Page 1

VLS 4mm

Installation

and

Operating Guide

Advanced Digital Information Corporation

Page 2

Copyright Notice

© Copyright

The information contained in this document is subject to change without notice.

This document contains proprietary information which is protected by copyright. All rights

are reserved. No part of this document may be photocopied, reproduced, or translated to

another language without the prior written consent of

DGLF

shall not be liable for errors contained herein or for incidental or consequential

damages (including lost profits) in connection with the furnishing, performance or use of

this material whether based on warranty, contract, or other legal theory.

Printed in the U.S.A.

DGLF

1994

DGLF

.

May 1997

Document Number 62-0075-01 Rev D

Advanced Digital Information Corporation

Telephone: (206) 881-8004

Fax: (206) 881-2296

Customer Assistance: (206) 883-HELP

World-Wide Web: http://www.adic.com

BBS: (206)883-3211

Shipping Address: 10201 Willows Road N.E.

Redmond, WA 98052

Mailing Address: P.O. Box 97057

Redmond, WA 98073-9757

DGLF

Europe

Z.A. du Bel-Air

21-23 Avenue Saint Fiacre,

Saint Germain-en-Laye,

78100 France

33 1 3087 5300

Fax: 33 1 3087 5301

DGLF

ii

and

DGLF

Europe are trademarks of Advanced Digital Information Corporation.

Page 3

Copyright Notice (Europe)

© Copyright 1995

All rights reserved. No part of this document may be copied or reproduced in any form or by

any means, without prior written permission of

Saint-Fiacre, 78100 - Saint-Germain en Laye, FRANCE.

DGLF

EUROPE assumes no responsibility for any errors that may appear in this document,

and retains the right to make changes to these specifications and descriptions at any time,

without notice.

This publication may describe designs for which patents are pending, or have been granted.

By publishing this information,

other right.

DGLF

EUROPE makes no representation or warranty with respect to the contents of this

document and specifically disclaims any implied warranties of merchantability or fitness for

any particular purpose. Further,

publication without obligation on the part of

organization of such revision of change.

Every effort has been made to acknowledge trademarks and their owners. Trademarked

names are used solely for identification or exemplary purposes, any omissions are made

unintentionally.

DGLF

Europe

DGLF

EUROPE, Z.A. du Bel-Air, 21 avenue

DGLF

EUROPE conveys no license under any patent or any

DGLF

EUROPE reserves the right to revise or change this

DGLF

EUROPE to notify any person or

iii

Page 4

EMI/RFI Compliance

United States – FCC

:

WARNING

B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or

television reception (which can be determined by turning the equipment off and on) the user

is encouraged to try to correct the interference by one or more of the following measures:

•

•

•

•

You may find the following booklet prepared by the Federal Communications Commission

helpful: How to Identify and Resolve Radio-TV Interference Problems. This booklet is

available from the U.S. Government Printing Office, Washington, DC 20402, Stock No.

004-000-00354-04.

Canada – Department of Communications

This equipment has been tested and found to comply with the limits for a Class

Re-orient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

This digital apparatus does not exceed the Class B limits for radio noise emissions from

digital apparatus as set out in the interference-causing equipment standard entitled "Digital

Apparatus", ICES-003 of the Department of Communications.

Cet appareil numérique respecte les limites de bruits radioélectriques applicables aux

appareils numériques de Class B prescriptes dans la norme sur le matériel brouilleur:

"Appareils Numériques", NMB-003 édictée par le ministre des Communications.

Shielded Cables

Shielded data cables are required in order to meet EMI/RFI limit specifications. The

data cable meets this requirement. If you need a replacement cable, be sure to use an

approved shielded cable (to assure acceptability to EMI/RFI requirements).

Two or more VLS units cabled to each other on the same SCSI channel must have a ferrite

bead clamped on the interface cable between the units. The ferrite bead is required to satisfy

the EMI/RFI limit specification. See Appendix A for instructions on installing the ferrite

bead.

iv

DGLF

DGLF

-

Page 5

Declaration of Conformity

according to EN 45014

Manufacturer’s Name: Advanced Digital Information Corporation

Manufacturer’s Address: 10201 Willows Road NE 21-23 Av. Saint-Fiacre

Redmond, WA

98052

USA France

declares, that the product:

Product Virtual Library System

(Produit, Erzeugnis):

Model Number VLS 4mm

(Marque Commercial,

Warenbezeichnung):

conforms to the following international specifications, as required by 89/336/EEC & 92/31/EEC:

EMI: EN 50081-1, EN-55022 Class B

EMC: EN 50082-1, IEC 801-2, IEC 801-3, IEC 801-4

Safety: EN 60950

F-78100 Saint-Germain-en-Laye

Supplementary Information:

Redmond, Washington USA 3-Jan-1996

Location Date Signature/Title

Project Engineering Mgr

v

Page 6

Safety Warnings

All safety and operating instructions should be read before this product

is operated, and should be retained for future reference. This unit has

been engineered and manufactured to assure your personal safety.

Improper use can result in potential electrical shock or fire hazards. In

order not to defeat the safeguards, observe the following basic rules for

its installation, use and servicing.

1. Heed Warnings - All warnings on the product and in the operating instructions

should be adhered to.

2. Power Source - The product should be connected to a power source only of the

type directed in the operating instructions or as marked on the product.

3. Power Cord Protection - The AC line cord should be routed so that it is not likely

to be walked on or pinched by items placed upon or against it, paying particular

attention to the cord at the wall receptacle, and the point where the cord exits from

the product.

4. Power Switch - The power switch used in this product does not disconnect both

supply conductors when placed in the

power from this product, unplug the AC power cord from the receptacle on the

back of the unit.

Caution

OFF

position. To completely disconnect

5. Servicing - The user should not attempt to service the product beyond that

described in the operating instructions. All other servicing should be referred to

qualified service personnel.

vi

Page 7

Table of Contents

Copyright Notice...................................................................................................................

Copyright Notice (Europe) ...................................................................................................

EMI/RFI Compliance...........................................................................................................

Safety Warnings ..................................................................................................................

Quickstart............................................................................................................................

Chapter 1: Getting Started.................................................................................................... 1

Introduction.............................................................................................................. 2

Requirements............................................................................................................ 2

Unpack and Inspect .................................................................................................. 3

Equipment Description ............................................................................................. 4

The VLS Unit .............................................................................................. 4

Magazine..................................................................................................... 4

Media .......................................................................................................... 5

Cleaning Cassette......................................................................................... 6

System Software....................................................................................................... 6

Preparing the Host Computer System........................................................................ 7

Power Off the Computer .............................................................................. 7

Confirm and/or Install the SCSI Host Interface............................................. 7

Chapter 2: Connecting the VLS ............................................................................................ 9

Connecting the Interface Cables.............................................................................. 10

Connecting More Than One VLS............................................................................ 12

Powering on the System.......................................................................................... 13

Installing the Backup Software ............................................................................... 14

iii

ii

iv

vi

ix

Chapter 3: Equipment Description ...................................................................................... 15

Front Panel Switches and Indicators........................................................................ 16

Rear Panel Switches and Connectors....................................................................... 18

Menu Items ............................................................................................................ 18

Configuration Menu................................................................................... 20

Buzzer Configuration .................................................................... 20

SCSI ID Config............................................................................. 21

SCSI Parity................................................................................... 22

Off-Line Time ............................................................................... 22

vii

Page 8

Drive Configuration....................................................................... 23

On-Line Mode............................................................................... 23

Sequential-Access Mode Configuration.......................................... 24

Diagnostics Menu ...................................................................................... 25

Write EEPROM Mode............................................................................... 26

Chapter 4: Operation and Maintenance ............................................................................... 27

DDS-2 Media......................................................................................................... 28

Inserting Data Cassettes into the Magazine ............................................................. 29

Inserting the Magazine into the VLS ....................................................................... 31

Loading the Magazine ............................................................................................ 33

Attempting to Load the Magazine with a Cassette Already in Drive......................... 34

Manually Removing a Cassette Loaded in the Drive ................................... 35

Removing the Magazine from the VLS.................................................................... 36

Removing the Magazine while a Cassette is in the Drive ............................. 37

Loading an Individual Cassette ............................................................................... 37

Removing a Cassette from the Magazine................................................................. 39

Storing the Magazine.............................................................................................. 39

Cleaning the Drive Head......................................................................................... 39

Cleaning the Enclosure ........................................................................................... 43

Chapter 5: Troubleshooting and Diagnostics...................................................................... 45

VLS Error Messages .............................................................................................. 46

Error Messages ...................................................................................................... 47

Drive Warning Signals ........................................................................................... 49

Environmental Considerations................................................................................. 52

When You Call ADIC Customer Assistance............................................................ 52

Return for Repair RMA (Return Merchandise Authorization).................................. 54

Appendix A: Installing the Ferrite Bead.............................................................................. 55

Appendix B: Diagnostics Menu.......................................................................................... 57

Appendix C: Glossary........................................................................................................ 65

Appendix D: Specifications................................................................................................ 71

Index .................................................................................................................................. 75

viii Table of Contents

Page 9

Quickstart

This Section …

❐

provides a quickstart guide for experts who are familiar with

installing computer hardware and software.

ix

Page 10

Note

DXU F<C XQc RUU^ cXY``UT gYdX dXU C3C9 94 V_b TbYfU 1 cUd Qd ²!³ TbYfU

2 cUd Qd ²"³ Q^T dXU b_R_dYSc cUd Qd ²#³

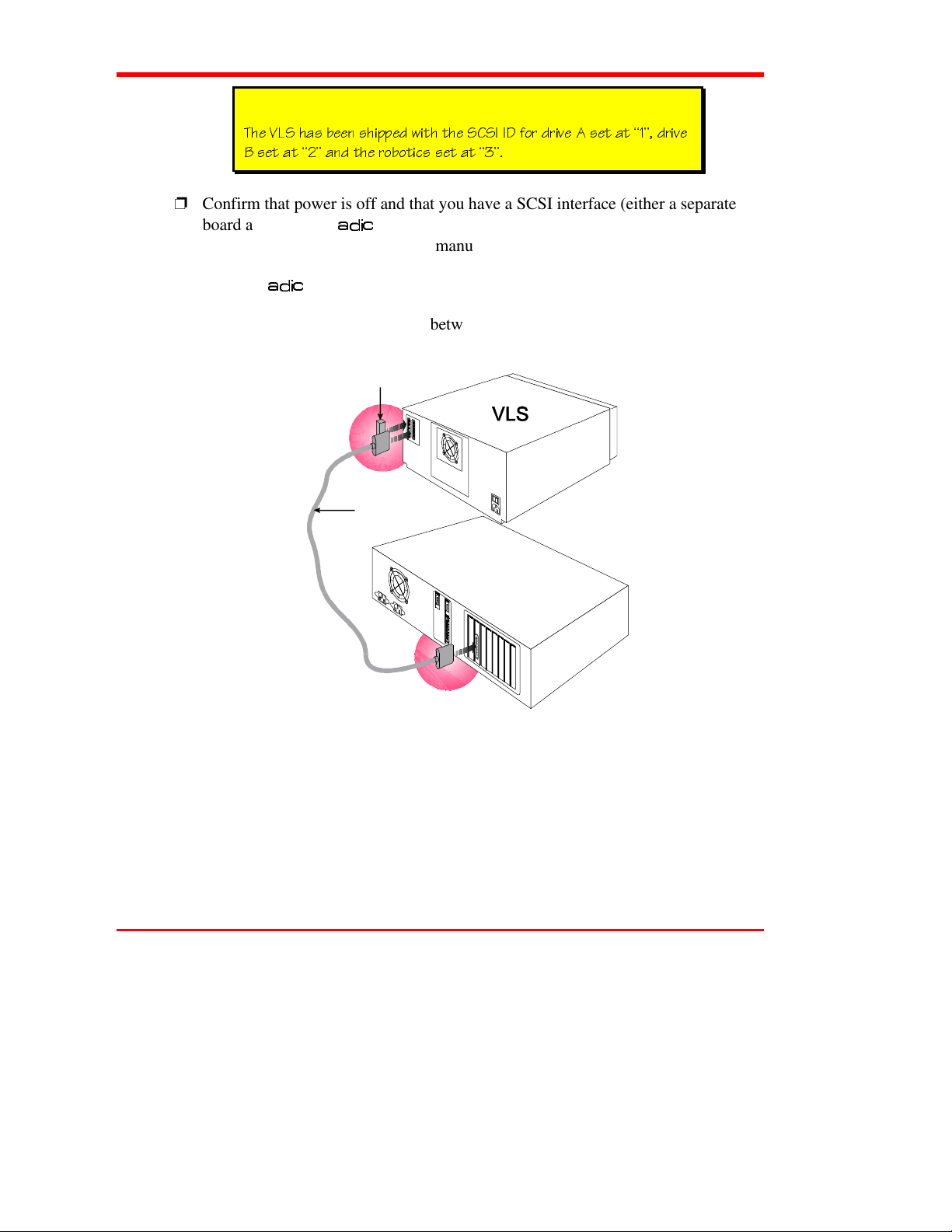

❐

Confirm that power is off and that you have a SCSI interface (either a separate

board as offered by

DGLF

or integrated on the mother-board) installed in the host

computer. Consult your computer manual.

