Page 1

Catalog

Courtesy of Steven Engineering, Inc. ● 230 Ryan Way, South San Francisco, CA 94080-6370 ● General Inquiries: (800) 670-4183 ● www.stevenengineering.com

January

07

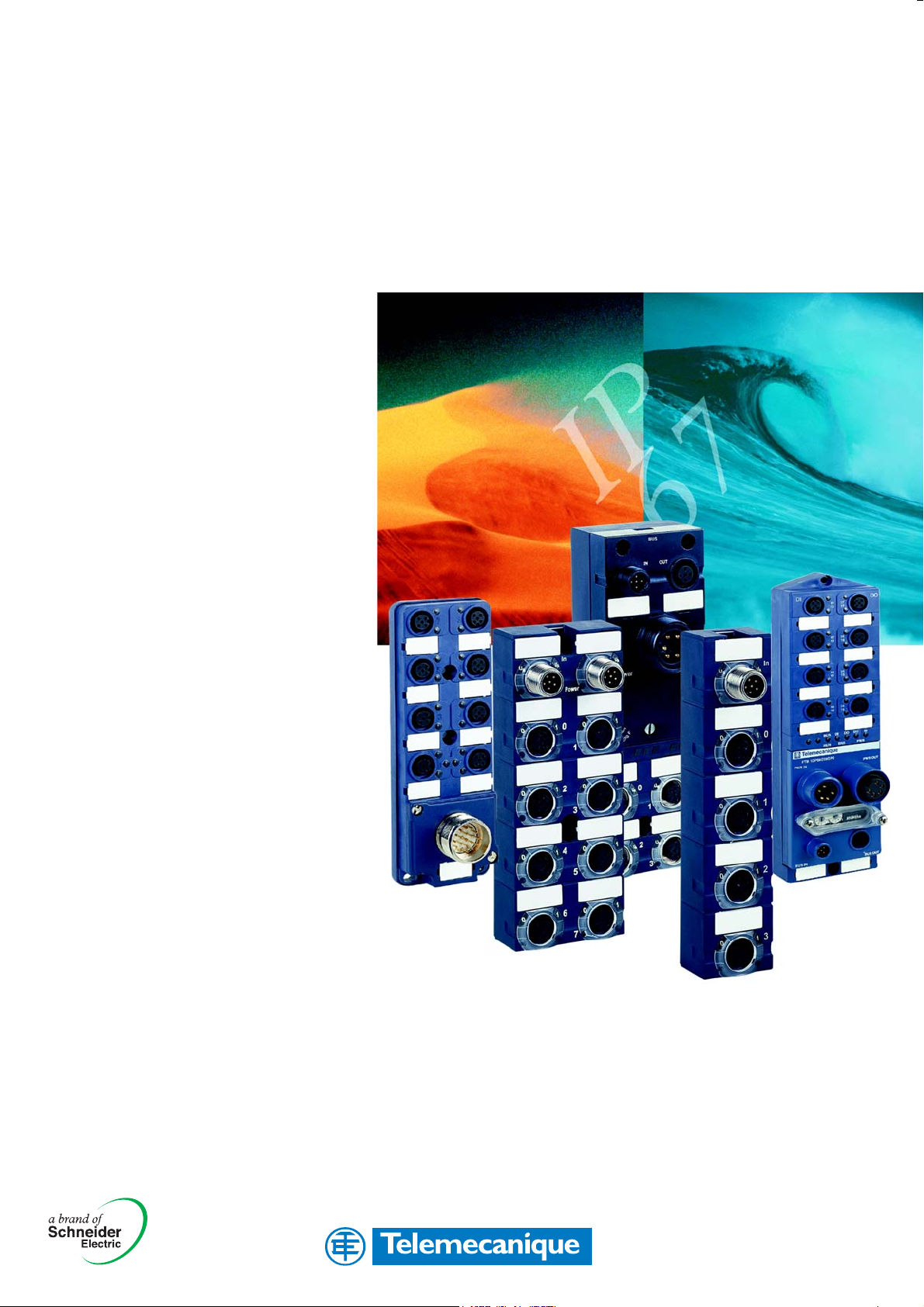

Automation and Control

IP 67 I/O Splitter Boxes

Page 2

Telefast®, Telemecanique®, Zelio®, Twido®, Modicon®, Phaseo®, TeSys®, Altivar®,

Courtesy of Steven Engineering, Inc. ● 230 Ryan Way, South San Francisco, CA 94080-6370 ● General Inquiries: (800) 670-4183 ● www.stevenengineering.com

Premium

™

, Advantys™, and Quantum™ are trademarks or registered trademarks of

Schneider Electric. Other trademarks used herein are the property of their respective

owners.

Page 3

Contents

Courtesy of Steven Engineering, Inc. ● 230 Ryan Way, South San Francisco, CA 94080-6370 ● General Inquiries: (800) 670-4183 ● www.stevenengineering.com

0

IP 67 I/O Splitter Boxes

IP 67 passive splitter boxes

Selection guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 4, 5

b Telefast® Distribution Systems, ABE9 splitter boxes. . . . . . . . . . . . . . . . page 6, 7

v Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

v References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 9

v Dimensions, Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 10, 11

IP 67 monobloc I/O splitter boxes for fieldbuses

Selection guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 12, 13

b Advantys

v Advantys, FTB splitter boxes for CANopen

v Advantys, FTB splitter boxes for Profibus

v Advantys, FTB splitter boxes for InterBus

v Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 26, 27

v References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 28 - 30

v Dimensions, Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 31 - 33

™

Distributed I/O, FTB splitter boxes. . . . . . . . . . . . . . . . . . . page 14, 15

™

& DeviceNet™ bus extensions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 16 - 19

™

-DP bus extensions . . page 20 - 22

™

bus extensions . . . . . page 23 - 25

IP 67 modular I/O splitter boxes for fieldbuses

Selection guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 34, 35

™

b Advantys

v Advantys, FTM bus modules for CANopen

v Advantys, FT

v Advantys, FT

v Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 43 - 45

v Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 46, 47

v References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 48, 49

v Dimensions, Schemes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 50, 51

Distributed I/O, FTM splitter boxes . . . . . . . . . . . . . . . . . page 36 - 39

™

bus extensions . . . . . . . . page 40

™

M bus modules for DeviceNet

M bus modules for Profibus

bus extensions . . . . . . . . page 41

™

-DP bus extensions. . . . . . . page 42

Power supplies for d.c. control circuits

Selection guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 52, 53

®

b Phaseo

v Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 55

v Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 56

v References, Dimensions, Schemes. . . . . . . . . . . . . . . . . . . . . . . . . . . . page 57

b Phaseo

v Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 60 - 61 & 66

v Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 62 - 65

v References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 67

v Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 68, 69

modular regulated power supplies . . . . . . . . . . . . . . . . . . . . . . . page 54

®

regulated switch mode power supplies. . . . . . . . . . . . . . . . . page 58, 59

3

Page 4

Selection guide

Courtesy of Steven Engineering, Inc. ● 230 Ryan Way, South San Francisco, CA 94080-6370 ● General Inquiries: (800) 670-4183 ● www.stevenengineering.com

0

IP 67 I/O Splitter Boxes and

Modules 0

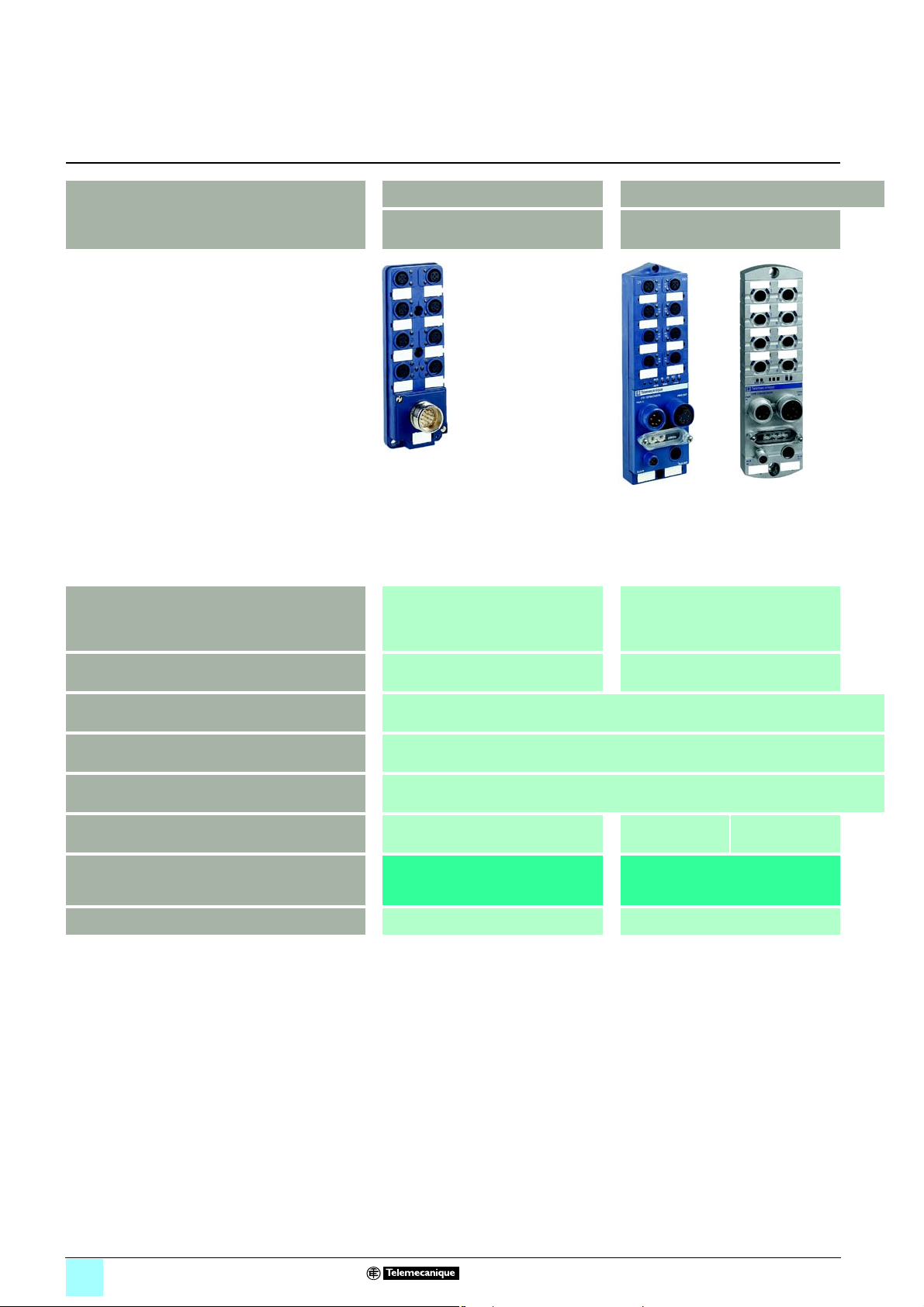

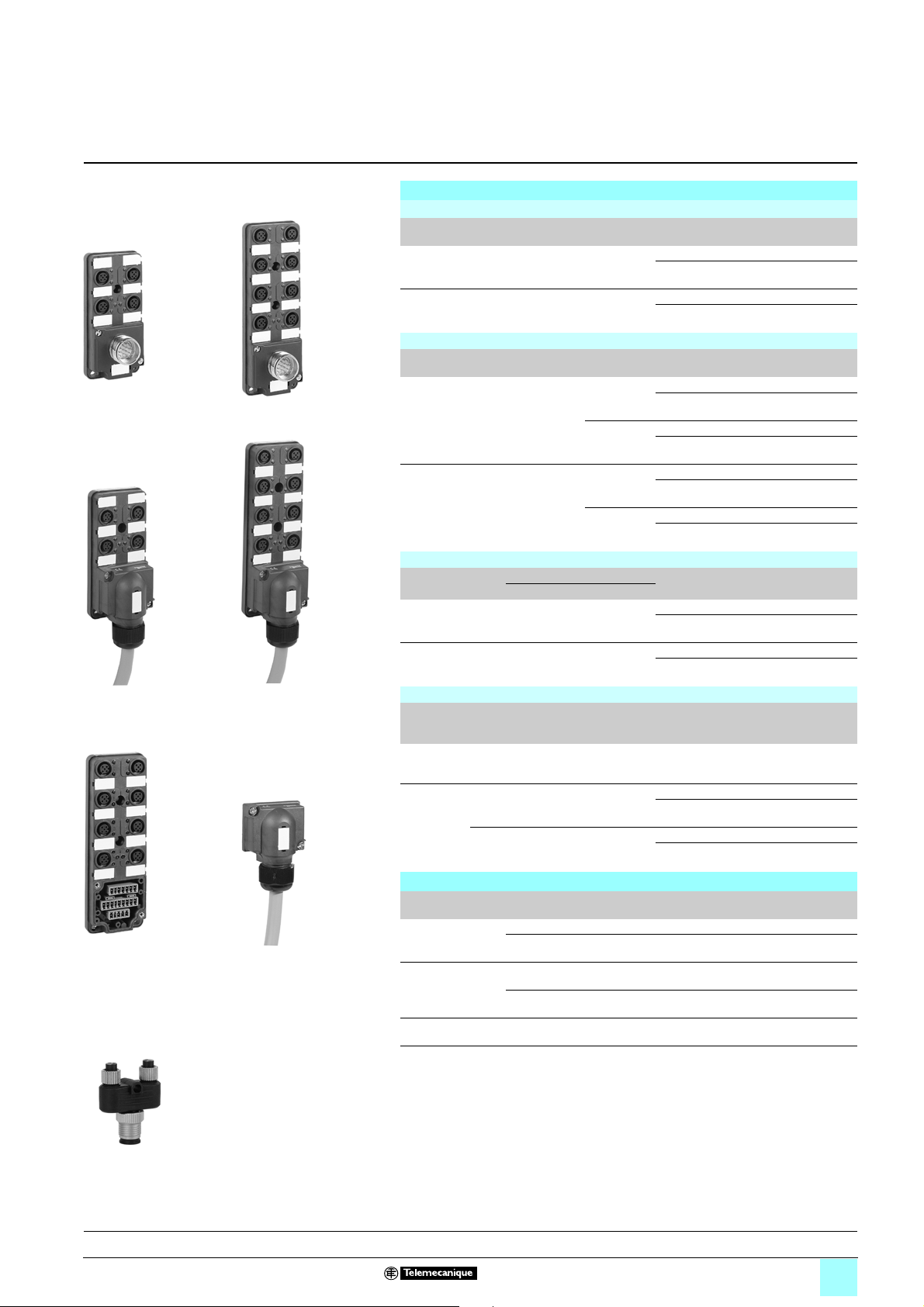

Splitter box and module type Passive splitter boxes Monobloc I/O splitter boxes and modules

Telefast® ABE9 splitter boxes Advantys™ FTB splitter boxes

108737

Fieldbus type – CANopen

Number of inputs/outputs 8 I/O, 16 I/O 16 I, 8 I + 8 O, 12 I + 4 O, 16 I/O,

Type of signal Digital

108733

DeviceNet

Profibus™-DP

™

InterBus

8I+8I/O

521940

™

™

Functions Connection of 1 to 16 sensors/actuators

Type of input/output connectors M12 (M8 connection available with T-connection accessory)

