Page 1

880000 AAmmpp BBoooosstteerr CCllaammppss

Booster Clamps

CCaabbllee AAsssseemmbbllyy aanndd SSaaffeettyy IInnssttrruuccttiioonnss

How to Make Booster Cables Using

800 Amp Booster Clamps

These instructions are designed for the professional mechanic who

wishes to make or repair a set of booster cables using 800 amp booster

clamps, Nos. 602070-002, 602071-001 and 602072-001.

These booster clamps can be used with 1, 1/0, 2/0, and 3/0 gauge

cable. The gauge of the cable you select is dependent on two factors, the

length of your booster cable and the amperage draw of the equipment

you are jump-starting.

Once you have selected the cable gauge, then you know which No.

4800 series heavy wall copper lugs you should use. These booster clamps

are made to be used with 1, 1/0, 2/0, or 3/0 gauge heavy wall copper lugs. The lugs are

clamps; they should be purchased separately. See #6 page 2

1. No. 602070-002 booster clamp kits contain the following:

not included with the booster

No. 602071-001 Kit

1 – 800 amp Solid Copper Clamp

2 – 3-3/4” (95mm) Handle Grip Tube - Black

1 – 5/16” - 18 x 5/8” Round Head Screw

1 – 5/16” - 18 Hex Nut

1 – 800 amp Solid Copper Clamp

2 – 3-3/4” (95mm) Handle Grip Tube - Red

1 – 5/16” - 18 x 5/8” Round Head Screw

1 – 5/16” - 18 Hex Nut

No. 602072-001 Kit

No. 602070-002 Kit

2 – 800 amp Solid Copper Clamp

2 – 3-3/4” (95mm) Handle Grip Tube - Red

2 – 3-3/4” (95mm) Handle Grip Tube - Black

2 – 5/16” - 18 x 5/8” Round Head Screw

2 – 5/16” - 18 Hex Nut

Items not included in the booster cable kit: copper cable and heavy wall copper lugs.

Cut cable to the length of the booster cables you desire. This cable should either be twin conductor or two separate

2.

conductors, one for the positive and one for the negative. We strongly recommend finely stranded welding-type

cable, with a neoprene or synthetic rubber insulation, as this will remain flexible in cold weather and give you maximum conductivity. See #5 (page 2)

3. Red for Positive, Black for Negative. Use red insulated or red marked cable for the positive booster cable and use

black insulated cable for the negative booster cable.

4. Length and Gauge. Generally, the longer the booster cables, the larger the gauge cable you need to use. Likewise,

the larger the displacement of the engine you are jump-starting, the larger the gauge cable you should use. If you

expect to use the booster cables in very cold conditions, where the temperature may be below 0° F or –20° C, use a

large gauge cable, as batteries will not be operating at their peak capability.

Battery Efficiency and Starting Power Requirements Depend on Temperature

Temperature

Degrees F

80° F

Temperature

Degrees C

26° C

Starting Power

Available from Battery

100 %

Starting Power

Required by Engine

100 %

32° F

0° F

-20° F

0° C

-20° C

-29° C

65 %

40 %

18 %

155 %

210 %

268 %

Page 2

. Guideline for Cable Gauge. For the proper gauge booster cable for your vehicle, please check your owner’s manual.

5

If this information is not available, use the following as a guideline. Important: the gauge size of your booster cables

should be larger than the largest and longest cable in your vehicle.

able Carrying Capacities

C

25’ (7.6M) Booster Cables

For Intermittent Duty

Only (Not Continuous Duty)

Copper Cable

auge

G

1 Gauge

1/0 Gauge

2/0 Gauge

3/0 Gauge

Note: For longer booster cables, increase the gauge of the cable.

