Page 1

8VHU¶V*XLGH8VHU¶V*XLGH8VHU¶V*XLGH8VHU¶V*XLGH8VHU¶V*XLGH8VHU¶V*XLGH

/72+DOI+HLJKW7DSH'ULYH

/72

%

Page 2

Quantum LTO-2 Half-Height Tape Drive, P/N 50002763, B01, July 2005

Made in USA.

Quantum Corporation provides this publication “as is” without warranty of any kind, either express or

implied, including but not limited to the implied warranties of merchantability or fitness for a particular

purpose. Quantum Corporation may revise this publication from time to time without notice.

COPYRIGHT STATEMENT

Copyright 2005 by Quantum Corporation. All rights reserved.

Your right to copy this manual is limited by copyright law. Making copies or adaptations without prior

written authorization of Quantum Corporation is prohibited by law and constitutes a punishable violation of

the law.

TRADEMARK STATEMENT

Quantum and the Quantum logo are all registered trademarks of Quantum Corporation.

Other trademarks may be mentioned herein which belong to other companies.

Page 3

Contents

Preface xi

Chapter 1 Introduction 1

Features ............................................................................................................... 2

Chapter 2 Installation and Quick Start 3

Quick Start Guide ..............................................................................................4

Internal LTO-2 Half-Height Tape Drive Quick Start ............................ 4

Desktop LTO-2 Half-Height Tape Drive Quick Start............................ 5

Unpacking and Inspection................................................................................6

Internal Tape Drive Guidelines and Cautions............................................... 6

Drive Installation Instructions .........................................................................7

Installing an Internal LTO-2 Half-Height Tape Drive..................................7

Configuring the Internal Tape Drive ....................................................... 7

Mounting the Internal Tape Drive ......................................................... 11

Connecting a SCSI Cable ......................................................................... 13

Checking the SCSI Termination.............................................................. 14

LTO-2 Half-Height Tape Drive User’s Guide iii

Page 4

Contents

Connecting a Serial Cable for Tape Libraries........................................14

Connecting a Power Cable.......................................................................15

Installing the LTO Driver.........................................................................15

Registering Your Tape Drive...................................................................15

Installing a Desktop LTO-2 Half-Height Tape Drive..................................16

Setting the SCSI ID....................................................................................16

Connecting a SCSI Cable..........................................................................16

Checking the SCSI Termination..............................................................17

Connecting a Power Cord........................................................................17

Installing the LTO Driver.........................................................................17

Registering Your Tape Drive...................................................................18

Chapter 3 Operation 19

Understanding the Front Panel Display .......................................................20

Blink Codes .......................................................................................................21

Using LTO Cartridges......................................................................................22

Loading a Cartridge..................................................................................22

Unloading a Cartridge..............................................................................22

Write-protecting a Cartridge ...................................................................22

Cartridge Care and Maintenance............................................................23

Drive Maintenance ...........................................................................................24

Cleaning the Tape Drive ..........................................................................24

Chapter 4 Theory 27

Track Layout .....................................................................................................27

Recording Method............................................................................................29

Data Buffer ........................................................................................................29

Data Integrity ....................................................................................................29

Error-correction Code (ECC)...................................................................29

Servo-tracking Faults................................................................................31

Data Compression............................................................................................31

Data Compression Considerations.........................................................32

Intelligent Data Compression..................................................................33

iv LTO-2 Half-Height Tape Drive User’s Guide

Page 5

Contents

Chapter 5 Specifications 35

Physical Specifications ....................................................................................36

Power Specifications........................................................................................ 38

Drive Performance Specifications.................................................................. 39

Environmental Requirements ........................................................................41

Injected Noise ............................................................................................ 42

Reliability ..........................................................................................................42

Mean Time Between Failures ......................................................................... 43

Mean Time to Replace.............................................................................. 44

LTO Cartridge Specifications ......................................................................... 44

Environmental Considerations............................................................... 44

Cartridge Memory....................................................................................45

Cartridge Reliability ................................................................................. 45

Regulatory Compliance .................................................................................. 45

Safety Compliance .................................................................................... 45

EMC Compliance...................................................................................... 47

Disposal of Electrical and Electronic Equipment ....................................... 48

Chapter 6 UNIX Settings 49

A Word About SCSI Controllers.................................................................... 50

Configuring for the DEC/Compaq UNIX Environment ........................... 50

Finding Existing SCSI Controllers and Devices ................................... 50

Configuring Digital UNIX Version 4.0 and later/Compaq Tru64 UNIX

5.x ................................................................................................................ 51

Configuring for the Sun Environment

(Solaris 2.4, 2.5, 2.6, 7, 8, and 9)...............................................................52

Finding Current SCSI Controllers and Targets .................................... 52

Types of Controllers ................................................................................. 52

Configuring the Device File st.conf........................................................ 53

Configuring for the IBM AIX Environment (AIX Version 4.1.x

and later) ....................................................................................................54

Finding Existing SCSI Controllers and Devices ................................... 54

Configuring the LTO-2 Half-Height Tape Drive using SMIT............ 54

Configuring for SCO Open Server 5.0.x ...................................................... 56

Finding Existing SCSI Controllers and Devices ................................... 56

Configuring the LTO-2 Half-Height Tape Drive with mkdev........... 57

Configuring for Linux ..................................................................................... 58

LTO-2 Half-Height Tape Drive User’s Guide v

Page 6

Contents

Finding Existing SCSI Controllers and Devices ...................................58

Using the LTO-2 Half-Height Tape Drive .............................................59

Configuring for SGI Irix ..................................................................................60

Finding Current SCSI Controllers and Targets.....................................60

Modifying the IRIX Configuration File..................................................60

Configuring for HP-UX 11.0 ...........................................................................61

Finding Current Hardware/Driver Configuration..............................61

Attaching the LTO-2 Half-Height Tape Drive......................................61

Chapter 7 Troubleshooting Guide 63

Installation Best Practices................................................................................63

Follow SCSI Best Practices .......................................................................63

SCSI Host Bus Adapters (HBA) ..............................................................63

Adding the Tape Drive.............................................................................64

Troubleshooting Suggestions .........................................................................65

Computer will not Boot............................................................................65

Computer Boots but Does not Recognize the Tape Drive...................65

Tape Drive Recognized during System Boot but not by Operating

System or Application ..............................................................................67

Problems with Tape Drive and Cartridge .............................................68

Emergency Reset and Emergency Cartridge Eject ......................................71

Problems During Backup/Restore Operations............................................71

Backup Failures .........................................................................................71

Tape is Write Protected ............................................................................73

Miscellaneous TapeAlert Messages........................................................73

Slow Backups.............................................................................................75

Index 77

vi LTO-2 Half-Height Tape Drive User’s Guide

Page 7

Figures

Figure 1 Drive Covered in this User’s Guide (Typical).......................... 1

Figure 2 Internal LTO-2 Half-Height Tape Drive Jumper Settings ...... 9

Figure 3 Acceptable Mounting Orientation ........................................... 11

Figure 4 Internal LTO-2 Half-Height Tape Drive Mounting

Dimensions.................................................................................. 12

Figure 5 Rear View of the Internal LTO-2 Half-Height Tape Drive .. 13

Figure 6 Two SCSI Termination Examples for the Internal LTO-2

Half-Height Tape Drive ............................................................ 14

Figure 7 SCSI Termination Examples for the Desktop LTO-2 Half-

Height Tape Drive...................................................................... 17

Figure 8 Generic Front Panel Display..................................................... 20

Figure 9 Ultrium Cartridge Showing Write-Protect Switch ................ 23

Figure 10 Layout of Tracks on LTO Ultrium Tapes .............................. 28

Figure 11 Internal LTO-2 Half-Height Tape Drive Dimensions ........... 37

LTO-2 Half-Height Tape Drive User’s Guide vii

Page 8

Figures

viii LTO-2 Half-Height Tape Drive User’s Guide

Page 9

Tables

Table 1 SCSI IDs and Jumper Settings for LTO-2 Half-Height

in Drive ........................................................................................ 10

Table 2 Serial Interface Connector Pin Assignments .......................... 15

Table 3 LTO-2 Tape Drive Blink Codes ................................................21

Table 4 Physical Specifications...............................................................36

Table 5 Voltage and Current .................................................................. 38

Table 6 Power Dissipation ...................................................................... 38

Table 7 Drive Performance Specification..............................................40

Table 8 Environmental Requirements................................................... 41

Table 9 Reliability..................................................................................... 43

Table 10 Environmental Tolerances ........................................................ 44

Table 11 SCSI Controllers..........................................................................50

LTO-2 Half-Height Tape Drive User’s Guide ix

Page 10

Tables

x LTO-2 Half-Height Tape Drive User’s Guide

Page 11

Preface

Audience This document was written for operators of the Quantum LTO-2 Half-

Height Tape Drive.

Purpose This document provides information about the Quantum LTO-2 Half-

Height Tape Drive including:

• Installing the drive

• Basic drive operations

• Maintenance

• Specifications

Document

Organization

• Troubleshooting

This document is organized as follows:

0

• Chapter 1,

technologies, and summarizes the drive’s key features.

LTO-2 Half-Height Tape Drive User’s Guide xi

Introduction, provides an overview of LTO and Ultrium

Page 12

Preface

• Chapter 2, Installation and Quick Start describes handling

precautions, unpacking tips, and installation instructions for the

internal and desktop drives, as well as a summary of cabling and

connector specifications. It also provides quick-start instructions for

getting the drives up and running in the shortest possible time.

Notational

Conventions

• Chapter 3,

Operation explains the use and operation of the drive and

describes maintenance procedures.

• Chapter 4,

Theory describes the theory of operation behind the

drives, including the technology used in various drive components.

• Chapter 5,

Specifications contains detailed drive and cartridge

specifications, as well as a summary of regulatory approvals and

WEEE Compliance statement.

• Chapter 6,

• Chapter 7,

UNIX Settings describes the settings for UNIX systems.

Troubleshooting Guide provides troubleshooting

procedures you can follow in the unlikely event you encounter a

problem with your drive.

This document concludes with a glossary and a detailed index.

This manual uses the following conventions:

Note: Notes emphasize important information related to the main

topic.

Tech Tip: Tech Tips provide technical information which may be

helpful in performing the procedure.

Caution: Cautions indicate potential hazards to equipment and are

included to prevent damage to equipment.

Warning: Warnings indicate potential hazards to personal safety and

are included to prevent injury.

xii LTO-2 Half-Height Tape Drive User’s Guide

Page 13

Preface

Related

Documents

Documents related to the LTO-2 Half-Height Tape Drive are shown

below:

SCSI-2 Specification

The SCSI-2 communications specification is the proposed American

National Standard for information systems, dated March 9, 1990. Copies

may be obtained from:

Global Engineering Documents

15 Inverness Way, East

Englewood, CO 80112

(800) 854-7179 or (303) 397-2740

Contacts Quantum company contacts are listed below.

Quantum Corporate Headquarters

To order documentation on the LTO-2 Half-Height Tape Drive User’s

Guide or other products contact:

Quantum Corporation

P.O. Box 57100

Irvine, CA 92619-7100

(949) 856-7800

(800) 284-5101

0

0

Technical Publications

To comment on existing documentation send e-mail to:

doc-comments@quantum.com

Quantum Home Page 0

Visit the Quantum home page at:

www.quantum.com

LTO-2 Half-Height Tape Drive User’s Guide xiii

0

Page 14

Preface

Customer Support 0

The Quantum Customer Support Department provides a 24-hour help

desk that can be reached at:

North/South America: (949) 725-2100 or (800) 284-5101

Asia/Pacific Rim: (International Code) + 61 7 3839 0988

Europe/Middle East/Africa: (International Code) + 44 (0) 1256 848748

Send faxes for the Customer Support Department to:

North/South America: (949) 725-2176

Asia/Pacific Rim: (International Code) + 61 7 3839 0955

Europe/Middle East/Africa: (International Code) + 44 (0) 1256 848777

Send e-mail for the Customer Support Department to:

Asia/Pacific Rim: apachelp@quantum.com

Europe/Middle East/Africa: eurohelp@quantum.com

Visit our web site:

www.quantum.com/support

xiv LTO-2 Half-Height Tape Drive User’s Guide

Page 15

Chapter 1

1Introduction

The LTO-2 Half-Height Tape Drive is a high-performance 8-channel tape

drive that complies with the LTO interchange specifications. It is suited

for mid-range to high-end servers, mainframe systems, and tape library

automation systems.

