Page 1

QuickWorldwide.com

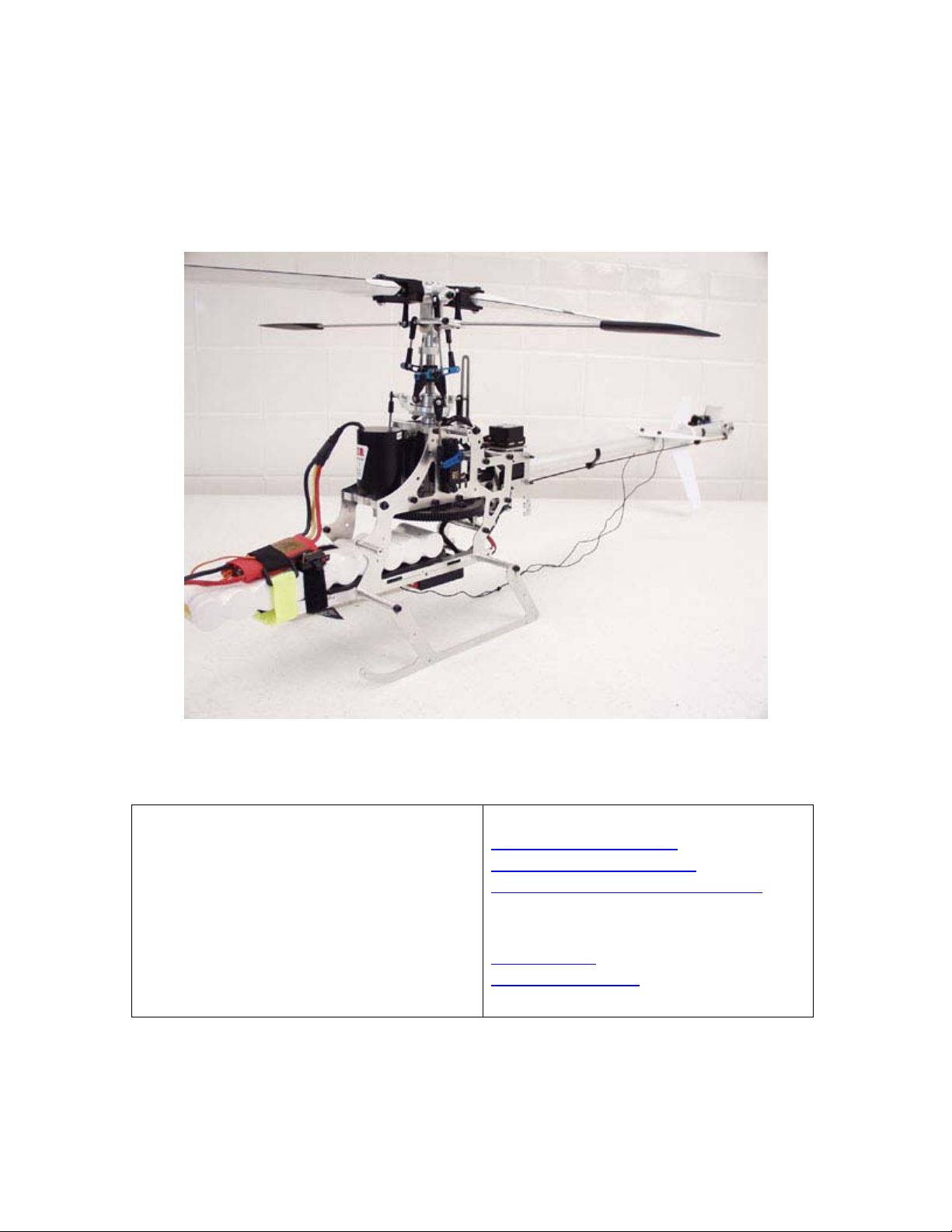

Quickie EP Helicopter

Exclusively distributed by:

Quick Worldwide

201 South 3rd. St. & 309 N.

Coopersburg, PA 18036

Phone: (610)-282-4811

Fax: (610)-282-4816

Websites:

http://www.hhiheli.com

http://www.quickheli.com

http://www.giantscaleplanes.com

E-mail:

hhi@fast.net

Jon@ewtech.com

(Tech. Support)

1

Page 2

Table Of Contents

Introduction......................................................................................................................... 3

Quickie EP Features............................................................................................................ 4

Tools Needed to Assemble the “Quickie EP”..................................................................... 5

Hardware & Accessories..................................................................................................... 6

Other Optional Accessories ................................................................................................ 7

Radio Requirements............................................................................................................ 8

Section 1 – Frame Assembly............................................................................................... 9

Section 2 – Main Gear Installation................................................................................... 13

Section 3 – Counter Gear Assembly ................................................................................. 15

Section 4 – Control Items ................................................................................................. 17

Section 5 – Head Assembly .............................................................................................. 19

Section 6 – Tail Assembly ................................................................................................ 22

Section 6 – Fin Set Installation ......................................................................................... 26

Section 7 – Linkage Rod Installation................................................................................ 27

Step 1 – Linkage Rod Setup.......................................................................................... 27

Step 1A – Shim Ball Installation .................................................................................. 27

Section 8 – Motor Installation........................................................................................... 31

2

Page 3

Introduction

Quick Worldwide & Hobbies & Helis International:

Quick of Japan and Hobbies & Helis International teamed up in 1997 to

manufacture various upgrades for many of the plastic helicopters on the market.

After four years of distributing numerous upgrades and crash parts for other

helicopters, Quick and HHI decided to develop a lin of their own. Starting with the

Quick 60, 30 and Quick Learner, the popularity of the Quick helicopter line

continued to grow. In 2003, Quick and HHI pushed the outside of the envelope

when they released a radical new design in the Quick 50, which immediately

became a tremendous success.

Now, using the same design concepts used

Building on the popularity of this, and severAs the development of the kit began,

initial designs were approved, proto-types were created and flown - all to ensure

that the design was flawless. No minor details were over-looked. After countless

hours of hard work and dedication, Quick-World-Wide is proud to release the first

in a new standard in Helicopters - the Quick Learner.

Warning:

The radio-controlled model helicopter contained in this kit is not a toy.

Rather, it is a sophisticated piece of equipment. This Product is not

recommended for use by children, without adult supervision. Radio controlled

models such as this, are capable of causing both property damage and/or bodily

harm to both the operator/assembler and/or spectator if not properly assembled

and operated. Hobbies & Helis assumes no liability for damage that could occur

from the assembly and/or use/misuse of this product.

AMA:

We strongly encourage all prospective and current R/C aircraft pilots to join the

Academy of Model Aeronautics. The AMA is a non-profit organization that

provides services to model aircraft pilots. As an AMA member, you will receive a

monthly magazine entitled Model Aviation, as well as a liability insurance plan to

cover against possible accident or injury. All AMA charter aircraft clubs require

individuals to hold a current AMA sporting license prior to the operation of their

model.

Pre-Assembly Information:

Quick Helicopters are put together with care and quality topping our priority list. A

recommendation when you are ready to begin building this model is that you

examine the kit and understand the contents of the packages and read

thoroughly before starting the assembly process. Purchase a parts box for all the

nuts, bolts, and other small parts. We take great care to ensure all parts are in

the box.

3

Page 4

Quickie EP Features

1. Frame Construction:

Quickie frames are made of the highest Quality Black G-10 or Carbon Frames.

These frames are not only rigid but will provide excellent vibration absorption

2. Belt driven Tail:

Belt Driven tail is not only a reliable way to drive a tail, but is also very smooth

with low maintenance.

3. High Quality Ball Bearings:

Quickie EP offers ball bearings on all moving parts.

4. EMS Collective System:

The EMS Collective design allows ease of setup with fewer moving parts. EMS

constitutes overall design simplicity and represents the future of helicopter

technology.

