Page 1

ODYSSEY, Q-VISION

™

HF Series™

X-ray Generators

Service Manual

Manual Part No. DC30-011 Revision W

Page 2

EU Authorized Representative:

Medizintechnik Berlin GmbH

Altentreptower, Strasse 59

12683 Berlin - Germany

Phone: +49-302-82 4726

Fax: +49-302-82 6382

E-mail: Medizintechnik.Berlin.GmbH@t-online.de

This manual is copyrighted and all rights are reserved. No portion of this document

may be copied, photocopied, reproduced, translated, or reduced to any electronic

medium or machine readable form without prior consent in writing from Quantum

Medical Imaging, LLC. (QMI)

This Service Manual is incomplete without Operator’s Manual part number DC30-010.

Copyright© 2010 QMI

Quantum Medical Imaging, LLC

2002-B Orville Drive North

Ronkonkoma, NY 11779-7661 USA

Phone: (631) 567-5800

Fax: (631) 567-5074

E-mail: info@qmiteam.com

www.quantummedical.net

Made in U.S.A.

Page 3

Revision History

REVISION DATE TYPE OF MODIFICATION

E 1/12/02 Incorporated ECO 0647, 0651, 0687

F 2/25/02 Incorporated ECO 0714, 0718, 0738, 0742

G 5/15/02 Incorporated ECO 0642, 0748, 0753, 0770, 0787, 0803, 0809,

0821, 0827, 0829, 0830, 0847, 0859, 0881, 0888

H 9/26/02 Incorporated ECO 0787

J 11/11/02 Incorporated ECO 0936, 1003, 1009, 1010, 1017, 1028, 1030

K 3/31/03 Incorporated ECO 1093, 1102, 1103, 1107, 1115, 1124, 1146

L 7/11/03 Incorporated ECO 1255, 1256

M 7/29/03 Incorporated ECO 1269, 1270, 1272

N 12/19/03 Incorporated ECO 1144, 1216, 1347, 1359, 13 62, 1380, 1383,

1400

P 9/10/04 Incorporated ECO 1346, 1438, 1485, 1518

Q 4/22/05 Incorporated ECO 1565, 1570, 1600, 1606, 1607

R 12/20/05 Incorporated ECO 1660, 1663, 1679

S 5/22/07 Assigned new part number to Non-QMI HSS ver sio n man ua l;

Incorporated ECO 1697, 1715, 1757, 1794, 1890

T 5/8 /2 00 8 Incorporate ECO 1895, 19 20 , 19 32 , 19 7 7, 198 5

U 11/21/2008 Incorporate ECO 2045, 2050, 2068, 2093, 2105

V 9/1/2009 Incorporate ECO 1980, 2160, 2166, 2169

W 1/15/2010 Incorporate ECO 2220, 2228, 2276

Page

Number

i thru xii W 4-1 thru 4-20 W B-1 thru B-56 W

1-1 thru 1-22 W 5-1 thru 5-96 W C-1 thru C-7 W

Rev

Page

Number

Rev

Page

Number

Rev

2-1 thru 2-56 W 6-1 thru 6-67 W D-1 thru D-66 W

3-1 thru 3-72 W A-1 thru A-16 W

HF Series X-ray Generators - Service Manual Revision W

Quantum Medical Imaging i

Page 4

Revision History

THIS PAGE INTENTIONALLY LEFT BLANK

Revision W HF Series X-ray Generators - Service Manual

ii Quantum Medical Imaging

Page 5

Table of Contents

CHAPTER 1 - SPECIFICATIONS

SYSTEM CONFIGURATIONS ................................................................. 1-3

PHYSICAL SPECIFICATIONS ................................................................. 1-5

GENERATOR CABINET SPECIFICATIONS ......................................... 1-5

OPERATOR CONTROL PANEL SPECIFICATIONS ............................... 1-5

ODYSSEY HF Control Panel: ............................... ...................... 1-5

Q-VISION HF Control Panel: .................................................... 1-5

SYSTEM SPECIFICATIONS .............................................................. 1-5

POWER REQUIREMENTS .................................................... .................. 1-6

SINGLE-PHASE X-RAY GENERATORS .. ............................................. 1-7

25 kW Single Phase (Model QG-25) .... ....................................... 1-7

25 kW Single Phase (Model QG-25-5)* ...................................... 1-7

32 kW Single Phase (Model QG-32) .... ....................................... 1-7

32 kW Single Phase (Model QG-32-5)* ...................................... 1-7

40 kW Single Phase (Model QG-40) .... ....................................... 1-8

40 kW Single Phase (Model QG-40-5)* ...................................... 1-8

32 kW Single Phase, Stored Energy ........................................... 1-8

40 kW Single Phase, Stored Energy ........................................... 1-8

50 kW Single Phase, Stored Energy ........................................... 1-8

THREE-PHASE X-RAY GENERATORS ................................................ 1-9

32 kW Three Phase (Model QG-32-2) ........................................ 1-9

32 kW Three Phase (Model QG-32-3) ........................................ 1-9

40 kW Three Phase (Model QG-40-2) ........................................ 1-9

40 kW Three Phase (Model QG-40-3) ........................................ 1-9

50 kW Three Phase (Model QG-50-2) ........................................ 1-9

50 kW Three Phase (Model QG-50-3) ........................................ 1-9

65 kW Three Phase (Model QG-65) ......................... .................1-10

80 kW Three Phase (Model QG-80) ......................... .................1-10

HIGH-SPEED STARTER POWER REQUIREMENTS ............................1-10

GENERATOR AUXILIARY POWER SUPPLIES ........................... ...............1-15

PERFORMANCE SPECIFICATIONS ........................................................1-15

SYSTEM OPTIONS ..............................................................................1-19

SYSTEM OPERATING ENVIRONMENT ....................................... ............1-19

NON-OPERATING ENVIRONMENT .......... .. .. .... .. .. ..... .. .. .... .. .. ..... .. .... .. .. ..1-20

CHAPTER 2 - ASSEMBLY & INSTALLATION

OVERVIEW .................. .. .. .... .. .. .. .. .. ... .. .... .. .. .. .. .. ... .... .. .. .. .. .. .. ... .... .. .. .. .. . 2-3

PRE-INSTALLATION GUIDELINES ................................................... 2-3

Verify Equipment Location ........................................................ 2-3

Electrical Requirements ............................................................ 2-5

UNPACKING .................................................................................. 2-5

INSTALLATION .............................. ............... ............... ................. ....... 2-6

REQUIRED TOOLS AND MATERIALS ............................. .................. 2-6

HF Series X-ray Generators - Service Manual Revision W

Quantum Medical Imaging

iii

Page 6

Table of Contents

CHAPTER 2 - ASSEMBLY & INSTALLATION (CONT’D)

GENERATOR CABINET SETUP ......................................................... 2-6

Transformer Line Tap Adjustment (Single Phase Non-SE Systems) 2-8

Transformer Line Tap Adjustment (Single Phase SE Systems) ....2-10

AC Input (Mains) Connection ...................................................2-12

High Voltage (H.V.) Tank ......................... ...............................2-15

High Voltage Cables ................. .. .. .. .. .. .. .... .. ... .. .. .. .. .... .. .. ... .. .. ...2-18

INTERFACE BOARD SETTINGS & CONNECTIONS ............................2-21

Door Interlock Switch Connection ............................................2-22

"In Use" Light Switch Connection .............................................2-22

Collimator Connections ............................................................2-23

Tube Stand/Peripheral Equipment Connections .........................2-23

Internal +28 VDC Power Supply Option (QG-28VPS) .................2-23

Tube Rotor Boost Voltage Verification (Systems without

High (Dual) Speed Starter Option) ..........................................2-24

RADIOGRAPHIC SYSTEM EQUIPMENT CONNECTIONS ....................2-25

Tube Rotor Cable (Systems without High (Dual) Speed

Starter Option) ......................................................................2-25

Tube Rotor Cable (Systems with AID External High

Speed Starter QG-HSS Option Only) ........................................2-27

Tube Rotor Cable (Systems with Internal High Speed

Starter Q-HSS Option Only) ................................ ....................2-30

Table/Wall Bucky Connections .................................................2-34

Table/Wall Ion Chamber Connections (AEC Option Only) ...........2-34

Interfacing to Canon Digital Radiographic Receptor

(When Applicable) .................................................................2-35

Interfacing to CMT Digital Radiographic Receptor

(When Applicable) .................................................................2-36

Interfacing to Siemens Ion Chambers (When Applicable) ...........2-36

Interfacing to Pausch Tomography System (When Applicable) ...2-39

OPERATOR CONTROL PANEL SETUP ..............................................2-41

ODYSSEY Operator Control Panel ............................................2-41

OCP Pedestal Mounting (QG-PDL Option) .................................2-41

OCP Wall Mounting (QG-WM Option) ................................ .......2-43

Q-VISION Operator Control Panel ............................................2-44

Integrated Workstation Operator Control Panel .........................2-46

Optional Remote Expose Switch Connection .............................2-47

INITIAL POWER UP ......................................................................2-47

TRANSFORMER TAP VALIDATION ..................................................2-48

Q-VISION OPERATOR CONTROL PANEL - NETWORK

SETTINGS VERIFICATION ............................................................2-49

ROTOR DRIVE BOARD A10 (AY40-013T) PERFORMANCE

VERIFICATION .............. ..............................................................2-55

CHAPTER 3 - CALIBRATION

OVERVIEW .................. .. ... .. .. .. .... .. .. .. ... .. .. .... .. .. .. .. .. ... .. .... .. .. .. .. .. ... .... .. .. 3-3

REQUIRED TOOLS AND MATERIALS ............................................... 3-3

Revision W HF Series X-ray Generators - Service Manual

iv Quantum Medical Imaging

Page 7

Table of Contents

CHAPTER 3 - CALIBRATION (CONT’D)

SYSTEM CONFIGURATION/CALIBRATION ..............................................3-3

ACCESSING SERVICE MODE ...........................................................3-4

SYSTEM CONFIGURATION ........................................ ......................3-6

Printer On/Off Setting ........................ .. ..... .. .. .... .. .. .... ... .. .... .. .... .3-7

Generator Configuration/Derating Settings .................................3-8

AEC Setting .............................................................................3-9

Rotor Drive Setting ................ .... .. .. .... .. .. ..... .. .. .... .. .. ..... .. .. .... .. . 3-10

Edit Facility/Welcome Facility Utility ......................................... 3-11

Tube Type Setting ...... .... .. .. ... .. .. .. .... .. .. .. ... .. .. .. .... .. .. .. ... .. .. .... .. . 3-12

Edit Digital Settings ................................................................3-13

Ion Chamber/Receptor Configuration .......................................3-14

Tomo Setting ............................ ............................................. 3-18

SYSTEM SETTINGS ......................................................................3-21

Set Date Screen ....... .. .... .... ... .. .... .. .. .... .. ... .... .. .. .... .. ..... .. .. .... .. . 3-22

Set Time Screen ................. ... .. .. .. .. .. .... .. ... .. .. .. .. .... .. .. ... .. .. .. .. ... 3-23

Film/Screen Defaults Screen ...................................................3-23

APR Format Setting ................................................................3-25

Language Setting ................................................................... 3-26

Back Up MAS Setting ................................ .............................. 3-27

Generator Timeout Setting ..................................................... . 3-28

Date/Time Format Setting ......................................................3-28

SYSTEM CALIBRATION ................................................................. 3-29

GENERAL CALIBRATION PROCEDURE NOTES ................................3-32

Film Speed Setting on non-AEC Systems .................................. 3-33

A/D Calibration ......................................................................3-34

kV Calibration Function ...........................................................3-37

Filament Offset Calibration ...................................................... 3-39

MA Calibration ..... ..................................................................3-43

AEC CALIBRATION .......................................................................3-46

AEC Calibration Procedures ..................................................... 3-48

NON-AEC REPRODUCIBILITY VERIFICATION .................................3-66

AEC REPRODUCIBILITY VERIFICATION (ONLY PERFORM

ON UNITS EQUIPPED WITH QG-AEC OPTION) .............................. 3-67

NON-AEC LINEARITY VERIFICATION .............................................3-67

AEC LINEARITY VERIFICATION (ONLY PERFORM ON

UNITS EQUIPPED WITH QG-AEC OPTION) ...................................3-68

MAXIMUM DEVIATION: KVP, TIME, MA, MAS ................................. 3-68

CHAPTER 4 - THEORY OF OPERATION

OVERVIEW .......................................................................................... 4-3

OPERATOR CONTROL PANEL CIRCUIT ............................................4-3

Microcontroller U3 Operation .....................................................4-3

