Page 1

Integrated Storage Solutions

A Raytheon E-Systems Company

THE AML/J Library

Planning Guide

Page 2

Copyright © 1996 EMASS, Inc.

All rights reserved.

No part of this work may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying and recording, or by any information storage or retrieval

system, except as may be expressly permitted by the 17 U.S.C. §101, et. seq., or in writing by

EMASS, Inc.

This document contains subject matter in which EMASS, Inc. has proprietary rights. Use,

duplication, or disclosure by the Government is subject to restrictions as set forth in the definition

of limited rights in (a) (15) of the “Rights in Technical Data and Computer Software” clause in

DFARS 52.227-703 and/or similar or successor clauses in the FAR, DoD , or NASA FAR

Supplement. Contractor is EMASS, Inc., 10949 East Peakview Avenue, Englewood, Colorado

80111.

Although the material contained herein has been carefully reviewed, EMAS S, Inc. does not warrant

it to be free of errors or omissions. EMASS, Inc. reserves the right to make corrections, updates,

revisions or changes to the information contained herein.

EMASS is a registered trademark of EMASS, Inc.

AML/J is a trademark of EMASS, Inc.

Other trademarks are property of their respective owners.

Document number: 600338-B

Published: 10 Oct 1996

EMASS• 10949 EAST PEAKVIEW AVENUE • ENGLEWOOD, COLORADO • 1-800-TAP-ETAC

Page 3

Contents

1

Introduction

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Associated Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

2

System Description

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

System Operational Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Hardware Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

AMU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Hardware Component . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Software Component . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Handling Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Page 4

Robot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Storage Segment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Linear Racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Drive/Control Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Insert/Eject Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Expansion Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 -12

Drive Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Software Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

MVS Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

Host Control Component (HCC) software . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

UNIX Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

AMASS software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

DataMgr software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

FileServ software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

VolServ software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

DAS software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 -16

Archive Management Software Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

3

System Specification

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Regulatory Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Media Quantity Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Flooring Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Barcode Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

iv Contents

600338-B

Page 5

4

System Configuration

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Base Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Media Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Drive Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Insert/Eject Media Boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Control Cabinet Drive Shelves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Drive Cabinet Drive Shelves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Base Unit Media Type Segments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Expansion Unit Media Type Segments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Software Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Host Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Communication Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Special Engineering Request . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Customer System Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

5

Survey Data

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Physical Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Customer Room Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Site Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

10 Oct 1996

Contents v

Page 6

Power Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Telephone Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Customer Building Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Access Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

Additional Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 -12

vi Contents

600338-B

Page 7

Figures

Figure 2-1 AML/J Example Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Figure 2-2 Handling Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Figure 2-3 Robot with Storage Bins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Figure 2-4 Linear racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Figure 2-5 Drive/Control Cabinet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Figure 2-6 Insert/Eject Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Figure 2-7 Insert/Eject Unit (IE/F-D) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

Figure 2-8 Expansion Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Figure 4-1 Customer AML/J Configuration Layout. . . . . . . . . . . . . . . . . . . . . .4-12

Figure 4-2 Example AML/J ConfigurationConfiguration. . . . . . . . . . . . . . . . .4 -13

Figure 4-3 Cutout Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

Figure 5-1 Room Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Figure 5-2 Building Scale. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Page 8

viii Figures

600338-B

Page 9

Tables

Table 3-1 AML/J Component Physical Dimensions . . . . . . . . . . . . . . . . . . . . 3-3

Table 3-2 AML/J Component Electrical Specifications . . . . . . . . . . . . . . . . . . 3-4

Table 3-3 AML/J Drive Component Electrical Specification . . . . . . . . . . . . . 3-4

Table 3-4 AML/J Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Table 3-5 AML/J Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Table 3-6 AML/J Regulatory Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Table 3-7 AML/J Media Segment Quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Page 10

xTables

600338-B

Page 11

1

Introduction

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Associated Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Page 12

1-2 Introduction

600338-B

Page 13

Overview

1-

This manual contains information that outlines the AML/J

library

are:

• Overview

• Intended Audience

• Organization

• Associated Documents

• Assistance

1

. The topics discussed in this section of the manual

Intended Audience

This manual is prepared for salespersons and perspective

purchasers of the AML/J library.

Organization

This manual contains chapters detailing the AML/J library.

The chapters include:

Chapter 1 Introduction - Describes the overview,

intended audience, organization,

associated documents, and where to

acquire additional assistance.

10 Oct 1996

Chapter 2 System Description - Describes general

information about the AML/J library

components.

Chapter 3 System Specifications - Describes the

physical and electrical specifications of the

AML/J library c om po nents.

Chapter 4 System Configuration - Describes the

structure of the basic AML/J library and

optional components availa ble for AML/J

library.

Chapter 5 Survey Data - Provides space for planning

physical, electrical, and environmental

requirements. This information is required

by the installation team.

1. AML/J is a trademark of EMASS, Inc. Throughout the remainder of this document, we refer to

AML/J library as AML/J

Overview 1-3

Page 14

Associated Documents

600337 AML/J Maintenance Guide

600303 AML/J Operator Guide

600304 AML/J Installation Guide

600300 AML Hardware Configuration

Information

600302 Product Order Information

600307 AMASS Documentation Set

600308-01 VolServ Documentation Set (for SGI)

600308-02 VolServ Documentation Set (for SUN)

600309 FileServ Documentation Set (for SGI)

600255-01 FileServ Documentation Set (for Convex)

600333 HCC-MVS Documentation Set

600336 DataMgr Documentation Set

Assistance

If questions cannot be solved with the aid of this document or

the immediate salesperson, contact the EMASS Technical

Assistance Center (ETAC).

1-4 Introduction

• United States 1-800-827-3822 (1-800-TAP-ETAC)

• Germany 0-130-817-021

• United Kingdom 0-800-893-179

600338-B

Page 15

2

System

Description

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

System Operational Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Hardware Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

AMU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Hardware Component . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Software Component . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Handling Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Robot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Storage Segment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Linear Racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Drive/Control Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Insert/Eject Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Expansion Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 -12

Drive Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Software Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

MVS Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

Host Control Component (HCC) software . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

UNIX Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

AMASS software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

DataMgr software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

FileServ software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

VolServ software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

DAS software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 -16

Archive Management Software Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

Page 16

2-2 System Description

600338-B

Page 17

Overview

2-

The EMASS Automated Media Library (AML) is a fully

automated, robotic media library that offers an enterprise

solution to data management and backup. An example of an

AML/J configuration is shown in Figure 2-1.

Drive/Con trol Cabi ne t

Media Shelves

Robot

Insert/Eject

Facility

Figure 2-1 AML/J Example Configuration

Insert/Eject

Facility

System Operational Flow

Major system operational components include the following:

• Host

•AMU

• Programmable Multi-Axis Controller (PMAC)

The basic operational philosophy of the AML/J is that the host

system is always the master. During normal processing, all

commands originate from the host sys tem.

10 Oct 1996

Overview 2-3

Page 18

When the host software determines that a media library

action is necessary, it creates the appropriate command string

and sends it to the AMU for processing. The AMU receives

and interprets the host command then issues appropriate

commands to the PMAC Controller hardware.

The PMAC Controller hardware provides the movement

signals for the Robot. After completing the actions, the PMAC

Controller hardware returns status to the AMU. When all

PMAC Controller status is returned, the AMU reports an

overall result to the host system.

Hardware Components

The main hardware components of the AML/J library are the:

• Handling Unit

• Storage Segment

• Control Cabinet

•I/E unit

• Add-on Modules (optional)

• Modem (optional)

AMU

The AMU is the central interface of the AML/J library. The

AMU maintains a copy of the library drives and media

information in a relational database. During normal

operations, the host computer directs the AML/J library. The

AMU hardware and software components operate

transparently.

