Page 1

ATL P1000 Series

Tape Library

User’s Guide

6221101-03

Ve r. 3, Rel. 0

Page 2

ATL P1000 Series User’s Guide, 6221101-03, Ver. 3, Rel. 0, September 1999. Pri nted in the USA.

ATL Products, Inc. provides this publication “as is” without warrant y of any k ind , eit her express or implied, including but

not limited to the implied warranties of merchantability or fitness for a particular purpose. ATL Products, Inc. may revise

this publication from time to time without notice.

COPYRIGHT STATEMENT

Copyright 1999 by ATL Products, Inc. All rights reserved.

Your right to copy this manual is limited by copyright law. Making copies or adaptations without prior written

authorization of ATL Products, Inc. is prohibited by law and constitutes a punishable violation of the law.

TRADEMARK STATEMENT

Prism Library Architecture, IntelliGrip, WebAdmin, and WebLibrarian are all trademarks of ATL Products, Inc.

Other trademarks may be mentioned herein which belong to other companies.

FCC STATEMENT

This equipment has been tested a nd foun d to compl y w ith th e limit s fo r a Class A digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to prov ide r easonable pr otect ion against harmful int erfer ence when the equipment is

operated in a commercial environment. This equipment generates , uses, and can radiate radio fr equency ener gy an d, if not

installed and used in accordance with the instruction manual, may cause harmful interference to radio communications.

Any changes or modifications made to this equipment may void the user's authority to operate this equipment.

Operation of this equipment in a residential area may cause interference in which case the user at his own expense will be

required to take whatever measures may be required to correct the interference.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following c onditions: (1) th is device may not

cause harmful interference, an d (2) this device must accept any interfer ence r eceived, in cluding interfer ence th at may cause

undesired o peration.

INDUSTRY CANADA (DIGITAL APPARATUS)

Interference-Causing Equipment Standard

ICES-003 Issue 2

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Reglément sur le matériel brouilleur du Canada.

CISPR-22 WARNING!

This is a Class A pr oduct. In a domestic en vironment this product may cause radi o in terference in which case the user may

be required to take adequate me asures.

ACHTUNG!

Dieses ist ein Gerät der Funkstörgrenzwertklasse A. In Wohnbereichen können bei Betrieb dieses Gerätes

Rundfunkstörungen auftreten, in welchen Fällen der Benutzer für entspr echende Gegenmassnahmen verantwortlich ist .

A TTENTION!

Ceci est un produit de classe A. Dans un environment domestique, ce produit peut causer des interférences

radioélectriques. Il appartient alors à l'utilisateur de prendre les mesures appropriées.

6207947-06cA 66

Page 3

NOTICE FOR USA AND CANADA ONLY

If shipped to USA, use the UL LISTED power cord specified below for 100-120 V operation. If shipped to Canada, use the

CSA CERTIFIED power cord specified below for 100-120V operation.

Plug Cap Parallel blade with ground pin (NEMA 5-15P configuration)

Cord Socket IEC 320 connector rate d 250V 15A

Cord Type: SJT, three 16 AWG or 18 AWG wires

Length Maximum 15 feet (4.5m)

Rating Minimum 10 A, 125 V

ATTENTION

LIRE LA REMARQUE DANS LE MODE D'EMPLOI.

REMARQUE

CETTE REMARQUE NE CONCERNE QUE LES ÉTATS-UNIS ET LE CANADA.

En cas d'envoi aux États-Unis, utiliser le cordon d'alimentation CERTIFIÉ UL et convenant pour 100-120 V.

En cas d'envoi au Canada, utiliser le cordon d'alimentation CERTIFIÉ CSA et convenant pour 100-120 V.

Fiche Broches parallèles avec une broche de mise à la terre (configuration NEMA 5-15P)

Cordon Type: SJT, trifilaire 16 AWG ou 18 AWG

Longeur Maximum 15 pieds (4.5m)

Capacité Minimum 10 A, 125 V

BATTERY STATEMENT

Caution

The Dallas Semiconductor DS1230AB-200 component on th e ro botic contr oller bo ar d inside t his pr oduct conta ins a lith ium

battery. Lithium is a hazardous material that must be disposed of in accordance with local, state, and federal law.

Forsigtig

Båndbiblioteket indeholder et lithiumbatteri. Dallas Semiconductor DS1230AB-200 på robotkontroltavlen indeholder et

lithiumbatteri. Lithium kan anses for at være et sundhedsfarligt materiale. Kassér dette batteri i overensstemmelse med

lokale og nationale lovbestemmelser.

Huomautus

Nauhakirjastossa on litiumparisto. Robottiohjainkortin Dallas Semiconductor DS1230AB-200-puolijohteessa on

litiumparisto. Litium voidaan luokitella vaaralliseksi aineeksi. Pariston hävittämisessä on noudatettava viranomaisten

antamia ohjeit a ja määräyksiä.

Attention

La bibliothèque de bande contient une pile au lithium. Le Dallas Semiconductor DS1230AB-200 sur la carte robotic

contrôleur contient une pile au lithium. Le lithium peut être considéré comme matériau dangereux. Jeter cette pile

conformément aux lois locales, d’état et fédérales.

Page 4

Achtung!

Die Bandbibliothek enthält eine Lithiumbatterie. Der Halbleiter Dallas Semiconductor DS1230AB-200 auf dem RoboterController enthält ein e Lithiumb at terie. Lithium gilt als Schadstoff. Bei der Entsorgung dieser Batterie alle entsprechenden

kommunalen, staatlichen und bundesweiten Vorschriften beachten!

Attenzione

La libreria a nastro magnetico contiene una batteria al litio. Il semiconduttore Dallas Semiconductor DS1230AB-200 sulla

scheda controller robotic contiene una batteria al litio. Il litio può essere considerato un materiale pericoloso. Eliminare

queste batterie in conformità alle normative locali e statali vigenti.

Forsiktig

Kassettbiblioteket inneholder et litiumbatteri. Enheten Dallas Semiconductor DS1230AB-200 på robotkontrollkortet

inneholder et litiumbatteri. Litium kan anses som et farlig materiale. Batteriet skal kastes i henhold til lokal og nasjonal

lovgivning.

Precaución

La biblioteca de cintas contiene una pila de litio. El semiconductor Dallas Semiconductor DS1230AB-200 en el tablero

controlador robotic contiene una pila de litio. El litio puede considerarse como un material peligroso. Deseche esta pila de

acuerdo con las leyes municipales, estatales y federales.

Varning!

Magnetbandsbibliot eket inn ehå ller ett lit iumb atter i. Dal las Sem icondu ctor D S1230 AB-20 0 på r ob otsty rkor tet inn ehå ller ett

litiumbatteri. Litium kan anses vara ett farligt material. Kassera detta batteri i enlighet med lokala och statliga lagar och

förordningar .

Page 5

Contents

Contents

Preface

Chapter 1

Library Description......................................................................................1

Configuration Options..................................................................................3

Library Elements ...........................................................................................5

Robotics Operation...................................................................... ......... .........7

Operator-Accessible Components..............................................................8

Front Panel...............................................................................................8

Load and Bulk Packs............................................................................10

Back Panel..............................................................................................11

Tape Drives............................................................................................12

0

Chapter 2

Installing the P1000 Library.....................................................................13

Site Requirements........................................................................................14

Floor Space.............................................................................................14

Floor Clearance .....................................................................................15

Floor Strength and Inclination............................................................15

Overhead Clearance.............................................................................15

Power and Grounding .........................................................................15

Environmental Requirements.............................................................16

Unpacking the P1000 ................................................ ......... .........................17

Unloading Space Requirements .........................................................17

Uncrating the Library...........................................................................18

Checking the Contents.........................................................................20

Installing the Slide Assembly in the Rack.........................................21

Removing the Library from the Pallet...............................................21

Removing the Internal Packing Materials.........................................27

Preparing and Inserting Tape Cartridges................................................30

Labeling a Tape Cartridge...................................................................30

Setting the Write-protect Switch.........................................................32

Placing Tape Cartridges in the Fixed Storage Bins..........................32

Placing Tape Cartridges in the Load and Bulk Packs .....................34

Connecting Host Computers.....................................................................35

SCSI Cabling Guidelines......................................................................35

vATL P1000 Series User’s Guide

Page 6

Contents

SCSI Cabling Examples.......................................................................35

Turning On the Library..............................................................................39

Configuring and Testing the Library.......................................................40

Chapter 3

Basic Operations ........................................................................................41

Using the GUI..............................................................................................42

GUI Components.................................................................................. 42

GUI Screens...........................................................................................45

Obtaining Library Status............................................................................46

Overview Screen................................................................................... 46

Tapes Screen..........................................................................................48

Changing the GUI Security Level.............................................................49

Securing the GUI .............................................. ......... ......... ..................49

Performing Manual Operations................................................................51

Turning On the Library.......................................................................51

Placing the Library On-line.................................................................51

Placing the Library Off-line ................................................................52

Turning Off the Library.......................................................................52

Inserting Tape Cartridges ...................................................................52

Opening the Library Doors.................................................................54

Manually Ejecting a Cartridge............................................................55

Chapter 4

Operator Commands.................................................................................57

Accessing the Operator Screen .................................................................58

Configuring the Library.............................................................................60

Configuring Library Options....................................................................62

Moving a Cartridge ....................................................................................64

Performing an Inventory ...........................................................................66

Calibrating the Library............................................................................... 67

Exercising the Library ................................................................................69

Unloading a Drive ......................................................................................70

Unloading the Load Port ...........................................................................71

Chapter 5

Service Commands....................................................................................73

Accessing the Service Screen.....................................................................74

Generating Reports.....................................................................................76

Testing the Library......................................................................................79

Performing a System Test ...................................................................79

Performing a Service Calibration.......................................................80

vi ATL P1000 Series User’s Guide

Page 7

Contents

Initializing Nonvolatile Information........................................................81

Changing Passwords ..................................................................................83

Chapter 6

Troubleshooting.........................................................................................85

Start-up Problems........................................................................................86

GUI Problems...............................................................................................87

Robotics Problems....................................................................... ......... .......88

Operating Problems....................................................................................90

Tape Drive Problems ......................................................... ......... ................92

Appendix A

Specifications....................................................................................... .......93

Appendix B

Installing the Slide Assembly in the Rack............................................97

Verifying the Rack Requirements.............................................................98

Rack Current Rating Consideration...................................................98

Grounding..............................................................................................98

Temperature ..........................................................................................98

Determining the Mounting Position.........................................................99

Installing the Slide Assembly in the Rack..............................................101

Adjusting the Slide Assembly .................................................................103

