Page 1

Product Specification

802.11b/g High Performance Enterprise

Device Server

Revision: 1.2

July 2010

File name: databook wlng dp500 family v1.2.doc

Document Number: 100-8080-120

Page 2

Quatech, Inc. Airborne Enterprise Module Databook

<Page Intentionally Left Blank>

2 7/15/2010 100-8080-120

Page 3

Airborne Enterprise Module Databook Quatech, Inc.

Quatech Confidential

Copyright © 2009 QUATECH ® Inc.

ALL RIGHTS RESERVED. No part of this publication may be copied in any form, by photocopy, microfilm, retrieval

system, or by any other means now known or hereafter invented without the prior written permission of QUATECH ® Inc..

This document may not be used as the basis for manufacture or sale of any items without the prior written consent of

QUATECH Inc. is a registered trademark of QUATECH Inc..

Airborne™ is a trademark of QUATECH Inc..

All other trademarks used in this document are the property of their respective owners.

The information in the document is believed to be correct at the time of print. The reader remains responsible for the

system design and for ensuring that the overall system satisfies its design objectives taking due account of the information

presented herein, the specifications of other associated equipment, and the test environment.

QUATECH ® Inc. has made commercially reasonable efforts to ensure that the information contained in this document is

accurate and reliable. However, the information is subject to change without notice. No responsibility is assumed by

QUATECH for the use of the information or for infringements of patents or other rights of third parties. This document is

the property of QUATECH ® Inc. and does not imply license under patents, copyrights, or trade secrets.

QUATECH Inc..

Disclaimer

Quatech, Inc. Headquarters

QUATECH ® Inc..

5675 Hudson Industrial Parkway

Hudson, OH 44236

USA

Telephone: 330-655-9000

Toll Free (USA): 800-553-1170

Fax: 330-655-9010

Technical Support: 714-899-7543 / wirelesssupport@quatech.com

Web Site: www.quatech.com

100-8080-120 7/15/2010 3

Page 4

Quatech, Inc. Airborne Enterprise Module Databook

<Page Intentionally Left Blank>

4 7/15/2010 100-8080-120

Page 5

Airborne Enterprise Module Databook Quatech, Inc.

Contents

Product Specification ............................................................................................................................... 1

1.0 Conventions ..................................................................................................................................... 7

1.1 Terminology ................................................................................................................................ 7

1.2 Notes ................................ ................................................................ ................................ ............ 7

1.3 Caution ......................................................................................................................................... 7

1.4 File Format .................................................................................................................................. 7

2.0 Product Description ........................................................................................................................ 8

3.0 Block Diagram ................................................................................................................................. 9

4.0 Model Numbers ..............................................................................................................................10

5.0 Pin out and Connectors ................................................................................................................11

5.1 Digital UART Ports ....................................................................................................................13

5.2 Ethernet PHY Port .....................................................................................................................13

5.3 Serial Peripheral Interface (SPI) .............................................................................................14

5.4 Debug/Console Port ..................................................................................................................14

5.5 General Purpose Input/Output (GPIO) ...................................................................................14

5.6 Connector Definition .................................................................................................................15

6.0 Electrical & RF Specification ........................................................................................................16

6.1 AC Electrical Characteristics – Transmitter ...........................................................................19

6.2 Performance/Range ..................................................................................................................19

7.0 SPI Interface ...................................................................................................................................21

7.1 Pinout ..........................................................................................................................................21

7.2 SPI AC Characteristics .............................................................................................................22

7.3 SPI Protocol ...............................................................................................................................23

7.4 SPI Commands..........................................................................................................................24

8.0 Antenna ................................................................................................ ................................ ...........27

8.1 Antenna Selection .....................................................................................................................27

8.2 Host Board Mounted Antenna .................................................................................................27

8.3 Host Chassis Mounted Antenna..............................................................................................28

8.4 Embedded Antenna ..................................................................................................................28

8.5 Antenna Location ......................................................................................................................29

8.6 Performance ...............................................................................................................................30

9.0 RESET Function ............................................................................................................................32

9.1 Reference RESET Circuit ........................................................................................................33

10.0 Mechanical Outline ........................................................................................................................34

10.1 Recommended Connectors .....................................................................................................35

11.0 Certification & Regulatory Approvals ..........................................................................................36

11.1 FCC Statement ..........................................................................................................................36

11.2 FCC RF Exposure Statement ..................................................................................................36

11.3 Information for Canadian Users (IC Notice) ..........................................................................36

11.4 FCC/IOC Modular Approval .....................................................................................................37

11.5 Regulatory Test Mode Support ...............................................................................................38

12.0 Physical & Environmental Approvals ..........................................................................................39

13.0 Change Log ....................................................................................................................................40

100-8080-120 7/15/2010 5

Page 6

Quatech, Inc. Airborne Enterprise Module Databook

Figures

Figure 1- WLNG-AN-DP500 Module Example ........................................................................................ 8

Figure 2 - WLNG-SE/SP/AN/ET-DP500 Block Diagram ........................................................................ 9

Figure 3 - SPI Read/Write Timing ............................................................................................................22

Figure 4 - SPI Clock and Select Timing ..................................................................................................22

Figure 5 - Power on RESET Timing .........................................................................................................32

Figure 6 - RESET Timing ..........................................................................................................................32

Figure 7 - RESET Circuit ...........................................................................................................................33

Figure 8 - Mechanical Outline ...................................................................................................................34

Tables

Table 1 - Model Numbers ..........................................................................................................................10

Table 2 – Module Pin Definition ................................................................................................................11

Table 3 - UART Pin Definition ...................................................................................................................13

Table 4- Absolute Maximum Values1 .......................................................................................................16

Table 5 – Operating Conditions & DC Specification ..............................................................................16

Table 6 - RF Characteristics – 802.11b/g ...............................................................................................18

Table 7 - Supported Data Rates by Band ...............................................................................................19

Table 8 - Operating Channels ...................................................................................................................19

Table 10 - Radio Typical Performance Range .......................................................................................20

Table 11 - SPI Pinout Details ....................................................................................................................21

Table 12 - SPI Signal Descriptions ..........................................................................................................21

Table 13 - SPI AC Timings ........................................................................................................................22

Table 14 - TX Message Header ...............................................................................................................23

Table 15 - RX Message Header ...............................................................................................................23

Table 16 - SPI Command Description .....................................................................................................24

Table 17 - Embedded Antenna Options ................................................................................................ ..28

Table 18 - RESET Timing ..........................................................................................................................32

Table 19 - Regulatory Approvals ..............................................................................................................36

Table 20 - Mechanical Approvals ................................................................................................ .............39

6 7/15/2010 100-8080-120

Page 7

Airborne Enterprise Module Databook Quatech, Inc.

The area next to the indicator will identify the specific information and make any

references necessary.

The area next to the indicator will identify the specific information and make any

references necessary.

1.0 Conventions

The following section outlines the conventions used within the document, where

convention is deviated from the deviation takes precedence and should be followed. If

you have any question related to the conventions used or clarification of indicated

deviation please contact Quatech Sales or Wireless Support.

1.1 Terminology

Airborne Enterprise Device Server and AirborneDirect Enterprise Device

Server is used in the opening section to describe the devices detailed in this

document, after this section the term module will be used to describe the

devices.

1.2 Notes

A note contains information that requires special attention. The following

convention will be used. The area next to the indicator will identify the specific

information and make any references necessary.

1.3 Caution

A caution contains information that, if not followed, may cause damage to the

product or injury to the user. The shaded area next to the indicator will identify

the specific information and make any references necessary.

1.4 File Format

These documents are provided as Portable Document Format (PDF) files. To

read them, you need Adobe Acrobat Reader 4.0.5 or higher. For your

convenience, Adobe Acrobat Reader is provided on the Radio Evaluation Kit CD.

Should you not have the CD, for the latest version of Adobe Acrobat Reader, go

to the Adobe Web site (www.adobe.com).

100-8080-120 7/15/2010 7

Page 8

Quatech, Inc. Airborne Enterprise Module Databook

2.0 Product Description

The WLNG-AN-DP500 family is the latest generation of 802.11 wireless device servers

from Quatech. The radio features the following:

802.11b/g WiFi Radio with 32bit ARM9 CPU (128Mb SDRAM, 64Mb Flash)

Supports WEP, WPA, WPA2 and 802.1x Supplicant, with Certificates.

