Page 1

quantum

MASCHINEN - GERMANY

© 2007

GB

Page 118 / 01 / 2008 Version 1.2.5 B 13 / B14 / B16 / B20 / B25 / B32 Drilling machine

Bench drill

B 13

B 14

B 16

B 20 / B20 Vario

Operating manual

Version 1.2.5

Keep for future reference !

Pillar drill

B 25 / B 25 Vario

B 32 / B 32 Vario

Illustr. 0-1: B13 B 25

Page 2

quantum

MASCHINEN - GERMANY

© 2007

GB

Page 2 Drilling machine B 13 / B14 / B16 / B20 / B25 / B32 Version 1.2.5 18 / 01 / 2008

Table of contents

1Safety

1.1 Safety warnings (warning notes) .................................................................................. 5

1.1.1 Classification of hazards ......................................... ... ... .... ... ... ...................... 5

1.1.2 Further ideograms ......................................................................................... 6

1.2 Proper use ....................................... ... .... ... ... ... .... ...................................... ... .... ... ... ...... 6

1.3 Possible dangers caused by the drilling machine .........................................................7

1.4 Qualification of employees ........................................................................................... 8

1.4.1 Target group ..................................................................................................8

1.4.2 Authorized persons .............................................. ......................................... 8

1.5 User’s position ........................................ ... ... ... .......................................... ... .... ............9

1.6 Safety devices ..............................................................................................................9

1.6.1 ON / OFF switch ..........................................................................................10

1.6.2 Drilling machine table .................................................................................. 10

1.7 Separating protective devices .................................................................................... 10

1.7.1 Drill chuck protection ................................................................................... 10

1.7.2 Protective cover of the pulleys .................................................................... 11

1.7.3 Prohibition, warning and mandatory labels .................................................11

1.8 Safety check ...............................................................................................................11

1.9 Personal protective equipment ................................................................................... 11

1.10 Safety during operation .............................................................................................. 12

1.11 Safety during maintenance ......................................................................................... 12

1.12 Use of lifting equipment ..............................................................................................13

1.12.1 Mechanical maintenance work .................................................................... 13

1.13 Accident report .......................... ... ... .......................................... ... .... ... ... ... ... ..............13

1.14 Electric ................................ ................................................. .......................................13

2 Technical Data

2.1 Power connection ....................................................................................................... 14

2.2 Drilling capacity ..................... .... ... ... ... .... ... .......................................... ... ... .................14

2.3 Spindle holding fixture ................................................................................................14

2.4 Drilling machine table ............ .... ... ... ... .......................................... .... ... ... ... ... .... ..........14

2.10 Emissions ................................................................................................................... 15

2.5 Dimensions ................................... .................................................... ..........................15

2.6 Working area ................................................... .... ... ... .......................................... ... ... . 15

2.7 Revolutions ................................ ................................................ .................................15

2.8 Environmental conditions ...........................................................................................15

2.9 Operating material ...................................................................................................... 15

3 Assembly

3.1 Extent of supply .......................................................................................................... 16

3.2 Transport .................................................................................................................... 16

3.3 Storage ...................................... .................................................................................17

3.4 Installation and assemby ............................................................................................17

3.4.1 Assembly .................................... ............................. ............................. ....... 17

3.4.2 Installation ................................................................................................... 20

3.4.3 Installation drawings ... ... ... ... .... ... ... ... .... ......................................... .... ... .......20

3.5 First use ........................... ... ... .... ... ... ... .... .......................................... ..........................21

3.5.1 Phase inverter for 400V - machines ............................................................22

Page 3

quantum

MASCHINEN - GERMANY

© 2007

GB

Page 318 / 01 / 2008 Version 1.2.5 B 13 / B14 / B16 / B20 / B25 / B32 Drilling machine

4Handling

4.1 Safety ......................................................................................................................... 23

4.2 Control and indicating elements ................................................................................. 23

4.2.1 B 13, B 14 ................................................................................................... 23

4.2.2 B 16, B 20, B 25, B 32, B20 Vario, B25 Vario, B32 Vario ........................... 24

4.2.3 Drill depth stop ............................................................................................ 24

4.2.4 Inclination of the drilling machine table ....................................................... 25

4.3 Speed alternation ....................................................................................................... 26

4.3.1 Speed table ................................................................................................. 27

4.4 Standard values for speeds with HSS – Eco – twist drill ............................................ 31

4.5 Drill chuck ................................................................................................................... 32

4.5.1 Gear rim-drill chuck ......................................................... ... .... ... ... ... ... .... ... .. 32

4.5.2 Disassembly of the drill chuck ..................................................................... 32

4.6 Cooling ....................................................................................................................... 32

4.7 Before starting the working process ........................................................................... 32

4.8 During the working process ........................................................................................ 33

5 Maintenance

5.1 Safety ......................................................................................................................... 35

5.1.1 Preparation ................................................................................................. 35

5.1.2 Restarting ........................................... ................................ ......................... 35

5.2 Inspection and maintenance ...................................................................................... 35

5.3 Repair ................................ ............................................. ............................................ 37

6 Ersatzteile - Spare parts B13, B14, B16, B20, B25, B32

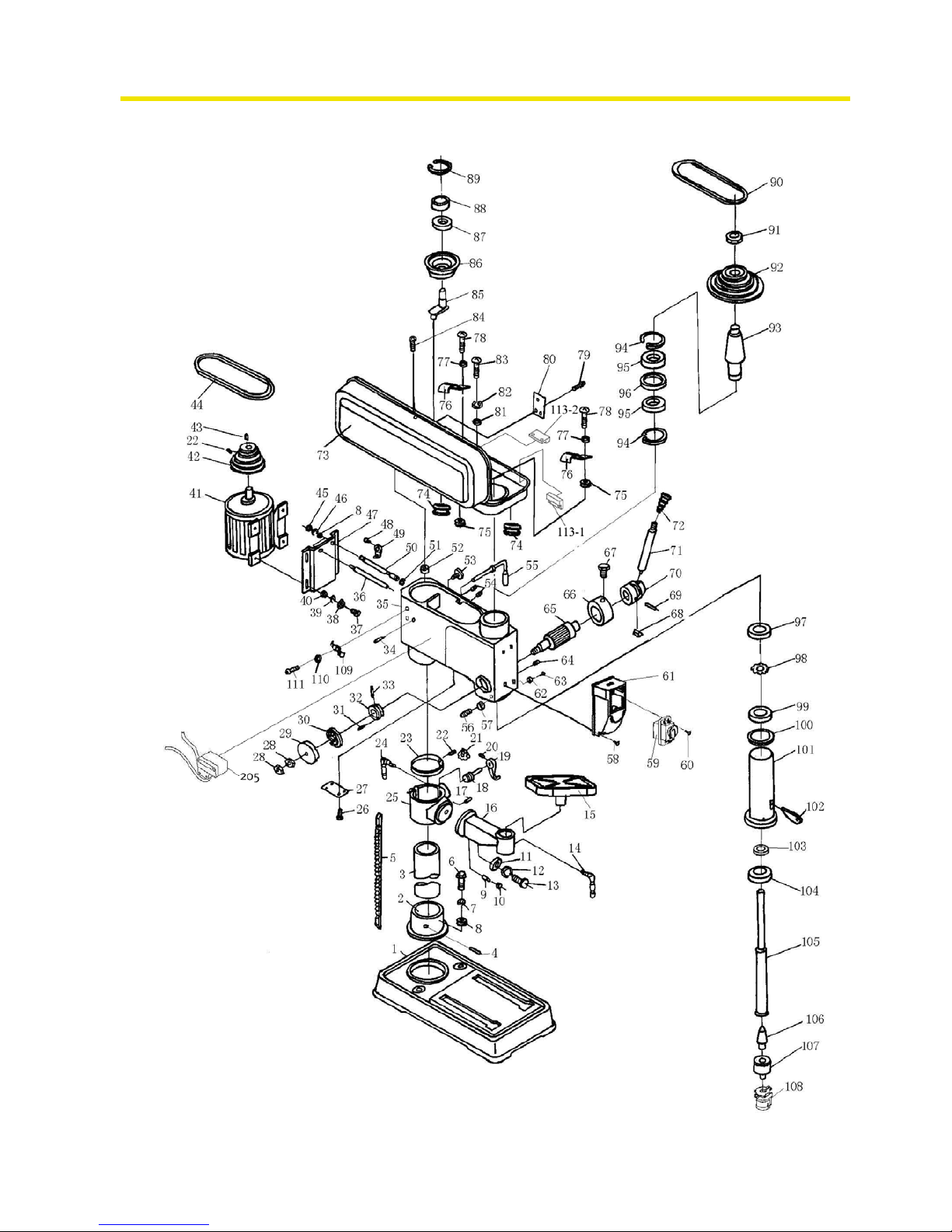

6.1 Ersatzteilzeichnung - Parts drawing B13 / B14 .......................................................... 38

6.2 Bohrfutterschutz B13, B14 - Drill chuck protection B13, B14 ..................................... 39

6.2.1 Ersatzteilliste - Parts list B13 / B14 ............................................................. 39

6.3 Ersatzteilzeichnung - Parts drawing B 16 ....................... ... ... .... ... ... ............................ 41

6.4 Bohrfutterschutz B16 - Drill chuck protection B16 ...................................................... 42

6.4.1 Ersatzteilliste - Parts list B16 ....................................................................... 42

6.5 Ersatzteilzeichnung - Parts drawing B20 / B25 (Vario) .............................................. 44

6.6 Bohrfutterschutz B20, B25 - Drill chuck protection B20, B25 ..................................... 45

6.6.1 Ersatzteilliste - Parts list B20 / B25 (Vario) ................................................. 45

6.7 Ersatzteilzeichnung - Parts drawing B32 (Vario) ........................................................ 48

6.8 Bohrfutterschutz B32 - Drill chuck protection B32 ...................................................... 49

6.8.1 Ersatzteilliste - Parts list B32 (Vario) ........................................................... 49

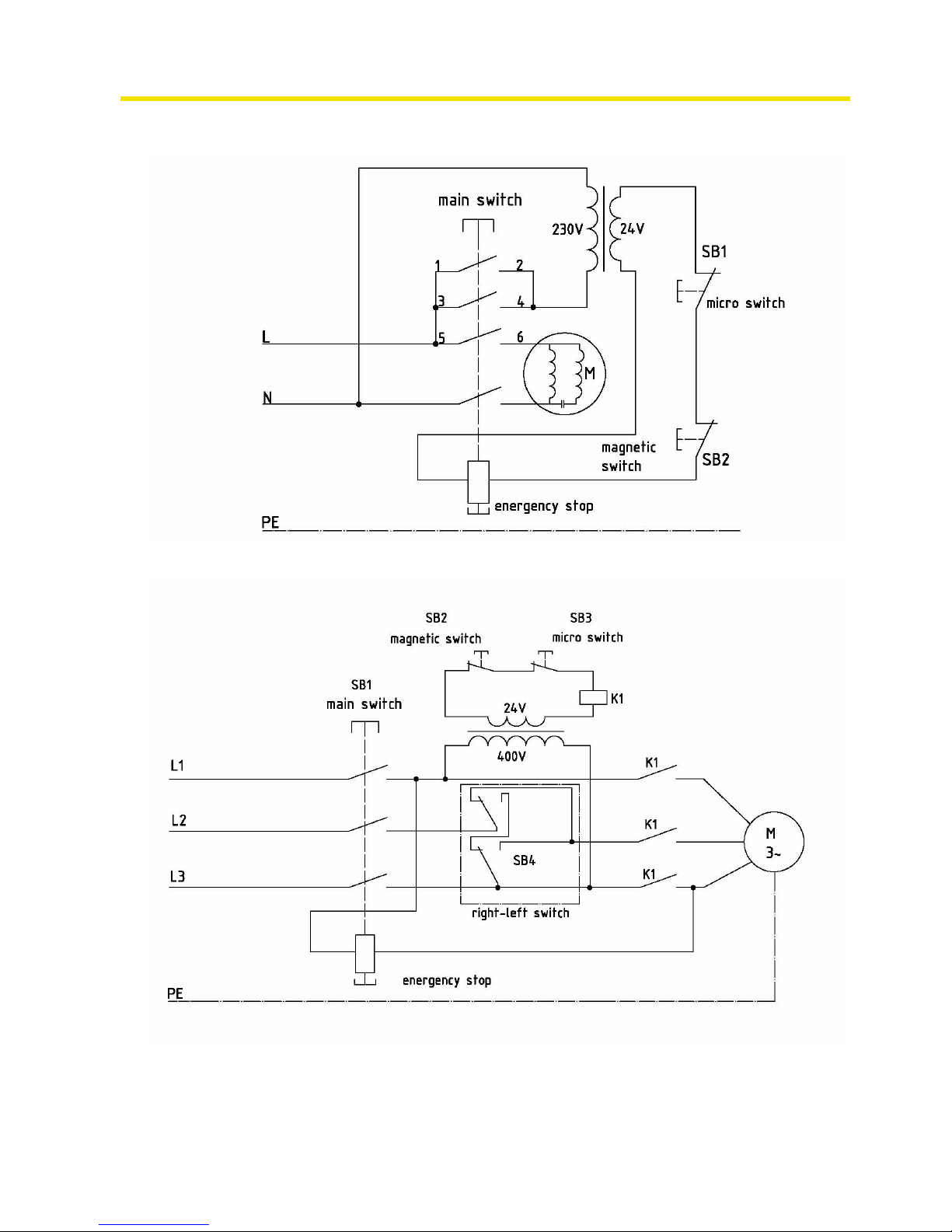

6.9 Schaltplan - Wiring diagram B13-B20 (230V) ............................................................ 52

6.10 Schaltplan - Wiring diagram B20-B32 (400V) ............................................................ 52

6.11 Schaltplan - Wiring diagram B20Vario-B32Vario (230V) ............................................ 53

7 Malfunctions

8 Appendix

8.1 Copyright .............................. ............................................................................. .........56