Adjusting the Slide Assembly on the Mounting Brackets............103

Adjusting the Slide Assembly Tray on the Slide Rails..................105

Glossary

Index

ATL P1000 Series User’s Guide vii

Page 8

Contents

viii ATL P1000 Series User’s Guide

Page 9

Figures

Figures

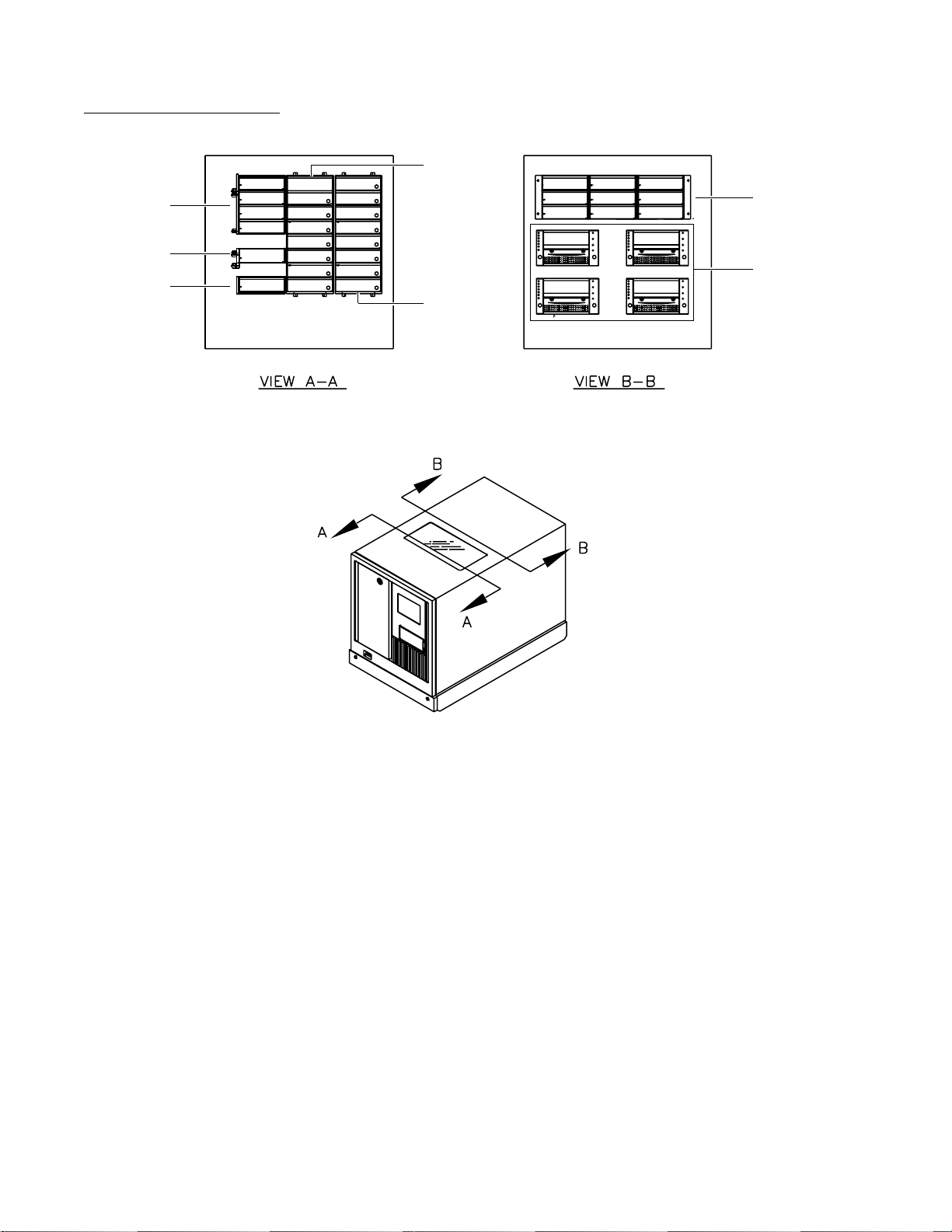

Figure 1 P1000 Front View, Stand-alone Library..................................1

Figure 2 P1000 Front View, Rack-mount Library.................................2

Figure 3 P1000 Library, Back View.........................................................4

Figure 4 Library Elements............................................. ......... ..................6

Figure 5 P1000 Front Panel ......................................................................8

Figure 6 GUI: Initial Screen......................................................................9

Figure 7 Load and Bulk Packs...............................................................10

Figure 8 Back Panel, Stand-alone Library............................................11

0

Figure 9 Floor Space Requirements, Stand-alone Library.................14

Figure 10 Floor Space Requirements, Rack-mount Library................15

Figure 11 AC Power Receptacle.............................................. ......... .......16

Figure 12 Unloading Space Requirements, Stand-alone Library.......18

Figure 13 Uncrating the Stand-alone Library........................................19

Figure 14 Uncrating the Rack-mount Library.......................................20

Figure 15 Removing the Foam Supports, Stand-alone Library..........22

Figure 16 Removing the Stand-alone Library from the Pallet............22

Figure 17 Lifting the Rack-mount Library from the Pallet..................24

Figure 18 Placing the Library on the Slide Assembly Tray.................25

Figure 19 Locking the Slide Tray in the Rack........................................26

Figure 20 Removing the Load and Bulk Packs.....................................28

Figure 21 Removing the Shipping Restraint .........................................29

Figure 22 Bar Code Label Dimensions...................................................31

Figure 23 Inserting a Bar Code Label .....................................................31

Figure 24 Setting the Write-protect Switch............................................32

Figure 25 Correct Tape Cartridge Orientation......................................33

Figure 26 Single-Host SCSI Configuration............................................36

Figure 27 Typical Two-Host SCSI Configuration.................................37

Figure 28 Five-Host SCSI Configuration ...............................................38

ixATL P1000 Series User’s Guide

Page 10

Figures

Figure 29 GUI: Initial Screen...................................................................42

Figure 30 Navigating through the GUI Screens...................................44

Figure 31 GUI Screens.............................................................................. 45

Figure 32 Overview Screen......................................................................46

Figure 33 Overview Screen with Expanded Tape Drive Status......... 47

Figure 34 Tapes Screen.............................................................................48

Figure 35 Password Screen......................................................................50

Figure 36 Inserting a Tape Cartridge.....................................................54

Figure 37 Enter Password Screen...........................................................58

Figure 38 Operator Screen.......................................................................59

Figure 39 Configure: Library Screen......................................................60

Figure 40 Configure: Library Settings Screen.......................................61

Figure 41 Configure: Options Screen.....................................................63

Figure 42 Control: Move Cartridge Screen ...........................................64

Figure 43 Calibrate Library Screen.........................................................67

Figure 44 Control: Unload Drive Screen ...............................................70

Figure 45 Enter Password Screen...........................................................74

Figure 46 Service Screen ..........................................................................75

Figure 47 Report: Statistics Screen.......................................................... 76

Figure 48 Report: Actuator Status Screen..............................................77

Figure 49 Report: SysTest Library Results Screen................................77

Figure 50 Report: AutoClean Status Screen..........................................78

Figure 51 Test: SysTest Library Screen..................................................79

Figure 52 Confirmation Screen...............................................................82

Figure 53 Service: Change Password Screen ........................................83

Figure 54 Positioning the Slide Assembly.............................................99

Figure 55 Installing the Slide Assembly in the Rack .........................102

Figure 56 Loosening the Outer Nuts....................................................103

Figure 57 Slide Assembly Tray, Fully Extended................................105

Figure 58 Loosening the Inner Nuts ....................................................106

x ATL P1000 Series User’s Guide

Page 11

Tables

Tables

Table 1 Related Documentation........................................................xiv

Table 2 Bar Code Label Specifications................................................30

Table 3 Sample Library Configuration ...............................................40

Table 4 Vertical Bar Buttons and Indicators......................................43

Table 5 Horizontal Bar Buttons...........................................................44

Table 6 GUI Screens ..............................................................................45

Table 7 GUI Security Levels.................................................................49

Table 8 Available Settings, Configure: Options Screen...................62

0

Table 9 Start-up Problems....................................................................86

Table 10 GUI Problems...........................................................................87

Table 11 Robotics Problems...................................................................88

Table 12 Operating Problems ................................................................90

Table 13 Tape Drive Problems...............................................................92

Table 14 Physical Characteristics ..........................................................93

Table 15 Performance Characteristics...................................................93

Table 16 Environmental Specifications ................................................94

xi ATL P1000 Series User’s Guide

Page 12

Tables

xii ATL P1000 Series User’s Guide

Page 13

Preface

Preface

0

Audience

Purpose

Document

Organization

0

0

This guide was written for operators of the P1000 library.

This guide provides procedures for unpacking, installing, operating,

and troubleshooting the basic P1000 library with a standard SCSI host

interface.

The optional Fibre Channel capabiliti es are detaile d in a separate series

of documents (see “Related Documents” on page xiv).

This guide is organized as follows:

0

• Chapter 1, “Library Description,” provides an overview of the

P1000 components and operation.

• Chapter 2, “Installing the P1000 Library,” explains how to unpack

and install the P1000.

• Chapter 3, “Basic Operations,” introduces the P1000’s touc h scr een

graphical user interface (GUI) and explains how to obtain library

status, change the GUI security level, and perform several manual

operations such as turning the library on and off and i nserting tape

cartridges.

• Chapter 4, “Operator Commands,” describes each of the

commands on the Operator screen of the GUI.

• Chapter 5, “Service Commands,” describes each of the commands

on the Service screen of the GUI.

• Chapter 6, “Troubleshooting,” discusses typical P1000 operating

problems and provides probable solutions.

• Appendix A, “Specifications,” pr ovides t he physic al, performance ,

and environmental characteristics of the P1000.

• Appendix B, “Installing the Slide Assembly in the Rack,” explains

how to install the slide assembly in the rack (for rack-mount units

only).

This guide concludes with a glossary and an index.

xiiiATL P1000 Series User’s Guide

Page 14

Preface

Notational

Conventions

This manual uses the following conventions:

0

0

Caution:

Cautions indicate potential hazards to equipment and are

included to prevent damage to equipment.

Note:

Notes emphasize important information related to the main topic.

Warning:

Warnings indicate potential hazards to personal safety and

are included to prevent injury.

This manual uses the following:

• Right side of the library — Refers to the right side as you face the

component being described.

• Left side of the library — Refers to the left side as you face the

component being described.

Related Documents

Table 1 Related

Documentation

0

Note:

This section lists documents related to the ATL P1000 library.

ATL P1000 Documentation

Table 1 lists other manuals associated with the P1000 library.

Document

Number Title Description

6221100

6331101

A TL P100 0 Series Library

Unpacking Instructi on s

A TL P ris m FC210 Ro uter

Addendum

This document explains how to

unpack the P1000 library.

This document provides

operating and troubleshooting

procedures that are specific to

P1000 libraries with the Prism

FC210 Router.

For information regardi ng your tape drive, see the appropriate

manual.

0

product

xiv ATL P1000 Series User’s Guide

Page 15

Preface

Contacts

SCSI-2 Specification

0

The SCSI-2 communications specification is the proposed American

National Standard for information systems, dated March 9, 1990.

Copies may be obtained from:

Global Engineering Documents

15 Inverness Way, East

Eaglewood, CO 80112

(800) 854-7179 or (303) 397-2740

0

This section provides contact information for ATL Products.

ATL Products Corporate Headquarters

0

To order documentation for the ATL P1000, contact:

ATL Products, Inc.

101 Innovation Drive

Irvine, CA 92612

(949) 856-7800

(800) 284-5101

Note:

When placing an order for a document, please specify its part number.

