Page 1

ACL 4/52 Automated Tape Library

for DLT Cartridges

Operator’s Guide

6211222-05

Ve r. 5, Rel. 0

Page 2

ACL 4/52 Operator’s Guide, 6211222-05, Ver. 5, Rel. 0, January 2000. Printed in the USA.

ATL Products, Inc. pr ov ides th is pub lic at ion “as i s” without warranty of any kind, either express or implied, including but

not limited to the implied warranties of merchantability or fitness for a particular purpose. ATL Products, Inc. may revise

this publication from time to time without notice.

COPYRIGHT STATEMENT

Copyright 2000 by ATL Products, Inc. All rights reserved.

Your right to copy this manual is limited by copyright law. Making copies or adaptations without prior written

authorization of ATL Products, Inc. is prohibited by law and constitutes a punishable violation of the law.

TRADEMARK STATEMENT

Prism Library Architecture, IntelliGrip, WebAdmin, and WebLibrarian are all trademarks of ATL Products, Inc.

Other trademarks may be mentioned herein which belong to other companies.

FCC STATEMENT

This equipment has been tested a nd foun d to compl y w ith th e limit s fo r a Class A digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide r easonable pr otection against harmful int erfer ence when the equipment is

operated in a commercia l envir on ment. This equipmen t gene rates, uses , and can ra diate r adio fr equen cy ener gy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference to radio communications.

Any changes or modifications made to this equipment may void the user's authority to operate this equipment.

Operation of this equipment in a residential area may cause interference in which case the user at his own expense will be

required to take whatever measures may be required to correct the interference.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following conditions: (1) this device may

not cause harmful interference, and (2) this device must accept any interference received, including interference that may

cause undesired operation.

INDUSTRY CANADA (DIGITAL APPARATUS)

Interference-Causing Equipment Standard

ICES-003 Issue 2

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Reglément sur le matériel brouilleur du Canada.

CISPR-22 WARNING!

This is a Class A pr oduct. In a domestic en vironment this product may caus e r adio in ter ference in which case the user may

be required to take adequate me asures.

ACHTUNG!

Dieses ist ein Gerät der Funkstörgrenzwertklasse A. In Wohnbereichen können bei Betrieb dieses Gerätes

Rundfunkstörungen auftreten, in welchen Fällen der Benutzer für entsprechende Gegenmassnahm en ver antw ort lic h ist .

A TTENTION!

Ceci est un produit de classe A. Dans un environment domestique, ce produit peut causer des interférences

radioélectriques. Il appartient alors à l'utilisateur de prendre les mesures appropriées.

6207947-06cA 34

Page 3

NOTICE FOR USA AND CANADA ONLY

If shipped to USA, use the UL LISTED power cord specified below for 100-120 V operation. If shipped to Canada, use the

CSA CERTIFIED power cord specified below for 100-120V operation.

Plug Cap Parallel blade with ground pin (NEMA 5-15P configuration)

2

Cord Type: SJT, three 16 AWG (1.5 mm

) or 18 AWG (1.0 mm2) wires

Length Maximum 15 feet (4.5m)

Rating Minimum 10 A, 125 V

ATTENTION

LIRE LA REMARQUE DANS LE MODE D'EMPLOI.

REMARQUE

CETTE REMARQUE NE CONCERNE QUE LES ÉTATS-UNIS ET LE CANADA.

En cas d'envoi aux États-Unis, utiliser le cordon d'alimentation CERTIFIÉ UL et convenant pour 100-120 V.

En cas d'envoi au Canada, utiliser le cordon d'alimentation CERTIFIÉ CSA et convenant pour 100-120 V.

Fiche Broches parallèles avec une broche de mise à la terre (configuration NEMA 5-15P)

2

Cordon Type: SJT, trifilaire 16 AWG (1.5 mm

) ou 18 AWG (1.0 mm2)

Longeur Maximum 15 pieds (4.5m)

Capacité Minimum 10 A, 125 V

LASER STATEMENT

Class 1 Laser Product

CAUTION: With all panels and enclosures in place, this product is rated as a Class I laser product. The bar code scanner

inside this product, ho wev er, is a Class II laser. Avoid exposure to the la ser lig ht emi tt ed from the bar code scanner. Do not

stare into the beam.

CAUTION: Use of controls or adjustments or performance of procedures other than those specified herein may result in

hazardous exposure.

Laser Klasse 1

VORSICHT: Dieses Produkt Enthdlt Einen Laser Der Kategorie II. Laserstrahlen - Der Strichcode-scanner Gibt

Laserstrahlen aus. VERMEIDEN SIE jeden Blickkontakt und direkten kvrperlichen Kontakt mit diesen Strahlen.

VORSICHT: Ein nicht ordnungsgemd_er (siehe hier enthaltene Anweisungen) Einsatz bzw. Dnderungen der

Betriebsleistung kvnnen einen gesundheitsgefdhrdenden Kontakt zur Folge haben.

Appareil à Laser de Classe 1

ATTENTION: Ce produit émet de la classe laser II. Rayonnement laser - NE PAS fixer des yeux le rayon. Éviter les

expositions - Le rayonnement laser est émis à partir du lecteur optique de code barre.

ATTENTION: L ’ut ilisation de contrôles ou d’ajustement s de performance des proc édures autr es que ceux indiqués ici peut

entraîner une exposition dangereuse.

Page 4

Producto Láser de Clase 1

¡ATENCIÓN! Este producto contiene laser de clase II. Luz de laser - NO mire el rayo. Evite el contacto con la luz: la luz de

laser se emite desde el explorador de código de barras.

¡ATENCIÓN! El uso de los controles o ajustes para realizar procedimientos que no son especificados puede provocar una

situación peligrosa.

Luokan 1 Laserlaite

ATTENZIONE: Questo prodotto emette una luce laser di Clas se II. NON g uar dar e il facsi o di luce ed e vitar e di es porsi all a

fonte del laser. Il fascio di luce laser h emesso dal dispositivo di scansione del codice a barre.

ATTENZIONE: L’uso di comandi o regolazioni per eseguire le procedure che non siano quelli specificati in questa

documentazione pur causare rischi all ‘incolumit’ delle persone.

BATTERY STATEMENT

Caution

The Dallas Semiconductor DS1230AB-200 component on th e ro botic contr oller bo ar d inside t his pr oduct conta ins a lith ium

battery. Lithium is a hazardous material that must be disposed of in accordance with local, state, and federal law.

Forsigtig

Båndbiblioteket indeholder et lithiumbatteri. Dallas Semiconductor DS1230AB-200 på robotkontroltavlen indeholder et

lithiumbatteri. Lithium kan anses for at være et sundhedsfarligt materiale. Kassér dette batteri i overensstemmelse med

lokale og nationale lovbestemmelser.

Huomautus

Nauhakirjastossa on litiumparisto. Robottiohjainkortin Dallas Semiconductor DS1230AB-200-puolijohteessa on

litiumparisto. Litium voidaan luokitella vaaralliseksi aineeksi. Pariston hävittämisessä on noudatettava viranomaisten

antamia ohjeit a ja määräyksiä.

Attention

La bibliothèque de bande contient une pile au lithium. Le Dallas Semiconductor DS1230AB-200 sur la carte robotic

contrôleur contient une pile au lithium. Le lithium peut être considéré comme matériau dangereux. Jeter cette pile

conformément aux lois locales, d’état et fédérales.

Achtung!

Die Bandbibliothek enthält eine Lithiumbatterie. Der Halbleiter Dallas Semiconductor DS1230AB-200 auf dem RoboterController enthält ein e Lithiumb at terie. Lithium gilt als Schadstoff. Bei der Ent sorgung dieser Batterie alle entspr ech end en

kommunalen, staatlichen und bundesweiten Vorschriften beachten!

Attenzione

La libreria a nastro magnetico contiene una batteria al litio. Il semiconduttore Dallas Semiconductor DS1230AB-200 sulla

scheda controller robotic contiene una batteria al litio. Il litio può essere considerato un materiale pericoloso. Eliminare

queste batterie in conformità alle normative locali e statali vigenti.

Forsiktig

Kassettbiblioteket inneholder et litiumbatteri. Enheten Dallas Semiconductor DS1230AB-200 på robotkontrollkortet

inneholder et litiumbatteri. Litium kan anses som et farlig materiale. Batteriet skal kastes i henhold til lokal og nasjonal

lovgivning.

Page 5

Precaución

La biblioteca de cintas contiene una pila de litio. El semiconductor Dallas Semiconductor DS1230AB-200 en el tablero

controlador robotic contiene una pila de litio. El litio puede considerarse como un material peligroso. Deseche esta pila de

acuerdo con las leyes municipales, estatales y federales.

Varning!

Magnetbandsbibliot eket inn ehå ller ett lit iumb atter i. Dal las Sem icondu ctor D S1230 AB-20 0 på r ob otsty rkor tet inn ehå ller ett

litiumbatteri. Litium kan anses vara ett farligt material. Kassera detta batteri i enlighet med lokala och statliga lagar och

förordningar .

Page 6

Page 7

Contents

Contents

Preface

Chapter 1

Library Overview.........................................................................................1

Library Description.......................................................................................2

ACL 4/52 Library Numbering Conventions......................................3

Operator Accessible Components...............................................................4

Control Panel...........................................................................................4

Load Port..................................................................................................6

Front Door (with Interlock Switch) 7

Rear Panel ................................................................................................8

DLT Tape Drive Status/Control Panel 9

Cartridge/Tape Drive Compatibility.......................................................12

Menu Mode Structure .................................................................................13

Menu Navigation ........................................................................................14

Operator Tasks (using the Menu Mode)..................................................16

Configuration Menu Functions 16

Drive Control Menu Functions 17

Diagnostics Menu Functions 18

Chapter 2

Operating Procedures................................................................................21

Operating Procedures.................................................................................22

Applying Power to the Library 22

Placing the Library On-Line 22

Taking the Library Off-Line 22

Removing Power from the Library 23

Inserting Tape Cartridges 23

Removing Tape Cartridges 24

Manually Unloading the DLT Tape Drive 25

Turning the Interior Light On/Off...........................................................28

Operating Procedures Using the Menu Mode........................................30

Entering the Menu Mode 30

Exiting the Menu Mode .......................................................................30

Setting/Changing the Library SCSI Address 31

Setting/Changing a Tape Drive SCSI Address 32

viiACL 4/52 Operator’s Guide

Page 8

Contents

Defining the Library Power-Up State 33

Enabling/Disabling the Auto Clean Option 34

Enabling/Disabling the Retry Option 34

Enabling/Disabling the Auto Load Feature 35

Setting/Changing the Status Display Area Language ...................36

Adjusting the Display Area Contrast 37

Unloading a Drive....................................................................... .........37

Cleaning a Drive...................................................................................38

Displaying the Library’s Actuator or Sensor Status........................39

Performing an Inventory.....................................................................40

Chapter 3

Operator Troubleshooting.......................................................................43

Operator Troubleshooting.........................................................................44

Other Problems ...........................................................................................46

Glossary

viii ACL 4/52 Operator’s Guide

Page 9

Figures

Figure 1 ACL 4/52 Library......................................................................2

Figure 2 ACL 4/52 Library Numbering Conventions.........................3

Figure 3 Control Panel............................................................ ......... .........4

Figure 4 Load Port.....................................................................................7

Figure 5 Front Door.......................................................................... .........8

Figure 6 Rear Panel ................................................................. ..................9

Figure 7 DLT 2000 Tape Drvie Status/Control Panel........................10

Figure 8 DLT 4000 Tape Drive Status/Control Panel........................10

Figure 9 DLT 7000 Tape Drive Status/Control Panel........................11

Figure 10 Menu Structure ........................................................................13

Figure 11 Menu Navigation example.....................................................15

Figure 12 Inserting/Removing Tapes............................................. .......24

Figure 13 DLT 2000 and DLT 4000 Manual Unload.............................26

Figure 14 DLT 7000 Manual Unload ......................................................27

Figure 15 Turning the Interior Light On/Off........................................29

ixACL 4/52 Operator’s Guide

Page 10

x ACL 4/52 Operator’s Guide

Page 11

Tables

Table 1 Control Panel Functions ...........................................................5

Table 2 DLT Tape Drive Status/Control Panel Functions..............11

Table 3 Cartridge/Tape Drive Campatibility ...................................12

Table 4 Status Messages .......................................................................44

Table 5 Other Problems........................................................................46

xiACL 4/52 Operator’s Guide

Page 12

xii ACL 4/52 Operator’s Guide

Page 13

Preface

Audience

Purpose

Document

Organization

0

This document was written for operators of the ACL 4/52 Automated

Tape Library (library).

0

This book contains a brief description of the library, discussions of the

operator accessible components, operating instructions and

troubleshooting procedures.

0

Following is a brief description of chapter contents.

0

• Chapter 1, “Library Overview,” contains a brief description of the

library and detailed discussions of the operator accessible

components.

• Chapter 2, “Operating Procedures,”provides procedures for

applying/removing library power, inserting/removing tapes

through the load port, manually unloading a tape cartridge and

procedures for all functions associated with the Control Panel

Menu Mode.

• Chapter 3, “Operator Troubleshooting,” provides explanations of

status messages shown in the Control Panel Status Display Area as

well as the associated action necessary (if any) to rectify specific

problems. This section allows you to diagnose problems and

determine the extent of repair necessary.

Notational

Conventions

0

Note:

This manual uses the following conventions:

Caution:

Cautions indicate potential hazards to equipment and are

included to prevent damage to equipment.

Notes emphasize important information related to the main topic.

ACL 4/52 Operator’s Guide

xiii

Page 14

Warning: Warnings indicate potential hazards to personal safety and

are included to prevent injury

.

This manual uses the following:

• Right side of the library — Refers to the right side as you face the

component being described.

• Left side of the library — Refers to the left side as you face the

component being described.

• b — All binary numbers are succeeded by “b.”

• h — All hexadecimal numbers are succeeded by “h.”