Flash Memory U2 .....................................................................4-3

EEPROM U17 Operation ............................................................4-4

LCD Controller U12 Operation ........ .. .... .. ... .... .. .. .... .. .. ..... .. .... .. .. .4-4

HF Series X-ray Generators - Service Manual Revision W

Quantum Medical Imaging

v

Page 8

Table of Contents

CHAPTER 4 - THEORY OF OPERATION (CONT’D)

Switching Power Supply Circuit ................................................. 4-5

Front Panel Key Activation Detection Circuit ............................... 4-5

Jumpers Installation ............................................................. .... 4-5

TechVision Compatibility .......................................................... 4-5

GENERATOR LOGIC CIRCUIT ......................................................... 4-5

Generator/OCP Communication ................................................ 4-6

Master and Slave Microcontroller Operation ............................... 4-6

FILAMENT CONTROL REGULATOR CIRCUIT .................................... 4-7

KVP & FILAMENT CONTROL CIRCUIT .. ............................................ 4-7

LINE MONITOR CIRCUIT (NON-SE SINGLE-PHASE AND

THREE-PHASE SYSTEMS) .............................................................. 4-8

Input Line Monitor Circuit ............................................ ............. 4-8

Capacitor Discharge Circuit ....................................................... 4-9

Auto-Shutoff Circuit ................................................................. 4-9

Three-Phase Line Monitor Circuit .............................................4-10

LINE MONITOR CIRCUIT (STORED ENERGY SYSTEMS) ...................4-10

Battery Monitor Circuit ............................................................4-10

Storage Capacitor Discharge Circuit .........................................4-10

Generator Auto-Shutoff Circuit .................................................4-11

Battery Charger Circuit ............................................................4-11

POWER SUPPLY CIRCUIT ..............................................................4-12

+48 VDC Power Supply ...........................................................4-12

+15 VDC Power Supply ...........................................................4-12

+24 VDC Power Supply ...........................................................4-12

ROTOR BOARD CIRCUIT (NON-HIGH SPEED STARTER SYSTEMS) ...4-13

ROTOR BOARD CIRCUIT (QUANTUM INTERNAL HIGH

SPEED STARTER SYSTEMS) .........................................................4-13

HSS Control Board A20A1 (AY40-035S) ....................................4-14

HSS Drive Board A20A2 (AY40-036S) .......................................4-15

AEC BOARD CIRCUIT ....................................................................4-16

Standard Type AEC .................................................................4-16

Universal Type AEC .................................................................4-17

+300 VDC Power Supply .........................................................4-18

AEC Control Circuitry ...............................................................4-18

Tomography Circuitry ..............................................................4-20

CHAPTER 5 - SERVICE INSTRUCTIONS

OVERVIEW .................. .. ... .. .. .. .... .. .. .. ... .. .. .... .. .. .. .. .. ... .. .... .. .. .. .. .. ... .... .. .. 5-3

DISPOSAL OF BATTERIES AND ACCUMULATORS

(DIRECTIVE 2006/66/EC) .............................................................. 5-3

SERVICE MAINTENANCE ................................................................ 5-4

Visual Inspection ..................................................................... 5-4

TROUBLESHOOTING ............... ........... ............ ........... .......... ........... 5-5

Warning Messages ................................................................... 5-5

Error Codes ............................................................................. 5-5

Optional +28 VDC Power Supply Troubleshooting .....................5-48

Revision W HF Series X-ray Generators - Service Manual

vi Quantum Medical Imaging

Page 9

Table of Contents

CHAPTER 5 - SERVICE INSTRUCTIONS (CONT’D)

SERVICE REPORTS .................................................................. .....5-49

Accessing Service Reports - ODYSSEY X-ray Generators ............5-49

Accessing Service Reports - Q-VISION Operator Control Panel ...5-56

Accessing Service Reports - Integrated X-ray Generators ..........5-63

REMOVAL/REPLACEMENT PROCEDURES ........................................5-72

Generator Cabinet Cover Removal ...........................................5-72

Generator Cabinet Cover Replacement .....................................5-72

High Voltage (H.V.) A17 Tank Removal .................................... 5-73

High Voltage (H.V.) Tank A17 Installation ................................ 5-74

Power Modules A18 and A19 (P/N AY20-047) Removal ............5-75

Power Modules A18 and A19 (P/N AY20-047) Replacement .......5-77

Logic Board A1 (P/N AY40-006S) Removal ...............................5-78

Logic Board A1 (P/N AY40-006S) Replacement .........................5-78

KVP Control Board A2 (P/N AY40-003S) Removal .....................5-80

KVP Control Board A2 (P/N AY40-003S) Replacement ...............5-80

Filament Control Board A5 (P/N AY40-007T) Removal ............... 5-82

Filament Control Board A5 (P/N AY40-007T) Replacement ........5-82

Power Supply Board A6 (P/N AY40-005T) Removal ...................5-83

Power Supply Board A6 (P/N AY40-005T) Replacement .............5-83

Line Monitor Board A8 Removal .............................................. 5-84

Line Monitor Board A8 Replacement ...................... ..................5-84

Stored Energy Systems Line Monitor/Charger Board A8

(AY40-028T) Removal ........................ .. ..... .. .... .. .. .... ... .. .... .. .. . 5-85

Stored Energy Systems Line Monitor/Charger Board

(AY40-028T) A8 Replacement ................................................5-86

Rotor Drive Board A10 (P/N AY40-013T) Removal .................... 5-87

Rotor Drive Board A10 (P/N AY40-013T) Replacement .............. 5-87

Standard AEC Control Board A11 (P/N AY40-031S) Removal .....5-88

Standard AEC Control Board A11 (P/N AY40-031S) Replacement 5-88

Universal AEC Control Board A11 (P/N AY40-027S) Removal .....5-89

Universal AEC Control Board A11 (P/N AY40-027S) Replacement 5-89

OCP Microprocessor Board A16 (P/N AY40-004S1) Removal

(Not Applicable on Q-VISION or Integrated Generators) ..........5-90

OCP Microprocessor Board A16 (P/N AY40-004S1) Replacement

(Not Applicable on Q-VISION or Integrated Generators) ..........5-90

Q-HSS Equipped Systems Only: High-Speed Starter Control

Board A20A1 (P/N AY40-035S) Removal .................................5-91

Q-HSS Equipped Systems Only: High-Speed Starter Control

Board A20A1 (P/N AY40-035S) Replacement ...........................5-91

Q-HSS Equipped Systems Only: High-Speed Starter Driver

Board A20A2 (P/N AY40-036S) Removal .................................5-92

Q-HSS Equipped Systems Only: High-Speed Starter Driver

Board A20A2 (P/N AY40-036S) Replacement ...........................5-92

Stored Energy System - Battery Tray Removal .........................5-93

Stored Energy System - Battery Tray Replacement ...................5-95

HF Series X-ray Generators - Service Manual Revision W

Quantum Medical Imaging

vii

Page 10

Table of Contents

CHAPTER 5 - SERVICE INSTRUCTIONS (CONT’D)

REPLACEMENT PARTS AND ORDERING INFORMATION ...................5-96

ORDERING INFORMATION .......... ... .... .. .. .... .. .. ..... .. .... .. .. .... .. ... .... .. .5-96

CHAPTER 6 - DIAGRAMS

Single-Phase (Non-STORED ENERGY) X-ray Generators, 25, 32 and

40 kW Parts Location Diagram (Sheet 1 of 2) ....................................... 6-3

Single-Phase (Non-STORED ENERGY) X-ray Generators, 25, 32

and 40 kW Parts Location Diagram (Sheet 2 of 2) ................................. 6-4

Single-Phase (STORED ENERGY) X-ray Generators, 20, 32 40 and

50 kW Parts Location Diagram (Sheet 1 of 2) ....................................... 6- 5

Single-Phase (STORED ENERGY) X-ray Generators, 20, 32, 40 and

50 kW Parts Location Diagram (Sheet 2 of 2) ....................................... 6-6

Three-Phase X-ray Generators, 32 and 40 kW Parts

Location Diagram (Sheet 1 of 2) .......................................................... 6-7

Three-Phase X-ray Generators, 32 and 40 kW Parts Location

Diagram (Sheet 2 of 2) ....................................................................... 6-8

Three-Phase X-ray Generators, 50, 65 and 80 kW Parts Location

Diagram (Sheet 1 of 2) ....................................................................... 6-9

Three-Phase X-ray Generators, 50, 65 and 80 kW Parts Location

Diagram (Sheet 2 of 2) ......................................................................6-10

Three-Phase X-ray Generators, 50, 65 and 80 kW (with QMI-HSS)

Parts Location Diagram (Sheet 1 of 2) .................................................6-11

Three-Phase X-ray Generators, 50, 65 and 80 kW (with QMI-HSS)

Parts Location Diagram (Sheet 2 of 2) .................................................6-12

Generator System Cabling Diagram (Internal High-Speed Starter) ..........6-13

Generator System Cabling Diagram (External High-Speed Starter Systems) 6-14

System Cabling Diagram (with Q-Connect Option) ................................6-15

HF Generator to Canon/TechVision System Interconnection Diagram

(Non-Widescreen) .............................................................................6-16

HF Generator to Canon/TechVision System Interconnection

Diagram (Widescreen) ....... ................................................................6-17

17 x 17 Midwest Bucky Interconnection Diagram ..................................6-18

17 x 17 Progeny and L-F Bucky Interconnection Diagram ..................... .6-19

14 x 36 Midwest Bucky Interconnection Diagram ..................................6-20

Single-Phase 208 - 260 VAC Input (Non-STORED ENERGY) X-ray

Generators, 25, 32 and 40 kW Interconnection Diagram .......................6-21

Single-Phase 380 - 480 VAC Input (Non-STORED ENERGY) X-ray

Generators, 25, 32 and 40 kW Interconnection Diagram .......................6-22

Single-Phase (STORED ENERGY) X-ray Generator, 20 kW

Interconnection Diagram ................................................................. ...6-23

Single-Phase (STORED ENERGY) X-ray Generators, 32, 40 and

50 kW Interconnection Diagram .........................................................6-24

Three-Phase (380-480) Input (32, 40 and 50 kW without High

Speed Starter) X-ray Generators Interconnection Diagram ....................6-25

Revision W HF Series X-ray Generators - Service Manual

viii Quantum Medical Imaging

Page 11

Table of Contents

CHAPTER 6 - DIAGRAMS (CONT’D)

Three-Phase (208-240) Input (32, 40 and 50 kW without High

Speed Starter) X-ray Generators Interconnection Diagram ................... 6-26

Three-Phase (50, 65 and 80 kW with AID High Speed Starter) X-ray

Generators Interconnection Diagram ..................................................6-27

Three-Phase (32, 40 and 50 kW without High Speed Starter, with

Universal AEC Board) X-ray Generators Interconnection Diagram .........6-28

Three-Phase (65 and 80 kW with AID High Speed Starter, Universal

AEC Board) X-ray Generators Interconnection Diagram ........................6-29

Three-Phase (208-240) Input (32, 40 and 50 kW without High Speed Starter,

with Universal AEC Board) X-ray Generators Interconnection Diagram AEC6-30

Three-Phase (208-240) Input (50 kW with QMI High Speed Starter) X-ray Generator

Interconnection Diagram .......... .. .... ... .... .. .. .... .. .. ..... .. .. .... .. .. ..... .. .... .. .. . 6-31

Three-Phase (208-240) Input (50 kW with QMI High Speed Starter and

Tomography Interface) X-ray Generator Interconnection Diagram ........ 6-32

Three-Phase (65 and 80 kW with QMI High Speed Starter) X-ray

Generator Interconnection Diagram ....................................................6-33

Three-Phase (65 and 80 kW with QMI High Speed Starter and Tomography

Interface) X-ray Generator Interconnection Diagram ...........................6-34

Operator Control Panel - ODYSSEY/QUEST Wiring Diagram ................... 6-35

Q-Connect Option System Interconnection Diagram .............................6-36

Operator Control Panel Circuit Block Diagram (Non-Q-VISION OCP) ...... . 6-37

Generator Logic Circuit Block Diagram ................................................. 6-38

Filament Regulator Control Circuit Block Diagram ................................. 6-39

KVP & Filament Control Circuit Block Diagram ..................................... . 6-40

Single-Phase (Non-STORED ENERGY) and Three-Phase Line Monitor

Circuit Block Diagram ........................................................................6-41

