Page 1

Quantum Cascade Laser

Starter Kit

Instructions Manual (Web version)

CAUTION

Before using the Quantum Cascade

Laser Starter Kit, read this

documentation and take special

note of all safety instructions

Page 2

Contents

1 Identification 4

1.1 Document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Limited waranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 General 5

2.1 Chapter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Generalities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3.1 Laser compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4.1 Persons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4.2 Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.5 Typographic conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Safety Instructions 10

3.1 Chapter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2.1 Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2.2 Importance of safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2.3 Non-compliance with the safety regulations . . . . . . . . . . . . . . . . . . . . . . 10

3.3 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.4 Environmental conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.5 Compliance and information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4 Description 12

4.1 Chapter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

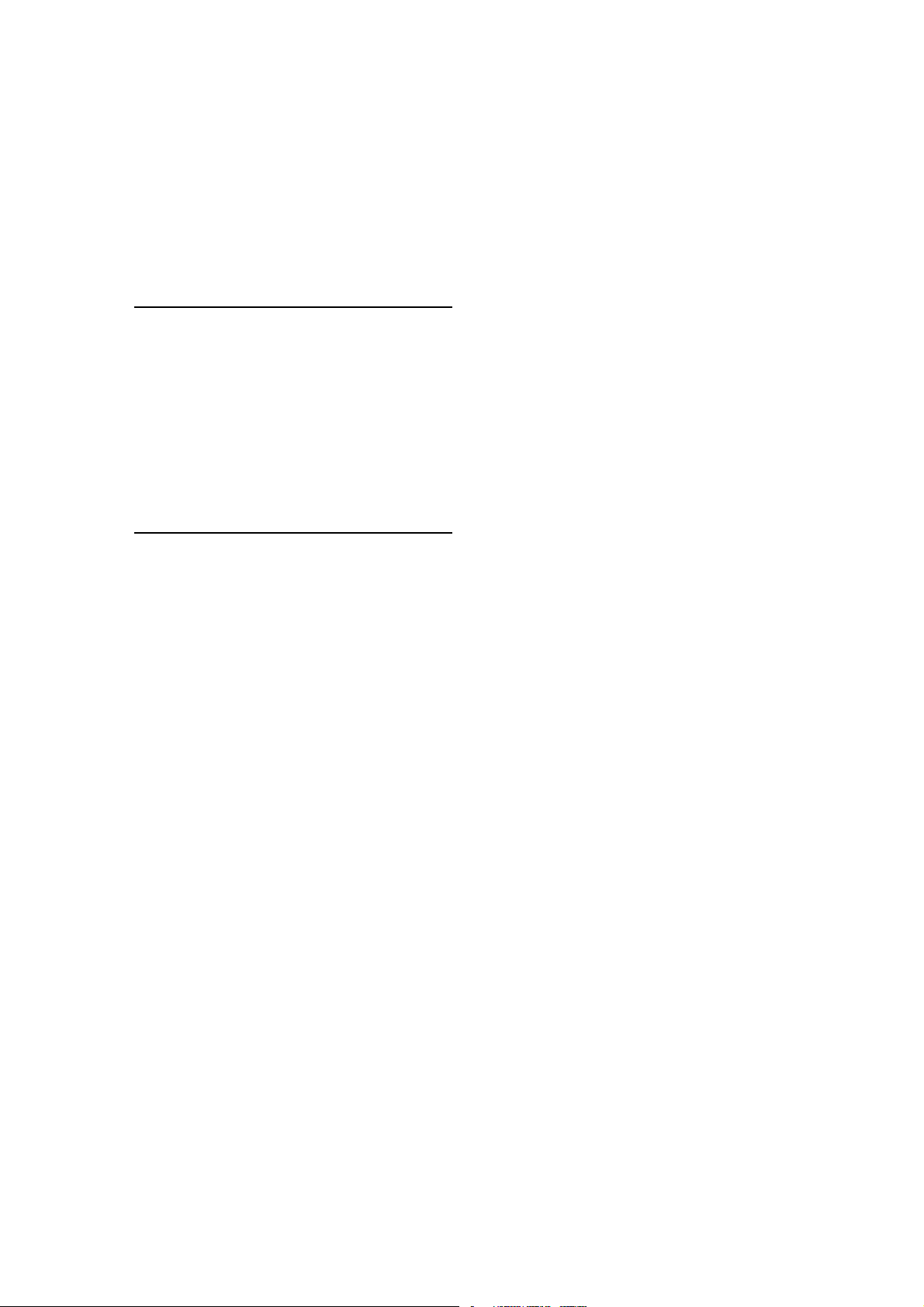

4.2 System Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3 DFB and FP Quantum Cascade Lasers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3.2 Geometry of QC lasers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3.3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3.4 Electrical model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.4 Laboratory Laser Housing(LLH100) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.4.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.4.2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.4.3 Thermo-Electric Cooler (TEC) and PT100 connections . . . . . . . . . . . . . . . 18

4.4.4 Measurement connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.5 QCL pulser switching unit(LDD100) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.5.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.5.2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.6 QCL pulse switching measuring unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.6.1 Generalities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.6.2 Measured voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.6.3 Timing data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.6.4 Laser peak current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1

Page 3

4.6.5 Laser peak voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.6.6 Average dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.6.7 Accuracy considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.7 QCL pulser timing unit (TPG128) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.7.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.7.2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.8 QCL temperature controller(TCU151) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.8.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.8.2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.8.3 Peltier and PT100 connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5 Installation 26

5.1 Chapter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.2 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.3 Packing list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.3.1 Standard items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.4 Setting the appropriate AC voltage on TCU151 . . . . . . . . . . . . . . . . . . . . . . . . 27

5.4.1 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.5 Installing the starter Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.5.1 Before beginning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.5.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2

6 Use 30

6.1 Chapter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.2 QCL pulse timing unit command description . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.3 TCU151 command description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.4 Laser utilisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.4.2 Proceedings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.5 Interlock utilisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.5.1 Before beginning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.5.2 Procedure Interlock utilisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7 Troubleshooting 35

7.1 Chapter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.2 Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8 Maintenance 37

8.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8.1.1 How to remove the covers of TCU151 and TPG128 . . . . . . . . . . . . . . . . . . 37

8.2 Replacement procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.2.1 Quantum Cascade Laser replacement . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.2.2 QCL ”UP” and ”DN” position exchange . . . . . . . . . . . . . . . . . . . . . . . . 40

8.3 TCU151 temperature controller interlock setting . . . . . . . . . . . . . . . . . . . . . . . 42

8.3.1 Generalities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.3.2 Before beggining interlock setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.3.3 Needed material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.3.4 Procedure interlock setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.4 Calibaration procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.4.1 TPG128 calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.4.2 TCU151 temperature controller calibration . . . . . . . . . . . . . . . . . . . . . . 46

9 Application notes 53

9.1 Detection techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

9.1.1 Direct absorption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

9.1.2 Frequency modulation technique (TILDAS) . . . . . . . . . . . . . . . . . . . . . . 53

9.1.3 Photoacoustic detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Page 4

10 Appendix 55

10.1 Bias Circut (”Bias-T”) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

10.1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

10.1.2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

10.1.3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

10.1.4 Utilisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

10.2 Unpacking NS laser from its transportation box . . . . . . . . . . . . . . . . . . . . . . . . 59

3

Page 5

Chapter 1

Identification

1.1 Document

Quantum Cascade Laser Starter Kit Instructions Manual.

Web Version 3.1 02.07

Manufacturer

Alpes Lasers SA

1-3 Passage Max-Meuron

CP 1766

CH-2001 Neuchˆatel

Tel. ++41 32 729951 0

Fax. ++41 32 721 3619

http://www.alpeslasers.ch

info@alpeslasers.ch

1.2 Limited waranty

Alpes Lasers SA will accept no responsibility for pro blems arising out of incorrect use of the instrument.

Under no circumstances w ill Alpes Lasers SA b e held liable for any damage, or financial loss imputable

to the instrument.

Copyright

The reproduction, even partially, of this do cument is forbidden. No part can be copied

in any form, and cannot be used, edited nor transmitted by any electronic means

(photocopy, photography, magnetic supports or other recording processes), without the

written authorization of Alpes Lasers SA. All rights and particularly reproduction,

translation, edition, distribution and also industrial property and recording are reserved.

Printed in Switzerland

c

4

Page 6

Chapter 2

LASER BEAM

DO NOT STARE INTO BEAM

CLASS I LASER PRODUCT

General

2.1 Chapter overview

This chapter gives basic information on system functions, specifications and documentation.

2.2 Generalities

The indications in the present Instructions Manual,

in particular the safety instructions must be complied with.

2.3 Compliance

The Quantum Cascade Laser Starter Kit has been

designed to meet all current safety at work and operating requirements.

2.3.1 Laser compliance

The system describe d in this manual contains a

laser device. Dep e nding of the emission power of

the laser used in the Starter Kit, the classification

may change.

According to the emission p ower, the laser pr od-

uct meets the following requirements:

CLASS I : . . . . . . . . Emission power < 10 mW

CLASS IIIb : . . . . Emission power > 10 mW

Fig.1: Class I lase r compliance

5

Page 7

Starter Kit Instruction Manual General 6

2.4 Glossary

The following terms, among others, are used in this

Instructions Manual.

2.4.1 Persons

Personnel

Personnel refers to all perso ns who carry out

any activity with the instrumentation and meet the

manufacturer’s requirements a bout personnel to run

those activities and have been therefore author iz e d.

