Page 1

Thank you for purchasing an Lead Free Soldering Station. It is designed for lead

free soldering. Please read this manual before operating the unit. Store this manual

in a safe, easily accessible place for future reference.

Lead Free Soldering Station

TS2200

Operation Manual

Page 2

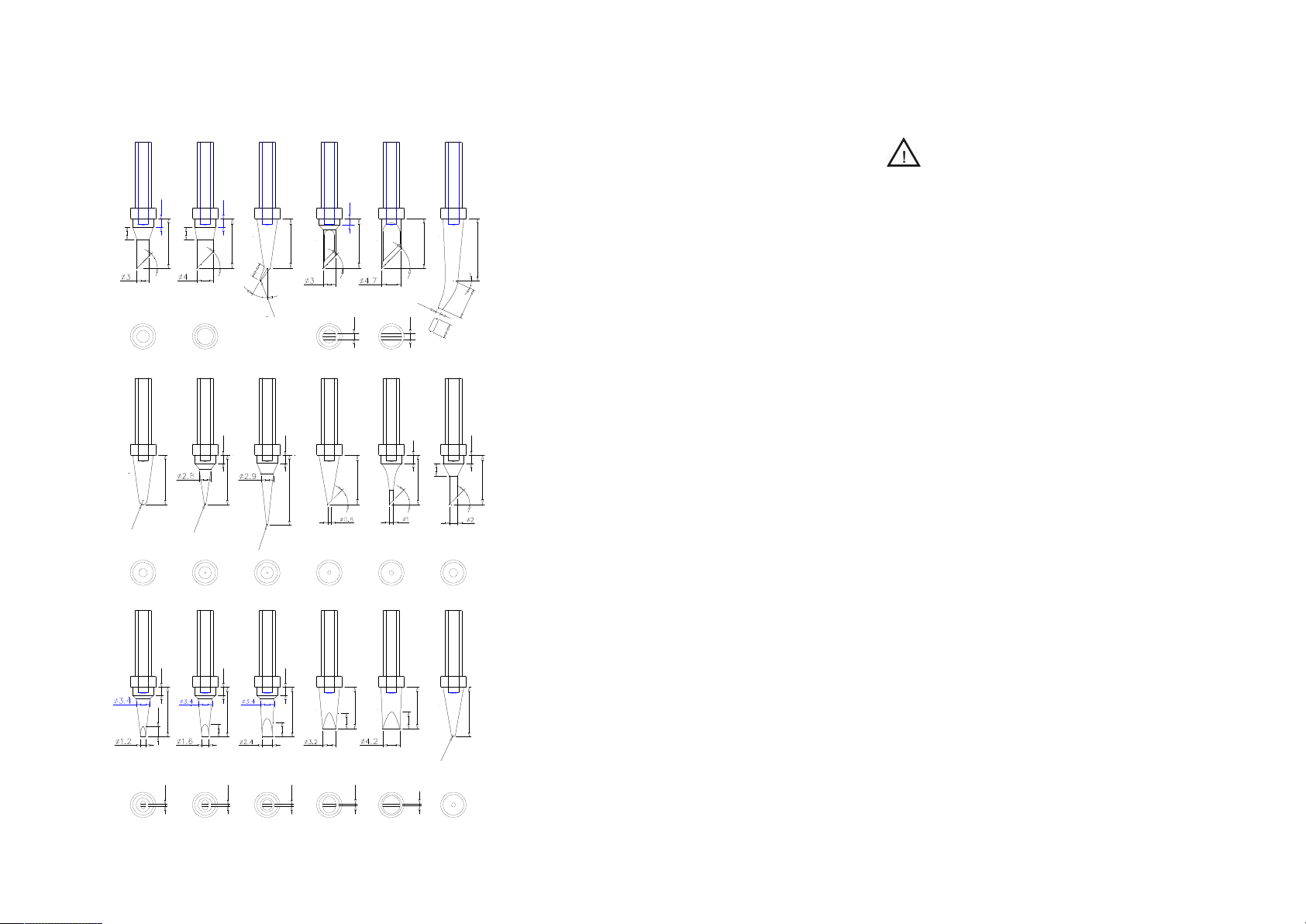

X.Tip

3

200-3C

1

R

200-2B

1.2D

200-

Ⅰ. Safety Instruction

CAUTION

2

12

4

5

°

12

2

12

2.5

0.5

3

200-4C

2

.

