Page 1

ATL P2000 Series Automated

Tape Library

User’s Guide

6316800-02

Ver. 2, Rel. 0

Page 2

ATL P2000 Series Automated Tape Library User’s Guide, 6316800-02, Ver. 2, Rel. 0, January, 2001, Made in

USA.

ATL Products, Inc. provides this publication “as is” without warranty of any kind, either express or implied,

including but not limite d to the impli ed warrantie s of merc hantabil ity or fitness for a particula r purpose. ATL

Products, Inc. may revise this publication from time to time without notice.

COPYRIGHT STATEMENT

Copyright 2001 by ATL Products, Inc. All rights reserved.

Your right to copy this manual is limited by copyright law. Making copies or adaptations without prior

written authorizat ion of ATL Products, I n c. is prohibited by law and constitut es a pu nish ab le v iol at ion of the

law.

ATL Products, Inc. provides this publication “as is” without warranty of any kind, either express or implied,

including but not limite d to the impli ed warrantie s of merc hantabil ity or fitness for a particula r purpose. ATL

Products, Inc. may revise this publication from time to time without notice.

TRADEMARK STATEMENT

Prism Library Architecture, IntelliGrip, and WebAdmin are all trademarks of ATL Products, Inc.

DLT, SDLT, DLTtape III, DLTtape IV and Super DLTtape I are trademarks of Quantum, In c.

IBM is a registered tradem ark. Linear Tape-Open, LTO and Ultrium are trademarks of IBM, HP, and Seagate

in the United States.

Other trademarks may be mentioned herein which belong to other companies.

6207947-06cP 73

Page 3

Contents

Contents

Preface xv

Chapter 1 Library Description 1

Overview .................................................................................................1

Library Models.................................................................................2

Element Numbering Convention..................................................3

Features and Benefits.............................................................................7

Library Components..............................................................................8

Cabinet...............................................................................................9

Touch Screen GUI..........................................................................12

IntelliGrip

Tape Drives.............................................................. ......... ..............14

Load Port and Magazines.............................................................15

TM

Mixed Media Cartridge Handling Mechanism.13

Chapter 2 Basic Library Operations 17

Installing Tape Cartridges...................................................................17

Taking ESD Precautions................................................................18

DLT/SDLT Cartridges..................................................................19

LTO Cartridges...............................................................................21

Placing Tape Cartridges in the Library.......................................21

Preparing the Library for Operation .................................................22

Closing the Library Doors and Access Panels...........................22

Connecting Host Workstations....................................................22

Turning the Library On and Off.........................................................25

Turning On the Library.................................................................25

Placing the Library On-line or Off-line.......................................25

Turning Off the Library ................................................................25

ATL P2000 Series Automated Tape Library User’s Guide iii

Page 4

Contents

Using the Touch Screen GUI...............................................................26

Opening a Screen ...........................................................................28

Library Status Information...........................................................29

Exiting a Screen..............................................................................29

Library Controls.............................................................................30

Obtaining Library Status.....................................................................31

Overview Screen ............................................................................32

Tapes Screen ...................................................................................34

Changing the Touch Screen GUI Security Levels............................ 3 5

Securing the Touch Screen GUI................................................... 36

Operating the Load Port......................................................................38

Removing/Installing a Tape Cartridge Magazine....................38

Loading a Tape Cartridge Magazine ..........................................39

Inserting Tape Cartridges into the Load Port...................................39

Inserting DLT/SDLT Tape Cartridges........................................ 39

Inserting LTO Tape Cartridges....................................................41

Manually Ejecting a Tape Cartridge..................................................42

DLT Tape Drives............................................................................42

Quantun SDLT and IBM Ultrium LTO Tape Drives ................43

Chapter 3 Operator Commands 45

Opening the Operator Screen ............................................................. 46

Configuring the Library.......................................................................47

SCSI ID Assignment Guidelines..................................................49

Configuring Library Options..............................................................49

Configuring a Library Option......................................................50

Performing an Inventory.....................................................................51

Moving Cartridges ...............................................................................52

Unloading a Drive.................................................... ......... ...................54

Unloading the Load Port.....................................................................55

Chapter 4 Service Commands 57

Opening the Service Screen.................................................................58

Changing Passwords............................................................................59

If You Lose a Password.................................................................60

iv ATL P2000 Series Automated Tape Library User’s Guide

Page 5

Contents

Generating Reports ..............................................................................60

Generating Any Service Report...................................................61

Testing the Library...............................................................................64

Performing a System Test.............................................................64

Initializing Non-Volatile Information...............................................65

Executing Either Command.........................................................66

Chapter 5 Multi-Unit Commands 67

Opening the Multi-Unit Screen..........................................................68

Configure Multi-Units (P2000/P3000)..............................................69

Calibrating the Libraries in a Multi-Unit Configuration................70

Appendix A Library Specifications 73

Physical Characteristics.......................................................................73

Performance and Reliability Characteristics....................................75

Environmental Specifications.............................................................76

Appendix B Relocating the Library 81

Checking the New Installation Site....................................................82

Preparing the Library for Relocation.................................................82

Removing Tape Cartridges...........................................................82

Installing Shipping Restraints and Packing...............................83

Load Port Shipping Plate..............................................................88

Disconnecting Library Cables......................................................88

Crating the Library...............................................................................90

Crating the Library........................................................................90

Preparing the Library for Operation .................................................93

Appendix C Automatic Drive Cleaning 95

Drive Cleaning Modes.........................................................................95

Host-Initiated Cleaning Mode .....................................................95

Automatic Drive Cleaning Mode ................................................95

ATL P2000 Series Automated Tape Library User’s Guide v

Page 6

Contents

Selection of Cleaning Mode ................................................................96

Diagnostic Software .......................................................................96

Touch Screen GUI ..........................................................................96

Mode Select Command.................................................................97

Reporting of Cleaning Mode ..............................................................97

Diagnostic Software .......................................................................97

Mode Sense Command .................................................................98

Cleaning Cartridges .............................................................................99

Capacity...........................................................................................99

Identification...................................................................................99

Storage and Tracking.....................................................................99

Monitoring Usage ........................................................................100

Element Status Information........................................................101

Monitoring the Drives........................................................................101

Media Movement to the Drive .........................................................102

Supervising the Drive Cleaning Operation....................................103

Media Movement from the Drive ....................................................103

Unloading Cleaning Cartridges .......................................................104

Appendix D Laser Regulations 105

Laser Regulation Labels.....................................................................105

Product Conformation Label......................................................105

Laser Warning Label....................................................................105

Exposure Warning Label ............................................................106