2.4.2 Product

QCL

This is the Quantum Cascade Laser manufactured by Alpes Lasers SA, CH-2001 Neuchˆatel.

Page 8

Starter Kit Instruction Manual General 7

2.5 Typographic conventions

The following styles are used in this manual.

Description style

This style, used in relatio n with a number in illustrations (figures) is preceded by the corresponding number:

Example:

(1) First item.

(2) Second item.

(3) etc...

Commands style

All software commands, buttons, function keys,

windows, icons, options, tabs, check boxes, select

boxes, items, menus, tool bars, sections and fields

used in this documentation will be shown with a

bold italic font.

Example:

The Exit command permits to leave the program.

Procedure style

The steps of a procedure to be carried out step

by step by the personnel are preceeded with num-

bers placed in brackets.

Example:

[1] Set the selector (4) to mode Real◦C.

[2] Check the power supplies +5V and -5V.

The error should be within +/- 50 mV.

Page 9

Starter Kit Instruction Manual General 8

Procedure effects style

The procedur e effects are described by using the

following symbol ,→.

Example:

[1] Click on the Delete Sample icon.

,→ The message Do you really want to

delete the sample ? appea rs.

Cross references style

This style is used to help the personnel to find

other information about the curre nt subject.

Example:

See page x-y.

Troubleshooting s tyle

The complete description with the problem, the

possible cause and the solution will be shown like

described below:

Problem

- Possible cause

√

Solution

List of items style

This style is used to give a list of items.

Example:

• item 1

• item 2

• item 3

Page 10

Starter Kit Instruction Manual General 9

Note style

Used when the personnel attention must be drawn

to a particular operation or information.

Example:

Note: The laboratory housing LLH100 makes

available two outputs giving access t o these voltage.

Caution style

Used to prevent the personnel from any danger

or hazardous situation. Non-compliance with such

instructions may lead to damage parts or environment.

Example:

CAUTION ! Take care about...

Warning style

Used to prevent the personnel from any important danger or hazardous situation. Non-compliance

with such instructions may lead to death or serious

injury.

Example:

! WARNING ! Never open this cover...

Page 11

Chapter 3

Safety Instructions

3.1 Chapter overview

This chapter sets out safety instructions for ensuring safe and trouble-free operation of the system

described in this manual.

3.2 Introduction

3.2.1 Principle

The personnel must have read and understood this

documentation before carrying out any activity whatsoever with the system described in this manual.

In case of unclear information, please contact

the manufacturer or Alpes Lasers SA representative.

3.2.2 Importance of safety instructions

All the safety instructions in this manual must be

carried out in order to avoid injury to persons or

damage to property and the environment.

Similarly, the statutory regulations, measures

for accidents prevention and protection of the environment and the recognized technical rules for

safe and appropriate working practices which are in

force in the country and place of use of the sy stem

must be complied with.

3.2.3 Non-compliance with the safety

regulations

Non-compliance with the safety instructions, statutory and technical regulations may lead to injuries

to persons, or dama ge to property and the environment. Moreover, this will result in loss of warranty.

10

Page 12

Starter Kit Instruction Manual Safety Instr uctio ns 11

3.3 General safety instructions

• Never attempt to use a s ystem for purposes

other than those detailed in this manual.

• Never attempt to use a system in conjunction with other instruments without obtaining prior information and approval from the

manufacturer.

• Never attempt to use spare parts other than

those supplied by the manufacturer.

• If an instrument is to be left unused for any

length of time, protect the instrument against

dust and/or humidity.

3.4 Environmental conditions

• Like any other electrical device, the system

must not be lo c ated near a water tap.

• The instrument must be kept away from potential sources of interference.

• The system must not be exposed to direct

sunlight, heat, dust or excessive humidity (use

only in a clean labor atory environment).

• Take care not to spill liquid on an instrument.

In the event of accidental spillage, proceed as

follows:

[1] Switch off the instrument immediately.

[2] Unplug the instrument from the mains.

[3] Wipe the instrument down with a dry

tissue.

[4] Check all the electrical functions.

• Ensure sufficient ventilation of the instrument

to prevent overheating.

3.5 Compliance and information

In the event of operating faults or other technical

incidents for which a remedy is not described in this

manual, please contact the manufacturer or Alpes

Lasers SA representative immediately.

(http://www.alpeslasers.ch/contacts.htm)

Page 13

Chapter 4

T

P

G

1

2

8

−

T

T

L

P

u

l

s

e

G

e

n

e

r

a

t

o

r

O

F

F

TCU151

O

N

P

o

w

e

T

r

e

m

p

e

r

a

t

u

r

0

e

.

C

2

o

t

n

o

t

2

r

.

o

2

l

µ

l

s

0

e

.

r

5

t

o

1

0

.

5

µ

s

5

t

o

1

0

5

µ

s

0

t

o

2

0

0

n

s

−

−

−

−

−

−

−

−

−

P

e

r

i

o

d

−

−

−

−

−

−

−

−

−

−

D

u

ra

t

i

o

n −

G

a

t

e

I

N

T

r

i

g O

U

T

O

u

t

1

O

u

t

2

5

0

o

h

m

s

5

0

o

h

m

s

5

0

o

h

m

s

m

a

x

6

0

m

A

+

1

2

V

0

V

connected to + hi High Voltage

Pulse on top, Bottom

Output

Current control Max 60V

Power supply 12V

Input

LDD 100

Monitor 20 A/V, Z50 Ohm

3

1

4

2

Description

4.1 Chapter overview

This chapter gives a basic description of the Quantum Cascade Laser Starter Kit system and its composition.

4.2 System Composition

The Quantum Cascade Laser Starter Kit is made

up of the following items:

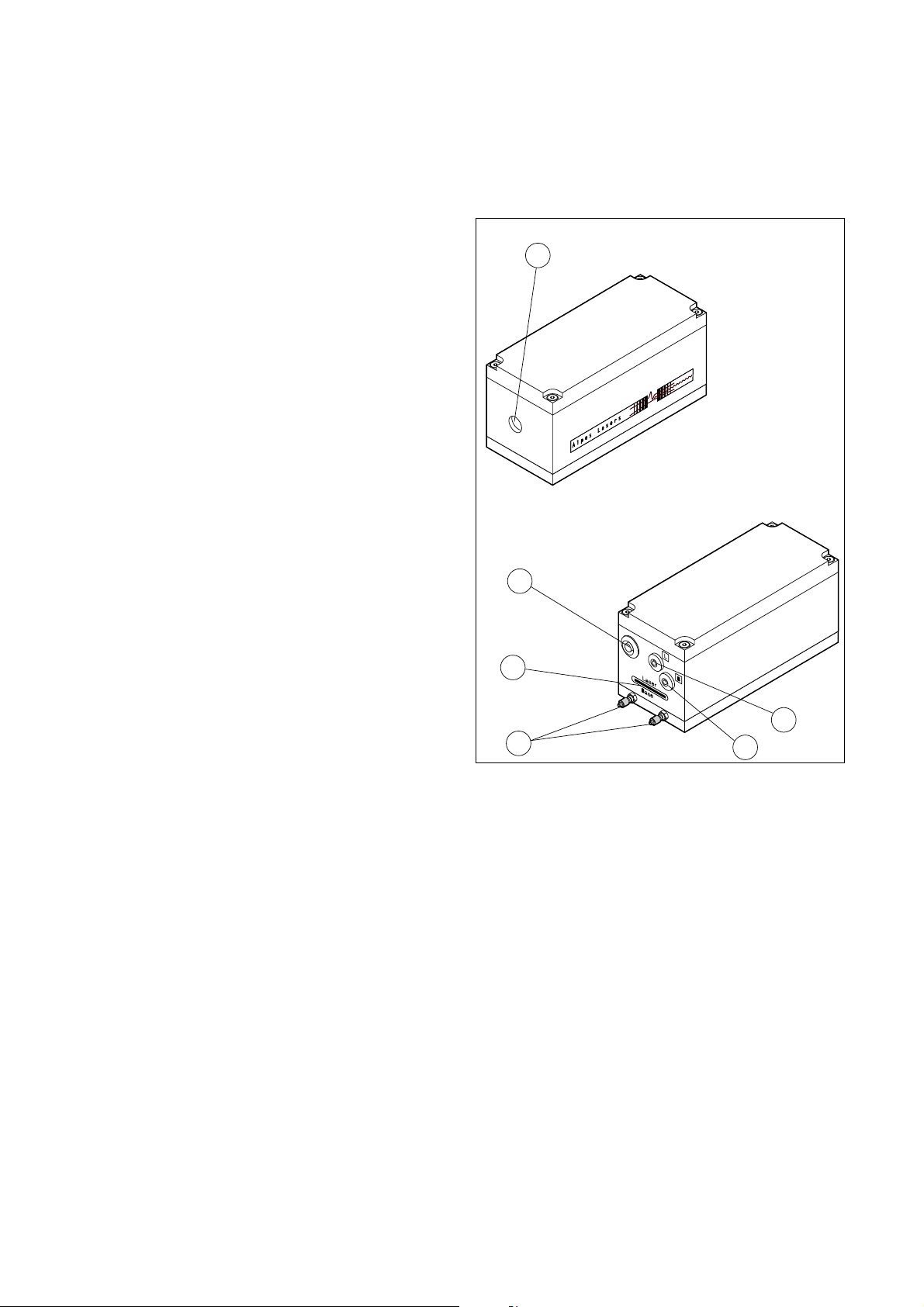

(1) Laboratory Laser Housing (LLH100)

(2) Temperature Controller (TCU151)

(3) QCL pulse switching unit (LDD100)

(4) QCL pulser timing unit (TPG128)

For operation of the system, the user must provide a stabilized DC power supply capable of delivering DC current that corresponds to the laser

peak current multiplied with the specified duty cycle at the specified LDD100 voltage: refer to the

datasheet of the laser.

