Page 1

FastStor

®

1 Installation and User Guide

Advanced Digital Information Corporation

Page 2

Copyright © 2005 ADIC

The information contained in this document is subject to change without notice.

This document contains proprietary information which is protected by copyright. All rights are

reserved. No part of this document may be reproduced, modified, distributed, or translated to

another language without prior written consent of ADIC.

ADIC USA

11431 Willows Road NE

Redmond, Washington

98052-4952

Tel.: 1-800-336-1233

Fax: 1-425-881-2296

This document may describe designs for which patents are pending, or have been granted. By

publishing this information, ADIC conveys no license under any patent or any other right.

ADIC shall not be liable for errors contained herein or for incidental or consequential damages

(including lost profits) in connection with the furnishing, performance or use of this material

whether based on warranty, contract, or other legal theory. ADIC makes no representation or

warranty with respect to the contents of this document and specifically disclaims any implied

warranties of merchantability or fitness for any particular purpose. Further, ADIC reserves the

right to revise or change this document without obligation on the part of ADIC to notify any

person or organization of such revision of change.

Every effort has been made to acknowledge trademarks and their owners. All trademarks within

this document are the property of their respective owners. Trademarked names are used solely

for identification or exemplary purposes, and any omissions are unintentional. ADIC is a

registered trademark of Advanced Digital Information Corporation.

Published: October 2005 Document Number: 6-01513-01 Rev A

Page 3

Table of Contents

1 About This Guide................................................................................1

2 General Information............................................................................ 3

Models..................................................................................................4

Capacity.....................................................................................4

Data Transfer Rates...................................................................4

Product Description...............................................................................4

Front Panel.................................................................................5

Rear Panel.................................................................................6

3 Installation...........................................................................................9

Performing the Installation....................................................................9

4 Operation and Configuration ........................................................... 20

System Power-On...............................................................................20

Front Panel Display Modes.................................................................23

Menus......................................................................................23

Dialogs.....................................................................................25

Messages.................................................................................27

Status and Information.............................................................27

Main Menu..........................................................................................28

Setup Menu ........................................................................................29

FastStor 1 setup....................................................................... 29

SCSI Setup ..............................................................................29

Remote Management setup.....................................................30

View Data Menu..................................................................................30

FastStor 1 Info..........................................................................31

Drive Info..................................................................................32

Remote Management Information............................................32

Statistics...................................................................................32

Utilities Menu ......................................................................................33

The Maintenance Menus..........................................................33

The Diagnostics Menu .............................................................33

Set Password...........................................................................34

Cartridge Handling..............................................................................34

Cartridge Slot Numbers............................................................34

Moving Cartridges to and from the Drive..................................34

Magazine Handling.............................................................................35

Removing the Magazine from the Unit.....................................35

Inserting Cartridges into the Magazine.....................................37

Removing Cartridges from the Magazine.................................37

Inserting a Magazine into the Unit............................................38

Manual/Emergency Release of Magazines..............................39

Standby Functionality..........................................................................40

5 Remote Management........................................................................41

FastStor 1 Installation and User Guide i

Page 4

Remote Management Configuration...................................................41

Quick Start Instructions............................................................41

Enabling the RMI Without Rebooting.......................................41

Remote Management Web Pages......................................................42

Information Boxes....................................................................42

FastStor 1 Start Page...............................................................43

Status Page .............................................................................44

Settings Pages.........................................................................45

Command Page.......................................................................45

Maintenance Pages .................................................................46

6 Maintenance ...................................................................................... 48

Using the Cleaning Cartridge..............................................................48

Running an Installed Cleaning Cartridge..................................48

Removing the Cleaning Cartridge............................................49

Installing Firmware Upgrades.............................................................49

Loader Firmware Upgrade via SCSI ........................................49

Loader Firmware Upgrade via Web .........................................50

Drive Firmware upgrade via SCSI............................................51

Possible Upgrade Problems.....................................................52

Embedded Diagnostics............................................................52

Reinstalling the Transport Lock ..........................................................52

Transport Lock Installation Procedure......................................52

7 Troubleshooting ...............................................................................54

How to Take Memory Dumps of the Loader .......................................54

How to Take Memory Dumps of the Drive..........................................54

Hardware checking.............................................................................54

Software checking ..............................................................................55

Verifying Recent Changes..................................................................55

Troubleshooting matrix .......................................................................56

The Error Screen...............................................................................61

Error Codes ........................................................................................63

Appendix A – Specifications................................................................65

A.1. Mechanical Dimensions and Weight........................................65

A.2. Power Requirements................................................................66

A.3. Vibration Specifications............................................................67

A.4. Mechanical Shock Specifications.............................................68

A.5. Drop.........................................................................................68

A.6. Climatic Specifications.............................................................69

A.7. Noise Specification...................................................................69

A.8. Product Reliability ....................................................................69

Appendix B – Safety and regulatory information...............................70

B.1 Safety Approvals......................................................................70

B.2 EMC Approvals........................................................................70

B.3 Conformity Declarations...........................................................71

B.4 Safety Precautions...................................................................71

ii FastStor 1 Installation and User Guide

Page 5

List of Figures and Tables

Figure 2.1 Overview of ADIC FastStor 1............................................................3

Table 2-1 Data Storage Capacity...............................................................4

Table 2-2 Data Transfer Rates...................................................................4

Figure 2.2 Front panel of the FastStor 1.............................................................5

Figure 2.5 Rear panel of the FastStor 1.............................................................6

Figure 3.1 Rack Mounting kit............................................................................11

Figure 3.2 Rack mount rail...............................................................................12

Figure 3.3 Mounting the Rack mounting kit to a rack .......................................13

Figure 3.4 Rack mounting kit mounted in rack.................................................13

Figure 3.5 Slide the FastStor 1 in from the front...............................................14

Figure 3.6 Fasten the front of the FastStor 1 to the rack..................................14

Figure 3.7 Fasten the rear of the FastStor 1 to the rails...................................14

Figure 3.8 Power switch, fuse holder and power cord connection ...................15

Figure 3.9 Magazine lock marked with red plastic tab......................................16

Figure 3.10 SCSI cable and SCSI terminator connection.................................18

Figure 3.11 Positioning of barcode label for LTO cartridges. ...........................19

Figure 4.1 Power-on Screen ............................................................................20

Figure 4.2 Snapshot while running Inventory...................................................20

Figure 4.3 The Default screen..........................................................................21

Table 4-1 Robot Operation Statuses................................................................21

Table 4-2 Drive Operation Statuses.................................................................22

Figure 4.4 Standard Menu Layout....................................................................23

Figure 4.5 The Complete Menu Tree ...............................................................24

Figure 4.6 Standard Dialog Layout...................................................................25

Figure 4.7 Dialog layout, entering discrete values............................................25

Figure 4.8 Slot dialog layout.............................................................................26

Figure 4.9 Predefined options, shown one at the time. ....................................26

Figure 4.10 A default screen............................................................................27

Figure 4.11 Load to Drive.................................................................................34

Figure 4.12 Unload From Drive........................................................................35

Figure 4.13 Empty Drive Message...................................................................35

Figure 4.14 Removing magazine......................................................................36

Figure 4.15 Magazine eject..............................................................................36

Figure 4.16 Removing the magazine from the loader.......................................37

Figure 4.17 Gently push the cartridge into the magazine slot ..........................37

Figure 4.18 Push the release knob towards the cartridge to eject....................38

Figure 4.19 Cartridge position after manual release from

magazine slot............................................................................................38

Figure 4.20 Push magazine until it clicks into place.........................................39

Figure 4.21 Pointing out hole used to insert release tool..................................39

Figure 4.22 Magazine release tool in use.........................................................40

Figure 5.1 Navigation Menu.............................................................................42

Figure 5.2 Remote Management Start Page....................................................43

Figure 5.3 Remote Management Status Page.................................................44

