Page 1

Modicon

TSX Momentum

Modbus to Ethernet Bridge

User Guide

890 USE 155 00 Version 1.0

Page 2

Page 3

174 CEV 300 10

Modicon TSX Momentum

Modbus to Ethernet Bridge

User Guide

890 USE 155 00

31001624

04/99

Breite: 185 mm

Höhe: 230 mm

Breite: 178 mm

Höhe: 216 mm

Page 4

Page 5

Preface

Data, Illustrations, Alterations

Data and illustrations are not binding. We reserve the right to alter products in

line with our policy of continuous product development.

Trademarks

All terms used in this publication to denote Schneider Automation products are

trademarks of Schneider Automation Incorporated.

All other terms used in this publication to denote products may be registered

trademarks and/or trademarks of the corresponding corporations.

Microsoft and MS-DOS are registered trademarks of Microsoft Corporation,

Windows is a brand name of Microsoft Corporation in the USA and other

countries.

IBM is a registered trademark of International Business Machines Corporation.

Intel is a registered trademark of Intel Corporation.

Copyright

All rights are reserved. No part of this document may be reproduced or

transmitted in any form or by any means, electronic or mechanical, including

copying, processing or by online file transfer, without permission in writing by

Schneider Automation Incorporated. You are not authorized to translate this

document into any other language.

1999 Schneider Automation Incorporated. All rights reserved.

v

Page 6

Page 7

Contents

Contents

Modbus to Ethernet Bridge

174 CEV 300 10 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Introducing the Modbus to Ethernet Bridge 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.1 Bridge Applications 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.2 Overview: Installation and Configuration 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Mapping Modbus and IP Addresses 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1 Mapping for a Modbus Master 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.2 Mapping for a Modbus Slave 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Front Panel Layout 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Specifications 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Bridge Hardware 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Mounting the Bridge on the DIN Rail 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1 Before You Install the Bridge 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.2 Mounting the Bridge 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Connecting the Power Wiring 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Connecting the Serial Cable (RJ45 Port) 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Compatible Modbus Devices and Cables 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Modbus Cable Pinouts 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 Connecting the Serial Cable (Wiring Terminals) 26. . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 Setting the Serial Port Switch 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8 Connecting the Ethernet Cable 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

890–USE–155–00

Configuring the Bridge 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Before You Start 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.1 Configuration Overview 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.2 Safety 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Connecting by the RS–232 Port 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Connecting by Telnet (IP Address Not Assigned) 32. . . . . . . . . . . . . . . . . . . . . . . .

3.4 Connecting by Telnet (IP Address Assigned) 33. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Using the Configuration Menu 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.1 Configuration Menu 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.2 Modbus Master Device: Additional Menu Items 34. . . . . . . . . . . . . . . . . . . . . . . . .

3.5.3 Configuration Options: 1 ... 5 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.4 Viewing and Changing Configuration Parameters 35. . . . . . . . . . . . . . . . . . . . . . . .

3.5.5 Commands: Default settings, Save, Quit without save 35. . . . . . . . . . . . . . . . . .

vii

Breite: 178 mm

Page 8

Contents

3.6 Option 1: Network/IP Settings 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7 Option 2: Serial and Mode Settings 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.8 Option 3: Modem Control Settings 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9 Option 4: Advanced Modbus Protocol Settings 40. . . . . . . . . . . . . . . . . . . . . . . . . .

3.10 Option 5: Unit ID to IP Address Mapping Table 42. . . . . . . . . . . . . . . . . . . . . . . . .

3.10.1 How the Address Mapping Works 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.10.2 Example: Address Mapping 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.10.3 Entering New Address Mapping 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.10.4 Exiting the Mapping Menu 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Panel Software 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Using Concept or Modsoft 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.1 Software Versions 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.2 Modbus Slave Address 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Using Other Software 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1 Intellution FIX MMI 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.2 WinTech Modscan 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.3 Worderware MMI 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii

890–USE–155–00

Page 9

Modbus to Ethernet Bridge

174 CEV 300 10

H Introducing the Modbus to Ethernet Bridge

H Mapping Modbus and IP Addresses

H Front Panel Layout

H Specifications

1

9

Page 10

Modbus to Ethernet Bridge

1.1 Introducing the Modbus to Ethernet Bridge

1.1.1 Bridge Applications

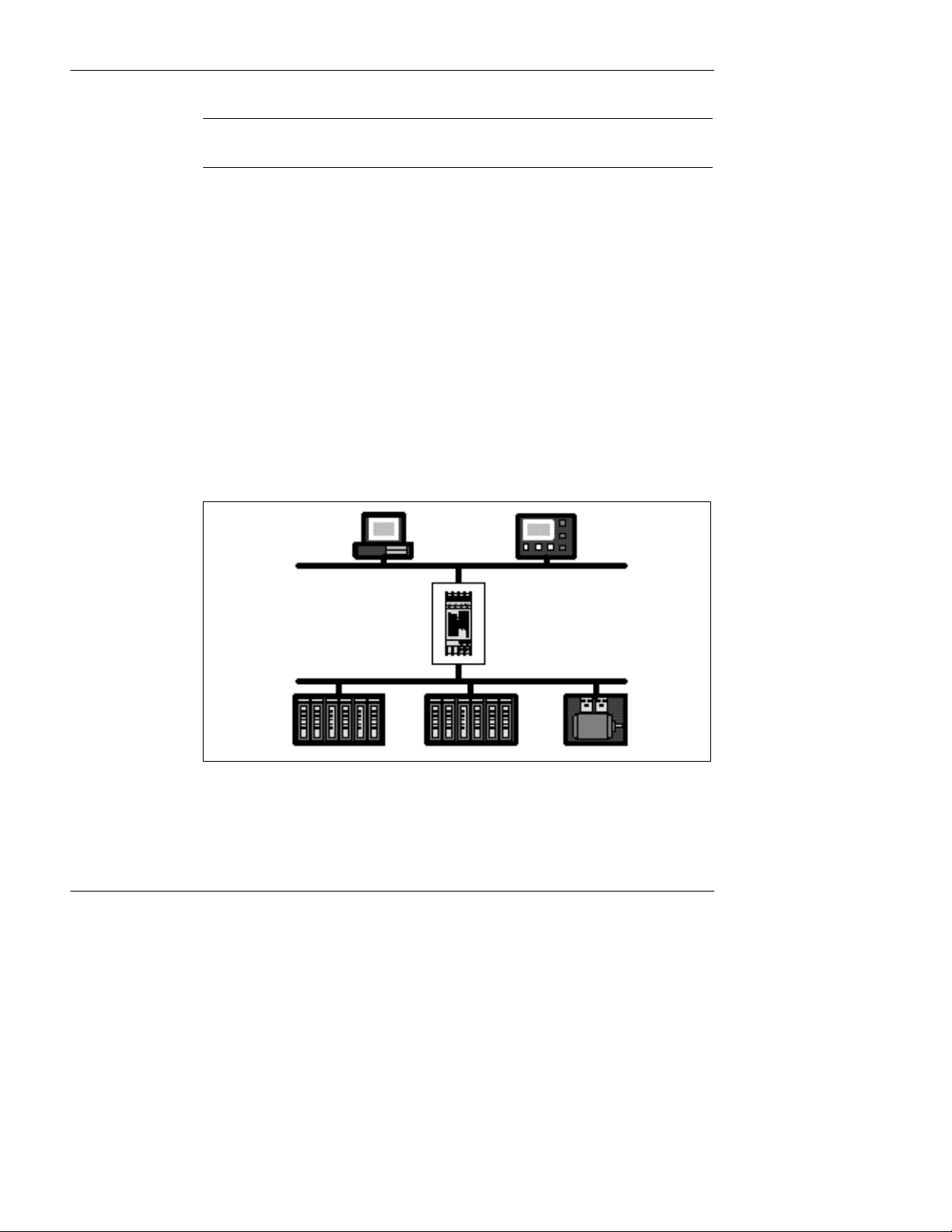

The Modicon Modbus to Ethernet Bridge provides a means for transacting messages

between Ethernet TCP/IP devices and Modbus serial devices. It supports up to eight

concurrent transactions between Modbus Master and Slave devices, handling the

conversion of TCP/IP and Modbus RTU/ASCII protocols transparently to the user

application.

Ethernet nodes using TCP/IP can function as Modbus Masters, originating messages

to the Bridge for delivery to Modbus Slave devices connected to the Bridge’s Modbus

port. The Bridge forwards the messages to the Slave devices using Modbus RTU or

ASCII protocol and returns their responses to the Master.

Figure 1 shows a typical application in which a Bridge connects two Modbus Masters

on Ethernet to several Modbus Slave serial devices.

Figure 1 Bridging Between Ethernet and Modbus

10

Ethernet

Bridge

174 CEV 300 10

Modbus

The bridge also allows multiple Modbus networks to be linked together across an

Ethernet connection. Multiple Bridges can furnish an Ethernet link between widely

separated Modbus networks. This extends the message path beyond the cable

lengths allowed for serial connections, and allows a Master on any Modbus network to

access Slave devices on another network.