CAUTION !

Do not lift TCU151 or TPG128 only on t he top

cover, since this might loosen the connection between the cover and the chassis.

Fig.2: Quantum Cascade Laser Starter Kit

Page 14

Starter Kit Instruction Manual Description 13

1

2

4.3 DFB and FP Quantum Cascade Lasers

4.3.1 Description

Quantum Cascade Lasers (QCL) are unipolar lasers

emitting in the mid-infrared from 4 to 17 microns.

The laser is a ridge of InGaAs and AlInAs grown

on InP providing gain and a Fabry-Perot cavity in

order to build the laser oscillation up. DistributedFeedback(DFB) Quantum Cascade Lasers are then

obtained by adding a grating, forcing the laser to

emit at the target wavelength.

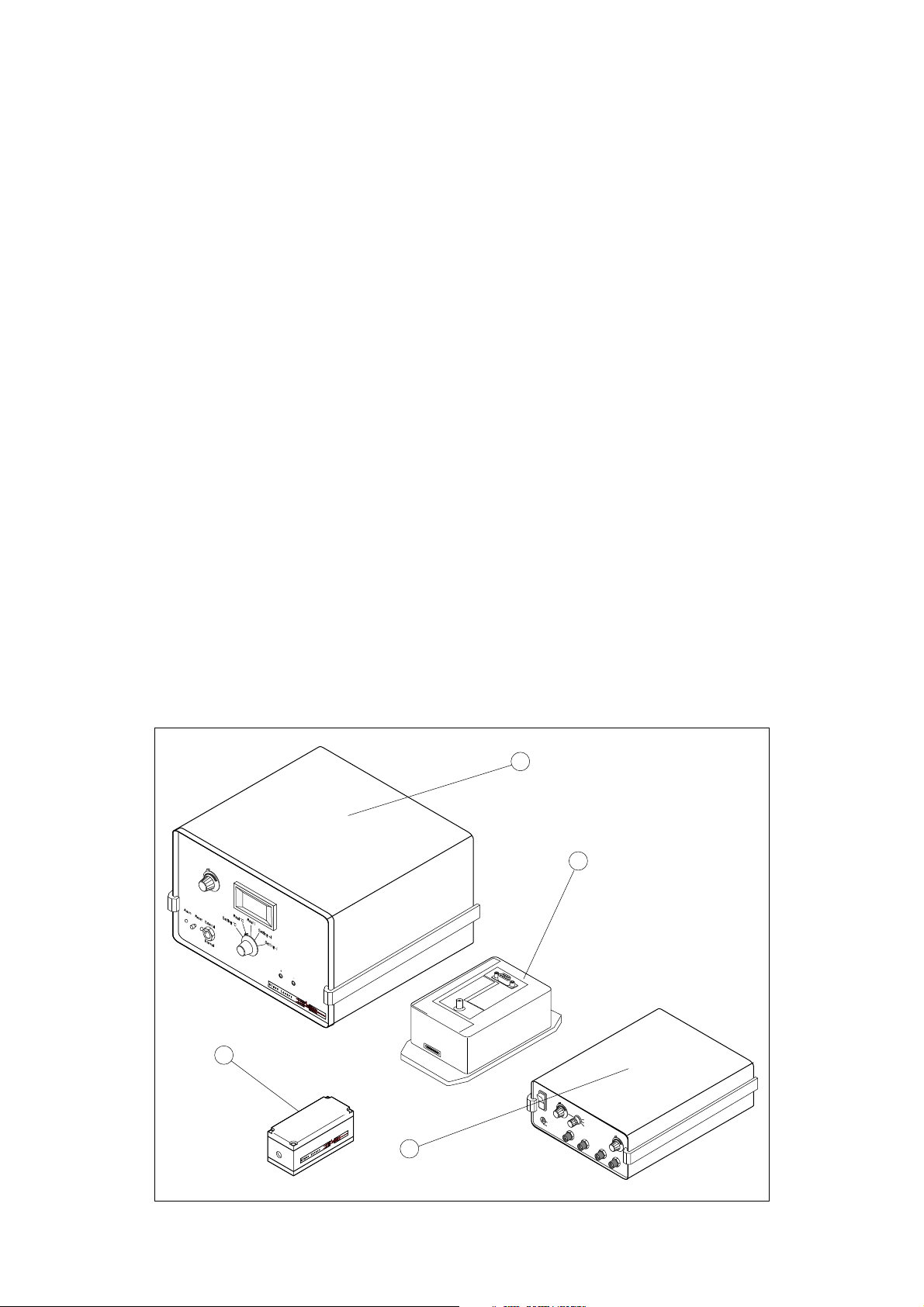

4.3.2 Geometry of QC lasers

Mountings

Lasers exist in two different packages:

• ST mounting (1)

• NS mounting (2)

Axes of QC lasers

The vertical direction is the so called growth dire c tion.

Device are mounted on a copper carrier which

has one or two ceramic pads carrying the bonding

wires. The pads are yellow on top due to a layer of

gold, and white around it and on the sides (colour

of the ceramic). If these pads are placed upwards,

the vertical for the laser is the same as the observer

vertical dire c tion.

If there are two ceramic pads pre sent, they are

named as follows:

Looking onto the front facet with the laser placed

as described above, the pad left of the laser chip is

called ”DN” (for DOWN), the one on the right of

it ”UP”.

Fig.3: ST submount

If no configuration is specified,

the ”DN” pad is used.

Never place the laser upside-down, since this will

damage the bonds connecting the pads to the laser

and possibly the laser itself !

The laser chips mounted on NS submounts provided separately from a LLH100 are supplied in a

round plastic box. For removing the laser from it,

please follow the instructions as described in appendix (appendix 10.2, p.59)

Fig.4: NS submount

Page 15

Starter Kit Instruction Manual Description 14

4.3.3 Specifications

Far field elliptical (FWHM):

Vertical: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Horizontal: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Operating temperature:

Might vary for each laser, but generally located in the range from -30◦C to +30◦C

Caution !

Before operating the laser at different temperature than specified in the datasheet, please contact

Alpes Lasers SA or a representative. Damages resulting from a non-respect of temperature operating range without approval from Alpes Lasers SA will led to a loss of warranty.

Submount size :

ST mounting: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 x 7 x 2 mm

NS mounting: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 x 7 x 2.5(top of the ceramic pads) mm

Typical lase r position:

Over the submount, centered laterally: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.2 mm

Inside the sub-mount top surface: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.03 mm

Laser emitting facet: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.005 - 0.030 x 0.004 mm