Housing type Plastic Plastic Metal

Module type

ABE 9 FTB 1

Pages 9 28

4

Page 5

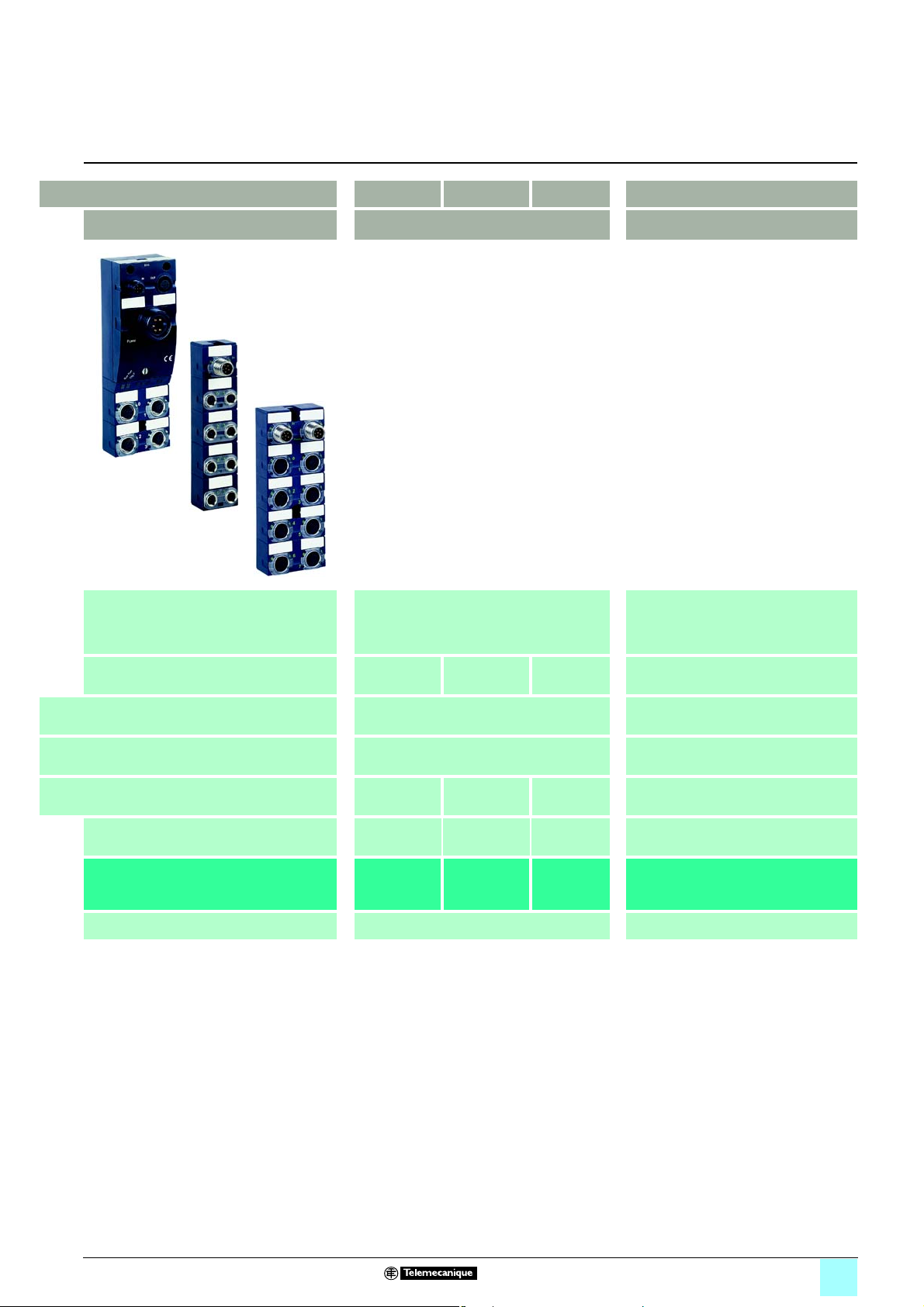

Modular I/O splitter boxes

Courtesy of Steven Engineering, Inc. ● 230 Ryan Way, South San Francisco, CA 94080-6370 ● General Inquiries: (800) 670-4183 ● www.stevenengineering.com

Advantys, FTM splitter boxes

540351

108743

0

108741

0

CANopen

DeviceNet

Profibus™-DP

™

™

8 I, 16 I, 8 I/O and 16 I/O, digital

4I or 4O, analog

Digital and analog

Connection of 1 to 256 sensor/actuators per bus

module

M8 and M12

Plastic only

FTM 1

48

5

Page 6

Presentation

Courtesy of Steven Engineering, Inc. ● 230 Ryan Way, South San Francisco, CA 94080-6370 ● General Inquiries: (800) 670-4183 ● www.stevenengineering.com

0

IP 67 passive splitter boxes 0

Telefast® Distribution System, ABE9 splitter boxes

Presentation

ABE9 passive splitter boxes for M12 connectors make it possible to eliminate long

and difficult cabling operations. Due to their modularity and their dimensions, they

are the ideal solution for a wide variety of customer applications.

Connection to the processing unit can either be made by connector or by multicore

cable of different lengths.

IP 67 protection allows these products to be used within processes or machines in

harsh environments (splashing water, oil, dust, etc.).

The splitter boxes, available in 4 or 8 channel versions, allow connection of up to 16

signals maximum, depending on the version (2 per channel).

The characteristics of splitter boxes ABE 9C12 are as follows:

b Connection of sensors and actuators using M12, 5-pin connectors.

b Modularity: 4 or 8 channels.

b Mounting system and connection to the processing unit conforming to market

standards:

v mounting holes,

v M23, 19-pin connector, enabling the use of pre-formed cables in order to reduce

installation time and the risk of error,

v multicore cable, 5 or 10 meters (16.4 or 32.8 ft.) long. The splitter box comprises

a connection cover fitted with plug-in terminals, which provides considerable

flexibility for:

- the replacement of damaged parts,

- modification of cable length.

Base units ABE 9C12ppLpp enable the use of 2 separate commons. This function is

accessible beneath the terminal cover using 2 removable links. If both links are

removed, the 2 supplies become independent.

The use of a Y-connector allows 2 signals to be connected to the same M12 channel

on the splitter box.

Example: splitter box ABE 9C1281 (8 channels) enables the connection of

16 signals to the processing unit.

The Y-connector is available in 2 versions:

b M12-M12 for connection of two M12 connectors to a single M12 channel on the

splitter box,

b M8-M12 for connection of two M8 connectors to a single M12 channel on the

splitter box.

Complete reference = Splitter box only + Connector with cable

ABE 9C1240L05 = ABE 9C1240M + ABE 9XCA1405

ABE 9C1240L10 = ABE 9C1240M + ABE 9XCA1410

ABE 9C1241L05 = ABE 9C1241M + ABE 9XCA1405

ABE 9C1241L10 = ABE 9C1241M + ABE 9XCA1410

ABE 9C1280L05 = ABE 9C1280M + ABE 9XCA1805

ABE 9C1280L10 = ABE 9C1280M + ABE 9XCA1810

ABE 9C1281L05 = ABE 9C1281M + ABE 9XCA1805

ABE 9C1281L10 = ABE 9C1281M + ABE 9XCA1810

Connector only

ABE 9CM12C

Description:

page 7

6

Characteristics:

page 8

References:

page 9

Dimensions:

page 10

Connections:

page 11

Page 7

Description

Courtesy of Steven Engineering, Inc. ● 230 Ryan Way, South San Francisco, CA 94080-6370 ● General Inquiries: (800) 670-4183 ● www.stevenengineering.com

0

IP 67 passive splitter boxes 0

Telefast® Distribution System,

ABE9 splitter boxes

Description

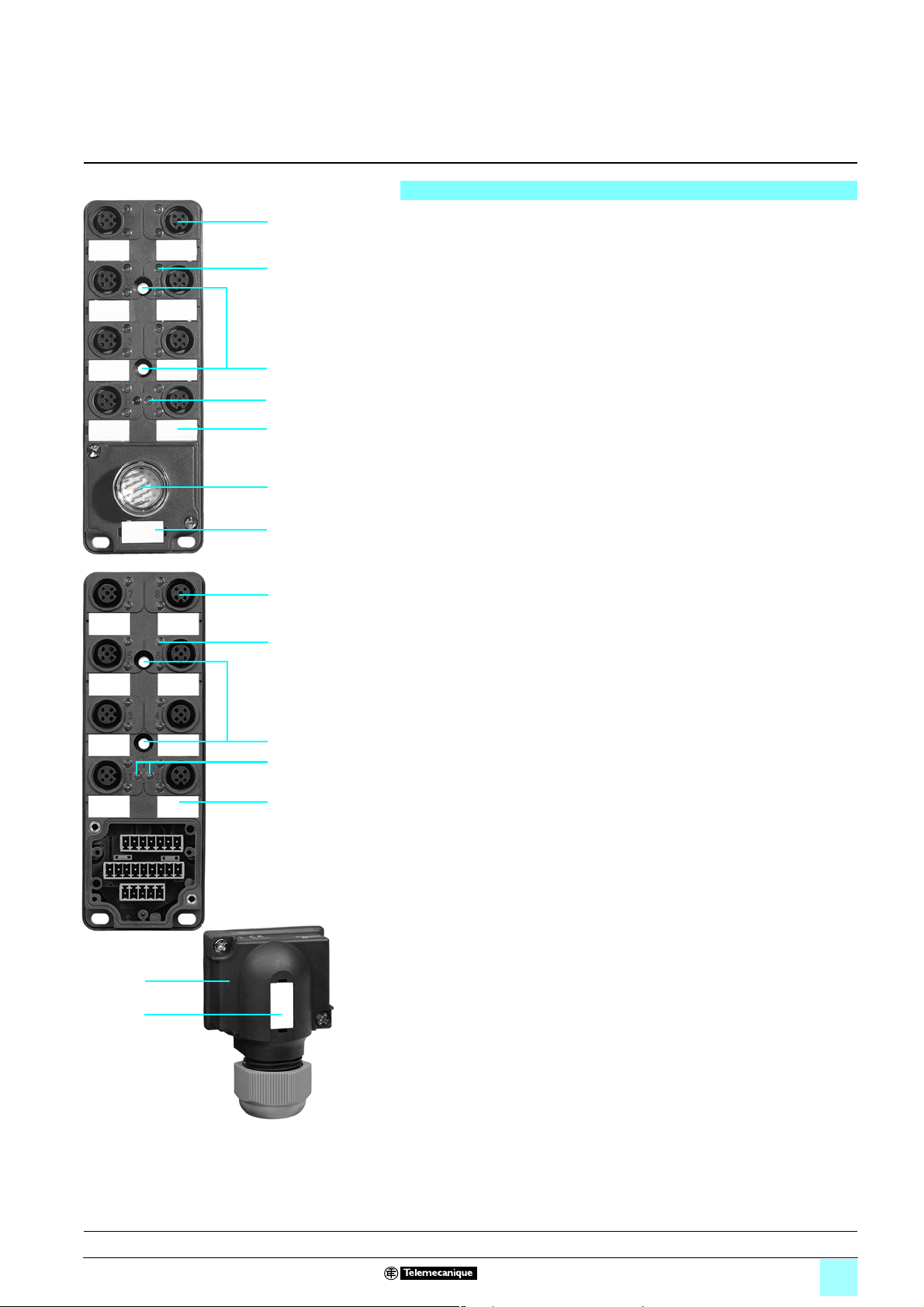

1

2

7

Passive splitter boxes ABE 9C12ppC23 have the following on the front face:

1 Four or eight M12 female connectors (depending on model) for connection of

sensors and actuators (2 channels per connector).

2 Eight or sixteen channel status indicator lights (depending on model).

3 One “Power on” indicator light on the splitter box (depending on model).

4 One M23, 19-pin male connector.

5 Four or eight channel marker labels.

3

5

4

6

1

2

7

3

5

6 One splitter box marker label.

7 Splitter box mounting holes.

Passive splitter boxes ABE 9C12ppLpp have the following on the front face:

1 Four or eight M12 female connectors (depending on model) for connection of

sensors and actuators (2 channels per connector).

2 Eight or sixteen channel status indicator lights (depending on model).

3 Two “Power on” indicator lights on the splitter box (depending on model).

4 One removable connection cover fitted with plug-in terminals.

5 Four or eight channel marker labels.

6 One splitter box marker label.

7 Splitter box mounting holes.

4

6

Presentation:

page 6

Characteristics:

page 8

References:

page 9

Dimensions:

page 10

Connections:

page 11

7

Page 8

Characteristics,

Courtesy of Steven Engineering, Inc. ● 230 Ryan Way, South San Francisco, CA 94080-6370 ● General Inquiries: (800) 670-4183 ● www.stevenengineering.com

substitution

IP 67 passive splitter boxes 0

Telefast® Distribution System,

0

ABE9 splitter boxes

Splitter box type ABE 9C12p0C23 ABE 9C12p1C23 ABE 9C12p0Lpp,

Environmental characteristics

Product certifications cULus

ABE 9C12p0M

ABE 9C12p1Lpp,

ABE 9C12p1M

Temperature Operation

Storage

Degree of protection Conforming to IEC 529

Vibration resistance Conforming to IEC 68-2-6,

test Fc

Shock resistance Conforming to IEC/EN 68-2-2

Insulation group VDE 0110

Mounting

Mechanical mounting

°C

- 20 to + 80

(°F)

(- 4 to + 176)

°C

- 40 to + 85

(°F)

(- 40 to + 185)

IP 67

Hz 10 ≤ f ≤ 57 (constant amplitude = 1.5 mm)

57 ≤ f ≤ 150 (constant acceleration = 0.20 gn)

30 gn, for 11 ms

Category 3

All positions

M4 screw mounting

Channel characteristics

Number of channels 4 or 8 (depending on model)

Type of connection per channel

Nominal voltage

Current per channel

Contact resistance

Power supply status indication

Channel status indication

M12, 5-pin female connectors

c V 24

A 4 maximum

mΩ 5

– Green LED – Green LED

– Yellow LED – Yellow LED

Connection characteristics

Type of connection M23, 19-pin male connector Multicore cable

Total current in commons 1mm

Separation of commons

2

(18 AWG) supply wire A 16

2

0.75 mm

(19 AWG) supply wire A 12

Without Without or with (by removing links BR1 and

BR2, see connections on 11)

Substitution table

Previous range New range

Splitter boxes with connection by M23 connector

XZ LC1241C3 ABE 9C1241C23

XZ LC1240C3 ABE 9C1240C23

XZ LC1281C3 ABE 9C1281C23

XZ LC1280C3 ABE 9C1280C23

Splitter boxes with connection by cable

XZ LC1241L5 ABE 9C1241L05

XZ LC1240L5 ABE 9C1240L05

XZ LC1241L10 ABE 9C1241L10

XZ LC1240L10 ABE 9C1240L10

XZ LC1281L5 ABE 9C1281L05

XZ LC1280L5 ABE 9C1280L05

XZ LC1281L10 ABE 9C1281L10

XZ LC1280L10 ABE 9C1280L10

Accessories

XZ LG102 FTX CM12B

XZ LC1220C1 FTX CY1212

Presentation:

page 6

Description:

page 7

References:

page 9

Dimensions:

page 10

Connections:

page 11

8

Page 9

References

Courtesy of Steven Engineering, Inc. ● 230 Ryan Way, South San Francisco, CA 94080-6370 ● General Inquiries: (800) 670-4183 ● www.stevenengineering.com

562511

562421

0

IP 67 passive splitter boxes 0

Telefast® Distribution System,

ABE9 splitter boxes

References

Splitter boxes with connection by M23 connector

Number of

channels

4 4 x M12 female connectors With ABE 9C1241C23 0.080

Connection

by

LED

indicator

Without ABE 9C1240C23 0.080

Reference Weight

kg

ABE 9C124pC23

562512

ABE 9C124pL

108886

pp

ABE 9C128pC23

562422

ABE 9C128pL

108887

pp

8 8 x M12 female connectors With ABE 9C1281C23 0.140

Without ABE 9C1280C23 0.140

Splitter boxes with connection by cable

Number of

channels

4 4 x M12 female

8 8 x M12 female

Connection byLength

connectors

connectors

m (ft.)

5 (16.4) With ABE 9C1241L05 0.680

10 (32.8) With ABE 9C1241L10 1.700

5 (16.4) With ABE 9C1281L05 1.610

10 (32.8) With ABE 9C1281L10 3.060

LED

indicator

Without ABE 9C1240L05 0.680

Without ABE 9C1240L10 1.700

Without ABE 9C1280L05 1.610

Without ABE 9C1280L10 3.060

Reference Weight

kg

Splitter boxes only, M12

Number of

channels

4 ABE 9CM12C ABE 9XCA14pp With ABE 9C1241M 0.060

8 ABE 9CM12C ABE 9XCA18pp With ABE 9C1281M 0.100

For use with connector LED Reference Weight

terminal with cable indicator kg

Without ABE 9C1240M 0.060

Without ABE 9C1280M 0.100

Separate components

Type No. of

Terminal

block

connector (1)

Connectors

with cable

For use with splitter box Length

channels

– ABE 9C124pM

ABE 9C128pM

4 ABE 9C124pM 5 (16.4) ABE 9XCA1405 1.060

8 ABE 9C128pM 5 (16.4) ABE 9XCA1805 1.510

m (ft.)

