Page 1

SOFTWARE BACKUP

AML/2

AUTOMATED

MIXED-MEDIA

LIBRARY

/JUNIOR

for Release 2.3.0

Order no. DOC E00 017-C

Page 2

Table of Contents

1 Description

2 KONFIG.DAT from version 2.3.0 (robot)

Robot 1 2 -1

Robot 2 2 -12

3 Parameter Files for Handling

PLW34907.DAT , PLW34909.DAT 3 -1

PLWDAT?.DAT 3 -2

4 Parameters of the Robot Amplifier

5 Machine Parameters RHO3 (robot)

6 Configuration File for Tower Control AML/2

7 Machine Parameter RHO3 (tower)

8 Parameters of the Tower Amplifier

599 DOC E00 017-C Software Backup AML/2 Page I

Page 3

Table of Contents

Page II Software Backup AML/2 599 DOC E00 017-C

Page 4

Description

1 Description

A software backup is necessary after each change on the AML system.

Change means also the reteaching of a drive or another unit.

After a small change or correction only the changed file must be saved.

The service technician is responsible for the actual backup.

The backup diskettes and the System Logbook are located under the keyboard of

the AMU PC.

Information

Please don’t change any values in the grey fields!

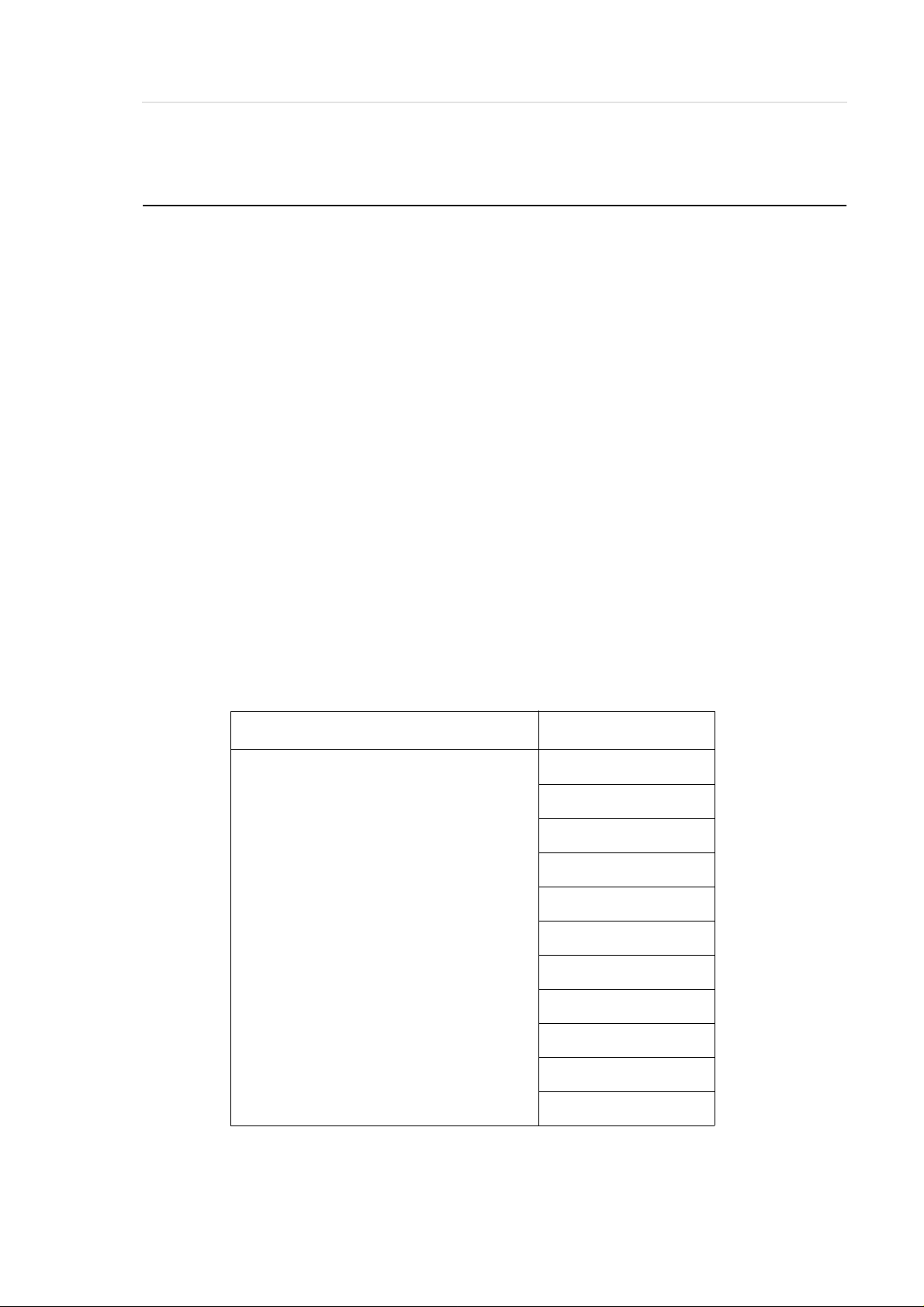

Backup diskettes

Diskette 1 - Robot & Tower software

In error situation, please check the files (size, creation date)

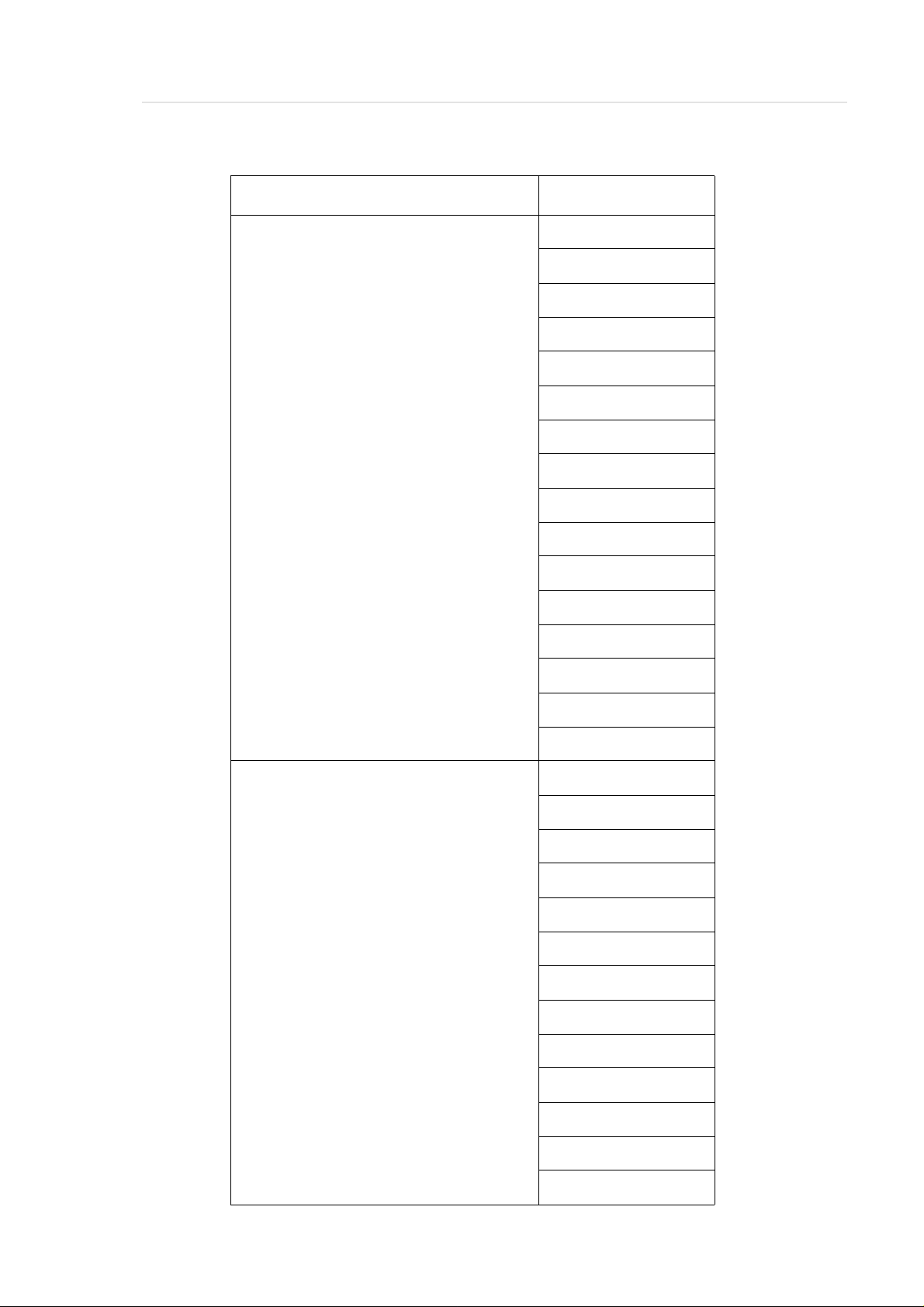

Directory Filename

ROBOT1\MOOG\

and

ROBOT2\MOOG\

140HLP.DEF

BA1G100.PRS

BA1G131.PRS

BA2G100.PRS

BA3G60.PRS

BA4G29.PRS

BA5G8.PRS

BA6G9.PRS

BOSCHTRM.CFG

BOSCHTRM.EXE

BIQ140-.001

599 DOC E00 017-C Software Backup AML/2 Seite 1 - 1

Page 5

Directory Filename

BIQ140E.002

BIQ140E.003

BIQ140E.004

A1G100.PRS

A1G131.PRS

A2G100.PRS

A3G60.PRS

A4G29.PRS

A5G8.PRS

A6G9.PRS

Description

ROBOT1\

and

ROBOT2\

MPRHO3.BIN

KONFIG.DAT

PLW3480.DAT

PLW34907.DAT

PLW34909.DAT

PLWDATx.DAT

VERSION.DAT

Seite 1 - 2 Software Backup AML/2 599 DOC E00 017-C

Page 6

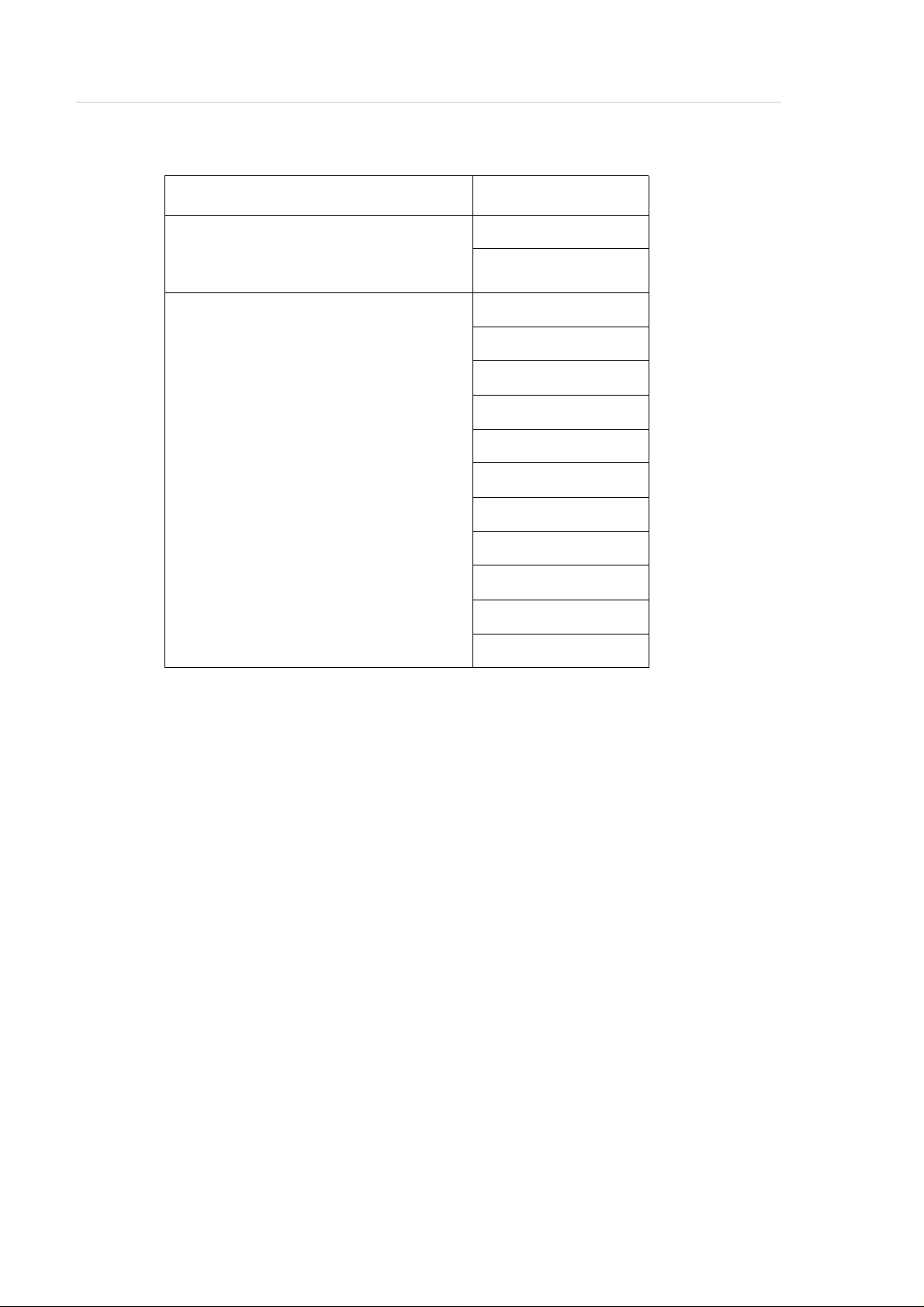

Description

Directory Filename

ROBOT\ IQ_ROBO.P2X

AMULESES.IRD

AMUSCHRS.IRD

EXPROG.DAT

INIT.IRD

KOPPLUNG.DAT

PERMAN.IRD

SBARCODE.IRD

PLW3480.IRD

PLW3490.IRD

PL WMULTI.IRD

SNEWGRIP.IRD

SRACK.IRD

STEACH.IRD

STEST.DAT

STEST.IRD

TOWER\ AMULESE.IRD

AMUSCHR.IRD

EXPROG.DAT

INIT.IRD

KOPPLUNG.DAT

PERMAN.IRD

QTURM1.IRD

QTURM2.IRD

QTURM3.IRD

TEST.DAT

TEST.GER

TEST.IRD

IQ_TURM.P2X

599 DOC E00 017-C Software Backup AML/2 Seite 1 - 3

Page 7

Directory Filename

Description

TOWER1-3\

and

TOWER4-6\

TOWER1-3\MOOG\

and

TOWER4-6\MOOG\

MPRHO3.BIN

KONFIG.DAT

140HLP.DEF

BIQ140-.001

BIQ140E.002

BIQ140E.003

BIQ140E.004

BHTURM.PRS

BNTURM.PRS

BOSCHTRM.CFG

BOSCHTRM.EXE

HTURM.PRS

NTURM.PRS

Seite 1 - 4 Software Backup AML/2 599 DOC E00 017-C

Page 8

Description

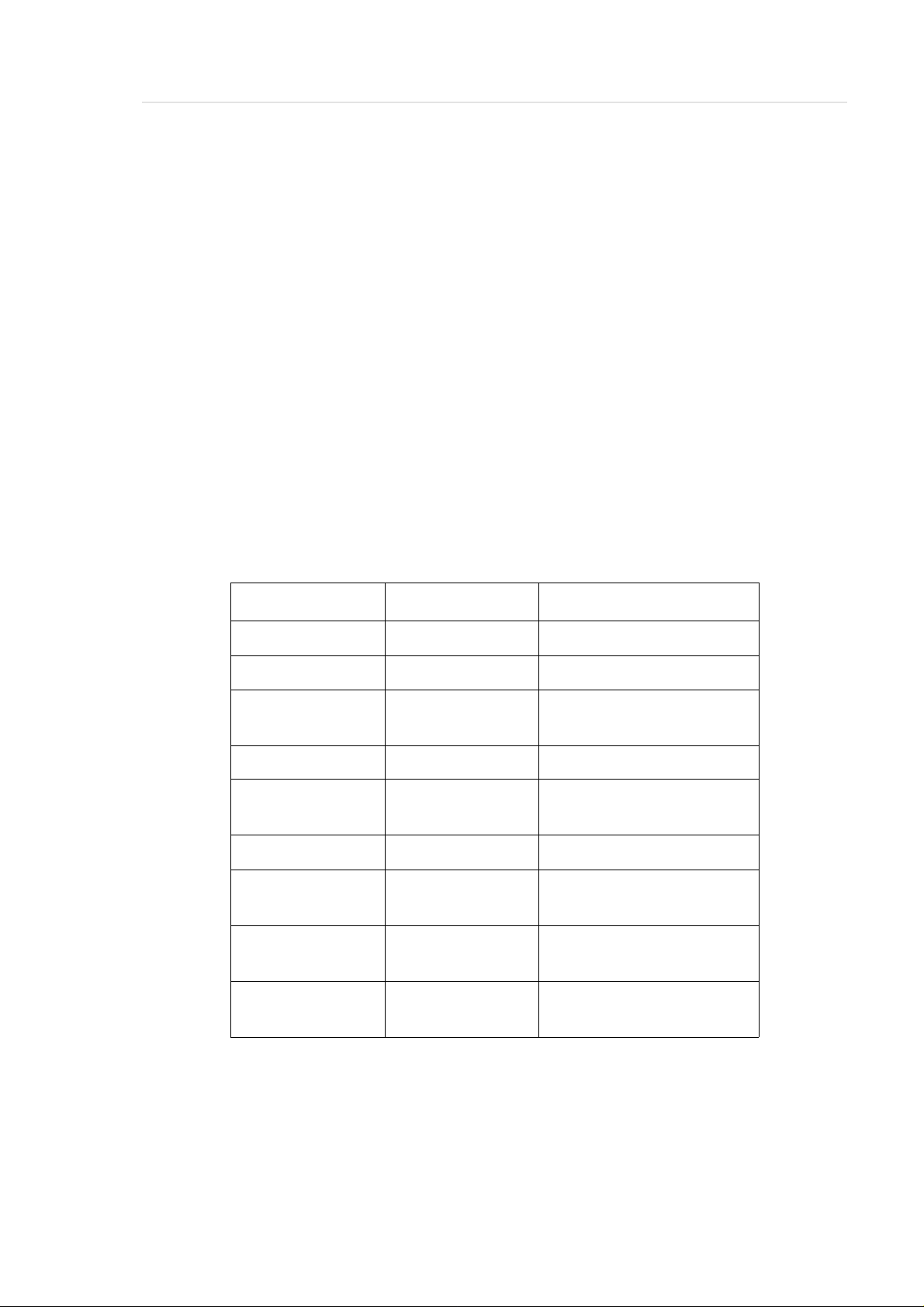

Diskette 2 - AMU Installation Diskette

Diskette 3 - actual updates from AMU software

- AMU*.ZIP

-INSTALL.CMD

- PKUNZIP2.EXE

- Directory \SYSTEM\

- AMUCONF.INI

- AMUCONST.INI

- CONFIG.SYS

- (CONCONT.INI)

