Page 1

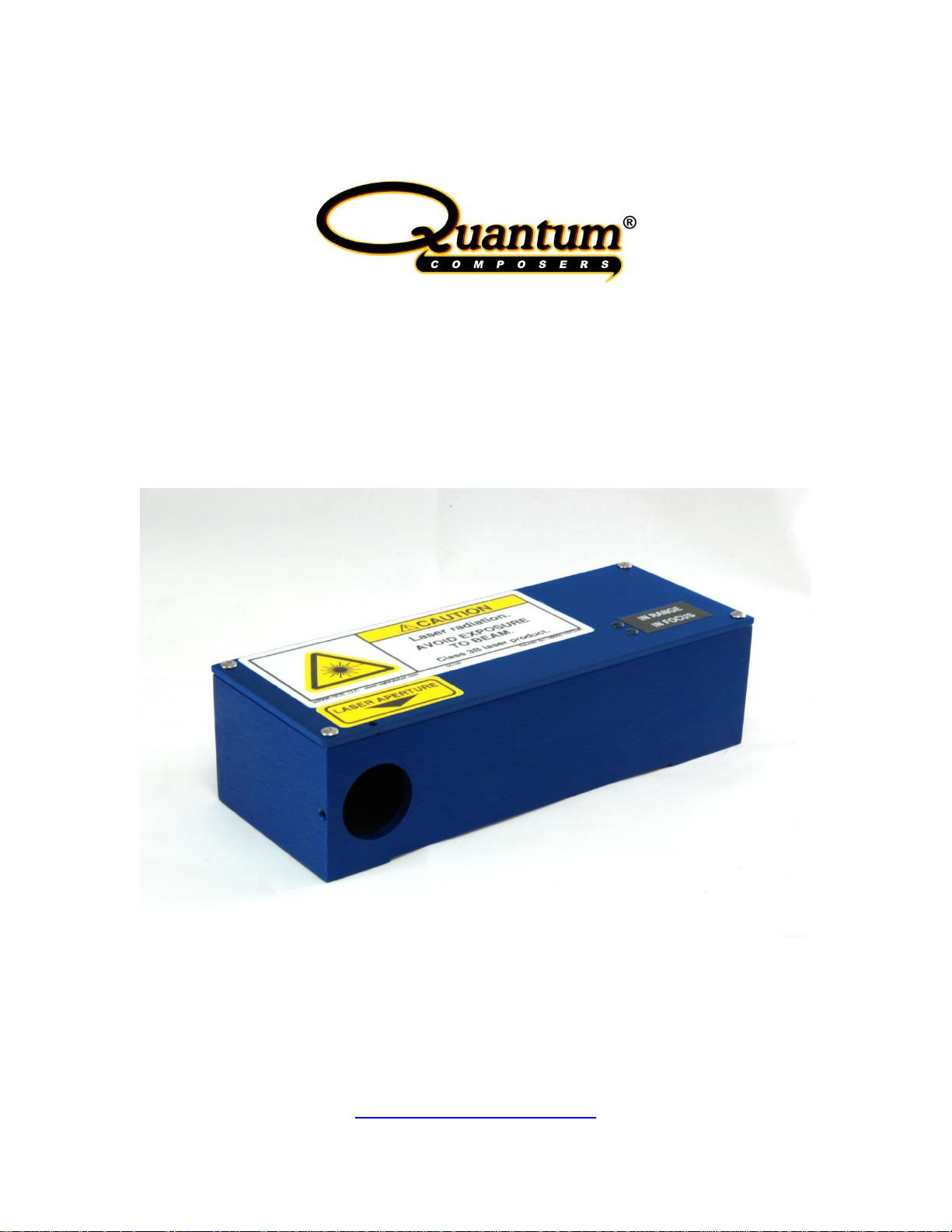

AF910 – Autofocus

Operating Manual

QUANTUM COMPOSERS, INC

212 Discovery Drive

Bozeman, MT 59718

Phone: (406)582-0227

Fax: (406)582-0237

www.quantumcomposers.com

Rev 1.4

Page 2

Table of Contents

PREFACE ..................................................................................................................................................... 3

CHAPTER 1 – PRODUCT OVERVIEW .................................................................................................. 4

PRODUCT FEATURES .................................................................................................................................. 4

ACCESSORIES ............................................................................................................................................. 5

CHAPTER 2 - SAFETY .............................................................................................................................. 6

SAFETY SUMMARY ..................................................................................................................................... 6

LASER SAFETY ........................................................................................................................................... 7

Precautions for Safe Operation of Class 3b laser products .................................................................. 7

Preventative Maintenance for Safety .................................................................................................... 7

Sources of Laser Safety Standards ........................................................................................................ 8

SAFETY LABELS AND LOCATIONS .............................................................................................................. 9

........................................................................................................................................................................ 9

CHAPTER 3 – INSTALLATION ..............................................................................................................11

CHAPTER 4 – OPERATING THE AF910 ...............................................................................................13

METHODS OF OPERATION ..........................................................................................................................13

SOFTWARE QUICK START ..........................................................................................................................13

ANALOG AND DIGITAL I/O ........................................................................................................................17

MOTOR CONTROLLER DESCRIPTION AND SETUP .......................................................................................18

COMMUNICATING WITH THE AF910 ..........................................................................................................25

COMMAND SET ..........................................................................................................................................26

CHAPTER 7 – MAINTENANCE ..............................................................................................................32

CHAPTER 9 – TROUBLE SHOOTING GUIDE ....................................................................................33

CHAPTER 10 – APPENDIXES .................................................................................................................34

PERFORMANCE SPECIFICATIONS ................................................................................................................34

MECHANICAL DIMENSIONS .......................................................................................................................35

ELECTRICAL SPECIFICATIONS AND CONNECTIONS ....................................................................................35

CHAPTER 11 – CUSTOMER SERVICE .................................................................................................39

WARRANTY ...............................................................................................................................................39

FEEDBACK .................................................................................................................................................39

Page 2 AF910 Manual Version 1.4

Page 3

PREFACE

This User’s Manual contains the technical information needed to properly install, operate

and maintain the AF910 – Autofocus unit. It provides instructions for installation, setup,

operation, service, preventive maintenance and troubleshooting (fault-isolation).

The autofocus product is a “turn-key” unit and has been shipped fully functional; only

minor adjustments may be necessary after installing the unit on a system.

Caution labels, in accordance with CDRH and CE requirements, are

prominently displayed on the unit.

The autofocus unit utilized a Class 3b laser. The AF91x is intended to be integrated into

an existing system and is sold as an OEM product. Direct eye exposure should be

avoided. The safety chapter contains essential information and user guidance about these

hazards.

AF910 Manual Version 1.4 Page 3

Page 4

CHAPTER 1 – Product Overview

Product Features

- Easy integration into any optical system that utilizes infinity corrected optics.

- High intensity laser diode @ 685nm to accommodate surfaces that may vary

in reflectivity.

The system has the ability to dynamically adjust the laser diode intensity

to maintain the optimal signal to noise ratio.

