Page 1

Service Manual

Room Air Conditioner

HQ-2243TH,LWC081

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to

service or repair the product or products deal with in this service information by anyone else could result in serious injury or death.

© 2003 Matsushita Electric Industrial co., Ltd.

All rights reserved. Unauthorized copying and

distribution is violation of law.

ORDER NO. RAC0212002C1

E9

Page 2

—2—

1. PREFACE

1.1 SAFETY PRECAUTIONS ...............................2

1.2 INSULATION RESISTANCE TEST.................2

1.3 FEATURES.....................................................3

1.4 SPECIFICATIONS ..........................................3

1.5 CONTROL LOCATIONS.................................4

2.

DISASSEMBLY INSTRUCTIONS

2.1 MECHANICAL PARTS....................................6

2.1.1 FRONT GRILLE.....................................6

2.1.2 CABINET................................................6

2.1.3 CONTROL BOX.....................................6

2.2 AIR HANDLING PARTS..................................7

2.2.1 COVER (AT THE TOP)..........................7

2.2.2 BLOWER................................................7

2.2.3 FAN........................................................8

2.2.4 SHROUD................................................8

2.3 ELECTRICAL PARTS.....................................8

2.3.1 MOTOR..................................................8

2.3.2 COMPRESSOR.....................................8

2.3.3 CAPACITOR..........................................9

2.3.4 POWER CORD......................................9

2.3.5 THERMOSTAT ......................................9

2.3.6 ROTARY SWITCH...............................10

2.3.7 SYNCHRONOUS MOTOR ..................10

2.4 REFRIGERATION CYCLE............................11

2.4.1 CONDENSER......................................11

2.4.2 EVAPORATOR....................................11

2.4.3 CAPILLARY TUBE...............................11

3.

INSTALLATION

3.1 HOW TO INSTALL THE UNIT ......................14

3.2 WINDOW REQUIREMENTS.........................14

3.3 INSTALLATION KITS CONTENTS...............14

3.4 SUGGESTED TOOL REQUIREMENTS.......16

3.5 CABINET INSTALLATION............................17

4.

TROUBLESHOOTING GUIDE

4.1 OUTSIDE DIMENSIONS...............................19

4.2 PIPING SYSTEM ..........................................19

4.3 TROUBLESHOOTING GUIDE......................20

5. SCHEMATIC DIAGRAM

5.1 CIRCUIT DIAGRAM......................................25

6. EXPLODED VIEW..................................26

7. REPLACEMENT PARTS LIST.......27

1. PREFACE

This

SERVICE MANUAL provides various service information, including the mechanical and electrical

parts etc. This room air conditioner was manufactured and assembled under a strict quality control system.

The refrigerant is charged at the factory. Be sure to read the safety precautions prior to servicing the unit.

1.1 SAFETY PRECAUTIONS

1. When servicing the unit, set the ROTARY SWITCH

or POWER SWITCH to OFF and unplug the power

cord.

2. Observe the original lead dress.

If a short circuit is found, replace all parts which

have been overheated or damaged by the short

circuit.

3. After servicing the unit, make an insulation

resistance test to protect the customer from being

exposed to shock hazards.

1.2

INSULATION RESISTANCE TEST

1. Unplug the power cord and connect a jumper

between 2 pins (black and white).

2. The grounding conductor (green or green & yellow)

is to be open.

3. Measure the resistance value with an ohm meter

between the jumpered lead and each exposed

metallic part on the equipment at all the positions

(except OFF or O) of the ROTARY SWITCH.

4. The value should be over 1MΩ.

CONTENTS

Page 3

—3—

1.3 FEATURES

• DESIGNED FOR COOLING ONLY

• POWERFUL AND INCREDIBLE COOLING

• BUILT-IN ADJUSTABLE THERMOSTAT

• WASHABLE ONE-TOUCH FILTER

• COMPACT SIZE

1.4 SPECIFICATIONS

HQ-2243TH

POWER SUPPLY Ø, V, Hz

COOLING CAPACITY Btu/h.

POWER INPUT W

RUNNING CURRENT A

EER Btu/h.W

OPERATING

INDOOR °F(°C)

CONDITION

OUTDOOR

°F(°C)

REFREIGERANT (R-22) CHARGE

EVAPORATOR

CONDENSER

FAN

INDOOR

OUTDOOR

FAN SPEED

FAN/COOLING

FAN MOTOR

OPERATION CONTROL

ROOM TEMP. CONTROL

AIR DIRECTION VERTICAL

CONTROL

HORIZONTAL

CONSTRUCTION

PROTECTOR

COMPRESSOR

FAN MOTOR

POWER CORD

DRAIN SYSTEM

NET WEIGHT lbs(kg)

DIMENSION(W*H*D) inch(mm)

1, 230/208, 60

2,350/2,300

2,500/2,450

11.2/12.0

9.4

DB : 80(26.7) WB : 67(19.4)

DB : 95(35) WB : 75(23.9)

980g (34.6 oz)

3 ROW 15 STACKS, SLIT-FIN TYPE

2 ROW 19 STACKS, LOUVERED-FIN TYPE

TURBO FAN

PROPELLER TYPE FAN WITH SLINGER-RING

2/3

6 POLES

ROTARY SWITCH

THERMOSTAT

MANUAL

AUTO

SLIDE IN-OUT CHASSIS

OVERLOAD PROTECTOR

INTERNAL TERMINAL PROTECTOR

3WIRE WITH GROUNDING

ATTACHMENT PLUG(CORD-CONNECTED TYPE)

DRAIN PIPE OR SPLASHED BY FAN SLINGER

146(66)

26 * 1627/32 * 3023/32 (660 * 428 * 770)

MODELS

ITEMS

* DB:Dry Bulb

**

WB:Wet Bulb

❈ The specifications will be changed without notice for further improvement.