Figure 5.4 Remote Management Command Page...........................................46

Figure 6.1 Transport lock marked with red plastic tab.....................................52

FastStor 1 Installation and User Guide iii

Page 6

Figure 7.1 Error Code Page.............................................................................61

Figure 7.2 Example of detailed information......................................................61

Figure 7.3 Example of further detailed information...........................................61

Figure 7.4 Example of action............................................................................62

Figure 7.5 Warning message concerning reboot..............................................62

Table A - 1 FastStor 1 Mechanical Dimensions and Weight.......................65

Table A - 2 FastStor 1 Power Requirements..............................................66

Table A - 3 FastStor 1 sine sweep levels ...................................................67

Table A - 4 FastStor 1 random vibration levels ...........................................67

Table A - 5 FastStor 1 mechanical shock levels.........................................68

Table A - 6 FastStor 1 drop test..................................................................68

Table A - 7 FastStor 1 temperature specification........................................69

Table A - 8 FastStor 1 humidity specification..............................................69

Table A - 9 FastStor 1 altitude specification ..............................................69

Table A - 10 FastStor 1 noise specification..................................................69

iv FastStor 1 Installation and User Guide

Page 7

1 About This Guide

This guide describes how to install and use the ADIC FastStor 1 with an LTO tape

drive. It is intended for use by anyone who installs, uses and maintains the device.

Chapter 2: General Information provides a product description of the FastStor 1.

Chapter 3: Installation describes how to install the device.

Chapter 4: Operating and Configuration describes how to use the local interface,

how to configure the device, and how to handle the cartridges and

magazines.

Chapter 5: Remote Management describes the functionality of the Remote

Management via Ethernet.

Chapter 6: Maintenance describes cleaning and upgrading procedures, and how

to prepare the FastStor 1 for shipping.

Chapter 7: Troubleshooting lists possible areas to investigate if you are having

problems with the FastStor 1.

Appendix A: Specifications provides the specification data for the ADIC FastStor 1.

Related Publications

• ADIC FastStor 1, SCSI Interface Functional Specifications provides the

SCSI interface specification for the ADIC FastStor 1. (ADIC part number 601512-01)

FastStor 1 Installation and User Guide 1

Page 8

2 FastStor 1 Installation and User Guide

Page 9

2 General Information

ADIC FastStor 1 is a compact tape cartridge loader designed for secure, reliable,

unattended system backup. The loader can be mounted in a 19” rack. Its height is

1U.

The loader is equipped with oneLTO tape drive and has room for 8 cartridges in

two 4-cartridge magazines.

Figure 2.1 Overview of ADIC FastStor 1

The entire system is under host control via an industry-standard SCSI interface. Its

robotic tape handling is both rugged and simple for utmost reliability.

The key features of the FastStor 1 include:

• Two removable cartridge magazines, each with space for four cartridges

• Integrated Barcode Reader

• Magazine release under system control

• Low Voltage Differential (LVD) / Single-Ended (SE) SCSI Interface

• On-board Diagnostics

• Remote management

• Operator interface with front panel display and four control buttons

• Standby functionality

FastStor 1 Installation and User Guide 3

Page 10

*** IMPORTANT ***

Review the READ ME FIRST caution at the beginning of

Chapter 3 before you power up the unit for the first time.

Models

For additional specification information for this model, refer to Appendix A.

Capacity

FastStor 1 Model Cartridge

ADIC FastStor 1

LTO2

Table 2-1 Data Storage Capacity

Data Transfer Rates

FastStor 1 Model Maximum Sustained

LTO2 24MB/s

Cartridge

Capacity

(Native)

200GB 400GB 1.6TB 3.2TB

Table 2-2 Data Transfer Rates

Capacity

(Comp 2:1)

Rate, Native

86.4GB/hr

Magazine

Capacity

(Native)

Maximum Sustained

Rate, Compressed

Magazine

Capacity

(Comp 2:1)

48MB/s

172.8GB/hr

Product Description

The FastStor 1 has several features designed to increase the product’s ease of

use and utility, such as:

• Two removable magazines allow easy management of data sets or archival

storage. For the FastStor 1 each magazine has room for four cartridges.

• A menu-driven operator control panel interface with backlit LCD provides

easy control for configuration and diagnostic activities.

• An Ethernet connection allows management by an operator with a standard

web browser on a remote computer. The remote operator can do most of

4 FastStor 1 Installation and User Guide

Page 11

the operations that can be done through the front panel, such as monitoring

the loader’s status and downloading statistical and diagnostic information.

For information on the installed tape drive, see the tape drive manuals referred to

in Chapter 1.

Front Panel

The Front Panel includes the User Control Panel with LCD display, four Control

Buttons, two LED indicators and a Standby switch. The bezels of the two

magazines are also visible from the front.

Magazine

front bezel

LED

indicators

Standby

switch

Figure 2.2 Front panel of the FastStor 1

LCD

display

Control buttons Magazine

front

bezel

LCD – liquid crystal display

The display is a backlit 122 x 32, dot-matrix graphical display that can show four

lines of 20 characters.

In various modes of operation, the display panel screens and control buttons allow

you to do the following:

• Enter settings for FastStor 1 configuration

• Issue operational commands

• View FastStor 1 status and information

• Test FastStor 1 functionality

Control Buttons

The labels for the four control buttons are displayed in the corners of the LCD. All

buttons have “soft labeling” for different modes of operation (i.e., the functions and

labels of the buttons change during different activities). The actual soft label for

each button for any activity is always visible on the display.

FastStor 1 Installation and User Guide 5

Page 12

LED Indicators

The two LED indicators are green and amber. They indicate the FastStor 1 activity

as follows:

• Green LED on: The FastStor 1 is either running or ready for operation.

• Green LED blinking: Short blinks followed by long intervals indicate that the

loader is in low power standby mode.

• Amber LED on: Fault LED; the FastStor 1 has encountered an electrical or

mechanical failure.

• Both LED’s off: The FastStor 1 is offline. This is the case while the loader is

initializing after power-on, and when a magazine is removed.

Standby Switch

A switch on the front panel provides a Loader Standby. If the switch is pushed

when the loader is active, the loader completes the current operation and then

goes offline and enters standby mode. See Standby Functionality for more details.

Magazine Front Bezel

The front bezel of the magazines is visible from the front. All magazine handling is

described in detail in Magazine Handling.

Rear Panel

The figure below shows the rear panel of the FastStor 1.

Power

switch

Fuse Power cord

connection

Figure 2.5 Rear panel of the FastStor 1

Fan Back panel

cover plate

Fan SCSI

connectors

Ethernet

port

Two Integrated Cooling Fans

The rear panel contains two forced-air cooling fans, which draw air inward through

the front and expel it out in the back. The fans start whenever the drive is operating

or when the internal temperature in the FastStor 1 gets too high.

6 FastStor 1 Installation and User Guide

Page 13

Main Power Switch/ Fuse/Power cord connection

The main power switch is found on the rear of the loader on the power supply

bracket. The power switch, the fuse holder (with a 250V 2A (H) fuse) and the AC

power cord connection are combined in one common unit.

SCSI Interface Connectors

The FastStor 1 has two shielded 68-pin VHDCI SCSI connectors on the rear panel.

The connectors are used for connecting the tape drive and the FastStor 1 to a

SCSI bus. These connectors can link to the following:

• A shielded male VHDCI SCSI cable

• A shielded male VHDCI SCSI terminator

Ethernet Port

This port is for the Remote Management system and allows you to connect the

FastStor 1 to a 10/100 BaseT Ethernet network.

FastStor 1 Installation and User Guide 7

Page 14

8 FastStor 1 Installation and User Guide

Page 15

3 Installation

This chapter provides step-by-step instructions on how to properly prepare and

install the ADIC FastStor 1.

READ ME FIRST

CAUTION! !