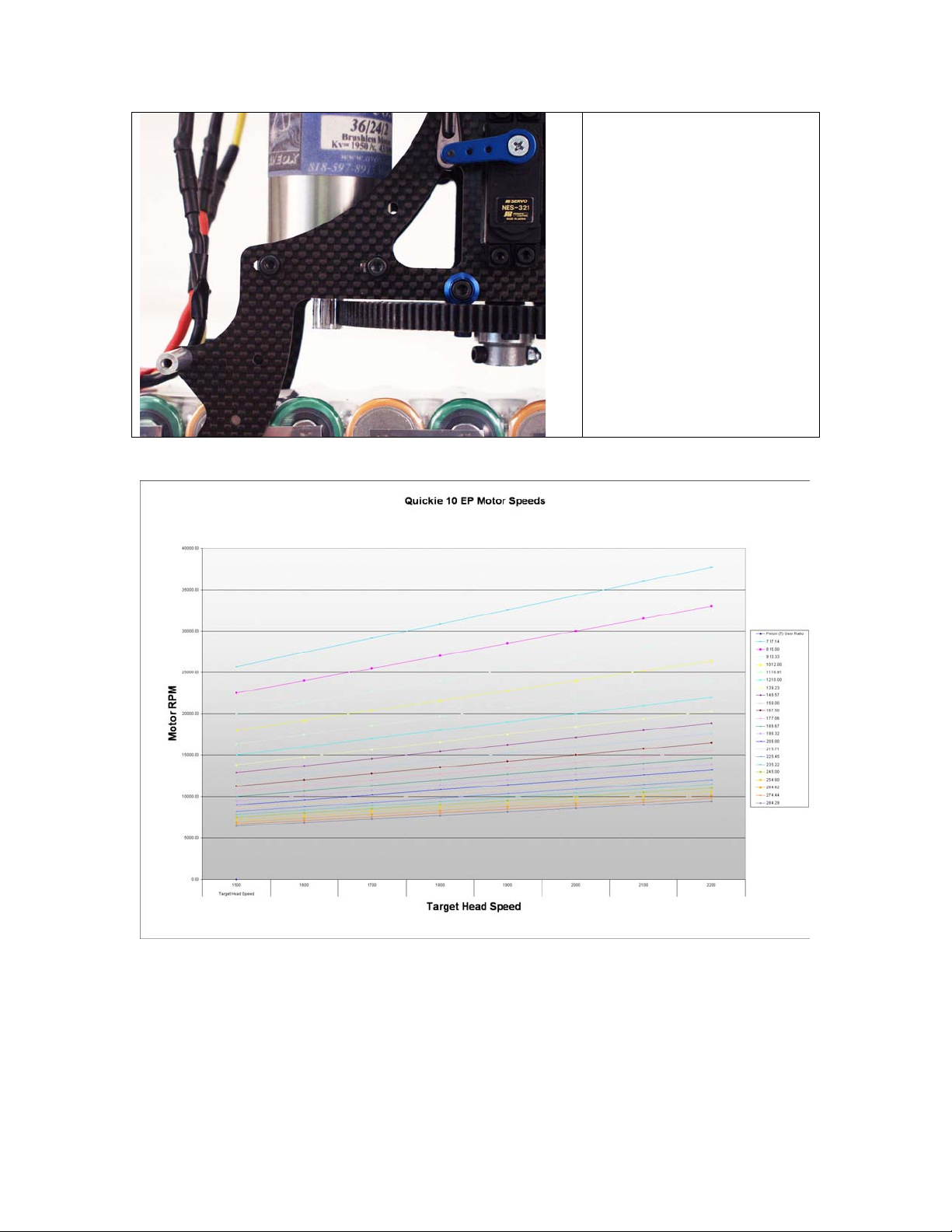

5. Heavy-Duty Motor Mount:

The Quickie EP sports a new heavy-duty top motor mount that allows the easy

removal and change of motors and pinions.

6. Control Linkages:

The control linkages that are provided with the Quickie EP are high quality

2.3mm stainless steel rods and the rod ends are made of a high quality Delrin.

7. Single Blade Axle Design:

The single blade axle design is simple very responsive system, with very

consistent flight characteristics.

8. Inside the Frame Battery Mount:

This design provides quick access to the flight battery and lots of protection in

case of a crash.

.

4

Page 5

Tools Needed to Assemble the “Quickie EP”

Phillips Screw Driver

Composite Paddle

Gauges

HHI7000

Ruler

Needle Nose Pliers

Ball End Drivers

HHI7050

HHI7320 – 6pc Nut &

Allen Driver Set

Hobby Knife

Scissors

Bubble Blade Balancer

HHI7010

High Point Balancer

DUB499

Pitch Gauge

HHI7001

Universal Flybar Lock

HHI7040

5

Page 6

Hardware & Accessories

Motors (These are our recommended motor but others will work)

Glues & Thread Lockers

CA Glue. …GBG1

JB Weld…JBW8265S

Radio Mounting Accessories

Single Sided Foam Tape… HHI2008

Receiver Strong Box… HHI2200

Locktite. …….PT40

Receiver Hold Down Straps

HHI55** $4.99

2 Per Bag & Colors: Red, White,

Purple, Black

Spiral Wrap

HHI2809 & HHI2810

Wire Ties…HHIWT01

6

Page 7

Other Optional Accessories

3mm Fly-bar Stiffeners…HHI402*

Quickie Servo Arm Set

3mm Finishing Caps

HHIM1110

Available in Blue, Silver, Gold, & Purple

Base Load Antenna

HHI53**

Available in Blue, Gold, Purple

& In 40, 50, 72mhz

7

Page 8

Radio Requirements

Radios:

Hobbies & Helis & its distributors carry various lines of helicopter radios. Any

radio that supports EMS/CCPM Mixing will work fine. We recommend using an

eight-channel or better radio, although a six-channel radio is all that is required.

Servos:

This is the single most important function of the helicopter. Any sport servo will

offer acceptable performance. You should be sure to use all the same type of

servo on the swash plate. Higher speed servo is recommended for tail, but not

required.

Introduction:

Please read through the entire manual before starting your construction of the

Quickie. If there are any questions or concerns regarding the assembly of the

helicopter you can call Hobbies & Helis International (610)-282-4811 or Email the

any of the following techs.

Technical Support Personnel:

Jon – Jon@ewtech.com

Threadlocker Warning (Very Important):

This is a general warning about the use of threadlocker and its importance.

Threadlocker must be used anywhere that a metal fastener i.e. (M2, M3, M4 Cap

Head Bolts, Set Screws etc.) are threaded into a metal part i.e. (Bearing Blocks,

Cross-members, etc.). The failure to use threadlocker can result in parts falling a

part and possible loss of control of the model, which can lead to a crash. Also,

be sure to check your bolts’ tightness after each flight. Many bolts, even with the

use of threadlocker can come loose from vibration in the helicopter.