The wireless device server includes integrated:

802.11b/g radio driver

TCP/IP stack, UDP, telnet, FTP server

Data bridging and buffering

Command Line Interface

Web interface

WPA Supplicant

802.11 Radio Driver

Supports antenna diversity

Operating Temperature (-40°C to 85°C)

Storage temp (-50°C to 125°C)

36 pin high density SMT connector (Hirose DF12-36)

Dual (2) Hirose U.FL RF connector for RF antenna

Multiple host interfaces supported:

Dual UART (960K BAUD)

Serial (RS232/422/485)

SPI

10/100 Ethernet PHY

Advanced Low power modes

Rugged mounting options.

No host driver required

Small form factor module (Dimensions: 29mm x 21mm x 6.0mm)

Worldwide Regulatory Support

Figure 1- WLNG-AN-DP500 Module Example

8 7/15/2010 100-8080-120

Page 9

Airborne Enterprise Module Databook Quatech, Inc.

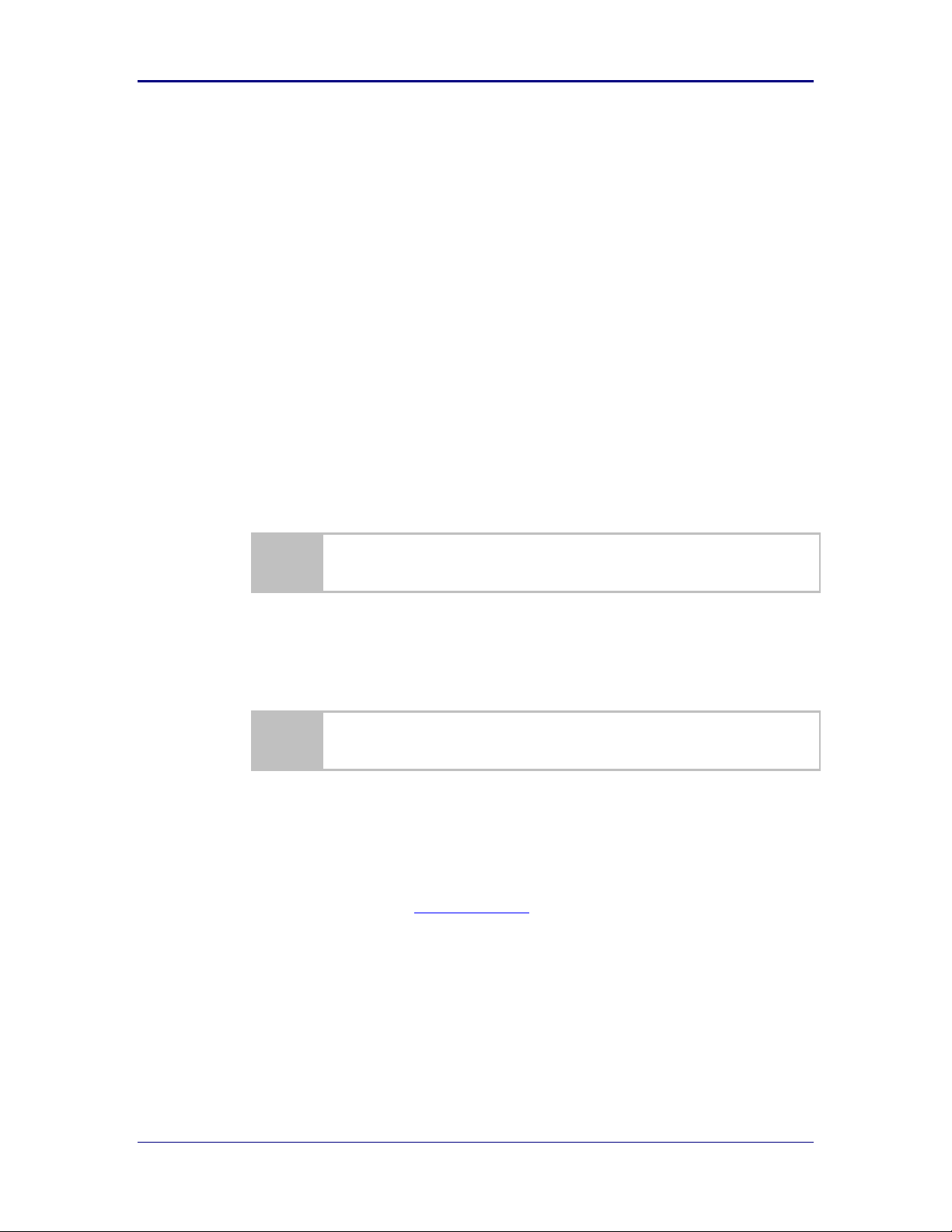

3.0 Block Diagram

The following outlines the block diagram of the radio:

Figure 2 - WLNG-SE/SP/AN/ET-DP500 Block Diagram

100-8080-120 7/15/2010 9

Page 10

Quatech, Inc. Airborne Enterprise Module Databook

WiFi

802.11b/g UART RS232 RS485 SPI Ethernet GPIO WEP WPA WPA2 EAP

WLNG-SE-DP501

802.11b/g, UART Interface with

RS232/422/485 Driver Control

l l l l l l l l l l

WLNG-SP-DP501

802.11b/g, SPI Interface

l l l l l l l l

WLNG-AN-DP501

802.11b/g, UART Interface

l l l l l l l l l l

WLNG-ET-DP501

802.11b/g, 10/100 Ethernet Interface

l l l l l l l l

WLNG-EK-DP501 802.11b/g Enterprise Class Serial Device Server Module Eval Kit (inc. WLNG-SE/AN-DP501)

l

WLNG-EK-DP502

802.11b/g Enterprise Class SPI Device Server Module Eval Kit (inc. WLNG-SP-DP501)

l

WLNG-EK-DP503 802.11b/g Enterprise Class Ethernet Bridge Module Eval Kit (inc. WLNG-ET-DP501)

l

RoHS

Eval Kit

Model Number

Interface

Security

Description

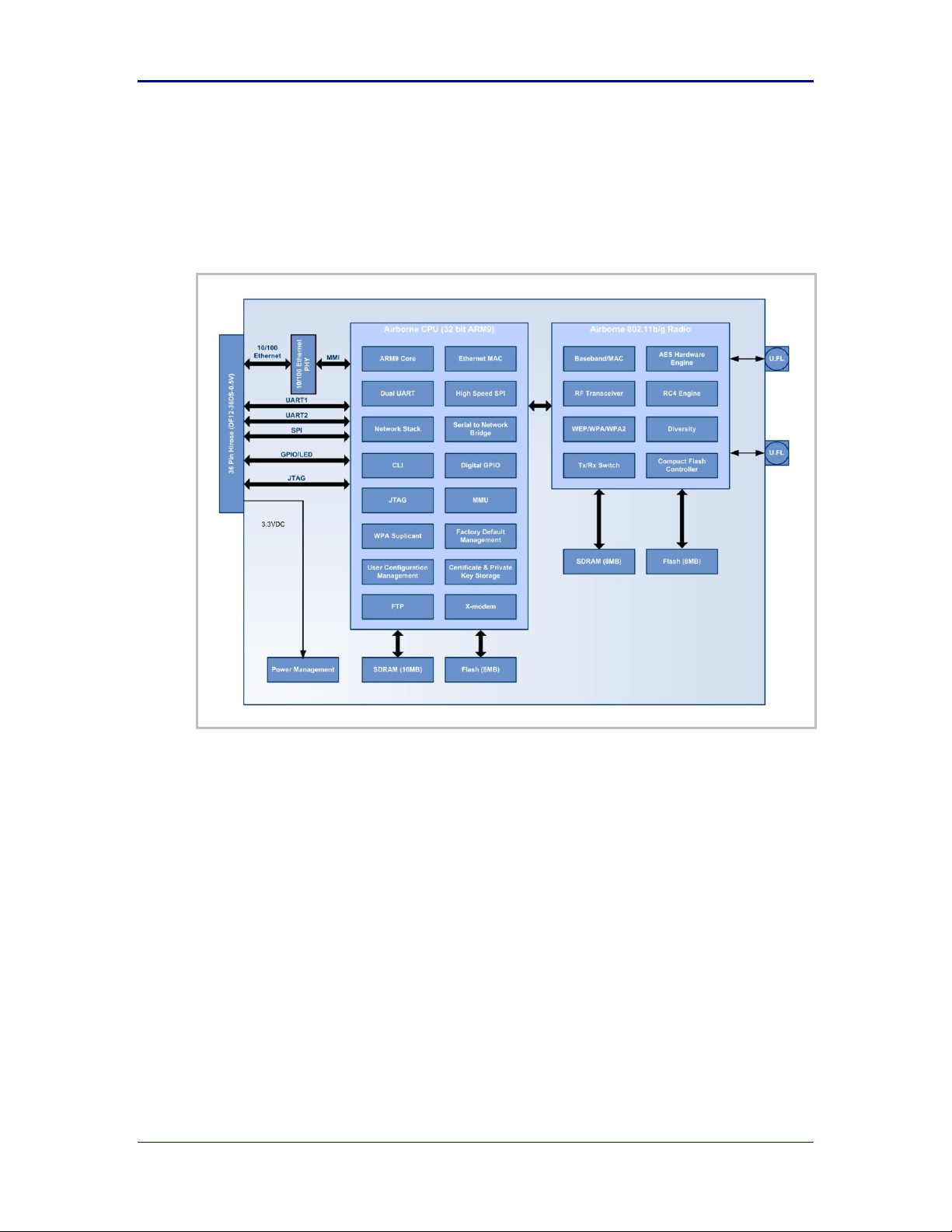

4.0 Model Numbers

The following table identifies the model numbers associated with the device server family.

