lQ QT60160, QT60240

16

AND

24 KEY QM

ATRIX

™ T

OUCH SENSOR

IC

s

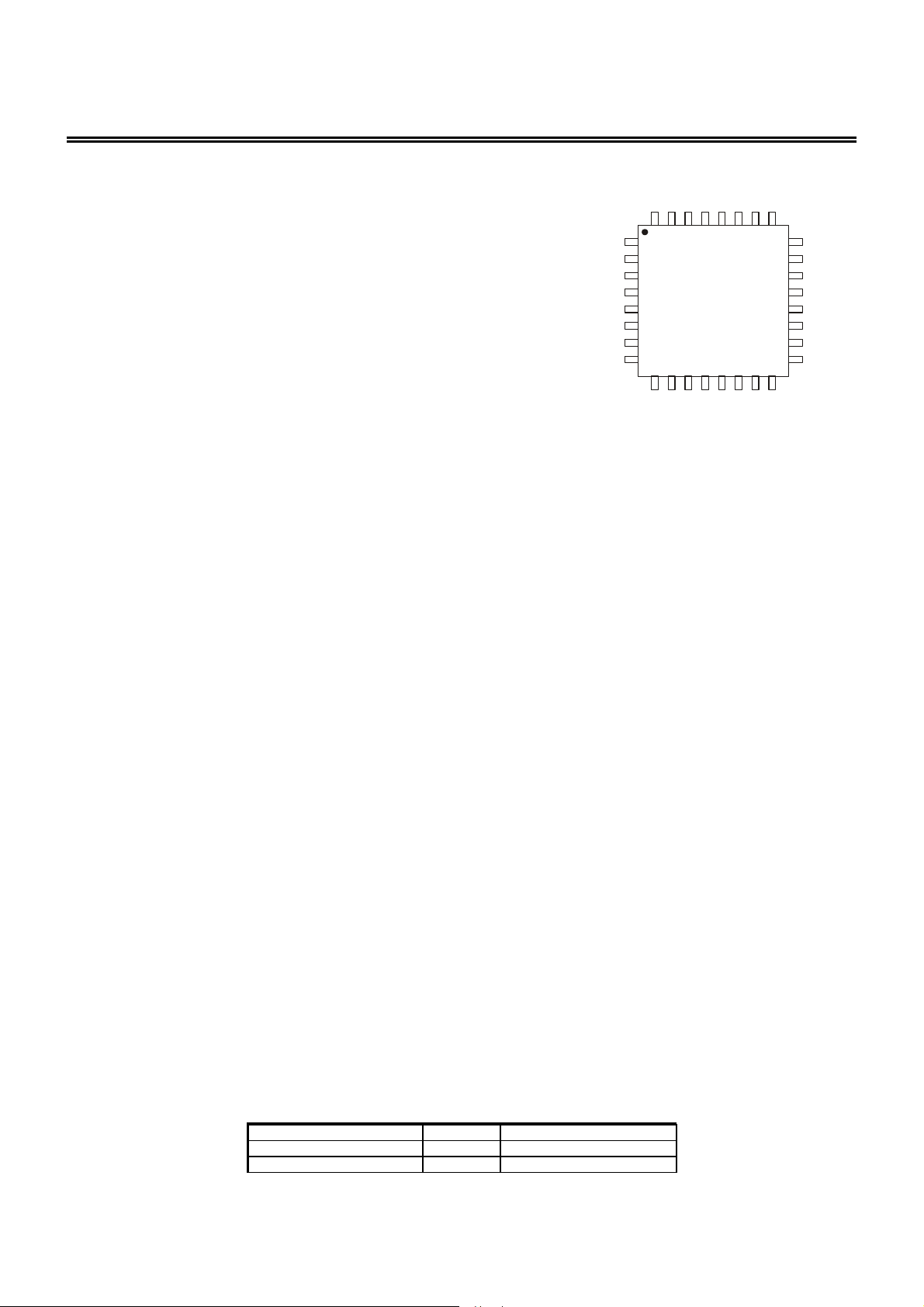

/RST

Y2A

Y1A

Y0A

SDA

SCL

These devices are designed for low cost mobile and consumer electronics

applications.

QMatrix™ technology employs transverse charge-transfer sensing electrode

designs which can be made very compact and are easily wired. Charge is

forced from an emitting electrode into the overlying panel dielectric, and then

collected on a receiver electrode which directs the charge into a sampling

capacitor which is then converted directly to digital form without the use of

amplifiers.

Keys are configured in a matrix format that minimizes the number of required

scan lines and device pins. The key electrodes can be designed into a

conventional Printed Circuit Board (PCB) or Flexible Printed Circuit Board

(FPCB) as a copper pattern, or as printed conductive ink on plastic film.

M_SYNC

CHANGE

VSS

VDD

VSS

VDD

32

2

3

4

5

6

X6

7

X7 X5

817

910

LATCH

29 282726

QT60240

QT60160

MLF-32

13

11

12

VREF

S_SYNCX0X1X2X3

14

31 30

AT A GLANCE

Number of keys: 1 to 16 (QT60160), or 1 to 24 (QT60240)

Technology: Patented spread-spectrum charge-transfer (transverse mode)

Key outline sizes: 6mm x 6mm or larger (panel thickness dependent); widely different sizes and shapes possible

Key spacings: 8mm or wider, center to center (panel thickness dependent)

Electrode design: Two-part electrode shapes (drive-receive); wide variety of possible layouts

Layers required: One layer (with jumpers), two layers (no jumpers)

†

Electrode materials: PCB, FPCB, silver or carbon on film, ITO on film, Orgacon

Panel materials: Plastic, glass, composites, painted surfaces (low particle density metallic paints possible)

Adjacent Metal: Compatible with grounded metal immediately next to keys

Panel thickness: Up to 50mm glass, 20mm plastic (key size dependent)

Key sensitivity: Individually settable via simple commands over serial interface

2

Interface: I

C slave mode (100kHz), or parallel output via external shift registers

Moisture tolerance: Best in class.

Power: 1.8V ~ 5.5V, 40µA (16 keys at 1.8V, 2s Low Power mode). Guaranteed to 1.62V.

Package: 32-pin 5 x 5mm MLF RoHS compliant

Signal processing: Self-calibration, auto drift compensation, noise filtering, Adjacent Key Suppression

Applications: Mobile phones, remote controls, domestic appliances, PC peripherals, automotive

ink on film

TM

SMP

25

1615

Y2B

X4

24

23

22

21

20

19

18

Y1B1

Y0B

A0

VSS

VDD

A1

VDD

†

Orgacon is a registered trademark of Agfa-Gevaert N.V

LQ

AVAILABLE OPTIONS

KeysPart Number

-40

-400C to +850C24QT60240-ISG

T

A

0

C to +850C16QT60160-ISG

Copyright © 2006 QRG Ltd

QT60240-ISG R8.06/0906

Contents

1 Overview

1.1 Introduction

1.2 Part Differences

1.3 Enabling / Disabling Keys

2 Hardware and Functional

2.1 Matrix Scan Sequence

2.2 Burst Paring

2.3 Cs Sample Capacitor Operation

2.4 Sample Capacitor Saturation

2.5 Sample Resistors

2.6 Signal Levels

2.7 Matrix Series Resistors

2.8 Key Design

2.9 PCB Layout, Construction

2.10 Power Supply Considerations

2.11 Startup / Calibration Times

2.12 Reset Input

2.13 Spread Spectrum Acquisitions

2.14 Detection Integrators

2.15 Sleep

2.16 Wiring

3 Interfaces

3.1 Introduction

3.2 Shift Register Output Mode

3.3 I2C Port

3.4 CHANGE Pin

4 Control Commands

4.1 Introduction

4.2 Writing Data to the Device

4.3 Reading Data From the Device

4.4 Report Detections for All Keys

4.5 Raw Data Commands

4.6 Cal All

4.7 Setups

...............................

............................

..........................

............................

.........................

...........................

............................

2.9.1 Overview

2.9.2 LED Traces and Other Switching Signals

2.9.3 PCB Cleanliness

...........................

........................

...........................

..............................

..............................

..............................

............................

..............................

...........................

........................

............................

...............................

..............................

.....................

.....................

.......................

..................

...................

......................

.....................

..............

..................

....................

..................

.......................

....................

.....................

..................

...................

.......................

5 I2C Operation

3

5.1 Interface Bus

3

5.2 Transferring Data Bits

3

5.3 START and STOP Conditions

3

5.4 Address Packet Format

3

5.5 Data Packet Format

3

5.6 Combining Address and Data Packets Into a Transmission

3

6 Setups

3

6.1 Introduction

4

6.2 Negative Threshold - NTHR

4

6.3 Positive Threshold - PTHR

4

6.4 Drift Compensation - NDRIFT, PDRIFT

5

6.5 Detect Integrators - NDIL, FDIL

6

6.6 Negative Recal Delay - NRD

6

6.7 Positive Recalibration Delay - PRD

6

6.8 Burst Length - BL

6

6.9 Adjacent Key Suppression - AKS

6

6.10 Oscilloscope Sync - SSYNC

6

6.11 Mains Sync - MSYNC

7

6.12 Sleep Duration - SLEEP

7

6.13 Wake on Key Touch - WAKE

7

6.14 Awake Timeout - AWAKE

7

6.15 Drift Hold Time - DHT

7

6.16 Setups Block

8

7 Specifications

10

10

10

10

11

12

12

12

12

12

13

13

13

7.1 Absolute Maximum Electrical Specifications

7.2 Recommended Operating Conditions

7.3 DC Specifications

7.4 Timing Specifications

7.5 Power Consumption

7.6 Mechanical Dimensions

7.7 Marking

7.8 Moisture Sensitivity Level (MSL)

............................

...........................

.......................

...................

......................

........................

....

................................

............................

....................

....................

..............

..................

....................

................

.........................

.................

...................

......................

.....................

...................

....................

......................

..........................

...........................

............

...............

.........................

.......................

........................

......................

..............................

..................

15

15

15

15

15

15

16

17

17

17

17

17

18

18

18

19

19

19

19

20

20

20

20

21

23

23

23

23

23

24

25

25

25

lQ

2 QT60240-ISG R8.06/0906

1 Overvie

w

1.1 Introduction

QT60xx0 devices are digital burst mode charge-transfer (QT)

sensors designed specifically for matrix layout touch controls;

they include all signal processing functions necessary to

provide stable sensing under a wide variety of changing

conditions. Only a few external parts are required for

operation. The entire circuit can be built within a few square

centimeters of single-sided PCB area. CEM-1 and FR1

punched, single-sided materials can be used for the lowest

possible cost. The PCB’s rear can be mounted flush on the

back of a glass or plastic panel using a conventional

adhesive, such as 3M VHB two-sided adhesive acrylic film.

1.3 Enabling / Disabling Keys

The NDIL parameter is used to enable and disable keys in the

matrix. Setting NDIL = 0 for a key disables it (Section 6.5). At

no time can the number of enabled keys exceed the

maximum specified for the device (see Section 1.2).

On the QT60160, only the first 2 Y lines (Y0, Y1) are

operational by default. On the QT60160, to use keys located

on line Y2, one or more of the pre-enabled keys must be

disabled simultaneously while enabling the desired new keys.

This can be done in one Setups block load operation.