◦

◦

3

3

2

Page 16

Starter Kit Instruction Manual Description 15

− −

+

=

+

R1

C1

C2

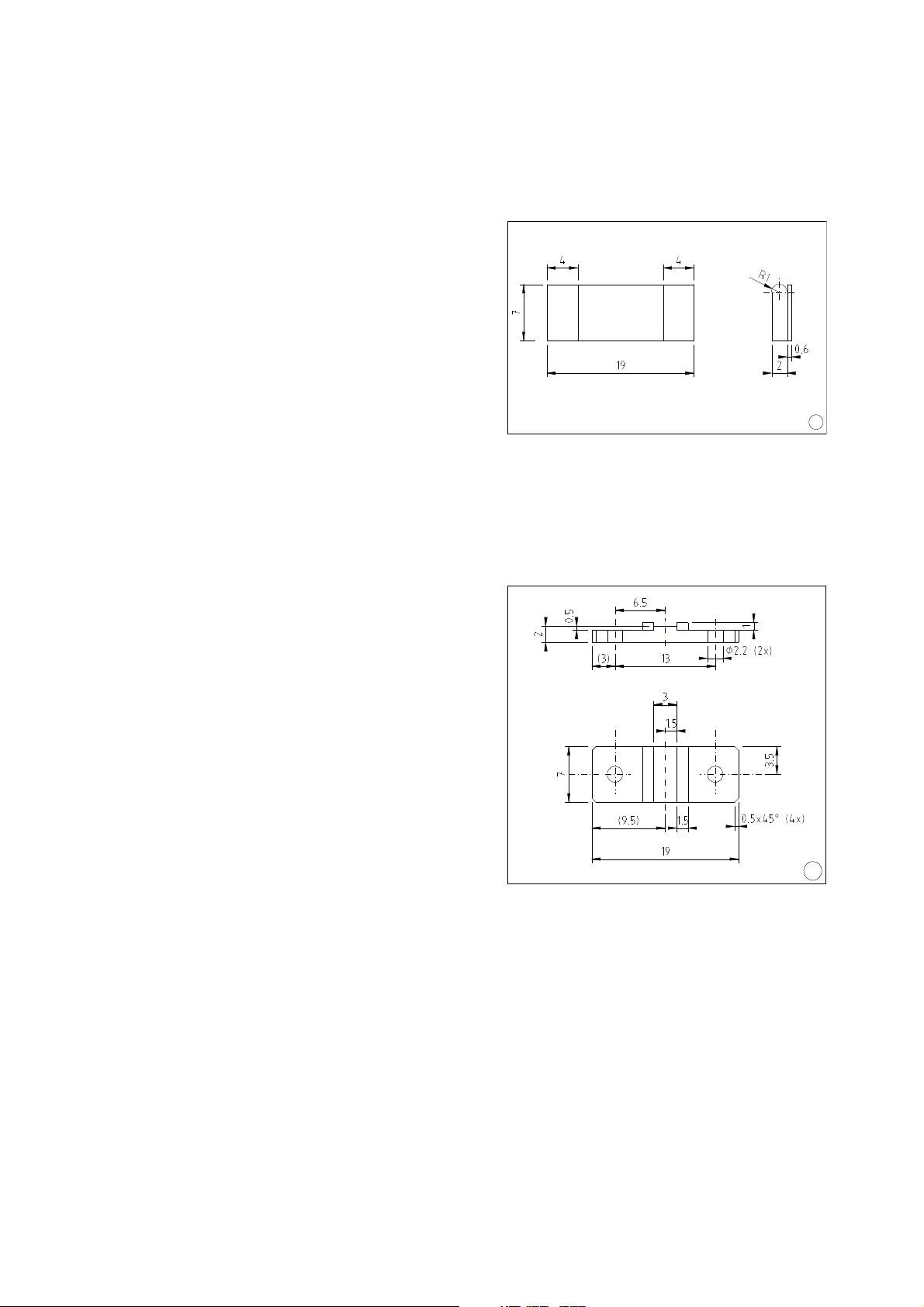

4.3.4 Electrical model

The QCL can be modelised in a RC circuit.

Electrical model characteristics

The values given below apply for a 10µm

laser wavelength.

Fig.5: Electrical model of QCL

Note: Voltage and resistor values may vary

according to the type of laser.

R1 : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 to 20Ω when a voltage of 4 to 6 Volts is applied

R1 : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 to 4Ω up to 10 - 12 Volts

R1 : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 to 20Ω over 12 Volts, after which the laser no longer operates

C1 : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100pF, capacitor between the anode and the cathode

C2 : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <100pF, depe nding on your mounting of the laser

Page 17

Starter Kit Instruction Manual Description 16

2

1

3

4

6

5

177

4.4 Laboratory Laser Housing(LLH100)

4.4.1 Description

The Laboratory Laser Housing is a Thermo-Electric

cooled box which encapsulates the Quantum Cascade Laser.

The internal temperature is controlled by a PT100 sensor and heat is dissipated by air or water.

The LLH100 is designed to ease the laser installation or replacement.

LLH100 external view description

The Laboratory Laser Housing is composed of the

following items:

(1) ZnSe coated laser beam window

(2) Peltier connector and PTC sensor

(3) Low impedance connector

(4) Cooling water flow fittings (recommended

flow: 0.25 l/min @ 10-20◦C)

(5) Monitoring base receptacle connector

(6) Monitoring laser connector

Fig.6: Laboratory Laser Housing front and rear view

Page 18

Starter Kit Instruction Manual Description 17

1

2

3

4

5

LLH100 internal view

The Laboratory Laser Housing includes the following items:

(1) LLH100 top cover

(2) PET U-shaped holder

(3) Gilded copper contact (UP and DN)

(4) Laser

(5) Laser receptacle

4.4.2 Specifications

Maximum Peltier current

(with water cooling): . . . . . . . . . . . . . . . . . . . . .5A

Lowest reachable temperature

(with water cooling): . . . . . . . . . . . . . . . . . -40◦C

Highest recommended temperature

(due to Peltier limitations): . . . . . . . . . . . 80◦C

Window:

Diameter : . . . . . . . . . . . . . . . . . . . . 12.7 mm

Clear aperture: . . . . . . . . . . . . . . . . . 11 mm

Coating: . . . . . . . . . . . . . . ZnSe, 3 to 12 µm

Temperature measurement: . . . PT100 4 wires

Fig.7: Laboratory Laser Housing internal view

Page 19

Starter Kit Instruction Manual Description 18

4

5

6

1

2

3

4.4.3 Thermo-Electric Cooler ( T EC)

and P T 100 connections

The pin 1 is recognised by a circle around it and

a thin noon ended circle starts from pin one and

turns around the pins until pin 6.

(1) Pin 1: +Peltier element

(2) Pin 2: - Peltier element

(3) Pin 3: I+ PT100

(4) Pin 4: Sens + PT100

(5) Pin 5: Sens - PT100

(6) Pin 6: I- PT100

Specifications of the Peltier connector

Vacuum case plug reference: . . . . . . . LEMO #

HGG.1b.306.CLLPV.

Cable plug reference: . . . . . . . . . . . . . LEMO #

FGG.1b.306.CLAD72Z.

Fig.8: Front view of the Peltier connector

Plastic protection for the cable: . . .LEMO #

GMA.1b.065.DG.

Cable:

Diameter : . . . . . . . . . . . . . . . . . . . . . 5.8 mm

Section : 6 x 0.25 mm (2 x 0.25 for each

Peltier connections)

or

Diameter : . . . . . . . . . . . . . . . . . . . . . 7.2 mm

Section : 10 x 0.25 mm (2 x 3 x 0.25 for

Peltier connections)

Page 20

Starter Kit Instruction Manual Description 19

4.4.4 Measurement connection

These connections give access to the voltage on the

laser.

The ”L” connection is connected AC coupled to

the cathode of the laser through a divider by ten.

The end of cable must be 50Ω terminated for accurate measurement. The ”B” is connected the same

to the anode of the laser (Base Receptacle).

By using the math trace of an oscilloscope showing the ”L” channel minus the ”B”, one can get the

voltage on the laser.

This measurement is more accurate than the information obtained from the LDD100 measurement

unit.

For more details, refer to LDD100 Diagram Block

on page ??.

Specifications of the measurement connector

Vacuum case plug reference: . . . . . . . LEMO #

HGP.00.250.CTLPV

Cable plug reference: . . . . . . . . . . . . . . LEMO #

FFS.00.250.CTCE31

Cable :. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RG174

Page 21

Starter Kit Instruction Manual Description 20

1

2

3

connected to + hi High Voltage

Pulse on top, Bottom

Output

Current control Max 60V

Power supply 12V

Input

LDD 100

Monitor 20 A/V, Z50 Ohm

4.5 QCL pulser switching unit(LDD100)

4.5.1 Description

The switching unit is based on dedicated power

MOS-FETS with up to 30A current compatibilities

and 60V. In addition, the circuit is limited in power

dissipation by the cooling o f the unit. During operation, the temperature of the case should not exceed 60C. While powering usual QC diodes, these

limitations are never reached because the laser has

usually much lower power ratings.

! WARNING !

An important feature of this unit is that

both lines going to the laser are ”HOT”, i.e.

have a postive voltage respective to the case.

this feature should be kept in mind when designing the laser holder. This one should be

insulated and have a low capacitance(< 100pF)

towards the ground.

The QCL pulse switching unit is composed of

the following connectors:

(1) Low impedance connector

(2) Drive c able connector

(3) Monitoring BNC connector

4.5.2 Specifications

Voltage : . . . . . . . . . . . . . . . . . . . . . . max 60 VDC

Current : . . . . . . . . . . . . . . . . . . . . . . max 30 ADC

Repetition rate : . . . . . upto 1MHz, limited by

average current

Rising/falling edge: . . typical 8ns (max 12ns)

Minimum pulse width: . . . . 16ns, typical 20ns

Maximum pulse width: 1µs, limited by power

supply

Support power: . . . . . . . . . . . . given by TPG128

Trigger IN: . . . . . . . . . . . . . . . . . . . . . . . . TTL 50Ω

Fig.9: QCL pulser switching unit front and rear view

Propagation delay: . . . . . . typical 35ns <40 ns

Size: . . . . . . . . . . . . . . . . . . . . . 90 x 130 x 50 mm

3

! WARNING !

The connection between the laser and the

QCL pulse switching unit is floating. It must

not be connected wi th the ground.

Page 22

Starter Kit Instruction Manual Description 21

4.6 QCL pulse switching measuring unit

4.6.1 Generalities

The measuring circuit contained in the LDD100

provides information about various laser pulse parameters (peak voltages, supply voltages, duty cycle, frequency). They are only estimated values,

since exact measurement of short and strong pulses

with diodes and averaging circuitry is difficult.

Keep in mind that you should always measure

the voltages on the LLH100 if you need accurate

time and voltage data (see final paragraph). However, these data are useful for monitoring and surveillance purposes, and to give a rough estimation of

the current parameters.

4.6.2 Measured voltages

• UHV: 1/2 of the average voltage, respective

to VHT (user supplied high voltage)

• ULH: 1/2 of the average laser anode voltage,

respective to VHT

• ULL: duty cycle dependent peak laser cathode

voltage, respective to VHT

• UD: duty cycle dependent peak transistor drain

voltage, respective to VHT

• UPI: 1/2 average internally reshaped drive voltage, respective to ground

• UPT: 1/2 average of a 37ns fixed length pulse,

respective to ground

4.6.3 Timing data

Pulse frequency calculation

UPT can be used to calculate the pulse frequency

as follows:

f = f

2UP T −ν

0

ν

Where f0is a frequency constant, v

v

are the TTL pulser voltage limits.

P high

P low

P high−νP low

P low

and

Actual values: f0=

1

37

ns , v

P low

=0.01V, v

P high

=5V

Page 23

Starter Kit Instruction Manual Description 22

Duty cycle calculation

UPI can be used to calculate the duty factor as

follows:

2UP I −ν

df =

ν

P low

P high−νP low

with v

P low

and v

P high

as above.