Please contact Quatech sales for details, quotes and availability.

Table 1 - Model Numbers

10 7/15/2010 100-8080-120

Page 11

Airborne Enterprise Module Databook Quatech, Inc.

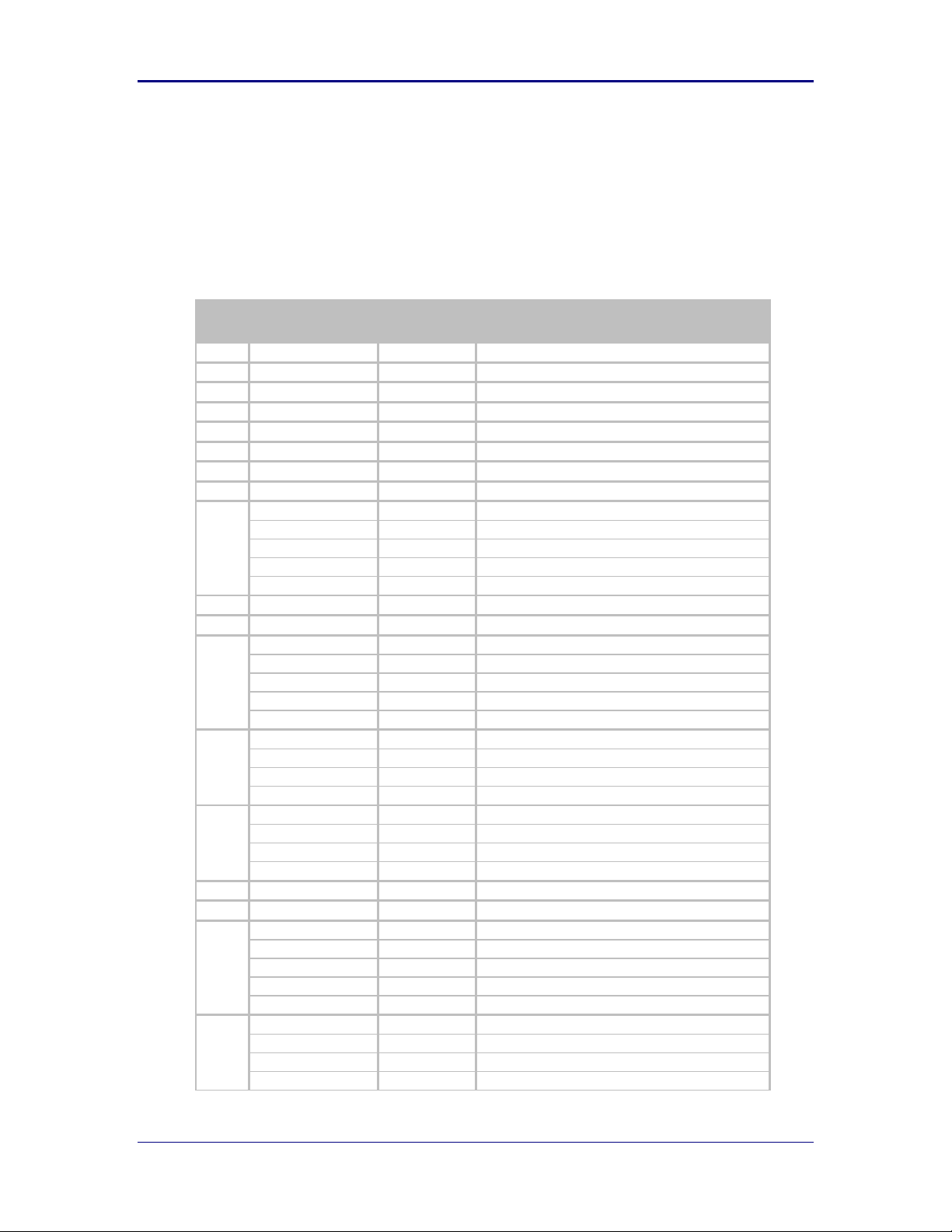

Pin

Name

Device

Type

Description

1

GND

All

Digital Ground

2

TDI

All

JTAG: Test data in

3

VDD

All

3.3VDC 4 VDD

All

3.3VDC 5 RTCK

All

JTAG: Return Test Clock

6

DTXD

All

D

OUT

Debug

7

/RESET

All

Module RESET 8 DRXD

All

DIN Debug

9

RXD2

UART

DIN UART2

RXD2

Serial

DIN UART2

RXD2

SPI

DIN UART2

RXD2

Ethernet

DIN UART2

G6

All

GPIO

10

TDO

All

JTAG: Test data out

11

/FRESET

All

Factory RESET

12

CTS1

UART

Clear-to-Send UART1

CTS

Serial

Clear-to-Send

/SPI_SEL

SPI

SPI Select

CTS1

Ethernet

Clear-to-Send UART1

F5

All

GPIO

13

NC

UART

No Connect

NC

Serial

No Connect

NC

SPI

No Connect

RX+

Ethernet

Ethernet RX+

14

NC

UART

No Connect

NC

Serial

No Connect

NC

SPI

No Connect

RX-

Ethernet

Ethernet RX-

15

GND

All

Digital Ground

16

GND

All

Digital Ground

17

RTS2

UART

Ready-to-Send UART2

/TXEN

Serial

Line Driver Tx enable

RTS2

SPI

Ready-to-Send UART2

RTS2

Ethernet

Ready-to-Send UART2

G2

All

GPIO

18

RTS1

UART

Ready-to-Send UART1

RTS

Serial

Ready-to-Send

SPI_CLK

SPI

SPI Clock Input

RTS1

Ethernet

Ready-to-Send UART1

5.0 Pin out and Connectors

Pin definition is dependent upon the device type selected. The specific pin function is

defined in Table 2 for each device type. Where multiple options are available for a single

device type, these options are software selectable by the device firmware.

Table 2 – Module Pin Definition

100-8080-120 7/15/2010 11

Page 12

Quatech, Inc. Airborne Enterprise Module Databook

Pin

Name

Device

Type

Description

F4

All

GPIO

19

CTS2

UART

Clear-to-Send UART2

RXEN

Serial

Line driver Rx enable

CTS2

SPI

Clear-to-Send UART2

CTS2

Ethernet

Clear-to-Send UART2

G1

All

GPIO

20

TCK

All

JTAG: Test clock

21

TXD2

UART

D

OUT

UART2

TXD2

Serial

D

OUT

UART2

TXD2

SPI

D

OUT

UART2

TXD2

Ethernet

D

OUT

UART2

G7

All

GPIO

22

G0

UART

GPIO

SER_MODE

Serial

Serial interface type selection (RS232/422/485)

SPI_INT

SPI

SPI Interrupt

G0

Ethernet

GPIO

23

LED_CON

All

Valid TCP/IP Connection Indicator

F6

GPIO

24

RXD1

UART

DIN UART1

RXD1

Serial

DIN UART1

MOSI

SPI

DIN SPI

RXD1

Ethernet

DIN UART1

F7

All

GPIO

25

LED_POST

All

POST Status Indicator

F0

GPIO

26

LED_WLN_CFG

All

Module TCP/IP Configuration Indicator

F3

GPIO

27

LED_RF_LINK

All

Module RF Link Status Indicator

F2

GPIO

28

TXD1

UART

D

OUT

UART1

TXD

Serial

D

OUT

MISO

SPI

D

OUT

SPI

TXD1

Ethernet

D

OUT

UART1

F1

All

GPIO

29

NC

UART

No Connect

NC

Serial

No Connect

NC

SPI

No Connect

TX-

Ethernet

Ethernet TX-

30

NC

UART

No Connect

NC

Serial

No Connect

NC

SPI

No Connect

TX+

Ethernet

Ethernet TX+

31

NTRST

All

JTAG: Test RESET signal

32

TMS

All

JTAG: Test mode select

33

VDD

All

3.3VDC

34

VDD

All

3.3VDC

35

LED_RF_ACT

All

Radio Status Indicator, driven by the radio.

