Page 1

Quantum

User Reference Guide

SDLT 600

Page 2

User Manual Statements for Class A Equipment (Internal Tape System)

This is a Class A product. This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are des igned to provide reasonable protection against

harmfu l interf erence when the equ ip ment is op er ated in a commercial environment. Th is equipment gener ates, uses,

and can radiate radio frequency energy and, if not install ed an d use d in ac cordance with the instruction manual, may

cause harmful interference to radio communications. Operation of this equipment in a residential area may cause

harmful in terference in which case the use r will be required to correct the interference at his own expense.

Any modifications to this device—unless expressly approved by the manufacturer—can void the user’s authority to

operate this equipment under Part 15 of the FCC rules.

User Manual Statements for Class B Equipment (Tabletop Tape System)

This equipmen t has been tested and found to comp ly with the limits for a Clas s B digital device , purs uant to Part 15

of the FCC rules. These limits are designed to provide reasonable protection agai nst harmful interferenc e in a residential installation. Any modifications to this device—unless expressly approved by the manufa cturer—can void the

user’s authority to operate this equipment under part 15 of the FCC rules. Operation is subject to the following two

conditions : (1) This device may not cause ha rmfu l interference, and (2) this device must accept any interference that

may cause undesirable operation.

This equipment generates, uses, and ca n radiate radio frequency energy and, if not insta lled and used in accordance

with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation . If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to

correct the interference by one or more of the followin g meas ures:

• Reori ent or relo cate the receivin g an tenna.

• Incre ase the separatio n b etw een the equipmen t and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an e xperienced radio or TV technician for help.

Page 3

Contents | SDLT 600 Tape Drive User Reference Guide

Contents

A Using the Tape Drive

A1 Handling the Tape Drive and Data Cartridges

A2 Interpreting the Front of the Tape Drive

A3 Loading and Unloading Data Cartridges

A4 Cleaning the Tape Heads

B Using Data Cartridges

B1 Choosing Data Cartridges

B2 Write-protecting Data Cartridges

B3 Caring for Data Cartridg es

B4 Inspecting Data Cartridges

C Connecting the Tape Drive

C1 Understanding the Tape Drive’s Interface

C2 Choosing Cables and Connectors

C3 Setting the SCSI ID

C4 Connecting the SCSI Model as a Single Device

C5 Connecting the SCSI Model in a Daisy Chain

C6 Connecting the Fibre Channel Model

D Troubleshooting Tape Drive Problems

D1 Using the Power-On Self-Test

D2 General Troubleshooting

D3 SCSI Troubleshooting

D4 Checking for Tape Drive Errors

D5 Optimizing the Tape Drive

E Tape Drive Info rmation

E1 Specifications

E2 Regulatory Information

Page 4

Pointers for Using this Guide

! Pay attention to these points. They are important for tape

drive operation.

A1

Follow these cross references for information on related

topics.

