Page 1

TEC - Controller QC-PC-C01C

Manual

Temperaturecontroller for Cooling

Scope of delivery:

1 TEC - Controller QC-PC-C01C

1 Temperaturesensor NTC 10KΩ (β=3977K)

1 Potentiometer 10KΩ

1 Manual

Technial Data:

Dimensions: 65mm x 50mm x 20mm

Temperature range: -20°C…+50°C

Input voltage: 10V…24V

Max. output voltage: equal to input voltage

Max. output current: 10A

1. Basic information QC-PC-C01C

The QC-PC-C01C was designed as controller for cooling to adjust a TEC (Thermoelectric coller)

at a certain temperature. The controller is operated by low DC voltage and should not be exposed

to main voltage. To set up the controller electrical wiring is required, which request some basic

knowledge of electrical circuits. All wiring must be done without connection to the power supply.

Be aware that same components can be damaged or destroyed be incorrect use. Despite of low

voltage, high currents can occur and serious warming and the danger of fire can appear by using

wrong lead wires. Please read this instruction carefully and consult an electrician by any question.

If you remark any warming during operation, the controller must be switched off immediately.

Quick-Ohm Küpper & Co. GmbH

Components – Heat-Management - Ceramics

www.quick-ohm.com vXIII/07/nk

- 1 -

Page 2

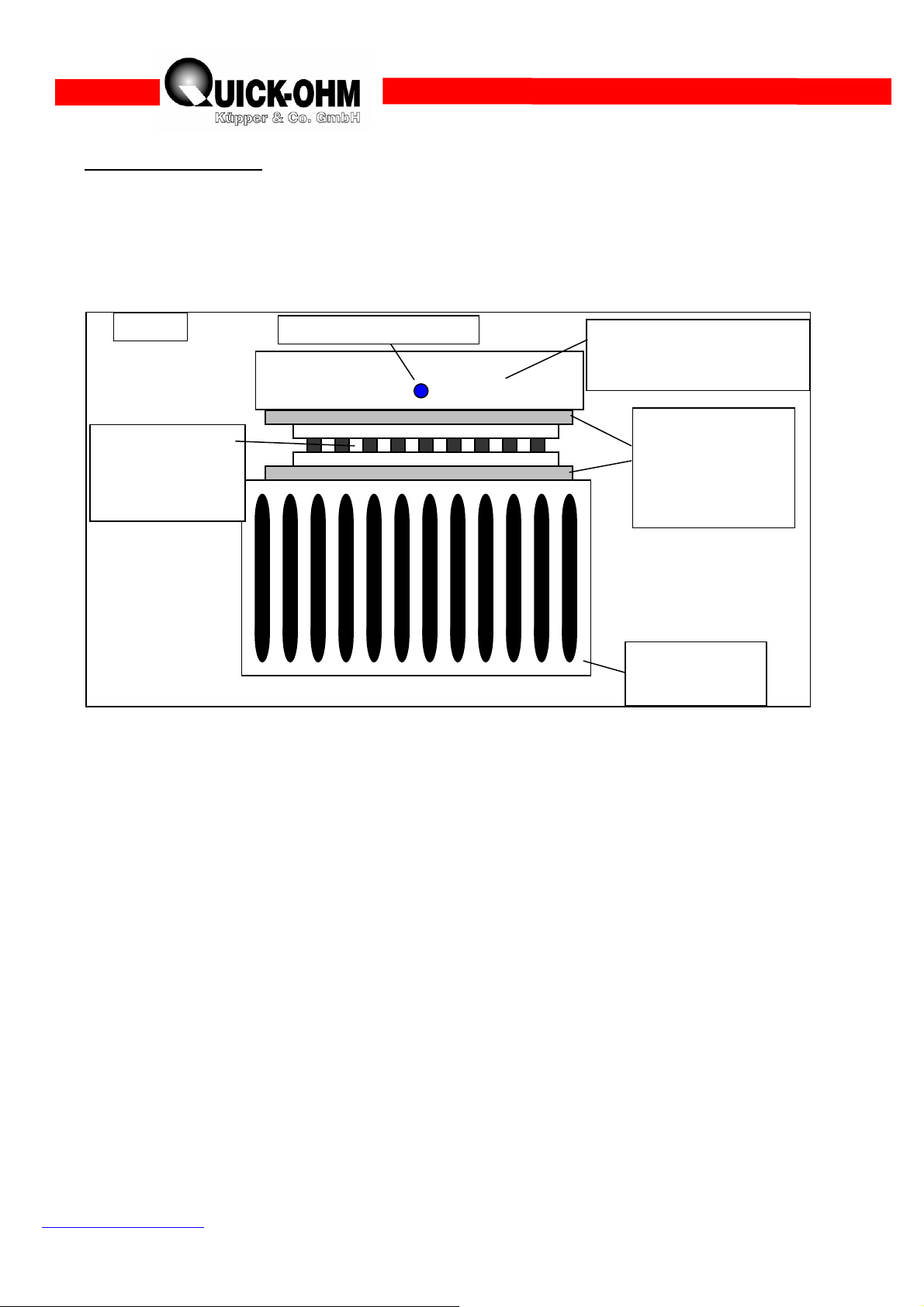

2. Operating principle:

Temperatur

e

sensor

A TEC is able to transfer thermal power from one side of the module to the other by consuming