• Error or attention conditions are represented in parenthesis that

translate as follows:

(SK=S ASC=AA ASCQ=QQ)

where:

S — hexadecimal sense key value

AA — hexadecimal additional sense code

Related Documents

QQ — hexadecimal additional sense code qualifier

0

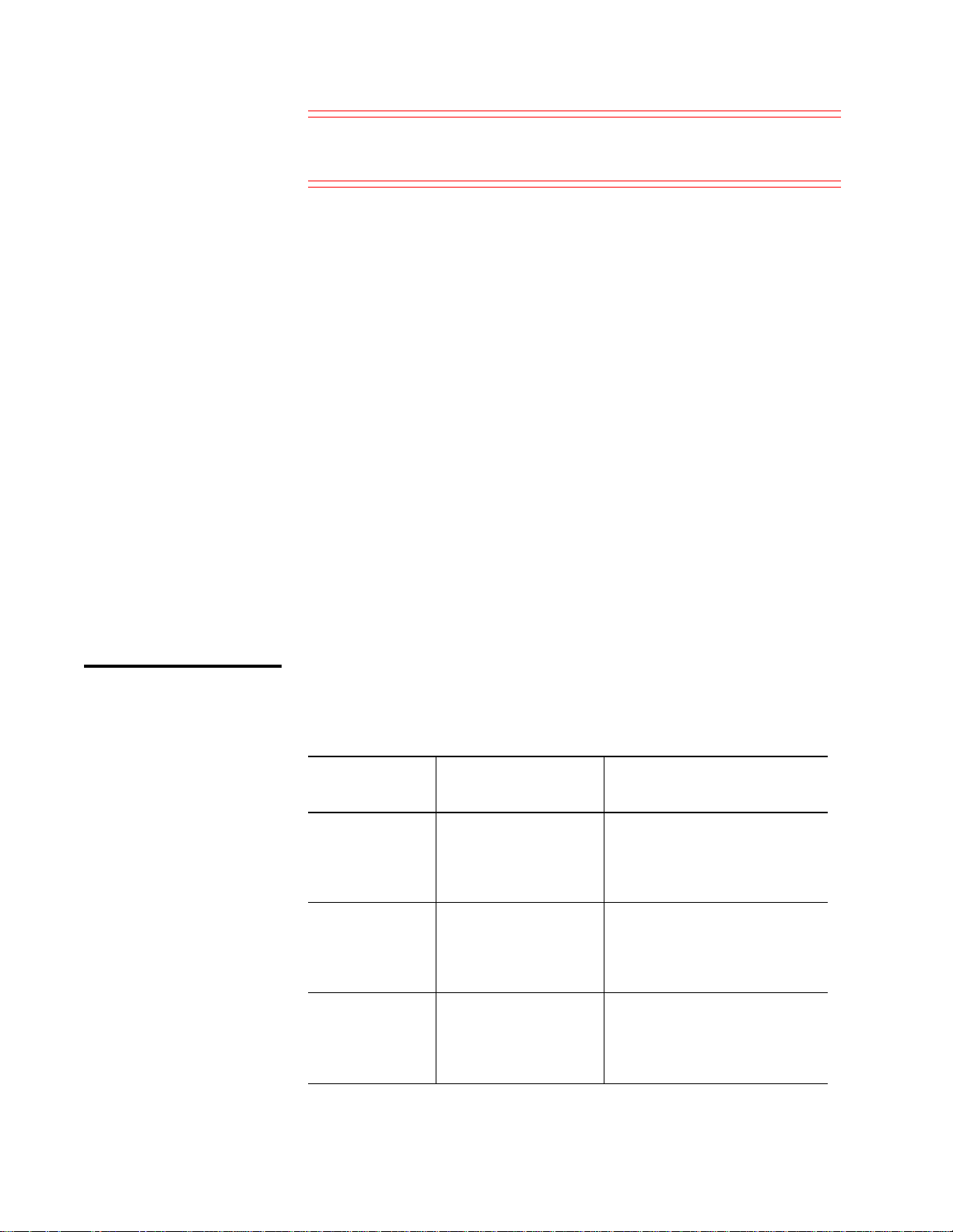

Documents related to the ACL 4/52 are shown below:

ACL 4/52 Documentation

Document

Number

6211221 ACL 4/52 Facilities

6211224 ACL 4/52 Diagnostic

6211225 ACL 4/52 Software

Document Title Document Description

This guide describes facility

Planning and

Installation Guide

Software User’s

Manual

Interface Guide

preparation and provides the

procedures for first-time

installation of the library.

This manual provides

procedures for installing and

using the ACL 4/52

Diagnostic Sof t ware.

This guide is for software

engineers and programmers

developing applications that

control the ACL 4/52 library.

er

0

xiv ACL 4/52 Operator’s Guide

Page 15

Refer to the appropriate pr oduct manual(s) f or information about your

tape drive and cartridges.

Contacts

SCSI-2 Specification

0

The SCSI-2 communications specification is the proposed American

National Standard for information systems, dated March 9, 1990.

Copies may be obtained from:

Global Engineering Documents

15 Inverness Way, East

Englewood, CO 80112

(800) 854-7179 or (303) 397-2740

0

ATL Products Corporate Headquarters

0

To order documentation on the LANvault 200 or other products

contact:

ATL Products, Inc.

101 Innovation Drive

Irvine, CA 92612-5872

(949) 856-7800

(800) 284-5101

Technical Publications

To comment on existing documentation send e-mail to:

atl-docs@atlp.com

World Wide Web

Visit the ATL Products home page at:

http://www.atlp.com

Professional Services

The ATL Products Professional Services Department provides a 24hour help desk that can be reached at:

Locally (949) 477-7924

North America/South America (800) 284-5101

Europe, Africa, Asia, and Australia

(International Code) +44 (0) 1256 848748

Send faxes for the Professional Services Department to:

0

0

0

ACL 4/52 Operator’s Guide xv

Page 16

Locally (949) 477-7940

North America/South America (949) 477-7940

Europe, Africa, Asia, and Australia

(International Code) + 1 + (949) 477-7940

Send e-mail for the Professional Services Department to:

North America/South America

Europe, Africa, Asia, and Australia

helpdesk@atlp.com

ukhelpdesk@atlp.com

xvi ACL 4/52 Operator’s Guide

Page 17

Chapter 1

Chapter 1 Library Overview

Library Overview

This section contains a brief description of the library and a discussion

of each of the operator-accessible components.