Appendix E Regulatory Statements 107

FCC STATEMENT..............................................................................107

INDUSTRY CANADA (DIGITAL APPARATUS) Interference-

Causing Equipment Standard ICES-003 Issue 2......................108

LASER STATEMENT.........................................................................109

BATTERY STATEMENT ...................................................................111

CAUTION.....................................................................................111

Glossary 113

vi ATL P2000 Series Automated Tape Library User’s Guide

Page 7

Contents

Index 121

ATL P2000 Series Automated Tape Library User’s Guide vii

Page 8

Contents

viii ATL P2000 Series Automated Tape Library User’s Guide

Page 9

Figures

Chapter 1

Figures

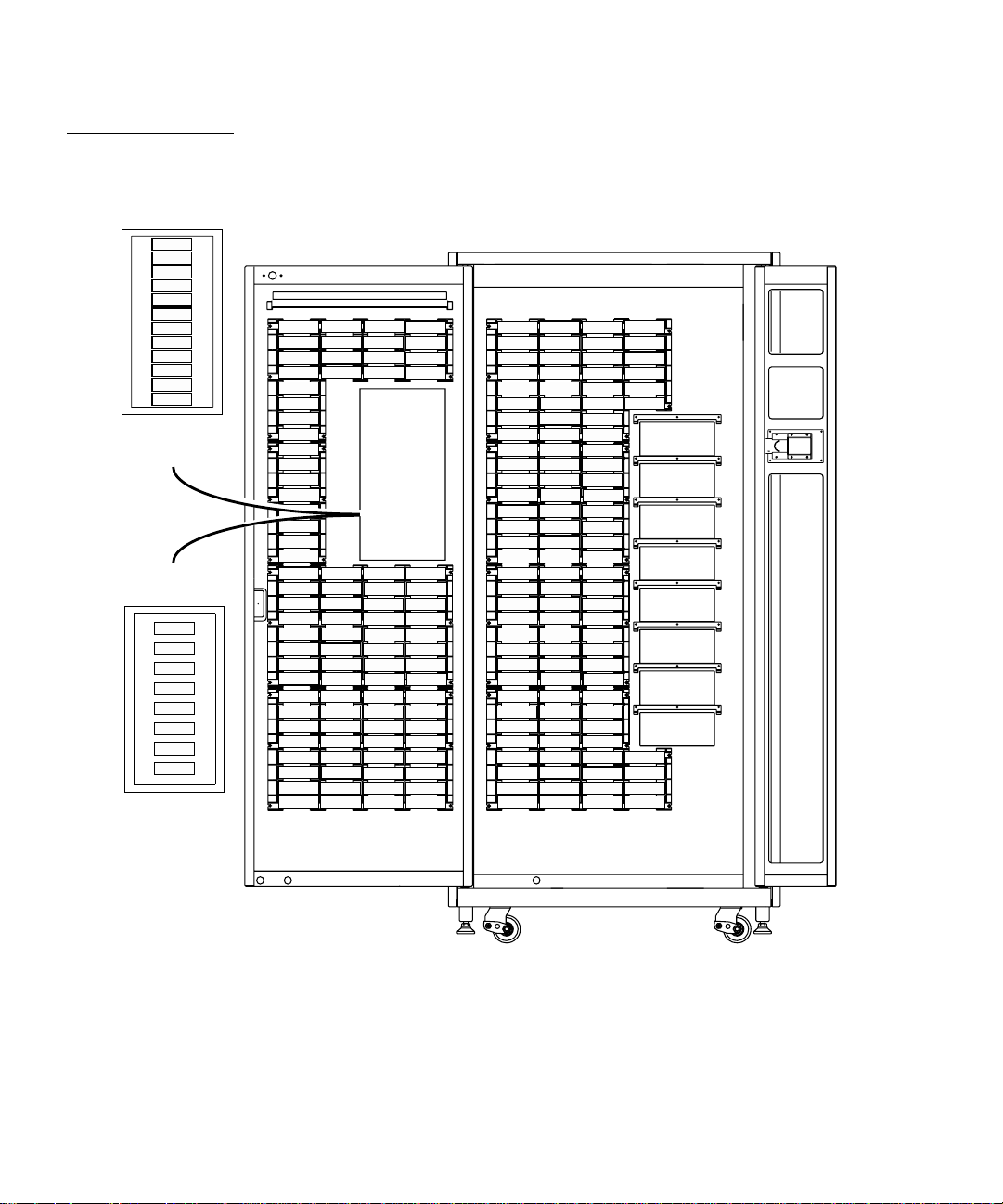

Figure 1 198-Bin, 8-Drive Numbering Conventions .....................4

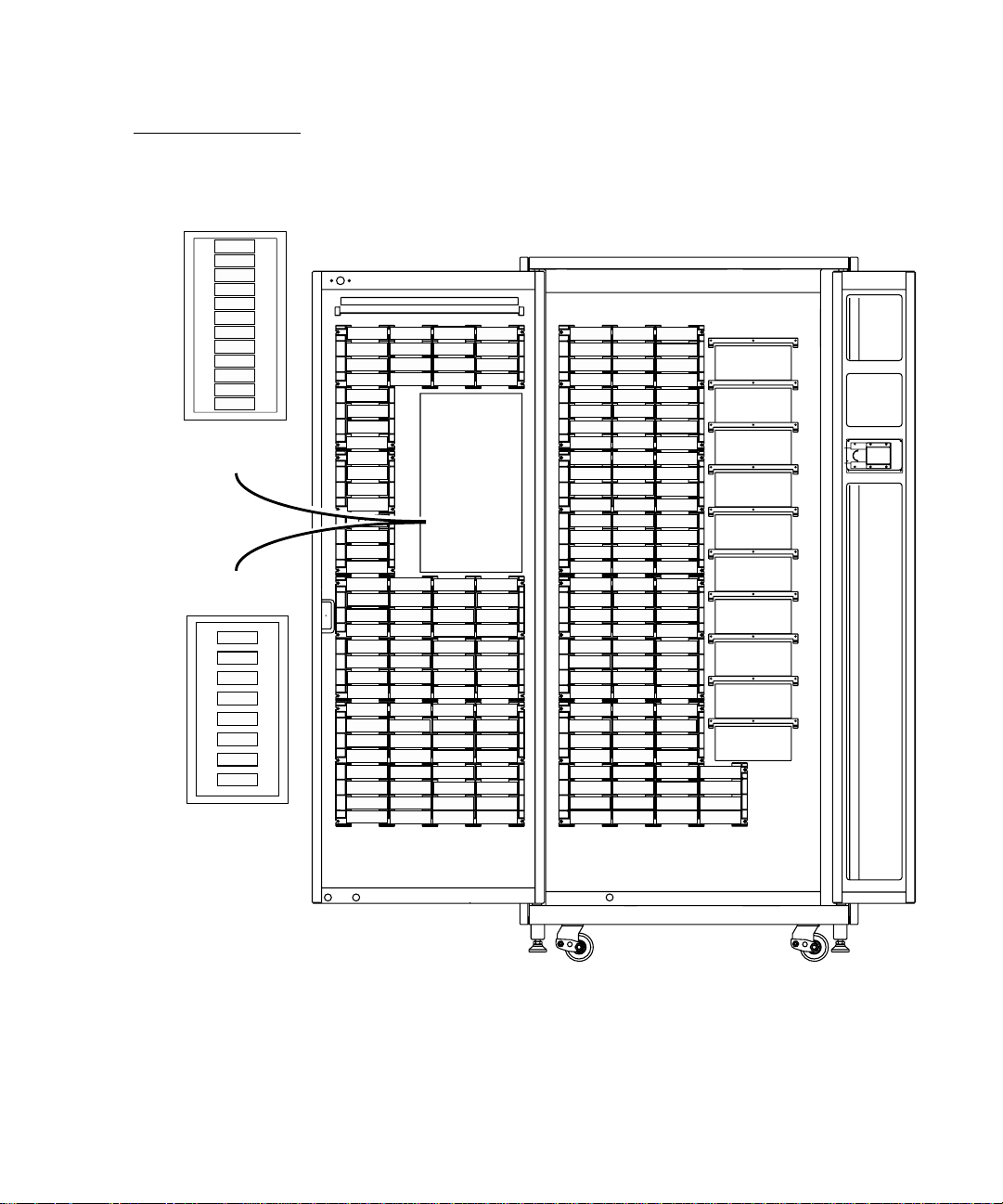

Figure 2 192-Bin, 10-Drive Numbering Conventions ...................5

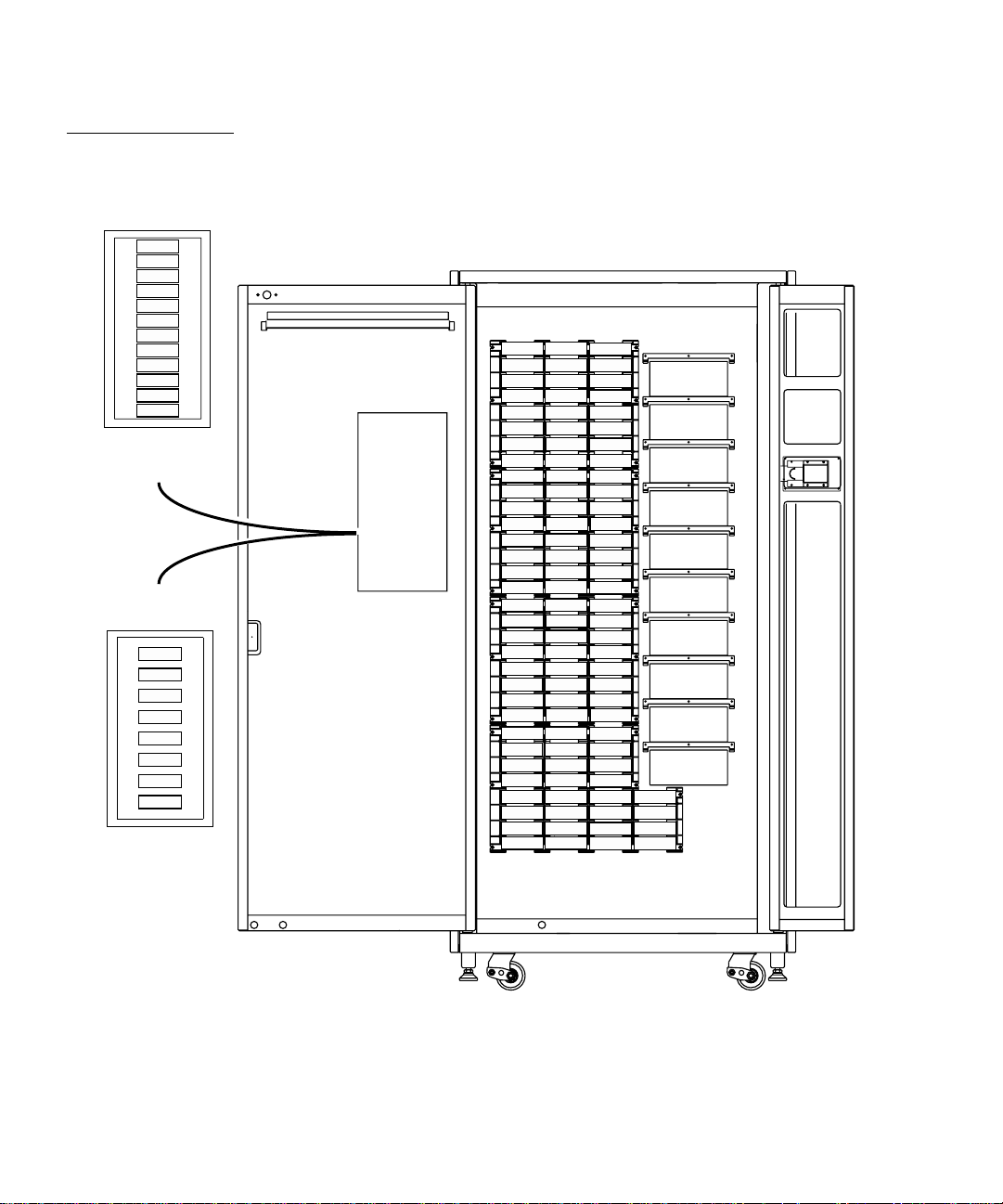

Figure 3 100-Bin, 10-Drive Numbering Conventions ...................6

Figure 4 Cabinet-Front View ..........................................................10

Figure 5 Cabinet - Back Panel.........................................................11

Figure 6 touch Screen GUI—Initial Screen...................................12

Chapter 2

Figure 7 Advanced Robotics System.............................................13

Figure 8 DLT/SDLT Load Port ......................................................16

Figure 9 LTO Load Port...................................................................16

Figure 10 Inserting a Bar Code Label (DLT/SDLT)).....................19

Figure 11 DLT and SDLT Cartridges...............................................20

Figure 12 LTO Cartridge...................................................................21

Figure 13 Cabling Configuration—10-Drive Library....................23

Figure 14 Cabling Configuration—8-Drive Library......................24

Figure 15 Touch Screen GUI—Initial Screen..................................27

Figure 16 Library Status Indicators .................................................29

Figure 17 Library Controls................................................................30

Figure 18 Overview Screen...............................................................32

ATL P2000 Series Automated Tape Library User’s Guide ix

Page 10

Figures

Chapter 3

Figure 19 Tape Drive Status Screen................................................33

Figure 20 Tapes Screen ......................................................................34