YOU MUST REMOVE THE ROBOT TRANSPORT LOCK

WHEN POWERING UP THE UNIT FOR THE FIRST TIME

OR IT WILL NOT OPERATE.

SEE THE PROCEDURE ON THE FOLLOWING PAGES.

Performing the Installation

To install the FastStor 1, complete the following steps.

Step 1. Unpacking the FastStor 1

Carefully unpack the unit from the shipping container. Save the container and

packing materials in case you need to transport the FastStor 1 in the future. The

packaging is specifically designed for the loader to ensure it is not damaged during

transportation.

Review the contents of the shipping container to be sure that all parts were

included in the shipment. A standard package for the FastStor 1 consists of the

following items:

• A factory-assembled FastStor 1 unit containing two cartridge magazines.

• A Standard Accessory Kit containing:

- 1 Warranty/Registration Card

- Rack Mount Hardware Kit

- 2 Line Power Cords: one for USA/Japan and one for European

power outlets

- 1 VHDCI SCSI Interface Cable

- 1 68-pin VHDCI LVD/SE SCSI Terminator

- 1 Ethernet cable

- Tool for Emergency Magazine Release

- Media barcode label kit (contains media labels and cleaning

FastStor 1 Installation and User Guide 9

Page 16

cartridge labels)

There may be variations of this list.

Note: The FastStor 1 contains no cartridges before shipment.

Step 2. Installing the FastStor 1 in a Rack

The FastStor 1 is designed for use in a 19” rack system using 1U of rack space.

The length of the power cord and the SCSI cable may restrict the placement.

Attention: The FastStor 1 is designed to operate in a horizontal position. Do not

attempt to operate the FastStor 1 in any other position than horizontally. Also make

sure that:

• The airflow around the front and back of the FastStor 1 is not obstructed.

• There is a minimum of 60cm free space in front of the unit to allow the

operator to safely remove the magazines.

• The display and operator controls are easily accessed.

• The FastStor 1 is away from the floor and in a clean environment with

temperatures within specifications. See Appendix A.

The Rack Mounting Kit includes the following items:

• Rail Left Assembly

• Rail Right Assembly

• Screw M6x12 (6 pieces)

• Screw M5x8 (2 pieces)

Recommended mounting tools:

• Folding rule or tape measure

• Screwdriver

• 7 mm open-end wrench

Note: The rails are mounted to the loader during transportation. Before mounting

the rails into the rack, dismount the rails from the loader and remove the spacers

between the rails and the loader.

10 FastStor 1 Installation and User Guide

Page 17

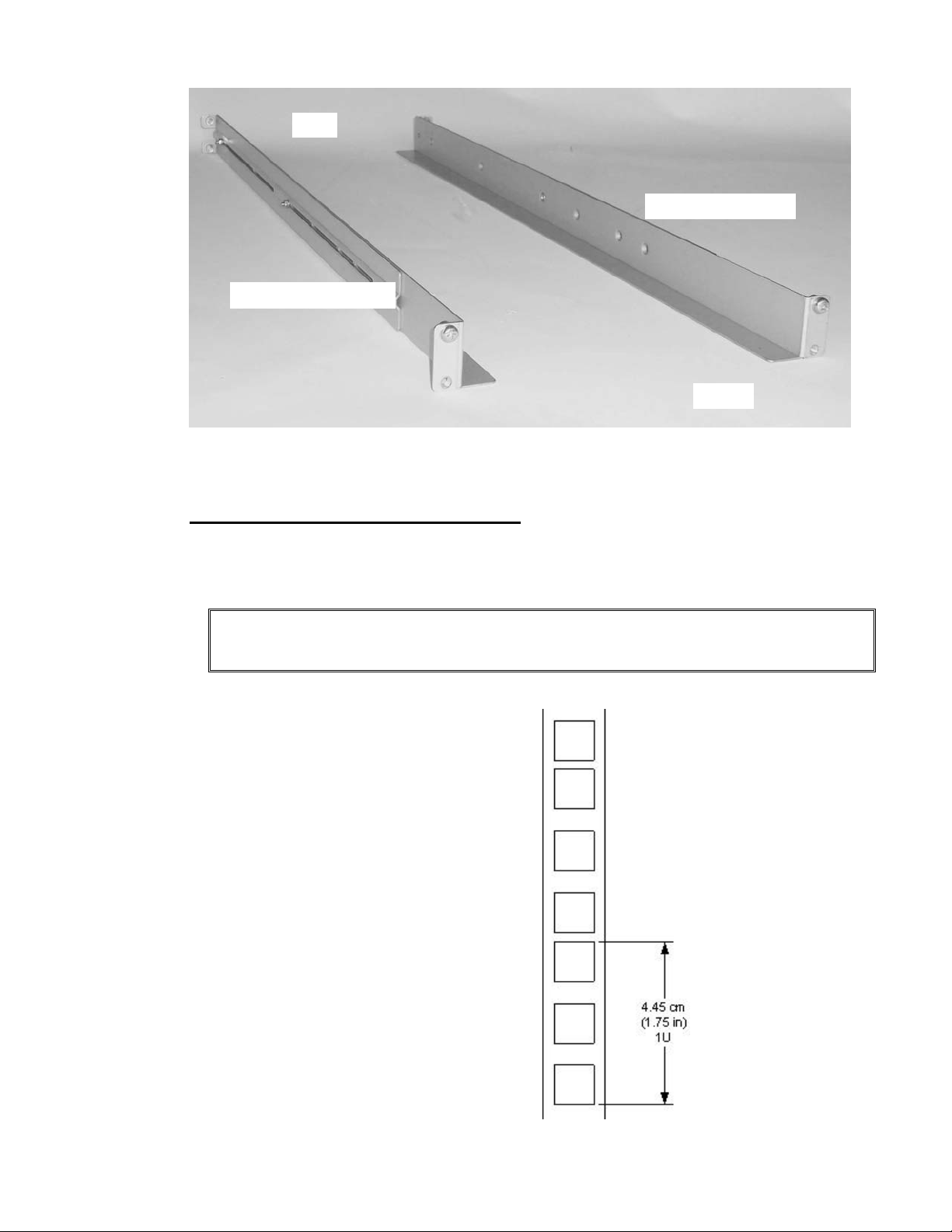

Back

Rail Right Assembly

Rail Left Assembly

Front

Figure 3.1 Rack Mounting kit

Installing the Rack Mounting Kit

• Determine the proper position of the rails in the rack.

Caution: Consider rack stability when deciding where to place the FastStor 1.

Hazardous conditions can result from uneven mechanical loading of a rack.

The FastStor 1 uses 1U of vertical

rack space. The rails must be

installed in a full U position (The

bottom of the rails must be aligned

with the bottom of a U). See figure

3.2.

FastStor 1 Installation and User Guide 11

Page 18

Figure 3.2 Rack mount rail

Installing the “Rail Left Assembly”

1. Measure the length between the rear rack mount rails and the front rack

mount rails. If the measurement is shorter than the FastStor 1, move the two

sets of screws M4x12, washers and nuts shown in Figure 3.3.

2. Adjust the “Rail Left Assembly” to fit the measurement in step 1.

3. Use a 7 mm open-end wrench together with the screwdriver to tighten the

two M4x12 screws to fix the rail length.

Note: Using more than two screws increases the stability of the Rack

Mounting Kit.

4. Place the “Rail Left Assembly” on the left side of the rack, between the rear

rack mount rail and the front rack mount rail.

5. Mount the “Rail Left Assembly” at the desired height using one M6x12 screw

in front (upper hole in rail only) and two M6x12 screws at the backside. See

figure 3.4.

12 FastStor 1 Installation and User Guide

Page 19

Installing the “Rail Right Assembly”

On the right side of the rack, follow the “Rail Left Assembly” instructions,

substituting “right” where “left” is referenced.