1

ACL 4/52 Operator’s Guide

1

Page 18

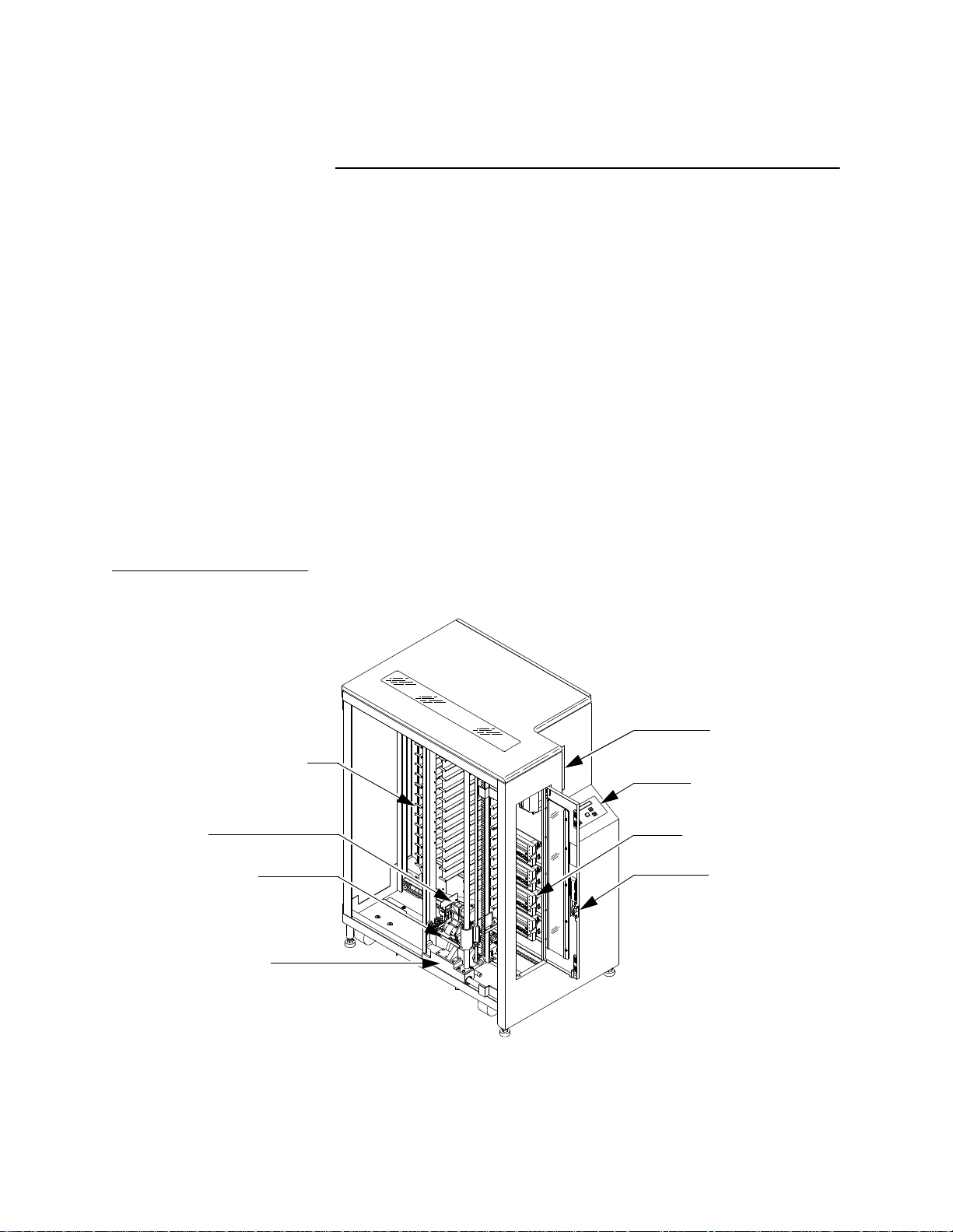

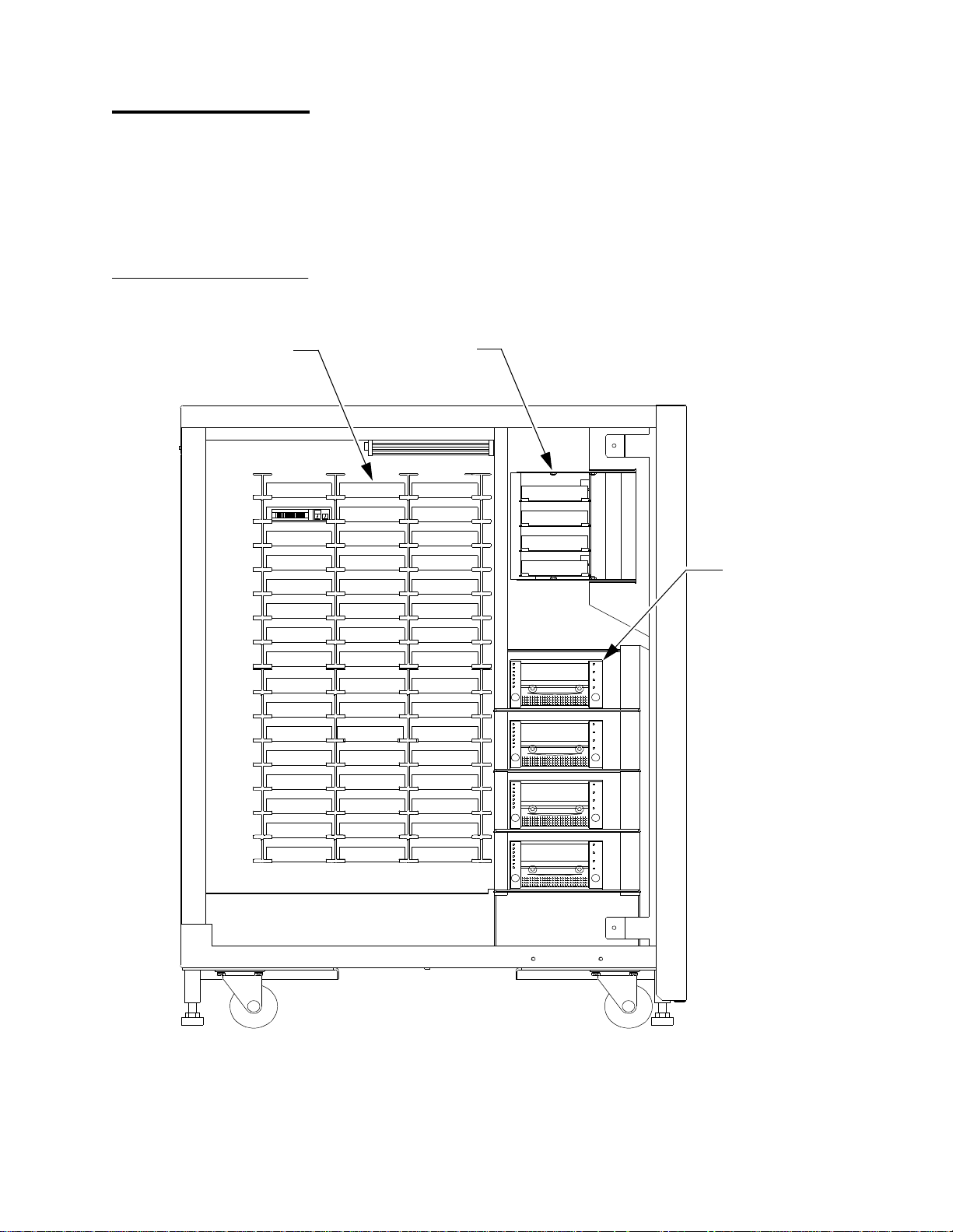

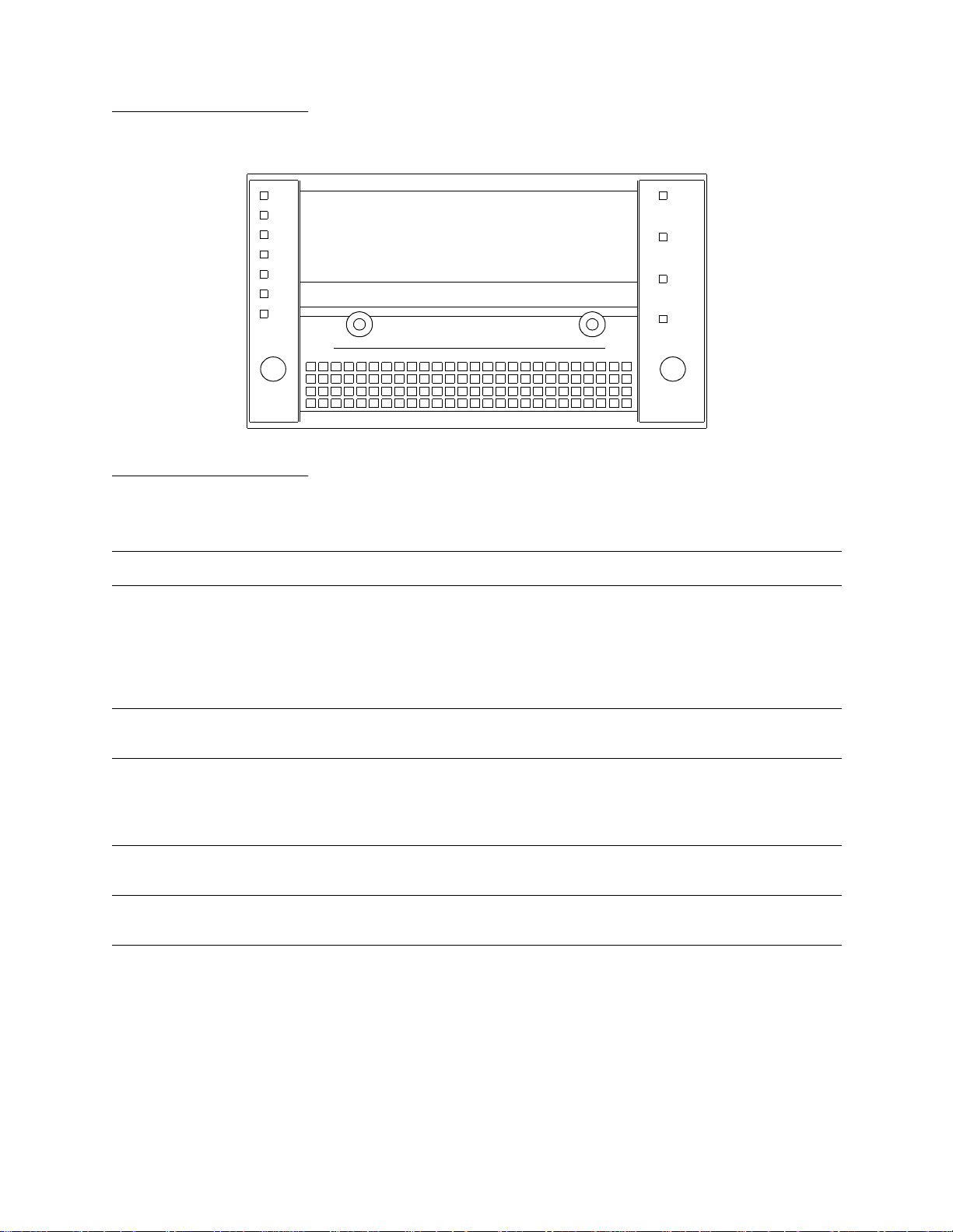

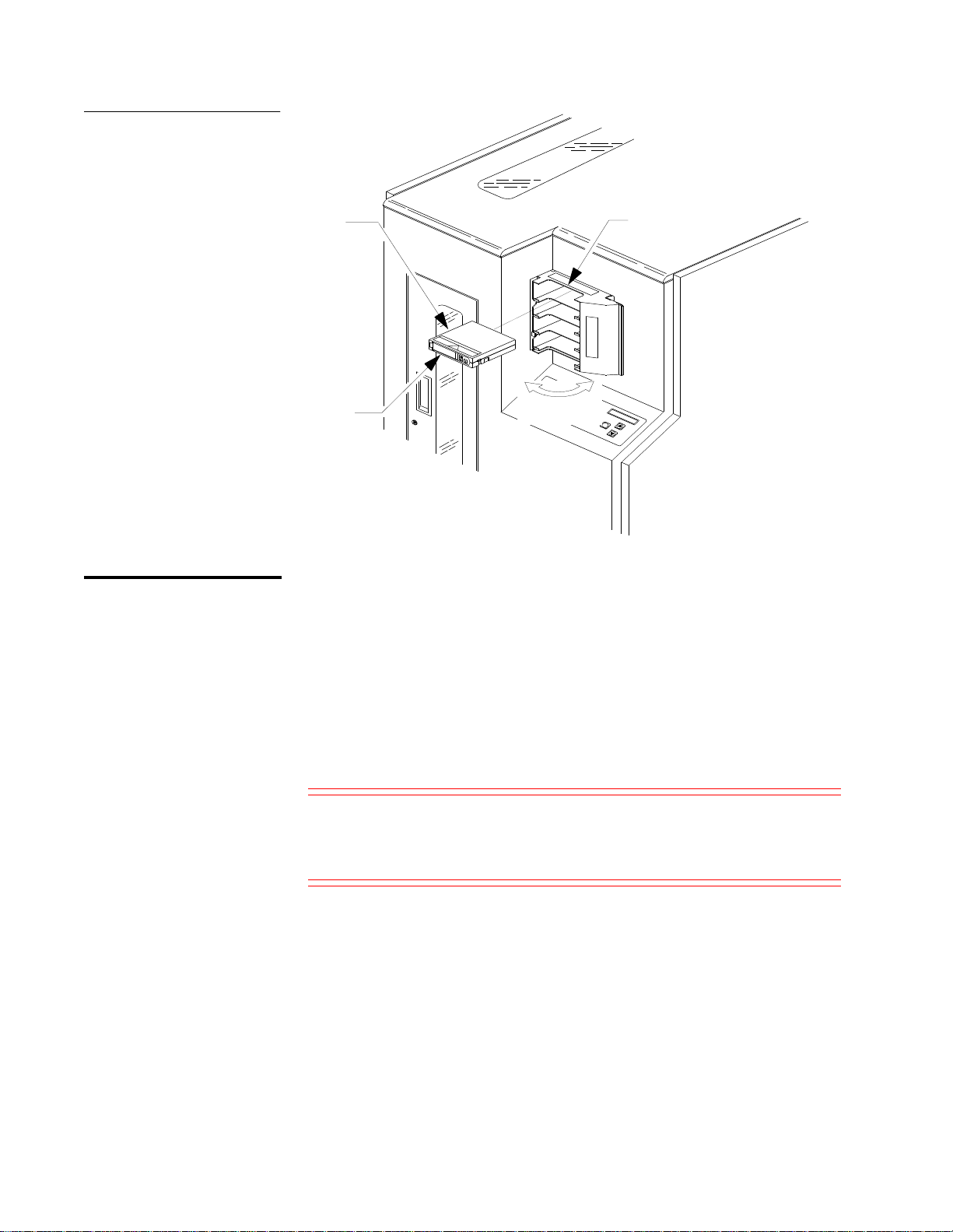

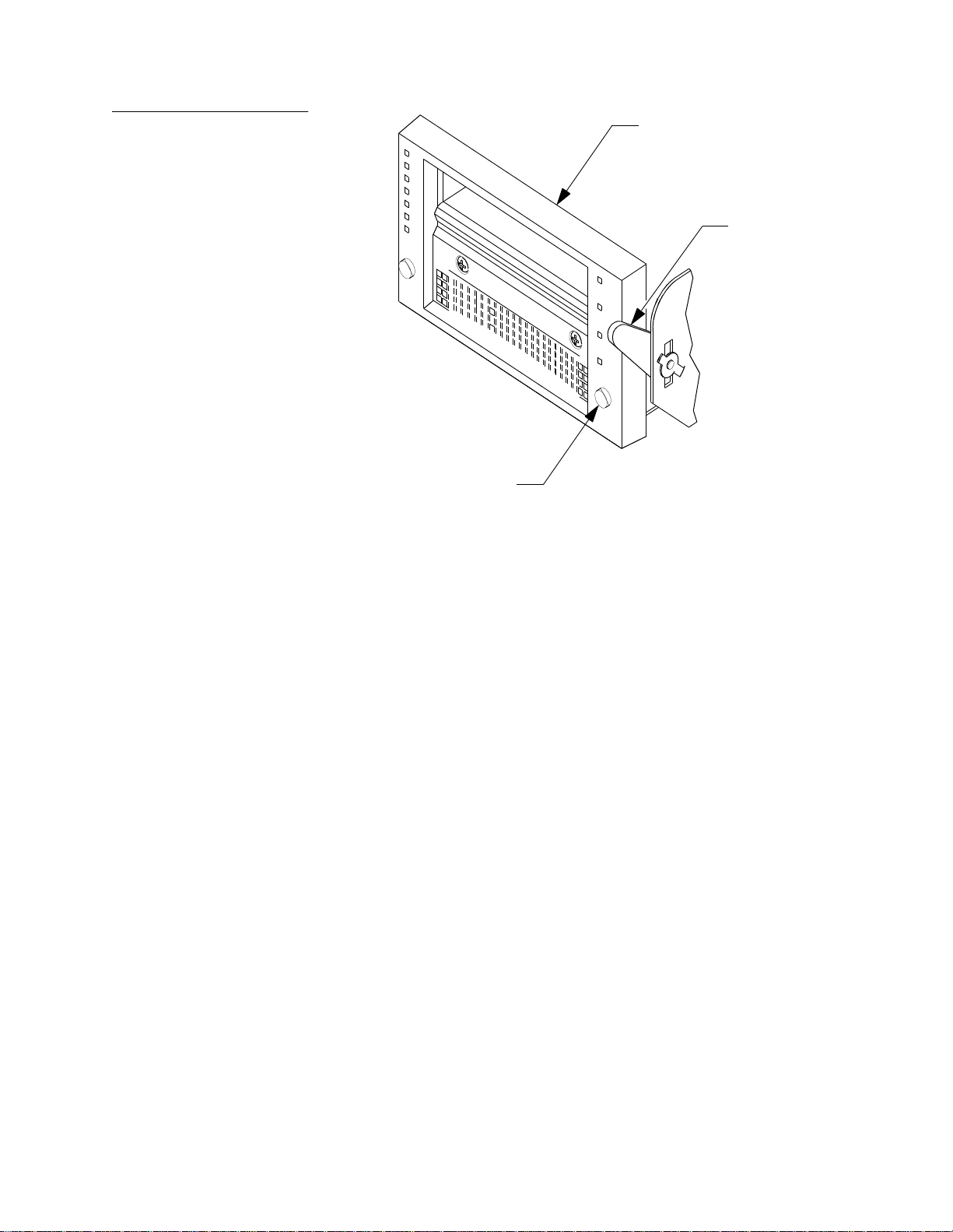

Figure 1 ACL 4/52 Librar

y

Library Description

The ACL 4/52 library (figure 1) is the automated storage and

retrieval component of an automated tape library system. It

accommodates either four DLT 2000, four DLT 4000, or four DLT

7000 tape drives and is capable of storing a maximum of 48 Digital

Linear Tape (DLT) cartridges in a Fixed Storage Array (FSA). An

operator-accessible load port at the front of the library can hold an

additional four tape cartridges for a total of 52. A host computer

communicates with the library through a SCSI interface using the

SCSI-2 medium changer command set. In a typical operation, the

host commands the robotics to transfer tape cartridges between

storage bins (in the FSA), tape drives, and the load port. Each time

a tape cartridge is transferred, a gripping mechanism is moved to

the tape cartridge location wher e it “picks” the tape cartridge, then

moves to and “places” the cartridge in the new location.

1

Fixed Storage Array (FSA)

(48 Cartridge Bins)

Gripper

Vertical Carriage

Horizontal Carriage

(Left Side Cosmetic Panel Removed)

2

(Front)

Load Port

Control Panel

Tape Drives (4)

(DLT 7000 shown)