Figure 21 Password Screen ...............................................................37

Figure 22 Rotating the Load Port Drum..........................................40

Figure 23 LTO Tape Cartridge Load Port.......................................41

Figure 24 DLT Tape Drive Front Bezel (Example)........................42

Figure 25 Password Screen ...............................................................46

Figure 26 Operator Screen................................................................. 47

Figure 27 Configure: Library Settings Screen.................................48

Figure 28 Configure: Library Settings Screen.................................48

Figure 29 Configure: Options Screen...............................................51

Figure 30 Control: Move Cartridges Screen ...................................53

Figure 31 Unload Drives Screen.......................................................54

Chapter 4

Figure 32 Enter Password Screen.....................................................58

Figure 33 Service: Change Password Screen..................................59

Figure 34 Service Screen - Reports...................................................61

Figure 35 Report: Statistics Screen...................................................62

Figure 36 Report: Actuator Status Screen.......................................62

Figure 37 Report: SysTest Library Results Screen.........................63

Figure 38 Report: AutoClean Status Screen....................................63

Figure 39 Test: SysTest Library Screen............................................64

x ATL P2000 Series Automated Tape Library User’s Guide

Page 11

Chapter 5

Appendix B

Figures

Figure 40 Enter Password Screen.....................................................68

Figure 41 Multi-Unit Screen..............................................................69

Figure 42 Configure Multi-Unit.......................................................70

Figure 43 Multi-Unit Screen..............................................................71

Figure 44 Extension Axis Restraints - Storage Location...............83

Figure 45 Installing the Vertical Carriage Restraint......................84

Figure 46 Installing the Horizontal Carriage Restraint.................85

Figure 47 Pivoting Gripper Restraint into Position.......................86

Figure 48 Gripper Restraint in Position ..........................................87

Figure 49 Installing the Gripper Restraint......................................87

Figure 50 Installing the Gripper Restraint Screw..........................88

Appendix D

Figure 51 Inserting the Shipping Plate............................................89

Figure 52 Crating the Library...........................................................92

Figure 53 Product Conformation Label ........................................105

Figure 54 Laser Light Warning Label............................................105

Figure 55 Exposure Warning Label.................................................10

ATL P2000 Series Automated Tape Library User’s Guide xi

Page 12

Figures

xii ATL P2000 Series Automated Tape Library User’s Guide

Page 13

Tables

Chapter 1

Tables

Table 1 Performance Characteristics Using DLT 8000 Tape

Drives....................................................................................2

Table 2 Performance Characteristics Using IBM LTO Ultrium

T200 Tape Drives ................................................................2

Table 3 Performance Characteristics Using Quantum SDLT

Tape Drives..........................................................................2

Table 4 Tape Drive and Cartridge Specifications.....................14

Chapter 2

Appendix A

Table 5 Touch Screen GUI Functions..........................................28

Table 6 Security Levels (listed from highest to lowest) ............36

Table 7 Physical Characteristics ...................................................73

Table 8 Interfaces............................................................................74

Table 9 Performance Characteristics............................................75

Table 10 Reliability Characteristics................................................75

Table 11 Environmental Specifications .........................................76

ATL P2000 Series Automated Tape Library User’s Guide xiii

Page 14

Tables

xiv ATL P2000 Series Automated Tape Library User’s Guide

Page 15

Preface

Preface

This manual introduces the ATL P2000 Series library and discusses

library operations, configuration, calibration, servicing, and basic

troubleshooting.

Audience 0

Purpose 0

Document

Organization

This manual is written for library operators and field service

engineers.

This document provides in formation about the P200 0 Series library

including:

• Library description

• Basic library operations

• Operator commands

• Service commands

• Multi-unit commands

Following is a brief description of chapter contents.

• Chapter 1,

library and orients the operator or field service engineer to the

numbering conventions for bins and tape drives.

• Chapter 2,

the library GUI and introduces the operator to the basic

procedures for placing the library on line.

Library Description, provides an overview of the

Basic Library Operations, provides an overview of

• Chapter 3,

library GUI and introduces the operator to the basic pr ocedures

for placing the library on line.

ATL P2000 Series Automated Tape Library User’s Guide xv

Operator Commands, provides an overview of the

Page 16

Preface

• Chapter 4, Service Commands, discusses using the Service

screen for generating reports and testing the library.

Notational

Conventions

• Chapter 5,

Multi-Unit Commands, discusses the commands

available through the Multi-Unit screen of the GUI. These

commands allow multi-unit configuration and calibration.

• The appendixes provide site requirements, unpacking/

repacking instructions, SCSI cabling options, and laser

regulation warning information.

This manual uses the following conventions:

Caution: Caution indicates potential hazard to equipment or

data and are included to prevent damage to

equipment.

Warning: W arning in dicates potential hazar d to personal safety

and are included to prevent injury

.

Note: Note emphasizes important information related to the

main topic.

xvi ATL P2000 Series Automated Tape Library User’s Guide

Page 17

Preface

This manual uses the following conventions:

• Right side of the library — Refers to the right side as you face

the component being described.

• Left side of the library — Refers to the left side as you face the

component being described.

• b — All binary numbers are succeeded by “b.”

• h — All hexadecimal numbers are succeeded by “h.”

• Error or attention conditions are represented in parenthesis

that translate as follows:

(SK=S ASC=AA ASCQ=QQ)

where:

S — hexadecimal sense key value

AA — hexadecimal additional sense code

Related Documents 0

QQ — hexadecimal additional sense code qualifier

er

The following ATL documents are also available for the P2000

Series library:

Document No. Document Title Document Description

6316803

6311602

6311615

ATL P2000 Series

Library

Unpacking

Instructions

ATL P2000/P3000

Series Library

Software Interface

Guide

ATL Pass Through

Mechanism

Installation

Instructions

Describes unpacking and

moving a P2000 library

For programmers writing

P2000/P3000 control software

Contains instructions for

interconnecting up to five P2000

and/or P3000 libraries

ATL P2000 Series Automated Tape Library User’s Guide xvii

Page 18

Preface

Refer to the appropriate product manual(s) for information about

your tape drive and cartridges.

SCSI-2 Specification

The SCSI-2 communications specification is the proposed

American National Standard for information systems, dated

March 9, 1990. Copies may be obtained from:

Global Engineering Documents

15 Inverness Way, East

Englewood, CO 80112

(800) 854-7179 or (303) 397-2740

Contacts 0

ATL Products Corporate Headquarters

To order documentation on the P2000 or other products contact:

ATL Products, Inc.

101 Innovation Drive

Irvine, CA 92612-5872

(949) 856-7800

(800) 284-5101

Technical Publications

To comment on existing documentation send e-mail to:

atl-docs@atlp.com

World Wide Web 0

Visit the ATL Products home page at:

http://www.atlp.com

xviii ATL P2000 Series Automated Tape Library User’s Guide

Page 19

Preface

Customer Support

The ATL Products Customer Support Department provides a 24hour help desk that can be reached at:

North/South America: (949) 477-7924 or

(800) 284-5101

Europe, Africa, Asia, or Australia: (International Code) +

44 (0) 1256 848748

Send faxes for the Customer Support Department to:

North/South America: (949) 477-7940

Europe, Africa, Asia, or Australia: (International Code) +

1 + (949) 477-7940

Send e-mail for the Customer Support Department to:

North/South America:

Europe, Africa, Asia, or Australia:

helpdesk@atlp.com

ukhelpdesk@atlp.com

ATL P2000 Series Automated Tape Library User’s Guide xix

Page 20

Preface

xx ATL P2000 Series Automated Tape Library User’s Guide

Page 21

Chapter 1

Library Description

This chapter describes the P2000 automated tape library and its

components. The chapter consists of:

Overview

•

Features and benefits

•

Library components

•

• Cabinet

• Touch screen GUI

• IntelliGrip

• Tape drives

• Mixed media load port

TM

mixed media cartridge handling mechanism

1

Overview

1

The P2000 is an automated storage and retrieval library that may

consist of up to 8 tape drives and 198 cartridges or 10 tape drives

and either 100 or 192 cartridges.

Tape drive choices include the Quantum DLT 8000 (HVD and

LVD), IBM LTO Ultrium T200 (LVD only), or the Quantum SDLT

(HVD and LVD). Throughput capabilties for these drives are 6

MB/sec, 20 MB/sec, and 16 MB/sec, respectively.