Page 11

Modbus to Ethernet Bridge

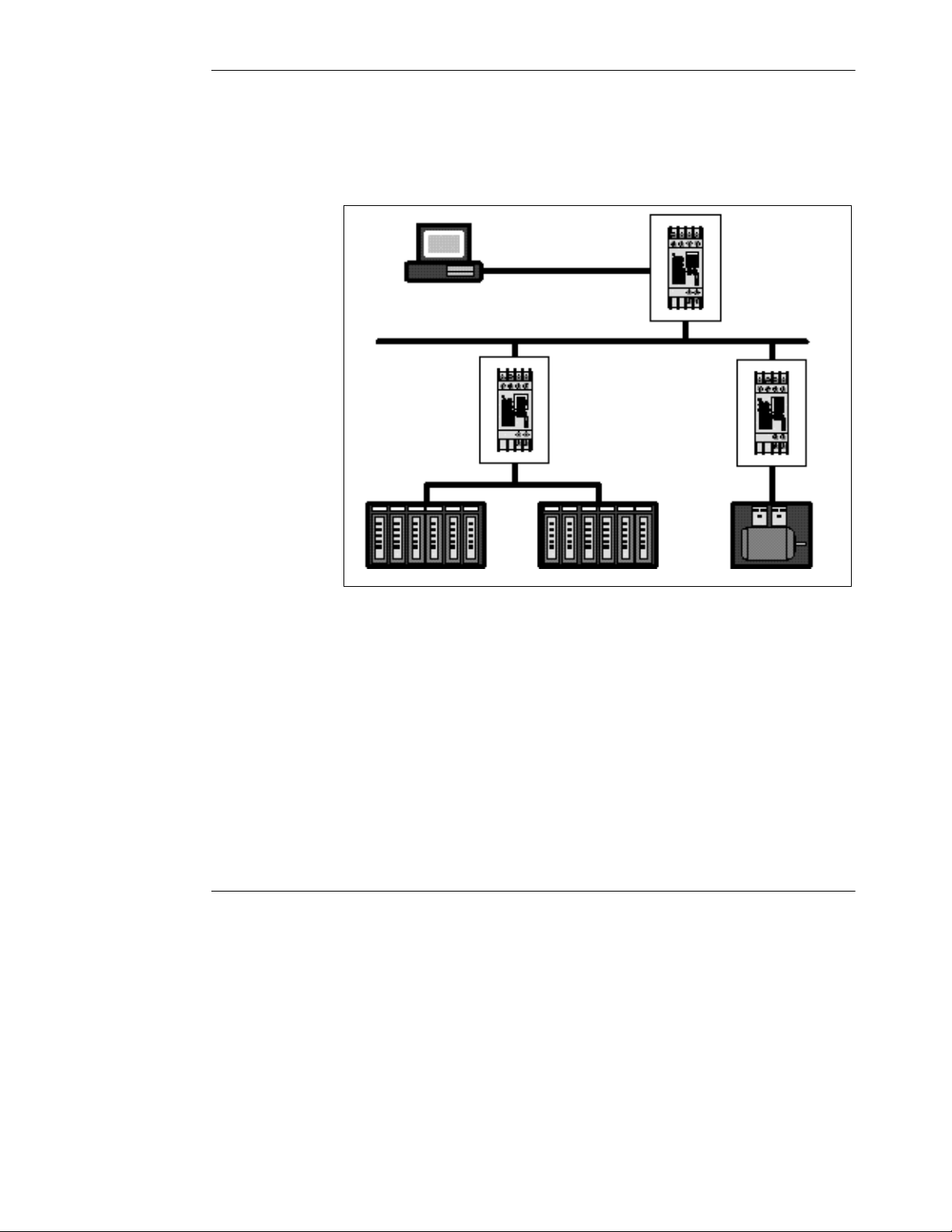

Figure 2 shows a typical application in which three Bridges join Modbus networks

through a common Ethernet link.

Figure 2 Bridging Between Multiple Modbus Networks

Modbus

Ethernet

Bridges (3 units)

174 CEV 300 10

Modbus

1.1.2 Overview: Installation and Configuration

The Bridge is designed for easy ‘snap’ mounting on a standard DIN rail.

Its front panel has connectors for power, ground, Ethernet and Modbus cables. It has

a switch for selecting either an RS–232 or RS–422/485 interface for the Modbus port.

Indicators show the status of communication at the Ethernet and Modbus ports.

The Bridge contains a configuraton utility program stored in its non–volatile memory .

With this utility you can assign the Bridge’s Ethernet and Modbus parameters, using an

ASCII terminal at the serial port or a Telnet connection over Ethernet.

The Bridge contains a factory–assigned MAC address that is derived from the serial

number printed on the Bridge’s label. This allows you to establish an Ethernet

connection to the Bridge to assign its IP address and the other parameters for your

application.

Modbus

11

Page 12

Modbus to Ethernet Bridge

1.2 Mapping Modbus and IP Addresses

The Bridge maps messages between Modbus and IP addresses according to the type

of device you have configured at its Modbus port.

1.2.1

1.2.2

Mapping for a Modbus Master

When you configure a Modbus Master device at the Bridge’s serial port, you can

assign up to eight entries into an internal mapping table that is maintained in the

Bridge’s memory. You enter your intended mapping into the table during your

configuration of the Bridge.

Each table entry maps a single Modbus address, or a range of addresses, to a

destination IP address.

When the Bridge receives a message from the Master, it searches the mapping table

for an entry matching the Modbus address in the message. If one is found, the Bridge

sends the message to the IP address for that entry . If a matching entry is not found,

the Bridge returns an exception response to the Master application.

Note that the original Modbus address is retained in the message transmitted to the IP

destination. If the remote IP node is another Bridge, the message’s Modbus address

can be used to identify a Slave device at that Bridge’s serial port.

Mapping for a Modbus Slave

When you configure a Modbus Slave device or network with multiple Slaves at the

Bridge’s serial port, you have two options for routing messages to a Slave destination.

You assign your choice during your configuration of the Bridge.

Your options are: Message address routing; or, Fixed address routing.

12

You can specify that the Bridge must route each message to the Slave device that is

identified in the Modbus address field of the message. This allows you to address any

Slave device in a network of up to 247 devices at the Bridge’s Modbus port.

You can specify that the Bridge must route all messages to one fixed Slave address

that you define in the Bridge’s configuration. With this option the Modbus address field

is ignored, and each message is routed to that fixed Slave address only . This limits

addressing to a single device at the port.

Page 13

Modbus to Ethernet Bridge

Figure 3 shows an example of message address mapping between a Modbus Master

and a Modbus Slave using two Bridges with an Ethernet link.

Figure 3 Mapping Modbus and IP Addresses

Modbus

Master

Modbus message to

Slave address 10

Bridge

A

Ethernet

192.168.001.024

Bridge

Modbus – IP Address

Mapping Entry:

010 : 192.168.001.024

B

Modbus

Slave(s)

These are the events in the message routing:

H The Modbus Master sends its message containing address 10 decimal to

Bridge A.

H You have set an entry in the mapping table in Bridge A. Your entry specifies that

messages with address 10 are to be mapped to IP address 192.168.001.024.

H Bridge B has that IP address and receives the message.

H Depending on the option you set in Bridge B, the message is routed either to

the Modbus Slave device at address 10 as specified in the message, or to a

fixed Slave address in the range 1 ... 247.

Bridge routes message to Slave

according to user–defined setup:

Message Slave Address (10)

or

Fixed Slave Address (1 ... 247)