8

Page 9

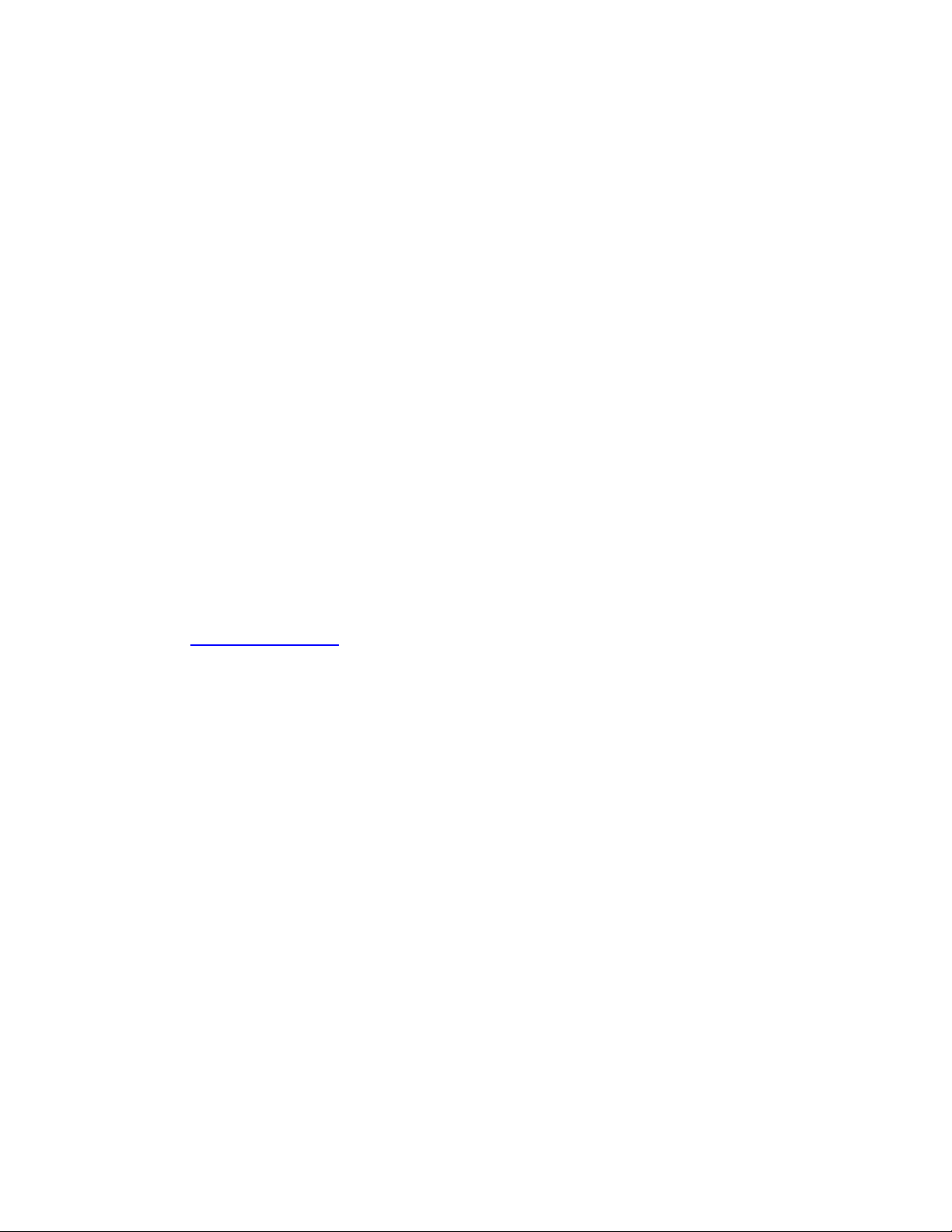

Section 1 – Frame Assembly

Parts List

Frame Set Bag

Main Frames X 2

Rear Sub-frame x 2

Landing gear x 2

Bag 1

Main-shaft Bearing Block X 2

Canopy Standoffs x 4

Motor Mount x 1

Frame Rails x 2

26mm Landing Gear Standoffs x 4

Antirotation Base x 1

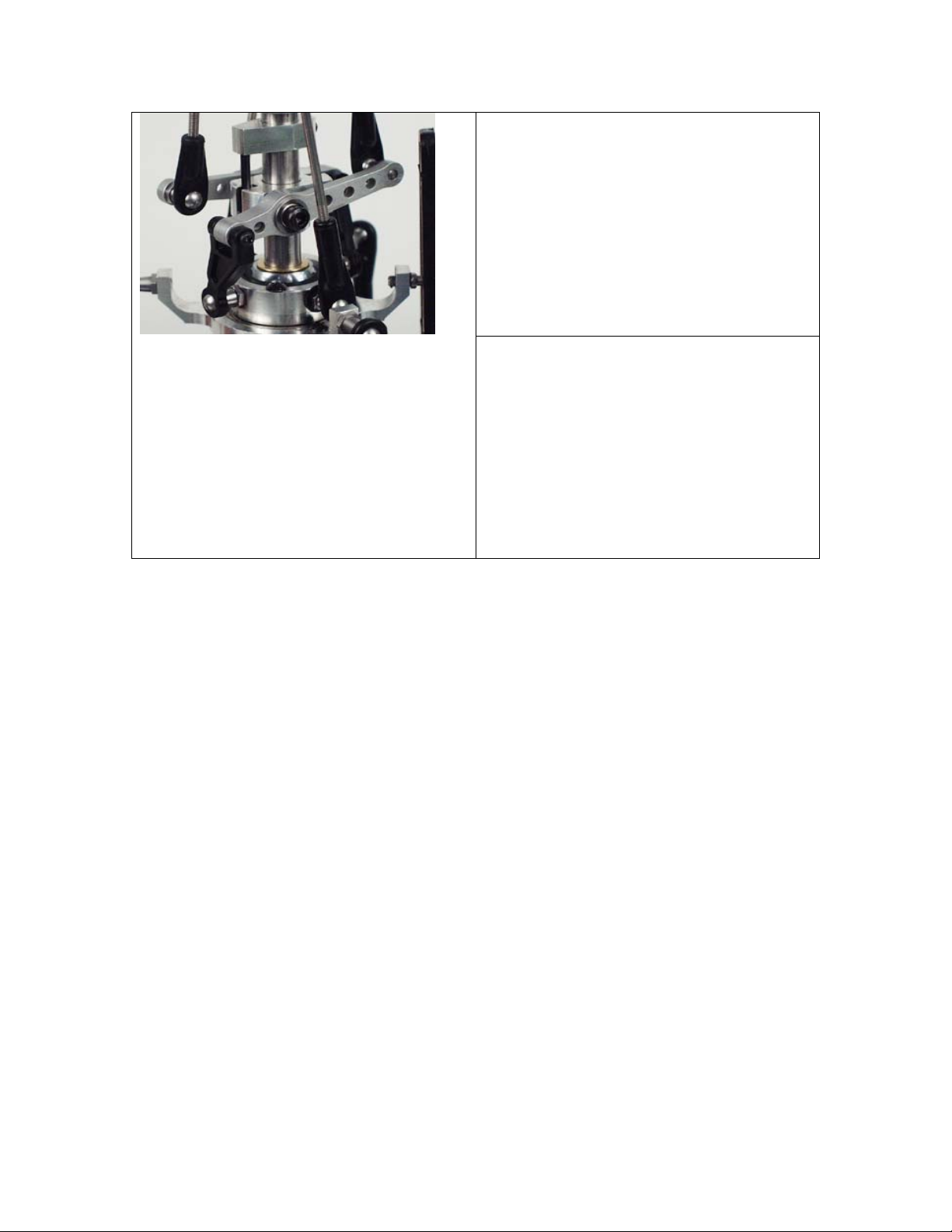

Assemble the main frames as shown in Figure 1. Open part is the bearing block opening that the bearing was inserted into.

Describe which is up or down, a sticker or indent or mark to designate the top part of the bearing block. You may not need the

washers that HHI sells as you want to keep the weight down

9

Page 10

Assemble the main frames as shown in the picture. Attach the canopy standoffs using (4)

M3x6 cap head screws. The bearing blocks will be inserted as follows; the upper block

will have the open part facing up, and the lower bearing block will have the open face

down. Each of the bearing blocks are attached with (4) M3x6 cap head screws.

Loosely install the motor mount.

This item will be coming out again

when you install your motor, so only

put this mount in loosely. Install the

motor mount (4) M3x6 cap head

screw and (4) M3 washers

Next, install the frame rails. The flat

part of the frame rail is oriented on

top. The slotted sides go against the

frames. Install the two 46mm cross

members into the frame. The frame

rails go on the inside of the frames.

Next put an M3x20 set screw into

each of the cross member ends. There

should be a bit still protruding.

10

Then attach a 26mm Landing gear

standoff onto each of the M3x20 set

screws. Attach the landing gear using

(4) M3x6 cap head screws.

Note that if you have problems

getting the standoff to screw down

entirely, remove it and use a hex head

driver to drive the screw into the

standoff, as there might be a little

excess material.

Page 11

Attach the antirotation upright piece

to the antirotation base using (2)

M3x6 cap head screws.

Attach the antirotation guide using

(4) M3x6 cap head screws and (4)

M3 washer.

When installing the antirotation

guide, do not tighten at first until after

the swash is installed.

11

Assemble the rear sub-frame as

shown. Attach the two frame halves

with the boom holders. They will be

attached using (4) M3x35 cap head

bolts and nuts.

Remove the two boom holders from

the bag with the tail rotor parts.

Page 12

Next you will attach the rear sub

frame to the helicopter.

There are eight attachment points,

four on each side. Take an M3x20

cap head screw and slide it through

the hole on the frame. Next, slide a

10mm spacer onto each of the bolts.

Slip the sub-frame into the middle

and secure each bolt with a 24mm

cross member in the middle.

When assembling the rear frame, do

not tighten all of the screws until you

loosely install and start all of the

M10 and M24 cross members. This

will take a little time so be patient.

12

Page 13

Section 2 – Main Gear Installation

Parts List

Bag 2

Main Gear

Autorotation Hub-Deluxe/Main Gear

Hub-Standard

M3x6 Cap Head Screws x 4

Main Shaft x 1

Main Shaft Collar x 1

M3x18 Cap Head Screw x 1

M3 Locknut x 1

M3x3 Set Screw x 4

Next, attach the main gear to the

antirotation/main gear hub as

shown. It will be attached with

(4) M3x6 cap head screws.

When attaching the antirotation

hub to the main gear, you may

need to open the holes slightly.

Use a hobby knife to gently open

the holes so that the M3x6 screws

will easily screw into the plastic.

Slide the main shaft down

through the upper and lower

bearing blocks and into the

autorotation hub. Note that the

smaller diameter part of the shaft

goes into the gear and

autorotation hub.