To get the real duty cycle, df must be corrected

as follows:

dc = f

LDD

df = f

LDD

2UP I −ν

ν

P low

P high−νP low

to compensate for sys tematic errors in the LDD100.

Actual value is f

LDD

= 1.1

4.6.4 Laser peak current

The laser peak curre nt can be calculated by the

measurement of the current through the series resistor Rs. This is provided by the values ULL and

UD, which are rectifier outputs. To correct for the

duty cycle, the rectifier values have to be taken into

account with the following fo rmula for a correction

factor:

p = 1 +

Rds

Rcdc

where Rds and Rc are resistors in the rectifier

circuit, dc is the duty cycle calculated as in the

preceding paragraph. Actual values are Rds=10kΩ

and Rc=10MΩ.

The corrected values for the peak laser cathode

and transistor drain voltage are then given as follows:

ULL

UD

= pU LL + U ds

peak

= pU D + U ds

peak

where Uds is the voltage drop across the rectifier diode, actual value Uds=0.25V.

Finally, the laser peak current is then given by:

I

peak

ULL

=

peak

−UD

Rs

peak

where Rs is the series resis tor, a c tua l value Rs

=0.85Ω.

Page 24

Starter Kit Instruction Manual Description 23

4.6.5 Laser peak voltage

The laser peak voltage is given by:

U

= 2U LH − U LL

peak

peak

where U LL

is the corrected peak value of

peak

ULL as calculated in the previous paragraph.

4.6.6 Average dissipation

The average therma l dissipation of the laser is given

by:

where U

peak

P = U

and I

peakIpeak

peak

dc

are the peak values of

laser voltage and current as calculated in the previous paragraphs, and dc is the (corrected) duty

cycle.

4.6.7 Ac c uracy considerations

The duty cycle (corrected) is accurate to about 5%

for pulse lengths in the range 50ns to 150ns and

pulse periods in the range 1µs to 10µs. Especially

for short pulses, the accuracy can deteriorate to over

10%. These calculations and data are compared to

the pulse lengths measured via the BNC connector of the LDD100. The TTL pulses generated by

the TPG128 are always longer, due to losses in the

LDD100.

Since the other calculations depend on the duty

cycle data, they are in general even less accurate.

The rectifier circuits used to measure the peak voltages show nonlinearities especially around 13V, and

therefore the voltage may seem to saturate at a

certain current for certain lasers. In addition, the

change in laser impedance around thresho ld can

generate remarkable nonlinearities compared to the

above calculations.

If you need accurate values, proceed as follows:

[1] Measure laser peak voltage, frequency and

duty cycle using a two-channel oscilloscope

(connected to the LEMO jacks of the LLH100)

in differential mode.

[2] Measure average current into the laser using the value given by the HV supply (or by

an attached RMS ampermeter).

[3] Calculate peak current by dividing average

current by the duty cycle.

Page 25

Starter Kit Instruction Manual Description 24

T

P

G

1

2

8

−

T

T

L

P

u

l

se

G

e

n

e

r

a

t

o

r

O

F

F

O

N

P

o

w

e

r

0

.

2

t

o

2

.

2

µ

s

0

.

5

t

o

1

0

.

5

µ

s

5

t

o

1

0

5

µ

s

0

t

o

2

0

0

n

s

−

−

−

−

−

−

−

−

−

P

e

r

i

o

d

−

−

−

−

−

−

−

−

−

−

D

u

r

a

t

i

o

n

−

G

a

t

e

I

N

T

r

i

g

O

U

T

O

u

t

1

O

u

t

2

5

0

o

h

m

s

5

0

o

h

m

s

5

0

o

h

m

s

m

a

x

6

0

m

A

+

1

2

V

0

V

4.7 QCL pulser timing unit (TPG128)

4.7.1 Description

The QCL pulser timing unit is designed to control

the QCL pulser switching unit.

It provides TTL pulses on 50Ω on two indep e ndent outputs. The pulse duration is adjustable from

0 to 200ns. The interval between pulses can be adjusted between 200ns and 105µs in 3 ranges.

A TTL level Gate in input and Trigger out

output have also been included. The trigger precedes the output pulse by about 100ns.

The QCL pulser timing unit includes the +12VDC

power supply needed by the QCL pulser switching

unit by means of a Lemo 00 connector with the

+12V on the centre wire.

! Warning !

Although the pulser system is capable of

delivering pulses with lengths up to 200 ns,

and duty cycles up to 50%, the laser may not

withstand this! The laser shall only be operated under conditions as specified in the

datasheet or by Alpe s Lasers directly: all

other operation may result in destruction of

the laser and loss of warranty.

Fig.10: QCL pulser timing unit

Limitations

Caution !

The generator can not operate with a 200 ns long

pulse at a 200ns repetition interval, therefore it is

limited in duty factor.

The following limitations apply:

4.7.2 Specifications

Voltage :. . . . . . . . . . . . . . . . . . . . . . . . .220V-240V

Frequency : . . . . . . . . . . . . . . . . . . . . . 50Hz-60Hz

Output voltage (for switching unit):+12VDC

Output max current (for switching unit):150mA

Delay between pulses:

. . . . . . . . . . . . . . . . . . . . . . . .200 ns to 2.2 µs

. . . . . . . . . . . . . . . . . . . . . . 500 ns to 10.5 µs

. . . . . . . . . . . . . . . . . . . . . . .5.1µs to 105.1 µs

trigger and logic output signals: . . . 50Ω TTL

driver circuit (74128)

gate level : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TTL

Maximum duty cycle: 50% (if larger cycles are

needed, the LDD100 should be fed by an external 12V power supply, not the one provided in the

TPG128, or else the fuse in the TPG128 may blow).

T=400ns: . . . . . . . . . . . . . . . . . . . . t max = 20 0ns

T=300ns: . . . . . . . . . . . . . . . . . . . . t max = 20 0ns

T=250ns: . . . . . . . . . . . . . . . . . . . . t max = 15 0ns

T=200ns: . . . . . . . . . . . . . . . . . . . . t max = 10 0ns

Page 26

Starter Kit Instruction Manual Description 25

TCU151

T

e

m

p

e

r

a

t

u

r

e

C

o

n

t

r

o

l

l

e

r

A

l

a

r

m

R

e

s

e

t

E

x

t

e

r

n

a

l

I

n

t

e

r

n

a

l

R

e

a

l

I

Re

a

l

C

S

e

t

t

i

n

g

C

S

e

t

t

i

n

g

+

I

S

e

t

t

i

n

g

−I

+

−

1

2

1

7

3

4

5

6

4.8 QCL temperature controller(TCU151)

4.8.1 Description

The TCU151 is used to co ntrol the laser’s temperature inside the Laboratory Laser Housing.

It uses a PT100 se ns or to measure the tempe rature of the cold plate and maintains a pre-set temperature either from a front panel knob or from a

user supplied voltage.

4.8.2 Specifications

Voltage: . . . . . . . . . . . . . . . . . . . . . . . 120 -240V AC

Frequency: . . . . . . . . . . . . . . . . . . . . . . . . . 50-60 Hz

Fuse:

. . . . . . . . . . . . . . . . . . . . 1.6 A T (220-240V)

. . . . . . . . . . . . . . . . . . . 3.2 A T (110 -120V)

Fig.11: TCU151 temperature controller

Peltier current maximum: . . . . . . . . . . . . . . . . 5A

Temperature control range: . -65◦C to 65◦C

Temperature measurement: . . . PT100 4 wires

Temperature monitor: . . . . 10mV/◦C, Zout =

200Ω

In addition, allow for 15 min. warm-up of

TCU151 to get stable readings

External driving temperature: . -6.5V to 6.5V

(-65◦C to 65◦C), Zin =1MΩ

4.8.3 Peltier and PT100 connections

The rear connector pinout is listed according to the

following items:

(1) Pin 1: +Peltier element

(2) Pin 2: - Peltier element

(3) Pin 3: +I PT100

(4) Pin 4: +Sense PT100

(5) Pin 5: -Sense PT100

(6) Pin 6: -I PT100

(7) Pin GND: Ground

Fig.12: TCU151 Peltier Connector

Page 27

Chapter 5

T

P

G

1

2

8

−

T

T

L

P

u

l

s

e

G

e

n

e

r

a

t

o

r

O

TCU151

F

F

O

N

P

o

T

w

e

e

m

r

p

e

r

a

t

u

r

e

0

C

.

o

2

n

t

t

o

r

2

o

.

l

2

l

m

e

s

r

0

.

5

t

o

1

0

.

5

m

s

5

t

o

1

0

5

m

s

0

t

o

2

0

0

n

s

−

−

−

−

−

−

−

−

−

P

e

ri

o

d

−

−

−

−

−

−

−

−

−

−

D

u

r

a

t

i

o

n

−

G

a

t

e

I

N

T

ri

g

O

U

T

O

u

t

1

O

u

t

2

5

0

o

h

m

s

5

0

o

h

m

s 5

0

o

h

m

s

m

a

x

6

0

m

A

+

1

2

V

0

V

connected to + hi High Voltage

Pulse on top, Bottom

Output

Current control Max 60V

Power supply 12V

Input

LDD 100

Monitor 20 A/V, Z50 Ohm

1

2

3

4

5

7

6

Installation

5.1 Chapter overview

This chapter describes the installation and the connection of the QCL Starter Kit. It also explains the

operating checks before the normal use.