36

GND

All

Digital Ground

12 7/15/2010 100-8080-120

Page 13

Airborne Enterprise Module Databook Quatech, Inc.

Device Type

UART

Serial

All

Pin Definition

UART1

Pin

UART2

Pin

UART1

Pin

UART2

Pin

Debug

Data out (D

OUT

)

28

21

28

21

6

Data In (DIN)

24 9 24 9 8

Clear-to-Send (CTS)

12

19

12

Ready-to-Send (RTS)

18

17

18

Transmit Enable (/TXEN)

17

Receive Enable (/RXEN)

19

Serial Mode (SER_MOD)

22

5.1 Digital UART Ports

The units supports two digital UART ports, use of these ports is determined by

the device type choice made in firmware. The details of the ports can be seen in

Table 3.

The availability of UART2 for these device types is selected in firmware.

Table 3 - UART Pin Definition

The primary UART supports a 4-wire interface; the secondary port supports 4wire interface except when being used with the Serial Device type, in which case

it is reduced to a 2-wire only.

The primary digital UART can be used as the primary connection for the Serial

device type. This type supports a 7-wire interface to allow the definition of the

serial interface type (RS232/3422/485) and the data transfer direction. Definitions

of this interface can be seen in Table 3.

The UART1 and UART2 interfaces support the following configurations:

BAUD: 300, 600, 1200, 2400, 4800, 9600, 14400, 19200, 28800, 38400,

57600, 115200, 230400, 460800, 921600

Flow Control: None, Hardware (CTS/RTS), Software (XON/XOFF)

Default settings: 9600, 8, N, 1, No Flow Control.

5.2 Ethernet PHY Port

A 10/100 Ethernet PHY interface is supported when the Ethernet device type is

selected in firmware. This interface is a 10/100Mbps interface that supports auto

negotiation and cross-over cabling. The interface also supports both half and full

duplex for 10Mbps and 100Mbps.

The interface uses a Broadcom BCM5241A Ethernet PHY, please refer to the

manufacturers datasheet for interface details and appropriate design guidelines.

100-8080-120 7/15/2010 13

Page 14

Quatech, Inc. Airborne Enterprise Module Databook

CAUTION: Do not use the debug port without contacting Quatech Technical

Support first. Potential damage to the module may occur.

5.3 Serial Peripheral Interface (SPI)

Please refer to section 7.0 for details on this interface.

5.4 Debug/Console Port

A debug/console port is supported by a 2-wire serial interface defined in Table 3.

This port is a bidirectional serial port intended for debug of the unit only, it does

not support data transfer.

It is recommended that a connection to this port be supported via test points or a

two pin header. The default settings for the debug port are 115200, 8, N 1, No

Flow Control.

5.5 General Purpose Input/Output (GPIO)

A number of the interface pins support multiple functional definitions. Those

defined as alternately GPIO pins can be selected as such via device firmware.

The GPIO pins are digital I/O capable of supporting up to a 16mA drive current at

3.3VDC.

14 7/15/2010 100-8080-120

Page 15

Airborne Enterprise Module Databook Quatech, Inc.

RF Shield

J2

Top View

Bottom

View

J1

Component

Area

J3

5.6 Connector Definition

There are a total of three connectors to the radio:

J1: 36 pin Digital Host interface.

Hirose: DF12-36DP-0.5V(XX) (0.50mm (.020") Pitch Plug, Surface

Mount, Dual Row, Vertical, 4.00mm Stack Height, 36 Circuits)

J2: Primary RF connector for 802.11b/g antenna.

Hirose U.FL

J3: Secondary RF connector for 802.11b/g antenna.

Hirose U.FL.

100-8080-120 7/15/2010 15

Page 16

Quatech, Inc. Airborne Enterprise Module Databook

Parameter

Min

Max

Unit

Maximum Supply Voltage

-0.3

4.0

VDC

Power Dissipation

2.00

W

Operating Temperature Range

-40

85 oC

Storage Temperature

-50

125 oC

Symbol

Parameter

Min

Typ

Max

Units

VDD

Supply Voltage

3.00

3.30

3.60

V

VIL

Input Low Level Voltage

-0.3 0.8

VIH

Input High Level Voltage

2.0

VDD + 0.3

VOL

Output Low Level Voltage

0.4

VOH

Output High Level Voltage

VDD - 0.4

I

CCTXG

Operating Current – UART Data In (802.11g)

Transmitting @ 54Mb/s

UART 100% Duty Cycle @ 920K BAUD

340

360

mA

I

CCRXG

Operating Current – UART Data Out

(802.11g)

Receiving valid packets @ 54Mb/s

UART 100% Duty Cycle@ 920K BAUD

480

490

mA

I

CCTXB

Operating Current – UART Data In (802.11b)

Transmitting @ 11Mb/s

UART 100% Duty Cycle @ 920K BAUD

340

360

mA

I

CCRXB

Operating Current – UART Data Out

(802.11b)

Receiving valid packets @ 11MB/s

UART 100% Duty Cycle @ 920K BAUD

480

490

mA

I

CCTXG_ETH

Operating Current – Ethernet Data In

(802.11g)

Transmitting @ 54Mb/s

10/100 Ethernet 100% Duty Cycle

470

500

mA

I

CCRXG_ETH

Operating Current – Ethernet Data Out

(802.11g)

Receiving @ 54Mb/s

10/100 Ethernet 100% Duty Cycle

520

560

mA

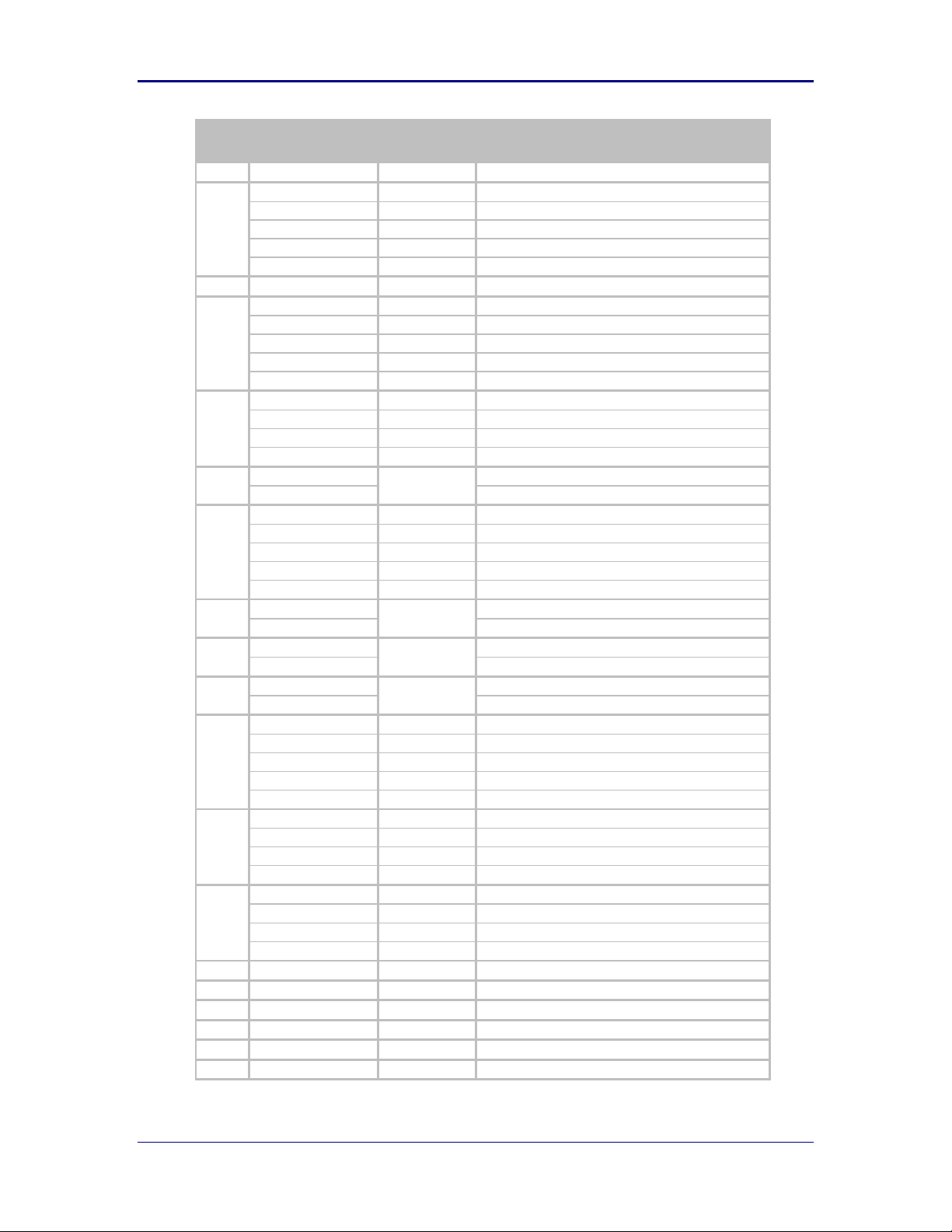

6.0 Electrical & RF Specification

Table 4- Absolute Maximum Values1

Note: 1. Values are absolute ratings, exceeding these values may cause permanent damage to the device.