ATL P2000 Series Automated Tape Library User’s Guide 1

Page 22

Chapter 1 Library Description

Overview

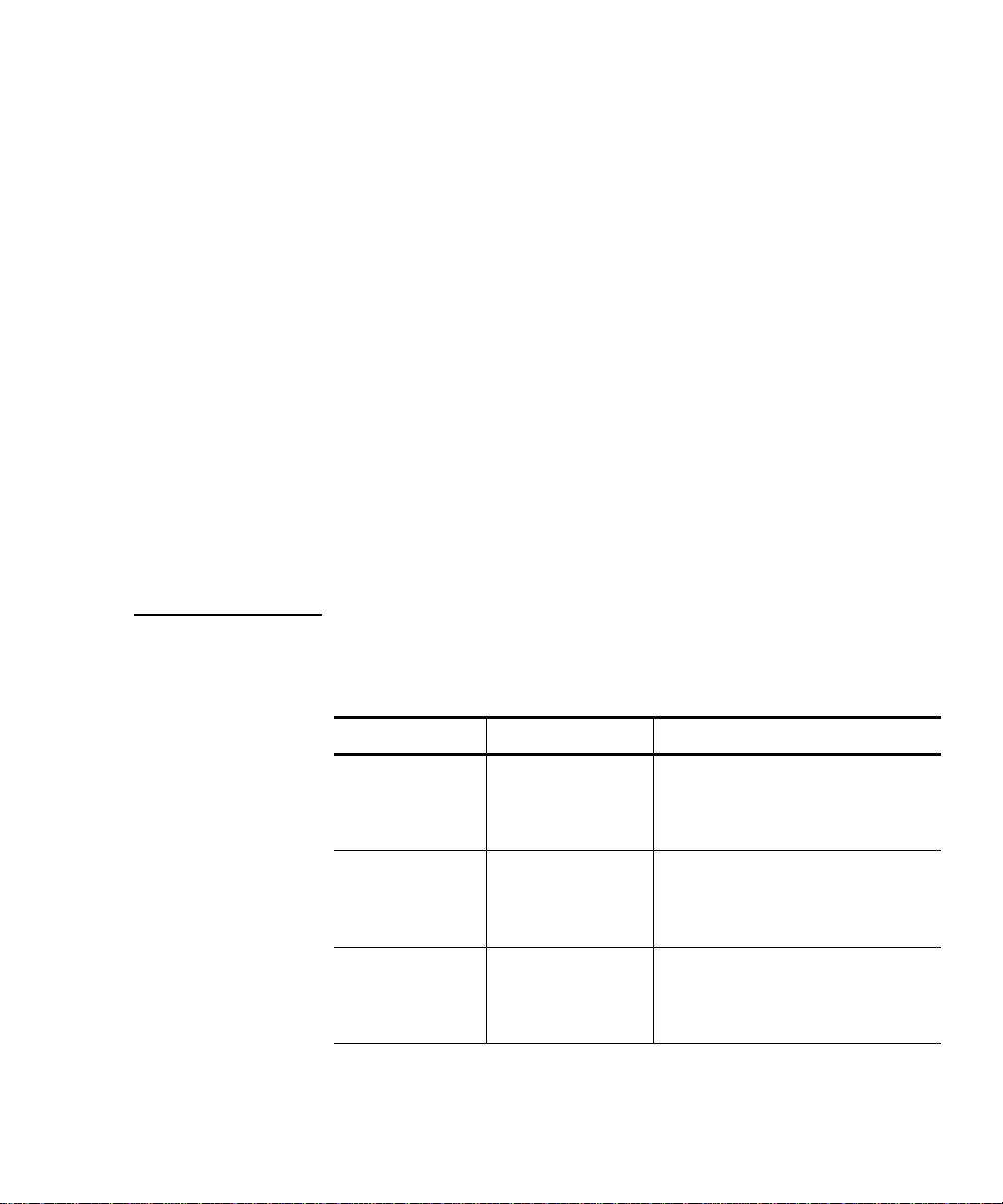

Library Models

Table 1 Performance

Characteristics Using

DL T 8000 Tape Driv es

Table 2 Performance

Characteristics Using

IBM LTO Ultrium T200

Tape Drives

1

The P2000 Series library comprises three models that support a

wide range of storage and performance requirements (see table 1

table 2

, and table 3). Model numbers are created by combining the

number of drives and the number of storage bins in the library.

Model 8/198 - 8 tape drives and 198 tape cartidge bins

•

Model 10/100 - 10 tape drives and 100 tape cartidge bins

•

Model 10/192 - 10 tape drives and 192 tape cartidge bins

•

P2000 Model (drives/bins) 8/198 10/100 10/192

Capacity in Terabytes (TB)

(40 GB per cartridge)

Throughput (GB/hr) based on 6

MB/sec transfer rate

P2000 Model (drives/bins) 8/198 10/100 10/192

Capacity in Terabytes

(100 GB per cartridge)

7.92 4.00 7.68

173 216 216

19.8 10 19.2

,

Throughput (GB/hr) based on 15

432 540 540

MB/sec transfer rate

Table 3 Performance

Characteristics Using

Quantum SDLT Tape

Drives

P2000 Model (drives/bins) 8/198 10/100 10/192

Capacity in Terabytes

22 11 21

(110 GB per cartridge)

Throughput (GB/hr) based on 16

461 576 576

MB/sec transfer rate

2 ATL P2000 Series Automated Tape Library User’s Guide

Page 23

Chapter 1 Library Description

Overview

Element Numbering Convention

The library stores tape cartridges in the following locations:

100 storage bins on the back wall

•

1

Up to 92 storage bins on inside of the front door

•

One load port

•

• 8 bins - two stationary LTO load port shelf bin modules (4

bin shelves each) are built into the load port assembly

12 bins - DL T an d SDL T tape c artridges use two remo veable

•

6-cartridge magazines

• If the library is configured with both DLT and LTO tape

drives, stationary LTO load port shelf bin modules are used

Up to 10 tape drives

•

Figure 1

shows the storage bin, load port bin, and tape drive

numbering conventions. These conventions are used by the library

touch screen graphical user interface (touch screen GUI) and the

diagnostic software program.

ATL P2000 Series Automated Tape Library User’s Guide 3

Page 24

Chapter 1 Library Description

Overview

Figure 1 198-Bin, 8Drive Numbering

Conventions

0

1

2

3

4

5

6

7

8

9

Load Port Bin Numbers

10

11

DLT and/or

SDLT

DLT and/or

LTO

0

1

2

3

4

5

6

Load Port Bin Numbers

7

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

180

181

182

183

184

185

186

187

188

189

190

191

192

193

194

195

196

197

000

001

002

003

004

005

006

007

008

009

010

011

012

013

014

015

016

017

018

019

020

021

022

023

024

025

026

027

028

029

030

031

032

033

034

035

036

037

038

039

040

041

042

043

044

045

046

047

048

049

050

051

052

053

054

055

056

057

058

059

060

061

062

063

064

065

066

067

068

069

070

071

072

073

074

075

076

077

078

079

080

081

082

083

084

085

086

087

088

089

090

091

092

093

094

095

096

097

098

099

100

101

Drive Bay 0

Drive Bay 1

Drive Bay 2

Drive Bay 3

Drive Bay 4

Drive Bay 5

Drive Bay 6

Drive Bay 7

102

103

104

105

4 ATL P2000 Series Automated Tape Library User’s Guide

Page 25

Figure 2 192-Bin, 10Drive Numbering

Conventions

0

1

2

3

4

5

6

7

8

9

Load Port Bin Numbers

10

11

DLT and/or SDLT

DLT and/or LTO

0

1

2

3

4

5

6

Load Port Bin Numbers

7

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

180

181

182

183

184

185

186

187

188

189

190

191

000

001

002

003

004

005

006

007

008

009

010

011

012

013

014

015

016

017

018

019

020

021

022

023

024

025

026

027

028

029

030

031

032

033

034

035

036

037

038

039

040

041

042

043

044

045

046

047

048

049

050

051

052

053

054

055

056

057

058

059

060

061

062

063

Chapter 1 Library Description

064

065

066

067

068

069

070

071

072

073

074

075

076

077

078

079

080

081

082

083

084

085

086

087

088

089

090

091

092

093

094

095

Drive Bay 8

Drive Bay 9

Drive Bay 0

Drive Bay 1

Drive Bay 2

Drive Bay 3

Drive Bay 4

Drive Bay 5

Drive Bay 6

Drive Bay 7

096

097

098

099

Overview

ATL P2000 Series Automated Tape Library User’s Guide 5

Page 26

Chapter 1 Library Description

Overview

Figure 3 100-Bin, 10Drive Numbering

Conventions

0

1

2

3

4

5

6

7

8

9

Load Port Bin Numbers

10

11

DLT and/or SDLT

DLT and/or LTO

0

1

2

3

4

5

6

Load Port Bin Numbers

7

000

001

002

003

004

005

006

007

008

009

010

011

012

013

014

015

016

017

018

019

020

021

022

023

024

025

026

027

028

029

030

031

032

033

034

035

036

037

038

039

040

041

042

043

044

045

046

047

048

049

050

051

052

053

054

055

056

057

058

059

060

061

062

063

064

065

066

067

068

069

070

071

072

073

074

075

076

077

078

079

080

081

082

083

084

085

086

087

088

089

090

091

092

093

094

095

Drive Bay 8

Drive Bay 9

Drive Bay 0

Drive Bay 1

Drive Bay 2

Drive Bay 3

Drive Bay 4

Drive Bay 5

Drive Bay 6

Drive Bay 7

096

097

098

099

6 ATL P2000 Series Automated Tape Library User’s Guide

Page 27

Chapter 1 Library Description

Features and Benefits

Features and Benefits

The P2000 library provides the following features and benefits:

High-capacity, high-performance data storage and retrieval

•

• The library may house up to 198 tape cartridges in

configurations with up to 8 tape drives in only 7.25 square

feet of floor space, or...

• The library may house up to 192 tape cartridges in

configurations with 9 or 10 tape drives

Expandable library configurations

•

• Up to five P2000 and/or P3000 libraries can be joined

together into one virtual library, which enables tape

cartridge sharing between libraries using ATL’s Pass

Through Mechanism (PTM)

Note:

1

When using a Pass Through Mechanism on the

right side of the P2000 library, 8 tape drives and up

to 192 tape cartidges may be used. When using a

PTM on the left side, tape cartridge capacity is

reduced to 168 while up to 10 tape drives may be

used. Finally, when PTMs are used on both sides,

tape cartridge capacity is 168 and 8 tape drive s may

be used.