2 Hardware and Functional

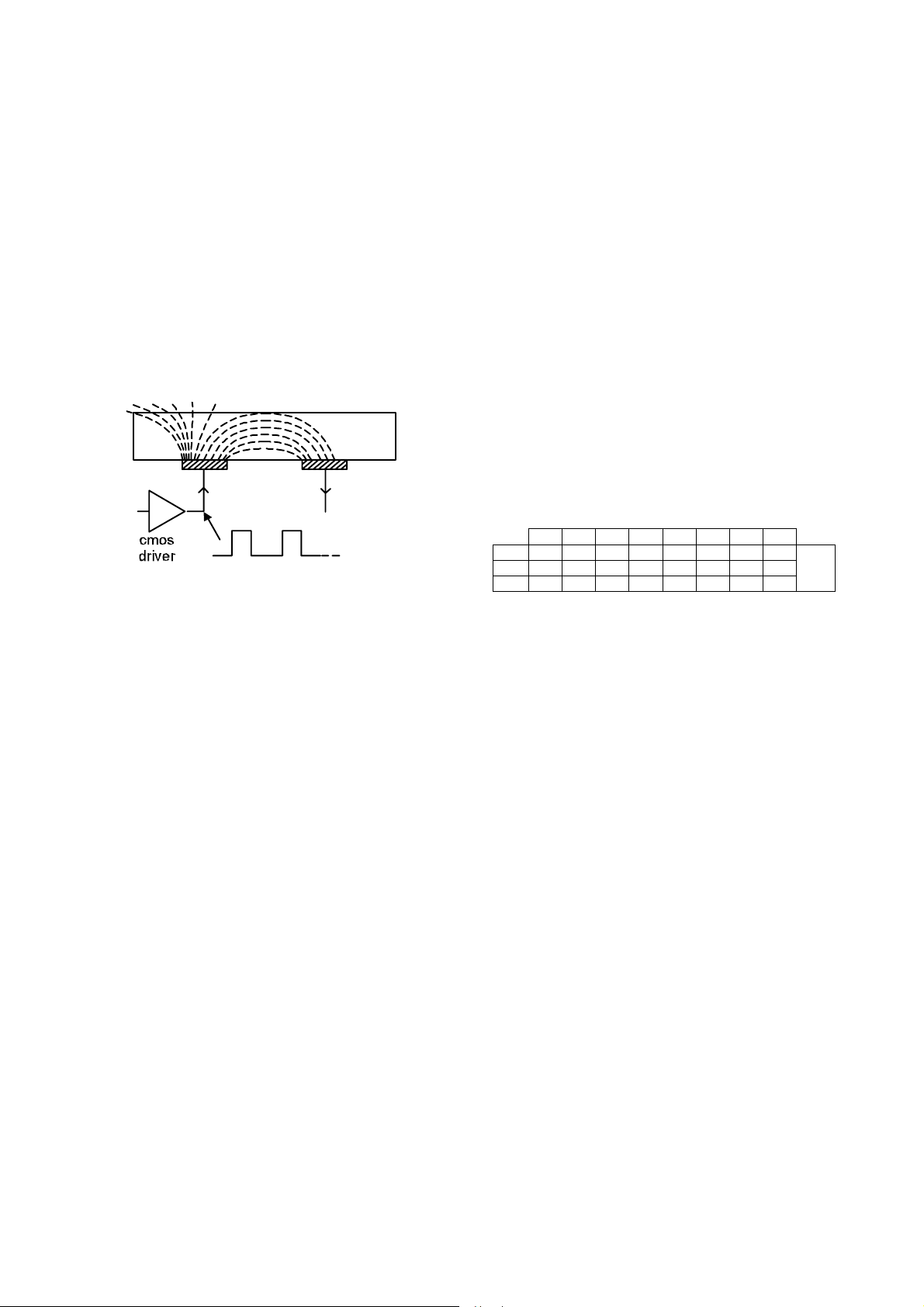

Figure 1.1 Field Flow Between X and Y Elements

overlying panel

X

element

QT60xx0 devices employ transverse charge-transfer ('QT')

sensing, a technology that senses changes in electrical

charge forced across two electrode elements by a pulse edge

(Figure 1.1). QT60xx0 devices allow a wide range of key sizes

and shapes to be mixed together in a single touch panel.

The devices use an I

extracted and to permit individual key parameter setup. The

command structure is designed to minimize the amount of

data traffic while maximizing the amount of information

conveyed.

In addition to normal operating and setup functions the device

can also report back actual signal strengths.

QmBtn™ software for the PC can be used to program the

operation of the IC, as well as read back key status and

signal levels in real time.

2

C interface to allow key data to be

Y

elem ent

2.1 Matrix Scan Sequence

The circuit operates by scanning each key sequentially, key

by key. Key scanning begins with location X=0 / Y=0 (key 0).

X axis keys are known as rows while Y axis keys are referred

to as columns although this has no reflection on actual wiring .

Keys are scanned sequentially by row, for example the

sequence X0Y0 X1Y0 .... X7Y0, X0Y1, X1Y1... etc. Keys are

also numbered from 0...23. Key 0 is located at X0Y0.

Table 2.1 shows the key numbering.

Table 2.1 Key Numbers

X0X1X2X3X4X5X6X7

Y0

Y1

Y2

Each key is sampled in a burst of acquisition pulses whose

length is determined by the Setups parameter BL (page 19);

this can be set on a per-key basis. A burst is completed

entirely before the next key is sampled; at the end of each

burst the resulting signal is converted to digital form and

processed. The burst length directly impacts key gain; each

key can have a unique burst length in order to allow tailoring

of key sensitivity on a key-by-key basis.

01234567

89101112131415

Key

1617181920212223

numbers

2.2 Burst Paring

Keys that are disabled by setting NDIL = 0 (Section 6.5,

page 18) have their bursts removed from the scan sequence

to save scan time. As a consequence, the fewer keys that are

used the faster the device can respond. All calibration times

are reduced when keys

are

disabled

.

1.2 Part Differences

There are two versions of the device; one is capable of a

maximum of 16 keys (QT60160), the other is capable of a

maximum of 24 keys (QT60240).

These devices are identical in all respects, except for the

maximum number of keys specified. The keys can be located

anywhere within an electrical grid of 8 X and 3 Y scan lines.

Unused keys are always pared from the burst sequence in

order to optimize speed. Similarly, in a given part a lesser

number of enabled keys will cause any unused acquisition

burst timeslots to be pared from the sampling sequence to

optimize acquire speed. Thus, if only 14 keys are actually

enabled, only 14 timeslots are used for scanning.

lQ

2.3 Cs Sample Capacitor Operation

Cs capacitors absorb charge from the key electrodes on the

rising edge of each X pulse. On each falling edge of X, the Y

matrix line is clamped to ground to allow the electrode and

wiring charges to neutralize in preparation for the next pulse.

With each X pulse charge accumulates on Cs causing a

staircase increase in its differential voltage.

After the burst completes, the device clamps the Y line to

ground causing the opposite terminal to go negative. The

charge on Cs is then measured using an external resistor to

ramp the negative terminal upwards until a zero crossing is

achieved. The time required to zero cross becomes the

measurement result.

3 QT60240-ISG R8.06/0906

The Cs should be connected as shown in Figure 2.7, page 9.

The value of these capacitors is not critical but 4.7nF is

recommended for most cases. They should be 10 percent

X7R ceramics. If the transverse capacitive coupling from X to

Y is large enough the voltage on a Cs capacitor can saturate,

destroying gain. In such cases the burst length should be

reduced and/or the Cs value increased. See Section 2.4.

If a Y line is not used its corresponding Cs capacitor may be

omitted and the pins left floating.