Technical Publications

To comment on existing documentation send e-mail to:

atl-docs@atlp.com

Internet

Visit ATL’s home page at:

http://www.atlp.com

Professional Services

The ATL Products Professional Services Department provides a

24-hour help desk that can be reached at:

voice: (949) 477-7924 or (800) 284-5101

fax: (949) 477-7940

e-mail: helpdesk@atlp.com

0

0

0

ATL P1000 Series User’s Guide xv

Page 16

Preface

xvi ATL P1000 Series User’s Guide

Page 17

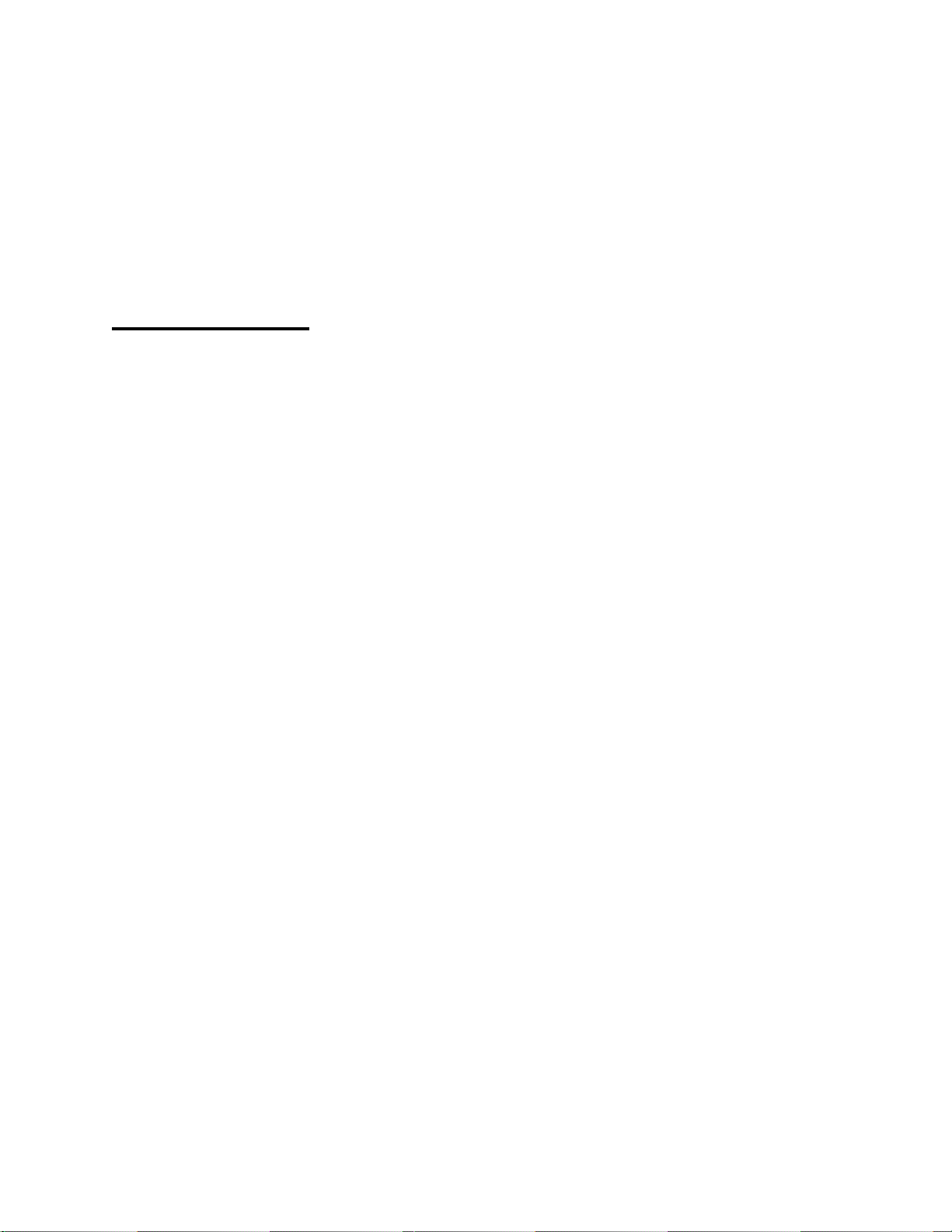

Chapter 1

Key lock

Bulk pack door

Power switch

Window

Touch screen

Load port

Load pack door

graphical user

interface (GUI)

Chapter 1 Library Description

Figure 1 P1000 Front

View, Stand-alone Library

Note:

Library Description

The ATL P1000 is an automated tape library system. When fully

configured, the P1000 consists of four tape drives and 30 cartridges.

The maximum storage capacity of the P1000 is 1050 GB (up to 2100 GB

compressed), based on 30 cartridges at 35 GB each (up to 70 GB

compressed).

The P1000 library is shipped in either a stand-alone (see figure 1) or

rack-mount configuration (see figure 2). The stand-alone P1000 is set

on casters. The rack-mount P1000 comes with a slide tray assembl y for

installation in a rack.

A rack is not provided with the rack-mount P1000; it must be obtained

separately.

1

1ATL P1000 Series User’s Guide

Page 18

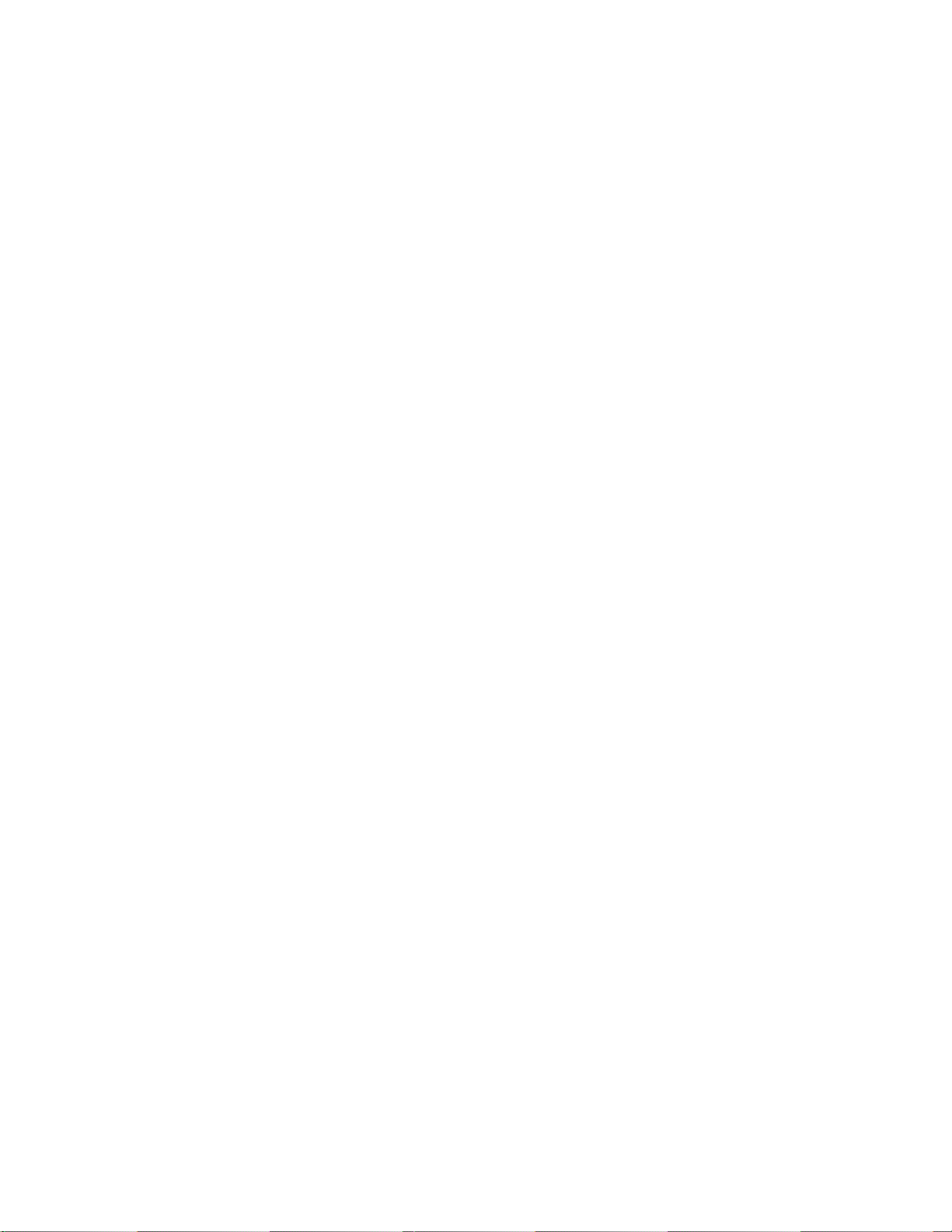

Chapter 1 Library Description

Figure 2 P1000 Front

View, Rack-mount Library

Rack (not included)

Key lock

GUI

Bulk pack door

Load pack door

Power switch

Load port

2 ATL P1000 Series User’s Guide

Page 19

Chapter 1 Library Description

Configuration Options

Configuration Options

As shown in figure 1 and figure 2, the P1000 library is available in

stand-alone and rack-mount configurations. Other library options

include:

•

the number of tape drives

The P1000 holds one to four tape drives.

•

high-density or low-density tape configuration

The high-density configuration consists of up to 30 tape cartridges:

9 in the back storage bins, 5 in the front storage bins, 8 in the load

pack, and 8 in the bulk pack.

The low-density configuration consists of 16 tape cartridges

housed in the load pack and bulk pack. All fixed storage bins are

removed from the low-density library.

•

single-ended or differential SCSI communication module

•

optical or copper-based Fibre Channel communication module

The P1000 can be supplied with (or upgraded to) various Fibre

Channel host interfaces, including a data router capability that

convert Fibre Channel to SCSI within the library. This o ption is

described in the

ATL Prism FC210 Router Addendum

(PN 6331101).

1

•

multiple SCSI bus capability

The P1000 supports one to five host computers, each on a separate

SCSI bus. The library is controlled by these host computers via a

SCSI communications link and the SCSI-2 medium changer

command set. The host computer SCSI interface port, the RS-232

port for diagnostics, and the power connectors are located on the

back panel (see figure 3 on page 4).

As you unpack and install the P1000, verify that the library is

configured with the options you require.