Made of

elding Cable

W

Up to 400 Amps

500 Amps

600 Amps

700 Amps

Made of

attery Cable

B

300 Amps

325 Amps

375 Amps

425 Amps

ypical Vehicle

T

Full-size Car or Van

Light Truck, Light Construction, Small Tractor

Tractor, Truck, Bus, Construction

HD Tractor, Off Highway

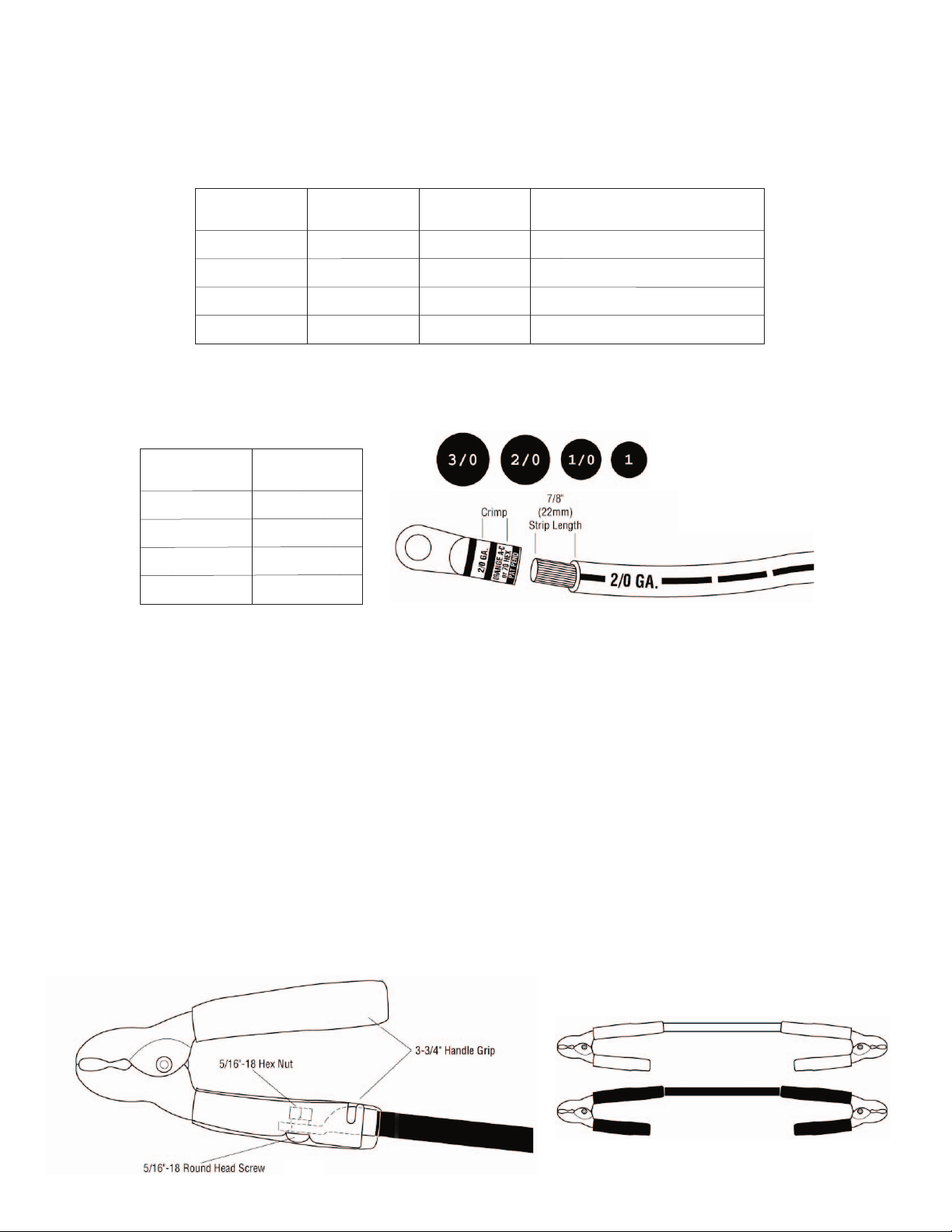

6. Heavy Wall Copper Lugs. Based on cable selected, use the appropriate heavy wall copper lugs below One lug is

required for one booster clamp. Four lugs are required for the typical set of booster cables. (The part numbers below

are for a box with five lugs.)