– ABE 9CM12C 0.040

10 (32.8) ABE 9XCA1410 2.080

10 (32.8) ABE 9XCA1810 2.240

Reference Weight

kg

Accessories

Description Composition Reference Weight

ABE 9C128pM

108768

FTXCY1208

Presentation:

page 6

ABE 9XCA1

Description:

page 7

ppp

Sealing plugs For M8 connector (lot of 10) FTX CM08B 0.100

Y-connectors Connection of 2 x M8 connectors to M12

Marker labels Lot of 12 ABE 9XLA10 –

(1) To be wired by user.

Characteristics:

page 8

For M12 connector (lot of 10) FTX CM12B 0.100

connector on splitter box

Connection of 2 x M12 connectors to M12

connector on splitter box

Dimensions:

page 10

FTX CY1208 0.020

FTX CY1212 0.030

Connections:

page 11

kg

9

Page 10

Dimensions,

Courtesy of Steven Engineering, Inc. ● 230 Ryan Way, South San Francisco, CA 94080-6370 ● General Inquiries: (800) 670-4183 ● www.stevenengineering.com

connections

IP 67 passive splitter boxes 0

Telefast® Distribution System,

0

ABE9 splitter boxes

Dimensions

ABE 9C124pC23 ABE 9C124pLpp

50.2

1.97"

92.2

3.62"

15.5 (0.61")

20.4 (0.80")

4.5

0.17"

33

1.29"

36.5

1.44"

ABE 9C128pC23 ABE 9C128pLpp

50.2

1.97"

39

1.53"

Ø4.5

73

4.5

2xØ4.5

2.87"

0.17"

1.04"

15.5 (0.61")26.5

42

1.65"

92.2

3.62"

4.5

0.17"

50.2

1.97"

33

1.29"

50.2

1.97"

39

1.53"

Ø4.5

73

2.87"

4.5

0.17"

2xØ4.5

34

1.33"

149.2

5.87"

73

2.87"

15.5 (0.61")

20.4 (0.80")

36.5

1.43"

4.5

0.17"

33

1.29"

39

1.53"

4.5

0.17"

1.04"

15.5 (0.61")26.5

42

1.65"

FTX CY1208 FTX CY1212

45

1.77"

15 (0.59")

33 (1.29")

15 (0.59")

Y-connector connection

FTX CY1208 FTX CY1212

M8

female

1

3

4

M8

female

1

3

4

M12

female

1

2

3

4

5

149.2

5.87"

35 (1.37")

M12

female

1

2

3

4

5

4.5

0.17"

33

1.29"

45

1.77"

39

1.53"

34

73

4.5

1.33"

2.87"

0.17"

Presentation:

page 6

1234

M12 male

Description:

page 7

Characteristics:

page 8

12345

M12 male

References:

page 9

Connections:

page 11

10

Page 11

Connections (continued)

Courtesy of Steven Engineering, Inc. ● 230 Ryan Way, South San Francisco, CA 94080-6370 ● General Inquiries: (800) 670-4183 ● www.stevenengineering.com

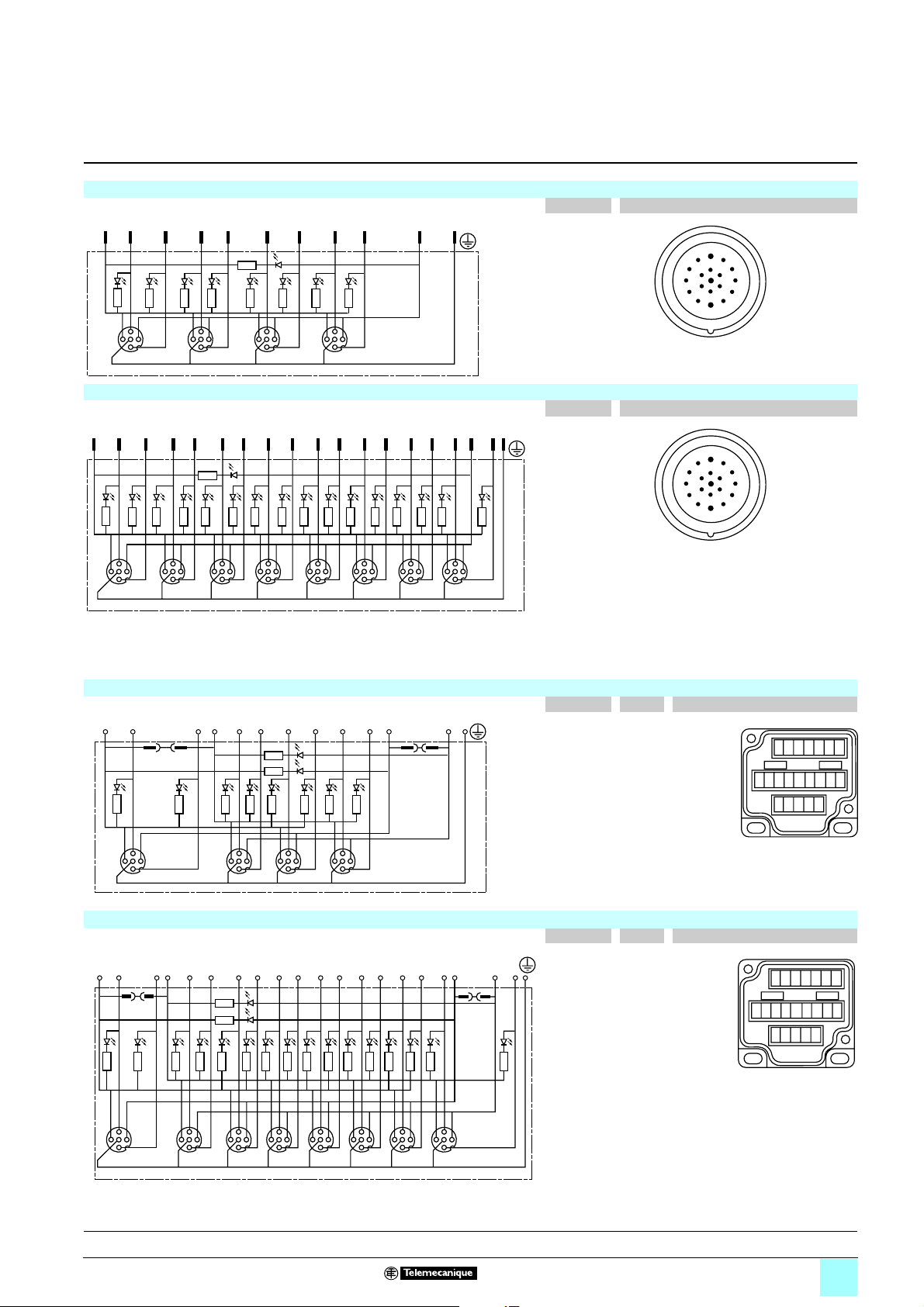

ABE 9C124pC23

1/4

1/2

2/4

2/2

3/4

1…4/3

–

4

321

5

1

4

321

5

234

ABE 9C128pC23

1/4

1/2

2/4

2/2

1…8/3

3/4

–

4

321

5

1

4

321

5

234567

4

3

215

ABE 9C124pLpp

1,3/3

–

321

BR1

4

5

1

1/2

2,4/3

–

321

5

(1)

1/4

(1) BR1 and BR2: removable link.

ABE 9C128pLpp

(1) (1)

1/4

1,3,5,7/3

BR1

–

4

321

5

1

(1) BR1 and BR2: removable link.

Presentation:

page 6

2/4

2/2

2,4,6,8/3

1/2

–

4

321

3

5

234567

3

3/2

3

2/4

4

23 4

3/4

4

215

Description:

page 7

3/2

4

215

4/4

4/2

4

3

215

2/4

2/2

4

3

215

4/4

4/2

3/2

4

3

3

215

0

IP 67 passive splitter boxes 0

Telefast® Distribution System,

ABE9 splitter boxes

Item Contact

4/4

4/2

1…4/1

1…4/5

+

4

3

215

1/4

1/2

2/4

2/2

3/4

3/2

4/4

4/2

1 and 3/1

2 and 4/1

1 and 3/3

2 and 4/3

1 to 4/5

Item Contact

8/4

5/4

5/2

6/4

6/2

7/4

7/2

8/2

1…8/1

+

4

4

3

215

4

4

3

3

215

215

215

8

1…8/5

1/4

1/2

2/4

2/2

3/4

3/2

4/4

4/2

5/4

5/2

6/4

6/2

7/4

7/2

8/4

8/2

1, 3, 5 & 7/1

2, 4, 6 & 8/1

1, 3, 5 & 7/3

2, 4, 6 & 8/3

1 to 8/5

Item Terml. Wire

(1)

1,3/1

4/4

2/2

4/2

+

4

3

215

BR2

2,4/1

+

1/4

1/2

2/4

2/2

3/4

3/2

4/4

4/2

1 and 3/1

2 and 4/1

1 and 3/3

2 and 4/3

1 to 4/5

Item Terml. Wire

1/4

5/5

5/2

6/4

6/2

4

4

3

3

215

215

8/4

7/4

7/2

1,3,5,7/1

+

4

4

3

215

215

8

Characteristics:

page 8

BR2

2,4,6,8/1

+

8/2

1/2

2/4

2/2

3/4

3/2

4/4

4/2

5/4

5/2

6/4

6/2

7/4

7/2

8/4

8/2

1, 3, 5 & 7/1

2, 4, 6 & 8/1

1, 3, 5 & 7/3

2, 4, 6 & 8/3

1 to 8/5

References:

page 9

15

7

5

4

16

8

3

14

19

19

6

6

12

15

7

5

4

16

8

3

14

17

9

2

13

11

10

1

18

19

19

6

6

12

1

9

2

10

3

11

4

12

+ 1

+ 2

– 1

– 2

PE

1

9

2

10

3

11

4

12

5

13

6

14

7

15

8

16

+ 1

+ 2

– 1

– 2

PE

12

11

18

10

17

19

9

16

8

15

7

6

M23 connector

12

11

18

10

17

19

9

16

8

15

7

6

M23 connector

White

Grey/pink

Green

Red/blue

Yellow

White/green

Grey

Brown/green

Brown 1

Brown 2

Blue 1

Blue 2

Green/yellow

White

Grey/pink

Green

Red/blue

Yellow

White/green

Grey

Brown/green

Pink

White/yellow

Red

Yellow/brown

Black

White/grey

Violet

Grey/brown

Brown 1

Brown 2

Blue 1

Blue 2

Green/yellow

1

2

13

3

14

4

5

1

2

13

3

14

4

5

Dimensions:

page 10

9

11 13 16 1412 10

BR1

PE 4 2

57 8 615

9

1113 16 1412 10

BR1

PE 4 2

57 8 615

BR2

-2-1 +1 +213

BR2

-2-1 +1 +213

11

Page 12

Selection guide

Courtesy of Steven Engineering, Inc. ● 230 Ryan Way, South San Francisco, CA 94080-6370 ● General Inquiries: (800) 670-4183 ● www.stevenengineering.com

0

IP 67 monobloc I/O splitter boxes

for fieldbuses 0

Advantys™ Distributed I/O, FTB splitter boxes

Applications

Industrial fieldbus type

Degree of protection IP 67

Modularity

(number of

channels)

Inputs Voltage c 24 V

8 I + 8 O (8 O + 8 diagnostic inputs)

12 I + 4 O (4 I + 4 O + 8 diagnostic inputs)

16 I (8 I + 8 diagnostic inputs)

16 I/O (8 I/O+ 8 diagnostic I/O)

8 I + 8 I/O (8 I + 8 diagnostic I/O) –

p

p

p p

p p

–

–

p

Conformity to IEC 1131-2 Type 2

Outputs Voltage c 24 V

Type Transistor

Current/output 1.6 A

Current/splitter box 8 A

Connection M12 connectors (5-pin)

