Page 1

SuperLoader 3A Series

SuperLoader™ 3A Series

Quick Start Guide

The Quantum® SuperLoader™ 3A Series autoloader is an automated

storage and retrieval device with an integrated A-Series tape drive and up

to two tape magazines holding up to eight cartridges each. It has a built-in

FTP server and Web interface.

For more information, see the SuperLoader 3A Series User’s Guide

(PN 81-81643) and the A-Series FTP File Server User’s Guide (PN 81-81800) on

the documentation CD provided with your autoloader.

This quick start guide uses the following conventions:

Contents 0

Choosing a Location.......................... 1

Preparing for the Installation........... 2

Providing Necessary Tools ............. 2

Taking ESD Precautions ................. 3

Preparing for Rack Mounting ........ 3

Unpacking the Autoloader................ 4

Checking Accessories ..................... 5

Rack Mounting the Autoloader ........ 6

Autoloader Panel Overviews........... 12

Connecting Ethernet

and Power Cables......................... 13

After the Installation....................... 14

Note: Notes emphasize important information related to the main

topic.

Caution: Cautions indicate potential hazards to equipment and are

included to prevent damage to equipment.

Warning: Warnings indicate potential hazards to personal safety and

are included to prevent injury.

This document explains how to unpack the SuperLoader 3A Series

autoloader and install it in a standard 19-inch rack.

Choosing a Location

The autoloader is designed to fit in a standard 19-inch rack using either the

long or short brackets (depending on the depth of the rack). The autoloader

uses standard rack mounting hardware.

Note: It is recommended that you review this entire document prior to

beginning the installation.

Page 2

SuperLoader™ 3A Series Quick Start Guide

Choose a location that meets the following criteria:

Criteria Description

Rack requirements Standard 19-inch rack

Room temperature 10–35° C (50–95° F)

Power source AC power voltage: 100–127 VAC; 200–240 VAC

Line frequency: 50–60 Hz

Locate the AC outlet near the autoloader. The AC power

cable is the product’s main disconnect device and must be

easily accessible at all times.

Weight 15.5 kg (34 lb.) unloaded

18.6 kg (41 lb.) loaded with 2 magazines, 16 cartridges

Air Quality Minimize sources of particulate contamination. Avoid areas

near frequently used doors and walkways, cooling or exhaust

vents, stacks of supplies that collect dust, printers, and

smoke-filled rooms.

Excessive dust and debris can damage tapes and tape drives.

Humidity 20–80% RH (non-condensing)

Clearance Back: Minimum of 43.2 cm (17 in.)

Preparing for the Installation

Before you begin the installation procedure in this section, make the following

preparations as described in this section:

• Providing Necessary Tools

• Taking ESD Precautions

• Preparing for Rack Mounting

Providing Necessary Tools 0

Provide the following tools for unpacking and installing the autoloader:

• #2 Phillips screwdriver

Front: Minimum of 68.6 cm (27 in.)

Sides: Minimum of 5.08 cm (2 in.)

• Level

• Antistatic wrist strap

2 Preparing for the Installation

Page 3

SuperLoader 3A Series

Taking ESD Precautions 0

Some components within the autoloader contain static-sensitive parts. To avoid damaging

these parts while performing installation procedures, always observe the following

precautions:

• Ensure that the work area is free from conditions that could cause electrostatic

discharge (ESD).

• Discharge static electricity from your body by touching a known grounded surface,

such as your computer's metal chassis.

• Keep the autoloader turned off during all installation procedures.

• Use an antistatic wrist strap.

• Keep static-sensitive parts in their original shipping containers until ready for

installation. Look for the ESD sticker to identify static sensitive parts.

• Avoid touching connectors and other components.

Note: Dry climates and cold-weather heating environments have lower relative

humidity and are more likely to produce static electricity.

Preparing for Rack Mounting 0

The autoloader can be rack mounted by attaching it directly to stationary cabinet rails.

Take the following general safety steps before beginning the rack-mount installation.

1 Lower the cabinet feet.

2 Extend the cabinet anti-tip device, if available.

Note: An anti-tip device may be extendable legs or similar equipment used to

stabilize the cabinet. This anti-tip equipment is to help avoid overbalancing the cabinet when installing or removing equipment.

3 Ensure that the cabinet and all rack mounted equipment have a reliable ground

connection.

4 Verify that the total current of all rack mounted components (including the

autoloader) will not exceed the current rating of the power distribution unit or outlet

receptacles.

