Page 1

lQ

QT1106

QW

HEEL

™/QS

LIDE

™/QT

OUCH

™ IC

This datasheet is applicable to all revision 8I chips

QT1106 charge-transfer (‘QT’) QTouchTM IC is a self-contained, patented

charge-transfer capacitive controller capable of detecting near-proximity

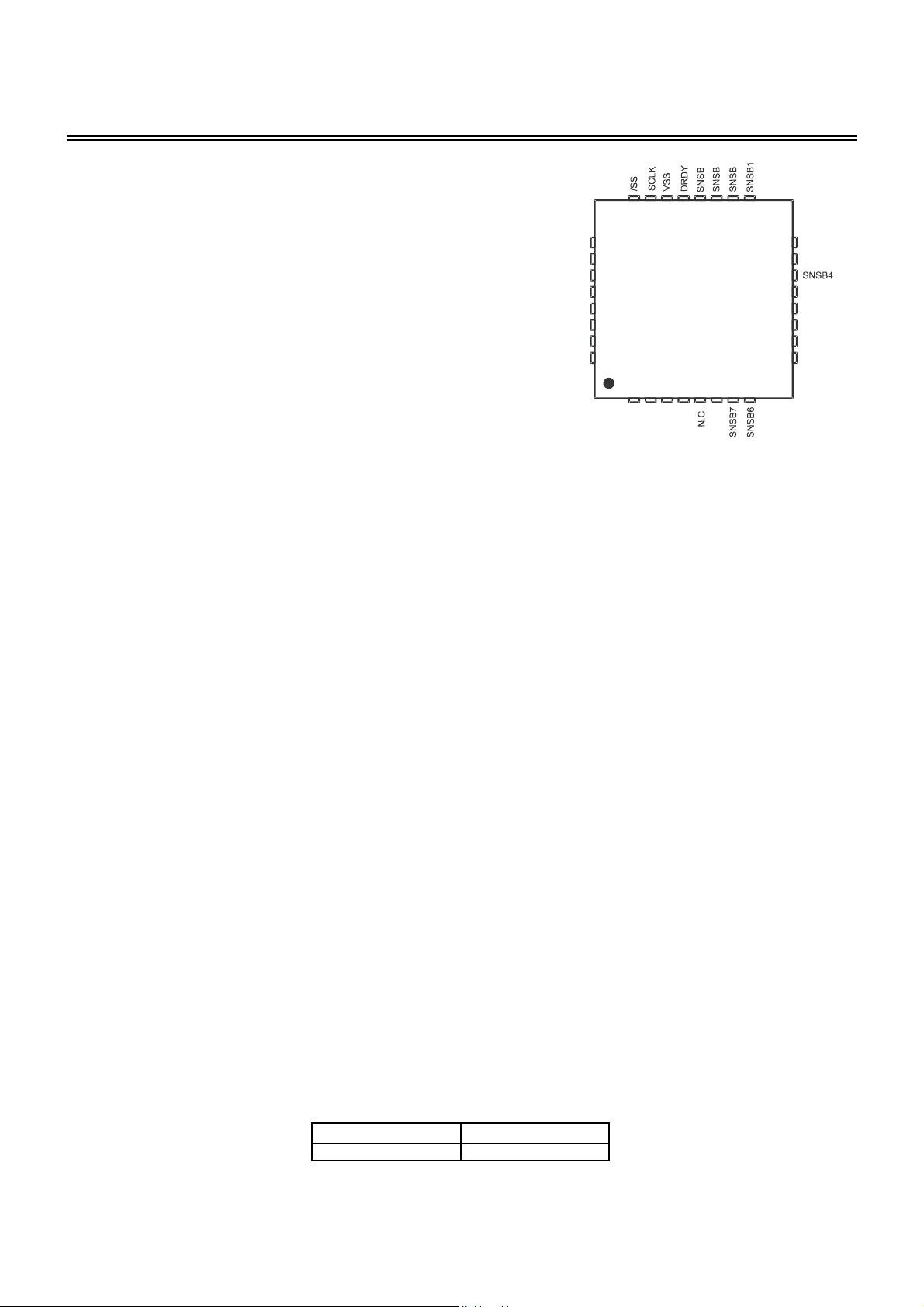

2423222120

19 18

17

or touch on up to seven electrodes and a wheel/slider. It allows

electrodes to project sense fields through any dielectric such as glass or

plastic. These electrodes are laid out as a scroller (e.g. a wheel or slider)

plus seven additional independent keys. Each key channel can be tuned

for a unique sensitivity level by simply changing a corresponding external

Cs capacitor, whereas the wheel/slider’s sensitivity can be changed

dynamically through SPI commands.

The wheel/slider uses a simple, inexpensive sensing element between

three connection points. The QT1106 can report a single rapid touch

MOSI

MISO

SNSA

SNSA

SNSA

SNSA1

SNSA2

SNSA3

25

26

27

28

29

30

31

32

QT1106

32-QFN

SNSB2

16

SNSB3

15

14

SNSB

13

SNSB

12

SNSB

11

SNSB

10

SNSB5

9

anywhere along the sense elements, or it can track a finger moving along

the wheel/slider’s surface in real time.

By using the charge-transfer principle, this device delivers a level of

performance clearly superior to older technologies yet

is highly cost-effective. Spread-spectrum burst technology provides

1

2345678

VDD

OSC

/RST

SPREAD

E

G

N

A

H

C

AT A GLANCE

Number of keys: 0 to 7, one slider or one wheel

Technology: Patented spread-spectrum charge-transfer

Key outline sizes: 5mm x 5mm or larger (panel thickness dependen t); w i de ly di fferent si ze s and sha pes po ssib le

Key spacings: 6mm or wider, center to center (panel thickness, human factors dependent)

Key design: Single solid or ring shaped electrodes; wide variety of possible layouts

Wheel size: Typically 30mm- 50mm diameter, resistored wheel up to 80mm diameter, typical width 12mm

Slider size: Typically 50mm-100mm length, typical width 12mm

Wheel electrode design: Resistorless/resistored design

Slider electrode design: Resistorless/resistored design (can be an arc or other irregular shape)

Layers required: One layer substrate; electrodes and components can be on same side

Substrates: FR-4, low cost CEM-1 or FR-2 PCB materials; polyamide FPCB; PET films, glass

†

Electrode materials: Copper, silver, carbon, ITO, Orgacon

Panel materials: Plastic, glass, composites, painted surfaces (nonconductive paints)

Adjacent Metal: Compatible with grounded metal immediately next to keys

Key panel thickness: Up to 15mm glass, 10mm plastic (key size dependent)

Wheel/Slider panel thickness: Up to 4mm glass, 3mm plastic

Key sensitivity: Adjustable via change in sampling capacitor (Cs) value

Outputs: SPI

Moisture tolerance: Good

Power: 2.8V ~ 5.0V

Package: 32-pin 5 x 5mm QFN RoHS compliant

Signal processing: Self-calibration, auto drift comp ensa ti on, no ise filte ring , pate nted Adjacent Key Suppressi on

Applications: Portable devices, domestic appliances and A/V gear, PC peripherals, office equipment

Patents: AKS™ (patented Adjacent Key Suppression)

QTouch™ (patented Charge-transfer method)

QWheel™/QSlide™ (patented Charge-transfer method) (patent-pending QWheel/QSlide

sensing configuration)

†

Orgacon is a registered trademark of Agfa-Gevaert N.V

AVAILABLE OPTIONS

A

LQC

ink (virtually anything electrically conductive)

TM

32-QFNT

QT1106-ISG-400C to +850C

Copyright © 2006-2007 QRG Ltd

QT1106_8IR0.06_0407

Page 2

Contents

1 Overview

1.1 Introduction

1.2 Burst Operation

1.3 User Interface Layout Options

1.4 Slider and Wheel Construction

1.5 QMagicTM Proximity Effect

1.6 SPI Interface

1.7 Basic Power Modes

2 Signal Processing

2.1 Power-up Self-calibration

2.2 Drift Compensation

2.3 Detection Integrator Filter

2.4 AKSTM Adjacent Key Suppression

2.5 Autorecalibration (MOD)

2.6 QMagicTM Proximity Sensor

2.7 Faulty and Unused Keys

2.8 Wiring

3 SPI Interface

3.1 Introduction

3.2 CHANGE Pin

3.3 SPI Parameters

3.4 SPI Operation

3.5 SPI Host Commands

3.6 SPI Responses

...........................................

.......................................

....................................

......................................

1.7.1 Overview

1.7.2 Free Run Mode

1.7.3 LP Mode

1.7.4 Sleep Mode

1.7.5 Sync Mode

.................................

.......................................

...................................

.......................................

.....................................

.....................................

...................................

..................................

...........................................

........................................

.......................................

......................................

....................................

.....................................

3.5.1 Overview

3.5.2 Normal Command Mode

3.5.3 Custom Threshold Command Mode

.......................................

................................

....................................

..........................

..........................

............................

..............................

..............................

.......................

..............................

...........................

..............................

..............................

......................

4 Operating Modes

3

4.1 Introduction

3

4.2 Free Run Mode

3

4.3 LP Mode

3

4.4 Sleep Mode

3

4.5 Sync Mode

3

5 Reset

3

5.1 Introduction

4

5.2 Delay to SPI Functionality

4

5.3 Reset Delay to Touch Detection

4

5.4 Mode Setting After Reset

4

6 Design Notes

4

6.1 Oscillator Frequency

4

6.2 Spread-spectrum Circuit

4

6.3 Cs Sample Capacitors - Sensitivity

4

6.4 Rsns Resistors

4

6.5 Thermal Stability

4

6.6 Power Supply

4

6.7 PCB Layout and Construction

4

7 Specifications

5

7.1 Absolute Maximum Specifications

5

7.2 Recommended Operating Conditions

6

7.3 AC Specifications

8

7.4 DC Specifications

8

7.5 Signal Processing

8

7.6 Idd Curves

8

7.7 Mechanical Dimensions - 32-QFN Package

8

7.8 Part Marking

9

7.9 Moisture Sensitivity Level (MSL)

9

8 Datasheet Control

9

10

10

8.1 Changes

8.2 Numbering Convention

...................................

......................................

...................................

........................................

......................................

.......................................

.............................................

......................................

............................

........................

.............................

......................................

................................

.............................

......................

....................................

...................................

.....................................

..........................

......................................

.......................

....................

..................................

..................................

.................................

.......................................

................

.....................................

........................

...................................

........................................

..............................

