Page 1

Add cover graphic to the master page in this space. (Ask the Art Director

in Irvine, who works for Elke Hirschmann, to design it for you; it should match

Note: Delete the DLTtape logo and the book title if already included in

the cover artwork.

Page 2

Copyright

Copyright © 2004 by Quantum Corporation. All rights reserved.

Document Origination: Boulder, Colorado, USA.

Trademarks

Quantum, the Quantum logo, and the DLTtape logo are trademarks of Quantum Corporat io n ,

registered in the U.S.A. and other countries. DLT, DLTtape, and DLTSage are trademarks

of Quantum Corporation.

Other company and product names used in this document are trademarks, registered

trademarks, or service marks of their respective owners.

Legal Disclaimers

The information contained in this document is the exclusive property of Quantum Corporation.

Quantum retains its copyright on the information contained herein in all cases and situations of

usage, including derivative works. The possessor agrees to safeguard this information and to

maintain it in confidence and not re-publish it in whole or in part without Quantum’s prior

written consent.

DLT VS160 Product Specification

Quantum reserves the right to make changes and improvements to its products, without

incurring any obligation to incorporate such changes or improvements in units previously sold

or shipped.

It is the responsibility of the user to carefully read and understand the User Manual statements

for Class A Equipment and Class B Equipment that appear on page iii and page iv,

respectively.

Contact Information

You can request Quantum publications from your Quantum Sales Representative or order them

directly from Quantum.

Telephone numbers and street addresses change frequently; for the latest, up-to-date contact

information, visit:

www.quantum.com

Telephone numbers, street addresses, time zones, and other pertinent facts are listed in the

Support section of the web site.

ii September 2004 81-81275-01

Page 3

DLT VS160 Product Specification

Revision History

All revisions made to this document are listed below in chronological order.

Document Release Date Summary of Changes

002287-01 14 December 2002 Initial Release

002287-01 A15 Jan. 22, 2004 Converted to FrameMaker, using Quantum template and St yle

Guide per ECO C008880.

81-81275-01 A01 July 27, 2004 Changed the GB definition from 1,073,741,824 bytes to

1,000,000,000 bytes in the glossary; changed document part

number per ECO C009974.

81-81275-01 A02 Sept. 14, 2004 Minor changes in Chapter 6. Per ECO C011131

User Manual Statements for Class A Equipment

(Internal Tape Drive)

CE Notice (European Union). Marking by the symbol indicates compliance of this tape drive

to the EMC Directive (89/336/EEC), and Low Voltage Directive (73/23/EEC) of the European

Union. Compliance with these directives implies conformity to the following European Norms

(the equivalent international standards and regulations are in parentheses):

• EN 60950/A11: 1997/(IEC 60950/A4: 1996), Safety of Information Technology Equipment including Electrical Business Equipment

• EN 55024: 1998 (IEC 1000-4-2, 1000-4-3, 1000-4-4, 1000-4-5, 1000-4-6, 1000-4-8,

1000-4-11) - “Information technology equipment – Immunity characteristics – Limits and

methods of measurement”

• Part 2 - Electrostatic Discharge (ESD) Requirements

• Part 3 - Radiated Electromagnetic Field Requirements

• Part 4 - Electrical Fast Transient/Burst (EFT) Requirements

• Part 5 - Surge Requirements

• Part 6 - Conducted disturbances, induced by radio-frequency fields Requirements

• Part 8 - Power frequency magnetic field Requirements

• Part 11 – Voltage dips, short interruptions and voltage variations Requirements

• EN 55022:1998/(CISPR 22:1997), Class B, “Limits and Methods of Measurement of

Radio Disturbance Characteristics of Information Technology Equipment.”

The following standards only apply to the tabletop tape drive:

• EN 61000-3-2: 1995, Limits for harmonic current emissions (equipment input) current up

to and including 16 A per phase

• EN 61000-3-3: 1995, Limitation of voltage fluctuations and flicker in low-voltage supply

systems for equipment with rated current up to and including 16A.

FCC Notices (U.S. Only). This device complies with Part 15 of the FCC Rules. Operation is subject

to the following two conditions: (1) this device may not cause harmful interference, and (2)

this device must accept any interference received, including interference that may cause

undesired operation.

81-81275-01 September 2004 iii

Page 4

User Manual Statements for Class B Equipment

(Tabletop Tape Drive)

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in residential installation. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instructions, may cause harmful interference to radio communications. However, there is

no guarantee that interference will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which can be determined by turning

the equipment off and on, the user is encouraged to try to correct the interference by one or

more, of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected.

• Consult the dealer or an experienced radio /TV technician for help.

The user may find the following booklet prepared by the Federal Communications

Commission helpful: How to Identify and Resolve Radio-TV Interference Problems. This

booklet is available from the U.S. Government Printing Office, Washington D.C., 20402.

Stock No. 004-00398-5

DLT VS160 Product Specification

All external I/O cables connecting to this unit need to be shielded. See the User Manual or

installation instructions for more options.

Caution Any changes or modifications made to this equipment may void the

user’s authority to operate this equipment.

FCC Label

iv September 2004 81-81275-01

Page 5

DLT VS160 Product Specification

IC Notice (Canada)

This Class [B] digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe [B] est conforme à la norme NMB-003 du Canada.

VCCI Notice (Japan)

Class B ITE Translation:

This is a Class B product based on the standard of the Voluntary Control Council for

Interference from Information Technology Equipment (VCCI). If this product is used near a

radio or television receiver in a domestic environment, it may cause radio interference. Install

and use the equipment according to the instruction manual.

VCCI Class B ITE Regulatory Mark

81-81275-01 September 2004 v

Page 6

DLT VS160 Product Specification

vi September 2004 81-81275-01

Page 7

Ta b l e o f C o n t e n t s

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Purpose and Scope. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Structure of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Conventions Used in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Typographical Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Reader Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2 Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Physical Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Physical Dimensions and Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Environmental Temperature Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Environmental Humidity Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Internal Tape Drive Mounting Hole Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

3 Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Power-On Self-Test (POST) Indicator Activity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Normal Operation — Ready LED Indicator Activity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Normal Operation — Fault / Clean / Media LEDs Indicator Activity . . . . . . . . . . . . . . . . . . . . 3-3

Unload Button Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Unload Button Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Diagnostic Mode Event Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

81-81275-01 REV A02 September 2004 vii

Page 8

Table of Contents DLT VS160 Product Specification

4 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Timing Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Data Cartridge and Media Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Reliability Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

5 Power Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Current Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

External Power Supply and Chassis Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

6 Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Temperature and Humidity Ranges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Altitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

7 Shock and Vibration Specifications . . . . . . . . . . . . . . . . . . . . . 7-1

Operating Shock and Vibration Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Operating Shock Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Operating Vibration Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Non-operating Shock and Vibration Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Non-operating Shock Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Non-operating Packaged Vibration Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Non-operating Unpackaged Vibration Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

8 Emission and Immunity Specifications. . . . . . . . . . . . . . . . . . . 8-1

Emissions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Radiated Emissions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Conducted Emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Harmonic Current Emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Acoustic Noise Emissions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

viii September 2004 81-81275-01 REV A02

Page 9

DLT VS160 Product Specification Table of Contents

Immunities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Electrostatic Discharge (ESD) Immunity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Radiated Immunity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Fast Transient Immunity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Surge Immunity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Conducted Immunity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Power Frequency Magnetic Field Immunity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Voltage Dips, Short Interruptions, and Variations Immunity . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Voltage Fluctuations and Flicker Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Direct Current (DC) Magnetic Field Interference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