5 Secure the help of at least one other person. At least two people are required to safely

install the autoloader into a rack cabinet.

Warning: Failure to take these safety steps may result in personal injury or

equipment damage.

Preparing for the Installation 3

Page 4

SuperLoader™ 3A Series Quick Start Guide

Caution: Do not remove the top cover of the autoloader during the installation

Unpacking the Autoloader

Before you begin, clear a desk or table so that you can unpack the autoloader.

process. Removing the top cover could result in damage to the

autoloader.

The SuperLoader 3A Series Quick Start Guide

and inspect your autoloader correctly.

You also need to select an open 2U computer rack location near the server that will host

the autoloader.

Caution: If the room in which you are working differs from the temperature in

which the autoloader was shipped or stored by 15° C (30° F) or more, let

the autoloader acclimate to the surrounding environment for at least 12

hours before removing it from the shipping carton.

Caution: If your unit was ordered as a one-magazine autoloader, be sure to remove

the plastic shipping insert from the magazine bay before connecting or

operating your autoloader. Insert either a magazine or a magazine blank

into the bay. The autoloader will not function without both magazine bays

equipped with either a magazine or a magazine blank.

Carefully unpack and inspect your new SuperLoader 3A Series autoloader by doing the

following:

1 Inspect the shipping box for damage. If you notice any damage, report it to the

shipping company immediately.

2 Open the shipping box and remove the accessories package. Set the accessories

package aside for now.

has all the necessary information to unpack

3 Lift the autoloader and padding out of the box and place it on the work surface, top

facing up. Do not set the autoloader on either end or sides.

4 Carefully remove the shipping padding from the left and right sides of the

autoloader. Then remove the bag from the autoloader.

5 Remove the foam insert from the magazine bay of the autoloader. Save the packing

materials in case you need to move or ship the autoloader in the future.

Note: If the cover must be taken off, there are 26 screws that need to be removed.