❐

Place the

❐

Connect the SCSI interface cable between the SCSI connectors on the computer

DGLF

VLS near the host computer to which it will be connected.

and the back of the VLS.

Terminator

SCSI

Interface

Cable

Host Computer

❐

Make sure there is a terminator installed on the last device of the SCSI chain.

x Quickstart

Page 11

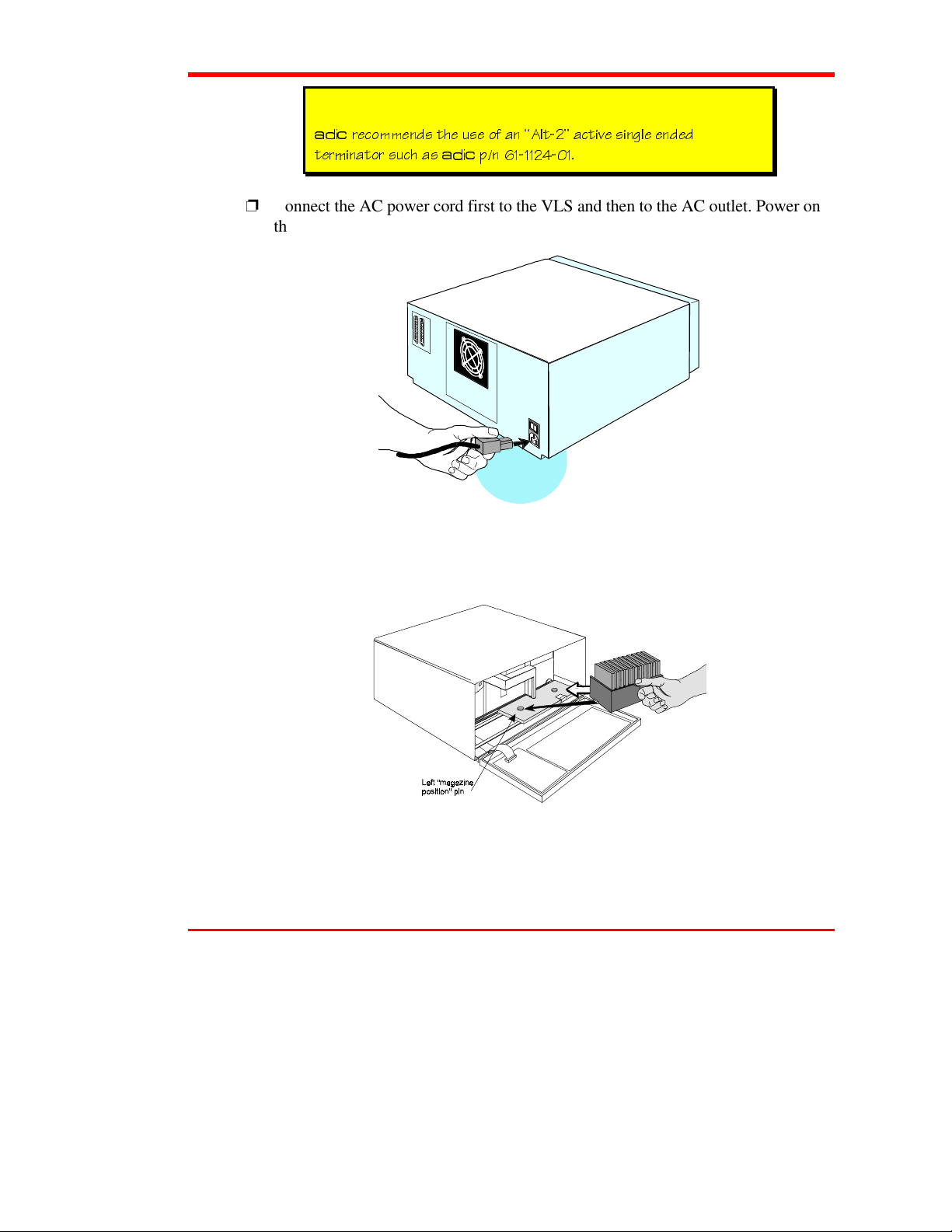

Note

DGLF

bUS_]]U^Tc dXU ecU _V Q^ ²1\d"³ QSdYfU cY^W\U U^TUT

DGLF

dUb]Y^Qd_b ceSX Qc

❐

Connect the AC power cord first to the VLS and then to the AC outlet. Power on

`^ &!!!"$ !

the VLS. Power on the host computer.

❐

Place the magazine on the carriage by slipping it over the left “magazine position”

pin and then rotating toward the right and pressing into place on the right

“magazine position” pin.

❐

If the application has not already done so, load the magazine by pressing first the

button and then the

ALT

LOAD

button. (If you are in sequential mode, the first

cassette will be inserted in the drive when the load finishes.)

Quickstart xi

Page 12

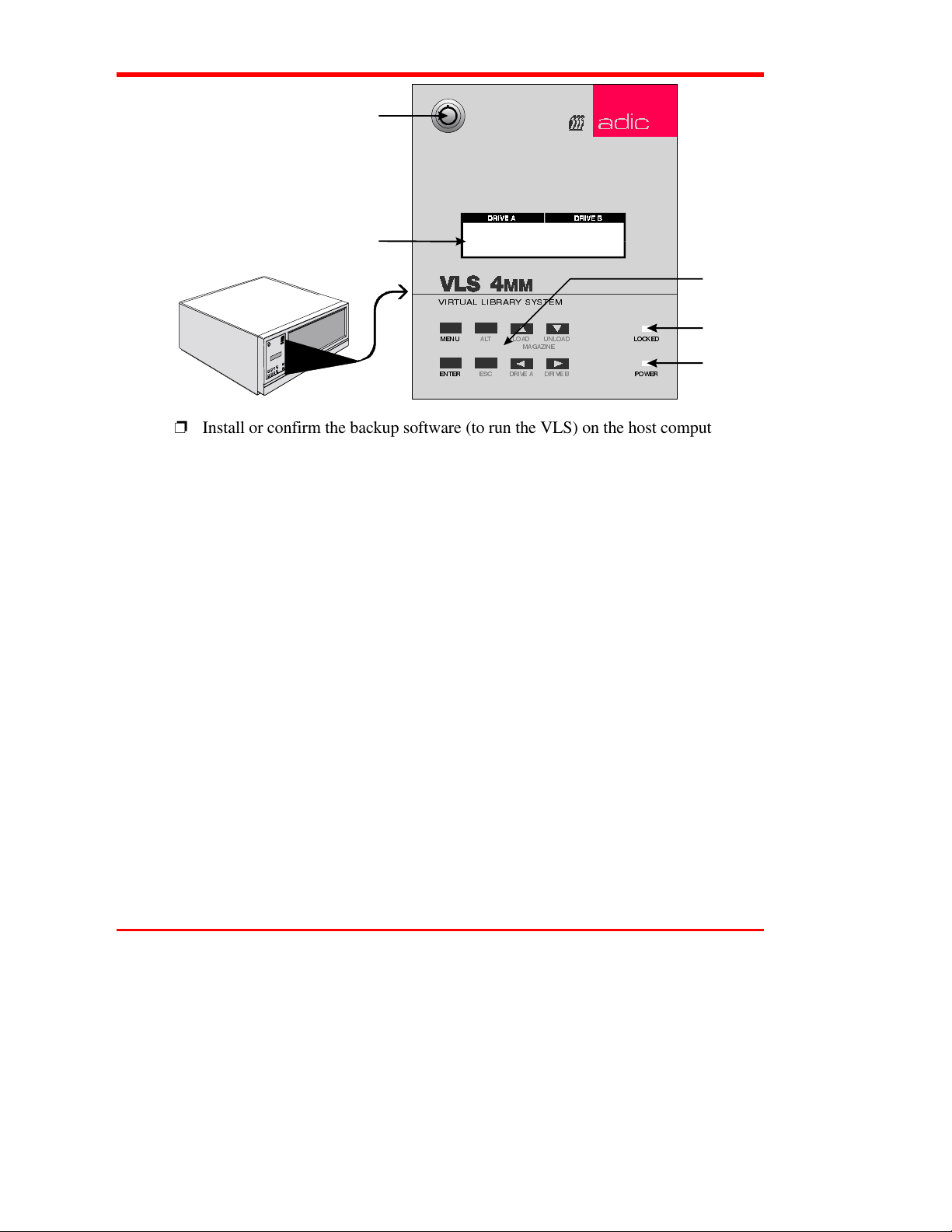

Lock

yKey

16-Character

Displa

9,578$/ /,%5$5<

❐

Install or confirm the backup software (to run the VLS) on the host computer.

❐

Run any diagnostic tests provided with the backup software to make sure the VLS

6<67(0

0$*$=,1(

'5,9( $

(6&(17(5 32:(5

'5,9(%

/2&.('/2$' 81/2$'$/70(18

is communicating correctly with the host computer.

You are now ready to run the VLS at a system level.

pad

Locked

LED

Power

LED

xii Quickstart

Page 13

Getting Started

This Chapter …

❐

covers what you need (and what you need to know) to install the

DGLF

Virtual Library System. Read this section before you begin

installation.

Chapter

1

1

Page 14

Introduction

The Virtual Library System (VLS) is designed for high-capacity, near and off-line

storage applications, backup, hierarchical storage management (HSM), and

video/design/data file libraries. For the most part, installation is simply a matter of

checking all necessary SCSI connections, installing the software (backup or otherwise)

and applying power. The defaults set at the factory should be sufficient for most

applications.

