3URGXFW0DQXDO 3URGXFW0DQXDO3URGXFW0DQXDO 3URGXFW0DQXDO

7DSH'ULYH

7DSH'ULYH

'/79

$

DLT-V4 Product Manual Guide, 81-81422-02 A01, November 2005, Made in USA.

Quantum Corporation provides this publication “as is” without warranty of any kind, either express or

implied, including but not limited to the implied warranties of merchantability or fitness for a particular

purpose. Quantum Corporation may revise this publication from time to time without notice.

COPYRIGHT STATEMENT

Copyright 2005 by Quantum Corporation. All rights reserved.

Your right to copy this document is limited by copyright law. Making copies or adaptations without prior

written authorization of Quantum Corporation is prohibited by law and constitutes a punishable violation of

the law.

TRADEMARK STATEMENT

Quantum, the Quantum logo, DLT, DLTtape, the DLTtape logo, and Super DLTtape logo are all registered

trademarks of Quantum Corporation. DLTIce, DLTSage, and Super DLTtape are all trademarks of Quantum

Corporation.

Other company and product names used in this document are trademarks, registered trademarks, or service

marks of their respective owners.

Contents

Preface ix

Chapter 1 Introduction 1

DLT-V4 Tape Drive Overview........................................................................................1

Features and Upgrades....................................................................................................2

Features.......................................................................................................................2

Firmware Upgrades and Drivers............................................................................2

Chapter 2 Installing the Tape Drive 4

Preparing to Install the Tape Drive................................................................................4

Before You Start.........................................................................................................4

SCSI Bus Requirements ............................................................................................4

Physical Considerations ...........................................................................................5

SATA Requirements..................................................................................................5

Installing the Tabletop SCSI Tape Drive.......................................................................6

Identifying the Steps .................................................................................................6

Unpacking the Tabletop Tape Drive and Selecting a Location ..........................7

Unpacking the Tabletop Tape Drive................................................................7

Selecting a Location for the Tabletop Tape Drive..........................................7

Setting the SCSI ID ....................................................................................................8

Connecting the SCSI Interface Cables ....................................................................9

DLT-V4 Product Manual iii

Contents

Terminating the SCSI Tabletop Tape Drive.................................................. 11

Powering the Terminator ................................................................................12

Completing the Tabletop SCSI Tape Drive Installation .................................... 13

Installing the Internal SCSI Tape Drive ......................................................................14

Identifying the Steps............................................................................................... 14

Unpacking the Internal SCSI Tape Drive ............................................................ 15

Configuring the Internal SCSI Tape Drive ..........................................................15

Setting the SCSI ID ........................................................................................... 16

Terminating the Internal SCSI Tape Drive ...................................................17

Installing the Internal SCSI Tape Drive ...............................................................19

Completing the Internal SCSI Tape Drive Installation......................................23

Installing the Internal SATA Tape Drive.................................................................... 25

Identifying the Steps............................................................................................... 25

Unpacking the Internal SATA Tape Drive..........................................................26

Installing the Internal SATA Tape Drive.............................................................26

Connecting the Internal SATA Tape Drive to the Server.................................. 29

Completing the Internal SATA Tape Drive Installation....................................30

Installing the Device Drivers ........................................................................................ 32

Microsoft Windows XP and Windows Server 2003...........................................32

Microsoft Windows 2000........................................................................................33

Chapter 3 Specifications 35

Physical Description ...................................................................................................... 36

Physical Dimensions and Weights .......................................................................36

Temperature and Humidity Ranges............................................................................37

Altitude............................................................................................................................ 38

Functional Specifications .......................................................................................38

Emissions......................................................................................................................... 39

Safety Requirement........................................................................................................39

Consumer Bulletin Scheme........................................................................................... 40

Timing Characteristics...................................................................................................40

Data Cartridge and Media Characteristics................................................................. 41

Reliability Factors...........................................................................................................41

Environmental Compliance..........................................................................................45

Disposal of Electrical and Electronic Equipment ......................................................46

DLT-V4 Product Manual iv

Contents

Chapter 4 Using Your Tape Drive 47

LED Indicators................................................................................................................47

Power-On Self-Test (POST) Indicator Activity...................................................47

Normal Operation — Ready LED Indicator Activity ........................................ 48

Normal Operation — Fault / Clean / Media LEDs Indicator Activity.......... 48

Unload Button Functions ..............................................................................................50

Unload Button Actions.................................................................................................. 51

Diagnostic Mode Event Codes ..................................................................................... 52

Chapter 5 Using Data and Cleaning Cartridges 54

Data Cartridge Use and Care........................................................................................54

Loading a Data Cartridge ......................................................................................54

Unloading a Data Cartridge .................................................................................. 55

Write-Protecting the Data Cartridge.................................................................... 56

Caring for Your Data Cartridges ..........................................................................57

Using the Cleaning Cartridge................................................................................ 58

Glossary 60

DLT-V4 Product Manual v

Figures

Figure 1 Rear Panel SCSI Tabletop Tape Drive ..................................................... 8

Figure 2 SCSI ID Selector Switch .............................................................................9

Figure 3 Tabletop Tape Drive SCSI and Power Cable Connections................. 10

Figure 4 Server SCSI Cable Connections .............................................................. 11

Figure 5 Tabletop SCSI Tape Drive Rear Panel Connections ............................12

Figure 6 Rear Panel Connections for the Internal SCSI Tape Drive ................. 16

Figure 7 SCSI Interface — Terminator Installation ............................................. 18

Figure 8 SCSI Cable with Built-in Terminator ..................................................... 19

Figure 9 Removing the Workstation Cover (example).......................................20

Figure 10 Installing the Internal SCSI Tape Drive in an Open Bay..................... 21

Figure 11 Internal SCSI Tape Drive SCSI and Power Cable Location................23

Figure 12 Securing the Internal SCSI Tape Drive in the Installation Bay ..........24

Figure 13 Removing the Workstation Cover (example).......................................27

Figure 14 Installing the Internal SATA Tape Drive .............................................. 28

Figure 15 Rear Panel Connections for the SATA Internal Tape Drive...............29

Figure 16 Internal SATA Tape Drive Power and Data Cable Connection

Locations................................................................................................. 30

Figure 17 Securing the Internal SATA Tape Drive in the Installation Bay........ 31

Figure 18 Loading a DLTtape VS1 Data Cartridge ............................................... 55

Figure 19 Unloading a DLTtape VS1 Data Cartridge from the Tape Drive ......56

DLT-V4 Product Manual vi

Figures

Figure 20 DLTtape VS1 Data Cartridge Write-Protect Switch ............................57

Figure 21 DLT VS1 Cleaning Cartridge ..................................................................58

DLT-V4 Product Manual vii

Tables

Table 1 Installing the Tabletop SCSI Tape Drive.................................................... 6

Table 2 Installing the DLT-V4 Internal SCSI Tape Drive — Overview ............ 14

Table 3 Selecting the SCSI ID ..................................................................................16

Table 4 Installing the DLT-V4 Internal SATA Tape Drive — Overview..........25

Table 5 Physical Dimensions...................................................................................36

Table 6 Weight Specifications .................................................................................36

Table 7 Operating Temperature/Humidity Ranges............................................37

Table 8 Storage and Shipment Temperature/Humidity Ranges (Packed or

Unpacked)................................................................................................. 37

Table 9 Functional Specifications ...........................................................................38

Table 10 Timing Characteristics................................................................................40

Table 11 Data Cartridge and Media Characteristics.............................................41

Table 12 Reliability Factors........................................................................................41

Table 13 Ready LED Indicator Activity................................................................... 48

Table 14 Fault / Clean / Media LEDs Indicator Activity.....................................48

Table 15 Unload Button Functions...........................................................................50

Table 16 Unload Button Actions............................................................................... 51

Table 17 Diagnostic Mode Event Codes..................................................................53

DLT-V4 Product Manual viii

Preface

This document serves as an easy-to-use information source to familiarize

Quantum customers and systems professionals with the DLT-V4 tape

drive system. The DLT-V4 tape drive is an extension of the Quantum

Digital Linear Tape (DLT

This chapter describes the purpose, scope, and audience of this

document. It also lists the typographical conventions used in this

document.

Purpose This document describes the DLT-V4 tape drive, listing its physical,

functional, and performance specifications, and describing the standards

that the tape drive meets.

Audience The primary audience for this document consists of engineers and

technicians interested in integrating the DLT-V4 tape drive into tape

libraries and other equipment.

®

) product family.

Document Organization This document is organized as follows:

• Chapter 1, Introduction

internal), and provides a general overview of the product.

• Chapter 2, Installing the Tape Drive

install the tape drive.

• Chapter 3, Specifications

DLT-V4 Product Manual ix

, introduces the tape drive (tabletop or

, explains how to configure and

, contains the tape drive specifications.

Preface

• Chapter 4, Using Your Tape Drive, contains functional information

useful during the operation of the tape drive.

• Chapter 5, Using Data and Cleaning Cartridges

regarding the care of tape cartridges.

Notational Conventions This document uses the following conventions:

Note: Notes emphasize important information related to the main

topic.

Caution: Cautions indicate potential hazards to equipment and are

included to prevent damage to equipment.

Warning: Warnings indicate potential hazards to personal safety and

are included to prevent injury.

This document uses the following:

• Tape Drive System — Refers to the complete system including the

cartridge.

• Tape Drive — Refers to just the tape drive and does not include the

cartridge.

, contains information

• Right side of the drive — Refers to the right side as you face the

component being described.

• Left side of the drive — Refers to the left side as you face the

component being described.

• b — All binary numbers are succeeded by “b.”

• h — All hexadecimal numbers are succeeded by “h.”