Use these holes

if rack depth is

equal or longer

than the

Rear Rack

Mount Rail

Step 5

(Screw

M6x12)

Step 1

FastStor 1

Step 1

Holes

used if rack

depth is shorter

than the

FastStor 1

to be

Step 3

(Screw M4x12,

nut and washer)

Figure 3.3 Mounting the Rack mounting kit to a rack

Figure 3.4 shows step 5 in the

description:

Rack mounting kit mounted in

rack with one screw M6x12 in

upper hole on both left and

right side.

On the rear side two screws

must be used on both left and

right side.

Step 2

Front Rack Mount Rail

Step 5

(Screw M6x12)

A total of six screws are used

to install the rack mounting kit

to the rack.

FastStor 1 Installation and User Guide 13

Figure 3.4 Rack mounting kit mounted in rack

Page 20

Mounting the FastStor 1 to the Rack

Make sure all the screws in the Rack Mounting Kit are tightened properly before

installing the FastStor 1 in the rack.

Slide the FastStor 1 on the rails from the front of the rack, as shown in figure 3.5.

Then fix the FastStor 1 using one M6x12 screw in front of the rack on both left and

right side (see figure 3.6) and one M5x8 on the backside of the Rack Mounting Kit

on both left and right side (see figure 3.7).

Figure 3.5 Slide the FastStor 1 in from

the front

Use one M5x8 screw on both left

and right side (M5-thread) to

fasten the FastStor 1 to the rails’

backside.

Figure 3.6 Fasten the front of the

FastStor 1 to the rack

Figure 3.7 Fasten the rear of the FastStor 1 to the rails.

How to dismount the FastStor 1 from the rack

Make sure you have disconnected all cables before you start dismounting the

FastStor 1 from the rack.

Unscrew the M5x8 screws at the back of the rack mounting kit. (See figure 3.7)

Unscrew the M6x12 screw at the front of the rack. Note that you only unscrew the

lowest screw. (See figures 3.5 and 3.6)

14 FastStor 1 Installation and User Guide

Page 21

Slide the FastStor 1 gently out of the rack. Note that the FastStor 1’s weight is 32

pounds.

Step 3. Connecting Power Cable

Before connecting the FastStor 1 to your host computer system, you should run the

unit’s self-diagnostic test. This preparation requires power to the FastStor 1. Follow

these steps to perform this test:

1. Use the power cables from the accessories included in the shipment. Make

sure you select the power cord suited for your power system.

2. Plug the power cable into the rear of the FastStor 1 (see figure 3.8). Plug

the other end of the cable into a properly grounded electrical outlet.

Note: Reliable grounding depends on grounding in the AC electrical outlet in which

the FastStor 1’s power cable is connected. For security, a 250V 2A (H) fuse is

located near the power switch.

3. Turn on the FastStor 1 by

switching the Power

Switch to “I”.

If the transport lock is

present, the loader will

detect this and instruct the

user to remove it. See

next step.

Figure 3.8 Power switch, fuse holder and

power cord connection

FastStor 1 Installation and User Guide 15

Page 22

Step 4. Removing the Transport Lock

Figure 3.9 Magazine lock marked with red plastic tab

The robot mechanism is protected from damage during shipment with a

screw holding the robotics in a locked position.

This locking screw is marked with a red plastic tab protruding between the

right magazine and the front panel assembly.

This locking screw must be removed before the FastStor 1 can operate

normally.

The locking screw will be detected when the FastStor 1 is powered on. The display

will show a message indicating the locking screw has been detected. The display

will instruct the user to remove the magazine to gain access to the locking screw.

Remove the screw and reinsert the magazine. The loader will now continue its

power-on sequence. See next step.

To release the magazine manually or perform an emergency release, see

Manual/Emergency Release of Magazines.

Note: Keep the locking screw in a safe place. You will need it to lock the robot if

you need to return your FastStor 1 for service or repair.

Important: The warranty does not cover damage to the loader if shipped without

the locking screw properly installed. See Reinstalling the Transport Lock for

instructions on how to re-install the transport lock.

Step 5. Running Power-On Self-test

After the transport lock is removed, the loader will continue running its power-on

self-test and doing an inventory of its cartridges.

The word “Idle” and the cartridge map will appear on the default display screen. If

the self-diagnostics and the inventory sequence are successfully completed, the

green LED illuminates. The FastStor 1 is now ready to be installed in the system.

If a problem occurs during the power-on sequence, the FastStor 1 displays an error

message on the display. Refer to Error! Reference source not found. to learn the

16 FastStor 1 Installation and User Guide

Page 23

procedures for resolving the problem.

Step 6. Setting the SCSI Address

The SCSI address is a unique address that identifies the unit connected to the

SCSI bus. The FastStor 1 uses two SCSI addresses or ID’s. One is for the loader

robotics controller, and the other is for the tape drive. The SCSI addresses can be

configured through the operator buttons and the display on the front panel. In most

cases the default addresses can be used. The default SCSI address for the

FastStor 1 robotics is 4, and the tape drive has SCSI address set to 5.

To set the SCSI addresses for the FastStor 1 and the built-in tape drive, refer to

SCSI Setup for more information. You may also wish to reserve a magazine slot for

a cleaning cartridge, and set a security password at this time. After some settings

are changed, the FastStor 1 and the drive may require rebooting.

Step 7. Connecting the SCSI Bus Cable

Guidelines before connecting the SCSI cable:

A) Before the SCSI bus cable is connected to the FastStor 1, turn the FastStor

1 power switch off.

B) Make sure your host system is in a state where a new SCSI device can be

safely connected to the SCSI bus.

C) Do not exceed SCSI bus length restrictions.

1. Add the length of all external and internal SCSI cables on the bus.

2. Add 80 cm (31.5 inch) for the internal cable length in the FastStor 1.

3. The maximum allowed length of an LVD SCSI bus is 12 m (39 ft) if the

number of SCSI devices exceeds two.

4. For an SE SCSI bus, be very careful regarding bus length. The normal

combination has an SE bus transfer speed of 160 Mbytes/s with a

maximum bus length of 3 m (9.8ft) and up to 4 SCSI devices connected.

If your SE system operates with a different transfer speed or has more

than 4 SCSI devices, we refer to the actual SCSI standard for complete

bus length restrictions.

D) Before the FastStor 1 is powered on and the system is restarted, make sure

the SCSI bus is properly terminated. If the FastStor 1 terminates the SCSI

bus, ADIC recommends connecting the terminator from the accessory kit

box on the lower SCSI connector on the back plane. See Figure 3.10.

To connect the SCSI bus cable:

1. On the rear of the FastStor 1, attach the device connector of the SCSI cable

to the upper SCSI connector. See Figure 3.10.

FastStor 1 Installation and User Guide 17

Page 24

2. Secure the cable with the thumbscrews on the connector.

3. Connect the other end of the SCSI cable to the appropriate SCSI adapter on

your system, and fasten it with the thumbscrews.

4. If the FastStor 1 is the last device on the SCSI bus, install a SCSI bus

terminator to the free SCSI connector on the FastStor 1. Make sure the

terminator is of the correct type for your SCSI system.

5. It is possible to daisy chain several SCSI devices on the SCSI bus. If you do

so, the terminator must be connected to the last device on the bus. Note

that there are limitations to the SCSI cable length.

Figure 3.10 SCSI cable and SCSI terminator connection

Step 8. Connecting the Ethernet Connector

To connect the FastStor 1 to the Ethernet, use the provided cable from the

accessory kit box.

1. Insert one end of the cable into the FastStor 1 Ethernet port. Push until it

snaps into place. The open port in Figure 3.10 is for Ethernet connection.

2. Connect the other end to a normal 10/100 BaseT Ethernet outlet.

The Ethernet-based Remote management system is described in

Management.

Remote

Step 9. Restarting Your System

ADIC recommends that all external SCSI devices, including the FastStor 1, are

powered on before the computer system is re-started. After restarting your system,

including the FastStor 1, the FastStor 1 runs a power up self-test (described in

Step 5). When the display reports that the FastStor 1 is in the “Idle“ state and the

green LED is on, the FastStor 1 is ready for further configuration and operation

(described in Operation and Configuration).