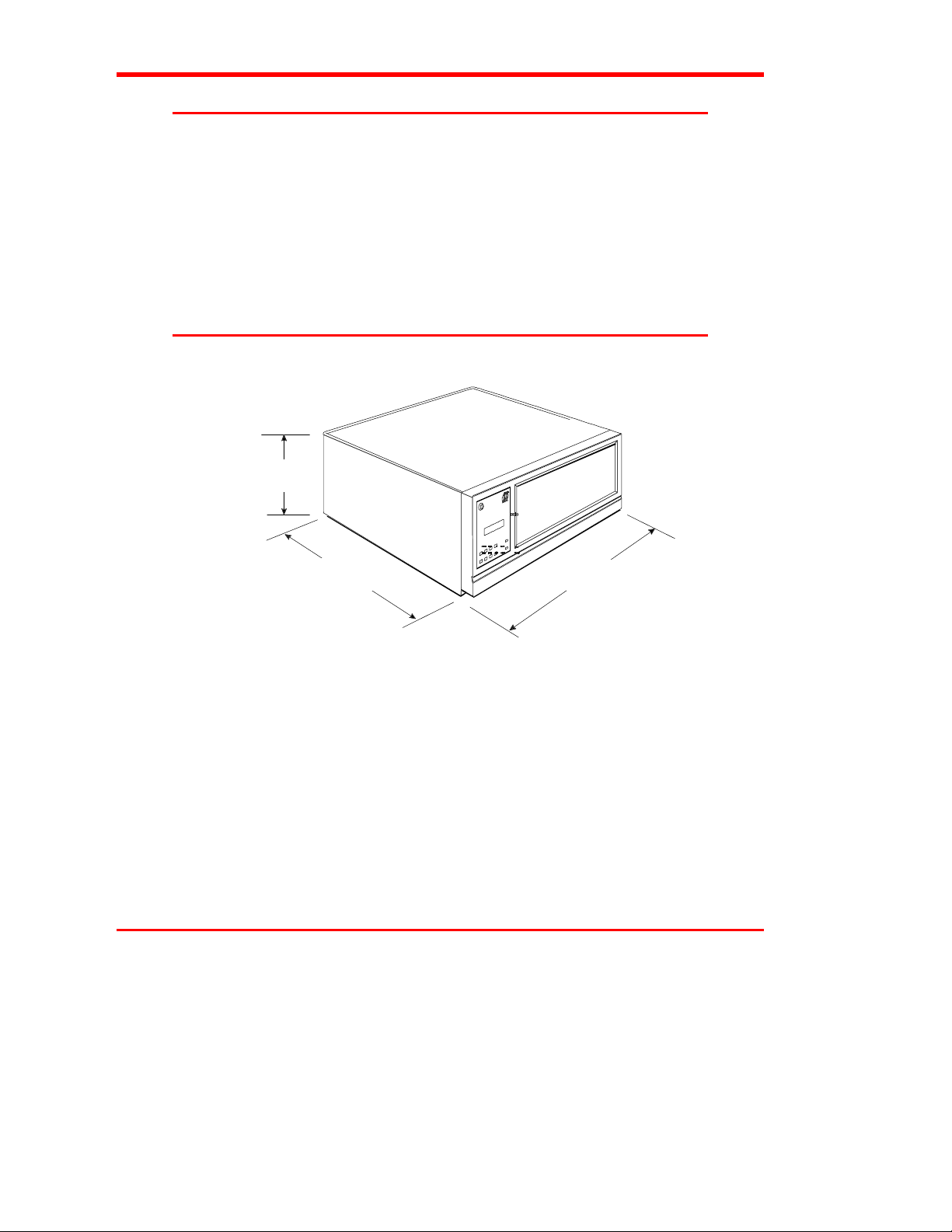

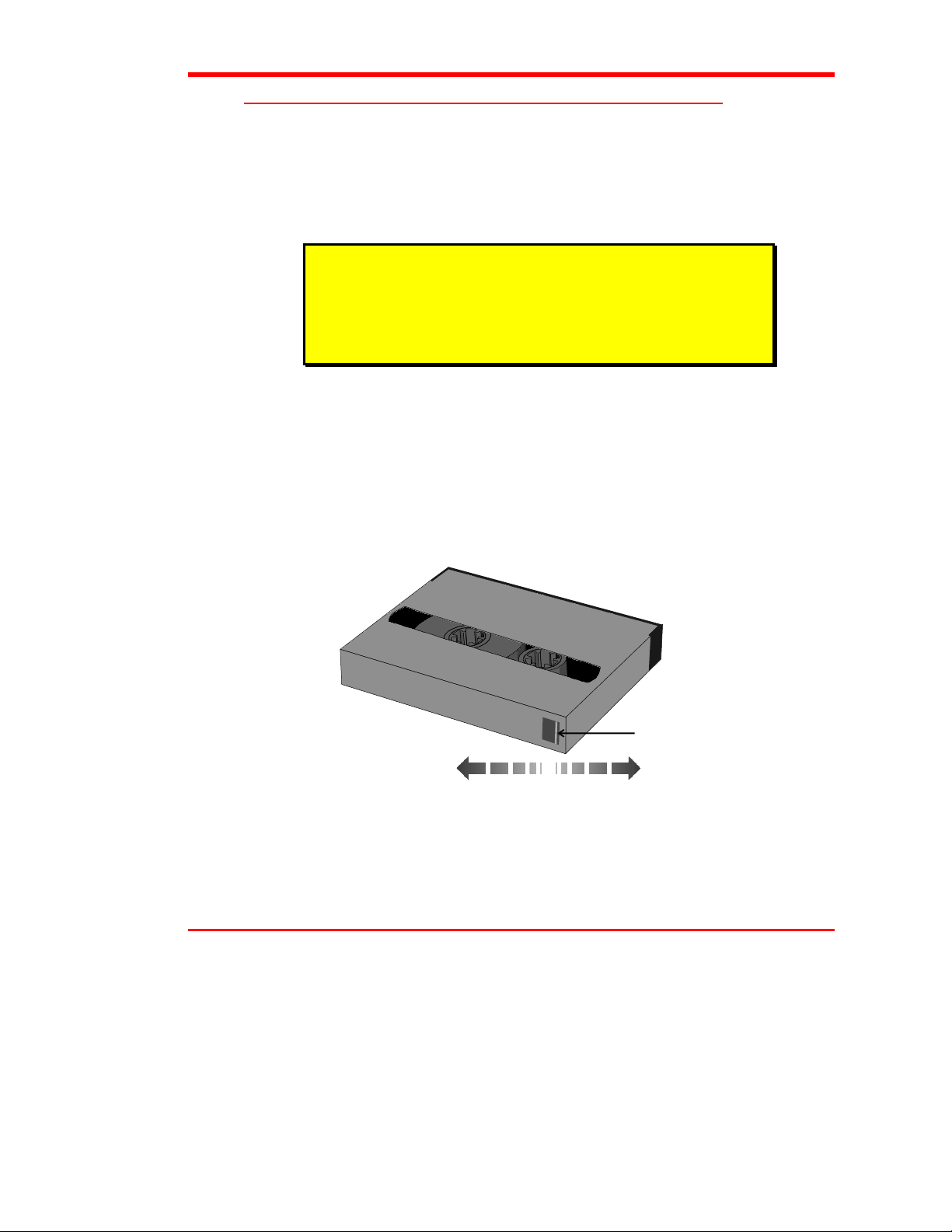

Requirements

8.0 in.

20.3 cm

❐

Space requirements: the VLS has a footprint of 17.4" x 15.8". You must allow

adequate clearance to the rear and bottom to allow air flow and enough room at

the front to open the door which stands 8" high and is hinged at the bottom.

❐

We assume that you are familiar with your computer system. The VLS must be

incorporated into the host computer system. The backup software, SCSI interface

and SCSI interface cable(s) must be purchased separately.

❐

Mode of operation: You must know whether the VLS will be operating in

sequential or random-access mode. This will be determined by the backup

software you use.

2 Getting Started

15.8 in.

40.1 cm

17.4 in

44.2 cm

Page 15

❐

Necessary tools: No special tools are required to install the VLS. If you are

installing a host adapter (SCSI controller) card at this time, refer to the installation

manual for your host adapter.

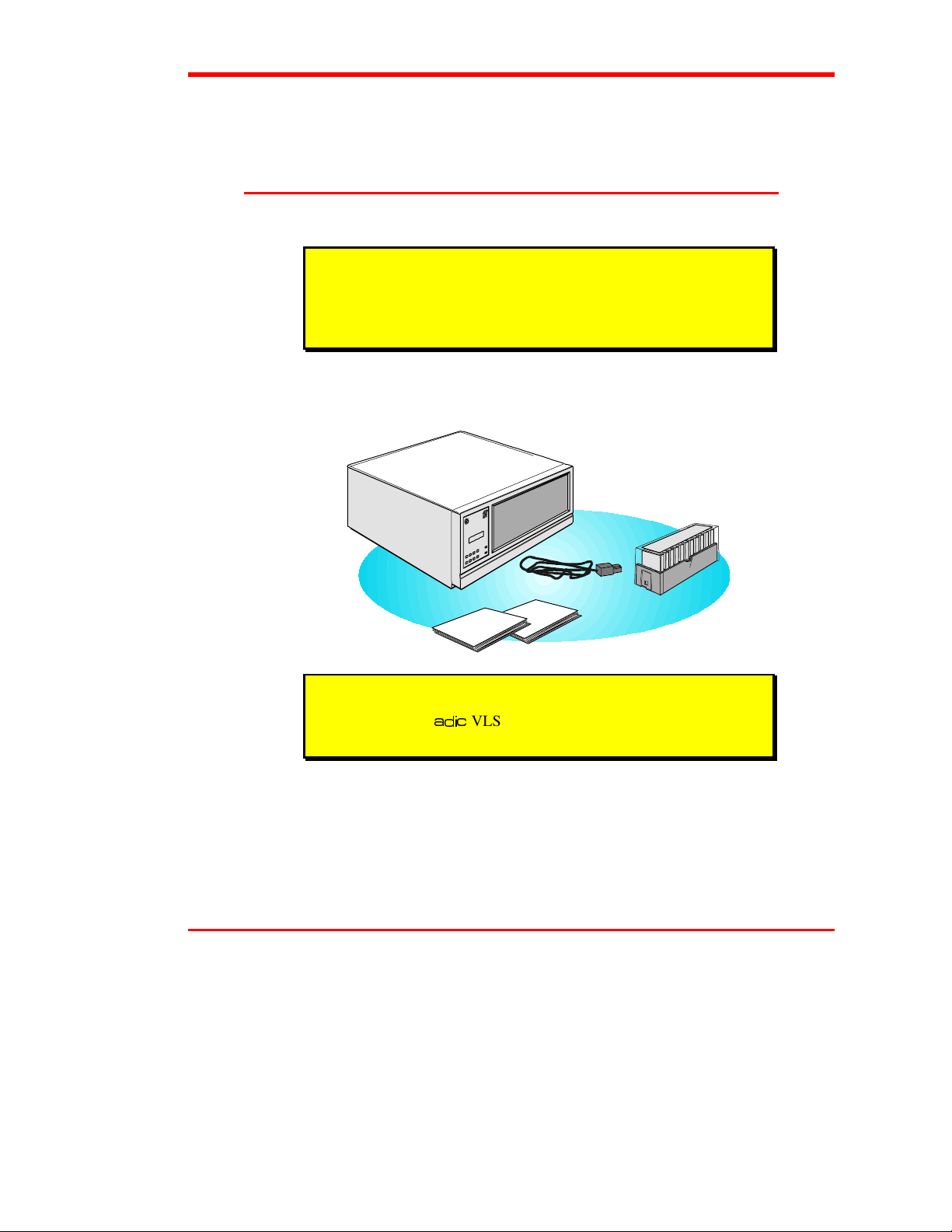

Unpack and Inspect

Caution

If the operating environment differs from the storage environment by

15° C (30° F) or more, let the unit acclimate to the surrounding

environment for at least 12 hours.

❐

Unpack all items from the carton. Save the packing materials in case you need to

move or ship the system in the future.

adic

ONLINERESET UP DOWN

LOCK

MENU ENTER LEFT RIGHT

POWER

Caution

DGLF

You must ship the

VLS in the original or equivalent packing

materials or your warranty may be invalidated.

Getting Started 3

Page 16

Equipment Description

The VLS Unit

DGLF

The

system designed with a removable data cassette magazine. The door can be locked to

deactivate the unit's keypad, assuring only authorized removal of the magazine and

media. In addition, to protect the unit, data and media, the VLS will not operate unless

the door is closed.

Magazine

VLS is a fully automated, high performance, high capacity, mass storage

Note

DGLF

cdb_^W\i bUS_]]U^Tc dXQd i_e ecU

]UTYQ

_^\i 4_ ^_d QddU]`d d_ ecU QeTY_WbQTU ]UTYQ ceSX ]UTYQ

SQ^ TQ]QWU dXU XUQTc Q^T dQ`U XQ^T\Y^W `Qbdc ° f_YTY^W i_eb

gQbbQ^di

DGLF

Q``b_fUT TQdQWbQTU

The magazine for the VLS holds fifteen 4mm cassettes. It includes a clear dust cover

to protect the cassettes and for ease of storage. Figure 1 shows a 4mm cassette and a

filled magazine with the cover in place.

Figure 1. VLS Magazine for 4mm Cassettes

4 Getting Started

Page 17

Media

The 4mm VLS uses 4mm DDS data cassettes. Before inserting the cassette into the

magazine check the position of the write-protect switch. Set all switches to the enabled

position – hole closed (refer to Figure 2). (The write-protect switch enables or disables

the ability to write [or delete] files on the data cassette.)

Caution

Only cassettes labeled "DDS" should be used.

cassettes, because the media is not certified. Also, DAT cassettes have

a different mechanical specification which can cause them to jam in

the mechanism.

❐

To write-protect the data cassette, move the write-protect switch away from the

Never

use audio DAT

edge of the data cassette, as shown in Figure 2. If the hole is open, the cassette is

write protected and cannot be written to (or erased).

❐

To write-enable the data cassette, move the write-protect switch toward the edge

of the data cassette, as shown. If the hole is closed, the data cassette is write

enabled and can be written to or erased. Use a ball-point pen or similar instrument

to set the write-protect switch.

Write-Protect

Switch

Open

(Protected)

Figure 2. 4mm Cassette Showing Write-Protect Switch

Closed

(Unprotected)

Getting Started 5

Page 18

Cleaning Cassette

The tape heads should be cleaned after every 8 to 10 hours of tape motion or when the

Media Caution indication is displayed. A cleaning cassette (ADIC 39-1028-01) is

shipped with your

with the same or equivalent type cleaning cassette. See Cleaning the Drive Head later

in this manual.

DGLF

VLS. Discard it after approximately 20 uses and replace it

System Software

A variety of backup and data storage software is available for use with the VLS.

Please check with

compatibility of a particular software package.

6 Getting Started

DGLF

Figure 3. 4mm Cleaning Cassette

Sales or Customer Assistance if you have a question on the

Page 19

Preparing the Host Computer System

Power Off the Computer

❐

Turn off the power switch.

❐

Unplug the cord from the AC outlet.

Confirm and/or Install the SCSI Host Interface

The VLS must be connected to either an integrated SCSI host or a SCSI interface

(host adapter) card installed in the computer – either directly to the I/O connector on

the card or as part of an existing SCSI chain. The SCSI interface must be installed

before you connect the VLS. Refer to the instructions supplied with your selected

SCSI interface.

Now you are ready to connect the VLS to your host computer. Follow the instructions

provided in the next chapter.

Note

DXU X_cd S_]`edUb cicdU] ^_b]Q\\i Yc dXU cUbfUb

Getting Started 7

Page 20

Blank Page

8 Getting Started

Page 21

Connecting the VLS

This Chapter …

❐

provides instructions for physically connecting your VLS to your

host system.

❐

steps you through the final phase of the installation process.

