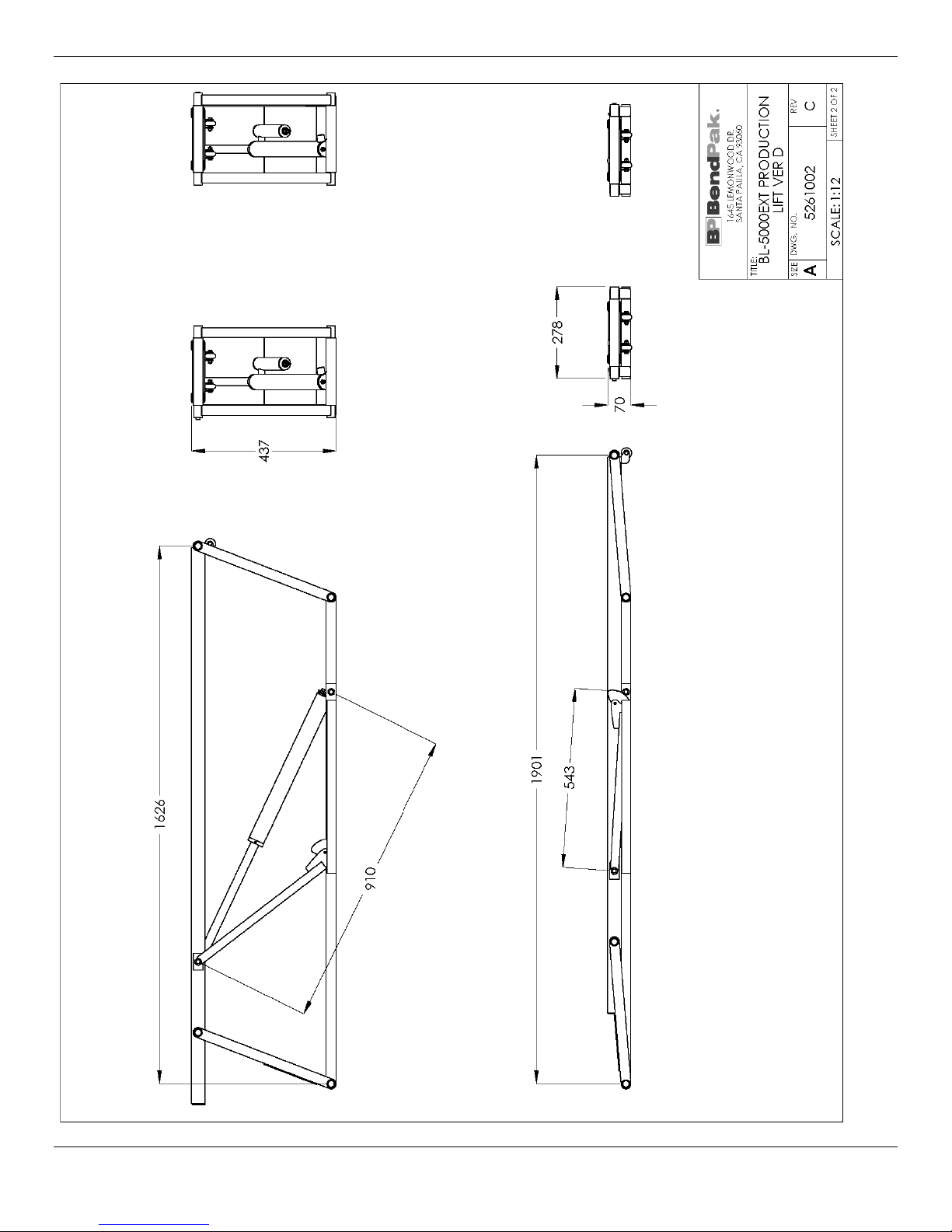

Model

BL-6000XLT BL-5000EXT BL-7000EXT

Lifting capacity per pair 6,000 lbs / 2,722 kg 5,000 lbs / 2,268 kg 7,000 lbs / 3,175 kg

A Collapsed height 3.6" / 91 mm 3" / 76 mm 3.6" / 91 mm

B Height, no blocks *

18.2" / 462 mm 17.6" / 447 mm 18.2" / 462 mm

C Height, small blocks 18.6" / 471 mm 18.4" / 467 mm 18.6" / 471 mm

D Height, tall blocks 19.4" / 493 mm 19.2" / 487 mm 19.4" / 493 mm

E Height, stacked blocks 21.6" / 548 mm 21.3" / 542 mm 21.6" / 548 mm

F Frame width 12.5" / 318 mm 11" / 278 mm 12.5" / 318 mm

G Block position, max spread 75.8" / 1,926 mm 66" / 1,676 mm 66" / 1,676 mm

H Block position, min spread 47.4" / 1,205 mm 37.4" / 951 mm 37.4" / 951 mm

I Frame length 86" / 2,185 mm 75" / 1,905 mm 76" / 1,930 mm

Individual frame weight 110 lbs / 50 kg 80 lbs / 36 kg 101 lbs / 46 kg

Power unit weight 35 lbs / 16 kg 35 lbs / 16 kg 35 lbs / 16 kg

Power Unit PRV setting 1,980 PSI 1,980 PSI 1,980 PSI

Sound (when raising/lowering) <70 dBA <70 dBA <70 dBA

Maximum allowed wind speed

*

For reference purposes only;

Specifications are subject to change without notice.

QuickJack™ Portable Car Jack 12 P/N 5900959 — Rev. J1 — Dec. 2018

do not

<60 mph / <96.5 kph <60 mph / <96.5 kph <60 mph / <96.5 kph

raise a Vehicle without Lift Blocks.

Page 13

Frequently Asked Questions

Question: What kinds of Vehicles can I raise using my QuickJack?

Answer: A wide variety. The two main criteria are: is the Vehicle under the weight capacity of your

QuickJack and do the QuickJack’s Lift Blocks hit the Vehicle’s factory-recommended Lifting Points? If

the answers are yes, and for most Vehicles the answers are yes, then you can raise the Vehicle.

Q: What if I want to raise a Vehicle that is slightly over the weight capacity of my QuickJack?

A: This is not an intended use of the product. We strongly recommend against trying to raise a Vehicle

that is heavier than the rated capacity of your QuickJack.

Q: How many locking positions does my QuickJack have?

A: Two. We call them the First Locking Position and the Top Locking Position.

Q: Do the QuickJack Frames have a “left” and “right” orientation?

A: Yes. If you put your QuickJack Frames next to each other with both Lock Bars on the outside and

the end with the sticker away from you, then the Frame on the left is the “left” Frame and the Frame on

the right is the “right” Frame. These are the orientations noted on the boxes the QuickJack Frames

come in and is shown in the drawing in Unpacking.

Q: Can I use my QuickJack outdoors?

A: No. The QuickJack is approved for indoor installation and use only.

prohibited

protect it from the weather (for example, from falling dirt, rain, sleet, and snow).

. Your QuickJack is portable, however, so if you end up taking it outdoors, remember to

Outdoor installation is

Q: If I am going to move my QuickJack, do I have to take it apart?

A: Only a little: disconnect the Long Hydraulic Hoses at the Power Unit or at the Short Hydraulic

Hoses, then move the sections separately. This is easier than trying to move the QuickJack with all of

the components connected.

Q: Can I drive on the QuickJack Frames?

A: A Vehicle can be

on

a Vehicle

Q: What happens if I raise a Vehicle on my QuickJack but

A: First, do not do this; it is a safety hazard. Second, because the QuickJack is not in a locked

position, the weight of the Vehicle will eventually lower it to the ground. Always follow this rule: if you

raise a Vehicle, engage it on a locking position or lower it back to the ground.

Q: How long can I leave a Vehicle raised on my QuickJack?

A: As long as you want,

engaged on one of its two locking positions, gravity holds it in place; a loss of power or leaking

Hydraulic Fluid would not cause the QuickJack to lower.

Q: Anything else I should know about my QuickJack?

A: Two things. First, do not raise your QuickJack Frames to full height with no Vehicle on it. QuickJack

Frames are built to hold the weight of a Vehicle; they may get stuck at full rise if there is no weight on

them. Always raise your QuickJack Frames with a Vehicle on them. Second, do not try to raise a

Vehicle from no net rise (meaning, if you lower the QuickJack Frames to the ground while the Vehicle’s

tires are removed). QuickJack needs some space to build up enough force to raise a Vehicle.

the QuickJack Frames or the Hydraulic Hoses; this damages them.

above

your QuickJack Frames (this is normal operation, in fact), but

do not

if it is engaged on a locking position

do not

leave it in a locked position?