11

11

11

11

12

12

13

13

13

13

13

13

13

13

13

14

14

14

14

15

15

15

15

15

16

17

19

19

20

21

21

21

LQ

2 QT1106_8IR0.06_0407

Page 3

1 Overview

1.1 Introduction

The QT1106 is an easy to use sensor IC based on

Quantum’s patented charge-transfer (‘QT’) principles for

robust operation and ease of design. This device has many

advanced features which provide for reliable, trouble-free

operation over the life of the product. In particular the

QT1106 features advanced self-calibration, drift

compensation, and fast thermal tracking. Unlike prior

devices, the QT1106 can tolerate power supply fluctuations

better in order to eliminate the need for a voltage regulator in

many cases.

1.2 Burst Operation

The device operates in burst mode. Each key is acquired

using a burst of charge-transfer sensing pulses whose count

varies depending on the value of the sense capacitor Cs and

the load capacitance Cx (finger touch capacitance and circuit

stray capacitance).

The channels’ signals are acquired using three successive

bursts of pulses:

Burst 1: B1, B3, B5, B7 (for discrete keys 1, 3, 5, 7)

Burst 2: B2, B4, B6 (for discrete keys 2, 4, 6)

Burst 3: A1, A2, A3 (for wheel or slider)

Bursts always operate in 1, 2, 3 sequence as a group and

occur one right after the other with minimum delay. The

groups are separated by an interval of time that can be used

for SPI communications.

Spread-spectrum operation - Bursts can operate over a

spread of frequencies, so that external fields will have

minimal effect on key operation and emissions are very

weak.

Spread-spectrum operation works together with the ‘detect

integrator’ (DI) mechanism to dramatically reduce the

probability of false detection due to noise. An external RC

circuit is required to implement spread spectrum, but this

circuit is optional.

1.3 User Interface Layout Options

The QT1106 can sense through all common plastics or glass

or other dielectric materials up to 10mm thick. It can be used

to implement a linear slider or rotary scroll wheel plus seven

additional discrete keys. The slider or wheel indicates

absolute positions.

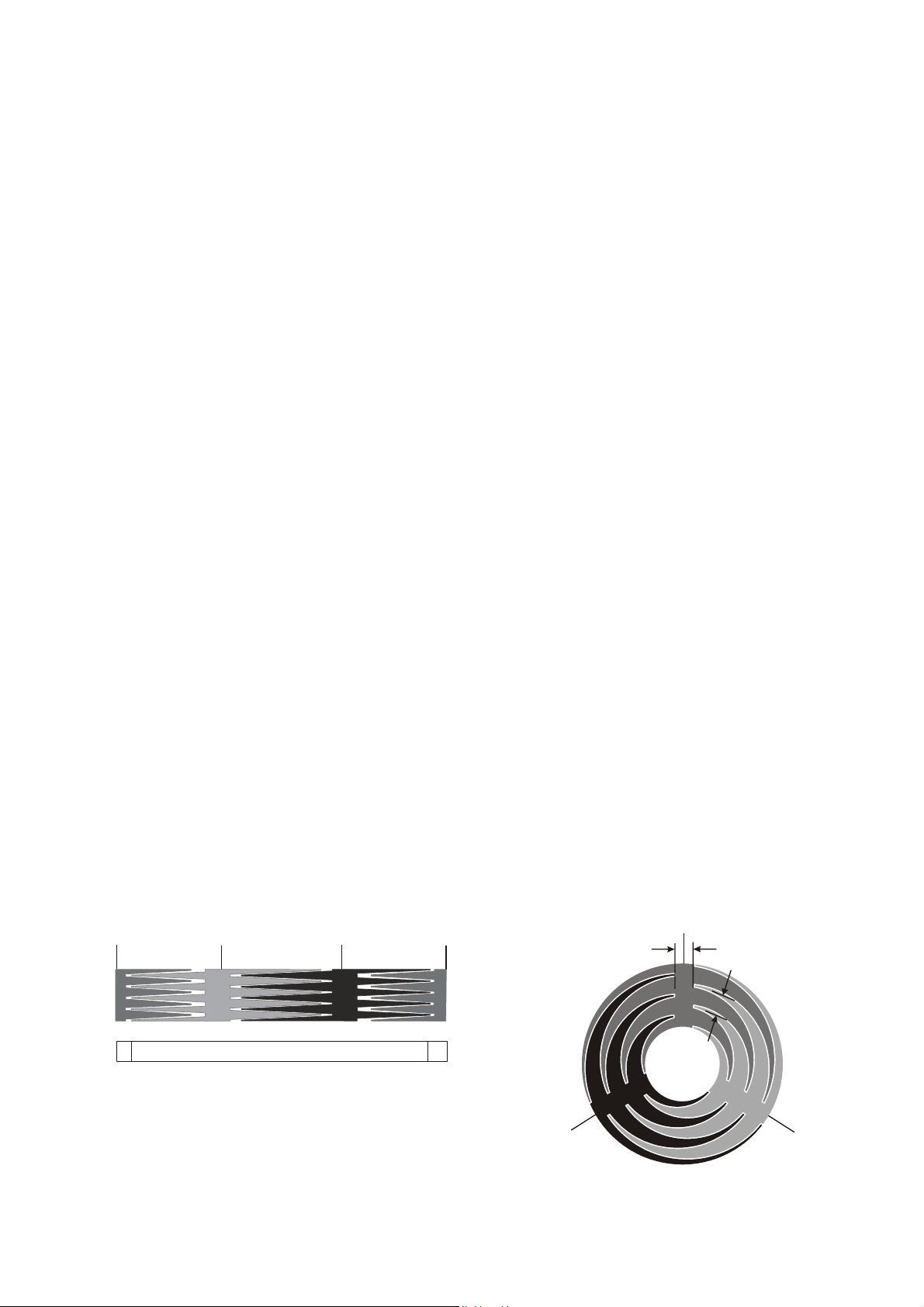

1.4 Slider and Wheel Construction

The QT1106 can connect to either a wheel or a linear slider

element (Figure 1.1). Selection of wheel or linear operation is

set through an SPI command. The basis of these designs is

found in US Patent 4,264,903 (expired).

The first and last positions of the linear slider have larger

touch areas.

As with touch button electrodes, wheels and sliders can be

constructed as etched areas on a PCB or flex circuit, or from

clear conductors such as Indium Tin Oxide (ITO) or screenprinted Orgacon™ (Agfa) to allow backlighting effects, or for

use over an LCD display.

1.5 QMagicTM Proximity Effect

Channel 7 of the QT1106 can optionally operate a ‘magic on’

function based on hand or body proximity to a product. By

using a relatively large electrode inside the product’s

enclosure and a larger value of Csb7 (see Figure 2.1), the

product can auto power up or activate its display with hand

approach. This simple feature can add enormous sales

appeal to almost any product.

1.6 SPI Interface

The QT1106 uses a five-wire SPI interface. In addition to the

standard four SPI signals (/SS, SCLK, MOSI and MISO),

there is a DRDY (data ready) output for flow control.

The QT1106 also provides a CHANGE signal to indicate

when there has been a change in detection state. This

removes the need for the host to poll the QT1106

continuously.

On each SPI transfer the host sends three bytes to the

QT1106 and the QT1106 simultaneously sends three bytes

to the host. The bytes sent from the host provide the QT1106

with all its configuration information; the bytes sent from the

QT1106 convey the key states.

(downloadable example CAD files for wheels and sliders can be found on the Quantum

SNSA3

0

SNSA1

Position (at 7 bits - 0 to 127)

Lq

Figure 1.1 All-Metal Slider and Wheel Construction

website,http://www.qprox.com/toolbox, then click QT1106)

Tips of triangles should be

spaced <=4mm apart.

<=4mm

Position 85

SNSA2

1 to 126

SNSA2

SNSA3

127

3 QT1106_8IR0.06_0407

Position 0

SNSA3

<=4mm

Position 43

SNSA1

Page 4

1.7 Basic Power Modes

1.7.1 Overview

The device features a number of modes to set the current

drain and speed of response.

The available operating modes are:

• Free Run - fastest detection response at all times

• LP mode - low power, slower touch sensing response

• Sleep - microamp-level current drain

• Sync mode - for noise suppression of low frequencies

1.7.2 Free Run Mode

This mode uses a continuous stream of acquire bursts. Free

Run mode has, in consequence, the highest power drain of

all the QT1106 operating modes but the fastest response

time.

1.7.3 LP Mode

In LP (low power) mode, the QT1106 spends most of the

time sleeping to conserve power; it wakes itself periodically to

perform acquire bursts, then normally goes back to sleep

again.

The QT1106 provides a choice of intervals between acquire

bursts to allow an appropriate speed/power trade-off to be

made for each product.

1.7.4 Sleep Mode

In Sleep mode, the QT1106 shuts down to conserve power; it

will remain in this mode forever or until the host wakes it

using the /SS pin.

1.7.5 Sync Mode

In this mode the device will synchronize to the host in a way

that allows for the suppression of heavy low frequency noise;

for example, from mains frequencies and their harmonics.

2 Signal Processing

2.1 Power-up Self-calibration

On power-up or after reset, all 10 channels are typically

calibrated and operational within 650ms.

2.2 Drift Compensation

This operates to correct the reference level of each key

automatically over time; it suppresses false detections

caused by changes in temperature, humidity, dirt and other

environmental effects.

2.3 Detection Integrator Filter

Detect Integrator (DI) filter confirmation reduces the effects of

noise on key states. The DI mechanism requires a specified

number of measurements that qualify as detections (and

these must occur in a row) or the detection will not be

reported.

In a similar manner, the end of a touch (loss of signal) also

has to be confirmed over several measurements. The

QT1106 provides a choice of either two or six DI

measurements for confirming start of touch; end of touch

always uses two measurements.

The DI mechanism works together with spread spectrum

operation to dramatically reduce the effects of noise.

2.4 AKSTM Adjacent Key Suppression

This patented feature works to prevent multiple keys from

responding to a single touch. This can happen with closely

spaced keys, or a scroll wheel that has buttons very near it.

AKS operates by comparing signal strengths from keys within

a group of keys to suppress touch detections from those that

have a weaker signal change than the dominant one.

When enabled globally on the QT1106, AKS allows only one

independent key, or the scroll section, to indicate a touch at a

time. Additionally, the QT1106 has options for partial AKS;

where some keys are included in the AKS operation and

others are not affected. In this case only one key in the AKS

group can indicate a touch at any time; other keys can

indicate touch in any combination.

AKS can also be disabled.

2.5 Autorecalibration (MOD)

The device can time out and recalibrate each key

independently after a continuous touch detection that lasts for

the chosen ‘Maximum on-duration’ (MOD). This ensures that

a key can never become ‘stuck on’ due to foreign objects or

other external influences.

After recalibration the key will continue to function normally.

The nominal delay is selectable to be either 10s, 20s, 60s, or

infinite (disabled), though the actual delay is different in some

operating modes (see Table 2.1).