13

Page 14

Modbus to Ethernet Bridge

1.3 Front Panel Layout

Figure 4 Front Panel Layout

1 2 3 4

5 6 7 8

9

14

MODBUS

10 11

15

12 13

16 17

18

ETHERNET

19 20

21 22

14

Page 15

Modbus to Ethernet Bridge

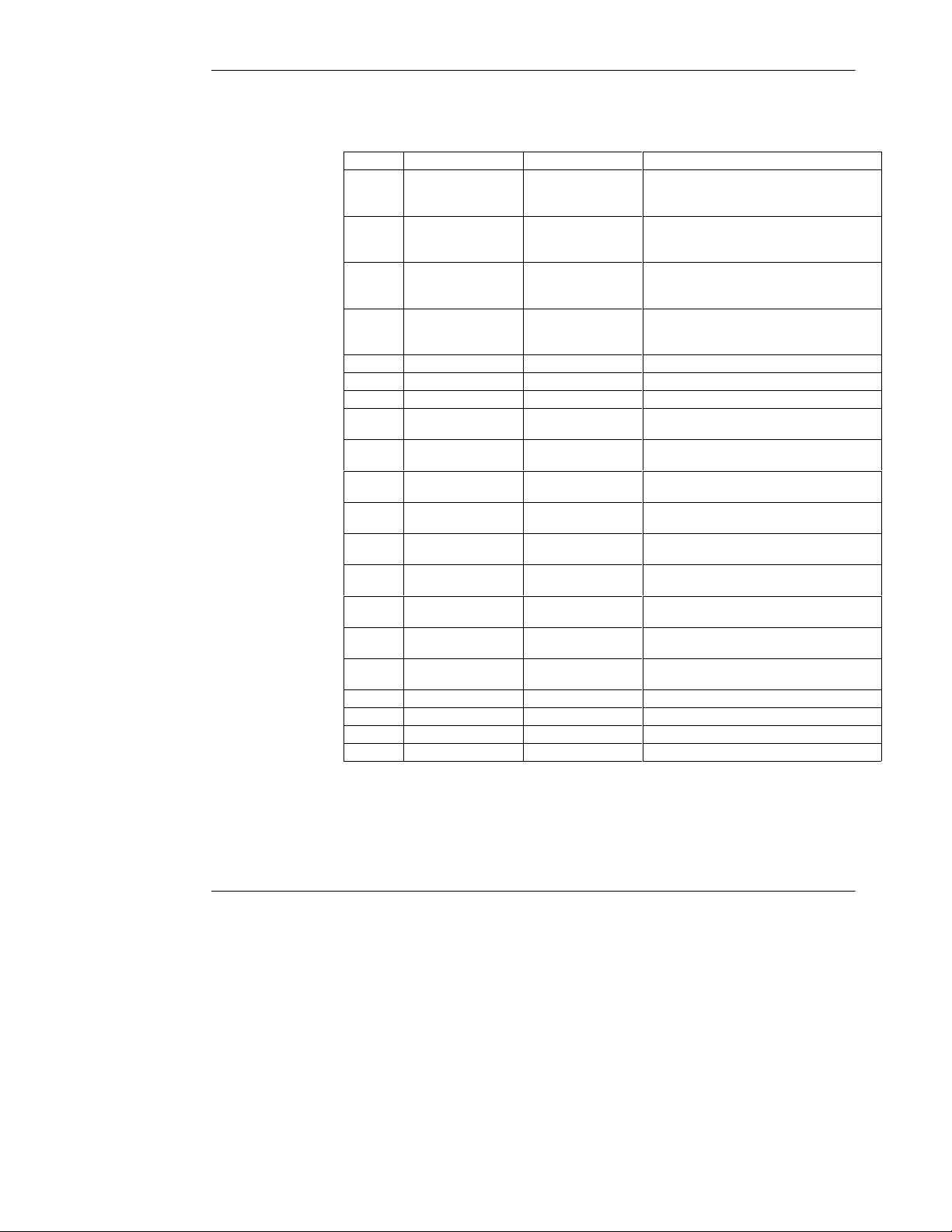

Table 1 Front Panel Components (See Figure 4)

Item

5, 6, 7 Wire terminal NC No connection

Component Name Purpose

1 Wire terminal RxD or Rx – Modbus signal:

2 Wire terminal CTS or Rx + Modbus signal:

3 Wire terminal RTS or Tx + Modbus signal:

4 Wire terminal TxD or Tx – Modbus signal:

8 Wire terminal GND Modbus signal ground

9 Reset switch RST Push to reset and initialize Bridge

10 LED (Red) Fault or

Configuration

11 LED (Green) Ready ON: Bridge is ready for communication

12 LED (Yellow) Active Ethernet Flashing: Indicates activity at Bridge’s

13 LED (Green) Link Good ON: Bridge has good connection at

14 Connector (RJ45) Ethernet port RJ45 connector for Ethernet 10BaseT

15 Connector (RJ45) Modbus port RJ45 connector for Modbus RS–232 or

16 LED (Yellow) Modbus Tx Flashing: Indicates transmission or

17 LED (Yellow) Modbus Rx Flashing: Indicates reception at Modbus

18 Switch Modbus interface

selection

19 Wire terminal DC + Operating power, positive

20 Wire terminal Ground Earth ground

21 Wire terminal DC – Operating power , negative

22 Wire terminal Ground Earth ground

RS–232: RxD (Receive Data)

RS–422.485: RxD– (Receive Data –)

RS–232: CTS (Clear to Send)

RS–422/485: RxD+ (Receive Data +)

RS–232: RTS (Request to Send)

RS–422/485: TxD– (Transmit Data +)

RS–232: TxD (Transmit Data)

RS–422/485: TxD– (Transmit Data –)

ON: Fault in Bridge communication

(or) Bridge is in Configuration Menu

on both ports

Ethernet port

Ethernet port

cable

RS–485 cable

upload at Modbus port

port

UP: Modbus port is RS–232

DOWN: Modbus port is RS–422/485

15

Page 16

Modbus to Ethernet Bridge

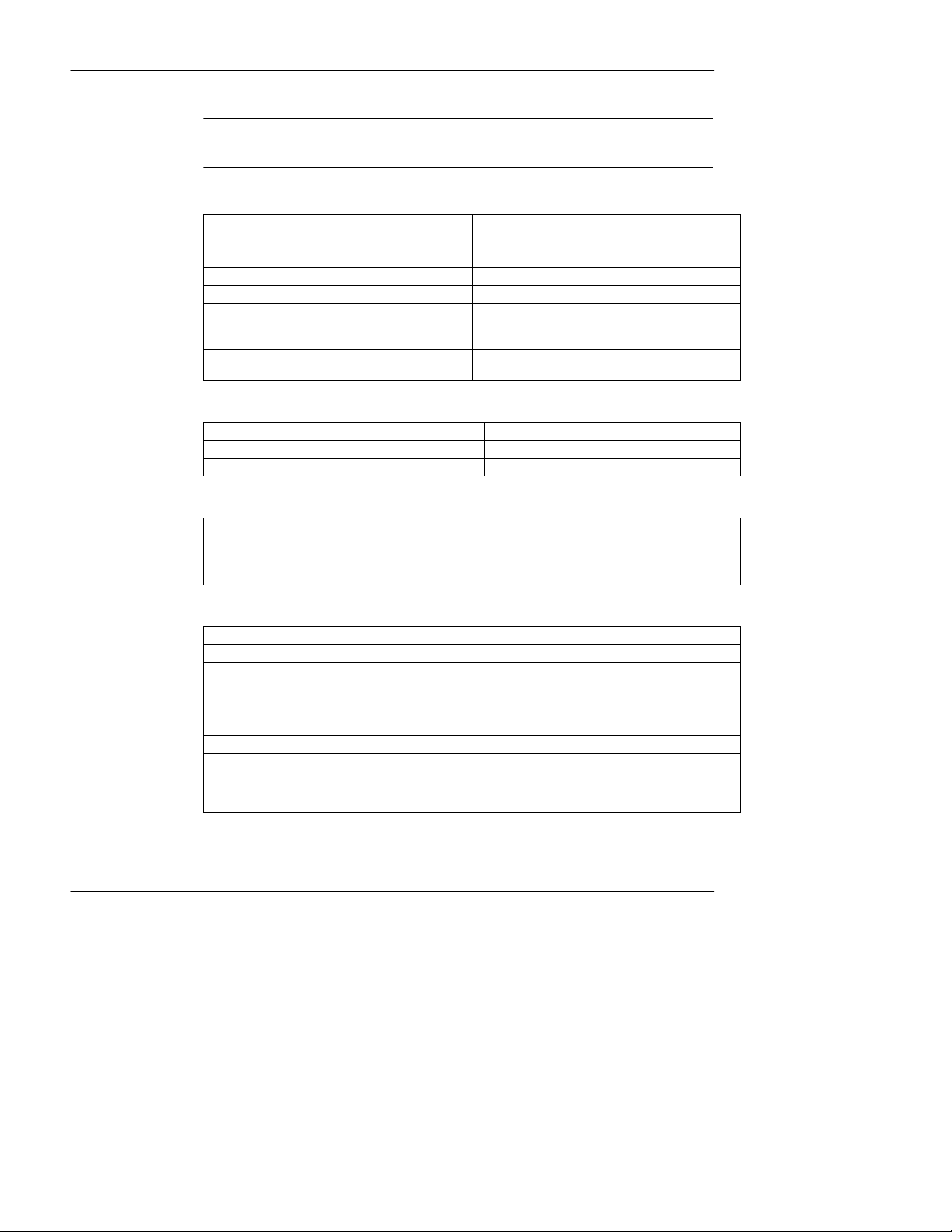

1.4 Specifications

Table 2 Power

Parameter

Operating Power, Nominal 12 or 24 V dc

Operating Power Range 9 ... 30 V dc

Maximum Power Drain 3 W

Connection Screw terminals

Fuse External, supplied by customer.