2-4 System Description

600338-B

Page 19

Hardware Component

AMU hardware consists of:

• a com puter with a color monitor, a m ouse, and a keyboa rd

• Ethernet Adapter

— and/or —

• a Token Ring with or without a 3270 emulation card

• PMAC Controller

Software Component

The AMU software components are:

• OS/2 Operating System

• Communication Manager/2, TCP/IP

• Database Manager/2

• AMU Archive Management Software (AMS). For

additional information, refer to

Software Support

on page 2-17.

Archive Management

10 Oct 1996

Hardware Components 2-5

Page 20

Handling Unit

The Handling Unit accomplishes the mechanical access to the

physical library storage and the drives via a robot. See Figure

2-2. The Handling Unit executes the PMAC commands and

returns status messages.

Figure 2-2 Handling Unit

2-6 System Description

600338-B

Page 21

Robot

Media movements are performed by a robot. The robot is

equipped with a multimedia gripper and a laser barcode

scanner, see Figure 2-3. Typical movements include movin g

media into and out of the library, storing and retrieving media

within the library, mounting and di smounting media from

drive units, and scanning media barcode labels.

Components of the robot system include:

• Multimedia gripper.

• Laser barcode scanner

• Robot X Axis platform

• Robot Y Axis column

10 Oct 1996

Figure 2-3 Robot with Storage Bins

Hardware Components 2-7

Page 22

Storage Segment

The AML/J product line consists of a family of Linear Racks

for storage. Two Linear racks are maximum per base or

expansion unit.

Linear Racks

See Figure 2-4. Each Linear Rack contains two segments. The

segments consists of:

• rows which are media type dependent

• the number of positions per row (columns) also depends

on the media type

Figure 2-4 Linear racks

2-8 System Description

600338-B

Page 23

Drive/Control Cabinet

Movement control signals are provided by the PMAC which

resides in the Drive/Control Cabinet. See Figure 2-5. The

control cabinet contains:

•AMU

•PMAC

• Power supply

•Drives

• Drive Controller (optional for some drives)

10 Oct 1996

Figure 2-5 Drive/Control Cabinet

Hardware Components 2-9

Page 24

Insert/Eject Unit

Media are inserted into and ej ected from th e AML/ J through

the I/EF. The media are loaded by an operator into bins.

Two types of IE/F are offered. With the base AML/J

Insert/Eject Unit, the media is entered or retrieved through

the door. See Figure 2-6. With the IE/F-D, the door must be

opened to insert or retrieve media. Refer to Figure 2-7 on page

2-11. The capacity and number of bins are determined by the

type of IE/F and media.

The I/EF incorporates a media depository that stores

unidentified volumes, defective media, and used cleaning

devices.

Figure 2-6 Insert/Eject Unit

2-10 System Description

600338-B

Page 25

Figure 2-7 Insert/Eject Unit (IE/F-D)

10 Oct 1996

Hardware Components 2-11

Page 26

Expansion Unit

Note

The media

Expansion Unit

does not require a

corresponding

Drive Expansion

Unit.

The Expansion Unit was designed to increase the capacity of

the AML/J. Additional Insert/Eject units and additional

media are available through the Expansion Unit. See

Figure 2-8.

Figure 2-8 Expansion Unit

Note

For each

additional Drive

Expansion Unit, a

corresponding

media Expansion

Unit is required.

2-12 System Description

Drive Unit

The Drive Expansion Unit was designed to increase the

number of available tape drives in the AML/J.

600338-B

Page 27

Software Components

EMASS software organizes and manages the AML/J. This

software makes automated data manipulation possible

without interfering with the performance of host system.

EMASS software automatically receives messages,

coordinates tasks, manages and updates the library database,

and provides recovery from media errors.

EMASS software can be tailored for many different library

configurations. In addition, it can be reconfigured to

accommodate an expanding library.

MVS Support

Unlimited MVS system images support is provided by Host

Control Component (HCC-MVS) software. This software

integrates transparently with MVS S/370, S/390, and Sysplex

environments.

Host Control Component (HCC) software

Media functions are routed from the host computer to the

AMU AMS software. Media functions supported by HCC

software include the following:

• Mount/Keep oper ations

• Volume insertion/ejection

• Administration of media transport cleaning

• Media label initialization and verification

• Automatic reply to outstanding Write to Operator with

Reply (WTOR)

• Scratch media management

Communications functions between the host and AMU AMS

software are provided by the following means:

• Local or remote VTAM LU2 (standard 3270 support)

• EXCP standard console communication (local NON-SNA

3x74 control unit)

• LU6.2 (APPC via Token-Ring or Ethernet adapter)

10 Oct 1996

Software Components 2-13

Page 28

Minimum software requirements to support EMASS software

in the MVS environment include the following:

• MVS-SP1.3.6 for JES2

• MVS-SP2.2 for JES3

•SMP/E

• Assembler H

• Standard MVS utilities

UNIX Support

Software solutions to accessing a media libraries are

implemented through the UNIX virtual file system layer.

AMASS software

AMASS software presents the AML/J library as o n-line direct

access mass storage. The AMASS software provides the

following features:

• The AML/J library appears a single device

• The AML/J library utilizes a single mount point

• The data on the media appears as a standard UNIX

directory with files

• Write or read to media utilizes the same approach as

magnetic disk

• Raw cache partitioning provide high performance

2-14 System Description

Files are accessible across the network through standard

communication protocol. The protocols include:

•NFS

•TCP/IP

•RFS

•FTP

•Telnet

• HYPERchannel

Requirements to support AMASS software are platform

dependent. Additional detailed information is provided in

the part number

600307 AMASS Documentation Set

manuals.

DataMgr software

DataMgr is an integrated, layered, file migration application

that requires and operates with AMASS software. DataMgr

provides the following features:

600338-B

Page 29

• Fully distributed architecture

• File migration from expensive magnetic disk space to

inexpensive storage media

• Transparent access to the migrated files

• Convenient access to migrated data during reloads

• Flexible migration policies determine the criteria for file

relocation

• File replication across distributed servers

• Multi-tier migration

Additional detailed information is provided in the part

number

600336 DataMgr Documentation Set

manuals.

FileServ software

FileServ software balances on-line media with stored library

media fro quick access to data. The FileServ software provides

the following features:

• The data on the media is accessed via standard UNIX

operations using filesystem(s) as tracking points

• Tracks multiple users of the same file to prevent multiple

mount actions

• File migration from expensive magnetic disk space to

inexpensive storage media

• Transparent access to the migrated files

• Flexible migration policies determine the criteria for file

relocation

• Media error are retained as a means to identify suspect

defective media

Files are accessible across the centralized or distributed

environments through:

• Ethernet

•FDDI

• HYPERchannel

• UltraNet

®

Requirements to support FileServ software are platform

dependent. Additional detailed information is provided in the

part number

600309 FileServ Documentation Set (for SGI)

manuals and the part number

Documentation Set (for Convex)

600255-01 FileServ

manuals.

10 Oct 1996

Software Components 2-15

Page 30

VolServ software

VolServ software handles volume manipulation by class of

data and media migration. The Volserv software provid es the

following features:

• Provides a robotic independent interface to a variety of

robotic systems

• Determines on-line or stored media volume location

• Issues manual or robotic commands to retrieve and

mount media

• Allows multiple clients to sha r e a single media library

• User defined classes of media share a media library

• Supports multiple media types

• Pools drives to allow drives to be shared among clients

• User defined migration policy allows media to be

migrated between on-line and off-line storage

Once a media volume is mounted, the files are accessible

across the centralized or distributed environments through:

• Ethernet

•FDDI

• HYPERchannel

• UltraNet

®

Requirements to support VolServ software are platform

dependent. Additional detailed information is provided in

the part number

and the part number

manuals.