Note: The tape drive needs up to 40 seconds after power on until it’s active on the

SCSI bus. You should turn on the power at least 40 seconds before the computer

18 FastStor 1 Installation and User Guide

Page 25

system is started.

Step 10. BCR: Labeling cartridges

Your loader is equipped with a barcode reader. If you want to use this functionality,

you must attach barcode labels to the cartridges.

Note: You must use FastStor 1-specific barcode labels to ensure reliable

functionality of the barcode reader.

Cartridge labels must be oriented on the cartridges as shown in the figure below

with the locking mechanism to the left.

Figure 3.11 Positioning of barcode label for LTO cartridges.

FastStor 1 Installation and User Guide 19

Page 26

4 Operation and Configuration

The Local User Interface (LUI) consists of a small LCD panel capable of displaying

four lines of 20 characters each, and four control buttons, one near each corner of

the display. The buttons have soft labels in the corners of the display. The figure

below shows the power-on screen on the panel.

Figure 4.1 Power-on Screen

System Power-On

With mechanical installation and electrical connection complete, turn on the AC

power switch. At power-on, for the first few seconds the unit performs a sequence

of diagnostic tests called Power-On Self Tests (POST). POST also includes a loopback test of the robot cabling. As the tests complete, the control panel displays a

sign-on message. See Figure 4.1.

After the POST sequence completes successfully, the loader will respond to SCSI

selections. Then the system starts a series of initialization functions, a process that

consists of robot calibration operation and cartridge inventory of magazines and

drive. If the barcode reader is enabled, the barcode labels on the cartridges will be

read when running inventory.

During these operations the loader continuously shows the map status on the

screen. See Figure 4.2. The status of all magazine slots and the drive are initially

unknown, and a ”?” is displayed for each slot. As the robot searches the magazine

slots for cartridges during inventory, the display is updated.

Cartridge

Inventory

Status

Taking Inventory

Map: ?????_7_

Figure 4.2 Snapshot while running Inventory

After the unit has completed the initialization processes, the Default screen

appears and the loader is ready for SCSI commands. See Figure 4.3

20 FastStor 1 Installation and User Guide

Page 27

The map of the cartridges has the following symbols:

1. A “?” when status is unknown and Inventory is still running.

2. A number indicates a slot occupied by a cartridge. (Figure 2.3 shows how

the cartridge slots are numbered in the magazines.)

3. An underscore line indicates an empty slot.

4. ”C” indicates that a Cleaning Cartridge occupies the slot.

The line below the map on the default screen gives the drive status. The drive

status displayed is drive dependent.

Robot operation status

Menu button

Soft Label

Line 2

Idle Menu

Map: __3_5_7_

Drive Empty

Figure 4.3 The Default screen

The robot operation status has the following options:

1 Idle The loader is idle

2 Fetching The loader is moving a cartridge from a magazine slot or

from the drive to the robot.

3 Stowing The loader is moving a cartridge from the robot to a

magazine slot or to the drive.

4 Moving The loader is moving the robot.

Table 4-1 Robot Operation Statuses

FastStor 1 Installation and User Guide 21

Page 28

The Drive Status line (line 3) can show the following statuses:

1 Drive Empty There is no cartridge in the drive.

2 Drive Loaded A cartridge is loaded.

3 Drive Idle A cartridge is loaded and the drive is

ready to use it.

Drive Rewinding The drive is rewinding the tape

4

Drive Seeking The drive is searching for specific data

5

on the tape.

Drive Reading The drive is reading data for transfer to

6

a host via the SCSI interface.

Drive Writing The drive is writing data received from

7

a host to the tape.

Drive Erasing The drive is erasing data from parts of

8

or the whole of the tape.

Drive Cleaning A cleaning tape has been inserted into

9

the drive, and the drive is using it to

clean the relevant mechanical parts.

Drive Loading A tape has been inserted into the drive.

10

The drive is in the process of

mechanically loading the tape.

Drive Unloading The drive is in the process of

11

mechanically unloading the tape.

Drive Update Ready The drive has completed an internal

12

update.

Drive Updating The drive is in the process of an

13

internal firmware update.

14

Drive Calibrating A data tape has been inserted and

loaded into the drive. The drive is in the

process of measuring its physical

properties.

Table 4-2 Drive Operation Statuses

22 FastStor 1 Installation and User Guide

Page 29

Front Panel Display Modes

The front panel displays three types of screens for different purposes: menus,

dialogs and messages.

Menus

The major contributor is the MENU. It is used to select operations to perform by

enabling the operator to navigate a menu tree using the control buttons.

Due to the size of the display, only one menu item is shown at a time. See Figure

4.4 for a standard menu layout, and Figure 4.5 for a complete menu tree.

▲ EXIT

Menu Entry.

▼ SELECT

Figure 4.4 Standard Menu Layout

The two arrows on the left are used to show the next (down arrow) and previous

(up arrow) entries on the current menu level.

The Exit button on the right is used to ascend to the menu level above, while the

Select button is used to descend to the submenu designated by the Menu Text, or

to activate the function selected if the Menu Entry describes a function.

FastStor 1 Installation and User Guide 23

Page 30

Figure 4.5 The Complete Menu Tree

24 FastStor 1 Installation and User Guide

Page 31

Dialogs

A dialog is a screen type used to get detailed input from the operator, such as a

SCSI ID, name, or password. See Figure 4.6.

▲ Ok

Main Dialog text

Dialog Entry value

▼ 4

Figure 4.6 Standard Dialog Layout.

The dialogs come in several forms, but there are only a few main types.

Dialogs, Discrete Values

The dialog in Figure 4.7 is used to enter discrete values. It handles one character

or digit at a time. The digit or character being manipulated is said to be in focus.

The digit or character in focus is shown in inverse video. As the character map on

the screen used restricts the flexibility of the inverse display of the character, some

digits and characters appear distorted when inverted. For example, the “0” digit

appears as an open rectangle when inverted.

The Up and Down arrows on the left are used to increment (up arrow) or

decrement (down arrow) the value of the character or digit in focus. If increment is

selected and the value of the character of digit in focus is at its highest legal value,

it wraps to its lowest legal value, and vice versa.

▲ Ok

Fixed IP address

00.000.000.000

▼ 4

Figure 4.7 Dialog layout, entering discrete values

The Right arrow (on the right side) is used to shift the focus one place to the right.

If the focus is already at the rightmost position, the focus wraps to the leftmost

position.

The Ok button is used to accept the value displayed.

If the value was changed, the selected and original values will then be displayed as

messages. The operator may then accept or reject the change.

The discrete value type of dialog does a running check of the validity of what the

user enters, and changes it if needed.

Examples: If the value “0” or “1” is selected in the Fixed IP address dialog above,

the user is allowed to select values between “0” and “9” as the next

FastStor 1 Installation and User Guide 25

Page 32

two digits. (The maximum value allowed in this dialog is “255” within

each group.) If, however, “2” is selected, only values between “0” and

”5” are available in the second digit. If a value between “0” and “4” is

selected for the second digit, “0” to “9” is available for the third, but if

“5” is selected for the second digit, only “0” to “5” is available for the

third one.

Or

the user selects the value “199” in one group in the above dialog,

then presses the “Next Digit” button until the “1” in “199” is selected,

and increments it to “2,” so the group shows “299.” Since this is an

illegal value, when the user selects the “Next Digit” or the Ok to leave

the group, the value is changed to “255” and the focus is repositioned

to the “2” in the first position of the group.

Dialogs, Predefined Options

The second form of dialog allows the operator to select between a predefined set

of options, which can be shown on-screen simultaneously, as when selecting a

magazine slot number, see Figure 4.8.