8.2 Terminology/Glossary ................................................................................................ 56

8.3 Warranty ............................ ............................................. ............................................ 57

8.4 Disposal ................................ ................ ................ ................ ................. ................ ..... 57

8.5 RoHS , 2002/95/CE .................................................................................................... 57

8.6 Product follow-up ..................... ... .... ... ... ... .... ... ... ... .......................................... ... .... ... .. 58

8.7 EC - declaration of conformity .................................................................................... 59

Page 4

Safety

quantum

MASCHINEN - GERMANY

© 2007

GB

Page 4 Drilling machine B 13 / B14 / B16 / B20 / B25 / B32 Version 1.2.5 18 / 01 / 2008

1 Safety

Glossary of symbols

This part of the operating manual

• does explain the meaning and how to use the war ning refe re n ce s c ontained in this ope ra tin g

manual,

• does explain how to use the drilling machine,

• highlights the dangers that might arise for you and others if these instructions are not followed thoroughly,

• informs you on how to prevent dangers.

In addition to this operating manual, please note

• applicable laws and regulations,

• legal regulations for preventing an accident,

• the prohibition, warning and mandatory signs as well as the warning notes on the drilling

machine.

European standards must be kept during installation, operation, maintenance and repair of the

drilling machine.

If European standards are not applied at the national legislation of the country of destination, the

specific applicable regulations of each country are to be observed.

If necessary, the required measures must be taken to comply with the specific regulations of

each country before the drilling machine is used for the first time.

Always keep the operating manual close to the drilling machine for further reference.

INFORMATION

If you are not able to solve a problem using this manual, please do not hesitate to contact us for

further professional advice:

Optimum Maschinen Germany GmbH

Dr. Robert-Pfleger-Str. 26

D- 96103 Hallstadt

info@optimum-maschinen.de

gives further advice

calls on you to get in action

• enumeration

notice

Page 5

quantum

MASCHINEN - GERMANY

Safety

© 2007

GB

Page 518 / 01 / 2008 Version 1.2.5 B 13 / B14 / B16 / B20 / B25 / B32 Drilling machine

1.1 Safety warnings (warning notes)

1.1.1 Classification of hazards

We classify the safety warnings into various levels. The table below gives an overview of the

classification of symbols (ideogram) and warning signs for each specific danger and its (possible) consequences.

ideogram warning alert definition / consequence

DANGER!

Threatening danger that will cause serious injury or

death to people.

WARNING!

Risk: A danger that might cause serious injury or death

to a person.

CAUTION!

Danger or unsafe procedure that might cause injury to

people or damage to property.

ATTENTION!

Situation that could cause damage to the machine and

to the product and other types of damages.

No risk of injury to people.

INFORMATION

Application advice and other important or useful information and notes.

No dangerous or harmful consequences for people or

objects.

In case of certain dangers, we replace the ideogram by

or

general danger

with a warning ofinjuries to

hands,

hazardous

electrical voltage,

rotating parts.

Page 6

Safety

quantum

MASCHINEN - GERMANY

© 2007

GB

Page 6 Drilling machine B 13 / B14 / B16 / B20 / B25 / B32 Version 1.2.5 18 / 01 / 2008

1.1.2 Further ideograms

1.2 Proper use

WARNING!

In the event of improper use, the drilling-milling machine

• will endanger personnel,

• will endanger the machine and other material property of the operator,

may affect proper operation of the drilling machine.

The drilling machine is constructed and designed for the use in non-explosive surrounding. The

drilling machine is designed and manufactured to be used for drilling cold metals or other nonflammable materials or materials that do not constitute a health hazard by using a rotating cutting tool with various chucking grooves.

If the drilling machine is used in any way other than as described above, modified without the

authorisation of Optimum Maschinen GmbH or operated with different process data, then it is

being used improperly.

We do not take liability for damage caused by improper use.

We would like to stress that any modifications to the construction, or technical or technological

modifications that have not been authorised by Optimum Maschinen GmbH will also render the

guarantee null and void.

It is also part of proper use that

• the maximum values for the drilling machine are complied with,

• the operating manual is observed,

• inspection and maintenance instructions are observed.

„Technical Data“ on page 14

Warning of auto-

matic start-up!

Activation forbid-

den!

Pull the main plug! Use safety

glasses!

Use ear protec-

tion!

Use protective

gloves!

Use protective

boots!

Wear a safety suit! Protect the envi-

ronment!

Contact address

Page 7

quantum

MASCHINEN - GERMANY

Safety

© 2007

GB

Page 718 / 01 / 2008 Version 1.2.5 B 13 / B14 / B16 / B20 / B25 / B32 Drilling machine

WARNING!

Very serious injury.

It is forbidden to make any modifications or alternations to the operating values of the

drilling machine! They could endanger employees and cause damage to the drilling

machine.

1.3 Possible dangers caused by the drilling machine

The drilling machine is state of the art.

Nevertheless, there is a residual risk as the drilling machine operates with

• high revolutions,

• rotating parts,

• electrical voltage and currents.

We have used construction resources an d safety techniques to minimize the health risk to per-

sons resulting from these hazards.

If the drilling machine is used and maintained by employees who are poorly qualified, then there

might be a risk resulting from incorrect operation and unsuitable maintenance of the drilling

machine.

INFORMATION

Everyone involved in the assembly, commissioning, operation and maintenance must

• be duly qualified,

• strictly follow this operating manual.

Due to improper use

• there is a risk for the employee,

• the machine and further property might be endangered,

• the function of the drilling machine could be affected.

Always disconnect the drilling machine if cleaning or maintenance work is being carried out.

WARNING!

The drilling machine may only be used with the safety devices activated.

Disconnect the drilling machine immediately whenever you detect a failure in the safety

devices or when they are not mounted!

All additional installations carried out by the operator must incorporate the safety

devices prescribed.

This is your responsibility being the operator!

„Safety devices“ on page 9

Page 8

Safety

quantum

MASCHINEN - GERMANY

© 2007

GB

Page 8 Drilling machine B 13 / B14 / B16 / B20 / B25 / B32 Version 1.2.5 18 / 01 / 2008

1.4 Qualification of employees

1.4.1 Target group

This manual applies to

• the operators,

• the users,

• the maintenance staff.

Therefore, the warning notes refer to both operation and maintenance of the drilling machine.

Determine clearly and make a permanent decision in who will be responsible for the different

activities on the machine (operation, ma in te na nc e an d re pair).

Vague and unclear assignment of responsibilities constitute a safety hazard!

Always disconnect the main plug of the drilling machine. This will prevent it from being used by

unauthorized persons.

1.4.2 Authorized persons

WARNING!

Incorrect use and maintenance of the drilling machine constitute a danger for the staff,

objects and the environment .

Only authorized persons may operate the drilling machine!

Persons authorized to operate and maintain should be trained technical staff and

instructed by the ones who are working for the operator and for the manufacturer.

The operator must

Obligations

of the opera-

tor

• train the staff,

• instruct the staff in regular intervals (at least once a year) on

- all safety standards that apply to the drilling machine,

- the operation,

- accredited technical guidelines,

• check the knowledge of the staff,

• document training / instructions,

• require the staff to confirm participation in training / instructions by means of a signature,

• check if the staff is aware of safety rules and dangers in the workplace so that they observe

the operating manual.

The user must

Obligations

of the user

• have followed a training on the operation of the drilling machine,

• know the function and performance,

• before commissioning

- have read and understood the operating manual,

- be familiar with all safety devices and regulations.

Further

require-

ments to the

qualification

For working on the following machine parts, additional requirements are being applied:

• Electrical parts or operating agents: shall only be performed by an electrician or under the

guidance and supervision of an electrician.

Before starting work on electrical parts or operating agents, following measures are to be performed in the following order.

Page 9

quantum

MASCHINEN - GERMANY

Safety

© 2007

GB

Page 918 / 01 / 2008 Version 1.2.5 B 13 / B14 / B16 / B20 / B25 / B32 Drilling machine

disconnect all poles

secure against switching on

check dead circuit

1.5 User’s position

The user must stand in front of the drilling machine.

INFORMATION

The main switch of the drilling machine must be easily accessible.

1.6 Safety devices

Operate the drilling machine only with properly functioning safety devices.

Stop the drilling machine immediately if there is a failure in the safety device or if it is not func-

tioning for some reason.

It is your responsibility!

If the safety device has been activated or has failed, the drilling machine must only be operated

again when

• the cause of the failure has been removed,

• you have made sure that there is no existing danger for persons or objects.

WARNING!

If you bypass, remove or override a safety device in any other way, you are endangering

yourself and other persons working on the drilling machine. The possible consequences

are the following

• injuries due to components or parts of components flying off at high speed,

• contact with rotating parts,

• fatal electrocution.

The drilling machine includes the following safety devices:

• an EMERGENCY-STOP button,

• a drilling machine table with grooves to fasten the workpiece or a vice,

• a fixed screwed-on protective cover for the pulleys with micro switch,

• a drill chuck guard with micro switch.

Page 10

Safety

quantum

MASCHINEN - GERMANY

© 2007

GB

Page 10 Drilling machine B 13 / B14 / B16 / B20 / B25 / B32 Version 1.2.5 18 / 01 / 2008

1.6.1 ON / OFF switch

The lockable switch is equipped with an

EMERGENCY-STOP function and a

release for undervoltage.

Illustr.1-1: On / OFF switch

Open the cap of the switch in order to switch the drilling machine on.

CAUTION!

Even if the EMERGENCY-STOP button is activated the spindle will keep turning for sev-

eral seconds - depending on the pre-selected number of revolutions.

1.6.2 Drilling machine table

On the drilling machine table there are

holding fittings for sliding blocks.

WARNING!

There is danger of injury because of the

parts flying off. Tighten the workpiece

properly into the drilling machine table.