Access to future expandability and technology upgrades

•

through ATL’s Prism™ architecture

• Prism architecture employs standar d PCI bus technology to

provide greater upgrade flexibility at reduced costs

• This technology ensures compatibility with future onboard technologies such as tape drive controllers, highspeed host and network interfaces, as well as server and

tape RAID

Reliable, versatile 120-240 volt AC auto-switching power

•

supplies

ATL P2000 Series Automated Tape Library User’s Guide 7

Page 28

Chapter 1 Library Description

Library Components

• The library may be optionally configured with up to six hot-

• An optional advanced cooling system is available to prevent

• On-line cartridge exchanges: load port with two removable

• Easy serviceability and manageability

swappable, redundant DC power supplies to ensure library

operations in the event of a power supply failure

failures from ove rheating

6-cartridge magazines for easy insertion of cartridges without

interrupting library operations

•

Hot-swappable drives, DC power supplies, and fan

modules enable field service engineers to make repairs

without taking the library off-line

•

Easy access and replacement of critical components

•

A user-friendly touch screen GUI provides a wide range of

configuration and service-related functions

•

WebAdmin™ provides library access through the Internet

Library Components

The P2000 mixed media tape library consists of these major

components:

• Cabinet

• Touch screen GUI

• Intelligrip™ mixed-media cartridge handling mechanism

• Mixed-media tape drives (DLT and SDLT, or DLT and LTO)

• Load port

8 ATL P2000 Series Automated Tape Library User’s Guide

1

Page 29

Chapter 1 Library Description

Library Component s

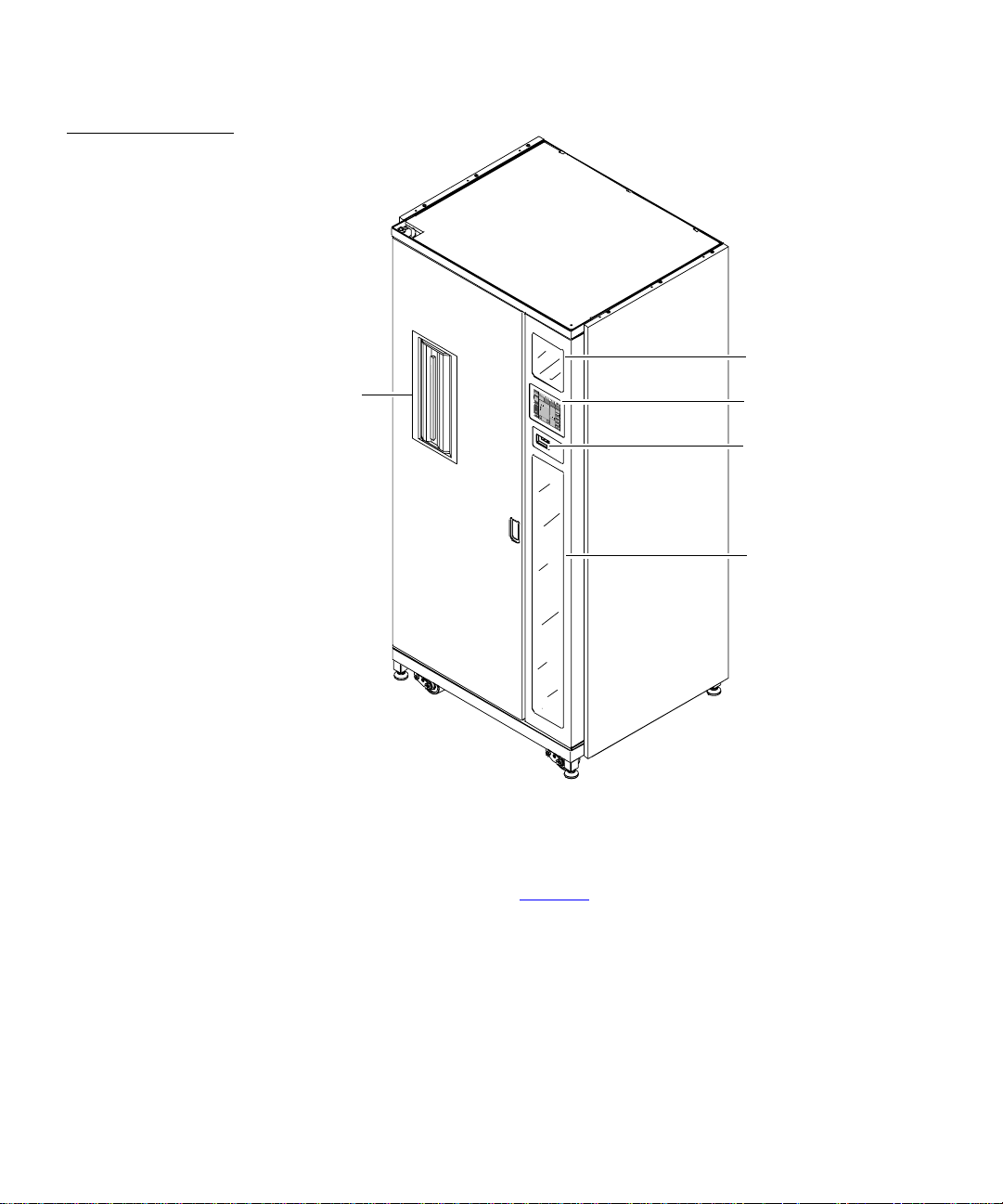

Cabinet

1

The cabinet houses all library components including:

Cartridge handling mechanism (CHM)

•

Storage bins

•

Control electronics

•

Power supply and distribution equipment

•

Fan modules

•

Tape drives

•

You can access these components through the front door and back

panel of t he library cabinet.

Front Panel

The front of the library cabinet (see figure 4

) provides the

following:

The front door provides easy access to the CHM and the

•

storage array

The viewing windows makes it possible to visually monitor

•

library operations

1

A touch screen GUI on the right side of the cabinet enables you

•

to monitor and control library operations

A mixed media load port with either two 8-cartridge stat ionary

•

load packs for libraries configured with L TO tape drives or two

6-cartridge removable load pack magazines for DLT and/or

SDLT tape drives provides easy insertion of additional tape

cartridges while the library is in operation.

The power switch for the library is located behind a sliding

•

panel on the front door

ATL P2000 Series Automated Tape Library User’s Guide 9

Page 30

Chapter 1 Library Description

Library Components

Figure 4 CabinetFront View

Load port

Viewing

window

B

a

ck

Ov

Ove

System

e

r

r

view

Forward

view

Of

f

-lin

Tapes

e

Ta

Home

p

Standby

e

D

rive Status

Operator

D00

D03

L

o

ANF 1

ad

BLT 581

P

Ser

ort

Ready

20

Ready

v

D0

ice

Activ

1

EM

Compression

i

ty

P

TY

Ready

Write Protect

L

o

D02

ad

DLT 7000

O

N

P

?

ac

U

?

?

ks

CompacTap

P0

Rea

O

FF

0

D03

ANF 14

dy

SCSI ID: 05

ANF 123

e

Stop

IV

6

Ready

GRP

P01

ANF 147

e

m

p

t

y

P02

ANF 148

P0

3

ANF 149

Touch

screen

GUI

Power

switch

Viewing

window

Cabinet-Back

The back of the cabinet (see figure 5

Cooling fans

•

Power, control, and data interfaces

•

Tape drives

•

10 ATL P2000 Series Automated Tape Library User’s Guid e

) provides easy accessibility to:

1

Page 31

Figure 5 Cabinet Back Panel

Chapter 1 Library Description

Library Component s

Hot-swappable,

removable fan

modules

Hot-swappable drives

in removable canisters

Easy-access

back panel

ATL P2000 Series Automated Tape Library User’s Guide 11

Page 32

Chapter 1 Library Description

Load Port

System

Off-line

Standby

Overview Tapes Operator

Back Forward

Home

U

Stop

ATL

PRODUCTS

ATL

PRODUCTS

P2000

SERIES

Service

http:/www.atlp.com/cust.html

Help: (USA) + 949-477-7924

Help in USA: 800-284-5101

BBS: (USA) + 949-477-7736

email: atlhelp@atlp.com

Revision: Application: 2.01

Revision: Boot Block: 1:11

Library Components

Touch Screen GUI

1

The touch screen GUI features a menu system for determining

library status, configuring the library, and performing certain

diagnostic functions.

Figure 6 touch Screen

GUI—Initial Screen

The touch screen GUI (see figure 6

Horizontal taskbar (top row)

•

Vertical taskbar (left column)

•

Main display area

•

Vertical

task bar

System

state

display

Standby

Load

port

Security

indicator

) consists of:

Horizontal

task bar

12 ATL P2000 Series Automated Tape Library User’s Guid e

The horizontal taskbar provides left and right arrow buttons to

scroll through the tabs for status, configuration, diagnostic, and

operating controls options.

The vertical taskbar provides various library controls:

System state display - indicates current tasks and requests in

•

process

Main display area

Page 33

Chapter 1 Library Description

Library Component s

• Standby - takes the library “off-line” or “on-line”

• Load port button - submits request to the library to open the

load port

• Security level indicator - shows “locked” on start-up and

initialization (defa ult)

• Stop button - immediately removes power from the library

robotics.

IntelliGripTM Mixed Media Cartridge Handling Mechanism

Figure 7 Advanced

Robotics System

The cartridge handling mechanism (CHM) of the library consists

of the following components:

1

• Mixed media gripper assembly

• Vertical carriage assembly

• Horizontal drive motor

• Extens ion axis assembly

Horizontal drive

motor

Mixed media

gripper assembly

Extension access

assembly

Vertical carriage

assembly

ATL P2000 Series Automated Tape Library User’s Guide 13

Page 34

Chapter 1 Library Description

Library Components

The vertical and horizontal actuators move the mixed media

gripper into position to pick and place tape cartridges. The rotary

actuator rotates the mixed media gri pper 180

mixed media gripper to pass cartridges between the front storage

bins and the back storage bins or tape drives. The extension

actuator extends the mixed media gripper forward to make contact

with the desired cartridge and then retracts the mixed media

gripper to remove the cartridge from a bin or drive.

The mixed media gripper includes a Clas s II l aser bar code s canner

that reads standard six-character, 3 of 9 bar code labels. The

scanner is used to maintain an inventory of the tape cartridges

within the library. An inventory occurs automatically whenever

the library is turned on or after the bulk load door has been closed.

An inventory can also be initiated from the host computer.

Although the library does not require tape cartridges to have bar

code labels, properly labeled tape cartridges and full storage bins

speed up the inventory process.

degrees, allowing the

Tape Drives

1

The P2000 library holds up to 10 tape drives

combinations of DLT and SDLT, or DLT and LTO

Table 4 Tape Drive

and Cartridge

Specifications

Cartridge

Tape

Cartridge

Quantum

DLT 8000

IBM LT O

Ultrium T200

Quantum

SDLT

14 ATL P2000 Series Automated Tape Library User’s Guid e

Transfer

Rate

6 GB/sec 40 GB 80 GB 7.92 TB 15.84 TB

15 GB/sec 100 GB 200 GB 19.8 TB 39.6 TB

11 GB/sec 110 GB 220 GB 21.78 TB 43.56 TB

Cartridge

Capacity

Capacity

(compressed)

T otal Library

Capacity

(198 bins)

, including

.