Chapter

2

9

Page 22

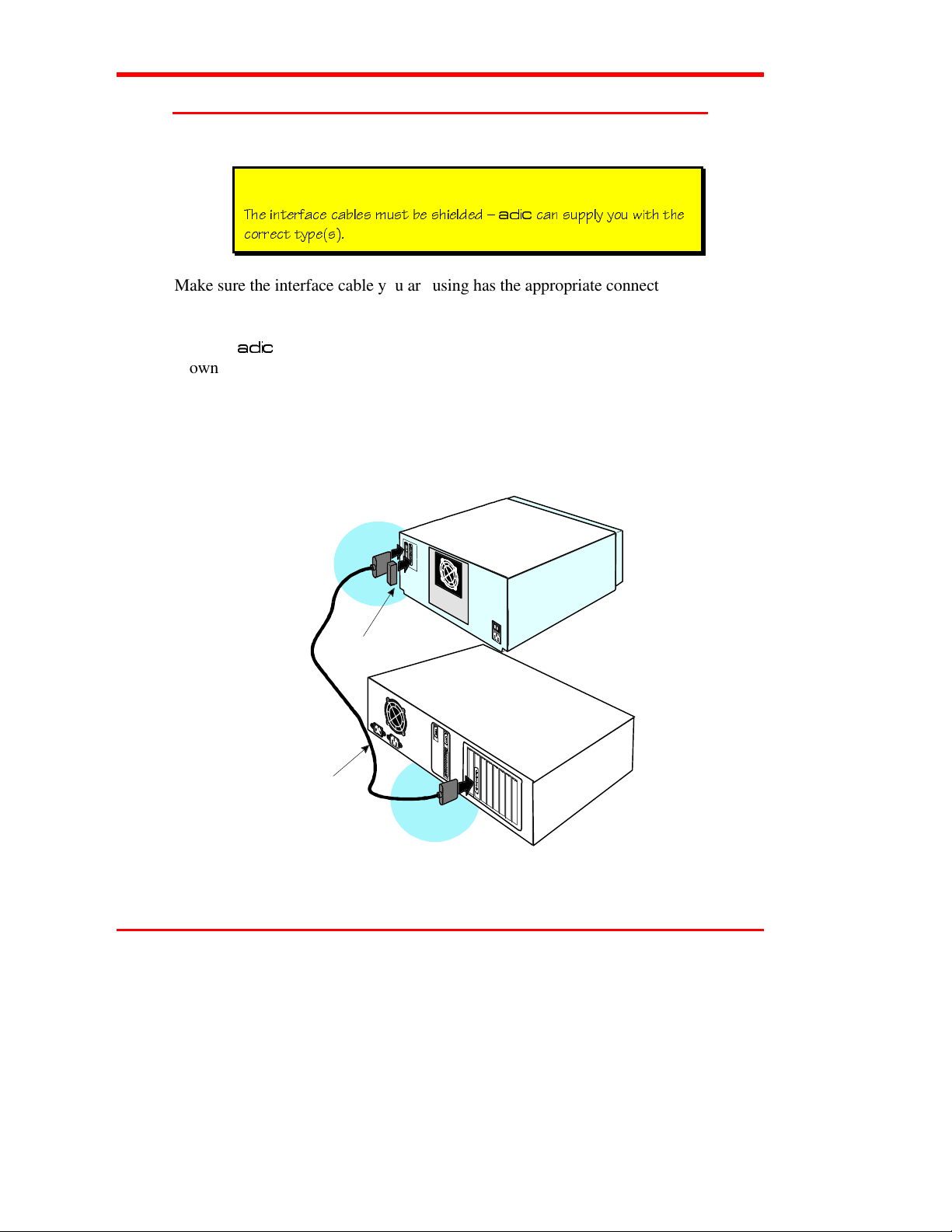

Connecting the Interface Cables

Note

DGLF

DXU Y^dUbVQSU SQR\Uc ]ecd RU cXYU\TUT °

S_bbUSd di`Uc

Make sure the interface cable you are using has the appropriate connectors on each

end. If the host computer's SCSI connector is different from that on the VLS, you will

need to obtain a different cable than the one supplied with the unit. Consult your

dealer or

DGLF

Customer Assistance if you need help. Connect the interface cables as

shown in Figure 4 and explained in the following steps:

❐

Check that the power switches on both the VLS and the host computer are off.

❐

Attach one end of the SCSI interface cable to either connector on the rear of the

VLS. Press firmly and secure the bail locks.

VLS

SQ^ ce``\i i_e gYdX dXU

Terminator

SCSI

Interfac e

Cable

Figure 4. Connecting the Interface Cables

10 Connecting the VLS

Host Computer

Page 23

Note

DXU RQY\ \_S[c Qd R_dX U^Tc _V dXU C3C9 SQR\U ]ecd RU cUSebU\i

VQcdU^UT Y^ _bTUb V_b dXU F<C d_ S_]]e^YSQdU `b_`Ub\i gYdX dXU

S_]`edUb

❐

Plug the other end of the SCSI interface cable into the external connector on the

SCSI port card. Secure firmly.

❐

If this is the only unit you are installing, insert an external terminator plug into the

second SCSI connector at the rear of the VLS. If you plan to connect another unit

on the same SCSI channel, see the next section.

Connecting the VLS 11

Page 24

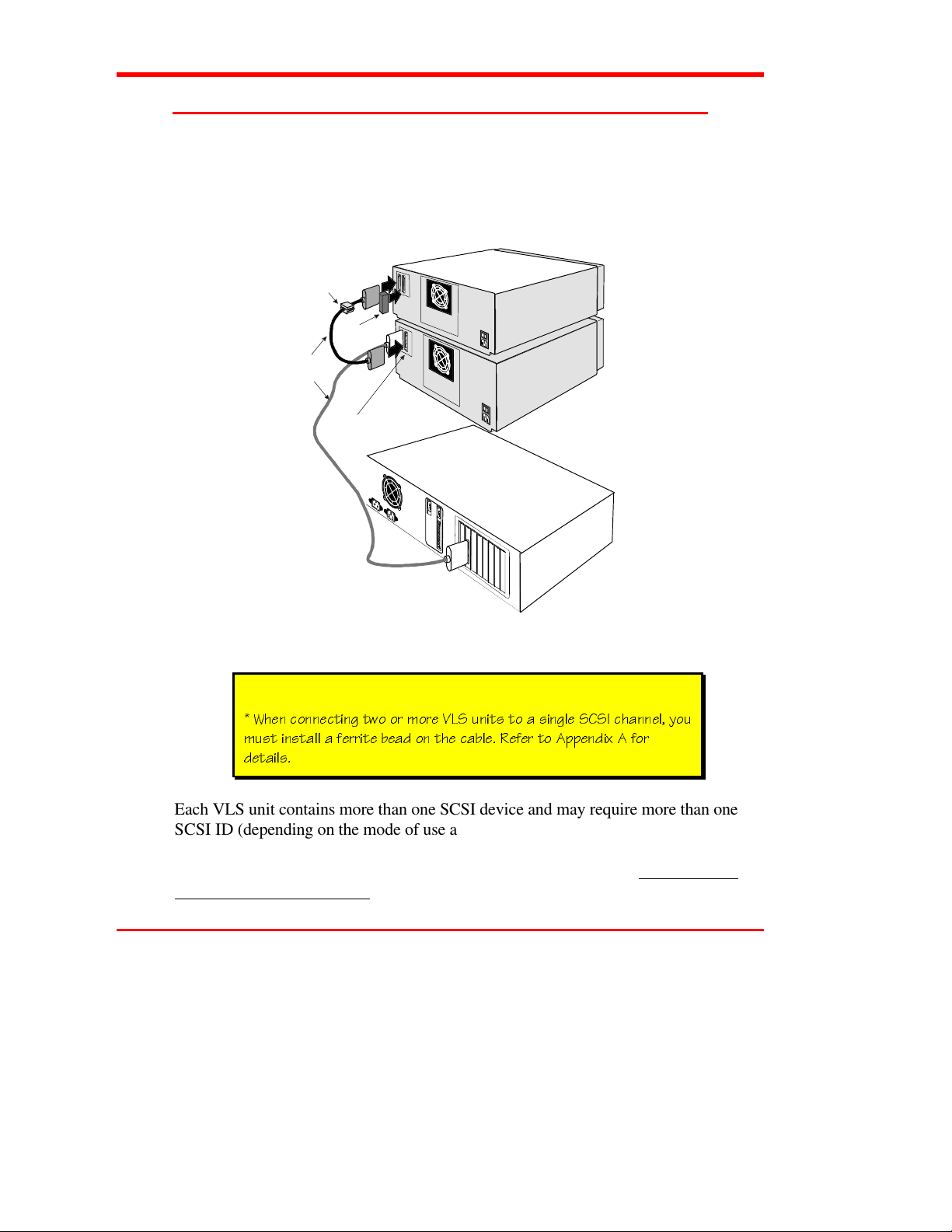

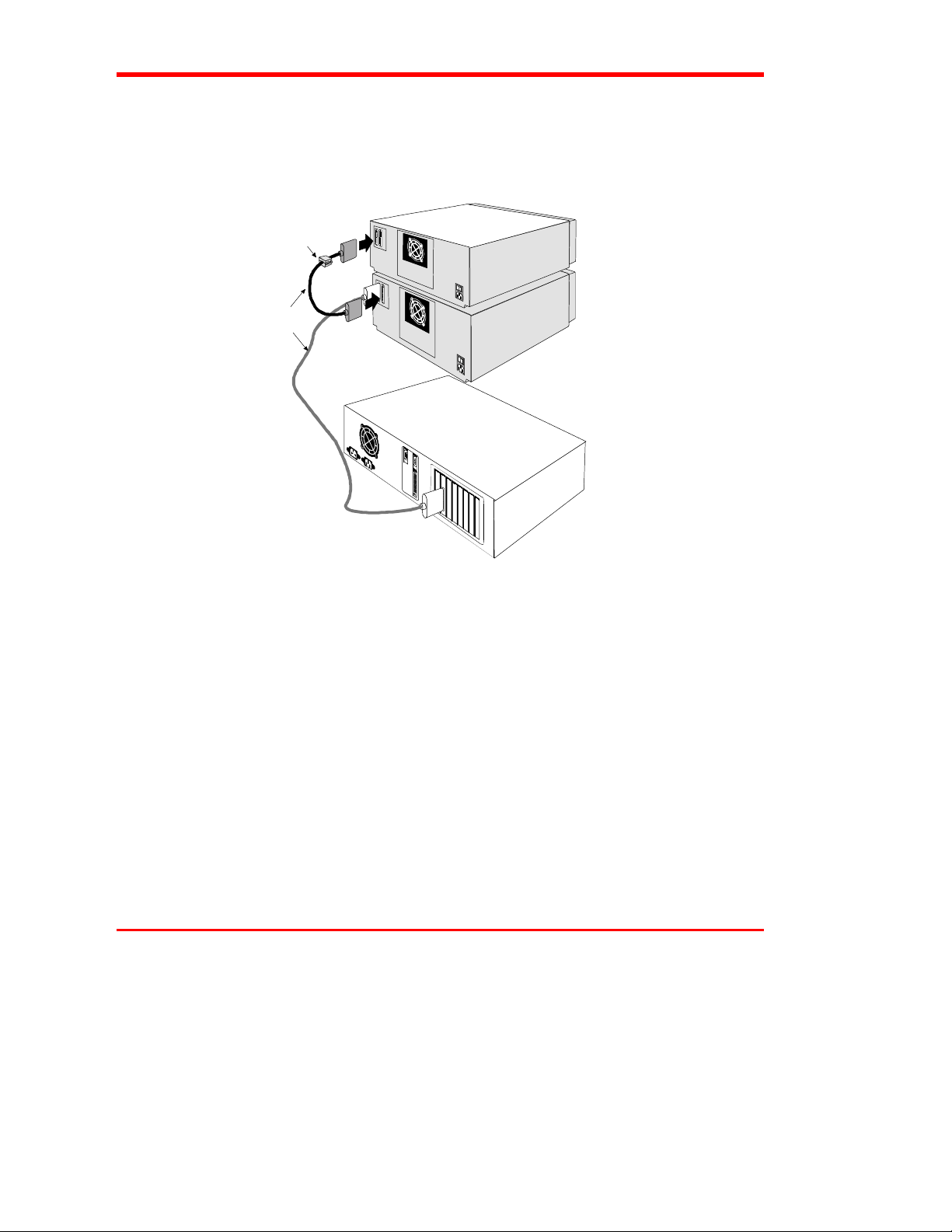

Connecting More Than One VLS

If you are connecting additional VLS units on the same SCSI channel, simply attach

each subsequent unit to the previous unit with an interface cable. Make sure all cables

are properly secured. You can attach up to seven devices on each SCSI channel.