- KRNREFPT.R01

- (KRNREFPT.R02)

-STARTUP.CMD

- Directory \CM\

Directory Filename Communication Type

C:\CMLIB\ AMU3270.* EXCP

AMU62S.* LU 6.2 Single Session

AMU62SC.* LU 6.2 Single Session

with additional Coax

AMU62P.* LU 6.2 Parallel Session

AMU62PC.* LU 6.2 Parallel Session

with additional Coax

BOCA.* only DCAF connection

C:\IBMCOM PROTOCOL.INI LANAdapter and Protocol

Support

C:\TCPIP\BIN TCP-

TCP/IP

START.CMD

C:\MPTN\ETC SETUP.CMD

TCP/IP

HOSTS

Diskette 4 - Backup of the database

599 DOC E00 017-C Software Backup AML/2 Seite 1 - 5

Page 9

Description

Seite 1 - 6 Software Backup AML/2 599 DOC E00 017-C

Page 10

KONFIG.DAT from version 2.3.0 (robot)

2 KONFIG.DAT from version 2.3.0 (robot)

Customer:

Installed:

Changes:

actual Version:

2.1 Robot 1

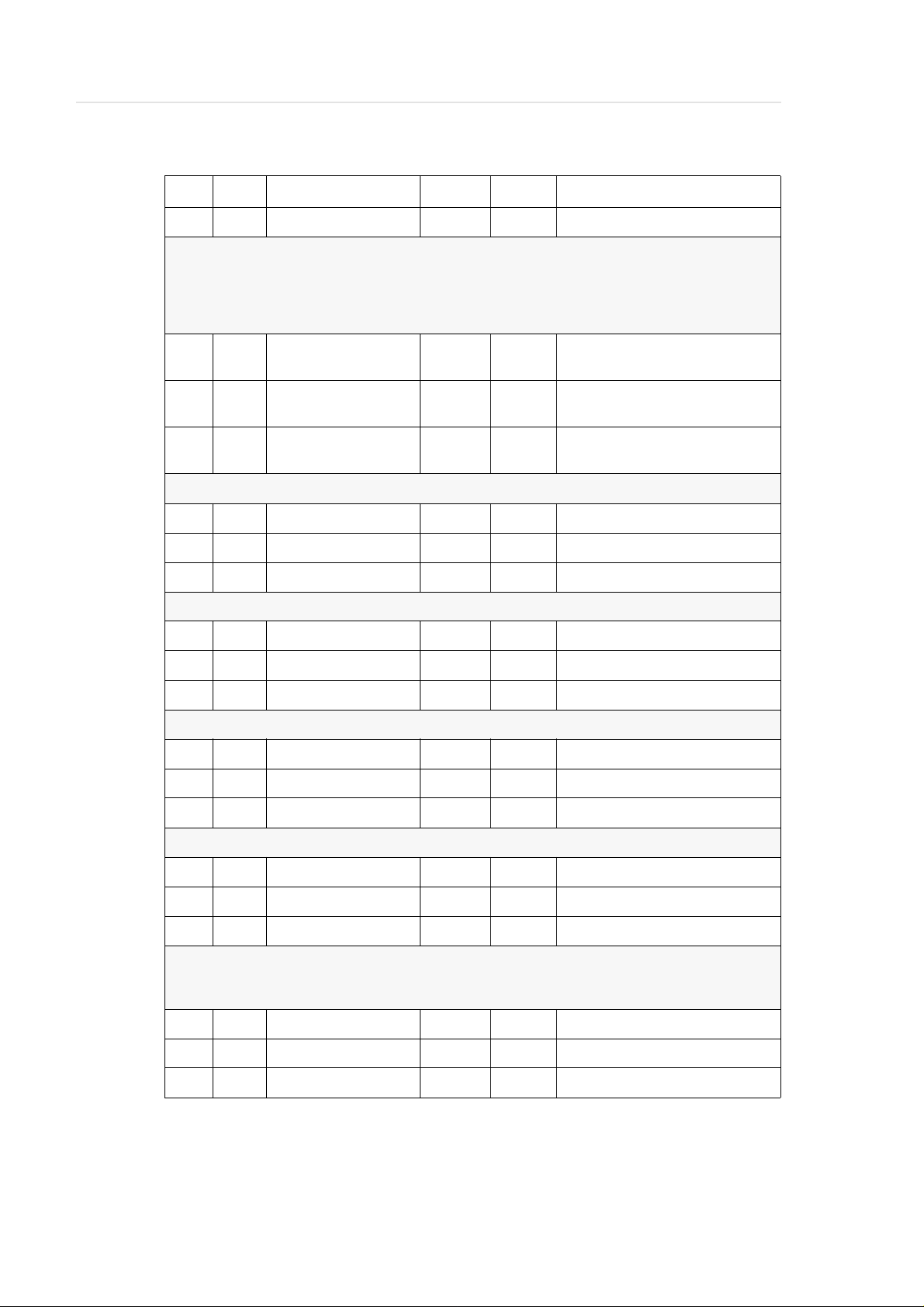

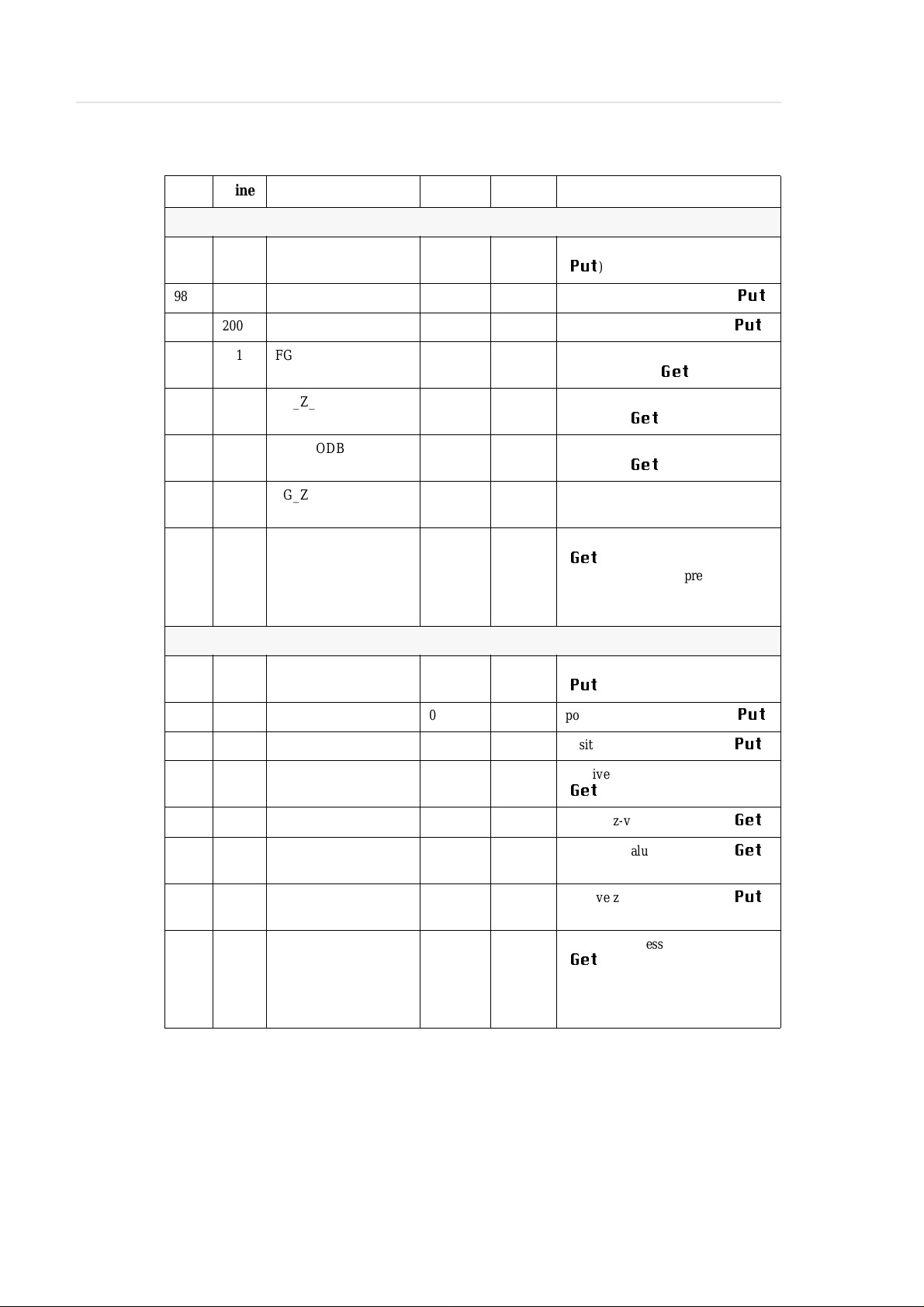

Pos. Line Parameter Default Actual Information

Addresses

1 12 T_ADR_RHO O01 Logical address of the control unit

(samesyntaxas AMU configuration:

O01).

2 13 T_EA1_TYP E0 Type of the first I/O unit ( same syn-

tax as AMU: E0, E1, ...).

The I/O unit/B control runs on the

robot control.

3 14 T_EA2_TYP -- Type of the second I/O unit.

4 15 G_EA1_Nr 1 Logical number of the first

I/O unit.

E001... means value 1

5 16 G_EA2_Nr 0 Logical number of the second

I/O unit.

6 17 G_ROBOTNR 1 Logical number of the robot.

1 = robot 1

2 = robot 2

Configuration of cartridge types

C0 - 1/2″ cartridge 34x0 + 3590

C1 - cartridge DLT

C2 - reseved

O0 - optical disk Reflection

O1 - optical disk 512

V0 - VHS cartridges V5 - Travan

V1-cartridge8mm V6-DTFsmall

V2-cartridge4mm V7-DTFlarge

V3 - D2 small cartridges V8 - BetaCAM small

V4 - D2 medium cartridges V9 - BetaCAM large

Use for each mediatype always the affiliated values,

eg media type 1 -> Offset media type 1, barcoderecognition media type 1 etc.

7 21 Z_Cart_Type1 -- media type 1

8 22 Z_Cart_Type2 -- media type 2

9 23 Z_Cart_Type3 -- media type 3

10 24 Z_Cart_Type4 -- media type 4

599 DOC E00 017-C Software Backup AML/2 Seite 2 - 1

Page 11

Robot 1

Pos. Line Parameter Default Actual Information

11 25 Z_Cart_Type5 -- media type 5

Calibration point coordinates (right arm) of media type 1 (NewGrip)

The NewGrip position is located on the robot console.

The controller needs for the media handling the arm values:

Positions 12 - 14 -> coordinates for right arm (media type 1)

Positions27 - 29 -> coordinatesf or left arm (media type 1)

12 29 FP_NewGripR[1].X_K 386.0 scanner: x-coordinate (in mm)

vision systemdefault: 395.0

13 30 FP_NewGripR[1].Y_K -230.0 scanner: y-coordinate (in mm)

vision systemdefault: 0.0

14 31 FP_NewGripR[1].Z_K 90.0 scanner: z-coordinate (in mm)

vision systemdefault: 80.0

Calibration point coordinates of media type 2 (NewGrip)

15 35 FP_NewGripR[2].X_K 386.0 x-coordinate (in mm)

16 36 FP_NewGripR[2].Y_K -230.0 y-coordinate (in mm)

17 37 FP_NewGripR[2].Z_K 90.0 z-coordinate (in mm)

Calibration point coordinates of media type 3 (NewGrip)

18 41 FP_NewGripR[3].X_K 386.0 x-coordinate (in mm)

19 42 FP_NewGripR[3].Y_K -230.0 y-coordinate (in mm)

20 43 FP_NewGripR[3].Z_K 90.0 z-coordinate (in mm)

Calibration point coordinates of media type 4 (NewGrip)

21 47 FP_NewGripR[4].X_K 386.0 x-coordinate (in mm)

22 48 FP_NewGripR[4].Y_K -230.0 y-coordinate (in mm)

23 49 FP_NewGripR[4].Z_K 90.0 z-coordinate (in mm)

Calibration point coordinates of media type 5 (NewGrip)

24 53 FP_NewGripR[5].X_K 386.0 x-coordinate (in mm)

25 54 FP_NewGripR[5].Y_K -230.0 y-coordinate (in mm)

26 55 FP_NewGripR[5].Z_K 90.0 z-coordinate (in mm)

Calibration point coordinates (left arm) of media type 1

The calibration point coordinates (left arm) of the other media types resultfrom

the following parameters.

27 59 FP_NewGripL[1].X_K 375.0 x-coordinate (in mm)

28 60 FP_NewGripL[1].Y_K 224.0 y-coordinate (in mm)

29 61 FP_NewGripL[1].Z_K 90.0 z-coordinate (in mm)

Seite 2 - 2 Software Backup AML/2 599 DOC E00 017-C

Page 12

Robot 1

Pos. Line Parameter Default Actual Information

Offset barcode recognition for rack (tower or linear shelf) media type 1 [1/100 mm]

30 65 FG_X_BC_Rack[1] 0 positivex-val.= gripper forward

31 66 FG_Y_BC_Rack[1] 0 positivey-value= gripper left

32 67 FG_Z_BC_Rack[1] 0 positive z-value = gripper up

Offset barcode recognition for rack (tower or linear shelf) media type 2 [1/100 mm]

33 71 FG_Y_BC_Rack[2] 0 positivey-value= gripper left

34 72 FG_Z_BC_Rack[2] 0 positive z-value = gripper up

Offset barcode recognition for rack (tower or linear shelf) media type 3 [1/100 mm]

35 76 FG_Y_BC_Rack[3] 0 positivey-value= gripper left

36 77 FG_Z_BC_Rack[3] 0 positive z-value = gripper up

Offset barcode recognition for rack (tower or linear shelf) media type 4 [1/100 mm]

37 81 FG_Y_BC_Rack[4] 0 positivey-value= gripper left

38 82 FG_Z_BC_Rack[4] 0 positive z-value = gripper up

Offset barcode recognition for rack (tower or linear shelf) media type 5 [1/100 mm]

39 86 FG_Y_BC_Rack[5] 0 positivey-value= gripper left

40 87 FG_Z_BC_Rack[5] 0 positive z-value = gripper up

Offset barcode recognition for I/O unit media type 1 [1/100 mm]

41 91 FG_X_BC_EA[1] 0 positive x-val. = gripper forward

42 92 FG_Y_BC_EA[1] 0 positive y-value = gripper left

43 93 FG_Z_BC_EA[1] 0 positive z-value = gripper up

Offset barcode recognition for I/O unit media type 2 [1/100 mm]

44 97 FG_Y_BC_EA[2] 0 positive y-value = gripper left

45 98 FG_Z_BC_EA[2] 0 positive z-value = gripper up

Offset barcode recognition for I/O unit media type 3 [1/100 mm]

46 102 FG_Y_BC_EA[3] 0 positive y-value = gripper left

47 103 FG_Z_BC_EA[3] 0 positive z-value = gripper up

Offset barcode recognition for I/O unit media type 4 [1/100 mm]

48 107 FG_Y_BC_EA[4] 0 positive y-value = gripper left

49 108 FG_Z_BC_EA[4] 0 positive z-value = gripper up

Offset barcode recognition for I/O unit media type 5 [1/100 mm]