Table 5 – Operating Conditions & DC Specification

16 7/15/2010 100-8080-120

Page 17

Airborne Enterprise Module Databook Quatech, Inc.

Symbol

Parameter

Min

Typ

Max

Units

I

CCTXB_ETH

Operating Current – Ethernet Data In

(802.11b)

Transmitting @ 11Mb/s

10/100 100% Duty Cycle

520

560

mA

I

CCRXB_ETH

Operating Current – Ethernet Data Out

(802.11b)

Receiving @ 11Mb/s

10/100 Ethernet 100% Duty Cycle

500

530

mA

I

CCU

Radio and CPU on. No data traffic (UART)

340

360

mA

I

CCE

Radio and CPU on. No data traffic (Ethernet)

330

350

mA

I

SBU0

Radio off (UART)

CPU Idle, radio off (f/w control)

350

360

mA

I

SBE0

Radio off (Ethernet)

CPU Idle, radio off (f/w control)

360

370

mA

I

SB1

Doze Mode

IEEE PSPoll mode, Associated, Idle, Beacon

Interval = 100ms

CPU Idle, wake on UART or Network traffic

140 210

mA

I

SB3U

Sleep Mode – UART/Serial

Radio in Deep Sleep (disassociated)

CPU Idle, wake on UART traffic

102 mA

I

SB3E

Sleep Mode – Ethernet

Radio in Deep Sleep (disassociated)

CPU Idle, wake on pm-mode

95 mA

100-8080-120 7/15/2010 17

Page 18

Quatech, Inc. Airborne Enterprise Module Databook

Symbol

Parameter

Rate (Mb/s)

Min

dBm

Average

dBm / mW

Peak

dBm / mW

Units

P

OUTB

Transmit Power

Output 802.11b

11, 5.5, 2, 1

13

15

31.6

19.3

85.1

dBm/mW

P

OUTG

Transmit Power

Output 802.11g

6, 9,12,18, 24,

36, 48, 54

10

12

15.9

21.5

141.3

dBm/mW

P

RSENB

Receive Sensitivity

802.11b

11

-84

dBm

5.5

-85 2

-86 1

-86

P

RSENG

Receive Sensitivity

802.11g

54

-69

dBm

48

-70 36

-74

24

-78 18

-81 12

-83 9

-85 6

-86 F

RANGEBG

Frequency Range

2412 2484

MHz

Table 6 - RF Characteristics – 802.11b/g

18 7/15/2010 100-8080-120

Page 19

Airborne Enterprise Module Databook Quatech, Inc.

Band

Supported Data Rates (Mb/s)

802.11b

11, 5.5, 2, 1

802.11g

54, 48, 36, 24, 18, 12, 9, 6

Band

Region

Freq Range

(GHz)

No. of

Channels

Channels

802.11b

US/Canada

2.401 - 2.473

11

1 – 11

Europe

2.401 - 2.483

13

1 – 13

France

2.401 - 2.483 4 10 – 13

Japan

2.401 - 2.495

14

1 – 14

802.11g

US/Canada

2.401 - 2.473

11

1 – 11

Europe

2.401 - 2.483

13

1 – 13

France

2.446 - 2.483 4 10 – 13

Japan

2.401 - 2.483

13

1 – 13

1. Only channels 1, 6 and 11 are non-overlapping.

Table 7 - Supported Data Rates by Band

Table 8 - Operating Channels

6.1 AC Electrical Characteristics – Transmitter

Transmit power is automatically managed by the device for minimum power

consumption. The MAXIMUM transmit power at the RF connector is typically

+15dBm 2 dB for B-Mode (all rates) and +12dBm+/-2dB for G-Mode (all rates).

6.2 Performance/Range

The following table illustrates the typical data rates, performance and range the

device is capable of providing using an omni-directional antenna.

100-8080-120 7/15/2010 19

Page 20

Quatech, Inc. Airborne Enterprise Module Databook

Data Rate

Typical Outdoor Distance

(Unity gain antenna)

Typical Outdoor Distance

(2dBi antenna gain on each end for

B/G mode)

1.0 Mb/s

240m

380m

11.0 Mb/s

135m

215m

6Mb/s 802.11g

135m

215m

6Mb/s 802.11a

49m

155m

54Mb/s 802.11g

12m

19m

54Mb/s 802.11a

4.5m

14m

Table 9 - Radio Typical Performance Range

Ranges are based on receiver sensitivity, Transmitter power, free-space path

loss estimates, antenna gain factors, and link margin estimates. Actual range will

vary from those stated. Non-line-of-site applications will result in typical values

less than shown above.

The Data Rate is the supported connection rate for the wireless link, the actual

data throughput for the link will be less than the stated data rates.

20 7/15/2010 100-8080-120

Page 21

Airborne Enterprise Module Databook Quatech, Inc.

Pin Definition

SPI

UART2 Pin

Debug

Master In Slave Out (MISO)

28

Master Out Slave In (MOSI)

24

SPI Interrupt (SPI_INT)

22

SPI Clock (SPI_CLK)

18

SPI Select (/SPI_SEL)

12

Data In (RxD2, DTXD)

9 8

Data out (TxD2, DRXD)

21

6

Ready-to-Send (RTS2)

17

Clear-to-Send (CTS2)

19

Pin Definition

Description

Master In Slave Out (MISO)

Serial Data OUT; must be connected to the serial data in of

the master.

Master Out Slave In (MOSI)

Serial Data IN; Must be connected to the serial data out of the

master.

SPI Interrupt (SPI_INT)

Interrupt signal driver by slave see Table 15 for details of

operation.

SPI Clock (SPI_CLK)

SPI clock sourced from the master.

SPI Select (/SPI_SEL)

Enable the SPI slave, sourced from the master. Active low

signal.

7.0 SPI Interface

The following section details the SPI interface specification for both hardware timing and

SPI protocol. The device is a SPI slave and requires a compatible SPI master for

operation.

7.1 Pinout

When the SPI interface is enabled, through the CLI or web interface, the

following pins are assigned for communication.

Table 10 - SPI Pinout Details

Table 11 - SPI Signal Descriptions

100-8080-120 7/15/2010 21

Page 22

Quatech, Inc. Airborne Enterprise Module Databook

Symbol

Parameter

Min

Typ

Max

Units

f

MAX

Maximum Clock Frequency

8.00

MHz

tCS

SPI Select Low to Clock Rising Edge

100

ns

tCH

Clock High

62.5

ns

tCL

Clock Low

62.5

ns

tDA

Clock High to Data Out

60

ns

tDS

Clock Low to Data In Valid Set-up time

14

ns

tDH

Clock Low to Data Valid Hold time

2

ns

t

CSH

Clock Falling Edge to SPI Select High

100

ns

t

DELAY

SPI Select High to SPI Select Low

40

µs

7.2 SPI AC Characteristics

The following specification identifies the required hardware timing to successfully

implement a SPI interface with the Airborne Device Server module.

Table 12 - SPI AC Timings

Figure 3 - SPI Read/Write Timing

Figure 4 - SPI Clock and Select Timing

22 7/15/2010 100-8080-120

Page 23

Airborne Enterprise Module Databook Quatech, Inc.

The /SPI_SEL signal must be deasserted between successive SPI messages. The

messages will not be processed correctly if /SPI_SEL is held asserted across multiple

messages.

0 1 2 3 CMD

PARM1

PARM2

0 1 2

3

RX Data Available

TX Buffer Available

7.3 SPI Protocol

A SPI message is composed of a 4 byte header followed by 0 or more bytes of

data. The header data is full-duplex. That is, the TX message header is sent to

the Airborne Device Server module by the host at the same time the RX

message header is sent to the host from the Airborne Device Server.

The TX message header consists of a Command (CMD) byte, followed by three

Parameter (PARM) bytes. They are described in the SPI Commands section 0

below.