. Once your QuickJack is

drive

QuickJack™ Portable Car Jack 13 P/N 5900959 — Rev. J1 — Dec. 2018

Page 14

Setup Checklist

Following are the steps needed to install a QuickJack. Perform them in the order shown.

☐ 1. Review the setup Safety Rules.

☐ 2. Make sure you have the necessary Tools.

☐ 3. Select the setup Site.

☐ 4. Unpack the Components that came with the QuickJack.

☐ 5. Make sure there is adequate Clearance on all sides and above.

☐ 6. Locate the QuickJack Assembly Kit.

☐ 7. Locate and examine the Air and Hydraulic Cylinders.

☐ 8. Install the Hydraulic Elbow Fittings.

☐ 9. Prepare the Short Hydraulic Hoses.

☐ 10. Understand Quick-Connect Fittings

☐ 11. Route the Short Hydraulic Hoses.

☐ 12. Prepare and connect the Long Hydraulic Hoses.

☐ 13. Pressurize the Air Cylinders.

☐ 14. Find a location for the Power Unit.

☐ 15. Install fittings on the Power Unit.

☐ 16. Connect the Power Unit to a Power Source.

☐ 17. Fill the Hydraulic Fluid Reservoir.

☐ 18. Check the Breather Valve.

☐ 19. Review the Final Checklist.

☐ 20. Test the QuickJack.

☐ 21. Leave the Manual for the owner/operator.

QuickJack™ Portable Car Jack 14 P/N 5900959 — Rev. J1 — Dec. 2018

Page 15

Setup

This section describes how to set up your QuickJack.

⚠ WARNING

Your QuickJack is supplied with setup instructions that meet the criteria set by the American National

Standard “Automotive Lifts – Safety Requirements for Construction, Testing, and Validation” ANSI/ALI

ALCTV-2011.

Use only the factory-supplied parts that came with your QuickJack

you use parts from a different source, you void your warranty and compromise the

safety of everyone who sets up or uses the QuickJack. If you are missing parts, visit

quickjack.com/support or contact QuickJack Technical Support at

support@quickjack.com, (888) 262-3880, or (805) 933-9970.

. If

Setup Safety Rules

When setting up a QuickJack, your safety depends on proper training and thoughtful operation.

⚠ WARNING Always use proper tools, such as a forklift or shop crane, to move heavy

components. Do not install this equipment without reading and understanding this

manual and the labels on the unit.

BendPak recommends referring to the ANSI/ALI ALIS Standard (R2015) Safety Requirements for

Installation and Service for more information about safely setting up, using, and servicing your

QuickJack.

Pay attention at all times during setup.

moving parts. Keep hands and fingers away from pinch points.

Use appropriate tools and equipment. Stay clear of

⚠ WARNING You must wear protective equipment at all times during setup: leather gloves, steel-

toed work boots, eye protection, back belts, and hearing protection.

Tools

You need the following tools to set up your QuickJack:

• SAE / metric hex key set

• SAE / metric socket and ratchet set

• SAE / metric wrench set or an adjustable wrench

• Screwdriver set

Tip Keep a rag handy during setup; Hydraulic Fluid sometimes leaks.

At some point during setup, you will need to provide some air pressure (to 50 PSI, for the Air Cylinder)

and 2.1 quarts / 2 liters of Hydraulic Fluid.

QuickJack™ Portable Car Jack 15 P/N 5900959 — Rev. J1 — Dec. 2018

Page 16

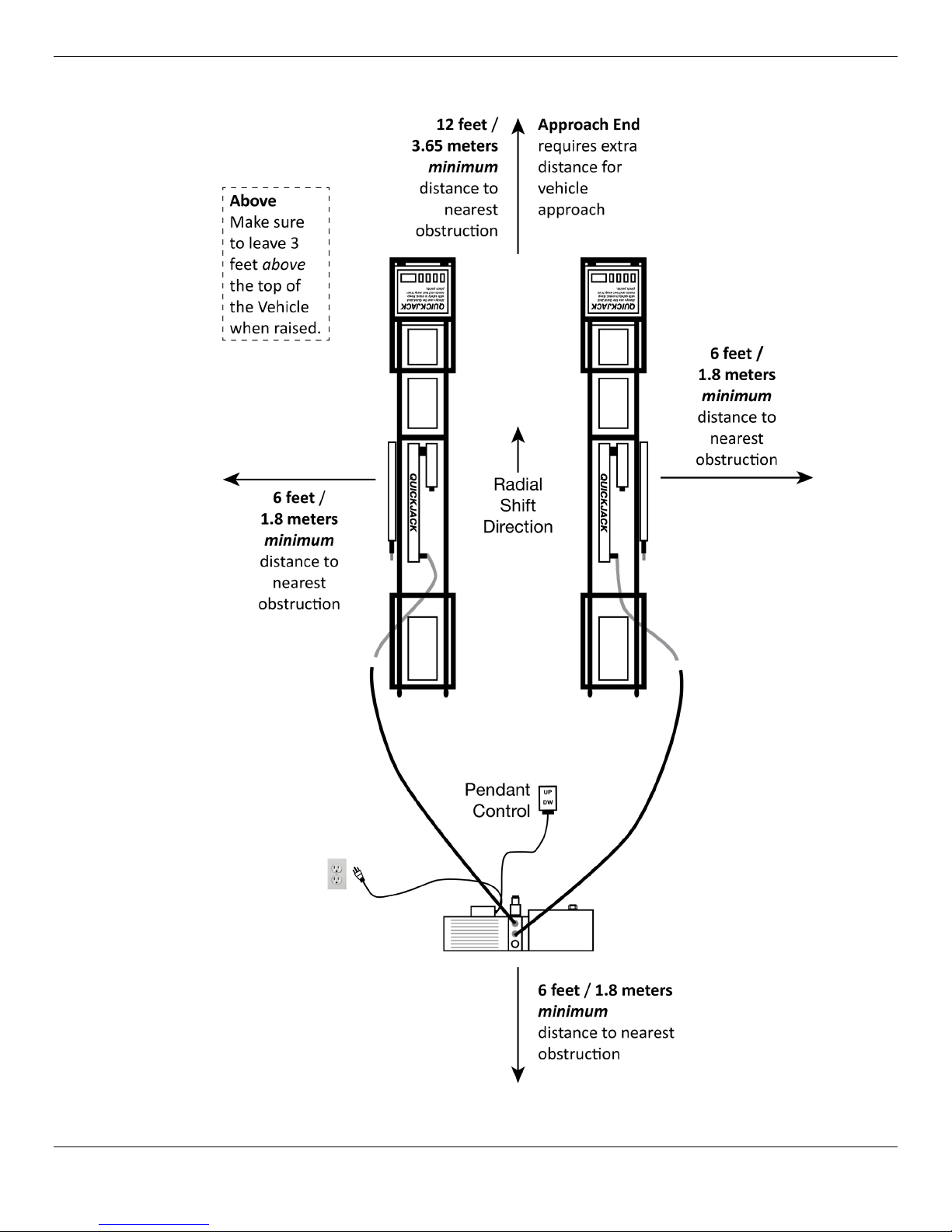

Selecting a Site

Keep the following in mind when selecting a site for your QuickJack:

• Enough space. Make sure there is adequate space for the QuickJack and the Vehicles you will

be raising.

• Radial Shift. When you raise your QuickJack with a Vehicle on it, the geometry of the Frames

moves the Vehicle up at a slight angle, towards the sticker end of the QuickJack; refer to the

graphic in Unpacking. Radial shift is always towards the sticker end of the QuickJack, no matter

which way the Vehicle is facing.

Radial shift can be anywhere from 11 to 15 inches, depending on QuickJack model.

Make sure to account for radial shift when choosing where to set up and use your QuickJack.

• No overhead obstructions. Make sure your site is free of overhead obstructions such as

heaters, building supports, electrical lines, low-hanging lights, and so on. We recommend leaving

at least three feet above the top of the Vehicle when raised on the QuickJack.

• Level floor. Inspect the floor and check for defective concrete or asphalt. Make sure the floor is

dry, level, and has a minimum compressive strength of 500 psi.

• Power in the right place. You will need to have a power source for your Power Unit. If you are

using 110 or 220/240 VAC power, the Power Unit must be close enough to the power source for

the cord to reach.