ATL P1000 Series User’s Guide 3

Page 20

Chapter 1 Library Description

Configuration Options

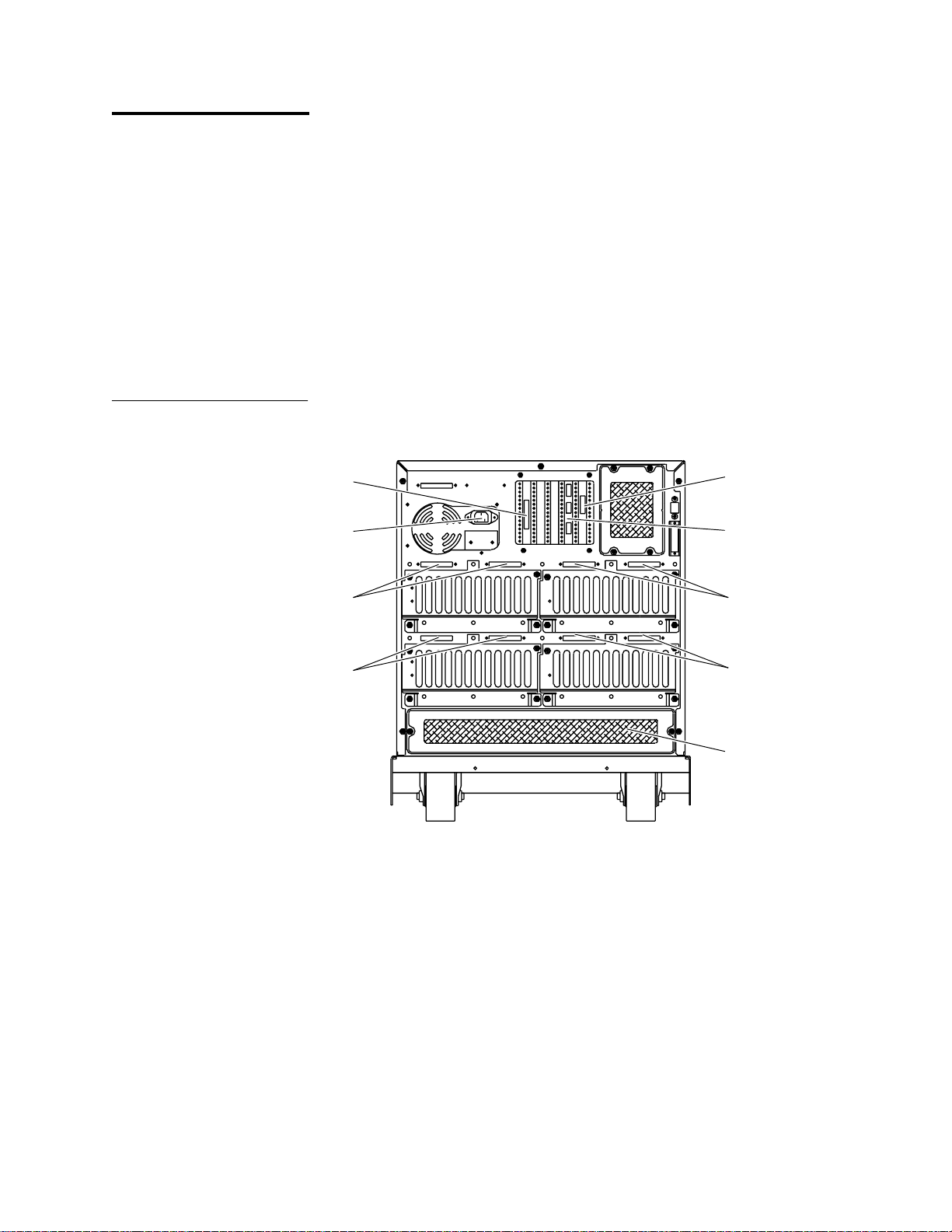

Figure 3 P1000 Library,

Back View

Host port, DIAG port, and

library printed circuit boards

Tape drive SCSI connectors

Bus connector

Power connector

4 ATL P1000 Series User’s Guide

Page 21

Chapter 1 Library Description

Library Elements

Library Elements

The P1000 has the following elements (see figure 4 on page 6):

•

storage bins

•

nine-pack fixed storage array (bins 0 to 8) (in high-density

configuration only)

•

four-pack fixed storage array (bins 9 to 12) (in high-density

configuration only)

•

one-pack fixed storage array (bin 13) (in high-density

configuration only)

•

bulk pack (bins 14 to 21)

•

load pack (bins 22 to 29)

Note:

•

In the low-density configuration, the P1000 stores tapes in the

load and bulk packs only. All fixed bins are removed from the

library.

import export elements

1

•

load port (load 0)

•

load pack (when configured for import or export operation,

these bins are numbered Load 1 to Load 8)

•

up to 4 tape drives (drives 0, 1, 2, and 3)

ATL P1000 Series User’s Guide 5

Page 22

Chapter 1 Library Description

Library Elements

Figure 4 Library Elements

Four-pack

3

array

Load port

One-pack

3

array

Bin 9

Bin 10

Bin 11

Bin 12

Load 0

Bin 13

Bin 14

Bin 15

Bin 16

Bin 17

Bin 18

Bin 19

Bin 20

Bin 21

Bin 22

Bin 23

Bin 24

Bin 25

Bin 26

Bin 27

Bin 28

Bin 29

Bulk pack

Load pack

Bin 0

Bin 1

Bin 2

Drive 0

Drive 2

1

Bin 3

Bin 4

Bin 5

Bin 6

Bin 7

Bin 8

Drive 1

Drive 3

1

When configured as an

Nine-pack

3

array

Tape

2

drives

import/export device, load

pack bins are numbered

“Load 1” to “Load 8.”

2

When fewer than four

drives are present in the

P1000, the drives occupy

consecutive bays, starting

with drive bay 0.

3

These bins are present

only in the high-density

configuration.

6 ATL P1000 Series User’s Guide

Page 23

Chapter 1 Library Description

Robotics Operation

Robotics Operation

Library robotics consist of the following components:

•

gripper mechanism/bar code reader

•

vertical actuator

•

horizontal actuator

•

extension ac tuator

The vertical and horizontal actuators move the gripper into position to

pick and place tape cartridges. The horizontal actuator also rotates the

gripper 180 degrees, allowing the gripper to pass cartridges between

the front storage bins and the back storage bins or tape drives. The

extension actuator extends the gripper forward to make contact with

the desired cartridge and then retracts the gripper to remove the

cartridge from a bin or drive.

The gripper includes bar code scanners which can read standard sixcharacter, 3 of 9 bar code labels. These scanners are used to maintain

an inventory of the tape cartridges within the P1000. For example, an

inventory occurs automatically when you turn on the library or close

the bulk pack door. You may also initiate an inventory manually from

the host computer.

1

Note:

Although the P1000 does not require tape cartridges to have bar code

labels, properly labeled tape cartridges and full storage bins speed the

inventory process.

The automatic inventory feature can be disabled using the touch

screen GUI (see chapter 4). This is useful for systems with unlabeled

tape cartridges or partially filled storage bins.

Caution:

The LED scanner is classified as a Class 1 LED light

emitting device by IEC 825. The wavelength is 850 nm

(invisible ultraviolet).

ATL P1000 Series User’s Guide 7

Page 24

Chapter 1 Library Description

Operator-Accessible Components

Front Panel

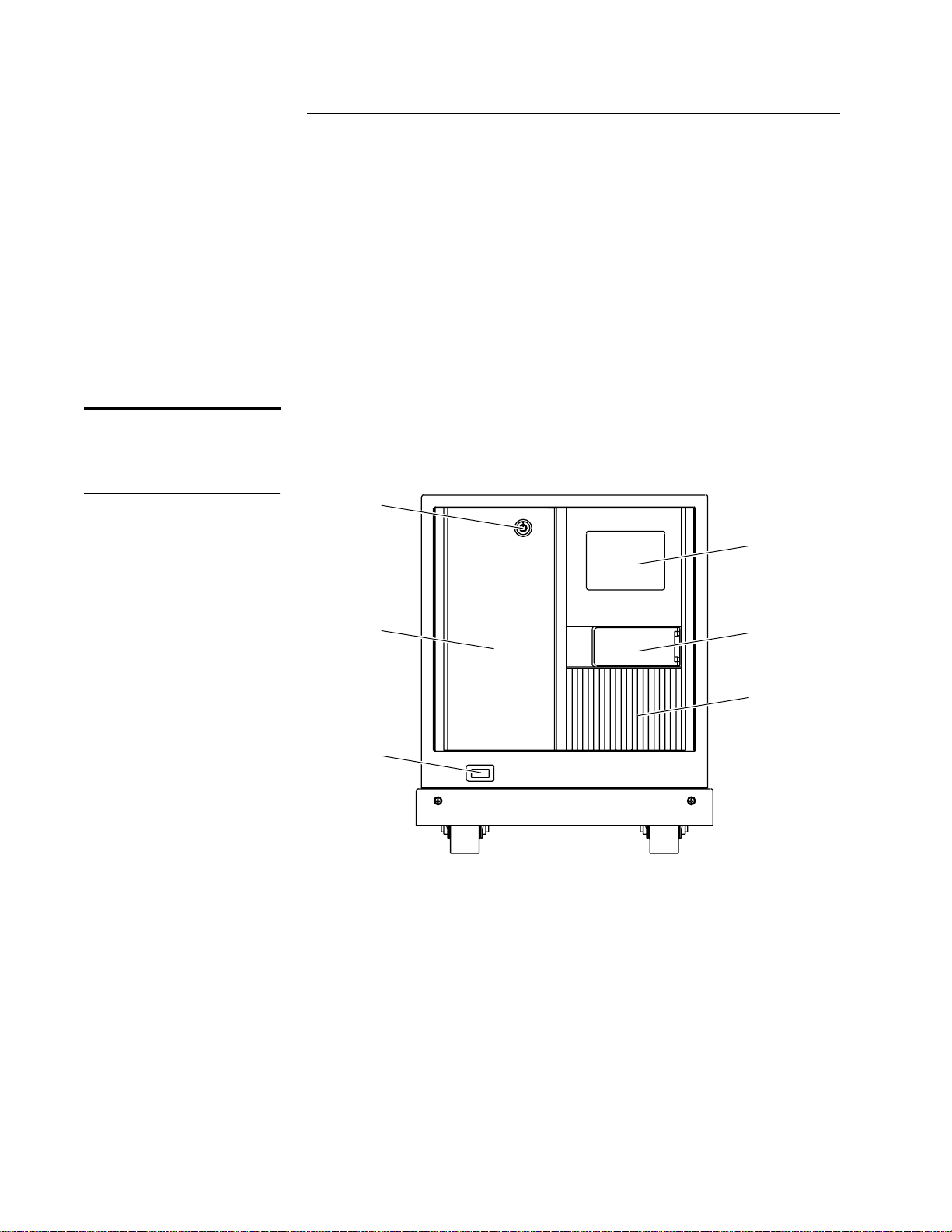

Figure 5 P1000 Front

Panel

Operator-Accessible Components

1

The following P1000 components are operator-accessible:

•

front panel

•

load and bulk packs

•

back panel

•

tape drives

The following sections describe each of these components.

1

The front panel consists of the GUI, the front doors and key lock, the

power switch, and the load port (see figure 5).

Key lock

GUI

Load pack door

Power switch

Load port

Bulk pack door

GUI

The GUI (see figure 6) displays touch screen menus that allow you to

determine library status, configure the library, and perform certain

diagnostic functions.