The RX message header is shifted out as the first four bytes of a SPI message

regardless of the contents of the TX message header. The RX message header

consists of a RX Data Available field, and a TX Buffer Available field. The RX

Data Available field indicates the number of data bytes the Device Server has

available for the host. The data can be received by the RXDATA command. The

TX Buffer Available field indicates how many data bytes the Device Server is

able to accept from the host. This data is to be shifted in by the host using the

TXDATA (Table 15) command. Both fields are 16 bit values and are stored in

little-endian format (LSB first).

Table 13 - TX Message Header

Table 14 - RX Message Header

100-8080-120 7/15/2010 23

Page 24

Quatech, Inc. Airborne Enterprise Module Databook

Unused parameters should be set to zero.

Command

(Hex)

Name

Description

0x00

NOP

The NOP command does nothing.

It is intended to be used when the host wants to simply retrieve

the RX Message Header without any other operation.

PARM1 and PARM2 are unused for this command and should

be set to zero.

0x04

BREAK

The BREAK command will issue a break sequence to the

module.

It is analogous to the BREAK signal on a common UART. Use

this command to issue a BREAK if the esc-mode-serial brk

setting is configured in the module.

PARM1 and PARM2 are unused for this command and should

be set to zero.

0x08

TXINTCLR

The TXINTCLR command will clear the TX interrupt.

Use this command when the module is issuing a TX interrupt

but the host has no more data to send. This is analogous to the

reset TX interrupt command on a common UART. The result of

this command is that the TX interrupt is cleared even though the

host is not writing more data to the module.

PARM1 and PARM2 are unused for this command and should

be set to zero.

7.4 SPI Commands

The following commands are available for use in the CMD message header.

Table 15 - SPI Command Description

24 7/15/2010 100-8080-120

Page 25

Airborne Enterprise Module Databook Quatech, Inc.

Command

(Hex)

Name

Description

0x10

INTENA

The INTENA command will configure the specific interrupts to

be enabled from the module. For this command, the PARM1

field will define the interrupts to be enabled.

The definition of the PARM1 field for this command is a bit-mask

and is formatted as follows:

Bit 7 Interrupt Sense – Determines the asserted state of

the interrupt pin. If this bit is set to a 1, the interrupt

pin will be active high, otherwise the interrupt pin will

be active low. The module will use the setting of this

bit from the most recently issued INTENA command

to determine the Interrupt Sense.

Bit 1 TX Interrupt – If this bit is set to a 1, the interrupt

pin will be asserted when there is space available in

the TX buffer. The interrupt will be cleared when the

module has TX data to process from the host.

Alternately, the host can clear this interrupt by using

the TXINTCLR command if the host has no more data

to send.

Bit 0 RX Interrupt – If this bit is set to a 1, the interrupt

pin will be asserted when there is RX data available.

The interrupt will be cleared when the host has

received all the RX data available from the module.

All other bits of PARM1 are unused for this command

and should be set to zero.

PARM2 is unused for this command and should be set to zero.

For example, to enable TX interrupts with the interrupt pin

active high, use the SPI message 0x10 0x82 0x00 0x00. That

is, SPI command 0x10, PARM1 is 0x82, PARM2 is 0x0000.

Important: The INTENA command can only be used to enable

the specified interrupts. This command cannot be used to

disable specified interrupts by setting the corresponding

interrupt enable bits to zero in PARM1. The INTDIS command

must be used to disable the specified interrupts.

0x20

INTDIS

The INTDIS command will configure the specific interrupts to be

disabled from the module. For this command, the PARM1 field

will define the interrupts to be disabled.

The definition of the PARM1 field for this command is a bit-mask

and is formatted as follows:

Bit 1 TX Interrupt – If this bit is set to a 1, The TX

interrupt function will be disabled.

Bit 0 RX Interrupt – If this bit is set to a 1, the RX

interrupt function will be disabled.

All other bits of PARM1 are unused for this command

and should be set to zero.

PARM2 is unused for this command and should be set to zero.

For example, to disable TX interrupts, use the SPI message

0x20 0x02 0x00 0x00. That is, SPI command 0x20, PARM1 is

0x02, PARM2 is 0x0000.

100-8080-120 7/15/2010 25

Page 26

Quatech, Inc. Airborne Enterprise Module Databook

Command

(Hex)

Name

Description

0x40

TXDATA

The TXDATA command is used to send data to the module to

be interpreted as commands if the module is in CLI mode, or to

be transmitted on the wireless link if the module has an active

data connection established.

The host may send at most the number of bytes indicated by the

TX Buffer Available field in the RX Message Header. The actual

number of bytes sent by the host is determined by the 16 bit

value in PARM2. The value in PARM2 is little-endian (LSB first)

and must be less than or equal to the number in the TX Buffer

Available field. Any bytes sent in excess of this number will be

ignored.

PARM1 is unused for this command and should be set to zero.

For example, to send the auth dpac dpac command, use the

SPI message 0x40 0x00 0x0F 0x00 0x61 0x75 0x74 0x68 0x20

0x64 0x70 0x61 0x63 0x20 0x64 0x70 0x61 0x63 0x0D. That

is, SPI command 0x40, PARM1 is 0x00, PARM2 is 0x000F,

followed by the text for auth dpac dpac.

0x80

RXDATA

The RXDATA command is used to receive data from the

module. In CLI mode, this data will be the local echoing of the

commands issued to the module, as well as the command

responses generated by the module. If the module has an

active data connection established, this data will be the data

received on the wireless link.

The host may receive at most the number of bytes indicated by

the RX Data Available field in the RX Message Header. The

actual number of bytes received by the host is determined by

the 16 bit value in PARM2. The value in PARM2 is little-endian

(LSB first) and must be less than or equal to the number in the

RX Data Available field. If additional clock cycles are sent to the

module beyond this number, meaningless data will be returned.

PARM1 is unused for this command and should be set to zero.

The TXDATA and RXDATA commands can be combined for full-duplex

operation. For example, a command byte of 0xC0 would be a TXDATA and

RXDATA command combined. The result of this command would be that the

module would accept data being shifted in as TX data, while at the same time,

RX data would be shifted out. In this case, the number of bytes transferred for

TXDATA must be equal to the number of bytes transferred for RXDATA. The

PARM2 parameter will indicate the number of bytes to be transferred for both the

TXDATA and RXDATA commands.

26 7/15/2010 100-8080-120

Page 27

Airborne Enterprise Module Databook Quatech, Inc.

8.0 Antenna

The unit supports antenna connection through a single Hirose U.FL connector, located on

the top surface of the radio next to the RF shielding.

Any antenna used with the system must be designed for operation within the 2.4GHz

ISM band and specifically must support the 2.412GHz to 2.482GHz for 802.11b/g

operation. They are required to have a VSWR of 2:1 maximum referenced to a 50

system impedance.

8.1 Antenna Selection

The Airborne radio supports a number of antenna options, all of which require

connection to the U.FL connectors on the radio. Ultimately the antenna option

selected will be determined by a number of factors, these include consideration

of the application, mechanical construction and desired performance. Since the

number of possible combinations is endless we will review some of the more

common solutions in this section. If your application is not covered during this

discussion please contact Technical Support for more specific answers.

The available antenna connections include:

Host board mounted antenna

Host Chassis mounted antenna

Embedded antenna

In addition to the above options, location and performance need to be

considered, the following sections discuss these items.

8.2 Host Board Mounted Antenna

Host board mounted requires that an antenna connection is physically mounted

to the host system board. It also requires that the host board include a U.FL

connector (two (2) if diversity is being used) to allow a U.FL to U.FL coaxial lead

to connect from the radio to the host board. It will then require 50 matched PCB

traces to be routed from the U.FL connector to the antenna mount.

There are several sources for the U.FL to U.FL coaxial cable these include

Hirose, Sunridge and IPEX. Please contact Quatech for further part numbers and

supply assistance.

This approach can simplify assembly but does require that the host system

configuration can accommodate an antenna location that is determined by the

host PCB. There are also limitations on the ability to seal the enclosure when

using this approach.

This approach also restricts the selection of available antenna. When using this

approach, antennas that screw or press fit to the PCB mount connector must be

used. There are many options for the antenna connector type, however if you

wish to utilize the FCC/IOC modular approval the connector choice must comply

100-8080-120 7/15/2010 27

Page 28

Quatech, Inc. Airborne Enterprise Module Databook

Antenna Type

Features

Cost

Size

Availability

Performance

PCB Embedded

Lowest

Largest

Custom

Poor

Chip

Low

Small

Standard

Poor

Flying Lead

Low

Small

Standard

Fair

with FCC regulations, these state a non-standard connector is required e.g.

TNC/SMA are not allowed, RP-TNC/RP-SMA are allowed.