5.2 General

The setup procedure s outlined below must be followed meticulously to ensure that QCL Starter Kit

operates correctly and safely.

5.3 Packing list

5.3.1 Standard items

The standard starter Kit is supplied with the following items:

(1) QCL pulse timing unit (TPG128)

(2) CPL100 cable

(3) QCL pulse switching unit (LDD100)

(4) Low impedance line (LBI100)

(5) Laboratory Laser Housing (LLH100)

(6) CTL100 cable

(7) Temperature controller (TCU151)

(8) Power cords

1 Instructions manual

Fig.13: QCL Starter Kit packing list

26

Page 28

Starter Kit Instruction Manual Installation 27

0

1

U

S

E

O

N

L

Y

W

I

T

H

2

5

0

V

F

U

S

E

S

/

E

M

P

L

OY

E

R

U

N

I

Q

U

E

M

E

N

T

A

V

E

C

D

E

S

F

USI

B

L

E

S

DE

2

5

0

v

1

1

0

−

1

2

0

V

2

2

0

−

2

4

0

V

U

T

P

U

T

M

a

x:

1

5

V

/

6

A

M

O

N

I

T

O

R

I

N

G

10

m

V

/

C

Z

o

ut

:

200

ohm

E

x

t

er

n

al

R

e

f

.

1

00

m

V

/

C

Z

i

n:

1

M

o

hm

I

nt

er

l

o

c

k

i

ng

1

O

I

USEONLY WITH250V

FUSES/ EMPLOYER

UNIQUEMENTAVEC

DESFUSIBLESDE250v

110−120V

2

2

0−2

4

0

V

2

3

5.4 Setting the appropriate AC

voltage on TCU151

The TCU151 temp e rature controller works on 110/120V

or 220/240V if the fuse holder is oriented in the appropriate position.

Note: There are two rates:

110-120V, 60Hz (USA)

220-240V, 50Hz (Europe)

5.4.1 Procedure

To set the appropriate voltage on the TCU151 temperature controller, proceed as fo llows:

[1] Pull out the fuse holder (1) from the socket.

[2] Verify the orientation of the fuse holder to

get the appropriate voltage. The arrow on the

fuse holder (3) should correspond to the mark

on the socket (2).

[3] Insert the fuse holder (1) into the socket.

Fig.14:TCU151 rear panel

Fig.15 : Setting the appropriate AC voltage rate

Page 29

Starter Kit Instruction Manual Installation 28

T

P

G

1

2

8

−

T

T

L

P

u

l

s

e

G

e

n

e

r

a

t

o

r

O

TCU151

F

F

O

N

P

o

T

w

e

e

m

r

p

e

r

a

t

u

r

e

0

C

.

o

2

n

t

t

o

r

2

o

.

l

2

l

m

e

s

r

0

.

5

t

o

1

0

.

5

m

s

5

t

o

1

0

5

m

s

0

t

o

2

0

0

n

s

−

−

−

−

−

−

−

−

−

P

e

r

i

o

d

−

−

−

−

−

−

−

−

−

−

D

u

r

a

t

i

o

n

−

G

a

t

e

I

N

T

r

i

g

O

U

T

O

u

t

1

O

u

t

2

5

0

o

h

m

s

5

0

o

h

m

s 5

0

o

h

m

s

m

a

x

6

0

m

A

+

1

2

V

0

V

connected to + hi High Voltage

Pulse on top, Bottom

Output

Current control Max 60V

Power supply 12V

Input

LDD 100

Monitor 20 A/V, Z50 Ohm

2

1

5.5 Installing the starter Kit

5.5.1 Before beginning

Make sure that the following devices are turned

OFF:

• TPG128

• TCU151

• User DC power supply

5.5.2 Procedure

To install the QCL Starter Kit, proce e d as follows:

[1] Plug the low impedance line into the LLH100

connector (2). The line connector is coded.

CAUTION ! Pay attention about the connection’s polarity. The laser must be floating

from ground for both anode and cathode.

[2] Plug the low impedance line into the QCL

pulser switching unit low impedance output

(1) paying attention for the polarity.

Fig.16: Installing the Quantum Cascade Laser Starter Kit

Page 30

Starter Kit Instruction Manual Installation 29

T

P

G

1

2

8

−

T

T

L

P

u

l

s

e

G

e

n

e

r

a

t

o

r

O

TCU151

F

F

O

N

P

o

T

w

e

e

m

r

p

e

r

a

t

u

r

e

0

C

.

o

2

n

t

t

o

r

2

o

.

l

2

l

m

e

s

r

0

.

5

t

o

1

0

.

5

m

s

5

t

o

1

0

5

m

s

0

t

o

2

0

0

n

s

−

−

−

−

−

−

−

−

−

P

e

r

i

o

d

−

−

−

−

−

−

−

−

−

−

D

u

r

a

t

i

o

n

−

G

a

t

e

I

N

T

r

i

g

O

U

T

O

u

t

1

O

u

t

2

5

0

o

h

m

s

5

0

o

h

m

s 5

0

o

h

m

s

m

a

x

6

0

m

A

+

1

2

V

0

V

connected to + hi High Voltage

Pulse on top, Bottom

Output

Current control Max 60V

Power supply 12V

Input

LDD 100

Monitor 20 A/V, Z50 Ohm

6

9

8

7

3

1

2

3

5

[3] Plug the cable (3) onto the LDD100(4).

[4] Plug the +12VDC connector (1) into the

TPG128 (9).

[5] Plug the trigger BNC connector (2) into

the TPG128 (9) Out 1 or Out 2 outptut.

CAUTION ! The unit must be floating.

[6] Plug the banana cables (8) (red a nd black)

into the DC power supply unit.

[7] Plug the LEMO connector (6) onto the

LLH100 module (5) and the connector (7) o nto

the TCU151 unit.

[8] Plug the cooling water tubing if available.

CAUTION ! If no water cooling is available, pay attention to the LLH100 module case

temperature, and be careful of either reducing

heat dissipation or providing air cooling to the

unit.

Fig.17: Connecting Starter Kit

Page 31

Chapter 6

T

P

G

1

2

8

−

T

T

L

P

u

l

se

G

e

n

e

r

a

t

o

r

O

F

F

O

N

P

o

w

e

r

0

.

2

t

o

2

.

2

µ

s

0

.

5

t

o

1

0

.

5

µ

s

5

t

o

1

0

5

µ

s

0

t

o

2

0

0

n

s

−

−

−

−

−

−

−

−

−

P

e

r

i

o

d

−

−

−

−

−

−

−

−

−

−

D

u

r

a

t

i

o

G

a

t

e

I

N

T

r

i

g

O

U

T

O

u

t

1

O

u

t

2

5

0

o

h

m

s

5

0

o

h

m

s

5

0

o

h

m

s

m

a

x

6

0

m

A

+

1

2

V

0

V

6

1

2

3

9

8

7

5

4

Use

6.1 Chapter overview

This chapter describes how to use the QCL Starter

Kit. It also explains the functionalities of the TPG128

and the Temperature Controller (TCU151).

6.2 QCL pulse timing unit command description

The Quantum Cascade Laser is controlled by the

QCL pulse timing unit TPG128. The TPG128 front

panel is composed of the following items:

(1) Power ON/OFF switch.

(2) Period fine 10 turns potentiometer.

(3) Period range 3 positions switch.

(4) Pulse duration 10 turns potentiometer.

(5) BNC 50Ω TTL pulse 2 output.

(6) BNC 50Ω TTL pulse 1 output.

(7) BNC 50Ω TTL Trig OUT.

(8) BNC TTL Gate IN.

(9) LEMO 00 12VDC output (for LDD100).

Fig.18: TPG128 front panel

30

Page 32

Starter Kit Instruction Manual Use 31

0

1

U

S

E

O

N

L

Y

W

I

T

H

2

5

0

V

F

U

S

E

S

/

E

M

P

L

OY

E

R

U

N

I

Q

U

E

M

E

N

T

A

V

E

C

D

E

S

F

USI

B

L

E

S

DE

2

5

0

v

1

1

0

−

1

2

0

V

2

2

0

−

2

4

0

V

U

T

P

U

T

M

a

x

:

1

5

V

/

6

A

M

O

N

I

T

O

R

I

N

G

1

0

m

V

/

C

Z

o

u

t

:

2

0

0

o

h

m

E

x

t

e

r

n

a

l

R

e

f

.

1

0

0

m

V

/

C

Z

i

n

:

1

M

o

h

m

I

n

t

e

r

l

o

c

k

i

n

g

9

12

11

10

8

TCU151

T

e

m

p

e

r

a

t

u

r

e

C

o

n

t

r

o

l

l

e

r

A

l

a

r

m

R

e

s

e

t

E

x

t

e

r

n

a

l

I

n

t

e

r

n

a

l

R

e

a

l

I

R

e

a

l

C

S

e

t

t

i

n

g

C

S

e

t

t

i

n

g

+

I

S

e

t

t

i

n

g

−

I

+

−

1

2

3

4

5

6

7

6.3 TCU151 command description

The internal temperature of the LLH100 is driven

by the TCU151 unit.

The Temperature Controler front and rear pan-

els are composed of the following items:

(1) Set Temperature 5 turns potentiometer:

Allows to set the internal temperature reference.

(2) LCD 3 digits display: Used to display either the actual sensor or reference temperature/current.

(3) Switch to select which temperature or current signals to display.