Page 5

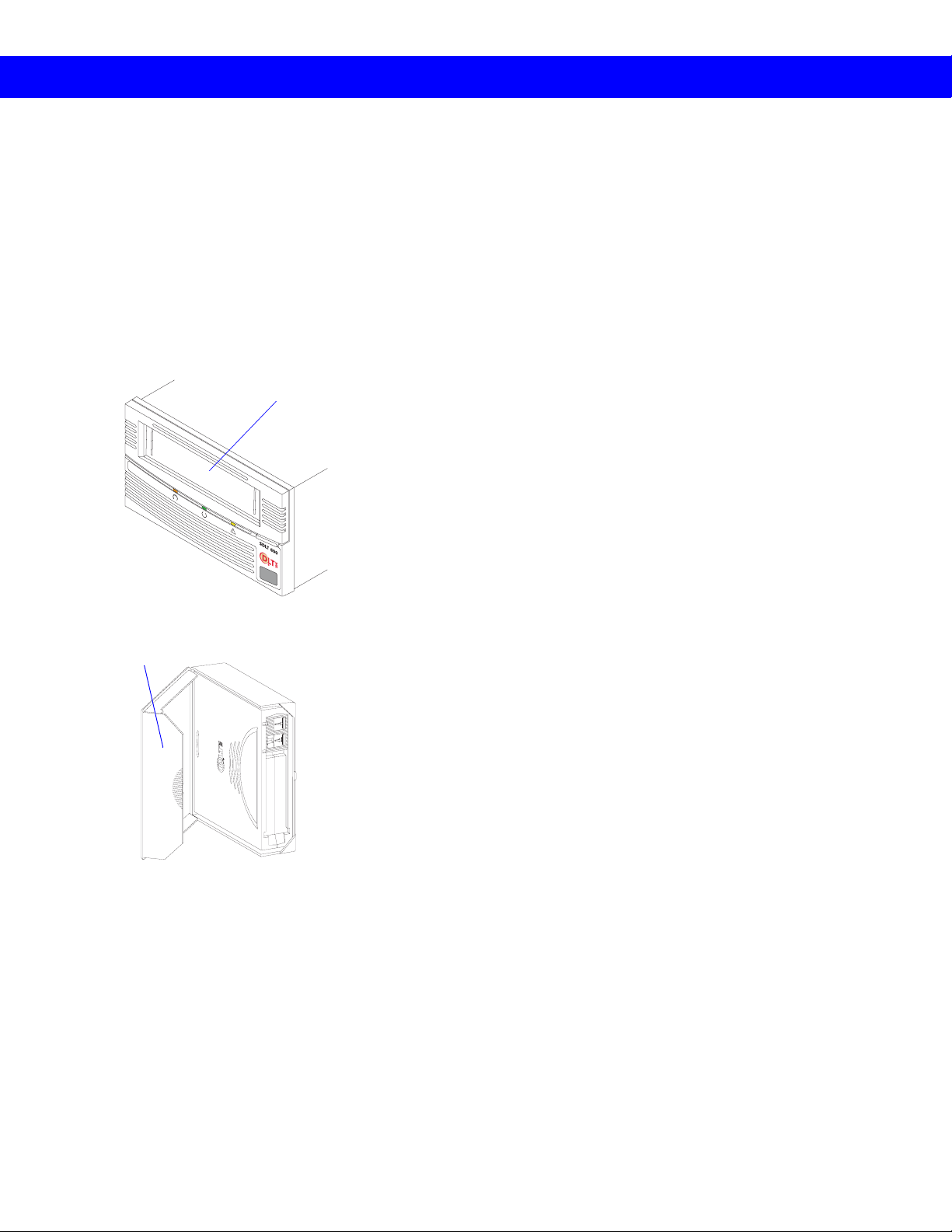

A1 | Handling the Tape Drive and Data Cartridges

A Using the Tape Drive

A1 Handling the Tape Drive

and Data Cartridges

Protective Case

Receiver

Area

Handling the Tape Drive

! Do not carry the tape drive by inserting your fingers into

the receiver area. You could damage the tape drive if you

lift or carry it in this mann e r.

Do not stand the tape drive on its front panel.

Always place the tape drive on a flat, stable surface.

Avoid dusty, humid, or smoke-filled areas.

Use proper electrostatic discharge (ESD) protection.

Handling Data Cartridges

Keep cartridges in their protective cases when not in use.

Protect cartridges from shock, vibration, moisture, direct

sunlight, dust, smoke, and magnetic f ields.

Use the slide-in labels provided. Do not use adhesive

labels or Post-it® notes, and do not write on the cartridge.

Never touch the tape or tape leader. Dust and oils from

your skin contaminate the tape and affect performance.

! Always visually inspect a data cartridge before placing it

in the tape drive. If it is damaged, do not use the cartridge.

B4

! Never power off the tape drive while it contains a

cartridge.

For a more comprehensive list of data cartridge handling

guidelines, B3.