1

8 ATL P1000 Series User’s Guide

Page 25

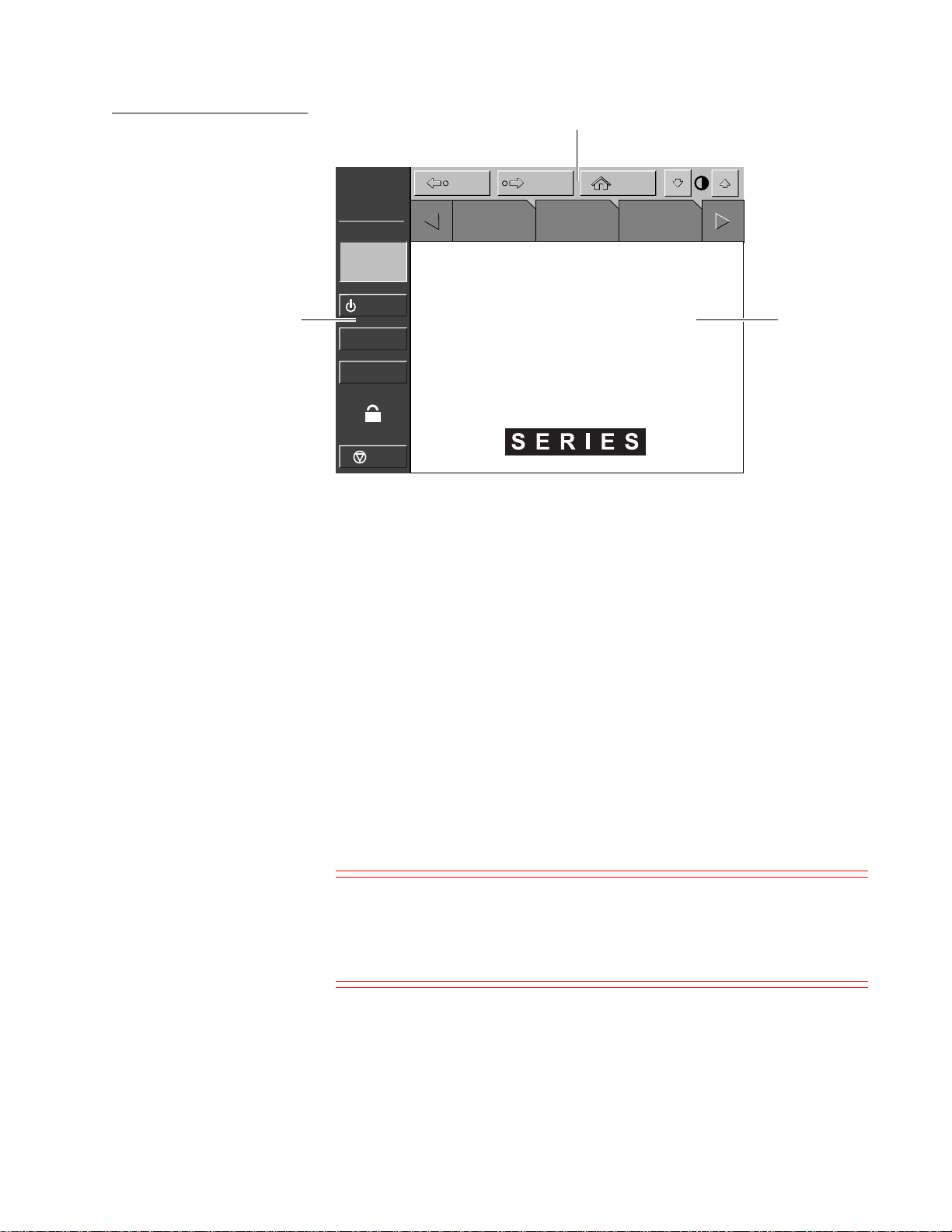

Figure 6 GUI: Initial

Horizontal bar

Vertical bar

Main display

area

Screen

Chapter 1 Library Description

Operator-Accessible C om pon ent s

Back Forward

ATL

PRODUCTS

System

Off-line

Standby

Load Port

Load Pack

U

Stop

The GUI screen consists of:

•

a horizontal bar (at the top of the screen)

•

a vertical bar (at the left side of the screen)

•

a main display area

The main display area contains a series of screens with status,

configuration, diagnostic, and operating controls. The horizontal and

vertical bars remain the same while the content of the main display

area changes.

Overview Tapes Operator

ATL

ATL

PRODUCTS

P1000

Home

For further information about the GUI, see chapters 3 and 4.

Front Doors

The front doors provide access to the load packs and the tape drives.

They allow you to insert and remove tape cartridges and manually

perform tape drive functions.

Warning:

Before opening the front doors of the P1000, make sure the

library is in standby mode and the robotics have come to a

complete stop. Failure to do so may result in personal

injury or damage to the P1000.

1

ATL P1000 Series User’s Guide 9

Page 26

Chapter 1 Library Description

Operator-Accessible Components

The front doors lock to prevent unauthorized access to the P1000. To

unlock and open the doors:

Procedure

1

If the library is on-line, press the Standby button on the GUI.

The system status indicator above the Standby button changes to

indicate that the library is in Standby mode.

2

Use the key to unlock the load pack door.

3

Press the Load Pack button on the GUI.

This prepares the library for load pack removal. Always press the

Load Pack button before opening the front door to access the load

pack.

4

Open the left door and then open the right door.

Load and Bulk Packs

Figure 7 Load and Bulk

Packs

Load Port

1

The load port enables you to insert a single tape cartridge into the

P1000. To open the load port, press the Load Port button on the GUI.

1

The load and bulk packs are eight-cartridge removable magazines that

attach to the front storage bin frame (see figure 7). Use these packs to

add or remove multiple tape cartridges.

The load pack can be configured as an additional load port.

Load pack

Bulk pack

To install or remove load or bulk packs, see chapters 2 and 3.

10 ATL P1000 Series User’s Guide

Page 27

Chapter 1 Library Description

Operator-Accessible C om pon ent s

Back Panel

Figure 8 Back Panel,

Stand-alone Library

1

The back panel of the P1000 (see figure 8) has the following

components:

•

•

•

•

•

These components provide the P1000 with power and communication

links to external systems.

Host SCSI port

Power connector

SCSI ports

RS-232C diagnostic (DIAG) port

power connector

drive access (hot swap)

air filters

Actuator driver card

Robotics controller card/

DIAG port

Drive 1 SCSI ports

Drive 3 SCSI ports

Drive 0 SCSI ports

Drive 2 SCSI ports

Air filter

ATL P1000 Series User’s Guide 11

Page 28

Chapter 1 Library Description

Operator-Accessible Components

Tape Drives

1

The P1000 holds up to four tape drives. When fewer than four tape

drives are installed, the tape drives must occupy consecutive drive

bays, beginning with drive bay 0 (see figure 4 on page 6).

12 ATL P1000 Series User’s Guide

Page 29

Chapter 2

Chapter 2 Installing the P1000 Library

Installing the P1000 Library

This chapter explains how to install the stand-alone and rack-mount

configurations of the P1000 library. Installation consists of the

following tasks:

•

verifying that the installation site meets the site requirements

•

unpacking and positioning the library

•

preparing and inserting tape cartridges

•

connecting host computer(s) to the library

•

turning on the library

•

configuring and testing the library

2

13ATL P1000 Series User’s Guide

Page 30

Chapter 2 Installing the P1000 Library

Site Requirements

Floor Space

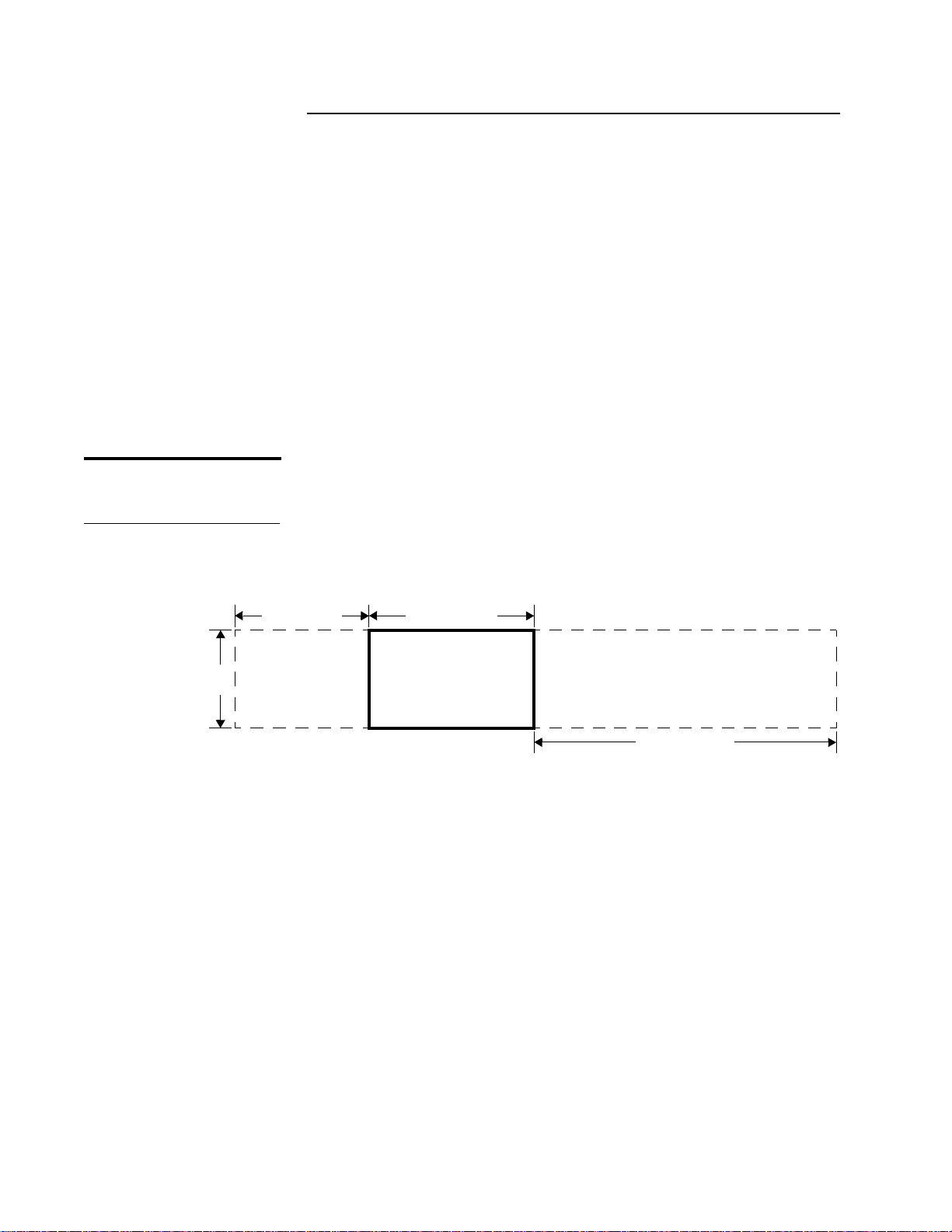

Figure 9 Floor Space

Requirements,

Stand-alone Library

Site Requirements

2

When selecting an installation site for the P1000 library, consider the

following requirements:

•

floor space

•

floor clearance

•

overhead clearance

•

floor strength and inclination

•

power and grounding

•

environmental factors

2

Figure 9 shows the floor space requirements of the stand-alone P1000.

17.5 in.

(45 cm)

24 in. (61 cm)

29.5 in. (75 cm)

Library FrontBack

54 in. (137.2 cm)

14 ATL P1000 Series User’s Guide

Page 31

Figure 10 Floor Space

Requirements,

Rack-mount Library

Chapter 2 Installing the P1000 Library

Site Requirements

Figure 10 shows the floor space requirements for the rack-mount

P1000.

24 in.

(61 cm)

each side

24 in. (61 cm)

Front

17.5 in.

(45 cm)

Floor Clearance

Floor Strength and Inclination

Library

Back

2

The stand-alone P1000 has a floor clearance of 0.75 in. (1.9 cm). Place

19-inch rack

(extended

from rack)

30 in. (76.2 cm)

24 in.

(61 cm)

the library on a level, uncarpeted floor free of defects.

The floor at the installation site must be rated at 250 lb/ft2

2

(1221 kg/m

2

). This is sufficient to support a fully loaded P1000 on the

floor or in a rack.

The floor at the installation site must be level to within 0. 25 in (6.4 mm)

over a 6 ft by 6 ft (1.8 m by 1.8 m) area.

Overhead Clearance

Power and Grounding

2

To remove the P1000 enclosure, there must be a minimum cl earance of

24 in. (61 cm) above the library. When combined with the height of the

library (21 in./53 cm), this is a total of 45 in. (114.5 cm) from the floor

(stand-alone library) or bottom of the slide (rack-mount library).

2

The library auto-ranging power supply accepts single-phase, 90 VAC

to 264 VAC input power at 47 Hz to 63 Hz.

ATL P1000 Series User’s Guide 15

Page 32

Chapter 2 Installing the P1000 Library

Site Requirements

Figure 11 AC Power

Receptacle

Power Inlet

The power inlet is an IEC-320 connector (see figure 11). For

international applications, replace the power cord with a harmonized

3x1.0 mm

Rack Current Rating Consideration

2

power cord approved by the country where used.

Ground

~100V to 120V / ~200V to 240V

6A/3A 50Hz/60Hz

IEC-320 Type

NeutralLine

Consider the current rating of the rack before instal ling more than one

P1000 library. The P1000 library is rated 6A/3A (120V/230V). This

means that no more than two libraries can be installed in a typical

15A/120V rack.