If you are using a 12 VDC power source, the Power Unit must be close enough to the power

source for your connection method to reach. For example, if you are powering your 12 VDC Power

Unit with a Vehicle Battery, the Power Unit must be within reach of the Jumper Cables attached to

the Vehicle’s Battery.

⚠ WARNING Do not set up or use a QuickJack on a surface with 3° of slope or more, as this

could lead to personal injury or death if a raised Vehicle were to fall off the

QuickJack. The greater the slope, the more likely the Vehicle will become

unbalanced and fall off the QuickJack, which could damage the Vehicle and injure

anyone in the area.

QuickJack™ Portable Car Jack 16 P/N 5900959 — Rev. J1 — Dec. 2018

Page 17

Unpacking

Open the boxes and arrange the QuickJack components where you will be setting them up.

⚠ WARNING Your two QuickJack Frames are similar, but they are

line up your Frames as parallel to each other as the Lifting Points will allow, with the

Lock Bars on the outside

, as shown below.

not

interchangeable. Always

⚠ CAUTION Be sure to route the Short Hydraulic Hoses

are routed over the QuickJack Frames, the QuickJack will not work correctly and

the Hoses could be damaged.

QuickJack™ Portable Car Jack 17 P/N 5900959 — Rev. J1 — Dec. 2018

under

the QuickJack Frames. If they

Page 18

Clearances

Not necessarily to scale. Not all components shown. Vehicle approach must be opposite Power Unit.

Do not drive Vehicle on Hydraulic Hoses, Power Unit, or QuickJack Frames.

QuickJack™ Portable Car Jack 18 P/N 5900959 — Rev. J1 — Dec. 2018

Page 19

QuickJack Assembly Kit

Many of the items you will be using during initial setup come in the QuickJack Assembly Kit, which is a

clear plastic container included in your QuickJack packaging.

The QuickJack Assembly Kit includes:

• Four female Quick-Connect Fittings (for Long Hydraulic Hoses, both ends of each hose)

• Two male Quick-Connect Fittings (one for each Short Hydraulic Hose)

• Two Power Unit Quick-Connect Fittings (both connect to the Hydraulic Ports on the front of the

Power Unit, one above the other; put on the bottom one first)

• Two Hydraulic Elbow Fittings (one for each Hydraulic Cylinder)

• Thread Seal Tape

• Four plastic feet (for Power Units with carriers)

• Two

replacement

wheels

Air and Hydraulic Cylinders

Each QuickJack Frame has one Air Cylinder and one Hydraulic Cylinder.

The components of the Air and Hydraulic Cylinders are:

• Air Inflation Valve. Used to add air pressure to the Air Cylinder. Comes with the appropriate

valve (also called a Schrader® valve) installed.

• Hydraulic Cylinder Connector. Hydraulic Elbow Fitting attaches here. Use a 6 mm hex key to

remove the shipping plug before installing the Hydraulic Elbow Fitting.

• Bleeder Screw. Used to “bleed” the air from the Hydraulic System, if necessary. Refer to

Troubleshooting for more information.

QuickJack™ Portable Car Jack 19 P/N 5900959 — Rev. J1 — Dec. 2018

Page 20

Installing the Hydraulic Elbow Fittings

You need to install one Hydraulic Elbow Fitting on each Hydraulic Cylinder.

To install a Hydraulic Elbow Fitting:

1. Remove the shipping plug from the Hydraulic Cylinder Port using a 6 mm hex key.

2. Get an Hydraulic Elbow Fitting from the QuickJack Assembly Kit; screw the O-ring fitting end into

the Hydraulic Cylinder Port.

Tip Raising the QuickJack Frame and putting a Lift Block under it or manually raising

the Platform to a locking position can provide a little bit of extra room, making it

easier to secure the Hydraulic Elbow Fitting.

Important: Do

3. Position the threaded fitting end as shown above; accessible but not pointed up.

You want the threaded fitting end accessible from above but

Hydraulic Hose would then angle up and could possibly impact the underside of a Vehicle.

not

use Thread Seal Tape on either end of the Hydraulic Elbow Fitting.

not

pointed up, as the Short

4. Tighten the fitting nut to 11 to 12 lbf-ft / 14 to 16 N-m.

5. Perform the same process for the Hydraulic Cylinder on the other QuickJack Frame.

QuickJack™ Portable Car Jack 20 P/N 5900959 — Rev. J1 — Dec. 2018

Page 21

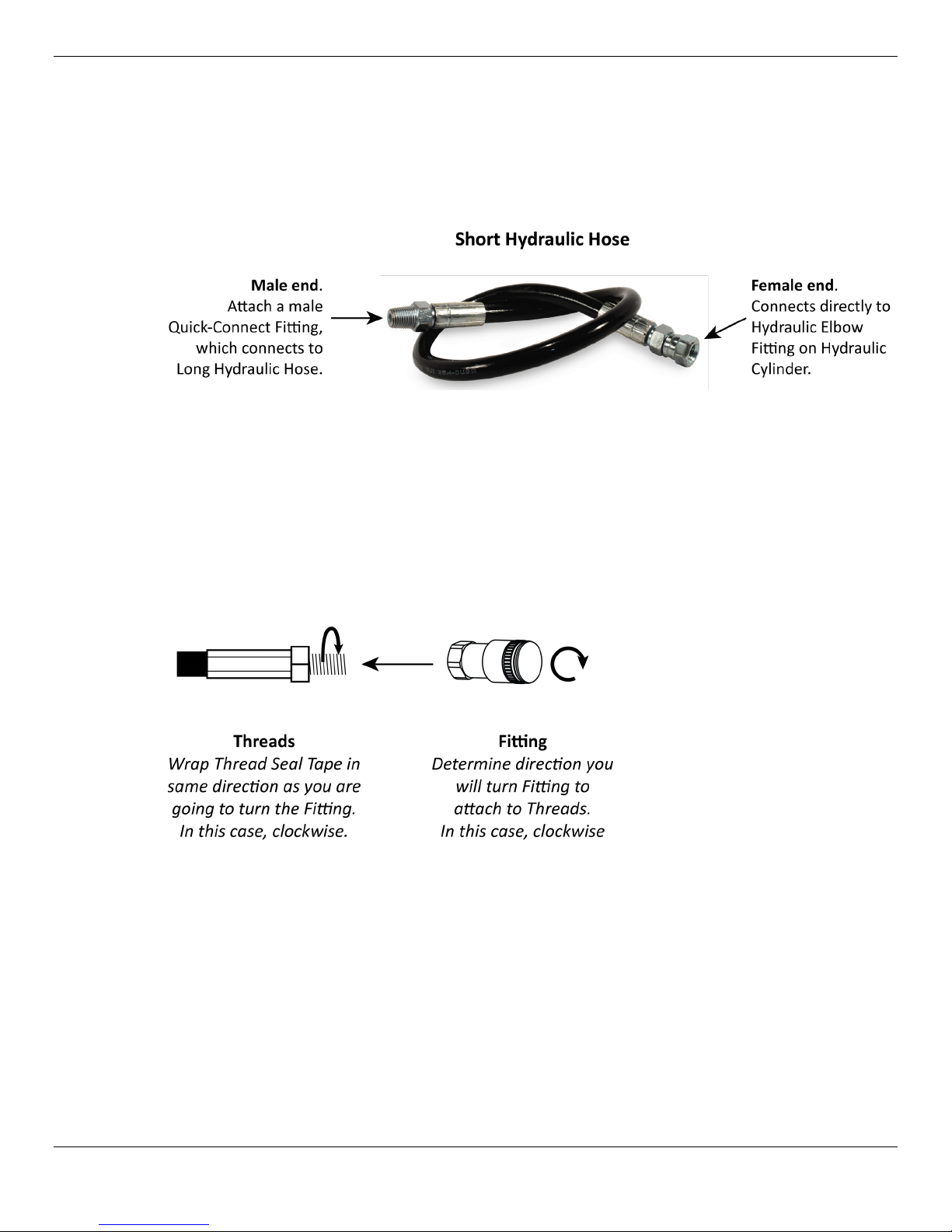

Preparing the Short Hydraulic Hoses

Your QuickJack comes with two Short Hydraulic Hoses:

• Female end. Attach directly to the Hydraulic Elbow Fitting on the Hydraulic Cylinder. You do not

need to add a fitting to this end of the Short Hydraulic Hose.

• Male end. Install a male Quick-Connect Fitting to the male end.

To set up and connect the Short Hydraulic Hoses:

1. Locate both Short Hydraulic Hoses and remove their protective caps.

2. Wrap the threaded fitting on the male end of each Short Hydraulic Hose with Thread Seal Tape.

Only one end of a Short Hydraulic Hose has a male threaded fitting; the other end has a female

fitting that attaches directly to the Hydraulic Elbow Fitting on the Hydraulic Cylinder.