Page 6

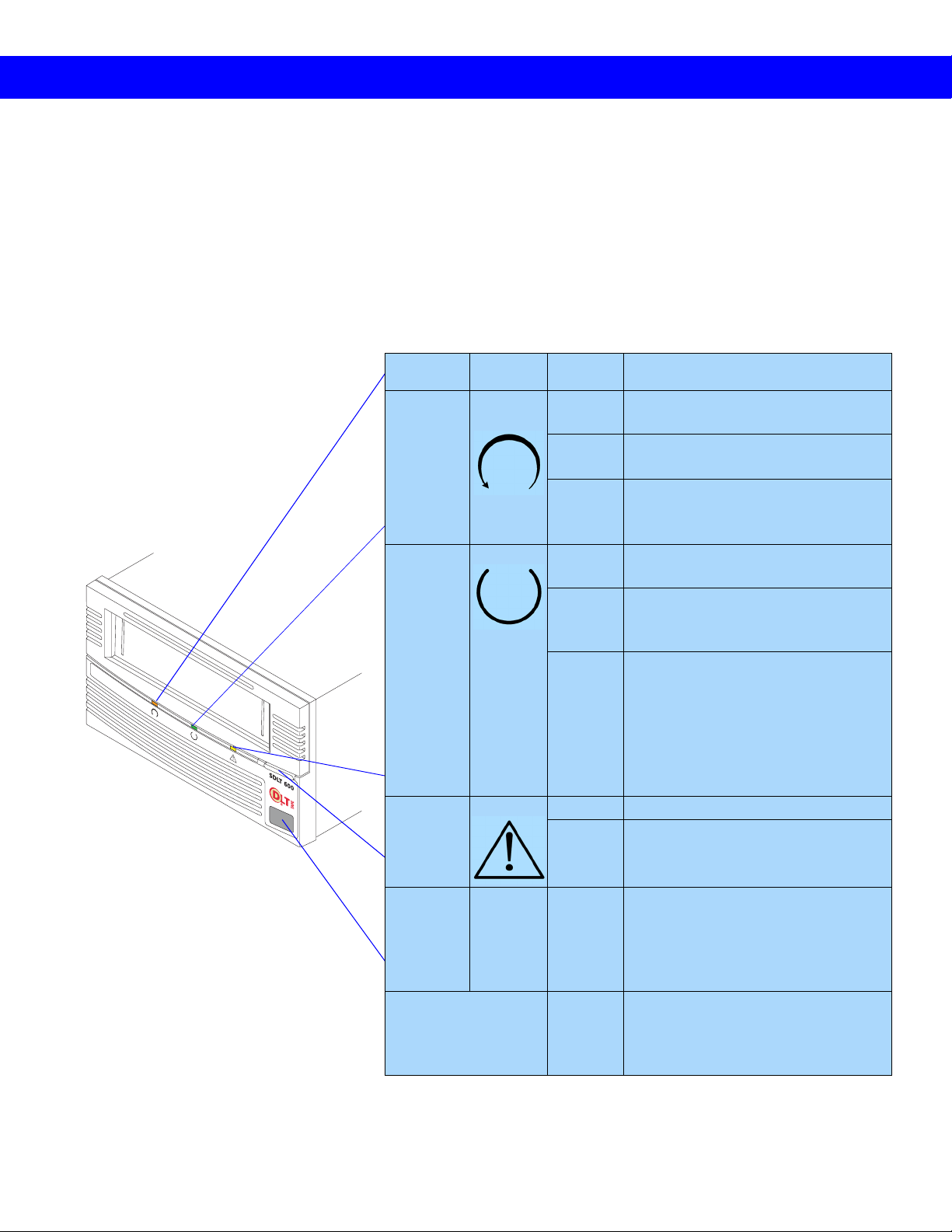

Interpreting the Front of the Tape Drive | A2

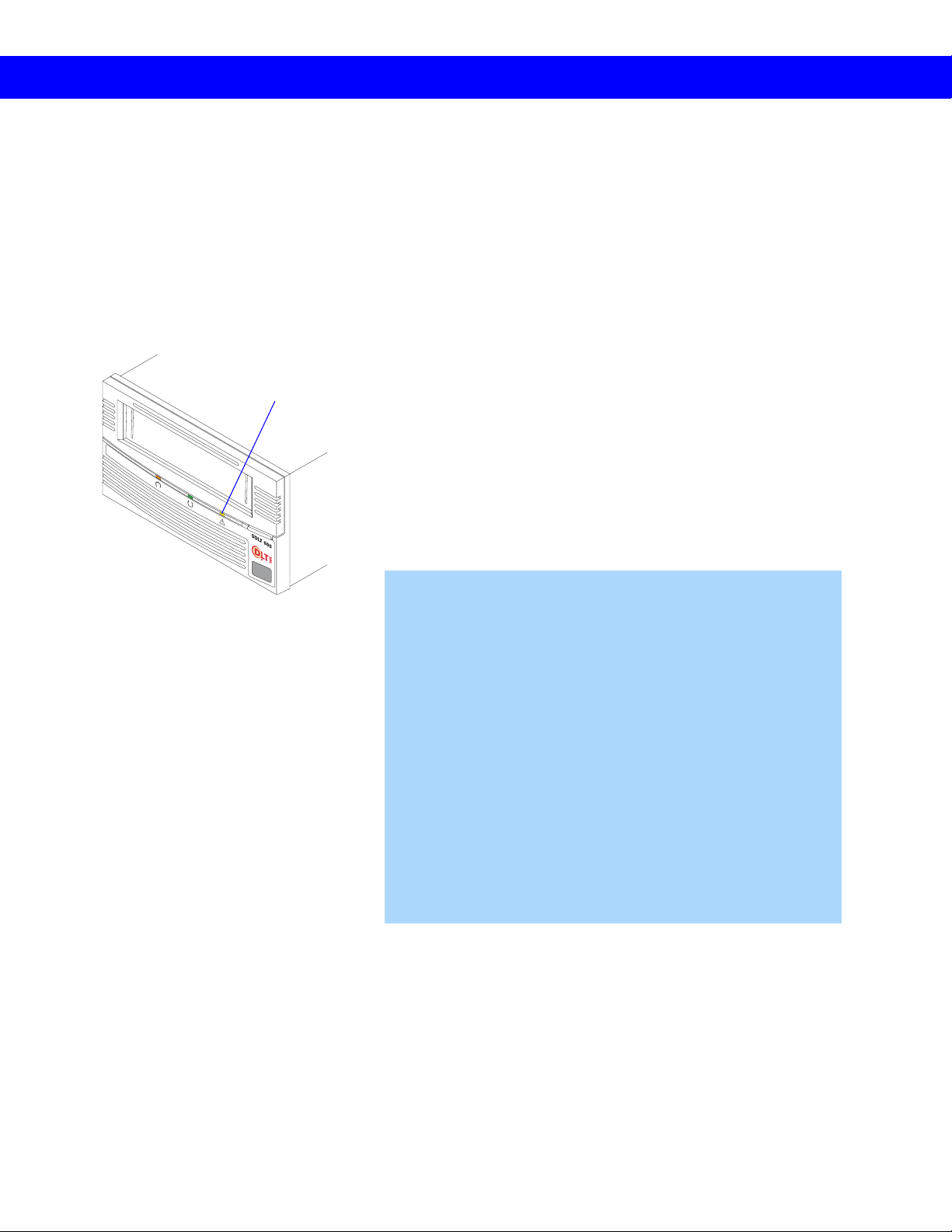

A2 Interpreting the Front of

the Tape Drive

This section describes the tape drive

controls as well as tape drive and

data cartridge conditions communicated by the LEDs on the front of

the tape drive.

Title Color/

Symbol

Drive

Density

Drive

Status

Cleaning

Required

Orange/

Green

Green On The tape drive is idle. The tape drive

Yellow On Cleaning is required.

Action Explanation

Off No cartridge is inserted, or an

incompatible cartr idge is inserted.

Green

Orange A backward-read cartridge, such as

Off The tape drive has not been powered

Flashing The tape drive is in use. This

Off Cleaning is not requir ed.

A Super DLTtape™ II cartridge is

inserted or has just been ejected.

Super DLTtape I or DLTtape

is inserted.

may or may not contain a cartridge.

on or is not plugged into a power

source.

includes functions such as:

• Loading and unloading tape

• Reading

• Writing

• Rewinding

• Calibrating

™ VS1,

Eject N/A Press Use the Eject button to eject a

cartridge from the tap e drive . When

you press Eject, the tape drive

finishes writing data to the tape, then

ejects the cartridge.

Infrared Port The infrared port prov ide s a wireless

remote testing base for cu stomers

and integrators to access system

diagnostic infor mation.

Note: Upon reset, all LEDs flash briefly and then illuminate

in sequence until the tape drive is ready for use. All

LEDs flash when the tape drive encounters an error.