If other equipment is installed in the rack, determine the total current

rating of all the equipment before adding the P1000 library to the rack.

2

2

Environmental Requirements

Grounding

2

The P1000 must be connected to a grounded power outlet. If the

library is rack-mounted, the rack must also be grounded.

T e mperature

2

The rack temperature should be less than 32°C.

The installation site (stand-alone library) or the interior of the rack

2

(rack-mount library) must meet the following environmental

requirements:

•

humidity: 20% to 80%, non-condensing

•

temperature: 59°F to 90°F (15°C to 32°C)

•

altitude: sea level to 10,000 feet (3,033 meters)

16 ATL P1000 Series User’s Guide

Page 33

Chapter 2 Installing the P1000 Library

Unpacking the P1000

Note:

Note:

Unpacking the P1000

This section explains how to receive and unpack the P1000.

If you have already unpacked the library following the procedures in

A TL P1000 Seri es Unpacking Inst ruct ion s

the

and Inserting Tape Cartridges” on page 30.

This procedure consists of the following steps:

•

receiving the library from the shipper

•

uncrating the library

•

checking the contents of the shipping carton and accessories tray

•

installing the slide assembly in the rack (rack-mount library only)

•

removing the library from the pallet

•

removing the internal packing materials from the library

Before performing the procedures in this section, verify that the

installation site meets the requirements listed in “Site Requirements”

on page 14.

, skip ahead to “Preparing

2

Unloading Space Requirements

2

Note:

Before uncrating the library, verify that you have sufficient space. For

the stand-alone unit, allow a minimum of six feet in front of the ramp

side of the pallet (see figure 12 on page 18).

Unpack the library as close to the installation site as possible.

ATL P1000 Series User’s Guide 17

Page 34

Chapter 2 Installing the P1000 Library

Unpacking the P1000

Figure 12 Unloading

Space Requirements,

Stand-alone Library

Pallet ramp

Unloading area

(minimum)

Library

Pallet

18 in. (46 cm)

Uncrating the Library

2

Note:

33 in. (84 cm)

30 in. (76 cm)

97 in. (2.5 m)

To uncrate the P1000 library:

Be careful not to damage the shipping materials while uncrating the

library. Save all packaging materials for possible future shipment of

the library.

Procedure

1

Open the top of the shipping carton by carefully cutting the

packaging tape.

The following items are stacked on top of the P1000:

•

accessories tray

•

ramp (stand-alone library) or slide assembly (rack-mount

library)

18 ATL P1000 Series User’s Guide

Page 35

Chapter 2 Installing the P1000 Library

Unpacking the P1000

Procedure (continued)

2

Remove these items from the carton and set them aside.

3

Remove all foam supports from inside the carton (see figure 13 on

page 19 and figure 14 on page 20).

Figure 13 Uncrating the

Stand-alone Library

Accessories tray

Ramp

Foam supports

Library

Clips

ATL P1000 Series User’s Guide 19

Page 36

Chapter 2 Installing the P1000 Library

Unpacking the P1000

Figure 14 Uncrating the

Rack-mount Library

Accessories tray

Slide assembly

Foam supports

Library

Checking the Contents

Clips

Procedure (continued)

4

Release the four clips that secure the carton to the pallet.

To release a clip, pinch the center tabs of the clip firmly together

and pull on the tabs.

5

Lift the carton off of the pallet and set it aside.

Compare the contents of the shipping carton and the accessories tray

2

with the packing list included in the shipping carton. If any items are

missing or damaged, contact your authorized reseller.

20 ATL P1000 Series User’s Guide

Page 37

Chapter 2 Installing the P1000 Library

Unpacking the P1000

Installing the Slide Assembly in the Rack

Removing the Library from the Pallet

If you are installing a rack-mount library, install the slide assembly in

2

the rack before proceeding to the next section, “Removing the Library

from the Pallet.” See appendix B for slide assembly installation

instructions.

This section provides separate procedures for the stand-alone and

2

rack-mount libraries:

•

To remove a stand-alone library from the pallet, see the following

section, “Removing a Stand-alone Library from the Pallet.”

•

To remove a rack-mount library from the pallet, see “Removing a

Rack-mount Library from the Pallet” on page 23.

Warning:

Two people should perform steps that involve lifting or

guiding the library. Use safe practices when lifting or

guiding the library and handling the slide assembly or the

ramp.

Removing a Stand-alone Library from the Pallet

2

To remove a stand-alone library from the pallet:

Procedure

1

Remove the plastic bag enclosing the P1000:

a

Cut along the front seam of the plastic bag.

b

Continue to cut all the way to the back of the library.

c

Fold the bag out of the way.

2

Remove the foam supports from between the li brary and the pallet

(see figure 15).

ATL P1000 Series User’s Guide 21

Page 38

Chapter 2 Installing the P1000 Library

Unpacking the P1000

Figure 15 Removing the

Foam Supports,

Stand-alone Library

Foam supports

Procedure (continued)

Figure 16 Removing the

Stand-alone Library from

the Pallet

3

Attach the ramp to the pallet using fastener strips (see figure 16).

4

Make any necessary preparations for moving the library.

This may involve clearing a path to the installation site, unlocking

doors, and placing mats over carpeted areas.

5

Carefully roll the library down the ramp.

Fastener strips

22 ATL P1000 Series User’s Guide

Page 39

Chapter 2 Installing the P1000 Library

Unpacking the P1000

Procedure (continued)

6

Detach the ramp and place it on top of the pallet.

7

Roll the library to the installation site.

8

Save the shipping carton, bag, foam supports, ramp, and pallet for

future use.

These items are required to package the library for reshipment.

Note:

Removing a Rack-mount Library from the Pallet

The instructions in this section assume you have already installed the

slide assembly in the rack. If you have not, do so now, following the

instructions in appendix B.

To remove a rack-mount library from the pallet:

Procedure

1

Remove the plastic bag enclosing the library:

a

Cut along the front seam of the plastic bag.

b

Continue to cut all the way to the back of the library.

c

Fold the bag out of the way.

2

Pull the slide tray forward in the rack so it is fully extended.

Warning:

The rack may tip forward when you extend the slide tray or

place the library on the slide tray. If rack stabilizing feet ar e

present, extend them during this procedure. If the rack

does not have stabilizing feet, use extreme caution when

extending the slide tray and mounting the P1000 in the

rack.

2

3

W ith the help of a second person, lift the library fr om the pallet (see

figure 17 on page 24).

ATL P1000 Series User’s Guide 23

Page 40

Chapter 2 Installing the P1000 Library

Unpacking the P1000

Figure 17 Lifting the

Rack-mount Library from

the Pallet

Library

Shipping bag

Pallet

Procedure (continued)

4

Place the library on the fully extended slide assembly tray (see

figure 18).

Foam supports

24 ATL P1000 Series User’s Guide

Page 41

Figure 18 Placing the

Library on the Slide

Assembly Tray

Chapter 2 Installing the P1000 Library

Unpacking the P1000

Inner channel lock

Screws

Procedure (continued)

5

Secure the library to the slide tray, using six screws from the

accessories kit (see figure 18).

6

Verify that, when the slide assembly is fully extended, there is

adequate clearance around the library to access the back panel and

remove the library enclosure.

7

Press on the inner channel loc ks t o release them (see figure 18) and

then push the slide assembly all the way into the rack.

8

To prevent the library from sliding out of the rack during

operation, secure the locking brackets to the retma rails (see

figure 19 on page 26).

ATL P1000 Series User’s Guide 25

Page 42

Chapter 2 Installing the P1000 Library

Unpacking the P1000

Figure 19 Locking the

Slide Tray in the Rack

Retma rail

Locking bracket

Procedure (continued)

9

Save the shipping carton, bag, foam supports, and pallet for future

use.

These items are required to package the library for reshipment.

26 ATL P1000 Series User’s Guide

Page 43

Chapter 2 Installing the P1000 Library

Unpacking the P1000

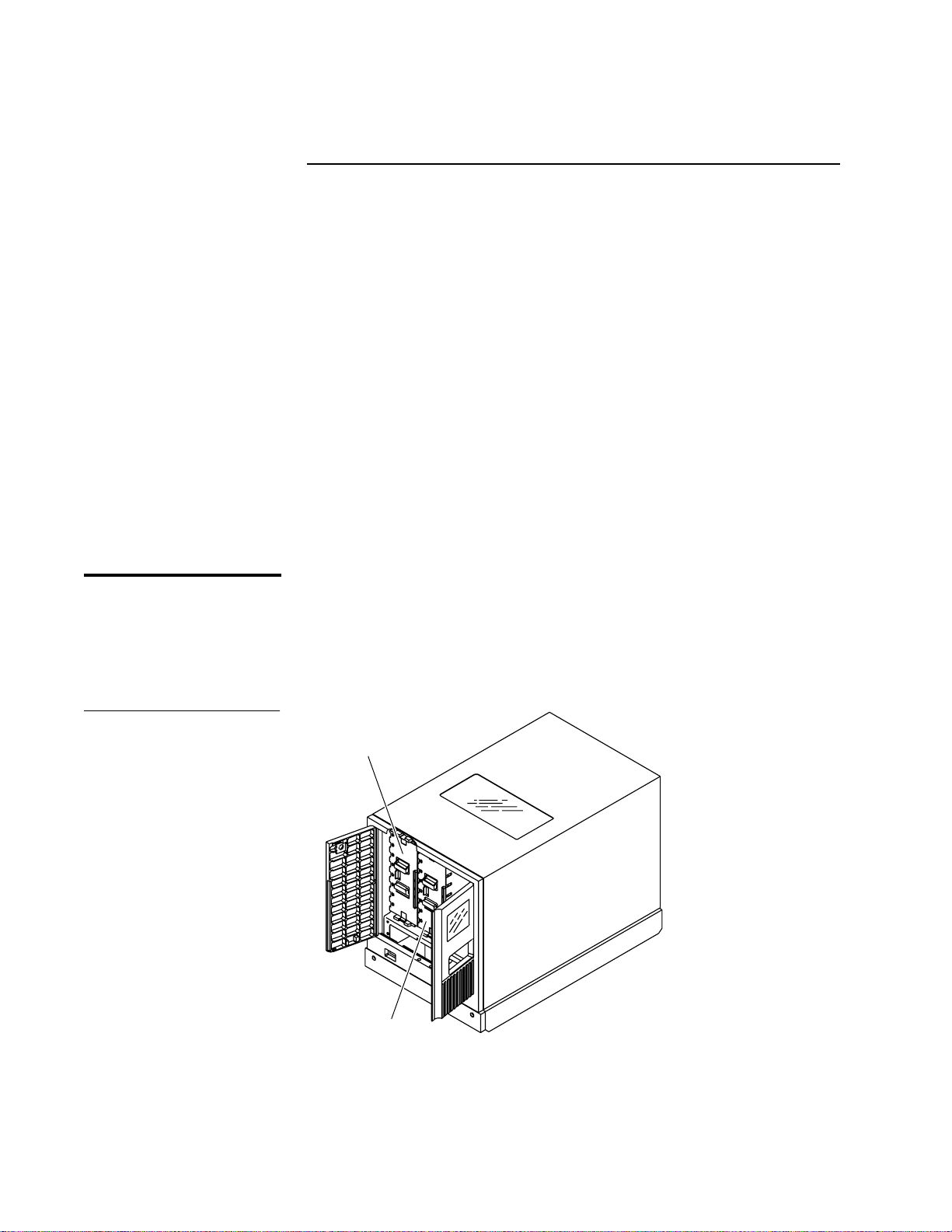

Removing the Internal Packing Materials

This section explains how to remove the internal packing materials

2

that protect the library during shipping and installation.