The size bullets (left) will help

ou determine the gauge (size)

Part Number

4801-005F

4810-005F

4820-005F

4830-005F

Fits Cable Gauge

1 Gauge

1/0 Gauge

2/0 Gauge

3/0 Gauge

y

f an unmarked cable.

o

easure the bare conductor

M

only, not the insulation. Actual

diameters vary depending on the

pecific stranding of the wire.

s

Fig. 1

7. Slide the handle grip onto and away from the end. Strip 7/8” to 1” (22 - 25 mm) of insulation from end of cable.

Insert bared wires into barrel of lug. Crimp lug on to cable. Use two crimps on barrel for best connection. See

Figure 1.

8. One handle of the booster clamp is formed so that the heavy wall lugs will nest inside. Bolt the lug into place

according to Figure 2.

9. Slide the 3-3/4" (95mm) handle grip down over the handle and lug, according to Figure 2.

The handle grip tube will seal the cable, reducing corrosion, and it will also act as a strain relief for the cable, extending the life of your booster cable.

10. Push the other handle grip onto the other handle. Make certain the grips are the same color on both handles. See

Figure 2.

For a typical set of booster cables, install a second clamp on the other end of the cable. Make certain the same color

11.

handle grip is used for both clamps on the same length of cable. Use black grips for the negative booster cable. Use

red grips for the positive cable. See Figure 3.

Fig. 2

Fig. 3

Page 3

SSaaffee UUssee ooff BBoooosstteerr CCllaammppss aanndd CCaabbllees

1. Follow instructions in the owner’s manual for your vehicle when jump-starting your vehicle.

2. If you don’t understand instructions for jump-starting, don’t attempt the procedure. Get someone who knows to do

t for you.

i

s

3. Make sure you know which is the

used to obtain the booster charge.

4. Make sure the booster battery and the rundown battery are of the

cle. The battery voltage should be marked on the battery. Generally, the battery voltage can be determined by the

number of vent openings on the top of the battery – 6-volt batteries have 3 vent openings, 12-volt batteries have 6

vent openings. Some batteries have no vent openings. If in doubt about your battery voltage, consult your owner’s

manual. If you don’t have the proper owner’s manual available, and if you can’t wait to borrow or refer to one, at

minimum be certain the batteries have the same voltage. If the batteries are not of the same voltage, do not jumpstart.

5. Use extreme caution when connecting or removing booster cables. Grasp the cables by the insulated handles, never

by the bare metal ends. Be careful of moving engine components like the fan and fan belt.

6. Position vehicles so that the booster cables will reach both batteries, but do not allow the vehicles to touch each other.

While this may seem to be an unnecessary precaution, it is extremely important. If vehicles touch, they will be

grounded, one with the other. If certain differences exist in the wiring of the two vehicles, jump-starting them while they

are touching could be hazardous.

7. Place the gear shift of gear selector of each vehicle in PARK (for vehicles with automatic transmissions) or in NEU-

TRAL (for cars with manual transmissions).

8. Apply the parking brakes and shut off all accessories in both vehicles.

9. Some people have been injured while jump-starting vehicles from a careless electrical contact with rings, metallic

watch bands, etc. It is wise to remove these when working with a battery.

10. Before jump-starting, be sure that vent caps are tight and level on both batteries. If water is available, you might also

place a damp cloth over the vent caps on each battery. This will reduce the possibility of batteries exploding. After

using a damp cloth, discard it carefully, as it may have corrosive battery acid on it.

positive and which is the negative terminal on your battery and the battery being

same voltage before trying to jump-start your vehi-

11.

Look at your booster cables and the batteries. Identify the positive and negative clamps and battery terminals.

Booster cables should be color-coded red for positive and black for negative. Battery terminals are usually marked

POSITIVE, POS, or

12. Connect one end of the POSITIVE booster cable, usually covered in red, to the positive battery terminal in one

vehicle. Connect the other end of the POSITIVE cable to the positive terminal in the other vehicle.

Connect the NEGATIVE booster cable, usually covered in black, to the negative battery in the vehicle with the good

13.

battery. You now have only one final connection to make. The other end of the NEGATIVE cable must be connected

to a negative or ground connection at some point on the vehicle with the rundown battery.