Table 2.1 Maximum On-duration

Max on-durationsOperating Mode

10s, 20s, 60sFree Run

LP mode,

200ms1 response (120ms2)

LP mode,

1

280ms

LP mode,

440ms1 response (360ms2)

LP mode,

760ms

(typ 55Hz sync)

1

response times are estimated using a DI of six counts.

2

response times are estimated using a DI of two counts.

Note: all response times are based on typical sense

capacitor values.

The device also autorecalibrates all keys when one or more

normal keys’ signal reflect a sufficient decrease in

capacitance from the reference level (signal error). If QMagic

Proximity mode is active, a signal error on the Proximity Key

(Key 7) will only recalibrate itself. This is filtered in a manner

similar to the DI filter; the decrease in capacitance must be

seen for at least six successive cycles. Hence, in Free Run

mode the device typically recalibrates within 400ms so as to

recover normal operation quickly.

response (200ms2)

1

response (680ms2)

10s, 20s, 60s

10s, 20s, 60s

15s, 30s, 88s

28s, 55s, 164s

10s, 20s, 60sSync mode

(vary with sync rate)

n/aSleep mode

Lq

4 QT1106_8IR0.06_0407

Page 5

2.6 QMagicTM Proximity Sensor

Key 7 (SNSB7) can be optimized for operation as a hand

proximity sensor via the serial interface (see Section 3.5.2,

Prox = 1). The proximity sensitivity of channel 7 can be

increased by a higher value of Cs. The AKS mode should be

set to mode 101, to ensure that the proximity key does not

lock out other keys or the wheel/slider.

Note that proximity fields are often unstable especially in

products that can move around, such as mobile phones and

MP3 players. In particular, the proximity channel can stick on

after a detection. As soon as possible after proximity

channel 7 becomes active, it should be recalibrated via the

serial interface (see Section 3.5.2, CalK = 1, Cal Key Num

bits = 111) in order to clear the proximity channel.

Design of proximity electrodes requires care, so as to ensure

that the electrode area is maximized whilst ensuring

adequate and easy coupling to a hand as it approaches the

equipment.

2.7 Faulty and Unused Keys

Any sense channel that does not have its sense capacitor

(Cs) fitted is assumed to be either faulty or unused. This

channel takes no further part in operation unless a

host-commanded recalibration operation shows it to have an

in-range burst count again.

This is important for sense channels that have an open or

short circuit fault across

cause very long acquire bursts, and in consequence would

slow the operation of the entire QT1106.

Cs. Such channels would otherwise

Lq

5 QT1106_8IR0.06_0407

Page 6

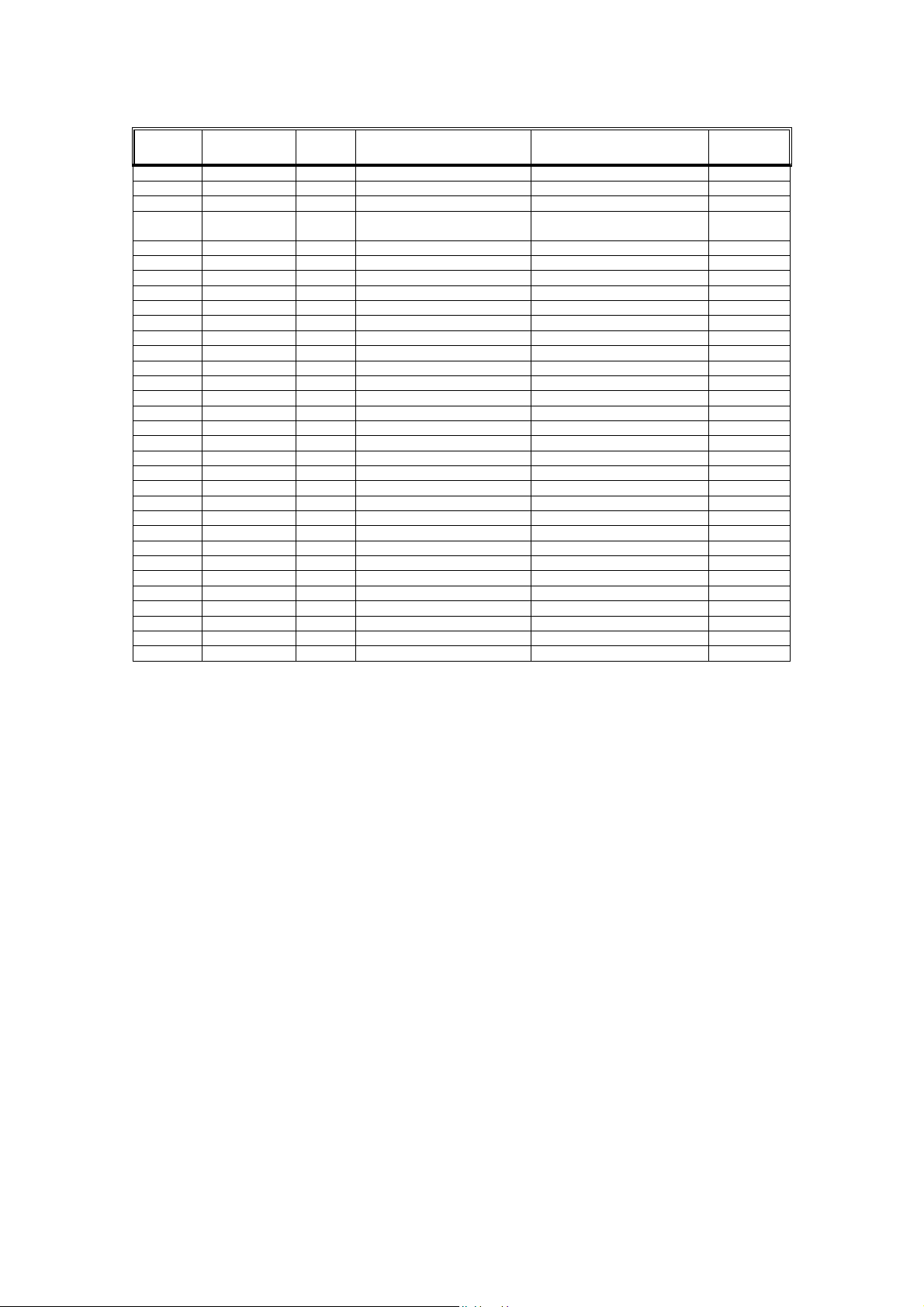

2.8 Wiring

Table 2.2 Pinlist

32-QFN

Pin

Oscillator current driveIOSC4

16

Pin Type

I/O CMOS input/output

I CMOS input only

OD CMOS open drain output (pull up to Vdd)

OF CMOS output that can float during Reset, Sleep or LP modes

P Ground or power

Resistor to Vdd and optional

spread-spectrum RC network

If UnusedNotesFunctionTypeName

Open-Spread-spectrum driveODSPREAD1

VddActive low resetReset inputI/RST2

-+2.8 to +5.0VPowerPVdd3

-

-Leave open--n/c5

-To hostState change notificationOFCHANGE6

OpenSense pinTo Csb7I/OSNSB77

OpenSense pinTo Csb6I/OSNSB68

OpenSense pinTo Csb5I/OSNSB59

OpenSense pinTo any Csb + KeyI/OSNSB10

OpenSense pinTo any Csb + KeyI/OSNSB11

OpenSense pinTo any Csb + KeyI/OSNSB12

OpenSense pinTo any Csb + KeyI/OSNSB13

OpenSense pinTo Csb4I/OSNSB414

OpenSense pinTo Csb3I/OSNSB315

OpenSense pinTo Csb2I/OSNSB2

OpenSense pinTo Csb1I/OSNSB117

OpenSense pinTo any Csb + KeyI/OSNSB18

OpenSense pinTo any Csb + KeyI/OSNSB19

OpenSense pinTo any Csb + KeyI/OSNSB20

-SPI handshake lineSPI Data ReadyOFDRDY21

--GroundPVss22

-SPI serial bit clockSPI ClockISCLK23

-Idle high, slave select lineSPI Slave Select inI/SS24

-Data from host to QT1106SPI Master Out /Slave InIMOSI25

-Data from QT1106 to hostSPI Master In / Serial OutOFMISO26

OpenSense pinTo any Csa + wheel/sliderI/OSNSA27

OpenSense pinTo any Csa + wheel/sliderI/OSNSA28

OpenSense pinTo any Csa + wheel/sliderI/OSNSA29

OpenSense pin position 43To Csa1I/OSNSA130

OpenSense pin position 85To Csa2I/OSNSA231

OpenSense pin position 0To Csa3I/OSNSA332

Note: Sense terminals can be twinned with any sense drive terminals of the same group, e.g. SNSA1 can be

paired with any SNSA terminal.

Suggested regulator manufacturers:

• Toko (XC6215 series)

• Seiko (S817 series)

• BCDSemi (AP2121 series)