• Error or attention conditions are represented in parenthesis that

translate as follows:

(SK=S ASC=AA ASCQ=QQ)

where:

S — hexadecimal sense key value

AA — hexadecimal additional sense code

DLT-V4 Product Manual x

QQ — hexadecimal additional sense code qualifier

Preface

Typographical

Conventions

This document uses the following typographical conventions:

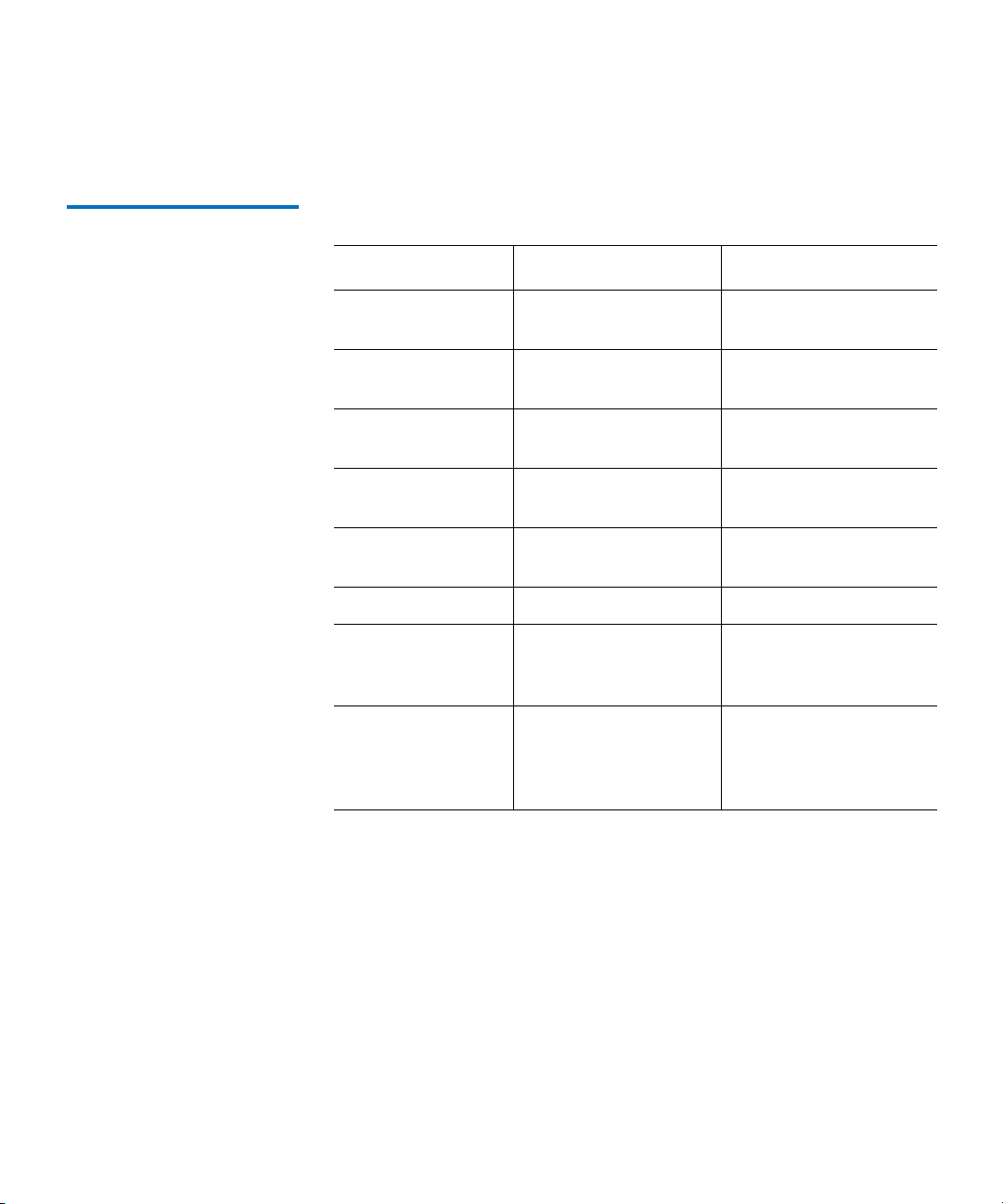

Element Convention Example

Commands Uppercase (unless

FORMAT UNIT

case-sensitive)

Messages Uppercase INVALID PRODUCT

NUMBER

Hexadecimal

Notation

Binary Notation Number followed by

Number followed by

lowercase h

25h

101b

lowercase b

Decimal Notation Number without

512

suffix

Acronyms Uppercase POST

Abbreviations Lowercase, except

where standard usage

Mb (megabits)

MB (megabytes)

requires uppercase

Dimensions in

Figures

No units specified

(Inches understood

0.57 EJECT DISTANCE

unless otherwise

specified)

DLT-V4 Product Manual xi

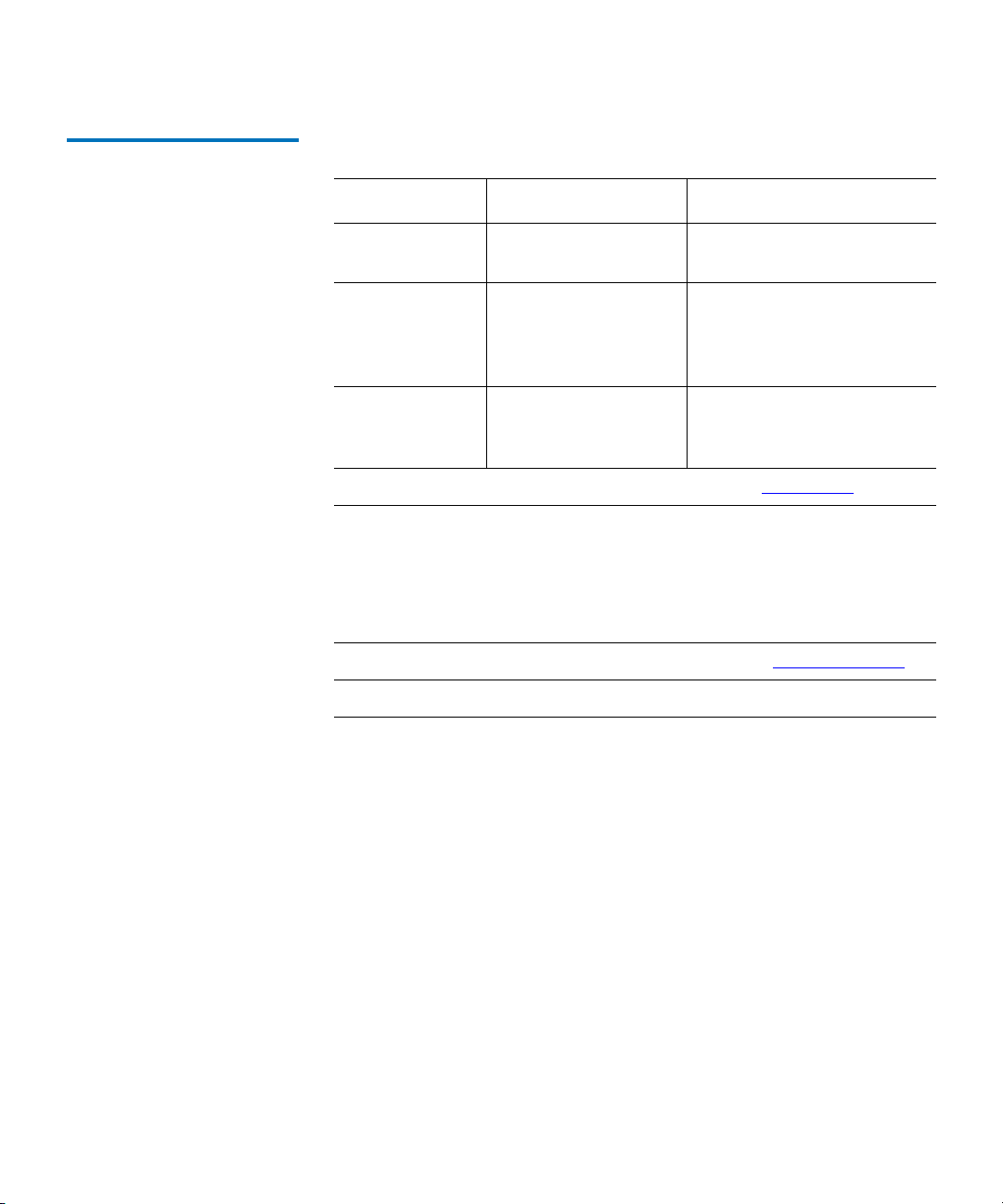

Related Documents The following documents are related to the DLT-V4 tape drive:

Document No. Document Title Document Description

Preface

81-81252-xx Bezel Replacement

Guide

81-81349-xx DLT-V4 Product

Specification

81-81355-xx DLT-V4 Quick Start

Guide

Current SCSI standards documents available from

Provides bezel replacement

instructions

This document provides

detailed product

specifications for the tape

drive.

This document provides

basic tape drive installation

instructions.

• SCSI Architecture Model (SAM-3)

• SCSI Primary Commands (SPC-3)

• SCSI Parallel Interface (SPI-5)

• SCSI Stream Commands (SSC-3)

Current SATA standards documents available from

• Serial ATA 1.0a Specification

SCSI Standards

www.t10.org

www.serialata.org

Copies of the approved version of the SCSI standards may be obtained

from:

Global Engineering Documents

15 Inverness Way, East

Englewood, CO 80112

(800) 854-7179 or (303) 397-2740

DLT-V4 Product Manual xii

Contacts Quantum company contacts are listed below.

Preface

Quantum Corporate Headquarters

To order documentation on this or other Quantum products, contact:

Quantum Corporation

141 Innovation Drive

Irvine, CA 92617

(949) 856-7800

(800) 284-5101

Technical Publications

To comment on existing documentation send e-mail to:

doc-comments@quantum.com

Quantum Home Page 0

Visit the Quantum home page at:

http://www.quantum.com

Customer Support 0

0

0

The Quantum Customer Support Department provides a 24-hour help

desk that can be reached at:

North/South America: (949) 725-2100 or (800) 284-5101

Asia/Pacific Rim: (International Code) + 61 7 3839 0988

Europe/Middle East/Africa: (International Code) + 44 (0) 1256 848748

Send faxes for the Customer Support Department to:

North/South America: (949) 725-2176

Asia/Pacific Rim: (International Code) + 61 7 3839 0955

Europe/Middle East/Africa: (International Code) + 44 (0) 1256 848777

DLT-V4 Product Manual xiii

Send e-mail for the Customer Support Department to:

North/South America: http://www.quantum.com/am/service_support/

Index.aspx

Asia/Pacific Rim: apachelp@quantum.com

Europe/Middle East/Africa: eurohelp@quantum.com

Preface

DLT-V4 Product Manual xiv

Chapter 1

1Introduction

This chapter introduces the DLT-V4 tape drive (tabletop or internal), and

provides a general overview of the product.

DLT-V4 Tape Drive Overview 1

The Quantum DLT-V4 tape drive is a value-priced, high-reliability, highcapacity linear streaming data cartridge tape drive designed for use on

entry- to mid-range computing platforms. With a combination of data

compression and compaction, the DLT-V4 tape drive offers a formatted

data cartridge capacity of 320 gigabytes (GB) (assuming a 2:1

compression ratio), and a sustained user data transfer rate of

20 megabytes (MB)/sec (assuming a 2:1 compression ratio).