9 Safety Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Safety Requirement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Consumer Bulletin Scheme. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

G Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G-1

81-81275-01 REV A02 September 2004 ix

Page 10

Table of Contents DLT VS160 Product Specification

Notes

x September 2004 81-81275-01 REV A02

Page 11

List of Tables

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Table 1-1. Chapters in this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Table 1-2. Typographical Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2 Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Table 2-1. Physical Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Table 2-2. Weight Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Table 2-3. Proper and Acceptable DLT VS160 Tape Drive Orientation. . . . . . . . . . . . . . . . . . . . . . 2-2

Table 2-4. Environmental Temperature Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Table 2-5. Environmental Humidity Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

3 Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Table 3-1. Functional Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Table 3-2. Normal Operation — Ready LED Indicator Activity . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Table 3-3. Normal Operation — Fault / Clean / Media LEDs Indicator Activity. . . . . . . . . . . . . . . 3-3

Table 3-4. Unload Button Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Table 3-5. Unload Button Actions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Table 3-6. Diagnostic Mode Event Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

4 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Table 4-1. Timing Characteristics of the Tape Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Table 4-2. Data Cartridge and Media Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Table 4-3. Reliability Factors for the Tape Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

81-81275-01 REV A02 September 2004 xi

Page 12

List of Tables DLT VS160 Product Specification

5 Power Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Table 5-1. Current Specifications of the Tape Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Table 5-2. Common Mode Noise Limitations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

6 Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Table 6-1. Operating — Temperature and Humidity Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Table 6-2. Storage and Shipment — Temperature and Humidity Ranges (Packed or Unpacked) . . 6-2

7 Shock and Vibration Specifications . . . . . . . . . . . . . . . . . . . . . 7-1

Table 7-1. Operating — Half Sine Wave Pulse Shock Specifications . . . . . . . . . . . . . . . . . . . . . . . 7-1

Table 7-2. Random — Operating Vibration Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Table 7-3. Random — Operating Vibration Specifications (PSD Spectrum). . . . . . . . . . . . . . . . . . 7-2

Table 7-4. Random Overstress — Operating Vibration Specifications. . . . . . . . . . . . . . . . . . . . . . . 7-2

Table 7-5. Random Overstress — Operating Vibration Specifications (PSD Spectrum) . . . . . . . . . 7-3

Table 7-6. Sweep / Dwell — Operating Vibration Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Table 7-7. Non-operating (Unpackaged) — Shock Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Table 7-8. Random Survival — Non-operating (Packaged) Vibration Specifications . . . . . . . . . . . 7-4

Table 7-9. Sweep/Dwell — Non-operating (Packaged) Vibration Specifications . . . . . . . . . . . . . . 7-5

Table 7-10. Impact Drop — Non-operating (Packaged) Shock (Drop) Specifications. . . . . . . . . . . 7-5

Table 7-11. Random — Non-operating (Unpackaged) Vibration Specifications . . . . . . . . . . . . . . . 7-5

Table 7-12. Standalone — Random Non-operating (Unpackaged) Vibration Specifications (PSD

Spectrum). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Table 7-13. Sweep/Dwell — Non-operating (Unpackaged) Vibration Specifications . . . . . . . . . . . 7-6

xii September 2004 81-81275-01 REV A02

Page 13

DLT VS160 Product Specification List of Tables

8 Emission and Immunity Specifications. . . . . . . . . . . . . . . . . . . 8-1

Table 8-1. Radiated Emissions Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Table 8-2. Conducted Emissions Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Table 8-3. Odd Harmonic Limits for Class A Equipment Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Table 8-4. Even Harmonic Limits for Class A Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Table 8-5. Acoustic Noise Emissions, Nominal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Table 8-6. Acoustic Noise Declaration for German Noise Declaration Law . . . . . . . . . . . . . . . . . . 8-4

Table 8-7. Electrostatic Discharge (ESD) Immunity Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Table 8-8. Radiated Immunity Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Table 8-9. Fast Transient Immunity Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Table 8-10. Surge Immunity Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Table 8-11. Conducted Immunity Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Table 8-12. Magnetic Field Immunity Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Table 8-13. Voltage Dips, Short Interruptions, and Variations Immunity Limits . . . . . . . . . . . . . . . 8-7

Table 8-14. Voltage Fluctuations and Flicker Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

9 Safety Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

81-81275-01 REV A02 September 2004 xiii

Page 14

List of Tables DLT VS160 Product Specification

Notes

xiv September 2004 81-81275-01 REV A02

Page 15

List of Figures

2 Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Figure 2-1. Internal Tape Drive Mounting Hole Dimensions (Bottom View) . . . . . . . . . . . . . . . . . 2-4

Figure 2-2. Mounting Hole Dimensions (Side View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

81-81275-01 REV A02 September 2004 xv

Page 16

List of Figures DLT VS160 Product Specification

Notes

xvi September 2004 81-81275-01 REV A02

Page 17

This chapter describes the purpose, scope, and audience of this manual. It also lists related

documentation and the conventions used in this manual.

1.1 Purpose and Scope

This manual describes the DLT VS160 tape drive, listing its physical, functional, and performance

specifications, and describing the standards that the tape drive meets.

CHAPTER 1

Chapter 1Introduction

1.2 Audience

The primary audience for this manual consists of engineers and technicians interested in integrating

the DLT VS160 tape drive into tape libraries and other equipment.

1.3 Related Documents

• DLT VS160 Tape Drive Installation and Operations Guide (81-81191-01)

• DLT VS160 SCSI Interface Guide (81-81268-01)

81-81275-01 REV A02 September 2004 1-1

Page 18

Structure of this Manual DLT VS160 Product Specification

1.4 Structure of this Manual

The manual contains the chapters listed in Table 1-1.

Table 1- 1. Chapters in this Manual

Chapter Description

Chapter 1, “Introduction” This is the chapter you are reading now.

Chapter 2, “Physical

Specifications”

Chapter 3, “Functional

Specifications”

Chapter 4, “Performance

Specifications”

Chapter 5, “Power Specifications” Describes the power specifications of the tape drive.

Chapter 6, “Environmental

Specifications”

Chapter 7, “Shock and Vibration

Specifications”

Chapter 8, “Emission and

Immunity Specifications”

Chapter 9, “Safety Specifications” Describes the safety specifications to which the tape drive complies.

“Glossary” Provides a list of technical terms commonly used in the computer

Contains the physical description of the tape drive, including the

environmental temperature and humidity specifications. This chapter

also shows the tape drive’s mounting hole dimensions.

Contains the functional specifications of the tape drive, including the

LED functions.

Describes the performance specifications of the tape drive, including

timing, media, and the reliability of the tape drive.

This chapter describes the tape drive’s environmental specifications.

Describes the shock and vibration specifications of the tape drive.

Describes the emission and immunity specifications of the tape drive.

industry and abbreviations specifically used in this manual.

1-2 September 2004 81-81275-01 REV A02

Page 19

DLT VS160 Product Specification Chapter 1: Introduction

1.5 Conventions Used in This Manual

This manual uses the following conventions:

NOTE: Notes provide supplemental information.

T

ECH TIP: Tech Tips provide information that helps you complete a procedure or

avoid additional steps.

AUTION Cautions provide information you must know to avoid

C

damaging the tape drive or losing data.

ARNING! Warnings provide information you must know to avoid

W

personal injury.

81-81275-01 REV A02 September 2004 1-3

Page 20

Typographical Conventions DLT VS160 Product Specification

1.6 Typographical Conventions

This manual uses the following conventions to designate specific elements.