SUN)

600308-01 VolServ Documentation Set (for SGI)

600308-02 VolServ Documen tation Set (f or

DAS software

The distributed AML Server (DAS) is a software product with

both client and server components. The server software

modules support the OS/2 operating system platform and the

client software modules support UNIX/AIX operating

system platforms. They communicate from the UNIX/A IX

clients to the OS/2 DAS server (AMU controller PC) across a

TCP/IP connected network.

2-16 System Description

600338-B

Page 31

DAS allows client systems to request actions on selected

media within the AML system. DAS performs the following

requested actions:

• mounts media in a drive

• dismounts media from a drive

• inserts media into the library

• ejects media from the library

Requirements to support DAS software are platform

dependent.

Archive Management Software Support

Operating in the OS/2 environment, AMU software consists

of five proprietary operational processes and two proprietary

utility processes. The task of each of the seven processes are

listed below:

• Communication with host computer, robot control,

Quadro Tower control, and Hexa Tower control

• Management of the library catalog using Source Query

Language (SQL) database

• Kernel logic converts host commands into control

commands

• User interface for operator requests

• Log and trace connection

• Database backup facility

• Remote file transfer

10 Oct 1996

In normal (Automatic) operating mode, the host computer

directs the AML/J and the AMU software operates

transparently. Usually, commands are only input at the AMU

console through the Graphical User Interface (GUI) for direct

operator intervention.

Software Components 2-17

Page 32

2-18 System Description

600338-B

Page 33

3

System

Specification

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Regulatory Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Media Quantity Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Flooring Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Barcode Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Page 34

3-2 System Specification

600338-B

Page 35

Overview

This section contains the following information for the

AML/J library:

• Physical Specification

• Electrical Specification

• Performance Specification

• Environmental Specification

• Regulatory Specifications

• Media Quantity Specification

• Flooring Requirement

• Barcode Requirement

Physical Specifications

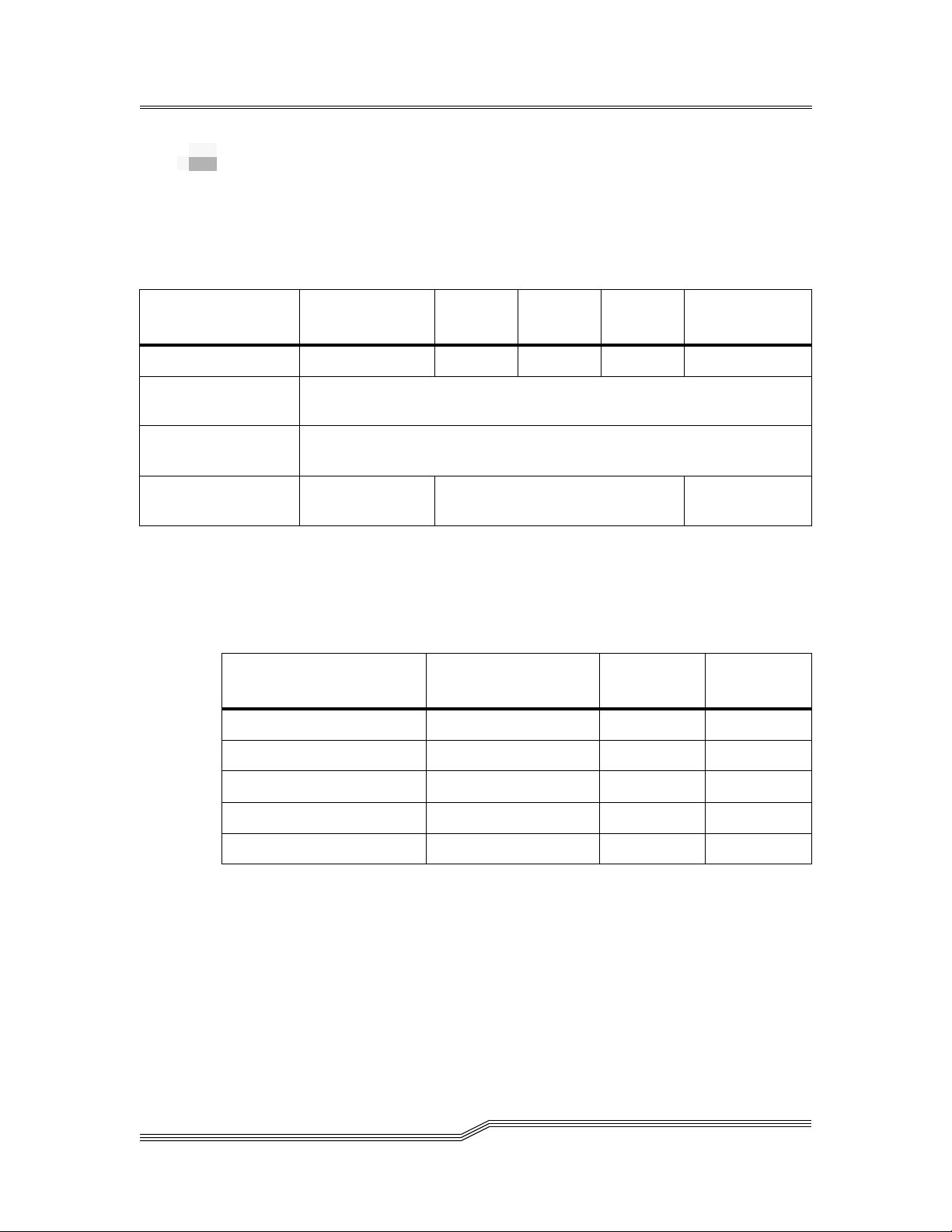

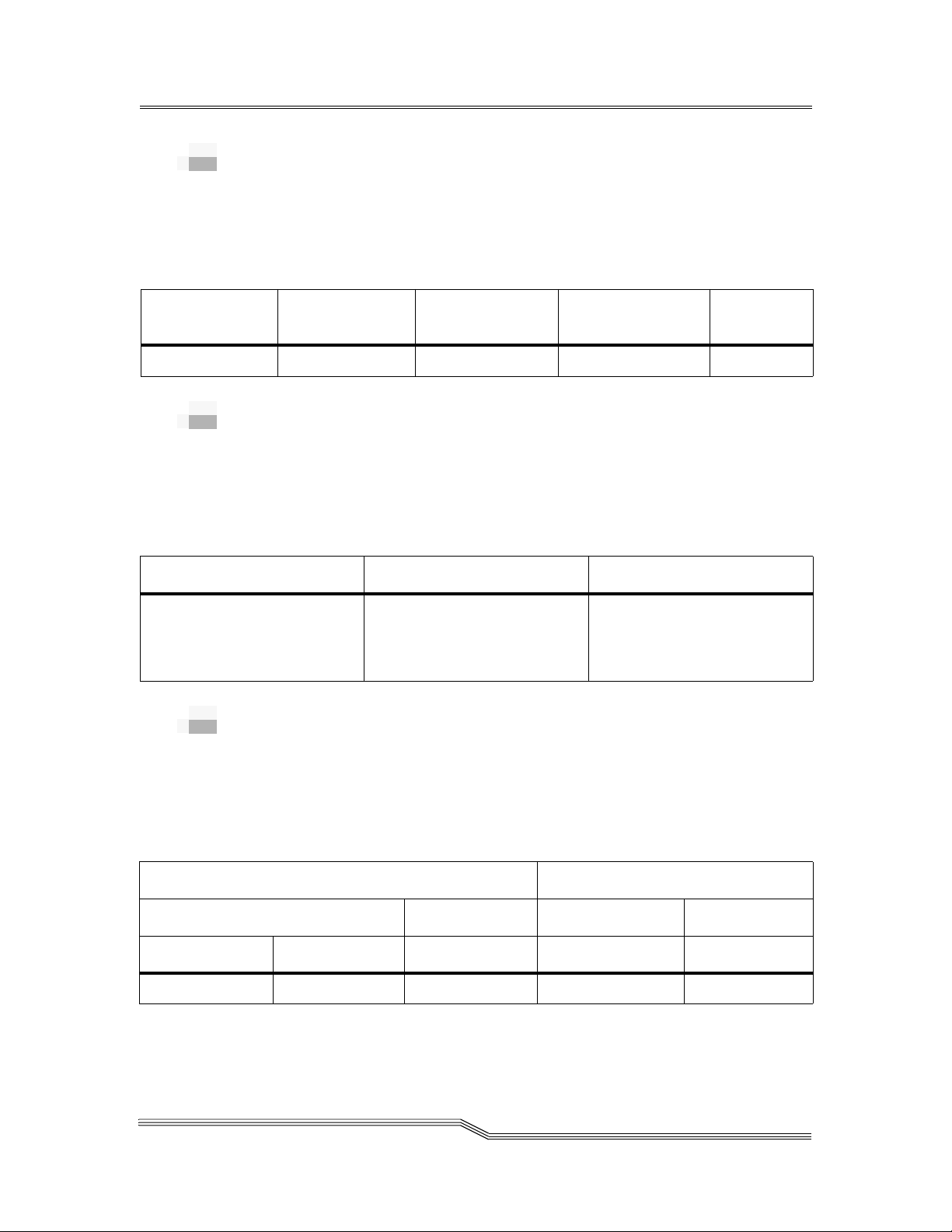

Table 3-1 lists the key physical information for the

components of the AML/J library.

3-

Table 3-1

AML/J Component Physical Dimensions

Device Height Width Depth

1

Control Cabinet 78 inches 29

Model J Base

Module

b

Model J Expansion

78 inches 42

78 inches 29

/8 inches 29 1/4 inches 524 lbs

3

/4 inches 32 1/2 inches 720 lbs 75 lbs/sq ft

1

/8 inches 31 1/4 inches 690 lbs 110 lbs/sq ft

Module

1

Drive Expansion

78 inches 29

/8 inches 29 1/4 inches 850

Cabinet

a. Includes the weight of the heaviest available drive.

b. Cabinet width includes 8 3/4 inch left side non-movable panel and

7

4

/8 inch right side movable panel as viewed from the front.

c. See Footnote a.

Maximum

Weight

a

c

Load

88 lbs/sq ft

144 lbs/sq ft

10 Oct 1996

Overview 3-3

Page 36

Electrical Specifications

Table 3-2 lists the key electrical information for the

components of the AML/J library.

Table 3-2

Device

Control Cabinet 120 VAC 0.7 6 2135 L5-15R

Model J Base

Module

Model J Expansion

Module

Drive Expansion

Cabinet

Table 3-3

AML/J Component Electrical Specifications

Voltage

(Single Phase)

120 VAC Tape Drive Dependent L5-15R

Table 3-3 lists the key electrical specifications of the EMASS

drive components for the AML/J.

AML/J Drive Component Electrical Specification

Device

kVA AMP BTU Receptacle

Not Applicable

Not Applicable

Voltage

(Single Phase)

AMP BTU

EMASS 8490 120 VAC 5 225

EMASS 8590 120 VAC 3 1024

EMASS DLT4002 120 VAC 2 340

EMASS DTF1242 120 VAC 3 598

EMASS ER90 120 VAC 2 1706

3-4 System Specification

600338-B

Page 37

Performance Specifications

Table 3-4 lists the key performance information for the

AML/J library.

Table 3-4

Avg Actions

per Hour

300 400 2.5 seconds 6 seconds 3 seconds

AML/J Performance Specifications

Peak Actions

per Hour

Avg Time to

Present Media

Max Time to

Present Media

Pick Time

Environmental Specifications

Table 3-5 lists the key environmental information for the

AML/J library.

Table 3-5

Temperature Humidity Altitude

Minimum to Maximum:

60° - 90° F (16° - 32° C)

Recommended:

70° - 75° F (21° - 24° C)

AML/J Environmental Specifications

Minimum to Maximum:

15 - 75 percent

Recommended:

45 - 65 percent

No limit

Regulatory Specifications

Table 3-6 lists the key safety and electromagnetic regulatory

information for the AML/J library.