The DLT-V4 tape drive is a 5¼-inch, half-height form-factor device that

uses ½-inch tape. Its design includes a four-channel read/write head,

Lempel-Ziv (DLZ) high-efficiency data compression, and a tape-mark

directory to achieve fast data throughput and data access times.

DLT-V4 Product Manual 1

Chapter 1 Introduction

Features and Upgrades

Features and Upgrades 1

This section covers the DLT-V4 tape drive features, and information

about obtaining drivers and firmware upgrades.

Features 1 The DLT-V4 tape drive offers the following features:

• Supported formats: DLT-V4 (read/write using DLTtape

data cartridges), DLT VS160 (read only using DLTtape VS1 Media

data cartridges), DLT1/VS80 (read only using DLTtape IV data

cartridges).

• Uses DLTtape VS1 data cartridge.

• 5¼-inch half-height form-factor.

• Formatted data cartridge capacity of 160 GB native, 320 GB

compressed.*

• Sustained user data transfer rate of 10 MB/s native, up to 20 MB/s

with compression*.

®

VS1 Media

• For the SCSI interface tape drive, to achieve 160 MB/s, an Ultra160,

or Ultra320, Low-Voltage Differential (LVD) or Single-Ended (SE)

Wide SCSI bus is required.

• For the SATA interface tape drive, a SATA interface card is required.

* In accordance with industry practice, a typical compression ratio of 2:1 is

quoted. The redundancy and type of data files being written determine the

actual compression ratios achieved.

Firmware Upgrades and Drivers

Quantum frequently provides new and updated tools to use with its tape

drives. These tools include such items as upgrades for product software

1

and firmware, and diagnostic software that may be newly developed. All

these tools are available on the Quantum Web site.

Note: These tools are only available to registered Quantum

customers.

1 See the following procedure to access these tools.

DLT-V4 Product Manual 2

Chapter 1 Introduction

Features and Upgrades

Go to the Quantum Web site: www.quantum.com.

2

3 Click SERVICE AND SUPPORT in the upper menu bar. This opens the

Service and Support window.

4 Explore the various pages that comprise Service and Support until

you find what you need.

New tools and utilities get added frequently, so check back often.

DLT-V4 Product Manual 3

Chapter 2

2Installing the Tape Drive

This chapter explains how to configure and install the tape drive.

Configuration and installation are not difficult and require only that you

follow the instructions presented in this chapter.

Preparing to Install the Tape Drive 2

This section helps you prepare to install the DLT-V4 tape drive (tabletop

or internal).

Before You Start 2 Installing the DLT-V4 SCSI tabletop tape drive requires no special tools.

For the SCSI interface, you will need a ballpoint pen to change the SCSI

ID switch on the rear panel of the tape drive.

If you are installing a DLT-V4 SATA internal tape drive, see Installing the

Internal SATA Tape Drive on page 25 for instructions. Installing the DLT-

V4 internal tape drive requires only the usual tools needed to install an

internal tape drive in the computer you have chosen to house the tape

drive (for example, a screwdriver and some ESD protection).

SCSI Bus Requirements 2 The DLT-V4 SCSI interface tape drive (tabletop and internal) incorporates

a wide Ultra160 low-voltage differential (LVD) small computer system

DLT-V4 Product Manual 4

Chapter 2 Installing the Tape Drive

Preparing to Install the Tape Drive

interface (SCSI) bus, but you can also attach it to a single-ended (SE) SCSI

bus.

Make sure the SCSI host adapter or controller supports these

configurations. If you connect the tape drive to an SE bus, or if there are

SE devices attached to the same SCSI bus, the tape drive’s performance is

limited to the maximum data transfer speed and maximum cable lengths

of the SE bus (usually 40 MB/s). The DLT-V4 is not compatible with a high-

voltage differential (HVD) SCSI bus.

Physical Considerations 2 If you attach the tape drive to a narrow (50-pin) SCSI bus, you must use a

customer-supplied 68-pin to 50-pin adapter that terminates the unused 18

pins. These adapters are sometimes labeled

high-byte termination.

Make sure the total length of the SCSI bus does not exceed the ANSI SCSI

standard of 19 feet (6 meters) for an SE SCSI bus, 40 feet (12 meters) for an

LVD SCSI bus with multiple devices, or 82 feet (25 meters) for an LVD

SCSI bus with a single device.

SATA Requirements 2 The DLT-V4 SATA interface tape drive (internal only) incorporates a

Serial ATA (SATA) bus.

Make sure the total length of the internal SATA data cable does not

exceed the SATA standard of approximately 40 inches (1 meter).

DLT-V4 Product Manual 5

Chapter 2 Installing the Tape Drive

Installing the Tabletop SCSI Tape Drive

Installing the Tabletop SCSI Tape Drive 2

This section contains step-by-step instructions for installing the tabletop

SCSI tape drive.

Identifying the Steps 2 Installing the tabletop SCSI tape drive is fast and easy when you follow

the instructions in this section in the order presented. Complete the

following steps, covered in the next few sections:

Table 1 Installing the Tabletop

SCSI Tape Drive

Step Instruction Refer to

1 Unpack and check the tape drive for shipping damage. page 7

2 Select a location near the server or workstation that is to

host the tape drive.

3 Set the SCSI ID for the tape drive, if you do not want to

use the factory-set default.

4 Shut down and power off the server or workstation that

is to host the tape drive.

5 Install an LVD/SE SCSI host adapter in the server or

workstation, if necessary.

6 Connect the SCSI cable to the tape drive and SCSI host

adapter.

7 Connect the terminator on the tape drive—if it is the last

or only device on the SCSI bus.

8 Connect the power cable to the tape drive, server or

workstation, and all peripheral devices. Plug the power

cable into the nearest power outlet and apply power to

all devices.

9 Check the tape drive to make sure it is working properly.

page 7

page 8

page 9

page 11

DLT-V4 Product Manual 6

Chapter 2 Installing the Tape Drive

Installing the Tabletop SCSI Tape Drive

Unpacking the Tabletop T ape Drive and Selecting a Location

Before you begin, clear a desk or table so that you can unpack the tape

drive. You also need to select a location near the server or workstation

that has room for the tape drive to sit without being crowded.

2

Note: If the room in which you are working differs from the

temperature at which the tape drive was shipped or stored by

30 ºF (17 ºC) or more, let the tape drive acclimate to the

surrounding environment for at least 12 hours before opening

the shipping carton.

Unpacking the Tabletop Tape Drive 2

Before you do anything else, unpack and inspect the tabletop SCSI tape

drive for shipping damage. If you notice any damage, report it both to the

sales representative and to the shipping company immediately.

Note: Save the packing materials in case you need to move or ship

the tape drive in the future. You must ship the tabletop tape

drive in the original (or equivalent) packing materials or you

will invalidate the warranty.

Selecting a Location for the Tabletop Tape Drive 2

Select a location for the tape drive that is flat, sturdy, level, and close to

the server or workstation. A desk or tabletop surface is most suitable.

Regardless of the location you choose for the tape drive, make sure the

environment is free from dust, cigarette smoke, and excessive

temperature and humidity. See the DLT-V4 Product Specification for

acceptable operating temperature and humidity limits.

Be sure to follow these additional guidelines when selecting a location for

the tape drive:

• Allow at least 6 inches (15.2 cm) behind the tape drive for proper

cooling.

• Avoid locations near printers or photocopy machines, both of which

produce paper fiber and other types of dust and airborne

contaminants.

• Do not place the tape drive on the floor.

DLT-V4 Product Manual 7

Chapter 2 Installing the Tape Drive

Installing the Tabletop SCSI Tape Drive

• Avoid locations near generators, electric motors, audio speakers, or

other sources of magnetic fields. Magnetic fields can adversely affect

the tape drive and data cartridges.

Setting the SCSI ID 2 All SCSI devices attached to the server or workstation must have a

unique SCSI ID. Check the SCSI IDs on all other devices on the selected

server or workstation, including the SCSI host adapter, and select an

unused SCSI ID for the tape drive. The factory default SCSI ID for this

tape drive is 5, as shown in figure 1

. If the tape drive’s factory default

SCSI ID is not already in use by another device on the same SCSI bus, you

do not need to change the SCSI ID.

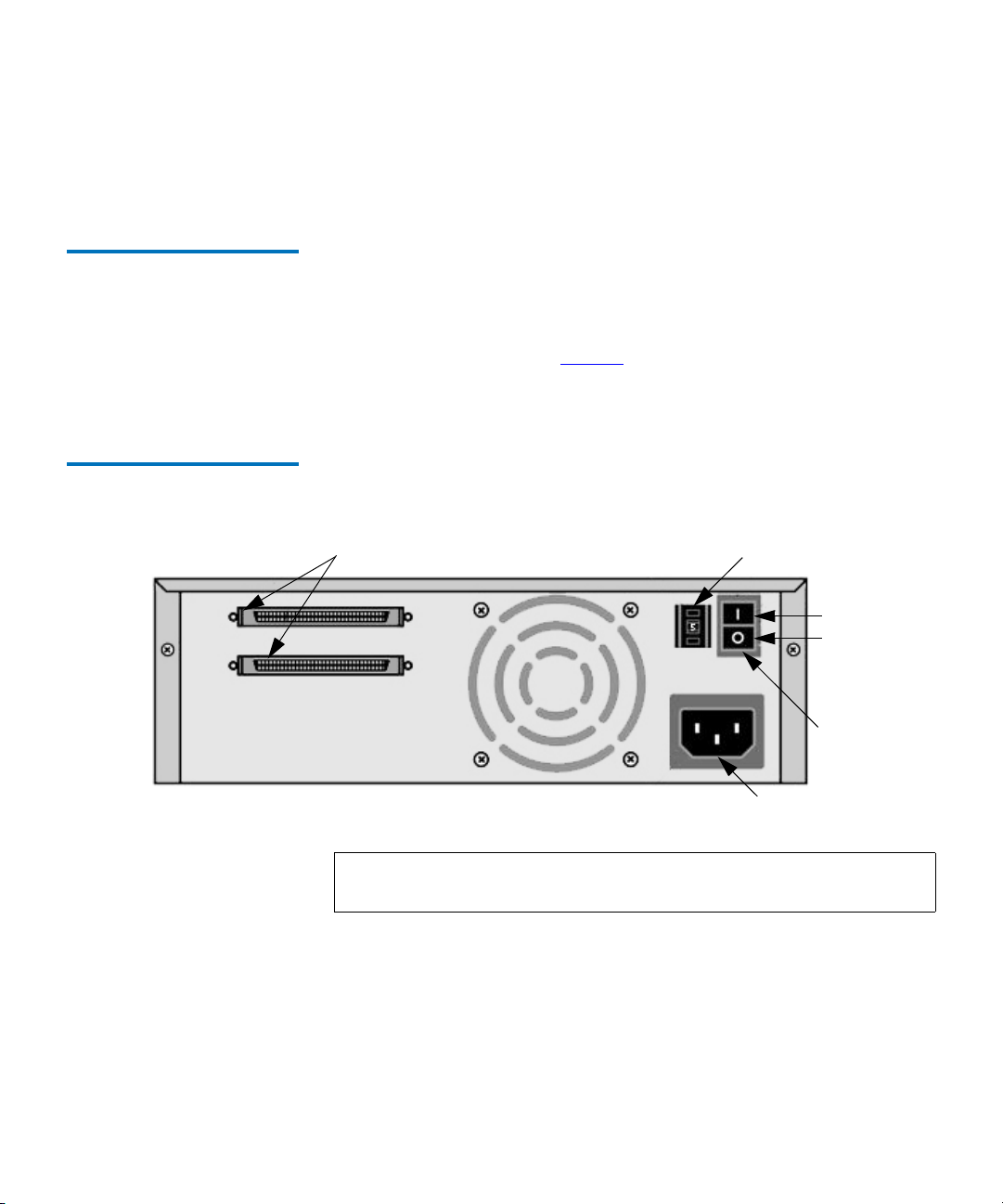

Figure 1 Rear Panel SCSI

Tableto p Tape Drive

68-pin high-density SCSI connectors

Note: If you attach the tape drive to a narrow (50-pin) SCSI bus, you

SCSI ID switch

On

Off

Power

switch

Power cable

connector

can only use IDs 0 through 7.