Secure the shaft in place with an

M3x18 cap head bolt and M3

locknut. Then secure the main

shaft on top with the main shaft

collar and (4) M3x3 set screws.

Pull up on the shaft when

tightening the setscrews to

remove any possible endplay.

13

Page 14

This is how the helicopter should

look at this point.

14

Page 15

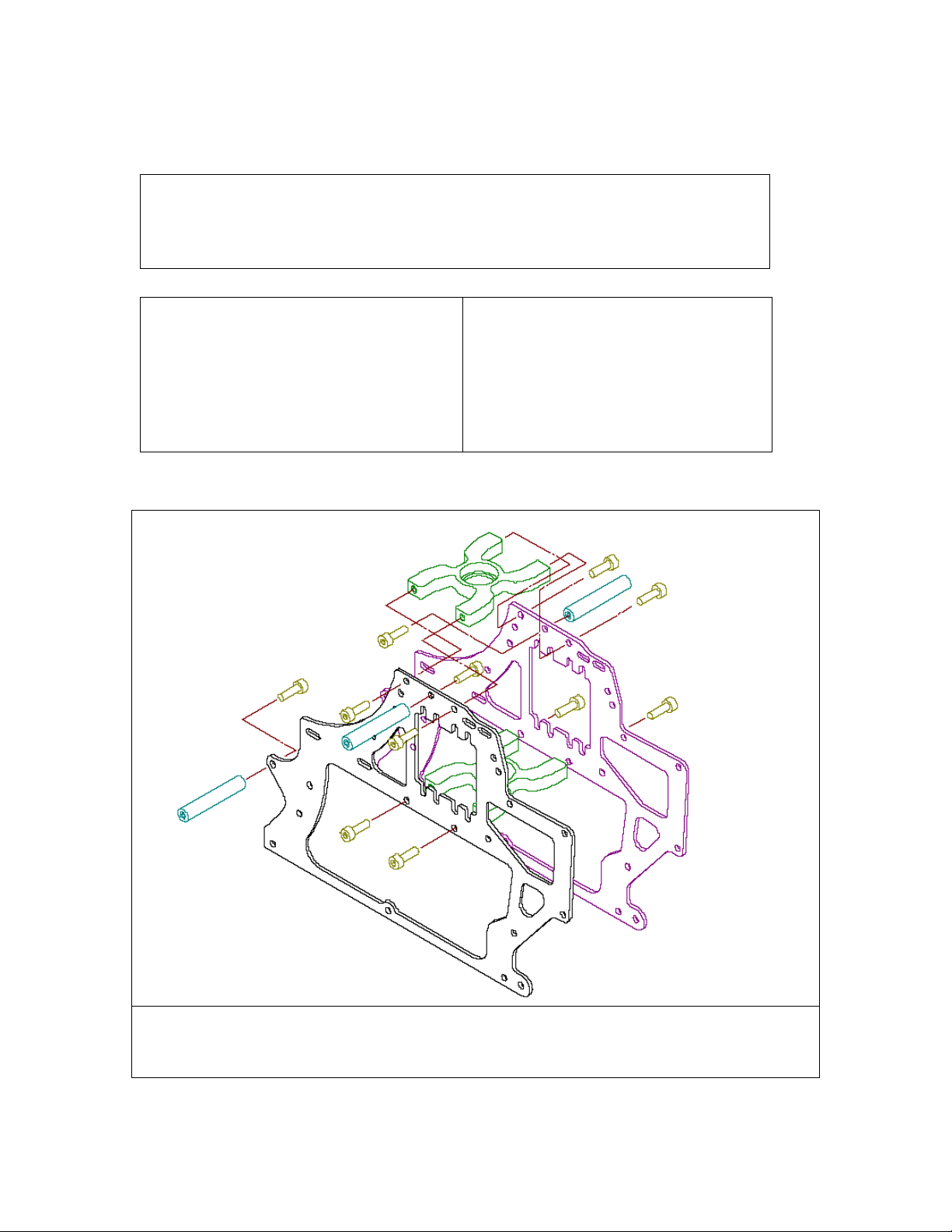

Section 3 – Counter Gear Assembly

Parts List

Bag 3

Counter Gear Shaft x 1

Counter Gear x 1

Lock Pin x 1

E-Clip x 1

Counter Gear Bearing Block x 2

Pulley Gear Plate x 1

Lock Pin x 1

Pulley Gear x 1

E-Clip x 1

M3x6 Cap Head Screw x 8

M3 Washer x 8

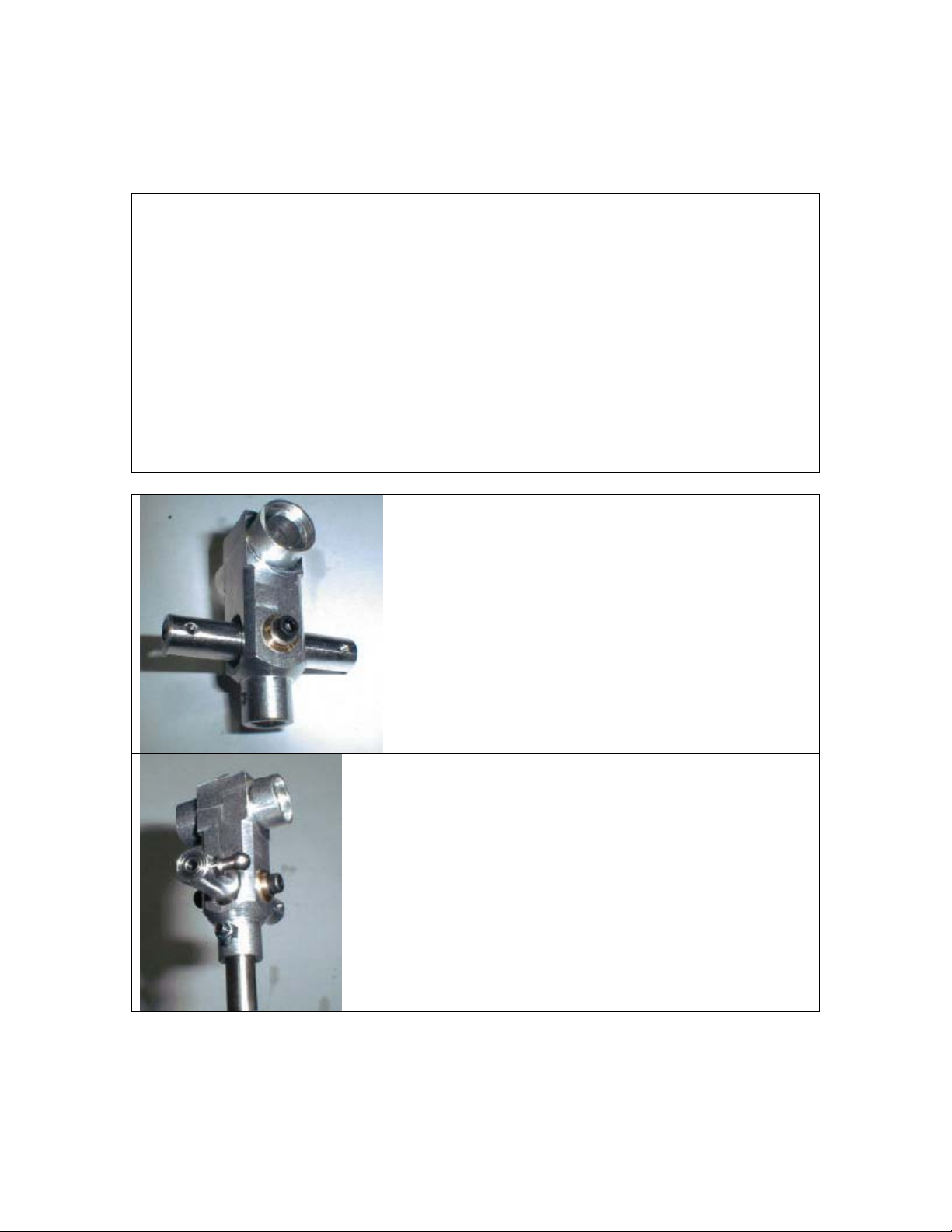

Install the steel stopper pin into the

counter gear shaft. Then slide the

counter gear onto the counter gear

shaft.

Secure the gear in place using an Eclip.

Locate the two counter gear bearing

blocks. Next slide each bearing block

onto the counter gear shaft. Each

bearing block has an open face. The

open faces should both face up as

shown in the picture.