Single-Phase STORED ENERGY Line Monitor Circuit Block Diagram ........6-42

Interface Board A9 (AY40-023T/AY40-023T1) Schematic Diagram ......... 6-43

Interface Board, Digital Receptor A9 (AY40-034T) Interface Diagram .....6-44

Interface Board, Digital Receptor A9 (AY40-061T) Interface Diagram .....6-45

Power Supply Board A6 (AY40-005T) Schematic Diagram 46

Rotor Circuit Block Diagram ................................................................6-47

QMI High-Speed Starter Circuit Block Diagram .....................................6-48

Logic Board A1 (AY40-006S) Test Point/Jumper Location Diagram .........6-49

KVP Control Board A2 (AY40-003S) Test Point/Jumper Location Diagram 6-50

Filament Control Board A5 (AY40-007T) - Test Point/Jumper Location

Diagram ............................... .. .. .. .. ... .. .... .. .. .. .. .. ... .... .. .. .. .. .. .. ... .... .. .. .. . 6-51

Power Supply Board A6 (AY40-005T) - Test Point/Jumper Location

Diagram ............................... .. .. .. .. ... .. .... .. .. .. .. .. ... .... .. .. .. .. .. .. ... .... .. .. .. . 6-52

Line Monitor Board A8 (AY40-022T1), Single-Phase Systems - Test

Point/Jumper Location Diagram ......................................................... 6-53

Line Monitor/Battery Charger Board A8 (AY40-028T), Stored-Energy

Systems - Test Point/Jumper Location Diagram ...................................6-54

Line Monitor Board A8 (AY40-022T2/T3), Three-Phase Systems - Test

Point/Jumper Location Diagram ......................................................... 6-55

Line Monitor Board A8 (AY40-053S2/AY40-053S3), Three-Phase QMI

High-Speed Starter Systems - Test Point/Jumper Location Diagram ...... 6-56

HF Series X-ray Generators - Service Manual Revision W

Quantum Medical Imaging

ix

Page 12

Table of Contents

CHAPTER 6 - DIAGRAMS (CONT’D)

Interface Board (No HSS Non-Digital) A9 (AY40-023T) - Terminal

Block/Jumper Location Diagram ..........................................................6-57

Digital Interface Board (No HSS with Digital Receptor) A9 (AY40-034T) -

Terminal Block/Jumper Location Diagram ............................................6-58

Interface Board (HSS Non-Digital) A9 (AY40-061T) Terminal Block/Jumper

Location Diagram ............................................................................. .6-59

Digital Interface Board (HSS with Digital Receptor) A9 (AY40-062T)

Terminal Block/Jumper Location Diagram ............................................6-60

Rotor Drive Board A10 (AY40-013T) - Terminal Block Location Diagram .6-61

Standard AEC Board A11 (AY40-031S) - Test Point/Jumper Location

Diagram ...........................................................................................6-62

Universal AEC Board A11 (AY40-027S) - Test Point/Jumper Location

Diagram ...........................................................................................6-63

OCP Control Board A16A1 (AY40-004S1) - Test Point/Jumper

Location Diagram ............................................................................. .6-64

OCP Interface Board A1A1 (AY40-073S) - Test Point/Jumper Location

Diagram ...........................................................................................6-65

QMI High-Speed Starter Control Board A20A1 (AY40-035S) - Test

Point/Potentiometer Location Diagram ................. ...............................6-66

QMI High-Speed Starter Driver Board A20A2 (AY40-036S) - Test

Point/Fuse Location Diagram ..............................................................6-67

APPENDIX A - AEC CALIBRATION WITH

DIGITAL RECEPTOR OR CR FILM PLATE

OVERVIEW .................. .. ... .. .. .. .... .. .. .. ... .. .. .... .. .. .. .. .. ... .. .... .. .. .. .. .. ... .... .. .. A-3

SPECIAL CANON DR SYSTEM CONFIGURATION INSTRUCTIONS ....... A-3

AEC CALIBRATION WITH DIGITAL RECEPTOR OR CR FILM PLATE

INSTALLED .................................................................................. A-4

AEC Calibration Instructions - One Ion Chamber Per Panel .........A-8

AEC Calibration Instructions - Single Panel, Dual Ion Chambers A-13

APPENDIX B - CALIBRATION (AGFA DIREX)

OVERVIEW .................. .. ... .. .. .. .... .. .. .. ... .. .. .... .. .. .. .. .. ... .. .... .. .. .. .. .. ... .... .. .. B-3

REQUIRED TOOLS AND MATERIALS ............................................... B-4

SYSTEM CONFIGURATION/CALIBRATION ............................................. B-4

ACCESSING SERVICE MODE ...... .. ... .... .. .. .... .. .. ..... .. .. .... .. .... .. ... .... .. .. B-4

FACTORY RESET ........................................................................... B-8

Factory Reset .......................................................................... B-8

Backup Configuration Utility ...................................................... B-9

GENERATOR CONFIGURATION ..................................................... B-10

Generator Settings ................................................ ................. B-13

Tube Settings ........................................................................ B-15

Ion Chamber Configuration .............. .... .. .... ... .. .... .. .. .... .. ... .... .. B-17

Film/Screen Default Settings ................................................... B-21

Revision W HF Series X-ray Generators - Service Manual

x Quantum Medical Imaging

Page 13

Table of Contents

APPENDIX B - CALIBRATION (AGFA DIREX) (CONT’D)

Copy Film Screen Utility ..........................................................B-23

GENERATOR CALIBRATION ..........................................................B-25

General Calibration Procedure Notes ........................................B-26

A/D Calibration ................ .. ... .. .. .. .. .... .. .. ... .. .. .. .... .. .. .. ... .. .. .. .... . B-27

kV Calibration ........................................................................ B-30

Filament Offset Calibration ......................................................B-32

MA Calibration ......................................................................B-37

AEC CALIBRATION ........... .. .... ..... .. .... .. .. .... .. ... .... .. .. .... .. .. ..... .. .... .. .B-40

Ion Chamber Balancing (Three-field Chambers) .......................B-43

AEC MAS Balance Verification .......................... .... .. .. ..... .. .. .... .. .B-45

Film Screen Selection .............................................................B-47

The AEC Calibration Menu ......................................................B-50

Optical Density Calibration ......................................................B-51

AEC Optical Density Calibration .......... .... ... .. .... .. .. .... .. ..... .. .. .... . B-52

AEC KV Calibration Procedure .................................................B-55

APPENDIX C - LOG4VIEW ERROR LOGGER

APPENDIX D - (QG-DIG-CXDI CANON/QUANTUM

INTEGRATION) CALIBRATION

OVERVIEW .................. .............................................. ......................... D-3

REQUIRED TOOLS AND MATERIALS ............................................... D-4

ACCESSING GENERATOR SERVICE TOOLS ...................................... D-4

Accessing Generator Service Tools - Q-VISION Operator

Control Panel ......................................................................... D-5

Accessing Generator Service Tools - Workstation-Based

Operator Control Panel ........................................................... D-7

SYSTEM CONFIGURATION/CALIBRATION ............................................D-10

GENERATOR CONFIGURATION .....................................................D -12

Generator Settings Tab .............. .............................................D-12

Generator Calibrations Tab .....................................................D-13

Tube Settings Tab ..................................................................D-13

Physical Receptors Tab ...................... .. .. ..... .. .. .... .. .. ..... .. .. .... .. .D-15

Receptors Tab .......................................................................D-16

Ion Chambers Tab ...................... .. .... .. ..... .. .. .... .. .. .... ... .. .... .. .. .D-18

Licensing Tab ........................................................................D-20

GENERATOR CALIBRATION ..........................................................D-21

A/D Tab .................... .. .. .... ... .. .. .. .. .. .. .... ... .. .. .. .. .. .... .. ... .. .. .. .. .. .D-24

kVp Calibration Tab ............... .. .... .. .. .... .. ... .... .. .... .. .. ..... .. .. .... .. .D-28

Filament Offset Calibration ......................................................D-31

MA Calibration Tab .................................................................D-41

AEC CALIBRATION ........... .. .... ..... .. .... .. .. .... .. ... .... .. .. .... .. .. ..... .. .... .. .D-45

Ion Chamber Balancing (Three-field Chambers) .......................D-47

AEC MAS Balance Verification .......................... .... .. .. ..... .. .. .... .. .D-50

The AEC Calibration Tab ............................... ..........................D-52

HF Series X-ray Generators - Service Manual Revision W

Quantum Medical Imaging

xi

Page 14

Table of Contents

APPENDIX D - (QG-DIG-CXDI CANON/QUANTUM

INTEGRATION) CALIBRATION (CONT’D)

Base OD Calibration Procedure .......................... ..................... D-56

AEC kVp Calibration Procedure ...............................................D-58

Copy Receptor Calibration Tab ................................................ D-62