2.4 Sample Capacitor Saturation

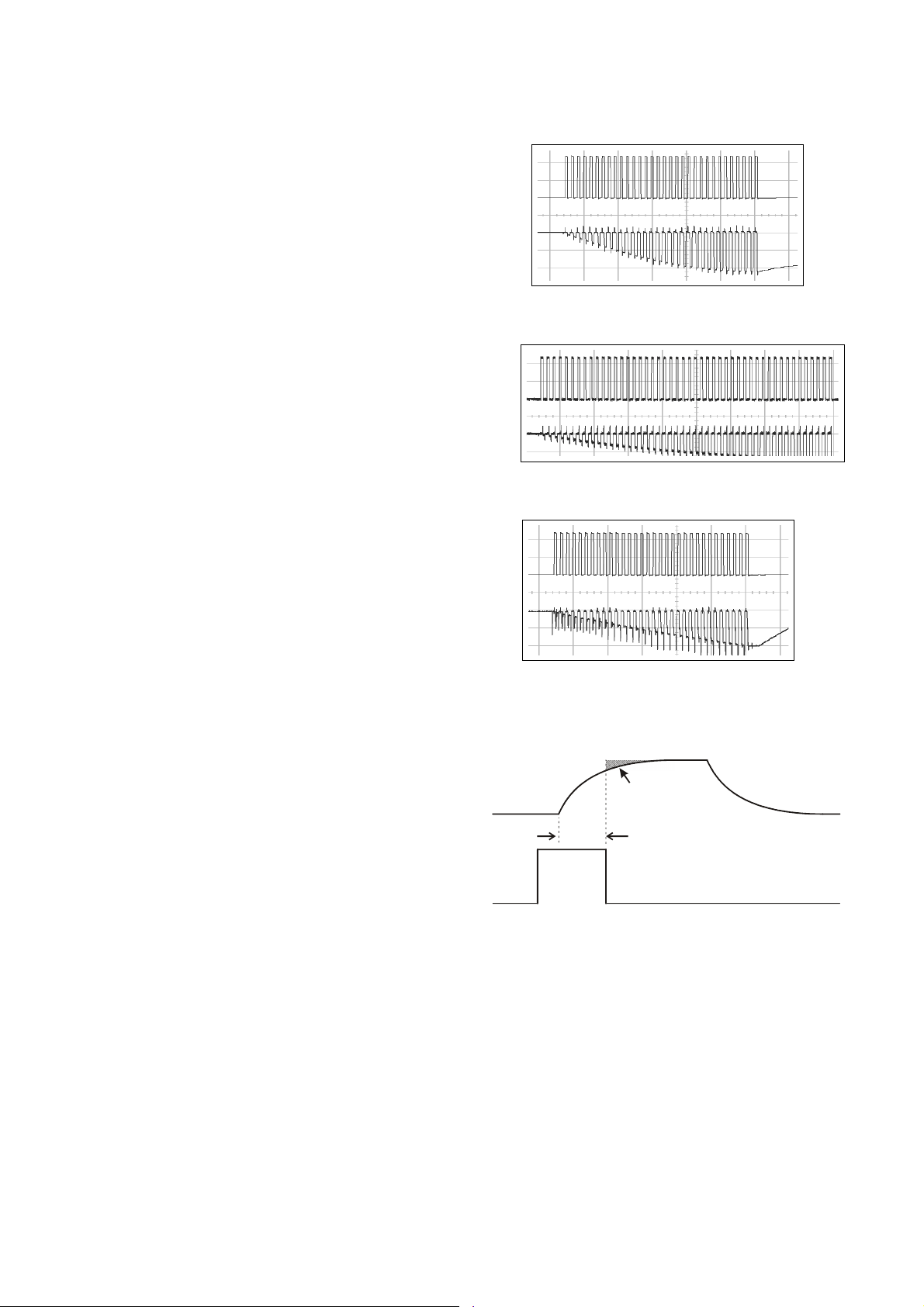

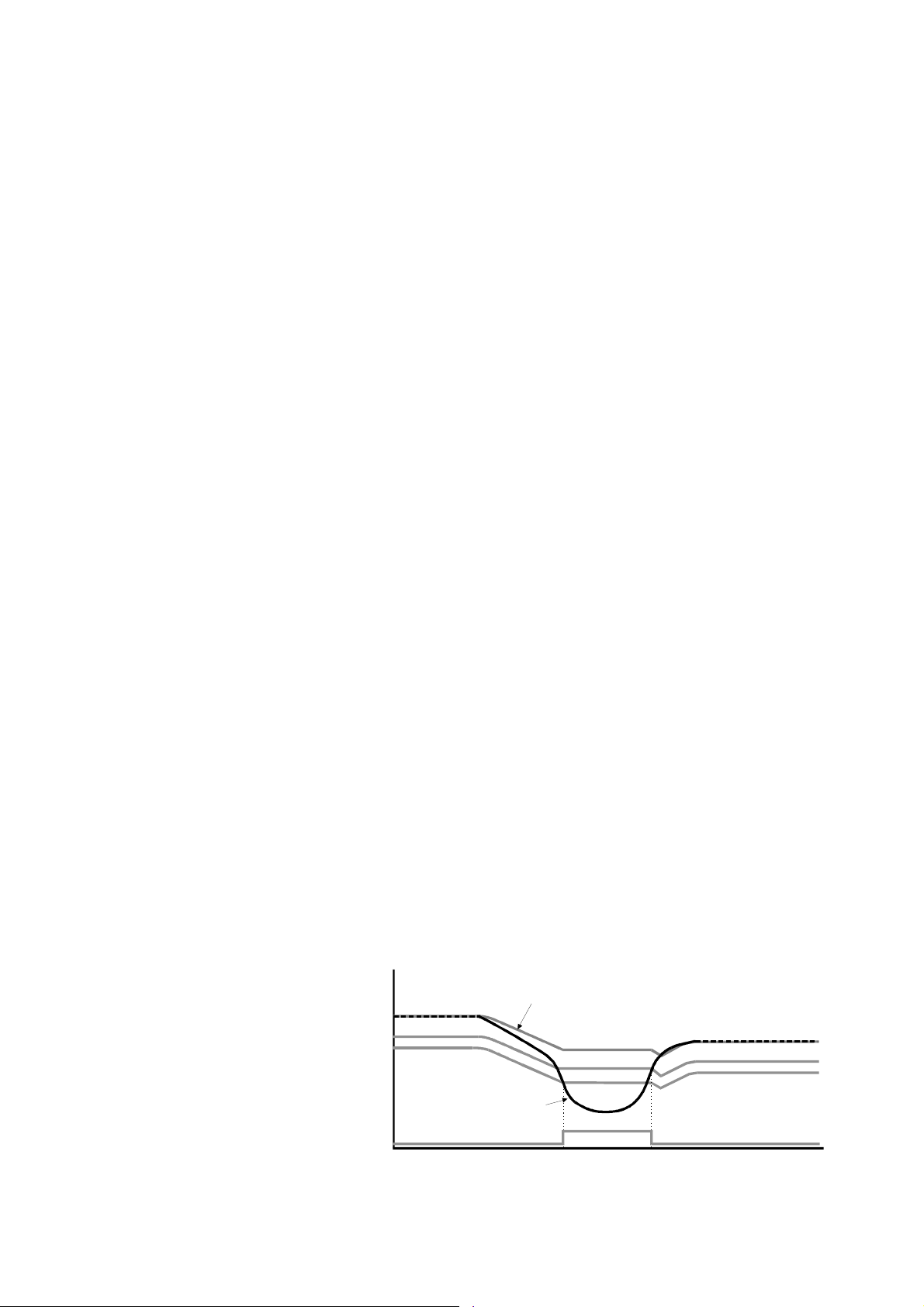

Cs voltage saturation at a pin YnB is shown in Figure 2.1

Saturation begins to occur when the voltage at a YnB pin

becomes more negative than -0.25V at the end of the burst.

This nonlinearity is caused by excessive voltage

accumulation on Cs inducing conduction in the pin protection

diodes. This badly saturated signal destroys key gain and

introduces a strong thermal coefficient which can cause

'phantom' detection. The cause of this is either from the burst

length being too long, the Cs value being too small, or the

X-Y transfer coupling being too large. Solutions include

loosening up the key structure interleaving, more separation

of the X and Y lines on the PCB, increasing Cs, and

decreasing the burst length.

Increasing Cs will make the part slower; decreasing burst

length will make it less sensitive. A better PCB layout and a

looser key structure (up to a point) have no negative effects.

Cs voltages should be observed on an oscilloscope with the

matrix layer bonded to the panel material; if the Rs side of

any Cs ramps more negative than -0.25 volts during any burst

(not counting overshoot spikes which are probe artifacts),

there is a potential saturation problem.

Figure 2.2 shows a defective waveform similar to that of 2.1,

but in this case the distortion is caused by excessive stray

capacitance coupling from the Y line to AC ground; for

example, from running too near and too far alongside a

ground trace, ground plane, or other traces. The excess

coupling causes the charge-transfer effect to dissipate a

significant portion of the received charge from a key into the

stray capacitance. This phenomenon is more subtle; it can be

best detected by increasing BL to a high count and watching

what the waveform does as it descends towards and below

-0.25V. The waveform will appear deceptively straight, but it

will slowly start to flatten even before the -0.25V level is

reached.

A correct waveform is shown in Figure 2.3. Note that the

bottom edge of the bottom trace is substantially straight

(ignoring the downward spikes).

Unlike other QT circuits, the Cs capacitor values on QT60xx0

devices have no effect on conversion gain. However, they do

affect conversion time.

Unused Y lines should be left open.

2.5 Sample Resistors

There are three sample resistors (Rs) used to perform

single-slope ADC conversion of the acquired charge on each

Cs capacitor. These resistors directly control acquisition gain;

larger values of Rs will proportionately increase signal gain.

For most applications Rs should be 1M✡. Unused Y lines do

not require an Rs resistor.

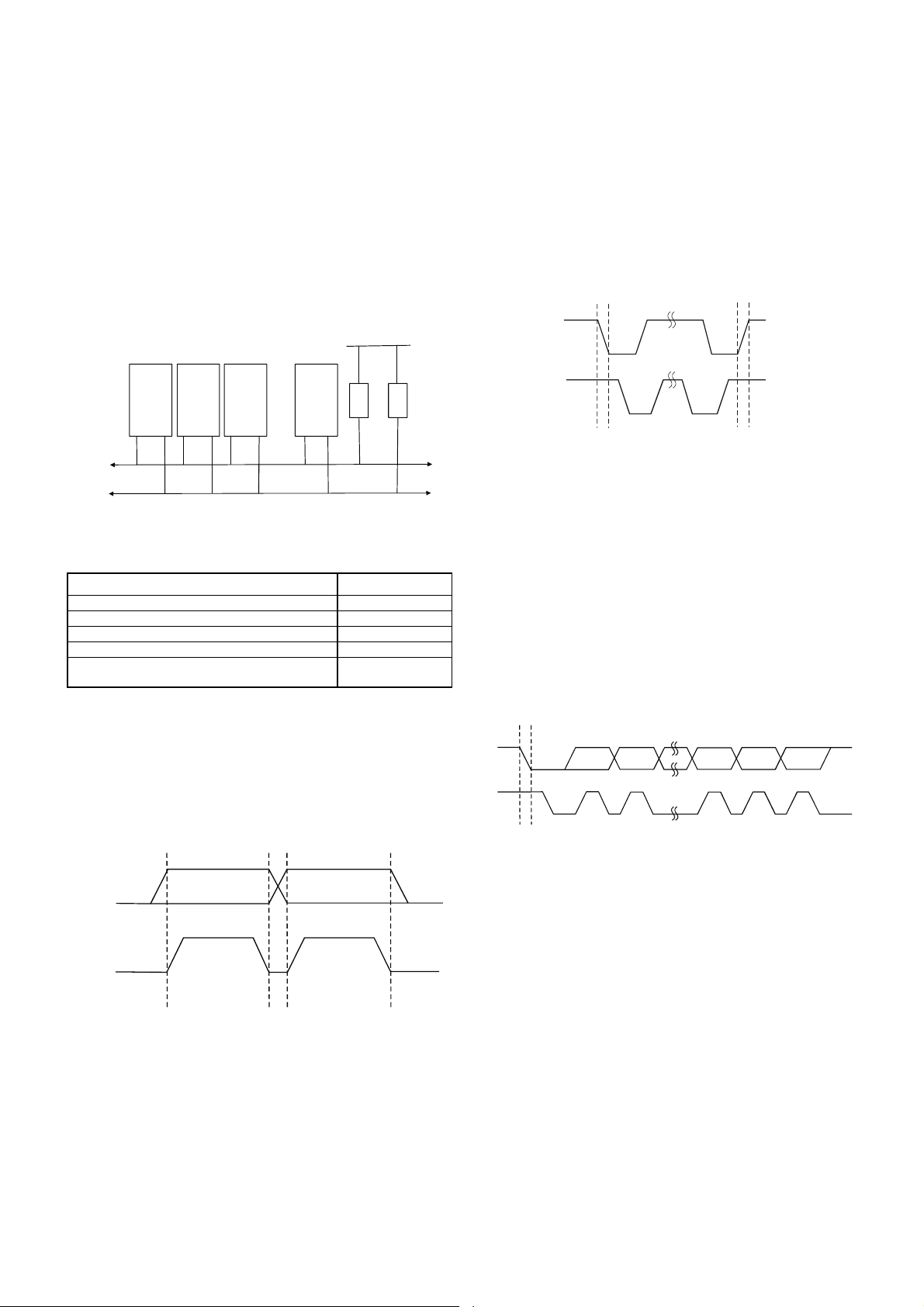

Figure 2.1 VCs - Nonlinear During Burst

(Burst too long, or Cs too small, or X-Y transcapacitance too large)

X Drive

YnB

Figure 2.2 VCs - Poor Gain, Nonlinear During Burst

(Excess capacitance from Y line to Gnd)

X Drive

YnB

Figure 2.3 VCs - Correct

X Drive

YnB

Figure 2.4 X-Drive Pulse Roll-off and Dwell Time

The Dwell time is fixed at ~500ns - see Section 2.7

X drive

Dwell time

Y gate

Lost charge due to

inadequate settling

before end of dwell time

2.6 Signal Levels

Quantum’s QmBtn software makes it is easy to observe the

absolute level of signal received by the sensor on each key.

The signal values should normally be in the range of 200 to

750 counts with properly designed key shapes and values of

Rs. However, long adjacent runs of X and Y lines can also

artificially boost the signal values, and induce signal

saturation; this is to be avoided. The X-to-Y coupling should

come mostly from intra-key electrode coupling, not from stray

X-to-Y trace coupling.