(4) Alarm display LED.

(5) Alarm reset switch.

(6) Switch which selects between the internal

and the remote temperature reference.

(7) Setting Current adjustment potentiometers.

(8) Power ON/OFF fuse combined main switch.

(9) To LLH100: Amphenol connector for LLH10 0

temperature control.

Fig.19: TCU151 temperature controler front panel

(10) Interlock BNC connector.

(11) External reference BNC connector.

(12) Monitoring: BNC connector providing

the temperature of the sensor as 10mV/◦C

signal.

Fig.20: TCU151 temperature controler rear panel

Page 33

Starter Kit Instruction Manual Use 32

TCU151

T

e

m

p

e

r

a

t

u

r

e

C

o

n

t

r

o

l

l

e

r

A

l

a

r

m

R

e

s

e

t

E

x

t

e

r

n

a

l

I

n

t

e

r

n

a

l

R

e

a

l

I

R

e

a

l

C

S

e

t

t

i

n

g

C

S

e

t

t

i

n

g

+

I

S

e

t

t

i

n

g

−

I

+

−

1

2

3

5

4

0

1

U

S

E

O

N

L

Y

W

I

T

H

2

5

0

V

F

U

S

E

S

/

E

M

P

L

OY

E

R

U

N

I

Q

U

E

M

E

N

T

A

V

E

C

D

E

S

F

USI

B

L

E

S

DE

2

5

0

v

1

1

0

−

1

2

0

V

2

2

0

−

2

4

0

V

U

T

P

U

T

M

a

x

:

1

5

V

/

6

A

M

O

N

I

T

O

R

I

N

G

1

0

m

V

/

C

Z

o

u

t

:

2

0

0

o

h

m

E

x

t

e

r

n

a

l

R

e

f

.

1

0

0

m

V

/

C

Z

i

n

:

1

M

o

h

m

I

n

t

e

r

l

o

c

k

i

n

g

6

7

6.4 Laser utilisation

6.4.1 Overview

In order to insure a correct use and and an appropriate lifetime to the laser, it is recommended to proceed according a specific order as below:

• Start water flow to cool the LLH100.

• Turn on the temperature controller and set

the desired temperature.

• Start the pulse ge nerator.

• Switch on the power supply.

6.4.2 Proceedings

To use the Quantum Cascade Laser, proceed as follows:

[1] Make sure tha t the laser has been installed

properly (see page 38.

[2] If available, turn on the water on the LLH100

module.

CAUTION ! If water is not available, check

the LLH100 module temperature until desired

operating temperature is reached. The unit

has a reduced laser temperature range under

reduced heat sinking conditions. The unit may

Fig.21: Starting the TCU151

become very hot, overheat and be destroyed.

A radiator and possibly a fan might be necessary to increase the laser operating temperature range.

[3] Turn on the TCU151 instrument (6).

Note: Set the desired temperature by first pushing the switch (3) to Setting◦C to display the

objective temperature and turn the 5 turn knob

(1) to change it. Turning the switch (3) to

Real◦C, the display shows the present temperature.

Note: To remote control the LLH100 temperature, set the switch (5) to external and provide

a voltage on the External reference (7) from

-6.5V (-65◦C) to + 6.5V (+65◦C).

[4] Plug the banana cables into the power supply unit and set output voltage to zero and

the compliance current to 100mA if pulsing a

QCL.

Fig.22: TCU151 remote control

Page 34

Starter Kit Instruction Manual Use 33

T

P

G

1

2

8

−

T

T

L

P

u

l

se

G

e

n

e

r

a

t

o

r

O

F

F

O

N

P

o

w

e

r

0

.

2

t

o

2

.

2

m

s

0

.

5

t

o

1

0

.

5

m

s

5

t

o

1

0

5

m

s

0

t

o

2

0

0

n

s

−

−

−

−

−

−

−

−

−

P

e

r

i

o

d

−

−

−

−

−

−

−

−

−

−

D

u

r

a

t

i

o

G

a

t

e

I

N

T

r

i

g

O

U

T

O

u

t

1

O

u

t

2

5

0

o

h

m

s

5

0

o

h

m

s

5

0

o

h

m

s

m

a

x

6

0

m

A

+

1

2

V

0

V

8

9

10

11

[5] Turn the TPG128 ON (8) and set the pulse

period to 2.0 and the range to 0.5 to 10.5 µs

(medium), co rresponding to a period length

of about 2.5us, or to the values specified on

the datasheet or by Alpes Lasers.

[6] Set the pulse duration (11) to 3.0, corresponding to a pulse length of about 50ns, or

to the values specified on the datasheet or by

Alpes Lasers.

[7] Verify laser cabling, power meter range

set corresponding to the power range of the

laser (specified in the datasheet), zeroed and

aligned.

[8] Turn the HV power supply ON, then the

TPG128 ON, and slowly increase the HV output voltage (but not hig her than specified in

the datasheet of the laser!)

Fig.23: Starting the TPG128

[9] If available, monitor the averaged output

to avoid overloading the laser. In any case

place one probe on both the anode and the

cathode of the laser and view it with an oscilloscope.

[10] Subtract the two traces and you get the

voltage across the laser that should not be

more than the specified max voltage.

Note: The laboratory housing LLH100 makes

available two outputs giving access to these

voltages (see documentation).

[11] Set the desired pulse and period length as

specified in the datasheet or by special agreement with Alpes Lasers.

Page 35

Starter Kit Instruction Manual Use 34

0

1

Z

i

n

:

1

M

o

h

m

I

n

t

e

r

l

o

c

k

i

n

g

1

A

l

a

r

m

R

e

s

e

t

E

x

t

e

r

n

a

l

I

n

t

e

r

n

a

l

2

3

6.5 Interlock utilisation

The temperature controller is designed with an builtin interlock (1). This function is activated when a

fault occurs on the TCU151 controller (over-temperature,

over-current, etc.).

The interlock is by default a NC (Normally Close)

relay c ontact.

CAUTION ! It is also possible to set the Interlock as a NO (Normally Open) contact. For more

details about the settings, see the procedure on page

42.

6.5.1 Before beginning

In order to recover the temperature controller from

an interlock event, please pay attention about the

following points:

• Lo cate the fault which caused the interlock

and fix it.

• Wait until the temperature driven by the TCU151

is lower than the max imum.

6.5.2 Procedure Interlock utilisation

To reset the temperatur e controller from an interlock event, proceed as follows:

[1] Press the RESET button (3) on the TCU151

front panel

,→ The interlock is re set and the red LED

ALARM (2) should be off.

Fig.24: Interlock BNC connector

Fig.25: Reseting the interlock

Page 36

Chapter 7

Troubleshooting

7.1 Chapter overview

This chapter sets out troubleshooting instructions

for ensuring safe and trouble-free operation of the

Quantum Cascade Laser Starter Kit system.

7.2 Principle

The personnel must have read and understood this

documentation before carrying out any activity whatsoever with the Quantum Cascade Laser Starter

Kit. In case of unclear information, please contact

the distributor.

The power supply reaches max cur-

rent for a very low voltage

- The low impedance line or the QCL is

shorted to ground.

√

Check the cabling.

√

Replace the laser if necessary.

- The DC power supply is NOT floating.

√

Change the cabling in order to leave

the laser floating.

- The laser tightening device is to o tight-

ened and the QCL laser is shorted to

ground.

√

Loose the laser fixture device.

35

Page 37

Starter Kit Instruction Manual Troubleshooting 36

Laser draws current but gives no

light

- The laser may be reversed polarized (it

is not a desirable situation but does generally not destroy the laser).

√

Check the polarity of the connection.

- The polarity is right. It draws too much

current and the power meter is misaligned.

√

Reduce the current at the maximum

specified for the operating temperature.

√

Check power meter alignement and

scale.

- The QCL laser is not used with the LLH

and is grounded.

√

Check that there is no short-circuit on

the circuit.

The laser does not draw current

- There is no contact with the laser.

√

Check that the gilded copper contact

is present and properly mounted.

√

Tighten the PET U-shaped holder in

order to effective the contact with the

laser by means of the POM fixing screws.

√

Check the connections on the LLH.

Measure the input resistance with an ohmmeter between the Laser connector and

the Base receptacle connector.

Page 38

Chapter 8

Maintenance

8.1 Overview

This chapter describes all procedures of maintenance and calibration for the QC L starter Kit. The

procedures described herein must be performed by

personnel trained on the electronic field, with acceptance by Alpes Lasers, o therwise the warranty

will be lost.

Note: The TTL Pulse Generator (TPG128) and

the Temperature Controller (TCU151) are calibrated

in factory.

8.1.1 How to remove the covers of

TCU151 and TPG128

Pull off the light gray plastic pieces of the side of the

front and back plates. Lift off the light gray plastic

shades form the side of the box, which gives access

to the screws holding the top and bottom covers.