- Integrated motor control that includes step, direction and limit inputs.

This allows for reduced component count and cost as well as faster

motor response times to changes in sample position.

- High resolution sensor.

A high resolution sensor can better maintain accuracy and repeatability

of the focus target.

- High speed DSP based microcontroller.

Allows for different algorithms to be used and computed quickly so the

focus position can be determined very quickly.

- Serial communications with selectable baud rates.

Ability to change baud rates so that existing systems can communicate

with the module.

- Up to 7 different objective configurations.

- ±10V analog output focus level signal.

- Digital I/O for various system states and control.

- Dual focal plane support with AF911 version.

When using objectives that may focus wavelengths differently (deep UV

for example), the system can handle switching between these types of

objectives without the need to re-calibration or optical adjustments.

- High update rate of 1KHz to maximize response times and throughput.

Enables faster response to changing sample heights, which is very

important when trying to maintain high throughputs. The system is able

to keep the focus well within the capture range when traversing across

the sample quickly.

- Various interface modules to accommodate almost any electrical connection

requirement. Custom interfaces available.

No need to redesign existing electrical interfaces to use the AF91x

series.

- Optimized for patterned surfaces to avoid “false focus” conditions.

Page 4 AF910 Manual Version 1.4

Page 5

Accessories

- Electrical interface adapters. Various interface adapters to accommodate and

type of connection.

Contact the factory for details on this accessory.

AF910 Manual Version 1.4 Page 5

Page 6

CHAPTER 2 - Safety

SYMBOL

DEFINITION OF SYMBOL

CAUTION: Calls attention to a procedure, practice, or condition that could cause damage to the

product, or cause bodily injury to the user. Refer to accompanying documentation.

ATTENTION: Ce symbole signale une procédure, une méthode ou une condition qui peut

endommager le produit ou blesser l’utilisateur. Se référer à la documentation jointe.

ACHTUNG!: Beachten Sie Verfahren, Praktiken oder Zustände, die das Produkt beschädigen oder

zu Verletzungen fuhren können. Lesen Sie die deigefugte Dokumentation.

ATTENZIONE: Porre estrema cautela alla procedura, uso o condizioni che potrebbero danneggiare

il prodotto o l’utilizzatore. Far riferimento alla documentazione inviata insieme al prodotto.

ADVERTENCIA: Llamar la atención de un producto, practica, o estado que puede causar daño al

producto o puede herir el usario.

CAUTION: Risk of Electric Shock.

ATTENTION: Risque d’éléctrocution.

ACHTUNG!: Gefahr durch Stromschlag.

ATTENZIONE: Rischio di shock elettrico.

ADVERTENCIA: Riesgo de choque eléctrico

CAUTION: Risk of exposure to hazardous laser radiation.

ATTENTION: Risque d’exposition à un rayonnement laser dangereux.

ACHTUNG!: Gefahr durch gefährliche Laserstrahlung.

ATTENZIONE: Rischio di esposizione a pericolose radiazioni laser.

ADVERTENCIA: Riesgo de exposición a radiaciên láser peligrosa.

Safety Summary

This product complies with safety standards EN61010:1993+A2:1995,

EN60825:1994+A11:1996, and CDRH 21 CFR 1040.10(d). Do not install substitute

parts or perform any unauthorized modifications to the product. Return the product to

manufacturer for service or repair to ensure that all safety features are maintained. Do

not operate this product beyond its specifications.

Page 6 AF910 Manual Version 1.4

Page 7

Laser Safety

CAUTION: The AF910 contains a Class 3b laser. The AF910 is sold as an

OEM device and is intended to be integrated into systems. Precautions should

be taken to avoid direct eye exposure. The following precautions should be used

as guidelines when installing into an existing system.

Precautions for Safe Operation of Class 3b laser products

Keep the protective covers on the unit. Do not operate the unit with the covers

removed for any reason.

Avoid looking at the laser output beam.

Do not wear reflective jewelry while using the laser as it might cause inadvertent

hazardous reflections.

Us protective eyewear. Consult the ANSI, AC GIH, or OSHA standards listed at

the end of this section for guidance on goggles and safety matters.

Avoid blocking the laser beam with any part of the body.

Establish a controlled access area for laser operation. Limit access to those

trained in the principles of laser safety.

Maintain a high ambient light level in the laser operation area so the eye pupil

remains constricted, thus reducing the possibility of hazardous exposure.

Post prominent warning signs near the laser operation area.

Provide enclosures for the beam path whenever possible.

Set up an energy absorber to capture the laser beam, preventing unnecessary

reflections or scattering.

CAUTION: Use of controls, adjustments or performance of procedures other than

those specified in this User’s Manual may result in hazardous radiation exposure.

Follow the instructions within this manual carefully to ensure the safe operation of your

laser. At all times during laser operation, maintenance or servicing avoid unnecessary

exposure to laser or collateral radiation that exceeds the accessible emission limits listed

in “Performance Standards for Laser Products,” United States Code of Federal

Regulations, 21 CFR 1040.10(d). This information is also available in EN60825-1:1994,

Section 8.2, titled “Measurements of Laser Radiation for Determining Classification.”

Preventative Maintenance for Safety

Preventative maintenance is required to ensure the laser remains in compliance with

Center for Devices and Radiological Health (CDRH) regulations and European Norm

(EN) requirements. This laser product complies with Title 21 of the United States Code

of Federal Regulations, Chapter 1, Subchapter J, Parts 1040.10, as applicable, and with

EN60825-1:1994, Part 1 for a Class 3b laser, as applicable.

AF910 Manual Version 1.4 Page 7

Page 8

Sources of Laser Safety Standards

“Safe Use of Lasers” (Z136.1)

American National Standards Institute (ANSI)

11th West 42nd Street

New York, NY 10036 USA

Phone: (212) 642-4900

“A Guide for Control of Laser Hazards”

American Conference of Governmental and Industrial Hygienists (ACGIH)

6500 Glenway Avenue, Bldg. D-7

Cincinnati, OH 45211 USA

Phone: (513) 661-7881

Occupational Safety and Health Administration

U.S. Department of Labor

200 Constitution Avenue N.W.

Washington, DC 20210 USA

Phone: (202) 523-8148

“Safety of Laser Products” (EN60825-1:1994)

Global Engineering Documents

15 Iverness Way East

Englewood, CO 80112-5704 USA

Phone: (303) 792-2181

Page 8 AF910 Manual Version 1.4

Page 9

Safety Labels and Locations

The following figures depict the safety, model number, serial number and origination

labels and their locations on the AF910. These labels are installed at the factory and

should not be removed by the user. If for some reason a label is removed, obscured or

damaged in any way, please contact the manufacturer for a replacement.