lQ

4 QT60240-ISG R8.06/0906

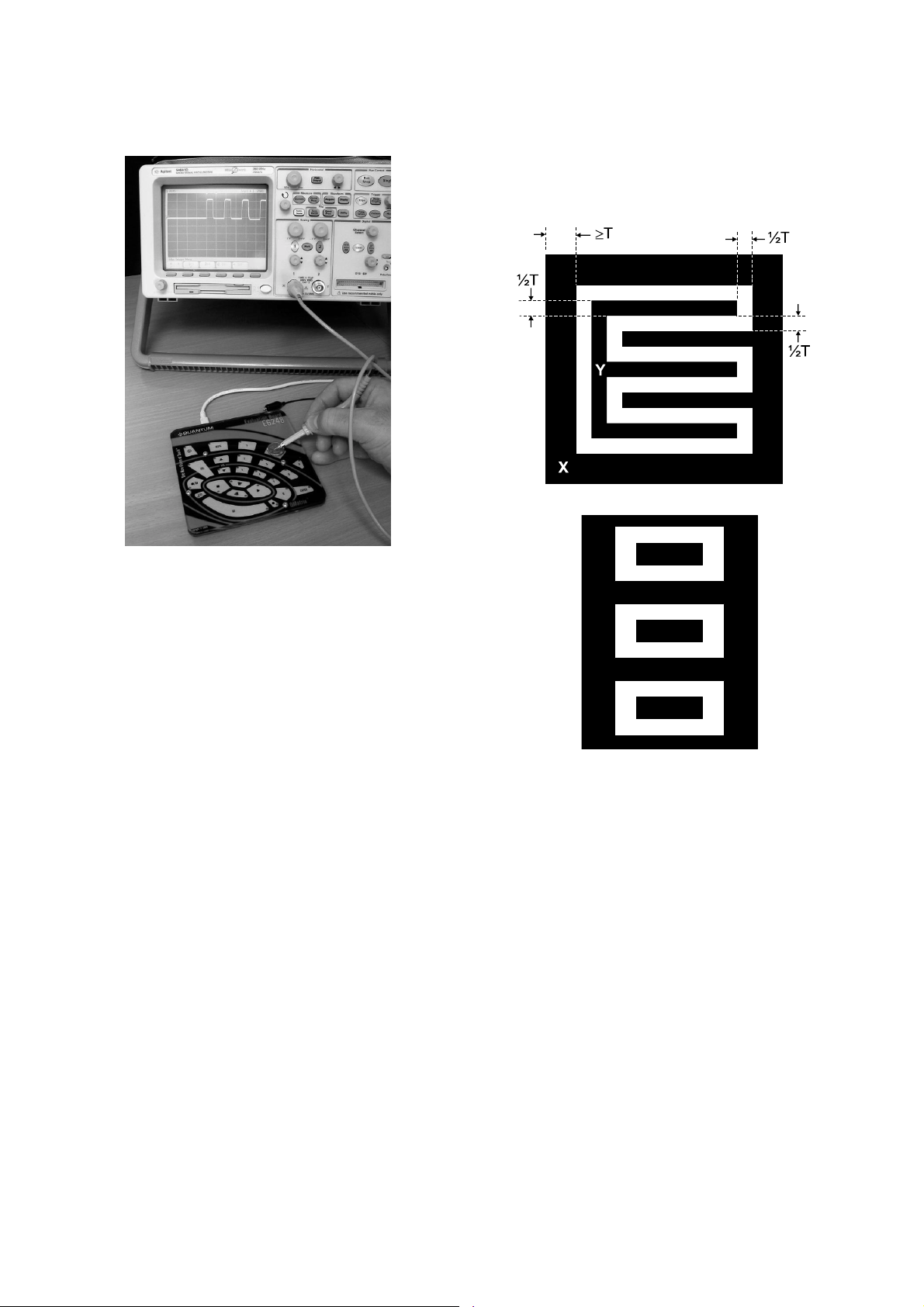

Figure 2.5 Probing X-Drive

Waveforms With a Coin

Figure 2.6 Recommended Key Structure

‘T’ should ideally be similar to the complete thickness the fields

need to penetrate to the touch surface. Sm aller dimens ions will also

work but will give less signal strength. If in doubt, make the pattern

coarser. The lower figure shows a simpler structure used for

compact key layouts, for exam ple for m obile phones. A layout with a

common X drive and three receive electrodes is depicted.

Y0

QmBtn software is available free of charge on Quantum’s

website www.qprox.com.

The signal swing from the smallest finger touch should

preferably exceed 8 counts, with 12 being a reasonable

target. The signal threshold setting (NTHR) should be set to a

value guaranteed to be less than the signal swing caused by

the smallest touch.

Increasing the burst length (BL) parameter will increase the

signal strengths as will increasing the sampling resistor (Rs)

values.

2.7 Matrix Series Resistors

The X and Y matrix scan lines can use series resistors

(referred to as Rx and Ry respectively) for improved EMC

performance (Figure 2.7, page 9).

X drive lines require Rx in most cases to reduce edge rates

and thus reduce RF emissions. Typical values range from

1K

✡

to 20K✡.

Y lines need Ry to reduce EMC susceptibility problems and in

some extreme cases, ESD. Typical Y values are about 1K

Y resistors act to reduce noise susceptibility problems by

forming a natural low-pass filter with the Cs capacitors.

It is essential that the Rx and Ry resistors and Cs capacitors

be placed very close to the chip. Placing these parts more

than a few millimeters away opens the circuit up to high

frequency interference problems (above 20MHz) as the trace

lengths between the components and the chip start to act as

RF antennae.

✡

X0

Y1

Y2

The upper limits of Rx and Ry are reached when the signal

level and hence key sensitivity are clearly reduced. The limits

of Rx and Ry will depend on key geometry and stray

capacitance, and thus an oscilloscope is required to

determine optimum values of both.

Dwell time is the duration in which charge coupled from X to

Y is captured (Figure 2.4, page 4). Increasing Rx values will

cause the leading edge of the X pulses to increasingly roll off,

causing the loss of captured charge (and hence loss of signal

.

strength) from the keys.

The dwell time of these parts is fixed at 500ns. If the X pulses

have not settled within 500ns, key gain will be reduced; if this

happens, either the stray capacitance on the X line(s) should

be reduced (by a layout change, for example by reducing X

line exposure to nearby ground planes or traces), or, the Rx

resistor needs to be reduced in value (or a combination of

both approaches).

lQ

5 QT60240-ISG R8.06/0906

One way to determine X line settling time is to monitor the

fields using a patch of metal foil or a small coin over the key

(Figure 2.5). Only one key along a particular X line needs to

be observed, as each of the keys along that X line will be

identical. The 500ns dwell time should exceed the observed

95 percent settling of the X-pulse by 25 percent or more.

In almost all cases, Ry should be set equal to Rx, which will

ensure that the charge on the Y line is fully captured into the

Cs capacitor.

2.8 Key Design

Circuits can be constructed out of a variety of materials

including conventional FR-4, Flexible Printed Circuit Boards

(FPCB), silver silk-screened on PET plastic film, and even

inexpensive punched single-sided CEM-1 and FR-2.

The actual internal pattern style is not as important as the

need to achieve regular X and Y widths and spacings of

sufficient size to cover the desired graphical key area or a

little bit more; ~3mm oversize is acceptable in most cases,

since the key’s electric fields drop off near the edges anyway.

The overall key size can range from 6mm x 6mm up to

100mm x 100mm but these are not hard limits. The keys can

be any shape including round, rectangular, square, etc. The

internal pattern can be interdigitated as shown in Figure 2.6.

For small, dense keypads, electrodes such as shown in the

lower half of Figure 2.6 can be used. Where the panels are

thin (usually mobile phones have panels under 2mm thick)

the electrode density can be quite high.

For better surface moisture suppression, the outer perimeter

of X should be as wide as possible, and there should be no

ground planes near the keys. The variable ‘T’ in this drawing

represents the total thickness of all materials that the keys

must penetrate.

2.9 PCB Layout, Construction

Ground planes, if used, should be placed under or around the

QT chip itself and the associated resistors and capacitors in

the circuit, under or around the power supply, and back to a

connector, but nowhere else.

2.9.2 LED Traces and Other Switching Signals

Digital switching signals near the Y lines will induce transients

into the acquired signals, deteriorating the SNR perfomance

of the device. Such signals should be routed away from the Y

lines, or the design should be such that these lines are not

switched during the course of signal acquisition (bursts).

LED terminals which are multiplexed or switched into a

floating state and which are within or physically very near a

key structure (even if on another nearby PCB) should be

bypassed to either Vss or Vdd with at least a 10nF capacitor

to suppress capacitive coupling effects which can induce

false signal shifts. The bypass capacitor does not need to be

next to the LED, in fact it can be quite distant. The bypass

capacitor is noncritical and can be of any type.

LED terminals which are constantly connected to Vss or Vdd

do not need further bypassing.

2.9.3 PCB Cleanliness

All capacitive sensors should be treated as highly sensitive

circuits which can be influenced by stray conductive leakage

paths. QT devices have a basic resolution in the femtofarad

range; in this region, there is no such thing as ‘no clean flux’.

Flux absorbs moisture and becomes conductive between

solder joints, causing signal drift and resultant false

detections or transient losses of sensitivity or instability.

Conformal coatings will trap in existing amounts of moisture

which will then become highly temperature sensitive.

The designer should specify ultrasonic cleaning as part of the

manufacturing process, and in cases where a high level of

humidity is anticipated, the use of conformal coatings after

cleaning to keep out moisture.

2.9.1 Overview

It is best to place the chip near the touch keys on the same

PCB so as to reduce X and Y trace lengths, thereby reducing

the chances for EMC problems. Long connection traces act

as RF antennae. The Y (receive) lines are much more

susceptible to noise pickup than the X (drive) lines.

Even more importantly, all signal related discrete parts

(resistors and capacitors) should be very close to the body of

the chip. Wiring between the chip and the various resistors

and capacitors should be as short and direct as possible to

suppress noise pickup.

Ground planes and traces should NOT

be used around the keys and the Y lines

from the keys. Ground areas, traces, and

other adjacent signal conductors that act

as AC ground (such as Vdd and LED drive

lines etc.) will absorb the received key signals and

reduce signal-to-noise ratio (SNR) and thus will be

counterproductive. Ground planes around keys will also

make water film effects worse.

2.10 Power Supply Considerations

The power supply can range from +1.8V to +5V nominal. The

device can tolerate ±5mV/s short-term power supply

fluctuations. If the power supply fluctuates slowly with

temperature, the device will track and compensate for these

changes automatically with only minor changes in sensitivity.

If the supply voltage drifts or shifts quickly, the drift

compensation mechanism will not be able to keep up,

causing sensitivity anomalies or false detections.

As these devices use the power supply itself as an analog

reference, the power should be very clean and come from a

separate regulator. A standard inexpensive Low Dropout

(LDO) type regulator should be used that is not also used to

power other loads such as LEDs, relays, or other high current

devices. Load shifts on the output of the LDO can cause Vdd

to fluctuate enough to cause false detection or sensitivity

shifts.

Caution: A regulator IC shared with other logic can result in

erratic operation and is not advised.

A regulator can be shared among two or more QT devices on

one board. One such regulator known to work well with QT

chips is the S-817 series from Seiko Instruments

(Seiko Instruments - www.sii-ic.com).

lQ

6 QT60240-ISG R8.06/0906

A single ceramic 0.1uF bypass capacitor, with short traces,

should be placed very close to supply pins 3, 4, 5 and 6 of the

IC. Failure to do so can result in device oscillation, high

current consumption, erratic operation etc. Pins 18, 20, and

21 do not require bypassing.

2.11 Startup / Calibration Times

The devices require initialization times of up to 20ms. A

calibration takes one matrix scan.

Disabled keys are subtracted from the burst sequence and

thus the cal time is shortened. The scan time should be

measured on an oscilloscope.

2.12 Reset Input

The /RST pin can be used to reset the device to simulate a

power-down cycle, in order to bring the device up into a

known state should communications with the device be lost.

The pin is active low, and a low pulse lasting at least 10µs

must be applied to this pin to cause a reset.

The reset pin has an internal 30K

capacitor plus a diode to Vdd can be connected to this pin as

a traditional reset circuit, but this is not required.

If an external hardware reset is not used, the reset pin may

be connected to Vdd or left floating.

✡

- 60K✡ resistor. A 2.2µF

The QT60xx0 uses a two-tier confirmation mechanism having

two such counters for each key. These can be thought of as

‘inner loop’ and ‘outer loop’ confirmation counters.

The ‘inner’ counter is referred to as the ‘fast-DI’; this acts to

attempt to confirm a detection via rapid successive

acquisition bursts, at the expense of delaying the sampling of

the next key. Each key has its own fast-DI counter and limit

value; these limits can be changed via the Setups block on a

per-key basis.

The ‘outer’ counter is referred to as the ‘normal-DI’; this DI

counter increments whenever the fast-DI counter has reached

its limit value. If a fast-DI counter failed to reach its terminal

count, the corresponding normal-DI counter is also reset. The

normal-DI counter also has a limit value which is settable on

a per-key basis. If a normal-DI counter reaches its terminal

count, the corresponding key is declared to be touched and

becomes ‘active’. Note that the normal-DI can only be

incremented once per complete keyscan cycle, i.e. more

slowly, whereas the fast-DI is incremented ‘on the spot’

without interruption.