Front Door

TA00038d

Page 19

Chapter 1 Library Overview

Library Description

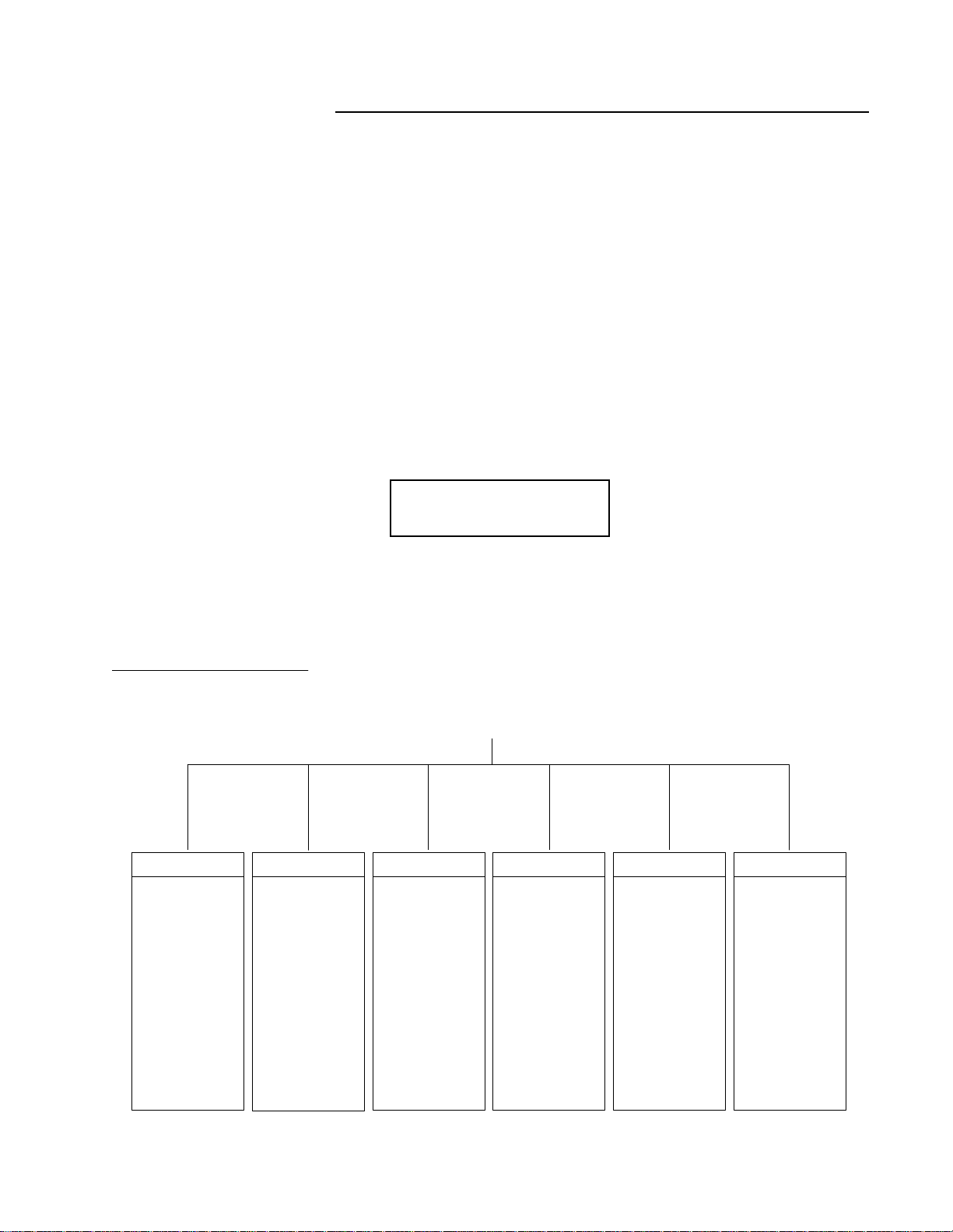

ACL 4/52 Library Numbering Conventions

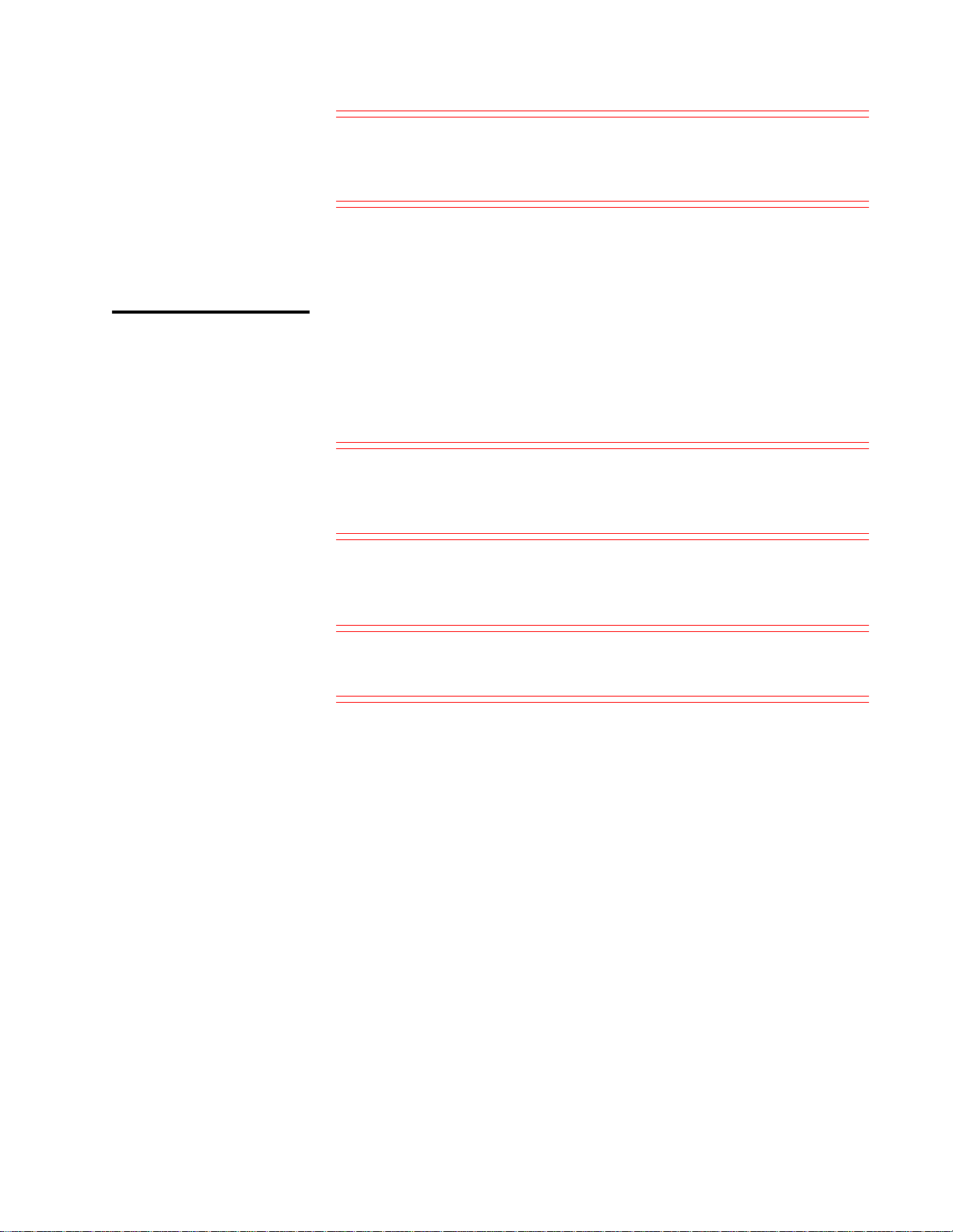

Figure 2 ACL 4/52 Library

Numbering Conventions

FSA Bins

1

Bin 0

Bin 2

Bin 3

Bin 4

Bin 5

Bin 6

Bin 7

Bin 8

Bin 9

Bin 10

Bin 11

Bin 12

Bin 13

Bin 14

Bin 15

Figure 2 is a view from the left si de of the library with the lef t cosmetic

panel removed. Figure 2 depicts the numbering convention for the

library's Fixed Storage Array bins, load port bins, and tape driv es. This

numbering convention is used in the diagnostic software and the

library menu mode, which is viewed in the status display area of the

control panel.

Load Port Bins

Bin 16

6711BA

Bin 17

Bin 18

Bin 19

Bin 20

Bin 21

Bin 22

Bin 23

Bin 24

Bin 25

Bin 26

Bin 27

Bin 28

Bin 29

Bin 30

Bin 31

Bin 32

Bin 33

Bin 34

Bin 35

Bin 36

Bin 37

Bin 38

Bin 39

Bin 40

Bin 41

Bin 42

Bin 43

Bin 44

Bin 45

Bin 46

Bin 47

Bin 0

Bin 1

Bin 2

Bin 3

Drive 0

Drive 1

Drive 2

Drive 3

DLT Tape Drives

(DLT 7000 shown)

TA00053c

ACL 4/52 Operator’s Guide 3

Page 20

Chapter 1 Library Overview

Operator Accessible Components

Control Panel

Operator Accessible Components

1

The operator of the ACL 4/52 library will need access t o the fol lowing:

• Control panel

• Load port

• Front door

• Rear panel

• DLT tape drive status/control panel

Additionally, the control panel allows you to perform several types of

functions (operational and diagnostic) using the menu mode. The

menu mode functions and the items listed above are discussed in the

following paragraphs.

1

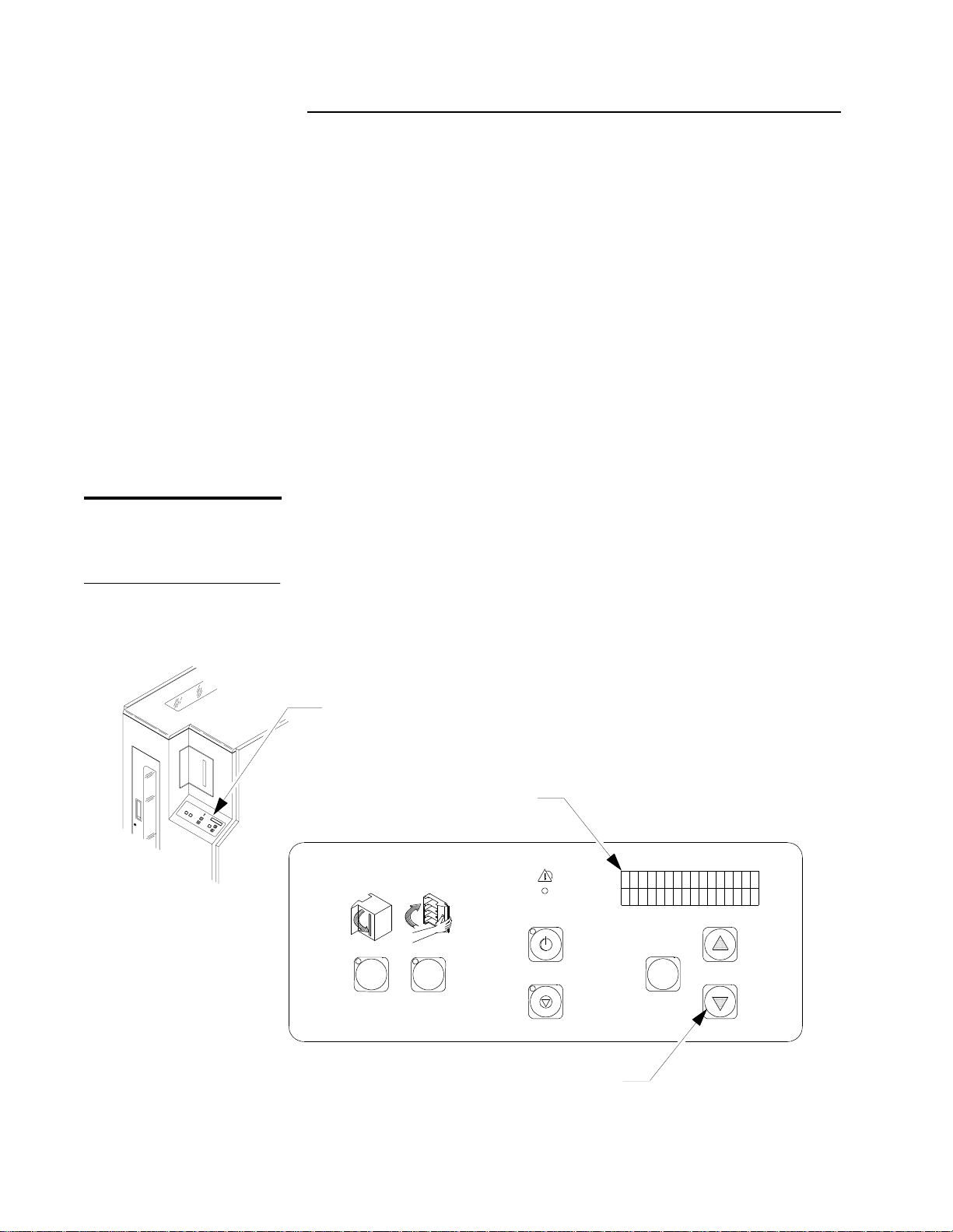

The control panel (figure 3) is located on the right front of the library.

Its features are described in table 2 on page 11.

Figure 3 Control Panel

Control Panel

OPEN CLOSE

Status Display Area

(16 Characters/2 Lines)

FAULT

STANDBY

SELECT

STOP

Scrolling Buttons

(Up

4 ACL 4/52 Operator’s Guide

{

and Down

}

↑

{↓})

TA00003/15

Page 21

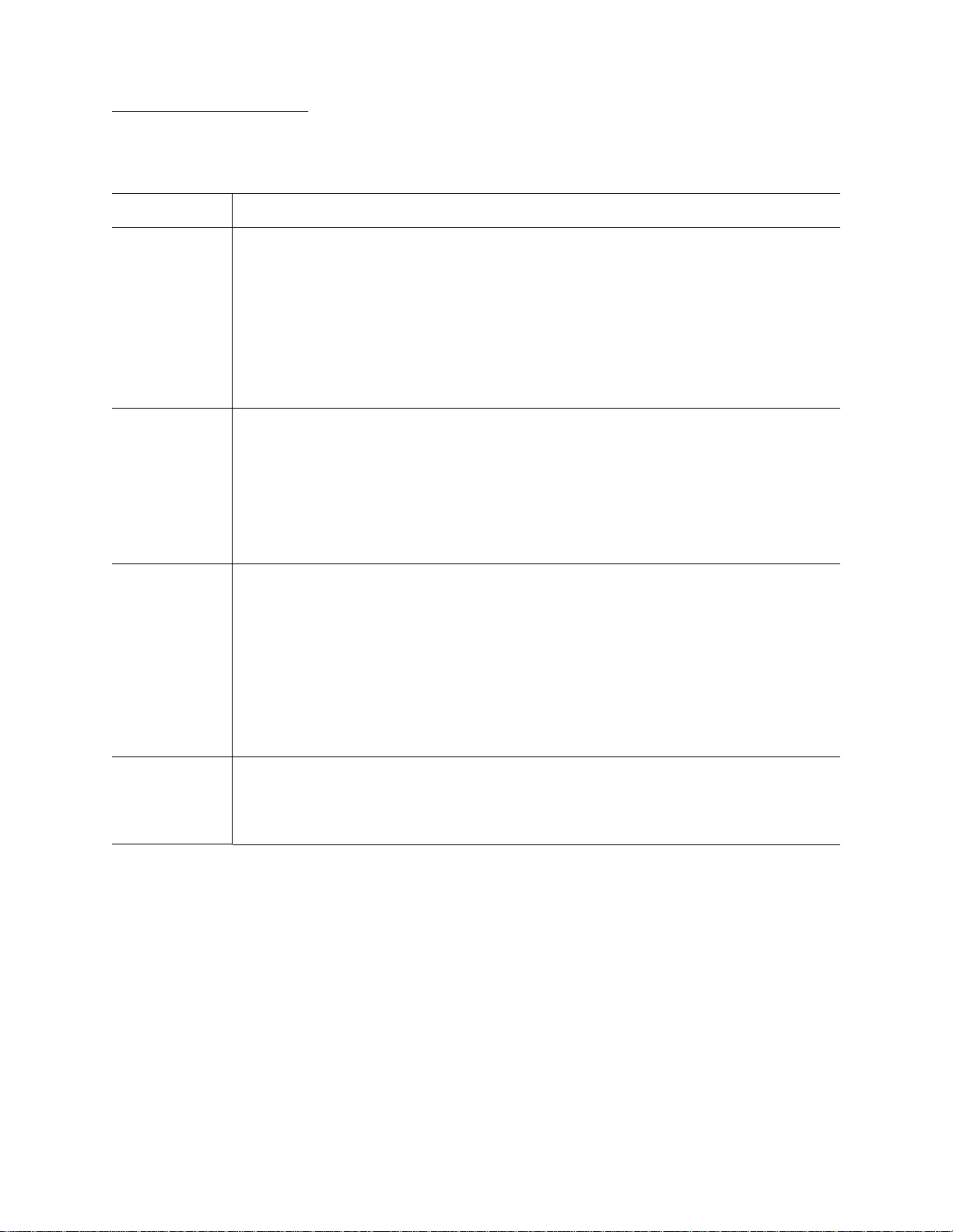

Table 1 Control Panel

Functions

Feature Function

Chapter 1 Library Overview

Operator Accessible Components

(load port)

OPEN

(button/

indicator)

(load port)

CLOSE

(button/

indicator)

STANDBY

(button/

indicator)

The (load port)

inserting or removing tape cartridges.