AF910 Manual Version 1.4 Page 9

Page 10

Figure 1 Certification and ID Label

Figure 2 Laser Radiation

Figure 3 Laser Aperture

Page 10 AF910 Manual Version 1.4

Page 11

CHAPTER 3 – Installation

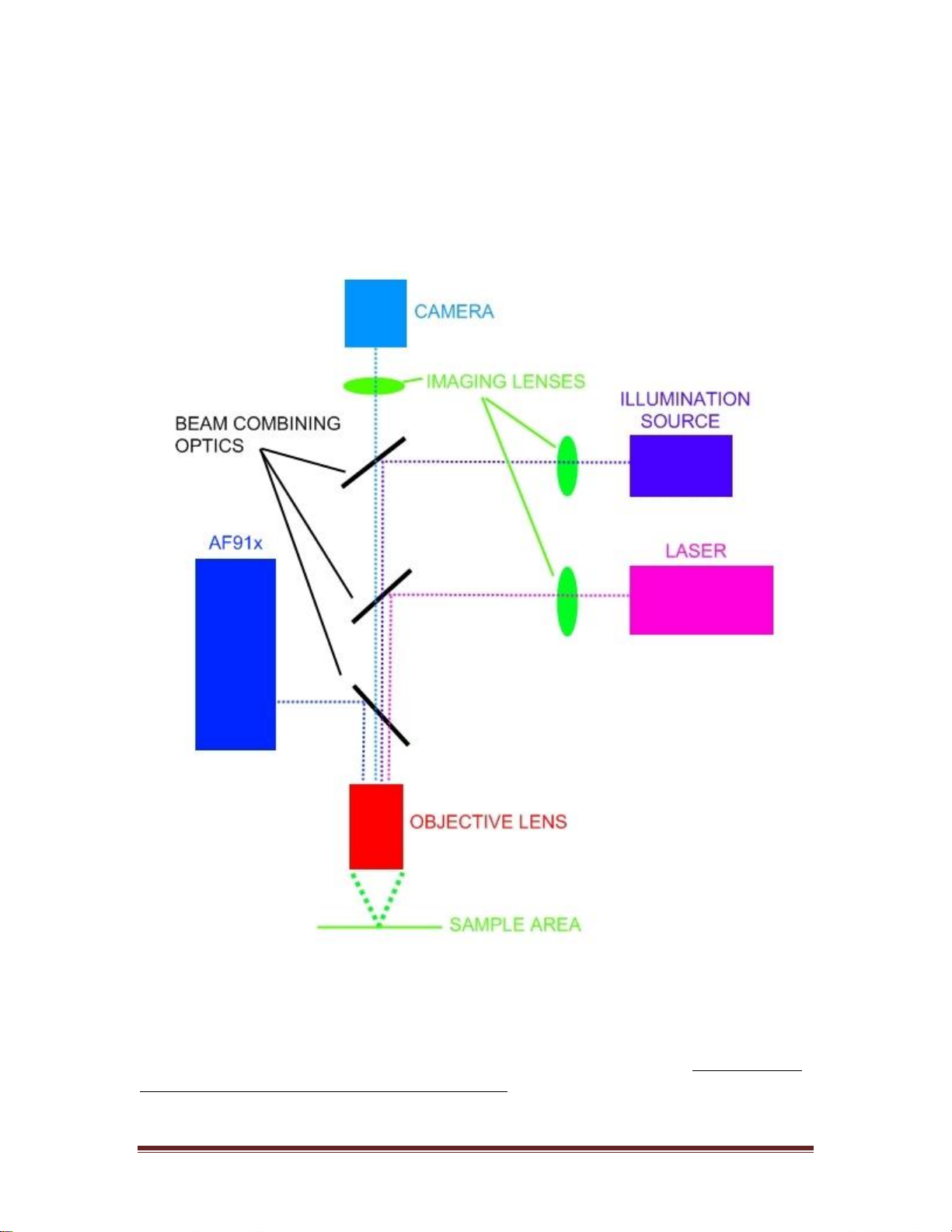

The AF91x can be installed on many types of video microscope setups that include the

use of infinity corrected optics. The diagram below shows a typical optical setup

including the AF91x unit.

The AF91x must be installed in the infinity region of the optical path. If using an infinity

corrected objective lens (typically noted by the ∞ symbol), then the unit must be placed

between the objective lens and any other focusing lenses. The AF91x has both metric and

imperial mounting points. Refer to the mechanical diagram for placement. The unit

should be mounted so that it is as stable as possible. A beam combining optic should be

used, preferably on an adjustable mount. If polarizing optics are used, the polarization of

the laser diode is vertical to the mounting surface of the AF91x. Be sure that the

polarization is correct or else the performance of the unit may suffer due to transmission

AF910 Manual Version 1.4 Page 11

Page 12

losses. Once the unit is mounted, then the electrical connections can be made. At the very

least, the unit needs +12VDC power at 300mA and serial (RS232) connections made.

Refer to the electrical connection tables. Once the electrical connections are made and the

unit is powered on, communication can be established by either running the AF91x

software or using an appropriate terminal program such as HyperTerminal. Refer to the

communication section of the manual for details on operating the unit via RS232

connections.

When adding the AF91x to an infinity corrected beam path, the laser diode should be

adjusted so that it enters the objective lens aperture correctly. If it does not enter the

objective lens on axis, then performance may be reduced. It is assumed that some kind of

beam combining optic is used on an adjustable mount. This optic should be adjusted so

that the laser diode beam at the entrance of the objective looks like the following image.

Figure 4 Laser Beam Centering

Be sure that the laser diode does not cross over the centerline of the objective aperture

otherwise performance may be reduced.

Page 12 AF910 Manual Version 1.4

Page 13

CHAPTER 4 – Operating the AF910

Methods of Operation

The AF91x can be operated in various ways. Communication via a serial port is always

necessary to control basic functions and to setup various parameters. The unit has two

methods for controlling or indicating where the focus point is. The first is the analog

output signal which can be monitored to determine when focus has been achieved. The

second is the motor control functions which provide both step and direction outputs to

control a focusing motor.

Software Quick Start

Once the unit is installed on a video system, proper power has been applied and the

communication lines connected, the system can then be run via the communications port.

The included software is meant to be a quick start way of operating the unit. After the

software is installed run it and select the appropriate communications port if necessary. If

the unit is not found on any of the communication ports, double check the connections.

The AF91x software communicates with the unit at the default baud rate of 57,600. Be

sure the communication speed has not been altered. See the command set section for

more details of setting different communication speeds.

Figure 5 Auto Focus Model 91x Software

AF910 Manual Version 1.4 Page 13

Page 14

The unit will then be enabled and its status displayed. You should see that the laser diode

has been enabled. This also means that the analog output is now active. To turn off the

autofocus and thereby disabling the analog output function, deselect the Autofocus

Enable checkbox.

Figure 6 Autofocus Enable

Determine what objective number you would like to assign to the current lens. This is

done via the OB command (OB1, OB2, OB3, etc). For example, a 10x objective lens

could be assigned to OB number 1. All calibration parameters for that particular objective

would be stored as OB1. This can be selected using the included software by selecting a

number from the drop down selector.