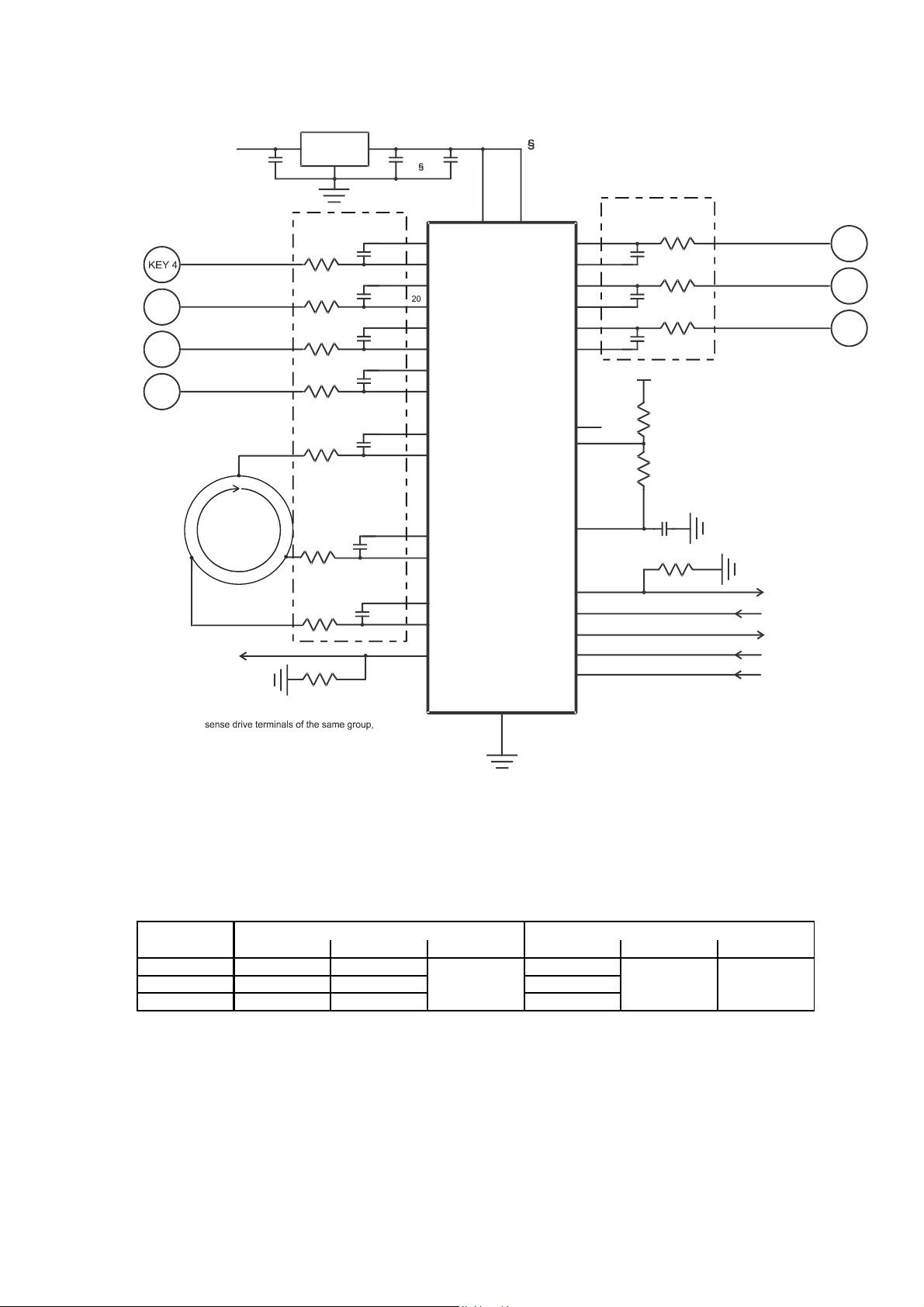

Re Figure 2.1 check the following sections for the variable component values:

• Section 6.3, page 13: Cs capacitors (Csb)

• Section 6.4, page 14: Sample resistors (R

SNS

)

• Section 6.6, page 14: Voltage levels

• Page 7: Css capacitor

Lq

6 QT1106_8IR0.06_0407

Page 7

Vunreg

KEY 3

KEY 2

KEY 1

The wheel shows positions at

7-bit resolution. See the table

at the end of Section 3.5.2 for

other resolutions.

CHANGE out

Sense terminals can be twinned with any

NOTE:

e.g. SNSA1 can be paired with any SNSA terminal.

SNSA pins: 27 ,28, 29

SNSB pins: 10, 11, 12, 13, 18, 19, 20

127 0

Figure 2.1 Connection Diagram (32-QFN Package)

VDD

Note: One bypass capacitor to be

tightly wired between Vdd and Vss.

Follow recommendations from regulator

manufacturer for input and output

capacitors.

2

/RST

SNSB

SNSB7

SNSB

SNSB6

SNSB

SNSB5

QT1106

4.7uF

Voltage Reg

Keep these parts

close to the IC

R

SNSB4

R

SNSB3

R

SNSB2

R

SNSB1

4.7uF 100nF

14

C

Sb4

C

Sb3

C

Sb2

C

Sb1

SNSB4

13

SNSB

15

SNSB3

SNSB

16

SNSB2

19

SNSB

17

SNSB1

18

SNSB

3

VDD

32-QFN

32

R

SNSA3

R

4385

SNSA1

R

SNSA2

100K

C

Sa3

C

Sa1

C

Sa2

27

30

29

31

28

6

SNSA3

SNSA

SNSA1

SNSA

SNSA2

SNSA

CHANGE

VSS

22

N.C.

OSC

SPREAD

DRDY

SCLK

MISO

MOSI

/SS

12

C

7

11

C

8

10

C

9

5

4

1

21

23

26

25

24

Keep these parts

close to the IC

Sb7

Sb6

Sb5

VDD

**Rb1

**

See the table below for

suggested resistor and capacitor

values, with and without spread

spectrum.

**Rb2

No Spread-spectrum:

Replace Css with 100k resistor and remove Rb2

*

Css

R

R

R

100k

SNSB7

KEY 7

SNSB6

KEY 6

SNSB5

KEY 5

SPI DRDY out

SPI SCLK in

SPI MISO out

SPI MOSI in

SPI /SS in

IMPORTANT DESIGN GUIDELINES:

• The sensitivities of the various sense channels are determined by the values of the respective Cs

capacitors (i.e. Csb1,

Csb7, etc.); these values will require adjustment based on building a prototype product and testing the sensitivity

experimentally.

• Rb1, Rb2 sets the oscillator frequency; recommended values are:

Without Spread SpectrumWith Spread SpectrumVdd Range

CssRb2Rb1CssRb2Rb1

27k12k< 3 V

see note

below

15k

18k22k12k3.0~3.6V

20k27k15k> 3.6V

not fitted

replace with

100k resistor

• The required value of the spread-spectrum capacitor (Css) will vary according to the lengths of the acquire bursts. A

typical value is 100nF-220nF.

• When the QT1106 is running the OSC pin has a DC voltage typically between 1V and 1.5V; the use of spread

spectrum will cause a small low-frequency variation in the voltage. The internal oscillator signal is not visible on this

pin.

• Signals DRDY and CHANGE may need pull-down resistors, see Section 5 on page 13.

Lq

7 QT1106_8IR0.06_0407

Page 8

3 SPI Interface

3.1 Introduction

The QT1106 is an SPI slave mode device. This section

describes the hardware operation of this interface.

3.2 CHANGE Pin

The QT1106 has a CHANGE output pin which allows for key

state change notification. Use of the CHANGE signal relieves

the host of the burden of regularly polling the QT1106 to get

key states. CHANGE goes high when there is a change of

state, i.e. when a new key is pressed, or released, or a

movement is detected on the wheel/slider.

CHANGE also goes high after a reset to indicate to the host

that it should do an SPI transfer in order to provide initial

configuration information to the QT1106 (as it does on every

SPI transfer).

CHANGE goes low after the status is read through an SPI

transfer.

3.3 SPI Parameters

The SPI transmission parameters are:

• 70kHz max clock rate

• 8 data bits

• 6.7µs min low clock period

• 6.7µs min high clock period

• Three bytes per transmission, byte 1 most significant

bit sent first

• Clock idle high

• Shift out on falling edge

• Shift in on rising edge

The host must always transfer three bytes in succession

within the allotted time (10ms maximum). If all bytes are not

received in this interval it is treated by the QT1106 as an

error and the DRDY line will go low before the transmission is

completed.

Messages from the host to the QT1106 carry configuration

information; return data from the QT1106 carries key state

information. For details of the message contents see

Sections 3.5 and 3.6.

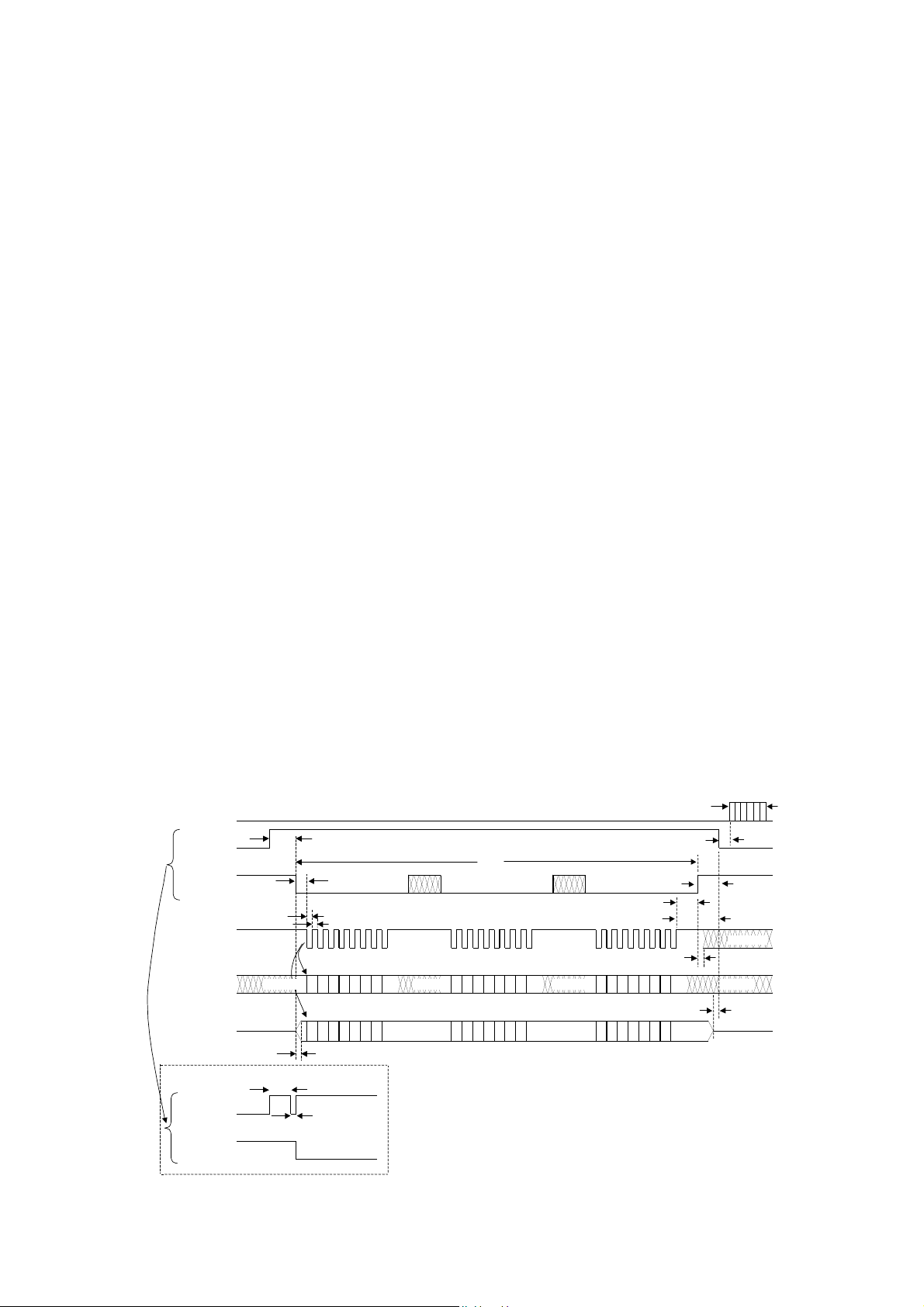

3.4 SPI Operation

The basic timing diagram for SPI operation is shown in

Figure 3.1 The host does the clocking and controls the timing

of the transfers, subject to Data Ready (DRDY), from the

QT1106. Transfers are always clocked as a set of three

bytes, Byte 1, 2 and 3.