To use Thread Seal Tape: determine what direction you will be turning the Fitting, wrap the

threads with Thread Seal Tape two or three times in the same direction, then attach the Fitting.

The following drawing shows how to apply Thread Seal Tape.

The drawing above show the Fitting being turned clockwise to attach it, so you would also attach

the Thread Seal Tape clockwise.

Important: Always wrap Thread Seal Tape in the same direction as you will be attaching the

Fitting.

If you apply Thread Seal Tape in the wrong direction, it is much more likely to come off as you

attach the Fitting, possibly getting into the Hydraulic Fluid and blocking fluid flow.

QuickJack™ Portable Car Jack 21 P/N 5900959 — Rev. J1 — Dec. 2018

Page 22

3. Attach one male Quick-Connect Fitting from the QuickJack Assembly Kit to the male threaded

fitting end of the Short Hydraulic Hose; tighten to 23 to 25 lbf-ft / 31 to 34 N-m.

To tighten, use one wrench to hold the Male threaded end in place and a second wrench on the

Male Quick-Connect Fitting.

Do the same for the other Short Hydraulic Hose.

4. Connect the female end of the Short Hydraulic Hose to the male connector on the Hydraulic Elbow

Fitting; tighten to 23 to 25 lbf-ft / 31 to 34 N-m.

The Hydraulic Elbow Fitting should already be installed on the Hydraulic Cylinder.

5. Route both Short Hydraulic Hoses

under

the Frame ends; make sure they are clear of pinch

points.

QuickJack™ Portable Car Jack 22 P/N 5900959 — Rev. J1 — Dec. 2018

Page 23

About Quick-Connect Fittings

Quick-Connect Fittings let you quickly connect and disconnect the QuickJack’s Hydraulic Hoses. This

makes it easier to separate the Hydraulic Hoses from the Power Unit for storage or to get the Power

Unit out of the way if the QuickJack Frames are engaged on a Locking Position.

Quick-Connect Fittings have a lock ball that lets you lock a connection.

To lock a connection: Push the Male Quick-Connect Fitting into the Female Quick-Connect Fitting,

then turn the Moveable Section so that the Lock Ball is not opposite the Notch.

To unlock and disconnect a connection: Turn the Moveable Section so that the Lock Ball is

opposite the Notch, then pull back on the Moveable Section and pull out the Male Quick-Connect

Fitting.

QuickJack™ Portable Car Jack 23 P/N 5900959 — Rev. J1 — Dec. 2018

Page 24

Routing the Short Hydraulic Hoses

After connecting the Short Hydraulic Hoses to the Hydraulic Elbow Fitting on the Hydraulic Cylinder,

make sure to route them

under the side of the QuickJack Frame

.

⚠ CAUTION If you mistakenly route a Short Hydraulic Hose over the QuickJack Frame, the

QuickJack will not work correctly and you could damage the hose and/or cause the

Vehicle on the QuickJack to become unstable.

The following drawing is a side view of a QuickJack with the Short Hydraulic Hose being routed under

the QuickJack Frame sections.

Drawing not necessarily to scale. Not all components shown, some exaggerated for clarity. Hydraulic

Elbow Fitting is shown pointed up for clarity; it is not actually installed this way.

QuickJack™ Portable Car Jack 24 P/N 5900959 — Rev. J1 — Dec. 2018

Page 25

Preparing and Connecting the Long Hydraulic Hoses

Your QuickJack comes with two Long Hydraulic Hoses:

• One end attaches to the Short Hydraulic Hose

• The other end attaches to the Power Unit

Both ends require the installation of a female Quick-Connect Fitting.

To prepare and connect your Long Hydraulic Hoses:

1. Locate both Long Hydraulic Hoses and remove their protective caps.

2. Wrap all four threaded ends with Thread Seal Tape.

Wrap the Thread Seal Tape in the same direction you will be turning the fittings.

3. Take all four female Quick-Connect Fittings from the QuickJack Assembly Kit.

4. Connect the female Quick-Connect Fittings to the male threaded connectors on both ends of both

Long Hydraulic Hoses; four connections in total.

To tighten, use one wrench to hold the Male connector in place and a second wrench on the

Female Quick-Connect Fitting to tighten it; tighten to 10 to 11 lbf-ft / 13 to 15 N-m.

QuickJack™ Portable Car Jack 25 P/N 5900959 — Rev. J1 — Dec. 2018

Page 26

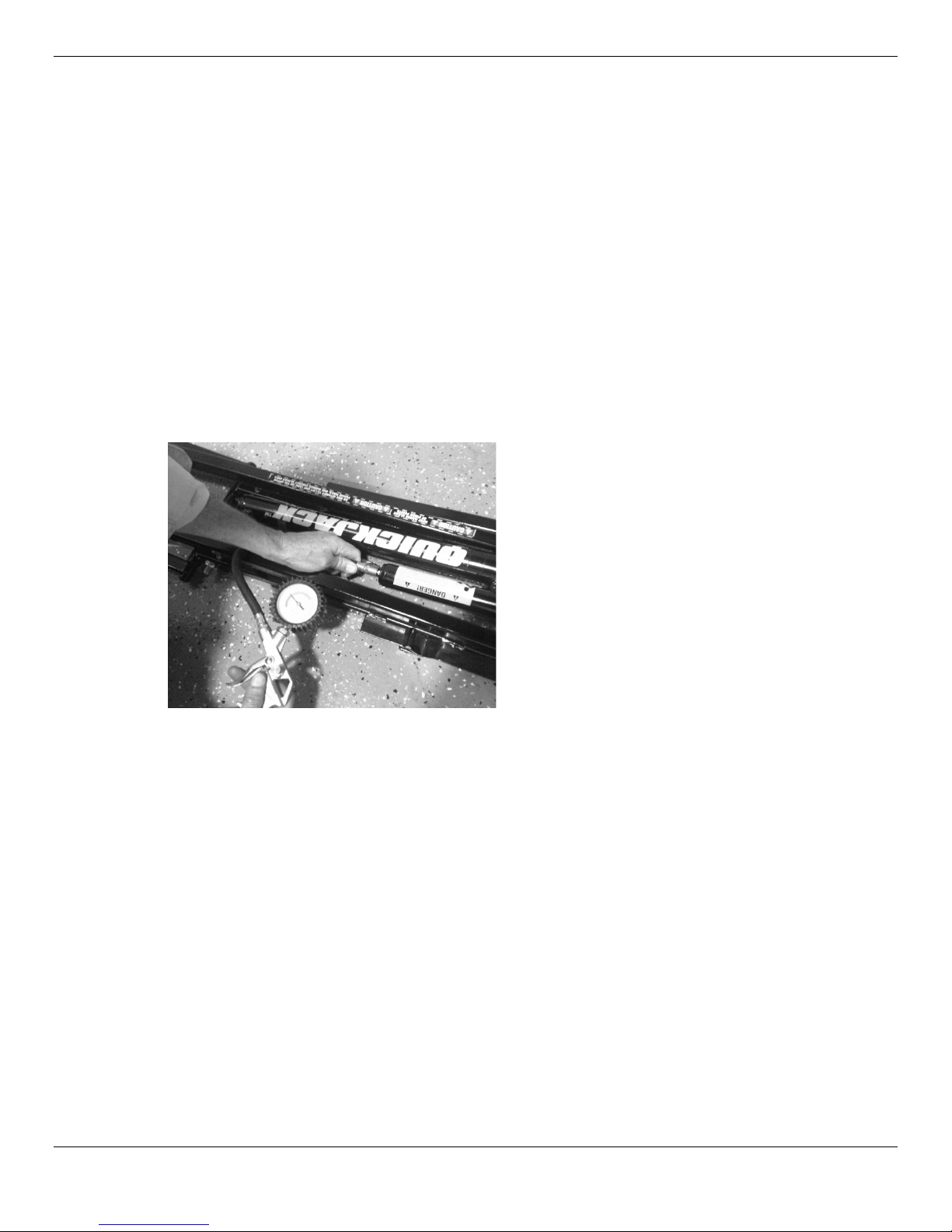

Pressurizing the Air Cylinders

The Air Cylinders (one on each QuickJack Frame) need to be pressurized before you can use your

QuickJack.

Air Cylinders help push the QuickJack Frames down.

Note that the valve stems on the Air Cylinders are installed at the factory.