Illustr. 1-2: drilling machine table

1.7 Separating protective devices

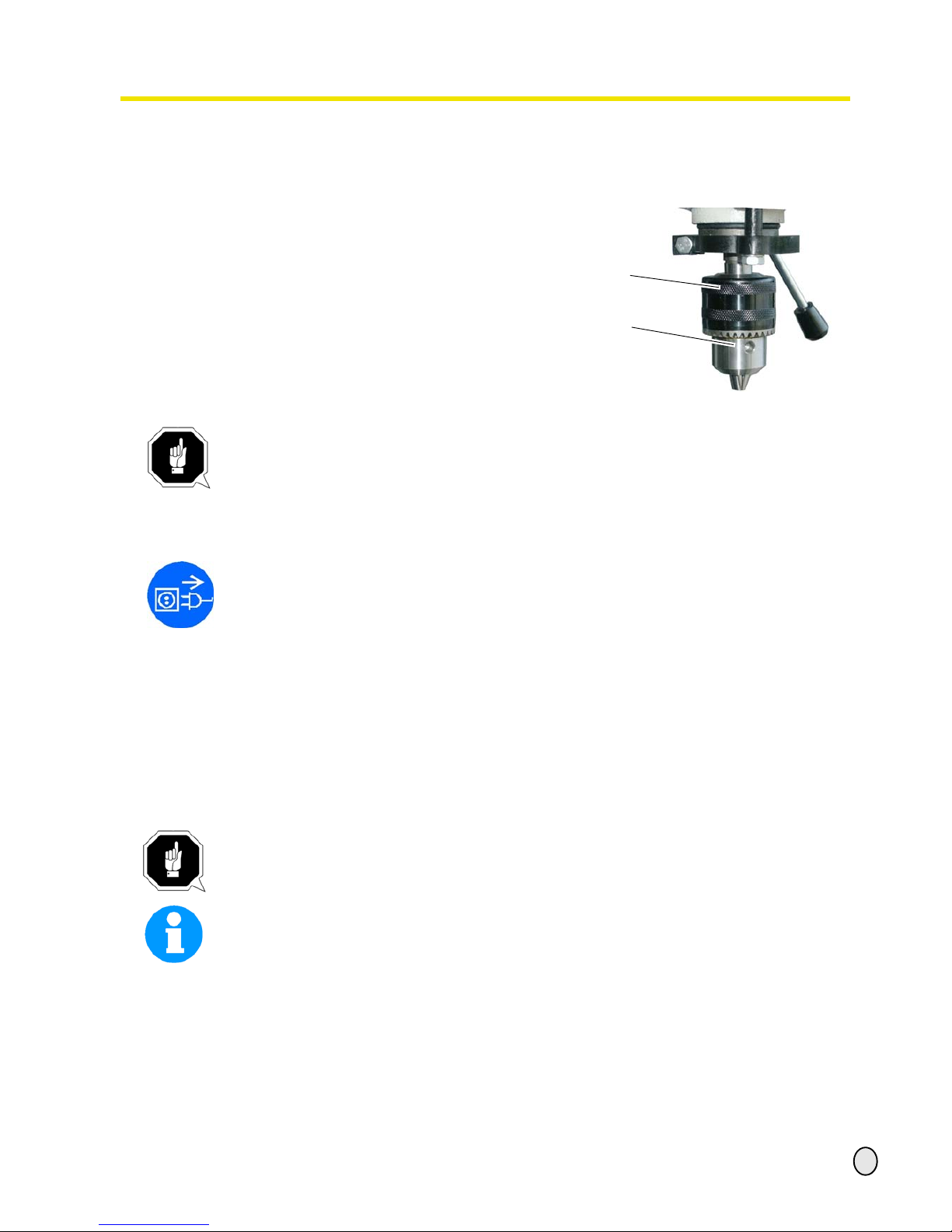

1.7.1 Drill chuck protection

Adjust the protective equipment to the correct height before you start working.

To do so, detach the clamping screw,

adjust the required height and retighten the

clamping screw.

A switch is integrated in the fixture of the

spindle protection which monitors that the

cover is closed.

INFORMATION

YOU CANNOT START THE MACHINE IF

THE DRILL CHUCK PROTECTION IS

NOT CLOSED.

Illustr.1-3: Drill chuck protection

ON / OFF switch

holding fixtures for

grooves

(14 mm)

Drill chuck protection

Page 11

quantum

MASCHINEN - GERMANY

Safety

© 2007

GB

Page 1118 / 01 / 2008 Version 1.2.5 B 13 / B14 / B16 / B20 / B25 / B32 Drilling machine

1.7.2 Protective cover of the pulleys

A protective cover for the belt pulleys is

mounted on the drilling head. A switch is

integrated in the protective cover which

monitors that the cover is closed.

INFORMATION

YOU CANNOT START THE MACHINE IF

THE PROTECTIVE COVER IS NOT

CLOSED.

Illustr.1-4: protective cover

1.7.3 Prohibition, warning and mandatory labels

INFORMATION

All warning labels must be legible. Check them regularly.

1.8 Safety check

Check the drilling machine at least once per shift. Inform the person responsible immediately of

any defect or change in the operating function.

Check all safety devices

• at the beginning of each shift (with the machine stopped),

• once a week (with the machine in operation),

• after every maintenance and repair work.

Check that the prohibition, warning and information labels as well as the markings on the drilling

machine

• are legible (clean them, if necessary),

• are complete.

1.9 Personal protective equipment

For certain work, personal protective equipment is required, such as:

• safety helmet,

• protective glasses or face guard,

• protective gloves,

• safety shoes with steel caps,

• ear protection.

Before starting work, make sure that the prescribed personal protective equipment is available

at the workplace.

CAUTION!

Dirty or eventually contaminated personal protective equipment might cause disease.

Clean your personal protective equipment

• after each use,

• regularly once a week.

protective cover

Page 12

Safety

quantum

MASCHINEN - GERMANY

© 2007

GB

Page 12 Drilling machine B 13 / B14 / B16 / B20 / B25 / B32 Version 1.2.5 18 / 01 / 2008

Personal protective equipment for special work

Protect your face and your eyes: Wear a safety helmet with a face guard for every work, especially for the kind of work where your face and eyes are exposed to hazards.

Use protective gloves when lifting or handling pieces with sharp edges.

Wear safety shoes when fitting, dismanteling or transporting heavy components.

1.10 Safety during operation

In the description of work with and on the drilling machine we highlight the dangers specific to

that work.

WARNING!

Before activating the drilling mac h ine, double check that this will

• not endanger other people,

• not cause damage to equipment.

Avoid unsafe working practice:

• Make sure that your work does not endanger anyone.

• The instructions of this manual must be observed strictly during assemby, operation, maintenance and repair.

• Do not work on the drilling machine, if your concentration is reduced, for example, because

you are taking medication.

• Observe the regulations for the prevention of accidents issued by your association for the

prevention of accidents and safety in the workplace or other inspection authorities.

• Inform the inspector of any danger or failure.

• Stay at the drilling machine until all rotating parts have come to a halt.

• Use the prescribed personal protective equipment. Make sure to wear a well-fitting work suit

and a hainet, if necessary.

• Do not use protective gloves when drilling.

1.11 Safety during maintenance

Inform the operating staff on time of any repair and maintenance work.

Report all safety-relevant changes or performance details of the drilling machine.Document all

changes, have the operating manual changed accordingly and train the machine operators.

Switching-off and securing the drilling machine

Unplug the main switch before starting any maintenance or repair work.

All machine components and hazardous voltages are d isc onnect ed.O nly the pos ition s which are

marked with the pictogram in the margin are excluded. Attach a warning sign on the machine.

Page 13

quantum

MASCHINEN - GERMANY

Safety

© 2007

GB

Page 1318 / 01 / 2008 Version 1.2.5 B 13 / B14 / B16 / B20 / B25 / B32 Drilling machine

1.12 Use of lifting equipment

WARNING!

Use of unstable lifting and load-suspension gear that might break under load can cause

very serious injuries or even death.

Check the lifting and load-suspension gear on

• sufficient load capacity,

• perfect condition.

Observe the regulations for the prevention of accidents issued by your association for

the prevention of occupational accidents and safety in the workplace or other inspection

authorities.

Fasten the loads properly. Do not walk under lifted loads !

1.12.1 Mechanical maintenance work

Remove all protection and safety de vices before starting maintenance wor k and re-install them

once the work has been completed, such as:

• covers,

• safety indications and warning signs,

• earth (ground) cables.

If you remove protection or safety devices, refit them immediately after completing the work.

Check if they are working properly!

1.13 Accident report

Inform your superiors and Optimum Maschinen GmbH immediately in case of accidents, possible sources of danger and any action which almost lead to an accident "near misses".

"Near misses" may have many possible causes.

The sooner they are notified, the faster theses causes can be eliminated.

1.14 Electric

Have the machine and / or the electrical equipment checked regularly, at least every six months.

Eliminate immediately all defects such as loose connections, defective wires, etc.

A second person must be present during work on live components, to disconnect the power in

case of an emergency.

Disconnect the drilling machine immediately if there is a malfunction in the power supply!

„Maintenance“ on page 34

Page 14

Technical Data

quantum

MASCHINEN - GERMANY

© 2007

GB

Page 14 Drilling machine B 13 / B14 / B16 / B20 / B25 / B32 Version 1.2.5 18 / 01 / 2008

2 Technical Data

The following data which give dimensions and weight are the manufacturer’s authorized

machine data.

2.1 Power connection

B 13 B 14 B 16 B 20

B 20 Vario

B 25

B 25 Vario

B 32

B 32 Vario

power connection~50Hz

230 V

300 W

230 V

350W

230 V

450 W

3 x 400 V

550 W

3 x 400 V

550 W

3 x 400 V

1,1 kW

or

230 V

550 W

230V

550 W

230V

1,1 kW

2.2 Drilling capacity

B 13 B 14 B 16 B 20 B 25 B 32

drilling capacity in steel

[mm]

13 14 16 20 20 32

reach [mm] 104 104 125 170 170 225

spindle sleve travel [mm] 50 50 65 80 80 125

2.3 Spindle holding fixture

B 13 B 14 B 16 B 20 B 25 B 32

spindle holding fixture firm/B16 firm/B16 MK2 MK2 MK3 MK4

2.4 Drilling machine table

B 13 B 14 B 16 B 20 B 25 B 32

slewable on the spindle

axis [mm]

length x width of the work-

ing area

160 x 160 160 x 160 200 x 200 275 x 275 275 x 275 360 x 360

T-groove dimension [mm] 14 14 14 14 14 14

maximum distance [mm]

spindle table

240 340 390 450 760 660

working area stand [mm]

length x width of the work-

ing area

135 x 175 140 x 180 160 x 170 205 x 200 235 x 220 260 x 270

Page 15

quantum

MASCHINEN - GERMANY

Technical Data

© 2007

GB

Page 1518 / 01 / 2008 Version 1.2.5 B 13 / B14 / B16 / B20 / B25 / B32 Drilling machine

2.10 Emissions

The emission of the drilling machine is below 76 dB(A). If the drilling machine is installed in an

area where various machines are in opera tion, the acoustic influence (immission) on the operator of the drilling machine may exceed 85 dB(A).

We recommend the use of soundproofing and ear protection.

Please note that the duration of the acoustic noise expose, the kind and nature of the working

area as well as other machines may influence the noise level in the workplace.

2.5 Dimensions

B 13 B 14 B 16 B 20 B 25 B 32

height [mm] 580 700 820 990 1570 1730

depth [mm] 420 420 510 700 690 790

width [mm] 220 230 270 300 390 400

total weight [kg] 21 24 38 56 63 138

column diameter [mm] 46 46 60 70 70 92

2.6 Working area

B 13 B 14 B 16 B 20 B 25 B 32

height [mm] 2050 205 0 2050 2050 2050 2050

depth [mm] 2000 200 0 2000 2000 2000 2000

width [mm] 1400 1400 1400 1400 1400 1400

2.7 Revolutions

B 13

B 14

B 16 B 20

B 25

B 20 Vario

B 25 Vario

B 32 B 32 Vario

spindle revolutions • 619

•837

•1314

•1807

•2435

• 459

• 579

• 787

• 1255

• 2100

•268

•323

•376

•453

•516

•533

•796

• 1029

• 1257

• 1274

• 1783

• 2209

• 16 - 686

• 19 - 827

• 22 - 963

• 27 - 1161

• 31 - 1323

• 32 - 1367

• 47 - 2041

• 61 - 2636

• 74 - 3221

• 75 - 3265

• 105 - 3500

• 131 - 3500

•167

•288

•339

•379

•489

•585

•1106

•1368

•1970

• 10 - 429

• 17 - 739

• 20 - 870

• 22 - 970

• 29 - 1253

• 35 - 1498

• 65 - 2835

• 81 - 3500

• 117 - 3500

2.8 Environmental conditions

B 13 B 14 B 16 B 20 B 25 B 32

temperature 5 - 35 °C

humidity 25 - 80 %

2.9 Operating material

toothed rack commercial slide bearing grease

drilling column acid-free lubricating oil

Page 16

Assembly

quantum

MASCHINEN - GERMANY

© 2007

GB

Page 16 Drilling machine B 13 / B14 / B16 / B20 / B25 / B32 Version 1.2.5 18 / 01 / 2008

3 Assembly

3.1 Extent of supply

When the drilling machine is delivered, check immediately that the machine has not been damaged during shipping and that all components are included. Also check that no fastening screws

have come loose.

The delivery volume contains:

3.2 Transport

WARNING!

Machine parts falling off forklift trucks or transport vehicles could cause very serious or

even fatal injuries. Follow the instructions and information on the transport case:

• centres of gravity

• suspension points

•weights

• means of transport to be used

• prescribed shipping position

WARNING!

Use of unstable lifting equipment and load-suspension devices that break under load can

cause very serious injuries or even death.

Check that lifting and load suspension gear has sufficient load capacity and that it is in

perfect condition.