The host should not attempt to clock the SPI bus to the

device while DRDY is low; during DRDY low the QT1106 is

busy and will ignore SPI activity, with the exception of a 20µs

grace period after the fall of DRDY, where there are no

communications during the high period of DRDY.

Note: DRDY can only become active (go high) if /SS is held

high when idle.

DRDY stays high for at least 450µs. It falls again after Byte 3

has shifted to indicate completion. After the fall of DRDY, the

device acquires (bursts). DRDY goes high to permit SPI

activity after each burst.

After the host asserts /SS low, it should wait >22µs before

starting SCLK. The QT1106 reads the MOSI pin with each

rising edge of SCLK, and shifts data out on the MISO pin on

falling edges. The host should do the same to ensure proper

operation.

Between the end of the Byte 1 shift and the start of the Byte 2

shift (and between Byte 2 and Byte 3), the host may raise

/SS again, but this is not required; the QT1106 ignores /SS

during transfer of the three bytes.

All timings not mentioned above should be as in Figure 3.1.

Acquire Bursts

DRDY from QT

/SS from host

SCLK from Host

Host Data Ou tp u t

(QT1106 Input - MOSI)

QT Data Outpu t

(QT1106 Out - MISO)

/SS pulse during 20us grace period

DRDY from QT

/SS from host

Lq

Figure 3.1 SPI Operation

~23ms

<470us

<10ms

>22us /SS m ay go high between between byt e s ; <5.7us

>6.7us >10.8us

>6.7us

Data sam ple d on ri sing edge

Data shifts out on falling

147 15674326

32

Command By te 1 Command By te 2 Command By te 3

3-state 3-state

>450us

(grace period)

Response B yte 1 Response Byte 2 Response B yte 3

?0576543210

<17us

<20us

bytes; QT1106 ignores this QT1106 ignores thi s

76

5

0

01

234567

/SS may go high

>0us

>0us

don't caredon't care don't care don't care

12 0

34

>0ns <500ns

01234567

8 QT1106_8IR0.06_0407

240ms

don't care

Page 9

/SS Wake Operation: /SS is also used to wake the device

from sleep, see Section 4.3

3.5 SPI Host Commands

3.5.1 Overview

The command from the host consists of three bytes, #1, #2

and #3. These three bytes contain operation mode settings

which must be transmitted every time. The setting information

in these three bytes becomes effective immediately after all

three are received by the QT1106.

The response to these three bytes are three data bytes

containing key detection information.

A downloadable host-driver software example for controlling

the QT1106 can be found on the Quantum website at

http://www.qprox.com/toolbox,

There are two command modes, selectable through bit CT.

CT - Custom threshold: Selects between normal command

bytes and custom threshold commands.

CT = 0: Normal commands.

CT = 1: Custom Threshold commands.

3.5.2 Normal Command Mode

When CT = 0, the three host command bytes should contain

the following bits:

Byte #

1

2

3

Bits labelled ‘0’ should not be altered.

The bits used in these three bytes are defined as follows:

AKS - Three bits used to determine the AKS mode. See

Section 2.4 for further information.

AKS

1

keys 1-4 AKS’d together

2

keys 5-7 AKS’d together

3

keys 1-6 AKS’d together

SLD - Scrolling device type selection.

SLD = 0: Wheel mode (default)

SLD = 1: Linear slider mode.

Prox - Key 7 QMagic Proximity mode. See Section 2.6 for

further information.

Prox = 0: Key 7 is a normal key (default)

Prox = 1: Key 7 is a proximity sensor.

Note: Once activated, Key 7 will be in QMagic Proximity

mode until a reset occurs.

Mode - These bits determine the Sleep / Low Power modes

the device runs in.

0

AKS Option

012

000

AKS disabled (default)

AKS global100

AKS keys + Wheel/Slider010

AKS 4 keys

AKS 4 keys

AKS (6 keys

then click QT1106.

BitHost

1

+ 3 Keys2 + Wheel/Slider110

1

+ (3 Keys2 + Wheel/Slider)001

3

+ Wheel/Slider) + key 7101

01234567

AKSSLDProx00CT=0

ModeLPBDIMOD

Cal Key NumCalKCalWResolution

Mode Bits

Operating Mode

012

000

Free Run (default)

LP mode, 200ms

LP mode, 280ms

LP mode, 440ms

LP mode, 760ms

1

response time (120ms2)100

1

response time (200ms2)010

1

response time (360ms2)110

1

response time (680ms2)001

Sync mode101

Sleep011

(reserved)111

1

response times are estimated using a DI of six counts.

2

response times are estimated using a DI of two counts.

LPB - Sets the LP mode ‘following burst’ option. See

Figures 4.1 and 4.2.

LPB = 0: If the host communicates with the device or there

is an /SS pulse during any LP mode (modes 001 to

100), there will be no following burst. The only bursts

that will take place are those that occur as naturally

defined by the LP mode noted above.

LPB = 1: If the host communicates with the device or there

is an /SS pulse during any LP mode (modes 001 to

100), there will be an additional burst following /SS

raising high. (default)

DI - Set the ‘Detect Integrator’ noise filter function.

DI = 0: Two detections required to confirm a touch (faster

but less noise immune).

DI = 1: Six detections required to confirm a touch (slower

but more noise immune; appropriate for most

applications). (default)

MOD (Recal Time) - Sets the 'Maximum On-duration' for all

keys. Controls the time from the start of a key detection to

when the key is automatically recalibrated. See Table 2.1

for MOD times in other operating modes.

MOD

Maximum On-duration in Free Run Mode

56

00

10s (default)

20s10

60s01

infinite MOD - timeout disabled11

Cal Key Num - key to be recalibrated when CalK = 1.

Cal Key

Num Bits

Key

012

Recalibrate all keys (excluding wheel/slider)000

Recalibrate Key 1100

Recalibrate Key 2010

Recalibrate Key 3110

Recalibrate Key 4001

Recalibrate Key 5101

Recalibrate Key 6011

Recalibrate Key 7111

CalK - Recalibrates the key(s) specified by Cal Key Num.

CalK = 0: No recalibration (normal state of this bit).

CalK = 1: The device recalibrates key(s).

CalW - Recalibrates the wheel/slider.

CalW = 0: No recalibration (normal state of this bit).

CalW = 1: The device recalibrates the wheel/slider.

Lq

9 QT1106_8IR0.06_0407

Page 10

Set CalK/CalW only once when required, and set CalK/CalW

= 0 thereafter. If the bit is constantly set to 1, the device will

keep recalibrating and will become non-responsive.

Note that the device recalibrates automatically on power-up,

so that the use of Recal should rarely be required excepting

Key 7 when used as a proximity sensor, in which case this

channel should be recalibrated soon after each proximity

detection to ensure stability.

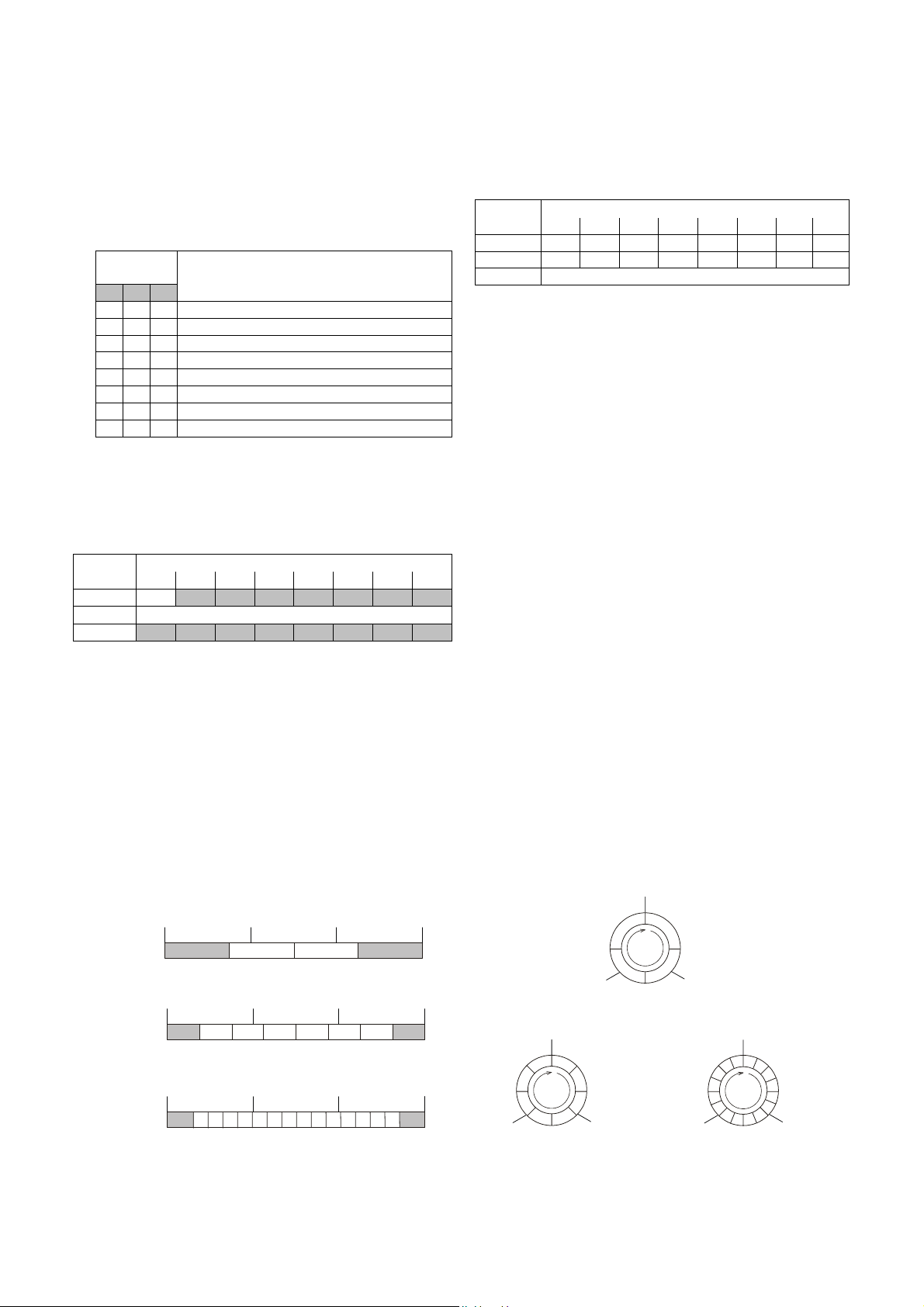

Resolution - the resolution of the wheel/slider’s reported

position. Refer to Figure 3.2.