2 VLS units

*Ferrite

Bead

SCSI

Interfac e

Cable

Terminator

I/O

Connectors

Host

Computer

(On s am e

SCSI

Channel)

Figure 5. Cable Diagram for two VLS Units

GXU^ S_^^USdY^W dg_ _b ]_bU F<C e^Ydc d_ Q cY^W\U C3C9 SXQ^^U\ i_e

]ecd Y^cdQ\\ Q VUbbYdU RUQT _^ dXU SQR\U BUVUb d_ 1``U^TYh 1 V_b

TUdQY\c

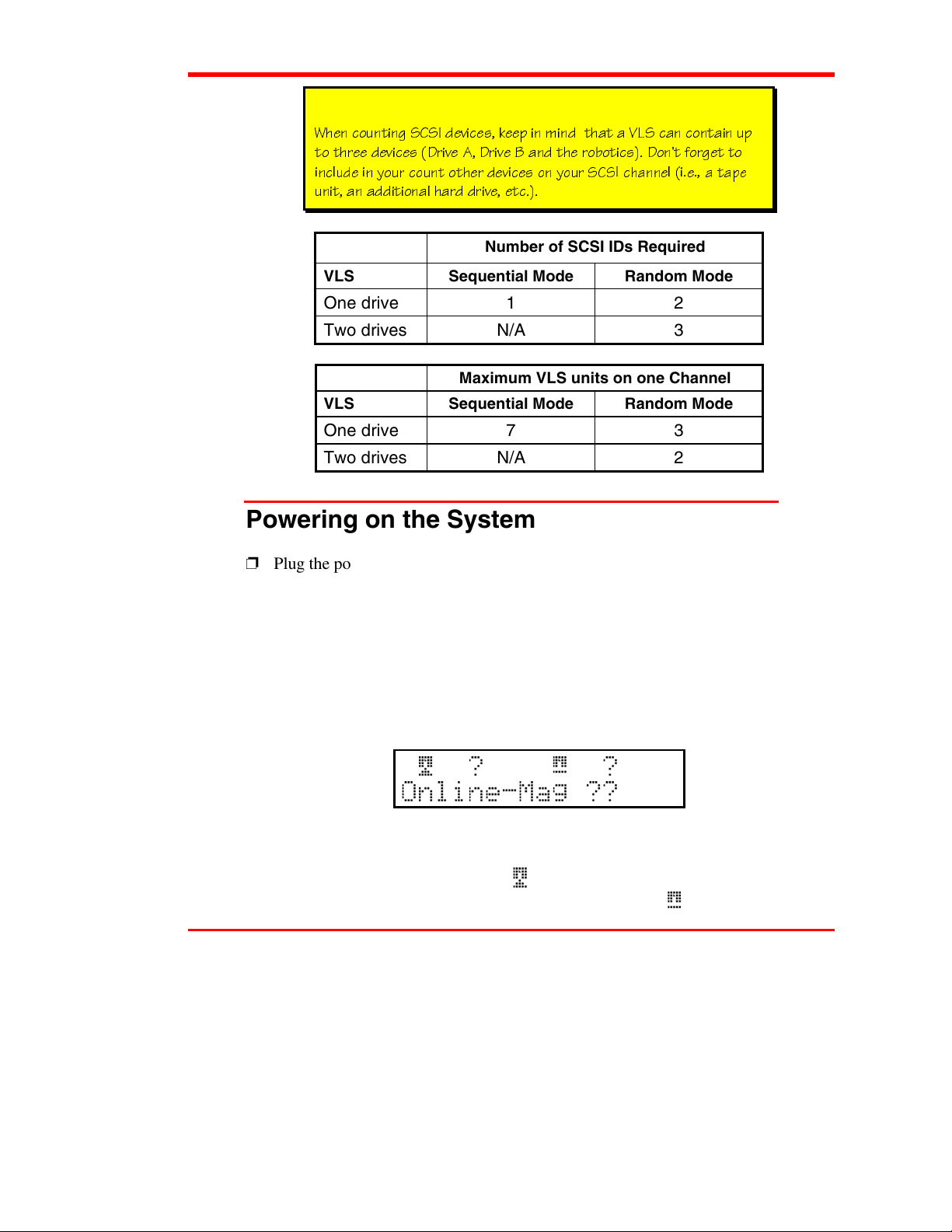

Each VLS unit contains more than one SCSI device and may require more than one

SCSI ID (depending on the mode of use and number of drives). The first chart below

shows various configurations and the number of SCSI IDs required. The second chart

illustrates how many VLS units you can attach to one SCSI channel (if there are no

other devices on the channel).

12 Connecting the VLS

Note

Page 25

Note

GXU^ S_e^dY^W C3C9 TUfYSUc [UU` Y^ ]Y^T dXQd Q F<C SQ^ S_^dQY^ e`

d_ dXbUU TUfYSUc 4bYfU 1 4bYfU 2 Q^T dXU b_R_dYSc 4_^d V_bWUd d_

Y^S\eTU Y^ i_eb S_e^d _dXUb TUfYSUc _^ i_eb C3C9 SXQ^^U\ YU Q dQ`U

e^Yd Q^ QTTYdY_^Q\ XQbT TbYfU UdS

Number of SCSI IDs Required

VLS Sequential Mode Random Mode

One drive 1 2

Two drives N/A 3

Maximum VLS units on one Channel

VLS Sequential Mode Random Mode

One drive 7 3

Two drives N/A 2

Powering on the System

❐

Plug the power cord into the back of the VLS.

❐

Plug the power cord from the VLS into a grounded electrical outlet.

❐

Plug the power cord from your host computer into a grounded electrical outlet.

❐

Turn on the VLS power. Turn on the host computer power.

A display similar to the following will appear on the VLS display:

The top line of the LCD is logically divided into a Drive A side (left), and a Drive B

side (right). When the VLS is in the On-Line mode, the LCD displays the current

status of the drives on the top line. The

configured, on-line, and is aligned with the Media Picker. The

symbol indicates that the drive is

symbol indicates that

Connecting the VLS 13

Page 26

the drive is configured and on-line, but is not aligned with the Media Picker. The

symbol indicates that there is no

configured

drive in that position. The in the 5

th

character position for each drive indicates that the VLS does not know if a cartridge is

currently loaded in that drive. If the VLS had loaded a cartridge into a drive prior to

shut-down, this character and the one proceeding it would reflect the slot number of

th

the magazine that the cartridge was loaded from (01 to 15). The 7

may display a

symbol, indicating that the drive is actively writing or reading.

character position

The bottom line of the LCD, when the VLS is in the On-Line mode, displays the

current status of the magazine. The

characters indicate that the VLS

does not know the current status of the magazine. This is normal immediately

following power-up. If the magazine had been loaded prior to shut-down, the VLS

would display

when repowered..

You are now ready to install the backup software – if it has not already been installed.

Installing the Backup Software

At this point you need to refer to your software installation guide for instructions on

installing the backup/controlling software for the VLS onto the host computer.

After you have completed installation of the VLS and the backup/controlling software,

make sure that your unit is operating correctly by running any diagnostic test(s)

supplied with the backup software.

14 Connecting the VLS

Page 27

Equipment Description

This Chapter …

❐

describes the switches, indicators and connectors on the front and

rear of the VLS.

❐

describes the various functions available via the front panel

buttons.

Chapter

3

❐

describes the power-up procedure and messages on the front

panel LED display.

15

Page 28

Once your VLS has been connected to your host computer system and the software

yKey

has been installed, the VLS is ready for use. Just turn on the power switch, place a

magazine on the carriage and press

DXYc Yc dXU c_VdgQbU dXQd be^c dXU F<C ^_d dXU TQdQ RUY^W

dbQ^cVUbbUT d_ dXU F<C SQccUddUc Dg_ UhQ]`\Uc _V RQS[e` c_VdgQbU

QbU 3XUiU^^Uc 1B3cUbfU Q^T <UWQd_c >UdG_b[Ub

ALT

and then

Note

LOAD

.

If you need to change certain operating functions, you can use the front panel buttons

(as described in the next section).

Front Panel Switches and Indicators

Switches and indicators on the front of the VLS are shown in Figure 6.

Lock

16-Character

Displa

Lock

Display

In the locked position, you cannot access any functions of the keypad.

The two-line 16-character LCD shows current drive status of the VLS,

allows access to change features or displays error messages.

16 Equipment Description

9,578$/ /,%5$5<

6<67(0

0$*$=,1(

'5,9( $

(6&(17(5 32:(5

'5,9(%

Figure 6. Front of ADIC VLS

pad

Locked

/2&.('/2$' 81/2$'$/70(18

LED

Power

LED

Page 29

Power LED

(green)

Lights when power is on.

Locked LED

(green)

MENU

ALT

Up

LOAD

DXU F<C ecUc dXU <?14 Ve^SdY_^ d_ TUdUSd SQccUddUc _b dXU QRcU^SU

_V Q SQccUddU

Down

UNLOAD

Lights when door is locked. The magazine, drive, or keypad cannot be

accessed while the Locked LED is on.

Press this button to enter or exit Off-line mode menus

Selects alternate function for another button. For example, press the

button and the

Selects previous item or value in the menu.

Press the

the VLS will check all cassettes in the magazine (making note of empty

spaces) and that all cassettes can be inserted in the drive.

UP

button and then this button to initiate a "load magazine" –

ALT

button to activate the load function.

ALT

Note

Selects next item or value in the menu.

Press the

the VLS will return the magazine to the unload position.

button and then this button to initiate the unload program –

ALT

Caution

ENTER

ESC

Left

DRIVE A

Right

DRIVE B

Never attempt to remove a magazine unless it is in the unload position

– you may damage the pick arm.

Selects currently displayed item.

Exits current menu and returns to previous menu.

Scrolls message display to the left or selects previous field on same line.

Press the

Scrolls message display to the right or selects next field on same line.

Press the

button and then this button to select drive A.

ALT

button and then this button to select drive B.

ALT

Equipment Description 17

Page 30

Rear Panel Switches and Connectors

Switches and connectors on the rear of the VLS are shown in Figure 7.

SCSI I/O

Connectors

Fan Filter

Rear

Access Panel

AC Power Connector

and Power Switch

Figure 7. Back of ADIC VLS

Power Switch

AC Power Connector

SCSI I/O Connectors

Menu Items

The menus and mode shown at the top of the following diagram are selections

available from the Main Menu. When you choose one of the Main Menu items, a set

of options appears; these options are listed below the Main Menu selections. If an

option has sub-options, these sub-options are listed below and to the right of the

option.

18 Equipment Description

Turns on the AC power to the VLS.

Plug the VLS AC power cord into this connector.

Connections for the interface cable which connects the

VLS to the computer, to other VLS units and/or to other

devices on the SCSI channel.

Page 31

Configuration Menu Diagnostics Menu Write EEPROM Mode

Buzzer Configuration Error Counters

ErrAlarm Yes/No Event Counters

Kybd Yes/No Operation Log

SCSI ID Config Firmware Revision

Drive B (0-7) Serial Number

Drive A (0-7) Position Drive

AC (0-7) Position Magazine

SCSI Parity Load Medium

Parity Check Yes/No Unload Medium

Off-Line Time Unload Drives

Max time 1-99 min

Drive Configuration

Drv A Yes/No

Drv B Yes/No

On-Line Mode* Random / Sequential

Sequential Mode Cfg*

First (0-11)

Last (0-11)

Loopback Yes/No

Available only when VLS is configured as a single-drive unit.

*

Equipment Description 19

Page 32

To access the Off-Line menu, press the

follows:

MENU

button. The display will appear as

Use the

select a displayed item. Use the

fields on the same line.

To exit the Off-Line menu press the

UP

or

DOWN

buttons to scroll through the menu. Press

RIGHT

MENU

or

LEFT

button.

buttons to scroll through

ENTER

Configuration Menu

The Configuration Menu allows you to select the following operating parameters:

Buzzer Configuration

•

SCSI ID Configuration

•

SCSI Parity

•

Off-Line Time

•

Drive Configuration

•

On-Line Mode (Single Drive models only)

•

Sequential-Access Mode Configuration (Single Drive models only)

•

Buzzer Configuration

to

Enables/disables the sounding of an alarm when an error message is displayed.

Enables/disables the beep sound when you press a keypad button.

When you select the Buzzer Configuration option a display similar to the following

appears:

20 Equipment Description

Page 33

To enable the error alarm use the

UP

or

DOWN

to select "Y" to enable alarm or "N" to disable alarm. When

LEFT

button to select the ErrAlarm field. Use

Error Alarm mode is enabled, a continuous alarm tone will sound in the event of an

error message. The alarm will sound until the condition that caused the error has been

removed or any key is pressed. To clear an error message from the display, press

and

ENTER.

ALT

If you wish to change the status of the keyboard beep, use the

select the Kybd field. Use

you press a button or "N" to disable the beep. Press

effective or press

2ejjUb 3_^VYWebQdY_^ TUVQe\d* 5bb 1\Qb]* > ;iRT* I

to return to previous menu item.

ESC

UP

or

DOWN

to select "Y" to enable a beep when

ENTER

Note

RIGHT

to make the changes

button to

SCSI ID Config

Lets you select the SCSI ID for drive A, drive B and the robotics on the VLS.

Use

LEFT

and AC is the robotic unit (autochanger) on the VLS. Use UP

scroll to the desired ID for that particular element. Press

or

RIGHT

to select the desired field. DA is Drive A, DB is Drive B

and

DOWN

ENTER.

Notes

to

C3C9 94 SXQ^WUc U^dUbUT T_ ^_d dQ[U UVVUSd e^dY\ i_e SiS\U `_gUb _^

dXU F<C e^Yd

C3C9 94 3_^VYWebQdY_^ TUVQe\d* 4bYfU 1*! 4bYfU 2*" 13*#

CUU dXU cUSdY_^ Y^ 3XQ`dUb " ^_dY^W dXU C3C9 94c ^UUTUT V_b dXU F<C

Equipment Description 21

Page 34

SCSI Parity

Lets you enable or disable the reporting of SCSI parity. Press

ENTER

to access this

function.