B13 / B14 B16 B20

B20 Vario

B25 / B32

B25 Vario

B32 Vario

• drilling head • drilling head • drilling head • drilling head

• drilling table with premounted clamping lever

• drilling table with premounted clamping lever

• drilling table

• drilling table support

• handle

• drilling table

• drilling table support

• handle

•stand •stand •stand •stand

• column component with

premounted table support

• column component with

premounted table support

• column component

• toothed rod

• guide ring

• column component

• toothed rod

• guide ring

• gear rim drill chuck (B13)

• quick action drill chuck

(B14)

• quick action drill chuck

• morse cone MK2

• drill drift

• quick action drill chuck

• morse cone MK2

• drill drift

• quick action drill chuck

• morse cone MK3

(B25 / Vario)

• morse cone MK4

(B32 / Vario)

• drill drift

• 3 x handle bar star handle

• 3 x handle bar star handle

• 3 x handle rod star handle

• 3 x handle rod star handle

• assembly set • assembly set • assembly set • assembly set

• operating manual • operating manual • operating manual • operating manual

• for 400 V: CEE - 16 A,

phase inverter

• CEE - 16 A,

phase inverter

Page 17

quantum

MASCHINEN - GERMANY

Assembly

© 2007

GB

Page 1718 / 01 / 2008 Version 1.2.5 B 13 / B14 / B16 / B20 / B25 / B32 Drilling machine

Observe the rules for preventing accidents issued by your association for the prevention

of accidents or other inspection authorities. Hold the loads properly. Never walk under

suspended loads!

3.3 Storage

ATTENTION!

Improper storage may cause important parts to be damaged or destroyed. Store packed

or unpacked parts only under the following ambient conditions:

„Environmental conditions“ on page 15

Consult Optimum Maschinen GmbH if the drilling machine and accessories have to be stored

for a period of over three monthes or under different external conditions than those given here.

3.4 Installation and assemby

3.4.1 Assembly

WARNING!

Danger of crushing when grouping, assembling and mounting the machine components.

Assembly of stand and tripod

INFORMATION

You need a hexagon spanner 17mm and the hexagon bolts contained in the delivery volume to

assemble the drilling machine.

Put the stand on the floor and fix the drill

column to the stand. Hexagon bolts are

provided to fix it.

Illustr.3-1: Assembly drill column

drill column

hexagon bolts

stand

Page 18

Assembly

quantum

MASCHINEN - GERMANY

© 2007

GB

Page 18 Drilling machine B 13 / B14 / B16 / B20 / B25 / B32 Version 1.2.5 18 / 01 / 2008

Assembly of the drilling machine table B16, B20, B25 and B32 / Vario

Introduce the toothed rack into the sup-

port for the drilling machine table.

Adjust the toothed rack within the drill-

ing machine table in a way that the

teeth of the toothed rack cam into the

spiral wheel of the support for the drilling machine table.

Push the complete table with the

toothed rack onto the tripod.

Illustr.3-2: Assembly of the drilling

machine table (B20)

INFORMATION

The larger part without toothing of the toothed rack must be upside.

Push the guide ring on the column and

on the toothed rack.

Fix the guide ring with the stud bolt.

Make sure that the drilling table is still turning easily around the drill column.

Illustr.3-3: Assembly guide ring

Mount the crank handle for height

adjustment of the drill head.

Clamp the crank handle with the stud

bolt.

Illustr.3-4: Assembly crank handle

support for drilling

machine table

toothed rack

tripod

guide ring

stud bolt

crank handle

Page 19

quantum

MASCHINEN - GERMANY

Assembly

© 2007

GB

Page 1918 / 01 / 2008 Version 1.2.5 B 13 / B14 / B16 / B20 / B25 / B32 Drilling machine

Put the drilling table onto the drilling

support. Mount the clamping lever.

Illustr.3-5: Assembly drilling table

Mount the drilling table B13 , B14

Push the drilling table support with

mounted drilling table onto the column.

Illustr.3-6: Assembly drilling table B13/

B14

Assembly of the drilling head

Put the drilling head on the tripod and

turn it until it aligns with the stand.

Make sure that the drilling head is

completely fixed onto the tripod.

Tighten the drilling head with the two set

screws.

Mount the three levers of the feed cross.

Illustr.3-7: Assembly drilling head

clamping lever

drilling table support

Lever

stud bolt

Page 20

Assembly

quantum

MASCHINEN - GERMANY

© 2007

GB

Page 20 Drilling machine B 13 / B14 / B16 / B20 / B25 / B32 Version 1.2.5 18 / 01 / 2008

3.4.2 Installation

Check the horizontal orientation of the base of the drilling machine with a spirit level.

Attach the drilling machine to the base using the holes in the stand.

The place where the drilling machine is installed must comply with ergonomic workplace require-

ments.

ATTENTION!

Tighten the setscrews on the drilling machine only until it is firmly secured and can nei-

ther move during operation nor be turned over.

If the setscrews are too tight and the base is uneven, the stand of the drilling machine may

break.

3.4.3 Installation drawings

B 25 / B32

Illustr. 3-8: B25 B32

Page 21

quantum

MASCHINEN - GERMANY

Assembly

© 2007

GB

Page 2118 / 01 / 2008 Version 1.2.5 B 13 / B14 / B16 / B20 / B25 / B32 Drilling machine

3.5 First use

WARNING!

Staff and equipment may be endangered if the drilling machine is first used by unexpert

staff. We do not take responsibility for damage caused by incorrect commissioning.

Power supply

Connect the main plug of the drilling machine to the power supply.

Check the fuse protection of your power supply to the technical data for the power consump-

tion of the engine.

ATTENTION!

Please pay attention that all three phases (L1, L2, L3) for 400V - drilling machines are

connected correctly.

Most engine failures result from incorrect connection, for instance the neutral connector

(N) is being connected to a phase.

This might lead to the following results:

• The engine does get quickly very hot.

• The engine noise increases, i. e. becomes louder.

• The engine has no power.

When the phases are connected incorrectly, the guarantee is null and void.

ATTENTION!

Drilling machines with frequency converter should not be operated with a CEE plug. Con-

nect the machine permanently to a connection box (see EN 50178/5.2.11.1)

INFORMATION

The frequency converter (driving regulator) might release the FI protected switch of your electrical supply. In order to avoid any malfunctioning, you either need an FI protected switch sensitive for pulse current or and AC / DC sensitive one.

In case of a malfunction or release of the FI protected switch, please check the type installed.

The following signs indicate if you have one of the FI protected switches described above.

We recommend you to use an FI protected switch sensitive to AC/DC. FI protected switches

sensitive to AC/DC (RCCB, type B are adequate for 1 phase and 3 phase fed frequency converters (driving regulators).

An FI protected switch type AC (only for alternating current (AC)) is not appropriate for frequency converters. FI protected switches type AC are no longer used.

„Qualification of employees“ on page 8

FI protected switch sensitive to pulse current

Typ A

FI protected switch sensitive to AC/DC

Typ B

300 mA

300 mA

Page 22

Assembly

quantum

MASCHINEN - GERMANY

© 2007

GB

Page 22 Drilling machine B 13 / B14 / B16 / B20 / B25 / B32 Version 1.2.5 18 / 01 / 2008

3.5.1 Phase inverter for 400V - machines

Change the poles by means of the phase

inverter if the turning direction of the drilling machine is not correct.

Illustr.3-9: Phase inverter

Phase inverter

Page 23

quantum

MASCHINEN - GERMANY

Handling

© 2007

GB

Page 2318 / 01 / 2008 Version 1.2.5 B 13 / B14 / B16 / B20 / B25 / B32 Drilling machine

4 Handling

4.1 Safety

Use the drilling machine only under the following conditions:

The drilling machine is in proper working order.

The drilling machine is used as prescribed.

The instruction manual has been followed.

All safety devices are installed and activated.

All malfunctions should be eliminated immediately. Stop the machine immediately at an event of

any malfunction in operation and make sure it cannot be started up accidentally or without

authorization.

Notify the person responsible immediately of any modification.

„Safety during operation“ on page 12

4.2 Control and indicating elements

4.2.1 B 13, B 14

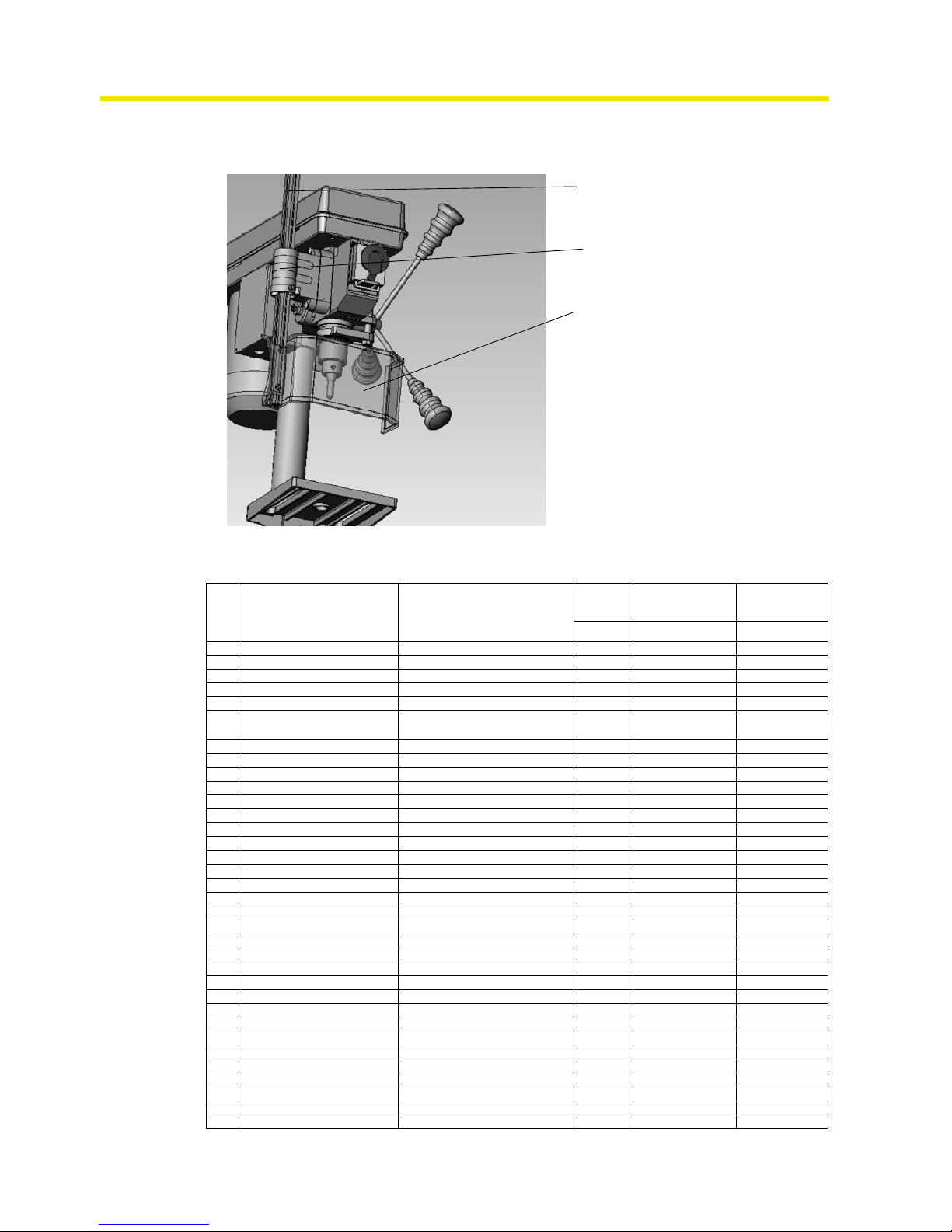

Illustr. 4-1: quantum B 13

pulley drive with housing

handle for V-belt tension

lever for spindle sleeve feed

drilling machine table

table height adjustment

ON / OFF switch with

EMERGENCY STOP

function

drill depth stop

drill chuck guard

Page 24

Handling

quantum

MASCHINEN - GERMANY

© 2007

GB

Page 24 Drilling machine B 13 / B14 / B16 / B20 / B25 / B32 Version 1.2.5 18 / 01 / 2008

4.2.2 B 16, B 20, B 25, B 32, B20 Vario, B25 Vario, B32 Vario

Illustr. 4-2: quantum B20 Vario

4.2.3 Drill depth stop

When drilling several holes of the same

depth, you can use the drill depth stop.

• Bei B16 / B20 / B25 / B32:

Unscrew the locking screw and turn the

graduated collar until the required drill

depth superimposes with the pointer.

Retighten the locking screw .

Illustr.4-3: Drill depth stop

B16 - B32

pulley drive with housing

handle for V-belt tension

lever for spindle sleeve feed

drill depth stop

drilling machine table

table height adjustment

adjustment for the inclination of

the drilling machine table

potentiometer speed

regulation (only Vario)

ON / OFF switch with

EMERGENCY STOP

function

reversing switch

drill chuck guard

clamping lever

locking screw

drill depth stop

scale

Page 25

quantum

MASCHINEN - GERMANY

Handling

© 2007

GB

Page 2518 / 01 / 2008 Version 1.2.5 B 13 / B14 / B16 / B20 / B25 / B32 Drilling machine

• For B 13 / B14:

Adjust the limit screw to the required drilling

depth.