To set the SCSI ID on the tape drive, use a small screwdriver or ballpoint

pen to press the button above the SCSI ID switch to select the next lower

SCSI ID. Press the button below the SCSI ID switch to select the next

higher SCSI ID. Each time you press one of these buttons, the SCSI ID

decreases or increases by one. Press the appropriate button until the

desired SCSI ID appears on the switch display.

DLT-V4 Product Manual 8

Figure 2 SCSI ID Selector

Switch

Chapter 2 Installing the Tape Drive

Installing the Tabletop SCSI Tape Drive

Press here to decrease

SCSI ID

Press here to increase

SCSI ID

Connecting the SCSI Interface Cables

In the final installation stage, you connect the SCSI and power cables to

the tape drive.

2

Note: If the selected server or workstation does not already have an

installed SCSI host adapter, you will need to install one. For

more information on SCSI host adapter requirements, see SCSI

Bus Requirements on page 4.

To connect the SCSI and power cables to the tape drive, follow these

steps:

1 Shut down the operating system and power down the server or

workstation.

2 Power off all peripheral devices, such as printers and other SCSI

devices.

Caution: Do not go to step 3 until you have completed steps 1

and 2

. Failure to follow these instructions may result

in damage to the tape drive or other devices.

3 Obtain a SCSI cable with an open 68-pin, high-density connector.

4 Connect one end of the SCSI cable to one of the connectors on the rear

panel of the tape drive as shown in figure 3

works equally well. Figure 3

does not show a terminator because

. Either SCSI connector

none of the three tape drives in the illustration are at the end of the

SCSI bus.

DLT-V4 Product Manual 9

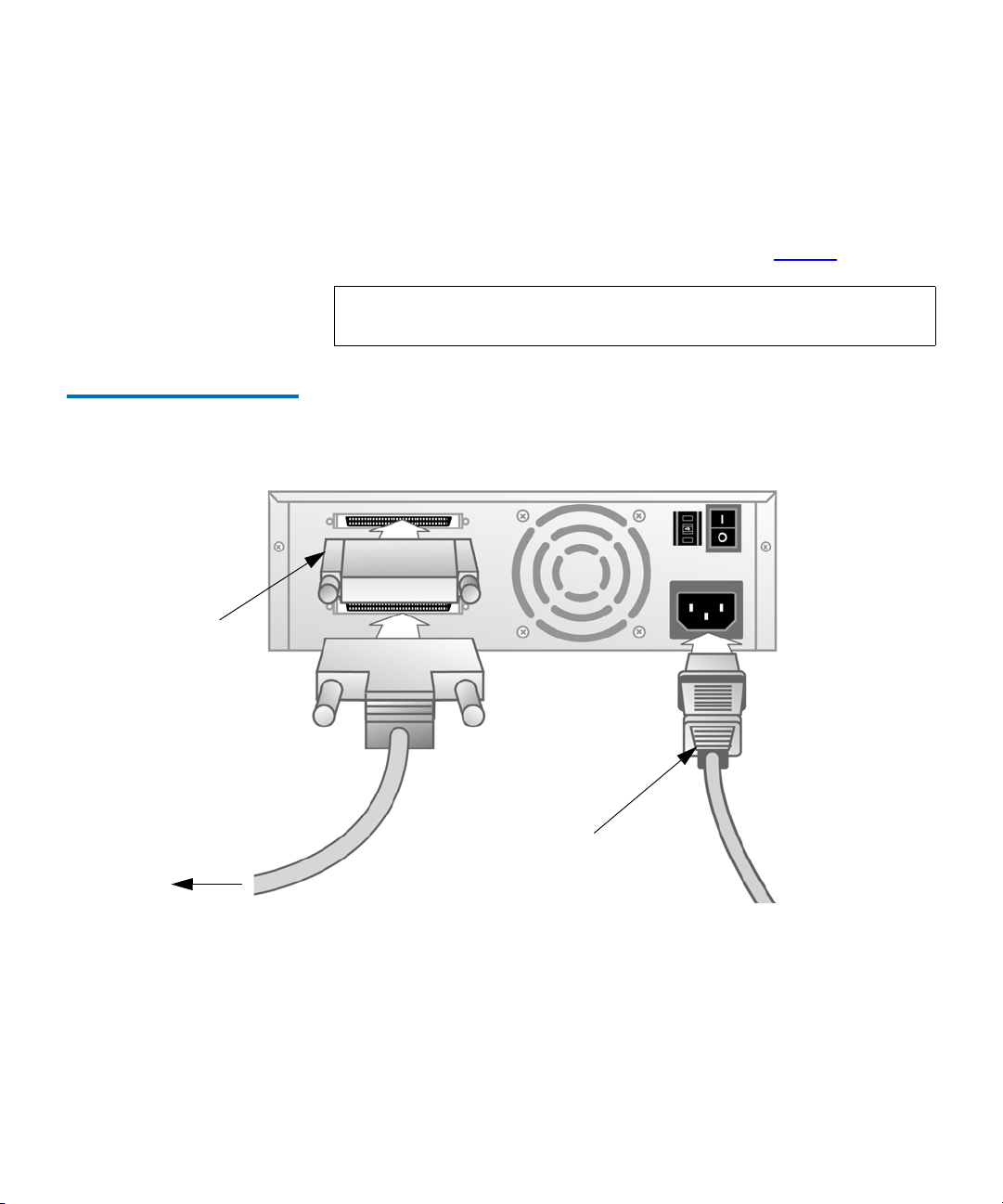

Figure 3 Tabletop Tape Drive

SCSI and Power Cable

Connections

Chapter 2 Installing the Tape Drive

Installing the Tabletop SCSI Tape Drive

To next

device

To SCSI

host adapter

Connect the other end of the SCSI cable to the connector on the SCSI

5

host adapter or to the connector on the previous SCSI device on the

SCSI bus, as shown in figure 4

.

Power

cords

DLT-V4 Product Manual 10

Figure 4 Server SCSI Cable

Connections

Chapter 2 Installing the Tape Drive

Installing the Tabletop SCSI Tape Drive

SCSI host

adapter

SCSI

cable

Terminating the SCSI Tabletop Tape Drive 2

You must terminate the tape drive if it is the last physical device on the

SCSI bus (at the end of the SCSI chain). If another SCSI device is the last

device on the SCSI bus, confirm that it is properly terminated and do not

terminate the tape drive.

Note: Regardless of which device terminates the SCSI bus, it must

have power applied and be powered on for proper

termination to occur.

To terminate the tape drive, locate the terminator in the accessories

package and press it firmly into either of the two SCSI connectors on the

rear panel of the tape drive. Secure the terminator by tightening the

screws until snug. See figure 5

DLT-V4 Product Manual 11

for more details.

Chapter 2 Installing the Tape Drive

Installing the Tabletop SCSI Tape Drive

Powering the Terminator 2

At least one device on the SCSI bus must supply terminator power

(

TERMPWR). The factory default for the tape drive is for TERMPWR to be

enabled. Only an authorized service provider can disable the tape drive

TERMPWR setting. Attach the terminator as shown in figure 5.

Figure 5 Tabletop SCSI Tape

Drive Rear Panel Connections

Terminator

(or cable to

next SCSI

device)

SCSI cable

(to computer or

previous SCSI

device)

Note:

It is acceptable for more than one device on the SCSI bus to

provide

TERMPWR.

Power cord

DLT-V4 Product Manual 12

Chapter 2 Installing the Tape Drive

Installing the Tabletop SCSI Tape Drive

Completing the Tabletop SCSI Tape Drive Installation

1 Secure the SCSI cable connectors by tightening the screws until snug.

2

Note: If the SCSI cable does not fit the connector on the SCSI

host adapter, you either have an incompatible SCSI host

adapter or you need to purchase a cable adapter. Contact

the sales representative or the SCSI host adapter

manufacturer for information.

2 Make sure the power switch on the rear panel of the tape drive is in

the OFF position (tabletop model only). Attach the female connector

on the power cable to the power connector on the rear panel of the

tape drive, as shown in figure 5

3 Connect the power cables to the server or workstation and all

.

peripheral devices.

4 Plug the power cable into a nearby power outlet.

5 Power on the tape drive and any other devices you powered off

earlier.

6 Power on the server or workstation and allow its operating system to

start.

7 Check the tape drive to make sure it is working properly. See Power-

On Self-Test (POST) Indicator Activity on page 47 to learn about the

tape drive’s self-test and initialization features.

DLT-V4 Product Manual 13

Chapter 2 Installing the Tape Drive

Installing the Internal SCSI Tape Drive

Installing the Internal SCSI Tape Drive 2

This section contains step-by-step instructions for installing the internal

SCSI tape drive.

Identifying the Steps 2 Installing the tape drive is fast and easy when you follow the instructions

in this section in the order presented. Complete the following steps,

covered in the next few sections:

Table 2 Installing the DLT-V4

Internal SCSI Tape Drive —

Overview

Step Instruction Refer to

1 Unpack and check the tape drive for shipping

page 15

damage.

2 Select a server or workstation that is to host

the tape drive.