Figure 7 Objective Selection

Focus the objective on the target sample by either using an external means or using the

built in motor controller function of the AF91x (if connected and utilized). Once focused

on the target, calibrate the autofocus by issuing the offset (OF) command or using the

software calibrate button.

Figure 8 Objective Offset Calibration

This now calibrates the selected objective to be in focus at that point. Repeat this step for

any other objectives to be used. Remember to change the objective number each time you

change objective lenses so that all the correct calibration parameters are recalled. The

calibration process should only be used if the target sample type changes or alignment of

the system is adjusted.

There are various focus windows that can be adjusted. When using the motor control

ouputs, these windows affect the speed at which the motor will move when outside the

windows. These are described in more detail under the Motor Controller section of the

manual. These windows will also affect the analog output and how it is set. In general,

Page 14 AF910 Manual Version 1.4

Page 15

when outside of the docking range, the motor will move at the high speed and the analog

output will be clamped at the highest level (either positive or negative depending on the

last known direction). When inside the docking range, the motor will slow down to the

slow speed and the analog output will follow the focus level. Once the focus level has hit

the target focus, the motor will not move again until it gets outside of the focus range

window.

Figure 9 Focus Windows

The manual stage controls are accessed by selecting the Move Stage tab. These controls

are enabled only when the Manual Drive Option is set to manual. Use these controls to

absolute and relative movement of the stage. These are described in more detail in the

Motor Controller description section of the manual.

Figure 10 Stage Manual Controls

Manual control of the laser diode intensity is provided for diagnostic and alignment

purposes only and is accessed by selecting the Diode Control Tab. For normal operation

of the autofocus the diode control must be set to Auto Diode Mode. If it is not set to auto

mode, then the system cannot dynamically adjust the diode intensity, which may affect

performance.

AF910 Manual Version 1.4 Page 15

Page 16

Figure 11 Laser Diode Controls

The autofocus data section of the software is used to view the current analog output based

on position as well as the sensor output if desired. The sensor output data should be used

only for diagnostic purposes and as a check to see that you are getting a strong signal on

the sensor. Pressing the “Single Sensor Capture” button will grab one frame of the sensor

and display it on the plot. A reasonable signal when in focus on the sample is shown in

the image below. Selecting “Continuous Data Scan” will constantly scan the sensor data.

This should only be used for diagnostics and alignment purposes. The enable polling

option will enable/disable polling any status from the autofocus. Normally, this can be

left in the selected mode.

Figure 12 Autofocus Data

Selecting the Comm Terminal Tab provides the user with the ability to send commands

directly to the autofocus controller. The commands described in the command set section

could be entered using this tab.

Page 16 AF910 Manual Version 1.4

Page 17

Figure 13 Communication Terminal

Analog and Digital I/O

The AF91x offers several I/O signals to help control and determine status of the unit.

Used in conjunction with the RS232 commands, these can offer a direct method of

determining distance to focus. The pins these signals are available on are listed in the

electrical connection section. The motor controller specific signals are described under

the motor controller section of the manual.

In Range. This signal is an active low output (open collector) that indicates when the

sample is inside the docking range window or inside the linear range. There is also an

LED indicator on the outside of the unit for this status.

In Focus. This signal is an active low output (open collector) that indicates when the

sample is inside the focus range window. When this status is active, the motor controller

function will be stopped. There is also an LED indicator on the outside of the unit for this

status.

EMO (Emergency Machine Off). This is an active high input that will stop all functions

of the autofocus unit when activated. The analog output will be zeroed and the motor

control functions will be stopped.

Laser Disable. This is an active low input (pull to 0V to activate) that will turn off the

laser diode and temporarily stop the motor control. Once the input is activated again (or

released), the laser diode will turn back on. The motor control functions (step) will stop

when this is disabled and must be manually enabled again. The analog output will

automatically start updating when released.

AF Status. This is an active high output that indicates when the autofocus has been

enabled.

Analog Output. This signal outputs a ±10V signal based on the distance from the

calibrated focus point. An output of zero volts will indicate that you are in focus. When

the output “clamps” at the maximum of ±10V, the unit is indicating you are outside of the

AF910 Manual Version 1.4 Page 17

Page 18

docking range, which is also outside of the linear range. The sign of the signal can be

used as a method to determine the direction of focus. There is a method to scale the

output when inside of the linear range. This is the analog scalar (AS) command described

in the command set section.

Figure 14 Analog Output

Motor Controller Description and Setup

The AF91x includes built in motor control functions that can directly drive most motor

driver modules that accept motor step and direction signals. This eliminates the need for a

separate motor controller module to process the analog output signal and convert to a step

and direction. The motor control functions consist of the following features:

- Motor step signal.

- Motor direction signal.

- Two limit switch inputs.

- Homing function.

- 32 bit position counter (± 2,147,483,647 counts).

- Configurable limit switch polarities.

- Configurable motor directions.

Page 18 AF910 Manual Version 1.4

Page 19

- Acceleration function.

- Adjustable step rates up to 80KHz.

- Two speeds for inside and outside of docking range.

- Algorithms for filtering out features that may cause false focus conditions.

- Focus loop update rate of 1KHz.

- Objective offset feature to allow for varying focal planes when switching

lenses.

Figure 11 below shows the typical connections made when using the AF91x for motor

control. Figure 12 shows the typical connections needed for other autofocus units.

Typically an additional motor controller is needed as well as some kind of analog to

digital converter module. Associated software must also be written to tie everything

together.

Figure 15 (AF91x Motor Control)

Figure 16 (Typical AutoFocus Motor Control)

Motor Controller Connections:

Refer to the electrical connection tables for pin numbering and types of connectors to use.

The step and direction signals should be connected to the inputs of the motor driver being

used. The step and direction outputs are TTL levels that can source up to 50mA. The step

output is a pulsed signal with period that is adjustable and a pulse width that is typically

5us. The two limit switch inputs can be connected to any type of limit switch that

AF910 Manual Version 1.4 Page 19

Page 20

provides either a TTL or an open collector type output. The limit switches can be

configured to be either active high or active low. Refer to the serial command set for a

description on how to configure the limit switch input polarities.

Setup and Control:

There are two modes of operation for the motor controller: manual and automatic. When

in manual mode, the motor control is initiated by the host and when in automatic mode,

the motor control is initiated by the sensor. When in automatic mode, the sensor will

control the speeds and direction of the motor as well as starting and stopping movement.

This allows for the unit to maintain focus without user intervention. Many of these

functions are also describe in the command set section.

- Motor Speed. There are two speeds available, high and low. When in manual

mode, the last set speed whether it is high or low becomes the active speed.

When in auto mode, the system determines the speed to be use based on the

distance away from the target focus. The speed command (SP) is used to set

the high and low speeds of the unit.

Figure 17 Motor High/Low Speeds

Initial Speed. This is the initial or starting speed that the motor will begin to move at.

This must be adjusted according to the dynamics of the motor controller and the type

of motor or stage being used. If set to fast, the motor may immediately stall, if set to

low, the motor may take too long to get up to the target speed (high or low). The IS

command is used to set this parameter. The motor will dynamically accelerate the

speed from the initial speed to the high or low target speed.