14. Make the final NEGATIVE connection on the engine block, vehicle frame, or some other good metallic ground (except

the carburetor, fuel line, or any moving part) on the vehicle with the discharged battery. It is not good practice to connect the negative booster clamp directly to the negative battery terminal.

15. Stand back from both vehicles before engaging the starter of the vehicle with the discharged battery. Start the vehicle

with the good battery, then try starting the vehicle with the discharged battery. If the vehicle with the discharged

battery does not start after cranking for thirty seconds (check your owner’s manual), stop the jump-starting proce

dure.

16. Remove booster cables in the reverse order of connection, beginning with the negative clamps attached to the engine

block or metallic ground.

17. Beware of moving engine parts as you remove the booster clamps and cable.

+ for positive, and NEGATIVE, NEG, or – for negative.

-

Page 4

SSaaffeettyy –– GGeenneerraal

Engineered by:

18. Batteries produce hydrogen gas which could explode if there is a spark or flame near a batery. Do not smoke. Do not work with an open flame near a battery. Provide adequate

t

entilation near the battery. Cover vent caps with a damp cloth to minimize gas seepage.

v

ever work leaning over a battery. Always wear eye protection.

N

19. Battery acid can cause sever burns or blindness. Battery acid will corrode most metals and destroy most fabrics.

Batteries contain lead that is poisonous. Wash your hands thoroughly after working with batteries.

0. Never allow children to play with batteries, battery cables or terminals.

2

21. If you get battery acid on your skin, flush thoroughly with water. If you get acid in your eyes, immediately flush

your eyes with water and get prompt medical attention. Continue flushing the eyes for at least fifteen minutes or

until medical attention is obtained.

22. If battery acid is taken internally, drink large quantities of water or milk. Do not induce vomiting. Call a physician

or Poison Control Center immediately.

23. Battery acid that spills on a vehicle or in a work area can be neutralized with baking soda. After neutralizing, thor-

oughly rinse the contaminated area with water.

l

24. To prevent leakage of acid, never turn

25. The use of terminal protectors is strongly recommended, even if they

did not come with the original equipment. Terminal Protectors will significantly reduce the chance of sparks and battery explosions. They will

help protect your alternator and electrical system from shorts.

You should check that the battery terminals do not touch compartment

walls, hold-downs, battery trays or battery box covers when the hood is

closed. Since this manual covers a wide variety of equipment, from

lawn and garden to autos to off-road machinery, it is impossible to be

specific in these instructions, except to say that care should be taken to

prevent batteries and their connections from shorting out on the vehicle.

If you need help with assembly instructions, cable specifications, or special applications not covered in this manual,

please feel free to call us. Our toll free voice number is 1-800-558-8667 and our toll free fax number is 1-800-733-8611.

any battery (seal, “leakproof”, or other type) upside down.

Fig. 4

HHeellpp LLiinne

e

Limited Warranty

Quick-Cable Corporation and Quick-Cable Canada Limited manufacture high quality electrical connectors and cable

products. We use copper which is certified to meet our metallurgical specifications. We use cable that meets or exceeds

Society of Automotive Engineers (SAE) Standard J1127.

Quick-Cable warrants that its connectors and cables are free from defects in materials and workmanship. Quick-Cable

will replace at no charge to you any defective product which is returned prepaid to us. Replaced products will be

shipped to you at our expense.

This warranty replaces all other warranties. Replacement of defective products is your exclusive remedy. Quick-Cable

is not responsible for injury, property damage, or the consequential damages arising directly or indirectly from the use

of our products, even though that injury, property damage, or other consequential damage may have been directly or

indirectly caused by an actual defect in material or workmanship.

We like to know how our products have performed for you. If you have suggestions, comments, or questions about

our products, their installation or service, please contact us.

Form No. X5004D

www.quickcable.com

Quick Cable Corporation

3700 Quick Drive • Franksville WI 53126-0509

Phone 262-824-3100 Fax 262-824-3199

Copyright ©2007 Quick-Cable Corporation. All rights reserved. Printed in U.S.A.

Quick Cable Canada Limited

6395 Kestral Road • Mississauga, Ontario L5T 1Z5

Phone 905-362-1606 Fax 905-362-1614

Loading...

Loading...