The net effect of this mechanism is a multiplication of the

inner and outer counters and hence a highly noise-resistance

sensing method. If the inner limit is set to 5, and the outer to

3, the net effect is 5x3=15 successive threshold crossings to

declare a key as active.

2.13 Spread Spectrum Acquisitions

QT60xx0 devices use spread-spectrum burst modulation.

This has the effect of drastically reducing the possibility of

EMI effects on the sensor keys, while simultaneously

spreading RF emissions. This feature is hard-wired into the

device and cannot be disabled or modified.

Spread spectrum is configured as a frequency chirp over a

wide range of frequencies for robust operation.

2.14 Detection Integrators

See also Section 6.5, page 18.

The devices feature a detection integration mechanism, which

acts to confirm a detection in a robust fashion. A per-key

counter is incremented each time the key has exceeded its

threshold and stayed there for a number of acquisitions.

When this counter reaches a preset limit the key is finally

declared to be touched.

For example, if the limit value is 10, then the device has to

exceed its threshold and stay there for 10 acquisitions in

succession without going below the threshold level, before

the key is declared to be touched. If on any acquisition the

signal is not seen to exceed the threshold level, the counter is

cleared and the process has to start from the beginning.

2.15 Sleep

The device will sleep whenever possible to conserve power.

Periodically, the part will wake automatically, scan the matrix,

and return to sleep unless there is activity which demands

further attention. The part will always return to sleep

automatically once all activity has ceased. The time for which

the part will sleep before automatically awakening can be

configured.

A new communication with the device while it is asleep will

cause it to wake up, service the communication and scan the

matrix. At least one full matrix scan is always performed after

waking up and before returning to sleep.

At the end of each matrix scan, the part will return to sleep

unless recent activity demands further attention. If there has

been recent activity, the part will perform another complete

matrix scan and then attempt to sleep once again. This

process is repeated indefinitely until the activity stops and the

part returns to sleep.

Key touch activity will prevent the part from sleeping. The part

will not sleep if any touch events were detected at any key in

the most recent scan of the key matrix.

lQ

7 QT60240-ISG R8.06/0906

2.16 Wiring

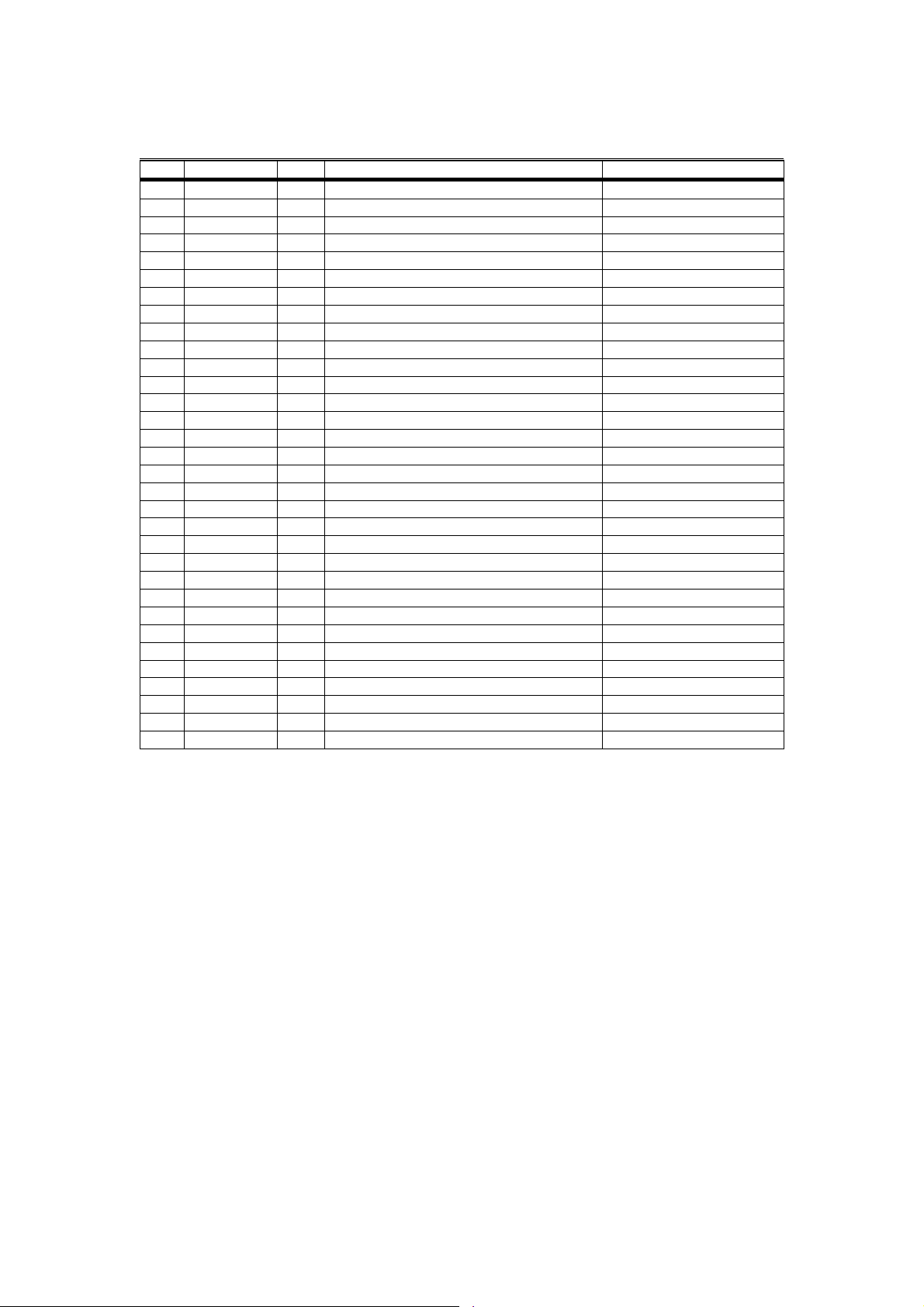

Table 2.2 Pin Listing

If Unused, Connect To...CommentsI/OFunctionPin

VddMains Sync inputIM_SYNC1

Leave openState change notification OCHANGE2

-Supply groundPVss3

-Power, +1.8V to +5VPVdd4

-Supply groundPVss5

-Power, +1.8V to +5VPVdd6

Leave openX matrix drive lineOX67

Leave openX matrix drive lineOX78

Leave openShift Register Latch OutputOLATCH9

-GroundIVref10

Leave openOscilloscope syncOS_SYNC11

Leave openX matrix drive lineOX012

Leave openX matrix drive lineOX113

Leave openX matrix drive lineOX214

Leave openX matrix drive lineOX315

Leave openX matrix drive lineOX416

Leave openX matrix drive lineOX517

-Power, +1.8V to +5VPVdd18

-Com port address 1IA119

-Power, +1.8V to +5VPVdd20

-Supply groundPVss21

-Com port address 0IA022

Leave openY line connectionIY0B23

Leave openY line connectionIY1B24

Leave openY line connectionIY2B25

-Sample output.OSMP26

-Serial Interface DataI/OSDA27

-Serial Interface ClockI/OSCL28

Leave open or VddReset low; has internal 30K - 60K pull-upI/RST29

Leave openY line connectionIY0A30

Leave openY line connectionIY1A31

Leave openY line connectionIY2A32

Input onlyI

Output only, push-pullO

Open drain outputOD

Input and outputI/O

Ground or powerP

lQ

8 QT60240-ISG R8.06/0906

See Table 2.2 for further connection information.

Figure 2.7 Wiring Diagram

Vunreg

follow regulator manufacturers

recommended values for input and

output bypass capacitors; keep output

capacitor close to QT60xx0 pins 4 and 6.

If not possible, add a 100nF capacitor

next to those pins.

I2C

CHANGE

LATCH

MAINS SYNC

SCOPE SYNC

+1.8V to +5V

VREG

10K

SDA

SCL

VDD

10K

VDD

QT60240

QT60160

*RX7

RS0

1M

*RX6

1K

*RX2

1K

*RX5

1K

*RX1

1K

4.7nFCS0

CS1 4.7nF

CS2 4.7nF

Note: Leave YnA, YnB unconnected

if not used

1K

*RX3

1K

* optional - for emission suppression

** optional - for RF susceptibility improvement

RS2

RS1

1M

1M

*RX4

1K

*RX0

1K

**RY0

1K

**RY1

1K

**RY2

1K

MATRIX Y SCAN IN MATRIX X DRIVE

Suggested regulator manufacturers:

• Toko (XC6215 series)

• Seiko (S817 series)

• BCDSemi (AP2121 series)

lQ

9 QT60240-ISG R8.06/0906

3 Interfaces

3.1 Introduction

The QT60xx0 can be configured to communicate either over

2

an I

C bus or a shift register type Serial Peripheral Interface

(SPI).

The pins A0, A1 are used to configure the type of interface

and the I

addresses are available as shown in Table 3.1 below.

3.2 Shift Register Output Mode

When the option jumpers are both set at Vss, the device

disables the I

suitable for driving a shift register.

The shift register data is output at pin 27 (SDA). The clock is

output at pin 28 (SCL). The data is clocked on the

positive-going transition of SCL. Data is transferred from the

shift registers to the latched outputs on the positive-going

transition of LATCH. An example shift register connection is

shown in Figure 3.1.

The shift register data is output over the duration of a matrix

scan, as each key is being processed, and it is latched at the

end of the scan. The overall communication time depends on

the matrix scan time.