Housing type Plastic Metal

Diagnostics Per splitter box Bus and I/O undervoltage

Per channel I/O short-circuit

Module type

I/O short-circuit

I/O supply

Wire breakage fault

Faulty sensors/actuators

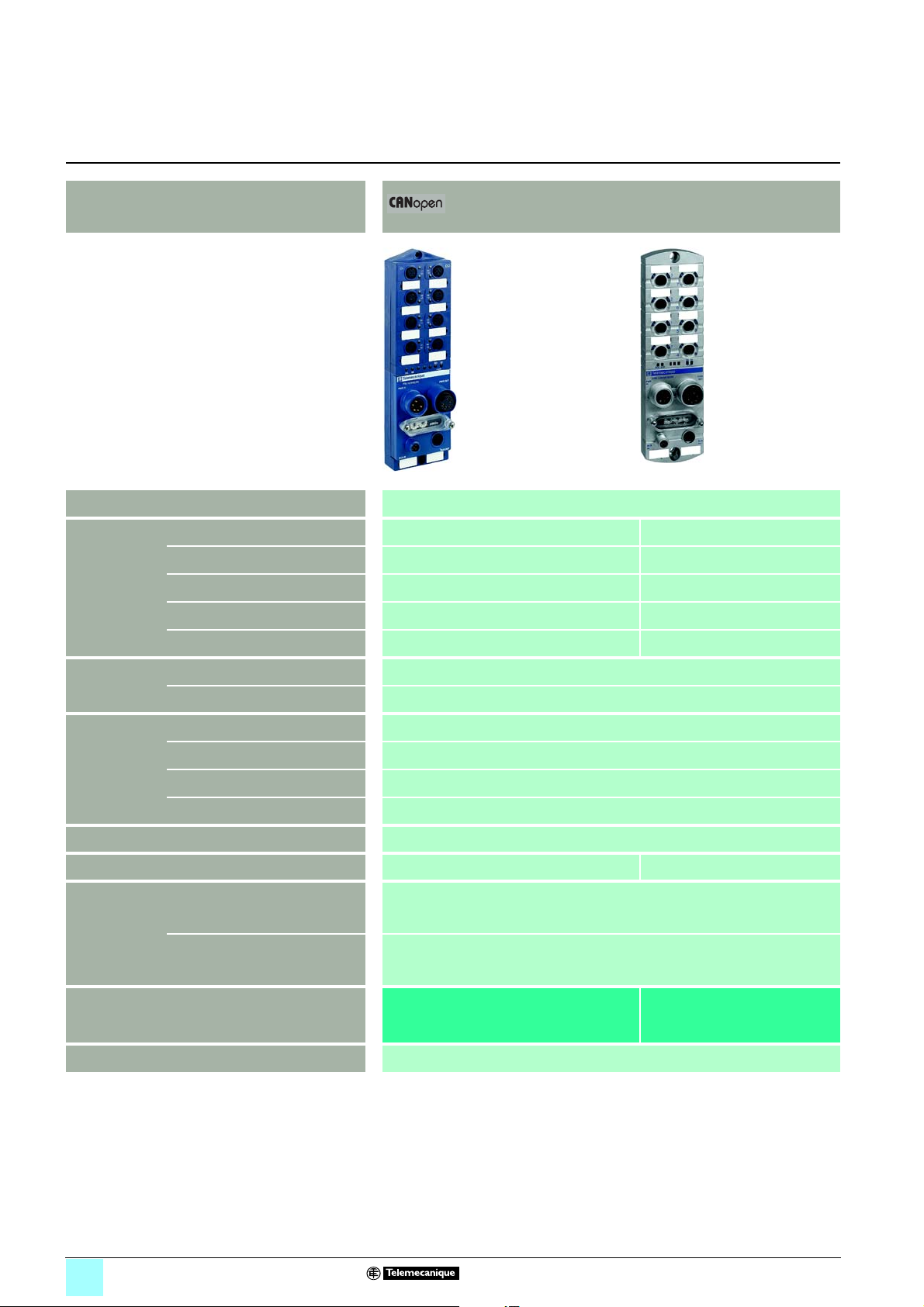

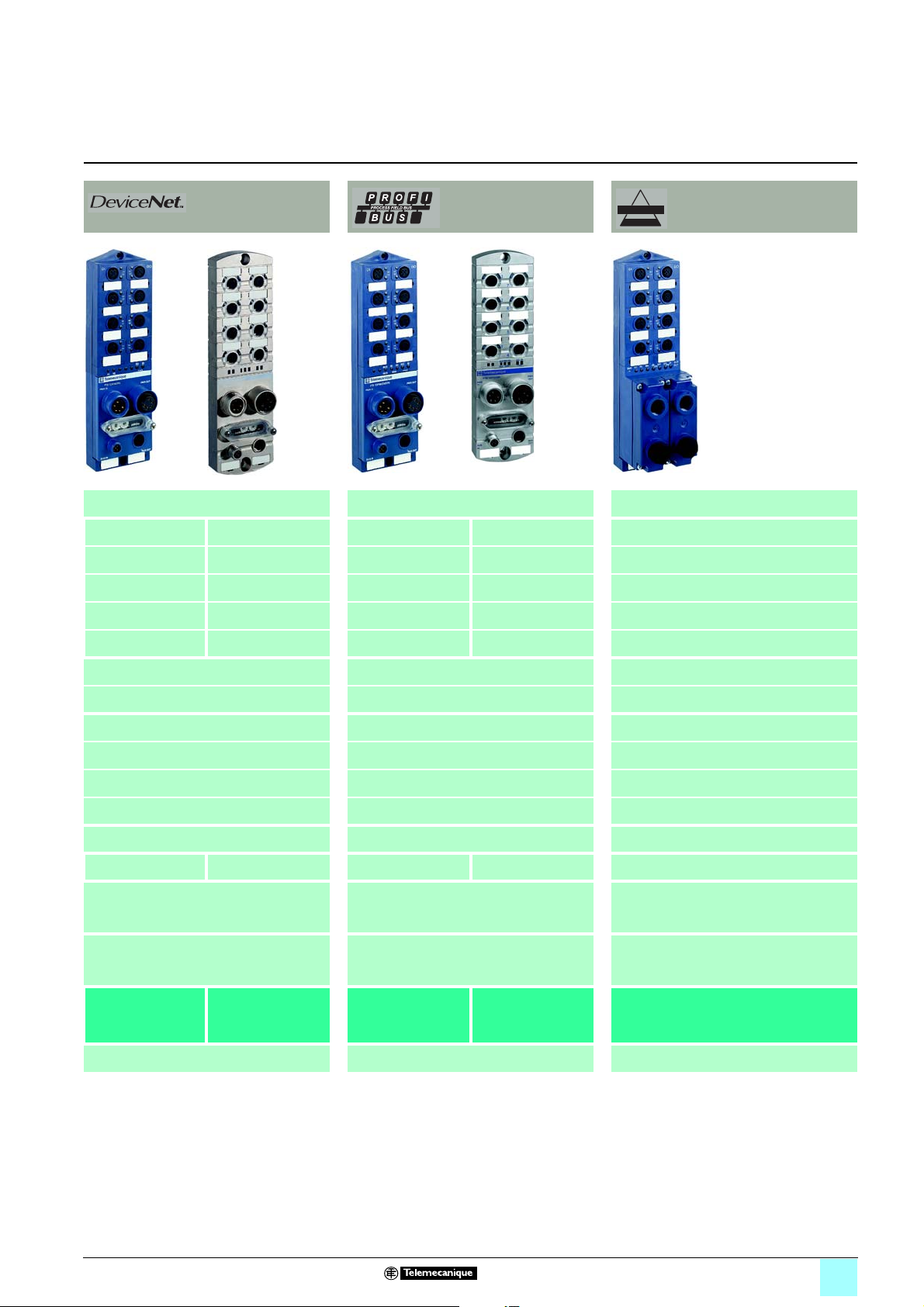

FTB 1CNpppP0 FTB 1CNpppM0

Page 28 28

12

Page 13

0

Courtesy of Steven Engineering, Inc. ● 230 Ryan Way, South San Francisco, CA 94080-6370 ● General Inquiries: (800) 670-4183 ● www.stevenengineering.com

INTERBUS

IP 67 IP 67 IP 67

0

p

p

–

–

p

p

–

–

p

p

p p p p p

p p p p p

–

c 24 V c 24 V c 24 V

Type 2 Type 2 Type 2

c 24 V c 24 V c 24 V

Transistor Transistor Transistor

1.6 A 1.6 A 1.6 A

8 A 8 A 10 A

M12 connectors (5-pin) M12 connectors (5-pin) M12 connectors (5-pin)

Plastic Metal Plastic Metal Plastic only

Bus and I/O undervoltage

I/O short-circuit

I/O supply

I/O short-circuit

Wire breakage fault

Faulty sensors/actuators

p

–

Bus and I/O undervoltage

I/O short-circuit

I/O supply

I/O short-circuit

Wire breakage fault

Faulty sensors/actuators

p

–

Bus and I/O undervoltage

I/O short-circuit

I/O supply

I/O short-circuit

Wire breakage fault

Faulty sensors/actuators

FTB 1DNpppP0 FTB 1DNpppM0 FTB 1DPpppP0 FTB 1DPpppM0 FTB 1IB

28 28 28

13

Page 14

Presentation,

Courtesy of Steven Engineering, Inc. ● 230 Ryan Way, South San Francisco, CA 94080-6370 ● General Inquiries: (800) 670-4183 ● www.stevenengineering.com

functions

IP 67 monobloc I/O splitter boxes

0

for fieldbuses 0

Advantys™

Presentation

To meet the needs of machine manufacturers and users, automation system

architectures are becoming decentralized, while offering performances comparable

to those obtained with a centralized structure.

Advantys FTB IP 67 monobloc I/O splitter boxes enable sensors and actuators to be

connected in distributed automation systems using pre-assembled cables, thus

reducing wiring time and costs, whilst at the same time increasing the operational

availability of the installation.

These IP 67 protected splitter boxes can also be used within processes or machines

in harsh environments (splashing water, oil, dust, etc.). For difficult environments

(welding shops etc.), a range of Advantys FTB splitter boxes with a metal housing is

available.

Advantys FTB splitter boxes allow distributed connection of sensors and actuators

on machines via a fieldbus. They communicate on different buses such as:

CANopen, DeviceNet, Profibus-DP and InterBus.

Sensors and actuators are connected by means of standard M12 connectors.

Configuration and parametering of the Advantys FTB splitter boxes is carried out

using configuration files (e.g.: .eds files for CANopen):

b either directly within the software workshop of the PLC used,

b or by using a SyCon type configurator (refer to our Modicon

automation platform catalog).

Distributed I/O, FTB splitter boxes

®

Premium™ PLC

Advantys FTB splitter boxes are available with different input (c 24 V IEC type 2)

and output (transistor c 24 V/1.6 A) configurations:

b Mixed 8 input and 8 output splitter boxes, allowing connection of either 8 sensors

and 8 actuators or 8 actuators with integrated diagnostics function.

b Mixed 12 input and 4 output splitter boxes, allowing connection of either

12 sensors and 4 actuators or 4 sensors and 4 actuators with integrated diagnostics

function.

b 16 input splitter boxes allowing connection of either 16 sensors or 8 sensors with

integrated diagnostics function.

b Mixed 16 input or output splitter boxes, configurable per channel, allowing all

possible combinations: 16 inputs, 15 inputs/1 output, 14 inputs/2 outputs, to .,

16 outputs.

Functions

Selection of signal type per channel

b Each M12, 5-pin connector on Advantys FTB splitter boxes allows the connection

of 2 signals. Depending on the type of splitter box, these can be:

v 1 sensor input signal,

v 1 diagnostic input signal,

v 1 actuator output signal.

Signal type, depending on splitter box selected:

FTB 1pp16E 1pp08E08S 1pp12E04S 1pp16C 1Dp08E08C

M12 Contact 4 Input Output 0 to 3: Input

Contact 2 Input

Note: either a normally open (N/O) or a normally closed (N/C) contact can be chosen for each

input signal.

Diagnostic

Input

Diagnostic

4 to 7: Output

Input

Diagnostic

Input

Output

Input

Output

Diagnostic

Input

Output

Input

Diagnostic

Description, configuration:

pages 18 , 21, 24,

14

Characteristics:

pages 26, 27

References:

pages 28 - 30

Dimensions:

pages 31 - 33

Page 15

Functions (continued)

Courtesy of Steven Engineering, Inc. ● 230 Ryan Way, South San Francisco, CA 94080-6370 ● General Inquiries: (800) 670-4183 ● www.stevenengineering.com

0

IP 67 monobloc I/O splitter boxes

for fieldbuses 0

Advantys™

Diagnostics

Each Advantys FTB splitter box has one LED per channel to indicate the status of

the channel and to enable fast and precise location of a fault. Fault monitoring

diagnostics are indicated on the splitter box by LEDs and are fed back to the control

system (PLC) via the bus.

There are 2 levels of diagnostics:

b diagnostics per channel,

b diagnostics per splitter box.

Diagnostics per channel

b Sensor short-circuit

A short-circuit or overload on contact 1 of the M12 female connector blows the selfresetting fuse. Each M12 connector is individually protected. A red LED indicates

the fault on the corresponding M12 connector. This fault is signalled to the Master.

Supply to the sensors is automatically restored after elimination of the fault.

b Actuator short-circuit

A short-circuit or overload of an output causes disconnection of this output. The fault

is signalled to the Master. A red LED indicates the fault on the corresponding M12

connector. The output does not restart automatically. After having eliminated the

cause of the fault, the channel must be reset by the PLC. This operation erases the

short-circuit memory.

b Actuator warning

When the output is at state 0, the contact corresponding to the M12 female

connector is checked for presence of 24 V voltage. If + 24 V is present, it means

there is a “short-circuit”. A red LED indicates the fault on the corresponding M12

connector. The fault is signalled to the Master.

Diagnostics per splitter box

b Sensor/actuator supply status.

Distributed I/O, FTB splitter boxes

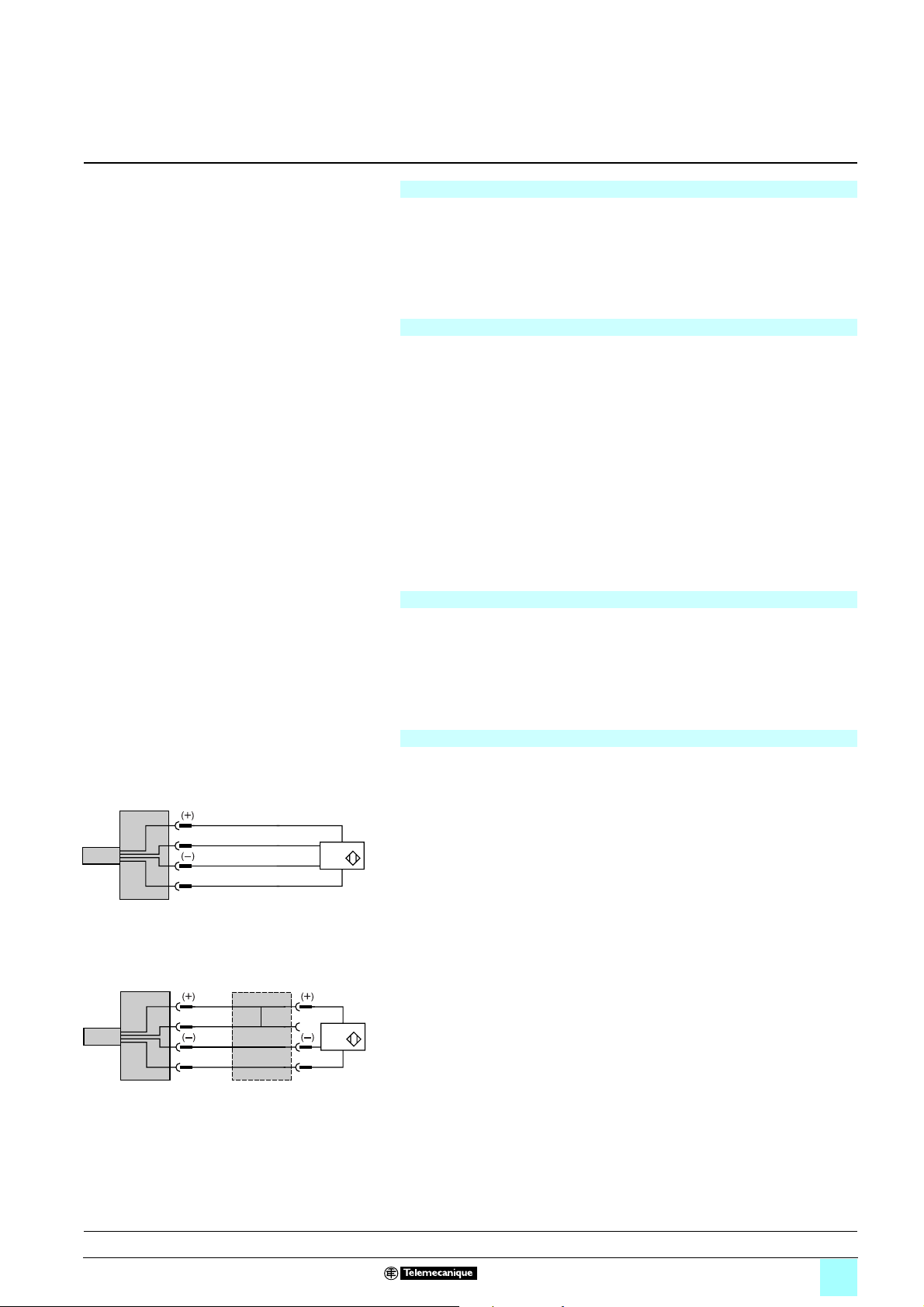

Example of connection of a sensor with integrated diagnostics

function

M12

connector

Example of connection of a standard sensor with the

diagnostics adaptor

M12

connector

1

Diagnostic

2

3

4 (S)

1

Diagnostic

2

3

4 (S)

M12 adaptor

FTX DG12

(by-pass)

1

3

4 (S)

DESINA

sensor

Sensor

b “Undervoltage” fault on the I/O supply.

b Sensor short-circuit.

b Actuator short-circuit.

Use of the sensor/actuator diagnostics function

Advantys FTB splitter boxes allow the use of sensors and actuators incorporating an

integrated diagnostics function (DESINA type c). Configuring contact 2 of each M12

connector as a diagnostic input enables detection of external faults associated with

the sensors or actuators.

This information enables the following faults to be detected:

b damage to the detection surface,

b faulty electronics,

b no load.

Selection of either the sensor input or diagnostic input function on contact 2 is made

channel by channel, by entering parameters, when configuring the splitter box.

Fault indication by a red LED is possible for each channel configured as a diagnostic

input (LEDs 10 to 17).

Example of connection of a sensor with integrated diagnostics function:

Using the M12 diagnostics adaptor accessory FTX DG12, it is possible to monitor

breaks in wiring to sensors or actuators which do not have an integrated diagnostics

function.

b DESINA - Standard relating to the connector technology of sensors, and actuators,

established by the German Machine Tool Builder’s Association.