Grounding Screw terminals provided for power ground

Table 3 Environmental

Parameter

T emperature, Operating IEC 68–2–14

Humidity, Operating IEC 68–2–3 20 ... 90% RH, non–condensing

Table 4 Ethernet Interface

Parameter

Protocol Ethernet v2 encapsulation

Connector RJ45 connector for 10baseT cable

Specification

Fuse value according to supply voltage

(see Maximum Power Drain)

and safety (Earth) ground

Reference Limits

0...60_ C ambient

Specification

TCP/IP Version 4

16

Table 5 Serial Interface

Parameter

Modbus Protocol RTU or ASCII

Serial Protocol Switch selectable, RS–232 or RS–485

Baud Rate 300 ... 38400 +/– 2%

Connector RJ45 connector, screw terminals

Specification

Supports RS–232 RTS/CTS handshaking

RS–485 setting supports RS–422 devices

Supports 2–wire and 4–wire RS–485

Supports up to 16 RS–485 devices

RJ45 port connects to Modicon M1, Compact, 984 Slot Mount

controllers by direct cable. Cable adapters and adapter kits

are available for other products.

Page 17

Modbus to Ethernet Bridge

Table 6 Packaging

Parameter

Dimensions 35 x 95 x 60 mm (1.4 x 3.7 x 2.4 in)

Enclosure Material High–impact plastic

Weight, Product 0.5 kg (1.0 lb)

Weight, Shipping 0.9 kg (2.0 lb)

Mounting Method DIN rail: DIN EN S0 022 (35 mm)

Table 7 Agency Approval

Parameter

UL, CSA, CE Approved

FM Pending

Description

Specification

17

Page 18

Page 19

Installing the Bridge Hardware

H Mounting the Bridge on the DIN Rail

H Connecting the Power Wiring

H Connecting the Serial Cable (RJ45 Port)

H Compatible Modbus Devices and Cables

H Modbus Cable Pinouts

H Connecting the Serial Cable (Wiring Terminals)

H Setting the Serial Port Switch

H Connecting the Ethernet Cable

2

19

Page 20

Installing the Bridge Hardware

2.1 Mounting the Bridge on the DIN Rail

2.1.1 Before You Install the Bridge

The Bridge has an Ethernet MAC address printed on the label on its side panel. The

address is required for your Ethernet network administrator to configure the Bridge.

Before you install the Bridge on the DIN rail, write down the MAC address and give it

to your network administrator. The label may not be visible after you install the Bridge.

Warning

COMMUNICATION DISRUPTION HAZARD Connecting any device to an active

Ethernet network can disrupt communication on the network. Before you

connect the Bridge to your network, and before you apply power to the Bridge,

heed the steps in Chapter 3 for configuring the Bridge in your application.

Failure to observe this precaution can result in injury or equipment damage.

2.1.2

Mounting the Bridge

The Bridge is designed for mounting on a standard DIN rail. Figure 5 shows how to

mount the Bridge

1. Note the slot on the Bridge’s rear panel. Position the top edge of the slot over the

top edge of the DIN rail.

2. Snap the Bridge into place on the lower edge of the rail.

Figure 5 Mounting the Bridge on the DIN Rail

1

2

Mounting Completed

20

Page 21

2.2 Connecting the Power Wiring

Figure 6 shows the connections for operating power and ground.

Operating power must be fused externally to the Bridge. The Bridge draws 3W

maximum (9 ... 30 V dc). Select a fuse value according to the supply voltage.

Figure 6 Connecting the Power Wiring

Installing the Bridge Hardware

9 ... 30 V DC

Fused

Ground

Frame

Safety

Ground

(Earth)

21

Page 22

Installing the Bridge Hardware

2.3 Connecting the Serial Cable (RJ45 Port)

Figure 7 shows serial cable connections for several Modicon CPUs for operation as

Modbus Master or Slave devices. The figure also shows a typical connection to a

standard PC 9–pin serial port for setting up the Bridge configuration.

Table 8 lists other compatible devices and cables.

Figure 7 Connecting the Serial Cable (RJ45 Port)

Modbus Port (RJ45)

RJ45 to RJ45 Cables

110 XCA 282 01 (3 ft / 1 m)

110 XCA 282 02 (10 ft / 3 m)

110 XCA 282 03 (20 ft / 6 m)

RJ45 to DB9 Adapters

1

110 XCA 203 01

(Kit)

2

110 XCA 203 00

(Pre–wired)

E984–26x/27x/28x

110 CPU 3x/4x/5x/6x 984–38x, 48x, 68x, 78x

TSX Momentum M1

NULL

Modem

2

MF

A984,

E984–24x/25x

1

1

PC

with

Serial Port

22

Page 23

Installing the Bridge Hardware

2.4 Compatible Modbus Devices and Cables

The Bridge connects directly by RJ45 cable to various products shown in Figure 7.

Table 8 below lists other Modbus devices and their cable connections to the Bridge.

Connections are RS–232 unless indicated otherwise.

Cable pinout references are to the diagrams in Figure 8 on page 24.

Table 8 Compatible Modbus Devices and Cables

Device

Part Number

MM–PM10–2xx PanelMate Plus 1000 (RS232) A

MM–PM10–2xx PanelMate Plus 1000 (RS422) B

AS–J478–000 Modbus Modem, Fixed Modem Control C

AS–J478–000 Modbus Modem, Variable Modem Control D

AS–J347–001 184/384 Controller Modbus Interface E

AS–J375–000 Micro 84 Controller Modbus Interface E

AS–P190–xxx P190 Programming Panel E

AS–884A–xxx 884 Controller E

AS–984x–xxx 984A, B, X Controller E

– – PC Serial Port, 9–Pin F

AS–P892–000 ASCII/RIO Interface G

140 CPU 424 xx Quantum Controller, 486 G

140 CPU 534 xx Quantum Controller, 586 G

PC–0984–xxx 984 Controller, 38x/48x/68x/78x Slot Mount G

PC–A984–xxx 984 Controller , Compact G

PC–E984–24x/25x 984 Controller, Compact G

PC–E984–455 984 Controller, 484 Replacement G

PC–M984–xxx Micro–984 Controller G

NW–BM85xxxx BM85 Bridge Multiplexer G

– – Generic Modbus Serial Device, 9–Pin G

110 VPU 192 00 Programmer, Handheld H

AS–A584–xxx 584A, L, M Controller See 584 Note

TSX SCx TSX Controllers, Modbus Interface See TSX Note

Device

Description

Cable Pinout

(Figure 8)

584 Note

Use cable AS–W192–XXX with Adapter 1 10 XCA 204 02, pinouts in Figure 8 cable E.

TSX Note

TSX Controller products offer multiple options for cable connection to the Bridge.

Refer to your product guidebook for more information.

23

Page 24

Installing the Bridge Hardware

2.5 Modbus Cable Pinouts

References in this figure are to the devices listed in Table 8 on page 23.

Figure 8 Modbus Cable Pinouts

A

Adapter Kit: 110 XCA 203 01

DB9M Wire RJ45

2 Red 4

3 Black 3

5 Green 5

Shield White 8

Adapter Kit: 110 XCA 203 01

B

DB9M Wire RJ45

1 Black 3

4 Red 4

5 Green 5

6 Yellow 6

9 Brown 7

Shield White 8

Adapter Kit: 110 XCA 204 01

C

DB25M Wire RJ45

1 White 8

2 Red 4

3 Black 3

7 Green 5

4

6

20

Adapter Kit: 110 XCA 204

D

DB25M Wire RJ45

2 Red 4

3 Black 3

6 Blue 1

7 Green 5

20 Orange 2

5 Yellow 6

4 Brown 7

1 White 8

01

Adapter Kit: 110 XCA 204 01

E

DB25M Wire RJ45

3 Red 4

2 Black 3

20 Blue 1

7 Green 5

6 Orange 2

4 Yellow 6

5 Brown 7

1 White 8

Adapter Kit: 110 XCA 203 02

F

DB9F Wire RJ45

2 Red 4

3 Black 3

4

6 Orange 2

5 Green 5

76

87

Shield White 8

Adapter Kit: 110 XCA 203 01

G

DB9M Wire RJ45

2 Red 4

3 Black 3

5 Green 5

6 Orange 2

7 Yellow 6

8 Brown 7

Shield White 8

H

Adapter: None

RJ45 (Prog) RJ45 (Bridge)

12

21

34

43

55

66

77

88

24

Page 25

Installing the Bridge Hardware

Figure 9 shows the layout of DB9–RJ45 and DB25–RJ45 Adapter Kits available from

Schneider Automation. Each kit contains three jumper wires and a pin insertion tool.

Follow the pinout diagrams in Figure 8 for assembling the adapter for your product.

Figure 9 DB to RJ45 Adapter Kits

DB9M (110 XCA 203 01)

Pin 1

Pin 1

DB9F (110 XCA 203 02)

DB25M (110 XCA 204 01)

Pin 1

Pin 1

DB25F (110 XCA 204 02)

Pin 1

Pin 1

25

Page 26

Installing the Bridge Hardware

2.6 Connecting the Serial Cable (Wiring Terminals)

Figure 10 shows the connection for serial cables at the Bridge’s wiring terminals.