3 Set the SCSI ID for the tape drive, if you do

page 16

not want to use the factory-set default.

4 Shut down and power off the server or

workstation that is to host the tape drive.

Power off all peripheral devices attached to

the server or workstation.

5 Install an active LVD/SE terminator on the

page 17

SCSI cable if the tape drive is the last or only

device on the SCSI bus.

6 Remove the cover from the server or

page 19

workstation, as explained in the server or

workstation’s documentation

7 Install an LVD/SE SCSI host adapter in the

server or workstation, if necessary.

8 Install the tape drive in an open drive bay.

DLT-V4 Product Manual 14

page 19

Chapter 2 Installing the Tape Drive

Installing the Internal SCSI Tape Drive

Step Instruction Refer to

Unpacking the Internal SCSI Tape Drive

9 Connect the SCSI cable to the tape drive and

SCSI host adapter.

Connect the terminator on the tape drive—if it

is the last or only device on the SCSI bus.

10 Connect a power cable to the tape drive.

11 Secure the tape drive in the selected server or

workstation.

12 Install the server or workstation’s cover,

connect power cables to all peripheral devices,

and apply power to the server or workstation

and all peripheral devices.

13 Check the tape drive to make sure it is

working properly.

Before you do anything else, unpack and inspect the tape drive for

shipping damage. If you notice any damage, report it both to the sales

2

representative and to the shipping company immediately.

Note: Save the packing materials in case you need to move or ship

the tape drive in the future. You must ship the tape drive in

the original (or equivalent) packing materials or you will

invalidate the warranty.

page 22

If there is no damage to the tape drive, select a server or workstation to

host the tape drive, then move on to the following installation steps.

Configuring the Internal SCSI Tape Drive

Configuring the tape drive is fast and easy. You only need to select a

unique SCSI ID and decide if the tape drive needs to be terminated. The

2

following sections explain how to configure the tape drive.

DLT-V4 Product Manual 15

Chapter 2 Installing the Tape Drive

Installing the Internal SCSI Tape Drive

Setting the SCSI ID 2

All SCSI devices attached to the server or workstation that is to host the

tape drive must have a unique SCSI ID. Check the SCSI IDs on all other

devices on the selected server or workstation, including the SCSI host

adapter, and select an unused SCSI ID for the tape drive. The factory

default SCSI ID is 5. If the tape drive’s factory default SCSI ID is not being

used, you do not need to change the SCSI ID.

Figure 6 Rear Panel

Connections for the Internal

SCSI Tape Drive

Note:

If you plan to attach the tape drive to a narrow (50-pin) SCSI

bus, you can only use IDs 0 through 7.

Locate the SCSI ID jumpers on the rear panel of the tape drive, as shown

in figure 6

68-pin high-density

SCSI connector

.

SCSI ID jumper block

Drive power connector

Use the supplied jumpers to select the desired SCSI ID as shown in

table 3

:

Table 3 Selecting the SCSI ID

SCSI ID 0 1 2 3

Jumper

Block

SCSI ID 4 5

DLT-V4 Product Manual 16

a

67

Chapter 2 Installing the Tape Drive

Installing the Internal SCSI Tape Drive

Jumper

Block

SCSI ID 8 9 10 11

Jumper

Block

SCSI ID 12 13 14 15

Jumper

Block

a. Factory default SCSI ID

Terminating the Internal SCSI Tape Drive 2

If the tape drive is the only SCSI device attached to the selected server

other than the SCSI host adapter, or if it is the last physical device on the

SCSI bus (at the end of the SCSI chain), you must terminate it. If another

SCSI device is the last device on the SCSI bus, confirm that it is properly

terminated and do not terminate the tape drive.

Note: Regardless of which device terminates the SCSI bus, that

device must have power applied and be powered on for

proper termination to occur.

To terminate the tape drive, install an active LVD/SE cable-end or inline

terminator on the SCSI cable you intend to use with the tape drive, as

shown in figure 7

. You can use a cable-end terminator or an inline

terminator, whichever is most convenient. See the terminator’s

instructions for more information.

DLT-V4 Product Manual 17

Figure 7 SCSI Interface —

Terminator Installation

Chapter 2 Installing the Tape Drive

Installing the Internal SCSI Tape Drive

Terminator

SCSI cable

Note: If the SCSI cable that came with the SCSI host adapter already

has a terminator built into it, do not use another terminator.

Figure 8

DLT-V4 Product Manual 18

shows an example of such a cable.

Figure 8 SCSI Cable with Builtin Terminator

Chapter 2 Installing the Tape Drive

Installing the Internal SCSI Tape Drive

Terminator

SCSI cable

(supplied with

host adapter)

Installing the Internal SCSI

Tape Drive

In the final installation stage, you install the tape drive in the server or

workstation and connect the SCSI and power cables.

2

To install the tape drive, follow these steps:

1 Shut down the operating system and power off the server or

workstation.

2 Power off all peripheral devices, such as printers and other SCSI

devices.

Caution: Do not go to step 3 until you have completed steps 1

and 2

. Failure to follow these instructions may result

in damage to the tape drive or other devices.

3 Remove the cover from the server or workstation as described in the

server or workstation’s documentation.

DLT-V4 Product Manual 19

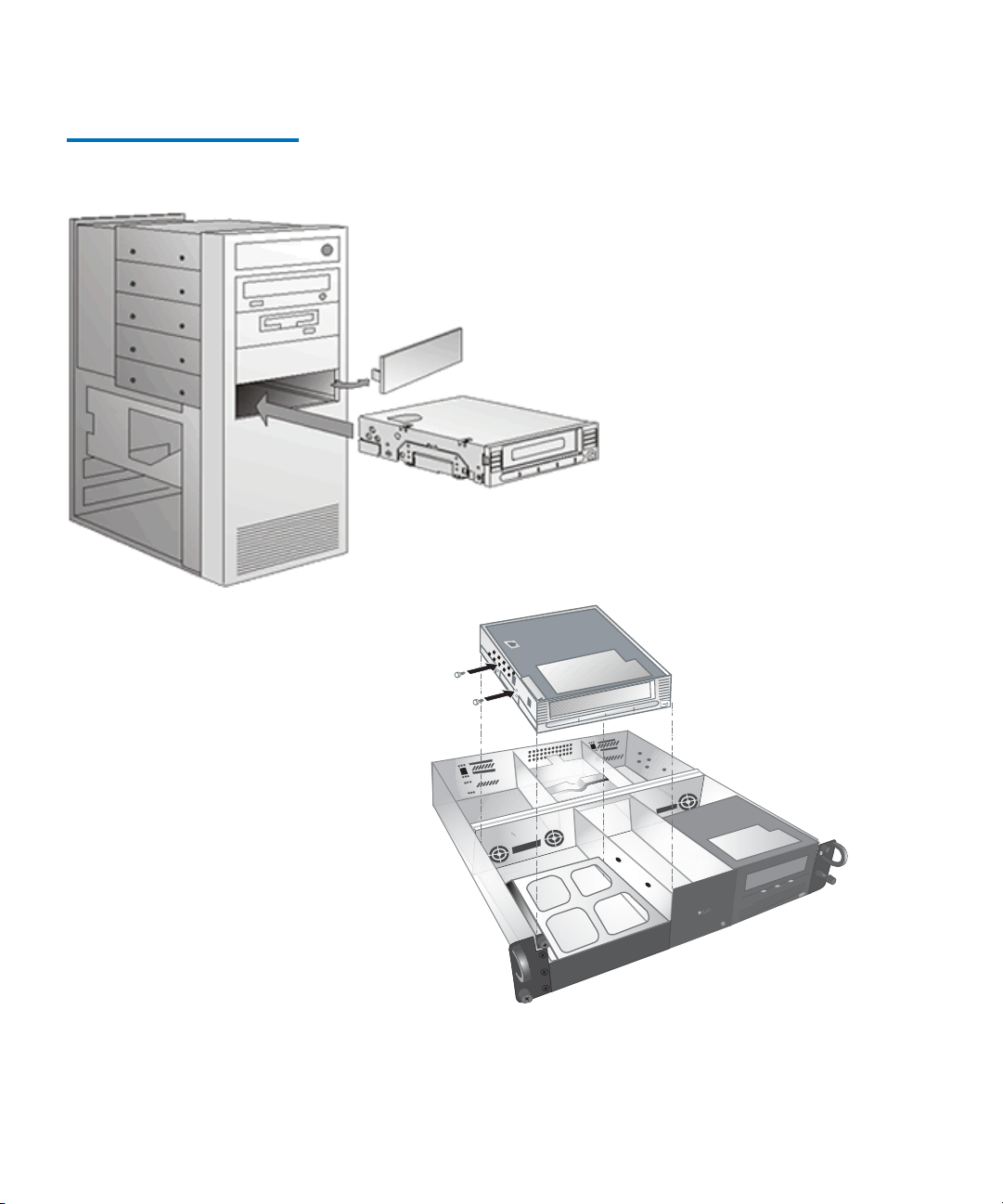

Figure 9 Removing the

Workstation Cover (example)

Chapter 2 Installing the Tape Drive

Installing the Internal SCSI Tape Drive

Locate an available 5¼-inch drive bay and remove the front cover

4

from the drive bay as described in the server or workstation’s

documentation.

Note: Install a SCSI host adapter in the selected server or

workstation now, if necessary. For more information on

SCSI host adapter requirements, see SCSI Bus

Requirements on page 4.

5 Slide the tape drive into the open drive bay.

DLT-V4 Product Manual 20

Figure 10 Installing the Internal

SCSI Tape Drive in an Open

Bay

Chapter 2 Installing the Tape Drive

Installing the Internal SCSI Tape Drive

Tower

2U enclosure

DLT-V4 Product Manual 21

Chapter 2 Installing the Tape Drive

Installing the Internal SCSI Tape Drive

Obtain a SCSI cable with an open 68-pin, high-density connector.

6

7 Connect one end of the SCSI cable to the SCSI connector on the rear

panel of the tape drive. The SCSI connectors are keyed, preventing

improper connection.

Note: If the SCSI cable does not fit the connector on the SCSI

host adapter, you either have an incompatible SCSI host

adapter or you need to purchase a cable adapter. Contact

your sales representative or the SCSI host adapter

manufacturer for information. See Terminating the

Internal SCSI Tape Drive on page 17 to determine if you

need to use an LVD/SE terminator with the SCSI cable.

8 Connect the other end of the SCSI cable to the SCSI host adapter,

aligning the colored stripe on the cable with pin 1 on the SCSI host

adapter’s connector.

9 Locate an available power cable in the server or workstation and

attach it to the power connector on the rear panel of the tape drive.