Library

Capacity

(compressed*)

Page 35

Chapter 1 Library Description

Library Component s

Note:

* Compressed capacity assumes a 2:1 compression ratio.

When fewer than 10 tape drives are installed, the tape drives must

occupy consecutive drive bays, beginning with drive bay 0.

The drives used in the P2000 library are more reliable than

standard drives due to the automated environment.

The P2000 can be populated simultaneously with DLT, SDLT, or

LTO tape drives .

If a DLT drive experiences read/write errors when the AutoClean

function is enabled, the library issues an error messa ge stating that

drive cleaning is required. Without user intervention, the

IntelliGrip CHM replaces the data cartridge with a cleaning

cartridge. When the cleaning procedure finishes, the CHM returns

the data cartridge to the drive.

Note:

When a DLT cleaning cartridge has completed its 20-use

limit, it is automatically exported from the library,

requiring a new one to be loaded through the load port.

Load Port and Magazines

The load port is a mechanical device in the front panel of the

1

library that enables you to import or export tape cartridges to and

from the library via two tape cartridge magazines without

interrupting library operations.

The DL T/SDLT load port uses two removeable 6-bin t ape cartridge

magazines (see figure 8

).

The LTO load port uses two stationary 4-bin tape cartridge

magazines (see figure 9

ATL P2000 Series Automated Tape Library User’s Guide 15

).

Page 36

Chapter 1 Library Description

A

F

L

0 5 3

Library Components

Figure 8 DLT/SDLT

Load Port

Figure 9 LTO Load

Port

Metal

tab

Metal tab

6-bin

magazine

DLT/SDLT

cartridge

Load port

assembly

LTO

cartridge

Stationary

4-bin

magazine

Load port

assembly

16 ATL P2000 Series Automated Tape Library User’s Guid e

Page 37

Chapter 2

Basic Library Operations

This chapter provides an overview of the touch screen graphical

user interface (GUI) and describes the following basic library

operating procedures:

Installing tape cartridges

•

Preparing the library for operation

•

Turning the library on and off

•

Using the touch screen GUI

•

Obtaining library status

•

Changing the touch screen GUI security level

•

Operating the load port

•

Inserting tape cartridges

•

Manually ejecting a cartridge

•

2

Installing Tape Cartridges

To install tape cartridges:

Label each cartridge

1

Set the write-protect switch

2

Place cartridges in the fixed library bins

3

ATL P2000 Series Automated Tape Library User’s Guide 17

2

Page 38

Chapter 2 Basic Library Operations

Installing Tape Cartridges

Taking ESD Precautions

Caution:

Handle tape cartridges with care. Do not drop or

bang them, or place them near sources of

electromagnetic interference. Rough handling can

displace the tape leader, making the cartridge

unusable and potentially hazardous to the tape

drives.

Components within the P2000 library contain static -sensitive parts.

2

To prevent damage to these parts while performing installation,

maintenance, or replacement procedures, observe the following

precautions:

Keep the library turned off during all installation,

•

maintenance, and replacement procedures.

Note:

Hosts without a direct SCSI interface r equir e external

communications bus converters.

Keep the library power cord connected to a grounded power

•

outlet except when working with AC electrical components.

Warning:

Avoid contact with the power supplies, EMI

filter, and all other AC electrical components

while the library is connected to a power outlet.

Use an antistatic wrist strap when touching i nternal library

•

components. To use the wrist strap properly, place the band

around your wrist and attach the clip to the library frame. Keep

the strap on until you are ready to close the library doors.

Keep static-sensitive parts in their shipping containers until

•

ready for installation.

Do not place static-sensitive parts on any metal surface. If you

•

need to put down a static-sensitive part, place it inside its

protective shipping bag or on a grounded antistatic mat.

18 ATL P2000 Series Automated Tape Library User’s Guid e

Page 39

Chapter 2 Basic Library Operations

Installing Tape Cartridges

• A v oid dir e ct contact with st atic-se nsitive parts . Avoid touching

connectors and discrete components.

• Close library door and access panel when not working on the

library.

• Be very careful when insta lling the library or handling

components in dry climates or environments where cold

weather heating is used. Environments such as these with

lower relative humidity have greater potential to produce static

electricity.

DLT/SDLT Cartridges

Figure 10 Inserting a

Bar Code Label (DLT/

SDLT))

Note:

In environments with high potential for static

electricity, you may want to take additional

precautions such as the use of an antistatic smock or

a grounded antistatic mat.

The following shows you how to label DLT/SDLT tape cartridges,

2

as well as setting the write-protect switch and proper orientation.

Labeling

Attaching a bar code label to each tape cartridge enables the library

to identify the cartridge quickly, thereby speeding up inventory

time.

Place the label in the slide-in slot on the front of the cartridge (see

figure 10

).

2

Slide-in slot

ATL P2000 Series Automated Tape Library User’s Guide 19

Page 40

Chapter 2 Basic Library Operations

A F L 0 5 3

DLTtape IV

Installing Tape Cartridges

Figure 11 DLT and

SDL T Cartridge s

Note:

Only use bar code labels that have been designed for

cartridges. Do not adhere labels to a cartridge anywhere

except the slide-in slot.

Setting the Write-Protect Switch

Each tape cartridge has a write-protect switch similar to that

shown in figure 11

be written to the cartridge (

cartridge is protected from being erased or overwritten (

protected

Proper Insertion Orientation

).

Refer to figure 11

. This switch determines whether new data can

write-enabled

) or whether data on the

write-

for proper label placement, write protection

settings and insertion orientation.

Insert this end into the bin

2

2

Insertion arrow

Barcode label

20 ATL P2000 Series Automated Tape Library User’s Guid e

Orange

window

Write

protect

Slide left Slide right (default)

Write

enable

(DLT cartridge shown)

Page 41

Chapter 2 Basic Library Operations

A B C 1 2 3 L 1

Installing Tape Cartridges

LTO Cartridges

Figure 12 LTO

Cartridge

2

LTO tape cartridges are different in size to the DLT/SDLT

cartridges as well as in the barcode labeling and write-protect

switch setting.

Adhesive-backed bar code labels are used on LTO tape cartridges.

Refer to figure 11 for proper label placement, write protection

settings and insertion orientation.

Write Protect

Switch

Slide left

(default)

Write

enable

Write

protect

Slide right

Insert this end into the bin

Insertion arrow

Placing Tape Cartridges in the Library

Barcode label

Caution:

LTO tape drive media cannot be degaussed due to

the fact that it uses “magnetic servos". Do not

attempt to degauss LTO tape drive media. If this

media is degaussed, it will no longer work.

Place a tape cartridge in each fixed storage bin on the back wall of

the library and on the inside of the front door. Be sure all cartridges

2

are properly oriented with the barcode facing you and that they

are fully seated in the bins.

ATL P2000 Series Automated Tape Library User’s Guide 21

Page 42

Chapter 2 Basic Library Operations

Preparing the Library for Operation

Preparing the Library for Operation

To prepare the library for operation:

Close the library door and access panels

•

Connect the host workstations

•

Closing the Library Doors and Access Panels

The library has one front door and one back access panel.

2

Close and lock the front door.

1

Turn the door latch to secure the door to the library frame.

a

Lower the latch over the door lock.

b

Using the key from the accessory kit, loc k the la tch in plac e.

c

Using the key from the accessory kit, lock the latches in

d

place.

Close and lock the back access panel using a 5/32 hex wrench

2

(not provided).

2

Connecting Host Workstations

Connect the SCSI cables and jumpers as shown in the applicable

2

figures.

Note:

ATL ships sufficient SCSI cables and terminators with

this library to set up two-drives per SCSI bus, as well as

adequate SCSI jumper cables to accommodate up to 4

drives per SCSI bus.

Figure 13

and figure 14 on the following pages show the

recommended cabling configurations for the 10-drive and 8-drive

library, respectively.

22 ATL P2000 Series Automated Tape Library User’s Guid e

Page 43

Figure 13 Cabling

Configuration—10Drive Library

Drive Column 1

Tape Drive

Drive position 8

SCSI ID 2

Tape Drive

Drive position 9

SCSI ID 3

Tape Drive

Drive position 0

SCSI ID 2

Tape Drive

Drive position 1

SCSI ID 3

Tape Drive

Drive position 2

SCSI ID 4

Tape Drive

Drive position 3

SCSI ID 5

Tape Drive

Drive position 4

SCSI ID 2

Tape Drive

Drive position 5

SCSI ID 3

Tape Drive

Drive position 6

SCSI ID 4

Tape Drive

Drive position 7

SCSI ID 5

J 8

SCSI Port H

Chapter 2 Basic Library Operations

Preparing t he Library for Operation

SCSI Diff. Terminator

Robotics Backplane

Pass Through

Comm Port

J15

J14

Robotics

Controller

J13

SCSI Distribution Assembly

J 6J 7

J 5

J 4 J 2 J 10

J 3 J 1 J 9

SCSI Port G

SCSI Port F

SCSI Port E

SCSI Port D

SCSI Port C

SCSI Adapter,

Differential

J12

SCSI Port B

SCSI Port A

RS-232

Diagnostics Port

J11

SCSI Port J

SCSI Port I

ATL P2000 Series Automated Tape Library User’s Guide 23

Page 44

Chapter 2 Basic Library Operations

Preparing the Library for Operation

Figure 14 Cabling

Configuration—8Drive Library

Drive Column 1

Tape Drive

Drive position 8

SCSI ID 2

Tape Drive

Drive position 9

SCSI ID 3

Tape Drive

Drive position 0

SCSI ID 2

Tape Drive

Drive position 1

SCSI ID 3

Tape Drive

Drive position 2

SCSI ID 4

Tape Drive

Drive position 3

SCSI ID 5

Tape Drive

Drive position 4

SCSI ID 2

Tape Drive

Drive position 5

SCSI ID 3

Tape Drive

Drive position 6

SCSI ID 4

Tape Drive

Drive position 7

SCSI ID 5

J 8

SCSI Port H

SCSI Diff. Terminator

Robotics Backplane

Pass Through

Comm Port

J15

J14

Robotics

Controller

J13

SCSI Distribution Assembly

J 6J 7

J 5

J 4 J 2 J 10

J 3 J 1 J 9

SCSI Port G

SCSI Port F

SCSI Port E

SCSI Port D

SCSI Port C

SCSI Adapter,

Differential

J12

SCSI Port B

SCSI Port A

RS-232

Diagnostics Port

J11

SCSI Port J

SCSI Port I

24 ATL P2000 Series Automated Tape Library User’s Guid e

Page 45

Chapter 2 Basic Library Operations

Turning the Library On and Off

Turning the Library On and Off

This section explains how to:

Turn the library on

•

Place the library on-line or off-line

•

Turn the library off

•

Test the installation

•

Turning On the Library

To turn on the library:

2

Verify that:

1

• Power cables are firmly in place

• All doors are closed

T urn on the power switch located behind the small sliding door

2

below the touch screen GUI.