Description, configuration:

pages 18 , 21, 24,

Characteristics:

pages 26, 27

References:

pages 28 - 30

Dimensions:

pages 31 - 33

15

Page 16

Presentation

Courtesy of Steven Engineering, Inc. ● 230 Ryan Way, South San Francisco, CA 94080-6370 ● General Inquiries: (800) 670-4183 ● www.stevenengineering.com

0

IP 67 monobloc I/O splitter boxes

for fieldbuses 0

Advantys™

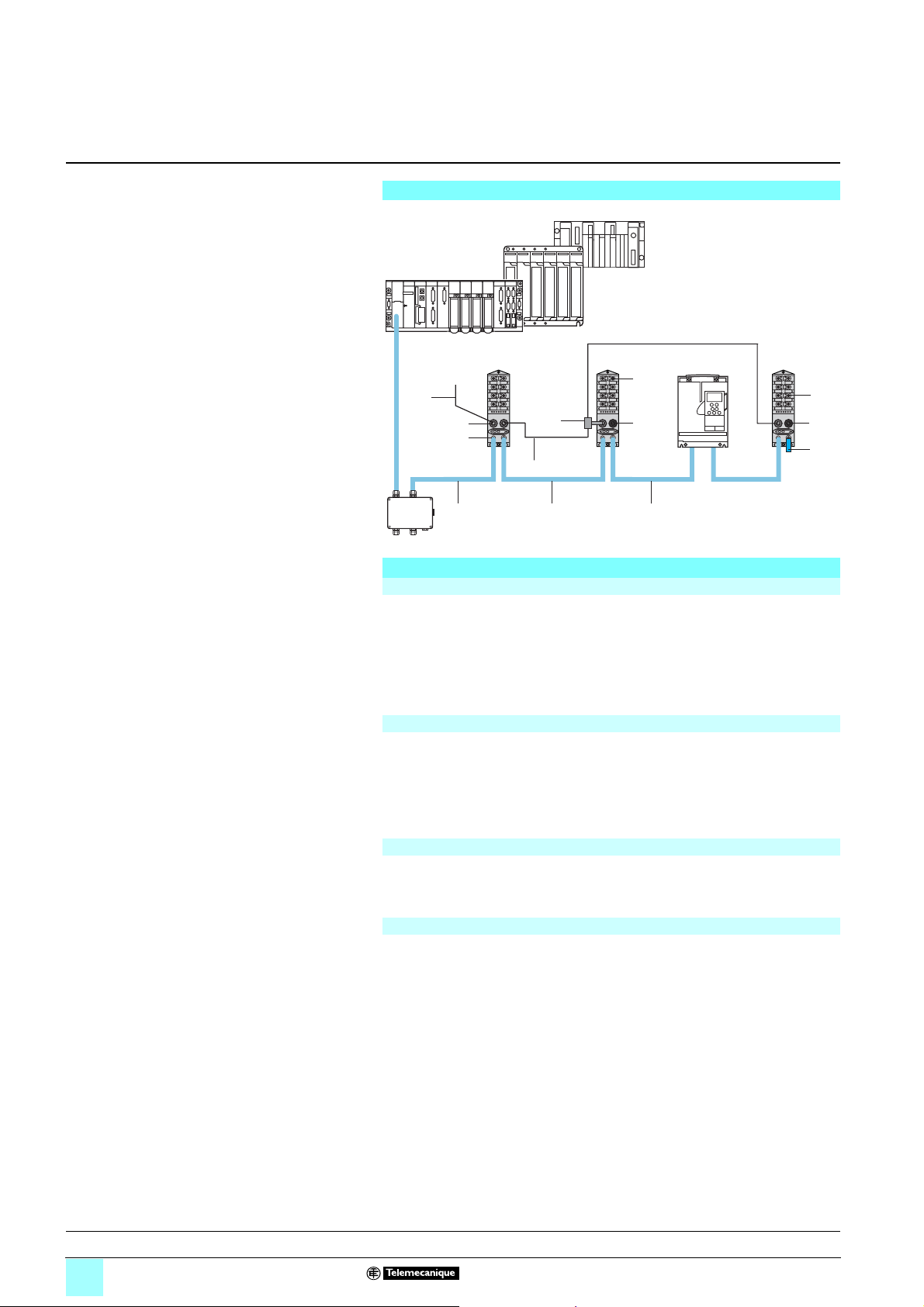

CANopen™ and DeviceNet™ bus extensions

Advantys FTB splitter boxes are of the monobloc type.

Each splitter box comprises one part for connection of sensors and actuators by

means of M12 connectors, and one part for connection of splitter boxes on CANopen

and DeviceNet fieldbuses.

These splitter boxes enable inputs/outputs to be located remotely, as close as

possible to the equipment being controlled.

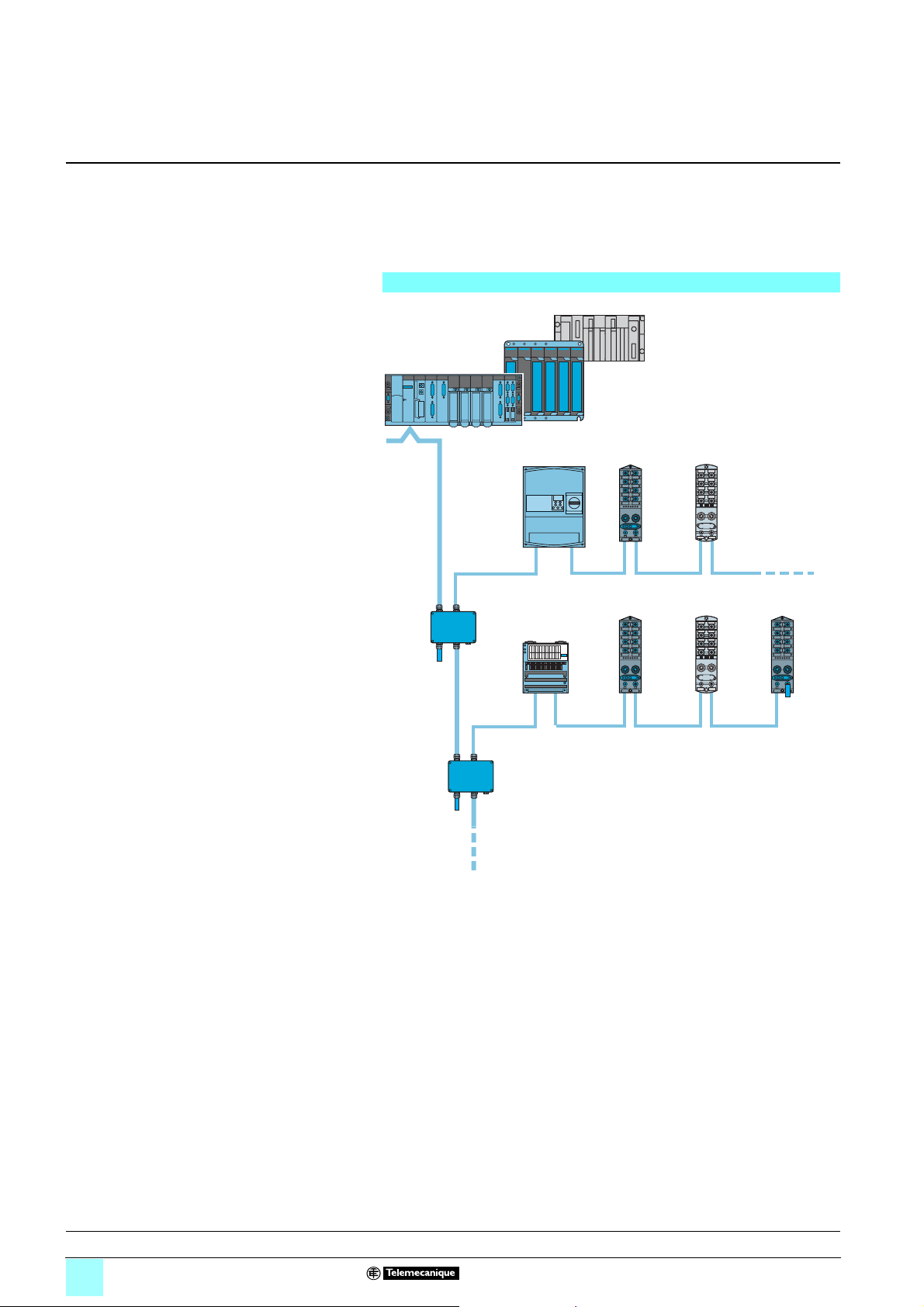

CANopen bus presentation

Modicon®

Premium

™ PLC

Distributed I/O, FTB splitter boxes

Master

®

From 1 to 127 Slaves

FTB 1CN

pppP0

FTB 1CN

pppM0

CANopen bus

Altivar® 38 Drive

Altivar

®

58/58F Drive

The CAN system, initially developed for real-time exchange of information in the

automobile industry, is now being used more and more throughout industry. There

are several fieldbuses based on CAN base layers and components.

The CANopen bus conforms to international standard ISO 11898, promoted by the

“CAN in Automation” association (a grouping of manufacturers and users), and

guarantees a high degree of openness and inter-operability due to its communication

profiles and its standardized equipment.

The CANopen bus is now recognized, in Europe, as the reference standard for

building industrial systems based on the CAN concept.

The CANopen bus is a Multimaster bus, based on the Master/Slave principle.

The physical link consists of a shielded twisted pair, to which up to a maximum of

127 Slaves can be connected by simple tap-off. The binary rate varies, depending

on the length of the bus, from 1 Mbits/s for 40m (131.2 ft.) to 50 kbits/s for 1000m

(3281 ft.).

Each end of the bus must be fitted with a line terminator.

The CANopen bus is a set of profiles on CAN systems, possessing the following

characteristics:

b Open bus system.

b Data exchanges in real-time without overloading the protocol.

b Modular design allowing modification of size.

b Interconnection and interchangeability of devices.

b Standardized configuration of networks.

b Access to all device parameters.

b Synchronization and circulation of data from cyclic and/or event-controlled

processes (short system response time).

b Exchanges possible with numerous international manufacturers.

TeSys

®

Model U

Tego Power

Presentation, functions:

pages 14 - 17

16

Description, configuration:

pages 18 , 21, 24,

Characteristics:

pages 26, 27

References:

pages 28 - 30

Dimensions:

pages 31 - 33

Page 17

Presentation (continued)

Courtesy of Steven Engineering, Inc. ● 230 Ryan Way, South San Francisco, CA 94080-6370 ● General Inquiries: (800) 670-4183 ● www.stevenengineering.com

0

IP 67 monobloc I/O splitter boxes

for fieldbuses 0

Advantys™

CANopen™ and DeviceNet™ bus extensions

DeviceNet bus presentation

DeviceNet Master

Distributed I/O, FTB splitter boxes

DeviceNet bus

Modicon®

Altivar® 38 Drive

®

58/58F Drive

Altivar

The DeviceNet system is a sensor/actuator bus system of the open Low-End type,

used in various industrial applications and, in particular, the automobile industry. It is

based on CAN technology (OSI layers 1 and 2).

The DeviceNet bus is based on the Master/Slave principle.

The physical link consists of 2 shielded twisted pairs (2 wires for data, 2 wires for

auxiliary supply to sensors), to which up to a maximum of 63 slaves can be

connected. The binary rate varies, depending on the length of the bus, from

500 kbits/s for 100m (328.1 ft.) to 125 kbits/s for 500m (1640 ft.).

Each end of the bus must be fitted with a line terminator.

TeSys

Momentum

®

Model U

™ PLC

Tego

Connections

From 1 to 63 Slaves

FTB 1DN FTB 1DN

® Power

Presentation, functions:

pages 14 - 17

Description, configuration:

pages 18 , 21, 24,

Characteristics:

pages 26, 27

References:

pages 28 - 30

Dimensions:

pages 31 - 33

17

Page 18

Description,

Courtesy of Steven Engineering, Inc. ● 230 Ryan Way, South San Francisco, CA 94080-6370 ● General Inquiries: (800) 670-4183 ● www.stevenengineering.com

configuration

540354

IP 67 monobloc I/O splitter boxes

0

for fieldbuses 0

Advantys™

CANopen™ and DeviceNet™ bus extensions

Description

CANopen and DeviceNet monobloc I/O splitter boxes FTB 1CN and FTB 1DN have

the following on the front face:

1

1 Eight M12 female connectors for connection of sensors and actuators (2 channels

per connector).

Distributed I/O, FTB splitter boxes

11

2

3

7

8

5

10

2 Eight channel status indicator lights (00 to 07).

3 Eight channel status indicator lights (10 to 17) or channel diagnostic indicator

lights (00 to 07) depending on the splitter box configuration.

4 Two 7/8 connectors for connecting the c 24 V sensor and actuator power

9

4

6

supplies: male for PWR IN, female for PWR OUT.

5 One M12 male connector (bus IN) and one M12 female connector (bus OUT) for

connection of the CANopen and DeviceNet buses.

6 Access to coding and speed selection wheels.

7 Two bus diagnostic LEDs.

8 Two c 24 V sensor and actuator supply status LEDs.

9 Eight channel marker labels.

10 Two splitter box marker labels.

11 Splitter box functional ground connection (beneath the label).

Configuration

CANopen bus configuration

An .eds file is assigned to each product, which contains all the important information

relating to the product. An icon (.dib for CANopen) is also available for installation in

the system configurator.

Please refer to the configuration software documentation for the import of .eds files.

Following the CANopen system initialization phase, all the Slaves signal their

presence on the bus by means of a “Boot-Up” message. A setting-up configurator

(e.g.: SyCon) can then start to read and register the CANopen bus and, on the basis

of the data obtained, assign a corresponding .eds file to each Slave. Based on the

.eds file data, the Master creates a peripheral image of all the Slaves detected by the

PLC. The user can assign I/O bytes to logic addresses within the PLC.

b Addressing

The addresses are configurable from 1 to 99 by means of 2 coding wheels (x 10 and

x 1). A 3rd coding wheel enables the data transmission speed to be selected

(position 0 = automatic speed recognition from 125 kbits/s to 1 Mbits/s).

DeviceNet bus configuration

An .eds file is assigned to each product, which contains all the important information

relating to the product. An icon (.ico for DeviceNet) is also available for installation in

the system configurator.

When the network is scanned, the identification data is compared with that of the

Slaves present on the network and assigned accordingly. After the scanning phase,

the scanner will have identified all the Slaves and saved information relating to data

length and operating mode.

The DeviceNet bus Master establishes a peripheral image of all the devices detected

on the DeviceNet bus and incorporates them according to their physical location in a

Scan list. The user can then assign the Scan list, according to the peripheral image

of the bus devices, to logic addresses in the PLC.

b Addressing

The addresses are configurable from 1 to 63 by means of 2 coding wheels (x 10 and

x 1). A 3rd coding wheel enables the data transmission speed to be selected

(3 speeds can be selected: 125, 250 and 500 kbits/s).

Presentation, functions:

pages 14 - 17

18

Description, configuration:

pages 18 , 21, 24,

Characteristics:

pages 26, 27

References:

pages 28 - 30

Dimensions:

pages 31 - 33

Page 19

Connections

Courtesy of Steven Engineering, Inc. ● 230 Ryan Way, South San Francisco, CA 94080-6370 ● General Inquiries: (800) 670-4183 ● www.stevenengineering.com

0

IP 67 monobloc I/O splitter boxes

for fieldbuses 0

Advantys™

CANopen™ and DeviceNet™ bus extensions

Cabling system

Master

ATV 58

Cabling accessories

CANopen and DeviceNet bus connection cables

Cables FTX CN32pp enable connection of splitter boxes FTB 1CN and FTB 1DN to

CANopen and DeviceNet fieldbuses.

1 FTX CN32pp: cables fitted with 2 elbowed M12, 5-pin connectors, one at each

end, for chaining the bus between two splitter boxes.

Sensor and actuator c 24 V power supply connection cables

Cables FTX DP2ppp enable connection of c 24 V power supplies to splitter boxes

FTB 1CN and FTB 1DN. Two types of cable are available, in various lengths:

2 FTX DP22pp: cables fitted with two 7/8, 5-pin connectors, one at each end, for

chaining c 24 V power supplies between two splitter boxes.

3 FTX DP21pp: cables fitted with a 7/8, 5-pin connector at one end, with the other

end free for connection of c 24 V power supplies.

Connectors

4 FTX CN12p5: M12, 5-pin, male and female connectors for bus cables.

5 FTX C78pp: 7/8, 5-pin, male and female connectors for c 24 V power supply

cables.