To select a cartridge and move it from a magazine slot to the drive or vice versa, a

slightly different dialog is used:

Ok Cancel

Load to drive

From Slot: 135

3 4

Figure 4.8 Slot dialog layout.

Here, the right and left arrows select the digit to load from. Ok accepts the cartridge

selected, and Cancel aborts the operation.

Figure 4.9 shows the third form, where the operator can select predefined options

that can be shown only one at a time.

Ok Cancel

Barcode scan

Enabled

3 4

Figure 4.9 Predefined options, shown one at the time.

Here, the user can scroll through a set of options one at a time by using the left

and right arrow buttons. Only one option is shown at a time. In the example above,

the user can select either “Enabled” or “Disabled” mode.

This kind of menu also has a Cancel function.

26 FastStor 1 Installation and User Guide

Page 33

Messages

Messages can inform the operator about situations that arise during operation,

such as error conditions and situations where a process requires operator approval

or intervention to continue.

An example of the latter is when the loader detects a wrong magazine type. The

loader will eject that magazine and show the message “Left (or right) magazine is

the wrong type”. This message is removed by inserting a correct type magazine.

Status and Information

Some of the menus, dialogs and messages provide status and information in the

form of one or two-word messages that appear within the display.

An example is the default screen shown in Figure 4.10. It has a navigation button

Menu, but it displays the cartridge map (Map: __3_5_7_ ) as the major menu text

and the robot’s and drive’s status (Idle, Empty).

Idle Menu

Map: __3_5_7_

Drive empty

Figure 4.10 A default screen.

Another example is the message displayed while a diagnostics self-test is running.

This message shows the progress of the self-test in the form of a loop counter, and

also shows the robot status.

FastStor 1 Installation and User Guide 27

Page 34

Main Men u

The Main menu contains a set of frequently used functions and links to a set of sub

menus.

Item name Description

Load to Drive Loads a cartridge from a selected magazine slot into the

drive. When Select is pressed on this menu item, a

magazine slot selection dialog is displayed. The operator

must scroll to the wanted slot and press Ok to start the

operation. The progress of the operation is displayed, and

when the loader part of the operation is completed, the main

menu is displayed. The loader must be idle to make this

function selectable.

See “

To load a cartridge to the drive: for more details

Unload from

Drive

Eject

Magazine

Setup Selects the loader and drive setup functions. The loader

Unloads a cartridge from the drive and stores it in a selected

magazine slot. When Select is pressed on this menu item, a

magazine slot selection dialog is displayed. The operator

has to scroll to the wanted destination slot and press Ok to

start the operation. The progress of the operation is

displayed, and when the operation is completed the main

menu is displayed. The loader must be idle to make this

function selectable.

See “

To unload a cartridge from drive: for more details.

Ejects one or both of the two magazines. When Select is

pressed on this item, a magazine selection menu is

displayed. The operator has to choose left, right or both

magazines and press Ok to start the operation. The

progress of the operation is displayed, and when the

operation is complete a status message informs the

operator that one or both magazines are not in place. The

loader must be idle to make this function selectable.

See “

Magazine Handling” for more details.

must be idle to make this function selectable.

See “

Setup Menu” for more details.

View Data Selects the access to loader and drive system data. This is

the only menu entry that is selectable when the loader is not

idle.

See “

View Data Menu” for more details.

Utilities Selects a set of the loader and drive maintenance and

diagnostic functions. The loader must be idle to make this

entry selectable.

See “

Utilities Menu” for more details.

The Main menu can be selected even if the loader is not in the idle state. While in

the main menu, the loader will accept and execute SCSI commands. When any of

28 FastStor 1 Installation and User Guide

Page 35

the main menu entries except the View Data entry is selected, the loader will go to

its busy state, and SCSI commands will be terminated with Check Condition and

Not Ready status.

Setup Menu

To enter this menu, scroll to the Setup item in the Main Menu and press the Select

button. The loader enters the busy state when this menu is selected.

Item name Description

FastStor 1 setup This menu item gives access to the FastStor 1 setup

menu.

SCSI setup This menu item gives access to the SCSI bus setup

menu. Both the FastStor 1 and the Drive SCSI bus

setup are available here.

Remote

Management

setup

This menu item gives access to the Remote

Management setup menu. It allows the operator to

enable, disable and configure the Loader Web

interface.

FastStor 1 setup

The number of selectable values for each FastStor 1 setting are listed in the

following table.

Item name Legal values. Default value

Cleaning Slot Legal Slot ID 1..8 or 0 = not

selected.

Barcode scan* Enabled, Disabled Enabled

Audible Alarm Enabled, Disabled Disabled

Set Language English English

* The barcode of the cartridge in each occupied magazine slot and in the drive (if any) will be

scanned during the Inventory process.

0 = not selected

SCSI Setup

The SCSI setup menu allows selecting SCSI addresses for both the loader and its

internal drive. In addition, the SCSI Bus Parity can be enabled or disabled.

Because of the SCSI protocol, the values selected take effect only after the next

reset of the loader and drive.

FastStor 1 Installation and User Guide 29

Page 36

Item name Legal values. Default value

Loader SCSI ID Legal SCSI ID: 00..15 04

Drive SCSI ID Legal SCSI ID: 00..15 05

Loader Parity Enabled, Disabled Disabled

Loader

Personality

LTO: FastStor 1

FastStor 1

Remote Management setup

The Remote management setup menu allows enabling, configuration and access

control to the loader via the loader’s Remote Management Web interface. The

loader may either obtain an IP address, the network mask, and default gateway

from a DHCP server, or they can be set manually.

Item name Legal values. Default value

IP Address

assignment

Static IP address * Legal IP address range:

Network mask * Legal IP address range:

Default Gateway * Legal IP address range:

Static mode, DHCP mode DHCP mode

255.255.255.255

000.000.000.000 to

255.255.255.255

255.255.255.255

000.000.000.000 to

255.255.255.255

255.255.255.255

000.000.000.000 to

255.255.255.255

Remote Management access control

* Used only while the IP address assignment is in Static mode.

This menu gives access to dialogs that enables

remote management and remote FW upgrading of

the Loader (see table below).

Remote Management Access Control

Item name Legal values. Default value

Allow Remote

Management

Allow Remote FW

download

Allowed, Not allowed Allowed

Allowed, Not allowed Not allowed

View Data Menu

To enter this menu, scroll to the View Data item in the main menu and press the

30 FastStor 1 Installation and User Guide

Page 37

Select button. The loader will remain in its ready state when this menu is selected.

The View Data menu contains the values assigned during device setup (see Setup

Menu), and also statistical data related to the drive and the robotics. The view-only

fields display data that can be changed from the Setup menu only. If you select the

Change button and the robot is idle, a dialog appears where the value may be

changed. This requires entering a password if the Loader Password system is

enabled.

Item name Description

FastStor 1 info This menu item gives access to the FastStor 1 view

menu.

SCSI info This menu item gives access to the SCSI bus view

menu. Both the FastStor 1 and the Drive SCSI bus

parameters are available here.

Remote

Management info

Statistics This menu item gives access to the loader’s view

This menu gives access to the Selected IP addresses

and masks. This menu also shows the MAC address

of the unit.

menus internal count and statistics values.

FastStor 1 Info

An overview of the possible values for each FastStor 1 setting is listed in the

following table.

Item name Legal values. Default value

Cleaning Slot Defined cleaning slot,

Disabled

Barcode Reader Enabled, Disabled Enabled if installed, else

Loader Serial No. Loader Serial number. --Loader FW

revision

Loader Vendor ID Current Inquiry Vendor Id “ADIC”

FastStor 1 FW id and

revision

Disabled

Disabled

xx.yy

Loader Product

ID

Loader SCSI ID SCSI Id 0 to SCSI Id 15 SCSI ID = 4

Loader Parity Disabled, Enabled Enabled

Loader Slots

State

Loader

personality

Audible Alarm Enabled, Disabled Disabled

FastStor 1 Installation and User Guide 31

Current HW/FW Product Id AT3200-1R LTO2

View status for each loader

slot

FastStor 1 FastStor 1

Not applicable

Page 38

Drive Info

The different drive types used in the FastStor 1 might not provide all the

information listed below. If an unavailable entry is selected, the string “Data

Unavailable” is displayed.