4 Unpacking the Autoloader

Page 5

SuperLoader 3A Series

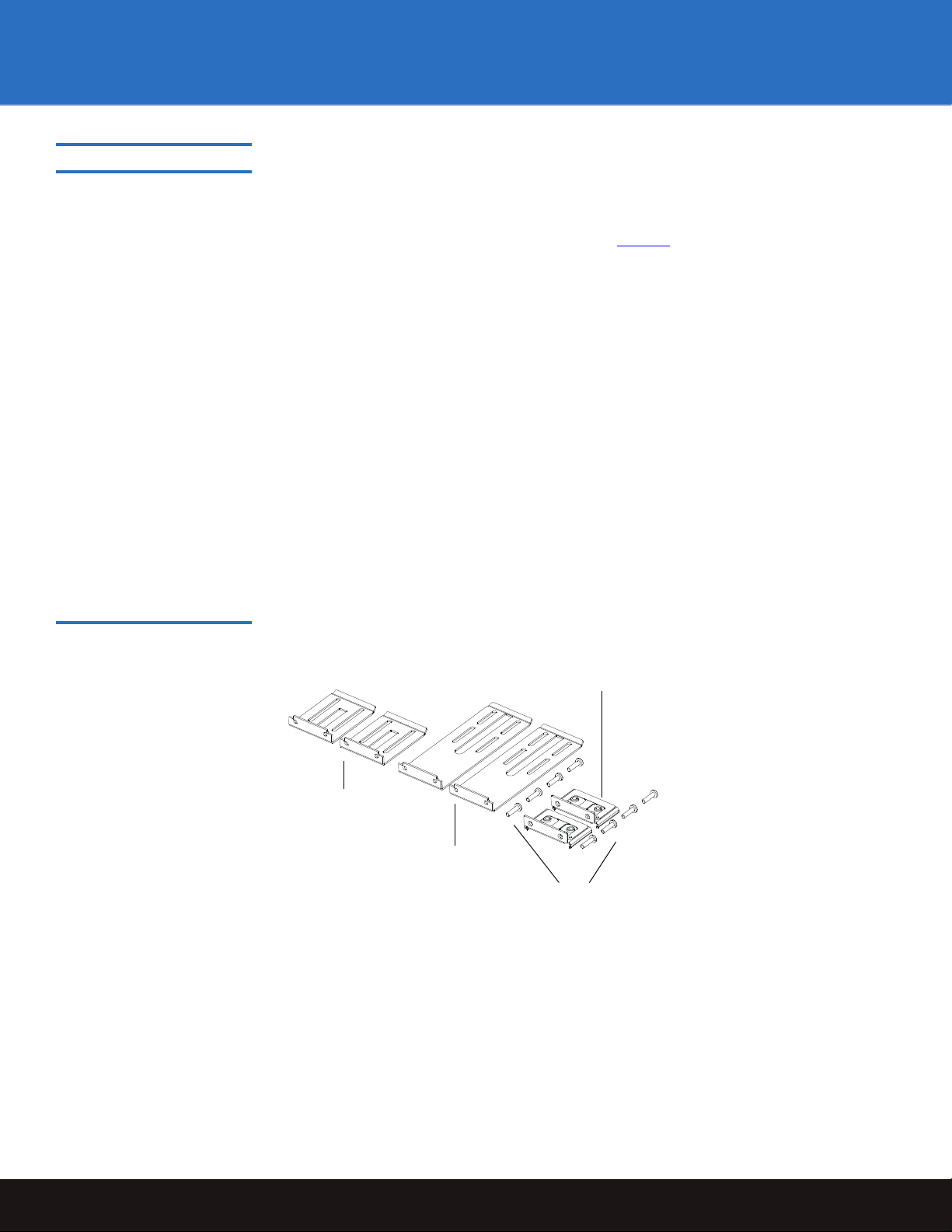

Short autoloader

brackets (72-A225-A)

Support brackets

(74-60605-01)

Long autoloader

brackets (72-A226-A)

Support bracket screws

72-A348-A (4) or 90-60227-50 (4)