Use UP or

DOWN

to disable the reporting of parity check. Press

C3C9 @QbYdi TUVQe\d* @QbYdi 3XUS[* >

to select "Y" to enable the reporting of parity check or "N"

ENTER

Note

to activate the change.

Off-Line Time

Lets you set the number of minutes the VLS will remain in the Off-Line mode. If

someone leaves the VLS in an Off-Line mode, after the pre-set number of minutes the

VLS will automatically return On-Line. This assures that your automatic backup will

be done even if the VLS has accidentally been left Off-Line.

Use UP or

DOWN

Off-Line. Press

?VV\Y^U dY]U TUVQe\d* % ]Y^edUc

22 Equipment Description

to select the number of minutes you wish the VLS to remain

ENTER

to execute the change.

Note

Page 35

Drive Configuration

This function lets you enable or disable which drives are on-line.

Use

DOWN

or

LEFT

RIGHT

to select "Y" to put the drive on-line or "N" to disable the drive. If you

to select the drive you wish to change. Use UP or

have only one drive installed, you cannot access the Drv B field.

Note

1 TYcQR\UT TbYfU Yc cdY\\ S_^^USdUT d_ dXU C3C9 Rec Q^T gY\\ bUc`_^T d_

dXU \Qcd QTTbUcc cUddY^W D_ QccebU dXQd QTTbUcc SXQ^WUc Q^T TbYfU

S_^VYWebQdY_^ SXQ^WUc QbU Ve\\i Y^YdYQdUT i_e ]ecd SiS\U `_gUb

Disabling both drives is not allowed (setting "N" in Drv A or Drv B field

automatically places "Y" in the other field).

Note

4bYfU 3_^VYWebQdY_^ TUVQe\d cUddY^W Yc I V_b UQSX Y^cdQ\\UT TbYfU

On-Line Mode

Lets you select random-access or sequential-access operating mode.

When used in random-access mode, the VLS allows software selection of any cassette

in the magazine in any order. You can logically divide cassette usage to satisfy

particular data storage needs. For example, you can assign one or more cassettes to

specific data functions (such as certain directories or network servers), or you can

assign specific cassettes to individual users.

Equipment Description 23

Page 36

Note

9V i_e XQfU R_dX TbYfUc _^ \Y^U i_e gY\\ ^_d RU QR\U d_ QSSUcc dXYc

Ve^SdY_^ DXU c_VdgQbU i_e ecU gYdX dXU F<C TUdUb]Y^Uc gXUdXUb i_e

SQ^ _`UbQdU dXU F<C Y^ cUaeU^dYQ\ Q^T_b bQ^T_] ]_TU

DGLF

's VLS can also be used as a stacker in sequential-access mode if your software

does not support the random-access mode function.

Use

or

UP

DOWN

?`UbQdY^W =_TU TUVQe\d cUddY^W Yc BQ^T_]³

to select "random" or "sequential".

Note

Sequential-Access Mode Configuration

If you are using Sequential-Access Mode, this option lets you select which cassettes

the drive will write to, and whether or not you wish the drive to start again at the

beginning after the last cassette has been written to.

Note

9V i_e XQfU Q TeQ\TbYfU cicdU] Q^T R_dX TbYfUc QbU _^ \Y^U i_e gY\\ ^_d

RU QR\U d_ QSSUcc dXYc Ve^SdY_^

Use

LEFT

or

RIGHT

of the First cassette you wish the VLS to insert into the drive. "L" is the number of the

Last cassette you wish the VLS to insert into the drive.

to select the item you wish to change. "F" is the number

24 Equipment Description

Page 37

The Loopback (LPBK) mode determines what happens when the last cassette has been

filled. If you select "Y" for "Lpbk" the designated first cassette will be loaded into the

tape drive after the last cassette has been filled and ejected. If you select "N" an error

message will be issued and the backup will stop.

Note

4UVQe\d cUddY^W Yc 6* ! <* !! <`R[* I

Diagnostics Menu

The following functions are available under the Diagnostics Menu:

Error Counters

•

Operation Log

•

Serial Number

•

Position Magazine

•

Unload Medium

•

Event Counters

•

F/W Revision

•

Position Drive

•

Load Medium

•

Unload Drives

•

For information on these options, refer to Appendix B.

Warning

We highly recommend that these diagnostic functions be used only by

a qualified service technician (or on the instruction of a qualified

technician). Some of these functions assume that the unit has been set

up correctly and thus many of the normal built-in safety checks are

turned off. Misusing these diagnostic functions without the normal

safety checks could result in improper operation (or even damage to

media or VLS).

Equipment Description 25

Page 38

Write EEPROM Mode

The Write EEPROM Mode is used whenever you upgrade the VLS firmware. Refer to

Appendix C in this manual for additional information.

26 Equipment Description

Page 39

Chapter

Operation and Maintenance

This Chapter …

❐

describes normal operation features of the VLS

❐

provides details on the media and magazine

4

❐

explains normal maintenance procedures

27

Page 40

The VLS unit is composed of one or two DAT drives and the robotics that control the

drive(s), magazine and media. The drive(s) are unmodified. The drive status LEDs

function per the manufacturer’s specifications.

No routine maintenance is required – apart from cleaning the heads after

approximately each 8 to 10 hours of tape motion or when the Media Caution

indication is displayed on the drive LEDs (see

manual).

CY^SU dXU TbYfU cdQdec <54c QbU \_SQdUT _^ dXU \_gUb Vb_^d _V dXU

TbYfU d_ cUU dXU] i_e ]ecd RU UiU\UfU\ gYdX dXU WbY``Ub Qb] _V dXU

F<C <__[ RUi_^T dXU Qb] d_ dXU TbYfU

Cleaning the Drive Head

Note

later in this

DDS Media

Use only industry-standard 4mm DAT cassettes with the VLS. These data-grade

cassettes are manufactured under more stringent environmental, reliability and

durability specifications than audio-grade cassettes, producing superior data

reliability. The 125-meter cassettes, used only in DDS-3 drives, and the 120-meter

cassettes, which can be used in both DDS-3 and DDS-2 drives, are marked with the

DDS-3 and DDS-2 logos, respectively.

A write-protect switch is used to prevent recording over existing data. To prevent

recording or deleting, place the write-protect switch to the open position. The drive

senses the position of the switch and will not allow writing in this position. When

inserting cassettes in the magazine, place the switch in the closed position (unless you

do not wish to record on a specific cassette).

28 Operation and Maintenance

Page 41

Write-Protect Switch

Open (Protected)

Closed (Unprotected)

Inserting Data Cassettes into the Magazine

The magazine for the 4mm VLS holds fifteen 4mm cassettes. It includes a clear dust

cover to protect the cassettes and for easy storage. See Figure 8. Insert each cassette

into a slot of the magazine making sure that the write-protect tab is on the top and the

cassette faces toward you when the magazine is loaded onto the carriage of the VLS

(as illustrated).

A spring holds each cassette in place even if the magazine is turned upside down.

Note

DGLF

cdb_^W\i bUS_]]U^Tc dXQd i_e ecU

WbQTU ]UTYQ _^\i 4_ ^_d QddU]`d d_ ecU QeTY_WbQTU ]UTYQ ceSX

]UTYQ SQ^ TQ]QWU dXU XUQTc Q^T dQ`U XQ^T\Y^W `Qbdc ° f_YTY^W i_eb

gQbbQ^di

DGLF

-

bUS_]]U^TUT TQdQ

Operation and Maintenance 29

Page 42

g

g

Ma

g

g

(

)

azine Cover

Write-Protect Switch

Data Cassettes

azine

Ma

Open side of

ma

azine

towards VLS

Figure 8. VLS Magazine

The open side of the magazine faces the VLS. Make sure each cassette touches the

bottom floor of the magazine.

Do not use wrap-around labels on the individual cassettes. Most labels use a

removable adhesive and have a tendency to curl or tear after multiple uses. This can

jam the movement of the VLS. Place labels only in the space provided on the cassette.

Note the following:

❐

Store magazines (and data cassettes) in a dry, cool environment. Keep the dust

cover on the magazine.

Closed side

of ma

azine

❐

Never reset or power down your computer or VLS while a function is in process

or a tape is moving. In addition to getting tape with missing or corrupted data, you

may also get tape run-on within the drive (a condition that can produce internal

contamination requiring factory cleaning).

❐

If a power outage occurs during a back-up sequence, restart your backup from the

beginning.

30 Operation and Maintenance

Page 43

Inserting the Magazine into the VLS

Note

4_ ^_d QddU]`d d_ `\QSU Q S_fUbUT ]QWQjY^U _^d_ dXU F<C SQbbYQWU

❐

Remove the magazine cover. You can remove the cover by pressing the middle of

both ends (where it is labeled PUSH) and lifting up (see Figure 9).

Figure 9. Removing the Magazine Cover

❐

Open the VLS door.

❐

Holding the magazine by the thumbhole handle, and at a 45° angle to the carriage,

slip the magazine onto the left side of the carriage, over the magazine position pin

(see Figure 10).

Operation and Maintenance 31

Page 44

639181

Left"magazine

position pin"

Figure 10. Placing the Magazine onto the VLS

❐

Push the right side of the magazine over the right hand magazine position pin until

you hear a click. See Figure 11.

Note

I_e ]Qi ^UUT d_ Q``\i T_g^gQbT `bUccebU Qc i_e c\Y` dXU ]QWQjY^U

_fUb dXU bYWXd ]QWQjY^U `Y^ Q^T dXU^ `bUcc dXU ]QWQjY^U Y^d_ `\QSU

gYdX i_eb Y^TUh VY^WUb

Figure 11. Pushing the Magazine in Place

32 Operation and Maintenance

Page 45

The magazine will snap into place. If you don't hear a click, make sure that the slot on

the right side of the magazine has slipped around its magazine position pin and is not

just sitting on top of it. The magazine will not load correctly in this position.

Loading the Magazine

Once you have placed the magazine on the carriage, the VLS must initiate a loading

process. During this procedure the VLS checks and maps the position of each cassette

and makes sure that all cassettes are inserted into the magazine correctly. If you are

using the sequential mode the VLS inserts the first cassette into the drive.

Note

DXU T__b ]ecd RU S\_cUT RUV_bU dXU <?14 _b E><?14 Ve^SdY_^c gY\\

QSdYfQdU

❐

Make sure the magazine is placed correctly on the carriage.

❐

Close the door and press

magazine procedure.

ALT

and then

LOAD

. The VLS will initiate the load

Note

9^ dXU cUaeU^dYQ\ ]_TU YV i_e `bUcc UNLOAD RUV_bU dXU F<C XQc

VY^YcXUT \_QTY^W dXU ]QWQjY^U dXU b_R_dYSc gY\\ VY^YcX ]Q``Y^W Q^T

SXUS[Y^W dXU SQccUddUc Q^T dXU^ ]_fU dXU ]QWQjY^U d_ dXU e^\_QT

`_cYdY_^ dXU VQb bYWXd gYdX_ed Y^cUbdY^W Q SQccUddU Y^d_ dXU TbYfU

9^ bQ^T_] ]_TU YV i_e `bUcc UNLOAD

\_QTY^W dXU ]QWQjY^U Yd gY\\ XQfU ^_ UVVUSd

RUV_bU dXU F<C VY^YcXUc

Operation and Maintenance 33

Page 46

Attempting to Load the Magazine with a

Cassette Already in Drive

Random Mode:

before you attempt to have the VLS load the magazine. Refer to the next section for

manual removal of a cassette. If the VLS robotics was used to load the cassette via

applications software, attempting to "load magazine" from the keyboard will fail – the

unit will remain on-line.

Sequential Mode:

– before you attempt to have the VLS load the magazine. Refer to the next section for

manual removal of a cassette. If the VLS robotics was used to load the cassette, the

VLS will remember and not allow a "load magazine" from the keyboard. Press

and then

ENTER

If the cassette was loaded manually, it must be unloaded manually –

If the cassette was loaded manually, it must be unloaded manually

ALT

to bring the VLS back on-line.

34 Operation and Maintenance

Page 47

Manually Removing a Cassette Loaded in the

Drive

❐

Press

ALT

and then

UNLOAD

. This will place the magazine in the unload

position.

❐

Open the VLS door. Remove the magazine from the carrier.

❐

Press the eject button on the drive (see Figure 12). It may take 30 seconds or more

for the drive to eject the cassette.

Drive

Eject

Button

Figure 12. Typical Position of Drive Eject Button.

Note

CY^SU dXU 4bYfU 5ZUSd 2edd_^ Q^T 4bYfU GQb^Y^W <YWXdc QbU \_SQdUT _^

dXU Vb_^d _V dXU TbYfU d_ cUU dXU] i_e ]ecd RU UiU\UfU\ gYdX dXU

WbY``Ub Qb] _V dXU F<C <__[ RUi_^T dXU Qb] d_ dXU TbYfU

❐

Remove the cassette manually.

❐

Replace the magazine onto the carriage.

❐

Close the door. You can now initiate the load procedure.