50 112 FG_Y_BC_EA[5] 0 positive y-value = gripper left

51 113 FG_Z_BC_EA[5] 0 positive z-value = gripper up

599 DOC E00 017-C Software Backup AML/2 Seite 2 - 3

Page 13

Robot 1

Pos. Line Parameter Default Actual Information

Offset gripper handling for rack (tower or linear shelf) media type 1 [1/100 mm]

52 117 FG_X_DelRack[1] 0 positive x-val. = gripper forward

53 118 FG_Y_DelRack[1] 0 positive y-value = gripper left

54 119 FG_Z_DelRack[1] 0 positive z-value = gripper up

Offset gripper handling for rack (tower or linear shelf) media type 2 [1/100 mm]

55 123 FG_X_DelRack[2] 0 positive x-val. = gripper forward

56 124 FG_Y_DelRack[2] 0 positive y-value = gripper left

57 125 FG_Z_DelRack[2] 0 positive z-value = gripper up

Offset gripper handling for rack (tower or linear shelf) media type 3 [1/100 mm]

58 129 FG_X_DelRack[3] 0 positive x-val. = gripper forward

59 130 FG_Y_DelRack[3] 0 positive y-value = gripper left

60 131 FG_Z_DelRack[3] 0 positive z-value = gripper up

Offset gripper handling for rack (tower or linear shelf) media type 4 [1/100 mm]

61 135 FG_X_DelRack[4] 0 positive x-val. = gripper forward

62 136 FG_Y_DelRack[4] 0 positive y-value = gripper left

63 137 FG_Z_DelRack[4] 0 positive z-value = gripper up

Offset gripper handling for rack (tower or linear shelf) media type 5 [1/100 mm]

64 141 FG_X_DelRack[5] 0 positive x-val. = gripper forward

65 142 FG_Y_DelRack[5] 0 positive y-value = gripper left

66 143 FG_Z_DelRack[5] 0 positive z-value = gripper up

Offset gripper handling for I/O unit media type 1 [1/100 mm]

67 147 FG_X_DelEA[1] 0 positive x-val. = gripper forward

68 148 FG_Y_DelEA[1] 0 positive y-value = gripper left

69 149 FG_Z_DelEA[1] 0 positive z-value = gripper up

Offset gripper handling for I/O unit media type 2 [1/100 mm]

70 153 FG_X_DelEA[2] 0 positive x-val. = gripper forward

71 154 FG_Y_DelEA[2] 0 positive y-value = gripper left

72 155 FG_Z_DelEA[2] 0 Positive z-value = gripper up

Offset gripper handling for I/O unit media type 3 [1/100 mm]

73 159 FG_X_DelEA[3] 0 positive x-val. = gripper forward

74 160 FG_Y_DelEA[3] 0 positive y-value = gripper left

75 161 FG_Z_DelEA[3] 0 positive z-value = gripper up

Offset gripper handling for I/O unit media type 4 [1/100 mm]

76 165 FG_X_DelEA[4] 0 positive x-val. = gripper forward

Seite 2 - 4 Software Backup AML/2 599 DOC E00 017-C

Page 14

Robot 1

Pos. Line Parameter Default Actual Information

77 166 FG_Y_DelEA[4] 0 positive y-value = gripper left

78 167 FG_Z_DelEA[4] 0 Positive z-value = gripper up

Offset gripper handling for I/O unit media type 5 [1/100 mm]

79 171 FG_X_DelEA[5] 0 positive x-val. = gripper forward

80 172 FG_Y_DelEA[5] 0 positive y-value = gripper left

81 173 FG_Z_DelEA[5] 0 Positive z-value = gripper up

Assignment of the drive types

Same syntax as AMU configuration: eg D3, D8, D9, DO...

Use for each drive type always the affiliated offsets.

Not used drive types you have to fill up with „-“.

82 177 LW1 -- drive type 1

83 178 LW2 -- drive type 2

84 179 LW3 -- drive type 3

85 180 LW4 -- drive type 4

86 181 LW5 -- drive type 5

87 182 LW6 -- drive type 6

88 183 LW7 -- drive type 7

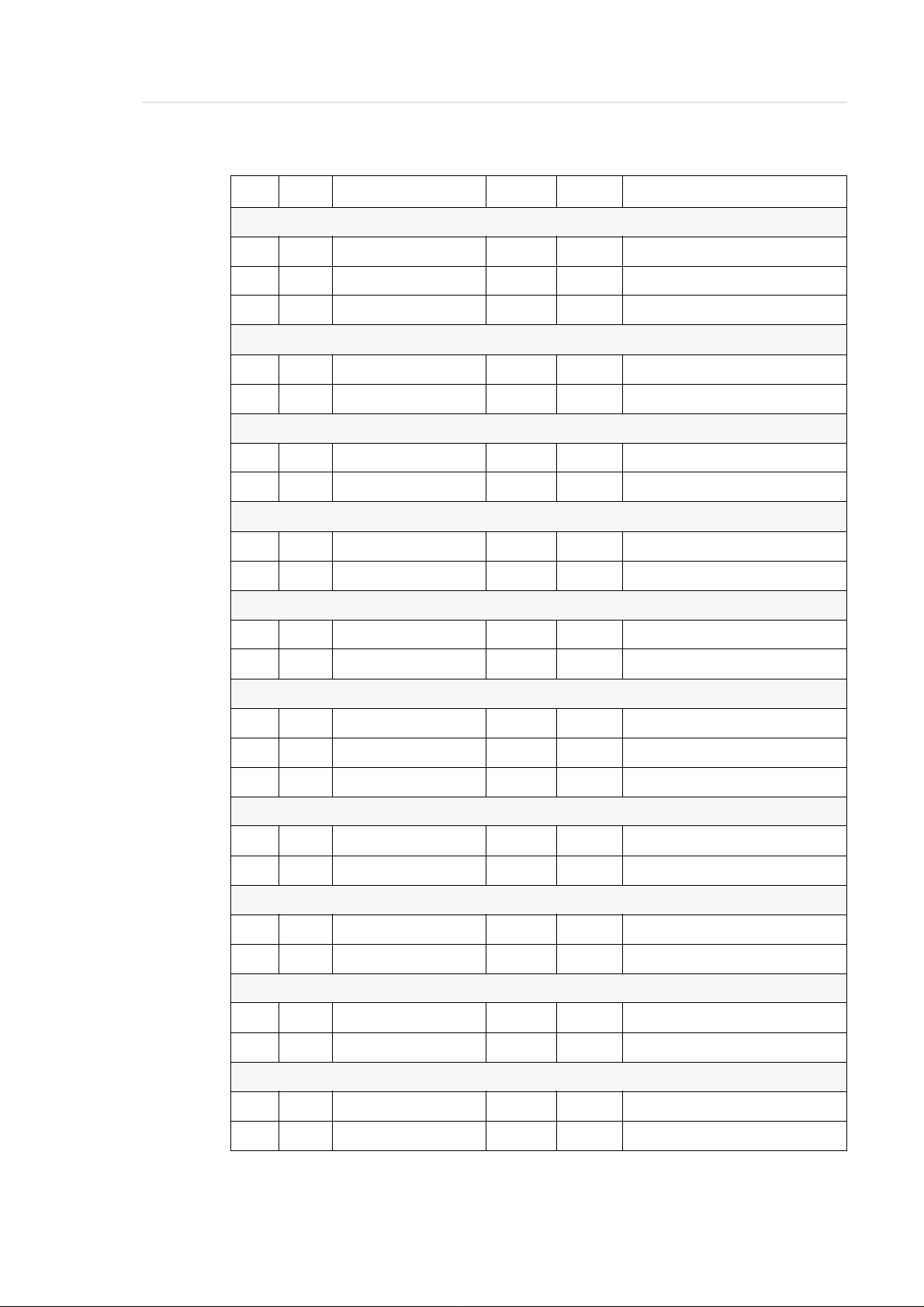

Parameters 63 - 98:

All parametersFG_Z_O... are only for OD drives.

They specify the offset for

Offset gripper handling and barcode recognition for drive type 1 [1/100 mm]

89 187 FG_X_Put_LW[1] 0 positive x-val. = gripperforward

90 188 FG_Y_Put_LW[1] 0 positive y-value= gripper left (

91 189 FG_Z_Put_LW[1] 0 positive z-value = gripper up (

92 190 FG_X_Get_LW[1] 0 positive x-val. = gripper forward

93 191 FG_Z_Get_LW[1] 0 positive z-value = gripperup (

94 192 FG_Z_ODB_LW[1] 0 positive z-value = gripper up (

95 193 FG_Z_ODP_LW[1] 0 positive z-value = gripper up (

Put

and

Get

of side B.

(

Put

)

(

Get

)

OD side B)

OD B-side)

Put

Get

Get

Put

Put

)

)

)

96 194 FZ_Unload[1] N Y = gripperpresses unload button

(

Get

),

N = gripperdoes not press the

unload button

599 DOC E00 017-C Software Backup AML/2 Seite 2 - 5

Page 15

Robot 1

Pos. Line Parameter Default Actual Information

Offset gripper handling and barcode recognition for drive type 2 [1/100 mm]

97 198 FG_X_Put_LW[2] 0 positive x-val. = gripper forward

(

Put

)

98 199 FG_Y_Put_LW[2] 0 positive y-value= gripperleft (

99 200 FG_Z_Put_LW [2] 0 positive z-value = gripper up (

100 201 FG_X_Get_LW[2] 0 positive x-value (in 1/100 mm) =

gripperf orward (

101 202 FG_Z_Get_LW[2] 0 positive z-value (in 1/100 mm) =

gripperup (

102 203 FG_Z_ODB_LW[2] 0 positivez-value (in 1/100 mm) =

gripperup (

103 204 FG_Z_ODP_LW[2] 0 positive z-value (in 1/100 mm) =

gripperup (put OD side B)

104 205 FZ_Unload[2] N Y = gripperpresses unload button

(

Get

),

N = gripper does not press the

unloadbutton

Offset gripper handling and barcode recognition for drive unit type 3 [1/100 mm]

105 209 FG_X_Put_LW[3] 0 positive x-val. = gripper forward

(

Put

)

106 210 FG_Y_Put_LW[3] 0 positive y-value= gripperleft (

107 211 FG_Z_Put_LW[3] 0 positive z-value = gripper up (

Get

Get

Get

)

)

OD side B)

Put

Put

Put

Put

)

)

)

)

108 212 FG_X_Get_LW[3] 0 positive x-val. = gripper forward

(

Get

)

109 213 FG_Z_Get_LW[3] 0 positive z-value = gripper up (

110 214 FG_Z_ODB_LW[3] 0 positive z-value= gripper up (

OD B-side)

111 215 FG_Z_ODP_LW[3] 0 positive z-value = gripper up (

OD B-side)

112 216 FZ_Unload[3] N Y = gripperpresses unload button

Get

)

(

N = gripper does not press the

unloadbutton

Get

Get

Put

)

Seite 2 - 6 Software Backup AML/2 599 DOC E00 017-C

Page 16

Robot 1

Pos. Line Parameter Default Actual Information

Offset gripper handling and barcode recognition for drive type 4 [1/100 mm]

113 220 FG_X_Put_LW[4] 0 positive x-val. = gripperforward

(

Put

)

114 221 FG_Y_Put_LW[4] 0 positive y-value= gripperleft (

115 222 FG_Z_Put_LW[4] 0 positive z-value = gripper up (

116 223 FG_X_Get_LW[4] 0 positive x-val. = gripper forward

(

Get

)

117 224 FG_Z_Get_LW[4] 0 positive z-value = gripper up (

118 225 FG_Z_ODB_LW[4] 0 positive z-value = gripper up (

OD side B)

119 226 FG_Z_ODP_LW[4] 0 positive z-value = gripper up (

OD side B)

120 227 FZ_Unload[4] N Y = gripper pressesunloadbutton

(

Get

),

N = gripperdoes not press the

unload button

Offset gripper handling and barcode recognition for drive type 5 [1/100 mm]

121 231 FG_X_Put_LW[5] 0 positive x-val. = gripper forward

(

Put

)

122 232 FG_Y_Put_LW[5] 0 positive y-value= gripperleft (

123 233 FG_Z_Put_LW[5] 0 positive z-value = gripper up (

Put

Put

Get

Get

Put

Put

Put

)

)

)

)

)

124 234 FG_X_Get_LW[5] 0 positive x-val. = gripper forward

Get

)

(

125 235 FG_Z_Get_LW[5] 0 positive z-value = gripper up (

126 236 FG_Z_ODB_LW[5] 0 positive z-value = gripper up (

OD side B)

127 237 FG_Z_ODP_LW[5] 0 positive z-value = gripper up (

OD side B)

128 238 FZ_Unload[5] N Y = gripper pressesunloadbutton

(

Get

),

N = gripperdoes not press the

unload button

Get

Get

Put

)

599 DOC E00 017-C Software Backup AML/2 Seite 2 - 7

Page 17

Robot 1

Pos. Line Parameter Default Actual Information

Offset gripper handling and barcode recognition for drive type 6 [1/100 mm]

129 242 FG_X_Put_LW[6] 0 positive x-val. = gripper forward

(

Put

)

130 243 FG_Y_Put_LW[6] 0 positive y-value= gripperleft (

131 244 FG_Z_Put_LW[6] 0 positive z-value = gripper up (

132 245 FG_X_Get_LW[6] 0 positive x-val. = gripper forward

(

Get

)

133 246 FG_Z_Get_LW[6] 0 positive z-value = gripper up (

134 247 FG_Z_ODB_LW[6] 0 positive z-value = gripper up (

OD side B)

135 248 FG_Z_ODP_LW[6] 0 positivez-value = gripper up (

OD side B)

136 249 FZ_Unload[6] N Y = gripperpresses unload button

(

Get

),

N = gripper does not press the

unloadbutton

Offset gripper handling and barcode recognition for drive type 7 [1/100 mm]

137 253 FG_X_Put_LW[7] 0 positive x-val. = gripper forward

(

Put

)

138 254 FG_Y_Put_LW[7] 0 positive y-value= gripperleft (

139 255 FG_Z_Put_LW[7] 0 positive z-value = gripper up (

Put

Put

Get

Get

Put

Put

Put

)

)

)

)

)

140 256 FG_X_Get_LW[7] 0 positive x-val. = gripper forward

Get

)

(

141 257 FG_Z_Get_LW[7] 0 positive z-value = gripper up (

142 258 FG_Z_ODB_LW[7] 0 positive z-value = gripper up (

OD side B)

143 259 FG_Z_ODP_LW[7] 0 positivez-value = gripper up (

OD side B)

144 260 FZ_Unload[7] N Y = gripperpresses unload button

(

Get

),

N = gripper does not press the

unloadbutton

Get

Get

Put

)

Seite 2 - 8 Software Backup AML/2 599 DOC E00 017-C

Page 18

Robot 1

Pos. Line Parameter Default Actual Information

Software limits (depending on your system)

145 264 G_X_MAXLIMIT 290000 Dependson the length ofthesystem.

Handlingat the end of the system (I/

O unit) must be possible. You get

this value with the test program on

the PHG. value = x-axis + h-axis

146 265 G_X_MINLIMIT 25000 minimal x-coordinateof AMU

147 266 G_Z_MAXLIMIT 142000 maximal z-coordinate of AMU

G_Z_MAXLIMIT = V_max + Z _max

„MPRHO3.BIN“ P204

3. axis (v), 6. axis (z)

148 267 G_Z_MINLIMIT -4500 -4500 minimal z-coordinate of AMU

149 268 G_H_SAVEELBO 100 Maximal h-coordinatefor a secure

arm change. You get this value with

the test program on the PHG: media

in gripper, arm in straight position,

drive to the first obstacle (eg the I/O

unit).

Speed and Acceleration

150 272 D_V_HANDL 250.0 Slow speed for linear interpolation

(during handling):

min. 10 / max. 250

Diagnosis

151 276 G_PHGECHO 1 0 = PHG not connected,

normal working conditions,

1 = PHG necessary,

tests possible,

2 = PHG connected,

only test mode,

stand-alone

3 = PHG connected,

only test mode,

stand-alone without gripper

Gripper offset (☞ gripper data sheet)

152 280 G_Y_BC 0 y-offset Scanner

153 282 G_X_TEACH 0 x-offset

154 283 G_Y_TEACH 0 y-offset

155 284 G_Z_TEACH 0 z-offset

Teach

Teach

Teach

156 286 G_X_OFFSET 0 gripper offset x-coordinate

(in 1/100 mm)

157 287 G_Y_OFFSET 0 gripper offset y-coordinate

(in 1/100 mm)

158 288 G_Z_OFFSET 0 gripper offset z-coordinate

(in 1/100 mm)

599 DOC E00 017-C Software Backup AML/2 Seite 2 - 9

Page 19

Robot 1

Pos. Line Parameter Default Actual Information

159 292 G_PARALLEL 1 Grippertype:

0=forsmallmedias

(401 004 930)

1 = for large medias

(401 004 920)

2 = Universal Gripper

(401 002 235)

160 293 G_BCErrIgn 1 Reaction on barcode-reading error.