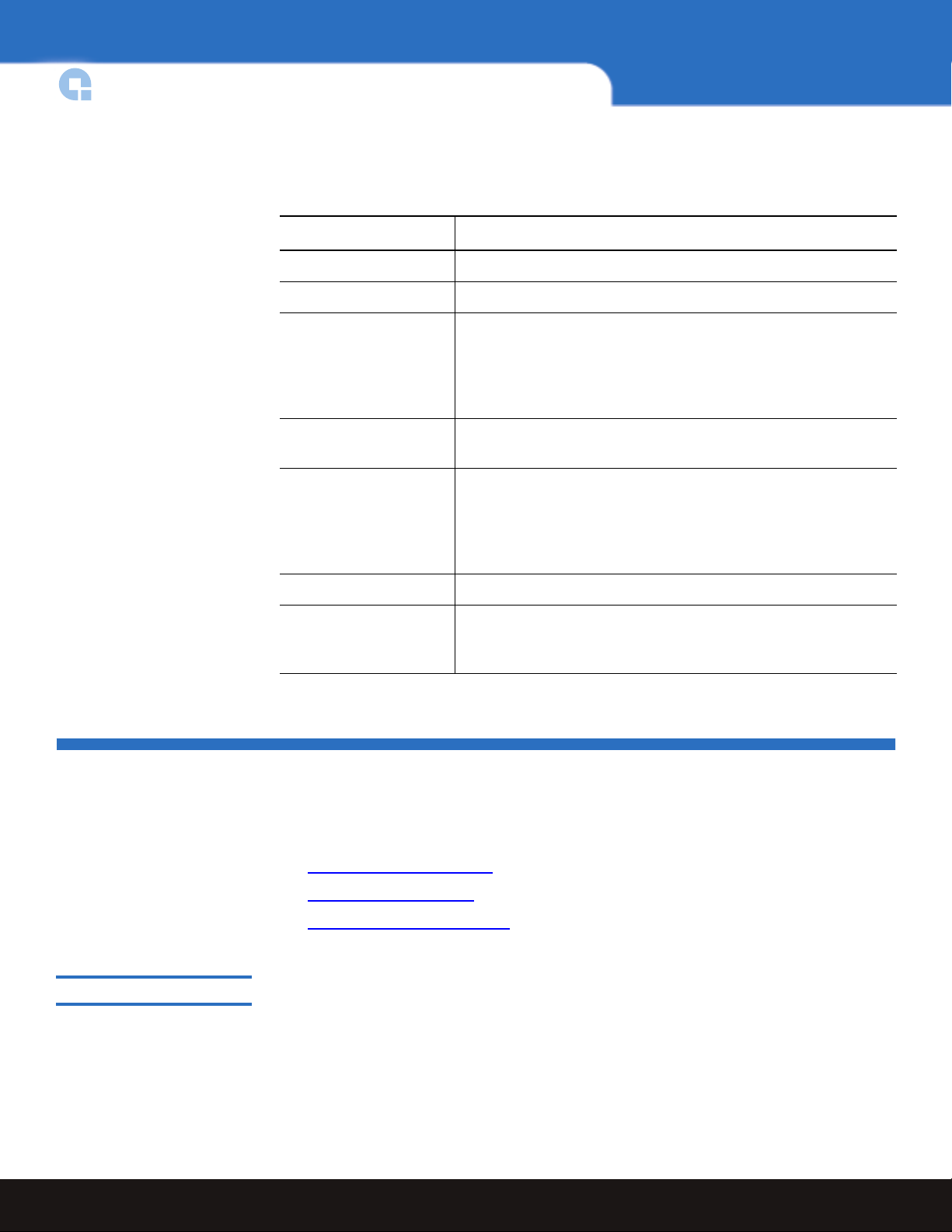

Checking Accessories 0

The following accessories are shipped with the SuperLoader 3A Series autoloader:

• SuperLoader 3A Series Quick Start Guide

•Ethernet cable

• Hardware to rack mount the autoloader (see figure 1

)

• Four autoloader brackets (two long and two short to accommodate different rack

depths)

• Two support brackets

• Two sets (decimal and metric) of four support bracket 10-32 x 1/4 inch button

head screws (two per support bracket)

•TORX

®

L-Key drivers (T8 and T10)

•Power cable

• Documentation CD containing all of the documentation in Adobe

®

Portable

Document Format (PDF)

•Bar code labels

You will also need the following parts that were shipped with your rack:

• Eight clip nuts

• Eight rack screws

Figure 1 Rack Mount

Hardware

Unpacking the Autoloader 5

Page 6

SuperLoader™ 3A Series Quick Start Guide

Cage nut

Clip nut

Clip nut

Rack Mounting the Autoloader

This section provides the steps for attaching the autoloader directly to the stationary rails

of a rack. Refer to table 1

Table 1 Rack Hole Types

Figure Description

for information on common rack hole types.

Square rack holes are the most

common type of rack holes.

They can accept either cage

nuts which mount from the back

of the rail or clip nuts which clip

on from the side of the rack rail.

Through holes require clip nuts

to accept mounting hardware.

Threaded holes require neither

cage or clip nuts to accept

mounting hardware.

Note: The rails within the rack have a hole pattern that repeats throughout the rail.

1 Install two clip nuts, 1.75 in. (44.45 mm) apart, onto each of the four rails of the rack,

making sure that you install each pair of clip nuts at exactly the same level (see

figure 2

).

6 Rack Mounting the Autoloader

Page 7

Figure 2 Installing Two Clip

Outer covers

of the rack

Rail

Rail

Rail

Clip nut

1.75 in

(44.45 mm)

Clip nut

Nuts

SuperLoader 3A Series

2 Select the long or short autoloader brackets (depending on the depth of the rack), and

then attach them to the rear of the autoloader (see figure 3

). Use the long autoloader

brackets (72-A226-A) when the distance from the front mounting rail to the rear

mounting rail is less than 30.25 in. (76.84 cm). Otherwise, use the short autoloader

brackets (72-A225-A).

Rack Mounting the Autoloader 7

Page 8

SuperLoader™ 3A Series Quick Start Guide

Autoloader

Autoloader bracket

Screws (10-32 x 1/4 only)