0

R

200-I

1.6D

200-

2

12

4

5

°

12

5

.

3

3

0

°

R

0

.

2

200-J

2

12

2

17

2

.

0

R

200-LI

2.4D

2

12

3.5

0.8

2

12

3

0.5

200-

200-SK

200-0.8C

3.2D

200-

1.5

12

4

5

°

1.5

200-K

12

4

5

°

200-1C

10

3.7

4.2D

0.8

200-

12

4

5

°

1

.

2

1.5

15

25°

5

.

7

5

.

3

200-H

2

12

4

5

°

2

3

12

4

5

°

200-2C

10

4

1

12

5

.

0

R

B

200-

When the power is on, the tip’s temperature is very high. The mishandling

may lead to burns or fire, be sure to comply with the following precautions:

Please avoid an abuse of the unit and use the appliance only as the described

manner.

Do not touch the metallic parts near the tip.

Do not use the product near flammable items.

Advise other people in the work area that the unit can reach a very high

temperature and should be considered potentially dangerous.

While replace parts or install tips, turn the power off and allow the unit to cool

to room temperature.

To prevent damage to the unit and ensure a safe working environment, be

sure to comply with the following precautions:

Appliance shall only be used with rated voltage and frequency. (Refer to the

trademark back of equipment.)

Don’t use the appliance if it is damaged, especially the supply cord.

This machine is equipped with a 3-wires grounding plug and must be plugged

into a 3-terminal grounded socket. Do not modify plug or use an ungrounded

power socket. If an extension cord is necessary, use only a 3-wire extension

cord that provides grounding.

Do not use the unit for other applications except soldering.

Only use genuine replacement parts.

Do not wet the unit. When your hands are wet, don’t use and disconnect the

unit, or to pull the supply cord.

The soldering process will produce smoke, so make sure the area is well

ventilated.

While using the unit, don’t do anything which may cause bodily harm or

physical damage.

Page20

Page1

Page 3

Ⅱ. Summary

The soldering station’s temperature adopts LCD double temperature display

and digital calibration, shortcut and convenience. The temperature induction is very

exact and sensitive, the speed of heating and recovery of temperature is very fast,

and so it is the one of the most perfect tools for lead free soldering.

. FeatureⅢ

1. Can preset technological parameter of three gallery, more practical.

2. Temperature alarm function, temperature changer.

3. Sensor preposition, real-time monitor temperature of tin, return temperature

rapidly.

4. Solder tip change convenience.

5. Anti-static device, ESD measuring ability.

Page2

Ⅷ、Tip Care and Maintenance

Select a Correct Tip

1. Select a tip that maximizes contact area between the tip and solder joint.

Maximizing contact area gives the most efficient heat transfer, allowing

operators to produce high quality solder joints quickly.

2. Select a tip that allows good access to the solder joint. Shorter tip lengths allow

more precise control. Longer or angled may be needed for soldering densely

populated boards.

Ⅸ.Error messages

Various error messages will be displayed when there is something wrong with the

unit.