Resolution

Bits

Resolution

567

Reserved

000

2 Bits : 4 positions (0...3)100

3 Bits : 8 positions (0...7)010

4 Bits : 16 positions (0...15)110

5 Bits : 32 positions (0...31)001

6 Bits : 64 positions (0...63)101

011

7 Bits : 128 positions (0...127) (default)

8 Bits : 256 positions (0...255)111

Note: a resolution change will only become effective on the

next touch.

3.5.3 Custom Threshold Command Mode

When CT = 1, the three host command bytes should contain

the following bits:

BitHost

Byte #

1

2

T1 - Wheel/Slider Threshold

3

T1: Custom threshold value of the wheel/slider. Higher

numbers are less sensitive. Touch detection uses this

threshold combined with a hysteresis equal to 12.5 percent of

the threshold (with a minimum hysteresis value of one).

Power-up default setting: 40

01234567

0000000CT=1

00000000

Note: Custom Threshold Command is only used if the

detection threshold of the wheel/slider needs to be changed

from the power-up default.

3.6 SPI Responses

The 3 return bytes which contain key states are as follows:

BitReturn

byte #

Position3

CTL: Custom Threshold Loaded: If CTL = 1, a custom

wheel/slider threshold has been loaded from the host. If a

custom threshold is utilised, CTL can be used to indicate

if the threshold needs to be resent due to a reset of the

device.

QM: QMagic Proximity Mode: If QM = 1, QMagic Proximity

mode is activated (see Section 2.6).

LPS: LP / Sleep State: If LPS = 1, the device was in LP,

Sync, or Sleep mode when the requesting command was

received. If LPS = 0, the device was in Free Run mode.

EK: Key(s) in Error: If EK = 1, there is a sufficient decrease

in capacitance of one or more normal key(s) from the

reference level. All keys will be recalibrated if this

condition is seen for six successive cycles. If QMagic

Proximity mode is active, an error on the Proximity Key

(Key 7) will only cause a recalibration on itself.

EW: Wheel/Slider in Error: If EW = 1, there is a sufficient

decrease in capacitance of the wheel/slider from the

reference level. The wheel/slider will be recalibrated if this

condition is seen for six successive cycles.

CK: Key(s) in Calibration: If CK = 1, one or more key(s) are

being calibrated.

CW: Wheel/Slider in Calibration: If CW = 1, the

wheel/slider is being calibrated.

01234567

CTL0QMLPSEKEWCKCW1

K1K2K3K4K5K6K7W2

Slider Mode

SNSA

A3

2 bits

SNSA

A3

3 bits

4 bits

0

SNSA

A3

03

Note

: the first and last slider positions

(shaded) have larger touch areas.

SNSA

A1

0

SNSA

A1

12 4

SNSA

A1

12

4

Lq

Figure 3.2 Wheel and Slider Resolution

SNSA

A2

12

SNSA

A2

3

5

6

78910

5

SNSA

A2

11 121314

(see end of Section 3.5.2)

SNSA

A3

3

SNSA

A3

7

6

SNSA

A3

15

SNSA

A2

6

5

10 QT1106_8IR0.06_0407

SNSA

A3

7

4

3 bits

0

3

SNSA

A2

1

2

SNSA

A1

Wheel Mode

SNSA

A3

3

2

2 bits

0

1

SNSA

A1

SNSA

A3

15

0

14

1

SNSA

A2

13

12

11

10

9

4 bits

2

3

4

5

SNSA

6

78

A1

Page 11

K1...K7: Contains the key states of each key. A ‘1’ in a bit

position means the key is confirmed as being touched.

W: The state of the wheel/rotor. A ‘1’ means the wheel/slider

is confirmed as being touched.

Position: The position of touch on the wheel/slider. If the

wheel/slider is not being touched, the position will be the

position of the last touch.

4 Operating Modes

4.1 Introduction

Four basic operating modes are possible: Free Run, LP (Low

Power), Sync and Sleep. Sleep is a special case of LP mode,

where the sleep time is infinite. Sync is a special case of LP

mode which acts as a noise filter over successive /SS pulses

rather than temporarily operating as in Free Run mode.

4.2 Free Run Mode

In this mode the device operates continuously with short

intervals between burst groups; there are three bursts, one

burst for each electrode group. Between burst sets, DRDY

goes high for 450µs to allow SPI communications.

In this mode, the acquisition bursts are unsynchronized,

making this mode unsuitable if synchronization to mains

frequency is needed.

4.3 LP Mode

LP mode is designed to allow low power operation while still

retaining basic operation but at a slower speed. This mode is

useful for devices that must use the touch keys to wake up a

product, yet be in a low power mode.

Several LP timings allow the user to trade power versus

response time: the slower the response time, the lower the

power consumed.

In LP mode, the device spends most of the time sleeping

between bursts; it wakes itself periodically to do a set of three

acquisition bursts, then goes back to sleep.

If a touch is detected, the device operates as in Free Run

mode and attempts to perform the DI (detect integrator noise

filter) function to completion; if the DI filter fails to confirm a

detection the device goes back to sleep and resumes LP

mode. During the DI function the LPS bit will be cleared.

If a key is found to be in detection the CHANGE pin will go

high and the part will remain in Free Run mode. To go back

into LP mode the host has to request LP mode again.

CHANGE Pin in LP Mode: During the sleep portion of LP

mode, CHANGE is held low.

If however a change of key state is confirmed, CHANGE

goes high and the part runs from then on in Free Run mode

until the host reads the key state and puts the device back

into LP mode or some other mode.

MISO in LP Mode: During the sleep portion of LP mode,

MISO floats.

DRDY during LP Mode: DRDY remains high while the

QT1106 is sleeping, to indicate to the host that SPI

communications are possible. In LP mode, the host should

wake the QT1106 using a pulse on /SS before transferring

data over SPI (see below). During an actual acquire burst,

DRDY is held low.

/SS Wake Pulse in LP Mode: In LP mode the host should

wake the device from sleep using a low pulse on /SS. The

pulse should be at least 125µs wide.

Within 100µs of the end of the /SS pulse, the QT1106 will

take DRDY low for at least 40µs to indicate that it has

received the /SS wake pulse.

Following the >45µs DRDY low pulse, the host can

communicate normally with the device (see ‘Command

During LP Mode’ on Page 12).

If the LPB bit (page 9) is set, the device will then perform a

set of acquire bursts during which DRDY will be low.

Provided no key is detected as being touched during that

burst, the QT1106 will go back to sleep, leaving DRDY high.

The CHANGE pin can go high if a key state changes during

the burst(s) following the wake pulse.

If a key is confirmed as touched, the device will transition to

Free Run mode automatically.

Acqui r e Bursts

DRDY from QT

/SS from host

SCLK from Host

Host Data Ou tp u t

(QT1106 Input - MOSI)

QT Data Output

(QT1106 O u t - M I SO)

>40us <240us <240us

<150us

Lq

Figure 4.1 LP Mode SPI Operation with LPB = 1

No SPI Communication

~23ms ~23ms

>450us

<100us <470us

>125us

don't car e don't caredon't car e

don't car e don't care

3-state 3-state

<20us

(grace pe ri od )

/SS timing as left

don't care

don't care

SPI Communication

command bytes

response bytes

11 QT1106_8IR0.06_0407

Page 12

Command During LP Mode: First read ‘/SS Wake Pulse in

LP Mode’, on Page 11. Following DRDY rising at the end of

the 45µs low pulse, the host may perform a normal SPI

transfer as shown in Figure 3.1. The SPI transfer may start

while DRDY is high (450µs), and for a 20µs grace period

thereafter.

After the SPI transfer is completed, the QT1106 will generate

a set of three acquire bursts if LPB = 1, during which DRDY

will be low.

The mode and options settings sent from the host to the

QT1106 during the SPI transfer take effect after the set of

acquire bursts.

• If Free Run mode is selected, the QT1106 will take

DRDY high to indicate the possibility of an SPI

transfer.

• If either LP mode or Sleep mode is selected, the

QT1106 will go back to sleep with DRDY high

provided no key is detected as possibly touched.

• If Sync mode is selected, the QT1106 will go back to

sleep with DRDY high provided no key is detected as

possibly touched.

The CHANGE pin will go high at this time if a key is

confirmed as touched.

4.4 Sleep Mode

Sleep mode offers the lowest possible current drain, in the

low microamp region.

Sleep mode is a special case of LP mode, where the sleep

duration between bursts is infinite. All comments concerning

LP mode, including about SPI communications, apply equally

to Sleep mode, except that the LPB bit is ignored and bursts

are always generated after an SPI transfer or /SS wake

pulse as if LPB = 1.

Note that in Sleep mode the QT1106 only performs

acquisition bursts following being woken by /SS. This has two

effects.

• Touch detection only occurs following /SS-wake

pulses, and hence CHANGE can only go high at that

time.

• The QT1106 cannot drift its internal references unless

the host sends periodic /SS wake pulses. If the host

does not do this, then it should command the QT1106

to recalibrate when it sets the QT1106 into a different

operating mode.

This mode can be used by the host to create its own ‘LP

Mode’ timings via the /SS wakeup pulse method.

4.5 Sync Mode

This mode is useful for low frequency noise suppression, for

example from mains frequencies in line-operated appliances.

Acquisition bursts are synchronized to the /SS-wake pulses

from the host.

Sync mode is very similar to ‘LP 760ms response time’

mode, with two differences:

• It does not operate as in Free Run mode when a

touch is first detected

• The LPB bit is ignored and a burst is always

generated after each /SS wakeup or SPI transfer as if

LPB = 1

Not operating as in Free Run mode when a touch is first

detected (before DI confirmation has taken place) means that

acquisition bursts are restricted to the immediate time after a

sync signal (/SS), heightening the effect of low frequency

noise suppression.

In many applications of Sync mode the DI filter will need to

be set to two counts, to avoid the QT1106 response time

being unacceptably lengthened as a consequence of this.

Acqui r e Bursts

DRDY from QT

/SS from host

SCLK from Host

Host Data O u tp u t

(QT1106 Input - MOSI)

QT Data Ou tput

(QT1106 Out - MISO)

Figure 4.2 LP Mode SPI Operation with LPB = 0

No SPI Communication

>40us >70us

<150us <200us

<100us <470us

>125us

/SS t i m i ng as left

don't care don't caredon't care

don't care don't care

3-state 3-state

don't care

don't care

SPI Communication

command bytes

response bytes

Lq

12 QT1106_8IR0.06_0407

Page 13

5 Reset

5.1 Introduction

When starting from power-up or /RST reset there are a few

additional factors to be aware of. In most applications the

host will not need to take special action.