Figure 3 Attaching Autoloader

Brackets

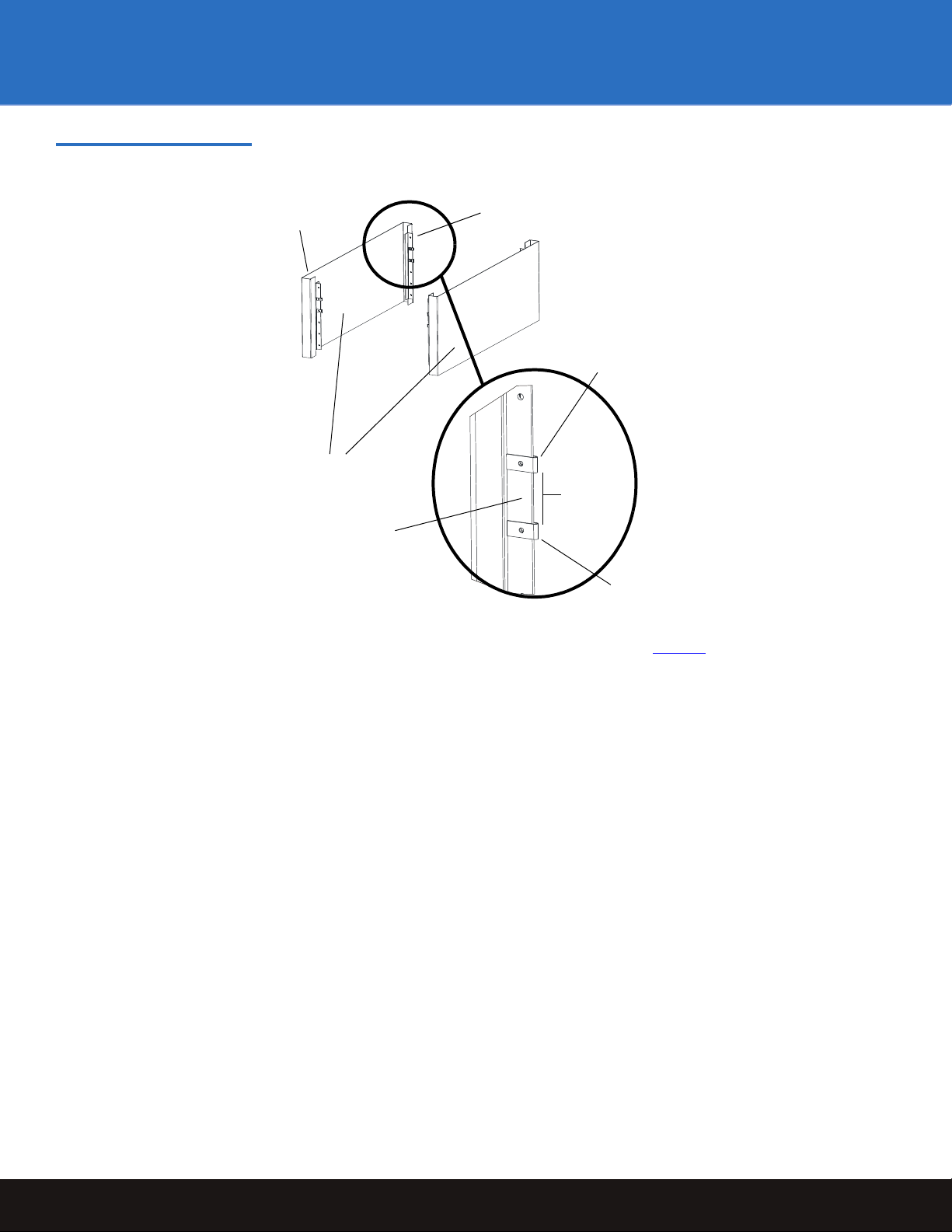

3 Using rack screws, attach a support bracket to the clip nuts on each rear rail (see

figure 4

.)

Note: Be sure to attach the support brackets correctly; the side of the bracket with

only two holes should be secured to the rail.

Tighten the screws just enough to hold the support brackets firmly against the rail

while still allowing the support bracket to be slightly shifted by hand. This shifting

will help facilitate the engagement of autoloader brackets as the autoloader is

installed in the rack. You will fully tighten the screws in step 8

.

8 Rack Mounting the Autoloader

Page 9

Figure 4 Attaching Support

Support bracket

Rack screws

Clip nuts

Rear rail in rack

Outer cover of rack

Brackets

SuperLoader 3A Series

4 With the help of a second installer, insert the autoloader into the rack so that the

autoloader brackets slide into corresponding support brackets on the rear rails and

the tabs at the front of the autoloader align flush with the clip nuts on the front rails

(see figure 5

).

Caution: Do not release the front end of the autoloader until it can be secured to

the rack.

Rack Mounting the Autoloader 9

Page 10

SuperLoader™ 3A Series Quick Start Guide

Support bracket

Autoloader bracket

Front rail

Rack screws

Tab (one per side)

Autoloader

(front)

Figure 5 Sliding Autoloader

into Rack

Figure 6 Front Alignment

5 While the other installer holds the front end of the autoloader, secure the front end of

the autoloader to the rack using four rack screws (two per tab) as shown in figure 6

Tighten the screws just enough to secure the autoloader to the front rails.

6 Install four screws (two per side) to secure the support brackets to the autoloader

brackets (see figure 7

.

).