8.3 Host Chassis Mounted Antenna

Host Chassis mounted antennas require no work on the host PCB. They utilize

an antenna type called ‘flying lead’. There are two types of flying leads; one

which provides a bulkhead mounted antenna connector and one which provides

a bulk head mounted antenna. The type you choose will be determined by the

application.

A flying lead system connects a U.FL coaxial lead to the radio’s U.FL connector,

the other end of the coax is attached to either a bulkhead mounted antenna

connector or directly to an antenna that has an integrated bulkhead mount.

In either of the two cases, the use of this approach significantly reduces the

antenna system development effort and provides for greater flexibility in the

available antenna types and placement in the host system chassis.

When using the flying lead antenna (integrated bulk head mounting), there are no

connector choice restrictions for use with the FCC/IOC modular certification.

However if the flying lead connector is used, the same restrictions as identified

for the Host Mounted Antenna apply.

There are many suppliers of flying lead antenna and connectors; Quatech’s

Airborne Antenna product line offers a range of antenna solutions.

8.4 Embedded Antenna

Use of Embedded antenna can be the most interesting approach for M2M,

industrial and medical applications. Their small form factor and absence of any

external mounting provides a very compelling argument for their use. There is a

downside to this antenna type and it comes with performance. Antenna

performance for all of the embedded options will, in most cases, be less that that

achievable with external antenna. This does not make them unusable; it will

impact choice of antenna type and requires more focus on placement.

The three main embedded antenna types are PCB embedded, chip (PCB

mounted) and flying lead; each has its advantages and disadvantages (See

Table 16).

Table 16 - Embedded Antenna Options

28 7/15/2010 100-8080-120

Page 29

Airborne Enterprise Module Databook Quatech, Inc.

PCB Embedded – This approach embeds an antenna design into the host PCB.

This approach is very common with add-in WiFi card (CF, PCMCIA, SDIO, etc.)

as it requires no external connections and is the cheapest production approach.

The lower production cost requires significant development cost and lack of

performance and flexibility.

Chip – The integration of a chip antenna is simple and requires a relatively small

footprint on the host system, however, it does suffer from the same limitations of

flexibility and performance seen with the PCB embedded approach. There are

relatively large numbers of suppliers of this type of antenna; there is also a range

of configuration and performance options.

Flying Lead – This approach is similar to the flying lead solution for external

antennas, the difference is that the form factors are smaller and provide a range

of chassis and board mounting options, all for internal use. This approach suffers

less from the performance and flexibility limitations of the other approaches,

since the location of the antenna it not determined by the host PCB design. The

assembly of a system using this approach maybe slightly more complex since

the antenna is not necessarily mounted on the host PCBA.

8.5 Antenna Location

The importance of this design choice cannot be over stressed; it can in fact be

the determining factor between success and failure of the WiFi implementation.

There are several factors that need to be considered when determining location:

Distance of Antenna from radio

Location of host system

Proximity to RF blocking or absorbing materials

Proximity to potential noise or interference

Position relative to infrastructure (Access Points or Laptops)

Orientation of host system relative to infrastructure

Is it known

Is it static

To minimize the impact of the factors above the following things need to be

considered during the development process:

Minimize the distance between the radio and the location of the antenna. The

coaxial cable between the two impacts the Transmit Power and Receive

Sensitivity negatively. Quatech recommends using 1.32-1.37mm outer

diameter U.FL coaxial cables.

Minimize the locations where metal surfaces come into contact or are close

to the location of the antenna.

Avoid locations where RF noise, close to or over lapping the ISM bands, may

occur. This would include microwave ovens and wireless telephone systems

in the 2.4GHz and 5.0GHz frequency range.

Mount the antenna as high on the equipment as possible.

100-8080-120 7/15/2010 29

Page 30

Quatech, Inc. Airborne Enterprise Module Databook

Locate the antenna where there is a minimum of obstruction between the

antenna and the location of the Access Points. Typically Access Points are

located in the ceiling or high on walls.

Keep the main antenna’s polarization vertical, or in-line with the antenna of

the Access Points. 802.11 systems utilize vertical polarization and aligning

both transmit and receive antenna maximizes the link quality.

Even addressing all of the above factors, does not guarantee a perfect

connection, however with experimentation an understanding of the best

combination will allow a preferred combination to be identified.

8.6 Performance

Performance is difficult to define as the appropriate metric changes with each

application or may indeed be a combination of parameters and application

requirements. The underlying characteristic that, in most cases, needs to be

observed is the link quality. This can be defined as the bandwidth available over

which communication, between the two devices, can be performed, the lower the

link quality the less likely the devices can communicate.

Measurement of link quality can be made in several ways; Bit Error Rate (BER),

Signal to Noise (SNR) ratio, Signal Strength and may also include the addition of

distortion. The link quality is used by the radio to determine the link rate,

generally as the link quality for a given link rate drops below a predefined limit,

the radio will drop to the next lowest link rate and try to communicate using it.

The reciprocal is also true, if the radio observes good link quality at one rate it will

try to move up to the next rate to see if communication can be sustained using it.

It is important to note that for a given position the link quality improves as the link

rate is reduced. This is because as the link rate drops the radios Transmit power

and Receive sensitivity improve.

From this it can be seen that looking at the link rate is an indirect way of

assessing the quality of the link between the device and an Access Point. You

should strive to make the communication quality as good as possible in order to

support the best link rate. However be careful not to over specify the link rate.

Consider your applications bandwidth requirements and tailor your link rate to

optimize the link quality e.g. the link quality for a location at 6Mb/s is better than it

would be for 54Mb/s, if the application only needs 2Mb/s of data throughput, the

6Mb/s rate would provide a better link quality.

Aside from the radio performance, there are a number of other things that

contribute to the link quality; these include the items discussed earlier and

choices made when looking at the overall antenna gain. The antenna gain

contributes to the Equivalent Isotropically Radiated Power (EIRP) of the system.

This is part of an overall measurement of the link quality called link margin.

30 7/15/2010 100-8080-120

Page 31

Airborne Enterprise Module Databook Quatech, Inc.

Link Margin provides a measure of all the parts of the RF path that impact the

ability of two systems to communicate. The basic equation looks like this:

EIRP (dB) = TxP + TxA – TxC

Link Margin (dB) = EIRP – FPL + (RxS + RxA – RxC)

Where: TxP = Transmitter output power (dBm)

TxA = Transmitter antenna gain (dBi)

TxC = Transmitter to Antenna coax cable loss (dB)

FPL = Free Path Loss (dB)

RxS = Receiver receive sensitivity (dBm)

RxA = Receiver antenna gain (dBi)

RxC = Receiver to Antenna coax cable loss (dB)

This is a complex subject and requires more information than is presented here,

Quatech recommends at reviewing the subject and evaluating any system at a

basic level.

It is then possible, with a combination of the above items and an understanding

of the application demands, to achieve a link quality optimized for the application

and host design. It is important to note that this is established with a combination

of hardware selection, design choices and configuration of the radio.

100-8080-120 7/15/2010 31

Page 32

Quatech, Inc. Airborne Enterprise Module Databook

Symbol

Parameter

Min

Typ

Max

Units

t

PURST

Valid VDD to RESET valid

200

ms

t

RLRV

RESET Valid to RESET Low

0

ms

t

RPWI

Valid VDD to Internal RESET completed

200

ms

t

RPW

RESET Pulse Width

100

µs

For Hardware revisions Rev C2 and earlier additional timing constraints apply. Please contact

Quatech Technical Support for details.

9.0 RESET Function

For correct operation of the on-board Power-on RESET (POR) and internal RESET

controllers, the RESET pin on the WLNG-XX-DP500 family must obey the following

timing and signal conditions.

Figure 5 - Power on RESET Timing

Figure 6 - RESET Timing

Table 17 - RESET Timing

32 7/15/2010 100-8080-120

Page 33

Airborne Enterprise Module Databook Quatech, Inc.

MCP120T-300

/RESET (pin 7)

R1

33KΩ

C1

0.01µF

SW

Momentary ON/OFF

C2

0.1µF

R2

22KΩ

V

DD

+3.3VDC

V

DD

/RST

V

SS

9.1 Reference RESET Circuit

Proper control of the RESET signal is required, if not controlled correctly the

power-on sequence of the module can be impacted and correct booting

impacted. It is recommended that where possible the RESET signal of the

module should be controlled by an external controller (MCU, POR controller).

Where control of the RESET signal by system level monitor is not possible

Quatech recommend the use of the circuit in Figure 7, or one similar. This circuit

controls the RESET signal relative to power supply to the module and delays

release of the RESET until a valid power supply is detected.

Figure 7 - RESET Circuit

The circuit also includes a manual RESET option should this be required. This

manual RESET option can be used with the Factory RESET input (pin11) as a

hardware factory REST option.