15

Page 16

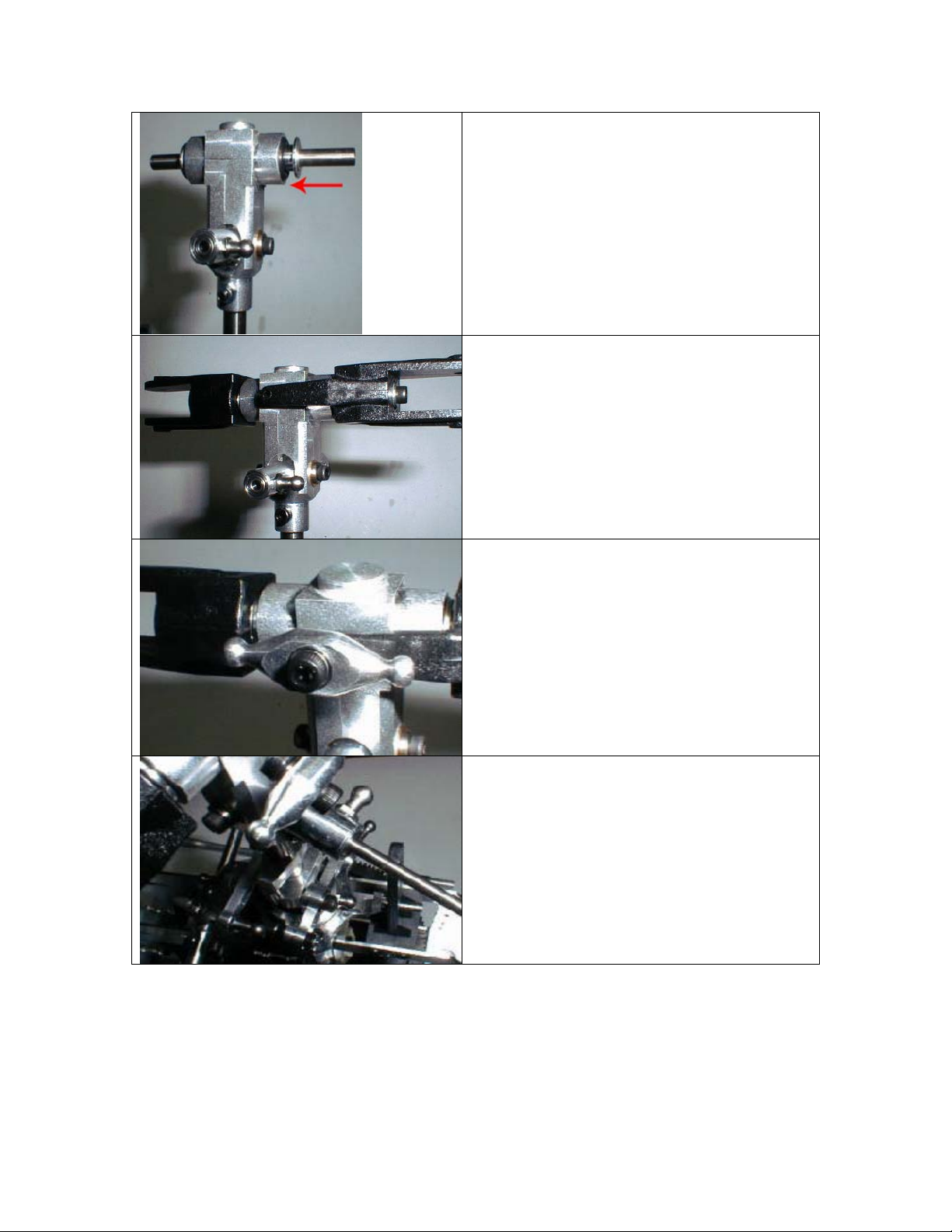

Then slide the pulley spacer on, with

the shoulder down and the bevel side

up, and finally the cross locking pin.

Next slide the gear on the shaft

capturing the cross pin with the slot in

the gear. Secure the gear down with

the second e-clip.

Next, slide the counter gear assembly

into the frame and secure it in place

using (8) M3x6 cap head screws with a

M3 washer under each.

16

Page 17

Section 4 – Control Items

Parts List

Swashplate

Washout Arms

Washout Base

Antirotation guide pin

Washout link x 2

M2x12 Pan head screw x 2

M3x3 Set Screw x 1

M3x6 Pivot studs x 2

M3x10 Cap head screws

M3x5x1 Spacer x 2

Install the antirotation pin/elevator ball

on to the swashplate. Install the two

sim balls on to the the swashplate as

shown. Locate the swashplate and

slide it on the main shaft first.

Next locate the washout base, arms,

links, M3x6 pivot studs, M3x10 cap

head screws, M3x5x1 spacers, and

M2x12 pan head screws. First slide an

M3x8 cap head screw through each

arm. Note which direction the screw

should go through the arm in the

picture. Slide an M3x5x1 on each bolt

and attach them to the base.

Next attach an M3x6 pivot stud to each

of the washout arms. Finally attach a

washout link to each arm with an

M2x12 pan head screw. Next slide the

washout onto the main shaft with the

protruding side going down first.

Attach the washout links to the longer

pivot studs on the inner ring of the

swashplate.

17

Page 18

Attach the washout links to the longer

pivot studs on the inner ring of the

swashplate.

Slide the Antirotation guide pin on the

main shaft next. Secure it using the

M3x3 set screw. This will be adjusted

later, so snug is all this screw needs to

be for now.

18

Page 19

Section 5 – Head Assembly

Parts List

Center Hub

Seesaw

Seesaw Collar x 2

M3x8 Cap head screw x 2

M3x6 Pivot studs x 2

M3x16 Cap head bolt

M3 Locknut

7x13x3 O-ring x 2

O-ring spacer x 2

Spindle

5x10x4R Bearing x 4

M3x10 Cap head screw

3x8x1 Washer x 2

Hiller arm x 2

M3x10 Cap head screw x 2

3x5x1 Spacer x 3

Flybar

Flybar control arm base x 2

Flybar control arm extension x 2

Flybar control arm spacer (3x5x5) x 2

M4x4 Set screw x 2

M3x8 Cap head screw x 2

Flybar paddle x 2

Blade Grip x 2

M3x24 Cap head bolt x 2

M3 Locknut x 2

Locate the head block, seesaw, seesaw

collars, and (2) M3x8 cap head screws. Slide

the seesaw into the opening on the head

block. Slide a seesaw collar into each of the

bushings on the head block. Secure the

seesaw using the (2) M3x8 cap head screws.

Be sure not to over tighten the seesaw

collars. Use threadlocker on the bolt to

secure it.

Locate (2) M3x6 pivot studs and (2) 3x5x1

spacers. Install the two pivot studs with

3x5x1 spacer into the seesaw. They should

be in holes opposite of each other. The other

two holes tapped in the seesaw will be

unused.

Attach the head block to the main shaft using

the M3x16 cap head bolt and an M3 locknut.

19

Page 20

Install two 7x13x3 o-rings into the head

block. Next slide the head spindle through

the o-rings. Then slide the head dampener

spacers onto the spindle

Each blade grip will have (2) 5x10x4R

bearings. Install the bearings into the blade

grips. Slide each one onto the spindle shaft.

Secure the blade grips to the spindle using

(2) M3x10 cap head screws. Place a 3x8x1

spacer under each bolt before installing them.

Attach each hiller arm to the blade grip using

an M3x10 cap head screw. Put the bolt

through the hiller arm and put a 3x5x1 spacer

on the bolt next, and screw it into the blade

grip.

Note that the open side should be towards

blade grip. Do this before mounting the

spindle.

Slide the flybar through the seesaw.

20

Page 21

Locate two 3x5x5 spacers, two flybar control

arm bases, two flybar control arm extensions,

and two M4x4 set screws. Slide (2) 3x5x5

spacers onto the flybar with the protruding

side going against the seesaw. Next slide the

flybar control arm bases onto the flybar.

They face in opposite directions and oppose

the M3x6 pivot studs on the seesaw

previously installed. Secure them with (2)

M3x5 set screws. Be sure that they are

parallel with each other and that the flybar is

equally distant from both ends.

You may find it easier to assemble the flybar

assembly before mounting the head.

Attach the (2) flybar control arm extensions

using (2) M3x8 cap head screws.

This needs to happen before the flybar

control arms are installed on to the flybar.

Note the side that the flybar control arm is

facing.

Screw each paddle onto the flybar 25mm. Be

sure the paddles are parallel with each other.