Other components

6 FTX CNTL12: bus line terminator fitted with an M12 connector.

7 FTX CpppB: sealing plugs for 7/8, M12 and M8 connectors.

8 FTX CY12pp: Y-connector for M12 and M8 connectors.

9 FTX CNCT1: T-connector fitted with two 7/8, 5-pin connectors for power supply

cable.

Distributed I/O, FTB splitter boxes

To other

c 24 V

3

5

4

FTB 1CN/1DN

splitter box

9

FTB 1CN/1DN

2

1

7

8

7

6

Presentation, functions:

pages 14 - 17

Description, configuration:

pages 18 , 21, 24,

Characteristics:

pages 26, 27

References:

pages 28 - 30

Dimensions:

pages 31 - 33

19

Page 20

Presentation

Courtesy of Steven Engineering, Inc. ● 230 Ryan Way, South San Francisco, CA 94080-6370 ● General Inquiries: (800) 670-4183 ● www.stevenengineering.com

0

IP 67 monobloc I/O splitter boxes

for fieldbuses 0

Advantys™

Profibus™-DP bus

Advantys FTB splitter boxes are of the monobloc type.

Each splitter box comprises one part for connection of sensors and actuators by

means of M12 connectors, and one part for connection of splitter boxes on

Profibus-DP fieldbus.

This splitter box enables inputs/outputs to be located remotely, as close as possible

to the equipment being controlled.

Profibus-DP presentation

Distributed I/O, FTB splitter boxes

Modicon®

Premium

Modicon®

Quantum™ PLC

™ PLC

Profibus-DP bus

Altivar® 58E Drive

Modicon®

Momentum

PLC

Other Master

FTB 1DP FTB 1DP

™

FTB 1DP FTB 1DP FTB 1DP

The Profibus-DP (Process Fieldbus Decentralized Peripheral) is an open type

fieldbus system for industrial applications. The Profibus standard is described in

standard EN 50170.

The physical link is a simple, type A, shielded twisted pair.

Data exchange between the Master (processing unit) and the Slaves (decentralized

devices) is performed in a cyclic manner.

A maximum of 32 Slaves can be connected to a bus segment. To increase the

number of Slaves, repeaters must be installed in order to create new bus segments.

The repeaters also provide galvanic isolation of the bus segments.

The total number of slaves must not exceed 126.

The bus must be fitted with a line terminator at each end of each segment created.

Presentation, functions:

pages 14 - 17

20

Description, configuration:

pages 18 , 21, 24,

Characteristics:

pages 26, 27

References:

pages 28 - 30

Dimensions:

pages 31 - 33

Page 21

Description,

Courtesy of Steven Engineering, Inc. ● 230 Ryan Way, South San Francisco, CA 94080-6370 ● General Inquiries: (800) 670-4183 ● www.stevenengineering.com

configuration

IP 67 monobloc I/O splitter boxes

0

for fieldbuses 0

Advantys™

Profibus™-DP bus

Distributed I/O, FTB splitter boxes

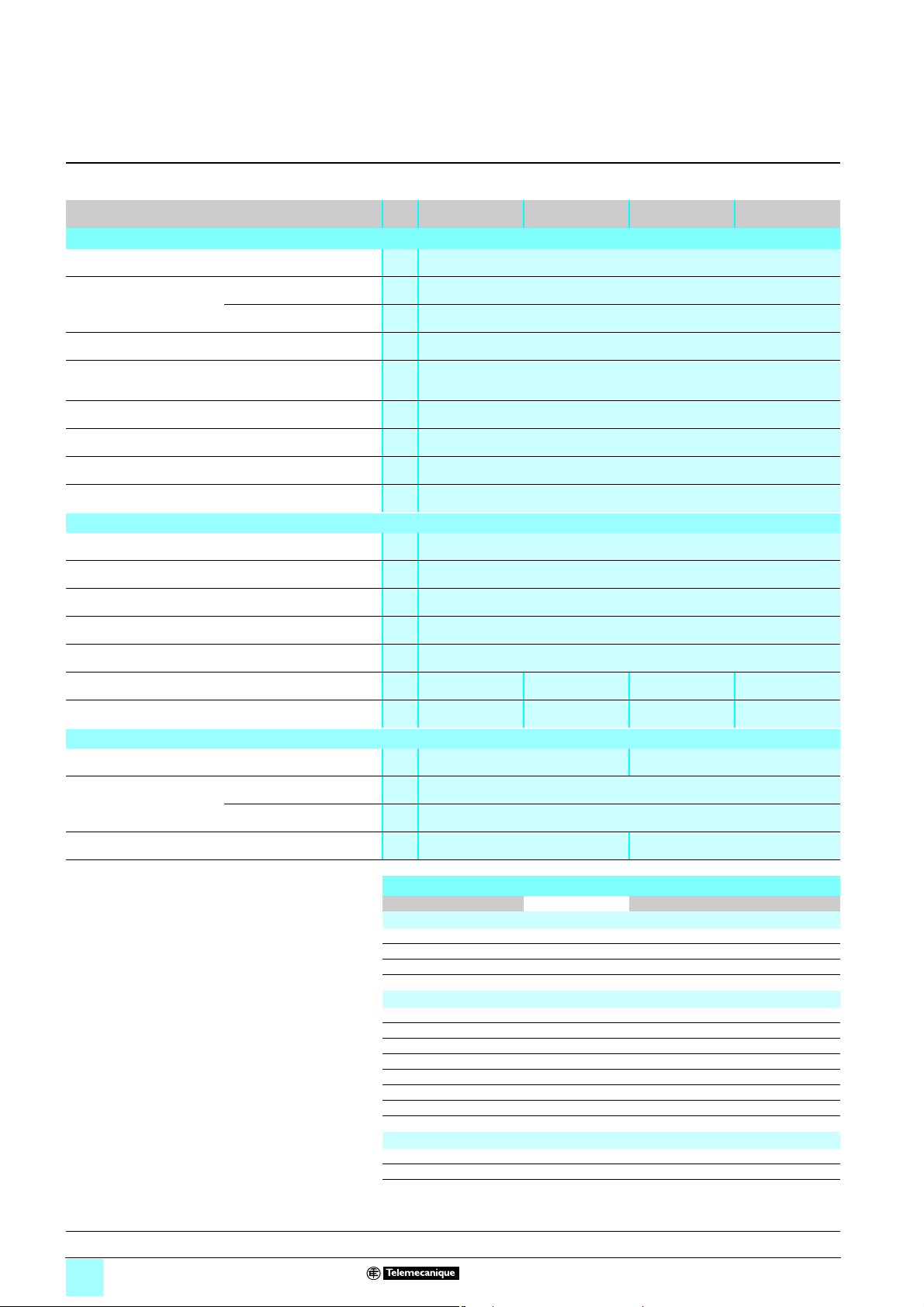

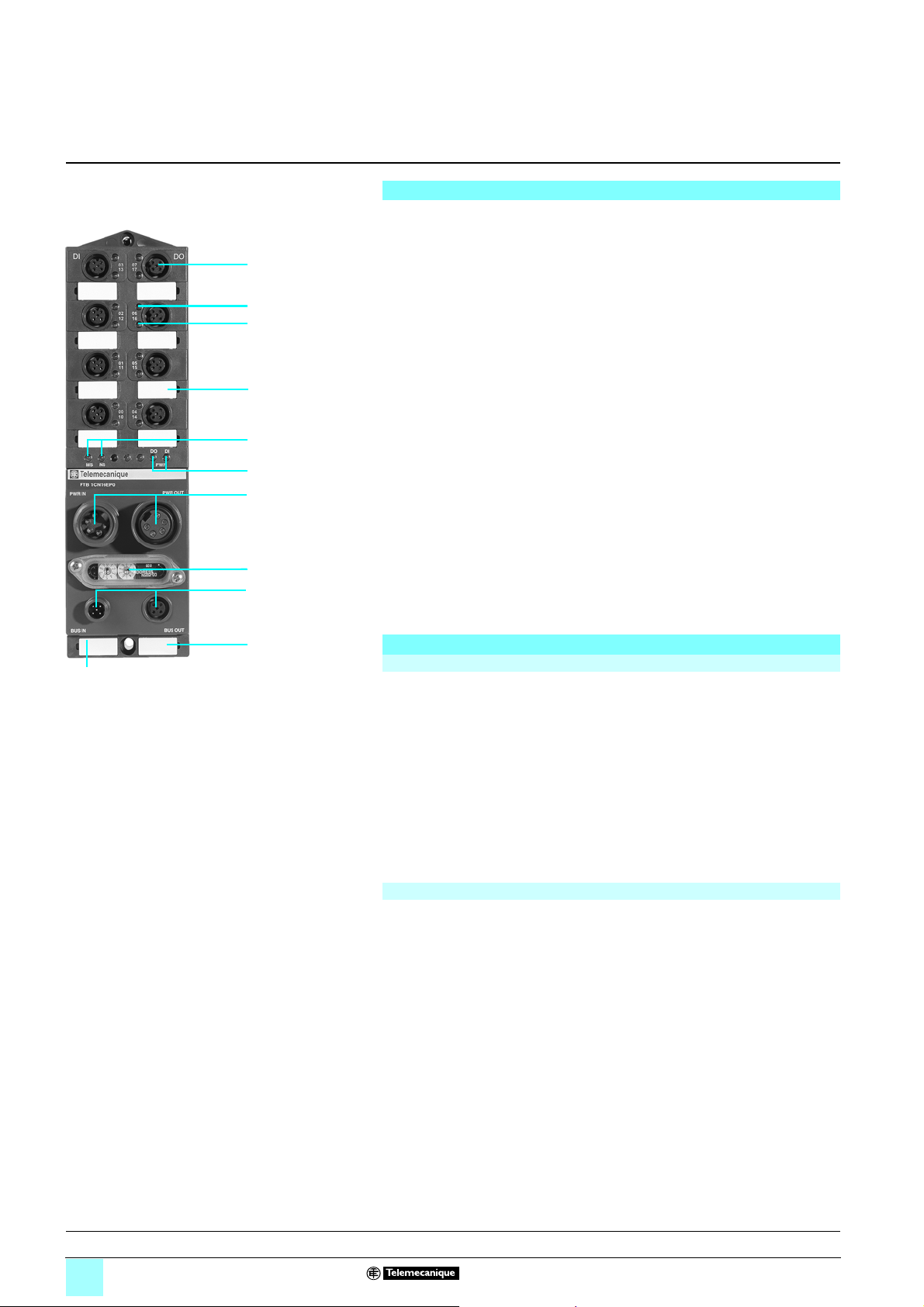

108734

12

1

2

3

7

6

5

11

10

9

8

4

Description

Profibus-DP monobloc I/O splitter boxes FTB 1DP have the following on the front

face:

1 Eight M12 female connectors for connection of sensors and actuators (2 channels

per connector).

2 Eight channel status indicator lights (00 to 07).

3 Eight channel status indicator lights (10 to 17) or channel diagnostic indicator

lights (00 to 07) depending on the splitter box configuration.

4 Two 7/8 connectors for connecting the c 24 V sensor and actuator power

supplies: male for PWR IN, female for PWR OUT.

5 One M12 male connector (bus IN) and one M12 female connector (bus OUT) for

connection of the Profibus-DP bus.

6 Access to the address coding wheels.

7 One bus diagnostics LED.

8 Two sensor/actuator diagnostic LEDs.

9 Two c 24 V sensor and actuator supply status LEDs.

10 Eight channel marker labels.

11 Two splitter box marker labels.

12 Splitter box functional ground connection (beneath the label).

562014

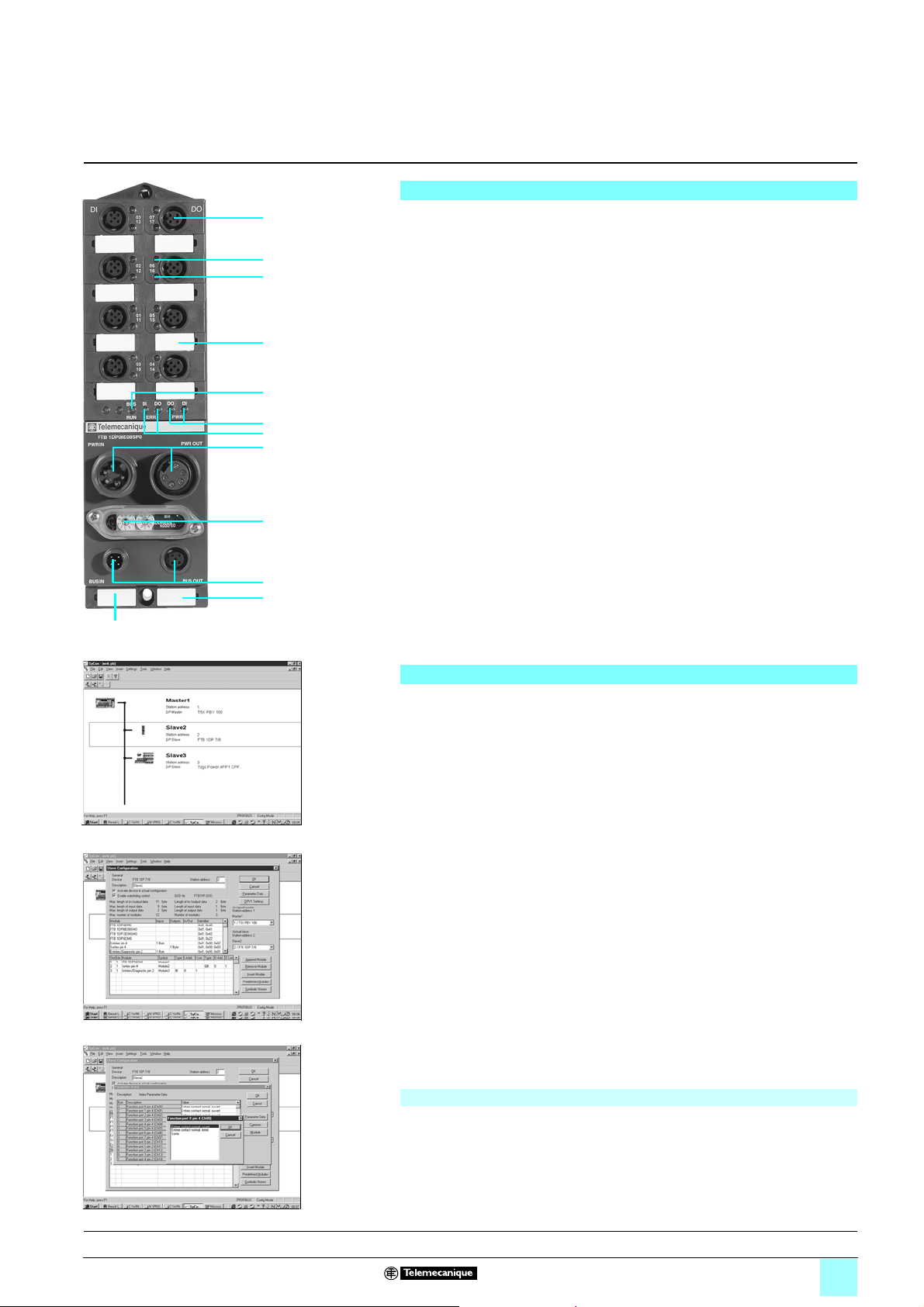

Step 1: Product selection

562015

Step 2: Access to the configuration menu

562016

Configuration

The Profibus-DP identification number is a preset, non-modifiable element exclusive

to each Slave.

An .gsd file is assigned to each product, which contains all the important information

relating to the product. An icon (.dib for Profibus-DP) is also available for installation

in the system configurator (please refer to the configuration software documentation

for the import of .gsd files).

During configuration of the equipment, the Master receives precise criteria relating to

the overall structure of the fieldbus via the system configurator. All necessary

information relating to the type and operational behavior of the various Slaves, as

well as data concerning the identification number, is included in the .gsd file.

Example with SyCon configurator (refer to our Modicon

platform catalog):

b Select the products for the application from the product catalog library in the

SyCon software (step 1),

b Product configuration (step 2):

d double-click on the product icon to access the product configuration menu,

d select the required product reference from the suggested list,

d select the associated functions that you wish to use with the product.

b Channel by channel, configure the type of signal that will be connected to it

(step 3):

d input (N/O or N/C contact),

d diagnostic input (only applicable to channels 10 to 17),

d output.