The connector is keyed, preventing improper connection.

DLT-V4 Product Manual 22

Figure 11 Internal SCSI Tape

Drive SCSI and Power Cable

Location

Chapter 2 Installing the Tape Drive

Installing the Internal SCSI Tape Drive

SCSI cable

(shown with terminator installed)

Power

cable

Completing the Internal SCSI Tape Drive Installation

2

1 Secure the internal SCSI tape drive with the necessary mounting

screws, either in the sides or bottom of the tape drive sled, as

appropriate for the server or workstation chassis. See figure 17

for an

example of where you might find these screws.

DLT-V4 Product Manual 23

Figure 12 Securing the Internal

SCSI Tape Drive in the

Installation Bay

Chapter 2 Installing the Tape Drive

Installing the Internal SCSI Tape Drive

Note: Some servers and workstations require mounting rails for

internal devices. Contact the server or workstation

manufacturer for information.

Replace the cover on the server or workstation.

2

3 Connect the power cord to the server or workstation and any

peripheral devices that you detached earlier.

4 Power on the server or workstation and allow its operating system to

start.

5 Check the tape drive to make sure it is working properly. See Power-

On Self-Test (POST) Indicator Activity on page 47 to learn about the

tape drive’s self-test and initialization features.

DLT-V4 Product Manual 24

Chapter 2 Installing the Tape Drive

Installing the Internal SATA Tape Drive

Installing the Internal SATA Tape Drive 2

This section contains step-by-step instructions for installing the DLT-V4

internal SATA tape drive.

Identifying the Steps 2 Installing the tape drive is fast and easy when you follow the instructions

in this section in the order presented. Complete the following steps,

covered in the next few sections:

Table 4 Installing the DLT-V4

Internal SATA Tape Drive —

Overview

Step Instruction Refer to

1 Unpack and check the tape drive for shipping

damage.

2 Select a server or workstation that is to host

the tape drive.

page 26

3 Shut down and power off the server or

workstation that is to host the tape drive.

Power off all peripheral devices attached to

the server or workstation.

4 Remove the cover from the server or

workstation, as explained in the server or

workstation’s documentation

5 Install a SATA host adapter in the server or

workstation, if necessary.

6 Install the tape drive in an open drive bay. page 27

7 Connect the SATA cable to the tape drive and

SATA host adapter.

8 Connect a SATA power cable to the tape

drive.

9 Secure the tape drive in the selected server or

workstation.

DLT-V4 Product Manual 25

page 26

page 29

Chapter 2 Installing the Tape Drive

Installing the Internal SATA Tape Drive

Step Instruction Refer to

Unpacking the Internal SATA Tape Drive

Installing the Internal

SATA Tape Drive

12 Install the server or workstation’s cover,

connect power cables to all peripheral devices,

and apply power to the server or workstation

and all peripheral devices.

13 Check the tape drive to make sure it is

working properly.

Before you do anything else, unpack and inspect the tape drive for

shipping damage. If you notice any damage, report it both to the sales

2

representative and to the shipping company immediately.

Note: Save the packing materials in case you need to move or ship

the tape drive in the future. You must ship the tape drive in

the original (or equivalent) packing materials or you will

invalidate the warranty.

If there is no damage to the tape drive, select a server or workstation to

host the tape drive, then move on to the following installation steps.

In the final installation stage, you install the tape drive in the server or

workstation and connect the data and power cables.

2

page 31

To install the tape drive, follow these steps:

1 Shut down the operating system and power off the server or

workstation.

2 Power off all peripheral devices, such as printers and other connected

devices.

Caution: Do not go to step 3 until you have completed steps 1

and 2

. Failure to follow these instructions may result

in damage to the tape drive or other devices.

3 Remove the cover from the server or workstation as described in the

server or workstation’s documentation.

DLT-V4 Product Manual 26

Figure 13 Removing the

Workstation Cover (example)

Chapter 2 Installing the Tape Drive

Installing the Internal SATA Tape Drive

Locate an available 5¼-inch drive bay and remove the front cover

4

from the drive bay as described in the server or workstation’s

documentation.

5 Slide the tape drive into the open drive bay.

DLT-V4 Product Manual 27

Figure 14 Installing the Internal

SATA Tape Drive

Chapter 2 Installing the Tape Drive

Installing the Internal SATA Tape Drive

Tower

2U enclosure

DLT-V4 Product Manual 28

Chapter 2 Installing the Tape Drive

Installing the Internal SATA Tape Drive

Connecting the Internal SATA Tape Drive to the Server

Figure 15 Rear Panel

Connections for the SATA

Internal Tape Drive

SATA power connector

The internal SATA tape drive attaches to the server through a SATA

interface card.

2

SATA data connector

Caution: Connect only one power cable to the drive; connecting

both the SATA power cable and the drive power cable to

the tape drive may damage the tape drive.

Drive power connector

Connect one end of the SATA data cable to the tape drive and the

1

other end of the SATA data cable to the SATA host bus adapter.

2 Connect either the SATA power cable or drive power cable to the tape

drive.

DLT-V4 Product Manual 29

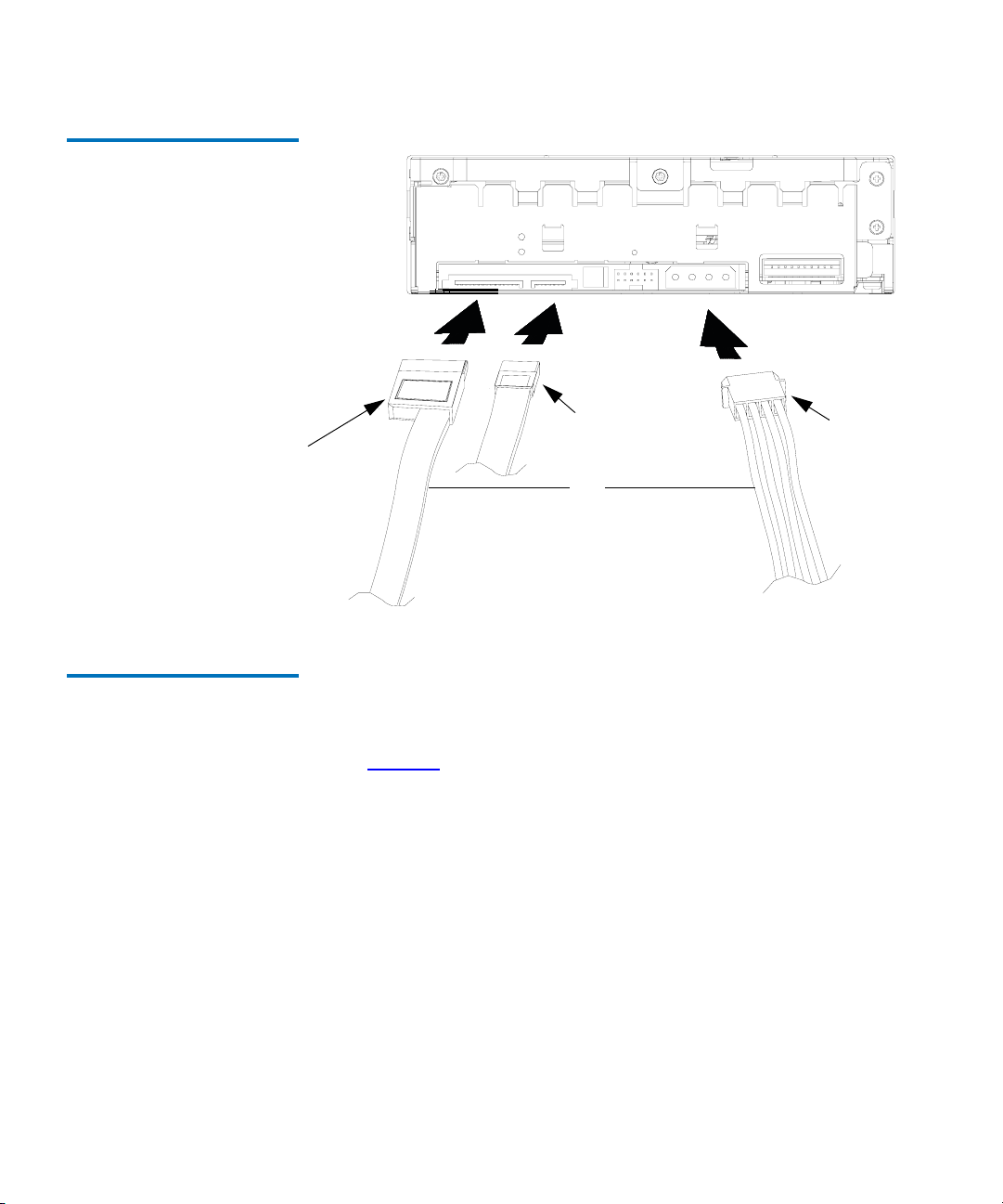

Figure 16 Internal SATA Tape

Drive Power and Data Cable

Connection Locations

Chapter 2 Installing the Tape Drive

Installing the Internal SATA Tape Drive

SATA power

cable

Completing the Internal SATA Tape Drive Installation

SATA data

cable

or

1 Secure the internal SATA tape drive with the supplied mounting

Drive power

cable

screws in the installation bay, either on the sides or bottom of the tape

2

drive sled, as appropriate for the server or workstation chassis. See

figure 17

for an example of where you might find these screws.

DLT-V4 Product Manual 30

Figure 17 Securing the Internal

SATA Tape Drive in the

Installation Bay

Chapter 2 Installing the Tape Drive

Installing the Internal SATA Tape Drive

Note: Some servers and workstations require mounting rails for

internal devices. Contact the server or workstation

manufacturer for information.

Replace the cover on the server or workstation.

2

3 Connect the power cord to the server or workstation and any

peripheral devices that you detached earlier.

4 Power on the server or workstation and allow its operating system to

start.

5 Check the tape drive to make sure it is working properly. See Power-

On Self-Test (POST) Indicator Activity on page 47 to learn about the

tape drive’s self-test and initialization features.

DLT-V4 Product Manual 31

Chapter 2 Installing the Tape Drive

Installing the Device Drivers

Installing the Device Drivers 2

This section describes how to install device drivers for Microsoft

Microsoft Windows 2000, Windows XP, and Windows 2003 Server.

Note: If you intend to use native operating system backup

applications, you can find the required device drivers at

www.quantum.com. Commercial backup applications generally

provide all necessary device driver support.

Microsoft Windows XP and Windows Server 2003

1 Make sure that you are logged on to the server or workstation with

2

Administrator privileges.