During hardware reset all outputs are disabled. To define the

levels of the CHANGE and DRDY during reset these signals

should pulled down by resistors to 0V. Otherwise, they may

drift high causing the host to detect a false logic 1.

When the initial reset phase ends, CHANGE and DRDY

outputs are enabled. DRDY will drive low and CHANGE will

drive high.

5.2 Delay to SPI Functionality

The QT1106 SPI interface is not operational while the device

is being reset. However, SPI is made operational early in the

start-up procedure.

After any reset (either via the /RST pin or via power-up), SPI

typically becomes operational within 100ms of /RST going

high or power-up. This is indicated to the host by DRDY

being pulsed high for at least 450µs, as occurs between

groups of acquire bursts when in Free Run mode. The

maximum delay is:

Vdd >= 4.5V: 150ms

Vdd < 4.5V: 200ms

5.3 Reset Delay to Touch Detection

After power up or reset, the QT1106 calibrates all electrodes.

During this time, touch detection cannot be reported. Four

dummy bursts are performed in 80ms after exiting from the

reset start-up delay. Calibration completes after 14 burst

cycles, which normally requires an additional 280ms.

In total, 460ms are required from reset or power-up for the

device to be fully functional.

Disabled Keys: Keys with missing Cs capacitors, or that

otherwise have an out-of-range signal during calibration, are

considered to be unused or faulty and are disabled. Disabled

keys are re-examined for operation after each reset or

recalibration event.

5.4 Mode Setting After Reset

After a reset the device will enter Free Run mode, with AKS

disabled.

6 Design Notes

6.1 Oscillator Frequency

The oscillator uses an external network connected to the

OSC and SPREAD pins as shown in Figure 2.1. The charts

in this figure show the recommended values to use

depending on nominal operating voltage and

spread-spectrum mode.

If spread-spectrum mode is not used, only resistor R

be used, the Css capacitor eliminated, and the SPREAD pin

pulled to Vss with a 100k resistor.

An out-of-specification oscillator can induce timing problems

such as large variations in response times as well as on the

SPI port.

B1

should

6.2 Spread-spectrum Circuit

The QT1106 offers the ability to spectrally spread its

frequency of operation to heavily reduce susceptibility to

external noise sources and to limit RF emissions. The

SPREAD pin is used to modulate an external passive RC

network that modulates the OSC pin. OSC is the main

oscillator current input. The circuit and recommended values

are shown in Figure 2.1.

The resistors Rb1 and Rb2 should be changed, depending

on Vdd. As shown in Figure 2.1, three sets of values are

recommended for these resistors, depending on Vdd. The

power curves in Section 7.6 also show the effect of these

resistors.

The spread-spectrum circuit can be eliminated if it is not

desired; see Section 6.1. Non spread-spectrum mode

consumes less current in the low power modes.

The spread-spectrum RC network should be adjusted to suit

the acquire burst lengths. The sawtooth waveform observed

on SPREAD should reach a crest height as follows:

Vdd >= 3.6V: 17 percent of Vdd

Vdd < 3.6V: 20 percent of Vdd

The Css capacitor connected to SPREAD (see Figure 2.1)

should be adjusted so that the waveform approximates the

above amplitude, ±10 percent, during normal operation in the

target circuit. If this is done, the circuit will give a spectral

modulation of 12 to 15 percent.

In cases where the three acquire bursts 1, 2, 3 are of

different lengths, the Css capacitor should be adjusted for the

longest acquire burst.

6.3 Cs Sample Capacitors - Sensitivity

The Cs sample capacitors accumulate the charge from the

key electrodes and determine sensitivity. Higher values of Cs

make the corresponding sensing channel more sensitive. The

values of Cs can differ for each channel, permitting

differences in sensitivity from key to key or to balance

unequal sensitivities.

Unequal sensitivities can occur due to key size and

placement differences and stray wiring capacitances. More

stray capacitance on a sense trace will desensitize the

corresponding key; increasing the Cs for that key will

compensate for the loss of sensitivity.

The Cs capacitors can be virtually any plastic film or low to

medium-K ceramic capacitor. The ‘normal’ Cs range is 1nF to

100nF for the keys and 4.7nF to 220nF for the wheel/slider,

depending on the sensitivity required; the larger values of Cs

require better quality to ensure reliable sensing. Acceptable

capacitor types for most uses include PPS film,

polypropylene film, and NP0 and X7R ceramics. Lower grade

ceramics than X7R are not advised; the X5R grade should be

avoided because it is less stable than X7R.

Lq

13 QT1106_8IR0.06_0407

Page 14

6.4 Rsns Resistors

Series resistors R

in-line with the electrode connections and are used to limit

electrostatic discharge (ESD) currents and to suppress radio

frequency interference (RFI). For most applications R

be in the range 4.7k to 33k each. In a few applications

with low loading on the sense keys the value may be up to

100k.

Although these resistors may be omitted, the device may

become susceptible to external noise or RFI. For details of

how to select these resistors see the Application Note

AN-KD02, downloadable from the Quantum website

http://www.qprox.com

Application Notes).

SNS

(R

SNSA

1...R

SNSA

3, R

SNSB

(go to the Support tab and click

1...R

SNSB

7) are

SNSB

will

6.5 Thermal Stability

The QT1106 can operate with or without the wheel/slider and

supports up to seven keys. Channels not fitted with a sense

capacitor will automatically be switched off during calibration.

For better thermal stability while operating with only one key,

it is best to fit a sense capacitor of the same type and value

for another spare key channel, in another burst group.

Additionally a small value Cx (~5pF COG) should be fitted to

simulate electrode capacitance.

The Cx value required for best thermal stability can be

obtained by matching the burst lengths of the key channel

and the dummy channel. The burst lengths of the channels

can be captured on an oscilloscope via the coin method, as

described in the Application note AN-KD02 (see Section 6.4).

This provides a stable reference for increased thermal

stability.

6.6 Power Supply

The power supply can range from 2.8 to 5.0 volts. If this

fluctuates slowly with temperature, the device will track and

compensate for these changes automatically with only minor

changes in sensitivity. If the supply voltage drifts or shifts

quickly, the drift compensation mechanism will not be able to

keep up, causing sensitivity anomalies or false detections.

The QT1106 power supply should be locally regulated using

a three-terminal device, to between 2.8V and 5.0V. If the

supply is shared with another electronic system, care should

be taken to ensure that the supply is free of digital spikes,

sags, and surges, all of which can cause adverse effects.

For proper operation a 0.1µF, or greater, bypass capacitor

must be used between Vdd and Vss; the bypass capacitor

should be routed with very short tracks to the QT1106's Vss

and Vdd pins.

6.7 PCB Layout and Construction

Refer to the Application Note AN-KD02 ‘Secrets of a

Successful QTouch Design’, downloadable from the

Quantum web site http://www.qprox.com

tab and click Application Notes) for information related to

layout and construction matters. Downloadable example CAD

files for wheels and sliders can also be found on the website)

The sensing channels used for the individual keys can be

implemented as per AN-KD02.

(go to the Support

Lq

14 QT1106_8IR0.06_0407

Page 15

7 Specifications

7.1 Absolute Maximum Specifications

Operating temperature, Ta............................................................................. -40 to +850C

Storage temp, Ts.....................................................................................-50 to +125

Vdd................................................................................................. -0.3 to +6.0V

Max continuous pin current, any control or drive pin............................................................ ±20mA

Short circuit duration to ground or Vdd, any pin.................................................................infinite

Voltage forced onto any pin................................................................. -0.3V to (Vdd + 0.3) Volts

7.2 Recommended Operating Conditions

Operating temperature, Ta............................................................................. -40 to +850C

Vdd.................................................................................................+2.8 to +5.0V

Short-term supply ripple+noise.............................................................................. ±5mV/s

Long-term supply stability.................................................................................. ±100mV

Cs range keys........................................................................................1nF to 100nF

Cs range wheel/slider............................................................................... 4.7nF to 220nF

Cx range................................................................................................0 to 50pF

7.3 AC Specifications

Vdd = 5.0V, Ta = recommended, Cx = 5pF, Cs keys = 4.7nF, Cs wheel/slider = 15nF, no spread-spectrum network,

Rb1 = 20k; circuit of Figure 2.1.

NotesUnitsMaxTypMinDescriptionParameter

From cold start

kHz125Burst center frequencyFc

ms

Vdd >= 4.5V

Vdd < 4.5V

ms280Recalibration timeTrc

Total deviation%15Burst modulation, percentFm

Keysµs2.33Sample pulse durationTpc

Total for all three acquire burst

ms20Acquire burst durationTbd

groups

ms120

ms40

280ms LP setting, DI = six countsms280Response time - LP modeTdl

End of touchms40Release time - all modesTdr

Tdf6

Tdf2

100Start-up to SPI timeTsu

150

200

Response time Free Run mode, DI 6 samples

Response time Free Run mode, DI 2 samples

0

C

7.4 DC Specifications

Vdd = 5.0V, Ta = recommended, Cx = 5pF, Cs keys = 4.7nF, Cs wheel/slider = 15nF, no spread-spectrum network,

Rb1 = 20k; circuit of Figure 2.1.

NotesUnitsMaxTypMinDescriptionParameter

Idd (FR)

Idd (LP280)

Idd (LP760)

Idd (Sleep)

Average supply current,

Free Run mode

Average supply current,

280ms LP mode

Average supply current,

760ms LP mode

Average supply current,

Sleep mode

Supply turn-on slopeVdds

2.2

1.9

1.6

1.3

mA83.6

Vdd = 5.0

Vdd = 4.0

Vdd = 3.6

Vdd = 3.3

Vdd = 2.8

Vdd = 3.0µA<165

Vdd = 3.0µA<75

Vdd = 3.0µA<6

V/s100

Required for start-up, w/o

external reset cct

V0.3Vdd0Low input logic levelVil

VVdd0.7VddHigh input logic levelVhl

7mA sinkV0.5Low output voltageVol

2.5mA sourceVVdd-0.5High output voltageVoh

µA±1Input leakage currentIil

bits14Acquisition resolutionAr

Lq

15 QT1106_8IR0.06_0407

Page 16

7.5 Signal Processing

Vdd = 5.0V, Ta = recommended, Cx = 5pF, Cs keys = 4.7nF, Cs wheel/slider = 15nF, no spread-spectrum network,

Rb1 = 20k; circuit of Figure 2.1

NotesUnitsValueDescription

Threshold for increase in Cx loadcounts10Detection threshold (keys)

Detection threshold

(wheel/slider)

Detection hysteresis

(wheel/slider)

DI filter, start of touch, normal

mode

DI filter, start of touch, fast DI

mode

Maximum On-duration

10, 20,

60,

infinite

counts2Detection hysteresis (keys)

samples2DI filter, end of touch

samples6Anti-detection filter

samples1Faulty channel filter

secs

Changeable through SPIcounts40

12.5 percent of wheel/slider detection threshold.counts5

Must be consecutive or detection failssamples6

Must be consecutive or detection failssamples2

Threshold for decrease of Cx loadcounts8Anti-detection threshold

In these modes: Free Run, 200ms LP, 280ms LP, Sync with 55Hz

sync

Lq

16 QT1106_8IR0.06_0407

Page 17

7.6 Idd Curves

Table 7.1 Typical Average Idd Curves (No Spread Spectrum)

Cs (keys) = 4.7nF, Cs (wheel) = 15nF Ta = 200, no spread-spectrum circuit (see Figure 2.1).