Pressing the

• park the robotics (the green indicator blinks until the robotics are parked)

• unlock and open the load port door (the indicator is steadily lit), and then

• re-lock the load port door in the open position (the indicator is off).

(Once the door is opened, you can insert/remove tape cartridges into/out of the four

bins).

When the load port door is in the open position, the (load port)

used to unlock the door before closing it.

Pressing the

• park the robotics (the green indicator blinks until the robotics are parked), then

• unlock the door (the indicator is steadily lit).

(Once the indicator is steadily lit, you can close the door. The library will lock it in the

closed position.)

You can set the state of the library (on-line or off-line) with this button. With the

library in the on-line mode, pressing this button toggles the library to the off-line state

(green indicator on). While in

control panel menu mode is available and the diagnostic port on the rear panel

DIAG

(

) is active. Pressing the button again toggles the library to the on-line state. The

green indicator functions as follows:

• Off (solid) -

• On (solid) -

• Blinking - Waiting for the current on-line operation to complete.

OPEN

OPEN

CLOSE

STANDBY

STANDBY

button is used to unlock the load port door for the purpose o f

button causes the library to:

button causes the library to:

STANDBY

is not selected. The library is on-line.

is selected. The library is off-line.

, host communications are disabled, the

CLOSE

button is

STOP

(button/

indicator)

You can stop the robotic equipment by pressing the

removes power to the robotic equipment and illuminates the (green) indicator.

Pressing the button again restores the power to the robotics and extinguishes the

indicator.

ACL 4/52 Operator’s Guide 5

STOP

button. When pressed, it

Page 22

Chapter 1 Library Overview

Operator Accessible Components

Feature Function

SELECT

↑

(scroll-up),

and

↓

(scroll-down)

(buttons)

FAULT

(indicator)

Status

Display

Area

Load Port

With the library in the

menu mode. While in the menu mode,

options, shown in the second line of the status display area (SDA), for execution.

The

and ↓ buttons are used in conjunction with the

↑

menu mode, these buttons are used for navigating through the menu options.

(For detailed procedures on using the menu mode, see Chapter 3, Operating

Procedures.)

When illuminated (red), it indicates the library is in an error condition. Observe the

SDA for a specific message. (For a listing and detailed description of all status

messages shown in the SDA, see Chapter 4, Operator Troubleshooting.)

This is a 16-character (5x7 dot-matrix Liquid Crystal Display {LCD}) /2-line display . It

shows status messages that describe the operating state of the library. It is also used

for displaying menu options wh ile the library is in the menu mode.

1

The load port (figure 4 on page 7) is located at the front of the library

STANDBY

state, pressing the

SELECT

SELECT

allows you to choose menus and

SELECT

button activates the

button. While in the

above and to the left of the control panel. Under library control and in

conjunction with the load port

OPEN

and

CLOSE

buttons, it allows

the operator to insert and/or remove up to four tape cartridges. (See

table 2 on page 11 for a description of the load port buttons.)

For a load operation, press the load port

OPEN

button. When the

indicator stops blinking, the load port door automatically opens (and

locks in the open position) allowing the operator to insert tape

cartridges.

After the operator presses the

CLOSE

button and closes the door, the

tape cartridge(s) is (are) made available to the library.

Caution:

You must release the

CLOSE

button before pushing the

load port door closed.

For the unload operation, the gripper places tape cartridges in the load

port bins. Looking through the view port, the operator will be able to

decide if an unload operation is necessary. Pressing the

OPEN

button

automatically opens the door allowing the operator to r emove the tape

cartridge(s).

6 ACL 4/52 Operator’s Guide

Page 23

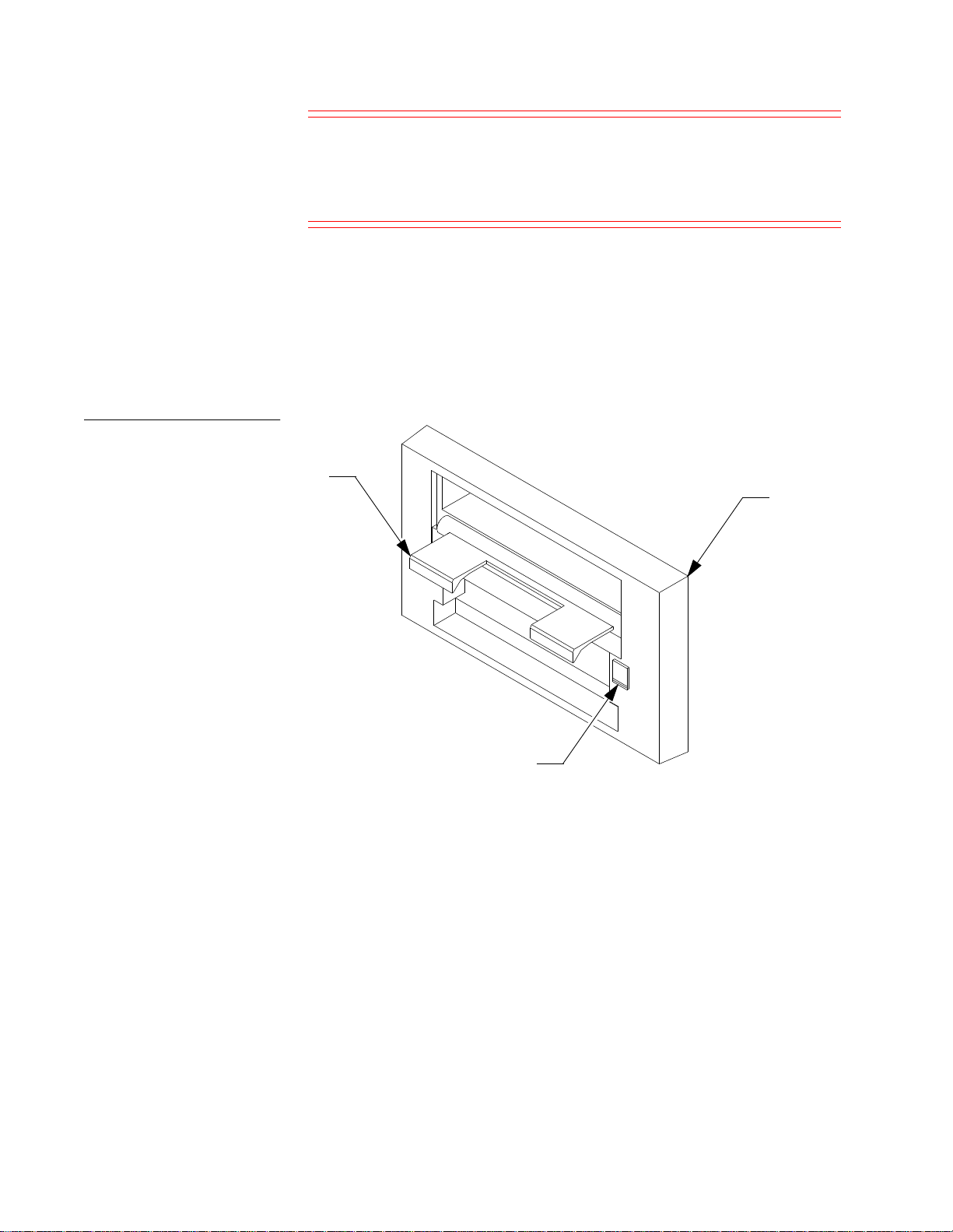

Figure 4 Load Port

Chapter 1 Library Overview

Operator Accessible Components

Load Port (Closed)

(View Port)

TA00015B

Load Port (Open)

Cartridge

Front Door (with Interlock Switch)

(Closes to Left)

The library door is shown in figure 5. This door can be used to access

1

the DLT tape drive status/control panels for manually unloading,

ejecting and removing a tape cartridge from the drives.

For safety purposes, an interlock switch (shown in Figure 4) removes

power from the robotics equipment when the door is opened.

Typically, the front door will be used by FSEs during maintenance

procedures.

ACL 4/52 Operator’s Guide 7

Page 24

Chapter 1 Library Overview

Operator Accessible Components

Warning: To prevent injury from moving components, always press

the control panel

front door. The

STANDBY

STANDBY

button before opening the

indicator will flash until the

current command is completed.

Figure 5 Front Door

Note: When the

displayed, the front door may be opened. Always press the control

panel

STOP

STANDBY

indicator is on solid and

button before opening the front door.

Front Door (Open)

Handle

System Off-line

is

Interlock

Switch

Interlock

Switch

(Open to Right)

Rear Panel

1

The rear panel of the library is shown in figure 6. It contains the AC

power switch, AC power receptacle and the communication ports for

the host, tape drives and diagnostic PC. The operator’s only

responsibility concerning the rear panel is verifying the cables are

properly connected and applying/removing power to/from the

library through the AC power switch.

8 ACL 4/52 Operator’s Guide

Page 25

Figure 6 Rear Panel

Chapter 1 Library Overview

Operator Accessible Components

DIAG

SCSI PORT 4

SCSI PORT 3

* Connectors shown for default

SCSI configuration.

DLT Tape Drive Status/Control Panel

AC Po wer Receptacle

and Switch

Spares

(Breakouts)

A status/control panel is located on each DLT tape drive (figure 7,

1

figure 8, and figure 9). The features of the status/control panel are

described in table 3 on page 12.

SCSI PORT 2

SCSI PORT 1

TA00032

For detailed discussions of the DLT tape drive, refer to the appropriate

product manual.

ACL 4/52 Operator’s Guide 9

Page 26

Chapter 1 Library Overview

Operator Accessible Components

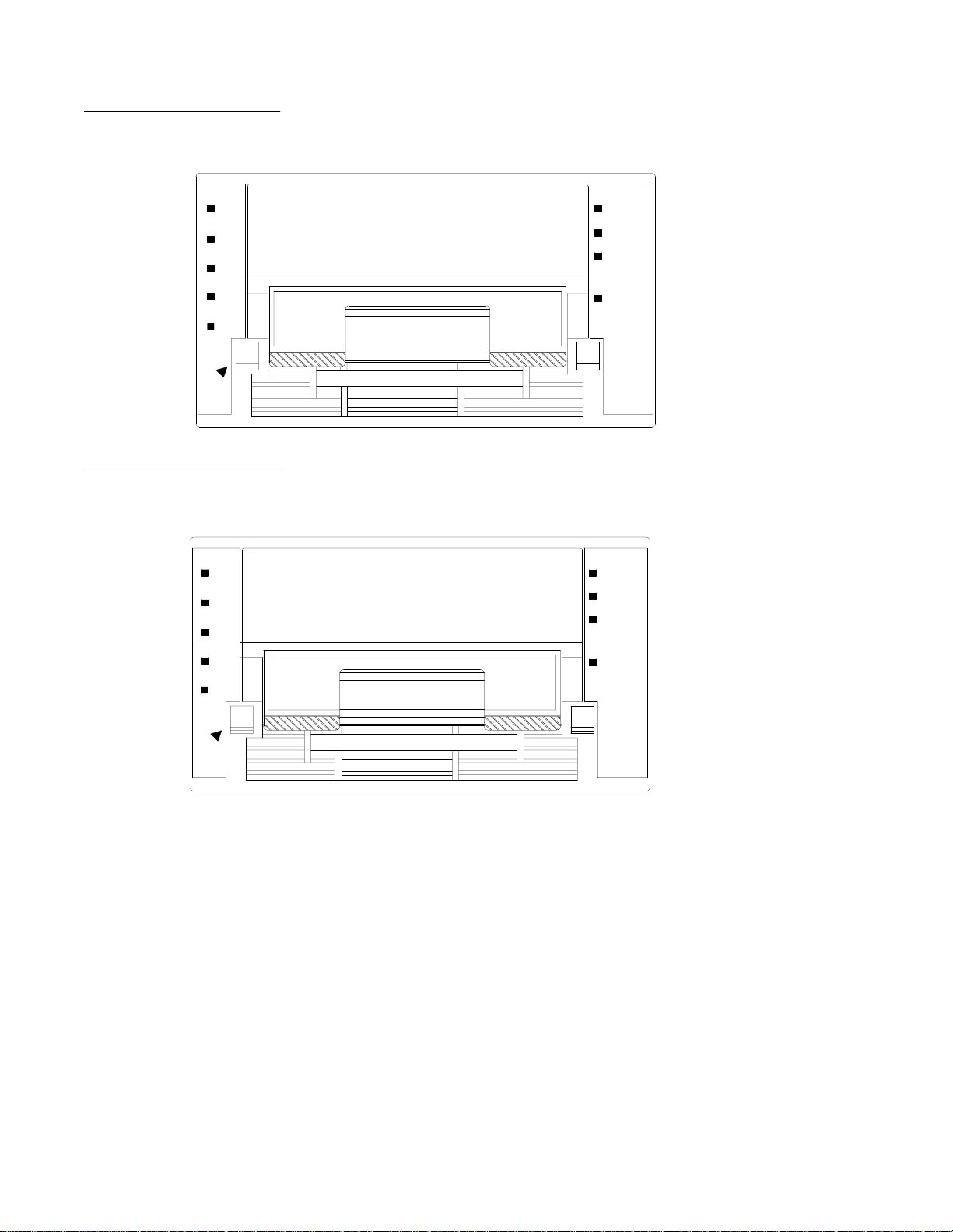

Figure 7 DLT 2000 Tape

Drvie Status/Control Panel

2.6

6.

0

10.

0

Compress

De

O

ns

v

erride

i

ty

De

Sele

ns

i

ty

c

t

Figure 8 DLT 4000 Tape

Drive Stat us/Control Panel

Protec

T

C

le

Ha

a

Use

O

U

W

r

ite

t

ed

pe

i

n

U

se

a

nin

g

T

a

pe

p

e

ra

n

te

dle

n

lo

ad

TA00040a

O

Select

De

v

Densit

erride

2.

6.0

10.0

Compres

ns

i

t

y

Wr

P

i

Tape

Clea

H

ro

t

U

s

e

n

Operate

an

d

Unloa

te

ect

e

d

i

n Use

ing Tape

le

6

s

y

d

TA00040a

10 ACL 4/52 Operator’s Guide

Page 27

Figure 9 DLT 7000 Tape Drive

Status/Control Panel

Chapter 1 Library Overview

Operator Accessible Components

Table 2 DLT Tape Drive

Status/Control Panel

Functions

Feature Function

Unload

(button)

Sele

2.6

6

10

2

35

Comp

De

O

.0

0.0

.0

/1

5

.0

.0

r

ess

n

sit

ve

y

r

rid

e

c

t

U

nl

Write

Pr

o

te

Tap

e

In

u

se

U

se

Cl

e

an

Ta

p

e

Operate

Handl

o

ad

c

ted

i

ng

e

This button moves all tape from the drive take-up reel to the tape cartridge

supply reel, and ejects the cartridge into position for removal.