Caution:

Before removing the internal packing materials, verify that

the library is at its final installation site. Moving the library

without these materials in place may damage the library.

Caution:

Take precautions to prevent electrostatic discharge

whenever you remove the library enclosure or open the

library doors.

Opening the Doors

2

To open the library doors:

Procedure

1

Locate the key in the accessories kit and unlock the front door of

the library.

2

Open the left door first, then open the right door.

Removing the Load and Bulk Packs

To remove the load and bulk packs (see figure 20):

Procedure

1

Grip the load pack handles and squeeze them together.

This releases the latches securing the load pack.

2

Still holding the load pack handles, pull the load pack forwar d and

out of the library.

3

Repeat steps 1 and 2 to remove the bulk pack.

2

ATL P1000 Series User’s Guide 27

Page 44

Chapter 2 Installing the P1000 Library

Unpacking the P1000

Figure 20 Removing the

Load and Bulk Packs

Handles

Note:

Removing the Shipping Restraint

The shipping restraint that protects the extension axis assembly is

attached to the bottom drive shelf and fits over the supports for the

load and bulk packs.

To remove the shipping restraint:

Procedure

1

Grasp the front edge of the shipping restraint and carefully push

inward at both corners while lifting i t up at an angle ( see figur e 21).

The tab on the shipping restraint (between the mounting blocks for

the load and bulk packs) pops up, releasing the shipping restraint

from the load pack shelf. The back of the shipping restraint

unhooks from the bottom drive shelf.

2

Lift the shipping restraint off the extension axis assembly.

2

28 ATL P1000 Series User’s Guide

Page 45

Chapter 2 Installing the P1000 Library

Unpacking the P1000

Procedure (continued)

3

Raise the extension axis assembly and remove the foam block

beneath it.

4

Lower the extension axis assembly to its normal position on the

floor of the library.

Figure 21 Removing the

Shipping Restraint

Note:

Extension

axis assembly

Retain the original shipping container and shipping bag, pallet,

ramp, accessories tray, and all packing materials for future use.

Shipping restraint

Drive shelf

ATL P1000 Series User’s Guide 29

Page 46

Chapter 2 Installing the P1000 Library

Preparing and Inserting Tape Cartridges

Preparing and Inserting Tape

Labeling a Tape Cartridge

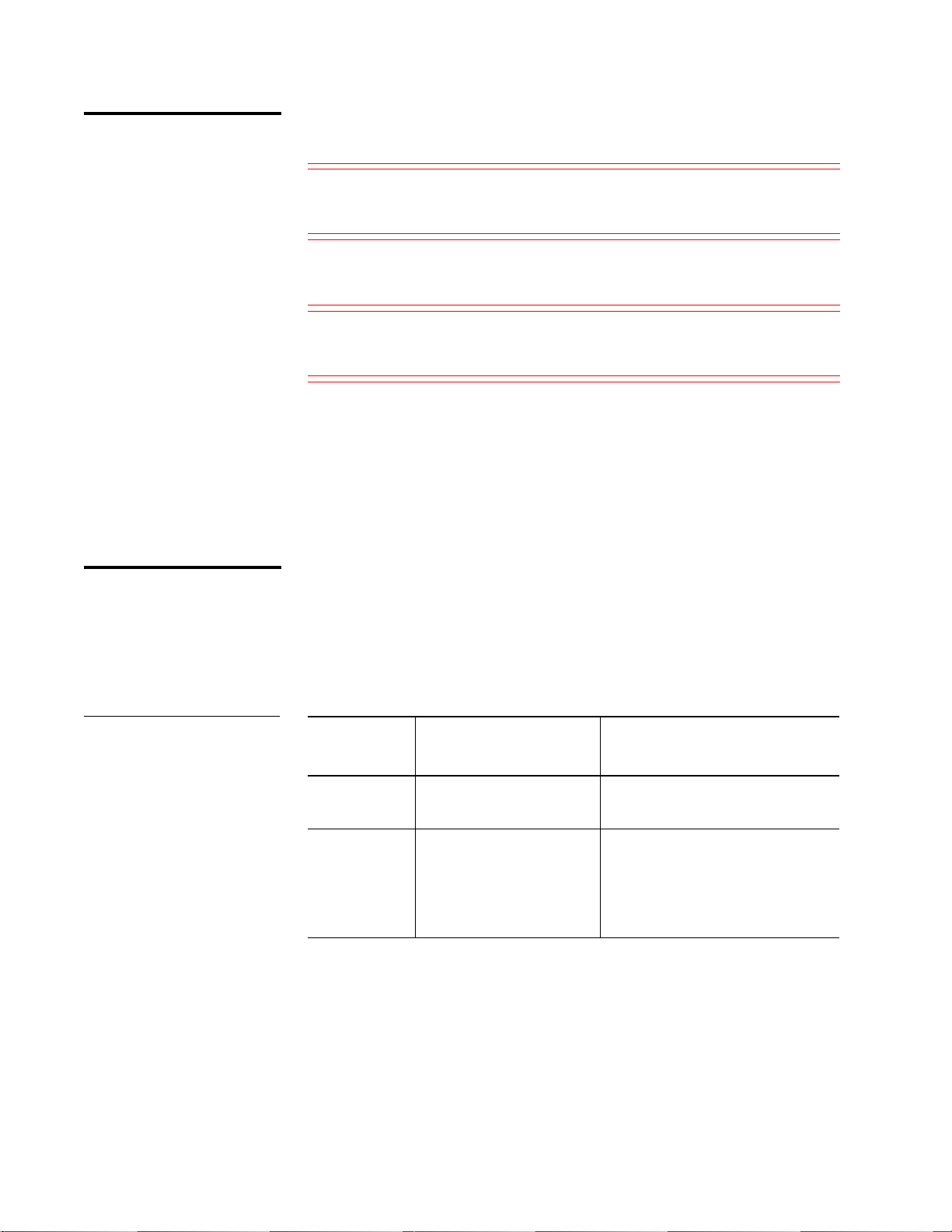

Table 2 Bar Code Label

Specifications

Cartridges

2

This section explains how to insert tape cartridges into the P1000

library during initial installation. This procedure consists of the

following steps:

•

labeling tape cartridges

•

setting the write-protect switch

•

placing cartridges in the load and bulk packs

•

placing cartridges in the fixed storage bins

Attaching a bar code label to each tape cartridge enables the library to

2

identify tape cartridges quickly, which speeds the inventory process.

Bar code labels must conform to the specifications listed in table 2 and

the dimensions shown in figure 22.

Sample Number Min.

Wide/narrow ratio 2.60 2.60 2.60

a

Max. Average

Average bar error 0.02 0.11 0.06

Ref. decode passes A A A

Decode margin 74% 86% 80%

Symbol total 112.0 120.0 116.0

Print contrast signal 94% 98% 96%

Reflectance (light) 69% 75% 72%

Reflectance (dark) 1% 2% 1%

Symbol contr ast 65% 74% 70 %

Global threshold passes A A A

R(min.) R(max.) 2% 3% 2%

Modulation 52% 62% 58%

Edge contrast (min.) 37% 44% 41%

Defects 5% 28% 8%

30 ATL P1000 Series User’s Guide

Page 47

Chapter 2 Installing the P1000 Library

Preparing and Inserting Tape Cartridges

Figure 22 Bar Code Label

Dimensions

Sample Number Min.

a

Max. Average

Message length 6.00 6.00 6.00

Traditional tests PASS PASS PASS

Bar growth IN TOL IN TOL IN TOL

PCS OK OK OK

Print quality grade B C C

Formatting checks PASS PASS PASS

a. All bar code parameters should fall within the Min./Max. values when

tested using a PSC Quick Check 500 bar code tester.

Keepout region

(top & bottom)

Human-readable

alphanumeric text

Bar code

Open region

2.20

.06

.20

.30

.82

Figure 23 Inserting a Bar

Code Label

To label a cartridge, insert the label into the label area on the front edge

of the tape cartridge (see figure23).

ATL P1000 Series User’s Guide 31

Page 48

Chapter 2 Installing the P1000 Library

Preparing and Inserting Tape Cartridges

Setting the

Write-protect Switch

Figure 24 Setting the

Write-protec t Switch

The write-protect switch controls whether the tape cartridge is

2

write-protected or write-enabled:

•

Write-protecting a cartridge protects the data it contains from

being erased or overwritten. To write-protect a cartridge, move the

write-protect switch to the left (see figure 24). An orange tab

appears above the switch.

•

Write-enabling a cartridge allows new data to be written to the

cartridge or existing data to be modified or erased. To write-enable

a cartridge, move the write-protect switch to the right (see

figure 24). The orange tab disappears.

Placing Tape Cartridges in the Fixed Storage Bins

Orange tab

Write-protect switch

To place tape cartridges in the fixed storage bins:

2

Note:

Low-density P1000 libraries do not have fixed storage bins. If

you are using one of these libraries, skip this procedure and

proceed to the following section, “Placing Tape Cartridges in

the Load and Bulk Packs” on page 34.

Procedure

1

Open the library doors:

a

Locate the key in the accessories kit and unlock the front door

of the library.

b

Open the left door first, then open the right door.

32 ATL P1000 Series User’s Guide

Page 49

Chapter 2 Installing the P1000 Library

Preparing and Inserting Tape Cartridges

Procedure (continued)

2

Remove the load and bulk packs from the library (see figure 20 on

page 28):

a

Grip the load pack handles and squeeze them together.

This releases the latches securing the load pack.

b

Still holding the load pack handles, pull the load pack forward

and out of the library.

c

Repeat steps 2a and 2b to remove the bulk pack.

3

Set both packs aside.

4

Reaching in through the front doors of the library, insert a tape

cartridge into each of the nine storage bins above the tape drives.

(See figure 25 for the correct tape cartridge orientation.)

Each cartridge should slide into place with very little force. If a

cartridge does not slide into place easily, check the cartridge for

correct orientation and structural integrity.

Figure 25 Correct Tape

Cartridge Orientation

Insertion arrow

Bar code label

Write-protect switch

5

Insert a cartridge into each of the five storage bins above and

below the load port at the front of the library.

This requires you to reach into the library through the front doors

and then back toward the front. There are four bins above the load

port and one bin below.

6

Verify that each cartridge is properly seated in the bin (see

figure 25 for correct cartridge orientation).

ATL P1000 Series User’s Guide 33

Page 50

Chapter 2 Installing the P1000 Library

Preparing and Inserting Tape Cartridges

Placing Tape Cartridges in the Load and Bulk Packs

To place cartridges in the load and bulk packs:

2

Note:

This procedure assumes that you have already removed the

load and bulk packs. If not, remove the load and bulk packs,

referring to steps 2a through 2c on page 33.

Procedure

1

Load eight cartridges into each pack.

As you slide each cartridge into a bin, there should be initial

resistance from the r etention mechanism befor e the cartridge snaps

into place. If a cartridge does not snap into place, check for correct

orientation and structural integrity.

2

Verify that each cartridge is properly oriented and seated in the bin

(see figure 25 on page 33 for proper cartridge orientation).

Caution:

Handle the load and bulk packs with care. The

retention mechanism that secures the cartridges may be

compromised by rough handling, causing the cartridges

to fall out.