Revision W HF Series X-ray Generators - Service Manual

xii Quantum Medical Imaging

Page 15

Chapter

1

SPECIFICATIONS

1-1

Page 16

1-2

Page 17

Chapter 1 Specifications

SYSTEM CONFIGURATIONS

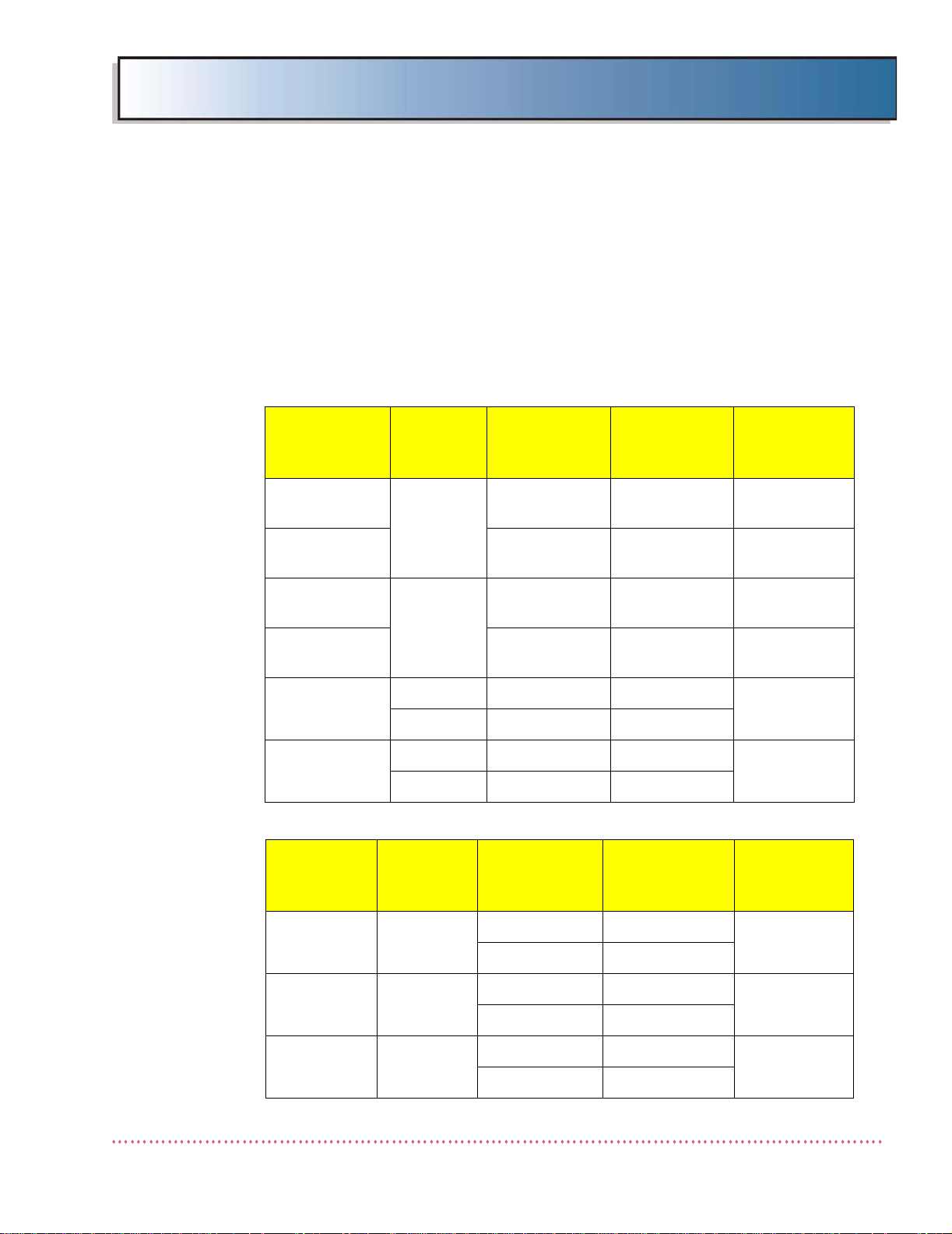

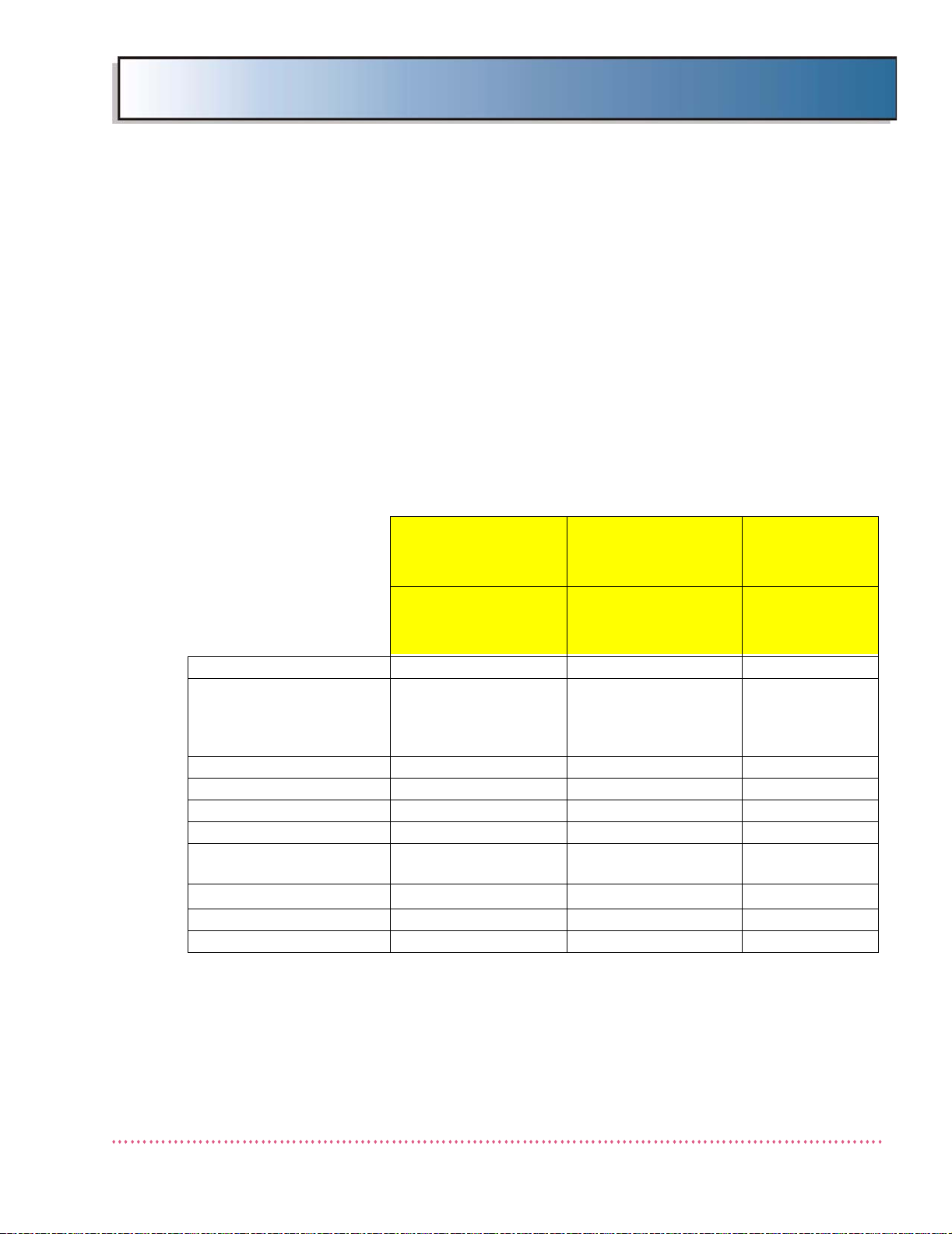

The tables below show model numbers of components in each type of HF Series

X-ray Generator system (hereinafter referred to as the "HF Series X-ray Generators").

Note: The X-Ray Control Models shown in the following

tables are not used if the HF generator system is integrated

with computed radiographic (CR) or digital radiographic (DR)

workstation computer (e.g., Agfa NX, Canon CXDI, etc.).

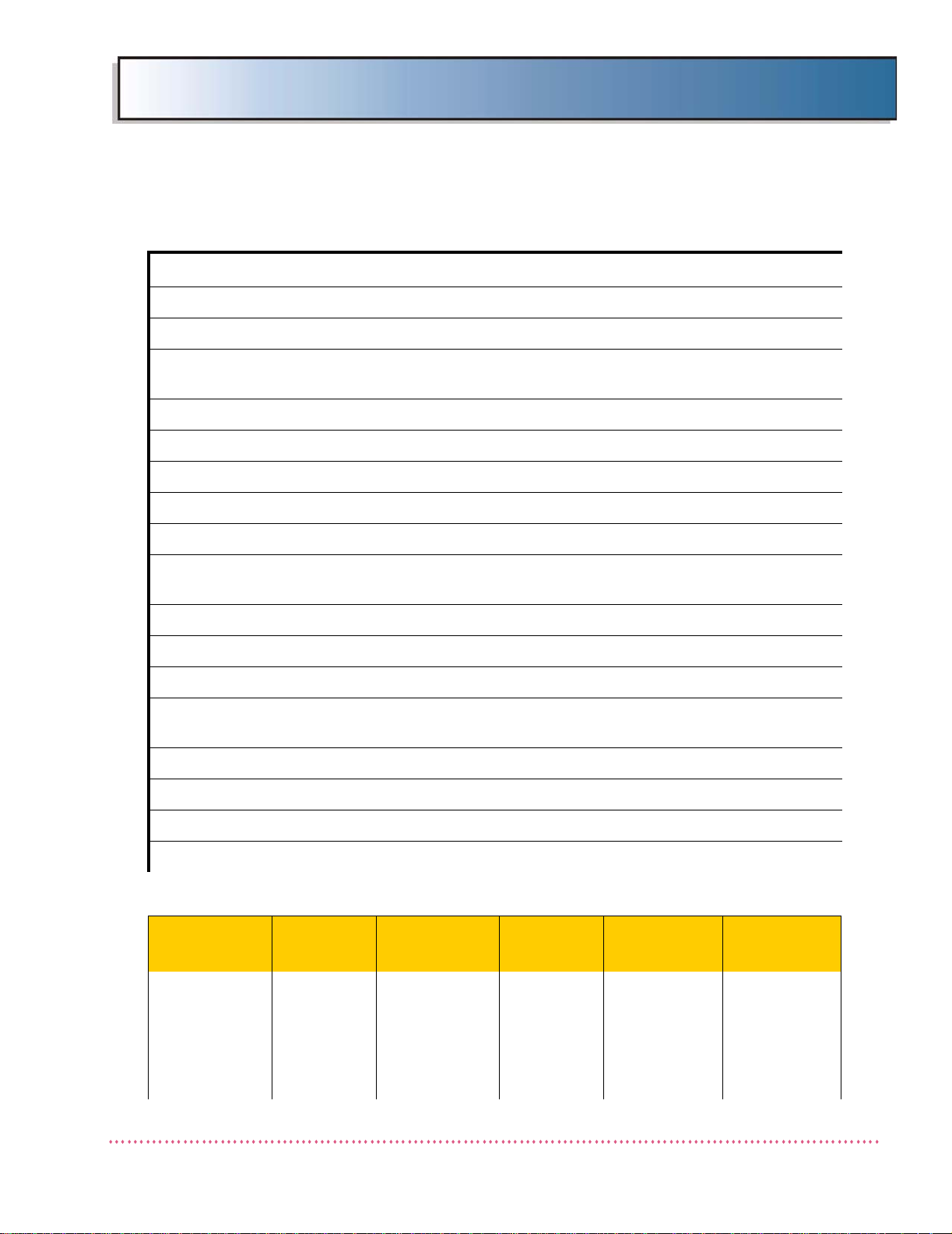

Single-Phase Model Generators

TM

SYSTEM

TYPE

ODYSSEY HF

32 kW

ODYSSEY HF

32 kW

ODYSSEY HF

40 kW

ODYSSEY HF

40 kW

Q-VISION HF

32 kW

Q-VISION HF

40 kW

SYSTEM

TYPE

CATALOG

NO.

QG-3200

QG-4000

QGV-32 QG-32 QG-32G

QGV-32-5 QG-32-5 QG-32G-5

QGV-40 QG-40 QG-40G

QGV-40-5 QG-40-5 QG-40G-5

Three-Phase Model Generators

CATALOG

NO.