Table 3-6

North America Europe North America Europe

UL CSA TUV Rhineland FCC, Part 15 CE Mark

UL1950 - ITE C22.2 #950 EN60950 Class A Class A

10 Oct 1996

AML/J Regulatory Specifications

Safety EMC - EMI

Performance Specifications 3-5

Page 38

3-6 System Specification

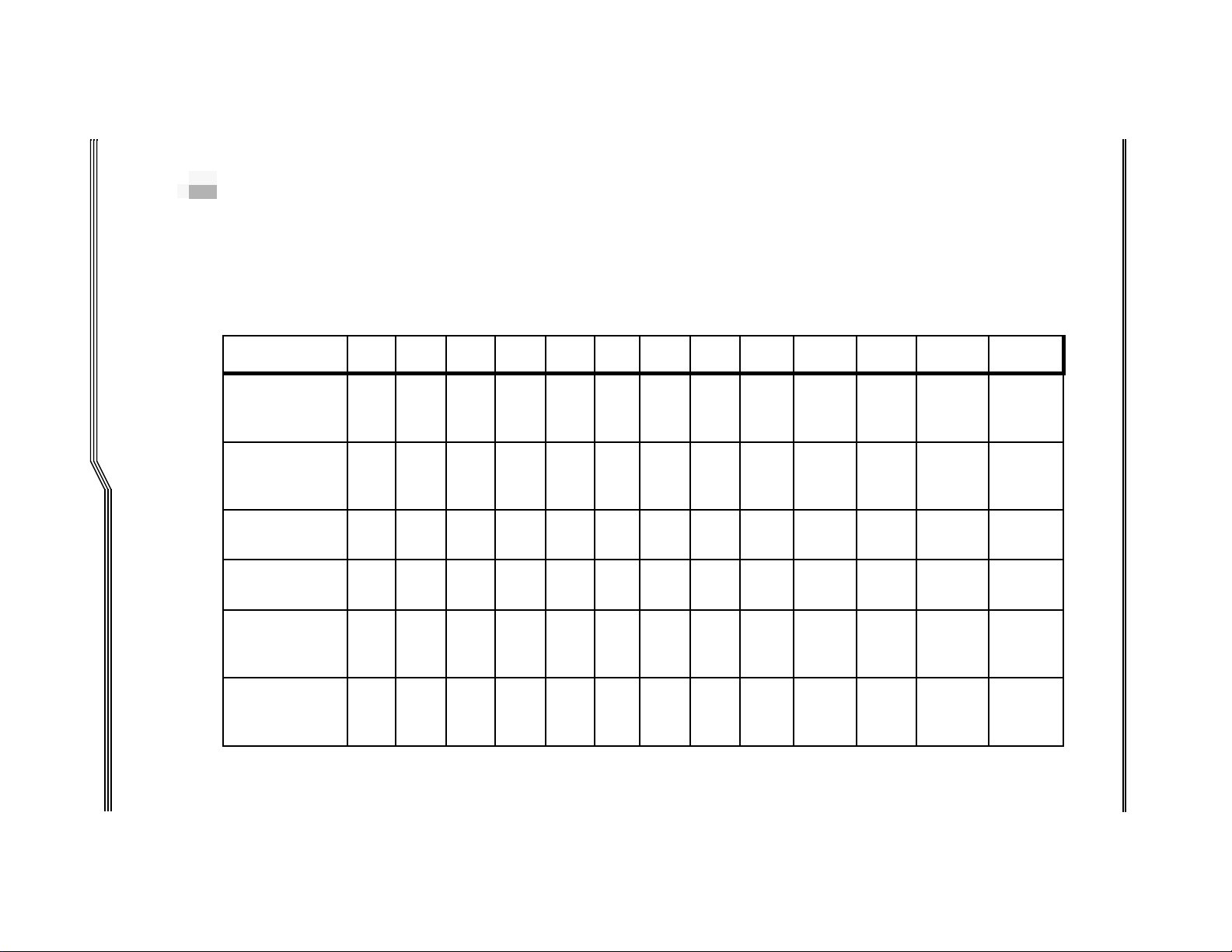

Media Quantity Specification

Table 3-7 lists the quantity of media contained in a single storage segment for the AML/J library.

Refer to the document number

configuration requirements.

Table 3-7 AML/J Media Segment Quantity

600300 AML Hardware Configuration Information

for capacity

Media J1

Half-Inch

a

110 90 60 40 20 100 70 40 130 30 90 30 260

J2

b

J3

c

J4

d

J5

e

J6fJ7

g

J8

h

J10

i

J11

j

J12

k

IE/F-ElIE/F-D

m

Cartridge

D-2 small

36 24 24 12 12 36 24 12 48 06 30 06 96

Cartridge

St-120 Cassette 48 40 32 16 08 40 32 08 56 08 40 08 112

DLT Cartridge 80 64 48 32 16 64 48 16 96 16 64 16 192

8-MM

99 81 63 36 18 81 63 18 117 27 81 27 224

Cartridge

4-MM

154 121 88 55 22 121 88 22 176 33 121 33 352

Cartridge

600338-B

Page 39

10 Oct 1996

Table 3-7 AML/J Media Segment Quantity (Continued)

Media J1

Optical Disk

a

88 66 55 33 11 66 55 11 99 22 66 22 189

J2

b

J3

c

J4

d

J5

e

J6fJ7

g

J8

h

J10

i

J11

j

J12

k

IE/F-ElIE/F-D

m

512

Optical Disk

96 72 60 36 12 72 60 12 108 24 72 24 216

Reflection

DTF small

56 48 32 24 8 48 32 8 72 16 48 16 144

Cartridge

a. Storage segment above 1 of 6 drive shelves

b. Storage segment above 2 of 6 drive shelves

c. Storage segment above 3 of 6 drive shelves

d. Storage segment above 4 of 6 drive shelves

e. Storage segment above 5 of 6 drive shelves

f. Storage segment above 1 of 4 drive shelves

g. Storage segment above 2 of 4 drive shelves

h. Storage segment above 3 of 4 drive shelves

i. Storage segment for a full height

Media Quantity Specification 3-7

j. Storage segment next to 1 IE/F-E

k. Storage segment ab ove IE/F - E

l. Storage segment IE/F-E

m. Storage segment IE/F -D

Page 40

Flooring Requirements

In addition to being dust-free, physically, chemically, and

acoustically appropriate, the flooring must meet the

insulation resistance specifications. The insulation resistance

between the floor surface and earth ground must be 1 x 10

8

1 x 10

ohms to prevent system failure or electrical shock.

Sufficient resistance is achieved by using antistatic,

nonconducting floor tile with a resistance of 1 x 10

ohms. Provide an appropriate connection to the m etal portion

of the ground plate as necessary to ensure the insulation

resistance.

Barcode Requirements

Barcode scanning of individual media labels is accurate if the

labels meets the ANSI MH10.8M-1983 standard and other

additional requirements. The requirements are:

• ANSI MH10.8M-1983 Standard

• Number of digits: 6

• Background reflection: at least 25 percent

• Print contrast: at least 75 percent

• Ratio: at least 2.2

• Module: 250 mm

• Print tolerance: ± 57 mm

5

6

to 1 x 109

to

• Additional Requirements

• Length of the rest zones: 5.25 mm ± 0.25 mm

• No black marks can be present in the intermediate

spaces or rest zones

• No white areas may be present on the bars

• Bars should read in a uniform direction. Nonunifor m

reading directions are feasible in principle, but have a

detrimental effect on performance

• Each label should be applied in the upper right corner

of the tape cartridge recess (when oriented vertically)

• Quality Testing

Compliance with these specifications can be checked and

documented with the Ergilaser 3000 High Density bar code

measuring device that is manufactured by the Laetus

Company.

3-8 System Specification

600338-B

Page 41

4

System

Configuration

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Base Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Media Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Drive Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Insert/Eject Media Boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Control Cabinet Drive Shelves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Drive Cabinet Drive Shelves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Base Unit Media Type Segments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Expansion Unit Media Type Segments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

Software Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Host Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Communication Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Special Engineering Request . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Customer System Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

Page 42

4-2 System Configuration

600338-B

Page 43

Overview

Base Level

This section of the manual solicits the information necessary

to configure an AML/J library. Detailed information about

drive, media, and storage support for the AML/J is located in

the part number

Information

components is located in the path number

Order Information

Check (✔) the desired base level configuration.

Entry Level (2 drive shelves, 1 I/E unit)

Base Module

Base Model + 1 Expansion Unit

Base Model + 2 Expansion Units

600300 AML Hardware Configuration

manual. Order information for the AML/J

600302 Product

manual.