The spindle may only be lowered to the

required drill depth.

Illustr.4-4: Drill depth stop

B13 - B14

4.2.4 Inclination of the drilling machine table

The drilling machine table can be inclined

to the right or to the left.

Loosen the fastening screws.

For B16 / B20 / B25 / B32:

Pull out the threaded pin.

Illustr.4-5: Fastening screw

INFORMATION

If the threaded pin may not be pulled out, the seat may be loosened by turning the nut clockwise.

Adjust the required angle by means of the scale.

Retighten the fastening screw firmly.

INFORMATION

The threaded pin is only provided for correct positioning of a horizontal level of the drilling table.

limit screw

drill depth stop

scale

fastening screw

threaded pin

scale

Page 26

Handling

quantum

MASCHINEN - GERMANY

© 2007

GB

Page 26 Drilling machine B 13 / B14 / B16 / B20 / B25 / B32 Version 1.2.5 18 / 01 / 2008

4.3 Speed alternation

WARNING!

Only open the cover hood when the drilling machine is disconnected from the electrical

power supply.

Close and screw the covering hood after each modification of the number of revolutions.

Disconnect the machine from the electrical

power supply.

Detach the screws on the protective

cover.

Open the protective cover of the belt

drive.

Illustr.4-6: Clamping screw V-belt

tension

Untighten the clamping screw of the V-belt tension and push the motor in direction of the drill

chuck.

Type Vario:

Adjust the required speed with the potentiometer. Depending on the position of the V-belts on

the V-belt pulleys you will get a certain speed range.

„Speed table“ on page 27

INFORMATION

The drilling machine B 20 , B 25 and B 32 are equipped with a handle by which you may push

the motor in direction of the drill chuck.

Thus the pre-tension of the V-belts is loosened.

Put the V-belt/-s onto the required V-belt pulley/-s.

Retighten the V-belt/-s

Close and rescrew the cover.

ATTENTION!

Make sure that the tension of the V-belts is correct.

If the tension of the V-belts is too high or too low, it may lead to damages. The V-belts are

well tightened if the they could be squeezed approximately 1 cm.

V-belt pulleys

clamping screw

V-belt tension

Page 27

quantum

MASCHINEN - GERMANY

Handling

© 2007

GB

Page 2718 / 01 / 2008 Version 1.2.5 B 13 / B14 / B16 / B20 / B25 / B32 Drilling machine

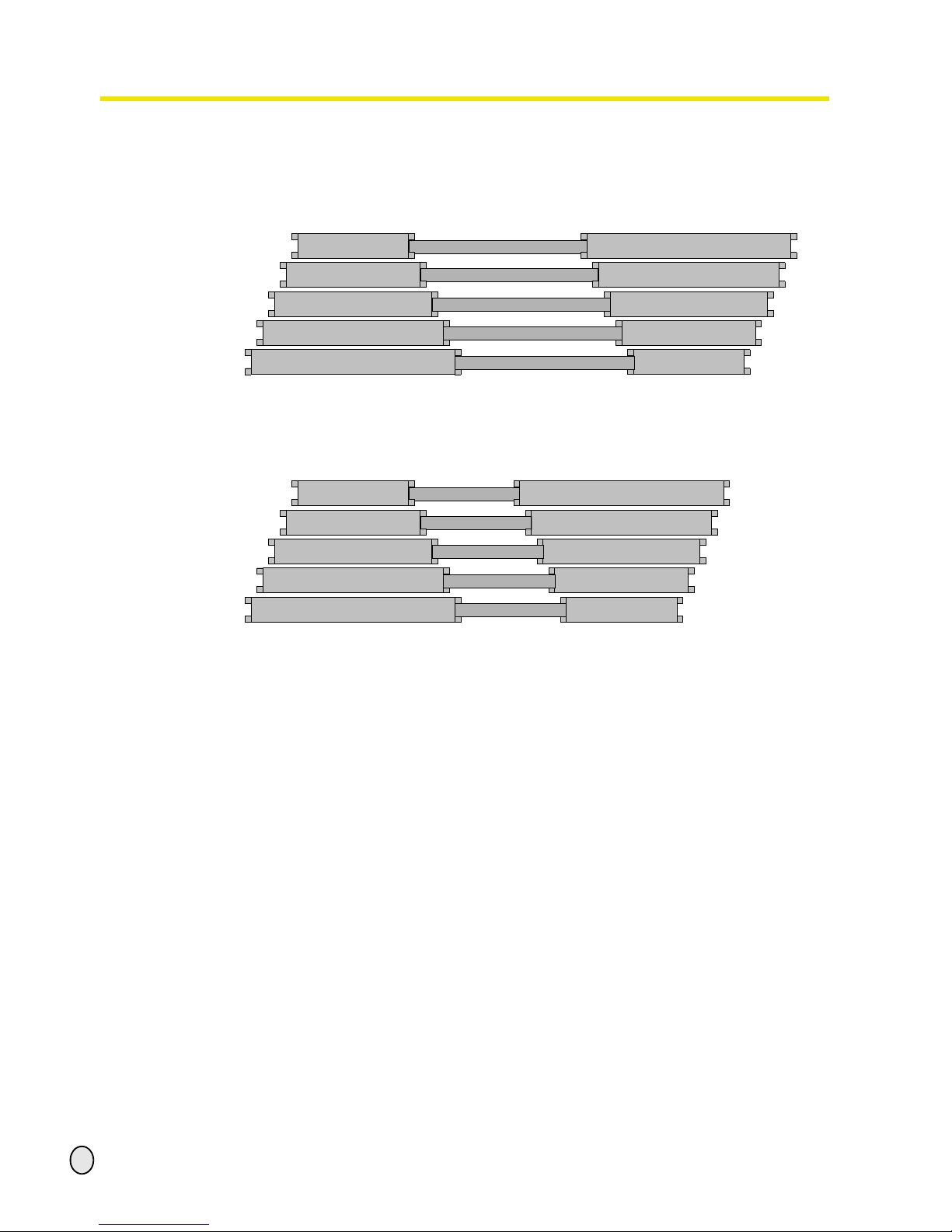

4.3.1 Speed table

Speed table B13 / B14

Illustr. 4-7: Speed table quantum B13 / B14

Speed table B16

Illustr. 4-8: Speed table quantum B16

2435

spindle

engine

1807

1314

837

619

2100

spindle

engine

1255

787

579

459

Page 28

Handling

quantum

MASCHINEN - GERMANY

© 2007

GB

Page 28 Drilling machine B 13 / B14 / B16 / B20 / B25 / B32 Version 1.2.5 18 / 01 / 2008

Speed table B20 / B25

Illustr. 4-9: Speed table B20 / B25

spindle

533

376

268

796

453

323

1029

1274

516

1783

2209

1257

engine

center pulleys

Page 29

quantum

MASCHINEN - GERMANY

Handling

© 2007

GB

Page 2918 / 01 / 2008 Version 1.2.5 B 13 / B14 / B16 / B20 / B25 / B32 Drilling machine

Speed table B20 Vario / B25 Vario

Illustr. 4-10: Speed table B20 Vario / B25 Vario

spindle

526

371

264

785

447

318

1014

1256

509

1757

2177

1239

engine

center pulleys

1367

963

686

2041

1161

827

2636

3265

1323

3500

3500

3221

32

22

16

47

27

19

61

75

31

105

131

74

15% 100% 225%

Page 30

Handling

quantum

MASCHINEN - GERMANY

© 2007

GB

Page 30 Drilling machine B 13 / B14 / B16 / B20 / B25 / B32 Version 1.2.5 18 / 01 / 2008

Speed table B32

Speed table B 32

spindle

379

288

167

1368

585

339

1106

1970

489

engine

center pulleys

Page 31

quantum

MASCHINEN - GERMANY

Handling

© 2007

GB

Page 3118 / 01 / 2008 Version 1.2.5 B 13 / B14 / B16 / B20 / B25 / B32 Drilling machine

Speed table B32 Vario

Illustr. 4-11: Speed table B 32 Vario

4.4 Standard values for speeds with HSS – Eco – twist drill

The preceding specifications are standard values. In some cases, it might be advantageous

to increase or to decrease those values.

Never do without coolant or lubricant when drilling.

Do not center rust-free materials (e.g. VA – or NIRO sheet metals), as the material will

harden and the drills will quickly get blunt.

The workpieces must always be tightened rigidly and strongly (vice, screw clamp).

spindle

373

284

165

1349

576

335

1090

1942

482

engine

center pulleys

15% 100% 225%

970

739

429

3507

1498

870

2835

3500

1253

22

17

10

81

35

20

65

117

29

material

drill diameter

cooling

3)

2345678910

steel, unalloyed,

up to 600 N7mm

2

n 1)5600 3550 2800 2240 2000 1600 1400 1250 1120

E

f

2)

0,04 0,063 0,08 0,10 0,125 0,125 0,16 0,16 0,20

structural steel, alloyed,

hardened and tempered, up

to 900N/mm

2

n 3150 2000 1600 1250 1000 900 800 710 630

E/Öl

f 0,032 0,05 0,063 0,08 0,10 0,10 0,125 0,125 0,16

structural steel, alloyed,

hardened and tempered, up

to 1200 n/mm

2

n 2500 1600 1250 1000 800 710 630 560 500

Öl

f" 0,032 0,04 0,05 0,063 0,08 0,10 0,10 0,125 0,125

rustproof steels of up to 900

N/mm

2

e.g. X5CrNi18 10

n 2000 1250 1000 800 630 500 500 400 400

Öl

f 0,032 0,05 0,063 0,08 0,10 0,10 0,125 0,125 0,16

1): speed [ n ] in r/min

2): feed [ f ] in mm/r

3): cooling: E = emulsion; Öl = cutting oil

Page 32

Handling

quantum

MASCHINEN - GERMANY

© 2007

GB

Page 32 Drilling machine B 13 / B14 / B16 / B20 / B25 / B32 Version 1.2.5 18 / 01 / 2008

4.5 Drill chuck

4.5.1 Gear rim-drill chuck

Open the drill chuck by means of the key

for chucks.

Illustr.4-12: gear rim-drill chuck

ATTENTION!

Make sure that the chucked tool is positioned firmly and correctly.

4.5.2 Disassembly of the drill chuck

WARNING!

Disassemble the drill chuck only when the drilling machine is disconnected from the

electrical power supply.

Disconnect the drilling machine from the electrical power supply.

The conical connection can be separated with a plastic or a rubber hammer.

4.6 Cooling

The friction generated during rotation can cause the edge of the tool to become very hot.

The tool should be cooled during the drilling process. Cooling the tool with a suitable cooling

lubricant ensures better working results and a longer edge life of the tools.

This is best realized by a separate cooling equipment. If there is no cooling equipment included

in the delivery volume, you can cool by means of a spray gun or a washing bottle.

ATTENTION!

Danger of injury due to brushes getting caught or pulled in.

Use a spray gun or a washing bottle for cooling.

INFORMATION

Use a water-soluble and non-polluant drilling emulsion which can be obtained from authorized

distributors.

Make sure that the cooling agent is being collected.

Respect the environment when disposing any lubricants and cooling agents.

Follow the manufacturer’s disposal instructions.

4.7 Before starting the working process

Before you start working, select the required speed. It is depending on the drilling diameter and

on the material used.

upper part

gear rim drill chuck

opening for the

key for chucks

Page 33

quantum

MASCHINEN - GERMANY

Handling

© 2007

GB

Page 3318 / 01 / 2008 Version 1.2.5 B 13 / B14 / B16 / B20 / B25 / B32 Drilling machine

„Speed table“ on page 27

WARNING!

For drilling jobs, it is necessary to clamp the workpiece firmly to prevent the bit catching

on the piece. Example of suitable clamping devices include a machine vice or clamping

jaws.

Put a wooden or plastic board beneath the workpiece to avoid drilling through to the work table,

vice, etc.

If necessary, adjust the required drill depth by means of the drill depth stop in order to achieve a

constant result.

Use a dust remover unit while working with wood. Sawdust can be health hazardous. Also use a

suitable protective mask for any work which generates dust.

4.8 During the working process

The spindle sleeve feed is being p erformed by th e star grip. Make sur e that the feed is being at

a regular pace and not too fast.

The reset of the spindle sleeve is being performed by a track recoil spring.

WARNING!

Danger of clothing and / or long hair getting caught.

• Make sure to wear a well-fitting work suit during drilling work.

• Do not use gloves.

• If necessary, wear a hairnet.

ATTENTION!

Danger of collision by the levers of the star grip.

Do not let the star grip get loose when resetting the drill sleeve.

Thin bits break easily.