The LTO-2 Half-Height Tape Drive uses Ultrium data cartridges. Its

capacity is maximized using intelligent data compression. The drive has a

native capacity of 200 Gbytes (400 Gbytes assuming 2:1 data

compression).

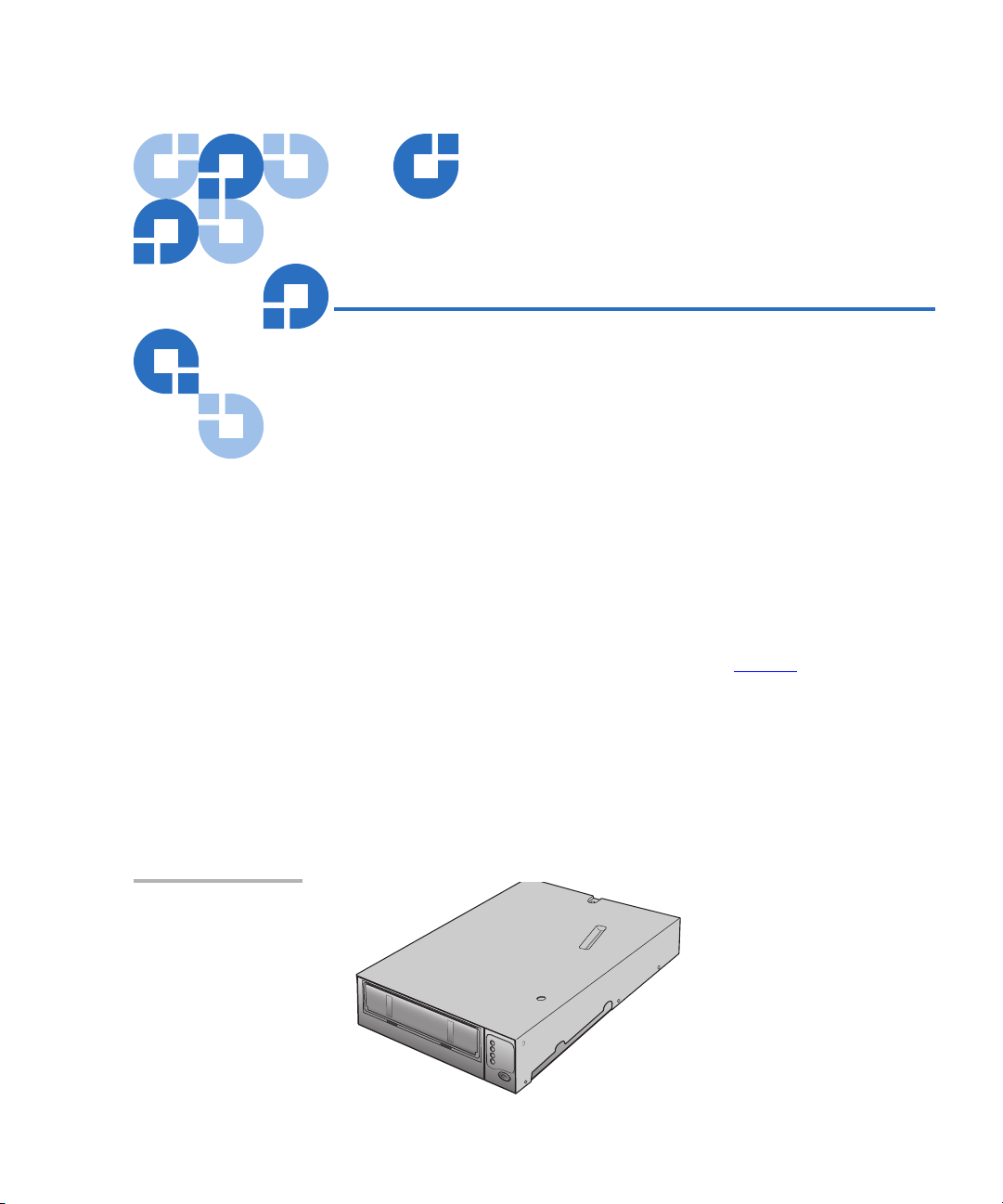

Figure 1 Drive

Covered in this User’s

Guide (Typical)

The LTO-2 Half-Height Tape Drive, as shown in figure 1

inch half-height form factor with automatic electromechanical cartridge

soft load. It is available as an internal and a desktop drive.

• The internal LTO--2 half-height drive is designed to fit in a 5¼-inch

half-height drive bay.

• The desktop LTO--2 half-height drive is a stand-alone unit with a

built-in power supply.

LTO-2 Half-Height Tape Drive User’s Guide 1

below, has a 5¼

Page 16

Chapter 1 Introduction

Features

Features 1

The following list summarizes the key features of the LTO-2 Half-Height

Tape Drives.

• Performance - Up to 26 Mbytes-per-second native transfer.

• 13-Speed Transfer matches tape drive speed to that of the host and

optimizes data transfers, resulting in shorter backup times and

increased reliability.

• Two convenient form-factors:

• 5¼-inch internal form-factor for installation in a 5¼-inch half-

height space.

• External desktop form-factor.

• Intelligent data compression maximizes performance and capacity by

analyzing compressibility prior to recording.

• Cartridge memory enables fast loading of cartridges and stores

pertinent information about the media.

• 32-Mbyte data buffer for extra fast backups on high-performance

systems.

• Tape Alert drive performance monitoring and reporting.

• Third generation read channel for increased maturity and data

integrity.

• Patented head positioner for increased data integrity.

• Shock dampened isolated chassis.

• Two levels of ECC for extra data safety and protection from errors.

• Reliable tape picking implementation for increased reliability.

• Custom-designed LSI circuitry for fast, efficient data processing.

• RISC processors for fast, efficient data processing.

• Supports a wide variety of UNIX platforms.

2 LTO-2 Half-Height Tape Drive User’s Guide

Page 17

Chapter 2

2Installation and Quick Start

This chapter explains how to install the internal and desktop LTO-2

Half-Height Tape Drives.

Topics covered in this chapter are:

• Quick Start Guide

• Unpacking and Inspection

• Internal Tape Drive Guidelines and Cautions

• Installing an Internal LTO-2 Half-Height Tape Drive

• Installing a Desktop LTO-2 Half-Height Tape Drive

LTO-2 Half-Height Tape Drive User’s Guide 3

Page 18

Chapter 2 Installation and Quick Start

Quick Start Guide

Quick Start Guide 2

Use the following quick-start instructions to get your tape drive up and

running as quickly as possible.

Internal LTO-2 Half-Height Tape Drive Quick Start

1 Unpack the contents of your drive package, and check for damaged items.

See Unpacking and Inspection

2 Review the drive’s default settings and change them if necessary:

•SCSI ID: 6

• Terminator Power: Disabled

See Configuring the Internal Tape Drive

3 Turn off your computer, remove its covers and power cable, and select a mounting

bay for the drive.

See Mounting the Internal Tape Drive

4 Connect a SCSI interface cable to the drive.

See Connecting a SCSI Cable

5 Terminate the SCSI bus if the internal tape drive is the last device on the SCSI bus.

See Checking the SCSI Termination

6 Connect a serial cable, if connecting the tape drive to a tape library.

See Connecting a Serial Cable for Tape Libraries

Use the following procedure to install internal LTO-2 Half-Height Tape

Drive. Print this page and check each step as you complete it. If you need

more information about a step, turn to the section referenced in the step.

2

.

on page 7.

on page 11.

on page 13.

on page 14.

on page 14.

7 Connect a power cable to the drive.

See Connecting a Power Cable

8 Replace the computer covers and power cable, turn on the computer, and verify

that the internal tape drive is operating properly.

9 Register your tape drive.

See Registering Your Tape Drive

4 LTO-2 Half-Height Tape Drive User’s Guide

on page 15.

on page 15.

Page 19

Chapter 2 Installation and Quick Start

Quick Start Guide

Desktop LTO-2 Half-Height Tape Drive Quick Start

Use the following procedure to install desktop LTO-2 Half-Height Tape

Drive. Print this page and check each step as you complete it. If you need

more information about a step, turn to the section referenced in the step.

2

1 Unpack the contents of your drive package, and check for damaged items.

See Unpacking and Inspection

.

2 Review the drive’s default settings and change them if necessary:

•SCSI ID: 6

SeeSetting the SCSI ID

on page 16.

3 Connect a SCSI interface cable to the drive.

See Connecting a SCSI Cable

on page 16.

4 Check the SCSI termination.

See Checking the SCSI Termination

on page 17.

5 Connect a power cable to the drive.

See Connecting a Power Cord

on page 17.

6 • Turn on the computer

• Turn on the desktop tape drive

• Verify that the desktop tape drive is operating properly.

7 Register your tape drive.

See Registering Your Tape Drive

LTO-2 Half-Height Tape Drive User’s Guide 5

on page 18.

Page 20

Chapter 2 Installation and Quick Start

Unpacking and Inspection

Unpacking and Inspection 2

Although drives are inspected and carefully packaged at the factory,

damage may occur during shipping. Follow these steps to unpack the

drive.

1 Visually inspect the shipping containers and notify your carrier

immediately of any damage.

2 Place shipping containers on a flat, clean, stable surface; then

carefully remove the contents. If the equipment is damaged, notify

your Quantum representative.

3 Always save the containers and packing materials for any future

reshipment.

Internal Tape Drive Guidelines and Cautions 2

The following guidelines and cautions apply to handling and installing

internal tape drives. Keep them in mind as you install the drive.

• Handle the drive by the sides rather than by the top cover to reduce

the risk of dropping the drive or damaging it during installation.

• Internal drives contain some exposed components that are sensitive

to static electricity. To reduce the possibility of damage from static

discharge, the drives are shipped in a protective antistatic bag. Do not

remove the drive from the antistatic bag until you are ready to install

it.

• Before you remove the drive from the antistatic bag, touch a metal or

grounded surface to discharge any static electricity buildup from

your body.

• Always lay the drive either on top of the antistatic bag or place it

inside of the bag to reduce the chance of damage from static

discharge.

• Install LVD drives only in an LVD environment. Do not mix LVD and

HVD devices on the same SCSI bus.

6 LTO-2 Half-Height Tape Drive User’s Guide

Page 21

Chapter 2 Installation and Quick Start

Drive Installation Instructions

• Due to the speed of the LTO-2 Half-Height Tape Drive, it is

recommended that a maximum of one LTO-2 drive be connected to

one channel on a host SCSI adapter.

Drive Installation Instructions 2

After unpacking and inspecting your shipping containers and reviewing

the installation guidelines and cautions, proceed to the appropriate

section in this chapter for instructions on installing your internal or

desktop LTO-2 Half- Height Tape Drive.

• Installing an Internal LTO-2 Half-Height Tape Drive

• Installing a Desktop LTO-2 Half-Height Tape Drive

.

on page 16.