Also the paddles should be inline/parallel

with the flybar control arms.

Use M3x24 cap head bolts with M3 locknuts

to attach each blade to the grip.

21

Page 22

Section 6 – Tail Assembly

Parts List

Tail boom

Belt

Boom holder half x 2

M3x35 x 4

M3 Locknut x 4

Tail output shaft

Pulley gear

M3 set screw x 2

Tail case side plate x 2

5x10x4R Bearing x 2

Tail pitch lever base

M2x6 Pan head screw x 2

M3x6 Cap head screw x 6

Tail Pitch Slider

M3x4 Pivot Stud

2.3 Medium ball ends

Tail Pitch Lever

M3x4 Pivot stud

M3x10 Cap head screw

M3x3 Set screw

Tail rotor hub

Tail blade grips x 2

3x7x3R Bearing x 2

M3x6 cap head screw x 2

M2x8 Pan head screw x 2

Shim ball x 2

Tail blades x 2

M3x20 Cap head screw x 2

M3 Locknut x 2

Tail blade spacers x 4

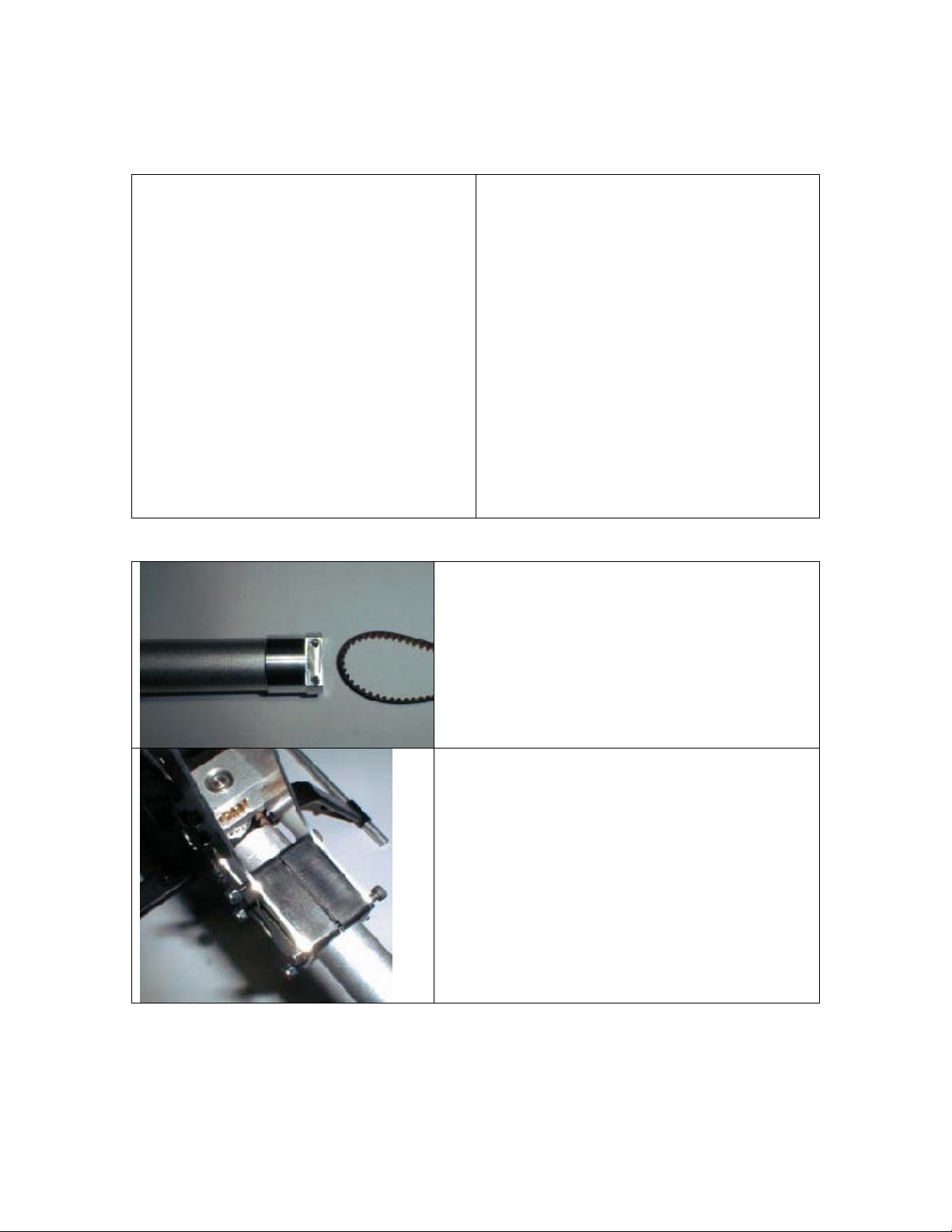

Locate the tail boom and the belt. Slide the belt

through the boom. Be sure you do not twist the

belt.

Install the two boom halves into the frames. Put

the (4) M3x35 cap head screws through the four

open holes in the boom halves. Loosely put the

nuts on the ends of the bolts.

22

Page 23

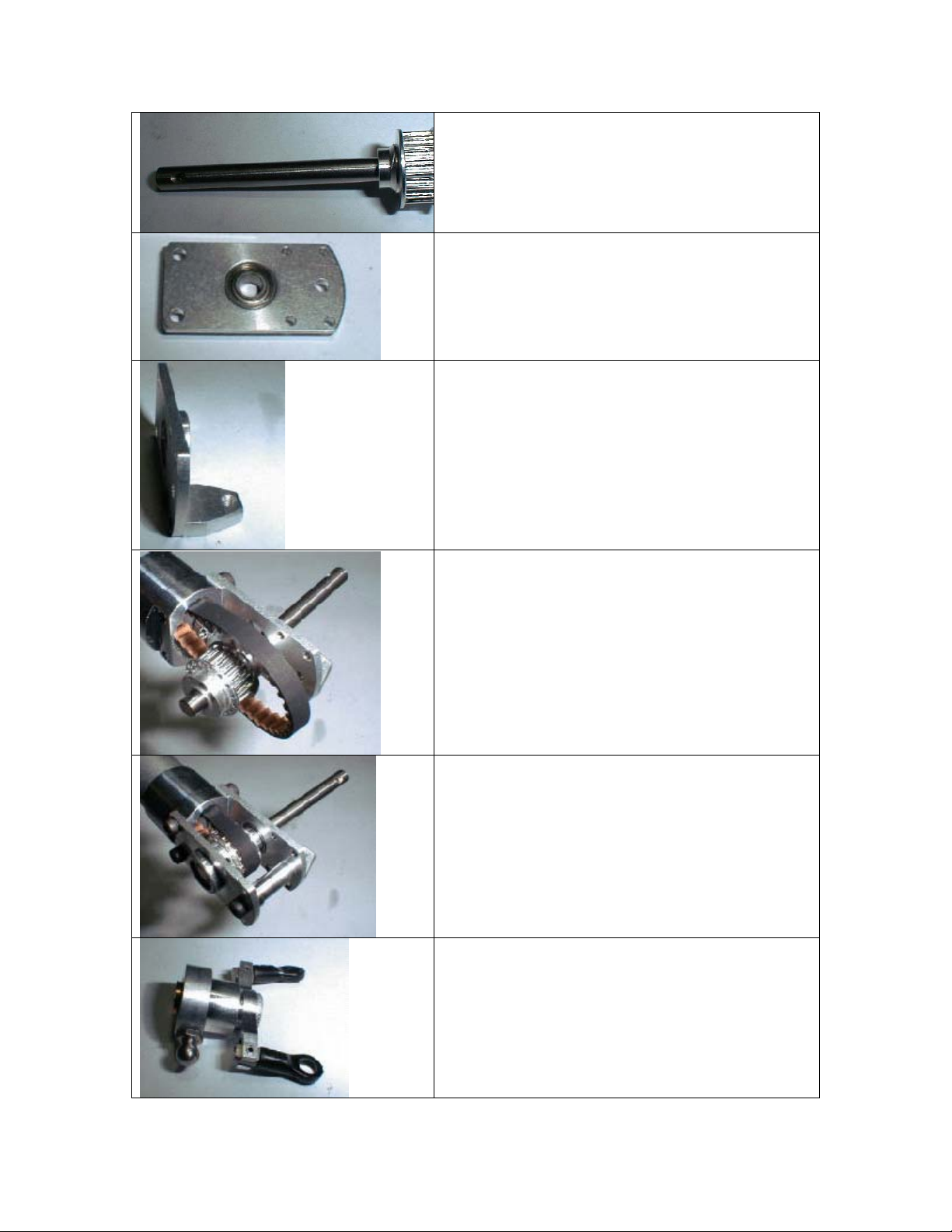

Locate your tail output shaft and tail pulley gear.