2

C address if this mode is used. The modes and I2C

Table 3.1 Interface Details

InterfaceA0A1

Shift RegisterVssVss

I2C Address 7VddVss

I2C Address 17VssVdd

I2C Address 117VddVdd

2

C interface and instead generates output

Table 3.2 Shift Register

SCL low pulse width

SCL high pulse width

LATCH pulse width

SDA data to SCL clock hold time

SCL

SCH

LATCH

SDA-SCL

UnitsLegendParameter

500ns mint

125us mint

500ns mint

75us mint

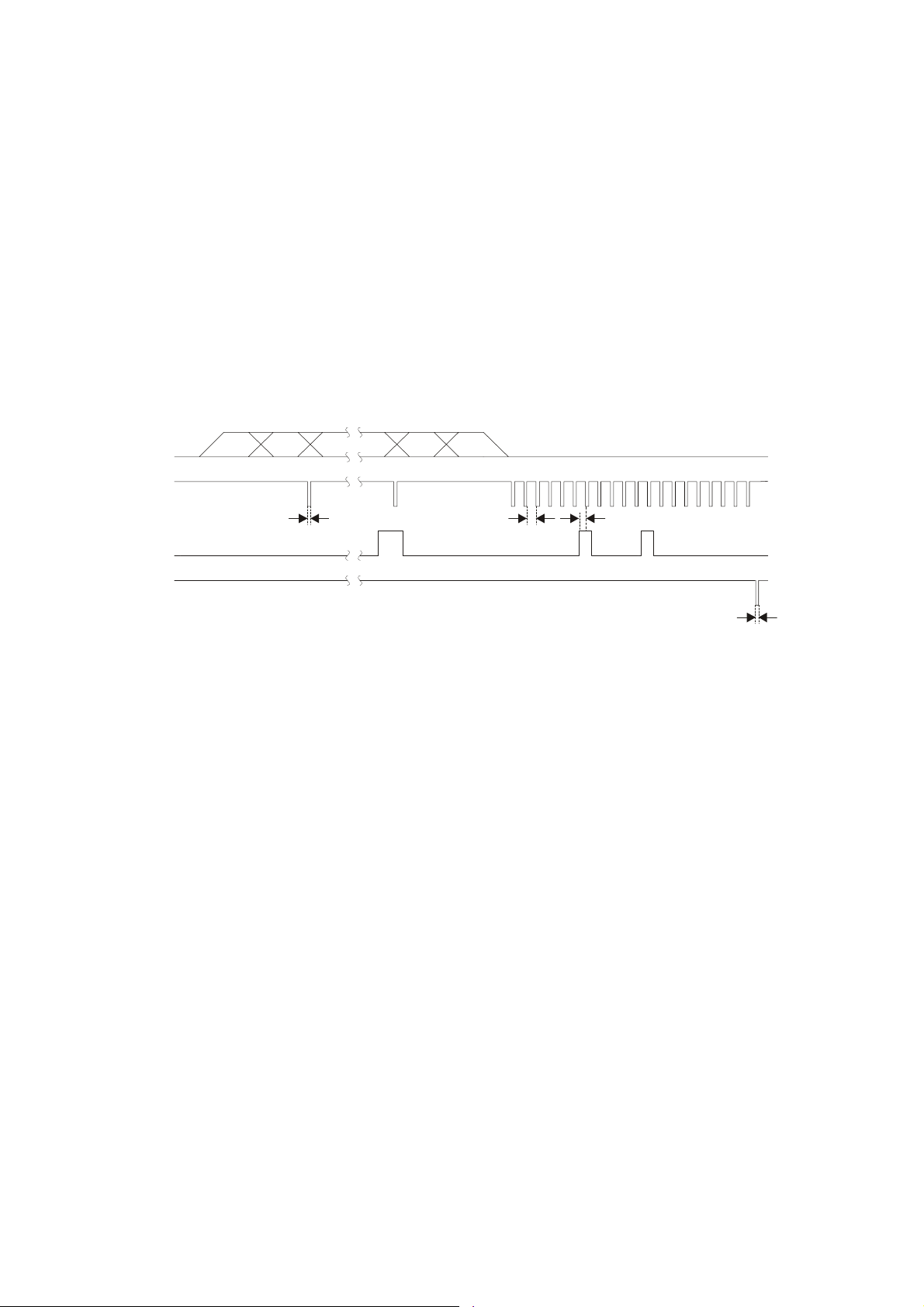

Figure 3.2, page 11 shows a full shift register cycle with keys

3, 10 and 15 activated. Key Scan represents the time when

the chip is measuring signal from each key. SCL, SDA and

LATCH represent their respective signals from the chip. SCL

is an active low clock output. SDA is the data output; high if

the key is in detect and low if it is not. LATCH pulses low

when the data transfer is complete.

Data output proceeds as soon as the key has been

processed. Most keys do not get processed during the key

scan. If so, these keys are processed and the data is output

after the complete key scan.

The internal settings of the device in Shift Register mode are

the default factory settings found in Table 6.2. This means the

device will operate with a Burst Length of 48 on all keys, and

a Sleep time of 125ms for example. These settings cannot be

changed in this mode.

In Shift Register mode, the CHANGE pin is inactive and

should be left open.

3.3 I2C Port

These devices use I2C communications, in slave mode only.

The QT60160/QT60240 will only respond to the correct

address match. I

Max Data Transfer: 100KHz

Address: 7-bit

The match address is selected via pins A0 and A1. Table 3.1

shows the address selections.

The QT60160/QT60240 allows multiple byte transmissions to

provide a more efficient communication. This is particularly

useful to retrieve several information bytes at once. Every

time the host retrieves data from the QT60160/QT60240, an

internal address pointer is incremented.

Therefore, the host only needs to write the initial address

pointer of interest (the lowest address), followed by read

cycles for as many bytes as required.

2

C operating parameters are as follows:

lQ

QT60160/60240

SDA

SCL

Latch

Figure 3.1 Shift Register Output

74HC595

Q0

27

28

9

DS

SH_CP

ST_CP

74HC595

DS

SH_CP

ST_CP

74HC595

DS

SH_CP

ST_CP

Q2

Q3

Q4

Q5

Q6

Q7

/Q7

Q0

Q2

Q3

Q4

Q5

Q6

Q7

/Q7

Q0

Q2

Q3

Q4

Q5

Q6

Q7

/Q7

Outputs, keys 16 to 23

Outputs, keys 8 to 15

Outputs, keys 0 to 7

10 QT60240-ISG R8.06/0906

3.4 CHANGE Pin

Pin 2 (CHANGE) is an active-high output that can be used to

alert the host to key touches or key releases, thus reducing

the need for wasteful I

can simply not bother to communicate with the device, except

when the CHANGE pin goes high.

CHANGE becomes active only when there is a change in key

state (either touch or touch release); CHANGE goes low

again only when the host performs a read from address 1, the

detect status register for all keys on Y0. CHANGE does not

self-clear; only an I

clear.

It is important to read all three key state addresses to ensure

the host has a complete picture of which keys have changed.

SCL

SDA

2

C communications. Normally, the host

2

C read from location 1 will cause it to

Figure 3.2 Shift Register Cycle

Key 0 Key 1 Key 2 Key 21 Key 22 Key 23Key Scan

Key 0 Key 3 Key 4 Key 23

t

SCL

In Shift Register mode the CHANGE pin does not operate

and should be left open.

Every key can be individually configured to wake a host

microcontroller upon a touch change; so, a product can wake

from sleep when any key state changes, or only when certain

desired keys change state. The configuration is set in the

Setups block (Section 6.13) on a key-by-key basis.

t

SCH

t

SDA-SCL

LATCH

t

LATCH

lQ

11 QT60240-ISG R8.06/0906

4 Control Commands

/

4.1 Introduction

The devices feature a set of commands which are used for

control and status reporting.

As well as Table 4.1 refer to Table 6.1, page 21 for further

details.

Table 4.1 Memory Map

AccessUseAddress

1

2

3

4 to 123

125

130

131 to

253

Detect status for keys 0 to 7, one bit

per key

Detect status for keys 8 to 15, one bit

per key

Detect status for keys 16 to 23, one

bit per key

Data for keys 0 to 23, in sequence.

Refer to Table 4.3 for details

Recalibrate all keys. Write 0x55 to

this address location to recalibrate all

the keys

Setups write-unlock. Write 0x55

immediately before writing setups

Poll rate: The host can make use of the CHANGE pin output

to initiate a communication; this will guarantee the optimal

polling rate.

If the host cannot make use of the CHANGE pin the poll rate

in normal ‘run’ operation should be no faster than once per

matrix scan (see Section 7.4, page 23). Typically 10 to 20ms

is more than fast enough to extract the key status. Anything

faster will not provide new information and will slow down the

chip operation.

Sending or reading the setup block is an exception, in this

case the host can send the data at the maximum possible

rate.

Run Poll Sequence: In normal run mode the host should

limit traffic with a minimalist control structure. The host should

just read the three detect status registers (see Figure 4.1,

page 14).

Repeated Start: Using repeated start is not allowed and can

cause communication failure.

4.2 Writing Data to the Device

The sequence of events required to write data to the device is

shown next.

Host to Device Device to Host

SLA+W

MemAddress

AAS

Data A P

ReadReserved0

Read

Read

Read

Read

Write

Write

Read/WriteSetups - refer to Table 5.2 for details

The host initiates the transfer by sending the START

condition, and follows this by sending the slave address of

the device together with the Write-bit. The device sends an

ACK. The host then sends the memory address within the

device it wishes to write to. The device sends an ACK. The

host transmits one or more data bytes; each will be

acknowledged by the device.

If the host sends more than one data byte, they will be written

to consecutive memory addresses. The device automatically

increments the target memory address after writing each data

byte. After writing the last data byte, the host should send the

STOP condition.

The host should not try to write beyond address 255 because

the device will not increment the internal memory address

beyond this.

4.3 Reading Data From the Device

The sequence of events required to read data from the device

is shown next.

Host to Device Device to Host

SLA+W MemAddressAASSSLA+RA

Data 1

Key

MemAddress

/A

Data 2

A

Start conditionS

Slave address plus write bitSLA+W

Acknowledge bitA

Target memory address within

device

Data from deviceData

Stop conditionP

Slave address plus read bitSLA+R

Not Acknowledge bit/indicates

last byte transmission

The host initiates the transfer by sending the START

condition, and follows this by sending the slave address of

the device together with the Write-bit. The device sends an

ACK. The host then sends the memory address within the

device it wishes to read from. The device sends an ACK.

The host must then send a STOP and a START condition

followed by the slave address again but this time

accompanied by the Read-bit. The device will return an ACK,

followed by a data byte. The host must return either an ACK

or NACK. If the host returns an ACK, the device will

subsequently transmit the data byte from the next address.

Each time a data byte is transmitted, the device automatically

increments the internal address. The device will continue to

return data bytes until the host responds with a NACK. The

host should terminate the transfer by issuing the STOP

condition.

P

A

Data n

A

P

Key

MemAddress

Start conditionS

Slave address plus write bitSLA+W

Acknowledge bitA

Target memory address within

device

Data to be writtenData

Stop conditionP

4.4 Report Detections for All Keys

Address 1: detect status for keys 0 to 7

Address 2: detect status for keys 8 to 15

Address 3: detect status for keys 16 to 23

Each location indicates all keys in detection, if any, as a

bitfield; touched keys report as 1’s, untouched or disabled

keys report as 0’s.

Note: the change pin is cleared on reading address 1.

lQ

12 QT60240-ISG R8.06/0906

Table 4.2 Bits for Key Reporting and Numbering

Address

1

2

3

Note: the device should be reset after disabling keys

because, if a key was in detect when it was disabled, it could

incorrectly report detect.

Bit Number

01234567

01234567

89101112131415

1617181920212223

4.5 Raw Data Commands

Addresses 4 to 123 allow data to be read for each key. There

are a total of 24 keys and 5 bytes of data per key, yielding a

total of 120 addresses. These addresses are read-only.

The data for the keys is mapped in sequence, starting with

key 0 at addresses 4 to 8. The data for key 15 is located at

addresses 79 to 83, and that for key 23 is located at

addresses 119 to 123. Table 4.3 summarizes this.

Table 4.3 Key Data

UseKey #Address

Signal LSB04

Signal MSB05

Reference LSB06

Reference MSB07

DetectCount (lower nibble)08

Signal LSB19

Signal MSB110

Reference LSB111

Reference MSB112

DetectCount (lower nibble)113

Signal LSB214

Signal MSB215

Reference LSB216

Reference MSB217

DetectCount (lower nibble)218

Range of values3 to 2219 to 118

Signal LSB23119

Signal MSB23120

Reference LSB23121

Reference MSB23122

DetectCount (lower nibble)23123

There are five bytes of data for each key. The first two are the

key’s 16-bit signal, and the second two are the key’s 16-bit

reference. These are followed by the Detect Integrator Count,

which is a 4-bit value stored in the lower nibble. In the case of

both the signal and reference, the 16-bit values are accessed

as two 8-bit bytes, stored LSB first.

4.6 Cal All

A value of 0x55 must be written to address 125. Upon

receiving this command the QT60xx0 will recalibrate all of the

keys. Recalibration will start at the beginning of the next full

matrix scan and last for one scan cycle.

4.7 Setups

The location “Setups write-unlock”, address 130, allows write

access to the setups. Normally the setups are write-protected;

the write-protection is engaged as soon as a read operation is

performed at any address. By writing a value of 0x55 to this

address, the write-protection is disengaged. This address is

located conveniently immediately before the setups so that

the write protection may be disengaged and the setups

written in a single I

address is undefined.

Addresses 131 to 252 provide read/write access to the

setups. Details of different setups can be found in Section 6,

page 17.

When the host is writing a new setup block the values are

being recorded into EEPROM as they arrive from the host.