Installing an Internal LTO-2 Half-Height Tape Drive 2

Installing an internal LTO-2 Half-Height Tape Drive involves the

following steps:

1 Configuring the Internal Tape Drive

2 Mounting the Internal Tape Drive on page 11

3 Connecting a SCSI Cable

4 Checking the SCSI Termination

5 Connecting a Serial Cable for Tape Libraries

6 Connecting a Power Cable

7 Registering Your Tape Drive

on page 13

on page 14

on page 14

on page 15

on page 15

Configuring the Internal Tape Drive

Before you install the LTO-2 Half-Height Tape Drive in your computer,

you may need to configure the drive’s SCSI ID and terminator power

2

features. The default configuration settings for the LTO-2 Half-Height

Tape Drive are:

LTO-2 Half-Height Tape Drive User’s Guide 7

Page 22

Chapter 2 Installation and Quick Start

Installing an Internal LTO-2 Half-Height Tape Drive

• SCSI ID: 6

• Terminator power: disabled

If you need to change these settings, refer to the following sections.

Otherwise, skip to Mounting the Internal Tape Drive

on page 11.

SCSI ID

• Jumper Pins: 1–2, 3–4, 5–6, 7–8

• Default Setting: SCSI ID 6

Each SCSI device on the bus must have its own unique SCSI ID. The

internal tape drive is shipped with a default SCSI ID of 6. If another SCSI

device in the SCSI chain is using this ID, use jumper pins 1–2, 3–4, 5–6,

and 7–8 to change the SCSI ID of the LTO-2 Half-Height Tape Drive (see

figure 2

and table 1), or assign a unique SCSI ID to the other SCSI device.

Note: The SCSI controller or host adapter generally uses ID 7. In

some systems, the boot drive uses ID 0 or ID 1. Avoid setting

your drive’s SCSI ID to these settings.

2

8 LTO-2 Half-Height Tape Drive User’s Guide

Page 23

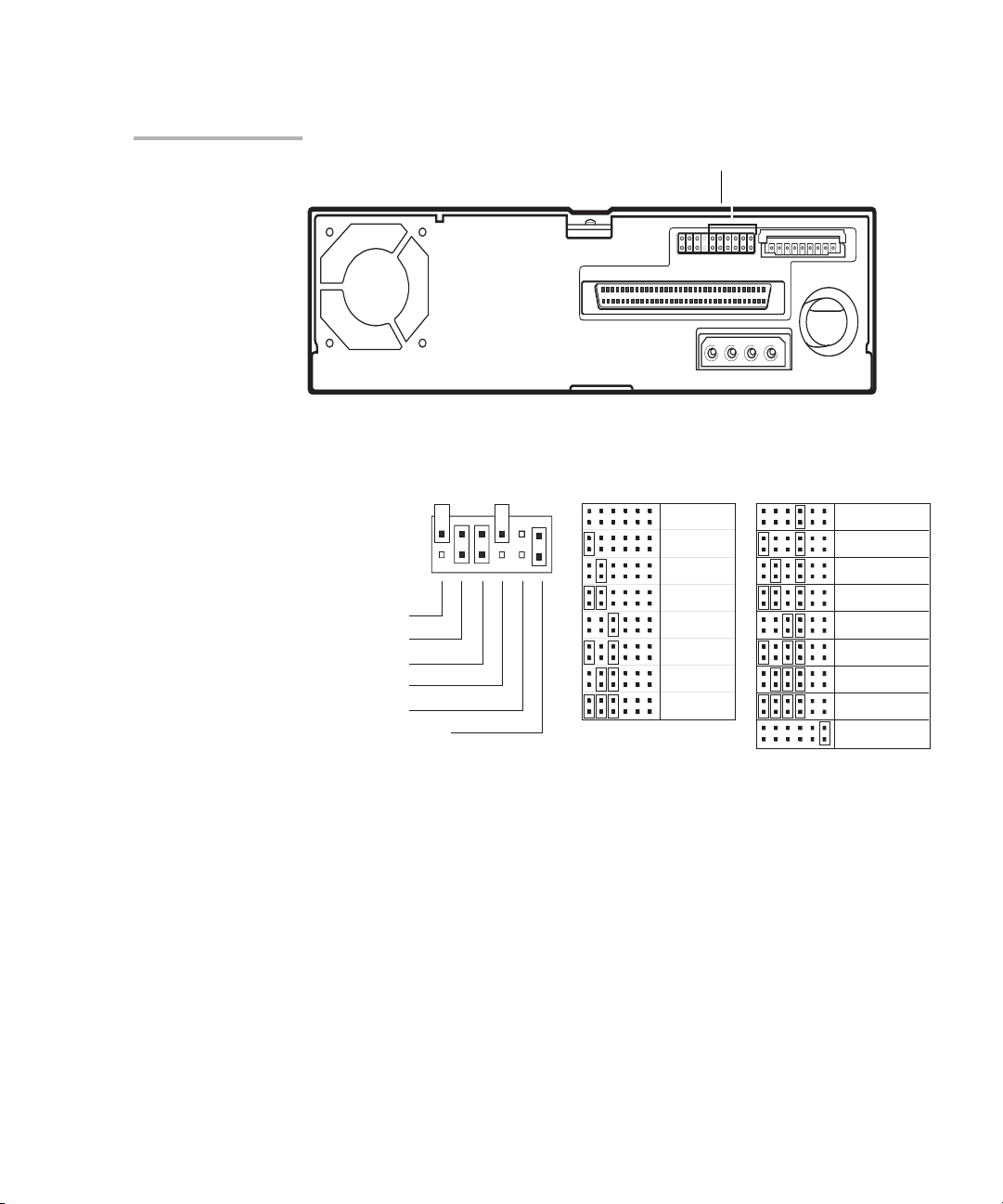

Figure 2 Internal

LTO-2 Half-Height

Tape Drive Jumper

Settings

Chapter 2 Installation and Quick Start

Installing an Internal LTO-2 Half-Height Tape Drive

Drive Configuration Jumper Pins

Drive Configuration

Default

settings:

Pins: Function:

1-2 SCSI ID bit 0

3-4 SCSI ID bit 1

5-6 SCSI ID bit 2

7-8 SCSI ID bit 3

9-10 Reserved

11-12Termination Power

Jumper Pins

SCSI ID=0

SCSI ID=1

SCSI ID=2

SCSI ID=3

SCSI ID=4

SCSI ID=5

SCSI ID=6

SCSI ID=7

Jumper Settings

SCSI ID=8

SCSI ID=9

SCSI ID=10

SCSI ID=11

SCSI ID=12

SCSI ID=13

SCSI ID=14

SCSI ID=15

Term. power

LTO-2 Half-Height Tape Drive User’s Guide 9

Page 24

Chapter 2 Installation and Quick Start

Installing an Internal LTO-2 Half-Height Tape Drive

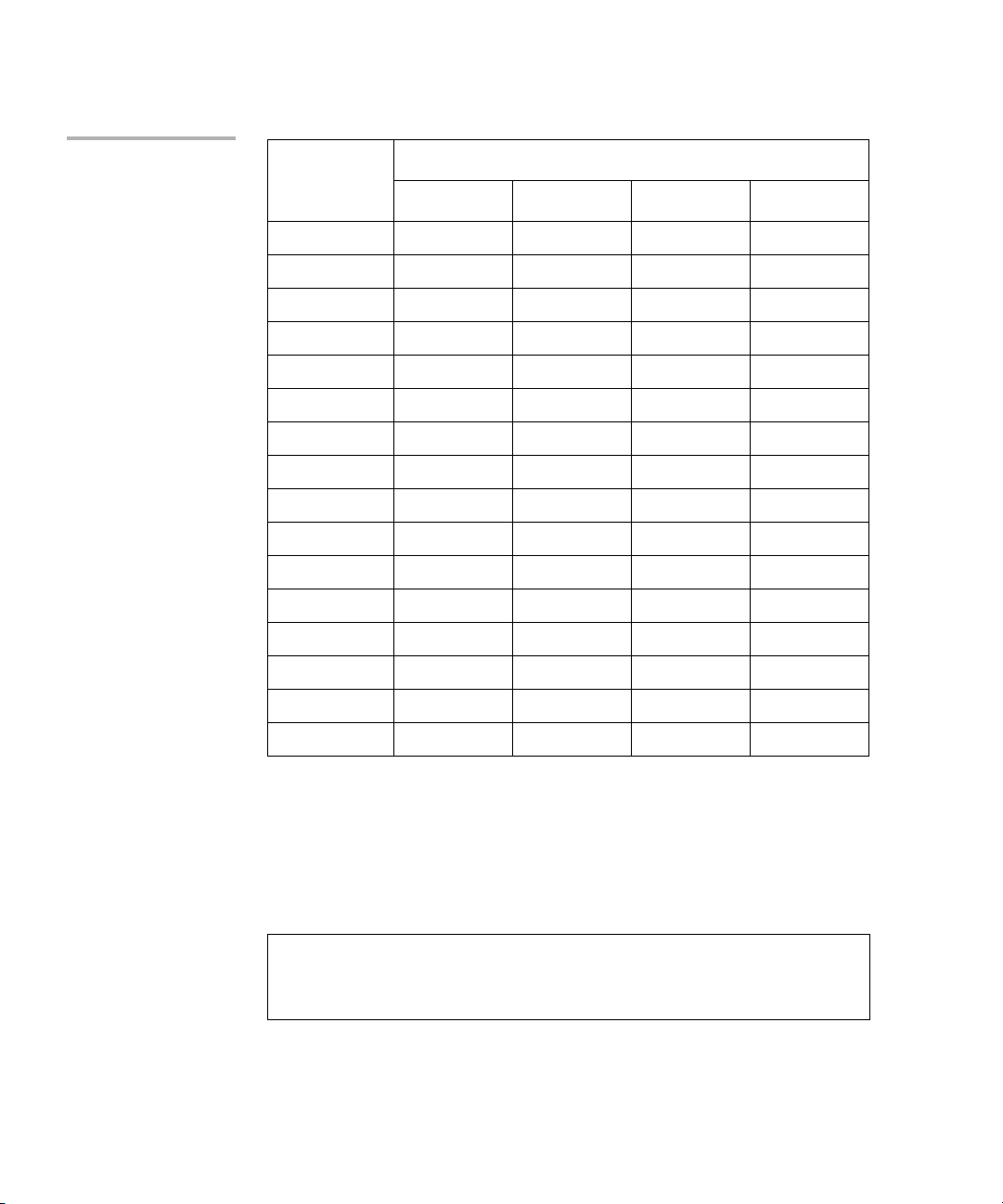

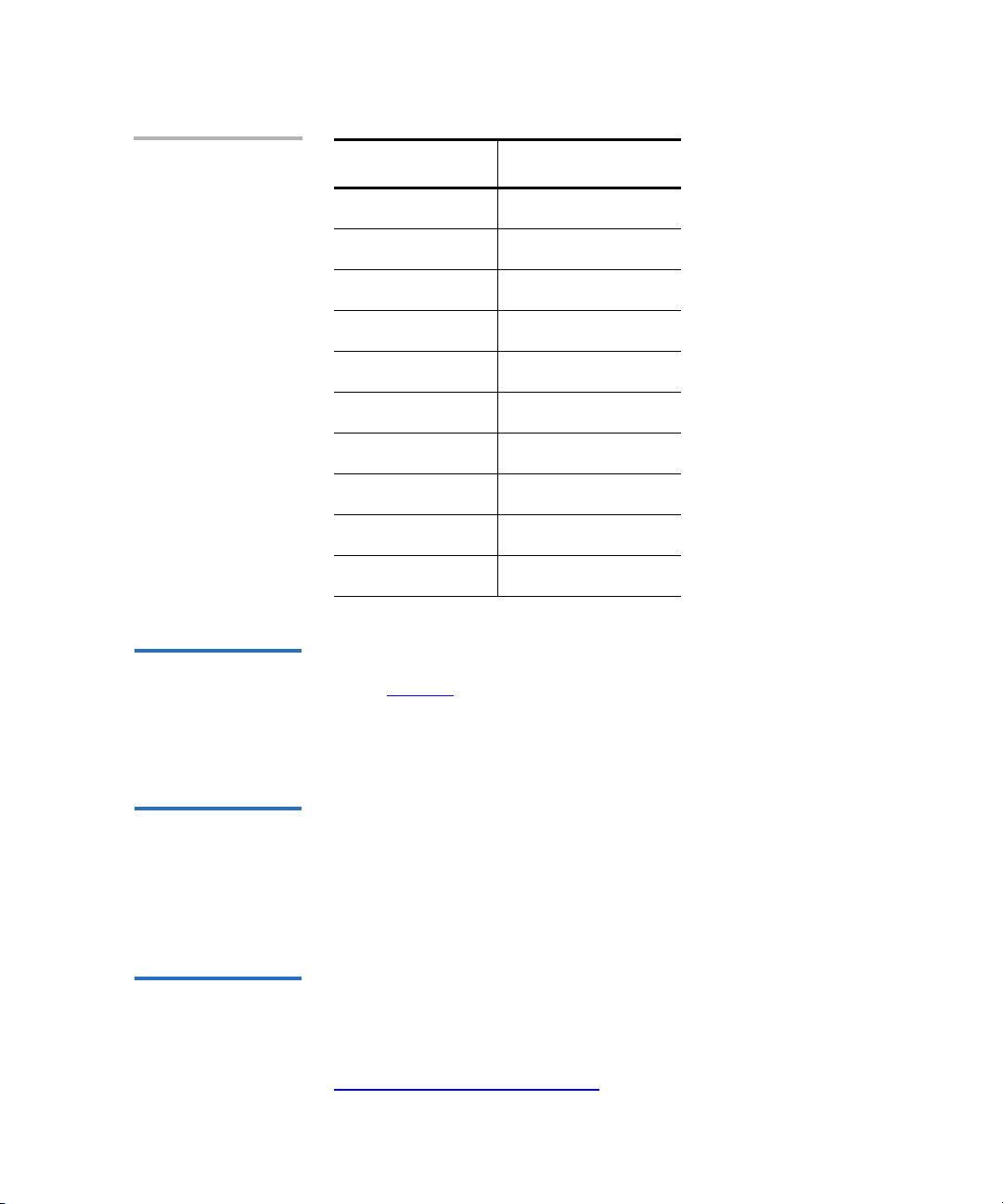

T able 1 SCSI IDs and

Jumper Settings for

LTO-2 Half-Height in

Drive

Jumpers

SCSI ID

1–2 3–4 5–6 7–8

0 Open Open Open Open

1 Shunted Open Open Open

2 Open Shunted Open Open

3 Shunted Shunted Open Open

4 Open Open Shunted Open

5 Shunted Open Shunted Open

6 (default) Open Shunted Shunted Open

7 Shunted Shunted Shunted Open

8 Open Open Open Shunted

9 Shunted Open Open Shunted

10 Open Shunted Open Shunted

11 Shunted Shunted Open Shunted

12 Open Open Shunted Shunted

13 Shunted Open Shunted Shunted

14 Open Shunted Shunted Shunted

15 Shunted Shunted Shunted Shunted

Terminator Power 2

By default, terminator power is disabled on the internal LTO-2

Half-Height Tape Drive. To enable terminator power, place a jumper

across pins 11 and 12.

Note: The internal LTO-2 Half-Height Tape Drive does not provide

SCSI termination. Thus, a terminator must be installed on the

drive if it is the last device in a SCSI chain.

10 LTO-2 Half-Height Tape Drive User’s Guide

Page 25

Chapter 2 Installation and Quick Start

Installing an Internal LTO-2 Half-Height Tape Drive

Mounting the Internal Tape Drive

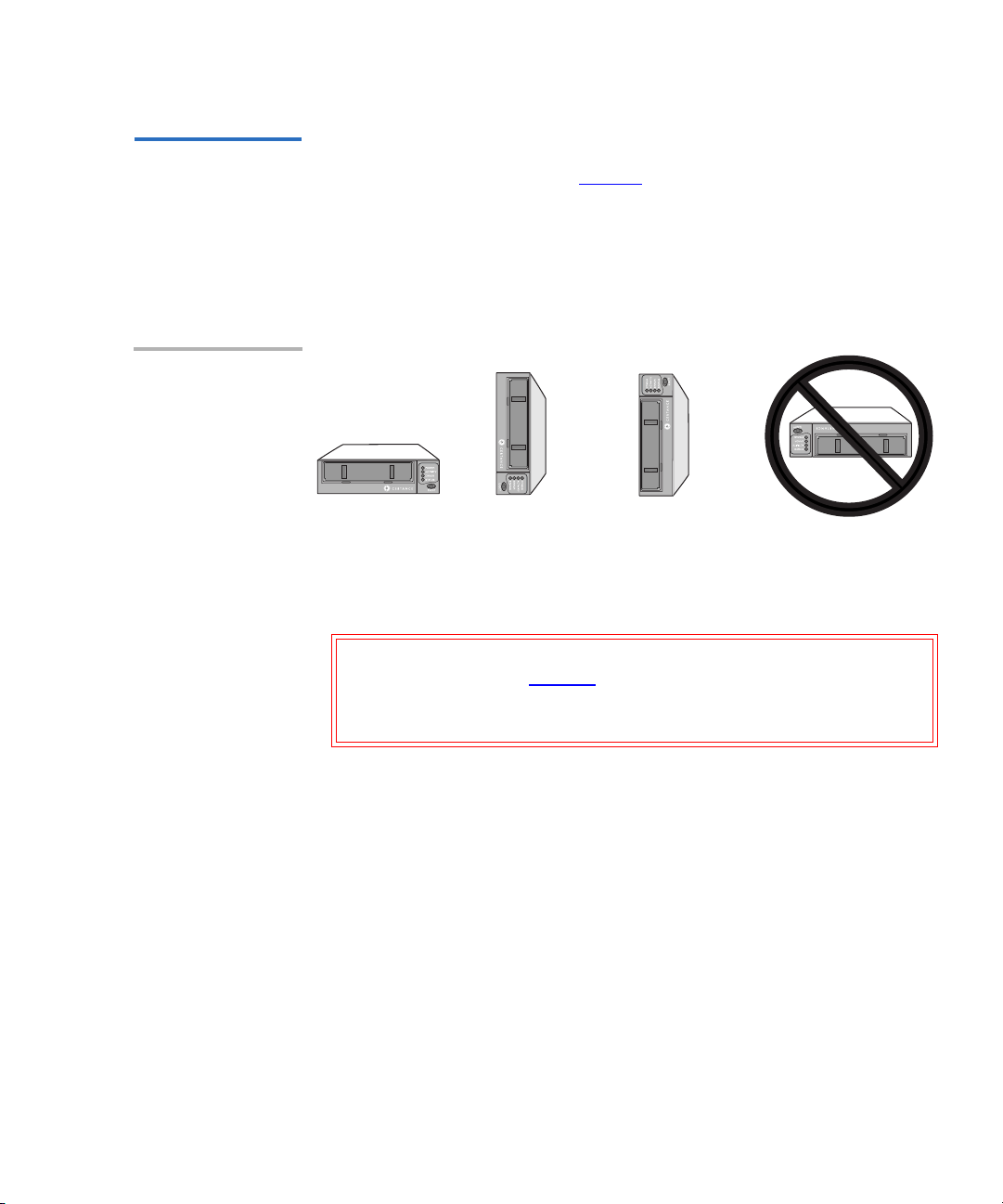

Figure 3 Acceptable

Mounting Orientation

You can mount the internal LTO-2 Half-Height Tape Drive either

horizontally or vertically (see figure 3

2

).

• If you mount the drive vertically, the side of the drive should be

within 5 degrees of horizontal.

• If you mount the drive horizontally, the base of the drive must be

within 15 degrees of horizontal and the drive must be right-side up.

YES NOYES YES

Mount the drive in a 5.25-inch, half-height drive bay and secure it using

two M3.0 X 3 metric screws on each side of the drive.

Caution: Do not use screws longer than 3 mm or you may damage

the drive. Figure 4

shows the locations of the mountingscrew holes on the side and bottom of the drive,

respectively.

LTO-2 Half-Height Tape Drive User’s Guide 11

Page 26

Chapter 2 Installation and Quick Start

Installing an Internal LTO-2 Half-Height Tape Drive

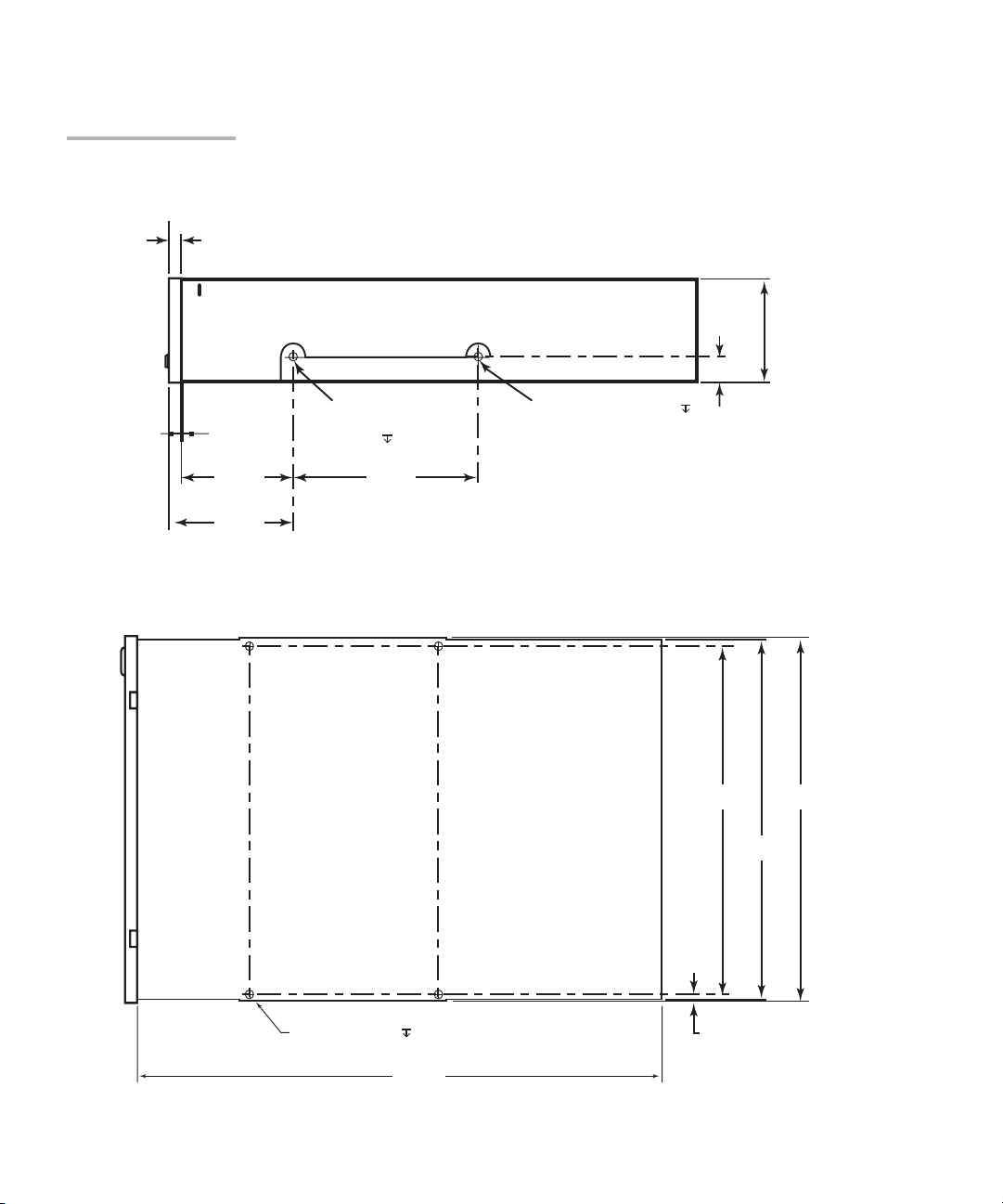

Figure 4 Internal LTO2 Half-Height Tape

Drive Mounting

Dimensions

5.0

BEZEL

THICKNESS

INCLUDING CONNECTORS

41.0 MAX

(40.75 NOMINAL)