Secure the gear to the shaft using (2) M3x3 set

screw.

The set screw should align with the hole in the

shaft and installs on the longer end

Locate your two tail case side plates. Install a

5x10x4R Bearing into each plate.

Attach the tail pitch lever mount to the side plate

using (2) M2x6 pan head screws.

Attach the side plate to the boom using two

M3x6 cap head screws. Next slide your tail

output and shaft through the side plate.

Attach the other tail case side plate to the tail

boom using (2) M3x6 cap head screws. Also

attach the tail case cross member using (2) M3x6

cap head screws.

Locate your tail pitch slider, (2) medium ball

ends, and an M3x4 pivot stud.

23

Page 24

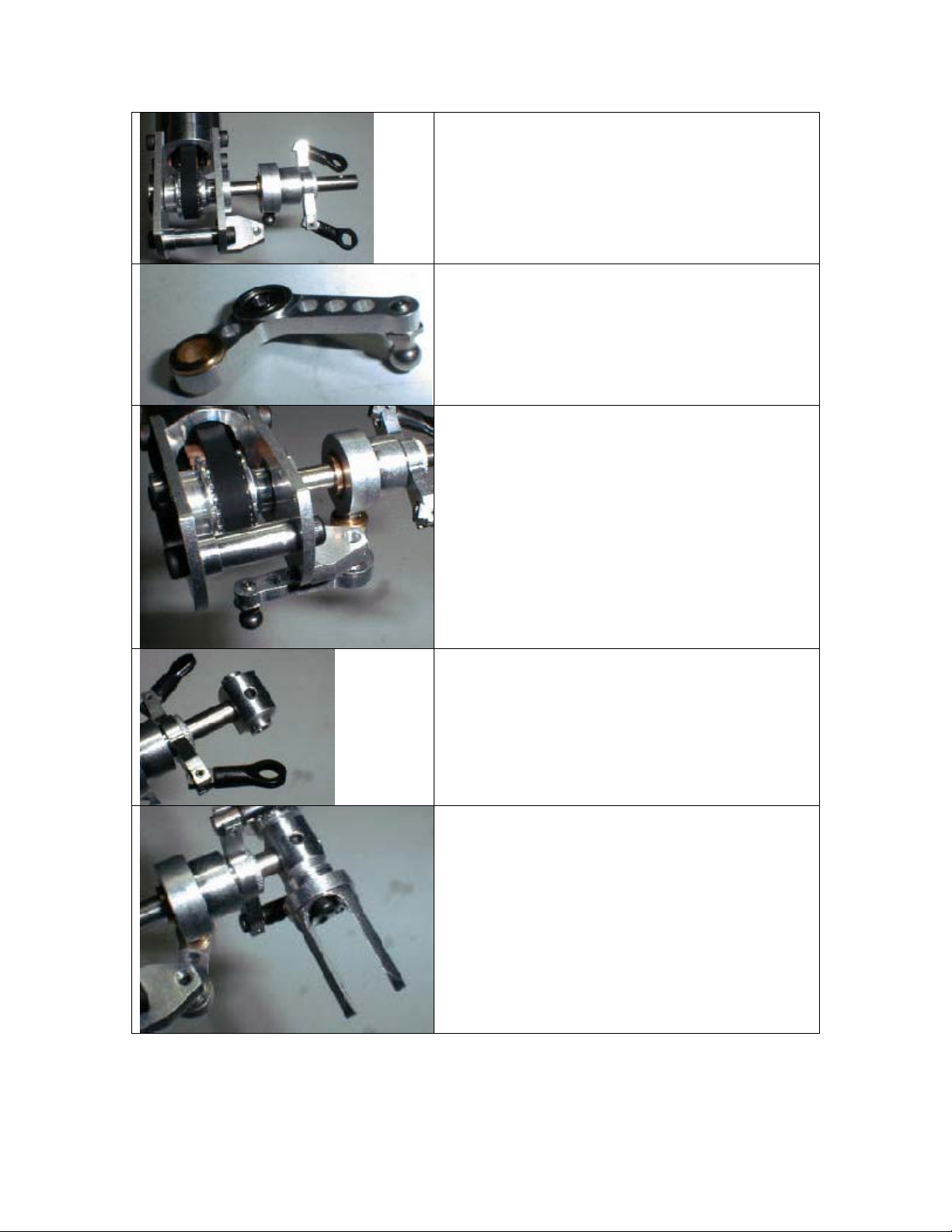

Slide the tail pitch slider assembly onto the tail

output shaft.

Attach the M3x4 pivot stud to the tail pitch lever.

Attach the tail pitch lever to the tail pitch lever

base using an M3x10 cap head screw. Be sure

that you capture the M3x4 pivot stud in the tail

pitch slider with the brass coupler in the tail

pitch lever.

Attach the tail rotor hub to the tail output shaft

using an M3x3 set screw.

Install a 3x7x3R bearing into each tail blade grip.

Then attach each grip to the tail rotor hub using

an M3x6 cap head screw.

Install a shim ball onto each blade grip using an

M2x8 pan head screw. They should go in the

outmost holes.

24

Page 25

Attach a tail blade to each grip using (2) tail

blade spacers, an M3x20 cap head bolt, and an

M3 locknut.

Note: The Tail Blades should rotate counter

clockwise when looking at the right side of the

Tail Case.

25

Page 26

Section 6 – Fin Set Installation

Parts List

Vertical Fin

Horizontal Fin

C-clamp x 2

M3x14 Cap head screw x 4

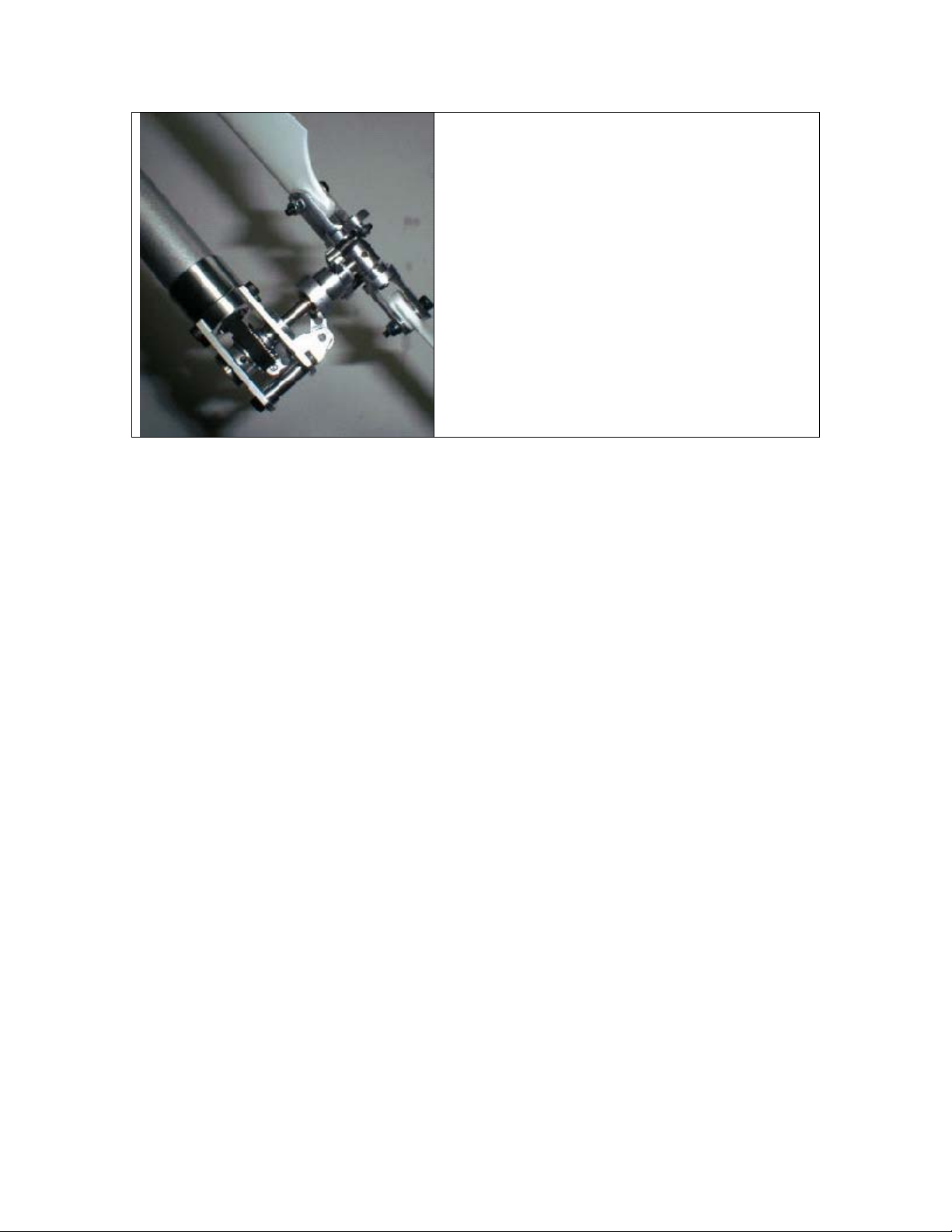

Attach the horizontal fin using one c-clamp

and (2) M3x14 cap head screws.