Table 1-2. Typographical Conventions

Element Convention Example

Commands Uppercase (unless case-sensitive) FORMAT UNIT

Messages Uppercase INVALID PRODUCT

NUMBER

Hexadecimal Notation Number followed by lowercase h 25h

Binary Notation Number followed by lowercase b 101b

Decimal Notation Number without suffix 512

Acronyms Uppercase POST

Abbreviations Lowercase, except where standard

usage requires uppercase

Dimensions in Figures No units specified (Inches understood

unless otherwise specified)

1.7 Reader Comments

Quantum is committed to providing the best products and service. We encourage your comments,

suggestions, and corrections for this manual. Please send all comments to this address:

Quantum Technical Publications

4001 Discovery Dr.

Suite 1100

Boulder, Colorado USA 80 303

Mb (megabits)

MB (megabytes)

0.57 EJECT DISTANCE

1-4 September 2004 81-81275-01 REV A02

Page 21

Chapter 2Physical Specifications

This chapter contains the physical description of the DLT VS160 tape drive, including the internal and

tabletop tape drives, and the environmental temperature and humidity specifications.

2.1 Physical Description

2.1.1 Physical Dimensions and Weights

CHAPTER 2

Table 2-1. Physical Dimensions

Specification Internal Tape Drive Tabletop Tape Drive

Height 1.656 in. (42.05 mm) with bezel

1.618 in. (41.10 mm) without bezel

Width 5.748 in. (146.00 mm) behind bezel

5.807 in. (147.50 mm) with bezel

Length 8.571 in. (217.70 mm) measured from back

of front bezel

8.770 in. (222.75 mm) including the bezel

Table 2-2. Weight Specifications

Specification Internal Tape Drive Tabletop Tape Drive

Unit Weight 3.00 lb (1.36 kg) 8.00 lb (3.63 kg)

Shipping

Weight

4.39 lb (1.99 kg) depending on

configuration

2.608 in. (66.24 mm)

8.352 in. (212.13 mm)

10.728 in. (272.49 mm)

11.81 lb (5.36 kg) depending on the

configuration

81-81275-01 REV A02 September 2004 2-1

Page 22

Physical Description DLT VS160 Product Specification

Table 2-3 shows the acceptable operating orientation for the DLT VS160 tape drive.

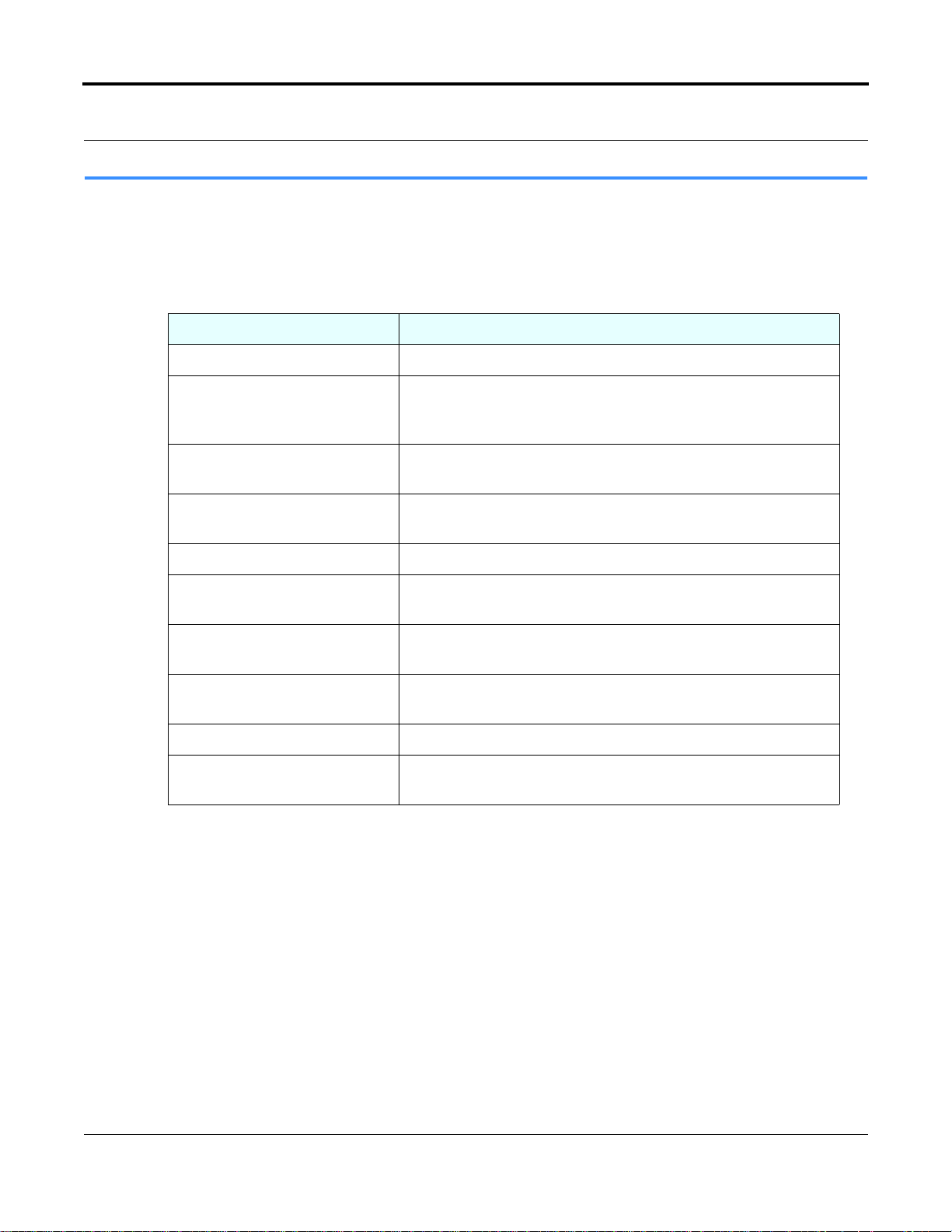

Table 2-3. Proper and Acceptable DLT VS160 Tape Drive Orientation

Orientation Internal Tape Drive

(looks like this)

Top Side Up

(typical)

Left Side Down

Tabletop Tape Drive

(looks like this)

Right Side

Down

2-2 September 2004 81-81275-01 REV A02

Page 23

DLT VS160 Product Specification Chapter 2: Physical Specifications

2.1.2 Environmental Temperature Specifications

Table 2-4. Environmental Temperature Specifications

Specification Value

Operating

Non-operating

Airflow

50 ºF to 104 °F (10 ºC to 40 °C)

-40 ºF to 150.8 °F (-40 ºC to 66 °C)

3.0 Cubic Feet per Minute (CFM) minimum

2.1.3 Environmental Humidity Specifications

Table 2-5. Environmental Humidity Specifications

Specification Value

Operating

Non-operating

20% to 80% non-condensing

10% to 95%

81-81275-01 REV A02 September 2004 2-3

Page 24

Internal Tape Drive Mounting Hole Dimensions DLT VS160 Product Specification

139.7 ± 0.381

[5.500 ± .015]

79.38 ± 0.25

[ 3.125 ± .010 ]

48.52± 0.254

[ 1.910 ± .010 ]

124.84

[ 4.92 ]

105.41

[ 4.15 ]

127.99

[ 5.04 ]

22.58 ± 0.55

[ .889 ± .021 ]

19.43 ± 0.7

[ .765 ± .027 ]

1

2

3

2.2 Internal Tape Drive Mounting Hole Dimensions

Figure 2-1 shows the mounting holes and dimensions in a bottom view for the internal tape drive.