Page 4

1.5 CONTROL LOCATIONS

—4—

• OPERATION

Off - Turns air conditioner off.

Med Fan - Med speed fan operation without cooling.

Low Fan - Low speed fan operation without cooling.

High Cool - Cooling with high speed fan operation.

Med Cool - Cooling with med speed fan operation.

Low Cool - Cooling with low speed fan operation.

• THERMOSTAT

This automatically controls the temperature of the indoor air.

Turn the knob so that arrow points to the higher number for

greater cooling. Point the arrow to the lower number for more

moderate cooling.

(i.e. the higher the number, the greater the cooling)

• FOR NORMAL COOLING

1. Turn the operation switch to the High Cool or the Low

Cool setting.

2. Set the Thermostat control to the desired temperature

mark 5 (the mid-point is a good starting position).

If the room temperature is not satisfactory after a

reasonable time, adjust the control to a cooler or warmer

setting, as appropriate.

• FOR MAXIMUM COOLING

1. Turn the Operation Knob to the High Cool setting.

2. Set the Thermostat control to the highest (9) temperature

mark.

• FOR QUIETER OPERATION

1. Turn the Operation Knob to the Low Cool setting.

2. Set the Thermostat control as needed.

• AIR SWING

ON - Air swing is operated while OPERATION Knob is

set to the COOL position.

OFF - Stop the operation of air swing.

When the air conditioner has performed its cooling operation and is turned off or set to the fan position, wait at least 3

minutes before resetting to the cooling operation again.

CAUTION

Page 5

VENTCLOSE

OPEN

Part

A

Part

B

Drain pipe

Drain cap

—5—

• VENTILATION

The ventilation lever must be in the CLOSE position in order to maintain the best cooling conditions.

When fresh air is necessary in the room, set the ventilation lever to the OPEN position.

The damper is opened and room air is drawn out.

NOTE: Before using the ventilation feature, and prior to installing the front grille, pull down part until level with part .

• AIR DIRECTION

The direction of air can be controlled wherever you want to cool by adjusting the horizontal louver and the vertical louver.

The vertical air direction is adjusted by rotating the horizontal louver

forward or backward manually.

The horizontal air direction is adjusted by rotating the

vertical louver right or left manually.

• VERTICAL AIR-DIRECTION CONTROL

•

HORIZONTAL AIR-DIRECTION CONTROL

• HOW TO SECURE THE DRAIN PIPE

In humid weather, excess water may cause the BASE PAN to overflow. To drain

the water, remove the DRAIN CAP and secure the DRAIN PIPE to the rear hole

of the BASE PAN. Press the drain pipe into the hole by pushing down and away

from the fins to avoid injury.

Page 6

—6—

2.1 MECHANICAL PARTS

2.1.1 FRONT GRILLE

1. Open the inlet grille upward or downward.

2. Remove the screw which fastens the front grille.

3. Pull the front grille from the right side.

4. Remove the front grille. (See Fig. 1)

5. Re-install the component by referring to the

removal procedure.

2.1.2 CABINET

1. After disassembling the FRONT GRILLE, remove

the screws which fasten the cabinet at both sides.

Keep these for later use.

2. Remove the two screws which fasten the cabinet

at back. (See Fig. 2)

3. Pull the base pan forward.

2.1.3 CONTROL BOX

1. Remove the front grille. (Refer to section 2.1.1)

2. Pull the base pan forward so that you can remove

the 2 screws which fasten the cover control at the

right side. (See Fig. 3)

3. Remove the 3 screws which fasten the control

box. (See Fig. 3)

4. Discharge the capacitor by placing a 20,000 ohm

resistor across the capacitor terminals.

5. Disconnect two wire housings in the control box.

6. Pull the control box forward completely.

7. Re-install the components by referring to the

removal procedure. (See Fig. 3)

(Refer to the circuit diagram found on page 28~31

in this manual and on the control box.)

2. DISASSEMBLY INSTRUCTIONS

— Before the following disassembly, POWER SWITCH is set to OFF and disconnected the power cord.

Figure 1

Figure 2

Figure 3

Page 7

—7—

2.2 AIR HANDLING PARTS

2.2.1 COVER (AT THE TOP)

1. Remove the front grille. (Refer to section 2.1.1)

2. Remove the cabinet. (Refer to section 2.1.2)

3. Remove 11 screws which fasten the brace and

covers.

4. Remove the covers and the brace. (See Fig. 4)

5. Re-install the components by referring to the

removal procedure, above.

2.2.2 BLOWER

1. Remove the cover. (Refer to section 2.2.1)

2. Remove the 3 screws which fasten the

evaporator at the left side and the top side.

(See Fig. 4)

3. Move the evaporator sideward carefully.

4. Remove the orifice from the air guide carefully.

5. Remove the clamp which secures the blower with

plier. (See Fig. 5)

6. Remove the blower with plier or your hand

without touching blades. (See Fig. 6)

7. Re-install the components by referring to the

removal procedure, above.

Figure 4

Figure 5

Figure 6

Page 8

—8—

2.2.3 FAN

1. Remove the cabinet. (Refer to section 2.1.2)

2. Remove the brace and shroud cover.

(Refer to section 2.2.1)

3. Remove the side cover with 2 screws.

(See Fig. 7)

4. Remove the 5 or 6 screws which fasten the

condenser.

5. Move the condenser sideways carefully.

6. Remove the clamp which secures the fan.

7. Remove the fan. (See Fig. 7)

8. Re-install the components by referring to the

removal procedure, above.

2.2.4 SHROUD

1. Remove the fan. (Refer to section 2.2.3)

2. Remove the 2 screws which fasten the shroud.

3. Remove the shroud. (See Fig. 8)

4. Re-install the component by referring to the

removal procedure, above.