Figure 18 Motor Initial Speed

- Home Speed. This is the speed at which the motor will move when the home

sequence is initiated. This speed should be set such that the motor can

accurately detect the limit switch without any possibility of over-running it.

This is set by using the HS command.

Page 20 AF910 Manual Version 1.4

Page 21

Figure 19 Motor Home Speed

- Limit Switches. The limit switches will stop motor movement when activated.

They also serve as a reference, or home position when using the motor home

function. The limit switches can be configured as active high or active low.

The limits sensor inputs are internally pulled high to a 5V level. The default

setting is active low. The motor configuration register contains the option for

active high or active low limits. See the MC command for details. The limits

can also be disabled if needed. The LD command performs this function. By

default, the limits are enabled. The limits can also be swapped in function by

setting the appropriate option in the motor configuration register.

Figure 20 Limit Switch Setup

- Homing Function. The system can automatically perform a home sequence so

that the position counter can be initialized to a known position (the limit

switch). When initiated by issuing the HM command, the motor will begin to

move at the home speed set by the HS command towards the “A” or positive

limit switch. Once this limit is reached, the motor will slowly back off of the

limit to accurately determine the limit position and zero the step counter. The

motor will then move to a post home position which is set by using the PH

command. The limit that the home sequence moves to can also be reversed by

setting the option in the motor configuration register.

Figure 21 Home Function

Figure 22 Reverse Homing

AF910 Manual Version 1.4 Page 21

Page 22

- Step Counter. The system uses an internal 32 bit position counter to keep track

of motor steps. This allows for step counts of ± 2,147,483,647. The position

counter is initialized when a homing sequence occurs or can be manually

zeroed as well. The SC command is used for both querying and resetting the

counter.

Figure 23 Step Counter

- Movement Functions. There are three ways to command the motor to move

when in manual movement mode: continuous, absolute and relative. A

continuous movement will continue to move unit a stop command is received.

It is up to the user to stop the motor when desired in this case. A CM

command is used to move continuously positive or continuously negative (jog

function). A ST command will stop movement. An absolute command will

move to the position given. This can be a positive or negative position. The

controller will determine the direction and number of steps to move until the

commanded absolute position is reached. A relative command will move the

number of steps given relative to the current step counter. The MV command

is also used for this function with the addition of the “+” or “-“ prefix to

indicated whether or not this is a positive or negative relative step command.

Figure 24 Motor Movements

- Automatic Mode. This mode will enable the motor to move based on the

position calculations from the sensor. The motor will automatically move and

determine direction in order to maintain focus on the sample. The AM

command is used to enable and disable this function. When in automatic mode

all manual movement commands will be ignored and responded to by

returning a “?3” error.

Figure 25 Motor Drive Mode

Page 22 AF910 Manual Version 1.4

Page 23

- Step Offset Function. This function will allow the motor to move any offset

distance when switching objective lenses. Since objectives may have different

focal lengths, this method will move the stage (using motor steps) a set

amount when switching lenses. The change disable command (CD) allows for

the switching of objectives and positioning the focus stage into a nominal

position before re-enabling the auto focus. Once this command is issued, the

auto focus will be disabled and the stage positioned into a nominal focus for

the next objective. This eliminates the need to manually adjust the focus stage

before re-enabling the auto focus if there is a variation in the focal lengths of

the objectives being used. Each objective number will have an associated

focus stage offset motor count. This will assure that the focus stage is

positioned within the auto focus’s capture range before it is enabled. Refer to

the command set section for detailed usage of the commands.

Figure 26

Procedure:

1. Select an objective as the reference objective. This will be the objective that

will have a zero step offset value to it (CO value).

2. Use the OB command to select the proper objective number. Example: select

OB 1 for the reference objective.

3. Focus the reference objective by moving the focus stage up and down using

the motor control commands.

4. Using the CO command, enter a value of 0 for the change offset. Take note of

the motor step position using the SC? command. Write this number down as

the reference position. This reference position will be used to calculate all the

other objective offsets.

5. Select the next objective to calibrate the step offset for. Change the objective

by using the OB command. Example: select OB 2 for the next objective.

6. Focus the objective using the motor control commands and take note of the

motor step position using the SC? command.

7. Subtract the reference objective motor step position from the new objective

focus position (New Position – Reference Obj Position = CO value). This will

be the value you enter using the CO command. This may be a positive or

negative offset depending on if the focus for the new objective was higher or

lower than the reference objective.

8. Repeat steps 5-7 for the next objectives. Be sure the change the objective

number each time using the OB command and recording the new objective

position and calculating the motor step difference between it and the original

reference objective.

AF910 Manual Version 1.4 Page 23

Page 24

Figure 27

Example (using picture above). Using this example, the home or zero position is above

focus, so raising objectives above sample will decrease motor counts, while lowering

objectives closer to sample will increase counts.

- Objective #1 is selected as the reference objective. When in focus its

motor step count position is 25,000.

- The remaining objectives have focus positions (motor steps) as follows:

o Objective #2 = 34,000.

o Objective #3 = 36,500.

o Objective #4 = 15,400.

o Objective #5 = 20,125.

o Objective #6 = 42,000.

- Each objective offset can be calculated like this:

o Objective #1 offset is zero since it is the reference objective. Any

objective number can be selected as the reference.

o Objective #2 offset: 34,000 – 25,000 = 9000 (or hex h2328).

o Objective #3 offset: 36,500 – 25,000 = 11,500 (h2CEC).

o Objective #4 offset: 15,400 – 25,000 = -9600 (negative, use 2’s

compliment, so hDA80).

o Objective #5 offset: 20,125 – 25,000 = -4875 (hECF5).

o Objective #6 offset: 42,000 – 25,000 = 17,000 (h4268).

Page 24 AF910 Manual Version 1.4

Page 25

- Focus Windows. Various windows can be adjusted to improve the

Pin No.

Name

Description

1

DCD

Data Carrier Detect †

2

Rx

RS232 Receive

3

Tx

RS232 Transmit

4

DTR

Data Terminal Ready †

5

Gnd

Ground

6

DSR

Data Set Ready †

7

RTS

Request to Send †

8

CTS

Clear to Send †

9

RI

Ring Indicator †

† denotes signal not used by the autofocus

performance of the motor control loop when approaching and stopping at the

target focus position. There are three (3) windows that can be adjusted that

affect how the motor speeds are utilized when in automatic mode.

o Focus Target Window. This is the absolute focus target variation. A ±

range that the focus signal can be within before the In Target Focus

condition is set and the motor movement is stopped. The FT command is

used to adjust this value.

o Focus Range Window. A ± range that the focus signal can be within

before the In Focus Range condition is set. Motor movement will not be

started until the focus signal level is greater than this value. The FR

command is used to adjust this value.

o Docking Range Window. A ± range that the signal can be within before

the Docking Range condition is set. When the focus signal is within this

window, the stage speed will be reduced to the slower speed. When

outside of this window, the high motor speed will be used. This allows the

motor to slow down when approaching the target focus so that

overshooting does not occur. The DR command is used to adjust this

value.