Item name Legal values Default value

Drive Product ID Drive Inquiry Product Id Drive dependent

Drive Vendor ID Drive Inquiry Vendor Id Drive dependent

Drive FW

Revision

Drive Serial No. Drive Serial Number Drive dependent

Drive SCSI Id SCSI Id 0 to SCSI Id 15 SCSI ID = 5

Drive Firmware Revision Drive dependent

Remote Management Information

The Remote Management (RMM) setup is shown in the choices listed below. This

menu tree is the place to find the currently allocated dynamic IP address, default

gateway and network mask when running in DHCP mode. The loader’s MAC

address is also shown here.

Item name Legal values Default value

IP address mode Static mode, DHCP mode DHCP mode

Static IP address 0.0.0.0 to 255.255.255.255 0.0.0.0

Static netmask 0.0.0.0 to 255.255.255.255 0.0.0.0

Static default

gateway

Dynamic IP

address

0.0.0.0 to 255.255.255.255 0.0.0.0

0.0.0.0 to 255.255.255.255 Not applicable

Dynamic netmask 0.0.0.0 to 255.255.255.255 Not applicable

Dynamic default

gateway

MAC-address Value is fixed Value is fixed

0.0.0.0 to 255.255.255.255 Not applicable

Statistics

Item name Description

Fetch Statistics When selected, the operator can scroll through the

fetch count and fetch retries for the drive and all

magazine slots.

32 FastStor 1 Installation and User Guide

Page 39

Stow Statistics When selected, the operator can scroll through the stow

count and stow retries for the drive and all magazine

slots.

Power On Time Displays Power On Hours for the loader

Time since

clean

If available from the drive, this entry displays the

number of hours since the drive was last cleaned.

Utilities Menu

Option Description

Maintenance Displays a set of maintenance functions

Diagnostics Displays a list of exercise test programs

Access control Set Password

The Maintenance Menus

Item name Description

Prepare to Ship When selected, the robotics are positioned for installing

the locking screw.

The right magazine is ejected to facilitate the

installation.

The left magazine is also ejected if it contains one or

more cartridges. The loader cannot be safely shipped

with cartridges in the magazines

This option must be executed before the loader is

prepared for transport by inserting the Locking Pin.

(See

Performing the Installation and Reinstalling the

Transport Lock

Clean Drive Performs a drive clean, provided a slot is reserved for a

cleaning tape and a cleaning tape is present

Restore default Sets the loader settings to their factory default values.

Clear Web

Password

Reboot Performs a hard reset of the loader.

Deletes the web passwords. This is useful when the

password is lost.

.)

The Diagnostics Menu

Item name Description

System test Starts a test where cartridges are moved randomly

between magazine slots and between the drive and

the magazines.

Move medium

test

Starts a test where cartridges are moved randomly

between magazine slots. The drive is excluded.

FastStor 1 Installation and User Guide 33

Page 40

Drive test Starts a drive self test. (Only when supported by the

installed tape drive.)

Hardware test Runs a test of the loader hardware, including the

Loader internal cabling.

Set Password

Item name Description

Set Password Allows the operator to set a four-digit password

protection for the menu system. The default password

is <0000>, meaning the password is disabled.

WARNING: If you set a password, make sure you do not forget it. If you do, it can only be

cleared with assistance from ADIC technical support or by a qualified service technician.

Cartridge Handling

Cartridge Slot Numbers

The cartridge slots have been given numbers as follows:

Left magazine: Slot 1, Slot 2, Slot 3 and Slot 4 (lowest number closest to the front)

Right magazine: Slot 5, Slot 6, Slot 7 and Slot 8 (lowest number closest to the

front)

Moving Cartridges to and from the Drive

The normal operations of the unit are controlled by the host software application.

When you must load or unload a specific cartridge using the control buttons on the

front panel, do the following:

To load a cartridge to the drive:

1. From the default display press the menu button and select Load to Drive from

the main menu. A screen picture like Figure 4.11 will be displayed. The

selected cartridge’s barcode is displayed in the bottom line.

Ok Cancel

Load to drive

From Slot: 135

3 4

Figure 4.11 Load to Drive

2. Select the slot number of your choice. The system ignores empty slots. Press

the 4 button to increment and the 3 button to decrement.

3. Press the Ok button.

34 FastStor 1 Installation and User Guide

Page 41

The robot removes the cartridge from the selected magazine slot and moves it

to the drive.

To unload a cartridge from drive:

1. From the default display, press the menu button and select Unload from Drive

from the main menu. A screen similar to Figure 4.12 displays the available

slots.

Ok Cancel

Unload from drive

To Slot: 24678

3 4

Figure 4.12 Unload From Drive

2. Select the cartridge slot number of your choice. Press the 4 button to

increment and the 3 button to decrement.

3. Press the Ok button.

The robot removes the cartridge from the drive and moves it to the selected

magazine slot.

If the drive is empty, a screen similar to the following figure appears.

No cartridge in

the drive to

unload

OK

Figure 4.13 Empty Drive Message

Magazine Handling

You must remove the magazine from the unit in order to insert or remove

cartridges. When inserting cartridges, be sure the slot you intend to use is not

already reserved by the software application for a cartridge in the drive. The best

way to avoid conflicts is to unload the cartridge from the drive; either through your

software application or by using the Unload from drive option in the main menu.

Removing the Magazine from the Unit

The following illustration shows the correct way to remove the magazine from its

bay.

Note: You cannot remove the magazine if the unit is password protected or locked

by host software through a Prevent Medium Removal SCSI command.

Before you can remove a magazine, the loader must be idle. When the loader is

idle, press the Menu button and select the Eject Magazine option from the Main

FastStor 1 Installation and User Guide 35

Page 42

Menu.

The following screen, Figure 4.14, appears, identifying the magazine:

▲ Exit

Eject both mags.

▼ Select

Figure 4.14 Removing magazine

Scroll to the correct magazine (Both, Left or Right magazine) and press Select.

The selected magazine will pop out 2 to 3 cm, See next figure.

The display will show a message telling that the magazine or magazines is/are

ejected. If only one magazine is ejected, the display indicates a button to push to

eject the other magazine.

Figure 4.15 Magazine eject

With one hand, grip the handle on the outer side of the magazine bezel and hold

the other hand under the magazine. Pull the magazine carefully out and keep it in

level with the loader. Use the hand under the magazine to prevent the back of the

magazine to fall down when it leaves the magazine bay. See the following

illustration.

36 FastStor 1 Installation and User Guide

Page 43

Figure 4.16 Removing the magazine from the loader

Inserting Cartridges into the Magazine

When inserting cartridges, the access door of the cartridge must face the

magazine. Push it carefully into the magazine until it locks in place. The rear side

of the cartridge with the Write Protect switch and the barcode label must face out.

Make sure the cartridges latch properly.

Figure 4.17 Gently push the cartridge into the magazine slot

Removing Cartridges from the Magazine

Press the cartridge release tab towards the cartridge until the cartridge is released.

The cartridge slot is spring loaded, so it is important to prevent the cartridge from

popping all the way out. If the cartridge falls down, it might be damaged and data

FastStor 1 Installation and User Guide 37

Page 44

could be lost. Pull the cartridge carefully out of the magazine slot.

Figure 4.18 Push the release knob

towards the cartridge to eject

Figure 4.19 Cartridge position after

manual release from magazine slot

Inserting a Magazine into the Unit

The right and left magazines are mirrored and can only be inserted into the correct

left or right magazine bay. See Figure 4.20.

1. Enter the back of the magazine into the correct magazine bay. Make sure it

is in level with the loader.