4-

Base Model + 3 Expansion Units

Base Model + 4 Expansion Units

Base Model + 5 Expansion Units

Base Model + 6 Expansion Units

Base Model + 7 Expansion Units

Base Model + 8 Expansion Units

Base Model + 9 Expansion Units

10 Oct 1996

Overview 4-3

Page 44

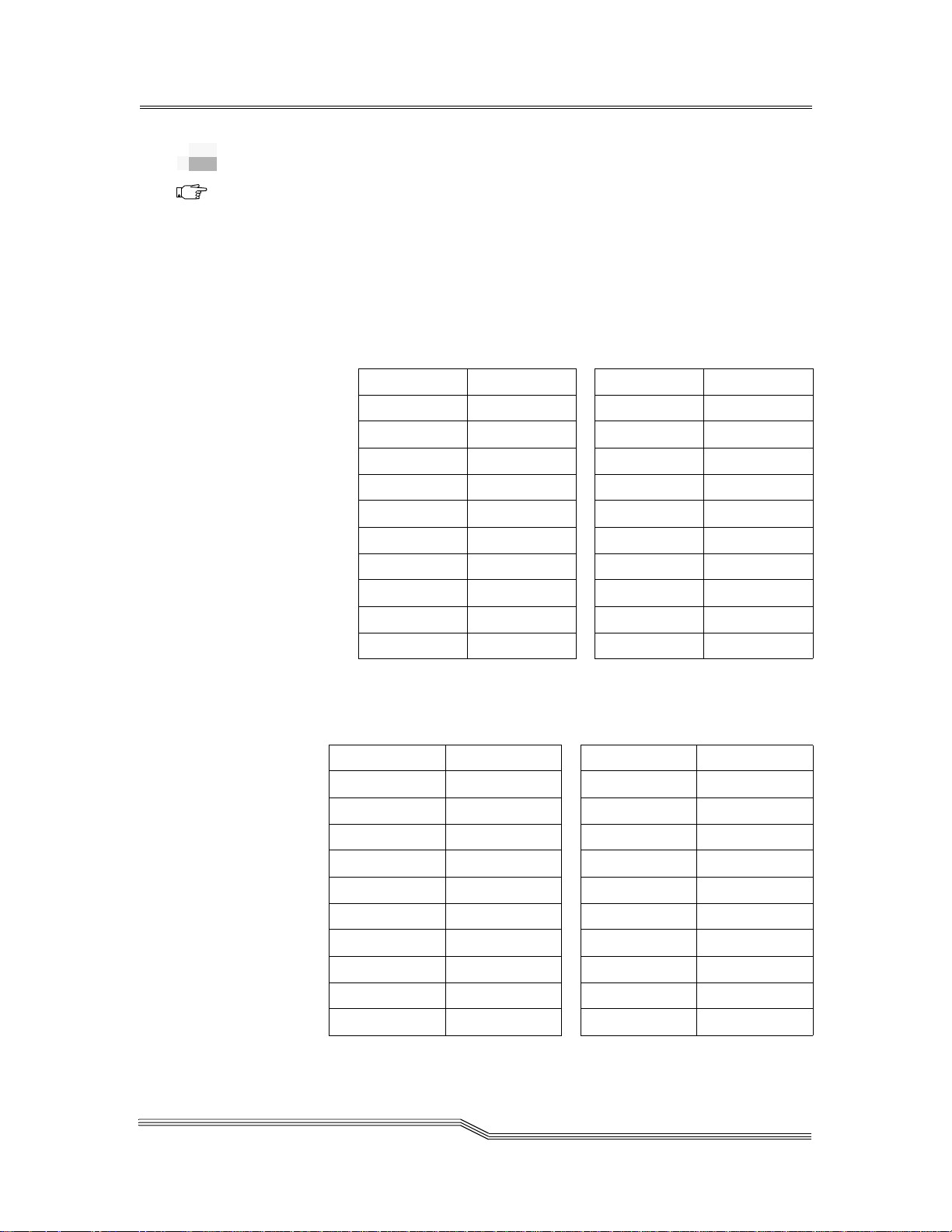

Media Types

Enter the quantity of the desired media type (maximum 4).

3480/3490E

EMASS 8490

EMASS 8590

OD512

OD-R

D2S

VHS

DLT

8mm

4mm

DTF small

DTF medium

other

4-4 System Configuration

600338-B

Page 45

Drive Types

Enter the quantity of the desired drive types (maximum 4) and

if the drive requires a rack mount.

Quantity Type Supported

(Yes or No)

Fujitsu 3490E Yes

EMASS 8490 Yes

IBM 3490 C1A Yes

IBM 3490 C2A Yes

EMASS 8590 Yes

MountainGate 2150 Yes

ER90 HiPPI Yes

ER90 IPI Yes

Exabyte 8mm Yes

Exabyte 4mm Yes

HP OD Yes

EMASS 4002 Yes

OTR Yes

DTF 1242 Yes

non-EMASS drive

Rack Mount

(Yes or No)

10 Oct 1996

Drive Types 4-5

Page 46

3480/3490E

EMASS 8490

EMASS 8590

OD512

OD-R

D2S

VHS

DLT

8mm

4mm

other

Insert/Eject Media Boxes

Enter the quantity of the requested media type handing

boxes.

I/E 1I/E 2I/E 3I/E 4I/E 5I/E 6

Drive

Shelves

Control

Cabinet

Control Cabinet Drive Shelves

Enter the quantity of the Control Cabinet Drive Shelves.

Check (✔) if any shelves are for EMASS 8490 (max 3),

EMASS 8590 (max 2), ER90 (max 2), DTF 1242 (max 2), or DLT

4002 (max 3).

Qty EMASS

8490

Yes No Yes No Yes No Yes No Yes No

EMASS

8590

ER90 DTF 1242 DLT 4002

4-6 System Configuration

600338-B

Page 47

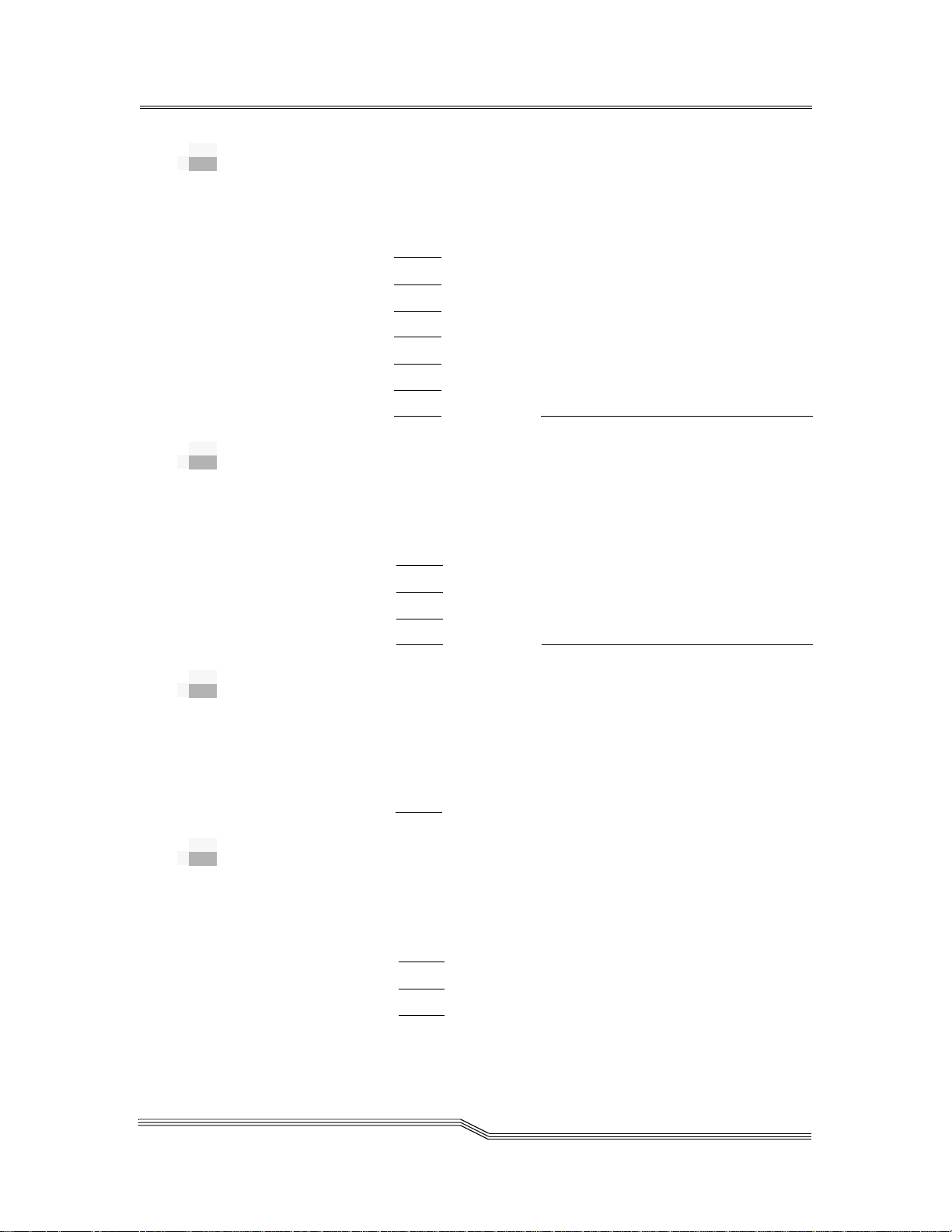

Drive Cabinet Drive Shelves

Enter the quantity of Drive Shelves (maximum 6) for the desired

number of Drive Cabinet. Check (✔) if any shelves are for

EMASS 8490 (max 6), EMASS 8590(max 4), EMASS ER90 (max

4), DTF 1242 (max 4), or DLT 4002 (max 6) type drives.