“Sensor Broken”: Sensor open away

“Handle Type”: Handle type wrong

“NO Handle ”: Handle is not insert

“Heater Broken”:Heater open away

“Heater Short”: Heater short circuit

Page19

Page 4

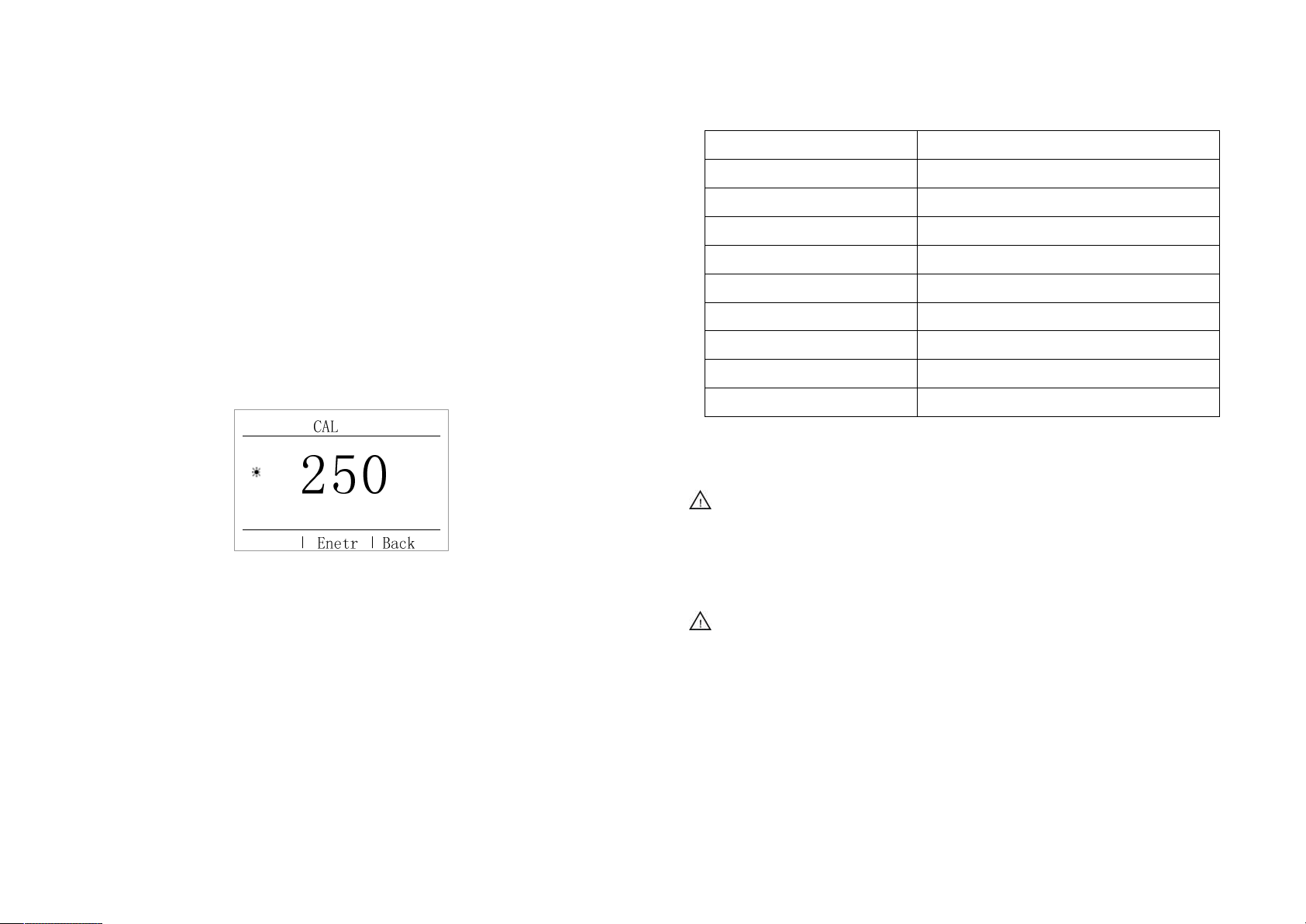

Ⅶ.Calibrating the Temperature

The soldering iron should be calibrated after changing the iron. The unit adopts

digital calibration mode and the revision value is inputted by pressing button, make

the adjustment easily.

Calibrate by using thermometer:

1. Set the unit’s temperature to a certain value.

2. When the temperature stabilizes, measure the tip’s temperature with

thermometer and write down the reading.

3. Press “1” and “3” button not loosen, the soldering station enters into

calibrating temperature mode and LCD display flash, press “+” or “—” key

change temperature value, fit with thermometer reading, press ENTER affirm.

. SpecificationsⅣ

Type TS2200

Temperature displaying type LCD

Power consumption

Working voltage 220VAC

Temperature Range

Temperature Stability

Ambient Temperature(Max)

Tip to Ground Resistance

Tip to Ground Potential

Dimension (W×H×D)

90W

100℃~480℃/212F~896F

±2℃

40℃

<2mV

<2Ω

137×114×168

mm

Ⅴ. Setting & Operating the Soldering Station

CAUTION:

Before operation, please check whether the voltage accords with the rated

voltage on the unit’s nameplate.