Make sure the QuickJack Frames are fully lowered when you pressurize the Air Cylinders.

To pressurize the Air Cylinders:

1. Use a valve tool to release a short hiss of air to check the air inflation valve for proper operation and

to drain any accumulated oil.

Holding the valve open releases the air currently in the Air Cylinder.

2. Using a pump or air compressor, inflate the Air Cylinder to from 40 to 50 PSI / 2.75 to 3.4 BAR;

not exceed 50 PSI / 3.4 BAR

The JackPak accessory can also be used to pressurize the Air Cylinders.

3. When the pressure is between 40 and 50 PSI / 2.75 to 3.4 BAR, remove the pump or air

compressor.

.

⚠ WARNING Do not exceed 50 PSI / 3.4 BAR with the QuickJack Frames in the fully lowered

position, as there is a chance of explosion. Make sure to remove power and bleed

off air pressure before servicing.

do

4. Repeat Steps 1 through 3 for the other Air Cylinder.

QuickJack™ Portable Car Jack 26 P/N 5900959 — Rev. J1 — Dec. 2018

Page 27

Find a Location for the Power Unit

Your Power Unit must be located near the QuickJack Frames.

Note: Some Power Units come with a carrier and handle, some with just a handle. They work the

same.

Based on the combined length of the Short and Long Hydraulic Hoses, your Power Unit should be

about 10 to 12 feet away from your QuickJack Frames and out of the way of the Vehicles you will be

driving on to and off of the QuickJack.

Important: Do not drive vehicles

likely that they will leak.

⚠ WARNING

Risk of explosion

should not be exposed to flammable vapors. The Power Unit should be located at

least 460 mm (18 inches) above the floor.

on

the Hydraulic Hoses; this damages the hoses, making it more

. The QuickJack Power Unit has arcing or sparking parts that

Installing the Hydraulic Fittings on the Power Unit

Before you can connect your Power Unit to the Long Hydraulic Hose, you first need to install QuickConnect Fittings to the hydraulic ports on the front of the Power Unit.

Tip QuickJack recommends installing the bottom Power Unit Quick-Connect Fitting

first, then the top one. It is difficult to access the bottom fitting if you install the top

fitting first.

You usually only have to install these fittings once. To move your QuickJack later, just disconnect the

Power Unit from the Long Hydraulic Hoses using the Quick-Connect Fittings.

To connect Power Unit Quick-Connect Fittings to Power Unit hydraulic ports:

1. On the Power Unit, remove the plastic shipping plugs from the two hydraulic ports on the front.

2. Get a Power Unit Quick-Connect Fitting from the QuickJack Assembly Kit, insert the O-ring side

into one of the two hydraulic ports on the front of the Power Unit, then tighten to 11 to 12 lbf-ft /

14 to 16 N-m.

QuickJack recommends connecting the bottom hydraulic port first, then the top one.

Do not use Thread Seal Tape on the O-ring threads.

3. Repeat Step 2 for the second Quick-Connect Fitting on the Power Unit.

QuickJack™ Portable Car Jack 27 P/N 5900959 — Rev. J1 — Dec. 2018

Page 28

Connect the Power Unit to a Power Source

Your Power Unit must also be located near an appropriate power source.

Refer to the manufacturer’s information tag on your Power Unit for current and wattage information for

your specific unit.

Power Sources for VAC Power Units

If you are using a 110 or 220/240 VAC Power Unit with your QuickJack, connect it to an appropriate

power source.

110 VAC Power Unit

Drawing not necessarily to scale. Some Power Units may be slightly different.

220/240 VAC Power Unit

220 and 240 Power Units come with wiring for connection to a power source, but

You will need to have a certified Electrician connect the wiring to a plug appropriate for your location.

⚠ DANGER All wiring

done incorrectly, you could damage the QuickJack and/or cause serious injury.

must

be performed by a licensed, certified Electrician. If wiring the plug is

without a plug

.

Drawing not necessarily to scale. Some Power Units may be slightly different.

The wiring on the 220/240 VAC units uses the international wiring standard of Brown (hot), Blue

(neutral), and Green/Yellow (ground). In the United States, the corresponding wiring is Black (L1 hot),

Red (L2 hot), and Green or Green/Yellow (ground).

QuickJack™ Portable Car Jack 28 P/N 5900959 — Rev. J1 — Dec. 2018

Page 29

Power Sources for 12 VDC Power Units

If you are using a 12 VDC Power Unit with your QuickJack, you can connect it to a Vehicle battery.

Refer to Using the 12 VDC Power Unit for usage information.

12 VDC Power Unit

Drawing not necessarily to scale. Some Power Units may be slightly different.

Keep the following in mind:

• Connect your 12 VDC Power Unit directly to a 12-volt power source. The minimum requirement for

Jumper Cables is 7 gauge / 10 mm.

• Make sure to connect the 12 VDC

and the 12 VDC positive (red, +) power source to the positive (red, +) terminal.

• Remove all jewelry while working with the 12 VDC Power Unit.

negative

(black, –) source to the

negative

(black, –) terminal

QuickJack™ Portable Car Jack 29 P/N 5900959 — Rev. J1 — Dec. 2018

Page 30

Filling the Hydraulic Fluid Reservoir on the Power Unit

The Hydraulic Fluid Reservoir must be filled with Hydraulic Fluid or Automatic Transmission Fluid

before

you begin operation of the QuickJack.

When you receive it, the Fluid Reservoir is empty.

until it is filled with approved fluids.

⚠ CAUTION If you use the QuickJack

Power Unit.

Approved fluids are any general purpose ISO-32, ISO-46, or ISO-68 Hydraulic Fluid, approved

Automatic Transmission Fluids such as Dexron III, Dexron VI, Mercon V, Mercon LV, or any synthetic

multi-vehicle Automatic Transmission Fluid.

The fluid level should be approximately .5 inch (12 mm) below the Fill Hole when the QuickJack is fully

lowered. Note that the fluid level drops some after you start using the QuickJack; this is because some

fluid stays in the Hydraulic Hoses. If you notice that the fluid level has dropped more than a little, you

should fill it back up to half an inch below the Fill Hole (with the Frames on the ground).

Important: Do not completely fill the Fluid Reservoir while there is fluid in the hoses. If you do, the

reservoir could overflow when the fluid in the hoses returns (when you lower the

QuickJack Frames).

QuickJack recommends having a couple of rags nearby in case any fluid leaks.

To fill the Fluid Reservoir:

1. Remove the Reservoir Cap (if it has a Breather Valve they both come off together) from the Fill Hole

and put it down in a non-contaminated area.

without

fluid in the reservoir, you could damage the

The Power Unit will not work correctly

2. Fill the Fluid Reservoir with approximately 2.1 quarts / 2 liters of approved fluids (see above).

You want the fluid level about .5 inch (12 mm) below the Fill Hole with the QuickJack Frames

lowered.

Make sure the Funnel is clean; if there are contaminants on it, they could get into the Fluid

Reservoir.

3. Replace the Reservoir Cap in the Fill Hole and hand tighten it firmly.

QuickJack™ Portable Car Jack 30 P/N 5900959 — Rev. J1 — Dec. 2018

Page 31

Check the Breather Valve

If your Power Unit has a Reservoir Cap with a Breather Valve, you need to loosen the Breather Valve

before using the Power Unit. It ships tightened, so that no contaminants will get inside.

If your Power Unit has a Self-Venting Reservoir Cap (see drawing below), you do

To check the Breather Valve:

1. Determine what Breather Valve is on your Power Unit:

• Reservoir Cap, with Breather Valve. The Breather Valve comes from the factory

tightened. You must loosen it before you start using the Power Unit.

• Reservoir Cap, Self-Venting. There’s nothing to loosen; proceed to the next section.

not

need to loosen it.

⚠ CAUTION If you have a Reservoir Cap with a Breather Valve, you

turn counterclockwise before using the Power Unit. If you do not, the excess

pressure could damage the pump or cause the Fluid Reservoir to overflow.

2. To loosen a Breather Valve, turn it from one quarter to one half turn

This moves it to the open position, allowing air to move into and out of the Fluid Reservoir.

3. If you are going to move the Power Unit to a different location, tighten the Breather Valve before

you move it. This helps prevent fluid from leaking and contaminants from getting into the Fluid

Reservoir during transport.

Make sure to loosen the Breather Valve again

before

using the Power Unit at the new location.

must

loosen it about half a

counterclockwise

.