Note: Be sure the fin doesn’t interfere with

the tail blades when they are rotating.

Attach the vertical fin using one c-clamp

and (2) M3x14 cap head screws.

26

Page 27

Section 7 – Linkage Rod Installation

Parts List

M2x8 Pan head screws x 6

Shim ball x 6

M2.3x35mm Linkage Rod x 3

M2.3x50mm Linkage Rod x 3

M2.3x20mm Linkage Rod x 2

2.3mm Ball end, Medium x 8

Tail Rotor Pushrod guide set. (Clips,

two inner sleeves (2))

Attach each servo using (4) M3x14 Cap head screws and (4) M3 Locknuts. Look at the

pictures that follow for the proper servo orientation.

Step 1 – Linkage Rod Setup

In the following table the linkages will

be measured center to center as per

the picture. The table explains the

amount of rods you need to make and

which ball links to use on each end.

This will get the helicopter close to

finished setup, as always you will need

to make some final adjustments to

maximize the performance of your

Helicopter

Replacement Part #:

Linkage Rod Set – QC150

All Linkages available individually just

know the size

2.3mm Ball end, Long x 10

Double Link x 2

Canopy

Rubber grommets x 4

M3x14 Cap head screws x 4

Stainless rudder control rod end x 2

M3x14 Cap head screw x 40

M3 Locknut x 40

Step 1A – Shim Ball Installation

Install (6) Shim Balls using (6) M2-8

Phillips Screws. Install each Shim ball

as close to the recommended distance

for the center of the servo splice and

the center of the shim balls.

Swashplate

Servos

Rudder Servo 11.75-13mm

27

18-20mm

Page 28

All three swashplate rods will

be the same length.

# of Rods

Rod Size

Ball Link 1

Ball Link 2

Center to

Center

3

2.3-35

Medium

Medium

50mm

Pitch and aileron servo arm balls are mounted on the inside.

Elevator ball is mounted facing outside of the servo arm.

Rod Use

# of Rods

Rod Size

Ball Link 1

Ball Link 2

Center to

Center

Washout to

Flybar Control

Arm

1

2.3-20

Medium

Medium

38mm

28

Page 29

Seesaw to Hiller Arm

Use a double link on this spot.

Assemble the push rod guides.

There are three pieces the main

clip and two inner sleeves.

Simply slide the two sleeves

into each other and then into the

main clip and glue. Putting

electrical tape onto the boom

before gluing is good, so it is

possible to reuse the clip later.

(HHI2900 – Rod Guides)

Install the carbon rudder control

rod. The rod should end up 22”

or 558mm long from ball to

ball. Slide the carbon rod

through the guides and glue the

ends on. Screw the links onto

the ends and attach to the balls.

29

Page 30

Swashplate to

Rod Use

# of Rods

Rod Size

Ball Link 1

Ball Link 2

Center to

Center

Hiller arm

2

2.3-50

Long

Long

83mm

Place the canopy where you

like, mark the holes for the

canopy standoffs. Use a ¼”

drill bit. Place the grommets in

the holes and secure the canopy

to the helicopter using (4)

M3x14 cap head screws.

30

Page 31

Section 8 – Motor Installation

Parts List

M3x6 Cap Head Screw x 2

Pinion Gear x 1

M3x5 Set Screw x 1

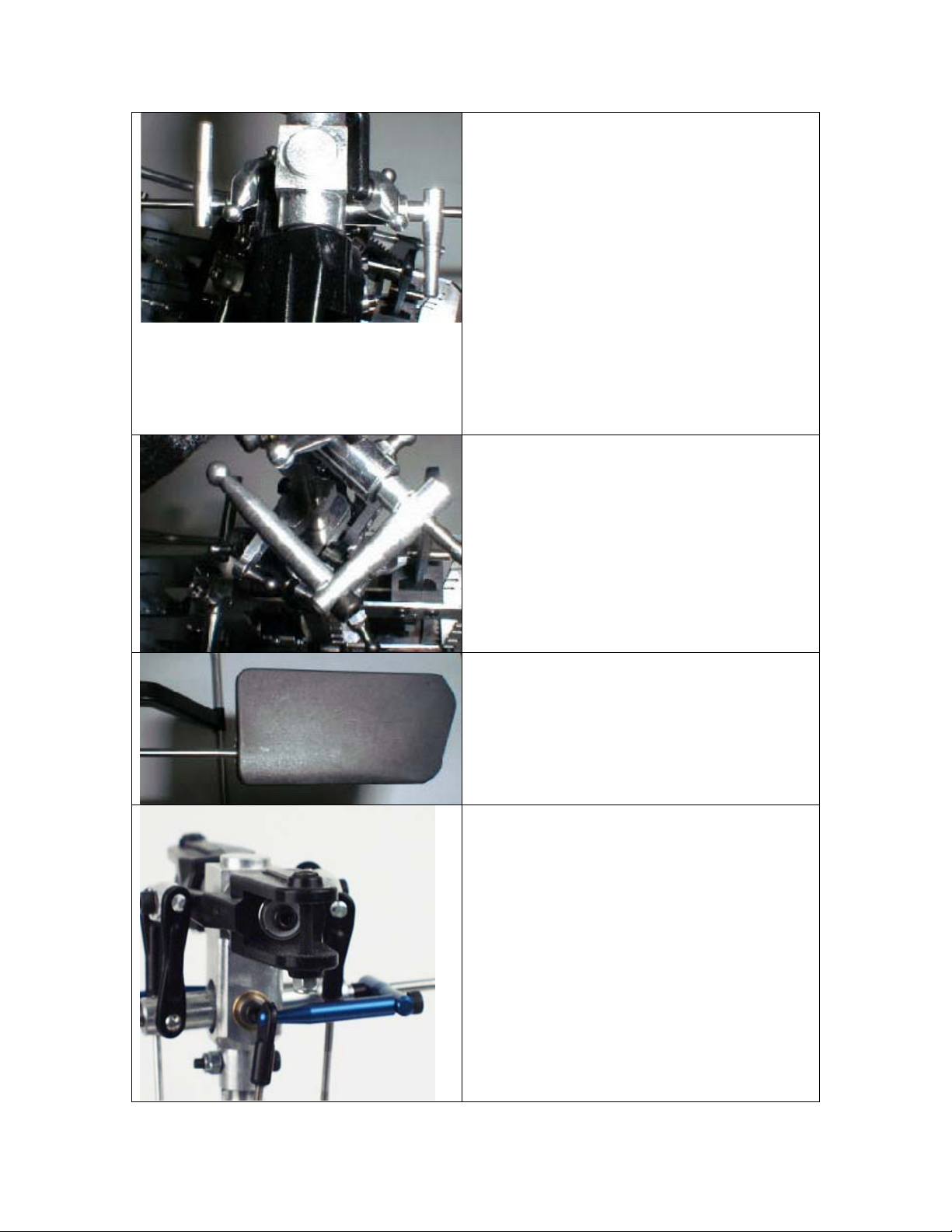

Attach your pinion gear to

the motor using an M3x5 set

screw. It is recommended to

grind a flat onto the output

shaft of the motor if there is

not already one there. This

will help to prevent the gear

from slipping.

Attach the motor to the

motor mount using (2) M3x6

cap head screws.

31

Page 32

Finally install the motor

assembly into the helicopter.

Be sure not to set the gear

mesh too tight or too loose.

A good way to set the mesh

is to slide a piece of

notebook paper between the

gears and then tighten the

bolts. This will give an idea

mesh.

32

Loading...

Loading...