2

C communication sequence. Reading this

lQ

13 QT60240-ISG R8.06/0906

Figure 4.1 Power-on or Hardware Reset Flow Chart

Power-on or

Hardware Rese t

Read key

status registers

Addr: 1, 2

and 3

Key Detection(s) / End of

Detection Processing

'CHANGE'

output set

Stuck Key

Detected

Verify Setup

Correct Setup

Block

Host main

Process

Keys OK

Block

Recalibrate All

Send 0x55 to

Setup Data

Addr 125

Incorrect

Send Correct

Setup Block

Legend

Intern a l Host

Processes

Comms

with QT

Recalibrate All

Send 0x55 to

Addr 125

lQ

14 QT60240-ISG R8.06/0906

5 I2C Operation

5.1 Interface Bus

More detailed information about I2C is available from

www.i2C-bus.org. Devices are connected onto the I

shown in Figure 5.1. Both bus lines are connected to Vdd via

pull-up resistors. The bus drivers of all I

2

C devices must be

open-drain type. This implements a wired-AND function which

allows any and all devices to drive the bus, one at a time. A

low level on the bus is generated when a device outputs a

zero.

Figure 5.1 I2C Interface Bus

Vcc

2

C bus as

5.3 START and STOP Conditions

The host initiates and terminates a data transmission. The

transmission is initiated when the host issues a START

condition on the bus, and is terminated when the host issues

a STOP condition. Between START and STOP conditions, the

bus is considered busy. As shown below, START and STOP

conditions are signaled by changing the level of the SDA line

when the SCL line is high.

Figure 5.3 START and STOP Conditions

SDA

Device 1 Device 2 Device 3 Device n R1 R2

SDA

SCL

Table 5.1 I2C Bus Specifications

UnitParameter

7-bitAddress space

100 kHzMaximum bus speed (SCL)

4µs minimumHold time START condition

4µs minimumSetup time for STOP condition

Bus free time between a STOP and START

condition

4.7µs minimum

5.2 Transferring Data Bits

Each data bit transferred on the bus is accompanied by a

pulse on the clock line. The level of the data line must be

stable when the clock line is high; The only exception to this

rule is for generating START and STOP conditions.

Figure 5.2 Data Transfer

SCL

START STOP

5.4 Address Packet Format

All address packets are 9 bits long, consisting of 7 address

bits, one READ/WRITE control bit and an acknowledge bit. If

the READ/WRITE bit is set, a read operation is performed,

otherwise a write operation is performed. When the device

recognizes that it is being addressed, it will acknowledge by

pulling SDA low in the ninth SCL (ACK) cycle. An address

packet consisting of a slave address and a READ or a

WRITE bit is called SLA+R or SLA+W, respectively.

The most significant bit of the address byte is transmitted

first. The address sent by the host must be consistent with

that selected with the option jumpers.

Figure 5.4 Address Packet Format

Addr MSB Addr LSB R/W ACK

DA

SCL

12 789

START

SDA

SCL

Data Stable Data Stable

lQ

5.5 Data Packet Format

All data packets are 9 bits long, consisting of one data byte

and an acknowledge bit. During a data transfer, the host

generates the clock and the START and STOP conditions,

while the Receiver is responsible for acknowledging the

reception. An acknowledge (ACK) is signaled by the Receiver

pulling the SDA line low during the ninth SCL cycle. If the

Receiver leaves the SDA line high, a NACK is signaled.

Data Change

15 QT60240-ISG R8.06/0906

5.6 Combining Address and Data Packets

Into a Transmission

A transmission consists of a START condition, an SLA+R/W,

one or more data packets and a STOP condition. The

wired-ANDing of the SCL line is used to implement

handshaking between the host and the device. The device

extends the SCL low period by pulling the SCL line low

whenever it needs extra time for processing between the data

transmissions.

Figure 5.5 Data Packet Format

Data MSB Data LSB ACK

Aggregate

SDA

SDA from

Transmitter

SDA from

Receiver

SCL from

Master

SLA+R/W

12 789

Figure 5.6 shows a typical data transmission. Note that

several data bytes can be transmitted between the SLA+R/W

and the STOP.

STOP,

Data Byte

or

Next Data Byte

Addr MSB Ad dr LSB R/W ACK

SDA

SCL

12 789

START SLA+R/W

Figure 5.6 Packet Transmission

Data MSB Data LSB ACK

12 789

Data Byte STOP

lQ

16 QT60240-ISG R8.06/0906

6 Setups

6.1 Introduction

The devices calibrate and process all signals using a

number of algorithms specifically designed to provide for

high survivability in the face of adverse environmental

challenges. They provide a large number of processing

options which can be user-selected to implement very

flexible, robust keypanel solutions.

User-defined Setups are employed to alter these

algorithms to suit each application. These setups are

loaded into the device over the I

Setups are stored in an onboard EEPROM array.

Many setups employ lookup-table value translation.

Table 6.2, the Setups Lookup Table on page 22 shows all

translation values. The default values are the factory

defaults.

Refer to Table 6.1 for all Setups.

6.2 Negative Threshold - NTHR

The negative threshold value is established relative to a

key’s signal reference value. The threshold is used to

determine key touch when crossed by a negative-going

signal swing after having been filtered by the detection

integrator. Larger absolute values of threshold desensitize

keys since the signal must travel farther in order to cross

the threshold level. Conversely, lower thresholds make

keys more sensitive.

As Cx and Cs drift, the reference point drift-compensates

for these changes at a user-settable rate; the threshold

level is recomputed whenever the reference point moves,

and thus it also is drift compensated.

The amount of NTHR required depends on the amount of

signal swing that occurs when a key is touched. Thicker

panels or smaller key geometries reduce ‘key gain’, i.e.

signal swing from touch, thus requiring smaller NTHR

values to detect touch.

The negative threshold is programmed on a per-key basis

using the Setup process. See

Negative hysteresis: NHYST is fixed at 12.5 percent of

the negative threshold value and cannot be altered.

Typical values: 3 to 8

(7 to 12 counts of threshold; 4 is internally added to

NTHR to generate the threshold).

Default value: 6

(10 counts of threshold)

2

C serial interfaces. The

Table 6.2, page 22.

6.3 Positive Threshold - PTHR

The positive threshold is used to provide a mechanism for

recalibration of the reference point when a key's signal

moves abruptly to the positive. This condition is not

normal, and usually occurs only after a recalibration when

an object is touching the key and is subsequently removed.

The desire is normally to recover from these events

quickly.

Positive hysteresis: PHYST is fixed at 12.5 percent of the

positive threshold value and cannot be altered.

Positive threshold levels are all fixed at six counts of signal

and cannot be modified.

6.4 Drift Compensation - NDRIFT, PDRIFT

Signals can drift because of changes in Cx and Cs over

time and temperature. It is crucial that such drift be

compensated, else false detections and sensitivity shifts

can occur.

Drift compensation (Figure 6.1) is performed by making the

reference level track the raw signal at a slow rate, but only

while there is no detection in effect. The rate of adjustment

must be performed slowly, otherwise legitimate detections

could be ignored. The devices drift compensate using a

slew-rate limited change to the reference level; the

threshold and hysteresis values are slaved to this

reference.

When a finger is sensed, the signal falls since the human

body acts to absorb charge from the cross-coupling

between X and Y lines. An isolated, untouched foreign

object (a coin, or a water film) will cause the signal to rise

very slightly due to an enhancement of coupling. This is

contrary to the way most capacitive sensors operate.

Once a finger is sensed, the drift compensation

mechanism ceases since the signal is legitimately

detecting an object. Drift compensation only works when

the signal in question has not crossed the negative

threshold level.

The drift compensation mechanism can be asymmetric; the

drift-compensation can be made to occur in one direction

faster than it does in the other simply by changing the

NDRIFT and PDRIFT Setup parameters. This can be done

on a per-key basis.

Figure 6.1 Thresholds and Drift Compensation

lQ

Reference

Hysteresis

Threshold

Signal

Output

17 QT60240-ISG R8.06/0906

Specifically, drift compensation should be set to compensate

faster for increasing signals than for decreasing signals.

Decreasin

since an approaching finger could be compensated for

partially or entirely before even touching the touch pad.

However, an obstruction over the sense pad, for which the

sensor has already made full allowance, could suddenly be

removed leaving the sensor with an artificially suppressed

reference level and thus become insensitive to touch. In

this latter case, the sensor should compensate for the

object's removal by raising the reference level relatively

quickly.

Drift compensation and the detection time-outs work

together to provide for robust, adaptive sensing. The

time-outs provide abrupt changes in reference calibration

depending on the duration of the signal 'event'.

NDRIFT Typical values: 9 to 11

NDRIFT Default value: 10

PDRIFT Typical values: 3 to 5

PDRIFT Default value: 4

g signals should not be compensated quickly,

(2 to 3.3 seconds per count of drift compensation)

(2.5s / count of drift compensation)

(0.4 to 0.8 seconds per count of drift compensation;

translation via LUT, page )

(0.6s / count of drift compensation)

6.5 Detect Integrators - NDIL, FDIL

NDIL is used to enable or disable keys and to provide

signal filtering. To enable a key, its NDIL parameter should

be nonzero (ie NDIL=0 disables a key). See Section 2.2.

To suppress false detections caused by spurious events

like electrical noise, the devices incorporate a 'detection

integrator' or DI counter mechanism. A per-key counter is

incremented each time the key has exceeded its threshold

and stayed there for a number of acquisitions in

succession, without going below the threshold level. When

this counter reaches a preset limit the key is finally

declared to be touched.

If on any acquisition the signal is not seen to exceed the

threshold level, the counter is cleared and the process has

to start from the beginning.

The DI mechanism uses two counters. The first is the ‘fast

DI’ counter FDIL. When a key’s signal is first noted to be

below the negative threshold, the key enters ‘fast burst’

mode. In this mode the burst is rapidly repeated for up to

the specified limit count of the fast DI counter. Each key

has its own counter and its own specified fast-DI limit

(FDIL), which can range from 1 to 15. When fast-burst is

entered the QT device locks onto the key and repeats the

acquire burst until the fast-DI counter reaches FDIL, or, the

detection fails beforehand. After this the device resumes

normal keyscanning and goes on to the next key.

The ‘Normal DI’ counter counts the number of times the

fast-DI counter reached its FDIL value. The Normal DI

counter can only increment once per complete scan of all

keys. Only when the Normal DI counter reaches NDIL does

the key become formally ‘active’.

The net effect of this is that the sensor can rapidly lock

onto and confirm a detection with many confirmations,

while still scanning other keys. The ratio of ‘fast’ to ‘normal’

counts is completely user-settable via the Setups process.

The total number of required confirmations is equal to FDIL

times NDIL.

If FDIL = 5 and NDIL = 2, the total detection confirmations

required is 10, even though the device only scanned

through all keys only twice.

The DI is extremely effective at reducing false detections at

the expense of slower reaction times. In some applications

a slow reaction time is desirable. The DI can be used to

intentionally slow down touch response in order to require

the user to touch longer to operate the key.

If FDIL = 1, the device functions conventionally. Each

channel acquires only once in rotation, and the normal

detect integrator counter (NDIL) operates to confirm a

detection. Fast-DI is in essence not operational.

If FDIL m 2, then the fast-DI counter also operates in

addition to the NDIL counter.

If Signal [ NTHR: The fast-DI counter is incremented

towards FDIL due to touch.

If Signal >NTHR then the fast-DI counter is cleared due to

lack of touch.

Disabling a key: If NDIL =0, the key becomes disabled.

Keys disabled in this way are pared from the burst

sequence in order to improve sampling rates and thus

response time. See Section 2.2, page 3.

NDIL Typical values:

NDIL Default value: 2

FDIL Typical values:

FDIL Default value: 5

2, 3

4 to 6

6.6 Negative Recal Delay - NRD

If an object unintentionally contacts a key resulting in a

detection for a prolonged interval it is usually desirable to

recalibrate the key in order to restore its function, perhaps

after a time delay of some seconds.