Data cartridge

Figure 2-1. Internal Tape Drive Mounting Hole Dimensions (Bottom View)

N

OTES:1The dimension referenced in boxed note 1 [1] is from the front of the base plate.

2 The dimension referenced in boxed note 2 [2] is from the right-side tape drive mounting plane to the

interior guiding surface of the media opening.

3 The dimension referenced in boxed note 3 [3] is from the bottom tape drive mounting hole to the

interior guiding surface of the media opening.

4 The tape drive width and length are standard 5¼-inch form factor measurements.

5 Dimensions are identical on left side and right sides.

6 Dimensions are in millimeters. The dimensions in brackets [x.x] are in inches.

2-4 September 2004 81-81275-01 REV A02

Page 25

DLT VS160 Product Specification Chapter 2: Physical Specifications

Figure 2-2 shows the mounting holes and dimensions in a side view for the internal tape drive.

±

52.37 .381

±

[ 2.062 .015 ]

Data

cartridge

5

+1

-3

+1

-3

+1

-3

+1

-3

±

13 .381

±

+.039

[.610 ]

-.118

+.039

[.807 ]

-.118

+.039

[1.003 ]

-.118

+.039

[1.161 ]

15.5

20.5

25.5

Standard Distance

29.5

[ .512 .015 ]

-.118

4

41.5 MAX

[ 1.633 ] MAX

±

21.79 .254

±

[ .858 .010 ]

10 .254

[ .394 .010 ]

±

±

12X M3, Max Screw

Insertion 10 MM

±

219.6 .254

±

[ 8.65 .011 ]

79.38 .254

[ 3.125 .010 ]

1

±

±

Figure 2-2. Mounting Hole Dimensions (Side View)

OTES:1The dimension referenced in boxed note 1 [1] is from the front of the base plate.

N

2 The dimension referenced in boxed note 4 [4] is from the bottom tape drive mounting plane to the

interior guiding surface of the media opening.

3 Boxed note 5 [5] states that the data cartridge is shown in the ejected position.

4 The tape drive width and length are standard 5¼-inch form factor measurements.

5 Dimensions are identical on left side and right sides.

6 Dimensions are in millimeters. The dimensions in brackets [x.x] are in inches.

81-81275-01 REV A02 September 2004 2-5

Page 26

Internal Tape Drive Mounting Hole Dimensions DLT VS160 Product Specification

Notes

2-6 September 2004 81-81275-01 REV A02

Page 27

CHAPTER 3

Chapter 3Functional Specifications

This chapter contains the functional specifications of the DLT VS160 tape drive, including the LED

functions.

This table lists the key functional specifications of the DLT VS160 tape drive.

Table 3-1. Functional Specifications

Specification Value

Formatted Capacity, Native Mode 80 gigabytes (GB)

Formatted Capacity, Compressed Mode

a

160 GB

Interface Wide Ultra SCSI 2, Low-Voltage Differential (LVD)

Tape Drive Type DLT Derivative, streaming, 80 / 160 GB; 16-bit LVD

Recording Type Partial Response Maximum Likelihood (PRML)

Read Compatibility

b

DLT VS160, DLT VS80 / DLT1

Write Compatibility DLT VS160

Form Factor

¼-in. Half-height

5

Transfer Rate, Native Mode 8.0 megabyte (MB) per second

Transfer Rate, Compressed Mode

a

Up to 16.0 MB / sec

Transfer Rate, Burst 160 MB / sec

Error Rate (Unrecoverable)

a. Compressed values use a nominal 2:1 compression ratio. Actual compression ratios achieved depend on the redundancy of

data files being recorded.

b. Performance may vary when the tape drive reads data previously written to the DLT VS80 and DLT1 formatted data

cartridges. Performance depends on the quality of the data cartridge you are reading, not the DLT VS160 tape drive.

1 in 10

17

bits (non-media error, clean tape drive)

81-81275-01 REV A02 September 2004 3-1

Page 28

LED Indicators DLT VS160 Product Specification

3.1 LED Indicators

The tape drive has four light emitting diodes (LEDs). This section describes the functions of the LEDs.

NOTE: The front panel controls and indicators are in the same locations on both

the internal and tabletop tape drives. The tabletop tape drive has a Power

LED.

3.1.1 Power-On Self-Test (POST) Indicator Activity

Each time you apply power to the tape drive, or reset the tape drive, it performs a power-on self-test

(POST). During POST, the LEDs illuminate one at a time, from left to right. First, the Ready LED

(Green) comes on, followed by the Fault LED (Orange) approximately one second later, then the

Clean LED (Orange) approximately one second later, then four seconds later the Media LED

(Orange) illuminates. Each LED signifies a different portion of the power-on process. All LEDs turn

off momentarily. If no data cartridge is loaded in the tape drive, the Ready LED then illuminates

steadily and POST is complete. This process takes approximately eight seconds. If a data cartridge is

in the tape drive during POST, the Ready LED flashes until the tape drive executes a mid-tape load,

which can take several minutes. As POST completes, the tape drive makes a faint buzzing noise for

several seconds. The noise associated with this activity is normal for this technology and does not

indicate a problem with the tape drive.

3.1.2 Normal Operation — Ready LED Indicator Activity

During normal operation, the Ready LED displays one of the three following states. The Ready LED

acts independently of the other LEDs.

Table 3-2. Normal Operation — Ready LED Indicator Activity

State Description

Off Indicates that there is no power to the tape drive.

On Indicates that power is on, no data cartridge is loaded, or a loaded data cartridge is

idle with no tape motion.

Blinking A data cartridge is in the process of loading, or there is tape motion on a loaded data

cartridge. Tape motion includes reading, writing, locating, rewinding, calibrating,

and so on.

3-2 September 2004 81-81275-01 REV A02

Page 29

DLT VS160 Product Specification Chapter 3: Functional Specifications

3.1.3 Normal Operation — Fault / Clean / Media LEDs

Indicator Activity

The Fault, Clean, and Media LEDs work together to display the status of the tape drive.

Table 3-3. Normal Operation — Fault / Clean / Media LEDs Indicator Activity

Fault Clean Media Description

– Unsupported format, unsupported data cartridge type, or

damaged data cartridge

A DLT1 (DLT VS 80) formatted DLTtape™ IV data

cartridge is loaded.

– Calibration error or permanent write/read error

Cleaning required—250 tape motion hours exceeded since

last cleaning

– Cleaning in process

Key

–Off

User invoked write/read diagnostic failed

Servo or mechanical error

– – Internal firmware error

On

Blinking–slow (approximately once per second)

Blinking–medium (approximately twice per second)

Blinking–fast (approximately three times per second)

Indicates that the status of this LED does not depend on the specific tape drive condition. This

means that certain tape drive conditions may result in a combination of two or more of the

LED states in the chart.

For example, if you need to clean the tape drive while a DLT1 tape is loaded, both the Clean

LED and Media LED are on steadily. If an internal write/read diagnostic fails due to a

permanent write error, both the Fault LED and Clean LED blink slowly.

81-81275-01 REV A02 September 2004 3-3

Page 30

Unload Button Functions DLT VS160 Product Specification

3.2 Unload Button Functions

You can use the unload button to unload and eject data cartridges, and for the additional features

shown in the following table. Press and hold the eject button for the time specified in the following

table to activate one of these features. Release the button when the LEDs display the desired sequence.

C

AUTION The two features noted in the following table will over-write

any data on the data cartridge. Do not use these features if the

data cartridge in the tape drive contains critical data.