Addressing

For the Slaves, the assignment of addresses generally starts at address 3 (0-2

reserved for the Master). The addresses are configurable from 1 to 99 by means of

2 coding wheels (x 10 and x 1).

®

Premium™ PLC automation

Step 3: Configuration

Presentation, functions:

pages 14 - 17

Characteristics:

pages 26, 27

References:

pages 28 - 30

Dimensions:

pages 31 - 33

21

Page 22

Connections

Courtesy of Steven Engineering, Inc. ● 230 Ryan Way, South San Francisco, CA 94080-6370 ● General Inquiries: (800) 670-4183 ● www.stevenengineering.com

0

IP 67 monobloc I/O splitter boxes

for fieldbuses 0

Advantys™

Profibus™-DP bus

Cabling system

Distributed I/O, FTB splitter boxes

Other Master

9

9

Altivar® 58

Drive

2

10

9

8

Modicon®

Premium

5

Modicon®

Quantum™ PLC

™ PLC

7

6

FTB 1DP FTB 1DP FTB 1DP

3

11

4

1

1

Cabling accessories

Profibus-DP bus connection cables

Cables FTX DPp2pp enable connection of splitter boxes FTB 1DP to Profibus-DP

fieldbus.

1 FTX DP12pp: cables fitted with 2 straight M12, 5-pin connectors, one at each end,

for chaining the bus between two splitter boxes.

2 FTX DP32pp: cables fitted with 2 elbowed M12, 5-pin connectors, one at each

end, for chaining the bus between two splitter boxes.

3 TSX PBSCAp00: cables with flying leads at both ends.

Sensor and actuator c 24 V power supply connection cables

Cables FTX DP2ppp enable connection of c 24 V power supplies to splitter boxes

FTB 1DP. Two types of cable are available, in various lengths:

4 FTX DP22pp: cables fitted with two 7/8, 5-pin connectors, one at each end, for

chaining c 24 V power supplies between two splitter boxes.

5 FTX DP21pp: cables fitted with a 7/8, 5-pin connector at one end, with the other

end free for connection of c 24 V power supplies.

Connectors

6 FTX DP12p5: M12, 5-pin, male and female connectors for bus cables.

7 FTX C78pp: 7/8, 5-pin, male and female connectors for c 24 V power supply

cables.

Other components

8 FTX DPTL12: bus line terminator fitted with an M12 connector.

9 FTX CpppB: sealing plugs for 7/8, M12 and M8 connectors.

10 FTX CY12pp: Y-connector for M12 and M8 connectors.

11 FTX CNCT1: T-connector fitted with two 7/8, 5-pin connectors for power supply

cable.

Presentation, functions:

pages 14 - 17

22

Description, configuration:

pages 18 , 21, 24,

Characteristics:

pages 26, 27

References:

pages 28 - 30

Dimensions:

pages 31 - 33

Page 23

Presentation

Courtesy of Steven Engineering, Inc. ● 230 Ryan Way, South San Francisco, CA 94080-6370 ● General Inquiries: (800) 670-4183 ● www.stevenengineering.com

0

IP 67 monobloc I/O splitter boxes

for fieldbuses 0

Advantys™

InterBus™ bus extenson

Advantys FTB splitter boxes are of the monobloc type.

Each splitter box comprises one part for connection of sensors and actuators by

means of M12 connectors, and one part for connection of splitter boxes on InterBus

fieldbus.

This splitter box enables inputs/outputs to be located remotely, as close as possible

to the equipment being controlled.

InterBus bus presentation

Distributed I/O, FTB splitter boxes

Modicon®

Quantum™ PLC

Modicon®

Premium™ PLC

InterBus bus

Modicon®

Momentum

InterBus is a serial link type fieldbus for sensors and actuators which satisfies the

requirements of industrial environments.

Conforming to the standard specification, an InterBus can operate with up to 256

Slaves:

b 12.8 km (41,999 ft.) with copper conductors,

b beyond 80 km (262,500 ft.) using fiber optic cables.

The distance between 2 different components of the bus must not exceed 400 m

(1312 ft.) when using copper conductors.

The InterBus system is designed in the form of a loop and has the structure of a shift

register distributed on the bus. Each Slave, with its registers, constitutes a

component in this shift register loop.

™ PLC

Altivar

®

58 Drive

Te go ® Power

Connections

Other Master

Main bus (12.8 km / 41,999 ft.)

FTB 1IB

FTB 1IB

Presentation, functions:

pages 14 - 17

Description, configuration:

pages 18 , 21, 24,

Master

The cyclic exchange of information between the Master and the Slaves is carried out

independently by the Master.

The physical link consists of 3 pairs of twisted wires with common shielding.

In addition to the main bus (long distance bus), a local bus can be set up.

b Characteristics of InterBus local bus,

Characteristics:

pages 26, 27

c

d the

wi res, 0.75 mm

d the maximum current is limited to 4.5 A, in accordance with the specification,

d the maximum distance is 50 m (164 ft.).

Slave Slave

24 V power supply also passes along the system cable (3 additional

2

/ #19 AWG) to supply the electronics and the Slave peripherals,

References:

pages 28 - 30

Slave

Dimensions:

pages 31 - 33

Slave

23

Page 24

Description,

Courtesy of Steven Engineering, Inc. ● 230 Ryan Way, South San Francisco, CA 94080-6370 ● General Inquiries: (800) 670-4183 ● www.stevenengineering.com

configuration

IP 67 monobloc I/O splitter boxes

0

for fieldbuses 0

Advantys™

InterBus™ bus extention

Distributed I/O, FTB splitter boxes

108730

11

Description

1

2

3

9

6

8

7

4

5

10

InterBus monobloc I/O splitter boxes FTB 1IB have the following on the front face:

1 Eight M12 female connectors for connection of sensors and actuators (2 channels

per connector).

2 Eight channel status indicator lights (00 to 07).

3 Eight channel status indicator lights (10 to 17) or channel diagnostic indicator

lights (00 to 07) depending on the splitter box configuration.

4 Two terminal blocks for connection of c 24 V sensor and actuator power supplies

(IN and OUT) (connectors included with product).

5 Four terminal blocks for connection of the InterBus bus (connectors included with

product).

6 Three bus diagnostic LEDs.

7 Two sensor/actuator diagnostic LEDs.

8 Two c 24 V sensor and actuator supply status LEDs.

9 Eight channel marker labels.

10 Two splitter box marker labels.

11 Splitter box functional ground connection (beneath the label).

Configuration

Each Slave has its own identification code, so that it can be clearly identified by the

InterBus Master. This code is configured by the manufacturer and cannot be

subsequently modified. The characteristics of this code are defined in the InterBus

specification.

Start-up of the system is immediately followed by an identification cycle. During this

system initialization phase, the identification data of all the Slaves is read by the

Master according to their position in the bus. This data will, in particular, be used to

prepare the peripheral image at the Master.

The following cycles are simple data cycles, whose only purpose is the exchange of

process data between the Master and the Slaves.

Presentation, functions:

pages 14 - 17

Characteristics:

pages 26, 27

Addressing

The InterBus system allows either physical addressing or logic addressing.

b Physical addressing

The assignment of the Master’s peripheral image to the process image within the

PLC corresponds to the layout of the splitter boxes in the fieldbus.

b Logic addressing

During configuration, it is possible to carry out manual logic addressing using

configuration software (for example: CMDtools), independently of the Master used.

During this operation, logic addressing of the peripheral image or of parts of this

image is carried out to the process image within the PLC.

References:

pages 28 - 30

Dimensions:

pages 31 - 33

24

Page 25

Connections

Courtesy of Steven Engineering, Inc. ● 230 Ryan Way, South San Francisco, CA 94080-6370 ● General Inquiries: (800) 670-4183 ● www.stevenengineering.com

0

IP 67 monobloc I/O splitter boxes

for fieldbuses 0

Advantys™

InterBus™ bus extension

Cabling system

Distributed I/O, FTB splitter boxes

Other Master

2

3

4

1

Modicon®

Premium™ PLC

Modicon®

Momentum

Modicon®

Quantum™ PLC

™ PLC

FTB 1IB FTB 1IB

Cabling accessories

Connection cables for the bus and for sensor and actuator c 24 V power

supplies

Cables FTX IB12pp enable connection of splitter boxes FTB 1IB to InterBus fieldbus.

1 FTX IB12pp: cables fitted with 2 sets of connectors at each end for chaining the

bus and power supplies between two splitter boxes.

Other components

2 FTX CMppB: sealing plugs for M12 and M8 connectors.

3 FTX CY12pp: Y-connector for M12 and M8 connectors.

4 FTX CPE10: cable gland.

Presentation, functions:

pages 14 - 17

Description, configuration:

pages 18 , 21, 24,

Characteristics:

pages 26, 27

References:

pages 28 - 30

Dimensions:

pages 31 - 33

25

Page 26

Characteristics

Courtesy of Steven Engineering, Inc. ● 230 Ryan Way, South San Francisco, CA 94080-6370 ● General Inquiries: (800) 670-4183 ● www.stevenengineering.com

0

IP 67 monobloc I/O splitter boxes

for fieldbuses 0

Advantys™

Environmental characteristics

Product certifications cULus

Distributed I/O, FTB splitter boxes

Temperature Operation

Degree of protection Conforming to IEC 60529

Altitude

Vibration resistance Conforming to IEC 68-2-6,

Shock resistance Conforming to IEC 68-2-27,

Resistance to electrostatic

discharge

Resistance to radiated fields Conforming to IEC 61000-4-3

Immunity to fast transient

currents

Surge withstand Conforming to IEC 61000-4-5

Immunity to conducted

disturbance

Resistance to magnetic

fields, 50 Hz

Mounting

Storage

test Fc

test Ea

Conforming to IEC 61000-4-2

Conforming to IEC 61000-4-4

Conforming to IEC 61000-4-6

Conforming to IEC 61000-4-8

°C (°F) 0 to + 55 (+ 32... 131)

°C (°F) - 25 to + 70 (-13...+ 158)

IP 67

m (ft.) 0 to 2000 (0 to 6562)

Hz For plastic housing 5 ≤ f ≤ 57.55 (constant amplitude = 1.5 mm)

For metal housing 5 ≤ f ≤ 70 (constant amplitude = 1.5 mm)

For plastic housing 30 gn, for 11 ms

For metal housing 50 gn, for 11 ms

kV Contact: ± 4

Air: ± 8

V/m 10

kV Power supply: ± 2

Signal: ± 2

V Power supply: (symmetrical) ± 500, (asymmetrical) ± 1000

Signals: (symmetrical) ± 500, (asymmetrical) ± 1000

Ground/PE: ± 500

Vrms 10

A/m 30

All positions

57.55 ≤ f ≤ 500 (constant acceleration = 10 gn)

70 ≤ f ≤ 500 (constant acceleration = 15 gn)

Mechanical mounting

Mounting by two M4 screws for plastic housing (tightening torque 1.5 Nm / 13.3 lbf-in)

Mounting by two M6 screws for metal housing (tightening torque 9 Nm / 79.7 lbf-in)

Fieldbus characteristics

Bus type CANopen DeviceNet Profibus-DP InterBus

Structure Type

Access method

Transmission Binary rate

Medium

Configuration Maximum number of devices

Maximum length of bus

EN 50325

ISO 11898

Multimaster, priority

information

1 Mbits/s 500 kbits/s 12 Mbits/s 500 kbits/s

2 twisted, shielded

wires

127 63 32 without repeater

At 1 Mbits/s:

- Max. tap-off length:

0.3 m (0.98 ft.)

- Max. cumulative

tap-off length: 1.5 m

(4.9 ft.)

At 500 kbits/s:

- Max. tap-off length:

6 m (19.7 ft.)

- Max. cumulative

tap-off length: 30 m

(32.8 ft.)

EN 50325

ISO 11898

CAN, layer 7

DeviceNet

Master-Slave Master-Slave,

4 twisted, shielded

wires

Main line:

- 500 m (1640 ft.)

without repeater,

- 3 km (9843 ft.)with

repeater

Tap-off:

6 m (19.7 ft.) max.

DIN 19245

EN 50170

Multi-Master

2 twisted, type A,

shielded wires

(RS 485)

126 with repeaters

Without repeater:

At 12 Mbits/s:

- 100 m (328.1 ft.)max.

At 1.5 Mbits/s:

- 200 m (656.2 ft.)max.

At 500 kbits/s:

- 400 m (1312 ft.)max.

At < 93.75 kbits/s:

- 1.2 km (3937 ft.)max.

DIN 19258

EN 50254

Master-Slave

3 twisted pairs with

common shielding

Fiber optic

256

Main bus link

(long distance bus):

12.8 km (41,999 ft.)

Local bus link:

50 m (164 ft.)

Presentation, functions:

pages 14 - 17

Description, configuration:

pages 18 , 21, 24,

References:

pages 28 - 30

Dimensions:

pages 31 - 33

26

Page 27

Characteristics (continued)

Courtesy of Steven Engineering, Inc. ● 230 Ryan Way, South San Francisco, CA 94080-6370 ● General Inquiries: (800) 670-4183 ● www.stevenengineering.com

0

IP 67 monobloc I/O splitter boxes

for fieldbuses 0

Advantys™

Input/output characteristics

Splitter box type FTB 1pp16Epp 1pp08E08SPp 1pp12E04SPp 1pp16Cpp 1pp08E08CM0

Bus type

Number of inputs/outputs

All types of bus CANopen bus,

16 I

(8 I +

8 diagnostic

inputs)

Distributed I/O, FTB splitter boxes

DeviceNet bus

and Profibus-DP

bus

16 I/O

(8 O +

8 diagnostic

inputs)

16 I/O

(4 I + 4 O +

8 diagnostic

inputs)

16 I/O

(8 I/O +

8 diagnostic

I/O)

8 I + 8 I/O

(8 I + 8 diagnostic

I/O)

Internal consumption of splitter box

Operating voltage

Splitter box max. supply current

Bus and I/O undervoltage detection

Built-in short-circuit protection

mA 120

c V 24

A 9 (10 for InterBus)

V < 18

mA < 100, automatic tripping

mA > 100, reset

Input characteristics

Number of inputs 16 I 8 I 12 I 0...16 I 8 I + 0...8 I

Conformity to IEC 1131-2

Compatibility with 2-wire/

3-wire proximity sensors

Input values Nominal voltage

Maximum current

Sensor power supply

Logic

Input filtering

Protection against reversed polarity

Type 2

Yes

c V 24

mA 200

V 18 to 30

Positive

ms 1

Yes

Output characteristics

Number of outputs – 8 O 4 O 0...16 O 0...8 O

Output type

– Transistor

Nominal output values Voltage

Current

Overvoltage protection

Maximum switching cycles

Maximum lamp load

Output connection/cable lengths

Presentation, functions:

pages 14 - 17

Description, configuration:

pages 18 , 21, 24,

V – c 24

A – 1.6

– Yes (suppressor diode)

Hz – 20

W – 10

2

mm

– 0.34 mm2 / 5 m (#22 AWG / 16.4 ft.) max.