We recommend using the 191/192 thermometer for measuring the tip

temperature.

If the soldering station is locked by password, it will not be able to

calibrate the tip temperature and you must input the right password.

Page18

5.1 Iron Holder and Sponge

CAUTION:

The sponge is compressed. It will swell when moistened with water.

If the sponge becomes dry during working, add appropriate water.

1. Dampen the small cleaning sponge with water and then squeeze it dry.

2. Place it in groove of the iron holder base.

3. Add a little water to iron holder. The small sponge will absorb water to keep

the large sponge around it wet at all times.

Dampen the large cleaning sponge and place it on the iron holder base.

Before using the unit, moisten the sponge with the water and squeeze it

dry. Failure to do so may result in damage to the soldering tip.

Page3

Page 5

1. Press 1 or +, select “Language”, press ENTER, enter into language setting

interface, press enter key select language, again enter key confirm.

5.2 Connection

CAUTION:

Be sure to turn off the power switch before connecting or disconnecting

the soldering iron. Failure to do so may damage the soldering station.

1. Connect the connector of the handle cord to the socket behind the unit. Take

notice of inserting position about connector.

2. Place the soldering iron at the iron holder.

3. Insert the power plug into grounded power socket.

4. Turn on the power switch.

5.3 Turn on/off

On/off: soft switching on/off and hard switching on/off;

1. Hard switching: power switch can realize hard switching;

2. Soft switching: “POWER” key use for soft switching, in hard switching state,

long press “POWER” about 3S,turn on and working; and then press “POWER”

P a s s w o r d

E S D t e s t

K e y T o n e

a d r e s s

>>>

SET

Enetr Back

Press ENTER

P a s s w o r d

E S D t e s t

K e y T o n e

a d r e s s

>>>

SET

A d r e s s

A d r e s s p a s s w o r d :

* * * * * *

Enetr Back

SET

P a s s w o r d

E S D t e s t

K e y T o n e

a d r e s s

>>>

Enetr Back

A d r e s s

A d r e s s p a s s w o r d :

* * * * * *

2.After setting , press “STORE” save, and press “Back” key return parameter

setting interface, and press “Back” key return main menu.

6.12 Language setting

Press power

Page4

pic4-1

6.11Address setting

Page17

Page 6

1. Press 1 or +, select “Address”, press ENTER, input address password by +

and 1 key( password is 865637), enter into address setting interface, press enter key

input address, again enter key confirm.

SET

P a s s w o r d

E S D t e s t

K e y T o n e

a d r e s s

Press ENTER

P a s s w o r d

E S D t e s t

K e y T o n e

a d r e s s

SET

A d r e s s

A d r e s s p a s s w o r d :

* * * * * *

start sleep function.

2.after turn on, take hand shank, solder work all the time, no sleeping,

until place hand shank on iron stand, and take up hand shank

again, start sleep function.

5.4 Setting the Temperature

>>>

Enetr Back

>>>

Enetr Back

SET

P a s s w o r d

E S D t e s t

K e y T o n e

a d r e s s

>>>

STORE Back

a d r e s s

6 4

2.After setting , press “STORE” save, and press “Back” key return parameter

setting interface, and press “Back” key return main menu.

Attention: 1. after turn on, hand shank place on iron stand, solder work all the time

no sleep, until take up hand shank and then place on iron stand again,

Page16

CAUTION:

Make sure the temperature of the unit can be adjusted (password is correct

or the password is initial 000). When setting temperature, the heating

element is on. Operation as following steps:

Have three gallery, long press 1,2,3 key enter into gallery 1 、2、3.as following:

Long press 1 key, enter into channel 1, as following 4-2

CH1

200

200 320 380

℃

ESD

pic4-2

Temperature rising:

Press “+” button directly. If so, the setting temperature will raise 1 and the ℃

display window will display the set temperature. When loosen the “+” button,

the display window will delay to display the set temperature about 2seconds. If

within 2seconds, press the “+” button again, the setting temperature will raise

1 ℃ again. If press the “+” button and not loose at least 1second, the setting

temperature will rise rapidly. Till the needed temperature reaches, then loose the

“+” button.