Figure 10 Connecting the Serial Cable (Wiring Terminals)

RxD CTS RTS TxD

Signal

Ground

26

Terminating

Resistor

1/8 W

120 Ω

R

Signal

Ground

RRR

RS–485

2–Wire

RS–232

RxD– RxD+ TxD+TxD–Data–Data+

RS–485 / RS–422

4–Wire

Signal

Ground

Page 27

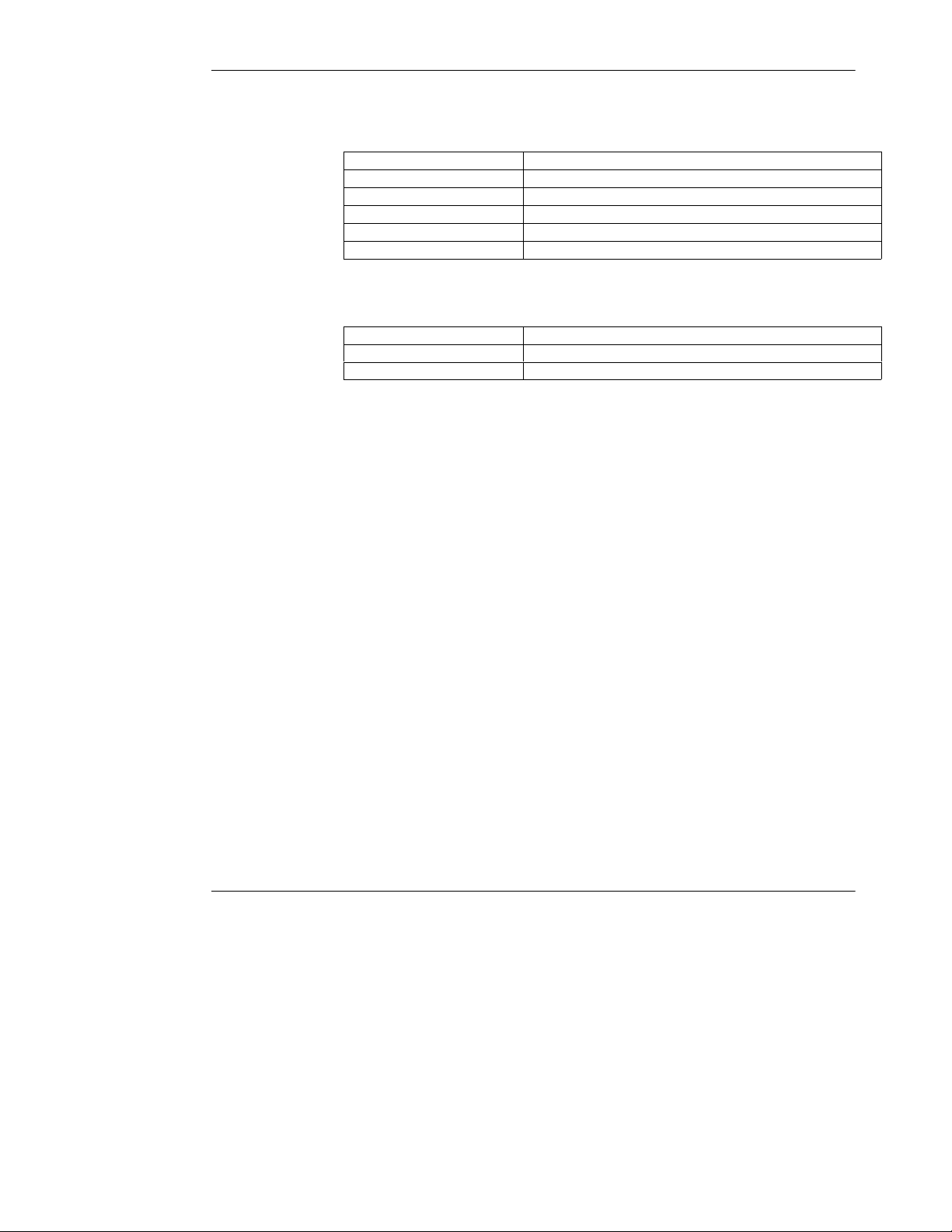

2.7 Setting the Serial Port Switch

Figure 1 1 shows the front panel switch for setting the Bridge’s serial port interface.

Before you place the Bridge into service, set the switch for the type of interface used in

your application:

H UP: RS–232 interface.

H DOWN: RS–422 or RS–485 interface.

Figure 11 Setting the Serial Port Switch

Installing the Bridge Hardware

Serial Port Switch

UP: RS–232

DOWN: RS–422 or RS–485

Warning

COMMUNICATION DISRUPTION HAZARD The serial port switch is a hardware

function. It is not sensed by the Bridge’s firmware. Changing the switch

setting while the Bridge is operating can disrupt communication on the

network. Do not change the switch setting unless you have first verified that it

will be safe for your application. Failure to observe this precaution can result

in injury or equipment damage.

27

Page 28

Installing the Bridge Hardware

2.8 Connecting the Ethernet Cable

Figure 12 shows the RJ45 port connection for the 10baseT Ethernet cable.

Figure 12 Connecting the Ethernet Cable

Ethernet Port (RJ45)

Warning

COMMUNICATION DISRUPTION HAZARD Connecting any device to an active

Ethernet network can disrupt communication on the network. Before you

connect the Bridge to your network, and before you apply power to the Bridge,

heed the steps in Chapter 3 for configuring the Bridge in your application.

Failure to observe this precaution can result in injury or equipment damage.

28

Page 29

Configuring the Bridge

H Before You Start

H Connecting by the RS–232 Port

H Connecting by Telnet (IP Address Not Assigned)

H Connecting by Telnet (IP Address Assigned)

H Using the Configuration Menu

H Option 1: Network/IP Settings

H Option 2: Serial and Mode Settings

H Option 3: Modem Control Settings

H Option 4: Advanced Modbus Protocol Settings

H Option 5: Unit_ID to IP Address Mapping Table

3

29

Page 30

Configuring the Bridge

3.1 Before You Start

3.1.1 Configuration Overview

Your Bridge must be configured to match your system application. Before you start to

configure the Bridge, get the Bridge’s Ethernet and serial port parameters from your

network administrator.

Here is your check list for obtaining the configuration information:

H Ethernet IP address.

H Ethernet Gateway address, if applicable to your Bridge’s network.

H Serial port interface: RS–232, RS–422, RS–485.

H Serial port communication: Baud rate, Data bits, Parity mode, Stop bits.

H Serial port modem controls: RTS/CTS timing values.

H Serial port device: Modbus Master or Modbus Slave.

H Modbus Protocol: RTU or ASCII.

H Modbus Timeout values: Character timeout, Message timeout.

H Modbus Slave only: Address source from Unit_ID header, or Fixed address.

H Modbus Slave only: Allowing broadcasts to serial port: Enable or Disable.

H Modbus Master only: Mapping of Modbus Slave addresses to IP addresses.

30

3.1.2

Safety

Warning

COMMUNICATION DISRUPTION HAZARD When you view or change the

configuration of a running Bridge, you will be restarting it on the network.

This will disrupt communication with the Bridge. Ensure that this action will

not cause any undesirable effect on your application. Failure to observe this

precaution can result in injury or equipment damage.

Warning

DUPLICATE ADDRESS HAZARD Having two or more devices with the same IP

address can cause unpredictable operation of your network. Ensure that you

will be assigning a unique IP address to the Bridge. Failure to observe this

precaution can result in injury or equipment damage.

Page 31

3.2 Connecting by the RS–232 Port

To configure the Bridge at its local RS–232 port, use a serial terminal emulation

program and a modem cable. See Figure 7 for a connection example.

Regardless of any serial parameters currently set into the Bridge for a user application,

it will always use the following parameters for setup: 9600 baud, 8 data bits, No parity ,

1 Stop bit (9600,8,N,1). Set your emulator to these parameters.

Figure 13 Example: RS–232 Serial Terminal Emulator Properties

Configuring the Bridge

Force the Bridge into its Configuration mode as follows:

H Ensure the emulator is connected to the Bridge’s serial port and ready.

H Hold down the ‘X’ key on your emulator keyboard. While holding the key down,

initialize the Bridge by cycling its power or by pressing its Reset button.

The Bridge will enter its configuration mode, and you will see this opening screen:

Schneider Automation, Inc. – Modbus Bridge (174 CEV 300 10)

Serial Number 101–161 Software Version V01.00 (990402)

Press Enter to go into Setup Mode, wait to close

At this screen, press <Enter> to go to the Configuration Menu (see Section 3.5).

31

Page 32

Configuring the Bridge

3.3 Connecting by Telnet (IP Address Not Assigned)

If the Bridge does not yet have an IP address stored in its memory , you can establish

an initial connection using its MAC address. This will allow you to access the Bridge’s

Configuration Menu, assign an IP address, and make it persistent in the Bridge.

If you are not sure about whether your Bridge has a stored IP address, you must

connect at its serial port and access its Configuration Menu. Section 3.2 describes

how to connect to the serial port.