In case of deep drilling, remove the bit from time to time, to remove drilling chips from the bore

hole. Some drops of oil reduce friction and ensure a longer edge life of the bit.

CAUTION!

Danger of crushing! Do not place your hand between the drill head and the spindle

sleeve.

Page 34

Maintenance

quantum

MASCHINEN - GERMANY

© 2007

GB

Page 34 Drilling machine B 13 / B14 / B16 / B20 / B25 / B32 Version 1.2.5 18 / 01 / 2008

5 Maintenance

In this chapter you will find important information about

• inspection,

• maintenance,

• repair of the drilling machine.

The diagram below shows which of these headings each task falls under.

Illustr. 5-1: Maintenance –Definition according to DIN 31051

ATTENTION!

Properly-performed regular maintenance is an essential prerequistite for

• safe operation,

• fault-free operation,

• long service life of the drilling machine and

• the quality of the products you manufacture.

Installations and equipment from other manufactures must also be in optimum condition.

ENVIRONMENTAL PROTECTION

During work on the spindle nose and the apron, make sure that

• collector vessels are used, with sufficient capacity for the amount of liquid to be collected,

• liquid and oils are not spilt on the ground.

Clean up any spilt liquid or oils immediately using proper oil-absorption methods and dispose of

them in accordance with current legal requirements on the environment.

Cleaning up spillages

Do not re-introduce liquids spilt outside the system during repair or as a result of leakage from

the reserve tank: collect them in a collecting vessel to be disposed of.

Disposal

Never dump oil or other pollutant substances in water inlet s, river s o r channels.

Maintenance

Inspection Maintenance

Repair

Measuring Rough cleaning Mending

Testing Fine cleaning Replacing

Conserving

Lubricating

Completing

Replacing

Readjusting

Adjusting

Page 35

quantum

MASCHINEN - GERMANY

Maintenance

© 2007

GB

Page 3518 / 01 / 2008 Version 1.2.5 B 13 / B14 / B16 / B20 / B25 / B32 Drilling machine

Used oils must be delivered to a collection centre. Consult your superior if you do not know

where the collection centre is.

5.1 Safety

WARNING!

The consequences of incorrect maintenance and repair work may include:

• very serious injury to personnel working on the drilling machine,

• damage to the drilling machine.

• Only qualified personnel should carry out maintenance and repair work on the drilling

machine.

5.1.1 Preparation

WARNING!

Only carry out work on the drilling machine if it has been switched off using the main

switch and secured with a padlock to prevent the machine from being turned on.

Attach a warning label.

5.1.2 Restarting

Before restarting run a safety check.

„Safety check“ on page 11

WARNING!

Before connecting the machine you must check that

• there is no danger for personnel

• the drilling machine is undamaged.

5.2 Inspection and maintenance

The type and extent of wear depends to a large extent on individual usage and service conditions. Therefore, the indicated intervals only apply fo r the approved conditions.

Interval Where? What? How?

start of shift

after each

maintenance or

repair operation

drilling machine

„Safety check“ on page 11

Page 36

Maintenance

quantum

MASCHINEN - GERMANY

© 2007

GB

Page 36 Drilling machine B 13 / B14 / B16 / B20 / B25 / B32 Version 1.2.5 18 / 01 / 2008

every week

attachment screws

V-belt tension

• Check if the attachment screws for the V-belt tension on the left

and right side of the drilling head are well fastened.

• Check if the V-belts are well tightened. Checking the tension of

the V-belts,

„Speed alternation“ on page 26.

Illustr. 5-2: B20 drilling head on the right

every month

tripod and rack

lubricate

• Lubricate the tripod regularly with commercial oil.

• Lubricate the rack regularly with commercial grease (e.g. friction bearing grease).

Illustr. 5-3: tripod

every six

months

V-belts on the drilling head

visual inspection

• Check the V-belt on the drilling head that it is not being porous

or used.

Illustr. 5-4: V-belts

Interval Where? What? How?

guide rail screws

on the right

tripod

toothed rack

V-belts

Page 37

quantum

MASCHINEN - GERMANY

Maintenance

© 2007

GB

Page 3718 / 01 / 2008 Version 1.2.5 B 13 / B14 / B16 / B20 / B25 / B32 Drilling machine

5.3 Repair

For any repair work, request the assistance of an employee of Optimum Maschinen GmbH’s

technical service or send us the drilling machine.

If the repairs are carried out by qualified technical staff, they must follow the indications given in

this manual.

Optimum Maschinen GmbH does not take responsiblity nor does it guarantee against damage

and operating malfunctions resulting from failure to observe this operating manual.

For repairs only use

• faultless and suitable tools,

• original parts or parts from series expressly authorized by Optimum Maschinen GmbH.

every six

months

electric

check

Check the electrical equipment/ parts of the drilling machine.

„Qualification of employees“ on page 8

Interval Where? What? How?

Page 38

Ersatzteile - Spare parts B13, B14, B16, B20, B25, B32

quantum

MASCHINEN - GERMANY

38

S:\Betriebsanleitungen\drilling_machines\B13_14_16_20_25_32\B13-B32_parts\B13-B32_parts.fm

18.1.08

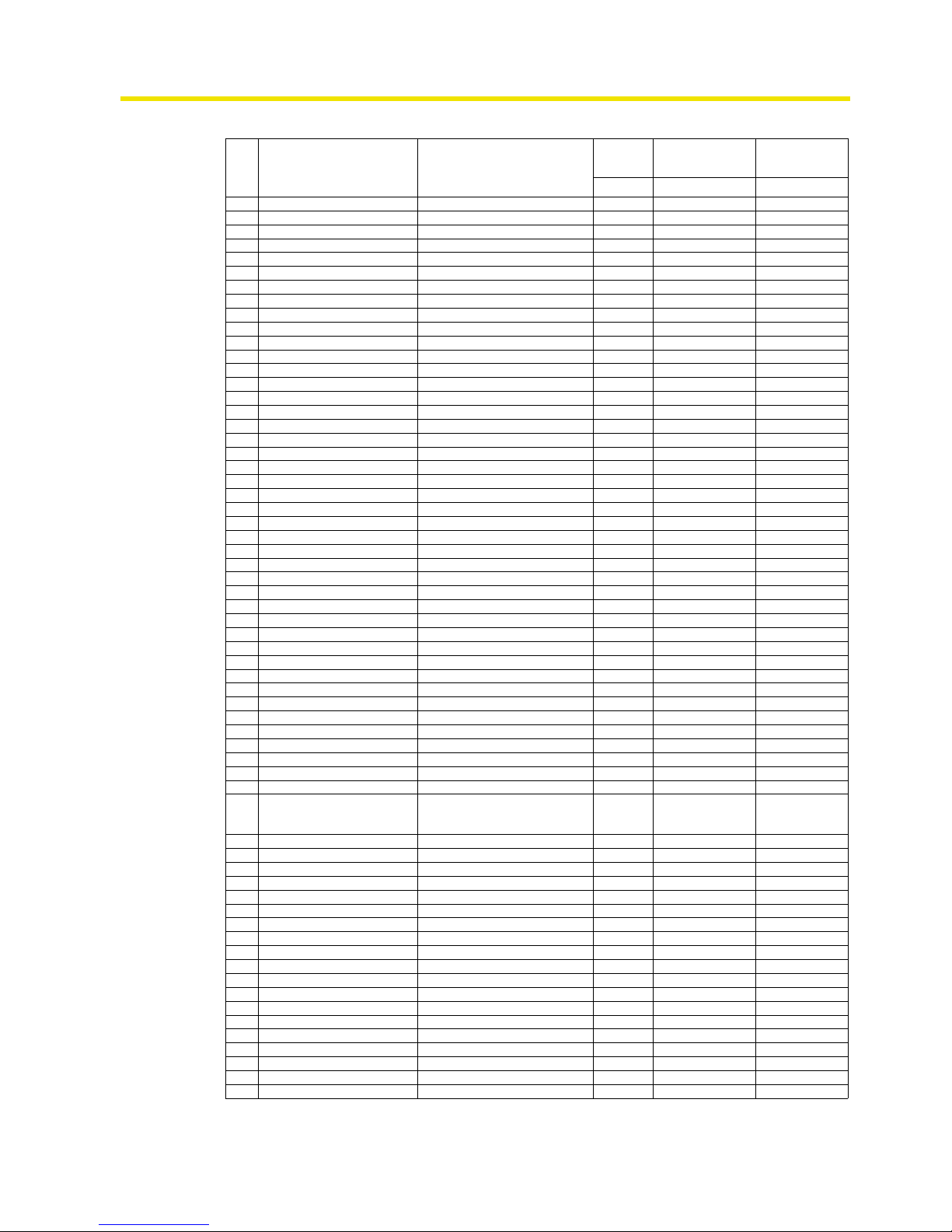

6 Ersatzteile - Spare parts B13, B14, B16, B20, B25, B32

6.1 Ersatzteilzeichnung - Parts drawing B13 / B14

Abb.6-1: B13 / B14

Page 39

quantum

MASCHINEN - GERMANY

Ersatzteile - Spare parts B13, B14, B16, B20, B25, B32

18.1.08

S:\Betriebsanleitungen\drilling_machines\B13_14_16_20_25_32\B13-B32_parts\B13-B32_parts.fm

39

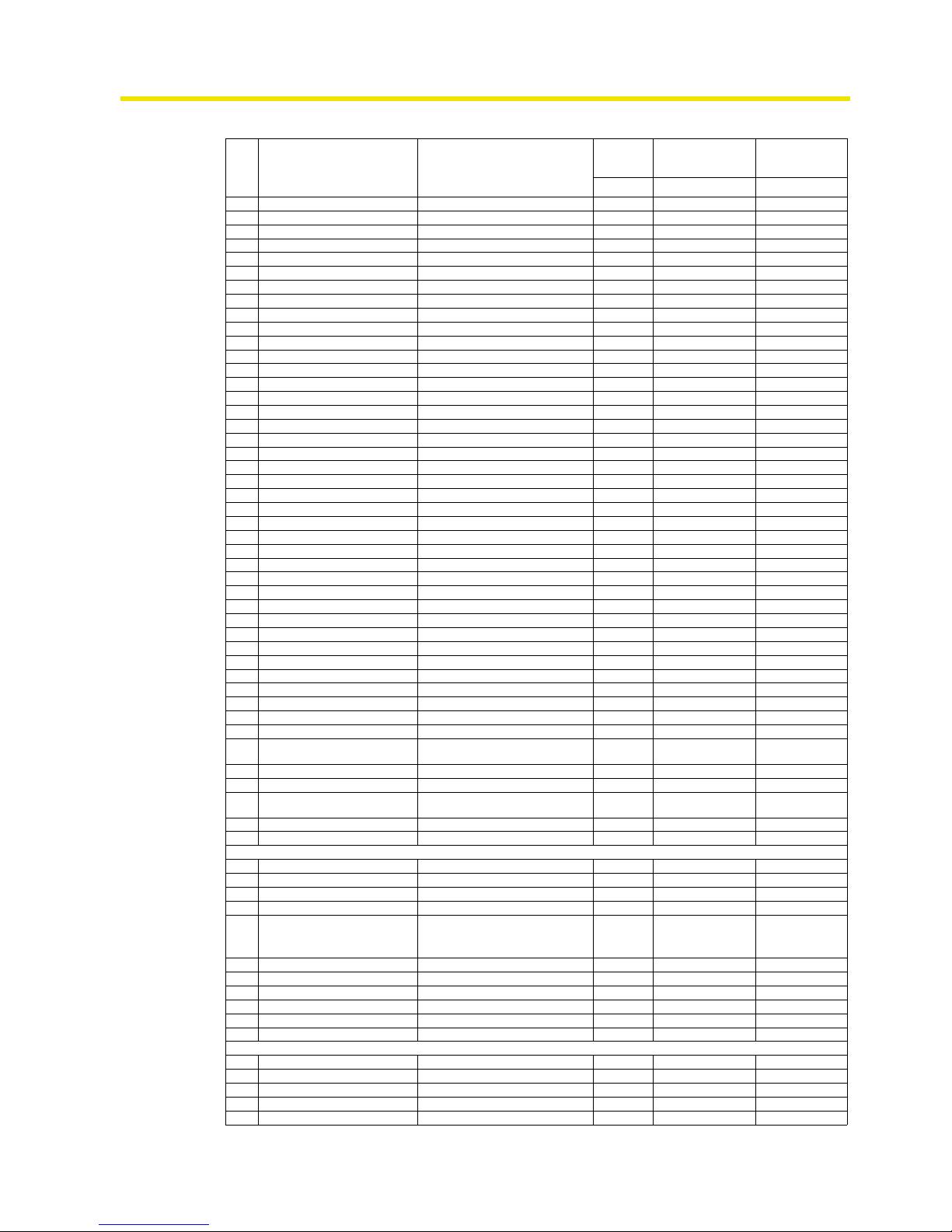

6.2 Bohrfutterschutz B13, B14 - Drill chuck protection B13, B14

6.2.1 Ersatzteilliste - Parts list B13 / B14

202

201

203

Pos.