Rb1 = 20k ohms

Rb1 = 18k ohm s

Rb1 = 15k ohms

QT1106 Idd ( Free Run mode) mA

4.0

3.0

2.0

Idd (mA)

1.0

0.0

2.5 3 3.5 4 4.5 5 5.5

Vdd (V)

QT 1106 Idd (L P 280ms mo de) u A

750

600

450

300

Idd (uA)

QT 1106 Idd (L P 200ms mo de) u A

1250

1000

750

500

Idd (mA)

250

0

2.5 3 3.5 4 4.5 5 5.5

Vdd (V)

QT1106 I dd ( LP 440ms mode) uA

500

400

300

200

Idd (uA)

150

0

2.5 3 3.5 4 4.5 5 5.5

Vdd (V)

QT 1106 Idd (L P 760ms mo de) u A

250

200

150

100

Idd (uA)

50

0

2.5 3 3.5 4 4.5 5 5.5

Vdd (V)

100

0

2.5 3 3.5 4 4.5 5 5.5

Vdd (V)

QT1106 Idd (Sleep mode) uA

18

16

14

12

10

8

Idd (uA)

6

4

2

0

2.5 3 3.5 4 4.5 5 5.5

Vdd (V)

lQ 17 QT1106_8IR0.06_0407

Page 18

Table 7.2 Typical Average Idd Curves (Spread Spectrum)

Cs (keys) = 4.7nF, Cs (wheel) = 15nF Ta = 200, spread-spectrum circuit (see Figure 2.1).

Rb1 = 15k ohms, Rb2 = 27k ohm s, Css = 100nF

Rb1 = 12k ohms, Rb2 = 22k ohm s, Css = 100nF

Rb1 = 12k ohms, Rb2 = 27k ohm s, Css = 100nF

QT1106 Idd ( Free Run mode) mA

4.0

3.0

2.0

Idd (mA)

1.0

0.0

2.5 3 3.5 4 4.5 5 5.5

Vdd (V)

QT 1106 Idd (L P 280ms mo de) u A

750

600

450

300

Idd (uA)

QT 1106 Idd (L P 200ms mo de) u A

1250

1000

750

500

Idd (mA)

250

0

2.5 3 3.5 4 4.5 5 5.5

Vdd (V)

QT1106 I dd ( LP 440ms mode) uA

500

400

300

200

Idd (uA)

150

0

2.5 3 3.5 4 4.5 5 5.5

Vdd (V)

QT 1106 Idd (L P 760ms mo de) u A

250

200

150

100

Idd (uA)

50

0

2.5 3 3.5 4 4.5 5 5.5

Vdd (V)

100

0

2.5 3 3.5 4 4.5 5 5.5

Vdd (V)

QT1106 Idd (Sleep mode) uA

18

16

14

12

10

8

Idd (uA)

6

4

2

0

2.5 3 3.5 4 4.5 5 5.5

Vdd (V)

lQ 18 QT1106_8IR0.06_0407

Page 19

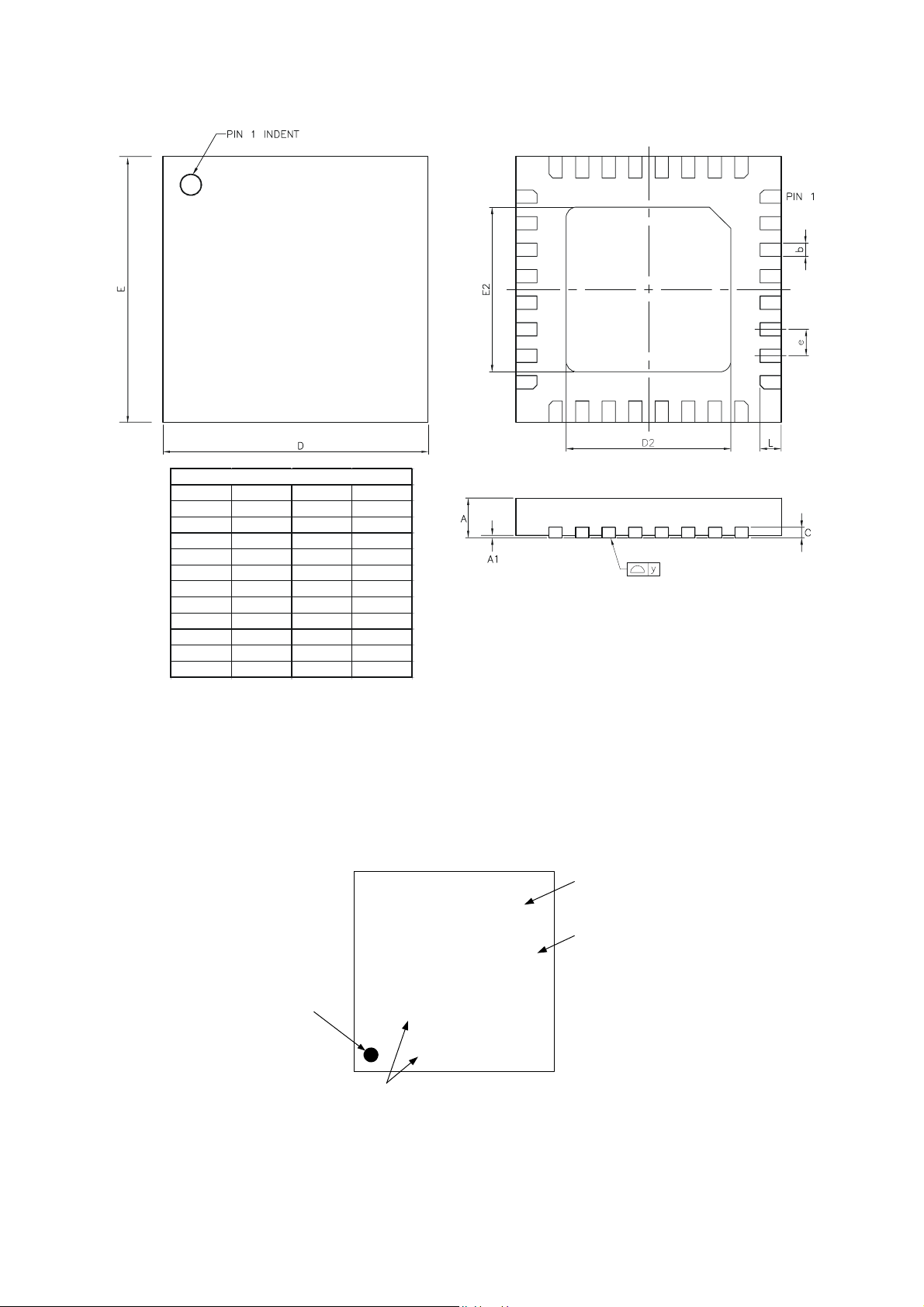

7.7 Mechanical Dimensions - 32-QFN Package

Dimensions In Millimeters

Symbol Minimum Nominal Maximum

A0.70 -0.95

A1 0.00 0.02 0.05

b 0.18 0.25 0.32

C - 0.20 REF D 4.90 5.00 5.10

D2 3.05 - 3.65

E 4.90 5.00 5.10

E2 3.05 - 3.65

e-0.50L 0.30 0.40 0.50

y0.00-0.075

Note:

there is no functional requirement for the large pad on the underside of the 32-QFN package to

be soldered to the substrate. If the final application does require this area to be soldered for

mechanical reasons, the pad(s) to which it is soldered to must be isolated and contained under the

32-QFN footprint only.

7.8 Part Marking

Pin 1 Identification

QT1106

©QRG 8I

YYWWG

run nr.

Two lines of text to ensure product traceability:

'YY' = Year of manufacture,

'WW' = Week of manufacture,

'G' = Green/RoHS Compliant,

'run nr.' = Run Number

QRG Part

Number

QRG

Revision

Code

lQ 19 QT1106_8IR0.06_0407

Page 20

7.9 Moisture Sensitivity Level (MSL)

SpecificationsPeak Body TemperatureMSL Rating

IPC/JEDEC J-STD-020C260OCMSL3

lQ 20 QT1106_8IR0.06_0407

Page 21

8 Datasheet Control

8.1 Changes

Changes this issue (datasheet issue 6)

Front page

Section 2.8.

Section 6.4, 6.5

Section 7.9

Section 8

Rear page

8.2 Numbering Convention

Part Number

Datasheet Issue Number

QT1106_MXN.nn_mmyy

Chip Revision

(Where M= Major chip revision,

N = Minor chip revision,

X = Prereleased Product

[or R = Released Product])

A minor chip revision (N) is defined as a revision change which does not affect product functionality or datasheet.

The value of N is only stated for released parts (R).

Datasheet Release Date;

(Where mm = Month, yy = Year)

lQ 21 QT1106_8IR0.06_0407

Page 22

lQ Copyright © 2006-2007 QRG Ltd. All rights reserved.

Patented and patents pending

Corporate Headquarters

1 Mitchell Point

Ensign Way, Hamble SO31 4RF

Great Britain

Tel: +44 (0)23 8056 5600 Fax: +44 (0)23 8045 3939

www.qprox.com

North America

651 Holiday Drive Bldg. 5 / 300

Pittsburgh, PA 15220 USA

Tel: 412-391-7367 Fax: 412-291-1015

The specifications set out in this document are subject to change without notice. All products sold and services supplied by QRG are

subject to QRG’s Terms and Conditions of sale and services. QRG patents, trademarks and Terms and Conditions can be found online at

http://www.qprox.com/about/legal.php. Numerous further patents are pending, one or more which may apply to this device or the

applications thereof.

QRG products are not suitable for medical (including lifesaving equipment), safety or mission critical applications or other similar

purposes. Except as expressly set out in QRG's Terms and Conditions, no licenses to patents or other intellectual property of QRG

(express or implied) are granted by QRG in connection with the sale of QRG products or provision of services. QRG will not be liable for

customer product design and customers are entirely responsible for their products and applications which incorporate QRG's produ cts.

Development Team: Lim Wei Jiun, Martin Simmons, Alan Bowens, Luben Hristov

Loading...

Loading...