Drive

Shelves

Drive

Cabinet 1

Drive

Cabinet 2

Drive

Cabinet 3

Drive

Cabinet 4

Drive

Cabinet 5

Drive

Cabinet 6

Qty EMASS

8490

Yes No Yes No Yes No Yes No Yes No

Yes No Yes No Yes No Yes No Yes No

Yes No Yes No Yes No Yes No Yes No

Yes No Yes No Yes No Yes No Yes No

Yes No Yes No Yes No Yes No Yes No

Yes No Yes No Yes No Yes No Yes No

EMASS

8590

ER90 DTF 1242 DLT 4002

10 Oct 1996

Drive Cabinet Drive Shelves 4-7

Page 48

Base Unit Media Type Segments

Note

There are two

segments in each

Insert/Eject

Facilities. A

Segment 5 is

available only if

one of two IE/F

segments is used

as a storage

segment.

Check (✔) the media type for each segment

Base Unit

Seg 1Seg 2Seg 3Seg 4

3480/3490E

EMASS 8490

EMASS 8590

OD512

OD-R

D2S

VHS

DLT

8mm

4mm

other

4-8 System Configuration

600338-B

Page 49

Expansion Unit Media Type Segments

Note

There are two

segments in each

Insert/Eject

Facilities. A

Segment 5 is

available only if

one of two IE/F

segments is used

as a storage

segment.

3480/3490E

EMASS 8490

EMASS 8590

OD512

OD-R

D2S

VHS

DLT

8mm

4mm

other

Check (✔) the media type for each segment

Expansion Unit 1 Expansion Unit 2

Seg 1 Seg 2 Seg 3 Seg 4 Seg 1 Seg 2 Seg 3 Seg 4

10 Oct 1996

Expansion Unit 3 Expansion Unit 4

Seg 1 Seg 2 Seg 3 Seg 4 Seg 1 Seg 2 Seg 3 Seg 4

3480/3490E

EMASS 8490

EMASS 8590

OD512

OD-R

D2S

VHS

DLT

8mm

4mm

other

Expansion Unit Media Type Segments 4-9

Page 50

3480/3490E

EMASS 8490

EMASS 8590

OD512

OD-R

D2S

VHS

DLT

8mm

4mm

other

3480/3490E

Expansion Unit 5 Expansion Unit 6

Seg 1 Seg 2 Seg 3 Seg 4 Seg 1 Seg 2 Seg 3 Seg 4

Expansion Unit 7 Expansion Unit 8

Seg 1 Seg 2 Seg 3 Seg 4 Seg 1 Seg 2 Seg 3 Seg 4

EMASS 8490

EMASS 8590

OD512

OD-R

D2S

VHS

DLT

8mm

4mm

other

Modem

Check (✔) if modem is desired.

Yes No

4-10 System Configuration

600338-B

Page 51

Software Types

Check (✔) the requested type of software.

HCC-MVS

AMASS

AMASS with DataMgr

FileServ

VolServ

DAS

Other

Host Connection

Check (✔) the requested type of connection.

Ethernet

Token Ring

Coax

Special

Communic ation Software

Check (✔) if Remote Access communication software is

desired (CM/2 and TCP/IP are included with the system).

Remote Access

Special Engineering Request

Check (✔) any desired special engineering requirements.

None

Hardware

Software

10 Oct 1996

Software Types 4-11

Page 52

Customer System Layout

Sketch the customer’s system layout or cut and paste from the

examples in Figure 4-3 on page 4-13. Figure 4-2 on page 4-13

represents a configuration example.

Figure 4-1 Customer AML/J Configuration Layout

4-12 System Configuration

Scale: 1/4" = 1’

600338-B

Page 53

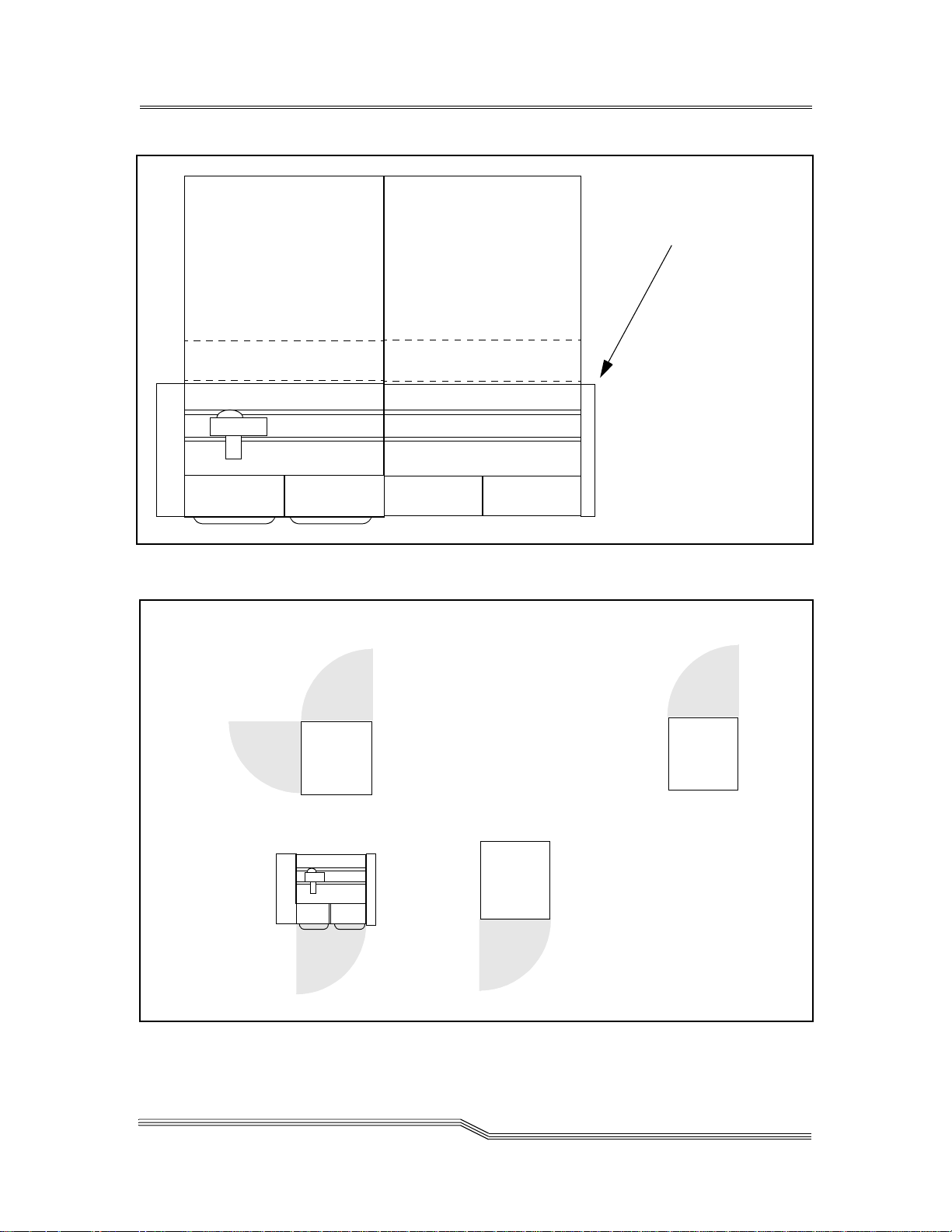

Drive/Control Cabinet

Media Shelves

This panel moves from the

end of the Base Cabinet

to the end of the last

Expansion Cabinet

Drive Expansion Cabinet

Robot

Insert/Eject

Facility

Insert/Eject

Facility

Expansion Cabine t

Media Shelves

Media Shelves

Figure 4-2 Example AML/J ConfigurationConfiguration

Drive/Control Cabinet

front

Base Expansion Cabinet

Base Cabinet

Drive Expansion Cabinet

front

10 Oct 1996

Figure 4-3 Cutout Examples

front

Service Area is gray

Scale: 1/4" = 1’

Customer System Layout 4-13

Page 54

4-14 System Configuration

600338-B

Page 55

5

Survey Data

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Physical Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Customer Room Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Site Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Power Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Telephone Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Customer Building Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Access Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

Additional Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 -12

Page 56

5-2 Survey Data

600338-B

Page 57

Overview

This section solicits pertinent informa tion about the delivery

site. Record all requested general information.