Figure 28 Focus Windows

Communicating with the AF910

The AF91x communicates via a standard RS232 connection. The default communication

settings are 57,600 baud, 8 data bits, even parity and 1 stop bit (57600, 8, E, 1). A typical

serial port pin out is shown below. Only the Rx, Tx and Gnd are used to communicate

with the AF91x. The included software can be used to operate the unit over the serial port

at the default baud rate of 57,600.

Typical PC Serial Port (DB9)

AF910 Manual Version 1.4 Page 25

Page 26

Command Set

Field

Description

Prefix

Single semicolon character ";", must precede all commands. All devices

will reset their command input buffer when the prefix is received.

Address

2 ASCII characters. Each device has a unique address which is

programmed into its firmware. See the table below for a list of addresses.

Delimiter

Single colon character “:”, must follow device address.

Command

String

Commands are specific to each device -- see the following sections for

the commands that each device supports.

Parameters

(optional field) Some commands may have parameters which

immediately follow the command string. Multiple parameters are

separated by commas.

Terminator

ASCII carriage return character (decimal value 13). The receiving device

does not process any commands until the terminator is received.

Address

Device

AF

Auto Focus Controller

Device Command Format

All commands use ASCII characters and are composed of the following fields:

<Prefix><Address>< Delimiter><Command String>[Parameters]<Terminator>

Device Address

Command Types

There are two types of commands -- those that set a value or initiate an actions (control

commands), and those that request information (query commands). Each device must

respond in the proper manner to each type of command.

Control Commands

A device must always parse a control command and return a response immediately.

If the command is a recognized command and the parameter is valid, then the device

returns an "OK<CR>". (<CR> = ASCII carriage return, decimal value 13).

If the command is not recognized by the device, then it responds with "?1<CR>

If the command is recognized, but the parameter value is missing or invalid, then the

device responds with a "?2<CR>".

If the command is recognized, but the parameter is out of range, then the device

responds with a “?3<CR>”.

Page 26 AF910 Manual Version 1.4

Page 27

If a control command is received while the device is in the midst of executing a previous

Command

Description

VN

Return firmware version number

RS

Reset, return to power-up defaults.

Command

Description

*RS

Reset, return to power-up defaults. All

devices

command, and the commands are mutually exclusive (cannot be executed in parallel),

then the previous command is aborted and the new one executed. It is up to the host

controller (the PC) to poll the device and make sure the previous command is finished, if

that is the needed.

Query Commands

Query commands return a value to the PC as soon as the command is parsed and

executed. The value returned will depend on the command. The response is always

terminated with a <CR>. If a query command is not recognized by the device, then a "?0"

is returned.

Common Commands

All devices are required to support some common commands as part of their command

set. Those commands are:

Global Commands

By using a special prefix (the * character), it is possible to send a command to all the

devices at once. When a global command is sent, no device will send a response.

Auto Focus Command Set

AE # Autofocus Enable. Enables or disables the auto focus process. A

“1” enables auto focus (not the motor) and a “0” disables it. A “?”

will return the current state.

AM #, AM? Auto Motor Enable. Enables or disables the automatic movement

of the motor to find the focus. A “1” enables it (default) and a “0”

disables it. A “?” will return the current state.

AS ####, AS? Analog Scalar. This parameter will effectively scale the amplitude

of the ±10V analog output when inside of the docking range. The

default scalar is 1. The higher the number, the steeper the slope

will be. Values are from 0x0001 to 0x000A. A “?” will return the

current value. This is an objective specific parameter.

AF910 Manual Version 1.4 Page 27

Page 28

BR?, BR # Baud Rate. Selects between two different RS-232 baud rates. A

“1” selects the high baud rate of 57600 with even parity and 8 data

bits and 1stop bit. A “0” selects a low baud rate of 9600 no parity

and 8 data bits and 1stop bit. The default is the high baud rate. This

command will executed after a power cycle of the unit.

CD #, CD? Change and Disable. This command will disable the auto focus,

change the objective to the given parameter, move the stage to a

nominal focus position and evoke the offset based on the CO

command for the given objective, then re-enable the auto focus.

Each objective may have a specific offset value associated with it

for calibration purposes. Values are from 0 to 7. A “?” will return

the current objective number being used.

CE #, CE? Change Enable. A “1” enables the auto focus, but first checks to

see if the data is valid. If the data is not valid, then a “?4” will be

returned. If the data is valid, the auto focus will be enabled as well

as the motor movement. A “0” will disable it. A “?” will return the

current value.

CM ± Continuous Move. When in manual motor mode, issuing a

continuous move will start moving the motor in the commanded

direction until either a limit is hit or a stop (ST) command is

received.

CO ####, CO? Change Offset. A ± motor step offset value that allows for optimal

positioning between objective changes. This value will be an offset

from some reference position such as the lowest magnification

objective. Values range from 0x7FFF (+32767) to 0x8001(-

32767). A 2’s compliment method is utilized to represent

maximum decimal values of ±32767. The parameter is a 4 digit

hex value. A “?” will return the current value.

DR ####, DR? Docking Range. A ± range that the signal can be within before the

Docking Range bit is set. When the focus is within this window,

the stage speed will be reduced to the slower speed. Values are

from 0x0000 to 0xFFFF. A “?” will return the current value.

DS #, DS? Diode Select. This selects the laser diode source for the currently

selected objective. Each diode (in a dual diode system) is focused

at a different plane. This will help the focusing process when a

specific objective may have a different focal plane than the other.

A “0” will enable diode 1 only, and a “1” will enable diode 2 only.

A “?” will return the current diode selection. Default value is “0”.

EC #, EC? Echo. A “1” turns communication echoing on and a “0” turns it

off. A “?” will return the current state.

Page 28 AF910 Manual Version 1.4

Page 29

FL? Focus Level. Returns the current focus level value from 0x0FFF to

7 6 5 4 3 2 1

0

Reserved

Low Speed

Mode

Auto Reset

Enable

Limits

Disabled

Active

High

Limits

Reverse

Homing

Reverse

Motor

Reverse

Limits

0x0000. A value of 0x07FF is in focus or 0V output from the ±10V

analog output.

FR ####, FR? Focus Range. A ± range that the focus signal can be within before

the In Focus Range bit is set. Once the target focus has been found,

the motor will not move again until it gets outside the focus range.

Values are from 0x0000 to 0xFFFF. A “?” will return the current

value.

FT ####, FT? Focus Target. This is the absolute focus target variation. A ±

range that the focus signal can be within before the In Target Focus

bit is set. When within this target range, motor movement will be

stopped. Values are from 0x0000 to 0xFFFF. A “?” will return the

current value.

HM Home. This command will home the motor to a limit switch and

reset the step counter to zero upon reaching the limit. After the step

counter is reset the motor will proceed to the Post Home position.