2.3 ELECTRICAL PARTS

2.3.1 MOTOR

1. Remove the cabinet. (Refer to section 2.1.2)

2. Remove the cover control and disconnect a wire

housing in control box. (Refer to section 2.1.3)

3. Remove the blower. (Refer to section 2.2.2)

4. Remove the fan. (Refer to section 2.2.3)

5. Remove the 4 screws which fasten the motor.

(See Fig. 9)

6. Remove the motor.

7. Re-install the components by referring to the

removal procedure, above.

2.3.2 COMPRESSOR

1. Remove the cabinet. (Refer to section 2.1.2)

2. Discharge the refrigerant system using Freon

TM

Recovery System.

If there is no valve to attach the recovery system,

install one (such as a WATCO A-1) before venting

the Freon

TM

. Leave the valve in place after

servicing the system.

3. Disconnect the 3 leads from the compressor.

4. After purging the unit completely, unbraze the

suction and discharge tubes at the compressor

connections.

5. Remove the 3 nuts and the 3 washers which

fasten the compressor. (See Fig. 10)

6. Remove the compressor.

7. Re-instill the components by referring to the

removal procedure, above.

Figure 7

Figure 8

Figure 9

Figure 10

Page 9

—9—

2.3.3 CAPACITOR

1. Remove the control box. (Refer to section 2.1.3)

2. Remove the screw and knobs which fasten the

display panel.

3. Disconnect the 2 leads from the rocker switch and

remove the panel.

4. Remove a screw and unfold the control box.

(See Fig. 11)

5. Remove the screw and the clamp which fastens

the capacitor. (See Fig. 11)

6. Disconnect all the leads of capacitor terminals.

7. Re-install the components by referring to the

removal procedure, above.

2.3.4 POWER CORD

1. Remove the control box. (Refer to section 2.1.3)

2. Unfold the control box. (Refer to section 2.3.3)

3. Disconnect the grounding screw from the control

box.

4. Disconnect 2 receptacles.

5. Remove a screw which fastens the clip cord.

6. Pull the power cord. (See Fig. 12)

7. Re-install the component by referring to the

removal procedure, above.

(Use only one ground-marked hole for ground

connection.)

8. If the supply cord of this appliance is damaged, it

must be replaced by the special cord.

(The special cord means the cord which has the

same specification marked on the supply cord

fitted to the unit.)

2.3.5 THERMOSTAT

1. Remove the control box. (Refer to section 2.1.3)

2. Unfold the control box. (Refer to section 2.3.3)

3. Remove the 2 screws which fasten the thermostat.

4. Disconnect all the leads of thermostat terminals.

5. Remove the thermostat. (See Fig. 13)

6. Re-install the components by referring to the

removal procedure, above.

Figure 12

Figure 11

Figure 13

Page 10

2.3.6 ROTARY SWITCH

1. Remove the control box. (Refer to section 2.1.3)

2. Unfold the control box. (Refer to section 2.3.3)

3. Remove 2 screws which fasten the rotary switch.

4. Disconnect all the leads of the rotary switch

terminals.

5. Remove the rotary switch. (See Fig. 14)

6. Re-install the components by referring to the

above removal procedure, above.

2.3.7 SYNCHRONOUS MOTOR

1. Remove the control box. (Refer to section 2.1.3)

2. Unfold the control box. (Refer to section 2.3.3)

3. Remove the crankshaft.

4. Disconnect all the leads of the synchronous

motor.

5. Remove the 2 screws which fasten the

synchronous motor. (See Fig. 15)

6. Re-install the components by referring to the

removal procedure, above.

—10—

Figure 15

Figure 14

Page 11

—11—

2.4 REFRIGERATION CYCLE

2.4.1 CONDENSER

1. Remove the cabinet. (Refer to section 2.1.2)

2. Remove the brace and the shroud cover.

(Refer to section 2.2.1)

3. Remove 2 screws which fasten the side

cover.(See Fig. 16)

4. Remove the 5 or 6 screws which fasten the

condenser.

5. After discharging the refrigerant completely,

unbraze the interconnecting tube at the condenser

connections.

6. Remove the condenser.

7. Re-install the components by referring to notes.

(See Fig. 16)

2.4.2 EVAPORATOR

1. Remove the cabinet. (Refer to section 2.1.2)

2. Remove the top cover and the brace.

(Refer to section 2.2.1)

3. Discharge the refrigerant completely.

4. Remove the 3 screws which fasten the evaporator

at the left side and the top side.

5. Move the evaporator sideward carefully and then

unbraze the interconnecting tube at the evaporator

connectors.

6. Remove the evaporator.

7. Re-install the components by referring to notes.

(See Fig. 17)

2.4.3 CAPILLARY TUBE

1. Remove the cabinet. (Refer to section 2.1.2)

2. Remove the brace. (Refer to section 2.2.1)

3. After discharging the refrigerant completely,

unbraze the interconnecting tube at the capillary

tube.

4. Remove the capillary tube.

5. Re-install the components by referring to notes.

Figure 16

Figure 17

Discharge the refrigerant system using Freon

TM

Recovery System.

If there is no valve to attach the recovery system,

install one (such as a WATCO A-1) before

venting the Freon

TM

. Leave the valve in place

after servicing the system.

CAUTION

Page 12

—12—

— Replacement of the refrigeration cycle.

1. When replacing the refrigeration cycle, be sure to

discharge the refrigerant system using a Freon

TM

recovery System.

If there is no valve to attach the recovery system,

install one (such as a WATCO A-1) before venting

the FreonTM. Leave the valve in place after

servicing the system.

2. After discharging the unit completely, remove the

desired component, and unbrace the pinch-off

tubes.