T elnet Host Requirement

In order to use Telnet to set an initial IP address for the Bridge, your Telnet host must

be on the same Ethernet subnetwork as the Bridge, both physically and in its IP range.

Otherwise the configuration will not work.

Step 1 Get the Bridge’s MAC Address. The Bridge’s MAC address is printed on the label

on the Bridge’s side panel.

Example: MAC address: 00 20 4A 01 65 A1.

Step 2 Issue an “arp” Command to the Bridge. Open a Console or DOS window. Issue

an arp command to the Bridge with this syntax:

32

Syntax: arp –s <IP_address> <MAC_address>

Example (UNIX): arp –s 192.168.1.23 00:20:4A:01:65:A1

Example (DOS): arp –s 192.168.1.23 00–20–4A–01–65–A1

Step 3 Connect by Telnet to Port 1. Open a Telnet connection to the IP address you

assigned in Step 2, using port 1. This connection will fail, but the Bridge will change

its IP address to the one in this Telnet connection. This will allow you to make your

final connection for configuring the Bridge.

Step 4 Connect by Telnet to Port 9999. Open a new a Telnet connection to the IP address

using port 9999. This connection will succeed. You should now see the Bridge’s

opening screen:

Schneider Automation, Inc. – Modbus Bridge (174 CEV 300 10)

Serial Number 101–161 Software Version V01.00 (990402)

Press Enter to go into Setup Mode, wait to close

At this screen, press <Enter> to go to the Configuration Menu (see Section 3.5).

Page 33

Configuring the Bridge

3.4 Connecting by Telnet (IP Address Assigned)

If the Bridge already has an IP address stored in its memory , and you know that

address, you can establish a Telnet connection to the Bridge using port 9999.

If you do not know the IP address currently stored in the Bridge, you can find that

address by connecting to the Bridge’s serial port and accessing its Configuration

Menu. Section 3.2 describes how to connect to the serial port.

If you want to verify the existence of an Ethernet device at a known IP address, you

can use the PING utility. Refer to your Ethernet documents for a description of PING.

T elnet Host Requirement

In order to use Telnet to set an initial IP address for the Bridge, your Telnet host must

be on the same Ethernet subnetwork as the Bridge, both physically and in its IP range.

Otherwise the configuration will not work.

Figure 14 Example: Telnet Connection

When the connection is established, you should see the Bridge’s opening screen:

Schneider Automation, Inc. – Modbus Bridge (174 CEV 300 10)

Serial Number 101–161 Software Version V01.00 (990402)

Press Enter to go into Setup Mode, wait to close

At this screen, press <Enter> to go to the Configuration Menu (see Section 3.5).

33

Page 34

Configuring the Bridge

3.5 Using the Configuration Menu

When the Bridge enters its configuration mode it displays its opening screen:

Schneider Automation, Inc. – Modbus Bridge (174 CEV 300 10)

Serial Number 101–161 Software Version V01.00 (990402)

Press Enter to go into Setup Mode, wait to close

At this screen, press <Enter> to see the Configuration Menu.

3.5.1

Configuration Menu

The Configuration Menu shows the Bridge’s current settings. Here is an example:

Modbus Bridge Firmware Setup, Schneider Automation, Inc.

1) Network/IP Settings:

IP Address ................... 192.168.1.23

Default Gateway .............. 192.168.1.30

Netmask ...................... 255.255.255.000

2) Serial & Mode Settings:

Protocol ..................... Modbus/RTU, Slave(s) attached

Serial Interface ............. 19200,8,E,1,RS232

3) Modem Control Settings:

RTS Output ................... Fixed High/Active

4) Advanced Modbus Protocol Settings:

Slave Addr/Unit ID Source .... Modbus/TCP header

Modbus Serial Broadcasts ..... Disabled

Character, Message Timeout ... 00050 ms, 05000 ms

Commands: D)efault settings, S)ave, Q)uit without save

Select Command or Parameter (1...4) to change: __

3.5.2 Modbus Master Device: Additional Menu Items

If the serial port has already been configured for a Modbus Master device, menu item

4 will omit references to a Slave device, showing only the following:

4) Advanced Modbus Protocol Settings:

Character, Message Timeout ... 00100 ms, 05000 ms

34

Menu item 5 will show current mapping between Modbus addresses and IP addresses.

5) Unit ID –> IP Address Table: (followed by the current mapping table).

Page 35

3.5.3 Configuration Options: 1 ... 5

These are your configuration options. Each option is described in detail in the

following sections of this book:

1) Network/IP Settings: See Section 3.6.

H

2) Serial & Mode Settings: See Section 3.7.

H

3) Modem Control Settings: See Section 3.8.

H

H

4) Advanced Modbus Protocol Settings: See Section 3.9.

5) Unit ID –> IP Address Table: See Section 3.10.

H

Configuring the Bridge

3.5.4

3.5.5

Viewing and Changing Configuration Parameters

When you view the Bridge’s configuration parameters, you can retain their current

values or change them.

Retaining the Current Value

In all cases, if you press <Enter> when the current value is displayed, you will retain

the current value. For example, if the Bridge’s current values are as shown below ,

pressing <Enter> at each field will retain that current value:

IP Address : (192) .(168) .(001) .(023)

Changing a Value

To change a value, type the new value into the field at the point shown on your screen.

For example, to change the Bridge’s IP address to: 192.168.1.24:

IP Address : (192) .(168) .(001) .(023) 24

In this example, you would type the 24 immediately following the (023). Then press

<Enter> for the Bridge to accept your entry .

Commands: Default settings, Save, Quit without save

These are your commands:

E D)efault settings: Restores the Bridge’s factory–installed default

H

settings for all parameters except the Ethernet IP settings.

H

S S)ave: Stores the current settings into the Bridge’s memory, and exits the

configuration. The Bridge will restart immediately using the current settings.

Q Q)uit without save: Exits the configuration. The Bridge will restart

H

immediately using the settings it had prior to the last Save.

35

Page 36

Configuring the Bridge

3.6 Option 1: Network/IP Settings

When you select option 1 on the Configuration Menu, the Bridge displays its current

Ethernet settings. Here is an example:

IP Address : (192) .(168) .(001) .(023)

Set Gateway IP Address (Y):

Gateway IP Address : (192) .(168) .(001) .(030)

Set Netmask (N for default) (Y): (255) .(255) .(255) .(000)

IP Address

The four entry fields for the IP address are shown as parenthesis ( ).

To retain the Bridge’s current IP address, just press <Enter> at each field. To assign

a new IP address, enter it into each field.

IP 0.0.0.0: Note that setting the IP address to all zero (0.0.0.0) causes the Bridge to

be in an “Address Not Assigned” status. It reports its address as: 0.0.0.0/DHCP.

Disregard the reference to DHCP.

36

Set Gateway IP Address

The Gateway IP Address is used only if your Ethernet network is larger than one

continuous network (it contains subnetworks).

Each node within the subnetwork can directly reach all the other nodes within the

same subnetwork. If the Bridge’s subnetwork has a gateway to another subnetwork,

the Gateway IP Address parameter identifies the gateway’s address.

Set Netmask

If the Bridge’s subnetwork has a gateway node, the Bridge needs to know how to

recognize which IP addresses it can communicate with directly on its own subnetwork

and which addresses it must refer to the gateway node.

The Netmask (subnetwork mask) specifies which portion of the an IP address defines

devices on the local subnetwork, and which portion defines the entire subnetwork the

devices are on. By comparing IP addresses with the subnetwork mask, the Bridge can

determine which addresses are on its subnetwork and which are not.

Users can define different subnetwork masks to support their requirements. For

example, common “Class C” IP addresses assume a default subnetwork mask of

Page 37

Configuring the Bridge

0xFFFFFF00 or 255.255.255.0, using the lower 8 bits for the host part of the IP

address. This allows up to 255 devices on the local subnetwork.

This default mask is the example shown in the menu above.

If the user desires to have multiple subnetworks with up to 32 devices on each the

subnetwork mask could define 5 “host” bits or 255.255.255.224. With this setting, the

decimal value 224 configures the lower 8 bits of the address, with the upper 3 of these

bits addressing up to 8 subnetworks, and the lowest 5 bits forming the part of the

address for the 32 local devices.

If you wish to specify a subnetwork mask, enter

your values for the mask.

Enter

N to use the default subnetwork mask of 255.255.255.0.

Y at the menu prompt and then enter

37

Page 38

Configuring the Bridge

3.7 Option 2: Serial and Mode Settings

When you select option 2 on the Configuration Menu, the Bridge displays its current

serial port settings. Here is an example:

Attached Device (1=Slave, 2=Master) (001):

Serial Protocol (1=Modbus/RTU, 2=Modbus/ASCII) (001):

Interface Type (1=RS232, 2=RS422, 3=RS485) (001):

Enter Serial Parameters (9600,8,E,1):

Attached Device

Identify the type of Modbus device (Slave or Master) attached to the Bridge’s serial

port. The default is Slave.