0 = cancelon error

1 = ignore error and continue

161 295 G_Z_BCOff_V 0 Vertical offset (difference between

label for side A and side B) for the

barcodelabel on optical disks

162 296 G_WarnAus 0 Messages from type „Warning“will

not displayed in AMU-log when

G_WarnAus = 1

Timeout

163 300 D_TIME1 140 140 time-out Quadro tower(in sec)

164 301 D_TIME2 140 time-out I/O unit (in sec)

10 = I/O unit/B

165 302 D_WARTE_KEEP 60 time-out

166 306 D_Z_TO_V 0.27164 Relation between z- and v-axis.

Enter all values in mm and with 5

digits aftert he point.

Formulas:

max. z-axis = Z_max

(„MPRH3.BIN“P204,3. axis)

max. v-axis = V_max

(„MPRHO3.BIN“ P204, 6. axis)

D_Z_TO_V =

for D2 medium handling:

D_Z_TO_V =

167 307 D_Y_Elb 0 only for scanner gripper:

positive y-coordinate(in mm) in

world coordinates

for drive gripper with medium

use for touchless movement on track

(eg tower covering)

0 = normal processing

Keep

from drive

Z_max - 12

(Z_max - 12) + V_max

Z_max - 30

(Z_max - 30) + V_max

Coordinates (in mm) for special handling of drives on the start of track (only scanner gripper)

168 308 D_X_Col 0 x-coordinatefor begin handling area

(only for special handling in the

back area)

169 309 D_Y_Col 0 y-coordinate handling area (onlyfor

special handling in the back area)

Seite 2 - 10 Software Backup AML/2 599 DOC E00 017-C

Page 20

Robot 1

Pos. Line Parameter Default Actual Information

170 311 G_UMSCHLAG 1 Definition of the robotarm for front

handling:

0 = arm not defined

1=leftarm

2=rightarm

171 312 G_FIRSTOWER 1 Numberof first connected Quadro

tower

Additional offset value for

172 316 FG_Y_PRaOff[1] 0 media 1 on rack

173 317 FG_Y_PIEOff[1] 0 media 1 on I/O unit

174 318 FG_Y_PRaOff[2] 0 media 2 on rack

175 319 FG_Y_PIEOff[2] 0 media 2 on I/O unit

176 320 FG_Y_PRaOff[3] 0 media 3 on rack

177 321 FG_Y_PIEOff[3] 0 media 3 on I/O unit

178 322 FG_Y_PRaOff[4] 0 media 4 on rack

179 323 FG_Y_PIEOff[4] 0 media 4 on I/O unit

180 324 FG_Y_PRaOff[5] 0 media 5 on rack

181 325 FG_Y_PIEOff[5] 0 media 5 on I/O unit

182 329 0 0 reserve

183 330 0 0 reserve

184 331 0 0 reserve

185 332 0 0 reserve

186 333 0 0 reserve

PUT

(positive y-value (1/100mm) = gripper left)

Check sum

187 337 G_SUMME 187 187 number of positions in this file

599 DOC E00 017-C Software Backup AML/2 Seite 2 - 11

Page 21

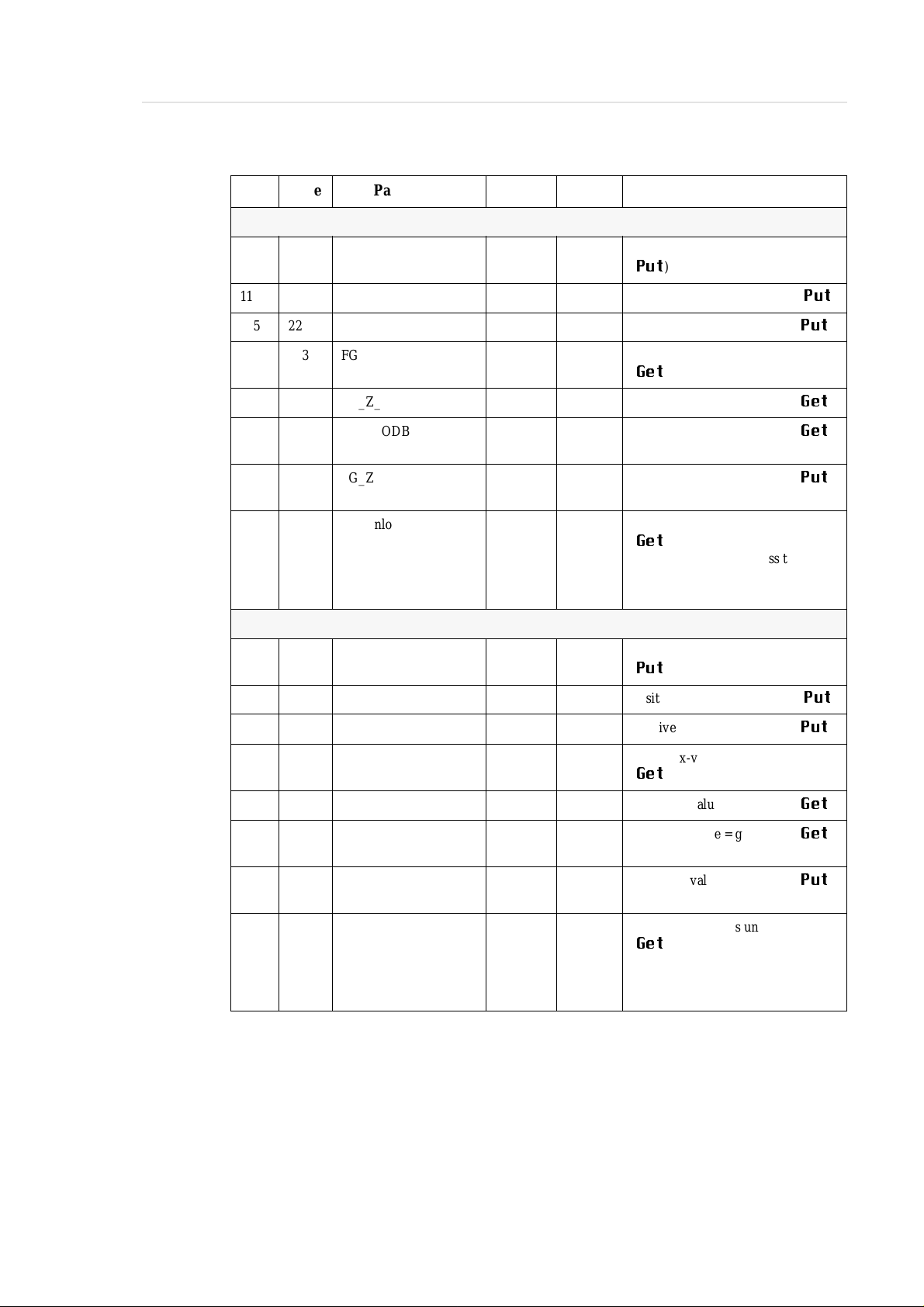

2.2 Robot 2

Pos. Line Parameter Default Actual Information

Addresses

1 12 T_ADR_RHO O01 Logical address of the controlunit

2 13 T_EA1_TYP E0 Type of the first I/O unit (same syn-

3 14 T_EA2_TYP -- Type of the second I/O unit.

4 15 G_EA1_Nr 1 Logical number of the first

Robot 2

(samesyntaxasAMU configuration:

O01).

tax as AMU: E0, E1, ...).

The I/O unit/B control runs on the

robot control.

I/O unit.

E001... means value 1

5 16 G_EA2_Nr 0 Logical number of the second

I/O unit.

6 17 G_ROBOTNR 1 Logical number of the robot.

1=robot1

2=robot2

Configuration of cartridgetypes

C0 - 1/2″ cartridge 34x0 + 3590

C1 - cartridge DLT

C2 - reseved

O0 - optical disk Reflection

O1 - optical disk 512

Use for each media type alwaysthe affiliated values,

eg media type 1 -> Offset media type 1, barcoderecognition media type 1 etc.

7 21 Z_Cart_Type1 -- media type 1

8 22 Z_Cart_Type2 -- media type 2

9 23 Z_Cart_Type3 -- media type 3

10 24 Z_Cart_Type4 -- media type 4

11 25 Z_Cart_Type5 -- media type 5

V0 - VHS cartridges V5 - Travan

V1 - cartridge 8 mm V6 - DTF small

V2 - cartridge 4 mm V7 - DTF large

V3 - D2 small cartridges V8 - BetaCAM small

V4 - D2 medium cartridges V9 - BetaCAM large

Seite 2 - 12 Software Backup AML/2 599 DOC E00 017-C

Page 22

Robot 2

Pos. Line Parameter Default Actual Information

Calibration point coordinates(right arm) of media type 1 (NewGrip)

The NewGrip position is located on the robot console.

The controller needs for the media handling the arm values:

Positions 11 - 13 -> coordinates for right arm (media type 1)

Positions27 - 29 -> coordinates for left arm (media type 1)

12 29 FP_NewGripR[1].X_K 386.0 scanner: x-coordinate (in mm)

vision systemdefault: 395.0

13 30 FP_NewGripR[1].Y_K -230.0 scanner: y-coordinate (in mm)

vision systemdefault: 0.0

14 31 FP_NewGripR[1].Z_K 90.0 scanner: z-coordinate (in mm)

vision systemdefault: 80.0

Calibration point coordinates of media type 2 (NewGrip)

15 35 FP_NewGripR[2].X_K 386.0 x-coordinate (in mm)

16 36 FP_NewGripR[2].Y_K -230.0 y-coordinate (in mm)

17 37 FP_NewGripR[2].Z_K 90.0 z-coordinate(in mm)

Calibration point coordinates of media type 3 (NewGrip)

18 41 FP_NewGripR[3].X_K 386.0 x-coordinate (in mm)

19 42 FP_NewGripR[3].Y_K -230.0 y-coordinate (in mm)

20 43 FP_NewGripR[3].Z_K 90.0 z-coordinate(in mm)

Calibration point coordinates of media type 4 (NewGrip)

21 47 FP_NewGripR[4].X_K 386.0 x-coordinate (in mm)

22 48 FP_NewGripR[4].Y_K -230.0 y-coordinate (in mm)

23 49 FP_NewGripR[4].Z_K 90.0 z-coordinate(in mm)

Calibration point coordinates of media type 5 (NewGrip)

24 53 FP_NewGripR[5].X_K 386.0 x-coordinate (in mm)

25 54 FP_NewGripR[5].Y_K -230.0 y-coordinate (in mm)

26 55 FP_NewGripR[5].Z_K 90.0 z-coordinate(in mm)

Calibration point coordinates(left arm) of media type 1

The calibration point coordinates (left arm) of the other media types result from

the following parameters.

27 59 FP_NewGripL[1].X_K 375.0 x-coordinate (in mm)

28 60 FP_NewGripL[1].Y_K 224.0 y-coordinate (in mm)

29 61 FP_NewGripL[1].Z_K 90.0 z-coordinate (in mm)

599 DOC E00 017-C Software Backup AML/2 Seite 2 - 13

Page 23

Robot 2

Pos. Line Parameter Default Actual Information

Offset barcode recognition for rack (tower or linear shelf) media type 1 [1/100 mm]

30 65 FG_X_BC_Rack[1] 0 positive x-val. = gripper forward

31 66 FG_Y_BC_Rack[1] 0 positive y-value = gripper left

32 67 FG_Z_BC_Rack[1] 0 positive z-value= gripper up

Offset barcode recognition for rack (tower or linear shelf) media type 2 [1/100 mm]

33 71 FG_Y_BC_Rack[2] 0 positive y-value = gripper left

34 72 FG_Z_BC_Rack[2] 0 positive z-value= gripper up

Offset barcode recognition for rack (tower or linear shelf) media type 3 [1/100 mm]

35 76 FG_Y_BC_Rack[3] 0 positive y-value = gripper left

36 77 FG_Z_BC_Rack[3] 0 positive z-value= gripper up

Offset barcode recognition for rack (tower or linear shelf) media type 4 [1/100 mm]

37 81 FG_Y_BC_Rack[4] 0 positive y-value = gripper left

38 82 FG_Z_BC_Rack[4] 0 positive z-value= gripper up

Offset barcode recognition for rack (tower or linear shelf) media type 5 [1/100 mm]

39 86 FG_Y_BC_Rack[5] 0 positive y-value = gripper left

40 87 FG_Z_BC_Rack[5] 0 positive z-value= gripper up

Offset barcode recognition for I/O unit media type 1 [1/100 mm]

41 91 FG_X_BC_EA[1] 0 positive x-val. = gripper forward

42 92 FG_Y_BC_EA[1] 0 positive y-value = gripper left

43 93 FG_Z_BC_EA[1] 0 positive z-value= gripper up

Offset barcode recognition for I/O unit media type 2 [1/100 mm]

44 97 FG_Y_BC_EA[2] 0 positive y-value = gripper left

45 98 FG_Z_BC_EA[2] 0 positive z-value= gripper up

Offset barcode recognition for I/O unit media type 3 [1/100 mm]

46 102 FG_Y_BC_EA[3] 0 positive y-value = gripper left

47 103 FG_Z_BC_EA[3] 0 positive z-value = gripper up

Offset barcode recognition for I/O unit media type 4 [1/100 mm]

48 107 FG_Y_BC_EA[4] 0 positive y-value = gripper left

49 108 FG_Z_BC_EA[4] 0 positive z-value = gripper up

Offset barcode recognition for I/O unit media type 5 [1/100 mm]

50 112 FG_Y_BC_EA[5] 0 positive y-value = gripper left

51 113 FG_Z_BC_EA[5] 0 positive z-value = gripper up

Seite 2 - 14 Software Backup AML/2 599 DOC E00 017-C

Page 24

Robot 2

Pos. Line Parameter Default Actual Information

Offset gripper handlingfor rack (tower or linear shelf) media type 1 [1/100 mm]

52 117 FG_X_DelRack[1] 0 positivex-val. = gripper forward

53 118 FG_Y_DelRack[1] 0 positivey-value = gripper left

54 119 FG_Z_DelRack[1] 0 positive z-value = gripper up

Offset gripper handling for rack (tower or linear shelf) media type 2 [1/100 mm]

55 123 FG_X_DelRack[2] 0 positivex-val. = gripper forward

56 124 FG_Y_DelRack[2] 0 positivey-value = gripper left

57 125 FG_Z_DelRack[2] 0 positive z-value = gripper up

Offset gripper handling for rack (tower or linear shelf) media type 3 [1/100 mm]

58 129 FG_X_DelRack[3] 0 positivex-val. = gripper forward

59 130 FG_Y_DelRack[3] 0 positivey-value = gripper left

60 131 FG_Z_DelRack[3] 0 positive z-value = gripper up

Offset gripper handling for rack (tower or linear shelf) media type 4 [1/100 mm]

61 135 FG_X_DelRack[4] 0 positivex-val. = gripper forward

62 136 FG_Y_DelRack[4] 0 positivey-value = gripper left

63 137 FG_Z_DelRack[4] 0 positive z-value = gripper up

Offset gripper handling for rack (tower or linear shelf) media type 5 [1/100 mm]

64 141 FG_X_DelRack[5] 0 positivex-val. = gripper forward

65 142 FG_Y_DelRack[5] 0 positivey-value = gripper left

66 143 FG_Z_DelRack[5] 0 positive z-value = gripper up

Offset gripper handling for I/O unit media type 1 [1/100 mm]

67 147 FG_X_DelEA[1] 0 positive x-val. = gripper forward

68 148 FG_Y_DelEA[1] 0 positive y-value = gripper left

69 149 FG_Z_DelEA[1] 0 positive z-value = gripper up

Offset gripper handling for I/O unit media type 2 [1/100 mm]

70 153 FG_X_DelEA[2] 0 positive x-val. = gripper forward

71 154 FG_Y_DelEA[2] 0 positive y-value = gripper left

72 155 FG_Z_DelEA[2] 0 Positive z-value = gripper up

Offset gripper handling for I/O unit media type 3 [1/100 mm]

73 159 FG_X_DelEA[3] 0 positive x-val. = gripper forward

74 160 FG_Y_DelEA[3] 0 positive y-value = gripper left

75 161 FG_Z_DelEA[3] 0 positive z-value = gripper up

Offset gripper handling for I/O unit media type 4 [1/100 mm]

76 165 FG_X_DelEA[4] 0 positive x-val. = gripper forward

599 DOC E00 017-C Software Backup AML/2 Seite 2 - 15

Page 25

Robot 2

Pos. Line Parameter Default Actual Information

77 166 FG_Y_DelEA[4] 0 positive y-value = gripper left

78 167 FG_Z_DelEA[4] 0 Positive z-value = gripper up

Offset gripper handling for I/O unit media type 5 [1/100 mm]