electrical power. The temperature drops on one side of the element, because of heat consumption

while it rises on the other side. For using this heatpump effect in a technical application, a setup

similar to figure 1 is to be built up.

figure 1:

Temp. controlled

area/ cold side

Thermal

TEC

(printing on

upper side)

conductive

(Paste, Foil,

etc.)

Heatsink/ hot

side

This is the basic setup for any TEC-Application. The area to be temperature controlled must be

equipped with a temperature sensor. On the opposite side, the removed heat must be dissipated to

the ambient. The size of the heatsink and the quality of the thermal contact to the TEC has the

biggest influence on the performance of the whole system. The gap between the TEC and the

mounted parts (hot/cold side) must be as small as possible and only a very little amount auf

thermal conductive should be used to avoid air inclusions in the contact areas. For further

information such as mechanical loads for a durable setup visit our website www.quick-ohm.com.

Quick-Ohm Küpper & Co. GmbH

Components – Heat-Management - Ceramics

www.quick-ohm.com vXIII/07/nk

- 2 -

Page 3

3. Electrical connection:

Potentiometer 10K

Ω

For operating the controller a DC power supply is needed. Please be aware that the controller has

no internal voltage or current limits and therefore will output the maximum voltage of the power

supply when the set-temperature is much lower than the actual temperature. Make sure, that the

maximum voltage of the power supply is within the range of the TEC. A series connection of

similar TECs can also be used to reduce the voltage for each TEC. Figure 2 shows the electrical

connection of the whole circuit, the colors follow the lead colors of the controller.

figure 2:

Controller

QC-PC-C01C

Orange

10..24V

Black

GND

+ -

Power supply

Blue

-PE

TEC

Yellow

Green

Grey

Red

Sensor

+PE

Signal

Temperatur-

Gnd

Sens/Poti

Control

Poti-Signal

Sensor

NTC 10KΩ

White

+5V Poti

10V … 24V

By following these instructions and using TECs from QUICK-OHM, the top side of the TEC will

get cold when the right wire showing in the direction of the viewer is red. Applied on the figure

above, the top side would be the warm side.

4. Temperature setting:

The controller has a working range from -20°C to + 50°C. Please notice, that the controller can

only be operated in cooling mode. 50°C can only be reached, when the hot side is above this

temperature. It could be useful to make marks on the potentiometer while the first use. By

adjusting some positions between the left and right stop of the potentiometer and while measuring

the temperature at that steps a small scale can be marked on the potentiometer.

It is possible to integrate a Display (QC-PC-D-100) in the setup. This device shows the settemperature as well as the actual temperature.

Quick-Ohm Küpper & Co. GmbH

Components – Heat-Management - Ceramics

www.quick-ohm.com vXIII/07/nk

- 3 -

Page 4

Controlling characteristics:

The following figures show a typical control mode of the temperature as function of time. In this

example, the set-temperature is lowered from ambient temperature to -15°C. The left figure shows

the current, the right figure the temperature. This shows an optimal behavior of the controller.

Stromverlauf Kühlen

Current while cooling

Temperaturv erlauf Kühlen

Temperature while cooling

120

100

80

60

urrent in %of Imax

Strom/100%xImax

40

20

0

1 3 5 7 9 11 13 15 17 19 21 2 3 25 27 29

Zeit

time in s time in s

50

30

10

1 3 5 7 9 11 13 15 17 19 21 23 25 27 29

Temperatur/°C

emperature in °C

-10

-30

-50

Zeit

5.Tips:

1. If the heatsink temperature is roughly above ambient temperature, the dimensions of the

heatsink are too small. A bigger heatsink and/or a fan can increase the heatexchange between the

heatsink ans te ambient.

2. The lowest temperature a single stage TEC can reach is around 70K below the temperature of

the hot side. Please regard that the temperature of the heatsink is always lower than the

temperature of the hot side because of the thermal resistance of the gap.

3. Mount the temperature for the controller close as possible to the TEC to improve the control

mode.

4. The heatsink must be able to dissipate the sum of cooling and electrical power as thermal

energy.

Quick-Ohm Küpper & Co. GmbH

Components – Heat-Management - Ceramics

www.quick-ohm.com vXIII/07/nk

- 4 -

Loading...

Loading...