Table 3-4. Unload Button Functions

Description

Normal unload function 0 to 6

Reserved –––6 to 9

Enter code load tape mode – – 9 to 12

Reserved – 12 to 15

Reserved 15 to 18

Revert back to normal mode – – – 18 to 21

Read/write diagnostic start.

CAUTION: This featur e overwrites any

data currently on the data cartridge.

Reserved.

CAUTION: This featur e overwrites any

data currently on the data cartridge.

Emergency Reset 27 to 30

Ready

(green)

Fault

(orange or

clear)

Clean

(orange or

clear)

– – 21 to 24

Media

(orange or

clear)

– 24 to 27

Hold Time

(seconds)

Revert back to normal mode ––––30+

Key

– Off

Blinking

3-4 September 2004 81-81275-01 REV A02

On (orange or green)

Unchanged from previous condition

Page 31

DLT VS160 Product Specification Chapter 3: Functional Specifications

3.3 Unload Button Actions

This section describes what happens when you release the unload button (as indicated in the previous

section).

Table 3-5. Unload Button Actions

Function/Mode Action

Normal unload function Release the unload button to unload the data cartridge.

Enter code load tape mode Release the unload button to accept a data cartridge that contains the

firmware image (code load). The LEDs then indicate code load mode.

Insert the data cartridge to begin the code update. The tape drive returns to

normal operation if you do not load a data cartridge within 15 seconds.

Read/write diagnostic start CAUTION: This feature overwrites any data currently on the data

cartridge. Before performing this action, confirm that the data cartridge in

the tape drive does not contain critical data.

Release the unload button to start an internal read/write diagnostic. You

must load a data cartridge to run the diagnostic. The tape drive writes and

reads 400 MB of data, then unloads the data cartridge. This process takes

approximately two minutes. The tape drive returns to normal operation if it

detects no errors. The appropriate LEDs illuminate if an error occurs.

Emergency reset Release the unload button to force an internal reset. The tape drive

initializes as if you turned power off and then on (POST).

Revert back to normal mode Release the unload button to return the tape drive to normal operation.

81-81275-01 REV A02 September 2004 3-5

Page 32

Diagnostic Mode Event Codes DLT VS160 Product Specification

3.4 Diagnostic Mode Event Codes

Press, hold, and release the unload button after six to nine seconds to start the diagnostic mode. This

displays the most recent event code. The unload button then becomes a scroll button for additional

event codes. Press and release the unload button for the next most recent event code. You can display

up to five total events using this method. Refer to Table 3-6 for details about the meaning of the

various patterns.

After you display the final available event code, the next button press causes all LEDs to flash

indicating that the next eight hex characters displayed are the detailed error code of the most recent

event. The first character is either a hex E (error) or a B (bug check). You can look up the remaining

seven characters in the error/bug check definition tables. When you display the last (eighth) detailed

error code digit, the next button press returns the tape drive to normal operation. All indications are a

four bit hex value.

During any time in this procedure, the tape drive returns to normal operation if you perform no scroll

action within 15 seconds.

Table 3-6. Diagnostic Mode Event Codes

LED Fault Code Failure

0001 SCSI Event

0010 General Error

0011 Software Bug Check

0100 Permanent Write Error

0101 Permanent Read Error

0110 Servo Fault

0111 Code Update was Completed

1000 Illegal Format

1001 Invalid Cartridge

1010 Calibration Failure

1011 Cleaning was Completed

1100 Directory Read or Write Failed

1101 Diagnostic Failed

1110 POST Failure

1111 Reserved

3-6 September 2004 81-81275-01 REV A02

Page 33

Chapter 4Performance Specifications

This chapter describes the performance specifications of the DLT VS160 tape drive, including timing

characteristics, data cartridge and media characteristics, and the reliability factors of the tape drive.

4.1 Timing Characteristics

Table 4-1 lists the timing characteristics of the DLT VS160.

Table 4-1. Timing Characteristics of the Tape Drive

CHAPTER 4

Specification Value

Read/Write Tape Speed 122 inches per second

Rewind Tape Speed 160 inches per second

Linear Search Tape Speed 122 inches per second

Average Rewind Time 68 seconds

Maximum Rewind Time 135 sec

Average Access Time (BOT) 90 sec

Maximum Access Time (from BOT) 180 sec

Load to BOT — previously recorded tape 120 sec

Unload from BOT 25 sec

81-81275-01 REV A02 September 2004 4-1

Page 34

Data Cartridge and Media Characteristics DLT VS160 Product Specification

4.2 Data Cartridge and Media Characteristics

Table 4-2 lists the data cartridge and media characteristics.

Table 4-2. Data Cartridge and Media Char acteristics

Characteristic Specification

Media Width 0.5 in.

Media Length 1,847 ft

Media Type Metal Particle

Data Cartridge Dimensions 4.1 in. x 4.1 in. x 1.0 in.

Shelf Life 30 years minimum @ 20 ºC and 40% relative

humidity (non-condensing)

Usage 1,000,000 passes (typical office/computer

environment)

4.3 Reliability Factors

Table 4-3 lists the reliability factors for the DLT VS160 tape drive.

Table 4-3. Reliability Factors for the Tape Drive

Factor Hours / Cycles Comments

Head Life 30,000 tape motion hours Continuous operation.

MTBF 250,000 hours Quantum Corporation does not warrant that

Load/Unload 50,000 cycles This excludes media errors.

predicted MTBF is representative of any

particular unit installed for customer use.

Actual figures vary from unit to unit.

MTBF is measured at 100% duty cycle,

excluding head life.

4-2 September 2004 81-81275-01 REV A02

Page 35

Chapter 5Power Specifications

This chapter describes the power specifications of the DLT VS160 tape drive.

5.1 Current Specifications

CHAPTER 5

NOTE: The +5 Volt bus is 5%; the +12 Volt bus is 10%.

±±

Table 5-1. Current Specifications of the Tape Drive

Mode 5V

Power Up 2.1 1.0 0.9 0.3 8.4 9 18

Load Tape 1.6 1.1 2.7 0.7 13.2 16 24

Unload Tape 1.6 1.0 2.6 0.8 14.1 16 24

Write Tape 1.8 1.6 1.3 0.5 14.6 20 21

Read Tape 1.7 1.4 1.3 0.5 13.3 19 21

Rewind 1.0 0.9 1.4 0.6 11.6 17 19

Idle (tape) 1.0 1.0 0.3 0.2 6.7 13 14

Idle (no tape) 1.0 1.0 0.1 0.1 5.6 11 12

DC

Apk

5V

DC

Arms

12V

Apk

DC

12V

Arms

DC

DC Pwr

W (typ)

AC Pwr

W (typ)

AC Pwr

W (max)

81-81275-01 REV A02 September 2004 5-1

Page 36

External Power Supply and Chassis Requirements DLT VS160 Product Specification

5.2 External Power Supply and Chassis Requirements

This section lists the common mode noise limitations between enclosures. The noise level can not

exceed the values listed in the following table. You must take all measurements with an active or

differential probe to reduce oscilloscope ground loops.

Table 5-2. Common Mode Noise Limitations

First Enclosure Second Enclosure Common Mode Noise Limit

Millivolt (mV)

Enclosure Chassis

(Host Server, Workstati on, or

DLT VS160 Tabletop Enclosure)

Enclosure Chassis

(Host Server, Workstati on, or

DLT VS160 Tabletop Enclosure)

DLT VS160 Tape Drive Chassis <1 mV

Peak to Peak

Power Supply Enclosure Ground <300 mV

Peak to Peak

5-2 September 2004 81-81275-01 REV A02

Page 37

CHAPTER 6

Chapter 6Environmental Specifications

This chapter describes the environmental specifications of the DLT VS160 tape drive.