3

Reinstall the load and bulk packs:

a

Insert a pack into the library, cartridge-side first.

b

Line up the pack with the plastic guides on the top and bottom

of the library frame.

c

Slide the pack onto the guides until it snaps into place.

d

Repeat steps 3a through 3c for the other pack.

4

Close and lock the library doors.

34 ATL P1000 Series User’s Guide

Page 51

Chapter 2 Installing the P1000 Library

Connecting Host Computers

SCSI Cabling Guidelines

Note:

2

Connecting Host Computers

You are now ready to connect one or more host computers to the

library. You can connect up to five host computers on separate SCSI

busses.

If your library is equipped with the Prism FC210 Router, disregard this

section. Instead, see the

(PN 6331101).

When connecting the host computer(s) to the library, follow these

guidelines:

•

Connect each host to a SCSI connector on the back panel of the

library.

•

When more than one device is on a SCSI bus, daisy-chain the

devices using the SCSI cables from the accessories kit.

•

Terminate the last device on each SCSI bus.

Using these guidelines, you can set up variations of one-, two-, three-,

four-, or five-host configurations.

ATL PrismFC210 Router Addendum

2

SCSI Cabling Examples

Note:

2

The SCSI cable(s) to the host computer(s) must be supplied by the user.

This section provides three SCSI cabling examples. Each of these

examples follows the guidelines introduced above.

ATL P1000 Series User’s Guide 35

Page 52

Chapter 2 Installing the P1000 Library

Connecting Host Computers

Figure 26 Single-Host

SCSI Configuration

Host connector

15 in. (38 cm)

SCSI cable

In the single-host configuration (see figure 26), the host computer is

connected to the host connector on the rear panel of the library. Since

there is only one SCSI bus, use all of the SCSI cables from the

accessories kit to daisy-chain the library to each of the tape drives.

P1000 back panel

21 in. (53 cm)

SCSI cable

7 in. (18 cm)

SCSI cables

Terminator

To host computer

36 ATL P1000 Series User’s Guide

Page 53

Figure 27 Typical

Two-Host SCSI

Configuration

Host connector

Chapter 2 Installing the P1000 Library

Connecting Host Computers

In the two-host configuration (see figure 27), host 1 is connected to the

library and daisy-chained to tape drives 0 and 1 (upper drives). Host 2

is connected to tape drive 3 and daisy-chained to tape drive 2 (lower

drives). The first SCSI bus is terminated at drive 0; the second is

terminated at drive 2.

For this configuration, you need the following items from the

accessories kit:

•

both 7-inch SCSI cables

•

15-inch SCSI cable

•

2 SCSI terminators

P1000 back panel

15 in. (38 cm)

SCSI cable

Terminators

7 in. (18 cm)

SCSI cables

To host computers

ATL P1000 Series User’s Guide 37

Page 54

Chapter 2 Installing the P1000 Library

Connecting Host Computers

Figure 28 Five-Host SCSI

Configuration

Terminators

In the five-host configuration (see figure 28), five hosts are connected

to the library, requiring five SCSI terminators.

P1000 back panel

To host computers

38 ATL P1000 Series User’s Guide

Page 55

Chapter 2 Installing the P1000 Library

Turning On the Library

Turning On the Library

To turn on the library:

Procedure

1

Ver ify that:

•

all internal packaging is removed

•

the front doors and load port are closed

•

the library enclosure is installed

•

all back panel connections are secure

2

At the front panel, set the power switch on.

3

After several seconds, verify that the touch screen graphical user

interface (GUI) comes on.

2

ATL P1000 Series User’s Guide 39

Page 56

Chapter 2 Installing the P1000 Library

Configuring and Testing the Library

Table 3 Sample Library

Configuration

Configuring and Testing the Library

When you finish installing the library, make any desired changes to the

library configuration and then calibrate the library and test its

functionality.

Table 3 shows a sample library configuration.

Sample Default

Item

Model number 6220000

Number of bins (fixed storage and load pack) 30

Number of drives 4

Library SCSI ID number 0

Drive 0 SCSI ID number 2

Drive 1 SCSI ID number 3

Condition

2

Note:

Drive 2 SCSI ID number 4

Drive 3 SCSI ID number 5

Library power-up state On-line

Automatic drive cleaning function Disabled

Retry move command Enabled

Auto load from load port Disabled

Auto inventory at power up Enabled

No bar code scan Disabled

4/52 identity Disabled

To view and make changes to the configuration or to calibrate the

library, see chapter 4. To test the library, see chapter 5.

You must have either Operator or Service access privileges to access

the options described in chapter 4 and Service access privileges to

access the options described in chapter 5.

40 ATL P1000 Series User’s Guide

Page 57

Chapter 3

Chapter 3 Basic Operations

Basic Operations

This chapter describes the following basic library operating

procedures:

•

using the touch screen graphical user interface (GUI)

•

GUI components

•

GUI screens

•

obtaining library status

•

changing the GUI security level

•

performing manual operations

•

turning the library on and off

•

placing the library on- or off-line

•

inserting tape cartridges

•

opening the library doors

3

•

manually ejecting a tape cartridge

For more advanced procedures such as configuring, calibrating, or

testing the library, see chapters 4 and 5.

41ATL P1000 Series User’s Guide

Page 58

Chapter 3 Basic Operations

Using the GUI

Figure 29 GUI: Initial

Screen

Using the GUI

At start-up, the GUI displays the following screen (see figure 29).

Horizontal bar

Back Forward

ATL

PRODUCTS

System

Off-line

Standby

Vertical bar Main display

Load Port

Load Pack

U

Overview Tapes Operator

ATL

ATL

PRODUCTS

P1000

Home

area

3

GUI Components

Stop

From this screen, you can access controls to configure and operate the

library. All operating procedures in this chapter and in chapters 4

and 5 require an understanding of the GUI screens.

3

The GUI screen consists of the following components:

•

a vertical bar (at the left side of the screen)

•

a horizontal bar (at the top of the screen)

•

a main display area

These components are described in the following sections.

42 ATL P1000 Series User’s Guide

Page 59

Chapter 3 Basic Operations

Using the GUI

Table 4 Vertical Bar

Buttons and Indicators

Vertical Bar

Table 4 describes each of the buttons and indicators on the vertical bar.

Button/Indicator Description

Company logo This area of the screen displays the ATL logo.

Pressing the logo causes the GUI to display an

“About ATL” screen.

System status

indicator

Standby button Pressing the Standby button togg les the library

Load Port button Pressing the Load Port button causes the load port

Load Pack button Pressing the Load Pack button prepares the library

The system status indicator shows the current

state of the library and displays important

messages relating to library operation.

between on-line and standby status.

to open, allowing you to insert or remove a tape

cartridge.

for load pack removal. Always press this button

before opening the front door to access the load

pack.

3

Security level

indicator

The security level indicator displays the current

security level of the GUI. There are five security

levels: service (S), operator (O), user (U), import

only (I), and locked (L).

For more information about security levels, see

“Changing the GUI Security Level” on page 49.

Stop button Pressing the Stop button cuts power to the library

robotics, thus stopping all library activity.

Pressing the Stop button a second time restores

power to the library robotics.

ATL P1000 Series User’s Guide 43

Page 60

Chapter 3 Basic Operations

Using the GUI

Table 5 Horizontal Bar

Buttons

Horizontal Bar

Table 5 describes each of the buttons on the horizontal bar.

Button Description

Back button Pressing this button moves you backward

screen-by-screen through previously selected

screens.

Forward button Pressing this button moves you forward

screen-by-screen through previously selected

screens.

Home button Pressing this button returns you to the initial GUI

screen (see figure 29 on page 42).

Contrast buttons

(↑ and ↓)

Pressing these buttons adjusts the contrast of the

GUI.

Main Display Area

The main display area provides access to five tabbed screens through

which you can issue commands to the library. To view a screen, press

its corresponding tab.

3

3

Figure 30 Navigating

through the GUI Screens

Since the GUI is not large enough to display all five tabbed screens at

once, the initial GUI screen displays only the first three screens

(Overview, Tapes, and Operator). To scroll forward to the remaining

screens (Service and Prism Router), press the right arrow button.

To scroll backward through the screens, press the left arrow button.

Press this button

to scroll to

previous tabs.

ATL

PRODUCTS

System

Report

Off-line

Standby

Load Port

Load Pack

Statistics

Actuator

S

Stop

Back Forward

Operator

SysTest

Library

Results

Auto

Clean

Home

Tapes

Test Misc.

SysTest

Library

Operate

Axes

Service

Calibrate

Service

Initialize

Nonvol

Statistics

Initialize

Nonvol

Config

Change

Password

ATL

PRODUCTS

System

Off-line

Standby

Load Port

Load Pack

U

Stop

Press this button

to scroll to the

next tabs.

Back Forward

Overview Tapes Operator

Drives Activity Load Pack

D00

ANF 120

Ready

D01

???

Ready

D02

empty

Ready

D03

ANF 123

Ready

GRP

empty

Home

P00

ANF146

P01

ANF147

P02

ANF148

P03

ANF149

44 ATL P1000 Series User’s Guide

Page 61

Table 6 describes each of the GUI screens.

Chapter 3 Basic Operations

Using the GUI

Table 6 GUI Screens

GUI Screens

Screen Description

Overview This screen provides an overview of the tape

drives, robot activity, and load pack inventory.

Tapes This screen displays the contents of the tape

drives, storage bins, load packs, the gripper, and

the load port.

Operator This screen contains the library configuration and

control functions. To use this screen, you must

have Operator or Service access privileges.

Service This screen contains reporting functions, system

tests, and miscellaneous commands. To use this

screen, you must have Service access privileges.

Prism Router This screen contains options related to the

optional Prism FC210 Router. For information

about these options, see the

Router Addendum

3

Figure 31 shows the commands that are available on the Overview,

(PN 6331101).

ATL Prism FC210

Tapes, Operator, and Service screens.

Figure 31 GUI Screens

Overview Tapes Operator

Tape Drive Status

Activity

Load Pack

Drives

Storage

Load Pack

Transport

Load Port

Configure Library

Configure Options

Move Cartridges

Inventory Tapes

Calibrate Library

Exercise Library

Unload Drive

Unload Imp/Exp

Service

Statistics

Actuator

Sys Test Library Results

Auto Clean

Sys Test Library

Operate Axes

Service Calibrate

Initialize Nonvol Statistics

Initialize Nonvol Config.

Change Password

ATL P1000 Series User’s Guide 45

Page 62

Chapter 3 Basic Operations

Obtaining Library Status

Overview Screen

Figure 32 Overview

Screen

ATL

PRODUCTS

Obtaining Library Status

You can obtain library status from the Overview and Tapes screens.

3

Back Forward

Overview Tapes Operator

To open the Overview screen, press the Overview tab on the GUI.

The Overview screen is divided into three sections (see figure 32):

•

Drives

•

Activity

•

Load Pack

Home

3

System

Off-line

Standby

Load Port

Load Pack

U

Stop

Drives Activity Load Pack

D00

ANF 120

Ready

D01

???

Ready

D02

empty

Ready

D03

ANF 123

Ready

GRP

empty

P00

ANF146

P01

ANF147

P02

ANF148

P03

ANF149

Drive

status

Drive

number

Compression

enabled

D03

ANF 123

Ready

Cartridge

present

Bar

code

Writeenabled

46 ATL P1000 Series User’s Guide

Page 63

Chapter 3 Basic Operations

Obtaining Library Status

Figure 33 Overview

Screen with Expanded

Tape Drive Status

Drives

The Drives section of the Overview screen displays the following

information:

•

whether a tape drive has a cartridge

•