79 171 FG_X_DelEA[5] 0 positive x-val. = gripper forward

80 172 FG_Y_DelEA[5] 0 positive y-value = gripper left

81 173 FG_Z_DelEA[5] 0 Positive z-value = gripper up

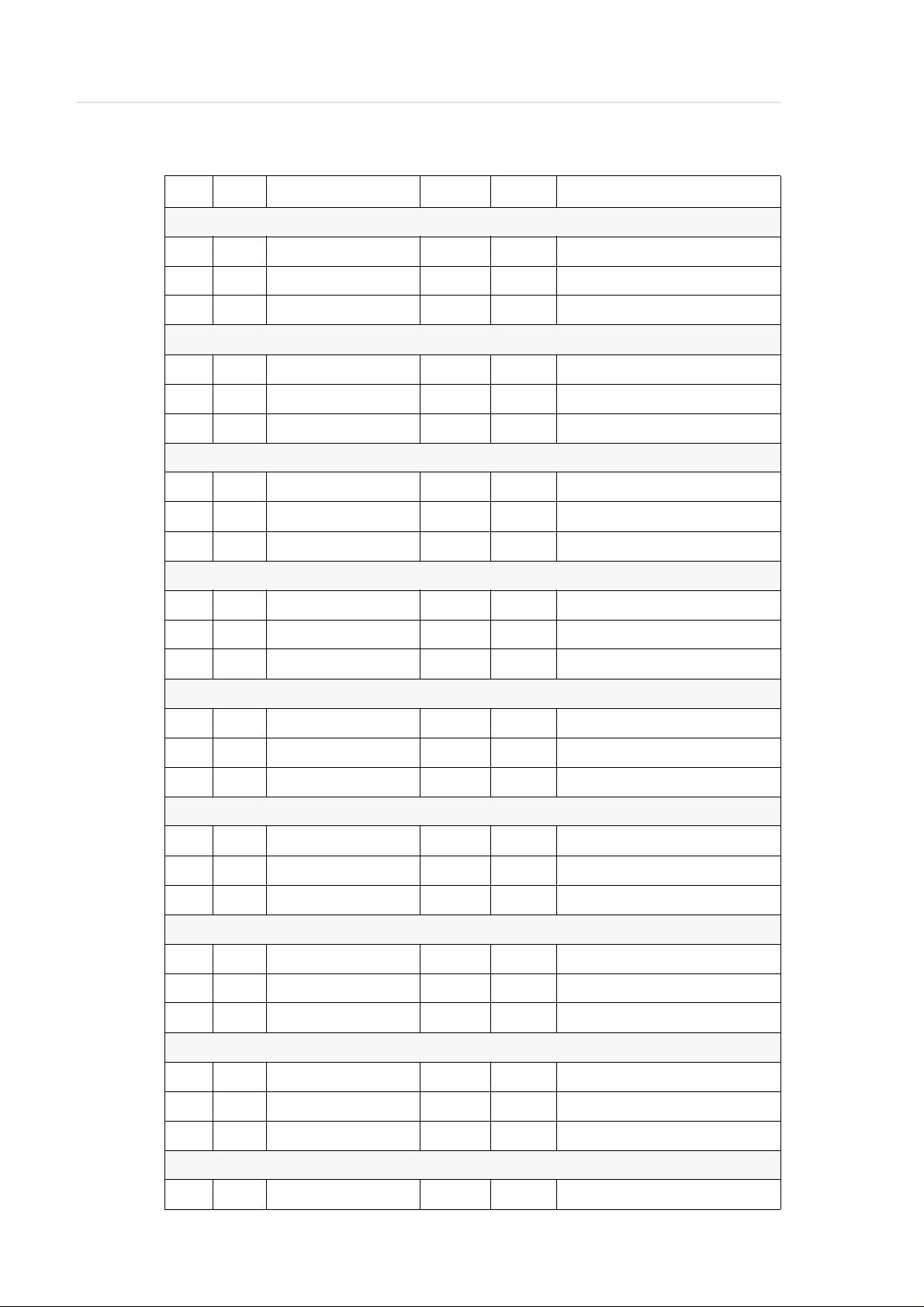

Assignment of the drive types

Same syntax as AMU configuration: eg D3, D8, D9, DO...

Use for each drivetype always the affiliated offsets.

Not used drive types you have to fill up with „-“.

82 177 LW1 -- drive type 1

83 178 LW2 -- drive type 2

84 179 LW3 -- drive type 3

85 180 LW4 -- drive type 4

86 181 LW5 -- drive type 5

87 182 LW6 -- drive type 6

88 183 LW7 -- drive type 7

Parameters 63 - 98:

All parameters FG_Z_O... are only for OD drives.

They specify the offset for

Offset gripper handling and barcode recognition for drive type 1 [1/100 mm]

89 187 FG_X_Put_LW[1] 0 positive x-val. = gripper forward

90 188 FG_Y_Put_LW[1] 0 positive y-value= gripper left (

91 189 FG_Z_Put_LW [1] 0 positivez-value = gripperup (

92 190 FG_X_Get_LW[1] 0 positive x-val. = gripper forward

93 191 FG_Z_Get_LW [1] 0 positive z-value = gripper up (

94 192 FG_Z_ODB_LW[1] 0 positive z-value = gripper up (

95 193 FG_Z_ODP_LW[1] 0 positive z-value = gripper up (

Put

and

Get

of side B.

(

Put

)

(

Get

)

OD side B)

OD B-side)

Put

Get

Get

Put

Put

)

)

)

96 194 FZ_Unload[1] N Y = gripper presses unload button

(

Get

),

N = gripper does not press the

unloadbutton

Seite 2 - 16 Software Backup AML/2 599 DOC E00 017-C

Page 26

Robot 2

Pos. Line Parameter Default Actual Information

Offset gripper handling and barcode recognition for drive type 2 [1/100 mm]

97 198 FG_X_Put_LW[2] 0 positive x-val. = gripper forward

(

Put

)

98 199 FG_Y_Put_LW[2] 0 positive y-value= gripper left(

99 200 FG_Z_Put_LW[2] 0 positive z-value = gripper up (

100 201 FG_X_Get_LW[2] 0 positive x-value (in 1/100 mm) =

gripper forward (

101 202 FG_Z_Get_LW[2] 0 positive z-value (in 1/100 mm) =

gripper up (

102 203 FG_Z_ODB_LW[2] 0 positive z-value (in 1/100 mm) =

gripper up (

103 204 FG_Z_ODP_LW [2] 0 positive z-value (in 1/100 mm) =

gripper up (put OD sideB)

104 205 FZ_Unload[2] N Y = gripper pressesunloadbutton

(

Get

),

N = gripperdoes not press the

unload button

Offset gripper handling and barcode recognition for drive unit type 3 [1/100 mm]

105 209 FG_X_Put_LW[3] 0 positive x-val. = gripper forward

(

Put

)

106 210 FG_Y_Put_LW[3] 0 positive y-value= gripper left (

107 211 FG_Z_Put_LW[3] 0 positivez-value = gripper up (

Get

Get

Get

)

)

OD side B)

Put

Put

Put

Put

)

)

)

)

108 212 FG_X_Get_LW[3] 0 positive x-val. = gripper forward

(

Get

)

109 213 FG_Z_Get_LW[3] 0 positive z-value = gripper up (

110 214 FG_Z_ODB_LW[3] 0 positive z-value = gripper up (

OD B-side)

111 215 FG_Z_ODP_LW[3] 0 positive z-value = gripper up (

OD B-side)

112 216 FZ_Unload[3] N Y = gripper pressesunloadbutton

Get

)

(

N = gripperdoes not press the

unload button

Get

Get

Put

)

599 DOC E00 017-C Software Backup AML/2 Seite 2 - 17

Page 27

Robot 2

Pos. Line Parameter Default Actual Information

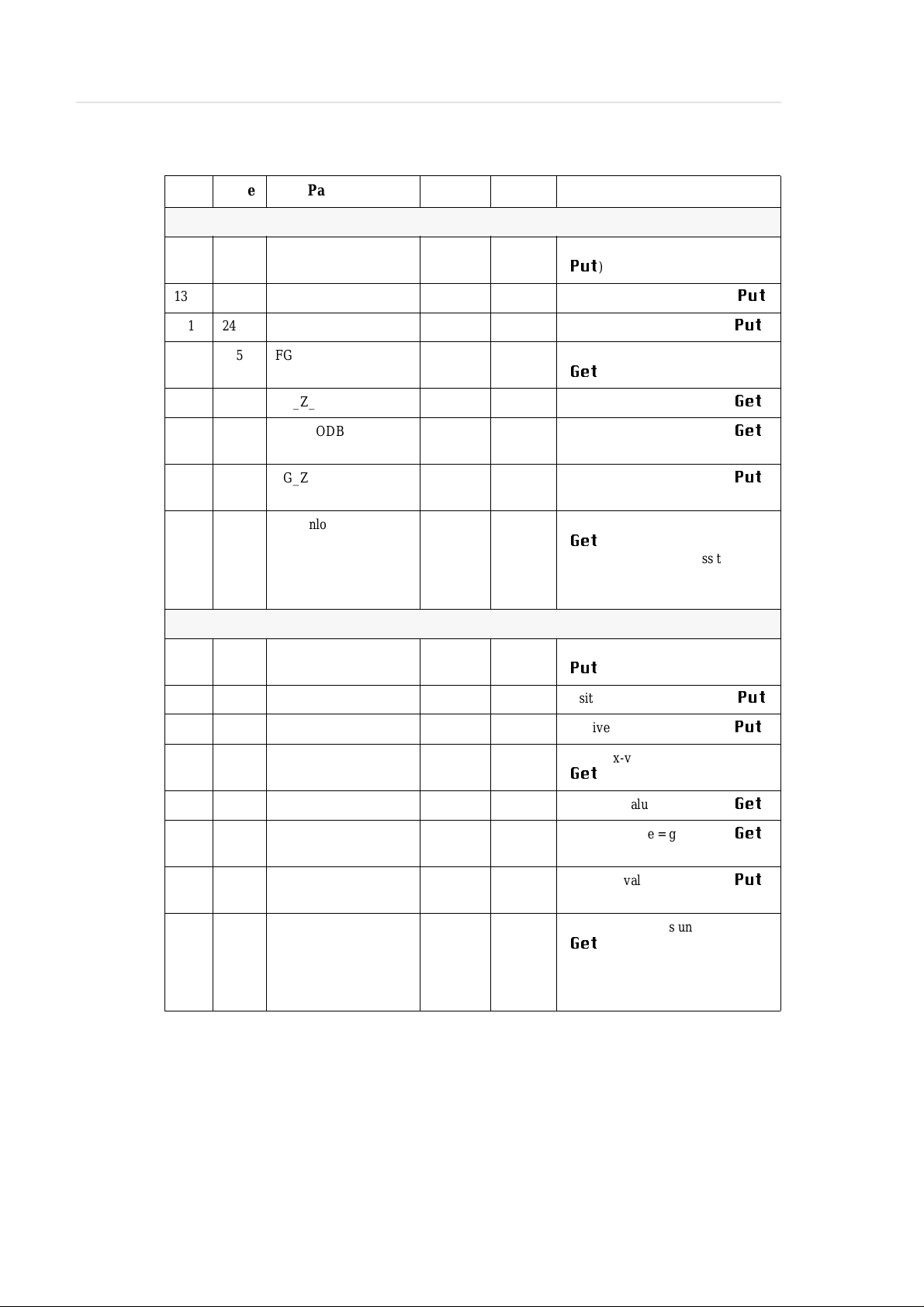

Offset gripper handling and barcode recognition for drive type 4 [1/100 mm]

113 220 FG_X_Put_LW[4] 0 positive x-val. = gripper forward

(

Put

)

114 221 FG_Y_Put_LW[4] 0 positive y-value = gripper left (

115 222 FG_Z_Put_LW[4] 0 positive z-value = gripper up (

116 223 FG_X_Get_LW[4] 0 positive x-val. = gripper forward

(

Get

)

117 224 FG_Z_Get_LW[4] 0 positive z-value = gripper up (

118 225 FG_Z_ODB_LW[4] 0 positive z-value= gripper up (

OD side B)

119 226 FG_Z_ODP_LW[4] 0 positive z-value = gripperup (

OD side B)

120 227 FZ_Unload[4] N Y = gripperpresses unload button

(

Get

),

N = gripper does not press the

unloadbutton

Offset gripper handling and barcode recognition for drive type 5 [1/100 mm]

121 231 FG_X_Put_LW[5] 0 positive x-val. = gripper forward

(

Put

)

122 232 FG_Y_Put_LW[5] 0 positive y-value = gripper left (

123 233 FG_Z_Put_LW[5] 0 positive z-value = gripper up (

Put

Put

Get

Get

Put

Put

Put

)

)

)

)

)

124 234 FG_X_Get_LW[5] 0 positive x-val. = gripper forward

Get

)

(

125 235 FG_Z_Get_LW[5] 0 positive z-value = gripper up (

126 236 FG_Z_ODB_LW[5] 0 positive z-value = gripper up (

OD side B)

127 237 FG_Z_ODP_LW[5] 0 positive z-value = gripperup (

OD side B)

128 238 FZ_Unload[5] N Y = gripperpresses unload button

(

Get

),

N = gripper does not press the

unloadbutton

Get

Get

Put

)

Seite 2 - 18 Software Backup AML/2 599 DOC E00 017-C

Page 28

Robot 2

Pos. Line Parameter Default Actual Information

Offset gripper handling and barcode recognition for drive type 6 [1/100 mm]

129 242 FG_X_Put_LW[6] 0 positive x-val. = gripper forward

(

Put

)

130 243 FG_Y_Put_LW[6] 0 positive y-value= gripper left (

131 244 FG_Z_Put_LW[6] 0 positivez-value = gripper up (

132 245 FG_X_Get_LW[6] 0 positive x-val. = gripper forward

(

Get

)

133 246 FG_Z_Get_LW[6] 0 positive z-value = gripper up (

134 247 FG_Z_ODB_LW[6] 0 positive z-value = gripper up (

OD side B)

135 248 FG_Z_ODP_LW[6] 0 positive z-value = gripper up (

OD side B)

136 249 FZ_Unload[6] N Y = gripper pressesunloadbutton

(

Get

),

N = gripperdoes not press the

unload button

Offset gripper handling and barcode recognition for drive type 7 [1/100 mm]

137 253 FG_X_Put_LW[7] 0 positive x-val. = gripper forward

(

Put

)

138 254 FG_Y_Put_LW[7] 0 positive y-value= gripper left (

139 255 FG_Z_Put_LW[7] 0 positivez-value = gripper up (

Put

Put

Get

Get

Put

Put

Put

)

)

)

)

)

140 256 FG_X_Get_LW[7] 0 positive x-val. = gripper forward

Get

)

(

141 257 FG_Z_Get_LW[7] 0 positive z-value = gripper up (

142 258 FG_Z_ODB_LW[7] 0 positive z-value = gripper up (

OD side B)

143 259 FG_Z_ODP_LW[7] 0 positive z-value = gripper up (

OD side B)

144 260 FZ_Unload[7] N Y = gripper pressesunloadbutton

(

Get

),

N = gripperdoes not press the

unload button

Get

Get

Put

)

599 DOC E00 017-C Software Backup AML/2 Seite 2 - 19

Page 29

Robot 2

Pos. Line Parameter Default Actual Information

Software limits (depending on your system)

145 264 G_X_MAXLIMIT 290000 Depends on the lengthof the system.

Handlingat the end of the system (I/

O unit) must be possible.You get

this value with the test program on

the PHG. value = x-axis + h-axis

146 265 G_X_MINLIMIT 25000 minimal x-coordinate of AM U

147 266 G_Z_MAXLIMIT 142000 maximal z-coordinate of AMU

G_Z_MAXLIMIT = V_max + Z_max

„MPRHO3.BIN“ P204

3. axis (v), 6. axis (z)

148 267 G_Z_MINLIMIT -4500 -4500 minimal z-coordinate of AMU

149 268 G_H_SAVEELBO 100 Maximalh-coordinate for a secure

arm change. You get this value with

thetestprogramonthePHG:media

in gripper, arm in straight position,

drive to the first obstacle (eg the I/O

unit).

Speed and Acceleration

150 272 D_V_HANDL 250.0 Slow speed for linear interpolation

(during handling):

min. 10 / max. 250

Diagnosis

151 276 G_PHGECHO 1 0 = PHG not connected,

normalworking conditions,

1 = PHG necessary,

tests possible,

2 = PHG connected,

only test mode,

stand-alone

3 = PHG connected,

only test mode,

stand-alone without gripper

Gripper offset (☞ gripper data sheet)

152 280 G_Y_BC 0 y-offset Scanner

153 282 G_X_TEACH 0 x-offset

154 283 G_Y_TEACH 0 y-offset

155 284 G_Z_TEACH 0 z-offset

Teach

Teach

Teach

156 286 G_X_OFFSET 0 gripper offset x-coordinate

(in 1/100 mm)

157 287 G_Y_OFFSET 0 gripper offset y-coordinate

(in 1/100 mm)

158 288 G_Z_OFFSET 0 gripper offset z-coordinate

(in 1/100 mm)

Seite 2 - 20 Software Backup AML/2 599 DOC E00 017-C

Page 30

Robot 2

Pos. Line Parameter Default Actual Information

159 292 G_PARALLEL 1 Grippertype:

0=forsmallmedias

(401 004 930)

1 = for large medias

(401 004 920)

2 = Universal Gripper

(401 002 235)

160 293 G_BCErrIgn 1 Reaction on barcode-reading error.

0 = cancel on error

1 = ignore error and continue

161 295 G_Z_BCOff_V 0 Vertical offset (difference between

label for side A and side B) for the

barcodelabel on optical disks

162 296 G_WarnAus 0 Messages from type „Warning“ will

not displayed in AMU-log when

G_WarnAus = 1

Timeout

163 300 D_TIME1 140 140 time-outQuadrotower (in sec)

164 301 D_TIME2 140 time-out I/O unit (in sec)

10 = I/O unit/B

165 302 D_WARTE_KEEP 60 time-out

166 306 D_Z_TO_V 0.27164 Relation betweenz- and v-axis.