The limit used in the homing will depend on the motor options set;

these settings can be verified using the Motor Config command

listed below.

HS ####, HS? Home Speed. This is the speed at which the motor will move

when homing (HM). Motor speeds are calculated the same as the

SP command. A “?” will return the current value.

IS ####, IS? Initial Speed. This sets the initial or starting speed of the motor.

The motor will start moving using this speed and then ramp up to

the target maximum speed. See the SP command for details in

calculating the parameter. Values are from 0x0000 to 0x4D58. A

“?” will return the current value.

LD #, LD? Limit Switch Disable. This will disable the motor limit switches.

If disabled, the motor will not be stopped when a limit is tripped. A

“1” disables the limits and a “0” will re-enable them. A “?” will

return the current state.

Note: This command will not affect the limits when a home command is

used.

MC?, MC ## Motor Config. This command will set the motor configuration

bits. These parameters are stored in EE Prom and recalled on

power up or reset.

AF910 Manual Version 1.4 Page 29

Page 30

MS Motor Status. Returns the current motor status bytes.

7 6 5 4 3 2 1

0

Reserved

Reserved

Homing

Moving

Direction

Motor

Enabled

Limit B

Limit A

15

14

13

12

11

10 9 8

Ignore

Focus Step

Decelerate

At Target

Speed

Focus

Positioning

Back Off

Continuous

Move

SC

Query

Motor

High

Speed

MV ±########,

MV ########

Move Command. Moves the motor either a specified number of

steps relative to current position or absolute relative to zero. Values

are 32 bit hex. A “-“ moves negative the number of specified steps

and a “+” moves positive the number of specified steps relative to

the current position. No + or – will move the motor to the specified

absolute position relative to zero.

OB #, OB? Objective. This command sets the objective number to be used.

Each objective may have a specific offset value associated with it

for calibration purposes. Values are from 0 to 7. A “?” will return

the current objective number being used.

OF !, OF? Objective Offset Value. This command sets the desired objective

offset value for the currently selected objective (OB command). A

“?” will return the offset value for the currently selected objective.

Using the “!” parameter will start auto calibration routine to set the

offset for you. This is the recommended method of calibrating the

offset. To use this parameter the system should be focused on the

material, and the desired bin should be selected, then send the “!”

parameter to store the calculated offset.

PH ########, PH? Post Home. This command sets the number of steps that the motor

will move after detecting the limit switch when the home

command has been received. See the HM command for the

sequence of operation. Values are from 0x00000000 to

0xFFFFFFFF. A “?” will return the current value.

RS Reset. This command will reset the system to the initial power on

state.

SC, SC - Step Count. This command will return the current step count

position. Adding a “-“ will zero out the position counter. The value

returned will be a 32 bit hex value. Values can range from

±2,147,483,648. A 2’s compliment method will indicate negative

step counts.

Page 30 AF910 Manual Version 1.4

Page 31

SO ####, SO? Sensor Offset. This is an objective specific offset that should be

SP?, SP L?,

SP L ####

SP H?, SP H ####

Speed. Sets the motor clock speed output. A “?” will return the

active speed. The last speed changed is by default the active speed

and the motor will move at that speed if no other commands are

altered before the move command is sent. Step rates are 16 bit hex

values based on the following decimal calculations:

Rate = 20,000,000/(65,536-Value)

Value = 65,536 – (20,000,000/Rate)

The maximum step rate available is ~80KHz or a decimal value of

65300. Rates above 10KHz may have an error of ~10%. A “H”

parameter sets the high speed value that is used when the focus is

outside of the docking area. A “L” parameter sets the low speed

which is used once focus is inside the docking range.

7 6 5 4 3 2 1

0

Signal

Power Too

High

Signal

Power Too

Low

High

Sensor

Gain

Invalid

Data

Auto

Focus

Enabled

In

Docking

Range

In Focus

Range

In Focus

15

14

13

12

11

10 9 8

Area

Invalid

Power

Invalid

CoM

Invalid

Peak

Invalid

Intensity

Error

EMO

Status

Laser

Disabled

Auto

Motor

set before data is collected off the sensor array. Each value is a

multiple of 8. The default is 2, which means that 2 x 8 = 16 pixels

of the linear array will be ignored before data is captured. This

command will allow the system to ignore a section of the array

data when determining the focus position. Values are from 0x0000

to 0x0020. A “?” will return the current offset value.

SP M Speed Maximum. This command returns the current max speed

for the system. Values will range from 0x0000 to 0xFFFF.

SS System Status. Returns two bytes that indicate the status of

various system states.

ST Stop. Stops motor movement. This will stop the motor and take it

out of auto motor mode if enabled.

VN Version Number. Returns the firmware revision number as a 3-

digit number followed by a release Alpha character in the format

“m.nnr”, where m = major version, n = minor version and r is the

release build. Ex: 1.22A.

AF910 Manual Version 1.4 Page 31

Page 32

CHAPTER 7 – Maintenance

The AF91x does not have any user serviceable components. Any need for maintenance

should be done by an authorized service representative. Please contact the factory for

details. The system should be kept free of dust and debris.

Page 32 AF910 Manual Version 1.4

Page 33

CHAPTER 9 – Trouble Shooting Guide

Problem

Solution

Indicated focus does not match

objective focus

- The offset has not been properly

calibrated. Refer to the OF

command.

- Laser diode alignment is not

properly aligned to objective

entrance aperture. Refer to the setup

section.

Cannot communicate with unit

- Be sure that the communication

settings on the host computer are

set to 57,600, E, 8, 1.

- Check to see if the baud rate has

been switched to 9600, N, 8, 1. See

the BR command.

The stage motor oscillates around the

focus point.

- Increase the In Focus window. See

the FR command.

- Slow down the slow speed setting.

The motor may be moving too fast.

See the SP L command.

AF910 Manual Version 1.4 Page 33

Page 34

CHAPTER 10 – Appendixes

Objective

2x

5x

10x

20x

50x

100x

Focus Repeatability (um)

+/- 6.0

+/-2.5

+/- 0.5

+/- 0.4

+/- 0.3

+/- 0.2

Focus Accuracy (um)

+/- 20.0

+/- 5.0

+/- 1.0

+/- 0.8

+/- 0.5

+/- 0.3

Resolution (um)

2.00

1.00

0.50

0.20

0.10

0.06

Linear Range (um)

+/- 500

+/- 500

+/- 250

+/- 100

+/- 40

+/- 15

Capture Range (um)

+/- 5000

+/- 3000

+/- 1500

+/- 600

+/- 240

+/- 40

General

Analog update rate

1.2 kHz

Step control update rate

1.2 kHz

Max step rate

50 kHz

Wavelength

685 nm

Power consumption

+12 VDC/500ma

Performance Specifications

Page 34 AF910 Manual Version 1.4

Page 35

Pin

Name

Type

Description

1

+12VDC

Power

Positive supply voltage (350mA)

2

GND

Power

Ground

3

+12VDC

Power

Positive supply voltage (350mA)

4

GND

Power

Ground

5

N/C

N/A

No connection

6

N/C

N/A

No connection

7

N/C

N/A

No connection

8

N/C

N/A

No connection

9

GND

Power

Ground

Mechanical Dimensions

Electrical Specifications and Connections

The AF91x requires 12 VDC power at 300mA to operate. It is important that 12 VDC

power not vary by more than +/- 200mV or damage to the unit may occur.