SYSTEM

MODEL

QG-32 QG-32G QG-3200

QG-32-5 QG-32G-5 QG-3200

QG-40 QG-40G QG-4000

QG-40-5 QG-40G-5 QG-4000

SYSTEM

MODEL

GENERATOR

CABINET

MODEL

GENERATOR

CABINET

MODEL

X-RAY

CONTROL

MODEL*

QGV-32

QGV-40

X-RAY

CONTROL

MODEL

ODYSSEY

HF 32 kW

ODYSSEY

HF 40 kW

ODYSSEY

HF 50 kW

QG-3200

QG-4000

QG-5000

QG-32-2 QG-32G-2

QG-3200

QG-32-3 QG-32G-3

QG-40-2 QG-40G-2

QG-4000

QG-40-3 QG-40G-3

QG-50-2 QG-50G-2

QG-5000

QG-50 QG-50G

HF Series X-ray Generators - Service Manual Revision W

Quantum Medical Imaging 1-3

Page 18

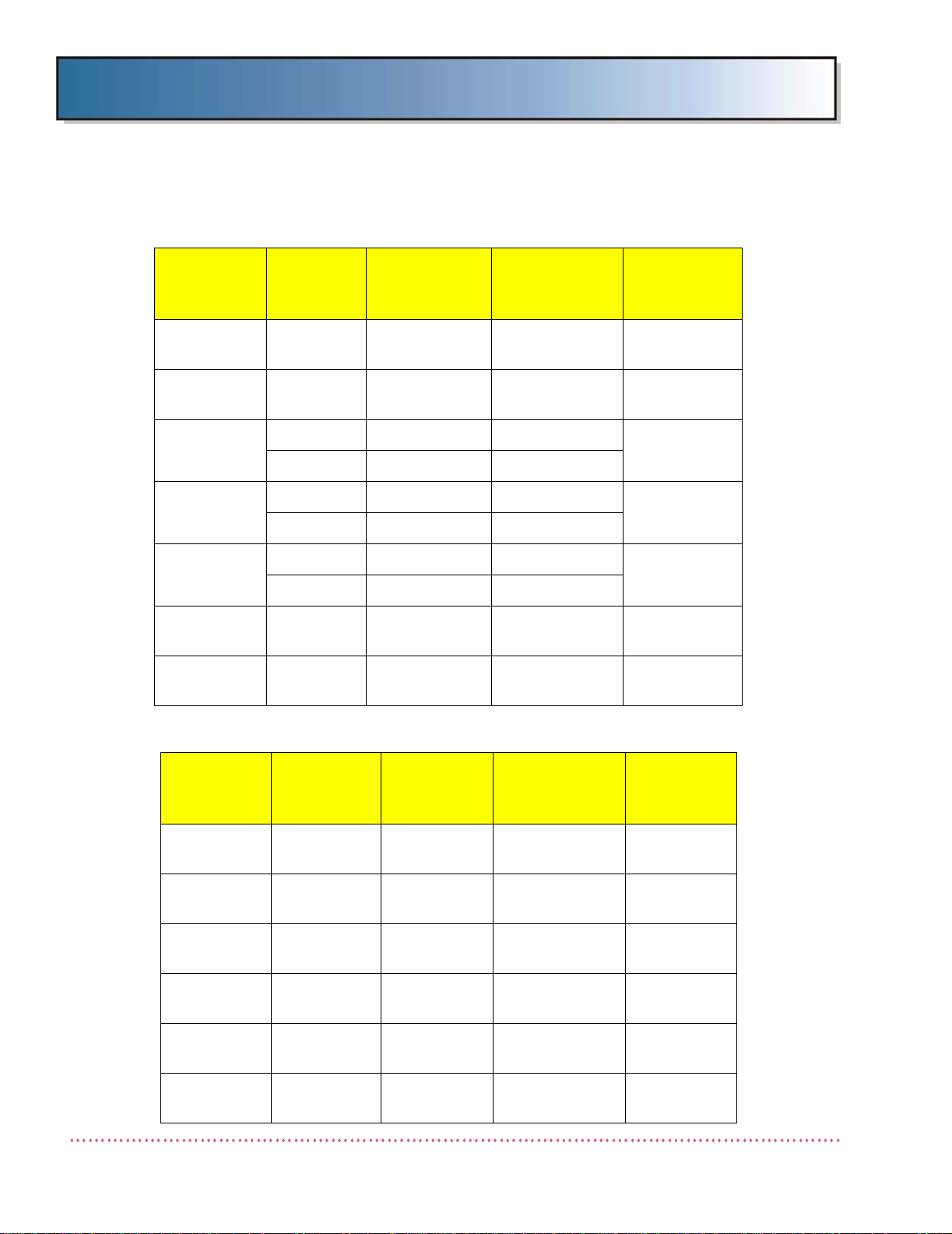

Chapter 1 Specifications

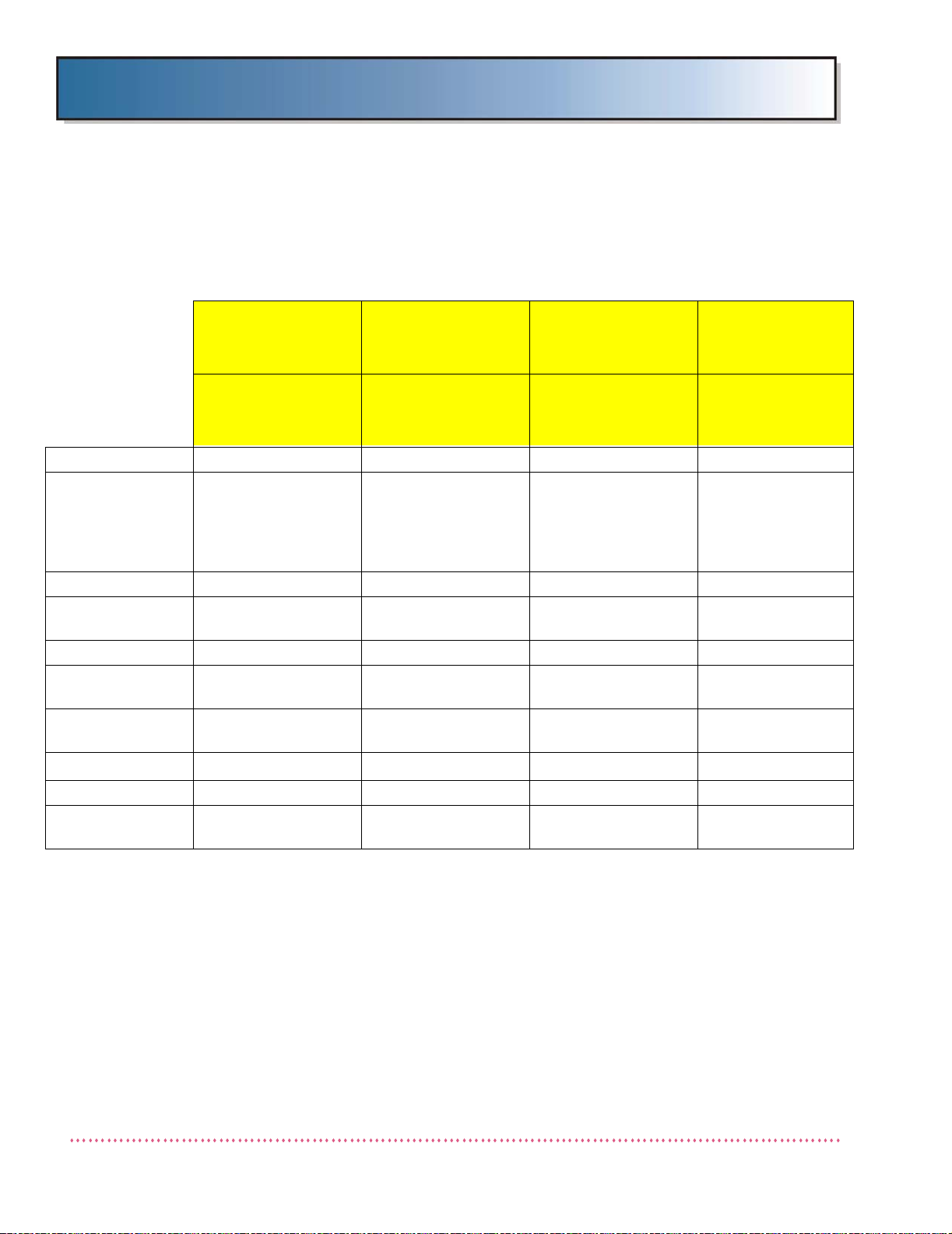

Three-Phase Model Generators

SYSTEM

TYPE

ODYSSEY

HF 65 kW

ODYSSEY

HF 80 kW

Q-VISION

HF 32 kW

Q-VISION

HF 40 kW

Q-VISION

HF 50 kW

Q-VISION

HF 65 kW

Q-VISION

HF 80 kW

CATALOG

NO.

QG-6500 QG-65 QG-65G QG-6500

QG-8000 QG-80 QG-80G QG-8000

QGV-32-2 QG-32-2 QG-32G-2

QGV-32-3 QG-32-3 QG-32G-3

QGV-40-2 QG-40-2 QG-40G-2

QGV-40-3 QG-40-3 QG-40G-3

QGV-50-2 QG-50-2 QG-50G-2

QGV-50 QG-50 QG-50G

QGV-65 QG-65 QG-65G QGV-65

QGV-80 QG-80 QG-80G QGV-80

SYSTEM

MODEL

GENERATOR

CABINET

MODEL

X-RAY

CONTROL

MODEL

QGV-32

QGV-40

QGV-50

STORED ENERGY (SE) Model Generators

SYSTEM

TYPE

ODYSSEY

HF 32 kW

ODYSSEY

HF 40 kW

ODYSSEY

HF 50 kW

Q-VISION

HF 32 kW

Q-VISION

HF 40 kW

Q-VISION

HF 50 kW

CATALOG

NO.

QG-3200-SE QG-32-SE QG-32G-SE QG-3200

QG-4000-SE QG-40-SE QG-40G-SE QG-4000

QG-5000-SE QG-50-SE QG-50G-SE QG-5000

QGV-32-SE QG-32-SE QG-32G-SE QGV-32-SE

QGV-40-SE QG-40-SE QG-40G-SE QGV-40-SE

QGV-50-SE QG-50-SE QG-50G-SE QGV-50-SE

SYSTEM

MODEL

GENERATOR

CABINET

MODEL

X-RAY

CONTROL

MODEL

Revision W HF Series X-ray Generators - Service Manual

1-4 Quantum Medical Imaging

Page 19

Chapter 1 Specifications

PHYSICAL SPECIFICATIONS

The following are physical specifications of the HF Series X-ray Generators:

GENERATOR CABINET SPECIFICATIONS

Width: 24.0 inches (609.6 mm)

Depth: 20.0 inches (508.0 mm)

Height: 34.7 inches (881.4 mm)

Weights:

Single-Phase (non-SE units): 298 lbs. (135.2 kg)

32, 40 and 50 kW Stored

Energy (SE) units: 431 lbs. (195.5 kg)

50, 65, 80 kW Three-Phase

units): 380 lbs. (712.4 kg) w/o internal HSS

388 lbs. (176.0 kg) w/internal HSS

OPERATOR CONTROL PANEL SPECIFICATIONS

Note: X-Ray Control Panels below are utilized with HF generator systems integrated with computed radiographic (CR) or

digital radiographic (DR) workstation computers (e.g., Agfa

NX, Canon CXDI, etc.).

The Q-VISION all-in-one operator control is not powered from the generator cabinet; it requires a separate 100-240 VAC, 3A power input.

ODYSSEY HF Control Panel:

Width: 17.9 inches (454.7 mm)

Depth: 12.25 inches (311.2 mm)

Height (without pedestal): 3.3 inches (83.8 mm)

Height (with pedestal): 36.5 inches (927.4 mm)

Weight (without pedestal): 5 lbs. (2.3 kg)

Weight (with pedestal): 25 lbs. (11.3 kg)

Q-VISION HF Control Panel:

Width: 18.7 inches (476.0 mm)

Depth (without stand): 1.9 inches (49.0 mm)

Depth (with stand): 7.125 inches (181.0 mm)

Height: 14.4 inches (365.0 mm)

Weight: 13 lbs. (5.9 kg)

SYSTEM SPECIFICATIONS

System Compatibility: Compatible with all Quantum Medical

Tube Compatibility: Toshiba Models E7239X, E7242X, E7252X,

Imaging tube stands, overhead tube

cranes, radiographic tables and wall stands

E7254X, E7255X, E7813X, E7869X

Varian Models RAD-8, RAD-13, RAD-14,

RAD-21, RAD-44, RAD-56, RAD-60,

RAD-68, RAD-74, RAD-92, A192, A272,

A292

HF Series X-ray Generators - Service Manual Revision W

Quantum Medical Imaging 1-5

Page 20

Chapter 1 Specifications

Collimators: Huestis Manual, Model 150MC

Note: The HF Series radiographic systems are compatible with any

automatic collimating system that provides an isolated normally open switch that closes when the Automatic Collimation System presents an “EXPOSURE READY” mode to the

control; they are also compatible with any beam limiting

device that complies with 21 CFR Subchapter J intended for

radiographic equipment.

POWER REQUIREMENTS

Dunlee Models PX 1302, PX 1429, PX 1436,

PX 1312, DU 309, DA 1092, MX100

replacement tube for GE Radiographic

Systems

(For tube types not listed, consult factory.)

Huestis Automatic, Model 150PBL

Huestis Selectable, Model 150A,

Progeny Linear MC150 (Manual)

Progeny Linear II and Linear IV

(Automatic)

In order to assure the proper operation of our equipment and subsequently, the production of high-qua lity radiographs, it is es se ntial that all pow er r e q u irements, as sp ec if ied in

the tables that follow, are suitably met by the facility in which the equipment is installed.

This includes usage of the proper size conductor between distribution transformer and disconnect switch, connection to a supply transformer of sufficient capacity (specified in

terms of KVA), insuring the AC input voltage tolerance meets specification (±5% or ±10%

depending on model), and voltage regulation of 5% at full load is maintained. All wiring

and grounding at the installation site must be in accordance with applicable National Electric Code (NEC) and/or local electrical codes.

THe generator requires a 3-phase "Y" connection, measured line-to-line, balanced to

earth or neutral. The "Y" connection can be 4-wire (L1, L2, L3, Neutral) and GND or

3-wire (L1, L2, L3) and GND. The 4-wire connection may be required by local electrical code and in connection where a roughly balanced 3-phase source exists (e.g.,

when using a delta-to-Y transformer).

Note that failure to comply with the above requirements not only may result in

improper generator operation and/or performance, but it will also void the warranty,

as the warranty is exclusive of the following conditions:

• "Failure of customer to prepare the site or provide power requirements or

operating environmental conditions in compliance with any applicable

instructions or recommendations of QMI.

• "Failure of customer to provide the proper incoming power required to support

the equipment in accordance with the recommendation of QMI.

• "Improper or extraordinary use of the Product, improper maintenance of the

Product, or failure to comply with any applicable instructions or

recommendations of Quantum Medical Imaging, LLC.

Revision W HF Series X-ray Generators - Service Manual

1-6 Quantum Medical Imaging

Page 21

Chapter 1 Specifications

NOTE: All single-phase x-ray generator input ratings assume the use of a

single-phase distribution transformer. When utilizing two legs of a 3phase transformer, review the National Electrical Code and any applicable local electrical code(s) to ensure the correct rating distribution

transformer (in terms of KVA) is used to assure line stability. This

configuration would require an increase in the overall power (KVA) of

the distribution transformer, depending on whether the input line

transformer is Wye or Delta type. Under no circumstances should a

Delta type transformer be used for input power to a 3-phase generator.

SINGLE-PHASE X-RAY GENERATORS

Non-Stored Energy Single-phase x-ray genera tors require three-wire line inputs in

either of the following two configurations:

• one hot wire, one neutral wire, and one earth ground wire

• two hot wires and one earth ground.

Refer to Table 1-1 for power requirements of single-phase (non-stored energy)

HF Series Generators.