3. Solder service valves into the pinch-off tube ports,

leaving the valves open.

4. Solder the pinch-off tubes with Service valves.

5. Evacuate as follows.

1) Connect the vacuum pump, as illustrated

Fig. 18.

2) Start the vacuum pump, slowly open manifold

valves A and B with two full turns

counterclockwise and leave the valves closed.

The vacuum pump is now pulling through valves

A and B up to valve C by means of the manifold

and entire system.

3) Operate the vacuum pump for 20 to 30 minutes,

until 600 microns of vacuum is obtained. Close

valves A and B, and observe vacuum gauge for

a few minutes. A rise in pressure would

indicate a possible leak or moisture remaining in

the system. With valves A and B closed, stop

the vacuum pump.

4) Remove the hose from the vacuum pump and

place it on the charging cylinder. See Fig. 19.

Open valve C.

Discharge the line at the manifold connection.

5) The system is now ready for final charging.

6. Recharge as follows :

1) Refrigeration cycle systems are charged from the

High-side. If the total charge cannot be put

in the High-side, the balance will be put in the

suction line through the access valve which you

installed as the system was opened.

2)

Connect the charging cylinder as shown in Fig. 19.

With valve C open, discharge the hose at the

manifold connection.

3) Open valve A and allow the proper charge to

enter the system. Valve B is still closed.

4) If more charge is required, the high-side will not

take it. Close valve A.

5) With the unit running, open valve B and add the

balance of the charge.

a. Do not add the liquid refrigerant to the Low-

side.

b. Watch the Low-side gauge; allow pressure to

rise to 30 lbs.

c. Turn off valve B and allow pressure to drop.

d. Repeat steps B and C until the balance of the

charge is in the system.

6) When satisfied the unit is operating correctly,

use the pinch-off tool with the unit still running

and clamp on to the pinch-off tube. Using a tube

cutter, cut the pinch-off tube about 2 inches from

the pinch-off tool. Use sil-fos solder and solder

pinch-off tube closed. Turn off the unit, allow it to

set for a while, and then test the leakage of the

pinch-off connection.

NOTES

If high vacuum equipment is used, just crack

valves A and B for a few minutes, then open

slowly with the two full turns counterclockwise.

This will keep oil from foaming and being

drawn into the vacuum pump.

CAUTION

Page 13

—13—

Equipment needed: Vacuum pump, Charging cylinder, Manifold gauge, Brazing equipment. Pinch-off tool

capable of making a vapor-proof seal, Leak detector, Tubing cutter, Hand Tools to remove components, Service

valve.

A

COMPOUND GAUGE

EVAPORATOR

(LOW PRESSURE SIDE)

COMPRESSOR

CAPILLARY TUBE

CONDENSER

(HIGH PRESSURE SIDE)

SEE INSETS

BELOW

MANIFOLD

GAUGE

B

Figure 18 - Pulling Vacuum

Figure 19 - Charging

A

B

EXTERNAL

VACUUM PUMP

LOW

B

HI

A

CHARGING

CYLINDER

C

Page 14

—14—

3. INSTALLATION

3.1 HOW TO INSTALL THE UNIT

1. To avoid vibration and noise, make sure the unit is installed

securely and firmly.

2. Install the unit where the sunlight does not shine directly on

the unit.

If the unit receives direct sunlight, build an awning to shade

the cabinet.

3. There should be no obstacle, like a fence, within 20" which

might restrict heat radiation from the condenser.

4. To prevent reducing performance, install the unit so that

louvers of the cabinet are not blocked.

5. Install the unit a little obliquely outward not to leak the

condensed water into the room (about 1/2" or 1/4 bubble

with level).

6. Install the unit with its bottom portion 30~60" above the floor

level.

7. Stuff the foam between the top of the unit and the wall to

prevent air and insects from getting into the room.

8. The power cord must be connected to an independent

circuit. The green wire must be grounded.

9. Connect the drain tube to the base pan hole in the rear side

if you need to drain (consult a dealer).

Plastic hose or equivalent may be connected to the drain

tube.

About 1/2"

Over 20"

HEAT

RADIATION

FENCE

AWNING

FOAM

COOLED

AIR

30-60"

Level

1/4 Bubble

3.2 WINDOW REQUIREMENTS

NOTE: All supporting parts should be secured to firm wood,

masonry, or metal.

3.2.1 WINDOW REQUIREMENTS

1. This unit is designed for installation in standard

double hung windows with actual opening widths from

29" to 41".

The top and bottom window sashes must open

sufficiently to allow a clear vertical opening of 18"

from the bottom of the upper sash to the window

stool.

2. The stool offset (height between the stool and sill)

must be less than 1 1/4".

29" to 41"

18" min

Offset

Less

than 1

1

/4"

Sill

Exterior

Interior wall

26" min.

(Without frame curtain)

Stool

Page 15

—15—

Foam-PE

(Adhesive-Backed)

Foam-PE

(Adhesive-Backed)

Type C (5) Type D (2)

Type A (14)

Carriage Bolt (2) Lock Nut (4)

Type B (7)

Foam strip

(Plain-Back)

Right frame

curtain

Drain pipe

Window locking

bracket

Left frame

curtain

Frame guide(2)

Sill

bracket

(2)

Support bracket(2)

3.3 INSTALLATION KITS CONTENTS

Page 16

—16—

3.4.1 PREPARATION OF CHASSIS

1. Remove the screws which fasten the cabinet at both sides

and at the back. Keep these two screws which fasten the

cabinet at both sides for later use.

2. Slide the unit out from the cabinet by gripping the base pan

handle and pulling forward while bracing the cabinet.

3. Cut the window sash seal to the proper length. Peel off the

backing and attach the FOAM-PE to the underside of the

window sash.