0.5

47.4

52.9

2X M3.0 NEARSIDE

2X M3.0 FARSIDE

3X 5.0

79.2

THIS HOLE

M3.0 x 2.5

10.0

146.0140.0

144.8

4X M3.0 X 5.0

221.0

12 LTO-2 Half-Height Tape Drive User’s Guide

2.4

Page 27

Chapter 2 Installation and Quick Start

Installing an Internal LTO-2 Half-Height Tape Drive

Connecting a SCSI Cable

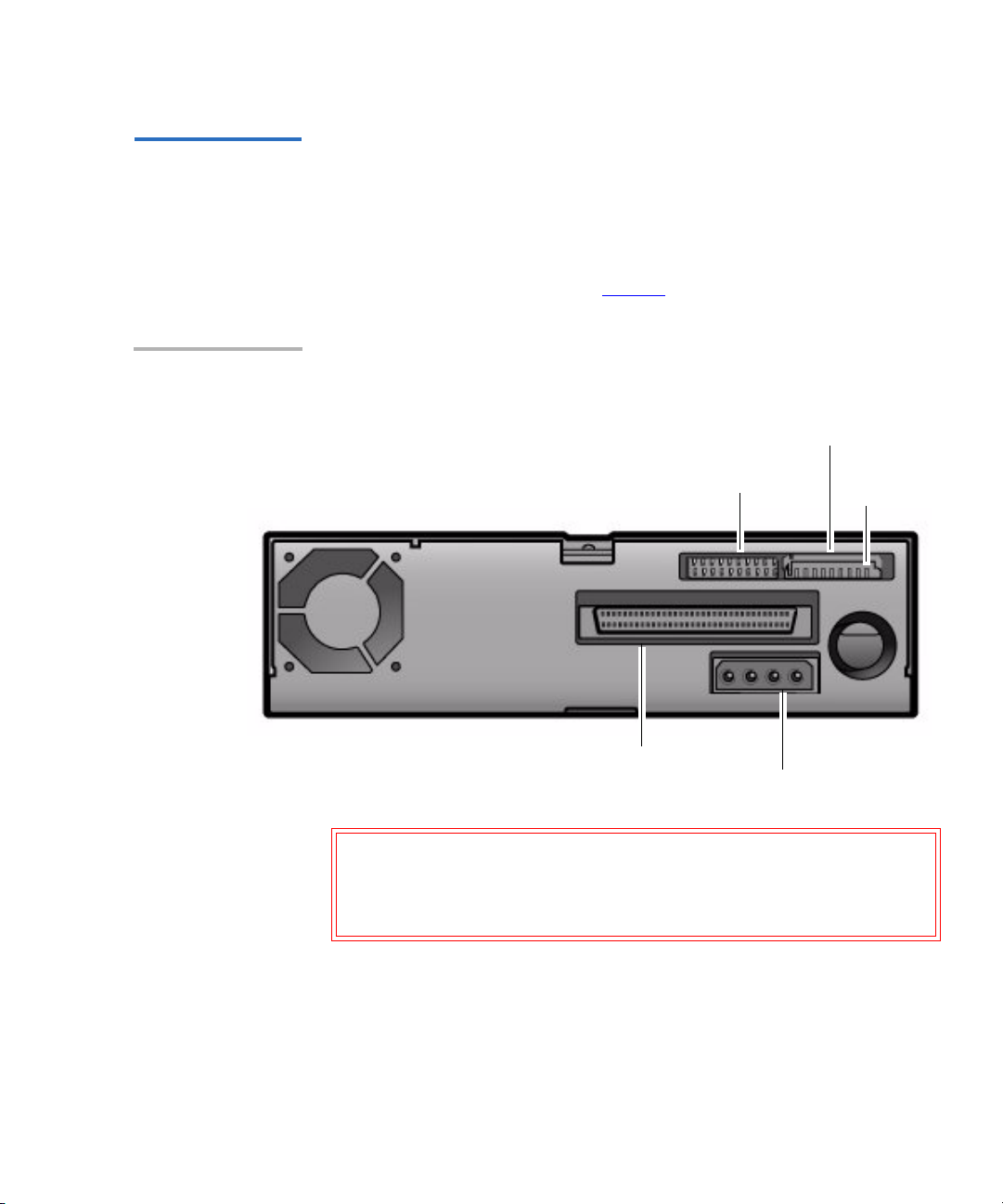

Figure 5 Rear View of

the Internal LTO-2

Half-Height T ape Drive

The internal LTO-2 Half-Height Tape Drive has an Ultra3 SCSI interface,

terminated by an LVD SCSI connector. Use the following procedure to

2

connect a SCSI cable to this connector.

1 Turn off all power to the drive and the computer.

2 Attach the SCSI interface cable to the 68-pin SCSI interface connector

on the back of the drive (see figure 5

).

Library Interface Connector

SCSI Jumper Block

Pin 1

SCSI Connector

Power Connector

Caution: Install an LVD drive only in an LVD environment.

Plugging an LVD drive into an HVD bus makes the entire

bus non-functional and may permanently damage the

drive or other SCSI devices on the bus.

LTO-2 Half-Height Tape Drive User’s Guide 13

Page 28

Chapter 2 Installation and Quick Start

e

b

Installing an Internal LTO-2 Half-Height Tape Drive

Checking the SCSI Termination

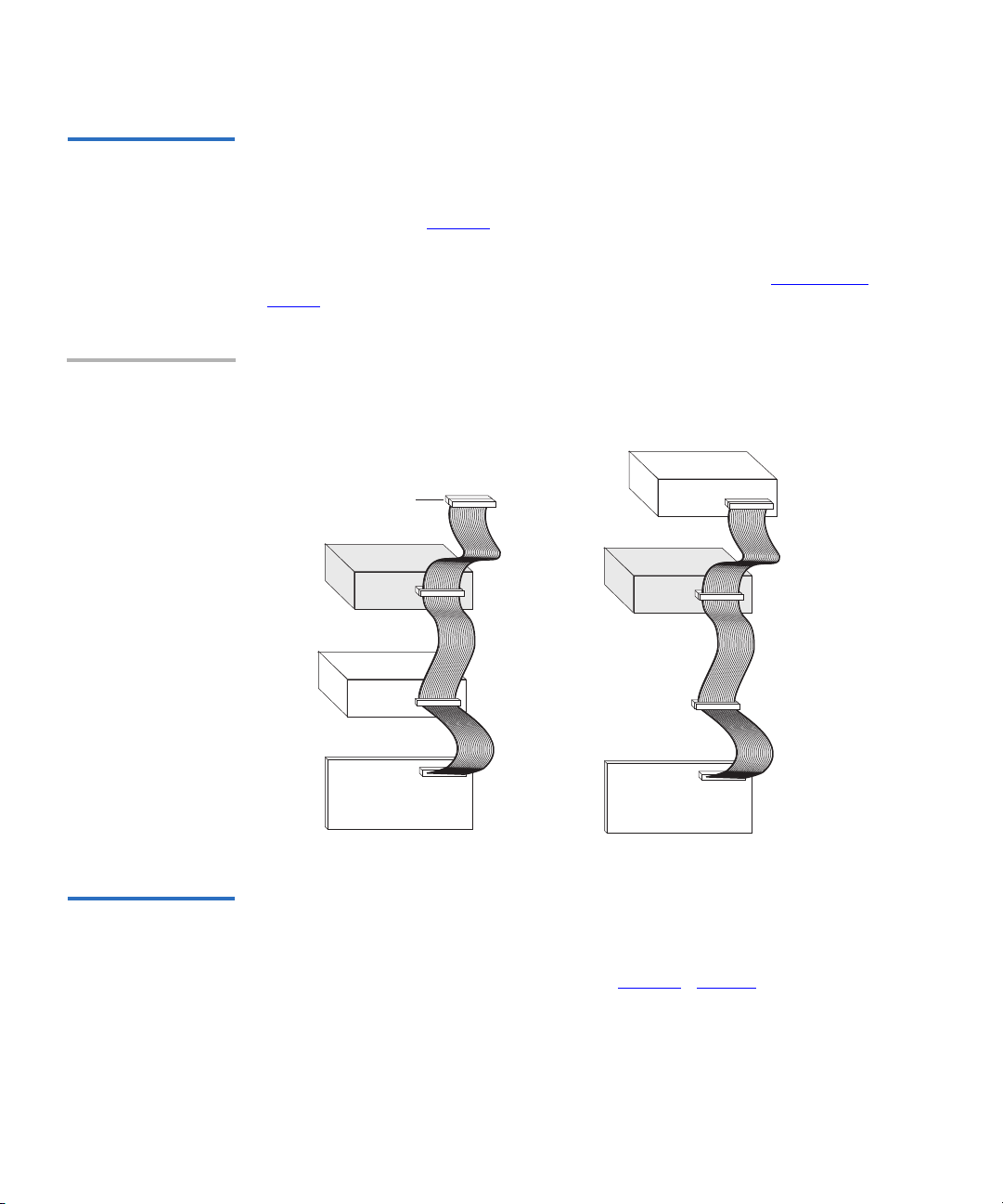

Figure 6 Two SCSI

T ermination Examples

for the Internal LTO-2

Half-Height T ape Drive

By default, the internal LTO-2 Half-Height Tape Drive does not provide

SCSI termination. If you use this default setting, you must place a SCSI

2

bus terminator or a SCSI device with termination enabled at the end of

the SCSI chain. See figure 6

for two examples of SCSI termination.

The internal LTO-2 Half-Height Tape Drive provides terminator power if

a jumper is placed on the termination power jumper pins (see Terminator

Power on page 10).

SCSI Terminator

Tape drive

(no

termination)

SCSI device

(termination

disabled)

Tape drive

(no

termination)

SCSI device

(termination

enabled)

CSI Controller

ination enabled)

Connecting a Serial Cable for Tape Libraries

The Internal LTO-2 Half-Height Tape Drive include an RS-422 serial

interface for tape libraries. The LTO-2 library interface uses an in-line

shrouded and keyed 10-pin connector. This connector is located on the

2

lower left side of the back of the drive (see figure 5

assignments.

14 LTO-2 Half-Height Tape Drive User’s Guide

SCSI Controll

(termination ena

). Table 2 shows pin

Page 29

Table 2 Serial

Interface Connector

Pin Assignments

Installing an Internal LTO-2 Half-Height Tape Drive

Pin Numbers Description

1+Tx

a

-Rx

Chapter 2 Installation and Quick Start

d

Connecting a Power Cable

2-Tx

a

-Rx

d

3Ground

4-Tx

5+Tx

6Sense

7Sense

8 Reset

9Signal

a

d

-Rx

-Rx

d

a

a

a

a

aux

10 Reserved

Attach a four-pin power cable to the power connector on the back of the

drive. Figure 5

2

shows the location of the power connector.

The recommended 4-pin power connector for internal drives is an AMP

1-48024-0 housing with AMP 60617-1 pins or equivalent.

Installing the LTO Driver

Registering Your Tape Drive

If you intend to use your drive with the Microsoft native backup applet

on Windows Server 2003, Windows XP, or Microsoft Windows 2000

2

operating system, install the appropriate LTO driver. See the Resource

CD. This driver is not necessary with commercial backup application

software.

After you install the internal tape drive, be sure to register it. Registering

your drive ensures that you will receive the latest information about your

2

drive, as well as other product, service, and support information. For

your convenience, you can register your drive through our Web site at:

www.quantum.com/registration

LTO-2 Half-Height Tape Drive User’s Guide 15

.