Bezeichnung Designation

Menge grösse

Artikel-

nummer

Qty. Size Item no.

1 Maschinenfuss Base 1 0300813101

2 Säulenflansch Column seat 1 0300813102

3 Scheibe Washer 3 M 8

4 Federscheibe Spring Washer 3 M 8

5 Schraube Screw 3 M8x16

6 Bohrsäule Column 1

B13

B14

0300813106

0300814106

7 Klemmhebel Clamp Handl e 1 0300813107

8 Schraube Screw 1 M12x26 0300813108

9 Federscheibe Spring Washer 1 M 12

10 Bohrtisch Work Table 1 0300813110

11 Bohrtischhalter Support 1 0300813111

12 Bolzen Bolt 1 M6x25

13 Mutter Nut 1 M6

14 Getriebeachse Gear Axis (pinion shaft) 1 0300813114

15 Hebel lever 3 0300813115

16 Knopf knob 3 0300820121

17 Bolzen Bolt 2 M8x10

18 Stellgriff Adjusting Handle 1 0300813118

19 Druckfeder Compress Spring 1 0300813119

20 Motorstange Motor Pole 1 0300813120

21 Elastische Unterlegscheibe Cushion Washer 1 0300813121

22 Schraube Screw 3 M6x12

23 Scheibe Washer 3 M 6

24 Motorbodenplatte Motor Bottom Board 1 0300813124

25 Scheibe Washer 2 M 6

26 Schraube Screw 2 M8x16

27 Motor Motor 1 0300813127

28 Motorriemenscheibe Motor pulley 1 0300813128

29 Bolzen Bolt 1 M6x10

30 Scheibe Washer 4 M 6

31 Bolzen Bolt 4 M8x12

32 Mutter Nut 1 M5x12

33 Scheibe Washer 1 M 5

34 Hebegriff Lifting Handle 1 0300813134

Page 40

Ersatzteile - Spare parts B13, B14, B16, B20, B25, B32

quantum

MASCHINEN - GERMANY

40

S:\Betriebsanleitungen\drilling_machines\B13_14_16_20_25_32\B13-B32_parts\B13-B32_parts.fm

18.1.08

35 Riemengehäuse pulley cover 1 0300813135

36 Bolzen Bolt 2 M4x12

37 Scheibe Washer 2 M 4

38 Kabelklemme Wire Clamp 2 M 4

39 Kabelöse Ring for Wire 1 0300813139

40 Scheibe Washer 2 0300813140

41 Kabelöse Ring for Wire 4 0300813141

42 Anschlusskabel Plug Wire 2 0300813142

43 Gehäuse Case 1 0300813143

44 Schaltgehäuse Switch Box 1 0300813144

46 Bolzen Bolt 1 0300813146

47 Schalter Switch 1 0300813147

48 Mutter Nut 1 M10x1

49 Mutter Nut 1 M10x1

50 Federgehäuse Cover of Spring 1 0300813150

51 Rückholfeder Turbination Spring 1 0300813151

52 Anzeigevorrichtung Indicator 1 0300813152

53 Mutter Nut 1 0300813153

54 Mutter Nut 1 0300813154

55 Stange Rod 1 0300813155

56 Haltevorrichtung Holder 1 0300813156

57 Mutter Nut 1 M6

58 Keilriemen V-belt 1 10 x 650 0391050

59 Spindelriemenscheibe Spindle pulley 1 0300813159

60 Bolzen Bolt 1 M6 x 10

61 Achsenring Ring of Axis 1 22 0300813161

62 Achsenabdeckung Square Axis Cover 1 0300813162

63 Bohrungsring Ring of Hole 1 40 0300813163

64 Kugellager Bearing 1 6203 0406203.2R

65 Kugellager Bearing 1 6203 0406203.2R

66 Bohrungsring Ring of Hole 1 40 0300813166

67 Achsenring Ring of Axis 1 12 0300813167

68 Kugellager Bearing 1 6201 0406201.2R

69 Gummiunterlegscheibe Rubber Washer 1 0300813169

70 Pinole Pinole 1 0300813170

71 Kugellager Bearing 1 6201 0406201.2R

72 Spindel Spindle 1 0300813172

73 Bohrfutter chuck 1 3050654

74 Kabelklemme Wire Clamp 1 0300813174

201

Bohrfutterschutz Sichtschutz-

scheibe

Drill chuck protection view sealing

pane

1 03008131201

202 Arm Bohrfutterschutz Arm drill chuck protection 1 03008131202

203 Halterung Bohrfutterschutz Fixing drill chuck protection 1 03008131203

203-1 Endlagenschalter Bohrfutterschutz

End position switch drill chuck protec-

tion

1 030081312031

205 Gehäuse (Trafo) Housing (trafo) 1 03008131205

T eile ohne Abbildung - Parts without illustration

0 Schalterkappe gelb switch cap yellow 1 0300813180

0 Abdeckung Lüfter (B13) cover fan (B13) 1 0300813182

0 Kondensator (Motor) condensator (engine) 1 0300813176

0 Lüfterrad (Motor) fan wheel (engine) 1 0300813178

0 Bohrfutterschutz alter typ Drill chuck protection old type 1

3008135

+

3008136

0 Reed Kontakt Reed contact 1 0302024192

0 Transformator Transformer 1 03008131301

0 Schütz Contactor 1 03008131302

0 Schaltkasten (leer) Electric box (empty) 1 0300813179

0 Nutenstein t-nut 1 0300813177

Komplett-Sätze - Complete sets

Pinole komplett pinole complete 1 0300813170CPL

201-1 Bohrfutterschutz komplett Drill chuck protection complete 1 030081312011

Säule kpl. column compl. 1 0300813106CPL

Halter kplt. Holder cplt. 1 03008131201CPL

Gehäuse (Trafo) kpl. Housing (transformer) compl. 1 03008131205CPL

Pos.

Bezeichnung Designation

Menge grösse

Artikel-

nummer

Qty. Size Item no.

Page 41

quantum

MASCHINEN - GERMANY

Ersatzteile - Spare parts B13, B14, B16, B20, B25, B32

18.1.08

S:\Betriebsanleitungen\drilling_machines\B13_14_16_20_25_32\B13-B32_parts\B13-B32_parts.fm

41

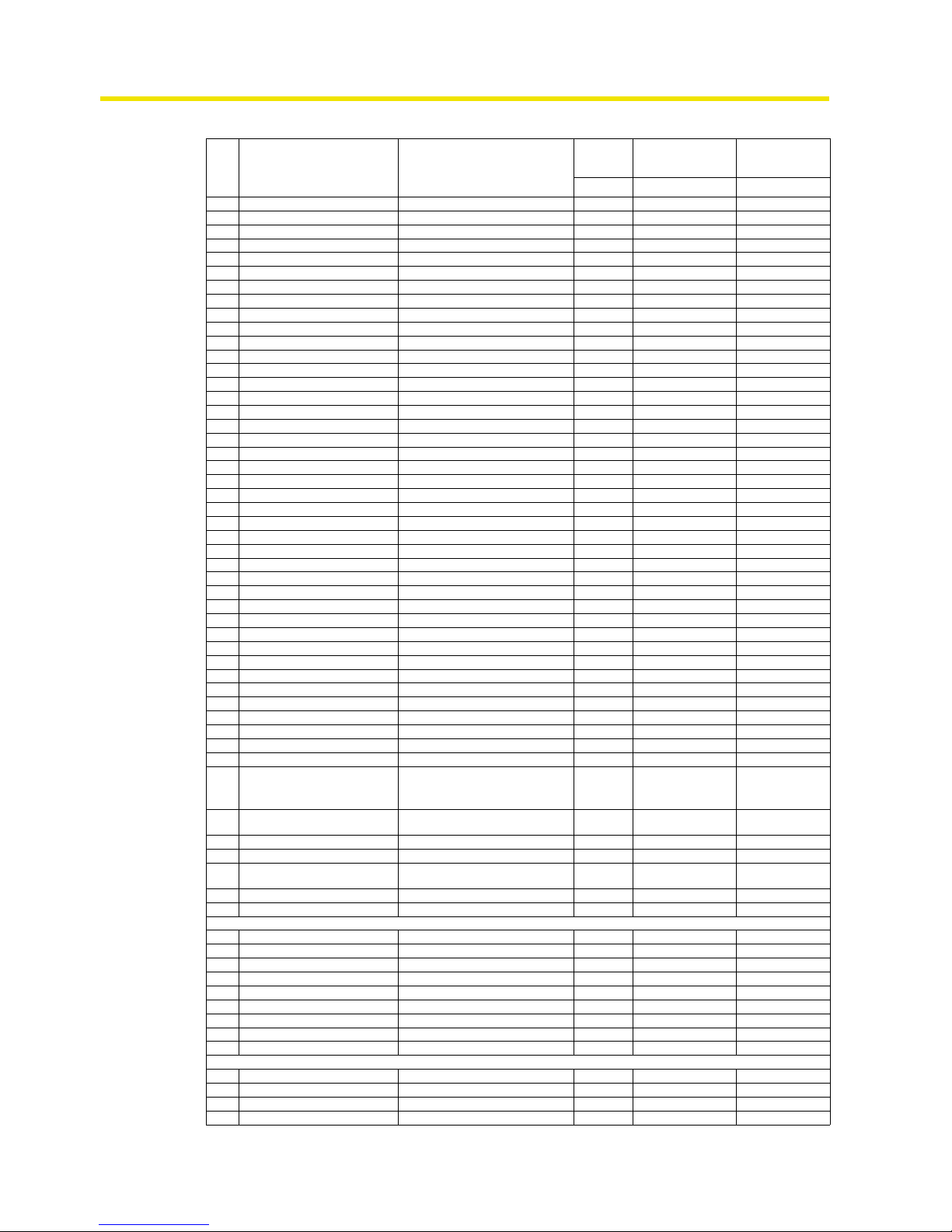

6.3 Ersatzteilzeichnung - Parts drawing B 16

Abb.6-2: B16

Page 42

Ersatzteile - Spare parts B13, B14, B16, B20, B25, B32

quantum

MASCHINEN - GERMANY

42

S:\Betriebsanleitungen\drilling_machines\B13_14_16_20_25_32\B13-B32_parts\B13-B32_parts.fm

18.1.08

6.4 Bohrfutterschutz B16 - Drill chuck protection B16

6.4.1 Ersatzteilliste - Parts list B16

202

201

203

Pos.

Bezeichnung Designation

Menge grösse

Artikelnum-

mer

Qty. Size Item no.

1 Maschinenfuss Base 1 0300816101

2 Säulenflansch Column Seat 1 0300816102

3 Scheibe Washer 3 M 8

4 Schraube Screw 3 M8x25

5 Säule Column 1 0300816105

6 Zahnstange Rack 1 0300816106

7 Säulenring Column Ring 1 0300816107

8 Bolzen Bolt 1 M8x10

9 Bohrtischhalter Support 1 0300816109

10 Kurbel crank 1 0300820110

11 Schraube Screw 1 M5x10

12 Bolzen Bolt 1 0300816112

13 Klemmhebel Cl amp Handle 1 0300816113

14 Zahnrad Gear 1 0300816114

15 Schneckenrad Gear Wheel 1 0300816115

16 Bohrtisch Work Table 1 0300816116

17 Scheibe Washer 1 M 12

18 Schraube Screw 1 M12x25

19 Knopf Knob 1 0300820121

20 Hebel Lever 1 0300816120

21 Hebelsitz Lever Seat 1 0300816121

22 Bolzen Pin 1 0300816122

23 Skalenring Dial 1 0300816123

24 Schaftritzel pinion shaft 1 0300816124

25 Niete Rivet 1 0300816125

26 Zeiger Pointer 1 0300816126

27 Gehäuse Case 1 0300816127

28 Bolzen Bolt 1 M8x16

29 Mutter Nut 1 M 8

30 Rückholfeder Turbination Spring 1 0300816130

31 Federgehäuse Cover of Spring 1 0300816131

32 Mutter Nut 2 M 12x1,5

33 Bolzen Bolt 2 M8x6

34 Feststellknopf Tight Knob 1 0300816134

35 Einstellknopf Adjust Knob 1 0300816134

36 Motorstange Motor Pole 1 0300816136

37 Schraube Screw 4 M8x16

Page 43

quantum

MASCHINEN - GERMANY

Ersatzteile - Spare parts B13, B14, B16, B20, B25, B32

18.1.08

S:\Betriebsanleitungen\drilling_machines\B13_14_16_20_25_32\B13-B32_parts\B13-B32_parts.fm