Enter all values in mm and with 5

digits after the point.

Formulas:

max. z-axis = Z_max

(„MPRH3.BIN“P204, 3. axis)

max. v-axis = V_max

(„MPRHO3.BIN“ P204, 6. axis)

D_Z_TO_V =

for D2 medium handling:

D_Z_TO_V =

167 307 D_Y_Elb 0 only for scanner gripper:

positive y-coordinate (in mm) in

world coordinates

for drive gripper with medium

use for touchless movementontrack

(eg tower covering)

0 = normal processing

Keep

from drive

Z_max - 12

(Z_max - 12) + V_max

Z_max - 30

(Z_max - 30) + V_max

Coordinates (in mm) for special handling of drives on the start of track (only scanner gripper)

168 308 D_X_Col 0 x-coordinate for begin handlingarea

(only for special handlingin the

back area)

169 309 D_Y_Col 0 y-coordinate handling area (only for

specialhandling in the back area)

599 DOC E00 017-C Software Backup AML/2 Seite 2 - 21

Page 31

Robot 2

Pos. Line Parameter Default Actual Information

170 311 G_UMSCHLAG 1 Definition of the robot arm for front

handling:

0 = arm not defined

1=leftarm

2 = right arm

171 312 G_FIRSTOWER 1 Number of first connected Quadro

tower

Additional offset value for

172 316 FG_Y_PRaOff[1] 0 media 1 on rack

173 317 FG_Y_PIEOff[1] 0 media 1 on I/O unit

174 318 FG_Y_PRaOff[2] 0 media 2 on rack

175 319 FG_Y_PIEOff[2] 0 media 2 on I/O unit

176 320 FG_Y_PRaOff[3] 0 media 3 on rack

177 321 FG_Y_PIEOff[3] 0 media 3 on I/O unit

178 322 FG_Y_PRaOff[4] 0 media 4 on rack

179 323 FG_Y_PIEOff[4] 0 media 4 on I/O unit

180 324 FG_Y_PRaOff[5] 0 media 5 on rack

181 325 FG_Y_PIEOff[5] 0 media 5 on I/O unit

182 329 0 0 reserve

183 330 0 0 reserve

184 331 0 0 reserve

185 332 0 0 reserve

186 333 0 0 reserve

PUT

(positive y-value (1/100mm) = gripper left)

Check sum

187 337 G_SUMME 187 187 number of positions in this file

Seite 2 - 22 Software Backup AML/2 599 DOC E00 017-C

Page 32

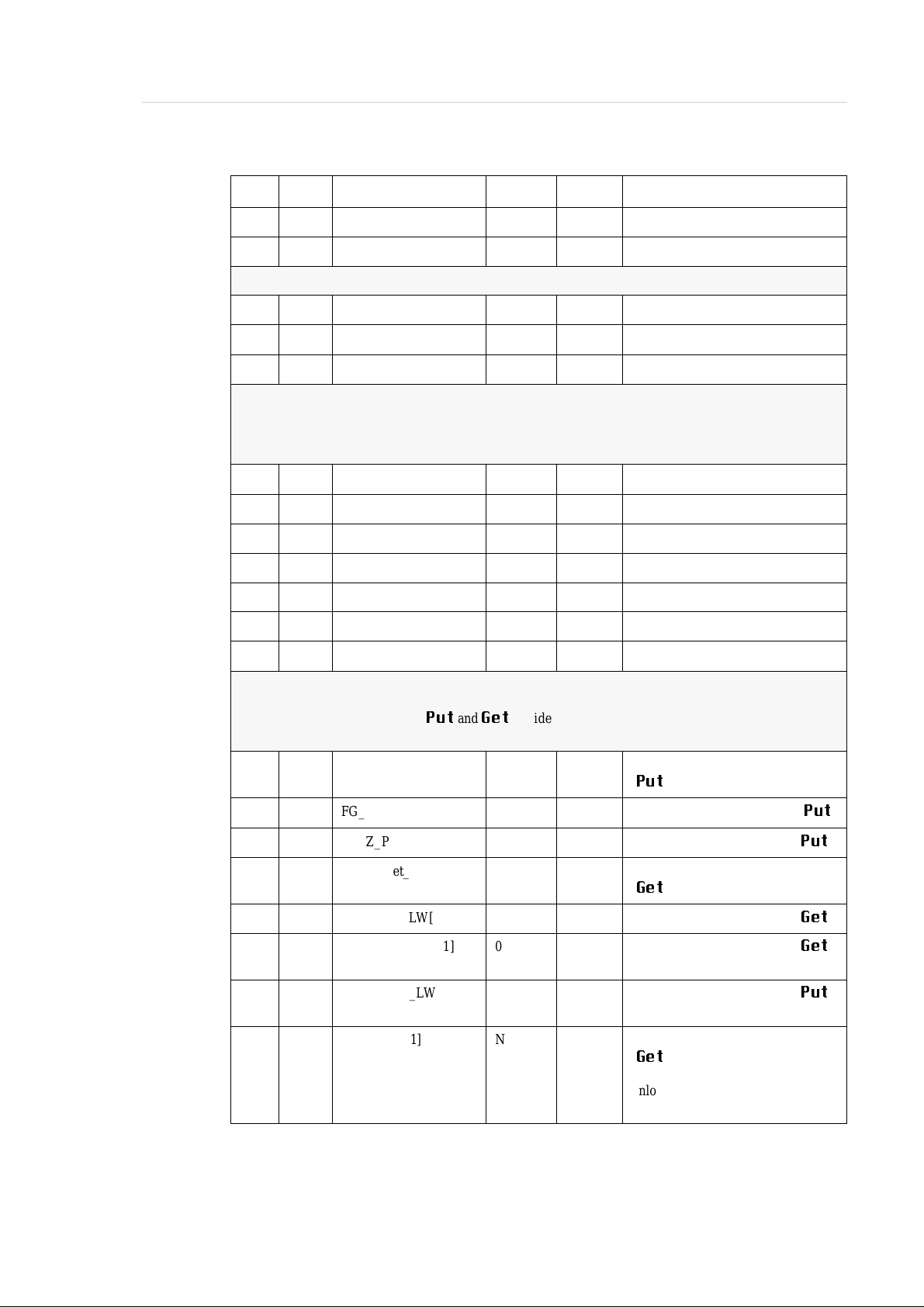

Parameter Files for Handling

3 Parameter Files for Handling

3.1 PLW34907.DAT , PLW34909.DAT

Correction values for drives, defined at pos. 82 - 88 in KONFIG.DAT with D7 0r

D9.

IBM 3490, Siemens 3590

Customer:

Installed:

Changes:

Line Parameter Default Actual Description

9 Unload allowed? 0 1= the command to the robot for press drive buttons

will canceled

0 = the command Unload will executed by the robot

10 D_X_ULU 0.0 X-offset for pressthe unload button[mm].

Positivex-value= gripper forward

11 D_Y_ULU 0.0 Y-offset for press the unload button [mm].

Positivey-value= gripper left

12 D_Z_ULU 0.0 Z-offset for press the unload button [mm].

Positive z-value = gripper up

13 D_X_ULU_GET 0.0 X-offset for the keep after an unload from the feed-

position[mm]. Positive x-value = gripper forward

14 D_Y_ULU_GET 0.0 Y-offset for the keep after an unload from the feed-

position [mm]. Positive y-value = gripper left

15 D_Z_ULU_GET 0.0 Z-offset for t he keep after an unload from the feed-

position[mm].

Positive z-value = gripper up

16 D_X_Touch_GET 0.0 X- offset for the search before the keep of the cart-

ridge, undependent from the GET position [mm]

17 D_Z_Touch_GET 0.0 positive or negative z-offsetfor the last search befor

theendofthekeepwaittime[mm]

0 = no other position for search

18 D_Z_Touch_GET2 0.0 positive or negative z-offsetfor the GET after a crash

on the drive [mm]

0 = no other position for GET

19 D_Z_OFFSET 0,0 Z-offsetfor endpos after GET [mm]

set to -50 if you use the device keeper

599 DOC E00 017-C Software Backup AML/2 Seite 3 - 1

Page 33

3.2 PLWDAT?.DAT

Correction values for drives, defined at pos. 82 - 88 in KONFIG.DAT

Customer:

Installed:

Changes:

Line Parameter Actual Explanation

9 D_X_PUT_2

Operating first unload button (not ready)

Automated button operating during

Get

will be defined in KONFIG.DAT

PLWDAT?.DAT

11 D_X_EJECT1 X-offset for press the 1st unload button [mm].

20 mm in front of the button

Positive x-value = gripper forward

12 D_Y_EJECT1 Y-offset for press the 1st unload button [mm].

Positive y-value = gripper left

13 D_Z_EJECT1 Z-offset for press the 1st unload button [mm].

Positive z-value = gripper up

Operating second unload button

15 G_Scnd_Btn allow

16 D_X_EJECT2 X-offset for press the 2nd unload button [mm].

17 D_Y_EJECT2 Y-offset for press the 2nd unload button[mm].

18 D_Z_EJECT2 Z-offset for press the 2nd unload button [mm].

Unload

0 = only one unload button

1=twounloadbuttons

20 mm in front of the button

Positive x-value = gripper forward

Positive y-value = gripper left

Positive z-value = gripper up

Command with 2 press buttons

Operating a flap of a drive

20 G_CL_U allowed automatic close flap with the

command

0 = no flap operating

1 = flap oerating

Put

21 D_X_CL_1 X-offset for gripper move to flap nut ( start

position)

22 D_Z_CL_1 Z-offset for gripper move to flap nut

23 D_Z_CL_2 distance for move in Z-axis for flap closing

Seite 3 - 2 Software Backup AML/2 599 DOC E00 017-C

Page 34

PLWDAT?.DAT

Line Parameter Actual Explanation

24 D_X_CL_2 X-offset for check the closed flap

25 D_Z_CL_3 Z-offset for check the closedflap

Put

27 D_X_PUT_Ra Reduced move in X-axis during Put after a get

Put

29 D_X_PUT_1 X-offset for the Put of the media in the drive

30 D_Z_PUT_1 Z-offset for the Put of the media in the drive

31 D_Vel_FctP1 Factor for speed for the first movement in the

32 D_Op_Fct Positionfor opening the gripper during the put

operating rack or shelf after a

operating

Get

on the drive

on the drive

use for small medias which not complete in the

gripper duringthe get

Put command

(relative position during the first movement)

(0 -1)

33 D_X_PUT_Ba X- offset for moving back for pushing with clo-

sed gripper

0 = no pushing

34 D_Z_PUT_Ba Z- offset for moving back for pushing with clo-

sed gripper

35 G_Close Command for close the gripper for Pushing

0 = pushingwith open gripper

1 0 pushing with closed gripper

36 G_Bgl Reserve

37 D_Vel_FctP2 Factor for speed during the media pushing in

the drive

(0.1 - 1.0)

38 D_Wait_Push Wait time after the pushing [sec],before the

grippergo back to the start position

40 D_X_GET_1 X-offset for first movement during

tion for media recognation)

41 D_Z_GET_1 Z-offset for first movement during

tion for media recognation)

42 D_Vel_FctG1 Factor for speed during the first

43 D_Wait_Get Wait time between media recognation and grip-

per closing

Get

Get

Get

handling

(Posi-

(Posi-

44 D_X_GET_2 X-offset for 2nd movement during

45 D_Z_GET_2 Z-offset for 2nd movement during

46 D_X_GET_3 X-offset for 3rd movement during

47 D_Z_GET_3 Z-offset for 3rd movement during

599 DOC E00 017-C Software Backup AML/2 Seite 3 - 3

Get

Get

Get

Get

Page 35

PLWDAT?.DAT

Line Parameter Actual Explanation

49 G_Detect Media recognation on the drive

0 = pusherwith slightly pressure

1 = pusherwithout pressure

50 G_GRP_DIS gripper postion during handling t he unload but-

ton

0 = pusherwith slightly pressure

gripper0°

1 = pusherwith full pressure

gripper0°

2 = pusherwithout pressure

gripper7°

3 = pusherwithout pressure

gripper0°

51 G_OpenGet Distance between the gripper jaws during

on the drive (especialy for drives unloading the

cartridge hanging down)

Valu es:

0 = default gripperopen (depended from media)

1= smallest grippergrap

2=medium gripper grap

3=maximum gripper grap

52 D_Beschl factor for acceleration during gripper handling

on the drive (for slow and soft handling)

values: 0.1 - 1.0 (1 = default and high acceleration)

GET

Startposition for Handling on drive (global move in the main program)

53 INIT Must not be changed

54 X x-coordinate

55 Y y-coordinate

56 Z z-coordinate

57 K gripper tilt angle

58 W drive angle to the covering

Seite 3 - 4 Software Backup AML/2 599 DOC E00 017-C

Page 36

Parameters of the Robot Amplifier

4 Parameters of the Robot Amplifier

Customer: Installed:

Changes:

Parameters of the Robot Amplifier (10 MHz) MOOG

Parameter Com. Axis 1 R 1 R 2 Axis 2 R 1 R 2

Drive Initialization

RHO Sample Period ms 20 20

ControllerType T161 212 T161 211

Motor ID M D313 L15 D313 L05

KT Nm/A 0.4 0.31

No Motor Poles 8 8

Current Limit A 15 6,5

max. Speed RPM

Parameter

Velocity Loop Gain Nm/

(Rad/s)

Integral Time Const. s SI 0.015 0.015

Position Loop Gain (Rad/s) /

Rad

2nd Ord. Filter Frequency Hz SW 250 250

2nd Filter Damping SZ 0.7 0.7

Acceleration Rad/s² SA 300000 300000

Maximum Speeds SL

AutomaticM ode Max. RPM 4520 3450 4600

Manual Mode Max. RPM 4520 3450 4600

Emerg. Braking Speed RPM 1 1

Torque Limit ST

Automatic Torque Limit Nm 2,5 1,6

Manual Torque Limit Nm 0,5 0.3

Emergency Torque Limit Nm 2,5 1,6

Emergency Decceleration Rad/s² SE 2000 2094 3141

Posn. Scaling Rev/10V SR 1 1

Ve l. Scaling RPM/10V SN 10000 10000

Options

CAN Direrctionof Rotation OD Plus Minus

Home Position Offset OO 0 0

CAN Position Scaling OR 16384

Information

You cannot enter any of the following factors!

Gear factor 131 100 100

Transmission mm/Rev,°/Rev 2,75 3,6 3,6

File name on diskette A1G131.

SP

SG

PRS

0.07

17

A1G100.

PRS

0.02

17

16384

A2G100.PRS

599 DOC E00 017-C Software Backup AML/2 Seite 4 - 1

Page 37

Parameters of the Robot Amplifier 16 MHz (BOSCH)

Parameter Com. Axis 1 R 1 R 2 Axis 2 R 1 R2

Software Version LV B80860-001 B80860-001

User Version C 1 2

ControllerType SM 4,7/20-GC SM 3,5/8-GC

Motor ID ms SM sg-ax1.016.060 sg-ax1.006.072

Following Error SF 400 400

StaticLoop Error SS Disabled (1023) Disabled (1023)

Signal on Tp10 OTA 3 3

Signal on Tp3 OTB 0 0

Input Offset OI (0.0) (0.0)

Can Position Scaling OR Revs/16384 Revs/16384

Actual Pos. Offset OO (0.0) (0.0)

Pos. CompensatorType OC Non-Decimated

Ve l. Compensator Type OC 2nd ord. filter 2nd ord. filter

ReferenceSource OR CAN CAN

Can Direction Flg OD Plus Minus

No Motor Poles SM 8 8

Calc. Factor Kr SM 3.419E-1 2.620E-1

Motor Current Limit SM 1.498E 1 6.480E 0

Peak Torque

Velocity Scaling SN 1.000E 4 1.000E 4

Position Scaling SR 1.000E 0 1.000E 0

Velocity Loop Gain SP 6.999E-2 1.999E-2

Ti s SI 1.440E-2 1.440E-2

Position Loop Gain SG 1.690E 1 1.690E 1

Torque Filter Freq. Hz SW 2.499E 2 2.499E 2

Torque Filter Zeta SZ 7.000E-1 7.000E-1

Emergency Deceleration SE 1.983E 3 2.080E 3 3.136E 3

Auto. Current Limit A

Man.CurrentLimit A

Emer. Current Limit A

Auto. Mode Max RPM RPM

Man.Mode Max RPM RPM

Emer.Braking Speed RPM

R2ph SM 4.4950E 0 1.3900E 1

L2ph SM

Maximum Motor RPM LM 8.000E 3 1.050E 4

Motor Rated RPM LM 4.900E 3 4.900E 3

Comm. Cycle Period ms SC 1.999E-2 1.999E-2

Pos’n Limit Switches OL

CClkwiseLimit Pos’n OL 99999999 99999999

ClkwiseLimit Pos’n OL 99999999 99999999

Thermal Protection OW Disabled Disabled

Gear factor 131 100 100

Transmission °/RPM

MCO Jumper L2-L3 L1-L2

File Name on Diskette

ST 7.095E 0 5.852E 0

ST

ST

1.387E 0 1.083E0

7.095E 0 5.852E0

SL 4.519E 3 3.450E 3 4.599E 3

4.519E 3 3.450E 3 4.599E 3

SL

SL

1.000E 0 1.000E0

2,75 3,6 3,6

BA1G131.