The tape drive operates in environments that include general offices and workspaces that consist of:

• Conditioned and marginally-conditioned areas with central or remote air-conditioning

• Complete temperature and humidity controls

• Moderate control tolerances

• Systems capable of maintaining consistent comfort levels.

The tape drive does not conform to environments that consist of:

• Marginal heating or cooling apparatus

• No humidity conditioning

• Uncontrolled tolerances

• Systems inadequate to maintain constant comfort levels.

For long-term trouble-free operation, we strongly recommend that you operate and store your

DLT VS160 tape drive in a clean, smoke-free environment.

The following tables provide the operating, non-operating, storage, and shipping environmental

specifications for the DLT VS160 tape drive systems (both the internal and the tabletop

configurations).

81-81275-01 REV A02 September 2004 6-1

Page 38

Temperature and Humidity Ranges DLT VS160 Product Specification

6.1 Temperature and Humidity Ranges

Table 6-1 lists the operating temperature and humidity ranges of the tape drive.

Table 6-1. Operating — Temperature and Humidity Ranges

Specification Value

Temperature Range 10 ºC to 40 ºC (50 ºF to 104 ºF)

Airflow 3.0 CFM (min.)

Wet Bulb Temperature 25 ºC (77 ºF)

Temperature Gradient 11 ºC (19.8 ºF) per hour (across range)

Temperature Shock 10 ºC (18 ºF) over two minutes

Relative Humidity 20% to 80% non-condensing

Humidity Gradient 10% per hour

Table 6-2 lists the storage and shipment temperature and humidity ranges of the tape drive.

Table 6-2. Storage and Shipme nt — Temperature and Humidity Ranges (Packed or Unpacked)

Specification Value

Dry Bulb Temperature

Wet Bulb Temperature 46 ºC (114.8 ºF)

Temperature Gradient 20 ºC (36 ºF) per hour with 5º margin (across the range)

Temperature Shock 15 ºC (27 ºF) with 5º margin (over two minutes)

Relative Humidity 10% to 95% non-condensing

Humidity Gradient 10% per hour

6.2 Altitude

The tape drive operates normally in pressures from -500 feet to 30,000 feet.

-40 ºC to 66 ºC (-40 ºF to 150.8 ºF)

6-2 September 2004 81-81275-01 REV A02

Page 39

CHAPTER 7

Chapter 7Shock and Vibration

Specifications

This chapter describes the shock and vibration specifications of the DLT VS160 tape drive. All testing

was done on both the internal and tabletop tape drives.

7.1 Operating Shock and Vibration Specifications

7.1.1 Operating Shock Specifications

Table 7-1 lists the shock specifications for the tape drive while it is operating.

Table 7-1. Operating — Half Sine Wave Pulse Shock Specifications

Specification 5 G Shock 8 G Shock 62 G Shock

Pulse Shape ½ Sine Pulse ½ Sine Pulse ½ Sine Pulse

Peak Acceleration 5 G 8 G 62 G

Duration 11 millisecond (ms) 10 ms 2 ms

Application X, Y, and Z axis, 10 pulses

per axis ( ), 60 total, 1

pulse every 6 seconds

±±±

X, Y, and Z axis, 1 pulse

per axis ( ), 6 total

X, Y, and Z axis, 1 pulse

per axis ( ), 6 total

81-81275-01 REV A02 September 2004 7-1

Page 40

Operating Shock and Vibration Specifications DLT VS160 Product Specification

7.1.2 Operating Vibration Specifications

Table 7-2, Table 7-3, Table 7-4, Table 7-5, and Table 7-6 list the vibration specifications for the tape

drive while it is operating.

Table 7-2. Random — Operating Vibration Specifications

Factor Criteria Comments

Frequency Range 5 to 50 Hertz (Hz)

Acceleration Level 0.25 G

Application X, Y, and Z axis Top to bottom, 10 minutes per axis

rms

(min.)

Table 7-3. Random — Operating Vibration Specifications (PSD Spectrum)

Power Spectral Density (PSD) Spectrum

(G

PSD

2

/Hz)

Frequency

(Hz)

5 0.00005

20 0.00017

200 0.00017

500 0.000065

Table 7-4. Random Overstress — Operating Vibration Specifications

Factor Criteria Comments

Frequency Range 10 to 500 Hz

Acceleration Level 0.5 G

Application X, Y, and Z axis Top to bottom, 10 minutes per axis

7-2 September 2004 81-81275-01 REV A02

rms

(min.)

Page 41

DLT VS160 Product Specification Chapter 7: Shock and Vibration Specifications

Table 7-5. Random Overstress — Operating Vibration Specifications (PSD Spectrum)

PSD Spectrum

(G

PSD

2

/Hz)

Frequency

(Hz)

10 0.000405

20 0.000689

200 0.000689

500 0.000264

Table 7-6. Sweep / Dwell — Operating Vibration Specifications

Factor Criteria Comments

Frequency Range 5 to 50 to 5 Hz 1 – Upward and Downward Sweep

Acceleration Level 0.5 G, 0 to Peak

Application X, Y, and Z axis Sweep Rate; ½ octave per minute

Dwell on 4 lowest resonances per

axis for 15 minutes each

81-81275-01 REV A02 September 2004 7-3

Page 42

Non-operating Shock and Vibration Specifications DLT VS160 Product Specification

7.2 Non-operating Shock and Vibration Specifications

7.2.1 Non-operating Shock Specifications

Table 7-7 lists the shock specifications for the tape drive without its shipping package (non-operating).

Table 7-7. Non-operating (Unpackaged) — Shock Specifications

Specification 40 G Shock 142 G Shock 90 G Shock

Pulse Shape Square Wave ½ Sine Pulse ½ Sine Pulse

Peak Acceleration 40 G 142 G 90 G

Duration 10 ms 2 ms 3 ms

Application X, Y, and Z axis, twice in

each axis (once in each

direction)

X, Y, and Z axis, twice in

each axis (once in each

direction)

X, Y, and Z axis, twice in

each axis (once in each

direction)

7.2.2 Non-operating Packaged Vibration Specifications

Table 7-8, Table 7-9, and Table 7-10 list the vibration specifications for the tape drive in its shipping

package (non-operating).

Table 7-8. Random Survival — Non-operating (Packaged) Vibration Specifications

Factor Criteria Co mment

Frequency Range 5 to 300 Hz

Acceleration Level 1.47 G

Application X, Y, and Z axis 30 minutes per axis

rms

7-4 September 2004 81-81275-01 REV A02

Page 43

DLT VS160 Product Specification Chapter 7: Shock and Vibration Specifications

Table 7-9. Sweep/Dwell — Non-operating (Packaged) Vibration Specifications

Factor Criteria Co mment

Frequency Range 5 to 200 to 5 Hz 1 – Upward and Downward Sweep

Acceleration Level 0.5 G

Application X, Y, and Z axis Sweep Rage: 1 octave per minute

, 0 to Peak

rms

Dwell on 4 lowest resonances per

axis for 5 minutes each

Table 7-10. Impact Drop — Non-operating (Packaged) Shock (Drop) Specifications

Factor Criteria

Test Type Drop Shock

Drop Height Internal Single Pack = 48 in.

External Single Pack = 42 in.