General Information

5-

Place any additional info rmation in

page 5-12.

Customer Name:

Mailing Address:

Sales Contact:

Telephone:

Additional Comments

on

10 Oct 1996

EMASS Sales Rep:

EMASS Account Mgr:

Shipping Address:

Overview 5-3

Page 58

Installation Contact:

Telephone:

Target Installation Date:

Target Operational Date:

Physical Environment

Place any additional info rmation in

page 5-12.

Room Dimension:

Ceiling Height

Ceiling Projection

Additional Comments

on

5-4 Survey Data

Floor Type

600338-B

Page 59

Floor Load Capacity

Fire Protection

10 Oct 1996

Physical Environment 5- 5

Page 60

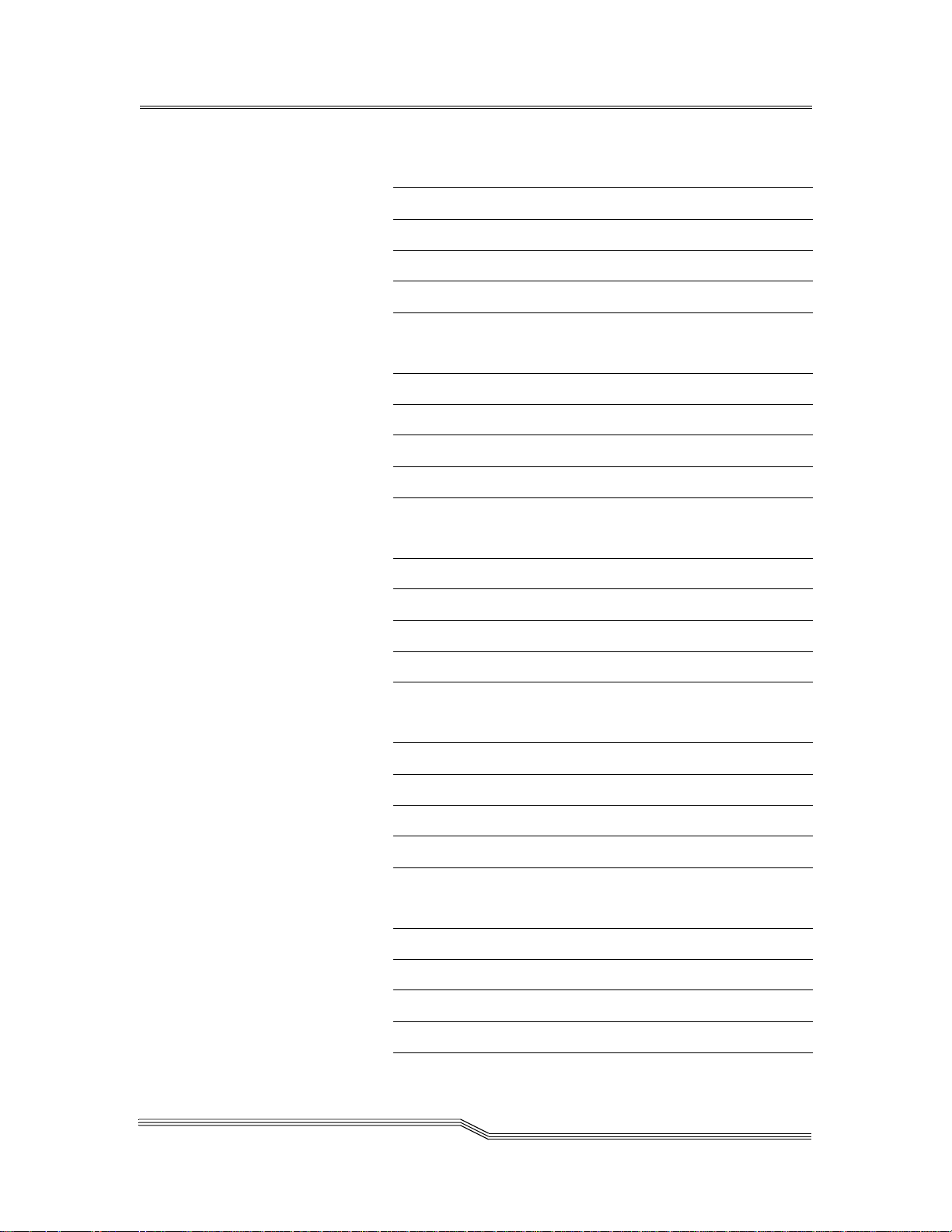

Customer Room Layout

Sketch the approximate measurements of the AML/J library

room and any obstructions.

Figure 5-1 Room Layout

5-6 Survey Data

Scale: 1/4" = 1’

600338-B

Page 61

Site Preparation

The following customer supplied circuits are necessary for the

proper installation and operation of the AML/J library.

Power Circuits

Note

This information

must be conveyed

to the customer to

enable site

preparation before

installation.

Note

This information

must be conveyed

to the customer to

enable site

preparation before

installation.

Refer to

Electrical Specifications

120 VAC, single phase, 15A, circuit terminated in a

NEMA L5-15R receptacle.

Telephone Connection

Refer to

Modem

Standard B1 analog telephone line terminating in an

RJ-11 connector. Each AMU requires a separate line for

the diagnostic modem.

on page 4-10.

on page 3-4

10 Oct 1996

Site Preparation 5-7

Page 62

Customer Building Layout

Sketch the building layout that indicates the route from the

loading dock to equipment final destination. Indicate

obstructions.

Figure 5-2 Building Scale

5-8 Survey Data

Grid = 1/4", No Scale

600338-B

Page 63

Access Conditions

Access to AML/J library room (elevator, stairs, door widths,

etc.):

Dimensions and Location of Smallest Door or Opening:

Loading Dock Specifications (dock height, type of ramps,

weather protection, etc.):

10 Oct 1996

Semitrailer Accessibility (Y or N): ________

Preferred/Required Local Carrier Company:

Site Preparation 5-9

Page 64

Where Can Trailer Be Left for Staging?

Availability of Material Ha ndling Equipment:

Location for Uncrating:

5-10 Survey Data

Preferred Time of Day for Unloading and Moving Materials:

Off Hours/Weekends Accessibilit y for Installation Team:

600338-B

Page 65

Procedure for Obtaining Building Passes:

Procedure for Scheduling the Elevator, Loading Dock, etc.:

Waste Disposal Considerations:

10 Oct 1996

Bargaining Unit Considerations:

Other Considerations:

Site Preparation 5-11

Page 66

Additional Comments

Record any additional information from other pages. For

reference purposes, note the page number with the

information. Add and number additional sheets as necessary.

5-12 Survey Data

600338-B

Loading...

Loading...