Operate Handle

(indicator)

Use Cleaning Tape

(indicator)

Tape in Use

(indicator)

Write Protect

(indicator)

Note The tape cartridge must be completely rewound and unloaded

before ejecting and removing the tape cartridge from the drive.

Depending on tape position, this operation takes 10 to 120 seconds.

This green indicator lights when the insert/release handle is ready to operate.

This yellow indicator lights when the drive hea d needs cleaning or the current

cleaning tape is bad. After unloading the cleaning tape cartridge, the indicator

remains lit if the cleaning operation was not completed or the cleaning tape

cartridge was bad.

This yellow indicator blinks while the tape cartridge loads and calibrates. After

calibration, it remains lit.

This orange indicator lights when the loaded tape cartridge is write-protected.

ACL 4/52 Operator’s Guide 11

Page 28

Chapter 1 Library Overview

Cartridge/Tape Drive Compatibility

Table 3 Cartridge/Tape

Drive Campatibility

Cartridge/Tape Drive Compatibility

The ACL 4/52 library is capable of supporting the DLT 2000, DLT

4000, and DLT 7000 tape drives. The library is also capable of

supporting the CompacTape III and CompacTa pe IV cartridges, which are

dark gray and black, respectively. When loading the library with

cartridges, observe the compatibility of cartridges and tape drives as

defined in table 3.

Cartridge Type

CompacTape III

Cartridge

CompacTape IV

Cartridge

DLT 2000

Tape Drive

Compatible Compatible Compatible

Not

Compatible

Caution: DO NOT USE CompacTape I, CompacTape II, or

CompacTape IIIXT tape cartridges in this library.

DLT 4000

Tape Drive

Compatible Compatible

DLT 7000

Tape Drive

1

12 ACL 4/52 Operator’s Guide

Page 29

Chapter 1 Library Overview

Menu Mode Structure

Menu Mode Structure

Some of the operator’ s responsibilities include using the control panel

menu mode. The menu mode is entered by placing the library in the

standby mode and then pressing the

panel. Once the menu mode is entered, the

DOWN-ARROW (

menu and the

)

buttons are used for navigating through the

↓

SELECT

button allows the operator to choose menus

and/or execute options. When in the menu mode, the Status Display

Area (SDA) displays two lines of the menu:

• The upper line (line #1) of the display is passive. It simply shows

the name of the current menu or sub-menu.

• The lower line (line #2) is the active line. When the operator

presses the

SELECT

button, the sub-menu or function displayed

on the lower line is the option selected or executed.

Line #1

Line #2

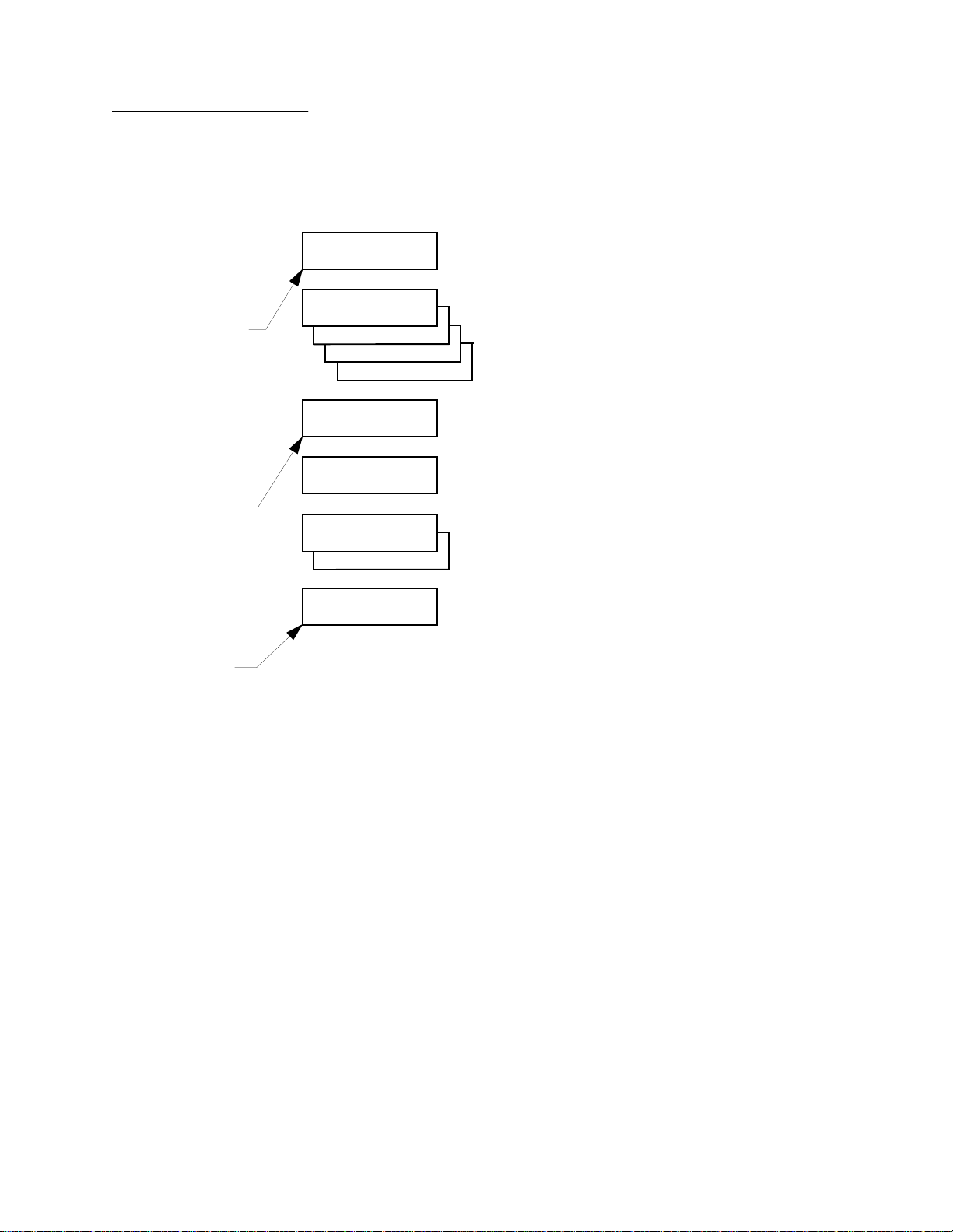

The overall structure and capabilities of the menu mode are shown in

figure 10 on page 13. The functions for which the operator will be

responsible, and a discussion of navigating through the menus is

provided in the paragraphs that follow.

SELECT

UP-ARROW

button on the control

)

and

(

↑

1

Figure 10 Menu Structure

Configuration

Inquiry

SCSI Address

Power-Up State

Num of Drives

Auto Clean

Retries

Auto Load

Language

Set View

Auto Inventory

No Barcode Scan

Emulate Exabyte

Temperature Det

Exit Menu

Unload

Clean

Exit Menu

Drive Control

MAIN MENU

Calibration

Cal All

Cal Storage

Cal Drives

Cal Load Port

Exit Menu

System Test Robot Control Diagnostics

Random Shuffle

Random /No Scan

Pick Each Bin

Pick All

Report Results

Exit Menu

Empty Load Port

Pick Bin

Pick Drive

Place Bin

Place Drive

Barcode Bin

Barcode Drive

Exit Menu

Home All

Selftest All

Status Actuator

Move Actuator

Inventory

Exercise All

Exit Menu

ACL 4/52 Operator’s Guide 13

Page 30

Chapter 1 Library Overview

Menu Navigation

Menu Navigation

After placing the library in the standby mode and pressing the

SELECT

To navigate through the menu, press the

of the desired main menu is displayed on line #2 of the SDA, then

release the

Line #1 changes to the main menu selection and line #2 shows the first

sub-menu. Press the

continue pressing the

displayed. Pressing

first option in line #2. Again, the operator must scroll through the

options list until the desired option is displayed. The operator selects

the option and it is executed.

An

option list. When the operator chooses

previous menu. At that point, another pr ocedure can be performed, or

the operator can scroll to the next

menu mode. The quickest way to exit the menu mode is to press the

SELECT

button on the control panel, the menu mode is activated.

or ↓ buttons until the name

↑

SELECT

Exit

option is provided at the end of each menu, sub-menu and

↑

and

button.

SELECT

↑

SELECT

or

buttons simultaneously.

↓

button for the first sub-menu, or

or

buttons until the sub-menu desired is

↓

chooses the sub-menu and displays the

Exit

, he/she are returned to the

Exit

until completely exiting the

1

Note: After an operation is executed, the results displayed in the SDA must

be cleared befor e the quick method of exiting will be avai lable. To clear

the results of an operation from the SDA, press the

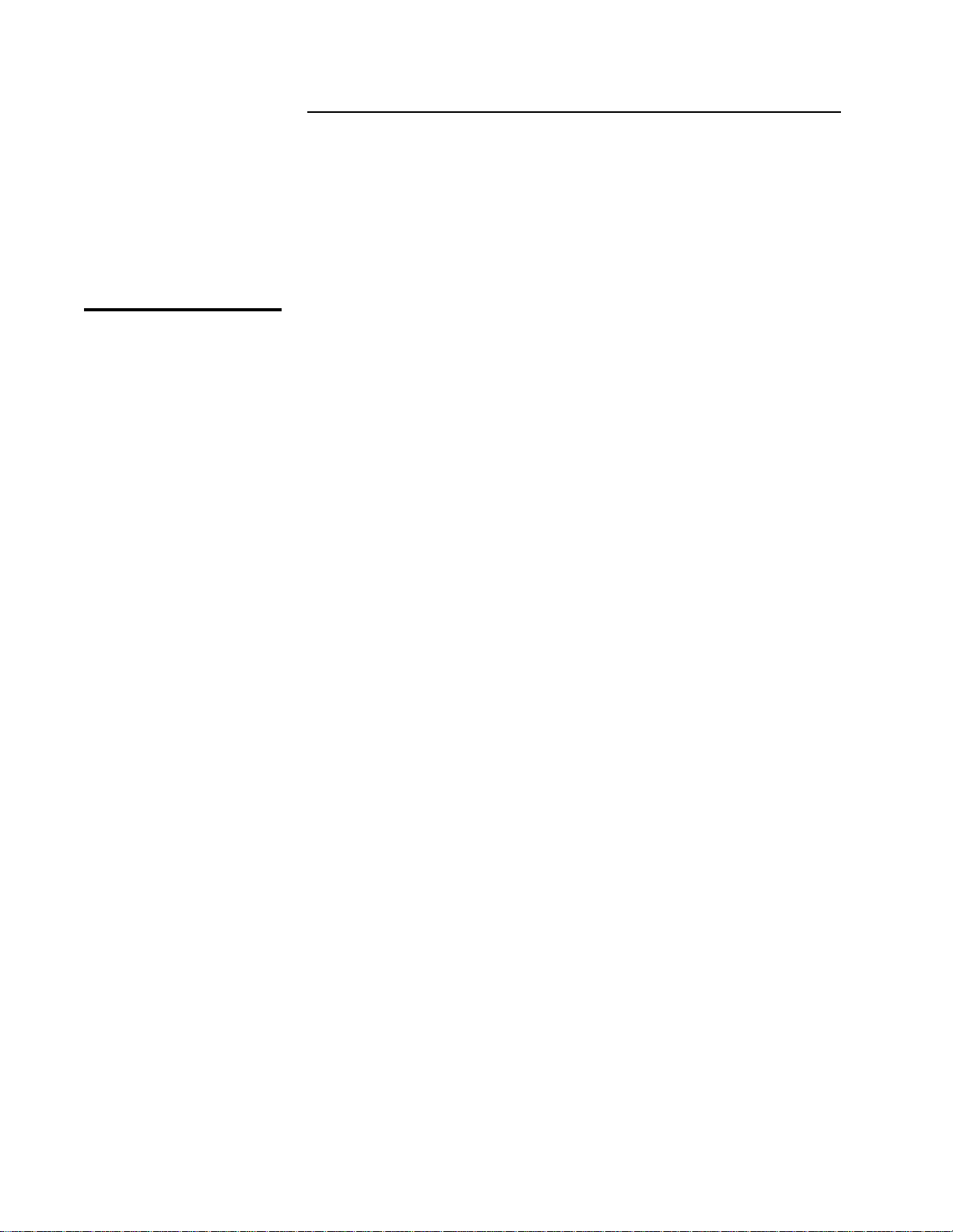

figure 11 on page 15 is an example of menu navigation. It shows the

commands and associated SDA displays involved in changing the

AUTO CLEAN

option from DISABLED (factory default) to ENABLED.

or ↓ button.

↑

14 ACL 4/52 Operator’s Guide

Page 31

Figure 11 Menu

Navigation example

Chapter 1 Library Overview

Menu Navigation

Status Display Switch Description

Menu:

Configuration

Menu: Configurati

M

a

S

u

Inquiry

SCSI Address

Pow er- Up S ta te

Num of Drives

Menu: Configurati

Auto Clean

Menu: Auto Clean

Enabled

Menu: Enabled

..Workin g

..SUCCESS..

S

-

E

the “Configuration” Men u

Select

L

E

C

-

T

-

the INQUIRY Sub-Menu

-

-

↓

↓

the SCSI ADDRESS Sub-Menu

the PWR-UP STATE Sub-Menu

↓

-

↓

the NUM OF DRIVES Sub-Menu

Bypass

Bypass

Bypass

Bypass

Menu: Auto Clean

Enabled<

-

S

<

(

E

e the A UTO CLEAN Sub-Menu

L

Choos

ACL 4/52 Operator’s Guide 15

Page 32

Chapter 1 Library Overview

Operator Tasks (using the Menu Mode)

Operator Tasks (using the Menu

Configuration Menu Functions

Mode)

As an operator, you may need to use the configuration, drive control

and diagnostics menus.