2 Download and extract the required driver files from

www.quantum.com. The system may automatically detect the DLT-V4

tape drive and display the “Found New Hardware Wizard”. If the

Wizard appears, proceed directly to step 3

, otherwise start the

Wizard manually as follows:

a Right-click My Computer, and select Manage from the drop-down

menu. This will start the Computer Management applet.

b In the left window under System Tools, double-click Device

Manager

c In Device Manager, the DLT-V4 tape drive will be listed under

.

either “Tape drives” or “Other devices”. Locate the entry for the

DLT-V4 tape drive. Then double-click that entry to display the

Drive Properties.

d Click the Driver tab. Then click Update Driver ....

e The “Hardware Update Wizard” will start. Proceed with step 3.

3 Select “Install from a list or specific location (Advanced)”. Then click

Next.

4 In the next view, ensure that the option “Search for the best driver in

these locations” is selected. Then clear the “Search removable media”

box and instead select “Include this location in the search”.

5 Click Browse ..., and select the folder where you saved the driver

files. Then click

DLT-V4 Product Manual 32

OK.

Chapter 2 Installing the Tape Drive

Installing the Device Drivers

Click Next to install the driver. The next view completes the Wizard.

6

7 Click Finish. You may be prompted to reboot your system.

The DLT-V4 device driver is installed.

Microsoft Windows 2000 2 1 Make sure that you are logged on to the server or workstation with

Administrator privileges.

2 Download and extract the required driver files from

www.quantum.com.

3 The system may automatically detect the DLT-V4 tape drive and

display the “Found New Hardware Wizard”. If the Wizard appears,

proceed directly to step 4

, otherwise start the Wizard manually as

follows:

a Right-click My Computer, and select Manage from the drop-down

menu. This will start the Computer Management applet.

b In the left window under System Tools, double-click Device

Manager

c In Device Manager, the DLT-V4 tape drive will be listed under

.

either “Tape drives” or “Other devices”. Locate the entry for the

DLT-V4 tape drive. Then double-click that entry to display the

Drive Properties.

d Click the Driver tab. Then click Update Driver ....

e The “Upgrade Device Driver Wizard” will start. Proceed with

step 4

.

4 In the “Upgrade Device Driver Wizard”, click Next to continue.

5 Select the radio button labeled “Display a list of the known drivers

for this device so that I can choose a specific driver”. Then click

6 If the drive is unknown to the system, the next view is “Hardware

Next.

Type”. Otherwise, the “Select a Device Driver” view is displayed.

a If the “Hardware Type” view appears, select either “Other

devices” or “Tape drives”. Then click

Next to continue on to the

“Select a Device Driver” view.

b In the “Select a Device Driver” view, click Have Disk ....

DLT-V4 Product Manual 33

Chapter 2 Installing the Tape Drive

Installing the Device Drivers

At the “Install From Disk” view, click Browse ..., and then locate the

7

folder where you saved the driver files. Select the “QntmDLT.inf” file

in that folder, and click

8 At the “Install From Disk” view, verify that the drive letter and path

shown are correct. Then click

9 In the next view, highlight the Quantum DLT-V4 tape drive, and then

click

Next. The “Start Device Driver Installation” view is displayed.

10 Click Next to install the driver.

Note: If the Wizard should indicate that a driver already exists

on the system and prompts you for a selection, select

Open.

OK.

New.

When the Windows 2000 Setup window is displayed,

verify the correct path to the driver, and then click

Continue.

11 The next view is “Completing the Upgrade Device Driver Wizard”.

Click

Finish. You may be prompted to reboot your system.

The DLT-V4 device driver is installed.

DLT-V4 Product Manual 34

3Specifications

This chapter contains the DLT-V4 tape drive specifications.

Chapter 3

DLT-V4 Product Manual 35

Chapter 3 Specifications

Physical Description

Physical Description 3

Physical Dimensions and Weights

3

Table 5 Physical Dimensions

Table 6 Weight Specifications

Specification Internal Tape Drive T abletop Tape Drive

Height 1.656 in. (42.05 mm)

with the bezel

1.618 in. (41.10 mm)

without the bezel

Width 5.748 in. (146.00 mm)

behind the bezel

5.807 in. (147.50 mm)

with the bezel

Length 8.614 in. (218.80 mm)

measured from the rear

of the front bezel

8.874 in. (225.40 mm)

including the bezel

Specification Internal Tape Drive Tabletop Tape Drive

Unit Weight 3.00 lb. (1.36 kg) 8.00 lb. (3.63 kg)

Shipping Weight 4.39 lb. (1.99 kg)

depending on the

configuration

2.608 in. (66.24 mm)

8.352 in. (212.13 mm)

10.728 in. (272.49 mm)

11.81 lb. (5.36 kg)

depending on the

configuration

DLT-V4 Product Manual 36

Chapter 3 Specifications

Temperature and Humidity Ranges

Temperature and Humidity Ranges 3

Table 7 lists the operating temperature and humidity ranges of the tape

drive.

Table 7 Operating

T emperature/Humidity Ranges

Table 8 Storage and Shipment

Temperature/Humidity Ranges

(Packed or Unpacked)

Specification Value

Temperature Range 10 ºC to 40 ºC (50 ºF to 104 ºF)

Airflow 3.0 CFM (min.)

Wet Bulb Temperature 25 ºC (77 ºF)

Temperature Gradient 11 ºC (19.8 ºF) per hour (across range)

Temperature Shock 10 ºC (18 ºF) over two minutes

Relative Humidity 20% to 80% non-condensing

Humidity Gradient 10% per hour

Table 8 lists the storage and shipment temperature and humidity ranges

of the tape drive.

Specification Value

Dry Bulb Temperature

Wet Bulb Temperature 46 ºC (114.8 ºF)

-40 ºC to 66 ºC (-40 ºF to 150.8 ºF)

Temperature Gradient 20 ºC (36 ºF) per hour with 5º margin

(across the range)

Temperature Shock 15 ºC (27 ºF) with 5º margin (over two

minutes)

Relative Humidity 10% to 95% non-condensing

Humidity Gradient 10% per hour

DLT-V4 Product Manual 37

Chapter 3 Specifications

Altitude

Altitude 3

The tape drive operates normally in pressures from -500 feet to 30,000 feet.

Functional Specifications 3 Table 9 lists the DLT-V4 tape drive’s functional specifications.

Table 9 Functional

Specifications

Specification Value

Formatted Capacity, Native Mode 160 gigabytes (GB)

Formatted Capacity, Compressed

a

Mode

320 GB

Interface Wide Ultra SCSI 2, Low-Voltage Differential (LVD) and SATA

Tape Drive Type DLT Derivative, streaming, 160 GB; 16-bit LVD

Recording Type Partial Response Maximum Likelihood (PRML)

Read Compatibility

b

DLT-V4, DLT VS160, DLT VS80 / DLT1

Write Compatibility DLT-V4

Form Factor 5

¼-in. half-height

Sustained Transfer Rate, Native Mode Up to 10 megabyte (MB) per second

Sustained Transfer Rate, Compressed

a

Mode

Up to 20 MB / sec

Transfer Rate, Burst 160 MB / sec

Error Rate (Unrecoverable) 1 in 10

a. Compressed values use a nominal 2:1 compression ratio. Actual compression ratios achieved depend on

the redundancy of data files being recorded.

b. Performance may vary when the tape drive reads data previously written to the DLT VS80 and DLT1

formatted data cartridges. Performance depends on the quality of the data cartridge you are reading, not

the DLT-V4 tape drive.

17

bits (non-media error)

DLT-V4 Product Manual 38

Chapter 3 Specifications

Emissions

Emissions 3

The tape drive meets the following standards:

• FCC CFR Part 15 Class B (ANSI C63.4: 1992, CISPR22: 1997)

• EMC Directive (89/336/EEC)

• EN 55022: 1998, +A1:2000, +A2:2003 Class B

• IEC/CISPR 22: 1997, +A1:2000, +A2: 2003 Class B

• VCCI-03:2004 Class B

• CNS 13438

• AS/NZS 3548

• ICES – 0003

Safety Requirement 3

The tape drive meets the following standards:

• Low Voltage Directive (73/23/EEC)

• UL 60950 – US Standard: Safety of Information Technology

Equipment including Electrical Business Equipment

• CSA C22.2 #950 – Canadian Standard: Safety of Information

Technology Equipment including Electrical Business Equipment

• EN 60950-1:2001, 1st Edition – European Standard: Safety of

Information Technology Equipment including Electrical Business

Equipment

DLT-V4 Product Manual 39

Chapter 3 Specifications

Consumer Bulletin Scheme

Consumer Bulletin Scheme 3

The tape drive meets this scheme: CB Scheme – The Scheme of the IECEE

for Mutual Recognition of Test Certificates for Electrical Equipment.

Timing Characteristics 3

Table 10 lists the timing characteristics of the DLT-V4 tape drive.

Table 10 Timing Characteristics

Specification Value

Read/Write Tape Speed 118 inches per second

Rewind Tape Speed 160 inches per second

Linear Search Tape Speed 118 inches per second

Average Rewind Time 68 seconds

Maximum Rewind Time 135 sec

Average Access Time (BOT) 84 sec

Maximum Access Time (from BOT) 168 sec

Load to BOT — previously recorded tape 90 sec

Unload from BOT 22 sec (no brush), 61

sec (brush)

DLT-V4 Product Manual 40

Chapter 3 Specifications

Data Cartridge and Media Characteristics

Data Cartridge and Media Characteristics 3

Table 11 lists the data cartridge and media characteristics.

Table 11 Data Cartridge and

Media Characteristics

Characteristic Specification

Media Width 0.5 in.

Media Length 1,847 ft

Media Type Metal Particle

Data Cartridge Dimensions 4.1 in. x 4.1 in. x 1.0 in.

Shelf Life 30 years minimum @ 20 ºC and 40%

relative humidity (non-condensing)

Usage 600 hrs (150 full read/write uses)

Reliability Factors 3

Table 12 lists the reliability factors for the DLT-V4 tape drive.

Table 12 Reliability Factors

Factor Hours / Cycles Comments

Head Life 30,000 tape motion hours Continuous operation.

MTBF 250,000 hours Quantum Corporation does not warrant that predicted

MTBF is representative of any particular unit installed for

customer use. Actual figures vary from unit to unit.

MTBF is measured at 100% duty cycle, excluding head

life.

Load/Unload 50,000 cycles This excludes media errors.