25 kW Single Phase (Model QG-25)

Line Voltage: 208-260 VAC (±5%), 100 Amps, 50/60 Hz

Momentary Current: 200 Amps (@208VAC)

Long Term Current: less than 1.0 Amp

Mode of Operation: Intermittent operation

25 kW Single Phase (Model QG-25-5)*

Line Voltage: 380 - 480 VAC (±10%), 60 Amps, 50/60 Hz

Momentary Current: 110 Amps @ 415 VAC

Long Term Current: less than 1.0 Amp

Mode of Operation: Intermittent operation

32 kW Single Phase (Model QG-32)

Line Voltage: 208-260 VAC (±5%), 120 Amps, 50/60 Hz

Momentary Current: 240 Amps (@208VAC)

Long Term Current: less than 1.0 Amp

Mode of Operation: Intermittent operation

32 kW Single Phase (Model QG-32-5)*

Line Voltage: 380 - 480 VAC (±10%), 75 Amps, 50/60 Hz

Momentary Current: 140 Amps @ 415 VAC

Long Term Current: less than 1.0 Amp

Mode of Operation: Intermittent operation

HF Series X-ray Generators - Service Manual Revision W

Quantum Medical Imaging 1-7

Page 22

Chapter 1 Specifications

40 kW Single Phase (Model QG-40)

Line Voltage: 208-260 VAC (±5%), 150 Amps, 50/60 Hz

Momentary Current: 300 Amps (@208VAC)

Long Term Current: less than 1.0 Amp

Mode of Operation: Intermittent operation

40 kW Single Phase (Model QG-40-5)*

Line Voltage: 380-480 VAC (±10%), 100 Amps, 50/60 Hz

Momentary Current: 170 Amps @ 415 VAC

Long Term Current: less than 1.0 Amp

Mode of Operation: Intermittent operation

32 kW Single Phase, Stored Energy

Line Voltage: 105-130 (±10%), 10 Amps, 50/60 Hz

Momentary Current: 13 Amps @ 115 VAC

Long Term Current: less than 1.0 Amp

Mode of Operation: Intermittent operation

40 kW Single Phase, Stored Energy

Line Voltage: 105-130 (±10%), 10 Amps, 50/60 Hz

Momentary Current: 13 Amps @ 115 VAC

Long Term Current: less than 1.0 Amp

Mode of Operation: Intermittent operation

50 kW Single Phase, Stored Energy

Line Voltage: 105-130 (±10%), 10 Amps, 50/60 Hz

Momentary Current: 13 Amps @ 115 VAC

Long Term Current: less than 1.0 Amp

Mode of Operation: Intermittent operation

210-250 VAC (±10%), 10 Amps, 50/60 Hz

7 Amps @ 230 VAC

210-250 VAC (±10%), 10 Amps, 50/60 Hz

7 Amps @ 230 VAC

210-250 VAC (±10%), 10 Amps, 50/60 Hz

7 Amps @ 230 VAC

Note: Models QG-25-5, QG-32-5, and QG-40-5 are not UL classified.

Revision W HF Series X-ray Generators - Service Manual

1-8 Quantum Medical Imaging

Page 23

Chapter 1 Specifications

THREE-PHASE X-RAY GENERATORS

Three-phase x-ray generators require three "hot" wires and one earth ground

wire. Refer to Tables 1-2 and 1-3 for power requirements of three-phase HF

Series Generators.

32 kW Three Phase (Model QG-32-2)

Line Voltage: 208-240 VAC (±5%), 70 Amps, 50/60 Hz

Momentary Current: 140 Amps (@220 VAC)

Long Term Current: less than 1.0 Amp

Mode of Operation: Intermittent operation

32 kW Three Phase (Model QG-32-3)

Line Voltage: 380-480 VAC (±10%), 60 Amps, 50/60 Hz

Momentary Current: 117 Amps (@440 VAC)

Long Term Current: less than 1.0 Amp

Mode of Operation: Intermittent operation

40 kW Three Phase (Model QG-40-2)

Line Voltage: 208-240 VAC (±5%), 85 Amps, 50/60 Hz

Momentary Current: 170 Amps (@220 VAC)

Long Term Current: less than 1.0 Amp

Mode of Operation: Intermittent operation

40 kW Three Phase (Model QG-40-3)

Line Voltage: 380-480 VAC (±10%), 60 Amps, 50/60 Hz

Momentary Current: 125 Amps (@440 VAC)

Long Term Current: less than 1.0 Amp

Mode of Operation: Intermittent operation

50 kW Three Phase (Model QG-50-2)

Line Voltage: 208-240 VAC (±5%), 110 Amps, 50/60 Hz

Momentary Current: 220 Amps (@220 VAC)

Long Term Current: less than 1.0 Amp

Mode of Operation: Intermittent operation

50 kW Three Phase (Model QG-50-3)

Line Voltage: 380-480 VAC (±10%), 80 Amps, 50/60 Hz

Momentary Current: 144 Amps (@440 VAC)

Long Term Current: less than 1.0 Amp

Mode of Operation: Intermittent operation

HF Series X-ray Generators - Service Manual Revision W

Quantum Medical Imaging 1-9

Page 24

Chapter 1 Specifications

65 kW Three Phase (Model QG-65)

Line Voltage: 380-480 VAC (±10%), 90 Amps, 50/60 Hz

Momentary Current: 190 Amps (@440 VAC)

Long Term Current: less than 1.0 Amp

Mode of Operation: Intermittent operation

80 kW Three Phase (Model QG-80)

Line Voltage: 380-480 VAC (±10%), 100 Amps, 50/60 Hz

Momentary Current: 200 Amps (@440 VAC)

Long Term Current: less than 1.0 Amp

Mode of Operation: Intermittent operation

HIGH-SPEED STARTER POWER REQUIREMENTS

A High-Speed Starter (HSS) unit is optional on Models QG-40 and

QG-50, and is standard equipment on Models QG-65 and QG-80.

The external HSS (QG-HSS) configuration requires a separate 200 - 240 VAC, 20A

line input. Note that a separate 200- 240 VAC line input is

erators equipped with Internal High Speed Starter (Q-HSS) configuration.

not required

on gen-

Revision W HF Series X-ray Generators - Service Manual

1-10 Quantum Medical Imaging

Page 25

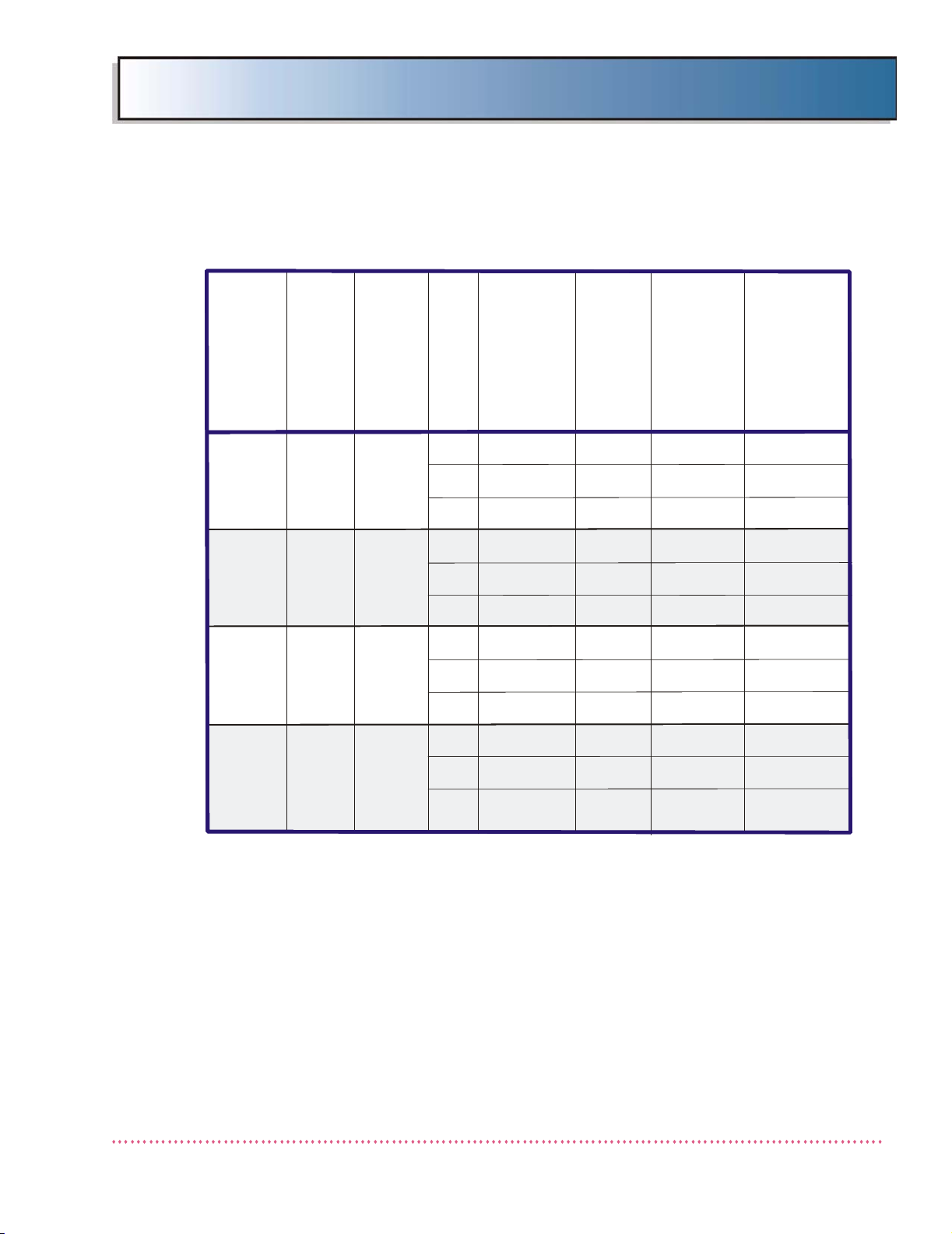

Chapter 1 Specifications

QG-25

QG-32

QG-40

GENERATOR

MODEL NO.

MAX. POWER

OUTPUT (kW)

NOMINAL LINE

VOLTAG E (VAC)

DISCONNECT

TO GENE R ATO R

15 FT. (5 M) M A X .

*SERVICE

RATING

*RECOMMENDED

DISTR IBU T IO N

TRANSFORMER

CAPACITY

MAX. INPUT LINE

RESISTANCE

(AT FULL-LOAD

RMS)

NOTE: All installations must meet the requirements of local electrical codes.

The above values are recommended as typical (unless otherwise specified).

*

1.

±5%)

Line Regulation: 5% at full load.

7. Ground wire size is 4 AWG.

8. Specifications are subject to change.

9. Specifications for single-phase “stored en ergy” Models QG-20-SE, QG-32-SE,

QG-40-SE and QG-50-SE are as follows:

105-130 VAC (±10%), 10 Amps, 50/60 Hz

210-250 VAC (±10%), 10 Amps, 50/60 Hz

All wire must be copper.

2. Actual wire size depends on power quality and distance between mains power

and the generator.

3. All wiring and grounding must be in accordance with National

Electric Code (NFPA #70) or local electrical codes.

4. The disconnect switch must be located within reach of the operator.

5. Input Voltage: 208-257 ( VAC 50/60 Hz (configured at time of installation).

6.

QG-250

QG-320,

QG-3200,

QGV-32

QG-400,

QG-4000,

QGV-40

GENERATOR

CATALOG NO.

208

25

32

40

240

208

240

208

240

#4 AWG

#4 AWG

#2 AWG

#2 AWG

#1 AWG

#1 AWG

100 AMPS

80 AMPS

120 AMPS

100 AMPS

150 AMPS

120 AMPS

30 KVA

30 KVA

40 KVA

40 KVA

50 KVA

50 KVA

0.06 OHMS

0.08 OHMS

0.04 OHMS

0.05 OHMS

0.035 OHMS

0.04 OHMS

Table 1-1. HF Series Generators -

Electrical Wiring Requirement s (208 - 260 VAC Single-Phase Input Units)

HF Series X-ray Generators - Service Manual Revision W

Quantum Medical Imaging 1-11

Page 26

Chapter 1 Specifications

*NOTE: All installations must meet the requirements of local electrical codes.

The above values are recommended as typical (unless otherwise specified).

*

1.

Input Voltage: 380-480 (±10%) VAC 50/60 Hz (configured at time of installation)

. Ground wire size is 4 AWG.

7. Specifications are subject to change.

All wire must be copper.

2. Actual wire size depends on power quality and distance between mains power

and the generator.

3. All wiring and grounding must be in accordance with National

Electric Code (NFPA #70) or local electrical codes.

4. The disconnect switch must be located within reach of the operator.

5. .

6

GENERATOR

MODEL NO.

MAX. POWER

OUTPUT (kW)

NOMINAL LINE

VOLTAGE (VAC)

DISCONNECT

TO GENERATOR

15 FT. (5 M) MAX.

*SERVICE

RATING

*RECOMMENDED

DISTRIBUTION

TRANSFORMER

CAP ACITY

MAX. INPUT LINE

RESISTANCE

(A T F U L L-LOAD

RMS)

GENERATOR

CATALOG NO .