PRS

BA1G100.

PRS

Non-Decimated

BA2G100.PRS

Seite 4 - 2 Software Backup AML/2 599 DOC E00 017-C

Page 38

Parameters of the Robot Amplifier (10 MHz) MOOG

Parameter Com. Axis 3 R 1 R 2 Axis 4 R 1 R 2

Drive Initialization

RHO Sample Period ms 20 20

ControllerType T161 211 T161 211

MotorID M D312 L05 D3 12 L05

KT Nm/A 0.26 0.26

No Motor Poles 8 8

Current Limit A 2.6 2.6

max.Speed RPM

Parameter

Velocity Loop Gain Nm/

(Rad/s)

IntegralTime Const. s SI 0.02 0.02

Position Loop Gain (Rad/s) /

Rad

2nd Ord. Filter Frequency Hz SW 250 250

2nd Filter Damping SZ 0.7 0.7

Acceleration Rad/s² SA 300000 300000

Maximum Speeds SL

Automatic Mode Max. RPM 8050 4059

Manual Mode Max. RPM 1725 846

Emerg. BrakingSpeed RPM 100 1

Torque Limit ST

AutomaticTorque Limit Nm 0.585 0.585

Manual Torque Limit Nm 0,15 0.1

Emergency Torque Limit Nm 0,585 0,585

EmergencyDecceleration Rad/s² SE 10470 286

Posn. Scaling Rev/10V SR 1 1

Vel. Scaling RPM/10V SN 10000 10000

Options

CAN Direrction of Rotation OD Plus Plus

Home Position Offset OO 0 0

CAN Position Scaling OR 8192

Information

You cannot enter any of the followingfactors!

Gear factor 60 29,41

Transmission mm/Rev, °/Rev 6 12,24

File name on diskette A3G60.PRS A4G29.PRS

SP

SG

0.006

17

0.0055

17

16384

599 DOC E00 017-C Software Backup AML/2 Seite 4 - 3

Page 39

Parameters of the Robot Amplifier 16 MHz (BOSCH)

Parameter Com. Axis 3 R 1 R 2 Axis 4 R 1 R2

Software Version LV B80860-001 B80860-001

User Version C 3 4

Controller Type SM 3,5/8-GC SM 3,5/8-GC

Motor ID ms SM sg-x0.002.091 sg-x0.002.091

Following Error SF 400 400

Static Loop Error SS Disabled (1023) Disabled (1023)

Signal on Tp10 OTA 3 3

Signal on Tp3 OTB 0 0

Input Offset OI (0.0) (0.0)

Can Position Scaling OR Revs/8192 Revs/16384

Actual Pos. Offset OO (0.0) (0.0)

Pos. Compensator Type OC Non-Decimated

Vel. Compensator Type OC 2nd ord. filter 2nd ord. filter

Reference Source OR CAN CAN

Can Direction Flg OD Plus Plus

No Motor Poles SM 8 8

Calc. Factor Kr SM 2.520E-1 2.520E-1

Motor Current Limit SM 2.600E 0 2.600E0

Peak Torque

Velocity Scaling SN 1.000E 4 1.000E 4

PositionScaling SR 1.000E 0 1.000E 0

Velocity Loop Gain SP 5.999E-3 5.499E-3

Ti s SI 1.980E-2 1.980E-2

PositionLoop Gain SG 1.690E 1 1.690E 1

Torque Filter Freq. Hz SW 2.499E 2 2.499E2

Torque Filter Zeta SZ 7.000E-1 7.000E-1

Emergency Deceleration SE 1.046E 4 2.560E 2

Auto. Current Limit A

Man. Curr ent Limit A

Emer.Current Limit A

Auto. Mode Max RPM RPM

Man. Mode Max RPM RPM

Emer.Braking Speed RPM

R2ph SM 5.039E 1 5.039E1

L2ph SM

Maximum Motor RPM LM 1.199E 4 1.199E 4

Motor Rated RPM LM

Comm. Cycle Period ms SC 1.999E-2 1.999E-2

Pos’n Limit Switches OL

CClkwise Limit Pos’n OL 99999999 99999999

Clkwise Limit Pos’n OL 99999999 99999999

Thermal Protection OW Disabled Disabled

Gear factor 60 29,41

Transmission °/RPM

MCO Jumper L1-L2 L1-L2

File name on diskette BA3G60.PRS BA4G29.PRS

ST 2.600E 0 2.600E 0

ST

ST

3.939E-1 3.939E-1

2.600E 0 2.600E 0

SL 8.050E 3 4.059E 3

SL

SL

1.725E 3 8.460E 2

1.000E 2 1.000E 0

6

Non-Decimated

12.24

Seite 4 - 4 Software Backup AML/2 599 DOC E00 017-C

Page 40

Parameter of the Robot Amplifier (10 MHz) MOOG

Parameter Com. Axis 5 R 1 R 2 Axis 6 R 1 R 2

Drive Initialization

RHO Sample Period ms 20 20

ControllerType T161 213 T161 213

MotorID M D315 L10 D3 14 L20

KT Nm/A 0.59 0.62

No Motor Poles 12 12

Current Limit A 25 306

max. Speed RPM 5800

Parameter

Velocity Loop Gain Nm/

(Rad/s)

IntegralTime Const. s SI 0.1 0.015

Position Loop Gain (Rad/s) /

Rad

2nd Ord. Filter Frequency Hz SW 250 250

2nd Filter Damping SZ 0.7 0.7

Acceleration Rad/s² SA 300000 300000

Maximum Speeds SL

Automatic Mode Max. RPM 3763 3191

Manual Mode Max. RPM 251 319

Emerg. BrakingSpeed RPM 1 100

Torque Limit ST

AutomaticTorque Limit Nm 11.25 16.1

Manual Torque Limit Nm 2 6.5

Emergency Torque Limit Nm 11.25 16.1

EmergencyDecceleration Rad/s² SE 459 1164

Posn. Scaling Rev/10V SR 1 1

Vel. Scaling RPM/10V SN 10000 10000

Options

CAN Direrction of Rotation OD Minus Minus

Home Position Offset OO 0 0

CAN Position Scaling OR 16384

Information

You cannot enter any of the followingfactors!

Gear factor 8 9,25

Transmission mm/Rev, °/Rev 27,5 21,6

File name on diskette A5G8.PRS A6G9.PRS

SP

SG

0.2

17

0.15

16384

17

599 DOC E00 017-C Software Backup AML/2 Seite 4 - 5

Page 41

Parameter of the Robot Amplifier 16 MHz (BOSCH)

Parameter Com. Axis 5 R 1 R 2 Axis 6 R 1 R2

Software Version LV B80860-002 B80860-001

User Version C 5 6

ControllerType SM 6,5/30-GC16 SM 3,5/8-GC

Motor ID ms SM sg-a3.055.049 sg-x0.002.091

FollowingError SF Disabled Disabled

StaticLoop Error SS Disabled (1023) Disabled (1023)

Signal on Tp10 OTA 3 3

Signal on Tp3 OTB 1 1

Input Offset OI (0.0) (0.0)

Can Position Scaling OR Revs/16384 Revs/16384

Actual Pos. Offset OO (0.0) (0.0)

Pos. CompensatorType OC Non-Decimated

Ve l. Compensator Type OC 2nd ord. filter 2nd ord. filter

ReferenceSource OR CAN CAN

Can Direction Flg OD Minus Minus

No Motor Poles SM 12 12

Calc. Factor Kr SM 4.500E-1 5.360E-1

Motor Current Limit SM 2.996E 1 2.996E 1

Peak Torque 1.350E 1 1.610E1

Velocity Scaling SN 1.000E 4 1.000E 4

Position Scaling SR 1.000E 0 1.000E 0

Velocity Loop Gain SP 1.999E-2 1.499E-1

Ti s SI 1.000E-1 1.440E-2

Position Loop Gain SG 1.690E 1 1.690E 1

Torque Filter Freq. Hz SW 2.499E 2 2.499E 2

Torque Filter Zeta SZ 7.000E-1 7.000E-1

Emergency Deceleration SE 4.480E 2 1.151E 3

Auto. Current Limit A

Man.CurrentLimit A

Emer. Current Limit A

Auto. Mode Max RPM RPM

Man.Mode Max RPM RPM

Emer.Braking Speed RPM

R2ph SM 8.549E-1 5.023E 0

L2ph SM 4.105E 0 5.500E 0

Maximum Motor RPM LM 1 .199E 4 3.799E 3

Motor Rated RPM LM 4.900E 3 4.900E 3

Comm. Cycle Period ms SC 6.000E 3 1.999E-2

Pos’n Limit Switches OL Diabled Disabled

CClkwiseLimit Pos’n OL 99999999 99999999

ClkwiseLimit Pos’n OL 99999999 99999999

Thermal Protection OW Disabled Disabled

Gear factor 8 9,25

Transmission °/RPM

MCO Jumper L2-L3 L1-L2

File name on diskette BA5G8.PRS BA6G9.PRS

ST 2.736E 1 2.975E 1

ST

ST

4.891E 0 1.198E1

2.736E 1 2.975E1

SL 3.762E 3 3.190E 3

SL

SL

2.509E 2 3.189E2

6.000E 1 1.000E2

27,56 21,6

Non-Decimated

Seite 4 - 6 Software Backup AML/2 599 DOC E00 017-C

Page 42

Machine Parameters RHO3 (robot)

5 Machine Parameters RHO3 (robot)

AML/2 robot for the operating system from TO02F/TO03G/TO05L)

Customer:

Robot-Nr. :

Installed:

Changes:

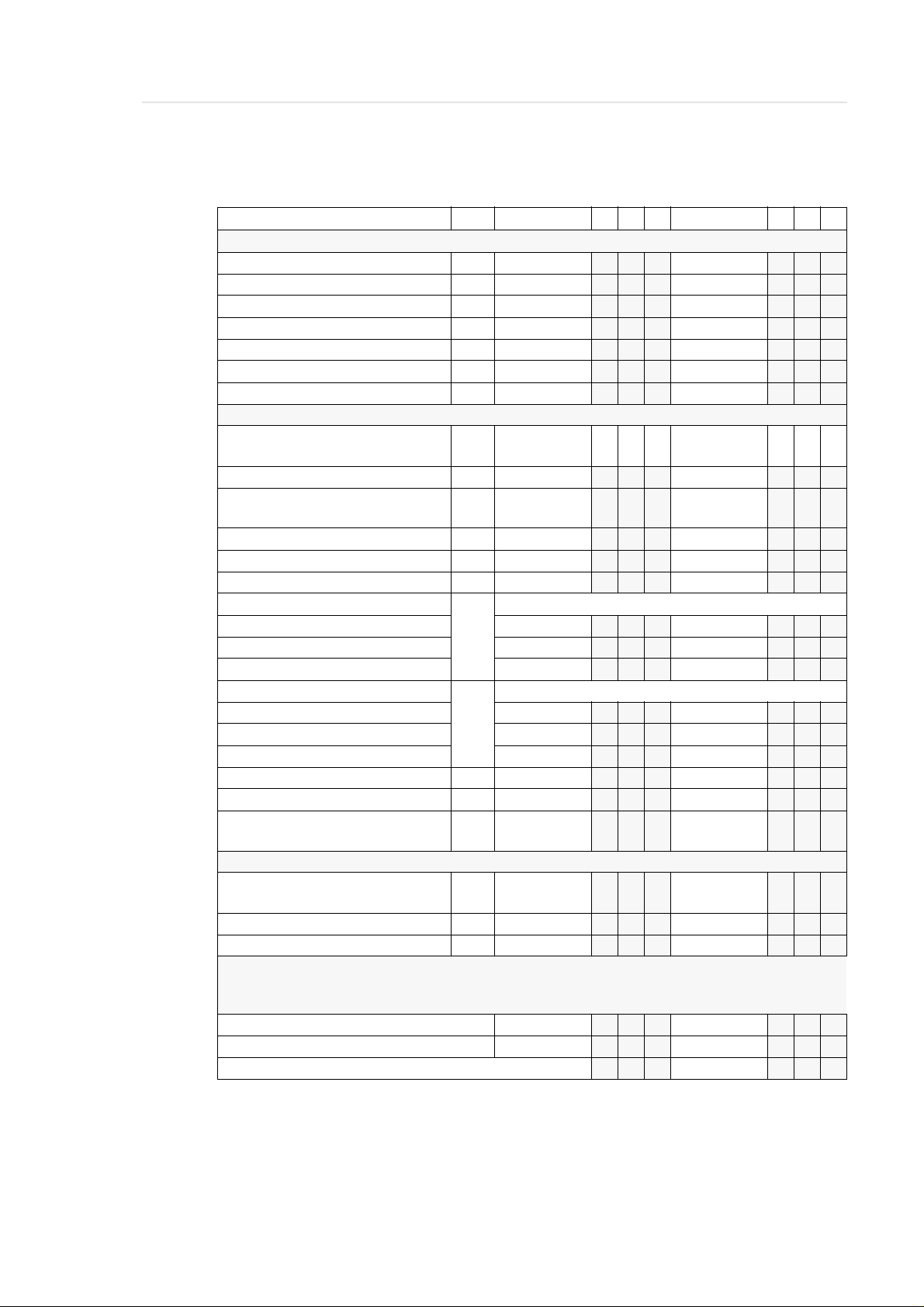

Parameter Description Default Robot 1 Robot 2

P000 GENERAL SYSTEM PARAMETERS

P010 SELECT LANGUAGE German (0),

English (1)

P013 Timer PIC 250

T2 1000 3000 3000

P100 S P E E D S

P109 1. red. ref. pkt speed in °/s or m m/s

A_1 4.8 4.8 4.8

A_2 6.4

A_3 10.0

A_4 20.1

A_5 50.0

A_6 50.0

P110 2. red. ref. pkt speed in °/s or m m/s

A_1 0.97 0.97 0.97

A_2 1.28

A_3 2.0

A_4 2.0

A_5 10.0

A_6 10.0

P200 POSITIONS

P202 SOFTWARE LIMIT SWITCH

POSITIVE WC in ° or mm

X_K 800.10 800.10 800.10

Y_K 800.10

Z_K 410.00

C_K 125.10

H_K 99999.90

V_K 9999.99

0

6.4 6.4

10.0 10.0

20.1 20.1

50.0 50.0

50.0 50.0

1.28 1.28

2.0 2.0

2.0 2.0

10.0 10.0

10.0 10.0

800.10 800.10

410.00 410.00

125.10 125.10

599 DOC E00 017-C Software Backup AML/2 Seite 5 - 1

Page 43

Parameter Description De fault Robot 1 Robot 2

P203 SOFTWARE LIMIT SWITCH

NEGAT IVE WC in ° or mm

X_K -550.0 -550.0 -550.0

Y_K -800.10

Z_K -0.10

C_K -125.10

H_K -99999.9

V_K -9999.99

P204 SOFTWARE LIMIT SWITCH

POSITIVE JC in ° or mm

A_1 120.10 120.10 120.10

A_2 150.10

A_3 410.00

A_4 125.10

A_5 99999.90

A_6 9999.99

P205 SOFTWARE LIMIT SWITCH

NEGAT IVE JC in ° or mm

A_1 -120.10 -120.10 -120.10

A_2 -150.10

A_3 -0.10

A_4 -125.10

A_5 -99999.90

A_6 -9999.99

P207 R E FERENCE POINT POSITION

in ° or mm

A_1 0.00

A_2 0.00

A_3 395.00

A_4 0.00

A_5 0.00

A_6 0.00

P208 R E FERENCE POINT OFFSET

in ° or mm

A_1 0.00 0.00 0.00

A_2 0.00

A_3 0.00

A_4 0.00

A_5 0.00

A_6 0.00

P300 KIN.-SUBJ.

SYSTEM-PARAMETERS

-800.10 -800.10

-0.10 -0.10

-125.10 -125.10

150.10 150.10

410.00 410.00

125.10 125.10

-150.10 -150.10

-0.10 -0.10

-125.10 -125.10

0.00 0.00

0.00 0.00

0.00 0.00

0.00 0.00

Seite 5 - 2 Software Backup AML/2 599 DOC E00 017-C

Page 44

Parameter Description Default Robot 1 Robot 2

P307 LENGTH OF AXIS in mm,

DEVIATION OF ANGLES

in mm/100 mm

axis length 1 430.00

axis length 2 370.00

axis length 3 215.00

axis length 4 10000.00

axis length 5 0.00

215.00 215.00

10000.00 10000.00

0.00 0.00

P310 OFFSET OF WORL D COORDINATE

SYSTEM in mm

X_0 0.00

Y_0 0.00

Z_0 0.00

0.00 0.00

01_0 0. 00

02_0 0. 00

03_0 0. 00

0.00 0.00

0.00 0.00

P400 MEASURING SYSTEM

PARAMETERS

P401 CONSTRUCTION OF MEASURING

SYSTEM BOARD

ROBI_1

Axis1

MS-CONVERSION FACTOR

5961.96

(Gearfactor 131)

MS-CONVERSION FACTOR

4551.11

(Gearfactor 100)

P402 REFERE NCING DIRECTION

-1 = negative

0 = no referencing

+1 = positive

ROBI_1

A_1 1

A_2 1

A_3 1

1 1

A_4 -1

A_5 -1

A_6 -1

-1 -1

-1 -1

599 DOC E00 017-C Software Backup AML/2 Seite 5 - 3

Page 45

Communication Parameter Rho Control - Barcode Read System

MODE

, , , , , (Default settings read/write SER_2)

Protocol 4 7 7

Interface 1 1 1

Baudrate 9600 9600 9600

Stop-Bitnumber 1.0 1.0 2.0

Parity (0, 1, 2) 2 (even) 2 (even) 0 (no)

Wordlength 7 7 7

Soft_Hardw. hsk 1 1 1

Timeout read 5000 20000 20000

Timeout write 5000 20000 20000

MODE

9

MODE

1

4

Scanner

(Default)

Vision

(Rel.