DLT-V4 Product Manual 41

Chapter 3 Specifications

Reliability Factors

Statements for Class A Equipment

(Internal Tape Drive) 3

CE Notice (European

Union)

Marking by the symbol indicates compliance of this tape drive to the

EMC Directive (89/336/EEC), and Low Voltage Directive (73/23/EEC)

of the European Union. Compliance with these directives implies

conformity to the following European Norms (the equivalent

international standards and regulations are in parentheses):

• EN 60950-1:2001, 1st Edition, Safety of Information Technology

Equipment including Electrical Business Equipment

• EN 55024: 1998 (IEC 1000-4-2, 1000-4-3, 1000-4-4, 1000-4-5, 1000-4-6,

1000-4-8, 1000-4-11) - “Information technology equipment –

Immunity characteristics – Limits and methods of measurement”

• Part 2 - Electrostatic Discharge (ESD) Requirements

• Part 3 - Radiated Electromagnetic Field Requirements

• Part 4 - Electrical Fast Transient/Burst (EFT) Requirements

• Part 5 - Surge Requirements

• Part 6 - Conducted disturbances, induced by radio-frequency fields

Requirements

• Part 8 - Power frequency magnetic field Requirements

• Part 11 – Voltage dips, short interruptions and voltage variations

Requirements

• EN 55022:1998/(CISPR 22:1997), Class B, “Limits and Methods of

Measurement of Radio Disturbance Characteristics of Information

Technology Equipment.”

The following standards only apply to the tabletop tape drive:

• EN 61000-3-2: 2000, Limits for harmonic current emissions

(equipment input) current up to and including 16 A per phase

• EN 61000-3-3: 2001, Limitation of voltage fluctuations and flicker in

low-voltage supply systems for equipment with rated current up to

and including 16A.

DLT-V4 Product Manual 42

Chapter 3 Specifications

Reliability Factors

FCC Notices (U.S. Only) 3 This device complies with Part 15 of the FCC Rules. Operation is subject

to the following two conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

User Manual Statement s for Class B Equipment

(Tabletop Tape Drive) 3

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful

interference in residential installation. This equipment generates, uses,

and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will

not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged

to try to correct the interference by one or more, of the following

measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that

to which the receiver is connected.

• Consult the dealer or an experienced radio /TV technician for help.

The user may find the following booklet prepared by the Federal

Communications Commission helpful: How to Identify and Resolve Radio-

TV Interference Problems. This booklet is available from the U.S.

Government Printing Office, Washington D.C., 20402. Stock No. 00400398-5

DLT-V4 Product Manual 43

Chapter 3 Specifications

Reliability Factors

All external I/O cables connecting to this unit need to be shielded. See

chapter 2, Installing the Tape Drive

or the Quick Start Guide for more

cabling options.

Caution: Any changes or modifications made to this equipment

may void the user’s authority to operate this equipment.

FCC Label 3

IC Notice (Canada) 3 This Class [B] digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe [B] est conforme à la norme NMB-003

du Canada.

VCCI Notice (Japan) 3

DEN-AN Notice (Japan) 3

DLT-V4 Product Manual 44

Chapter 3 Specifications

Environmental Compliance

Class B ITE Translation 3 This is a Class B product based on the standard of the Voluntary Control

Council for Interference from Information Technology Equipment

(VCCI). If this product is used near a radio or television receiver in a

domestic environment, it may cause radio interference. Install and use the

equipment according to the instruction manual.

VCCI Class B ITE

Regulatory Mark

3

Environmental Compliance 3

Quantum is committed to providing quality products in an

environmentally sound manner and to comply with all applicable

environmental laws, rules and regulations.

This product was designed, manufactured and made available with

consideration to worldwide laws, rules and regulations applicable to the

product and the electronics industry including the European Union

Directives 2002/95/EC & 2002/96/EC (RoHS and WEEE).

For further information on Quantum’s Environmental Compliance and

Global Citizenship, please consult the following Web site at

http://qcare.quantum.com.

DLT-V4 Product Manual 45

Chapter 3 Specifications

Disposal of Electrical and Electronic Equipment

Disposal of Electrical and Electronic Equipment 3

This symbol on the product or on its packaging

indicates that this product should not be disposed of

with your other waste. Instead, it should be handed

over to a designated collection point for the recycling of

electrical and electronic equipment. The separate

collection and recycling of your waste equipment at the

time of disposal will help to conserve natural resources

and ensure that it is recycled in a manner that protects

human health and the environment. For more information about where

you can drop off your waste equipment for recycling, please visit our

Web site at

authority, your household waste disposal service or the business from

which you purchased the product.

http://qcare.quantum.com or contact your local government

DLT-V4 Product Manual 46

Chapter 4

4Using Your Tape Drive

This chapter contains information regarding the functional operation of

the DLT-V4 tape drive.

LED Indicators 4

The tape drive has four light emitting diodes (LEDs). This section

describes the functions of the LEDs.

Note: The front panel controls and indicators are in the same

locations on both the internal and tabletop tape drives. The

tabletop tape drive has a

Power LED.

Power-On Self-Test (POST) Indicator Activity

DLT-V4 Product Manual 47

Each time you apply power to the tape drive, or reset the tape drive, it

performs a power-on self-test (POST). During POST, the LEDs illuminate

4

one at a time, from left to right. First, the

followed by the

the

Clean LED (Orange) approximately one second later, then four

seconds later the

different portion of the power-on process. All LEDs turn off momentarily.

If no data cartridge is loaded in the tape drive, the

illuminates steadily and POST is complete. This process takes

Fault LED (Orange) approximately one second later, then

Media LED (Orange) illuminates. Each LED signifies a

Ready LED (Green) comes on,

Ready LED then

Chapter 4 Using Your Tape Drive

LED Indicators

approximately eight seconds. If a data cartridge is in the tape drive

during POST, the

Ready LED flashes until the tape drive executes a mid-

tape load, which can take several minutes. As POST completes, the tape

drive makes a faint buzzing noise for several seconds. The noise

associated with this activity is normal for this technology and does not

indicate a problem with the tape drive.

Normal Operation —

Ready LED Indicator

Activity

Table 13 Ready LED Indicator

Activity

Normal Operation — Fault /

Clean / Media LEDs

Indicator Activity

Table 14 Fault / Clean / Media

LEDs Indicator Activity

During normal operation, the Ready LED displays one of the three

following states. The

Ready LED acts independently of the other LEDs.

4

State Description

Off Indicates that there is no power to the tape drive.

On Indicates that power is on, no data cartridge is

loaded, or a loaded data cartridge is idle with no

tape motion.

Blinking A data cartridge is in the process of loading, or

there is tape motion on a loaded data cartridge.

Tape motion includes reading, writing, locating,

rewinding, calibrating, and so on.

The Fault, Clean, and Media LEDs work together to display the status of

the tape drive.

4

Fault Clean Media Description

– Unsupported format, unsupported

data cartridge type, or damaged data

cartridge

A DLT1 (DLT VS 80) formatted

DLTtape IV data cartridge is loaded.

Represents a read-only or VS160

formatted cartridge.

DLT-V4 Product Manual 48

Chapter 4 Using Your Tape Drive

Fault Clean Media Description

– Calibration error or permanent write/

read error, cleaning suggested

Cleaning required—250 tape motion

hours exceeded since last cleaning

– Cleaning in process

User invoked write/read diagnostic

failed

Servo or mechanical error

––Internal firmware error

Key

– Off

LED Indicators

On

Blinking–slow (approximately once per second)

Blinking–medium (approximately twice per

second)

Blinking–fast (approximately three times per

second)

Indicates that the status of this LED does not

depend on the specific tape drive condition. This

means that certain tape drive conditions may result

in a combination of two or more of the LED states

in the chart.

For example, if you need to clean the tape drive

while a DLT1 tape is loaded, both the

and

Media LED are on steadily. If an internal

Clean LED

write/read diagnostic fails due to a permanent

write error, both the

Fault LED and Clean LED

blink slowly.

DLT-V4 Product Manual 49

Chapter 4 Using Your Tape Drive

Unload Button Functions

Unload Button Functions 4

You can use the unload button to unload and eject data cartridges, and

for the additional features shown in the following table. Press and hold

the eject button for the time specified in the following table to activate one

of these features. Release the button when the LEDs display the desired

sequence.

Table 15 Unload Button

Functions

Description

Normal unload function

Reserved

Enter code load tape mode

Reserved

Reserved

Revert back to normal mode

Caution:

The two features noted in the following table will overwrite any data on the data cartridge. Do not use this

feature if the data cartridge in the tape drive contains

critical data.

Ready

(green)

Fault

(orange

or clear)

–––6 to 9

–––18 to 21

Clean

(orange

or clear)

––9 to 12

Media

(orange

or clear)

–12 to 15

Hold Time

(seconds)

0 to 6

15 to 18

Read/write diagnostic start

Caution: This feature overwrites any

data currently on the data

cartridge.

Reserved

DLT-V4 Product Manual 50

– – 21 to 24

–24 to 27

Chapter 4 Using Your Tape Drive

Unload Button Actions

Description

Emergency reset

Revert back to normal mode

Key

– Off

Blinking

Fault

Ready

(green)

––––30+

(orange

or clear)

On (orange or green)

Unchanged from previous condition

Clean

(orange

or clear)

Media

(orange

or clear)

Hold Time

(seconds)

27 to 30

Unload Button Actions 4

This section describes the unload button activity.

Table 16 Unload Button

Actions

DLT-V4 Product Manual 51

Field/Mode Actions

Normal unload

function

Enter code load

tape mode

Release the unload button to unload the data

cartridge.

Release the unload button to accept a data

cartridge that contains the firmware image (code

load). The LEDs then indicate code load mode.

Insert the data cartridge to begin the code update.

The tape drive returns to normal operation if you

do not load a data cartridge within 15 seconds.

Field/Mode Actions

Chapter 4 Using Your Tape Drive

Diagnostic Mode Event Codes

Read/write

diagnostic start

Emergency reset Release the unload button to force an internal reset.

Revert back to

normal mode

Caution: This feature overwrites any data

currently on the data cartridge. Before

performing this action, confirm that the

data cartridge in the tape drive does not

contain critical data.

Release the unload button to start an internal read/

write diagnostic. You must then load a data

cartridge to run the diagnostic. The tape drive

writes and reads 3.6 GB of data, then unloads the

data cartridge. This process takes approximately 13

minutes. When completed, the green LED remains

steadily on. At this point, push the

eject the cartridge.

The tape drive returns to normal operation if it

detects no errors. The appropriate LEDs illuminate

if an error occurs.

The tape drive initializes as if you turned power off

and then on (POST).

Release the unload button to return the tape drive

to normal operation.

Eject button to

Diagnostic Mode Event Codes 4

Press, hold, and release the unload button after six to nine seconds to start

the diagnostic mode. This displays the most recent event code. The

unload button then becomes a scroll button for additional event codes.