25

32

40

QG-25-5

QG-32-5

QG-40-5

QG-250-5

QG-320-5,

QG-3200-5,

QGV-32-5

QG-400-5,

QG-4000-5,

QGV-40-5

380

#6 AWG 60 AMPS

32 KVA

0.028 OHMS

415 #6 AWG 55 AMPS 32 KVA 0.028 OHMS

480 #6 AWG 40 AMPS 32 KVA 0.032 OHMS

380 #6 AWG 75 AMPS 40 KVA 0.024 OHMS

415 #6 AWG 70 AMPS 40 KVA 0.024 OHMS

480

#6 AWG 60 AMPS

40 KVA

0.028 OHMS

380 #4 A WG 100 AMPS 50 KVA 0.015 OHMS

415

#4 AWG 90 AMPS

50 KVA

0.020 OHMS

480

#6 AWG 70 AMPS

50 KVA

0.024 OHMS

Table 1-2. HF Series Generators -

Electrical Wiring Requirements (380 - 480 VAC Single-Phase Input Units)

Revision W HF Series X-ray Generators - Service Manual

1-12 Quantum Medical Imaging

Page 27

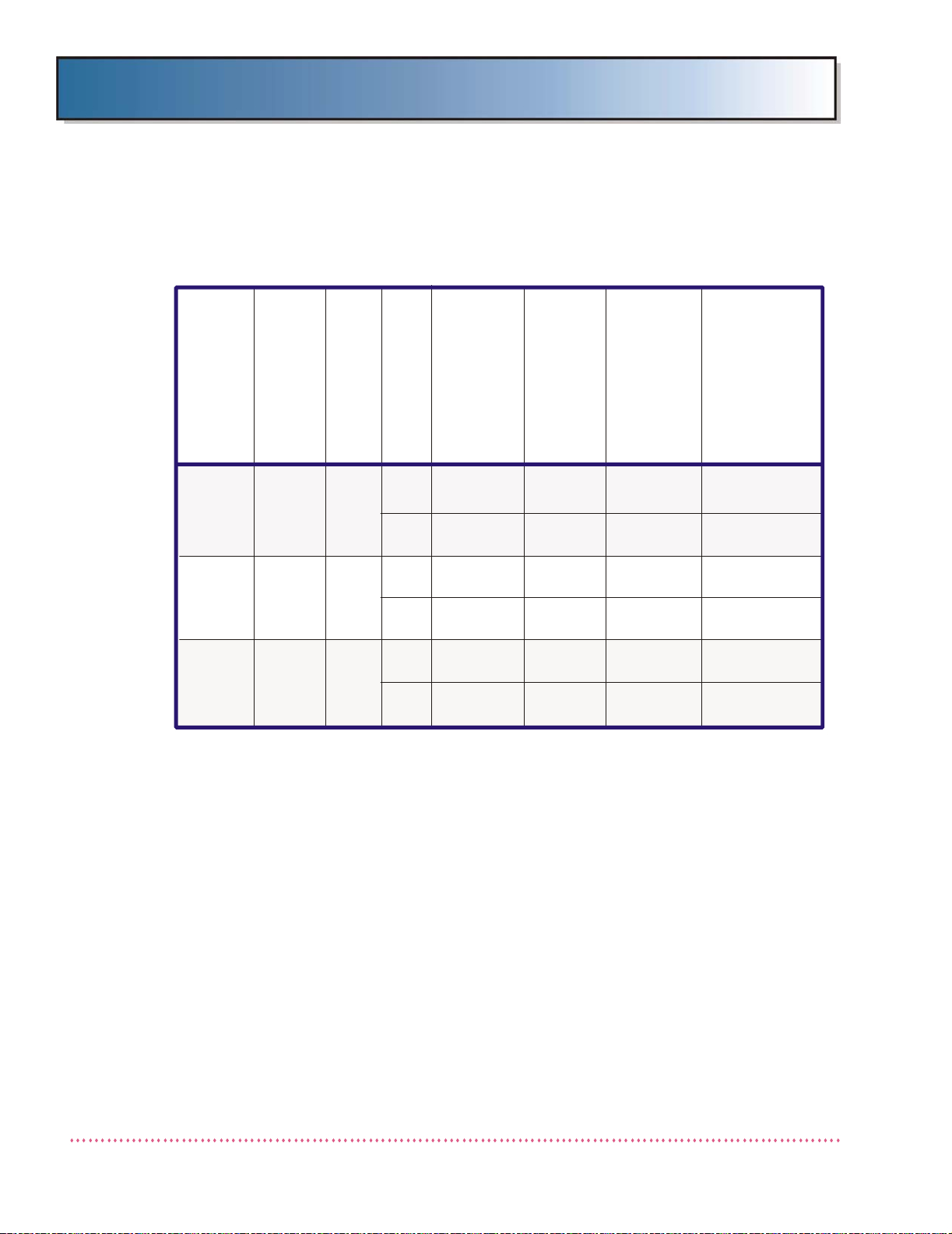

Chapter 1 Specifications

QG-32-3,

QG-40-3

QG-50

QG-65

QG-80

32

(QG-32

-3)

40

(QG-40-3)

50

65

80

G

E

N

E

R

A

T

O

R

M

O

D

E

L

N

O

.

MAX. POWER

O

UTPUT (kW)

N

O

M

I

N

A

L

L

I

N

E

V

O

L

T

A

G

E

(

V

A

C

)

DISCONNECT

TO GENERATOR

15 FT. (5 M) MAX.

*

S

E

R

V

I

C

E

R

A

T

I

N

G

*

R

E

C

O

M

M

E

N

D

E

D

D

I

S

T

R

I

B

U

T

I

O

N

T

R

A

N

S

F

O

R

M

E

R

C

A

P

A

C

I

T

Y

MAX. INPUT LINE

RESISTANCE

(AT FULL-LO AD RMS)

380#6 AWG60 AMP

S

50 KV

A

0.23 OHMS380#4 AWG80 AMPS65 KVA0.17 OHMS380#4 AWG90 AMPS80 KVA0.12 OHMS380#4 AWG100 AMPS100 KVA0.10 OHMS440#6 AWG60 AMPS50 KVA0.33 OHMS440#6 AWG80 AMPS65 KVA0.20 OHMS440#4 AWG90 AMPS80 KVA0.17 OHMS440#4 AW

G

100 AMP

S

100 KVA

0.14 OHMS

480#6 AWG50 AMPS50 KVA0.4 OHMS480#6 AWG75 AMPS65 KVA0.24 OHMS480#4 AWG90 AMPS80 KVA0.19 OHMS480

#4 AWG100 AMPS100 KVA0.16 OHM

S

QG-320,

QG-3200,

QGV

-32-3,

QG-400,

QG-4000,

QG

V-40-3

QG-500,

Q

G-5000,

Q

GV-50

QG-6500,

QGV-65

QG-8000,

QGV-80

G

E

N

E

R

A

T

O

R

C

A

T

A

L

O

G

N

O

.

*NOTE: All installations must meet the requirements of local electrical codes.

The above values are recommended as typical (unless otherwise specified).

*

1.

Input Voltage: 380-480 (±10%) VAC 50/60 Hz (configured at time of installation)

. Voltage is three-phase Y-configuration, measured line-to-line, balanced to earth

ground. (Note: Additional Neutral wire may be used if required by local electrical code.)

7. Ground wire size is 4 AWG.

8. Specifications are subject to change.

All wire must be copper.

2. Actual wire size depends on power quality and distance between mains power

and the generator.

3. All wiring and grounding must be in accordance with National

Electric Code (NFPA #70) or local electrical codes.

4. The disconnect switch must be located within reach of the operator.

5. .

6

Table 1-3. HF Series Generators - Electrical Wiring Requirements

(380-480 VAC Three-Phase Input Units)

HF Series X-ray Generators - Service Manual Revision W

Quantum Medical Imaging 1-13

Page 28

Chapter 1 Specifications

QG-32-2

QG-40-2

QG-50-2

208

32

40

50

240

208

240

208

240

#6 AWG

#6 AWG

#4 AWG

#6 AWG

#4 AWG

#4 AWG

70 AMPS

60 AMPS

90 AMPS

70 AMPS

110 AMPS

90 AMPS

40 KVA

40 KVA

50 KVA

50 KVA

65 KVA

65 KVA

0.026 OHMS

0.023 OHMS

0.017 OHMS

0.024 OHMS

0.014 OHMS

0.016 OHMS

GENERATOR

MODEL NO.

MAX. POWER

OUTPUT (kW)

NOMINAL LINE

VOLTAGE (VAC)

DISCONNECT

TO GENERATOR

15 FT. (5 M) MAX.

*SERVICE

RATING

*RECOMMENDED

DISTRIBUTION

TRANSFORMER

CAPACITY

MAX. INPUT LINE

RESISTANCE

(AT FULL-LOAD

RMS)

QG-320,

QG-3200,

QGV-32-2

QG-400,

QG-4000,

QGV-40-2

QG-500,

QG-5000,

QGV-50-2

GENERATOR

CATALOG NO.

*NOTE: All installations must meet the requirements of local electrical codes.

The above values are recommended as typical (unless otherwise specified).

*

1.

Input Voltage: 208-257 (±5%) VAC 50/60 Hz (configured at time of installation)

. Voltage is three-phase Y-configuration, measured line-to-line, balanced to earth

ground. (Note: Additional Neutral wire may be used if required by local electrical code.)

Line Regulation: 5% at full load.

8. Ground wire size is 4 AWG.

9. Specifications are subject to change.

All wire must be copper.

2. Actual wire size depends on power quality and distance between mains power

and the generator.

3. All wiring and grounding must be in accordance with National

Electric Code (NFPA #70) or local electrical codes.

4. The disconnect switch must be located within reach of the operator.

5. .

6

7.

Table 1-4. HF Series Generators -

Electrical Wiring Requirements (208-240 VAC Three-Phase Input Units)

Revision W HF Series X-ray Generators - Service Manual

1-14 Quantum Medical Imaging

Page 29

Chapter 1 Specifications

GENERATOR AUXILIARY POWER SUPPLIES

The HF Series X-ray Generator supplies the following supply voltages for powering

X-ray room equipment:

• 24 VDC, 1.5A

• 24 VAC, 150W (collimator lamp not to exceed 150W)

• 115 VAC, 3A

NOTE: The above voltage outputs are not to be used as power

PERFORMANCE SPECIFICATIONS

Table 1-5 provides performance specifications of single-phase (non-stored

energy) HF Series Generators.

Table 1-5. HF Series Single-Phase Generator Performance Specifications

sources for collimator lamps or for inductive loads (e.g.,

motorized tables, solenoids, etc.)

Cat. No.

N/A

QG-3200,

QGV-32

Models

N/A

QG-32,

QG-32-5

Maximum kW N/A 32 40

mA Stations;

Small Focus (S)

Large Focus (L)

kVp Range (kVp) N/A 40-125 40-125

kVp increments (kVp/step) N/A 1.0 1.0

150 kVp option N/A Yes Yes

Time Range (sec.)* N/A 0.001 - 6.3 0.001 - 6.3

Minimum Exposure Time

(sec.)

mAs Range†

High-Speed Starter

Ripple Voltage (output) N/A 5% 5%

* Time measured at 75% of the peak kVp waveform

NOTE: AEC TECHNIQUES SHOULD HAVE EXPOSURE TIMES EXCEEDING 8

MILLISECONDS.

†

mAs is tube dependent

N/A

N/A 0.001 0.001

N/A 0.025-600 0.025-600

N/A No No

25S, 75S, 150S

100L, 200L, 250L,

320L, 400L, 500L

Cat. No.

QG-4000,

QGV-40

Models

QG-40,

QG-40-5

25S, 75S, 150S

100L, 200L,

250L, 320L,

400L, 500L

HF Series X-ray Generators - Service Manual Revision W

Quantum Medical Imaging 1-15

Page 30

Chapter 1 Specifications

Refer to Table 1-6 for performance specifications of single-phase stored energy (SE) HF

Series Generators.

Table 1-6. HF Series Single-Phase STORED ENERGY Generator Performance Specifications

Cat. No.

N/A

QG-3200-SE,

QGV-32-SE

Model QG-32-SE

N/A

(STORED

ENERGY)

Maximum kW N/A 32 40 50

mA Stations;

Small Focus (S)

Large Focus (L) N/A

kVp Range (kVp) N/A 40-125 40-125 40-125

kVp increments

(kVp/step)

150 kVp optional? N/A No No No

Time Range

(sec.)*

Minimum Expo-

sure Time (sec.)*

mAs Range

High-Speed Starter

Ripple Voltage

(output)

N/A 1.0 1.0 1.0

N/A 0.001 - 6.3 0.001 - 6.3 0.001 - 6.3

N/A 0.001 0.001 0.001

N/A 0.025-400 0.025-500 0.025-500

N/A No No No

N/A 5% 5% 5%

25S, 50S, 75S, 150S

100L, 160L, 200L,

250L, 320L, 400L

Cat. No.