Connect All the Hydraulic Hoses

If you have not done so already, connect all of the Hydraulic Hoses:

• Short Hydraulic Hoses. Connect to the Hydraulic Cylinders on the QuickJack Frames on one

end and to the Long Hydraulic Hoses on the other end.

• Long Hydraulic Hoses. Connect to the Short Hydraulic Hoses on one end and to the QuickConnect Fittings on the front of the Power Unit on the other end.

The drawing in Unpacking shows the locations of the Hydraulic Hoses in relation to the QuickJack

Frames and the Power Unit.

QuickJack™ Portable Car Jack 31 P/N 5900959 — Rev. J1 — Dec. 2018

Page 32

Final Checklist Before Operation

Make sure these things have been done

• Review the Setup Checklist to make sure all steps have been performed.

• Make sure the Power Unit is getting power from the power source.

• Check the Hydraulic Fluid Reservoir; it must be full of approved Hydraulic Fluid or automatic

transmission fluid.

• Check the Hydraulic System for leaks.

• Make sure both Lock Bars are moving freely and in their tracks; make sure there are no

obstructions in the tracks.

You can harm the motor by running it without enough fluid.

before

using your QuickJack:

Test the QuickJack

Make a visual check of all components to make sure they are in good working order

Vehicle; do this

damage, or leakage; do not raise a Vehicle if the Quick-Connect Fittings are damaged or worn—you

must replace them.

Important:

⚠ WARNING

every time

Only raise the QuickJack Frames with a Vehicle on them

Frames are engineered and designed to support the weight of a Vehicle; they can

occasionally get stuck at full height if there is no Vehicle on them.

When raising or lowering a QuickJack, pay attention!

issue is lack of Operator attention; for example, do not be looking at a smartphone

while raising or lowering the QuickJack. It is your responsibility to pay attention; if

you do not, you could damage the QuickJack or the Vehicle on it and/or injure

people near it.

you use your QuickJack. Check the Quick-Connect Fittings for wear,

prior

to raising a

. The QuickJack

A common safety

Refer to Raising the QuickJack Frames for detailed information about raising the QuickJack

Frames and engaging the QuickJack on a locking position.

To test your QuickJack:

1. Place the QuickJack Frames in the desired location with

2. Check both Lock Bars and all of the Hydraulic Hoses.

The Lock Bars must be on the able to move freely along the bottom of their Channels; they must

not come up out of their Channels when you raise the Frames (if they do, the most likely problem is

that the Lock Bar Bolt is over-tightened). The Hydraulic Hoses must all be connected.

3. Make sure the Power Unit has been set up correctly and is connected to a power source.

The Power Unit fluid reservoir must have 2.1 quarts/2 liters of approved fluid. Use Dexron III,

Dexron VI, Mercon V, Mercon LV or comparable.

The fluid level should be approximately .5 inch (12 mm) below the fill hole.

Important: If you do not put enough Hydraulic Fluid in the reservoir, the QuickJack may start to

rise but will slow and then stop when the reservoir is out of fluid. To fix this, lower

the QuickJack Frames back down to the ground and then add additional fluid to

the reservoir. Fill it to approximately .5 inch (12 mm) below the Fill Hole.

4. Check the pressure in the Air Cylinders; they should register from 40 to 50 PSI (2.75 to 3.4 BAR).

Do

not

exceed 50 PSI / 3.4 BAR.

both Lock Bars on the outside

.

QuickJack™ Portable Car Jack 32 P/N 5900959 — Rev. J1 — Dec. 2018

Page 33

5. Put a Vehicle into place.

6. Position the Lift Blocks in the Receiver Trays for the Vehicle you are going to raise.

Be sure to use the factory-recommended Lifting Points for the Vehicle.

7. Press Up on the Pendant Control for a couple of seconds.

After a few seconds, the QuickJack Frames will start moving up. As this is the first use, it takes a

couple of seconds for the Hydraulic Hoses to fill with fluid.

If the QuickJack Frames do not move, make sure the Power Unit is connected to an appropriate

power source, make sure the Hydraulic Hoses are connected to the Power Unit, and make sure

there is sufficient Hydraulic Fluid in the reservoir. If you find any of these issues, fix them and then

try again. If the Frames still do not move, refer to Troubleshooting.

8. Just

9. Press Up to raise the Frames to just past the First Locking Position, then press Down for a

before

The Frames stop moving.

Check the locations where the Lift Blocks will hit the Lifting Points. If necessary, adjust the Lift

Blocks so they are properly positioned (you may need to lower the Vehicle to adjust them).

second or two.

the Frames make contact with the Lifting Points on the Vehicle, release Up.

⚠ WARNING If one Frame goes up faster than the other with the weight of a Vehicle on it, this is

a safety hazard. Release Up immediately and then press Down to lower the

Vehicle back down to the ground. Wait a minute and then try again. If the issue

continues, refer to Troubleshooting.

The Lock Bar will lock at the First Locking Position and the Frames will stop moving.

10. With the QuickJack engaged on the First Locking Position, check all Hydraulic Hose connections

for leaks. If you find any, tighten the leaking connection and wipe up the fluid.

If the motor gets hot or sounds irregular, check the Power Unit and all electrical connections.

11. Carefully rock the Vehicle to test its stability.

If the Vehicle seems stable, the QuickJack is ready for normal operation.

If the Vehicle does

Lift Blocks in the Receiver Trays.

not

seem stable, lower it back to the ground and check the positioning of the

12. If everything appears to be working normally, lower the QuickJack Frames back down to the

ground. To do this: press Up for a second or two so that the Lock Bars go past the Lock Blocks,

then press Down until the Lock Bars lower past the Lock Blocks.

When the Frames get to the ground, hold Down for another ~5 seconds so that the Hydraulic

Fluid returns to the reservoir.

If there are issues you cannot resolve, stop using the QuickJack, then refer to Troubleshooting,

or call QuickJack at (888) 262-3880 or (805) 933-9970.

Leave the Manual with the Owner/Operator

Make sure to leave the Setup and Operation Manual with the owner/operator so that it is available to

everyone who is going to use the QuickJack.

QuickJack™ Portable Car Jack 33 P/N 5900959 — Rev. J1 — Dec. 2018

Page 34

Operation

This section describes how to operate your QuickJack.

This manual must delivered to the owner/user/employer and be kept near the QuickJack.

QuickJack recommends using Vehicle Lifting Points for Frame-Engaging Lifts for proper positioning of

Vehicles on your QuickJack. It shows the factory-recommended Lifting Points for a wide variety of

Vehicles. It was supplied with your QuickJack.

QuickJack also recommends SAE Standard J2184, Vehicle Lift Points for Service Garage Lifting, as a

resource to assist you in the proper positioning of a Vehicle for raising.

⚠ WARNING Make sure to properly position each Vehicle on its Lifting Points. Improper

Safety

Before you raise or lower a Vehicle using your QuickJack:

• Check the QuickJack. Check the QuickJack Frames for any missing, heavily worn, or

damaged parts. Make sure the Lift Blocks are in their Receiver Trays. Do not operate the

QuickJack if you find any issues; instead, stop using it, then visit quickjack.com/support, email

support@quickjack.com, or call (888) 262-3880.

• Check the area. Check the area around the QuickJack for obstructions; anything that might

impact the raising or lowering of the Vehicle. Do not forget to check

find an obstruction, move it out of the way. Do not allow unauthorized people, children, or animals

near the QuickJack while it is being used.

• Check the operators. Make sure everyone who is going to operate the QuickJack has been

trained in its use, has read the labels on the unit, is not under the influence of drugs or alcohol, and

has read the manual.

positioning of a Vehicle could lead to it being unstable and potentially falling off the

QuickJack. This could damage the Vehicle, damage the QuickJack, and potentially

injure anyone nearby.

above

the QuickJack. If you

⚠ WARNING

• Check for safety. Make sure everyone who is going to be walking near the QuickJack is aware

of its presence and takes appropriate safety measures.

leave the QuickJack engaged on a locking position

not leave it until it is on the ground.

Do not work under an elevated Vehicle unless properly rated Vehicle Jack Stands are in place

under the factory-recommended Lifting Points.

⚠ WARNING

• Check the Vehicle. Never exceed the QuickJack’s weight rating. Do not allow people inside a

Vehicle you are raising. Make sure the Vehicle is not overbalanced on either end. You must use the

factory-recommended Lifting Points for the Vehicle. Never raise just one side, one corner, or one

end of a Vehicle.

QuickJack™ Portable Car Jack 34 P/N 5900959 — Rev. J1 — Dec. 2018

When raising or lowering a QuickJack, the Operator must pay

attention!

must

A common safety issue is lack of attention; for example, Operators

not

be looking at a smartphone.