Application 10 drops total; 1 each side, 3 edges, 1 corner

7.2.3 Non-operating Unpackaged Vibration Specifications

Table 7-11, Table 7-12, and Table 7-13 lists the vibration specifications for the tape drive without its

shipping package (non-operating).

Table 7-1 1. Random — Non-operating (Unpackaged) Vibration Specifications

Factor Criteria Co mment

Frequency Range 5 to 500 Hz

Acceleration Level 2.41 G

Application X, Y, and Z axis 10 minutes per axis (min.)

81-81275-01 REV A02 September 2004 7-5

rms

Page 44

Non-operating Shock and Vibration Specifications DLT VS160 Product Specification

Table 7-12. Standalone — Random Non-operating (Unpackaged) Vibration Specifications (PSD

Spectrum)

PSD Spectrum

Frequency (Hz)

PSD (G2/Hz)

50.0201

100 0.0201

137 0.0107

350 0.0107

500 0.0052

Table 7-13. Sweep/Dwell — Non-o perating (Unpackaged) Vibration Specifications

Factor Criteria Comment

Frequency Range 5 to 500 to 5 Hz 1 – Upward and Downward Sweep

Acceleration Level 1.0 G

Application X, Y, and Z axis Sweep Rate; ½ octave per minute

, 0 to Peak

rms

Dwell on 4 lowest resonances per

axis for 15 minutes each

7-6 September 2004 81-81275-01 REV A02

Page 45

This chapter describes the emission and immunity specifications of the DLT VS160 tape drive.

8.1 Emissions

The tape drive meets the following standards:

• FCC Part 15 Class B (ANSI C63.4: 1992, CISPR22: 1997)

• EMC Directive (89/336/EEC)

CHAPTER 8

Chapter 8Emission and Immunity

Specifications

• EN55022: 1998, Class B

• CISPR 22: 1997, Class B

• VCCI Class B

• CNS 13438

• AS/NZS 3548

• ICES – 0003

8.1.1 Radiated Emissions

The tape drive meets the radiated emissions limits per CISPR 22: 1997 listed in Table 8-1.

Table 8-1. Radiated Emissions Limits

Frequency Range

Megahertz (MHz)

30 to 230 30

230 to 1000 37

Quasi-peak limit decibel (dB)

microVolt per meter (µV/m) @ 10m

81-81275-01 REV A02 September 2004 8-1

Page 46

Emissions DLT VS160 Product Specification

8.1.2 Conducted Emissions

The tape drive meets the conducted emissions limits per CISPR 22: 1997 listed in Table 8-2.

Table 8-2. Conducted Emissions Limits

Limits

Frequency Range

(MHz)

Quasi–peak Average

dB(µV)

0.15 to 0.50

0.50 to 5 56 46

5 to 30 60 50

a. The limit decreases with the logarithm of the frequency.

66 to 56

a

8.1.3 Harmonic Current Emissions

The tape drive meets this standard: EN 61000–3–3: 1995, Limitation of voltage fluctuations and

flicker in low-voltage supply systems for equipment with rated current up to and including 16A.

Table 8-3 lists the odd harmonic limits for Class A equipment. The harmonics of the input current do

not exceed the maximum permissible values given in this table multiplied by a factor of 1.5.

Table 8-3. Odd Harmonic Limits for Class A Equipment Limits

Harmonic Order

(n)

32.3

51.14

Maximum Permissible Harmonic Current

(A)

56 to 46

a

70.77

90.40

11 0.33

13 0.21

15 <= n <= 39 0.15 x (15/n)

8-2 September 2004 81-81275-01 REV A02

Page 47

DLT VS160 Product Specification Chapter 8: Emission and Immunity Specifications

Table 8-4 lists the even harmonic limits for Class A equipment.

Table 8-4. Even Harmonic Limits for Class A Equipment

Harmonic Order

(n)

21.08

40.43

60.30

8 <= n <= 40 0.23 x (8/n)

8.1.4 Acoustic Noise Emissions

Table 8-5 lists the acoustic noise emission levels, both as noise power and sound pressure for the tape

drive. The table provides the preliminary declared values per ISO 9296 and 7779 / EN27779.

Table 8-5. Acoustic Noise Emissions, Nominal

Mode Noise Power Emission Level (LwA, B)

Internal Tabletop Internal Tabletop

Idle Not applicable Not applicable Not applicable Not applicable

Maximum Permissible Harmonic Current

(A)

Sound Pressure Level (LpAm, dBA)

(bystander positions)

Streaming 5.8 5.8 54 54

NOTE: Current values for specific configurations are available from Quantum

Corporation representatives.

81-81275-01 REV A02 September 2004 8-3

Page 48

Immunities DLT VS160 Product Specification

Table 8-6 lists the acoustic noise declaration for the German Noise Declaration Law.

Table 8-6. Acoustic Noise Declaration for German Noise Declaration Law

Schallemissionswerte – Werteangaben nach ISO 9296 und ISO 7779 / DIN EN27779

Schalleistungspegel Schalldruckpegel

Gerät

DLT VS160 N/A 5,8 N/A 54

NOTE: Aktuelle Werte für spezielle Ausrüstungsstufen sind über die Quantum

Corporation Equipment Vertretungen erhältlich.

8.2 Immunities

The tape drive meets the following standards:

• EMC Directive (89/336/EEC)

• EN55024: 1998 Information Technology Equipment – Immunity

(reference the basic standard IEC 61000–4–n)

LwA, B

Leerlauf Betrieb Leerlauf Betrieb

LpAm, dBA

(Zuschauerpositionen)

• CISPR 24: 1997 Information Technology Equipment – Immunity

8-4 September 2004 81-81275-01 REV A02

Page 49

DLT VS160 Product Specification Chapter 8: Emission and Immunity Specifications

8.2.1 Electrostatic Discharge (ESD) Immunity

The tape drive meets the ESD immunity limits per EN 61000–4–2: 1995 listed in Table 8-7 for

operator access areas of the tape drive.

Table 8-7. Electrostatic Discharge (ESD) Immunity Limits

Specification Performance Criteria

Contact discharge 8 kV

Air discharge 10 kV

Air discharge (stress) 15 kV

Survival 25 kV

±

±

±

±

NOTE: The product meets the product reliability levels (air discharge to 10 kV,

with 15 kV desired).

8.2.2 Radiated Immunity

The tape drive meets the radiated immunity limits per EN 61000–4–3: 1995 listed in Table 8-8.

Table 8-8. Radiated Immunity Limits

Specification Performance Criteria

80 to 1000 MHz, 1 kHz (80% AM)

900 MHz, 200 Hz, 3V/m

No operator intervention

(soft recoverable errors allowed)

No physical damage

No errors allowed

8.2.3 Fast Transient Immunity

The tape drive meets the fast transient immunity limits per EN 61000–4–4: 1995 listed in Table 8-9.

Table 8-9. Fast Transient Immunity Limits

Specification Performance Criteria

AC Mains 1 kV

Signal Port (L 3m) 500V

81-81275-01 REV A02 September 2004 8-5

±

≥±

No operator intervention

(soft recoverable errors allowed)

Page 50

Immunities DLT VS160 Product Specification

8.2.4 Surge Immunity

The tape drive meets the surge immunity limits per EN 61000–4–5: 1995 listed in Table 8-10.

Table 8-10. Surge Immunity Limits

Specification Performance Criteria

Common/Differential Mode

AC Mains 2 kV / 1 kV

±±

No operator intervention

(soft recoverable errors allowed)

8.2.5 Conducted Immunity

The tape drive meets the conducted immunity limits per EN 61000–4–6: 1996 listed in Table 8-11.