After several seconds, verify that the current state of the library

3

(“System On-line” or “System Off-line”) appears in the System

State display on the touch screen GUI.

2

Placing the Library On-line or Off-line

Turning Off the Library

With the library turned on, press the Standby button on the touch

2

screen GUI.

Pressing the Standby button toggles the library between on-line

and off-line states.

To turn off the library:

2

Place the library off-line by pressing the Standby button.

1

The library robotics completes any current commands and then

stops.

ATL P2000 Series Automated Tape Library User’s Guide 25

Page 46

Chapter 2 Basic Library Operations

Using the Touch Screen GUI

2

Verify that the touch screen GUI display indicates “System Offline.”

3

Verify that the CHM is empty by checking the Overview screen

on the touch screen GUI (see chapter 3,

If there is a tape cartridge in the CHM, perform a Move

command to place the cartridge in an available bin.

4

Turn off the power switch located below the touch screen GUI.

Operator Commands).

Note:

Wait ten seconds before turning on the power switch

again.

Using the Touch Screen GUI

The touch screen GUI is activated by touching the screen, and is

located on the front of the library. The menus displayed on the

touch screen GUI allow you to obtain information about the

library, execute library commands, and test library functions (see

figure 15

The touch screen GUI’s functions are grouped into the following

four screens:

• Overview screen—displays current tape drive, CHM, and load

• Tapes screen—displays tape drive, storage bin, load port, and

• Operator screen—contains library configuration and control

).

port content and activities

gripper inventories

functions (password protected)

2

• Service screen—contains reporting functions, system tests, and

service commands (password protected)

• Multi-Unit screen—contains multi-unit configuration and

calibration

26 ATL P2000 Series Automated Tape Library User’s Guid e

Page 47

Figure 15 Touch

Load Port

System

Off-line

Standby

Overview Tapes Operator

Back Forward

Home

U

Stop

ATL

PRODUCTS

ATL

PRODUCTS

P2000

SERIES

Service

http:/www.atlp.com/cust.html

Help: (USA) + 949-477-7924

Help in USA: 800-284-5101

BBS: (USA) + 949-477-7736

email: atlhelp@atlp.com

Revision: Application: 2.01

Revision: Boot Block: 1:11

Screen GUI—Initial

Screen

Chapter 2 Basic Library Operations

Using the Touch Screen GUI

Table 5, “Touch Screen GUI Functions,” on page 28, lays out the

various functions of the touch screen GUI.

ATL P2000 Series Automated Tape Library User’s Guide 27

Page 48

Chapter 2 Basic Library Operations

Using the Touch Screen GUI

Table 5 Touch

Screen GUI Functions

Overview

Screen Tapes Screen Operator Screen* Service Screen*

Status display

•

Tape drives

•

Activity

•

Load port

Inventory

display

•

Tape drives

•

Storage bins

•

Load port

•

Transport

(CHM)

Configure

•

Configure Library

•

Configure Options

•

Control

•

Move Cartridges

•

Inventory Tapes

•

Calibrate Library

•

Unload Drive

•

Unload Imp/Exp

(CHM)

Reports

•

Statistics

•

Actuator

•

SysTest Results

•

Auto Clean

•

Tests

•

SysTest Library

•

Operate Axes

•

Miscellaneous

•

Initialize

Nonvol Stats

•

Initialize

Nonvol Config

•

Change

Password

Multi-Unit

Screen*

Configuration

Calibration

*These screens are password protected.

Opening a Screen

2

To open one of the four main screens, touch the desired tab at the

top of the touch screen GUI. The Overview and Tapes screens are

accessible to any user. The Operator and Service screens require a

password.

Once the desired screen appears on the touch screen GUI, you can

view information or press buttons to execute commands and open

other screens.

28 ATL P2000 Series Automated Tape Library User’s Guid e

Page 49

Chapter 2 Basic Library Operations

Load Port

System

Off-line

Standby

Overview Tapes Operator

Back Forward

Home

U

Stop

ATL

PRODUCTS

ATL

PRODUCTS

P2000

SERIES

Service

http:/www.atlp.com/cust.html

Help: (USA) + 949-477-7924

Help in USA: 800-284-5101

BBS: (USA) + 949-477-7736

email: atlhelp@atlp.com

Revision: Application: 2.01

Revision: Boot Block: 1:11

Using the Touch Screen GUI

Library Status Information

Figure 16 Library

Status Indicators

Some information about the library firmware version, security

2

status, and library status can be found on the left side of the GUI.

• Company logo

pressed

• System state display

—displays a company information screen when

, as well as the application level and boot block level

—shows the current state of the library

(system on-line, system off-line, system stopped, door open,

and so on).

• Lock icon

—shows the current security level at the touch screen

GUI. Five security levels are available: service (S), operator (O),

user (U), import only (I), and locked (L). Table 6

describes the

attributes of each security level.

Company logo

System

state

display

.

Exiting a Screen

Lock

icon

2

To exit any screen, press the Back or Home button.

While the command is executing, the touch screen GUI displays a

Command In Progress dialog box with an Abort button. Pressing

Abort cancels the command and stops the ongoing operation.

ATL P2000 Series Automated Tape Library User’s Guide 29

Page 50

Chapter 2 Basic Library Operations

Load Port

System

Off-line

Standby

Overview Tapes Operator

Back Forward

Home

U

Stop

ATL

PRODUCTS

ATL

PRODUCTS

P2000

SERIES

Service

http:/www.atlp.com/cust.html

Help: (USA) + 949-477-7924

Help in USA: 800-284-5101

BBS: (USA) + 949-477-7736

email: atlhelp@atlp.com

Revision: Application: 2.01

Revision: Boot Block: 1:11

Using the Touch Screen GUI

After pressing Abort, it is still necessary to pr ess the Back button to

exit the screen associated with the aborted command.

Library Controls

Figure 17 Li brary

Controls

2

Library controls are located along the top and left side of the touch

screen GUI in the horizontal and vertical bars (see figure 17

Back Forward Home Contrast

Standby

button

Load Port

button

Stop

button

).

These controls function as follows:

• Home button—returns to the home (initial) screen.

• Forward button—moves forward screen by screen through

previous selections.

30 ATL P2000 Series Automated Tape Library User’s Guid e

• Back button—moves backward screen by screen through

previous selections.

• Contrast buttons—adjust the contrast of the touch screen GUI

screen.

• Standby button—toggles the library between on-line and off-

line states.

Page 51

Chapter 2 Basic Library Operations

Obtaining Library Status

• Load Port button—releases and locks the load port door. If the

load port is locked in the closed position, pressing this button

releases the load port and then lock s the door. If the load port is

locked in the open position, pressing this button unlocks the

load port, allowing you to rotate the load port to the closed

position where it automatically locks.

• Stop button—halts library activity immediately by cutting

power to library robotics. Pressing the Stop button a second

time restores power to library robotics.

Note: The default passwords are:

• Service “5678”

• Operator “1234”

• User “2222”

• Import Only “1111”

For more information on password and security levels, refer to

Changing the Touch Screen GUI Security Levels

Obtaining Library Status

The Overview and Tapes screens on the touch screen GUI provide

library status. The Overview screen displays a “snapshot” of the

tape drive, robot activity, and load port inventory (see figure 18

The Tapes screen displays the inventory of all elements in the

library (see figure 20

To display the Overview or T apes scr ee n, pre ss the appr opriate tab

on the touch screen GUI.

ATL P2000 Series Automated Tape Library User’s Guide 31

on page 35.

2

).

).

Page 52

Chapter 2 Basic Library Operations

System

Off-line

Standby

Load Port

Overview Tapes Operator

Back Forward

Home

U

Drives Activity Load Port

D00

ANF 120

Ready

D02

empty

Ready

D01

???

Ready

D03

ANF 123

Ready

P01

ANF147

P00

ANF146

P03

ANF149

P02

ANF148

GRP

empty

Stop

ATL

PRODUCTS

Obtaining Library Status

Overview Screen

Figure 18 Overview

Screen

2

The Overview screen prov ides informa tion f or the following items:

Drives

•

Activity

•

Load port

•

Element

number

Element

status

Cartridge

present

D03

ANF 123

Ready

Compression

enabled

Bar code

number

Write-

enabled

Drives

The Drives area reports whether:

A tape drive contains a tape cartridge

•

32 ATL P2000 Series Automated Tape Library User’s Guid e

2

Page 53

Figure 19 Tape Drive

D03

ANF 123

Ready

Compression ON

Write Protect OFF

DLT8000 SCSI ID: 05

CompacTape IV, 35/70 Gb

Drive Code Rev: 000037

Controller Code Rev: 96

S/N: JF71100038

System

Off-line

Standby

Load Port

Overview

Tapes Operator

Back Forward

Home

U

Tape Drive Status

Stop

Prevent: OFF

Cleaning Required: OFF

Cleaning Requested: OFF

Tape Remain: 033769 MB

Compr Ratio (R): N/A

Compr Ratio (W): N/A

Clean Cart Loads: 0000005

Hrs Since Cleaned: 00326

Clean Tape Used 000 times

ATL

PRODUCTS

Status Screen

Chapter 2 Basic Library Operations

Obtaining Library Status

• The tape cartridge is write-enabled or write-protected

• Compression is enabled

It also displays the bar code number of the cartridge.