100-8080-120 7/15/2010 33

Page 34

Quatech, Inc. Airborne Enterprise Module Databook

Dimensions mm [inches]

Tolerance ± 1.27 [0.05] unless noted

40.60 [1.60] MAX

30.70 [1.21] MIN

1.84 [0.07]

12.37 [0.49] MAX

29.60 [1.17] MAX

18.27 [0.72] MIN

15.90 [0.63]

3X Ø1.00 [Ø0.04]

3X Ø2.00 [Ø0.08]

Part# Hirose DF12-36DS-0.5V

Not available for mounting

36

35

2

1

10.50 [0.41]

16.02 [0.63]

2.75 [0.11]

16.00 [0.63]

16.00 [0.63]

10.50 [0.41]

Part# Hirose U.FL-R SMT Coaxial Antenna Connector (2X)

2.25 [0.09]

10.0 Mechanical Outline

Figure 8 - Mechanical Outline

34 7/15/2010 100-8080-120

Page 35

Airborne Enterprise Module Databook Quatech, Inc.

10.1 Recommended Connectors

Radio Connector: DF12-36DS-0.5V(XX) (Hirose)

Hirose: 0.50mm (.020") Pitch Plug, Surface Mount, Dual Row, Vertical,

4.00mm Stack Height, 36 Circuits

Board Connector: DF12-36DP-0.5V(XX) (Hirose)

Hirose: 0.50mm (.020") Pitch Plug, Surface Mount, Dual Row, Vertical,

4.00mm Stack Height, 36 Circuits

RF Connector: U.FL

Hirose: Ultra Small Surface Mount Coaxial Connector

Mounting Screw: 3/8 inch length, 0-42 thread Zinc Plated Steel Tri-P

Torx Thread-Form Screw for plastic

McMaster-Carr: 99512A117 (Zinc Plated Steel)

McMaster-Carr: 96001A107 (Stainless Steel)

100-8080-120 7/15/2010 35

Page 36

Quatech, Inc. Airborne Enterprise Module Databook

Country

Standard

Status

North America

(US & Canada)

FCC Part 15

Sec. 15.107, 15.109, 15.207, 15.209, 15.247

Modular Approval

Granted

Europe

CISPR 16-1 :1993

ETSI EN 300 328 Part 1 V1.2.2 (2000-07)

ETSI EN 300 328 Part 2 V1.1.1 (2000-07)

Completed

Japan

ARIB STD-T71 v1.0, 14 (Dec 2000)

ARIB RCR STD-T33 (June 19, 1997)

ARIB STD-T66 v2.0 (March 28, 2002)

Pending

11.0 Certification & Regulatory Approvals

The unit complies with the following agency approvals:

Table 18 - Regulatory Approvals

11.1 FCC Statement

This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference in a residential

installation. This equipment generates uses and can radiate radio frequency

energy and if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is encouraged

to try to correct the interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment to an outlet on a circuit different from that to which

the receiver is connected.

Consult the dealer or an experienced radio/TV technician for assistance.

11.2 FCC RF Exposure Statement

To satisfy RF exposure requirements, this device and its antenna must operate

with a separation distance of a least 20 cm from all persons and must not be colocated or operating in conjunction with any other antenna or transmitter.

11.3 Information for Canadian Users (IC Notice)

36 7/15/2010 100-8080-120

This device has been designed to operate with an antenna having a maximum

gain of 5dBi for 802.11b/g band. An antenna having a higher gain is strictly

Page 37

Airborne Enterprise Module Databook Quatech, Inc.

Country

Standard

Grant

North America (US)

FCC Part 15

Sec. 15.107, 15.109, 15.207, 15.209, 15.247

Modular Approval

F4AWLNG1

Canada

RSS 210

Modular Approval

39139A-WLNG1

prohibited per regulations of Industry Canada. The required antenna impedance

is 50 ohms.

To reduce potential radio interference to other users, the antenna type and its

gain should be so chosen that the equivalent isotropically radiated power (EIRP)

is not more than required for successful communication.

Operation is subject to the following two conditions: (1) this device may not cause

interference, and (2) this device must accept any interference, including

interference that may cause undesired operation of the device.

11.4 FCC/IOC Modular Approval

This document describes the Airborne WLN FCC modular approval and the

guidelines for use as outlined in FCC Public Notice (DA-00-1407A1).

The WLRG-RA-DP101 is covered by the following modular grants:

By providing FCC modular approval on the Airborne WLN modules, the

customers are relieved of any need to perform FCC part15 subpart C Intentional

Radiator testing and certification, except where they wish to use an antenna that

is not already certified.

Quatech supports a group of pre-approved antenna; use of one of these

antennas eliminates the need to do any further subpart C testing or certification.

If an antenna is not on the list, it is a simple process to add it to the pre-approved

list without having to complete a full set of emissions testing. Please contact

Quatech Technical support for details of our qualification processes.

Please note that as part of the FCC requirements for the use of the modular

approval, the installation of any antenna must require a professional installer.

This is to prevent any non-authorized antenna being used with the radio. There

are ways to support this requirement but the most popular is to utilize a nonstandard antenna connector, this designation includes the reverse polarity

versions of the most popular RF antenna types (SMA, TNC, etc.). For more

details please contact Quatech.

The following documents are associated with this applications note:

FCC Part 15 – Radio Frequency Devices

FCC Public Notice – DA-00-1407A1 (June 26

th

, 2000)

100-8080-120 7/15/2010 37

Page 38

Quatech, Inc. Airborne Enterprise Module Databook

Quatech recommends that during the integration of the radio, into the customers

system, that any design guidelines be followed. Please contact Quatech

Technical Support if you have any concerns regarding the hardware integration.

Contact Quatech Technical support for a copy of the FCC and IOC grant

certificates, the test reports and updated approved antenna list.

11.5 Regulatory Test Mode Support

The Airborne Device Server includes support for all FCC, IC and ETSI test

modes required to perform regulatory compliance testing on the module, please

contact Quatech Technical Support for details on enabling and using these

modes.

38 7/15/2010 100-8080-120

Page 39

Airborne Enterprise Module Databook Quatech, Inc.

Test

Reference

Conditions

Temperature Range

(Operational)

Table 1B, Type 2b

-40°C to +85°C

Temperature Range (NonOperational)

-50°C to +125°C

Humidity

Sect 4.2.3

0-95%RH @ 38°C condensing

Fig 4a – 8 hours active humidity cycle

Altitude

Sect 4.8

Operational: 0-12,000ft (62 KPa absolute pressure)

Non-operational: 0-40,000ft (18.6 KPa absolute

pressure)

Vibration

Sect 4.9

Operational: 2.4 Grms, 10-1K Hz, 1hr per axis

Non-operational: 5.2 Grms, 10-1K Hz, 1hr per axis

Shock

Sect 4.10

Operational: 20Gs MAX, 11ms half-sine pulse

Product Drop

Sect 4.10.3.1

1m onto concrete, any face or corner, 1 drop

Packaging Drop

Sect 4.10.2.1

32 inches onto concrete on each face and corner.

Packaged in ‘for transit’ configuration.

Accelerated Life Test

MIL-STD-883

Method 1015

1000hrs @ 125°C, static bias

12.0 Physical & Environmental Approvals

The device has passed the following primary physical and environmental tests. The test

methods referenced are defined in SAE J1455 Aug1994.

Table 19 - Mechanical Approvals

Test reports are available from Quatech Technical Support, please contact directly for the

latest documentation.

100-8080-120 7/15/2010 39

Page 40

Quatech, Inc. Airborne Enterprise Module Databook

Version

Date

Section

Change Description

Author

1.0

04/16/2009

-

Initial Release

ACR

1.1

08/11/2009

3.0

Updated block diagram with SPI interface.

ACR

5.0

Table 2: Removed reference to GPIO on pin 35

5.3

Added section 5.3 SPI interface section.

6.0

Table 4.0: Changed maximum voltage to 4.0VDC

Table 5.0: Updated Power state labels and values

7.0

Added section 7.0 SPI interface specification.

11.5

Added reference to Regulatory Test Mode Support in

module

12.0

Table 16: Removed reference to Salt Spray

environmental test.

1.2

7/15/2010

7.0

Revised description of SPI commands and protocol for

clarification

JGS

7.2

Table 13: Changed units for t

DELAY

to s

6.0

Replaced table 6 with table 9. Deleted table 9.

ACR

9.1

Added Section and Figures

10.1

Added section by reformatting 10.0

13.0 Change Log

The following table indicates all changes made to this document:

40 7/15/2010 100-8080-120

Loading...

Loading...