Main Sensor Connection

Connector Type(s): Molex Milli-Grid (ribbon cable type), # 87568-3063 or Molex MilliGrid (crimp style), #51110-3051 and contacts #50394-8100.

AF910 Manual Version 1.4 Page 35

Page 36

10

LIMIT B

Input

TTL active low input. Negative direction limit switch

input (B)

11

LIMIT A

Input

TTL active low input. Positive direction limit switch

input (A)

12

RESERVED

N/A

Reserved – Do not connect

13

RESERVED

N/A

Reserved – Do not connect

14

Rx IN

Input

RS232 receive

15

Tx OUT

Output

RS232 transmit

16

GND

Power

Ground

17

RESERVED

N/A

Reserved – Do not connect

18

RESERVED

N/A

Reserved – Do not connect

19

RESERVED

N/A

Reserved – Do not connect

20

+5VDC

Output

Reference output. 50mA max.

21

/LASER DISABLE

Input

Active low input to disable laser diode

22

RESERVED

N/A

Reserved – Do not connect

23

AF STATUS

Output

TTL active high output. High level indicates autofocus

is enabled

24

EMO

Input

TTL active high input. Stops autofocus and motor

movement

25

GND

Power

Ground

26

/IN RANGE

Output

Open collector output. Active low when signal is in

range

27

/IN FOCUS

Output

Open collector output. Active low when signal is in

focus

28

ANALOG OUT

Output

+/-10V analog output corresponding to focus position.

Zero volts indicates in focus

29

STEP

Output

TTL signal output for motor step

30

DIRECTION

Output

TTL signal output for motor direction

Adapter Board # 300001-018 Connections

Pin

Name

Type

Description

1

GND

Power

Ground

2

N/C

N/A

No connection

3

+12VDC

Power

Positive supply voltage (350mA)

4

+12VDC

Power

Positive supply voltage (350mA)

5

GND

Power

Ground

6

GND

Power

Ground

7

Rx IN

Input

RS232 receive

8

Tx OUT

Output

RS232 transmit

9

N/C

N/A

No connection

10

GND

Power

Ground

11

N/C

N/A

No connection

12

N/C

N/A

No connection

Connector Types: Hirose DF11 Series, # DF11-12DS-2C.

Sockets: # DF11-2428SC (24-28 AWG).

Power and Communication

Page 36 AF910 Manual Version 1.4

Page 37

Pin

Name

Type

Description

1

ANALOG OUT

Output

+/-10V analog output corresponding to focus position.

Zero volts indicates in focus

2

/IN RANGE

Output

Open collector output. Active low when signal is in

range

3

/IN FOCUS

Output

Open collector output. Active low when signal is in

focus

4

AF STATUS

Output

TTL active high output. High level indicates autofocus

is enabled

5

GND

Power

Ground

6

EMO

Input

TTL active high input. Stops autofocus and motor

movement

7

/LASER DISABLE

Input

Active low input to disable laser diode

8

LIMIT A

Input

TTL active low input. Positive direction limit switch

input (A)

9

LIMIT B

Input

TTL active low input. Negative direction limit switch

input (B)

10

RESERVED

N/A

Reserved – Do not connect

11

GND

Power

Ground

12

STEP

Output

TTL signal output for motor step

13

DIRECTION

Output

TTL signal output for motor direction

14

RESERVED

N/A

Reserved – Do not connect

Connector Types: Hirose DF11 Series, # DF11-14DS-2C.

Sockets: # DF11-2428SC (24-28 AWG).

Signals

AF910 Manual Version 1.4 Page 37

Page 38

Adapter Board # 300001-026 Connections (Opto-Isolated)

Pin

Name

Type

Description

1

GND

Power

Ground

2

N/C

N/A

No connection

3

+12VDC

Power

Positive supply voltage (350mA)

4

+12VDC

Power

Positive supply voltage (350mA)

5

GND

Power

Ground

6

GND

Power

Ground

7

Rx IN

Input

RS232 receive

8

Tx OUT

Output

RS232 transmit

9

N/C

N/A

No connection

10

GND

Power

Ground

11

N/C

N/A

No connection

12

N/C

N/A

No connection

Pin

Name

Type

Description

1

ANALOG OUT

Output

+/-10V analog output corresponding to focus position.

Zero volts indicates in focus. Not opto-isolated.

2

/IN RANGE

Output

Open collector output. Active low when signal is in

range

3

/IN FOCUS

Output

Open collector output. Active low when signal is in

focus

4

AF STATUS

Output

TTL active high output. High level indicates autofocus

is enabled

5

GND

Power

Ground

6

EMO

Input

TTL active high input. Stops autofocus and motor

movement

7

/LASER DISABLE

Input

Active low input to disable laser diode

8

LIMIT A

Input

TTL active low input. Positive direction limit switch

input (A)

9

LIMIT B

Input

TTL active low input. Negative direction limit switch

input (B)

10

RESERVED

N/A

Reserved – Do not connect

11

GND

Power

Ground

12

STEP

Output

Buffered TTL signal output for motor step. Not optoisolated.

13

DIRECTION

Output

Buffered TTL signal output for motor direction. Not

opto-isolated.

14

+24V External

Opto Power

+24V from external source to power opto-isolators.

Connector Types: Hirose DF11 Series, # DF11-12DS-2C.

Sockets: # DF11-2428SC (24-28 AWG).

Power and Communication

Connector Types: Hirose DF11 Series, # DF11-14DS-2C.

Sockets: # DF11-2428SC (24-28 AWG).

Opto-Isolated Signals

Page 38 AF910 Manual Version 1.4

Page 39

CHAPTER 11 – Customer Service

Warranty

The manufacturer warrants the AF910 it produces to be free from defects in materials and

workmanship for one year following the date of shipment. This warranty is limited to the

original purchaser of the laser and is not transferable.

During the one year warranty, the manufacturer will repair or replace, at option, any

defective products or parts at no additional charge. This is provided that the product is

returned, shipping prepaid, to the manufacturer. All replaced parts and products become

the property of the manufacturer.

This warranty does not extend to any unit which has been damaged as a result of

accident, misuse, abuse (such as use of incorrect input voltages, improper or insufficient

ventilation, failure to follow the operating instructions provided by the manufacturer, or

other contingencies beyond our control) or as a result of service or modification by

anyone other than the manufacturer.

Feedback

We welcome your feedback in regard to the use and performance of our products.

Product improvements and refinements come about from these contact and continually

improve our product reliability, performance and customer satisfaction.

AF910 Manual Version 1.4 Page 39

Loading...

Loading...