4. Remove the backing from FOAM-PE with 3 holes and

attach it to the bottom of the Top retainer bar.

5. Attach the Top retainer bar onto the top of the cabinet with 3

screws (Type A).

6. Insert the Frame guides into the bottom of the cabinet.

7. Insert the Frame Curtain into the Top retainer bar and

Frame guides.

8. Fasten the curtains to the unit with 10 screws (Type A) at

both sides.

SCREWDRIVER(+, -), RULER, KNIFE, HAMMER, PENCIL, LEVEL

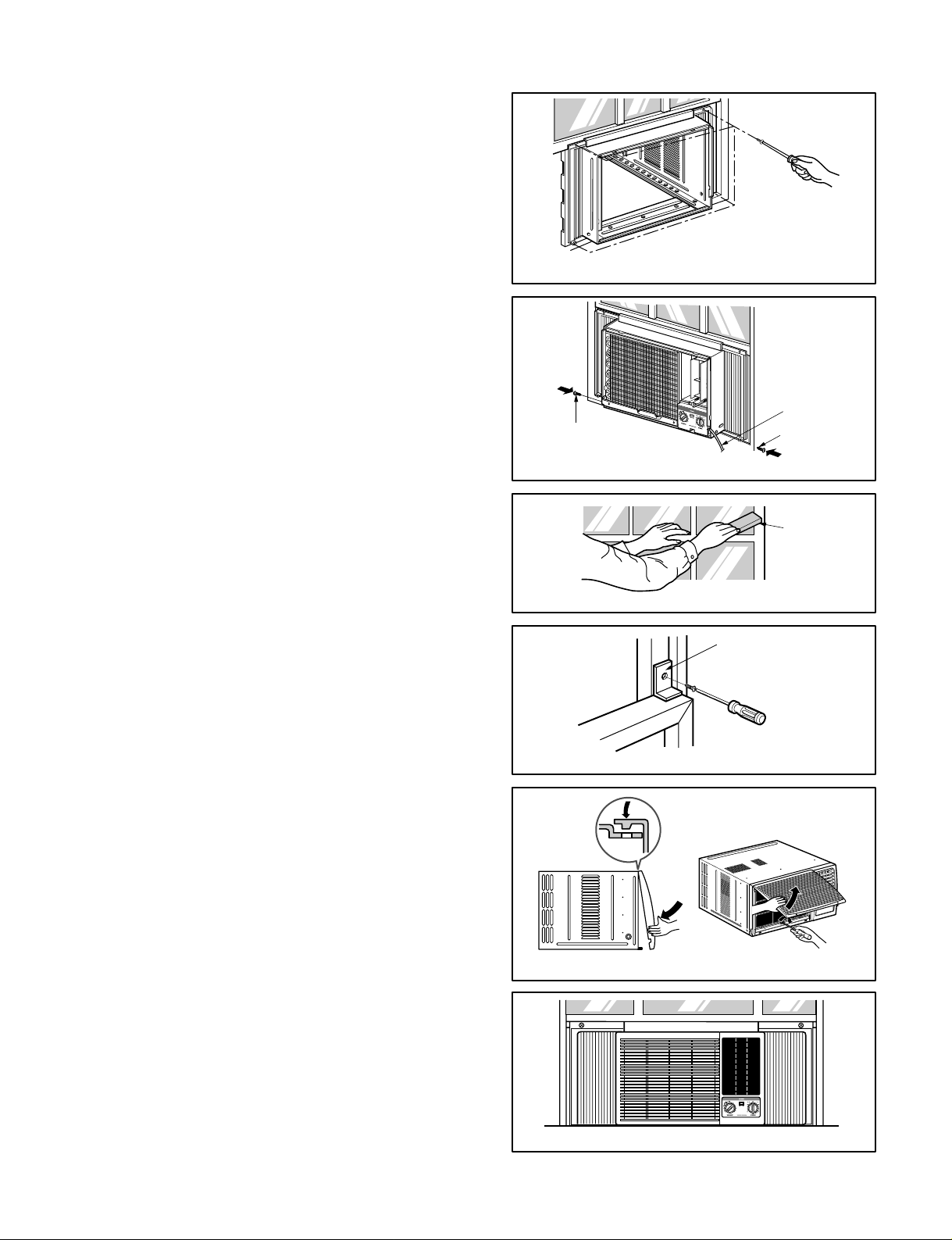

Figure 20

Figure 21

Figure 22

Figure 23

3.4 SUGGESTED TOOL REQUIREMENTS

Shipping screws

FOAM-PE

Top retainer bar

Screw

(Type A)

Top retainer bar

FOAM-PE

Screw(Type A)

Frame guide

Page 17

—17—

3.5 CABINET INSTALLATION

1. Open the window. Mark a line on the center of the window

stool between the side window stop moldings.

Loosely attach the sill bracket to the support bracket using

the carriage bolt and the lock nut.

2. Attach the sill bracket to the window sill using the screws

(Type B).

Carefully place the cabinet on the window stool and align the

center mark on the bottom front with the center line marked

window stool.

3. Using the M-screw and the lock nut, attach the support

bracket to the cabinet track hole. Use the first track hole

after the sill bracket on the outer edge of the window sill.

Tighten the carriage bolt and the lock nut. Be sure the

cabinet slants outward.

CAUTION: Do not drill a hole in the bottom pan. The unit is

designed to operate with approximately 1/2" of

water in bottom pan.

4. Pull the bottom window sash down behind the Top retainer

bar until they meet.

NOTE: 1. Do not pull the window sash down so tightly that the

movement of Frame curtain is restricted. Attach the

cabinet to the window stool by driving the screws

(Type B) through the cabinet into window stool.