Page 30

Chapter 2 Installation and Quick Start

Installing a Desktop LTO-2 Half-Height Tape Drive

Installing a Desktop LTO-2 Half-Height Tape Drive 2

The desktop LTO-2 Half-Height Tape Drive is a compact subsystem that

connects to the host computer through a SCSI port. Installing a desktop

drive involves the following steps:

1 Setting the SCSI ID

2 Connecting a SCSI Cable

3 Checking the SCSI Termination

4 Connecting a Power Cord

5 Registering Your Tape Drive

Setting the SCSI ID2 Each SCSI device on the bus must have its own unique SCSI ID. The

desktop tape drive is shipped with a default SCSI ID of 6. Avoid setting

drive ID to 7. If another SCSI device in the SCSI chain is already using this

ID, either use the push-button switch on the back of the drive to change

the drive’s SCSI ID or assign a unique SCSI ID to the other SCSI device.

If you change the SCSI ID on the tape drive, turn off the tape drive before

changing the SCSI ID. The change takes effect when you turn on the

drive.

Note: The SCSI controller or host adapter generally uses ID 7. In

some systems, the boot drive uses ID 0 or ID 1. Avoid setting

your drive’s SCSI ID to these settings.

Connecting a SCSI Cable

16 LTO-2 Half-Height Tape Drive User’s Guide

The desktop LTO-2 Half-Height Tape Drive has two 68-pin, shielded

SCSI interface connectors (ANSI Alternative 2) on the rear panel. These

2

connectors consist of two rows of ribbon contacts spaced 2.16 mm (0.085

in) apart. Either connector can be used as a SCSI IN or SCSI OUT

connection. This means you can use either connector to attach the drive to

a host computer or to another SCSI device.

1 Turn off all power to the drive and the computer.

2 Attach the SCSI interface cable to one of the 68-pin SCSI interface

connectors on the back of the drive.

Page 31

Chapter 2 Installation and Quick Start

Installing a Desktop LTO-2 Half-Height Tape Drive

Checking the SCSI Termination

Figure 7 SCSI

T ermination Examples

for the Desktop LTO-2

Half-Height Tape Drive

If the desktop LTO-2 Half-Height Tape Drive is the last or only device in

a SCSI chain, install a 68-pin LVD terminating plug on the unused SCSI

2

connector. See figure 7

for two SCSI termination examples.

Note: Termination power is enabled as a default for desktop drives.

External

SCSI device

SCSI terminators

External

tape drive

External

SCSI device

SCSI controller

(termination enabled)

External

tape drive

SCSI controller

(termination disabled)

Internal

SCSI device

(termination

enabled)

Connecting a Power Cord

Installing the LTO Driver

Example 1: SCSI termination

in a system that has only

external SCSI devices.

Example 2: SCSI termination

in a system that has both

internal and external SCSI

devices.

Attach the power cord securely to the power connector on the back of the

desktop LTO-2 Half-Height Tape Drive.

2

If you intend to use your drive with either the Microsoft Windows Server

2003, Windows XP, or Microsoft Windows 2000 operating system, install

2

the LTO driver. See the Resource CD. This driver is not necessary with

commercial backup application software.

LTO-2 Half-Height Tape Drive User’s Guide 17

Page 32

Chapter 2 Installation and Quick Start

Installing a Desktop LTO-2 Half-Height Tape Drive

Registering Your Tape Drive

After you install the desktop tape drive, be sure to register it. Registering

your drive ensures that you will receive the latest information about your

2

drive, as well as other product, service, and support information. For

your convenience, you can register your drive through our Web site at:

www.quantum.com/registration

.

18 LTO-2 Half-Height Tape Drive User’s Guide

Page 33

Chapter 3

3Operation

This chapter describes how to operate the LTO-2 Half-Height Tape Drive.

Topics covered in this chapter are:

• Understanding the Front Panel Display

• Blink Codes

• Using LTO Cartridges

• Drive Maintenance

LTO-2 Half-Height Tape Drive User’s Guide 19

Page 34

Chapter 3 Operation

Understanding the Front Panel Display

Understanding the Front Panel Display 3

Figure 8 shows a generalized view of the LTO-2 Half-Height Tape Drive

front-panel display.

Figure 8 Generic

Front Panel Display

Power LED

Activity LED

Error LED

Status LED

Tape Load/Unload

Button

All drives have four LEDs on the front panel. The LED colors and

functions are as follows:

•

Power LED (green)

•

Activity LED (green)

•

Error LED (orange)

•

Status LED (amber)

The

Activity, Error, and Status LEDs blink or go on to indicate information

about the tape drive, see Blink Codes

20 LTO-2 Half-Height Tape Drive User’s Guide

.

Page 35

Chapter 3 Operation

Blink Codes

Blink Codes 3

Table 3 below summarizes the blink codes for the LTO-2 Half-Height

Tape Drives.

Table 3 LTO-2 Tape

Drive Blink Codes

Activity LED

Drive Condition

Cleaning Request ON

Hardware error Fast

Positioning – loading,

unloading, rewinding,

spacing, or locating

Tape Active – writing,

reading, or verifying

Manual intervention

required

Power On Self Test

(POST) failure

Cleaning cartridge

present

Cleaning cartridge at

EOT

Servo initialization Slow Slow

(Green)

Slow

Slow

ON ON

ON Fast

Error LED

(Orange)

ON

Fast ON

Status LED

(Amber)

Power On Self Test

(POST) in progress

Cleaning failure or

media error

Microcode download Fast Slow Fast

Microcode download

error

LTO-2 Half-Height Tape Drive User’s Guide 21

Slow Slow Slow

Fast Fast

Fast Fast Fast

Page 36

Chapter 3 Operation

Using LTO Cartridges

Note:

•

ON refers to a constant light

•

Slow refers to a blink rate of 1/2 second on, 1/2 second off

•

Fast refers to a blink rate of 1/8 second on, 1/8 second off.

Using LTO Cartridges 3

Loading a Cartridge

Unloading a Cartridge

To load an Ultrium cartridge into the LTO-2 Half-Height Tape Drive,

place the cartridge in the slot and then do one of the following:

3

• Continue to push the cartridge the rest of the way into the drive.

•Press the

cartridge.

• Use a library or host command to finish loading the tape.

To unload an Ultrium cartridge from the LTO-2 Half-Height Tape Drive,

either:

3

• Use a library or host command to unload the tape, or

•Push the

Caution: Several seconds may elapse between the time you press

load/unload button on the front of the drive to seat the

load/unload button on the front of the drive.

load/unload button and the time the cartridge is

the

ejected. Do not power down the tape drive or the host

computer until the drive has completely ejected the

cartridge.

Write-protecting a Cartridge

22 LTO-2 Half-Height Tape Drive User’s Guide

Ultrium cartridges have a sliding write-protect switch near the back right

corner of the cartridge, see figure 9

3

• If you slide the switch toward the center of the cartridge, data can be

read from the cartridge but not written to it.

.

Page 37

Figure 9 Ultrium

Cartridge Showing

Write-Protect Switch

Chapter 3 Operation

Using LTO Cartridges

• If you slide the switch all the way toward the corner (see figure 9),

data can be read from and written to the cartridge.

Note: LTO cartridges have prewritten servo patterns and should not

be bulk erased.

Writeprotect

switch

(unlocked)

Locked

Unlocked

Cartridge Care and Maintenance

To protect the data on your Ultrium data cartridges, observe the

following precautions:

3

• Always remove the cartridge from the drive when not in use and

store it in its protective case.

• Do not expose cartridges to dirt, dust or moisture.

• Do not touch the tape media within a cartridge.

• Do not use data cartridges outside the specified operating conditions:

o

10

C to 40o C, 10% to 80% relative humidity.

If a data cartridge has been exposed to temperature or humidity changes

within the limits listed above, allow the tape cartridge to acclimate to its

surroundings for at least one hour before use. Then retension the tape to

allow the tape pack to become stable for better performance.

LTO-2 Half-Height Tape Drive User’s Guide 23

Page 38

Chapter 3 Operation

Drive Maintenance

Retensioning the Tape 3

If, during storage and/or transportation, a data cartridge has been

exposed to conditions outside the above range, it must be conditioned

before use in the operating environment. The conditioning process

requires exposure to the operating environment for a time equal to, or

greater than, the time away from the operating environment, up to a

maximum of 24 hours.

• Keep the cartridge away from direct sunlight and heat sources, such

as radiators, heaters, or warm air ducts.

• Keep the cartridge away from sources of electromagnetic fields, such

as telephones, computer monitors, dictation equipment, mechanical

or printing calculators, motors, magnetic tools, and bulk erasers.

• Avoid dropping the cartridges.

This can damage components inside the cartridge, possibly rendering

the tape unusable. If a tape is dropped it is advisable to open the

cartridge door and make sure that the leader pin is in the correct

position. A dropped cartridge should be retensioned before use.

• Do not bulk erase Ultrium cartridges.

Bulk-erased cartridges cannot be reformatted by the tape drive and

will be rendered unusable.

Drive Maintenance 3

The Ultrium drive requires little or no maintenance. However, the drive

mechanism may need to be cleaned.

Cleaning the Tape Drive

Excessive tape debris or other material may accumulate on the tape heads

if the drive is used with non-approved media or operated in a hot, dusty

3

environment. In this case, the drive may experience excessive errors

while reading or writing, and the amber

continuously during operation. This means that the drive heads need to

be cleaned.

Status LED remains on

24 LTO-2 Half-Height Tape Drive User’s Guide

Page 39

Chapter 3 Operation

Drive Maintenance

The LTO cleaning cartridge has the same dimensions as the data

cartridge and contains an LTO-CM (Cartridge Memory), but is loaded

with cleaning media instead of recording media. Always keep the

cleaning cartridge in its protective case when not in use.

To clean the drive, insert an LTO Ultrium cleaning cartridge. During the

cleaning process, both the

Status and Drive LEDs remain lit. After the

cleaning process is completed, the cartridge may be ejected automatically,

or you may need to press the load/unload button to remove the

cartridge, depending on the drive configuration. Each time you use the

cleaning cartridge, write the date on the label for future reference.

Note: If the

Status LED comes on continuously within 24 hours after

a cleaning cycle, perform the cleaning cycle again. If, after

three cleaning cycles in a 72-hour period, the

Status LED lights

up again, contact Technical Support.

Each time the drive is cleaned, the tape advances to a new, unused

section of media. After approximately 50 cleanings, all of the media will

be used up and you should discard the cleaning cartridge. When a

cleaning cartridge is used up, the amber

green

Drive LED remains on. Do not reuse a spent cleaning cartridge

Status LED flashes, while the

Note: The cleaning procedure will not run and the cleaning cartridge

will be ejected in the following circumstances:

• The drive does not recognize the cartridge as an LTO

cleaning cartridge.

• All of the tape on the cleaning cartridge has been used up

(at EOT). In this case, the

while the

Drive LED remains on.

Status LED will flash rapidly

LTO-2 Half-Height Tape Drive User’s Guide 25

Page 40

Chapter 3 Operation

Drive Maintenance

26 LTO-2 Half-Height Tape Drive User’s Guide

Page 41

Chapter 4

4Theory

This chapter describes operational theories used in the LTO-2

Half-Height Tape Drive.

The topics covered in this chapter are:

• Track Layout

• Recording Method

• Data Buffer

• Data Integrity

• Data Compression

Track Layout 4

With the LTO-2 Half-Height Tape Drive, there are 512 data tracks on the

LTO tape, numbered 0 through 511.

• Data track 511 is the track closest to the bottom edge of the tape (the

reference edge).

• The area between adjacent servo bands is a data band.

LTO-2 Half-Height Tape Drive User’s Guide 27

Page 42

Chapter 4 Theory

0

5

0

5

Track Layout

• There are 4 data bands, each of which includes 128 data tracks.