The Negative Recal Delay timer monitors such detections;

if a detection event exceeds the timer's setting, the key will

be automatically recalibrated. After a recalibration has

taken place, the affected key will once again function

normally even if it is still being contacted by the foreign

object. This feature is set on a per-key basis using the

NRD setup parameter.

NRD can be disabled by setting it to zero (infinite timeout)

in which case the key will never auto-recalibrate during a

continuous detection (but the host could still command it).

NRD is set using one byte per key, which can range in

value from 0...254. NRD above 0 is expressed in 0.5s

increments. Thus if NRD =120, the timeout value will

actually be 60 seconds. 255 is not a legal number to use.

NRD Typical values:

NRD Default value: 20 (10 seconds)

NRD Range: 0..254 (∞, 0.5...127s)

NRD Accuracy: to within ± 250ms

20 to 60 (10 to 30 seconds)

6.7 Positive Recalibration Delay - PRD

A recalibration occurs automatically if the signal swings

more positive than the positive threshold level. This

condition can occur if there is positive drift but insufficient

positive drift compensation, or, if the reference moved

negative due to a NRD auto-recalibration, and thereafter

the signal rapidly returned to normal (positive excursion).

lQ

18 QT60240-ISG R8.06/0906

As an example of the latter, if a foreign object or a finger

contacts a key for period longer than the Negative Recal

Delay (NRD), the key is by recalibrated to a new lower

reference level. Then, when the condition causing the

negative swing ceases to exist (e.g. the object is removed)

the signal suddenly swings positive to its normal reference.

It is almost always desirable in these cases to cause the

key to recalibrate quickly so as to restore normal touch

operation. The time required to do this is governed by

PRD. In order for this to work, the signal must rise through

the positive threshold level PTHR continuously for the PRD

period.

After the PRD interval has expired and the

autorecalibration has taken place, the affected key will

once again function normally.

PRD Accuracy: to within ± 50ms

Delay: PRD is fixed at 200ms for all keys,

and cannot be altered.

6.8 Burst Length - BL

The signal gain for each key is controlled by circuit

parameters as well as the burst length.

The burst length is simply the number of times the

charge-transfer (‘QT’) process is performed on a given key.

Each QT process is simply the pulsing of an X line once,

with a corresponding Y line enabled to capture the

resulting charge passed through the key’s capacitance Cx.

QT60xx0 devices use a fixed number of QT cycles which

are executed in burst mode. There can be up to 64 QT

cycles in a burst, in accordance with the list of permitted

values shown in Table 6.2, page 22.

Increasing burst length directly affects key sensitivity. This

occurs because the accumulation of charge in the charge

integrator is directly linked to the burst length. The burst

length of each key can be set individually, allowing for

direct digital control over the signal gains of each key

individually.

Apparent touch sensitivity is also controlled by the

Negative Threshold level (NTHR). Burst length and NTHR

interact; normally burst lengths should be kept as short as

possible to limit RF emissions, but NTHR should be kept

above 6 to reduce false detections due to external noise.

The detection integrator mechanism also helps to prevent

false detections.

BL Typical values: 1, 2 (32, 48 pulses / burst)

BL Default value: 2 (48 pulses / burst)

BL Possible values: 0, 1, 2, 3 (16, 32, 48, 64

pulses/burst)

6.9 Adjacent Key Suppression - AKS

These devices incorporate adjacent key suppression

(‘AKS’ - patent pending) that can be selected on a per-key

basis. AKS permits the suppression of multiple key

presses based on relative signal strength. This feature

assists in solving the problem of surface moisture which

can bridge a key touch to an adjacent key, causing multiple

key presses. This feature is also useful for panels with

tightly spaced keys, where a fingertip might inadvertently

activate an adjacent key.

AKS works for keys that are AKS-enabled anywhere in the

matrix and is not restricted to physically adjacent keys; the

device has no knowledge of which keys are actually

physically adjacent. When enabled for a key, adjacent key

suppression causes detections on that key to be

suppressed if any other AKS-enabled key in the panel has

a more negative signal deviation from its reference.

This feature does not account for varying key gains (burst

length) but ignores the actual negative detection threshold

setting for the key. If AKS-enabled keys in a panel have

different sizes, it may be necessary to reduce the gains of

larger keys relative to smaller ones to equalize the effects

of AKS. The signal threshold of the larger keys can be

altered to compensate for this without causing problems

with key suppression.

Adjacent key suppression works to augment the natural

moisture suppression of narrow gated transfer switches

creating a more robust sensing method.

AKS Default value: 0 (Off)

6.10 Oscilloscope Sync - SSYNC

Pin 11 (S_SYNC) can output a positive pulse oscilloscope

sync that brackets the burst of a selected key. More than

one burst can output a sync pulse as determined by the

Setups parameter SSYNC for each key.

This feature is invaluable for diagnostics; without it,

observing signals clearly on an oscilloscope for a particular

burst is very difficult.

This function is supported in Quantum’s QmBtn PC

software.

SSYNC Default value: 0 (Off)

6.11 Mains Sync - MSYNC

The Mains Sync feature uses M_SYNC pin 1.

External fields can cause interference leading to false

detections or sensitivity shifts. Most fields come from AC

power sources. RFI noise sources are heavily suppressed

by the low impedance nature of the QT circuitry itself.

Noise such as from 50Hz or 60Hz fields becomes a

problem if it is uncorrelated with acquisition signal

sampling; uncorrelated noise can cause aliasing effects in

the key signals. To suppress this problem the M_SYNC

input allows bursts to synchronize to the noise source.

The noise synchronization operating mode is set by

parameter MSYNC in Setups.

The synchronization occurs only at the burst for the lowest

numbered enabled key in the matrix. The device waits for

the synchronization signal for up to 100ms after the end of

a preceding full matrix scan, then when a negative

synchronization edge is received, the matrix is scanned in

its entirety again.

The sync signal drive should be a buffered logic signal, or

perhaps a diode-clamped signal, but never a raw AC signal

from the mains. The device will synchronize to the falling

edge.

lQ

19 QT60240-ISG R8.06/0906

Since noise synchronization is highly effective and

inexpensive to implement, it is strongly advised to take

advantage of it anywhere there is a possibility of

encountering low frequency (i.e. 50/60Hz) electric fields.

Quantum’s QmBtn software can show such noise effects

on signals, and will hence assist in determining the need to

make use of this feature.

If the synchronization feature is enabled but no

synchronization signal exists, the sensor will continue to

operate but with a delay of 100ms before the start of each

matrix scan, and hence will have a slow response time.

SYNC Default value: 0 (Off)

SYNC Possible range: 0, 1 (Off, On)

6.12 Sleep Duration - SLEEP

The QT60xx0 is designed to sleep as much as possible to

conserve power. Periodically, the part wakes automatically,

scans the keyboard matrix and then returns to sleep. The

length of time the part sleeps before automatically waking

up can be configured to one of eight different values, via a

look-up table. The look-up table index must be written to

the setups (see Table 6.2, page 22).

Note that when a key changes state, the CHANGE pin can

be made to go active and the device can go into ‘fast

mode’ automatically if the WAKE feature is enabled on that

key (next section).

SLEEP default value: 3 (125ms)

SLEEP range: 0...7 (16ms...2s)

In Shift Register mode, the WAKE function is enabled for

all keys, however the CHANGE pin does not function in

this mode. The AWAKE timeout in Shift Register mode is

2.5s (note default setting of AWAKE parameter in Table

6.2).

WAKE Default value: 1 (On)

WAKE Possible range: 0, 1 (Off, On)

6.14 Awake Timeout - AWAKE

After each matrix scan, the part will automatically go to

sleep whenever possible to conserve power, unless there

has been a key state change on a key with the WAKE

feature enabled (Section 6.13), in which case the part will

wake up into ‘fast mode’ which has no sleep states and

operates at the fastest possible speed. The AWAKE

timeout feature determines how long the device will remain

in this mode from the last key state change.

Subsequent key state changes further prolong the AWAKE

interval. In other words, once the part has been awakened

by a change on a WAKE enabled key, the key response

time will be fast for as long as the keyboard remains in

use. Once key activity lapses for a period longer than the

AWAKE timeout, the part will return to sleep mode.

The AWAKE period can be configured to a value between

100ms and 25.5s, in increments of 100ms.

AWAKE default value: 25 (2.5s)

AWAKE range: 1...255 (100ms...25.5s)

AWAKE Timeout accuracy: to within ±50ms

6.13 Wake on Key Touch - WAKE

The device can be configured for full time wake-up from

Sleep mode when specific keys are touched or released

using this feature, in order to improve response time after

each key state change. Once awake the key will remain

awake until the AWAKE function times out (Section 6.14).

Also this feature makes the CHANGE pin go active on a

key touch or key release (Section 3.4).

Each key has its own WAKE configuration bit so that any

combination of keys can be configured for this function.

The time the part will remain awake after any key state

change can also be configured in the Setup block (AWAKE

feature, next section).

Any key, even one where the WAKE feature is not

enabled, will prolong the time the part remains awake once

the part is awake

6.15 Drift Hold Time - DHT

Drift Hold Time (DHT) is used to restrict drift on all keys

while one or more keys are activated. DHT defines the

length of time the drift is halted after a key detection.

This feature is particularly useful in cases of high-density

keypads where touching a key or hovering a finger over the

keypad would cause untouched keys to drift, and therefore

create a sensitivity shift, and ultimately inhibit any touch

detection.

DHT can be configured to a value of between 100ms and

25.5s, in increments of 100ms. Setting this parameter to 0

will disable this feature and the drift compensation on any

key will not be dependent on the state of other keys.

DHT default value: 10 (1s)

DHT range: 0...255 (Off, 100ms...25.5s)

lQ

20 QT60240-ISG R8.06/0906

6.16 Setups Block

Table 6.1 Setups Table

Setups data is sent from the host to the QT using the I2C interface. The setups block is memory mapped onto this interface. Thus each setup can be accessed by

reading/writing the appropriate address. Setups can be accessed individually or as a block. Before writing to any setup, an unlock code (value 0x55) must be written to the

setups write unlock address (130). Refer also to Table 6.2, page 22 for further details, and all of Section 6.

BitsValid RangeSymbolParameterBytesAddressItem

Neg thresh

1

24131...154

Neg Drift Comp

NTHR

NDRIFT

NTHR = 0...15

NDRIFT = 0...15

Key

Scope

4

4

2

Normal DI Limit

3

24179...202

Fast DI Limit

NDIL

FDIL

NDIL = 0...15

FDIL = 0...15

4

4

4

BL

WAKE = 0,1

BL = 0...3

AKS = 0,1

SSYNC = 0,1

SLEEP = 0...7

MSYNC = 0,1

Wake On Touch

Burst Length

5

6

24227...250

1251

AKS

Scope Sync

Sleep Duration

Mains Sync

WAKE

AKS

SSYNC

SLEEP

MSYNC

1

2

1

1

3

1

24

24

7

8

Default

Value

Lower nibble = Neg Threshold - take operand and add 4 to get value

1

1

1

1

1

1

1

1

6

Upper nibble = Neg Drift comp - via Lookup Table (LUT) (Table 6.2, page 22)

10

Upper nibble = Pos Drift comp - via LUT (Table 6.2, page 22)414PDRIFT = 0...15PDRIFTPos Drift Comp24155...178

Lower nibble = Normal DI Limit, values same as operand (0 = disabled burst)

2

For QT60160, only the first 16 locations are set to 2, the last eight are set to 0

5

Upper nibble = Fast DI Limit, values same as operand (0 does not work)

Range is in 0.5 sec increments; 0 = infinite, default = 10s

20180...254NRDNeg recal delay24203...226

Range is {infinite, 0.5...127s}; 255 is illegal to use