Serial Protocol

Identify the type of Modbus protocol (RTU or ASCII) to be used at the serial port.

The default is RTU.

Interface T ype

Identify the type of communication interface (RS232, RS422 or RS485) used at the

serial port. The default is RS232.

38

Enter Serial Parameters

Enter the serial communication parameters used at the port, delimited by commas:

<baudrate>,<databits>,<parity>,<stopbits>

The defaults are: 9600,8,E,1.

The allowed values are:

H Baud rate: 300, 1200, 2400, 4800, 9600, 19200, 38400

H Data bits: 7, 8

H Parity: E, O, N

H Stop bits: 1, 2.

Page 39

3.8 Option 3: Modem Control Settings

When you select option 3 on the Configuration Menu, the Bridge displays:

RTS/CTS Mode (1=Fixed, 2=Variable) (001):

RTS/CTS Mode

RTS (Request to Send) and CTS (Clear to Send) are serial port signals that coordinate

the starting and stopping of data requests between the Bridge and its port device. You

can customize the RTS/CTS mode.

The options are: Fixed or V ariable. The default is Fixed. This causes the Bridge to

apply RTS/CTS with no time delays.

if you enter

2 to select the Variable option, you can specify timing values to allow a

slower device to respond in the RTS/CTS dialog. When you choose this option the

Bridge displays:

Delay after output RTS (0–1275 msec, 5 ms resolution) (00000):

Wait for CTS to go active (N):

Delay after CTS going active (0–1275 msec, 5 ms res) (00000):

Delay dropping RTS after TX (0–1275 msec, 5 ms res) (00000):

Configuring the Bridge

Example

If you select the RTS/CTS Variable mode and enter the following values:

RTS/CTS Mode (1=Fixed, 2=Variable) (001): 2

Delay after output RTS (0–1275 msec, 5 ms resolution) (00000): 200

Wait for CTS to go active (N): Y

Delay after CTS going active (0–1275 msec, 5 ms res) (00000): 250

Delay dropping RTS after TX (0–1275 msec, 5 ms res) (00000): 300

... you are specifying that after the Bridge asserts RTS it should wait up to 200 ms for

the serial port device to respond with CTS. It will then wait 250 ms before sending

data to the device. It will wait 300 ms before dropping RTS at the end of transmission.

Your new values will be now be shown in the Bridge’s Configuration Menu:

3) Modem Control Settings:

RTS Output ................... Variable, Delay 0200 ms, Hold 0250 ms

CTS Input to TX Delay ........ 0300 ms

39

Page 40

Configuring the Bridge

3.9 Option 4: Advanced Modbus Protocol Settings

When you select option 4 on the Configuration Menu, the Bridge displays parameters

for the type of Modbus device (Slave or Master) at its serial port.

Slave Device: Slave device parameters are:

Slave Address (0 for auto, or 1...255 fixed) (000):

Allow Modbus Broadcasts (1–Yes, 2=No) (002):

Character Timeout (10–1275 msec, 5 ms res) (00050):

Message Timeout (500–60000 msec, 250 ms res) (05000):

Master Device: Master device parameters are:

Character Timeout (10–1275 msec, 5 ms res) (00050):

Message Timeout (500–60000 msec, 250 ms res) (05000):

Slave Address

The Bridge’s Slave Address parameter specifies how the Bridge will direct messages

received from Ethernet to a Slave device at the serial port.

40

Each message originated from a Modbus Master contains a Unit_ID field that

addresses a Modbus Slave destination device. The Bridge can be configured to use

that Unit_ID address as received, or to substitute a fixed address instead.

Setting the Slave Address parameter to 0 (zero) configures the Bridge to use the

Unit_ID field as received in the message. It will pass the message out its Modbus port

to the Slave device addressed in the Unit_ID field.

Setting the Slave Address parameter to any non–zero value causes the Bridge to

always use that fixed value as the Slave address for all messages sent out its Modbus

port, regardless of the Unit_ID contained in the message. This routes all messages to

a single device.

The allowable non–zero range for entering this value is 1 ... 255 decimal. Note that

Modbus Slave addresses are valid in the range 1 ... 247 only .

The default is 0 (zero), specifying the Bridge to use the received Unit_ID field.

Page 41

Configuring the Bridge

Allow Modbus Broadcasts

This parameter specifies whether the Bridge may allow a Modbus Broadcast message

to be sent to Slave devices at its serial port, or not allow those messages. Broadcast

messages are those received by the Bridge containing a Unit_ID of 0 (zero).

If Modbus Broadcasts are allowed, broadcast messages are passed to the serial port

as received with the Unit_ID contents of 0 (zero).

If Modbus Broadcasts are not allowed, the Unit_ID in the message is disregarded and

the message is sent to Slave address 1 at the serial port.

The default is to not allow Broadcast messages to the serial port.

Character Timeout

This parameter sets the timeout value between successive characters in messages.

If this timeout is exceeded, the Bridge returns an error response to the originating

Master. Typically RTU protocol already contains a 3.5 character timeout, but some

serial devices might have internal interrupts or other delays which can cause pauses of

5 to 10 characters during transmission. This parameter can be set to accommodate

those devices.

The allowable range is 10 ... 1275 msec in 5 msec increments.

The default is 50 msec.

Message Timeout

This parameter sets the timeout value for the expected response from a Slave device.

If a response is not received within this time, the Bridge continues with other tasks if

any are pending from other Master devices. The Master application must provide its

own method of handling the message timeout.

The allowable range is 500 ... 60000 msec (0.5 ... 60 sec) in 250 msec increments.

The default is 5000 msec (5 sec).

41

Page 42

Configuring the Bridge

3.10 Option 5: Unit ID to IP Address Mapping Table

If you have specified the Bridge’s serial port Attached Device parameter as a Modbus

Master (see Section 3.7), you will need to map the Slave addresses received in

messages from that Master to their intended IP address destinations. The Bridge

maps the one–byte Modbus Slave address to an IP address for delivery on Ethernet.

3.10.1

3.10.2

How the Address Mapping Works

The Bridge contains an address mapping table with eight entries. Each entry maps a

Modbus Slave address (range 1 ... 247 decimal) to a standard IP address

(XXX.XXX.XXX.XXX).

When the Bridge receives a message from the Master at its serial port, the Bridge

searches the table for a match between the message’s Slave address and a Slave

address entry in the mapping table. If a match is found, the Bridge forwards the

message to the IP address specified in that location in the table. If a match is not

found, a message timeout will occur. If a match is found, but there is not an active

TCP connection at the IP address, a message timeout will occur. The Master

application must provide its own method of handling the message timeout.

The Bridge begins its search at table location 1, and continues in the sequence

1, 2 ... 8. It stops at the first location which matches the Slave address, and sends the

message to the corresponding IP address. Thus any duplicate entry , if one exists in

the table, will be ignored.

If you have configured the serial port for a Modbus Master, you must use the mapping

table to associate the ranges of Slave addresses in your Master application to the IP

destination addresses for those Slaves.

Example: Address Mapping

If you have configured the serial port for a Modbus Master, and have entered your

mapping, it will appear on the Bridge’s initial Configuration Menu. Here is an example.

5) Unit ID –> IP Address Table:

001–001: 192.168.001.020 002–002: 192.168.001.021

003–003: 192.168.001.022 010–010: 192.168.001.024

011–247: 192.168.001.025

42

In this example, the Bridge maps Modbus Slave address 1 to IP address 192.168.1.20.

It maps Slave addresses 2, 3, 10 as shown in the table. It maps any Slave address in

the range 1 1 ... 247 to IP address 192.168.1.25.

Page 43

3.10.3 Entering New Address Mapping

When you select option 5 on the Configuration Menu, the Bridge displays it current

mapping. Then it prompts:

A)dd, D)elete, E)xit –– select function:

Adding a New Map Entry

Press

A to add a new entry into the mapping table. The Bridge will prompt you to

enter the new mapping values. The values will go into the first available (empty) table

location. Here is an example:

Modbus addr from (000): 1

Modbus addr to (000): 1

Slave IP address (192) .(168) . (001) .(020)

Deleting a Map Entry

D to delete an entry from the mapping table. The Bridge will prompt you to

Press

enter the number of the table location you want to delete. Here is an example:

Delete entry number: 1

Configuring the Bridge

3.10.4

Changing an Existing Map Entry

If you want to change an existing entry in the mapping table, you must first delete that

entry and then add your changes as a new entry .

H Press

H Press

D to delete the current entry from the table.

A to add a new entry into the table, supplying the values for the new

entry.

Exiting the Mapping Menu

Press E to exit the Mapping Table menu and return to the initial Configuration Menu.

The Configuration Menu will display the new mapping (see Section 3.10.2).

Note that when you return to the Configuration Menu, you must select Save on that

menu to save the address mapping in the Bridge’s memory. Selecting Save will also

restart the Bridge. See Section 3.5 for a description of your Configuration Menu.