2. The cabinet should be installed with a very slight tilt

downward toward the outside.

Support

Bracket

Lock nut

Sill

Bracket

Carriage

Bolt

(M-Screw)

Front angle

Window stool

Window sash

Top retainer bar

Cabinet

Foam-PE

Frame curtain

Screw(Type B)

Front Angle

Sash track

Foam-PE

Cabinet

Track hole

Support

Bracket

Carriage bolt

and lock nut

Machine screw (Type D)

and lock nut

Outer edge

of window

sill

Screw(Type B)

Sill bracket

Top

retainer

bar

Figure 24

Figure 25

Figure 26

Figure 27

Figure 28

Page 18

—18—

5. Pull each Frame curtain fully to each window sash

track, and pull the bottom window sash down behind

the Top retainer bar until it meets.

6. Attach each Frame curtain the window sash by using

screws (Type C). (See Fig. 29)

7. Slide the unit into the cabinet. (See Fig. 30)

CAUTION: For security purpose, reinstall screws (Type

A) at cabinet's sides.

8. Cut the Foam-strip to the proper length and insert

between the upper window sash and the lower

window sash. (See Fig. 31)

9. Attach the Window locking bracket with a screw

(Type C). (See Fig. 32)

10. Attach the front grille to the cabinet by inserting the

tabs on the grille into the tabs on the front of the

cabinet. Push the grille in until it snaps into place.

(See Fig.33)

NOTE: Please refer p.5 for setting ventilation kit.

11. Lift the inlet grille and secure it with a screw (Type A)

through the front grille. (See Fig. 33)

12. Window installation of room air conditioner is now

completed.

Power Cord

Screw (Type A)

Screw

Window locking

bracket

Foam-Strip

Screw(Type C)

Figure 29

Figure 30

Figure 31

Figure 32

Figure 33

Figure 34

Page 19

—19—

4. TROUBLESHOOTING GUIDE

4.1 OUTSIDE DIMENSIONS

3023/32 (770)

26(660)

16

27

/32 (428)

CAPILLARY TUBE

COMPRESSOR

BLOWER

EVAPORATOR COIL

CONDENSER COIL

FAN

MOTOR

4.2 PIPING SYSTEM

Following is a brief description of the important components and their functions in the refrigeration system.

Refer to Fig. 35 to follow the refrigeration cycle and the flow of the refrigerant in the cooling cycle.

MOTOR

COMPRESSOR

OIL

(LIQUID REFRIGERANT)

CAPILLARY TUBE

OUTSIDE COOLING

AIR FOR REFRIGERANT

PASS THROUGH

SUCTION LIME

COOL LOW PRESSURE VAPOR

COOLED

AIR

COMPLETE LIQUID

BOIL OFF POINT

LIQUID

PRESSURE

DROP

ROOM AIR HEAT LOAD

VAPOR INLET

HOT

DISCHARGED

AIR

LIQUID OUTLET

HIGH PRESSURE VAPOR

LIQUID PEFRIGERANT

LOW PRESSURE VAPOR

ROOM AIR CONDITIONER

EVAPORATOR COILS CONDENSER COILS

CYCLE OF REFRIGERATION

Figure 35

Page 20

—20—

4.3 TROUBLESHOOTING GUIDE

In general, possible trouble is classified in two causes.

The one is called Starting Failure which is caused from an electrical defect, and the other is Ineffective Air

Conditioning caused by a defect in the refrigeration circuit and improper application.

Unit runs but poor cooling

Ineffective Cooling

Check of outdoor coil

(heat exchanger) & the fan

operation.

Check gas leakage.

Repair gas leak.

Replacement of unit if the

unit is beyond repair.

Satisfactory operation with

temperature difference of

inlet & outlet air ; 44.6~50°F

Check heat load increase.

Unexpected residue

Overloaded Circuit

Check of inside gas

pressure.

Adjusting of refrigerant

charge

Malfunction of compressor

Replacement of

compressor

Check of cold air circulation

for smooth flow.

Dirty indoor coil

(Heat exchanger)

Malfunction of fan

Clogged of air filter

Obstruction at air outlet

Correct above trouble

Stop of auto air-swing

Check clogging in

refrigeration circuit.

Repair clogging in

refrigeration circuit.

Page 21

—21—

Fails to Start

Check of circuit breaker

and fuse.

Gas leakage of feeler bulb

of thermostat

Check of control switch.

Only fan fails to start.

Improper wiring.

Defect of fan motor

capacitor.

Irregular motor resistance

( ).

Irregular motor insulation

( ).

Replacement of fan motor

Regular but fails to start

Replacement of compressor

(locking of rotor, metal)

Improper thermostat setting

Loose terminal connection.

Improper wiring

Irregular motor resistance ( )

Irregular motor insulation ( )

Replacement of compressor

(Motor damaged)

Drop of power voltage.

Check capacitor.

Replacement.

Only compressor fails to

start.

Defect of compressor

capacitor.

Check of power source.

Check of control switch

setting.

Page 22

—22——22—

COMPLAINT CAUSE REMEDY

Check voltage at outlet. Correct if none.

Check voltage to rotary switch. If none, check

power supply cord. Replace cord if circuit is open.

Check switch continuity. Refer to wiring diagram

for terminal identification. Replace switch if

defective.

Connect wire. Refer to wiring diagram for terminal

identification. Repair or replace loose terminal.

Test capacitor.

Replace if not within ±10% of manufacturer's

rating. Replace if shorted, open, or damaged.

Fan blade hitting shroud or blower wheel hitting

scroll. Realign assembly.

Units using slinger ring condenser fans must

have 1/4to 5/16inch clearance to the base. If it is

hitting the base, shim up the bottom of the fan

motor with mounting screw(s).