Temperature dropping:

Press “-” button directly. If so, the setting temperature will drop 1℃ and the

Page5

Page 7

display window will display the set temperature. When loose the “-” button, the

display window will delay to display the set temperature about 2seconds. If

2seconds later, press the “-” button again, the setting temperature will drop

1℃again. If press the “-” button and not loose at least 1second, the setting

temperature will drop rapidly. Till the needed temperature reaches, then loose

the “-” button.

Long press 2 key, enter into channel 2, as following 4-2

1. press 1 or + , select “Key tone”, press ENTER, enter into key tone setting

interface, press ENTER again, enter into select key tone interface, press 1 select

ON or OFF, ON express open key tone, OFF express close key tone, press

“ENTER affirm.

P a s s w o r d

E S D t e s t

K e y T o n e

a d r e s s

SET

Press ENTER

Temperature setting method the same as CH1

Long press 3 key, enter into channel 3, as following 4-2

Temperature setting method the same as CH1

Ⅵ. Setting Working Parameters

6.1 Enter into password interface

1. Press “2” and “3” key at the same time, enter into setting main menu, as

following:

>>>

2. After setting key tone, press “STORE” key affirm, press “Back” key return

parameter setting interface, press “Back” again, return setting interface.

Enetr Back

Press ENTER

6.10 Setting key tone

Page6

6.9 ESD

Page15

Page 8

1. press 1 or +, select “ESD test”, press ENTER, enter into ESD interface, press

ENTER again, enter into ESD select interface, press 1 select ON or OFF, ON

express open ESD function, OFF express close ESD function, press “ENTER”

affirm.

SET

P a s s w o r d

E S D t e s t

K e y T o n e

a d r e s s

>>>

Enetr Back

Press ENTER

Press ENTER

Note: when select ON, the ground hole must be connect with ESD

ground, otherwise, alarm hint(ESD in main interface show as red)

2. after setting ESD function ,press STORE save, press “Back” return parameter

setting interface, press “Back” return main interface.

pic5-1

6.2 Temperature setting

1. Selected the first item, press ENTER key, enter into temperature setting

interface, press ENTER key again, CH1 temperature color turn to blue, it can

be modify, press “+” key and “-” key modify value ; press 1 key, move down,

CH2 temperature color turn to blue, it can be modify, press “+” key and “-”

key modify value; move down, CH3 temperature color turn to blue, it can be

modify, press “+” key and “-” key modify value. As following:

SET

C H 1 - 3 T e m p

u i n t

s l e e p

C l o s e

A l a r m t e m p +

A l a r m t e m p -

>>>

C H 1 - 3 T e m p

C H 1 : 2 0 0

C H 2 : 3 2 0

C H 3 : 3 8 0

Enetr Back

Press ENTER

C H 1 - 3 T e m p

u i n t

s l e e p

C l o s e

A l a r m t e m p +

A l a r m t e m p -

>>>

pic5-2 temperature setting

2. After modify, press “STORE” save, press “Back” return to setting interface,

press “Back” again, return to main interface.

SET

C H 1 - 3 T e m p

C H 1 : 2 0 0

C H 2 : 3 2 0

C H 3 : 3 8 0

STORE Back

Page14

Page7

Page 9

6.3 Temperature unit Setting

1. . Press 1 or +, select “uint”, press ENTER, enter into temperature unit setting

interface, press ENTER again, enter into temperature changer select interface, press

1 select temperature unit. As following 5-3

SET

C H 1 - 3 T e m p

u i n t

s l e e p

C l o s e

A l a r m t e m p +

A l a r m t e m p -

>>>

Enetr Back

Press ENTER

C H 1 - 3 T e m p

u i n t

s l e e p

C l o s e

A l a r m t e m p +

A l a r m t e m p -

>>>

SET

C H 1 - 3 T e m p

Press ENTER

u i n t

s l e e p

C l o s e

A l a r m t e m p +

A l a r m t e m p -

℃ ℉

STORE Back

/

u n i t

℃

℃

℉

pic5-3

2. After selecting temperature unit, press “STORE” save, press “Back” return

setting interface, press “Back” again , return main menu interface.

Page8

SET

u i n t

℃

℃

Enetr Back

℉

6.8 Reset password

1. press 1 or +, select “password”, press ENTER, enter reset password interface,

press ENTER again enter into password interface, press “+” or “—” import 0,

press 1 import original password 000000, press ENTER affirm, enter into new

password import interface, If the two passwords are the same ,it will modify the

password successfully.