When raising a Vehicle, always

. When lowering the QuickJack, do

Risk of explosion

should not be exposed to flammable vapors. The Power Unit should be located at

least 460 mm (18 inches) above the floor.

. The QuickJack Power Unit has arcing or sparking parts that

Page 35

About Lift Blocks

When raising a Vehicle with your QuickJack, the Vehicle should not touch the QuickJack Frames.

Instead, they should touch the Lift Blocks that are sitting in the QuickJack’s Receiver Trays.

There are three types of Lift Blocks available:

• Medium/Tall. Four Medium and four Tall Lift Blocks are included with each QuickJack. You can

stack one Medium on one Tall, but no more than that.

• Pinch Weld. Ideal for raising Vehicles by their pinch welds. Separate purchase.

• SUV and Light Truck Adapter. Each set includes four round Contact Pads, four Extenders,

and four Bases. Perfect for Vehicles with high ground clearance or non-standard Lifting Points.

Separate purchase.

⚠ CAUTION Do not raise a Vehicle on the QuickJack Frames; always use Lift Blocks, Pinch-

Weld Blocks, or SUV and Light Truck Adapters in the Receiver Trays. Raising a

Vehicle on the Frames could damage the Vehicle and/or damage the QuickJack.

Drawing not necessarily to scale. Not all components shown.

QuickJack™ Portable Car Jack 35 P/N 5900959 — Rev. J1 — Dec. 2018

Page 36

Special QuickJack Warnings

There are two special cases with QuickJack of which you need to be aware:

• Do not raise QuickJack Frames without a Vehicle on them. QuickJack Frames are

designed and engineered to be used with the weight of a Vehicle on them. You should only raise

the QuickJack Frames with the weight of a Vehicle on them,

. There is simply no reason to raise your QuickJack Frames unless there’s a Vehicle on them.

them

QuickJack Frames can occasionally get stuck in a raised position if you raise them without the

weight of a Vehicle. There is nothing wrong with them if this happens, and the issue can be quickly

and easily fixed, it’s just that they are designed and engineered to work with the weight of a

Vehicle.

• Do not try to raise a load at no net rise. Your QuickJack requires some space between the

ground and your Vehicle to build up enough pressure to raise a load. It cannot raise a full load from

a completely flat starting position, as shown below.

This is not a problem in normal operation, as the Vehicles you want to raise are being held well

above the ground by their tires. The problem happens if you lower the QuickJack to a completely

flat position when the Vehicle’s tires are removed.

Only raise your QuickJack Frames with a Vehicle on them

even the very first time you use

.

⚠ WARNING This image shows the QuickJack Frames at a completely flat position holding a

Vehicle with no tires. Do not do this; the QuickJack will not be able to raise the

weight of the Vehicle under these circumstances. If this happens to you, refer to

Troubleshooting, visit quickjack.com/support, or send email to

support@quickjack.com for instructions.

QuickJack™ Portable Car Jack 36 P/N 5900959 — Rev. J1 — Dec. 2018

Page 37

Positioning the Lift Blocks and Frames

⚠ WARNING Always position the two QuickJack Frames as close to parallel as the Lifting Points

of the Vehicle allow; load stability can be compromised if they are too far off from

parallel.

There are two methods for positioning your QuickJack Frames:

• Outside in: Drive the Vehicle to the desired location, position the QuickJack Frames

Vehicle on different sides and between the wheels. If the distance between the wheels is not long

enough to accommodate the length of the QuickJack Frames, turn the Frames and push one end

under the Vehicle first, then the other end. Quick Frame Handles are typically not required. Make

not

sure

under the Vehicle when ready.

• Inside out: Position the QuickJack Frames next to each other, drive the Vehicle above the

Frames, then use your Quick Frame Handles to pull each Frame out to the desired location under

the Vehicle based on the factory-recommended Lifting Points. Make sure

QuickJack’s Hydraulic Hoses.

to drive on the QuickJack’s Hydraulic Hoses. Slide each Frame to the desired location

Make sure each Lock Bar is on the outside

not

to drive on the

Make sure each Lock Bar is on the outside

outside

.

.

⚠ CAUTION Before positioning QuickJack Frames, make sure they are both fully lowered and

that your working area is clear of obstructions. Also, make sure the Vehicle you will

be raising is neither rear or front heavy, which throws off its balance.

To position the QuickJack Frames:

1. Determine the desired method for positioning your QuickJack Frames.

2. Position the Lift Blocks, Pinch-Weld Blocks, or SUV and Light Truck Adapters in the Receiver

Trays.

Note: You can stack one Medium and one Tall Lift Block together, but not more than that.

⚠ CAUTION Do not raise any load on the Frames alone;

Blocks, or the SUV and Light Truck Adapters in the Receiver Trays.

always

use Lift Blocks, Pinch-Weld

the

3. Move the QuickJack Frames to the appropriate locations, based on positioning method.

4. If you are using the Inside out method, drive the Vehicle above the Frames.

5. Move the QuickJack Frames to the correct locations under the Vehicle based on the factoryrecommended Lifting Points.

⚠ WARNING If you do not know the factory-recommended Lifting Points for the Vehicle you are

raising, consult Vehicle Lifting Points for Frame-Engaging Lifts, supplied with your

QuickJack, and SAE Standard J2184, Vehicle Lift Points for Service Garage Lifting,

as a resource to assist you in the proper positioning of a Vehicle for raising. If the

Vehicle has an additional or uniquely positioned payload, have a qualified person

calculate the Vehicle center of gravity or have the Vehicle center of gravity

determined at a Vehicle scale.

6. Adjust the Lift Blocks in the Receiver Trays so that they are directly underneath the factory-

recommended Lifting Points for the Vehicle you are raising.

The QuickJack Frames and Lift Blocks are now positioned correctly for raising a Vehicle.