2. Slide the magazine carefully in until the eject spring engages.

3. Push the magazine further in against the spring until the magazine is

latched.

38 FastStor 1 Installation and User Guide

Page 45

Figure 4.20 Push magazine until it clicks into place

Manual/Emergency Release of Magazines

In failure situations (either in the loader itself, a power loss, or situations where you

need to manually release the magazines), a manual/emergency release is

available. To activate the emergency magazine feature, you must use the special

magazine release tool that is part of the accessory kit shipped together with the

FastStor 1. This tool must be inserted through the hole marked in Figure 4.21.

Note: The manual eject must only be used when power is turned off.

Insert the release tool in

hole four from the center

Figure 4.21 Pointing out hole used to insert release tool

FastStor 1 Installation and User Guide 39

Page 46

Figure 4.22 shows the

release tool inserted into

the correct hole on the

right hand side magazine

bezel.

Figure 4.22 Magazine release tool in use

Standby Functionality

On the front panel a standby button is available.

To activate Standby mode, press the button for a minimum of 2 seconds. The

FastStor 1 will enter a standby mode in a controlled manner. The following takes

place before the FastStor 1 goes into standby mode:

1. Finish any FastStor 1 activity.

2. Controlled aborting of tape drive activity; buffered data is flushed to tape;

cartridge is unloaded from drive but not ejected.

3. The display is turned off.

4. No FastStor 1 activity is allowed until the standby button is pressed again.

5. While in standby mode, the attached server/host can see the two SCSI

devices in the FastStor 1, but the SCSI status will be “not ready.”

6. The green LED on the front will blink with short blinks- long intervals.

7. To leave the standby mode, press the standby button for 2 second. The

FastStor 1 will then restart and perform a full inventory.

40 FastStor 1 Installation and User Guide

Page 47

5 Remote Management

In order to facilitate Remote Management, the FastStor 1 is equipped with an

Ethernet interface and a built in web server. The Remote Management Interface

(RMI) can be accessed with a standard web browser, such as Internet Explorer,

Mozilla or Opera.

Remote Management Configuration

In order to start the FastStor 1 Remote Management Interface, the FastStor 1

must obtain a valid IP address. By default, the FastStor 1 connects to a DHCP

server to dynamically configure its network interface. If a DHCP server is

available, the loader will get an IP address automatically after booting.

If no DHCP server is available, select Static mode and enter a legal IP-address,

netmask and default gateway with the buttons. In the browser’s address field,

enter the IP address of your FastStor 1. See Remote Management setup for

details.

Quick Start Instructions

The following is intended to help you get a new FastStor 1 online as quickly as

possible. If you need to enable the RMI to perform a memory dump of a faulty

FastStor 1, please see Enabling the RMI Without Rebooting instead.

1. Connect the FastStor 1 to the network and reboot it.

2. From the front panel, check the dynamic IP address by accessing Menu

→View data → Remote man. info → Dyn IP Addr. state.

2.1. If the response is a valid IP address, the remote management interface

is ready and can be accessed at the URL http://IP-address/, e.g.

http://192.168.0.5/.

2.2. If the response is 0.0.0.0, enable remote management from the front

panel by setting Menu → Setup → Remote management → Access

control → Allow remote management to “Allowed.” Check the network

cable and the DHCP server and reboot.

Enabling the RMI Without Rebooting

1. Connect the FastStor 1 to the network.

2. Configure network:

If you want to use a static IP address, use the front panel to enter a valid

static IP configuration, see Remote Management setup.

If you want to configure the network subsystem dynamically, from the

front panel set Menu → Setup → Remote management → Set IP

FastStor 1 Installation and User Guide 41

Page 48

Addr. mode to DHCP mode.

3. Via the front panel, first set Setup → Remote management → Access

control → Allow remote man. to “Not allowed” and select “OK.” Then set

the same value to “Allowed” and select “OK.” This will restart the networking

subsystem. Obtaining a new IP address may take some time if the FastStor

1 is in DHCP mode.

4. Check the IP address via the front panel by accessing either View Data →

Remote man. info → Sta IP Addr. state or View Data → Remote man.

info → Dyn IP Addr. state, depending on whether the FastStor 1 is in static

or dynamic IP address mode.

Remote Management Web Pages

Most of the operations you can perform from the front panel can also be

performed remotely using Web Administration. The Remote Management

interface provides access to loader and drive status and statistical operation

information.

The Web pages include a

navigation menu making it

easy to use, see Figure 5.1.

Status

Settings

Personalization

Network

SCSI-ID

Cleaning options

Command

Maintenance

Diagnostics

Debugging

FW upgrade

Figure 5.1 Navigation Menu

Information Boxes

All the Remote Management web pages show FastStor 1 and drive information.

This information includes:

• FastStor 1 information containing model, serial number, firmware

version, cumulative power-on time and present activity of the loader.

• Drive information containing technology, serial number, firmware version

and activity

42 FastStor 1 Installation and User Guide

Page 49

FastStor 1 Start Page

After successfully connecting to the FastStor 1 from your browser, you will see

the FastStor 1 Start page, Figure 5.2. This contains:

• Select language

for user-interface.

1. The language used last time will come up as the default language at

start-up.

2. The default language is English.

• Log in

to use Remote Management. The system has two levels of login.

By default the passwords are blank. (That is, type in the user ID and

leave the password field blank.) To secure your system, change both

passwords under Settings > Personalization, the first time you use

Remote Management.

1. The user ID Administrator has full access to the Remote Management

pages.

2. The user ID Operator has limited access to the Remote Management,

and cannot access the Settings and Maintenance pages.

Figure 5.2 Remote Management Start Page

Note: FastStor 1 network traffic is not encrypted, so anyone with physical

access to the network path will be able to access the information with a packet

sniffer. Passwords, however, are encrypted. It is not possible to reach the

FastStor 1 Installation and User Guide 43

Page 50

plaintext password, but it is possible to sniff “the challenge key” and use it to

gain access. The system is therefore not safer than the network it is using.

If you need high security, make sure packets to and from the FastStor 1 do not

leave the secure network, and employ separate encryption when traffic

traverses unsecured networks.

Status Page

The FastStor 1 Status page looks like the figure below.

Figure 5.3 Remote Management Status Page

The figure provides an updated status of drives, robotics and cartridges using

color-coding and symbols.

The Drive and Robot statuses are shown as a green (OK), yellow (Warning) or

red (Error) dot. If you click on the text, additional information appears in a popup window.

The cartridge locations are shown with rectangles in the slots or the drive. The

status codes are:

• Black

• Grey

• Blue

• Yellow

• Red

Empty slot, no cartridge present

Cartridge present

Cleaning cartridge in the slot

Warning

Error

44 FastStor 1 Installation and User Guide

Page 51

If you click on a slot, additional cartridge information is shown in a pop-up

window. This information includes the cartridge barcode (if label and barcode

reader are installed) and the error code.

Settings Pages

You can change the FastStor 1 configuration on the setting pages. These pages

can be accessed only by someone who is logged in as Administrator.

Personalization

On this page you can change the Remote Management passwords. To secure

your system, change both the passwords the first time you use the system. It is

possible to clear the remote management passwords via the front panel. Please

see The Maintenance Menus.

Here you may also turn on email event notification. When event notification is

enabled, the FastStor 1 sends warnings and errors by email to the recipient’s email address.

Network

On this page it is possible to change the IP configuration. See details in Remote

Management setup. The new configuration will take effect at next system reset.

Warning: Please verify that the chosen settings are correct and consistent

before resetting the loader. Any mistakes must be corrected via the front panel.

SCSI-ID

On this page it is possible to change the SCSI-ID on your drive and loader. See

details in SCSI Setup.

Cleaning Options

By defining a cleaning slot, the FastStor 1 regards the cartridge in this slot as

the cleaning cartridge unless:

1. another cartridge has previously been designated a cleaning