Operation and Maintenance 35

Page 48

Removing the Magazine from the VLS

Before physically removing the magazine from the carrier, you must first initiate the

UNLOAD procedure.

❐

Make sure there is no cassette in the drive. If there is, go to the next procedure,

Removing the Magazine while a Cassette is in Drive

Note

I_e SQ^^_d Y^YdYQdU Q^ E><?14 _b bU]_fU dXU ]QWQjY^U YV dXU T__b Yc

\_S[UT GXU^ dXU <_S[UT \YWXd Yc _^ dXU F<C YW^_bUc dXU <?14 Q^T

E><?14 Redd_^c

❐

Press

the carriage is not in the unload position, it will move to the right. In addition, the

grippers on the pick arm will close.)Press the Magazine Release on the carriage.

See Figure 13. The magazine will release from the holding pins.

ALT

and then

UNLOAD

and wait until the unload procedure is finished. (If

Magazine

Release

Catch

Figure 13. The Magazine Release

❐

Grab the thumb handle on the magazine and pull the right side of the magazine

toward you. The magazine will come out at a 30-40 degree angle.

36 Operation and Maintenance

Page 49

❐

Place the transparent cover over the magazine and store the unit in a cool, dry

place.

Note

=Q[U cebU i_e XQfU \QRU\UT UQSX SQccUddU Qc d_ ]QWQjY^U Q^T c\_d

^e]RUb 9V i_e Tb_` dXU ]QWQjY^U gYdX_ed dXU S_fUb _^ dXU SQccUddUc

gY\\ VQ\\ _ed

Removing the Magazine while a Cassette is in

the Drive

If you wish to remove the magazine but there is a cassette in the drive, do the

following:

❐

Open the VLS door.

❐

Press the eject button on the drive (see Figure 12).

❐

Close the door of the VLS. It will take about 30 seconds for the drive to unload

the tape.

❐

❐

ALT

and then

Press

slot and the VLS will move the magazine to the unload position.

Remove the magazine as noted earlier.

UNLOAD

. The arm will return the cassette to the magazine

Loading an Individual Cassette

If for some reason you need to use a single cassette, you can load it manually (this

operation is the same as loading a cleaning cassette).

❐

Unload the magazine by pressing

move completely to the right.

❐

Open the door and remove the magazine from the carriage. (See previous

instructions).

ALT

and then

Operation and Maintenance 37

UNLOAD

. The magazine will

Page 50

❐

Insert the cassette into the drive opening with the label side to your left and the

write-protect switch positioned down. Apply steady pressure on the back of the

cassette until the autoloading mechanism takes the cassette and loads it into the

drive. The cassette is now in a semi-loaded state. If the humidity level is

acceptable, the drive threads the tape, initiates a load sequence and goes on-line.

The drive will take approximately 20 seconds to load the cassette.

Note

9V dXU Xe]YTYdi _^ dXU Y^dUb^Q\ XUQTTbe] Yc UhSUccYfU dXU SQccUddU

gY\\ ^_d RU QSSU`dUT

9V i_e cX_e\T UfUb Uh`UbYU^SU dXYc S_^TYdY_^ Q\\_g dXU cicdU] d_

cdQRY\YjU d_ dXU cebb_e^TY^W dU]`UbQdebU Q^T Xe]YTYdi Q^T dbi QWQY^

❐

Close the door and initiate desired program.

❐

If the drive does not eject the cassette when the program is finished, open the VLS

door (the gripper arm should still be fully extended) and press the drive eject

button (refer back to Figure 12 if necessary). It will take about 30 seconds for the

drive to eject the cassette.

If the normal eject procedure fails to eject a cassette, a Power Eject can be initiated.

Press and hold the drive’s Eject button. The upper LED (on the drive) will begin

flashing amber, as it does during a normal Eject cycle. Holding down the Eject button

for 10 seconds will initiate a Power Eject cycle. The cassette will be ejected

immediately. Using the Power Eject function may cause a tape to be generated that

does not conform to the format standard. After the cassette is ejected, the drive will

reset.

Power Eject should only be used as a last resort in case of an apparent

drive failure, or if there is no other way to eject a cassette.

38 Operation and Maintenance

Warning

Page 51

Removing a Cassette from the Magazine

The data cassettes easily slip into and out of the slots of the magazine. To remove a

cassette, simply grasp it with two fingers and pull up. Make sure each cassette is

labeled so you know the contents (and where it belongs in the magazine sequence).

Storing the Magazine

Store magazines in a dry, cool environment. Always keep the dust cover on the

magazine.

The removable magazine allows for long-term archiving or off-site safety storage of

groups of data.

You can duplex multiple changers so your system can mirror data backups on each

separate unit. With duplexing you have real time data assurance and the ability to

remove one magazine set for off-site storage while the other remains for on-line data

access.

Cleaning the Drive Head

Caution

Using cloth swabs, cotton swabs, cleaning agents, or

cleaning cassettes will void the warranty. Use only an

recommended cleaning cassette. Audio DAT cleaning cassettes do not

have the proper ID hole configuration to initiate the cleaning cycle:

their use will cause excessive head-wear (voiding the warranty).

To prevent contamination of the drive and damage to the heads, do not use the

cleaning cassette for more than the number of cleaning cycles specified on the cassette

label. Discard the cleaning cassette after you have used it the specified number of

cleaning cycles.

reuse it.

Do not attempt to rewind the material in the cleaning cassette and

Operation and Maintenance 39

unapproved

DGLF

Page 52

Clean the drive head and tape path after every 8-10 tape motion hours (about once a

week under typical use). You should also clean after the first use of a new tape

cassette.

As an absolute visual reminder, the drive status LEDs will flash the Media Caution

indication during cassette load/unload operations after approximately 24 hours of

head-tape motion since the last cleaning. To see the status LEDs, the magazine must

be in the unloaded position and you must look at the drive (see Figure 13). We urge

you to clean the drive as soon as possible after the LEDs begin flashing the Media

Caution indication.

Drive Status LEDs

Figure 13. Typical Position of Drive LEDs

Please follow these cleaning directions carefully to assure that no damage will occur to

the tape drive, VLS or media.

❐

Unload the magazine by pressing

move completely to the right .

❐

Open the VLS door and remove the magazine from the carriage.

❐

Check the usage record on the label of the cleaning cassette to make sure that there

is at least one cleaning cycle remaining. If there are no cleaning cycles remaining,

discard the cleaning cassette and use a new one. If you attempt to insert a cleaning

cassette which is fully used, the drive will eject the cassette immediately and will

not reset the internal 24-hour cleaning timer. Both drive LEDs will continue to

40 Operation and Maintenance

ALT

and then

UNLOAD

The magazine will

.

Page 53

flash amber during cassette load/unload operations. Figure 14 shows a sample

cleaning cassette with the label on which to write the date of each use.

Figure 14. Representative Cleaning Cassette

Caution

DO not attempt to RE-USE or REWIND the cleaning cassette after all

the cleaning cycles (approx. 20) have been used.

❐

Insert the cleaning cassette into the drive opening (see Figure 15). The drive will

load the cassette and automatically begin the cleaning process. The cleaning cycle

may take from 2 to 3 minutes. The media status LED will flash amber during the

entire cleaning cycle.

Operation and Maintenance 41

Page 54

Figure 15. Inserting the Cleaning Cassette into the Drive.

❐

When the cleaning is finished the drive will automatically eject the cassette.

Remove the cleaning cassette and write the date on the label so you have a record

of how many times it has been used and when.

❐

To confirm that a cleaning was done, look at the LEDs on the front panel of the

drive. If the cleaning cycle was successful, the LEDs will be off. If the cleaning

cycle was not performed, the LEDs will continue to flash.

❐

Place the magazine onto the carriage. Close the VLS door. Press

LOAD

42 Operation and Maintenance

to initiate the load procedure.

ALT

and then

Page 55

Caution

Cleaning cassettes are considerably more abrasive to the drive's

recording heads than standard data cassettes. Usage should be kept

within the recommended limits, or the warranty may not be applicable

to the affected equipment.

The VLS is once again ready for use.

Caution

If you encounter a hard error during normal operation, first try a new

4mm data cassette. If this solves the problem, continue on with the

new cassette.

If the symptom persists, try one cleaning cycle with the cleaning

cassette. If this does not resolve the problem, we recommend that you

do NOT use the cleaning cassette again – instead, call the

Customer Assistance group.

DGLF

’s

Cleaning the Enclosure

The outside of the enclosure can be cleaned with a damp towel. If you use a liquid allpurpose cleaner, apply it to the towel. Do not directly spray the enclosure.

Operation and Maintenance 43

Page 56

Blank Page

44 Operation and Maintenance

Page 57

Troubleshooting

and Diagnostics

This Chapter …

❐

contains some general suggestions to aid you in solving problems

– should you ever run into them.

Chapter

5

❐

includes information on error codes and the built-in diagnostics.

45

Page 58

VLS Error Messages

If any component of the VLS is not communicating correctly, a warning message will

appear on the front display.

A list of error messages in included on the following page. If the error you see is not

on this list, please call

In all cases, after removing the cause of the problem (or if you can't find a cause) push

MENU

to return the VLS to the on-line condition.

DGLF

Customer Assistance.

f the error message is not listed, try to return to the on-line mode by pressing

and/or

Customer Assistance and be prepared to tell them what the error message is – and

what the conditions are.

ENTER

. If that does not work or if you get the error again, call

ALT

DGLF

46 Troubleshooting and Diagnostics

Page 59

Error Messages

C_]U _b Q\\ _V dXU Ubb_b ]UccQWUc ]Qi bUce\d Vb_] _^U _b ]_bU

S_^TYdY_^c DXU TUVY^YdY_^ WYfU^ Yc V_b Q cY^W\U S_^TYdY_^ _^\i 9V i_e

RU\YUfU dXQd dXU S_^TYdY_^ gXYSX SQecUT i_eb Ubb_b ]UccQWU Yc _dXUb

dXQ^ dXU TUVY^YdY_^ `\UQcU SQ\\

((#$#%'

Error Name Description

Note

DGLF

3ecd_]Ub 1ccYcdQ^SU Qd* " &

Source location empty

Destination location full

Mag unload disabled by

software

Can’t unload, media in

drive

Drive failed to eject

media

Unexpected Gripper

Arm Sensor break

Unexpected Magazine

Sensor break

No Gripper Arm Sensor

break

No Magazine Sensor

break

Unexpected Medium

Sensor break

The source location was empty when the VLS attempted to pick

a cartridge from it.

The destination location was full when the VLS attempted to

place a cartridge in it.

The application has issued the SCSI PREVENT/ALLOW

MEDIA REMOVAL command, preventing the magazine from

being unloaded.

The VLS will unload the magazine only if all drives are empty.

The VLS attempted to return a cartridge to a magazine slot, but

the drive had not previously ejected it.

The VLS sensed that the Gripper Arm Sensor was blocked

when it should not have been.

The VLS sensed that the Magazine Sensor was blocked when it

should not have been.

The VLS sensed that the Gripper Arm Sensor was not blocked

when it should have been.

The VLS sensed that the Magazine Sensor was not blocked

when it should have been.

The VLS sensed that the Medium Sensor was blocked when it

should not have been.

Unable to return

medium to slot

The VLS attempted to return a cartridge to a magazine slot but

failed, possibly due to a magazine positioning error.

Troubleshooting and Diagnostics 47

Page 60

Error Name Description

Unable to load medium

in drive

Door has been opened

Door is open

Operation disabled by

keyboard lockout

All configured drives are

empty

Slot not empty, can’t

unload drive

SCSI RESET

OCCURRED

Drive positioning timeout

Medium incorrectly

oriented

Flash RAM erase failure

The VLS attempted to load a cartridge into a drive but failed,

possibly due to a drive positioning error.

The front door of the VLS had been opened, but is now closed.

The front door of the VLS is open. This error will appear

whenever the front door is opened while power is on.

Whenever the front panel lock is engaged, the keypad is

disabled, disabling any off-line operations.

The VLS received a command (through SCSI, or the front panel

keypad) to unload medium from a drive, but, since the VLS had

not previously loaded a cartridge, the drives are empty.

A cartridge is occupying the magazine slot currently aligned

with the drive, and the VLS cannot place the cartridge ejected

by the drive into this slot.

A SCSI RESET has occurred, coming from either the SCSI bus,

or from the front panel keypad.

The drive shuttle failed to position correctly in the allowed time.

The cartridge is incorrectly oriented in the magazine. This can

occur when the VLS attempts to load the magazine.

The VLS could not successfully erase the Flash RAM during the

firmware download process.

Flash RAM write failure

NV-RAM selection

failure

NV-RAM write failure

Boot ROM checksum

failure

Unknown error code

XXh

48 Troubleshooting and Diagnostics

The VLS could not successfully write to the Flash RAM during

the firmware download process.

The VLS could not successfully select a particular area of the

NV-RAM.

The VLS could not successfully write to the NV-RAM.

The checksum of the boot code in the Boot ROM is incorrect.

An unknown error has occurred.