10 Rack Mounting the Autoloader

Page 11

Figure 7 Connecting Support

Screws

Support bracket

Autoloader bracket

Brackets

SuperLoader 3A Series

7 Verify that the autoloader is level. Adjust as needed.

8 When the autoloader is level, tighten all screws securing the autoloader to the rack.

This includes the following:

• Four screws securing the autoloader tabs to the front rails.

• Four screws securing the support brackets to the rear rails.

• Four screws securing the autoloader brackets to the support brackets.

Rack Mounting the Autoloader 11

Page 12

SuperLoader™ 3A Series Quick Start Guide

Autoloader Panel Overviews

The front panel allows you to configure the autoloader, enter commands, and obtain

status information.

Figure 8 Front Panel Overview

1 Power switch

2Mailslot

3 Front panel LEDs

4 Front panel LCD screen

5 Function keys

6 Left magazine (or blank)

7 Right magazine (or blank)

Figure 9 Back Panel Overview

The Ethernet ports on the back panel allow you to connect to the A-Series tape drive FTP

file server and to the autoloader remote management interface.

1 A-Series tape drive FTP file server Ethernet port

2Fan vent

3 Power connector

4 Autoloader remote management Ethernet port

5 Power switch

12 Autoloader Panel Overviews

Page 13

Connecting Ethernet and Power Cables

To connect the Ethernet and power cables to the autoloader, follow these steps:

1 Attach one end of the Ethernet cable (included in the accessory kit) to the tape drive

Ethernet port on the back panel of the autoloader.

2 Attach the other end of the Ethernet cable to your host network port or router.

3 Attach the female connector of the power cable to the power connector on the back

panel of the autoloader.

4 Plug in the power cable to the nearest properly grounded power outlet, then turn on

the power switch on the back panel of the autoloader.

Caution: Whenever you power cycle the autoloader, allow 10 seconds before

turning the power back on. The power supply requires at least two to

three seconds for the capacitors to discharge. This ensures a complete

system reset on power down and may avoid system errors.

SuperLoader 3A Series

5 Turn on the autoloader by setting the power switch on the back panel to the

position and pressing the power switch on the front panel. Check the LCD screen to

make sure the autoloader is receiving power. If it is not, check the power connections

and your power source.

During the Power-on Self Test (POST), both LEDs are illuminated briefly, followed by

only the

the LCD screen displays the

Note: The autoloader will not complete the initialization sequence unless both

Note: When the SuperLoader 3A Series is powered up, it undergoes a media

Ready/Activity LED flashing. When the initialization sequence is complete,

Home screen.

tape magazine openings are properly closed. You can use two magazines

or one magazine and one magazine blank.

inventory. Each tape cartridge in the autoloader is inserted into the

A-Series tape drive and inventoried. Depending upon the number of

cartridges in each magazine and the amount of content or data on each

cartridge, the media cartridge inventory may take up to forty minutes.

ON

Connecting Ethernet and Power Cables 13

Page 14

SuperLoader™ 3A Series Quick Start Guide

After the Installation

From the front panel of the autoloader, use the menus to set the IP address (DHCP or

Static), Subnet Mask (if required), Gateway (if required), SNMP Server (optional), and

Time Server (optional).

The default IP address is

The default login and password for the On-board Remote Manager is

192.168.20.128.

guest and guest.

For detailed information on the setup, operation, and administration of your system

(including accessing and using the FTP file server), see the SuperLoader 3A Series User’s

Guide (PN 81-81643) and the A-Series FTP File Server User’s Guide (PN 81-81800) on the

documentation CD provided with your autoloader.

For assistance contact Quantum Technical Assistance center:

North America +1-800-284-5101

UK, France, and Germany 00800 4 QUANTUM

EMEA +44 1256 848 766

For worldwide support: www.quantum.com/contactsupport

Backup. Recovery. Archive. It’s What We Do.

©2007 Quantum Corporation. All rights reserved. Quantum, the Quantum logo, and all other

logos are registered trademarks of Quantum Corporation or their respective owners.

*81-81667-02 A01*

81-81667-02 A01

Quantum Corp. (NYSE: QTM) is the leading global storage company

specializing in backup, recovery and archive. Combining focused

expertise, customer-driven innovation, and platform independence,

Quantum provides a comprehensive range of disk, tape, media, and

software solutions supported by a world-class sales and service

organization. As a long-standing and trusted partner, the company works

closely with a broad network of resellers, OEMs, and other suppliers to

meet customer’s evolving data protection needs.

81-81667-02 A01 August 2007

Loading...

Loading...