43

38 Scheibe Washer 4 M 8

39 Motorbodenplatte Motor Bottom Board 1 0300816139

40 Motor Motor 1 0300816140

41 Scheibe Washer 1 8

42 Federscheibe Spring Washer 1 8

43 Mutter Nut 1 M8

44 Mutter Nut 1 M8

45 Scheibe Washer 1 8

46 Kabel Wire Plug 1 0300816146

47 Motorstange Motor Pole 1 0300816147

48 Mutter Nut 1 M6

49 Gummiring Rubber Ring 1 0300816149

50 Scheibe Washer 4 6

51 Bolzen Bolt 1 M6x8

52 Bolzen Bolt 1 M5x22

53 Motorriemenscheibe Motor Pulley 1 0300816153

54 Bolzen Bolt 2 M6x16

55 Schalte r gehäuse S witch housing 2 0300816155

56 Schraube screw 1 0300816156

57 Schalter switch 1 0300813147

58 Bolzen Bolt 1 M5x8

59 Riemengehäuse Pulley Cover 1 0300816159

60 Presskabelblock Press Wire Block 2 0300816160

61 Keilriemen V-belt 1 0391100

62 Mutter Nut 1 0300816162

63 Spindelriemenscheibe Spindle pulley 1 0300816163

64 Schaft pinion 1 0300816164

65 Bohrungsring Ring for Hole 1 0300816165

66 Kugellager Bearing 1 6204 0406204.2R

67 Kugellagerring Ring for Bearing 1 0300816167

68 Kugellager Bearing 1 6204 0406204.2R

69 Bohrungsring Ring for Hole 1 0300816165

70 Schaftring Ring for Shaft 1 0300816170

71 Kugellager Bearing 1 6201 0406201.2R

72 Gummiring Rubber ring 1 0300816172

73 Pinole Pinole 1 0300816173

74 Austreiber Drill Drift 1 0300816174

75 Kugellager Bearing 1 6205 0406205.2R

76 Spindel Spindle 1 0300816176

77 Kegeldorn Taper mandril 1 0300816177

78 Bohrfutter chuck 1 3050626

79 Bohrfutterschutz alter typ Drill chuck protection old type 1

3008205

+

3008206

201

Bohrfutterschutz Sichtschutz-

scheibe

Drill chuck protection view sealing

pane

1 03008161201

202 Arm Bohrfutterschutz Arm drill chuck protection 1 03008161202

203 Halterung Bohrfutterschutz Fixing drill chuck protection 1 03008161203

203-1 Endlagenschalter Bohrfutterschutz

End position switch drill chuck protec-

tion

1 030081312031

205 Gehäuse (Trafo) Housing (trafo) 1 03008161205

Teile ohne Abbildung - Parts without illustration

0 Kondensator capacitor 1 0300816182

0 Reed Kontakt Reed contact 1 0302024192

0 Transformator Transformer 1 03008131301

0 Schütz Contactor 1 03008131302

0 Schaltkasten Motor (leer) Electric box motor (empty) 1 0300816181

0 Nutenstein t-nut 1 0300813177

0 Motorlüfterdeckel motor fan cover 1 0300816180

0 O-Anzeige O-Pointer 1 0322025

Komplett-Sätze - Complete sets

Pinole Komplett Pinole complete 1 0300816173CPL

Säule mit Halter Column with base ring 1 0300816105CPL

201-1 Bohrfutterschutz komplett Drill chuck protection complete 1 030081612011

Gehäuse (Trafo) kpl. Housing (transformer) compl. 1 03008161205CPL

Pos.

Bezeichnung Designation

Menge grösse

Artikelnum-

mer

Qty. Size Item no.

Page 44

Ersatzteile - Spare parts B13, B14, B16, B20, B25, B32

quantum

MASCHINEN - GERMANY

44

S:\Betriebsanleitungen\drilling_machines\B13_14_16_20_25_32\B13-B32_parts\B13-B32_parts.fm

18.1.08

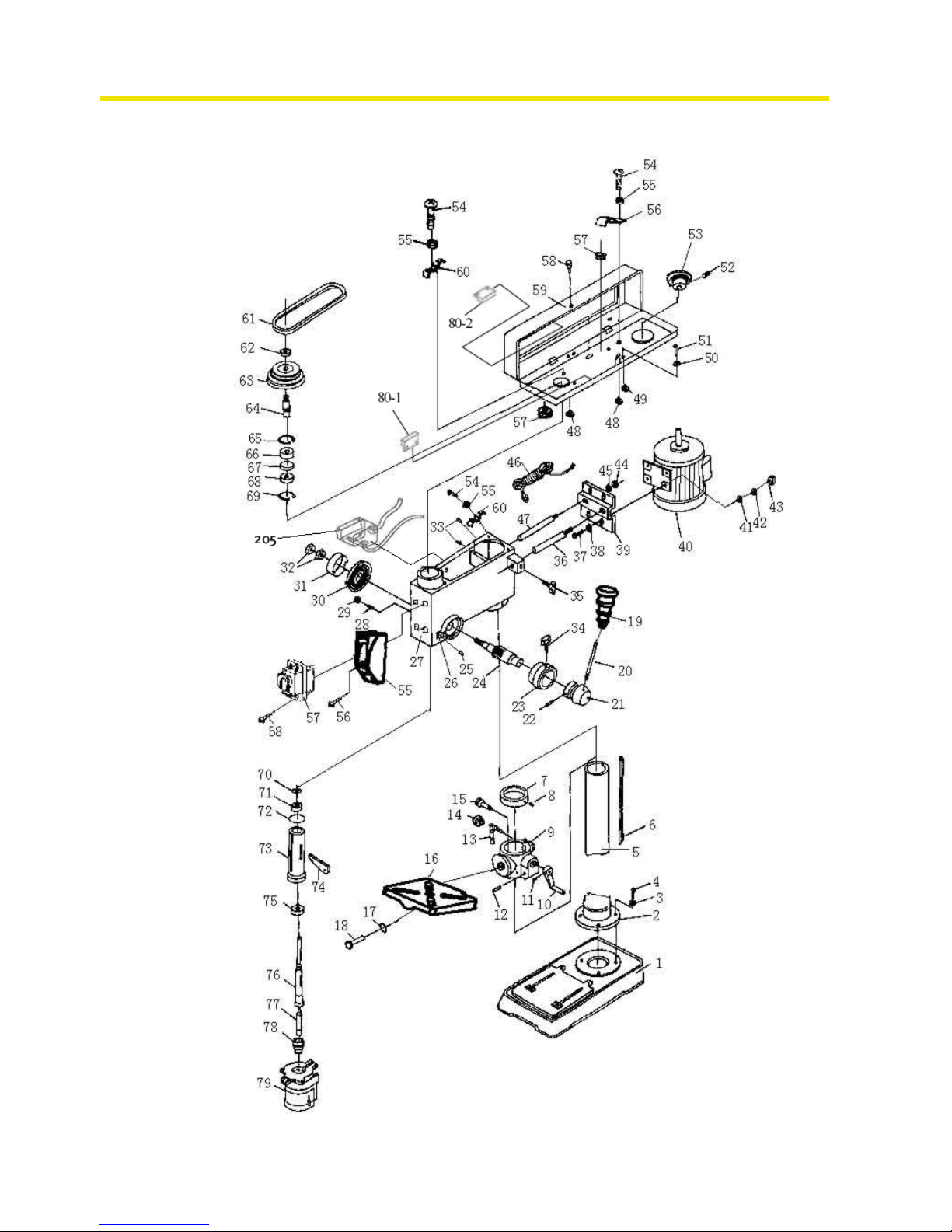

6.5 Ersatzteilzeichnung - Parts drawing B20 / B25 (Vario)

Abb.6-3: B20 / B25

Page 45

quantum

MASCHINEN - GERMANY

Ersatzteile - Spare parts B13, B14, B16, B20, B25, B32

18.1.08

S:\Betriebsanleitungen\drilling_machines\B13_14_16_20_25_32\B13-B32_parts\B13-B32_parts.fm

45

6.6 Bohrfutterschutz B20, B25 - Drill chuck protection B20, B25

6.6.1 Ersatzteilliste - Parts list B20 / B25 (Vario)

202

201

203

Pos.

Bezeichnung Designation

Menge grösse

Artikel-

nummer

Qty. Size Item no.

1 Maschinenfuss Base 1 0300820101

2 Säulenflansch 1

B20 0300820102

B25 0300825302

3 Scheibe Washer 4 0300820103

4 Schraube Screw 4 10 0300820104

5 Säule Column 1

B20 0300820105

B25 0300825305

6 Zahnstange Rack 1

B20 0300820106

B25 0300825306

7 Säulenring Colum Ring 1 0300820107

8 Bolzen Bolt 1 M 6x10

9 Bohrtischhalter Support 1 0300820109

10 Kurbel Crank 1 0300820110

11 Schraube Screw 1 M 6x15

12 Getriebewelle Gear Shaft 1 0300820112

14 Schraube Screw 1 M 6x15

15 Klemmhebel Clamp Handle 1 0300820115

16 Arm Arm 1 0300820116

17 Bohrtisch W ork Table 1 0300820117

18 Klemmhebel Clamp Handle 1 0300820118

19 Zahnrad Gear 1 0300820119

20 Schneckenrad Worm Gear 1 0300820120

21 Knopf Knob 3 0300820121

22 Hebel Lever 3 0300820122

23 Hebelsitz Lever Seat 1 0300820123

24 Bolzen Pin 1 5 x 32 0300820124

25 Skalenring Dial 1 0300820125

26 Ritzelwelle Pinion Shaft 1 0300820126

27 Gehäuse Case 1 0300820127

28 Bolzen Bolt 1 M10 x 10

29 Mutter Nut 1 M 10

30 Rückholfeder Turbination Spring 1 0300820130

31 Federgehäuse Cover of Spring 1 0300820131

32 Mutter Nut 2 M12x1,5

33 Schraube Screw 1 0300820133

34 Bolzen Bolt 2 M10 x 10

35 Nockenwelle Camshaft 1 0300820135

36 Schraube Screw 1 0300820136

Page 46

Ersatzteile - Spare parts B13, B14, B16, B20, B25, B32

quantum

MASCHINEN - GERMANY

46

S:\Betriebsanleitungen\drilling_machines\B13_14_16_20_25_32\B13-B32_parts\B13-B32_parts.fm

18.1.08

37 Motorstange Motor Pole 1 0300820137

38 Schraube Screw 4 M8 x 25

39 Scheibe Washer 9 8

40 Motorbodenplatte Motor Bottom Board 1 0300820140

41

Motor Motor 1

230 V 0300820141

400 V 0300825341

42 Federscheibe Lock washer 4 8

43 Mutter nut 4 M 8

44 Mutter nut 2 M 10

45 Scheibe Washer 2 10

46 Motorstange Motor Pole 1 0300820146

47 Schraube Screw 1 M 6x12

48 Nocke Cam 1 0300820148

49 Schaltergehäuse Switch housing 1

230 V 0300820149

400 V 0300820349

51 Bolzen Bolt 1 0300820151

52 Schalter Switch 1

230 V 0300820152

400 V 0300820352

53 Anschlusskabel Power Wire 1

230V 0300820153

400V 0300825353

54 Kabelblock Wire Block 1 0300820154

55 Bolzen Bolt 1 M 6x10

56 Scheibe Washer 4 6

57 Bolzen Bolt 4 M 6x12

58 Riemenscheibe Motor Motor pulley 1 0300820158

59 Bolzen Bolt 1 M 5 x 6

60 Bohrungsring Ring for Hole 1 35 0300820160

61 Kugellager Bearing 2 6201 0406201.2R

62 Keilriemen V-belt 1 10 x 610 0300820162

63 Riemenscheibe Mitte Middle Pulley 1 0300820163

64 Zentrierteil Centering Device 1 0300820164

65 Hebel Lifting Handle 1 0300820165

66 Riemenabdeckung Pulley Cover 1 0300820166

67 Keilriemen V-belt 1 10 x 625 0300820167

68 Rundmutter Round Nut 1 0300820168

69 Spindelriemenscheibe Spindle pulley 1 0300820169

70 Schaft Pinion 1 0300820170

71 Bohrungsring Ring for Hole 1 47 0300820171

72 Kugellager Bearing 1 6005 0406005.2R

73 Lagerscheibe Bearing Washer 1 0300820173

74 Kugellager Bearing 1 6005 0406005.2R

75 Bohrungsring Ring for Hole 1 47 0300820175

76 Spindelring Ring for Spindle 1 15 0300820176

77 Kugellager Bearing 1 6005 0406204.2R

78 Elastischer Unterlegscheibe Cushion Washer 1

B25

B20

0300825378