Configuration

The

1

• Set or change the library’s SCSI address

• Set or change the tape drive SCSI addresses

• Define the state of the library after the power-up sequence has

completed

• Enable or disable the automatic drive cleaning option

• Enable or disable the retry operation option

• Enable or disable the automatic loading feature

• Set or change the language displayed in the SDA

• Adjust the SDA contrast level

menu allows you to:

1

Setting/Changing the Library’s SCSI Address

The SCSI address (0...7) of the library can be set using the

Address/Robotics

Setting/Changing the Tape Drive SCSI Addresses

This function is used to set the SCSI address (0...7 for libraries with

DLT 2000 or DLT 4000 tape drives, and 0...15 for libraries with DLT

7000 tape drives) of each tape drive in the library. This can be done

through the

Defining the Library’s Power-Up State

You have the option of defining the starting co ndi t ion of the library,

either on-line or standby (off-line), after power-up, self-tests and

initialization has occurred. The default is on-line. You can change it by

using the

Enabling/Disabling Automatic Drive Cleaning

The automatic drive cleaning feature has two modes of drive cleaning

support: Host Initiated and Fully Automatic.

Power-Up State

sub-menus.

SCSI Address/ Drive n

sub-menu .

sub-menus.

SCSI

1

1

1

1

16 ACL 4/52 Operator’s Guide

Page 33

Chapter 1 Library Overview

Operator Tasks (using the Menu Mode)

In Host Initiated Cleaning Mode, drive cleaning is enabled by your

System Administrator at the host computer. Although the library unit

will internally track cleaning tape cartridge movement and use, the

library unit provides no cleaning support in this mode. The host is

responsible for all cleaning functions such as detecting when a drive

requires cleaning, tracking and selecting cleaning tape cartridges,

initiating media movement of the cleaning tape cartridge to the drive

and determining when a cleaning tape cartridge has been “used up.”

Drive cleaning in the Fully Automatic Cleaning Mode is also enabled by

your System Administrator at the host computer. However, in this

mode, the library unit monitors each drive’s status to determine when

a drive requires cleaning and initiates action when that determination

is made. In this case, the library unit selects an available cleaning tape

cartridge, handles media movement of the cleaning tape cartridge to

and from the drive and supervises the cleaning operation in the drive.

The library unit tracks cleaning tape cartridges within the library,

monitors cleaning tape cartridge use and determines when a cleaning

tape cartridge has been “used up.” A “used up” cleaning tape

cartridge is exported from the library to the load port under control of

the library.

The library is shipped with automatic drive cleaning disabled. If you

want this feature enabled, you can use the

Enabling/Disabling the Retry Option

Auto Clean

sub-menu.

If a failure occurs during a movement command and this option is

enabled, the library will attempt to recover and retry the operation. If

this option is disabled, no r etries ar e made and the err or is reported the

first time. The default is to have retries enabled. If you want this

feature disabled, you can use the

Setting/Changing the Library’s Language

Retries

sub-menu .

This function allows you to change the language displayed in the SDA.

The default language is English. If you want to change the language,

you can use the

Francais, Deutsch, Espanol

Adjusting the Display Area Contrast

Language

sub-menu. The options are:

Italiano

and

.

English

,

This function allows you to change the contrast of the SDA for easy

viewing at different angles. There are ten different contrast settings to

choose from in this menu. The default setting is five. To change the

contrast, use the

Set View

sub-menu.

1

1

1

Drive Control Menu Functions

You can use the

Drive Control

menu to:

1

ACL 4/52 Operator’s Guide 17

Page 34

Chapter 1 Library Overview

Operator Tasks (using the Menu Mode)

• Unload a tape cartridge from a specific drive

• Clean a specific drive

Unloading a Tape

This feature allows you to unload the tape (preparing to eject and

remove the tape cartridge) in a drive that you specify. To perform this

function, use the

Drive 2, Drive 3,

Unload

where:

sub-menu. The options are:

Drive 0, Drive 1

,

Menu ModePhysical Location

Drive 0

Drive 1

Drive 2

Drive 3

Cleaning a Drive

= Top Drive

= Second Drive

=Third Drive

=Bottom Drive

This feature allows you to direct a cleaning tape cartridge to a tape

drive that you specify. To perform this function, use the

menu. The options are:

Drive 0, Drive 1, Drive 2, Drive 3,

Clean

where:

sub-

Menu ModePhysical Location

Drive 0

Drive 1

Drive 2

Drive 3

= Top Drive

= Second Drive

=Third Drive

=Bottom Drive

1

1

Diagnostics Menu Functions

You can use the

1

Diagnostics

menu to:

• Display the status of the library

• Perform an inventory of the library

Displaying the Library’s Status

There are two options concerning the status of the library. These

options allow you to display the current condition of each sensor and

the buttons in the library (

Status Sensor

four actuators (horizontal, vertical, extension and gripper) in the

library (

the

menus and the

Status Actuator

Status Sensor

↑

). To display this information in the SDA, use

(not currently supported) and

↓

and

buttons to scroll through the returned

information.

18 ACL 4/52 Operator’s Guide

) or display the position of the

Status Actuator

sub-

1

Page 35

Chapter 1 Library Overview

Operator Tasks (using the Menu Mode)

Note:

Note:

Performing an Inventory

This feature simply allows you to perform an inventory of the library.

The inventory information is then written to nonvolatile RAM. To

perform this function, use the

Inventory

sub-menu.

Currently, all other menu options are reserved for FSEs and are not

discussed here. For detailed instructions on using the control panel in

the menu mode, see Chapter 2, “Operating Procedures.”

With a full library, the inventory will take less than three minutes if all

of the cartridges are properly bar code labeled. The actual inventory

time can take longer if the library is not completely full or if any of the

cartridges are not properly labeled. When the library is full of

unlabeled cartridges the inventory will take over twenty-seven

minutes.

1

ACL 4/52 Operator’s Guide 19

Page 36

Chapter 1 Library Overview

Operator Tasks (using the Menu Mode)

20 ACL 4/52 Operator’s Guide

Page 37

Chapter 2

Chapter 2 Operating Procedures

Operating Procedures

This chapter provides procedures for applying/removing power,

inserting/removing tape cartridges through the load port, manually

unloading a cartridge from a tape drive, and performing procedures

for all functions associated with the control panel menu mode.

2

ACL 4/52 Operator’s Guide

21

Page 38

Operating Procedures

This section contains procedures for executing the following

operator tasks:

• Applying and removing power

• Placing the library on-line or taking it off-line

• Inserting and removing tape cartridges using the load port

• Manually unloading a tape cartridge from a DLT tape drive

2

Applying Power to the Library

Placing the Library On-Line

To apply power to the library:

2

Note:

2

1 Verify the following:

a Front door and load port closed

b All outer skins attached

c All rear panel connections secured

2 At the rear panel, set the AC power switch to the | (on)

position.

3 After several seconds, verify that SDA shows

System On-line

configured for

the SDA. (See Chapter 3, “Operator Troubleshooting,”)

To place the library on-line:

1 With the library power applied and the SDA showing

Off-line

2 Verify that

is only displayed if the library power-up state is

On-line

, press the control panel

System On-line

. Otherwise,

is displayed in the SDA.

System Off-line

STANDBY

System On-line

is displayed in

button.

System

.

Taking the Library Off-Line

22

To take the library off-line:

2

1 With the library power applied and the SDA showing

On-line

2 Verify that

, press the control panel

System Off-line

STANDBY

is displayed in the SDA.

button.

System

Page 39

Chapter 2 Operating Procedures

Operating Procedures

Removing Power from the Library

Inserting Tape Cartridges

To remove power from the library:

2

1 Press the control panel

2 Press the control panel

Off-line

is displayed in the SDA.

STOP

button.

STANDBY

button and verify that

System

3 At the rear panel, set the AC power switch to the O (off) position.

To insert a tape cartridge:

2

Caution:

DO NOT USE CompacTape I, CompacTape II

or CompacTape

IIIXT tape cartridges in this library.

Caution:

Examine all cartridges before loading them into the library

or tape drive. Look for label stock or other foreign material

that may be clinging to the cartridges.

1 Press the load port

OPEN

button and verify the indicator begins

blinking. (It may require several seconds for the load port door to

automatically open.)

Warning:

Mechanical hazards could be exposed when the load port is

partially open or closed. Do not attempt to insert hands or

fingers into the load port opening at any time.

2 With the load port door open, place the tape cartridge(s) in any

available bin. (The pr oper orientation for tape cartridg e insertion is

shown in figure 12 on page 24).

3 Press the load port

Caution:

The load port door is locked in the open position. You must

press the

CLOSE

CLOSE

button.

button before attempting to close the l oad

port door.

4When the

CLOSE

indicator is steadily lit, push the load port door

closed. (The library will lock the door.)

ACL 4/52 Operator’s Guide 23

Page 40

Chapter 2 Operating Procedures

Operating Procedures

Figure 12 Inserting/Removing

Tapes

Removing Tape Cartridges

Tape Cartridge

Bar code Label

To remove a tape cartridge:

2

Note:

Use the view port to determine whether or not the load port contains

tape cartridges to be removed.

Opens to Right/

Closes to Left

Load Port

TA30010d

1 When tape cartridges are ready to be removed, press the load port

OPEN

button and verify the indicator begins blinking. (It may

require several seconds for the load port door to automatically

open.)

Warning:

Mechanical hazards could be exposed when the load port is

partially open or closed. Do not attempt to insert hands or

fingers into the load port opening at any time.

2 Remove the tape cartridge(s) from the load port bin(s).

3 Press the load port

CLOSE

button.

24 ACL 4/52 Operator’s Guide

Page 41

Chapter 2 Operating Procedures

Operating Procedures

Caution: The load port door is locked when in the open position. You

must press the

CLOSE

button before attempting to close

the load port door.

Manually Unloading the DLT Tape Drive

4When the

CLOSE

indicator is steadily lit, push the load port door

closed. (The library will lock the door.)

To manually unload a DLT tape drive:

2

1 Press the control panel

Off-line

is displayed in the SDA.

2 Press the control panel

STANDBY

STOP

button.

button and verify that

System

Warning: To prevent injury from moving components, always press

the control panel

STOP

button before opening the front

door.

3 Open the front door by pulling the door towards you. (The door

opens to your right.)

Warning: The front door is the only location for manually removing

tape cartridges from the interior of the tape library.

4 On the drive to be unloaded, press the

figure 14) and verify the

on page 9 & figure 8 on page 10).

Note: When you press

Depending on the tape cartridge position, it will ta ke 10 to 120 seconds

before the Operator Handle indicator lights.

5With the

Operator Handle

handle to eject the DLT tape cartridge.

6 Pause for two seconds, then grasp the tape cartridge and slowly

pull it one-half way out of the drive mouth.

ACL 4/52 Operator’s Guide 25

Unload

Unload

Operator Handle

button (figure 13 or

indicator is lit (figure 6

, the tape cartridge will completely rewind.

indicator lit, raise the insert/release

Page 42

Chapter 2 Operating Procedures

Operating Procedures

Caution: If the tape cartridge leader failed to detach f rom the take-up

leader, push the tape cartridge all of the way back into the

drive mouth, press down the insert/release handle, and

return to step #4. Otherwise, continue to step #7.

7 Pull the tape cartridge completely out of the drive.

8 Close the library door.

Figure 13 DLT 2000 and

DLT 4000 Manual Unload

10 Press the control panel

Insert/Release

Handle

(Shown in Up

Position)

9 Press the control panel

On-line

is displayed in the SDA.

Unload Button

STOP

button.

STANDBY

button and verify that

System

DLT2000

DLT4000

Front Bezel

TA00056a

26 ACL 4/52 Operator’s Guide

Page 43

Figure 14 DLT 7000

Unload Button

Insert/Release

Handle

(Shown in Up Position)

TA00056b

DLT 7000

Front Bezel

Manual Unload

Chapter 2 Operating Procedures

Operating Procedures

ACL 4/52 Operator’s Guide 27

Page 44

Chapter 2 Operating Procedures

Turning the Interior Light On/Off

Turning the Interior Light On/Off

Note: The Interior light bulb is not operator replaceable. Notify your Field

Service Engineer to replace the bulb.

The library is normally shipped with the interior light set to the “On”

position. Use the following procedur e to t urn the interior light “On” or

“Off .”

1 Press the control panel

Off-line”

2 Press the control panel

Warning: To prevent injury from moving components, always press

3 Using a 5/32” hex wrench, unlatch the front door.

4 Open the library front door.

is displayed in the SDA.

the control panel

door.

STANDBY

STOP

button.

STOP

button before opening the front

button and verify that “

System

2

Note: The front door is the only access for manually turning the inte rior light

On or Off.

5 Reach through the front door and set the light switch (located on

the far side of the light) to the desired position.

6 Close and latch the library front door.

7 Press (to release) the control panel

8 Press (to release) the control panel

that the library completes the initialization sequence, and

On-line”

is displayed in the SDA.

STOP

button.

STANDBY

button and verify

“System

28 ACL 4/52 Operator’s Guide

Page 45

Chapter 2 Operating Procedures

Turning the Inte rior Lig ht On/ Off

Figure 15 Turning the

Interior Light On/Off

Power Switch

(Shown in Off Position)

Interior Light

Front Door

(Opens to Right)

TA00038d

ACL 4/52 Operator’s Guide 29

Page 46

Chapter 2 Operating Procedures

Operating Procedures Usi ng the Me nu Mod e

Operating Procedures Usin g the Menu Mode

This section contains procedures for entering and exiting the control

panel menu mode and instructions for executing the operator tasks

listed below:

• Setting or changing the library or tape drive SCSI addresses

• Defining the state of the library after the power-up sequence has

completed

• Enabling or disabling the automatic drive cleaning option

• Enabling or disabling the retry operation option

• Setting or changing the language displayed in the SDA

• Adjusting the SDA contrast level

• Unloading a tape cartridge from a specific drive

• Directing cleaning tape cartridges to specific drives for cleaning

• Performing the initial loading of the library

• Displaying the status of the library

2

Entering the Menu Mode

Exiting the Menu Mode

• Performing an inventory of the library

To enter the menu mode:

2

1 Press the control panel

shows

2 Press the

3 Verify the following is displayed in the SDA:

2

There are two different ways to exit from menu mode.

The fast method:

1 From anywhere in the menu, press the

buttons, simultaneously and verify that

displayed in the SDA.

System Off-line

SELECT

Menu:

Configuration

STANDBY

.

button to enter the menu mode.

button and verify the SDA

SELECT

System Off-line

and

↑ or ↓

is

30 ACL 4/52 Operator’s Guide

Page 47

Chapter 2 Operating Procedures

Operating Procedures Using the Menu Mode

Note: After an operation is executed, the results displayed in the SDA, must

be cleared befor e the quick method of exiting will be avai lable. To clear

the results of an operation from the SDA, press the

or ↓ button.