Page 7

A3 | Loading and Unloading Data Cartridges

t

A3 Loading and Unloading

Data Cartridges

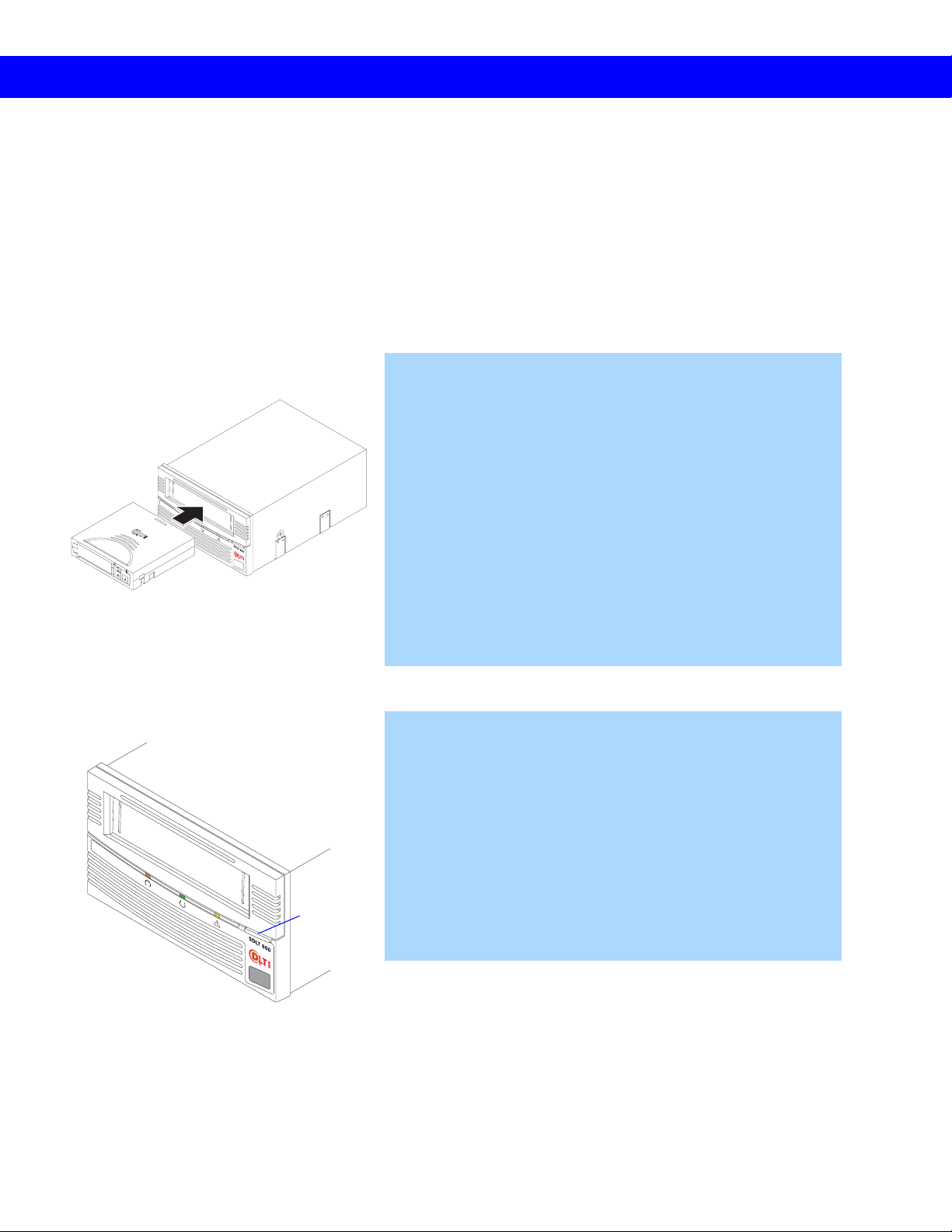

To Load a Data Cartri dge

1. Insert the data cartridge into the receiver on the front of the

tape drive.

2. Push the cartridge completely into the receiver.

The green Drive Status LED ( A2) flashes as the tape loads.

When the tape reaches the Beginning of Tape (BOT) marker,

the Drive Status and Drive Density LEDs (

steadily, indicating that the cartridge is ready for use.

A2) light

Ejec

Note: The Drive Density LED is green when a

Super DLTtape II cartridge is inserted; orange when a

Super DLTtape I or DLTtape VS1 car tr idge i s inse rt ed;

and off when no car tridg e is inserted or an incom pat i ble

cartridg e is inserted (

choosing data cartridges , B1.

A2). For information about

To Unload a Data Cartridge

1. Press the Eject button on the front bezel.

The tape drive completes writing data to the tape, and the

Drive Status LED ( A2) flashes as the tape rewinds.

When the tape reaches the BOT marker, the tape drive ejects

the data cartridge. The Drive Status LED lights steadily, and

the Drive Density LED:

• Remains green if you ejected a Super DLTtape II cartridge

• Turns off if you ejecte d a backwar d-read cartridge.

2. Remove the cartridge from the tape drive and ret urn it to its

plastic case (

A1).

Page 8

Cleaning the Tape Heads | A4

A4 Cleaning the Tape Heads

Cleaning

Required

Over time, ambient pollution and particulates in the

environment contaminate the tape heads. The tape drive

indicates when cleaning is required by illuminating the

yellow Cleaning Required LED. A2

! Do not clean the tape heads unless the Cleaning Required

LED is illuminated.