Page 61

Drive Warning Signals

y

The 4mm drives used in the VLS employ front panel LEDs to indicate SCSI interface

activity, drive fault conditions, and cartridge status. Figure 16 is a close-up of the

Sony SDT-5000 (SDT-7000/SDT-9000 are the same) drive and the location of the

warning LEDs. The LEDs on all other drives are located in approximately the same

place. Refer to the following tables for descriptions of the methods employed by

different drives to indicate activity, status, and fault conditions.

Drive

Status

LEDs

Son

SDT-5000

Figure 16. VLS Drive Status LEDs

Troubleshooting and Diagnostics 49

Page 62

Hewlett Packard C1533A/C1537A Drive Status LEDs

Tape LED

(bottom)

Flashing green

(½ sec on, ½ sec off)

Fast flashing green

(¼ sec on, ¼ sec off)

Steady green Off Cartridge loaded, drive online

Off Flashing amber

Off Steady amber Drive fault

Flashing green

(½ sec on, ½ sec off)

Clean LED

(top)

Off Cartridge activity — load or unload

Off SCSI activity — read or write

Media Caution Signal

(½ sec on, ½ sec off)

Off Self-test in progress

Meaning

Table 3. HP C1533A/C1537A LEDs

50 Troubleshooting and Diagnostics

Page 63

Sony SDT-5000/SDT-7000/SDT-9000 Drive Status LEDs

Busy LED (Top) Tape LED

(Middle)

Off Off Off No cartridge present/no

On Off Off SCSI activity — read or write

Fast flashing

(¼ sec on, ¼ sec off)

Fast flashing

(¼ sec on, ¼ sec off)

Off On Fast flashing

Off On Off Cartridge loaded/no activity

On On Off Cartridge loaded/SCSI

Fast flashing (¼ sec on,

¼ sec off)

* On On Cartridge loaded/write

* Long, slow flashing

Long, slow flashing

(3½ sec on, ½ sec off)

* * Long, slow flashing

* * Flashes once for ¼ sec

* * Flashes twice once for

Flashes once for ¼ sec

then stays off for 1 sec

* Flashes once for ¼ sec

Fast flashing

(¼ sec on, ¼ sec off)

Fast flashing (¼ sec on,

¼ sec off)

On Off Cartridge loaded/SCSI and

(3½ sec on, ½ sec off)

* * High humidity detected

* * Waiting for reset

then stays off for 1 sec

Status LED

MEANING

(Bottom)

activity

Off Drive loading/unloading

On Drive loading/unloading with

cartridge write protected

Cleaning cartridge at end of

(¼ sec on, ¼ sec off)

* Media Caution Signal —

(3½ sec on, ½ sec off)

then stays off for 1 sec

¼ sec then stays off for

1 sec

* Waiting for eject

media (no cleaning cycles

remaining)

activity

drive activity

protected

excessive errors detected

Media Caution Signal —

predetermined number of tape

head motion hours reached

Drive mechanical failure

detected

Drive circuitry failure

detected

Table 4. Sony SDT-5000/SDT-7000/SDT-9000 LEDs

Troubleshooting and Diagnostics 51

Page 64

Environmental Considerations

For best performance of your VLS, please observe the following guidelines:

❐

If you expose cassettes to temperatures outside the operating limits – 40-113°F (540°C) – stabilize them by leaving the cassettes in the operating temperature for a

minimum of two hours before you use them.

❐

Avoid temperature problems by ensuring that the VLS's side and rear are not

obstructed so that the drive has adequate ventilation.

❐

Position the VLS where the temperature is relatively stable (i.e., away from open

windows, fan heaters, and doors).

❐

Avoid leaving cassettes in severe temperature conditions, for example, in a car

standing in bright sunlight.

❐

Avoid transferring data (reading from and writing to cassettes) when the

temperature is changing by more than 15°F (10°C) per hour.

When You Call

Before calling

take full advantage of your call:

❐

Review all documentation carefully. (Experience has demonstrated that most

questions are answered in your documentation.)

❐

Be prepared to explain whether the software or hardware has worked properly at

anytime in the past. Have you changed anything recently?

❐

Pinpoint the exact location of your problem, if possible. Note the steps that led to

the problem. Are you able to duplicate the same problem or is it a one-time occurrence?

❐

Note any error messages displayed on your PC screen or file server. Write down

the exact error message.

52 Troubleshooting and Diagnostics

DGLF

DGLF

DGLF

Customer Assistance, follow these steps – which will help you

Customer Assistance

Page 65

❐

If at all possible, call while at your computer, with

DGLF

's system installed and

turned on.

❐

If running on a network, have all relevant information available (i.e. type, version

#, network hardware, etc.).

Be prepared to provide:

Your name and your Company’s name

•

Model number

•

Serial number of unit (located on the rear face by the power switch)

•

Software version numbers

•

– device driver

– archive/restore

Hardware configuration, including firmware version, date and number

•

Type of PC, DOS version, clock speed, RAM, network type, network version,

•

and any special boards installed

A brief description of the problem

•

Where you purchased the

•

DGLF

system

Having this information available when you call for customer assistance will enable

DGLF

to resolve your problem in the most efficient manner possible.

Note

DGLF

3Q\\

9V i_e gYcX i_e ]Qi S_^dQSd

DGLF

ce``_bd0QTYSS_]

3ecd_]Ub 1ccYcdQ^SU Qd* " & ((#$#%'

DGLF

3ecd_]Ub CUbfYSU dXb_eWX dXU

22C Qd* " & ((##"!! _b Ri \UQfY^W 9^dUb^Ud 5]QY\ Qd*

Troubleshooting and Diagnostics 53

Page 66

Return for Repair RMA

Authorization)

(Return Merchandise

When you and

number (see previous section When You Call

with the following information:

•

•

•

•

Current labor rates will be quoted at the time the RMA is issued.

Loaner or replacement systems are generally NOT available. In extreme

circumstances, they may be arranged for, depending on the nature of the problem and

past history with the customer.

DGLF

Customer Assistance have determined that you need an RMA

DGLF

Customer Assistance). be prepared

Model number, serial number, and a brief, descriptive explanation of the

problem.

Complete address information (be sure you give any mail stops or special

codes at the time the RMA is issued).

If the item is NOT in warranty, you will be charged for the repairs. Therefore,

the Customer Assistance personnel will need a P.O. number at the time the

RMA number is issued. Until credit information can be obtained by our

accounting department, the system may be shipped back COD to first-time

customers.

It is also necessary to send the complete system, including the SCSI interface

card/controller, interface cables, and the unit. Problems may have been caused

by a defective external component and/or the drive itself.

Keep the RMA number as a reference if you call to check on the status of an open

RMA. It MUST also be written on the outside of the package for identification

purposes.

6_\\_gY^W dXYc B=1 `b_SUTebU gY\\ Uh`UTYdU XQ^T\Y^W bU`QYbc Q^T dXU

bUdeb^ _V UaeY`]U^d

54 Troubleshooting and Diagnostics

Note

Page 67

Appendix

Installing the Ferrite Bead

This Appendix …

❐

describes how to install a ferrite bead (supplied) on the SCSI

cable to assure compliance with EMI/RFI suppression

specifications with dual VLS installations.

A

55

Page 68

If you are using two or more VLS units on the same SCSI channel, you must install a

ferrite bead on the interface cable between the units.

❐

Clip the clamp-on bead on the cable at any point between the two units. Refer to

Figure 17.

Ferrite

Bead

SCSI

Interface

Cable

2 VLS units

(On same

SCSI Channel)

Host Computer

Figure 17. Installing the Ferrite Bead

The ferrite bead is required to satisfy the EMI/RFI suppression limits. The bead does

not affect the functionality of your system in any way.

56 Installing the Ferrite Bead

639104

Page 69

Diagnostics Menu

This Appendix …

❐

describes the built-in diagnostic functions as available via the

Diagnostics Menu

Appendix

B

57

Page 70

One of the most valuable features of the VLS is the extensive built-in diagnostics. In

this Appendix we discuss each of the Diagnostic functions available through the front

panel keypad.

To access the Diagnostics Menu, press the

MENU

button. The display will read as

follows:

Press

DOWN

to access the Diagnostics Menu. Press

ENTER

the following will appear.

The following items are available under the Diagnostics Menu:

Error Counters

•

Operation Log

•

Serial Number

•

Position Magazine

•

Unload Medium

•

Event Counters

•

F/W Revision

•

Position Drive

•

Load Medium

•

Unload Drives

•

; a display similar to

UP

or

DOWN

Use

function.

Use the

58 Diagnostics Menu

button to return to a previous menu (or to abandon current change).

ESC

to scroll through the list. Press

ENTER

to choose a particular

Page 71

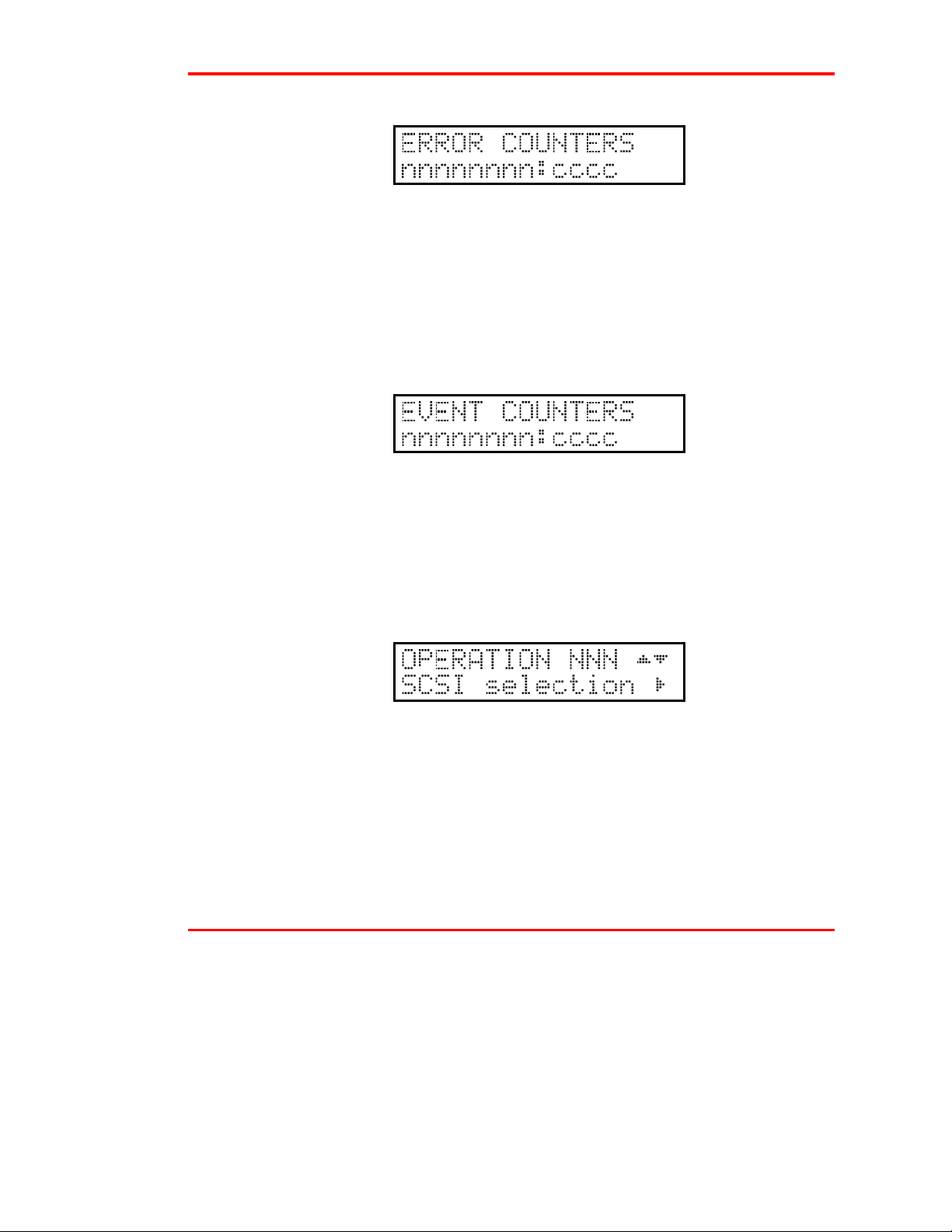

Error Counters

Provides a chronological listing (beginning with the last error issued) of the errors

encountered by the VLS system. These are VLS internal hardware/firmware errors.

This register records each error name and assigns it a sequential number.

nnnnnnnn = Counter name.

ccccc = Counter value (0 - 65535)

Event Counters

Provides a listing of the various VLS operations and how many times they have

occurred.

nnnnnnnn = Counter name.

ccccc = Counter value (0 - 65535)

Operation Log

Provides a chronological logging (beginning with the latest) of up to 255 operations.

These operations can be SCSI commands, operator requested operations, errors, and

status operations. This information can be vital for trouble shooting problems. The

following is a partial listing of some of the loggable operations. You may encounter

other operations not included here.

Diagnostics Menu 59

Page 72

NNN = Logged operation number (1-255).

When log is full, new operations are

logged in as operation 255, scrolling the