43

Page 44

Page 45

Using Panel Software

H Using Concept or Modsoft

H Using Other Software

4

45

Page 46

Using Panel Software

4.1 Using Concept or Modsoft

4.1.1 Software Versions

To support Modbus/TCP to the Bridge, you need Concept version 2.1 or later, or

Modsoft version 2.6 or later. Set the communications parameters as follows:

H Protocol: TCP/IP

H Dest_Port: 502

H Dest_Index: Modbus Slave address

Note that the Bridge contains an internal Slave Address configuration option

which might affect the delivery of messages to a Slave device at its serial port.

With this option, the Bridge may be configured internally to use the Dest_Index

address exactly as received in the message, or it may be configured to steer all

messages to a fixed Slave address, ignoring the Dest_Index address.

H TCP/IP Address: as required.

46

4.1.2

Modbus Slave Address

This is an additional explanation of how the Bridge uses the Modbus Slave address.

In a Modbus TCP message sent to the Bridge, the Slave address (defined in panel

software as the Dest_Index address) is stored in the Unit_ID field of the message.

This field is used to address a unique Slave device on a Modbus network which may

contain multiple Slave devices.

The Bridge’s internal configuration contains a Slave Address parameter which can be

set to override the Unit_ID address received in the message. Section 3.9 of this book

describes how to set up the Slave Address parameter.

If the parameter is set to 0 (zero), the message will be delivered to the Slave device

whose address is defined in the Unit_ID field. If the parameter is set to a non–zero

value (range 1 ... 255), the message will be delivered to the Slave device at that

numerical address, regardless of the contents of the Unit_ID field.

For example: If you are accessing the device at Modbus Slave address 34, you must:

H Set the Dest_Index field to 34, and

H Ensure the Bridge’s internal Slave Address parameter is configured to 0 (zero).

Page 47

4.2 Using Other Software

4.2.1 Intellution FIX MMI

The Bridge allows Windows workstations with Intellution FIX software to access

Modbus devices by TCP/IP over Ethernet.

The current version of this software does not support the Modbus/TCP Unit_ID field.

Therefore if you have configured the Bridge for a Slave device at its serial port, you

must configure the Bridge’s internal Slave Address parameter for that device. This

restricts the Bridge to a single Slave device at its port.

Refer to your software product’s documentation for further information.

Using Panel Software

4.2.2

4.2.3

WinTech Modscan

WinTech supplies ModScan32 software, which can select and poll coils and registers

from various Modbus RTU/ASCII and Modbus TCP devices.

This software supports the Modbus/TCP Unit_ID field, so RS–485 multiple–drop

configurations are supported through the Bridge.

Refer to your software product’s documentation for further information.

Worderware MMI

The Bridge allows Windows workstations with Wonderware software to access

Modbus devices by TCP/IP over Ethernet. You will need the Wonderware Modicon

Ethernet I/O Server software, at version 7.0.0.15 or higher.

The current version of this software does not support the Modbus/TCP Unit_ID field.

Therefore if you have configured the Bridge for a Slave device at its serial port, you

must configure the Bridge’s internal Slave Address parameter for that device. This

restricts the Bridge to a single Slave device at its port.

Refer to your software product’s documentation for further information.

47

Page 48

Page 49

Glossary

5

address

On a network, the identification of a station. In a frame, a grouping of bits that identifies

the frame’s source or destination.

API

Application Program Interface. The specification of functions and data used by one

program module to access another; the programming interface that corresponds to the

boundary between protocol layers.

ARP

Address Resolution Protocol. A network layer protocol used to determine the physical

address which corresponds to the IP address for a host on the network. ARP is a

sub–protocol which operates under TCP/IP.

BOOTP

Bootstrap Protocol. A TCP/IP–based protocol that allows a host to configure itself

dynamically. Provides a means to assign a host its IP address, typically without user

intervention.

bps

Bits per second.

bridge

A device that connects two or more physical networks which use the same protocol.

Bridges read frames and decide whether to transmit or block them based on their

destination address.

client

A computer process requesting service from other computer processes.

dest_idx

The destination field in a Modbus message. Corresponds to the Modbus device

addressed in the message.

49

Page 50

Glossary

default gateway

The IP address of the network or host to which all packets addressed to an unknown

network or host are sent. The default gateway is typically a router or other device.

DHCP

Dynamic Host Configuration Protocol. A network protocol used to configure IP

addresses dynamically. DHCP is an extension of BOOTP.

DNS

Domain Name System. A protocol within TCP/IP used to find IP addresses based on

host names.

field

A logical grouping of contiguous bits that convey one kind of information, such as the

start or end of a message, an address, data or an error check.

frame

A group of bits which form a discrete block of information. Frames contain network

control information or data. The size and composition of a frame is determined by the

network technology being used.

framing types

Two common framing types are Ethernet II and IEEE 802.3.

50

FTP

File Transfer Protocol. A networking protocol used to exchange files between stations

on a network or over the Internet.

gateway

A device which connects networks with dissimilar network architectures and which

operates at the Application Layer. This term may refer to a router.

host

A node on a network.

hostname

A domain name given to a specific computer on a network and used to address that

computer.

HTTP

HyperText Transport Protocol. A protocol used to deliver hypertext documents.

hub

A device which connects a series of flexible and centralized modules to create a

network.

Page 51

Glossary

ICMP

Internet Control Message Protocol. A protocol within TCP/IP used to report errors in

datagram transmission.

Internet

The global interconnection of TCP/IP based computer communication networks.

IP

Internet Protocol. A common network layer protocol. IP is most often used with TCP.

IP Address

Internet Protocol Address. A 32–bit address assigned to hosts using TCP/IP.

layer

In the OSI model, a portion of the structure of a device which provides defined services

for the transfer of information.

MAC Address

Media Access Control address. The hardware address of a device. A MAC address is

assigned to an Ethernet TCP/IP module in the factory .

network

Interconnected devices sharing a common data path and protocol for communication.

node

An addressable device on a communications network.

OSI model

Open System Interconnection model. A reference standard describing the required

performance of devices for data communication. Produced by the International

Standards Organization.

packet

The unit of data sent across a network.

PING

Packet Internet Groper. A program used to test whether a destination on a network can

be reached.

port

An access point for data entry or exit within a host using TCP services.

protocol

Describes message formats and a set of rules used by two or more devices to

communicate using those formats.

51

Page 52

Glossary

repeater

A device that connects two sections of a network and conveys signals between them

without making routing decisions or filtering packets.

router

A device that connects two or more sections of a network and allows information to

flow between them. A router examines every packet it receives and decides whether to

block the packet from the rest of the network or transmit it. The router will attempt to

send the packet through the network by the most efficient path.

server

Provides services to clients. This term may also refer to the computer on which the

service is based.

socket

The association of a port with an IP address, serving as an identification of sender or

recipient.

stack

The software code which implements the protocol being used. In the case of the NOE

modules it is TCP/IP.

STP

Shielded Twisted Pair. A type of cabling consisting of several strands of wire

surrounded by foil shielding, twisted together.

52

subnet

A physical or logical network within an IP network, which shares a network address

with other portions of the network.

subnet mask

Used to indicate which bits in an IP address identify a subnet.

switch

A network device which connects two or more separate network segments and allows

traffic to be passed between them. A switch determines whether a frame should be

blocked or transmitted based on its destination address.

TCP

Transmission Control Protocol.

TCP/IP

A protocol suite consisting of the Transmission Control Protocol and the Internet

Protocol; the suite of communications protocols on which the Internet is based.

Page 53

Glossary

UDP

User Datagram Protocol. A protocol which transmits data over IP.

URL

Uniform Resource Locator. The network address of a file.

UTP

Unshielded Twisted Pair. A type of cabling consisting of insulated cable strands which

are twisted together in pairs.

Winsock

The Microsoft implementation of the Windows Sockets networking API based on the

Berkeley UNIX Sockets interface for supporting TCP/IP.

WWW

World Wide Web. A hypertext–based, distributed information system in which clients

and servers are freely available.

53

Page 54

Page 55

Modicon, Square D and Telemacanique are PLC brand names from Schneider. These products are sold in

the US by Square D; in Canada, Latin America, Europe, Asia, Asia/Pacific and Middle East by Schneider;

in Germany by AEG Schneider Automation; in China and Persian Gulf by Schneider Automation; in South

Africa by ASA Systems Automation; in Austria by Online.

United States:

Schneider Automation, Inc.

One High Street

North Andover, MA 01845

Tel: (1) 978–794–0800

Fax: (1) 978–975–9400

France:

Schneider Automation S.A.

245, Route des Lucioles - BP147

F–06903 Sophia - Antipolis Cedex

Tel: (33) 92 96 20 00

Fax: (33) 93 65 37 15

Germany:

Schneider Automation GmbH

Steinheimer Strasse 117

D–63500 Seligenstadt

Tel: (49) 6182 81–2584

Fax: (49) 6182 81–2860

Loading...

Loading...