! Use ONLY the SDLT CleaningTape. Other cleaning tapes,

such as CleaningTape III o r DLT VS CleaningTap e, are

incompatible with the SDLT 600 tape drive heads.

To Clean the Tape Heads

1. Insert a Super DLTtape cleaning cartridge (the brand name

to look for is SDLTtape™ CleaningTape) into the tape

drive.

The green Drive Status LED flashes and the cleaning cycle

begins automatically.

When the cleaning cycle completes, the tape drive

automatically ejects the CleaningTape; turns off the Cleaning

Required LED; and steadily illuminate s the Drive Status

LED.

2. Remove the CleaningTape, place it back in its plastic case,

and mark the l abel after each cleaning.

Note: On the last cleaning, the tape drive does not eje ct the

Cleanin gTape. Use the Eject but t on on the fron t of the

tape drive to ej ect the ex pi red clean i ng cartri d ge an d

dispose of it.

Page 9

B Using Data Cartridges

B1 Choosing Data Cartridges

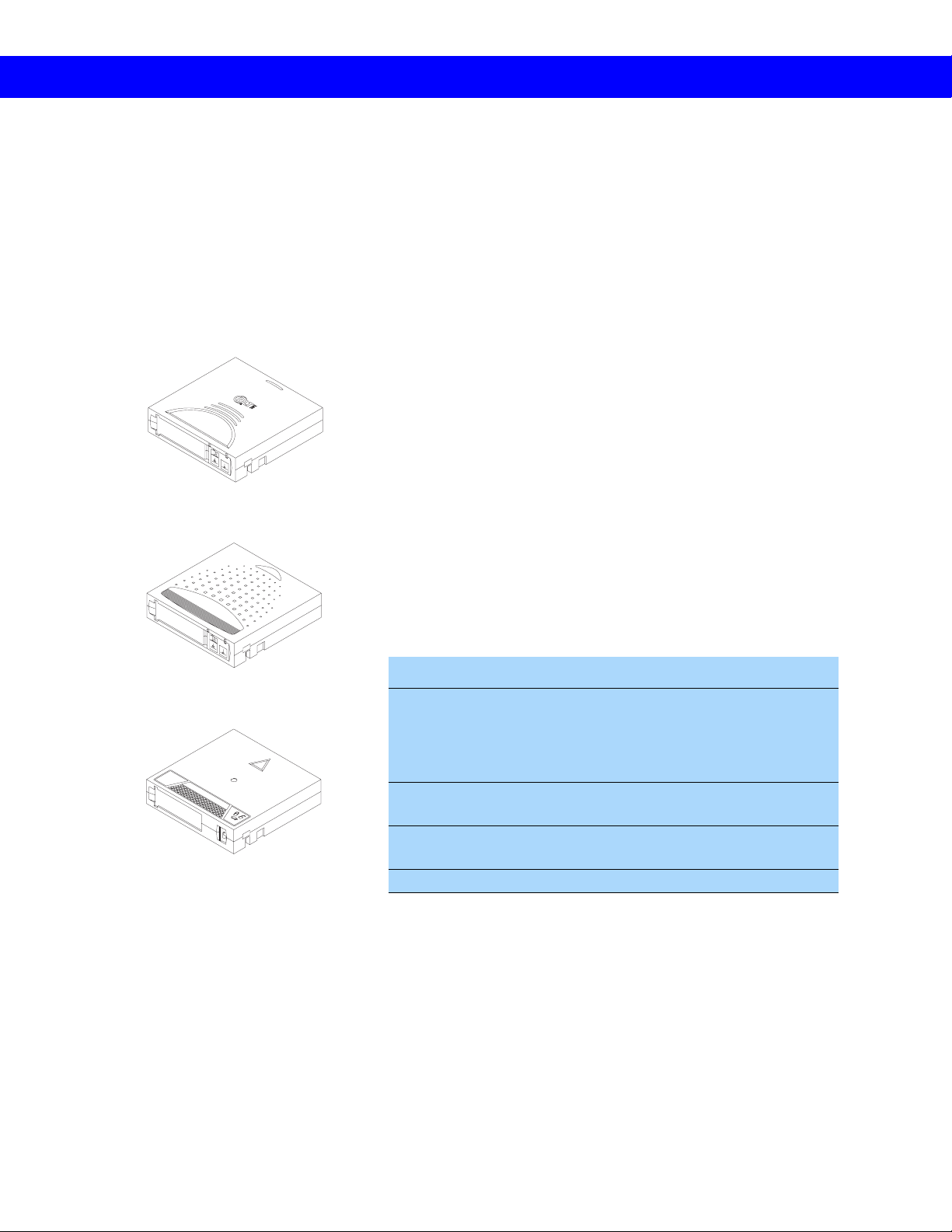

Super DLTtape II Data Cartridge

B1 | Choosing Data Cartridges

The SDLT 600 tape drive writes to Super DLTtape II data

cartridges. The Super DLTt ape II cartridge is blue and has a

distinctive pattern molded into the plastic, along with the

DLTtape logo. The cartridge’s geometry is similar to

previous DLTtape cartridges to simplify integration with

existing tape library designs. Its keying feature, however,

ensures that it cannot be loaded into pr evious generation tape

drives.

Super DLTtape I Data Cartridge

DLT tape VS1 Data Cartridge

The SDLT 600 tape drive includes a backward-read

compatibility feature tha t en able s it to read (but not write to)

Super DLTtape I and DLTtape VS1 cartridges. The

following table lists the transfer rates for backward-read

cartridges.

Backward-read Transfer Rates

Cartridge Type Native

Capacity (GB)

Super DLTtape I,

SDLT 320-formatted

Super DLTtape I,

SDLT 220-formatted

DLT t ape V S1 80 6.4

* Transfer rates quoted are nominal, measured reading

uncompressed data.

160 12.8

110 8.8

BRC Transfer

Rate: 80% of

Native Read

Transfer Rate

(MB/second)

*

Page 10

Write-protecting Data Cartridges | B2

B2 Write-protecting Data

Cartridges

To prevent accidental erasure of your data, each data

cartridge has a write-protec t switch. When ac tive, this switch

prevents the tape drive from writing data to the cartridge.

! For valuable data, always make sure the cartridge is

write-protected before inserting it into the tape drive.

To enable write-protection:

Move the write-protec t switch left so that the bright