Check fan motor bearings; if motor shaft will not

rotate, replace the motor.

Check voltage. See limits on this page. If not within

limits, call an electrician.

Test capacitor.

Check bearings. Does the fan blade rotate freely?

If not, replace fan motor.

Pay attention to any change from high speed to

low speed. If the speed does not change, replace

the motor.

Check grommets; if worn or missing, replace them.

If cracked, out of balance, or partially missing,

replace it.

If cracked, out of balance, or partially missing,

replace it.

Tighten it.

If knocking sounds continue when running or

loose, replace the motor. If the motor hums or

noise appears to be internal while running,

replace motor.

No power

Power supply cord

Rotary switch

Wire disconnected or

connection loose

Capacitor (Discharge

capacitor before testing.)

Will not rotate

Revolves on overload.

Grommets

Fan

Blower

Loose set screw

Worn bearings

Fan motor will not run.

Fan motor runs

intermittently

Fan motor noise.

Page 23

—23—

COMPLAINT CAUSE REMEDY

Check voltage. See the limits on the preceding.

page. If not within limits, call an electrician.

Check the wire connections, if loose, repair or

replace the terminal. If wires are off, refer to wiring

diagram for identification, and replace. Check wire

locations. If not per wiring diagram, correct.

Check for continuity, refer to the wiring diagram

for terminal identification. Replace the switch if

circuit is open.

Check the position of knob If not at the coldest

setting, advance the knob to this setting and

restart unit.

Check continuity of the thermostat. Replace

thermostat if circuit is open.

Check the capacitor.

Replace if not within ±10% of manufacturers

rating. Replace if shorted, open, or damaged.

Check the compressor for open circuit or

ground. If open or grounded, replace the

compressor.

Check the compressor overload, if externally

mounted. Replace if open. (If the compressor

temperature is high, remove the overload, cool it,

and retest.)

Check the voltage. See the limits on the preceding page. If not within limits, call an electrician.

Check overload, if externally mounted.

Replace if open. (If the compressor temperature

is high, remove the overload, cool, and retest.)

If not running, determine the cause. Replace if

required.

Remove the cabinet. inspect the interior surface

of the condenser; if restricted, clean carefully

with a vacuum cleaner (do not damage fins) or

brush. Clean the interior base before

reassembling.

If condenser fins are closed over a large area

on the coil surface, head pressures will increase,

causing the compressor to cycle. Straighten the

fins or replace the coil.

Voltage

Wiring

Rotary

Thermostat

Capacitor (Discharge

capacitor before

servicing.)

Compressor

Overload

Voltage

Overload

Fan motor

Condenser air flow

restriction

Condenser fins

(damaged)

Compressor will not run,

but fan motor runs.

Compressor cycles

on overload.

Page 24

—24—

COMPLAINT CAUSE

REMEDY

Test capacitor.

Check the terminals. If loose, repair or replace.

Check the system for a restriction.

If restricted, clean of replace.

Close if open.

Determine if the unit is properly sized for the area to

be cooled.

Check the set screw or clamp. If loose or missing,

correct. If the blower or fan is hitting air guide,

rearrange the air handling parts.

Remove the cabinet and carefully rearrange tubing

not to contact cabinet, compressor, shroud, and

barrier.

Set the knob to HIGH COOL or LOW COOL while

rocker switch is ON.

Check terminals. If loose, repair or replace.

Check the synchronous motor for open circuit.

Capacitor

Wiring

Refrigerating system

Air filter

Exhaust damper door

Unit undersized

Blower or fan

Copper tubing

Rotary switch.

Wiring

Synchronous motor.

Compressor cycles

on overload.

Insufficient cooling or

heating

Excessive noise.

Auto air-swing fails.

Page 25

—25—

5. SCHEMATIC DIAGRAM

5.1 CIRCUIT DIAGRAM

• MODEL : HQ-2243TH

1

3

4

7

2

6

5

WIRING DIACRAM

ROCKER SWITCH

WH

WH

SYNC. M.

POWER INPUT

WH(BL)BK(BR)

(Ribbed)

(Plain)

NO.