Table 8-1 1. Conducted Immunity Limits

Specification Performance Criteria

0.150 to 80 MHz, 1 kHz (80% AM), 3V No errors allowed

8.2.6 Power Frequency Magnetic Field Immunity

The tape drive meets the magnetic field immunity limits per EN 61000–4–8: 1993 listed in Table 8-12.

Table 8-12. Magnetic Field Immunity Limits

Specification Performance Criteria

50 Hz, 10 Amps per meter (A/m) No errors allowed

8-6 September 2004 81-81275-01 REV A02

Page 51

DLT VS160 Product Specification Chapter 8: Emission and Immunity Specifications

8.2.7 Voltage Dips, Short Interruptions, and Variations Immunity

The tape drive meets the AC dips, interruptions, and variations immunity limits per

EN 61000–4–11: 1994 listed in Table 8-13.

Table 8-13. Voltage Dips, Short Interruptions, and Variations Immunity Limits

Specification Performance Criteria

95% Vreduction 10 milliseconds per 0.5 periods

(Dips)

30% Vreduction 500 ms per 25 periods

(Dips)

95% Vreduction 5 sec per 250 periods

(Interruptions)

Soft recoverable errors allowed

Operator intervention allowed

Operator intervention allowed

8.3 Voltage Fluctuations and Flicker Limits

The tape drive meets this standard: EN 61000–3–3: 1995, Limitation of voltage fluctuations and

flicker in low-voltage supply systems for equipment with rated current up to and including 16A.

Table 8-14 lists the EN 61000–3–3: 1995 Fluctuation and Flickers limits.

Table 8-14. Voltage Fluctuations and Flicker Limits

P

st

P

lt

dc (%) d

max

(%)

d(t)ms

<1.0 <0.65 <3.0 <4.0 <200

8.4 Direct Current (DC) Magnetic Field Interference

The tape drive meets the following standards:

• IATA Dangerous Goods Regulations, 30th Edition, 1989–01–01

• U.S. CFR 49, paragraph 173.1020, rev. date: 1983–11–01

81-81275-01 REV A02 September 2004 8-7

Page 52

Direct Current (DC) Magnetic Field Interference DLT VS160 Product Specification

Notes

8-8 September 2004 81-81275-01 REV A02

Page 53

Chapter 9Safety Specifications

This chapter describes the safety specifications of the DLT VS160 tape drive.

9.1 Safety Requirement

The tape drive meets the following standards:

• Low Voltage Directive (73/23/EEC)

• UL 1950: 1995 – US Standard: Safety of Information Technology Equipment including Electrical

Business Equipment

CHAPTER 9

• CSA C22.2 #950 – Canadian Standard: Safety of Information Technology Equipment including

Electrical Business Equipment

• EN 60950/A11: 1997 – European Standard: Safety of Information Technology Equipment

including Electrical Business Equipment

• IEC 60950/A4: 1996 – International Standard: Safety of Information Technology Equipment

including Electrical Business Equipment

9.2 Consumer Bulletin Scheme

The tape drive meets this scheme: CB Scheme – The Scheme of the IECEE for Mutual Recognition of

Test Certificates for Electrical Equipment.

81-81275-01 REV A02 September 2004 9-1

Page 54

Consumer Bulletin Scheme DLT VS160 Product Specification

Notes

9-2 September 2004 81-81275-01 REV A02

Page 55

A

Glossary

The following is an alphabetical list of specialized words and technical terms with their definitions,

commonly used in the tape drive and tape media industry, and specifically included in this manual.

AAmps.

AC Alternating Current.

AC Pwr Alternating Current Power.

B

C

AM Amplitude Modulation.

Apk Amps Peak.

Arms Amps Root Mean Square.

ASME American Society of Mechanical Engineers.

ASTM American Society for Testing and Materials.

BOT Beginning of Tape. The physical beginning of the media.

CFM Cubic Feet per Minute.

CSA Canadian Standards Association, also known as CSA

International.

81-81275-01 REV A02 September 2004 G-1

Page 56

D DLT VS160 Product Specification

D

Db Decibel.

dBA Decibels, A-weighted.

E

F

d

c

DC Direct Current.

DC Pwr Direct Current Power.

d

max

d(t)ms Delta time in milliseconds.

ESD Electrostatic discharge. A sudden discharge of electrostatic

FCC Federal Communications Commission.

ft Feet.

The relative steady-state voltage change.

Maximum relative voltage change.

energy that can damage delicate electronic circuitry.

G-2 September 2004 81-81275-01 REV A02

Page 57

DLT VS160 Product Specification Glossary

G

G Gravitational Constant.

GB Gigabyte.

• SI — 1,000,000,000 bytes or 109. This is the International System

of Units (SI) definition commonly used by telecommunications and

storage manufacturers.

3

• GiB — 1,073,741,824 bytes, equal to 1024

definition often used in computer science, computer programming,

and in the majority of computer operating systems documentation.

This measurement can be abbreviated as GiB (gibibyte) to avoid

ambiguity, as defined in IEC 60027-2.

Note: For the purpose of this document we are using SI.

GS German Safety

, or 230. This is the

H

I

K

Hz Hertz. A measure of frequency (cycles per second).

IEC

in.

kg Kilogram.

kHz Kilohertz.

kV Kilovolt.

International Electrotechnical Commission, an international

standards organization for electronics and electrotechnical

matters.

Inch (or inches).

81-81275-01 REV A02 September 2004 G-3

Page 58

L DLT VS160 Product Specification

L

L Length.

lb Pound.

LED Light Emitting Diode.

LpAm, dBA Declared A-weighted Sound Pressure Level, Decibels A-

Weighted.

L VD Low Voltage Differential. LVD is a physical interface with power

low enough to allow integration within the SCSI controller chip.

Ultra 160 SCSI uses a low-voltage differential interface.

LwA, B Sound power A-weighted, Bells.

M

N

m Meter (or meters).

MB Megabyte. A unit of measure equal to 1 million bytes.

MHz Megahertz.

mm Millimeter.

ms Millisecond.

MTBF Mean Time Between Failure. The probable average number of

service hours between failures.

mV Millivolt.

n Variable number.

G-4 September 2004 81-81275-01 REV A02

Page 59

DLT VS160 Product Specification Glossary

P

Peripheral A device added to a system as a complement to the basic central

processing unit (CPU), such as a disk drive, tape drive, or printer.

R

S

P

lt

POST Power-On Self-Test (POST). When power is applied to the tape

PSD Power Spectral Density.

P

st

RH Relative humidity.

rms Root mean square.

SCSI Small Computer System Interface. An American National

Flicker evaluated over a long period of time (a few hours).

drive, it performs a POST.

Flicker evaluated over a short period of time.

Standards Institute (ANSI) standard for the interface between a

computer and peripheral controllers.

sec Second.

U

UL Underwriters Laboratory; a United States safety organization.

81-81275-01 REV A02 September 2004 G-5

Page 60

V DLT VS160 Product Specification

V

VVolt.

W

V

DC

Vreduction Voltage reduction.

WWatt (or watts).

Volt Direct Current.

G-6 September 2004 81-81275-01 REV A02

Page 61

Page 62

4001 Discovery Dr., Ste. 1100

Boulder, CO 80303

720.406.5700

September 2004

81-81275-01

*81-81275-01 REV A02*

81-81275-01 REV A02

Loading...

Loading...