QG-4000-SE,

QGV-40-SE

Model QG-40-SE

(STORED

ENERGY)

25S, 50S, 75S, 150S

100L, 200L, 250L,

320L, 400L, 500L

Cat. No.

QG-5000-SE,

QGV-50-SE

Model QG-50-SE

(STORED

ENERGY)

25S, 50S, 75S,

150S

100L, 200L, 250L,

320L, 400L, 500L,

600L

* Maximum exposure time is a function of kV and mAs settings and the age of the

batteries; Time measured at 75% of the peak kVp waveform

NOTE: AEC TECHNIQUES SHOULD HAVE EXPOSURE TIMES EXCEEDING 8

MILLISECONDS.

mAs is tube dependent; the generator may not reach maximum mAs due t o tube type.

In AEC mode, the mAs is limited to 600.

Revision W HF Series X-ray Generators - Service Manual

1-16 Quantum Medical Imaging

Page 31

Chapter 1 Specifications

Refer to Table 1-7 for performance specifications of three-phase HF Series Generators.

Table 1-7. HF Series Three-Phase Generator Performance Specifications

Cat. No.

QG-3200-2,

QG-3200-3

QGV-32-2,

QGV-32-3

Model

Model QG-32-2,

QG-32-3

Maximum kW 32 40 50 65 80

mA Stations;

Small Focus (S)

Large Focus (L)

kVp Range

(kVp) 40-125

kVp increments

(kVp/step)

150 kVp

optional?

Time Range

(sec.)*

Minimum Exposure Time (sec.)

mAs Range† 0.025-600 0.025-600 0.025-800 0.025-800 0.025-800

High-Speed

Starter

Ripple Voltage

(output)

25S, 75S, 150S

100L, 200L,

250L, 320L,

400L, 500L

1.0 1.0 1.0 1.0 1.0

Yes Yes Yes Standard Standard

0.001 - 6.3 0.001 - 6.3 0.001 - 6.3 0.001 - 6.3 0.001 - 6.3

0.001 0.001 0.001 0.001 0.001

No Option Option Yes Yes

5% 5% 5% 5% 5%

Cat. No.

QG-4000-2,

QG-4000-3

QGV-40-2,

QGV-40-3

Model

Model QG-40-2,

QG-40-3

25S, 75S, 150S

100L, 200L,

250L, 320L,

400L, 500L

40-125

(40-150 with

QG-150 option)

Cat. No.

QG-5000-2,

QG-5000-3

QGV-50,

QGV-50-2

Model

QG-50-2,

QG-50

25S, 75S, 150S

100L, 200L,

320L, 400L,

500L, 650L

40-125

(40-150 with

QG-150 option)

Cat. No.

QG-6500,

QGV-65

Model

Model QG-65

25S, 75S, 150S

100L, 200L,

320L, 400L,

500L, 650L, 800

40-150 40-150

25S, 75S, 150S

Cat. No.

QG-8000,

QGV-80

Model

Model QG-80

100L, 200L,

320L, 400L,

500L, 650L,

800

* Time measured at 75% of the p eak kVp waveform

NOTE: AEC TECHNIQUES SHOULD HAVE EXPOSURE TIMES EXCEEDING 8

MILLISECONDS.

†

mAs is tube dependent; the generator may not reach maximum mAs

due to tube type. In AEC mode, the mAs is limited to 600.

High-Speed Starter Duty Cycle: do no t to exceed two activations

within any one minute period

HF Series X-ray Generators - Service Manual Revision W

Quantum Medical Imaging 1-17

Page 32

Chapter 1 Specifications

Accuracy Specifications

kVp Accuracy: kVp = ± ( 4.0% kV )

mA Accuracy: mA = ± ( 5.0% mA + 1 mA )

Time Accuracy:

mAs Accuracy:

mAs = ± ( 5.0% mAs + 0.5 mAs )

time = ± ( 2.0% time + 1 msec. )

time = ± ( 1.0% time + 1 msec. )

time = ± ( 0.5% time + 1 msec. )

Table 1-8. Accuracy Specifications

Revision W HF Series X-ray Generators - Service Manual

1-18 Quantum Medical Imaging

Page 33

Chapter 1 Specifications

SYSTEM OPTIONS

The following lists the available options for HF Series X-Ray Generators. Note that

some options, such as QG-150 and Q-HSS, may only be used on certain generator

models (refer to Tables 1-5 through 1-7 for compatibility):

• R80-HS: Exposure Hand Switch and R80-FS Foot Switch

• QG-PDL: Operator Control Panel Pedestal Mount (used with ODYSSEY

control panel)

• QG-WM: Operator Control Panel Wall Mount (used with ODYSSEY control

panel)

• QGV-WM: Operator Control Panel Wall Mount (used with Q-VISION control

panel)

• QG-150: 150 kV High Voltage Transformer (standard equipment on Models

QG-65 and QG-80)

• Q-HSS: Internal High (Dual) Speed Starter Unit (standard equipment on

Models QG-65 and QG-80

• Q-Connect: Enables ethernet connection to a PC computer using Quantum’s

"QBus" network integration software; required on systems utilizing a touchscreen operator control panel

• QG-28VPS: Internally mounted Auxiliary +28 VDC/8A Power Supply (only

available with three-phase input generators)

• QG-TOMO: Provides interface for operation with Siemens and Pausch

tomographic systems (not available with Q-VISION HF Series OCP’s)

• TechVision: Supplementary x-ray control panel, mounts on tube support

device. Refer to the TechVision Remote Control Panel Service and

Operator’s Manuals for complete installation and operation instructions.

NOTE: The use of ACCESSORY equipment not complying with the

equivalent safety requireme nts of this equipment may lead to

a reduced level of safety of the resulting system. Consideration relating to the choice shall include:

-use of the accessory in the PATIENT VICINITY

-evidence that the safety certification of the ACCESSORY has

been performed in accordance with the appropriate IEC 601-1

and/or IEC 601-1-1 harmonized national standard.

SYSTEM OPERATING ENVIRONMENT

Ambient Temperature: +10°C to +40°C

Relative Humidity: 30 to 75%, non-condensing

Atmospheric Pressure: 700 hPa to 1060 hPa

Typical Heat Output of

Generator Cabinet: 3600 BTU per hour

Typical Heat Output of

operator control panel (OCP): 130 BTU per hour

HF Series X-ray Generators - Service Manual Revision W

Quantum Medical Imaging 1-19

Page 34

Chapter 1 Specifications

NOTE: The above calculations are typical, based upon average usage.

Air circulation around the electronic cabinet must be provided.

This includes the sides, back, front and top of cabinet.

NON-OPERATING ENVIRONMENT

Ambient Temperature: -18°C to +70°C

Relative Humidity: 20 to 95%, non-condensing

Atmospheric Pressure: 500 hPa to 1060 hPa

Figure 1-1. HF Series X-ray Generator Cabinet Dimensions

Revision W HF Series X-ray Generators - Service Manual

1-20 Quantum Medical Imaging

Page 35

Chapter 1 Specifications

Figure 1-2. Odyssey HF Series X-ray Generator Operator Control

Panel Dimensions

HF Series X-ray Generators - Service Manual Revision W

Quantum Medical Imaging 1-21

Page 36

Chapter 1 Specifications

18.7

(476.0)

14.4

(365.0)

7.125

(181.0)

Figure 1-3. Q-VISION HF Series X-Ray Generator Operator Control

Panel Dimensions

Revision W HF Series X-ray Generators - Service Manual

1-22 Quantum Medical Imaging

Page 37

Chapter

2

ASSEMBLY &

INSTALLATION

2-1

Page 38

2-2

Page 39

Chapter 2 Assembly & Installation

OVERVIEW

This chapter provides procedures for installing the HF Series x-ray generator, from

pre-installation guidelines to final system inspection prior to operational readiness.

These procedures should be reviewed carefully before beginning the actual installation. Preparing the X-r ay generator f or operation require s completion of the following

tasks:

• Installing the X-ray generator cabinet

• Installing the Operator Control Panel (OCP)

• Making the Electrical Cable Connections

•Power-up

• Calibrating the generator

• Inspecting the system

• Verifying programmed techniques

WARNING! Equipment installation and servicing

procedures should be performed by properly

trained and qualified service personnel only.

PRE-INSTALLATION GUIDELINES

While site planning is the customer's responsibility, the following are recommended guidelines.

Verify Equipment Location

In radiology site preparation, it is essential to verify the location and space

allocated for the equipment is sufficient. See Figures 1-1 through 1-3 for HF

Series x-ray generator dimensions. The room plan should show the following

for the equipment:

• All working and parked positions

• Overall dimensions

• Total equipment weights and power outputs

• Structural mounting and attachment methods

Ensure sufficient air circulation space is provided between the rear side of

Generator Cabinet and wall (4.0" min.). The floor where the generator is

installed should be flat and approximately level (minor shimming is acceptable) and capable of supporting a load of 500 lbs. (226.8 kg).

If the generator is equipped with the "Q-Connect option" (ethernet adapter

for connection to Q-VISION or for integration with a Digital Radiographic System), the associated computer monitor functions as the generator operator

control panel (OCP). If the workstation is qualified to standard UL 60950/IEC

HF Series X-ray Generators - Service Manual Revision W

Quantum Medical Imaging 2-3

Page 40

Chapter 2 Assembly & Installation

2.5 m

1.5 m

1.5 m

1.5 m

60950 for Information Technology Equipment, the workstation must be

placed outside the radius of the patient environment, shown in Figure 2-1.

Only devices conforming to UL 60601-1/IEC 60601-1 may be placed within

this environment. Consult with the user of the system when determining the

location for the workstation computer; consider all areas the patient may

access, including the room entrance and/or exit, when establishing the

patient environment.

Figure 2-1. Patient Environment

Revision W HF Series X-ray Generators - Service Manual

2-4 Quantum Medical Imaging

Page 41

Chapter 2 Assembly & Installation

NOTE

Examine all cartons an d cr a t es

carefully at time

of delivery. If

damage is apparent, have del i very driver write a

"Damaged Shipment Note" on

copies of freight

bill, sign it, and

file appropriate

carrier claim.

Should you discove r co nc e aled

damage, immediately notify the

transporting

age nt and ask

for an

"Inspection of

Damage". Carrier

will not accept

concealed damage claim if filed

after 15 days

from date of

receipt of merchandise.

Electrical Requirements

In addition to providing for the physical requirements of the equipment,

it is also vital to prepare for the power requirements. Refer to Chapter

1, SPECIFICATIONS for model-dependent power specifications. This

information should be used to prepare system wiring and cabling.

UNPACKING

The HF Series x-ray generator is shipped in a single crate. To unpack, proceed as follows:

1. Remove packing list and use it as a guide to open the remaining cartons.

Do not dispose of packing material until packing list is matched with

actual parts received. Should there be a shortage or damage, notify

Quantum Medical Imaging, LLC.’s customer service department immediately . The manufacturer is relieved of any responsibility for damage during shipment after unit is picked up by the carrier.

HF Series X-ray Generators - Service Manual Revision W

Quantum Medical Imaging 2-5

WARNING! The X-ray generator cabinet can

weigh as much as 430 lbs. (195 kg), depending on configuration. Use lifting straps and

hoist or other suitable lifting device to transport generator. The H.V. Tank weighs

approximately 100 lbs. and requires two persons to lift.

2. Remove the Generator Cabinet from its crate (lifting straps and hoist or

other suitable lifting device is recommended).

3. Using a hand truck from the rear side of the cabinet, lift the generator

and place it as close to its final installation location as possible.

WARNING! When unpacking the generator;

keep upright at all times. Verify there is no

damage caused during shipping, with no

apparent oil leakage from H.V. Tank; check that

the tank lid and oil plug (in tank lid) are secure.

4. Locate the OCP and Pedestal (optional) or Wall Mount Bracket (optional) and

place on the side (not applicable on Q-VISION equipped systems or with integrated systems (e.g., Agfa, Canon, etc.).

Page 42

Chapter 2 Assembly & Installation

INSTALLATION

The following paragraphs provide information necessary for installing the Generator

Cabinet and Operator Control Panel (OCP), including all required external equipment

cable connections with the X-ray generator.

CAUTION! This equipment contains electrostatic

sensitive devices. Observe proper grounding precautions before handling components or printed

circuit boards.