1.7.2)

Vision

(Rel. 1.5,

1.6)

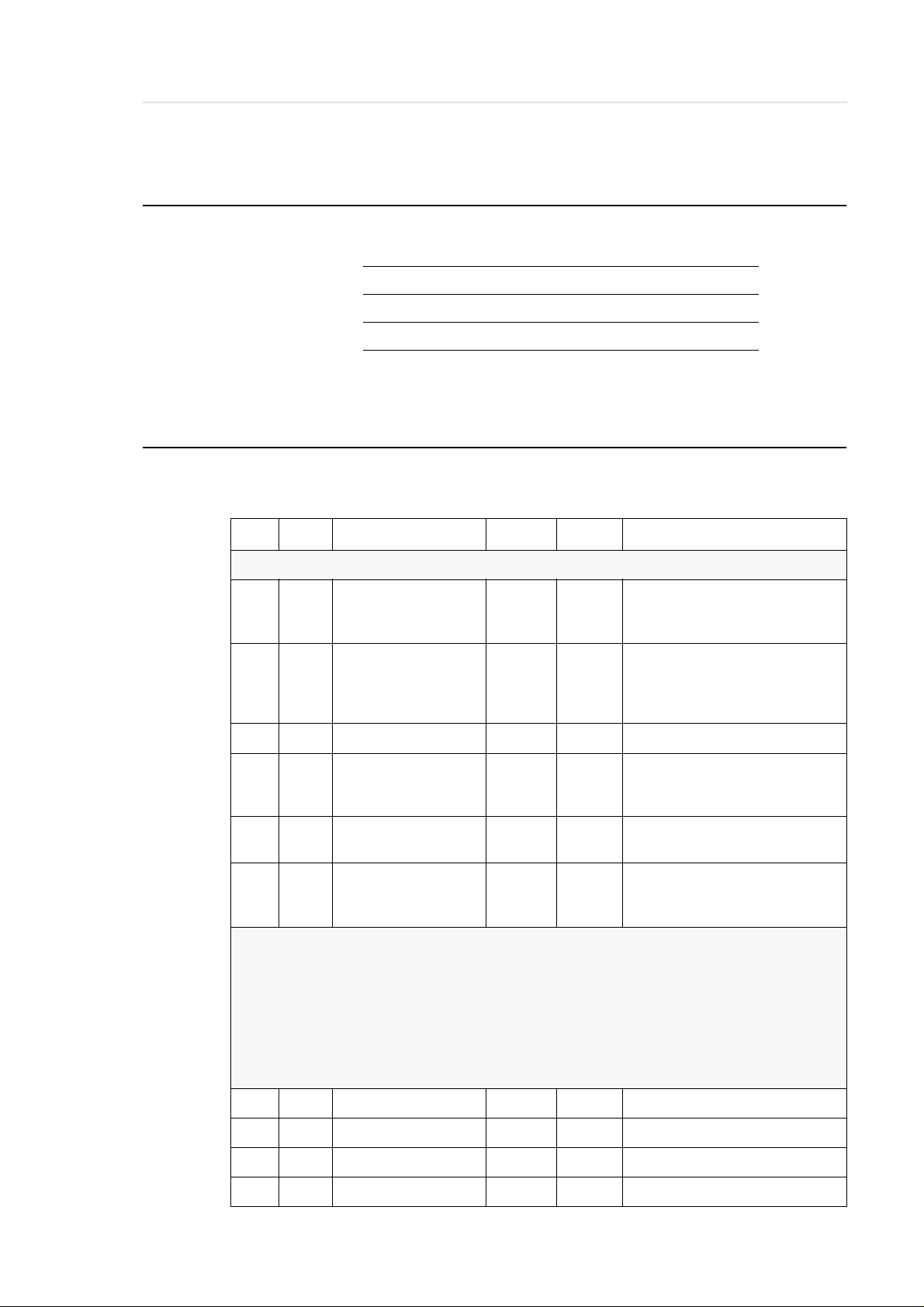

Communication Parameter Rho Control - AMU

Robot 1 Robot 2

1 1

9600 9600

7 7

1 1

MODE

, , , , , (Default settings read/write SER_1)

MODE

9

MODE

1

3

Default Robot 1 Robot 2

Protocol 8 8 8

Interface 0

Baudrate 9600

Stop-Bitnumber 1.0

Parity (0, 1, 2) 2 (even)

Wordlength 8

Soft_Hardw. hsk 1

0 0

1.0 1.0

2(even) 2(even)

8 8

1 1

Seite 5 - 4 Software Backup AML/2 599 DOC E00 017-C

Page 46

Configuration File for Tower Control AML/2

6 Configuration File for Tower Control AML/2

KONFIG.DAT Version 2.2.0

Customer:

Tower Control-No.:

Installed:

Changes:

Pos Line Parameter Default 1 2 3 Description

1 25 T_ADR_RHO O02 Logical address of c ontrol unit

from the AMU-configuration

(e.g. O02).

2 26 T_ADR_AMU A01

3 27 G_Adr_QT1 1 Number of 1st Quadro tower of

4 28 G_Adr_QT2 0 Number of 2nd Quadro tower of

5 29 G_Adr_QT3 0 Number of 3rd Quadro tower of

6-9 Reserve 0

10 34 D_Vers_HT1 -55.000 Offset of the 1st main tower of

11 35 D_Vers_NT1 85.000 Offset of the 1st auxillary tower

12 36 D_Vers_HT2 -55.000 Offset of the 2nd main tower of

13 37 D_Vers_NT2 85.000 Offset of the 2nd auxillarytower

14 38 D_Vers_HT3 -55.000 Offset of the 3rd main tower of

15 39 D_Vers_NT3 85.000 Offset of the 3rd auxillary tower

16 40 D_TIME1 180.0 Max. wait time for robot to

17 41 D_TIME2 60.0

18 42 D_Speed 0.9

A01 A01 A01 Address AMU.

this AMU (same number as at

Graphical Configuration ).

this AMU (same number as at

Graphical Configuration ).

0 = no 2nd Quadro tower

this AMU (same number as at

Graphical Configuration ).

0 = no 3rd Quadro tower

0 0 0

the Q uadro tower. Please use the

test program for adjusting.

of the Quadro tower. Please use

the test program for adjusting.

the Q uadro tower. Please use the

test program for adjusting.

of the Quadro tower. Please use

the test program for adjusting.

the Q uadro tower. Please use the

test program for adjusting.

of the Quadro tower. Please use

the test program for adjusting.

access the turned tower.

60.0 60.0 60.0 Max. wait time for robot to

release the tower.

0.9 0.9 0.9 Max. speed of the Quadro t ower.

599 DOC E00 017-C Software Backup AML/2 Seite 6 - 1

Page 47

Pos Line Parameter Default 1 2 3 Description

19 43 G_Anz_Robo 1 Number of robots in the system

(1 or 2)

20 44 G_PHG_Echo 1 0: PHG not c onnected, normal

working conditions with AMU,

test possible

1: PHG necessary, test possible,

AMU necessary

2: Stand-olone test with PHG

Seite 6 - 2 Software Backup AML/2 599 DOC E00 017-C

Page 48

Machine Parameter RHO3 (tower)

7 Machine Parameter RHO3 (tower)

AML/2 tower for the operating system from TO02F/TO03G/TO05L

Customer:

Installed:

Changes:

Parameter Description Default

P000 General System Parameters

P001 Number of Kinematics 3

P010 Select language

German (0), English (1)

0

Control1Control2Control

Communication P arameter Rho Control - AMU

MODE

, , , , , (default settings read/write SER_1)

MODE

9

MODE

1

3

Default Control 1 Control 2 Control 3

Protocol 8 8 8 8

Interface 0

Baudrate 9600

Stop-Bit number 1.0

0 0 0

1.0 1.0 1.0

3

Parity(0,1,2) 2(even)

Wordlength 8

Soft_Hardw. hsk 1

599 DOC E00 017-C Software Backup AML/2 Seite 7 - 1

2(even) 2(even) 2 (even)

8 8 8

1 1 1

Page 49

Seite 7 - 2 Software Backup AML/2 599 DOC E00 017-C

Page 50

Parameters of the Tower Amplifier

8 Parameters of the Tower Amplifier

Customer: Installed:

Changes:

Parameter of the Tower Amplifier (10 MHz) MOOG

Parameter Com. Main tower 1 2 3 Aux. tower 1 2 3

Drive Initialization

RHO Sample Period ms

Controller Type

Motor ID

M

KT Nm/A 0.59 0.59

No Motor Poles

Current Limit A

max. Speed RPM 5800 5800

Parameter

Velocity Loop Gain Nm/

SP

(Rad/s)

Integral Time Const. s

Position Loop Gain (Rad/s) /

SI

SG

Rad

2nd Ord. Filter Frequency Hz

2nd Filter Damping

Acceleration Rad/s²

Maximum Speeds

SW

SZ

SA

SL

AutomaticModeMax. RPM 4145 3915

Manual Mode Max. RPM

Emerg. Braking Speed RPM

Torque Limit

ST

Automatic Torque Limit Nm

Manual Torque Limit Nm

Emergency Torque Limit Nm 8 4

Emergency Decceleration Rad/s²

Posn. Scaling Rev/10V

Vel. Scaling RPM/

SE

SR

SN

10V

Options

CAN Direrction of Rota-

OD

tion

Home Position Offset OO 0 0

CAN Position Scaling OR

Information

20 20

T161 213 T161 213

D315 L10

12

25 25

0.4 0.2

0.025

6

250

0.7

300000

2303 2175

1 1

8 4

4 2.3

2097

1

10000

Minus

16384 16384

D315L10

12

0.025

6

250

0.7

300000

1981

1

10000

Minus

You cannot enter any of the followingfactors!

Gear factor

600,75 567.375

Transmission mm /Rev, °/Rev

File name on diskette

599 DOC E00 017-C Software Backup AML/2 Seite 8 - 1

HTURM.PRS NTURM.PRS

Page 51

Parameter of the Tower Amplifier 16 MHz (BOSCH)

Parameter Com Main tower 1 2 3 Aux. tower 1 2 3

Software Version LV B80860-002 B80860-002

User Version C 1 2

Controller Type SM 6,5/30-GC16 SM 6,5/30-GC16

Motor ID SM sg-a3.055.049 sg-a3.055.049

Following Error SF Disabled Disabled

StaticLoop Error SS Disabled Disabled

Signal on Tp10 OTA 3 3

Signal on Tp3 OTB 1 1

Input Offset OI (0.0) (0.0)

Can Position Scaling OR Revs/16384 Revs/16384

Actual Pos. Offset OO (0.0) (0.0)

Pos. CompensatorType OC Non-Decimated Non-Decimated

Vel. Compensator Type OC 2nd ord. filter 2nd ord. filter

Reference Source OR CAN CAN

Can Direction Flg OD Minus Mi nus

No Motor Poles SM 12 12

Calc. Factor Kr SM 4.500E-1 4.500E-1

Motor Current Limit SM 2.996E 1 2.996E 1

Peak Torque 1.350E 1 1.350E 1

Velocity Scaling SN 1.000E 4 1.000E 4

PositionScaling SR 1.000E 0 1.000E 0

VelocityLoop Gain SP 3.999E-1 1.999E-1

Ti s SI 2.500E-2

Position Loop Gain SG 6.000E 0 6.000E 0

Torque Filter Freq. Hz SW 2.499E 2 2.499E 2

Torque Filter Zeta SZ 7.000E-1 7.000E-1

Emergency Deceleration SE 2.080E 3 1.951E 3

Auto. Current Li mit A

Man. Curr ent Limit A

Emer. Current Limit A

Auto. Mode Max RPM RPM

Man. Mode Max RPM R PM

Emer.Braking Speed RPM

R2ph SM 8.699E-1 8.599E-1

L2ph SM 4.105E 0 4.105E 0

Maximum Motor RPM LM 6.000E 3 6.000E 3

Motor Rated RPM LM 4.900E 3 4.900E 3

Comm. Cycle Pe riod SC 1.999E-2 1.999E-2

Pos’n Limit Switches OL Disabled Disabled

CClkwise Limit Pos’n OL 99999999 99999999

Clkwise Limit Pos’n OL 99999999 99999999

ThermalProtection OW Disabled Disabled

Gear factor / Tansmission 600.75 567.375

MCO Jumper L2-L3 L2-L3

File name on diskette BHTURM.PRS BNTURM.PRS

ST

ST 8.873E 0 5.579E 0

ST

SL

SL 2.302E 3 2.174E 3

SL

1.766E 1 9.783E 1

1.766E 1 9.783E 1

4.144E 3 3.915E 3

6.000E 1 6.000E 1

2.500E-2

Seite 8 - 2 Software Backup AML/2 599 DOC E00 017-C

Page 52

Parameter of the Tower Amplifier (10 MHz) MOOG

Parameter com. Main tower 4 5 6 Aux. tower 4 5 6

Drive Initialisation

RHO Sample Period ms

Controller Type

Motor ID

M

KT Nm/A

No Motor Poles

Current Limit A 25 25

max. Speed RPM

Parameter

Velocity Loop Gain Nm/

SP

(Rad/s)

Integral Time Const. s

Position Loop Gain (Rad/s) /

SI

SG

Rad

2nd Ord. Filter Frequency Hz

2nd Filter Damping

Acceleration Rad/s²

Maximum Speeds

SW

SZ

SA

SL

AutomaticModeMax. RPM

Manual Mode Max. RPM

Emerg. Braking Speed RPM 1 1

Torque Limit

ST

Automatic Torque Limit Nm

Manual Torque Limit Nm 4 2.3

Emergency Torque Limit Nm

Emergency Decceleration Rad/s²

Posn. Scaling Rev/10V

Vel. Scaling RPM/

SE

SR

SN

10V

Options

CAN Direrction of Rota-

OD

tion

Home Position Offset OO

CAN Position Scaling OR

20 20

T161 213 T161 213

D315 L10

0.59 0.59

12

5800 5800

0.4 0.2

0.025

6

250

0.7

300000

4145 3915

2303 2175

8 4

8 4

2097

1

10000

Minus

0 0

16384 16384

D315L10

12

0.025

250

0.7

300000

1981

10000

Minus

Information

6

1

You cannot enter any of the following factors!

Gear factor

600,75 567.375

Transmission mm /Rev, °/Rev

File Name on Diskette HTURM.PRS NTURM.PRS

599 DOC E00 017-C Software Backup AML/2 Seite 8 - 3

Page 53

Parameter of the Tower Amplifier 16 MHz (BOSCH)

Parameter com. Main tower 4 5 6 Aux. t ower 4 5 6

Software Version LV B80860-002 B80860-002

User Version C 1 2

Controller Type SM 6,5/30-GC16 SM 6,5/30-GC16

Motor ID SM sg-a3.055.049 sg-a3.055.049

Following Error SF Disabled Disabled

StaticLoop Error SS Disabled Disabled

Signal on Tp10 OTA 3 3

Signal on Tp3 OTB 1 1

Input Offset OI (0.0) (0.0)

Can Position Scaling OR Revs/16384 Revs/16384

Actual Pos. Offset OO (0.0) (0.0)

Pos. CompensatorType OC Non-Decimated Non-Decimated

Vel. Compensator Type OC 2nd ord. filter 2nd ord. filter

Reference Source OR CAN CAN

Can Direction Flg OD M inus Minus

No Motor Poles SM 12 12

Calc. Factor Kr SM 4.500E-1 4.500E-1

Motor Current Limit SM 2.996E 1 2.996E 1

Peak Torque 1.350E 1 1.350E 1

Velocity Scaling SN 1.000E 4 1.000E 4

PositionScaling SR 1.000E 0 1.000E 0

VelocityLoop Gain SP 3.999E-1 1.999E-1

Ti s SI 2.500E-2

Position Loop Gain SG 6.000E 0 6.000E 0

Torque Filter Freq. Hz SW 2.499E 2 2.499E 2

Torque Filter Zeta SZ 7.000E-1 7.000E-1

Emergency Deceleration SE 2.080E 3 1.951E 3

Auto. Current Li mit A

Man. Curr ent Limit A

Emer. Current Limit A

Auto. Mode Max RPM RPM

Man. Mode Max RPM R PM

Emer.Braking Speed RPM