orange rectangle is visible.

Move switch left to writ e protect media. Orange

indicates write-protected.

To disable write-protection:

Move the write-protect switch right so that the ora nge

rectangle is not visible.

Page 11

B3 Caring for Data

Store data cartridges vertically

in plastic case s.

B3 | Caring for Data Cartridges

Cartridges

Super DLTtape II data cartridges are engineered to be

reliable, robust, and durable. They are manufactured to

withstand 1,000,000 passes, and have a shelf life of 30 years.

For best results, follow these guidelines for data cartridge

handling and storage:

Follow the handling instructions and obs erve the

environmental specifications provided in the plastic

cartridge case.

Use slide-in labels.

Keep cartridges in their protective cases when not in use.

Protect cartridges from shock, vibration, moisture, direct

sunlight, dust, smoke, and magnetic f ields.

Do not stack more than five cartridges on top of each

other.

Store cartridges vertically in protective cases for archival.

Use the slide-in labels provided. Do not use adhesive

labels or Post-it® notes, and do not write on the cartridge.

Do not write on the labels with debris-producing writing

instruments, such as graphite pencils and water-soluble

felt pens. Replace labels instead of erasing them.

Never touch the tape or tape leader. Dust and oils from

your skin contaminate the tape and affect performance.

A void unnecessarily opening the cartridge door to prevent

contamination and physical damage.

Inspect data cartridges for damage after dropping them.

B4

Condition cartridges to the recommended normal

operating environment for 24 hours after exposing them

to abnormal temperature or humidity (such as after

transporting the cartridges from one location to another).

The safet y of your data depends on proper care an d

!

handling of cartridges.

Page 12

Inspecting Data Cartridges | B4

B4 Inspecting Data

Cartridges

Check reel locks.

Inspect spring-loaded hub for

proper tension.

Check for toed-in clips.

Improper data cartridge handling is the primary reason for

tape drive problems. To avoid losing data or damaging the

tape drive, inspect cartridges:

Before loading a new cartridge

After dropping a cartridge or subjecting it to physical

shock

When the tape drive becomes inoperable after loading a

cartridge

When you receive a shipment of data cartridges that

shows any sign of shipping damage.

Use the following procedure to inspect a cartridge. If the

cartridge shows any sign of damage, do not use it.