↑

Or the conventional method:

Setting/Changing the Library SCSI Address

1 Use the

SELECT

the

↓

↑

and

buttons to navigate to an

button. (This method will take you one-level up in the

Exit

option, then press

menu each time that you perform it.)

2 Continue to perform step #1 until the following is displayed in the

SDA.

Menu:

Exit

3 Press

SELECT

one final time to exit the menu mode.

To set or change the library SCSI address:

2

1 Enter the menu mode.

2 Press the

SELECT

button to choose the

Configuration

menu and

verify the following is displayed in the SDA:

Menu: Configurati

Inquiry

3 Press the

↓

button one (1) time to bypass the

Inquiry

menu and

verify the following is displayed in the SDA:

Menu: Configurati

SCSI Address

4 Press the

SELECT

button to choose the

SCSI Address

and verify the following is displayed in the SDAl:

Menu: SCSI Addres

Robotics

5 Press the

SELECT

button to choose the

Robotics

verify the following is displayed in the SDA:

Menu: Robotics

SCSI ID 0

6 Use the

library (

and

↑

SCSI ID 0, SCSI ID 1...SCSI ID 7

7 With the proper

SELECT

button.

buttons to navigate to the SCSI ID number for the

↓

).

SCSI ID

number displayed on line #2, press the

8 Exit the menu mode.

sub-menu

sub-menu and

ACL 4/52 Operator’s Guide 31

Page 48

Chapter 2 Operating Procedures

Operating Procedures Usi ng the Me nu Mod e

Note: After changing the SCSI address of the library, one of two things must

happen to set the new SCSI ID. The host controller must issue a “SCSI

Bus Reset,” or the library must be powered off and on again.

Setting/Changing a Tape Drive SCSI Address

To set or change a tape drive SCSI address:

2

1 Enter the menu mode.

2 Press the

SELECT

button to choose the

verify the following is displayed in the SDA:

Menu: Configurati

Inquiry

3 Use the

↓

button to bypass the

following is displayed in the SDA:

Menu: Configurati

SCSI Address

4 Press the

SELECT

button again to choose

the following is displayed in the SDA:

Menu: SCSI Addres

Robotics

5 Use the

↓

button to bypass the

following is displayed in the SDA:

Inquiry

Robotics

Configuration

menu and

menu and verify the

SCSI Address

and verify

sub-menu and verify the

Menu: SCSI Addres

Drive 0

6 Use the

↑

and

↓

buttons to navigate to the proper drive number

(Drive 0, Drive 1, Drive 2, Drive 3), where:

Menu Mode Physical Location

Drive 0

Drive 1

Drive 2

Drive 3

= Top Drive

= Second Drive

=Third Drive

=Bottom Drive

7 With the proper drive number displayed on line #2, press the

SELECT

button and verify the following is displayed in the SDA:

Menu: Drive 0

SCSI ID 0

8 Use the

↑

and

buttons to navigate to the SCSI ID number for the

↓

selected drive (0...7 for libraries with DLT 2000 or DLT 4000 tape

drives and 0...15 for libraries with DLT 7000 tape drives).

32 ACL 4/52 Operator’s Guide

Page 49

Chapter 2 Operating Procedures

Operating Procedures Using the Menu Mode

9 With the proper SCSI ID number displayed on line #2, press the

10

SELECT

Exit

button.

the menu mode.

Note: After changing the SCSI address of the drives, one of three

things must happen to set the new SCSI ID. The Reset Drives

command must be performed from the Diagnostic Software

Package, the host controller must issue a “SCSI Bus Reset,” or

the library must be powered off and on again.

Defining the Library Power-Up State

To define the library power-up state:

2

1 Enter the menu mode.

2 Press the

SELECT

button to choose the

Configuration

menu and

verify the following is displayed in the SDA:

Menu: Configurati

Inquiry

3 Use the

↓

button to bypass the

Inquiry

menu and verify the

following is displayed in the SDA:

Menu: Configurati

Power-Up State

4 Press the

SELECT

button to choose the

Power-Up State

menu and

verify the following is displayed in the SDA:

Menu: Power-Up St

On-line<

Note:

System On-line

is the default. If you want to change t he powerup state to standby, proceed to step 6. Otherwise, exit the menu

mode.

5 Use the

↓

button to bypass the

System On-line

option and verify

the following is displayed in the SDA:

Menu: Power-Up St

Standby

6 With the desired option displayed on line #2, press the

button.

7 Exit the menu mode.

ACL 4/52 Operator’s Guide 33

SELECT

Page 50

Chapter 2 Operating Procedures

Operating Procedures Usi ng the Me nu Mod e

Enabling/Disabling the Auto Clean Option

2

Note:

To enable or disable the auto clean option:

1 Enter the menu mode.

2 Press the

SELECT

button to choose the

Configuration

menu and

verify the following is displayed in the SDA:

Menu: Configurati

Inquiry

3 Use the

Up State

↓

button to bypass the

menus and verify the following is displayed in the SDA:

Inquiry, SCSI Address

and

Menu: Configurati

Auto Clean

4With

Auto Clean

SELECT

displayed on line #2 of the SDA, press the

button and verify the following is displayed in the SDA:

Menu: Auto Clean

Enabled

Auto Clean Disabled

is the default. If you want to enable the automatic

cleaning, proceed to step 6. Otherwise, exit the menu mode.

Power-

Enabling/Disabling the Retry Option

5 With the desired option displayed on line #2, press the

SELECT

button.

6 Exit the menu mode.

To enable or disable the retry option:

2

1 Enter the menu mode.

2 Press the

SELECT

button to choose the

Configuration

menu.

3 Verify the following is displayed in the SDA:

Menu: Configurati

Inquiry

4 Use the

State

and the

↓

button to bypass the

Auto Clean

Inquiry, SCSI Address, Power-Up

menus and verify the following is

displayed in the SDA:

Menu: Configurati

Retries

34 ACL 4/52 Operator’s Guide

Page 51

Chapter 2 Operating Procedures

Operating Procedures Using the Menu Mode

Enabling/Disabling the Auto Load Feature

Note:

2

5With

Retries

displayed on line #2 of the SDA, press the

button and verify the following is displayed in the SDA:

Menu: Retries

Enabled<

Retries Enabled

is the default. If you want to disable this feature,

proceed to step 6. Otherwise, exit the menu mode.

6 Use the

↓

button to bypass the

Enabled

option and verify the

following is displayed in the SDA:

Menu: Retries

Disabled

7 With the desired option displayed on line #2, press the

button.

8 Exit the menu mode.

To enable or disable the auto load feature:

1 Enter the menu mode.

SELECT

SELECT

Note:

2 Press the

SELECT

button to choose the

Configuration

3 Verify the following is displayed in the SDA:

Menu: Configurati

Inquiry

4 Use the

State

, Number of Drives,

↓

button to bypass the

Inquiry, SCSI Address, Power-Up

Auto Clean,

and

Retries

verify the following is displayed in the SDA:

Menu: Configurati

Auto Load

5With

Auto Load

displayed on line #2 of the SDA, pr ess the

button and verify the following is displayed in the SDA:

Menu: Auto Load

Disabled<

Auto Load Disabled

is the default. If you want to enable this feature,

proceed to step 6. Otherwise, exit the menu mode.

menu.

menus and

SELECT

ACL 4/52 Operator’s Guide 35

Page 52

Chapter 2 Operating Procedures

Operating Procedures Usi ng the Me nu Mod e

Setting/Changing the Status Display Area Language

6 Use the

↓

button to bypass the

Enabled

option and verify the

following is displayed in the SDA:

Menu: Auto Load

Enabled

7 With the desired option displayed on line #2, press the

button.

8 Exit the menu mode.

To set or change the status display area language:

1 Enter the menu mode.

2

2 Press the

SELECT

button to choose the

Configuration

3 Verify the following is displayed in the SDA:

Menu: Configurati

Inquiry

4 Use the

↓

button to bypass the

State, Auto Clean, Retries

Inquiry, SCSI Address, Power-Up

Auto Load

and

sub-menus and verify the

following is displayed in the SDA:

SELECT

menu.

Menu: Configurati

Language

Note:

With

SELECT

button and verify the following is displayed in the

displayed on line #2 of the SDA, press the

Language

SDA:

Menu: Language

English<

Note:

English

is the default. If you want to change the language,

proceed to step 6. Otherwise, exit the menu mode.

5 Use the

↑

and

↓

buttons to navigate to the desired language.

English

Francais

Deutsch

Espanol

Italiano

6 With the desired language displayed on line #2, press the

button.

SELECT

7 Exit the menu mode.

36 ACL 4/52 Operator’s Guide

Page 53

Chapter 2 Operating Procedures

Operating Procedures Using the Menu Mode

Adjusting the Display Area Contrast

2

Note:

To adjust the display area contrast:

1 Enter the menu mode.

2 Press the

SELECT

button to choose the

Configuration

menu.

3 Verify the following is displayed in the SDA:

Menu: Configurati

Inquiry

4 Use the

↓

button to bypass the

State, Auto Clean, Retries, Auto Load

Inquiry, SCSI Address, Power-Up

Language

and

sub-menus

and verify the following is displayed in the SDA:

Menu: Configurati

Set View

5With

Set View

displayed on line #2 of the SDA, press the

button and verify the following is displayed in the SDA:

Menu: Set View

Contrast 9

Contrast 5

is the default contrast setting. If you want to change the

contrast, proceed to step 6. Otherwise, exit the menu mode.

SELECT

Unloading a Drive

6 Use the

↑

and

↓

buttons to navigate to the desired contrast.

Contrast 9

Contrast 8

Contrast 7

Contrast 6

Contrast 5<

Contrast 4

Contrast 3

Contrast 2

Contrast 1

Exit

7 With the desired contrast displayed on line #2, press the

SELECT

button.

8 Exit the menu mode.

2

To unload a drive:

1 Enter the menu mode.

ACL 4/52 Operator’s Guide 37

Page 54

Chapter 2 Operating Procedures

Operating Procedures Usi ng the Me nu Mod e

2 Use the

↓

button to bypass the

Configuration

menu and verify the

following is displayed in the SDA:

Menu:

Drive Control

3 Press the

SELECT

button to choose the

Drive Control

menu.

4 Verify the following is displayed in the SDA:

Menu: Drive Contr

Unload

5 Press the

SELECT

button to choose the

Unload

sub-menu and

verify the following is displayed in the SDA:

Menu: Unload

Drive 1

6 Use the

Drive 0

Drive 1

Drive 2

Drive 3

↑

↓

and

buttons to navigate to the proper drive number.

= Top Drive

= Second Drive

=Third Drive

=Bottom Drive

7 With the proper drive number displayed on line #2, press the

SELECT

button and verify the following is displayed in the SDA:

Cleaning a Drive

Menu: Drive n

..Working..

Where “n” = the number of the drive that you selected.

8 When the following is displayed in the SDA, exit the menu mode.

Menu: Unload

Drive n

2

To clean a drive:

1 Enter the menu mode.

2 Use the

↓

button to bypass the

Configuration

menu and verify the

following is displayed in the SDA:

Menu:

Drive Control

3 Press the

SELECT

button to choose the

Drive Control

menu.

38 ACL 4/52 Operator’s Guide

Page 55

Chapter 2 Operating Procedures

Operating Procedures Using the Menu Mode

4 Verify the following is displayed in the SDA:

Menu: Drive Contr

Unload

5 Use the

↓

button to bypass the

Unload

sub-menu and verify the

following is displayed in the SDA:

Menu: Drive Contr

Clean

6 Press the

SELECT

button to choose the

Clean

sub-menu and verify

the following is displayed in the SDA:

Menu: Clean

Drive 1

7 Use the

Drive 0

Drive 1

Drive 2

Drive 3

↑

= Top Drive

= Second Drive

=Third Drive

=Bottom Drive

and

↓

buttons to navigate to the proper drive number.

8 With the proper drive number displayed on line #2, press the

SELECT

button and verify the following is displayed:

Menu: Drive n

..Working..

Displaying the Library’s Actuator or Sensor Status

Where “n” = the number of the drive that you selected.

9 When the following is displayed in the SDA, exit the menu mode.

Menu: Clean

Drive n

To display the library’s actuator or sensor status:

2

1 Enter the menu mode.

2 Use the

↓

button to bypass the

Calibration, System Test

Configuration, Drive Control

Robot Control

and

,

menus and verify the

following is displayed in the SDA:

Menu:

Diagnostics

ACL 4/52 Operator’s Guide 39

Page 56

Chapter 2 Operating Procedures

Operating Procedures Usi ng the Me nu Mod e

3 Press the

verify the following is displayed in the SDA:

4 Press the

Selftest All

the SDA:

5 Use the

display (

Note:

6 With the selection displayed on line #2, press the

7 Use the

displays to review the information returned.

Examples are shown below.

SELECT

Menu: Diagnostics

Home All

↓

button two (2) times to bypass the

sub-menus. Then verify the following is displayed in

Menu: Diagnostics

Status Actuator

↑

and

Status Actuator

Status Sensor

↑

and

button to choose the

↓

buttons to scroll to the function that you want to

or

is not currently supported.

↓

buttons to scroll through the (SDA line #2)

Status Sensor

Diagnostics

).

menu and

Home All

SELECT

and

button.

Performing an Inventory

Status Actuator

Menu: Status Actu

1.51 11.8 3.25 C

1.51

11.8

3.25

C

8 When you have finished viewing the status of the library sensors

or actuators, exit the menu mode.

2

To perform an inventory:

1 Enter the menu mode.

2 Use the

Calibration, System Test

following is displayed in the SDA:

= Horizontal position

= Vertical position

= Extension position

= Gripper state (Closed, Open and Unknown)

↓

Menu:

Diagnostics

Example

button to bypass the

Robot Control

and

Configuration, Drive Control

menus and verify the

,

40 ACL 4/52 Operator’s Guide

Page 57

Chapter 2 Operating Procedures

Operating Procedures Using the Menu Mode

3 Press the

SELECT

button to choose the

Diagnostics

menu and

verify the following is displayed in the SDA:

Menu: Diagnostics

Home All

4 Press the

↓

button five (5) times to bypass the

All, Status Actuator, Status Sensor

Move Actuator

and

Home All, Selftest

sub-menu s.

Then verify the following is displayed in the SDA:

Menu: Diagnostics

Inventory

5With

Inventory

displayed on line #2, press the

SELECT

button.

Note: With a full library, the inventory will take less than three

minutes if all of the cartridges are properly bar code labeled.

The actual inventory time can take longer if the library is not

completely full or if any of the cartridges are not properly