• The data bands are numbered 2,0,1,3. Data band 2 is closest to the

bottom edge of the tape.

A track group should it be: is a set of 16 data tracks that record

concurrently. The sets of 16 data tracks in a data band are data sub bands.

There are 8 data sub bands per data band. The data tracks are accessed in

a serpentine manner.

A wrap is a track group recorded in the physical forward or physical

reverse direction. The wraps are recorded in a serpentine fashion starting

in data band 0. The tape contains 64 track groups, 32 written in the

forward direction and 32 written in the reverse direction. Even-numbered

wraps are recorded in the forward direction (BOT to EOT), and oddnumbered wraps are recorded in the reverse direction (EOT to BOT).

Figure 10

Figure 10 Layout of

Tracks on L T O Ultrium

Tapes

shows the layout of data on an LTO tape.

Beginning of

tape (BOT)

End of

tape (EOT)

Tape edge

Servo band

Even # wrap

Odd # wrap

Sub bands 1 through 6

(not shown)

Even # wrap

Odd # wrap

Servo band

Tape edge

Sub band 0

Sub band 7

DATA

BAND

28 LTO-2 Half-Height Tape Drive User’s Guide

Page 43

Chapter 4 Theory

Recording Method

Recording Method 4

The LTO-2 Half-Height Tape Drive records data using write-equalized

(1,7) Run Length Limited (RLL) code. RLL (1,7) Data bits are defined as

follows:

•A

ONE is represented by a flux transition at the center of a bit-cell.

•A

ZERO is represented by no flux transition in the bit-cell.

Data Buffer 4

In their default configuration, the LTO-2 Half-Height Tape Drive has a

32-Mbyte buffer. The buffer controller has a burst transfer rate of 320

Mbytes/sec. The high bandwidth is needed to support look-aside data

compression in the case of compressible data being transferred from SCSI

at 160 Mbytes/sec.

Data Integrity 4

The mechanical and electrical design of the drives ensures that drive

performance does not degrade over a drive’s operating life. Changes in

head alignment, head wear, component drift, and other factors are

minimized to ensure that data integrity and interchange capability are

not compromised over the drive's operating life.

Error-correction Code (ECC)

The error rate of the LTO-2 Half-Height Tape Drive is less than 1 hard

error in 10

The use of Cyclic Redundancy Checking (CRC), two-level orthogonal

Error Correction Coding (ECC) provides a very low probability of

4

encountering a hard error. During the read process, ECC correction is

performed on the fly without affecting tape streaming.

17

bits. The drive’s undetectable error rate is 1 in 1027 bits read.

LTO-2 Half-Height Tape Drive User’s Guide 29

Page 44

Chapter 4 Theory

Data Integrity

There are two levels of Error Correction Coding (ECC). These two levels

are orthogonal — that is, an ECC codeword at one level intersects ECC

codewords at the other level just once, which means there will be only

one common symbol between them. The two levels are called C1 and C2.

C1 ECC

As data is written to memory from the Data Processing unit, the DMA /

ECC interface generates C1 ECC bytes and writes them to memory.

As data is written to tape, the C1 ECC is checked and an interrupt

generated if there is an error. The C1 ECC read from memory is the ECC

that is written to tape.

When data is read from tape and stored into memory, C1 ECC is checked.

• If the C1 ECC is good, that codeword pair’s “Valid” bit is set.

• Otherwise, a pointer to the invalid Codeword Pair is passed to the C1

ECC correction engine.

• If the C1 ECC correction engine can correct the error, then the

corrected bytes are written to memory, and the Valid bit is set.

• Otherwise, the Valid bit is left cleared.

As data is read from memory to the Data Processor for decompression,

the C1 ECC is again checked and an interrupt generated if it is not correct.

C2 ECC

C2 ECC involves three distinct operations:

4

4

1

Encoding: Generating C2 ECC bytes from data bytes (performed by

ECC co-processor hardware)

2

Decoding: Generating ECC syndromes from data and ECC bytes,

testing for all-zeroes (performed by ECC co-processor hardware)

3

Correction: Generating corrected data from syndromes.

The correction depends on the number and types of errors involved:

• For one known C1 codeword pair in error in a sub-data set (C2

codeword), the operation is performed by the ECC co-processor

hardware.

30 LTO-2 Half-Height Tape Drive User’s Guide

Page 45

Chapter 4 Theory

Data Compression

• For two or more known C1 codeword pairs in error, the matrix is

computed by firmware and the correction is performed by hardware.

• For one or more unknown C1 codeword pairs, syndromes are

generated by hardware, error location is computed by firmware, the

matrix is computed by firmware and the correction is performed by

hardware.

Servo-tracking Faults

During a write operation, if the servo system detects an error that may

result in adjacent data tracks being over-written, the write operation is

4

aborted. The write operation will not continue until the correct servo

tracking is re-established.

Data Compression 4

Typical data streams of text, graphics, software code, or other forms of

data contain repeated information of some sort, whether it is at the text

level where you can readily recognize regular repetitions of a single

word, or at the binary level where the repetitions are in bits or bytes.

Although most data is unique and random, the binary level data exhibits

patterns of various sizes that repeat with varying degrees of regularity.

Storage efficiency is increased if the redundancies or repetition in the

data are removed before the data is recorded to tape. Data compression

technology significantly reduces or eliminates redundancies in data

before recording the information to tape. This increases the amount of

data that can be stored on a finite medium and increases the overall

storage efficiency of the system.

With data compression, the redundant information in a data stream is

identified and represented by codewords or symbols, which allow the

same data to be recorded in a fewer number of bits. These codewords or

symbols point back to the original data string, using fewer characters to

represent the strings. Because these smaller symbols are substituted for

the longer strings of data, more data can be stored in the same physical

space.

Some important benefits result from data compression in tape drives:

LTO-2 Half-Height Tape Drive User’s Guide 31

Page 46

Chapter 4 Theory

Data Compression

• The same amount of information can be stored on a smaller length of

tape.

• More data can be stored on a given length of tape.

• Performance can more closely parallel to that of high-transfer-rate

computers.

• More information can be transferred in the same time interval.

Data Compression Considerations

In an effective data-compression method, several factors are important:

4

• The amount of compression. The amount of compression is measured

by the compression ratio. This ratio compares the amount of

uncompressed data to the amount of compressed data. It is obtained

by dividing the size of the uncompressed data by the size of the

compressed data)

• The speed with which data is compressed and decompressed relative

to the host transfer rate.

• The types of data to be compressed.

• The data integrity of the compressed data.

The amount of compression possible in a data stream depends on factors

such as:

• Data pattern

• Compression algorithm

• Pattern repetition length

• Pattern repetition frequency

• Object size (block of information to be compressed)

• Starting pattern chosen

The transfer rate depends on factors such as:

• Compression ratio

•Drive buffer size

• Host computer input/output (I/O) speed

• Effective disc speeds of the host computer

• Record lengths that the host computer transmits

32 LTO-2 Half-Height Tape Drive User’s Guide

Page 47

Chapter 4 Theory

Data Compression

Data compression algorithms can be tailored to provide maximum

compression for specific types of data. Because varying types of data are

encountered in normal day-to-day operating circumstances, however, an

effective data compression method for a tape drive must serve various

data types. Additionally, the data compression method must adapt to

different data types, automatically providing optimum handling for all

types of data.

Intelligent Data Compression

The tape’s compressed capacity is maximized through the use of

intelligent data compression. The intelligent data compression hardware

4

determines the compressibility of each record. If the size of the record is

larger after a compression attempt than the native (uncompressed) size,

then the record is written in its native form.

The intelligent data compression utilizes two compression schemes:

• Scheme-1 is a LZ1 based compression scheme using a history buffer

to achieve data compression.

• Scheme-2 is a pass-through compression scheme designed to pass

uncompressible data through with minimal expansion.

There are three specific requirements for compliance with the LTO

specification.

• The output data stream must be decompressible following LTO rules

to create the input sequence of records and File Marks perfectly.

• An LTO compressed data stream may not contain any of the eight

reserved Control Symbols.

• While control symbols allow switching to Scheme 2, this should

never be used by operational software because this capability is only

for diagnostic and testing purposes.

Software data compression should never be used because the LTO-2

Half-Height Tape Drive's built-in intelligent data compression is much

more efficient than software data compression systems.

The LTO-2 Half-Height Tape Drive uses a derivative of ALDC-2 lossless

data compression that includes additional control codes for intelligent

data compression.

LTO-2 Half-Height Tape Drive User’s Guide 33

Page 48

Chapter 4 Theory

Data Compression

34 LTO-2 Half-Height Tape Drive User’s Guide

Page 49

Chapter 5

5Specifications

This chapter provides technical specifications for the LTO-2 Half-Height

Tape Drive.

The topics covered in this chapter are:

• Physical Specifications

• Power Specifications

• Drive Performance Specifications

• Environmental Requirements

• Reliability

• Mean Time Between Failures

• LTO Cartridge Specifications

• Regulatory Compliance

• Disposal of Electrical and Electronic Equipment

LTO-2 Half-Height Tape Drive User’s Guide 35

Page 50

Chapter 5 Specifications

Physical Specifications

Physical Specifications 5

Table 4 below lists the physical specifications of the LTO-2 Half-Height

Tape Drive.

Table 4 Physical

Specifications

Internal SCSI Drive

Specification

Height 1.6 inches

Width 5.75 inches

Length 8.74 inches

Weight 3.660 lb.

Figure 11 shows the dimensions of the internal LTO--2 half-height drive.

without Bezel

(41.0 mm) max

(146.05 ± 0.25)

(222 mm)

(1.66 kg)

Internal SCSI Drive

with Bezel

1.69 inches

(43.1 mm +/- 0.3 mm)

5.81 inches

(147.8 mm +/- 0.3 mm)

8.93 inches

(227 mm) max

(less connector)

3.715 lb.

(1.685 kg)

36 LTO-2 Half-Height Tape Drive User’s Guide

Page 51

Figure 11 Internal

)

LTO-2 Half-Height

Tape Drive

Dimensions

Chapter 5 Specifications

Physical Spe cifications

5.0

BEZEL

THICKNESS

0.5

47.4

52.9

OVERALL LENGTH

226.5

INCLUDING CONNECTORS

2X M3.0 NEARSIDE

2X M3.0 FARSIDE

3X 5.0

79.2

THIS HOLE

M3.0 x 2.5

41.0 MAX

(40.75 NOMINAL

10.0

146.0140.0

144.8

LTO-2 Half-Height Tape Drive User’s Guide 37

Page 52

Chapter 5 Specifications

Power Specifications

Power Specifications 5

The desktop LTO-2 Half-Height Tape Drive comes with a built-in 90260VAC (47-63 Hz) automatic switching power supply.

Maximum voltage and power specifications for the internal LTO-2

Table 5 Voltage and

Current

Half-Height Tape Drive are listed in table 5

Specification +12 VDC + 5VDC

DC Voltage Tolerance

(1)

12.00 + or – 10% 5.00 + or – 5%

Non-operating max voltage 14 Volts peak 7 Volts peak

and table 6.

Table 6 Power

Dissipation

(5)

(1)

(2)

(4)

0.13 amps RMS 1.4 amps RMS

0.45 amps RMS 1.4 amps RMS*

(3)

0.71 amps RMS 2.9 amps RMS

0.83 amps RMS 3.0 amps max RMS

2.34 amps

3.0 amps max RMS

(1 sec max)

100 mV < 100 mV

Idle current

Standby current (max)

Typical operating current

Max operating current

Max. Peak operating

current

Ripple (peak-to-peak) <

* RMS parameters measured at the power connector using a true RMS

digital meter.