P a s s w o r d

E S D t e s t

K e y T o n e

a d r e s s

>>>

P a s s w o r d

E S D t e s t

K e y T o n e

a d r e s s

>>>

SET

Enetr Back

SET

E n t e r o l d P W D

******

**

Enetr Back

Press ENTER

Press ENTER

P a s s w o r d

E S D t e s t

K e y T o n e

a d r e s s

>>>

P a s s w o r d

E S D t e s t

K e y T o n e

a d r e s s

>>>

SET

P a s s w o r d

******

**

Enetr Back

SET

E n t e r n e w P W D

******

**

Enetr Back

Note: after change password, the temperature cannot be modify, enter

into parameter setting interface with new right password.

Page13

Page 10

6.7 Setting alarm temperature-

1. press 1 or +, select “Alarm temp-”, press ENTER, enter into alarm temperature

setting interface, press ENTER again , select temperature alarm- function, press 1

select ON or OFF, OFF express not alarm, ON express alarm, press “+” or “—”

modify temperature range. The range of alarm temperature is: 2~99℃.

SET

a l a r m t e m p

O N O F F

P a r a m e t e r ( ℃ )

2 5

Enetr Back

C H 1 - 3 T e m p

u i n t

s l e e p

c l o s e

A l a r m t e m p +

A l a r m t e m p -

>>>

Press ENTER

SET

Enetr Back

Press ENTER

C H 1 - 3 T e m p

u i n t

s l e e p

c l o s e

A l a r m t e m p +

A l a r m t e m p -

>>>

6.4 Sleep time setting

1. Press 1 or +, press ENTER, enter into sleep time setting interface, press ENTER

again, enter into sleep time interface, press 1 select ON or OFF,OFF is not sleeping,

when choose ON, press “+” or “—“ modify sleeping time.

SET

C H 1 - 3 T e m p

u i n t

s l e e p

C l o s e

A l a r m t e m p +

A l a r m t e m p -

>>>

Enetr Back

Press ENTER

Press ENTER

2. After setting alarm temperature-, press “store” affirm, press “Back” return

parameter setting interface, press “Back” again, return menu interface.

Page12

Note : The range of sleep time is between 5S and 99 minute, Press any

key button can awake sleep. If sleep 60 minute nonactivated, it will auto

power-off.

Tip temperature when sleeping is 200℃

Enter into sleep: send warning tone , LCD display teacup, and turn darken.

2.after setting sleeping time ,press “STORE” key affirm, press “Back” key return

parameter setting interface, press “Back” again, return setting interface.

Page9

Page 11

6.5 Close time setting

1. Press 1 or + key, select “Close”, press ENTER key, enter into close time setting

interface, press ENTER key again setting close time, press “+” or “—”key modify

value. Close time setting scope is :1-999min。

SET

C H 1 - 3 T e m p

u i n t

s l e e p

C l o s e

A l a r m t e m p +

A l a r m t e m p -

>>>

Press ENTER

Enetr Back

Press ENTER

2. After setting close time ,press “STORE” key affirm, press “Back” key return

parameter setting interface, press “Back” again, return setting interface.

6.6 setting alarm temperature+

1. press 1 or +, select “Alarm temp+”, press ENTER, enter into alarm temperature

setting interface, press ENTER again , select temperature alarm function, press 1

select ON or OFF, OFF express not alarm, ON express alarm, press “+” or “—”

modify temperature range. The range of alarm temperature is: 2~99℃.

SET

C H 1 - 3 T e m p

c l o s e

A l a r m t e m p +

A l a r m t e m p -

>>>

u i n t

s l e e p

Enetr Back

Press ENTER

Press ENTER

C H 1 - 3 T e m p

u i n t

s l e e p

c l o s e

A l a r m t e m p +

A l a r m t e m p -

>>>

2. after setting alarm temperature+, press “store” affirm, press “Back” return

parameter setting interface, press “Back” again, return menu interface.

SET

a l a r m t e m p

O N O F F

P a r a m e t e r ( ℃ )

Enetr Back

2 5

Page10

Page11

Loading...

Loading...