AWG

References:

pages 28 - 30

Dimensions:

pages 31 - 33

27

Page 28

References

Courtesy of Steven Engineering, Inc. ● 230 Ryan Way, South San Francisco, CA 94080-6370 ● General Inquiries: (800) 670-4183 ● www.stevenengineering.com

0

IP 67 monobloc I/O splitter boxes

for fieldbuses 0

Advantys™

Distributed I/O, FTB splitter boxes

108733

FTB 1CN

108733

FTB 1DN

108733

ppp

ppp

P0

P0

521940

FTB 1CN

108727

FTB 1DN

521945

ppp

ppp

M0

M0

Number

of I/O

Number,

type of

inputs

(1)

Number,

type of

outputs

(2)

Connection byHousing

Monobloc splitter boxes for CANopen bus

16 88,

12 4,

16 – 8 x M12 female

16

configurable

16 of

which 8

configurable

0...16 0...16,

8 + 0...8 0...8,

transistor

transistor

transistor

transistor

8 x M12 female

connectors

8 x M12 female

connectors

connectors

8 x M12 female

connectors

8 x M12 female

connectors

Monobloc splitter boxes for DeviceNet bus

16 88,

12 4,

16 – 8 x M12 female

16

configurable

16 of

which 8

configurable

0...16 0...16,

8 + 0...8 0...8,

transistor

transistor

transistor

transistor

8 x M12 female

connectors

8 x M12 female

connectors

connectors

8 x M12 female

connectors

8 x M12 female

connectors

Monobloc splitter boxes for Profibus-DP bus

16 8 8 8 x M12 female

12 4 8 x M12 female

16 – 8 x M12 female

connectors

connectors

connectors

type

Plastic FTB 1CN08E08SP0 0.430

Plastic FTB 1CN12E04SP0 0.450

Plastic FTB 1CN16EP0 0.440

Metal FTB 1CN16EM0 0.820

Plastic FTB 1CN16CP0 0.450

Metal FTB 1CN16CM0 0.820

Metal FTB 1CN08E08CM0 0.820

Plastic FTB 1DN08E08SP0 0.450

Plastic FTB 1DN12E04SP0 0.450

Plastic FTB 1DN16EP0 0.430

Metal FTB 1DN16EM0 0.820

Plastic FTB 1DN16CP0 0.450

Metal FTB 1DN16CM0 0.820

Metal FTB 1DN08E08CM0 0.820

Plastic FTB 1DP08E08SP0 0.430

Plastic FTB 1DP12E04SP0 0.430

Plastic FTB 1DP16EP0 0.430

Metal FTB 1DP16EM0 0.820

Reference Weight

kg

FTB 1DP

ppp

P0

108729

FTB 1IB

Presentation, functions:

pages 14 - 17

FTB 1DP

ppp

M0

Description, configuration:

pages 18 , 21, 24,

16

configurable

16 of

which 8

configurable

0...16 0...16 8 x M12 female

8 + 0...8 0...8 8 x M12 female

connectors

connectors

Monobloc splitter boxes for InterBus bus

16 8 8 8 x M12 female

12 4 8 x M12 female

16 – 8 x M12 female

16

configurable

(1) c 24 V IEC type 2.

(2) c 24 V/1.6 A.

Characteristics:

pages 26, 27

0...16 0...16 8 x M12 female

connectors

connectors

connectors

connectors

Dimensions:

pages 31 - 33

Plastic FTB 1DP16CP0 0.430

Metal FTB 1DP16CM0 0.820

Metal FTB 1DP08E08CM0 0.820

Plastic FTB 1IB08E08SP1 0.430

Plastic FTB 1IB12E04SP1 0.440

Plastic FTB 1IB16EP1 0.430

Plastic FTB 1IB16CP1 0.430

28

Page 29

References (continued)

Courtesy of Steven Engineering, Inc. ● 230 Ryan Way, South San Francisco, CA 94080-6370 ● General Inquiries: (800) 670-4183 ● www.stevenengineering.com

108767

FTX DP2115

0

IP 67 monobloc I/O splitter boxes

for fieldbuses 0

Advantys™

Connection accessories

Description Composition Length

For CANopen/DeviceNet buses

Bus connection cables Fitted with 2 elbowed

c 24 V power supply

connection cables

Connectors M12 male, 5-pin,

Line terminator

(for end of bus)

T-connector

for power supply

For Profibus-DP bus

Bus connection cables Fitted with 2 straight

c 24 V power supply

connection cables

Connectors M12 male, 5-pin,

Line terminator

(for end of bus)

T-connector

for power supply

Cables Flying leads at both ends 100 (328.1) TSX PBSCA100

For InterBus bus

Cables with connectors

for bus and power supply

Cable gland M16 x 1.5 (set of 2) – FTX CPE10 0.020

Distributed I/O, FTB splitter boxes

Reference Weight

M12, 5-pin connectors,

A encoded, one at each

end

Fitted with two 7/8, 5-pin

connectors, one at each

end

Fitted with one 7/8, 5-pin

connector, other end has

flying leads

A encoded

M12 female, 5-pin,

A encoded

Fitted with one M12

connector

Fitted with two 7/8, 5-pin

connectors

M12, 5-pin connectors,

one at each end

Fitted with 2 elbowed

M12, 5-pin connectors,

one at each end

Fitted with two 7/8, 5-pin

connectors, one at each

end

Fitted with one 7/8, 5-pin

connector, other end has

flying leads

B encoded

M12 female, 5-pin,

B encoded

Fitted with one M12

connector

Fitted with two 7/8, 5-pin

connectors

Fitted with 2 sets of

connectors

m (ft.)

0.3 (0.98) FTX CN3203 0.040

0.6 (1.97) FTX CN3206 0.070

1 (3.28) FTX CN3210 0.100

2 (6.56) FTX CN3220 0.160

3 (9.8) FTX CN3230 0.220

5 (16.4) FTX CN3250 0.430

0.6 (1.97) FTX DP2206 0.150

1 (3.28) FTX DP2210 0.190

2 (6.56) FTX DP2220 0.310

5 (16.4) FTX DP2250 0.750

1.5 (4.92) FTX DP2115 0.240

3 (9.8) FTX DP2130 0.430

5 (16.4) FTX DP2150 0.700

– FTX CN12M5 0.050

– FTX CN12F5 0.050

– FTX CNTL12 0.010

– FTX CNCT1 0.100

0.3 (0.98) FTX DP1203 0.040

0.6 (1.97) FTX DP1206 0.070

1 (3.28) FTX DP1210 0.100

2 (6.56) FTX DP1220 0.160

3 (9.8) FTX DP1230 0.220

5 (16.4) FTX DP1250 0.430

0.3 (0.98) FTX DP3203 0.040

0.6 (1.97) FTX DP3206 0.070

1 (3.28) FTX DP3210 0.100

2 (6.56) FTX DP3220 0.160

3 (9.8) FTX DP3230 0.220

5 (16.4) FTX DP3250 0.430

0.6 (1.97) FTX DP2206 0.150

1 (3.28) FTX DP2210 0.190

2 (6.56) FTX DP2220 0.310

5 (16.4) FTX DP2250 0.750

1.5 (4.92) FTX DP2115 0.240

3 (9.8) FTX DP2130 0.430

5 (16.4) FTX DP2150 0.700

– FTX DP12M5 0.050

– FTX DP12F5 0.050

– FTX DPTL12 0.010

– FTX CNCT1 0.100

400 (1213) TSX PBSCA400 –

0.6 (1.97) FTX IB1206 0.250

1 (3.28) FTX IB1210 0.400

2 (6.56) FTX IB1220 0.650

5 (16.4) FTX IB1250 –

kg

–

Presentation, functions:

pages 14 - 17

Description, configuration:

pages 18 , 21, 24,

Characteristics:

pages 26, 27

Dimensions:

pages 31 - 33

29

Page 30

References (continued)

Courtesy of Steven Engineering, Inc. ● 230 Ryan Way, South San Francisco, CA 94080-6370 ● General Inquiries: (800) 670-4183 ● www.stevenengineering.com

0

IP 67 monobloc I/O splitter boxes

for fieldbuses 0

Advantys™

Separate components

Description Composition Reference Weight

For all bus types

Connectors 7/8 male, 5-pin FTX C78M5 0.050

Sealing plugs For M8 connector (lot of 10) FTX CM08B 0.100

Distributed I/O, FTB splitter boxes

7/8 female, 5-pin FTX C78F5 0.050

For M12 connector (lot of 10) FTX CM12B 0.100

For 7/8 connector FTX C78B 0.020

kg

108768

FTX CY1208

Y-connectors Connection of 2 x M8 connectors to

Diagnostics adaptor Fitted with two M12 connectors FTX DG12 0.020

Marker labels For plastic splitter boxes

M12 connector on splitter box

Connection of 2 x M12 connectors to

M12 connector on splitter box

(lot of 10)

For metal splitter boxes

(lot of 10)

FTX CY1208 0.020

FTX CY1212 0.030

FTX BLA10 0.010

FTX MLA10 0.010

Presentation, functions:

pages 14 - 17

30

Description, configuration:

pages 18 , 21, 24,

Characteristics:

pages 26, 27

Dimensions:

pages 31 - 33

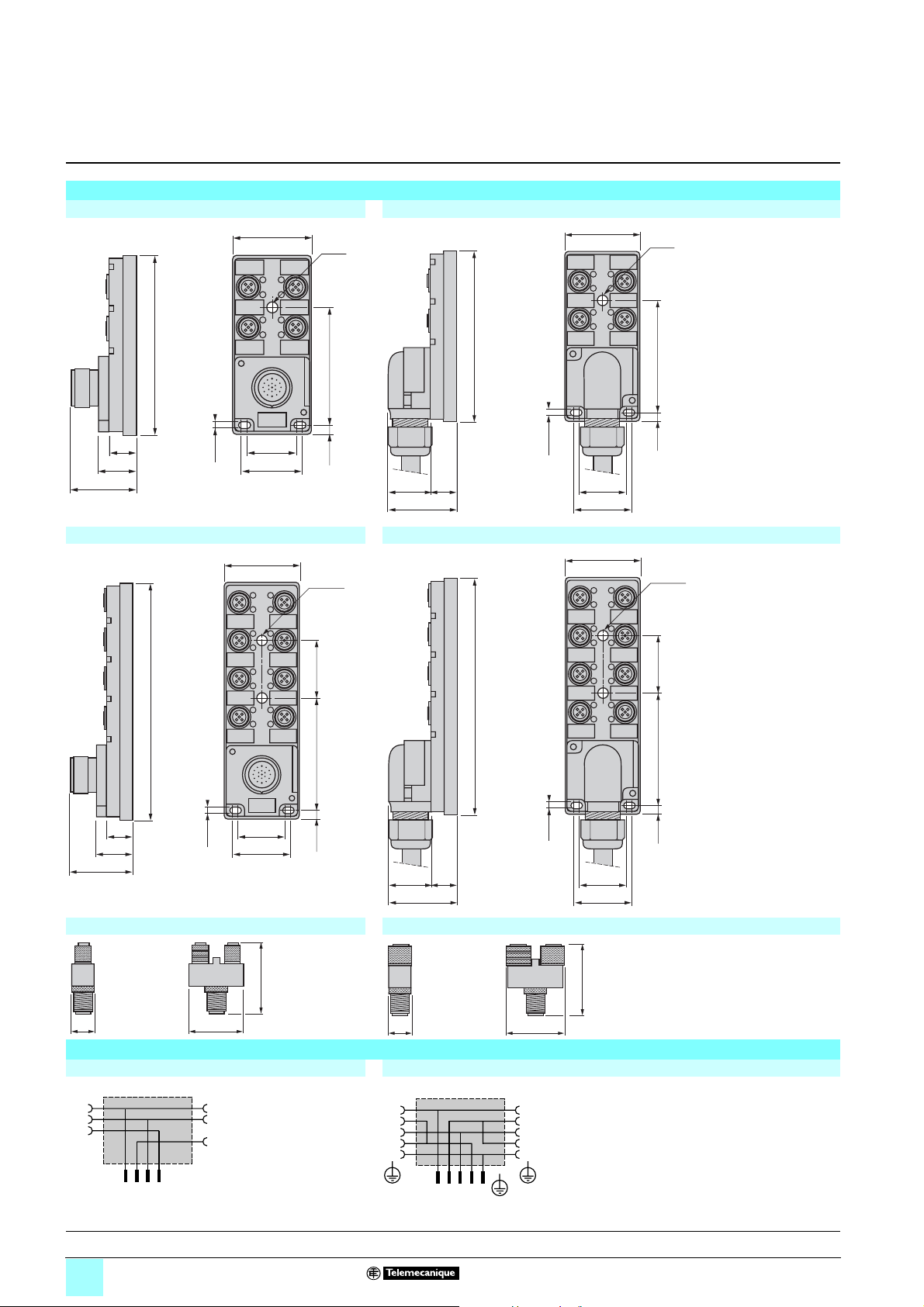

Page 31

Dimensions

Courtesy of Steven Engineering, Inc. ● 230 Ryan Way, South San Francisco, CA 94080-6370 ● General Inquiries: (800) 670-4183 ● www.stevenengineering.com

0

IP 67 monobloc I/O splitter boxes

for fieldbuses 0

Advantys™

FTB 1CNpppP0, FTB 1DNpppP0, FTB 1DPpppP0 FTB 1IBpppP1

Distributed I/O, FTB splitter boxes

220 (8.66")

63 (2.48")50.5 (1.98")

(1) Ø 4 elongated hole

FTB 1CNppppppM0, FTB 1DNppppppM0, FTB 1DPppppppM0

224.7 (8.84")

208 (8.18")

(1)

208.5 (8.20")

69 (2.71")

(1) Ø 4 elongated hole

220 (8.66")

63 (2.48")

208 (8.18")

(1)

20.5 (0.80")

38.9

"

(1) Ø 6 elongated hole

FTX CY1208 FTX CY1212

15 (0.59")

Presentation, functions:

pages 14 - 17

62.7 (2.46")

33 (1.29")

Description, configuration:

pages 18 , 21, 24,

(1)

45 (1.77")

15 (0.59") 35 (1.29")

Characteristics:

pages 26, 27

References:

pages 28 - 30

45 (1.77")

31

Page 32

Connections

)

)

)

)

Courtesy of Steven Engineering, Inc. ● 230 Ryan Way, South San Francisco, CA 94080-6370 ● General Inquiries: (800) 670-4183 ● www.stevenengineering.com

0

IP 67 monobloc I/O splitter boxes

for fieldbuses 0

Advantys™

Sensor/actuator connection Y-connector connection

FTX CY1208 FTX CY1212

Distributed I/O, FTB splitter boxes

M8

1

24 V S2

S1 0 V

2

5

3

4

M12 female connector

female

1

3

4

1234

M12 male

CANopen and DeviceNet buses

Supply to splitter box Bus input/Bus output

Supply input

24 V

24 V

(1)

(2)

3

4

5

2

1

7/8 male connector

(1) Supply to splitter box and sensors.

(2) Supply to actuators.

Supply output

0 V

0 V

0 V

0 V

7/8 female connector

Bus input

3

2

1

24 V

4

24 V

5

CAN-H

(1

(2

4

5

2

1

M12 male connector

3

M8

female

1

3

4

CAN-L

24 V

0 V

M12

female

1

2

3

4

5

12345

M12 male

Bus output

CAN-L

0 V

24 V

3

5

21

M12 female connector

M12

female

1

2

3

4

5

4

CAN-H

Profibus-DP bus

Supply to splitter box Bus input/Bus output

Supply input

24 V

24 V

(1)

(2)

3

4

5

2

1

7/8 male connector

(1) Supply to splitter box and sensors.

(2) Supply to actuators.

Supply output

0 V

0 V

0 V

0 V

7/8 female connector

Bus input

3

2

1

24 V

4

24 V

5

(1

(2

Cable B (red)

5 V

43

5

2

1

M12 male connector

Note: connectors linked to shielding.

0 V

Cable A (green)

Bus output

0 V

Cable A (green)

34

2

M12 female connector

5

1

Cable B (red)

5 V

Presentation, functions:

pages 14 - 17

32

Description, configuration:

pages 18 , 21, 24,

Characteristics:

pages 26, 27

References:

pages 28 - 30

Page 33

Connections (continued)

3

Courtesy of Steven Engineering, Inc. ● 230 Ryan Way, South San Francisco, CA 94080-6370 ● General Inquiries: (800) 670-4183 ● www.stevenengineering.com

0

IP 67 monobloc I/O splitter boxes

for fieldbuses 0

Advantys™

InterBus bus

Connections to splitter box Supply to splitter box

1

2

4

1 Supply input

+

24 V/L

+

24 V/R

+

24 V/IN

0/ 24 V

0/ 24 V

Bus input/Bus output

3

Local bus, bus input

Green

/ DO1

Yellow

DO1

Pink

/ DI1

Grey

DI1

Brown

COM