Specification LTO-2

Idle Power

Standby Power

Typical Operating Power

(1)

(2)

(3)

9 watts RMS

12.5 watts RMS*

23 watts RMS

38 LTO-2 Half-Height Tape Drive User’s Guide

Page 53

Drive Performance Specifications

Specification LTO-2

Chapter 5 Specifications

Max Continuous Operating Power

Max Peak Operating Power

(1)

Note:

No cartridge loaded (typical drive idle current/power)

(2)

Cartridge loaded and tape-threaded -- drive ready for

transfer (typical drive standby current/power)

(3)

Average drive current/power measured during Read/Write

mode at 4.53 m/s on a typical drive.

(4)

Maximum drive current measured during Read/Write mode

(5)

(4)

25 watts RMS*

40 watts RMS (1 sec max)

at 4.53 m/s. Worst case 1 second RMS measurement. Measured

at the following worst case voltages (5.25V and 10.8V).

(5)

Peak current/power, RMS current measured for maximum

current do not occur at the same time max current condition.

(1-5)

RMS parameters measured at the power connector using a

nominal voltages of 5.0V and 12.0V unless stated otherwise.

Drive Performance Specifications 5

Table 7 lists the performance specifications for the LTO-2 Half-Height

Tape Drive.

LTO-2 Half-Height Tape Drive User’s Guide 39

Page 54

Chapter 5 Specifications

Drive Performance Specifications

Table 7 Drive

Performance

Specification

Specification Value

Capacity

LTO-2 (609 m)

Ultrium type A (609 m)

Ultrium type B (319 m)

Ultrium type C (203 m)

Ultrium type D (87 m)

200 Gbytes (native)

100 Gbytes (native)

50 Gbytes (native)

30 Gbytes (native)

10 Gbytes (native)

Recording density 3,930 RLL-encoded ONEs per mm

Flux density 3,660 flux transitions per mm

Track density 3 tracks per mm

Error recovery Read-after-write Reed Solomon ECC (2 levels)

Recording unrecoverable errors <1 in 10

Recording undetectable errors < 1 in 10

17

data bits

27

data bits

Tape drive type LTO-2 (Ultrium)

Head configuration 16 thin-film write heads

16 MR read heads

4 MR servo heads

During operation 8 write heads, 8 read heads, and

2 servo heads are active at the same time

Recording format Ultrium 8-channel (U-28)

Recording method 0, 13/11 RLL

Transfer rate (sustained) 20 Mbytes/second (max, native)

Cartridge unload time 3 seconds

40 LTO-2 Half-Height Tape Drive User’s Guide

Page 55

Specification Value

Average rewind time (609-m tape) > 4.5 seconds

Chapter 5 Specifications

Environmental Requirements

Maximum rewind time (609-m tape) <

Average data access time (609-m tape)

from BOW

Maximum data access time (609-m tape)

from BOW

Average rewind time (609-m tape) < 76 seconds

Tape speed Up to 3.48 meters per second

136 seconds

68 seconds

136 seconds

Environmental Requirements 5

Table 8 lists the environmental specifications for the LTO-2 Half-Height

Tape Drive.

Table 8 Environmental

Requirements

Specification Operational Non-operational

Temperature +50° to +104°F

(+10° to + 40°C)

Airflow requirements Internal: 9 CFM (front to back) N/A

Thermal gradient 11°C per hour (10-40°C) 11°C per hour (10-40°C)

Relative humidity 20% to 80% non-condensing 10% to 95% non-

Humidity gradient 10% per hour 10% per hour

LTO-2 Half-Height Tape Drive User’s Guide 41

–40° to +149°F

(–40° to + 66°C)

condensing

Page 56

Chapter 5 Specifications

Reliability

Specification Operational Non-operational

Altitude max 10,000 feet MSL (at 25°C) 40,000 feet (power off)

Shock (1/2 sine wave) 10 Gs peak, 11 msec 25 Gs peak, 11 msec

Vibration (sweep test) 0.005 inches DA (5-43 Hz) 0.20 G

peak (43–1000 Hz) sweep rate 51000Hz;

(1.0 octave per minute)

Acoustic level idling

(A-wt sum)

Acoustic level operational

(A-wt sum)

Injected Noise 5 The internal drive operates without degradation of error rates with 100

mV of noise injected between the chassis and 0 V at the power connector

at any frequency between 45 Hz and 20 MHz.

52 dBA maximum 5.0 LwA Bels —

57 dBA maximum 5.5 LwA Bels —

0.1 inches DA (5-15 Hz)

1.0 G peak (15–500 Hz)

sweep rate 5-500Hz;

(1.0 octave per minute)

Reliability 5

The LTO-2 Half-Height Tape Drive is designed for maximum reliability

and data integrity. Table 9

summarizes the reliability specifications.

42 LTO-2 Half-Height Tape Drive User’s Guide

Page 57

Chapter 5 Specifications

Mean Time Between Failures

Table 9 Reliability

Specification Description

Non-recoverable error rate < 1 in 10

Error recovery and control • Error correction code techniques (C1

• Read-after-write (RAW)

• Error monitoring and reporting (error

•Retry on

Mean time between

failures (MTBF)

Cartridge load/unload 100,000 cartridge load/unload cycles (no

Mean time to replace

(MTTR)

250,000 hours MTBF at 100% duty cycle:

power applied and tape moving

continuously

(Desktop drive; 50,000 hours at full load

and 25°C)

thread)

Less than 30 minutes

17

bits

and C2 ECC)

log)

Mean Time Between Failures 5

The mean time between failures (MTBF) for the internal drive is specified

at 250,000 hours minimum. This specification includes all power-on and

operational time but excludes maintenance periods. Operational time is

assumed to be 100 percent of the power-on time. Operational time is the

time the tape is loaded.

The MTBF for the desktop drive power supply is 50,000 hours with the

unit operated at full load and 25°C.

Note: The MTBF rating does not represent any particular drive, but

is derived from a large database of test samples. Actual rates

may vary from unit to unit.

LTO-2 Half-Height Tape Drive User’s Guide 43

Page 58

Chapter 5 Specifications

LTO Cartridge Specifications

Mean Time to Replace

The mean time to replace (MTTR) is the average time required by a

qualified service technician to diagnose a defective drive and to install a

5

replacement drive. The MTTR for LTO products is less than 0.5 hour (30

minutes).

The Quantum LTO drives are field-replaceable units. If a problem occurs

with a subassembly or component in the drive, you should replace the

entire unit. Return the drive to the factory in its original packaging.

Contact your distributor, dealer, your computer system company or your

Quantum sales representative to arrange the return.

LTO Cartridge Specifications 5

Environmental Considerations

Table 10 Environmental

Tolerances

Table 10 lists the basic environmental tolerances for LTO Ultrium

cartridges.

5

Specification Value

Operating temperature 10°C to 40°C

Relative humidity 20% to 80%

Wet bulb temperature 26° C max

Max localized temperature-permanent tape damage > 52°C

If during storage and/or transportation a cartridge has been exposed to

conditions outside the above values, it must be conditioned before use in

the operating environment. The conditioning shall be exposure to the

operating environment for a time equal to, or greater than, the time away

from the operating environment, up to a maximum of 24 hours. There

shall be no deposit of moisture anywhere on or in the cartridge.

The stray magnetic field at any point on the tape shall not exceed

4000 A/m.

44 LTO-2 Half-Height Tape Drive User’s Guide

Page 59

Chapter 5 Specifications

Regulatory Compliance

Cartridge Memory 5 Each Ultrium cartridge has 4 Kbytes of nonvolatile memory: 3 Kbytes are

used to store tape-directory and hardware specific information. 1 Kbyte is

available for application and OEM use. The cartridge memory is

powered, read, and written to via a radio-frequency link.

Cartridge Reliability

Recommended cartridge use: After 5,000 load/unload cycles, replace the

cartridge to ensure data integrity.

5

See chapter 3, Operation

illustrations.

for additional cartridge information and

Regulatory Compliance 5

These drives comply with the safety and EMC regulations listed in the

following tables.

Safety Compliance 5

Country Regulatory Organization Compliant to:

United States

Canada

Mexico Normas Oficiales Mexicanas

Canadian Standards Association

(CSA)

(NOM), similar to UL

UL/CSA 60950-1

NOM standards

EU member nations Comité Europèen de

Normalisation Electrotechnique –

the European Committee for

Electrotechnical Standardization

(CENELEC)

LTO-2 Half-Height Tape Drive User’s Guide 45

Page 60

Chapter 5 Specifications

Regulatory Compliance

Country Regulatory Organization Compliant to:

Member nations of

IECEE*

IECEE* International

Electrotechnical Commission on

Electrical Equipment (IECEE) for

CB Scheme per IEC 60950-1 with

details and exceptions for each

member country

Mutual Recognition of Test

Certificates for Electrical

Equipment “CB Scheme”

Singapore Productivity and Standards Board

(PSB)

PSB safety certification

CB Scheme

South Korea JEON JEON safety certification

CB Scheme

Argentina Instituto Argentino de

Racionalization de Materiales

IRAM safety certification

CB Scheme

(IRAM)

China CCC safety certification

CB Scheme

Malaysia JBE SIRIM CB Scheme

Thailand TISI CB Scheme

India STQC BIS

South Africa SABS CB Scheme

Israel SII CB Scheme

* Member nations of the IECEE include Austria, Australia, Belgium,

Canada, China (PR), Czech Republic, Denmark, Finland, France,

Germany, Hungary, India, Ireland, Israel, Italy, Japan, (South) Korea,

Netherlands, Norway, Poland, Russian Federation, Singapore, Slovakia,

Slovenia, South Africa, Spain, Switzerland, United Kingdom, USA,

Yugoslavia.

46 LTO-2 Half-Height Tape Drive User’s Guide

Page 61

EMC Compliance 5

Country Regulatory Organization Compliant to:

Chapter 5 Specifications

Regulatory Compliance

United States Federal Communications

Commission (FCC)

Title 47: Code of Federal

Regulations, Part 15, Subpart B,

Class B: Digital Device

(47CFR15B)

Canada Industry Canada Digital

Apparaus - Interference-Causing

ICES-003 Class B: Digital

Apparatus

Equipment Standard (ICES-003)

EU member nations CE Emissions per CISPR 22, EN55022

and Immunity per CISPR 24,

EN55024

Australia and New

Zealand

Japan Voluntary Control Council for

Standards Australia Spectrum

Management “C-Tick”

Interface (VCCI)

AS/NZS 3548 (same as CISPR 22)

This is a voluntary compliance

standard; the drives meet it via

CE/EMC compliance

South Korea Radio Research Lab of Korea

RRL EMC certification

(RRL)

Taiwan Bureau of Commodity

BSMI EMC certification

Inspection and Quarantine

(BSMI)

China CNCA CCC Mark

Russia GOSSTANDART (GOST) CISPR-22, Class B

Israel SII CISPR-22, Class B

Note: Use these drives only in equipment where the combination has

been determined to be suitable by an appropriate certification

organization (for example, Underwriters Laboratories Inc. or

the Canadian Standards Association in North America).

LTO-2 Half-Height Tape Drive User’s Guide 47

Page 62

Chapter 5 Specifications

Disposal of Electrical and Electronic Equipment

You should also consider the following safety points:

• Install the drive in an enclosure that limits the user’s access to live

parts, gives adequate system stability and provides the necessary

grounding for the drive.

• Provide the correct voltages (+5 VDC and +12 VDC) based on the

regulation applied—Extra Low Voltage (SEC) for UL and CSA, and

Safety Extra Low Voltage for BSI and VDE (if applicable).

Disposal of Electrical and Electronic Equipment 5

This symbol on the product or on its

packaging indicates that this product

should not be disposed of with your other

waste. Instead, it should be handed over to

a designated collection point for the

recycling of electrical and electronic

equipment. The separate collection and

recycling of your waste equipment at the time of disposal

will help to conserve natural resources and ensure that it is

recycled in a manner that protects human health and the