QuickJack™ Portable Car Jack 37 P/N 5900959 — Rev. J1 — Dec. 2018

Page 38

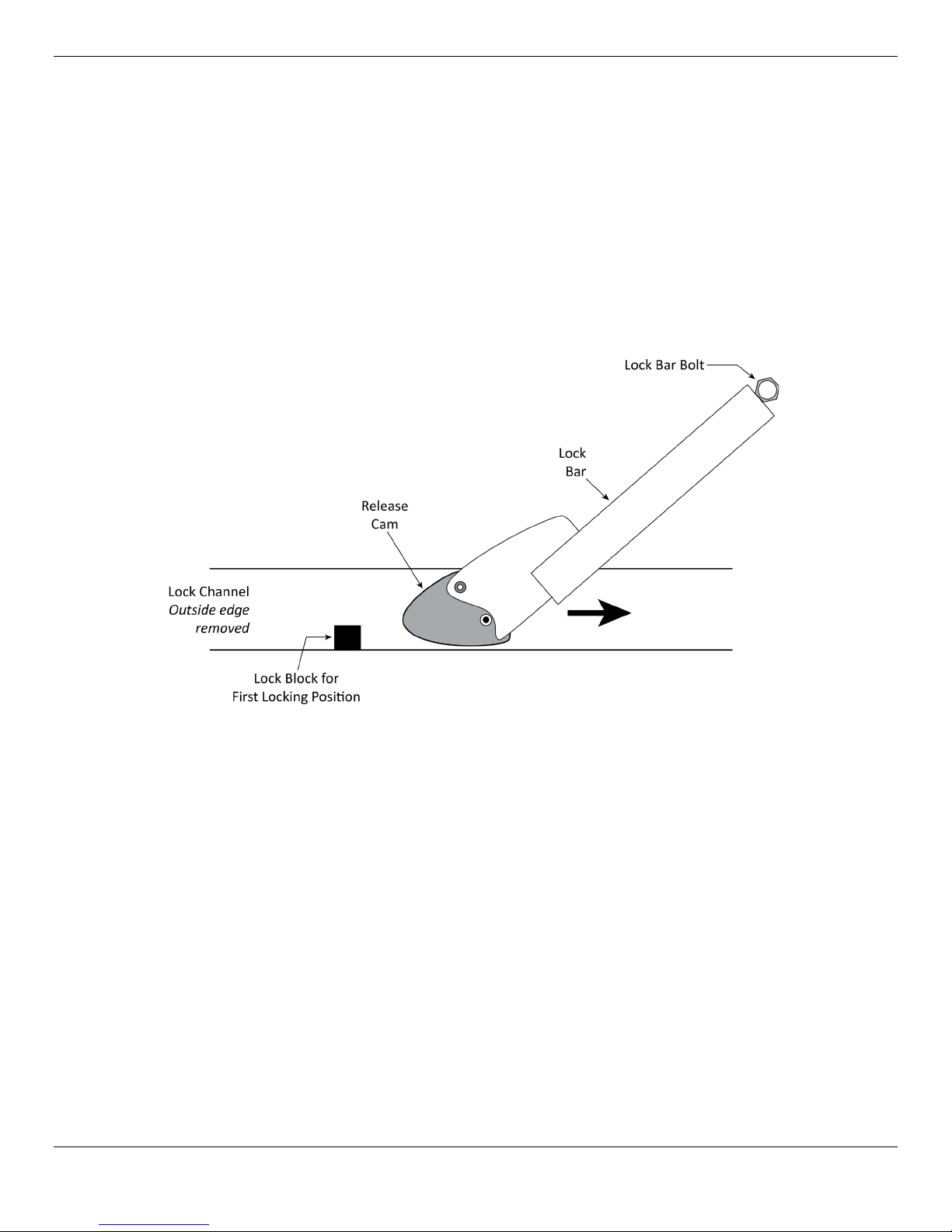

Raising the QuickJack Frames

QuickJack Frames have two locking positions, called First Locking Position and Top Locking Position.

When you raise the QuickJack Frames, always engage (lock) the Frames on either the First Locking

Position or the Top Locking Position, or lower them back down to the ground.

⚠ WARNING Do not raise a Vehicle unless the QuickJack Frames are properly positioned under

the Vehicle, the Frames are as close to parallel as possible, all personnel are a

sufficient distance away from the Vehicle, both Lock Bars are on the outside, there

is open space on all sides and above the Vehicle, and the operator is paying

attention (the operator must maintain visual contact with the Vehicle and the

surrounding area while raising or lowering the QuickJack Frames).

To raise a Vehicle:

1. Position the Lift Blocks, Pinch-Weld Blocks, or SUV and Light Truck Adapters in the Receiver

Trays.

Note: You can stack one Medium Lift Block on one Tall Lift Block, but

Do not stack Lift Blocks on Pinch-Weld Blocks or SUV and Light Truck Adapters.

⚠ CAUTION Do not raise any load on the Frames alone;

Blocks, or the SUV and Light Truck Adapters in the Receiver Trays.

2. Move the QuickJack Frames to the appropriate locations, based on positioning method.

3. If you are using the Inside out method, drive the Vehicle over the Frames.

4. Move the QuickJack Frames to the correct locations under the Vehicle based on the factoryrecommended Lifting Points.

always

use Lift Blocks, Pinch-Weld

not more than that

⚠ WARNING If you do not know the factory-recommended Lifting Points for the Vehicle you are

raising, consult Vehicle Lifting Points for Frame-Engaging Lifts, supplied with your

QuickJack, and SAE Standard J2184, Vehicle Lift Points for Service Garage Lifting,

as a resource to assist you in the proper positioning of a Vehicle for raising. If the

Vehicle has an additional or uniquely positioned payload, have a qualified person

calculate the Vehicle center of gravity or have the Vehicle center of gravity

determined at a Vehicle scale.

5. Adjust the Lift Blocks in the Receiver Trays so that they are directly underneath the factory-

recommended Lifting Points for the Vehicle you are raising.

6. Check both Lock Bars; raise them up and let them drop.

.

Not necessarily to scale. Not all components shown. Left side shows Lock Bar moving freely in

Lock Channel, right side shows Lock Bar stuck up in air, which

QuickJack™ Portable Car Jack 38 P/N 5900959 — Rev. J1 — Dec. 2018

must

be corrected.

Page 39

If the Lock Bar Bolt is too tight, it does not allow the Lock Bar to move freely in the Lock Channel.

This is a safety issue

moving freely in its Lock Channel. If the Lock Bar moves up with the Vehicle as it is raised (as

shown above on the right), it cannot lock.

; the QuickJack locks cannot be engaged unless each Lock Bar is

⚠ WARNING The Lock Bar

QuickJack cannot be put into a safe, locked position.

To fix an overtight Lock Bar Bolt, loosen the Lock Bar Bolt until the Lock Bar moves freely and

stays in the Lock Channel (as shown above, on the left).

7. Walk around the Vehicle and the QuickJack Frames; make sure everything is set up correctly.

8. Press and hold Up on the Pendant Control.

The QuickJack Frames start going up.

9. Just

10. After confirming the Lift Blocks are properly positioned, press Up on the Pendant Control.

before

Check the locations where the Lift Blocks will hit the factory-recommended Lifting Points on the

Vehicle. If necessary, adjust the Lift Blocks so that they are properly positioned (you may need to

lower the Vehicle some to adjust the Lift Blocks).

The QuickJack Frames start going up and the Lift Blocks hit the Vehicle’s Lifting Points.

the Frames make contact with the Vehicle, release Up. The Frames stop moving.

must

be moving freely in the Lock Channel. If it is not, the

⚠ WARNING Do not stop raising the Frames until you have passed the First Locking Position.

11. Stop raising the QuickJack Frames just past the First Locking Position (even if you eventually want

them on the Top Locking Position).

12. Make sure both Lock Bars are moving freely in their respective Lock Channels.

13. Make sure all Lift Blocks are still in contact with the factory-recommended Lifting Points.

If the Lift Blocks

If the Lift Blocks are

return the Vehicle to the ground, then make the necessary adjustments.

14. Rock the Vehicle gently to test for stability.

If the Vehicle is stable, press Up to continue raising the QuickJack Frames.

If the Vehicle is

the necessary adjustments.

15. To engage the QuickJack on the First Locking Position, press Down to lower the Frames until

they lock.

16. To engage the QuickJack on the Top Locking Position, press Up until you go just past the Top

Locking Position.

17. When you have gone just past the desired locking position, press Down on the Pendant Control

to lower the Frames onto the locking position. The Frames will stop moving down when they lock.

18. Release Down.

are

in the right positions, continue with raising the QuickJack Frames.

not

in the right positions, press Down on the Pendant Control and carefully

not

stable, press Down to

carefully

return the Vehicle to the ground, then make

QuickJack™ Portable Car Jack 39 P/N 5900959 — Rev. J1 — Dec. 2018

Page 40

19. Visually check to make sure both QuickJack Frames are engaged on the same locking position.

Not necessarily to scale. Not all components shown. Shows Release Cam and Lock Bar in Locked

Position.

⚠ WARNING Before doing anything else (like starting work on the Vehicle or leaving the area),

visually confirm

and that all Lift Blocks are in contact with the factory-recommended Lifting Points

of the Vehicle.

You can work on your Vehicle once you have visually confirmed that both Frames are engaged on the

same locking position and that all Lift Blocks are in contact with the Vehicle at the factoryrecommended Lifting Points.

that

both

QuickJack Frames are on the same locking positions

⚠ WARNING Do not work under an elevated Vehicle unless properly rated Vehicle Jack Stands in

place at the factory-recommended Lifting Points.

QuickJack™ Portable Car Jack 40 P/N 5900959 — Rev. J1 — Dec. 2018

Page 41

Lowering the Frames from the First Locking Position

Lowering the QuickJack’s Frames from the First Locking Position is different from lowering them from

the Top Locking Position, so it is described separately.

⚠ WARNING When lowering QuickJack Frames, make sure the Lock Bar and the Release Cam

stay in their Lock Channel. If they get knocked sideways they can get stuck on the

rail of the Lock Channel, which results in the QuickJack not lowering correctly.

To lower QuickJack Frames from the First Locking Position:

1. Press and hold Up on the Pendant Control just until the Release Cam clears the Lock Block, then

release Up.

The Release Cam / Lock Bar moves away from the Lock Block towards the Top Locking Position.

Not necessarily to scale. Not all components shown. Release Cam and the Lock Bar shown

moving off of the First Locking Position towards the Top Locking Position.

2. When the Release Cam and Lock Bar are clear of the Lock Block, press and hold Down until both

QuickJack Frames lower to the ground.

The Release Cam moves the Lock Bar over the Lock Block.

Note: If the Lock Bar locks again on the Lock Block, try again, going up a little bit further this

time. What you want is for the Release Cam to be in the Down position, as shown in the

drawing above.

QuickJack™ Portable Car Jack 41 P/N 5900959 — Rev. J1 — Dec. 2018

Page 42

Do not lower the Release Cam / Lock Bar if the Release Cam is in the Up

position