37

Page 39

Starter Kit Instruction Manual Maintenance 38

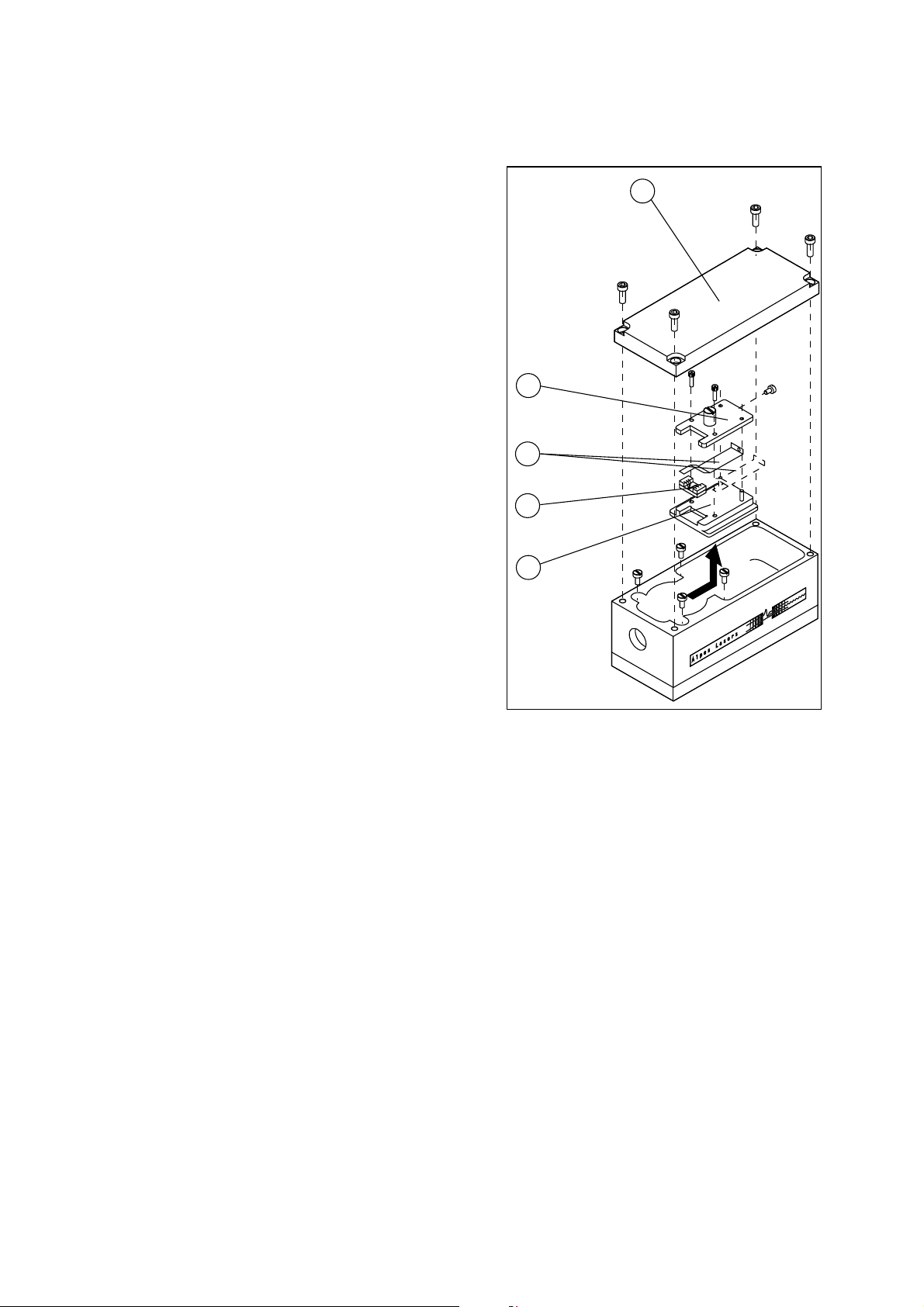

2

3

4

5

1

8.2 Replacement procedures

8.2.1 Quantum Cascade Laser replace-

ment

Before beginning

[1] Switch the QCL Starter Kit OFF

Material needed

• 1 set of Allen keys.

• 1 ohmmeter.

• 1 QCL laser.

• a pair of tweezers.

Procedure

To replace the Quantum Cascade Laser, proceed as

follows:

[1] Remove the top cover (2) of the Laboratory

Laser Housing (LLH100) by unscrewing the

screws (1)

[2] Remove the PET U-shaped holder (5) by

unscrewing the fixing screws (3)

CAUTION ! Pay attention NOT to drop the

laser!

[3] Remove the laser (4). Hold the laser on

the gilded ceramic pads with the tweezers pins

along the axis of the largest leng th of the copper submount

! WARNING ! Take especially care not

to touch the active region of the laser

or the wire bonds!

Fig.26: Removing the laser

Page 40

Starter Kit Instruction Manual Maintenance 39

4

2

1

3

5

6

[4] Install the new laser (4) into the holder

using small tweezers ( 0.5cm aperture).

[5] Hold the laser (4) on the gilded ceramic

pads with the tweezers pins along the axis of

the largest length of the copper submount.

[6] Plac e it in the receptacle parallel to the

window.

! Warning ! Avoid hitting the laser chip

facet o n the case, it is extremely fragile.

[7] Place the screws (3) in the PET holder (5).

[8] Place the PET holder (5) on the two guides

(6) on the back of the laser receptacle being

careful of maintaining the PET holder higher

on the laser side than on the back side.

[9] Once the P ET holder (5) is engaged in the

guides, push it down until contact with the

gilded ceramic pads is established.

[10] Screw it to the receptacle.

[11] Verify that the contact is e stablished by

measuring with an ohm meter on the LLH100

low impedance plug.

Note: For reproducible measurement be careful of measuring with the positive probe on the

+ LLH100 connection.

Note: If the contact is bad, adjust the plastic

screws at the pressing end of the PET holder

(5).

Note: If the contact is bad, clean the bottom

of the submount with grinding paper, be careful of not damaging the bonding wires and the

laser facet.

[12] Place the dry desiccant bag close to the

low impedance line plug. Only applicable if

desiccation is needed and the lasers has been

shipped with a desiccant bag.

Note: This operation is preferably performed

in a gloves box under dry nitrogen atmosphere

if the ambient atmosphere is humid (this is

not necessary under normal conditions 50-60%

humidity).

Fig.27: Replacing the laser

[13] Close the cover (2) with the screws (1).

Page 41

Starter Kit Instruction Manual Maintenance 40

2

3

1

4

5

6

8.2.2 QCL ”UP” and ”DN” position

exchange

Before beginning

[1] Switch the QCL Starter Kit OFF.

Material needed

• 1 set of Allen keys.

• 1 ohmmeter.

• 1 FP-QCL laser co ntact plate.

• 1 pair of tweezers.

Procedure

To exchange the beam of a Quantum Cascade Laser,

proceed as follows:

[1] Remove the top cover (2) of the Laboratory

Laser Housing (LLH100) by unscrewing the

screws (1).

[2] Remove the PET U-shaped holder (4) by

unscrewing the fixing screws (3).

Caution ! Pay attention NOT to drop the

laser!

[3] Remove the gilded copper contact (6) by

unscrewing the back screw (5).

[4] Install the opposite gilded copper contact

(6) by screwing back the screw (5).

Fig.28: Removing the laser recptacle

Fig.29: Exchanging the laser

Page 42

Starter Kit Instruction Manual Maintenance 41

2

1

3

4

5

6

[5] Place the screws (3) in the PET holder (4).

[6] Place the PET holder (4) on the two guides

(5) on the back of the laser receptacle (6)

being careful o f maintaining the PET holder

higher on the laser side than on the back side.

[7] Once the holder (4) is engaged in the guides,

push it down until contact with the gilded ceramic pads of the laser is established.

[8] Screw the PET holder (4) to the r e c e pta cle

(6).

[9] Verify that the contact is established by

measuring with an ohm meter on the LLH100

low impedance plug.

Note: For reproducible measurement be careful of measuring with the positive probe on the

+ LLH100 connection.

Note: If the contact is bad, adjust the plastic screws (7) at the pressing end of the PET

holder (4).

[10] Place a dry desiccant bag close to the

low impedance line plug. Only applicable if

desiccation is needed and the lasers has been

shipped with a desiccant bag.

Note: This operation is preferably performed

in a gloves box under dry nitrogen atmosphere

if the ambient atmosphere is humid (this is

not necessary under normal conditions 50-60%

humidity).

[11] Close the cover (2) with the screws (1).

Fig.30: Placing the PET U-shaped holder

Page 43

Starter Kit Instruction Manual Maintenance 42

2

1

T

e

m

p

e

r

a

t

u

r

e

C

o

n

t

r

o

l

l

e

r

A

l

a

r

m

R

e

s

e

t

E

x

t

e

r

n

a

l

I

n

t

e

r

n

a

l

R

e

a

l

I

R

e

a

l

C

Se

t

t

i

n

g

C

S

e

t

t

i

n

g

+

I

S

e

t

t

i

n

g

−

I

+

−

TCU151

3

4

5

8.3 TCU151 temperature con-

troller interlock setting

8.3.1 Generalities

The interlock is located on the main board.

Note: By default, the interlock is set to NC (Normally Close) contact.

8.3.2 Before beggining interlock set-

ting

[1] Switch the instrument OFF.

[2] Unplug the power cord.

[3] Remove the cover (1) to acces the main

board (2).

8.3.3 Needed material

• 1 set of screwdriver.

• 1 tweezer.

8.3.4 Procedure interlock setting

To set the type of interlock, proceed as follows:

[1] Locate the J9 Inter lock connector .

[2] Place the associated jumper according to

the type of desired interlock.

Note: The common pin is on the center (4)

and by placing the jumper on a side defines

the interlock type as:

– for a NC contact: jumper on pins (4) and

(5)

– for a NO contact: jumper on pins (3)

and (4)

Fig.31: Opening the TCU151 cover

Fig.32: J9 Interlock connector

Page 44