For a more detailed screen showing an individual drive’s status,

press the screen anywhere in the Drives area to display the Tape

Drive Status screen (see figure 19

). Use the arrow buttons at the

bottom of the box to scroll to the desired drive.

To return to the Overview screen, press the screen anywhere in the

Tape Drive Status box.

Activity

The Activity area shows the sourc e element, the transport medium,

and the destination element involved in the activity; the current

location of the tape cartridge; and the progress of the activity.

ATL P2000 Series Automated Tape Library User’s Guide 33

2

Page 54

Chapter 2 Basic Library Operations

System

Off-line

Standby

Load Port

Overview Tapes Operator

Back Forward

Home

U

Drives

000

ANF 099

001

ANF 100

002

ANF 101

003

ANF 102

P00

ANF 146

P01

ANF 147

P02

ANF 148

P03

ANF 149

00

EMPTY

GRP

EMPTY

01

EMPTY

02

EMPTY

03

EMPTY

Storage Load Port Transport

Stop

ATL

PRODUCTS

Obtaining Library Status

Tapes Screen

Figure 20 Tapes

Screen

Load Port

The Load Port area identifies tape cartridges currently stored in

either magazine in the load port. Use the arrow button to view

contents not currently displayed.

2

The Tapes screen identifies the tape cartridges residing in the

following elements (see figure 20

Drives

•

Storage (fixed storage bins)

•

Load port

•

Transport (gripper)

•

):

2

34 ATL P2000 Series Automated Tape Library User’s Guid e

Page 55

Chapter 2 Basic Library Operations

Changing the Touch Screen GUI Security Levels

Viewing Storage and Load Port Elements

The Drives, Storage, and Load Port categories may contain too

many elements to display at once. To scrol l through these element s,

use the arrow buttons at the bottom of each category.

You can also expand the Drives, Storage, or Load Port list to fi ll the

screen by touching the desired category anywhere above the

scrolling arrows. To re turn to the start of the Tapes screen, pr ess the

button.

Back

Changing the Touch Screen GUI Security Levels

There are five le vels of securit y for the P20 00 librar y’s touch screen

GUI (see Table 6

• Service (S)

set of screens and all functions on the system bar.

• Operator (O)

and all functions on the system bar.

on page 36):

—provides access to both the Operator and Service

—provides access to the Operator set of screens

2

2

• User (U)

protected (Overview and Tapes screens) and all functions on

the status bar.

• Import Only (I)

screens and the Load Port button on the system bar (no Stop or

Standby).

• Locked(L)

only.

The security level indicator (lock icon) at the lower left corner of

the touch screen GUI indicates the current security level ( S, O, U, I,

or L).

ATL P2000 Series Automated Tape Library User’s Guide 35

—provides access to screens that are not password-

—provides access to Overview and Tapes

—provides access to Overview and Tapes screens

Page 56

Chapter 2 Basic Library Operations

Changing the Touch Screen GUI Security Levels

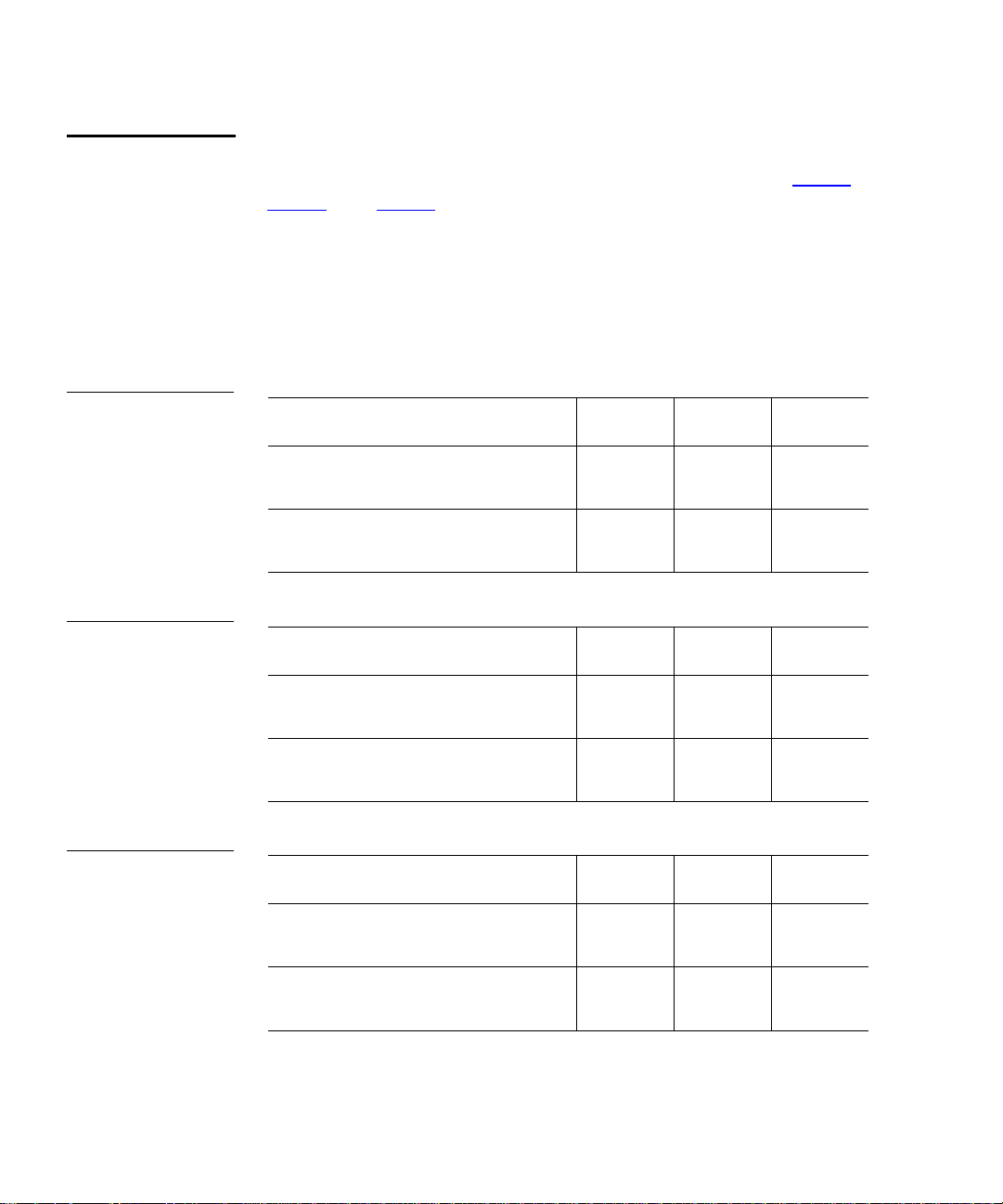

Table 6 S ecurity

Levels (listed from

highest to lowest)

Lock

Icon

Level

Service S Yes Yes Yes Yes Yes Yes Yes

Operator O Yes Yes Yes Yes No Yes Yes

User U Yes Yes Yes No No Yes Yes

Multi-Unit O Yes No No No No No No

Import

Only

Locked L No Yes Yes No No No No

Indicator

I Yes Yes Yes No No Yes No

Securing the T ouch Screen GUI

Password

Protected

When the User security level is set, access is restricted to the

2

Operator and Service screens. Since these screens control library

Overview

Screen

Access

Tapes

Screen

Access

Operator

Screen

Access

Service

Screen

Access

Load

Port

Access

Stop and

Standby

Access

configuration, testing, and initializing functions, the User security

level is appropriate default condition for routine library operation.

Changing Security Levels

2

To change security levels:

Press the Lock icon.

1

The Password screen appears (see figure 21

Press the desir ed sec urity l evel b utt on (Se rvice, Operator, User,

2

Import Only, or Locked).

36 ATL P2000 Series Automated Tape Library User’s Guid e

).

Page 57

Figure 21 Password

System

Off-line

Standby

Load Port

Back Forward

Home

O

Enter Password

Enter

9 0

7 8

5 6

3 4

1 2

Enter Password: _

Stop

ATL

PRODUCTS

Service

Tapes

Operator

Security

Level:

Operator

Import Only

Locked

User

Service

Screen

Chapter 2 Basic Library Operations

Changing the Touch Screen GUI Security Levels

3

Enter a password if necessary.

A password is requir ed to enter a higher security lev el than the

current level.

4

Press the Select button.

A screen appears indicating that the new security level has

been set successfully.

5

Press Okay.

The lock icon displays the new security level (S, O, U, I, or L).

Note:

This procedure is especially useful to change fr om the

Operator or Service levels to the User level after

executing an Operator or Service level command.

Note:

ATL P2000 Series Automated Tape Library User’s Guide 37

If the touch screen GUI is accessed from the Service

(S) or Operator (O) level, and no activity has occurr ed

for 15 minutes, the touch screen GUI will return to

the initial screen (see figure 15

).

Page 58

Chapter 2 Basic Library Operations

Operating the Load Port

Operating the Load Port

After pressing the Load Port button on the touch screen GUI, the

library will release the lock on the load port (you will hear an

audible ‘click’). The touch screen GUI displays “Wait Open Load

Port.” Pull on the load port’s finger grip. The load port pulls

outward about an inch to its unlocked position which allows its

interior drum to be rotated 180

unloading.

Warning:

After loading or unloading the magazines, rotate the load port

drum back 180

Note:

Opening or closing the load port door presents

mechanical hazards. Use both hands to pull or push

the load port finger grip and use the top and bottom

surfaces of the load port drum to keep fingers out of