1 POWER CORD 1

2 ROTARY SWITCH 1

3 FAN MOTOR 1

4 CAPACITOR 1

5 THERMOSTAT 1

6 COMPRESSOR 1

7 SYNCHRONOUS MOTOR 1

Q'TY PER SET

DESCRIPTION

Page 26

—26—

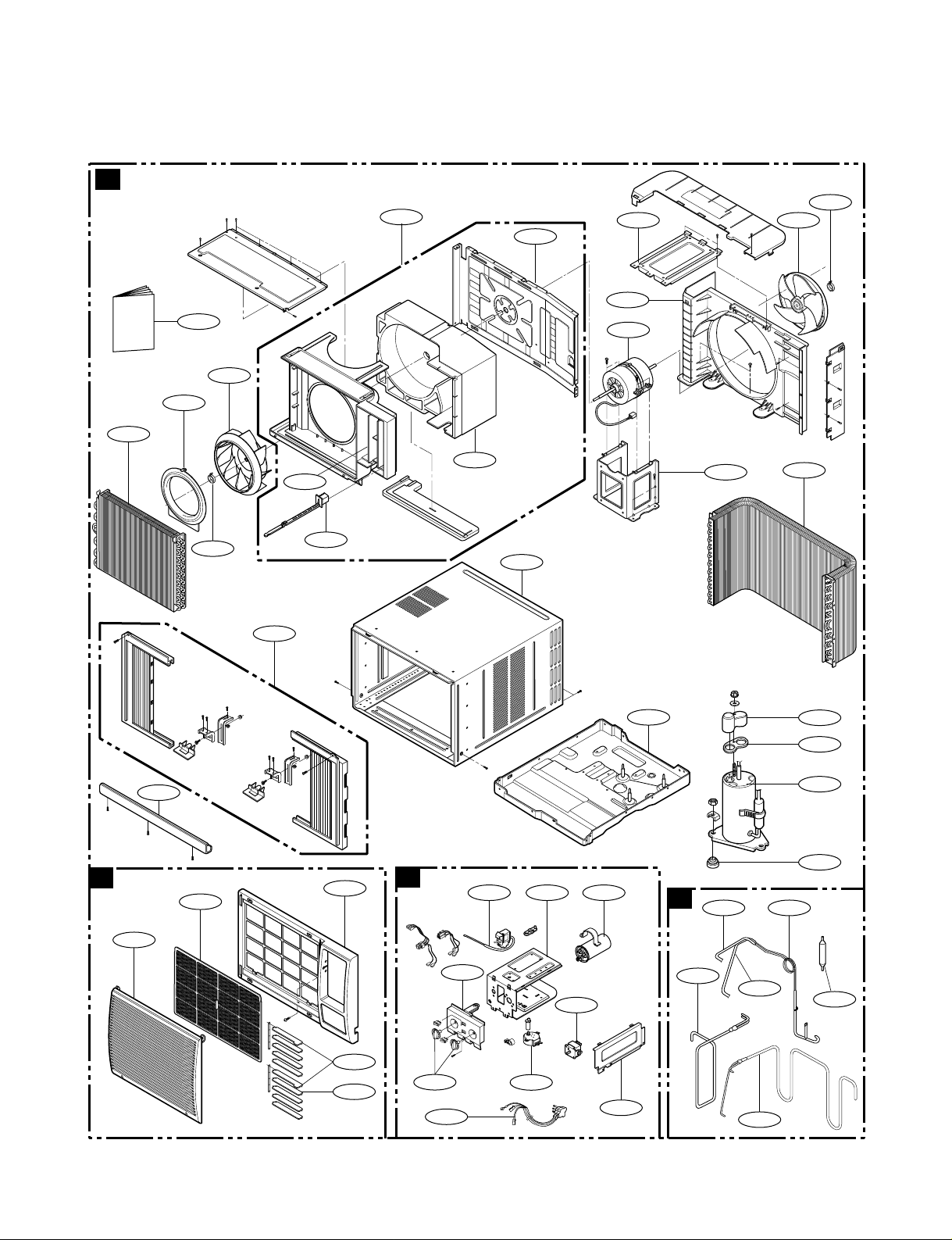

6. EXPLODED VIEW

• MODEL: HQ-2243TH,LWC081

11

4

4

5

3

2

6

1

13

5

9

6

14

17

19

23

24

1

6 1 4

7

8

2

1

9

3

4

3

2

5

3

2

5

18

12

15

16

20

7

10

16

8

22

O

wner's M

anual

A

C

B

D

21

Page 27

—27—

7. REPLACEMENT PARTS LIST

• MODEL: HQ-2243TH

PART NO.

DESCRIPTION

REMARK

A FRONT GRILLE ASS'Y CW353110189B R

1 GRILLE, FRONT CW353010138A

2 INLET, GRILLE CW353010139A

3 AIR FILTER ASS'Y CW5231R6159F

4 HORIZONTAL LOUVER CW4758R7264J

5 HORIZONTAL LOUVER CW4758R7278J

B COMP&ACCESSORY ASS'Y

1 ANTI-VIBRATION BUSH CW4022-L005A

2 COMPRESSOR CW2520HFK2CA R

3 GASKET CW4986-L004A

4 TERMINAL COVER CW355030048C

5 BASE PAN WELD ASS'Y CW304110010F

6 BARRIER, SINGLE CW479010036A

7 SCROLL CW307220009A

8 AIR GUIDE ASSEMBLY CW523920001V

9 CABINET ASS'Y CW3091R6056A

10 DAMPER ASS'Y CW4900R7265A

11 MOUNT, MOTOR CW4960R2895B

12 MOTOR ASSEMBLY, SINGLE CW468120011L R

13 SHROUD CW4998R1602A

14 FAN, TURBO CW590120009A R

15 FAN, AXIAL CW5900R1330B R

16 CLAMP, SPRING CW3H02932C

17 ORIFICE CW494820014A

18 BRACE CW4800R7271A

19 EVAPORATOR ASSEMBLY, FIRST CW542120017N

20 CONDENSER ASSEMBLY, FIRST CW540320032F

21 VERTICAL LOUVER CW4758R6157A

22 OPERATING INSTRUCTION CW382820046H

23 INSTALLATION KIT CW3127R3403U R

24 UPPER GUIDE CW2H00858D

C CONTROL BOX ASSEMBLY CW499520088N

1 CONTROL BOX , SINGLE CW4994R1587A

2 CONTROL PANEL CW372120058J

3 KNOB ASS'Y CW494130001M

4 CAPACITOR CW6120R2194P R

5 POWER CORD ASS'Y CW2H00677U R

6 THERMOSTAT CW2H01109L R

7 COVER CW355130001A

8 ROTARY, SWITCH CW2H00598E R

9 MOTOR ASSY, SYNC CW2H01102A R

D PIPE

1 TUBE ASSEMBLY, SUCTION INDOOR CW521110094B

2 TUBE ASSEMBLY, DISCHARGE SINGLE CW521130325D

3 TUBE ASSEMBLY, EVAPORATOR CW521030144U

4 TUBE ASSEMBLY, EVAPORATOR CW521030144V

5 TUBE, CAPILLARY BEND CW521130296E

6 DRIER ASSEMBLY CW585130001K

LOCATION

NO.

R: RECOMMANDABLE PARTS.

Page 28

September, 2003

P/No.: 3828A20163N Printed in Korea

Loading...

Loading...