To Inspect a Cartridge

1. Inspect the exterior of the cartridge for physi cal damage

(cracks, broken parts) and conta mination (sticky or oily

substances, attached debr is).

2. Gently shake the cartridge. Listen for loose pieces.

3. Check that both reel locks on the cartridge are visible. One

reel lock is located on the end of the cartridge that is

inserted into the tape drive. The other is on the bottom of

the cartridg e.

4. Confirm that the spring-loaded hub on the bottom of the

cartridge is cente red. Press the hub to ensure that the spring

is functioning properl y and t hat the hub retur ns to i ts n ormal

position.

5. Verify that the orange write-protect switch snaps sma rtly

into position and is not damaged.

6. Open the cartridge door by pr essing the ta b in the d oor pivo t

notch. Check for possible damage to the tape leader buckle,

including a bent or toed-in appearance or improper seating.

7. Examine the visible tape leader (without touching it) for

excessive debris, oily or sticky residue, condensed droplets

of moisture, or any other signs of contamination.

Note: For more detailed and thorough information about

inspecting a data cartridge, refer to the SDLT 600

Product Manual.

B2

Page 13

C1 | Understanding the Tape Drive’s Interface

C Connecting the Tape Drive

C1 Understandi ng the Tap e

Drive’s Interface

The tabletop model of the SDL T 600 tape dr ive has an Ultra 160

SCSI interface. The internal model has either a Fibre Channel

interface or an Ultra 160 SCSI interface.

The Ultra 160 SCSI Interface

Ultra 160 provides a low-voltage differential (L VD) mode

running up to 160 MB/second and a single-ended (SE) mode

running up to 40 MB/second.

Note: The host computer’s SCSI controller c ard may limit the se

speeds. For the best performance, make sure the SCSI

controller card can operate at 160 MB/second.

The tape drive automatically senses the SCSI bus mode and

switches between LVD and SE accordingly. Although the tape

drive defaults to LVD, it switches to SE if the SCSI bus operates

in SE mode. For example, if the SCSI controller card is SE (or

multi-mode set to SE), the tape drive automatically switches to

SE mode. Also, if any device on the SCSI bus is SE, the entire

bus switches to SE, including the tape drive.

In SE mode, the SCSI bus can support up to 7 devices using

cable lengths up to 3 meters. In LVD mode, the SCSI bus can

support up to 15 devices using cable lengths up to 25 meters.

For more information about using the SCSI interface, refer to

the SDLT 600 SCSI Interface Guide.

The Fibre Channel Interface

The Fibre Channel interface runs at speeds up to either

1 Gb/second or 2 Gb/second, depending on the configuration

you choose during installation.

Fibre Channel can support up to 126 devices in a loop

configuration. Longwave transceivers (with fiber optic cable)

support distances up to 10 kilometers; short pulsewave

transceivers (with fiber optic cable) support distances up to 500

meters.

For more information about using the Fibr e Channel interface,

refe r t o th e SDLT 600 Fibre Channel Interface Guide.

Page 14

Choosing Cables and Connectors | C2

F

C2 Choosing Cables and

Connectors

This section describes the cables and connectors to use with

the SDLT 600 tape drive.

SCSI Cables and Connectors

SCSI versions of the SDLT 600 tape drive have two highdensity 68-pin SCSI connectors. Connect the tape drive to

the host computer using a SCSI ca ble with the correct type of

connector on each end. The tape drive operates best when the

host computer and host end of the cable have one of the

following types of connector.

SCSI Connectors

iber Optic Cable

High-density 68-pin Micro DB68 or Mini DB68

SCA 80-pin Hot Swap Connector

Very High-density Interconnect Connector

The tape drive will, however, operate with other host-end

connectors.

Fibre Channel Cables and Connectors

Fibre Channel versions of the SDLT 600 tape drive

(internal model only) have one Fibre Channel port. The Fibre

Channel port is equipped with a Small Form- fac tor,

Pluggable (SFP) converter for connecting the fiber optic

cable. You may have to supply the SFP for the other end of

the cable; some host bus adapters have the transceiver

already built in to the adapter, in which case, you do not have

to supply the SFP for the other end of the cable.

Note: Both ends of the cable require a transceiver.

Page 15

C3 | Setting the SCSI ID

3

C3 Setting the SCSI ID

This section describes how to set the SCSI ID on the tabletop

tape drive. For information about setting the SCSI ID on an

internal tape drive, refer to the SDLT 600 Pr oduct Manual.

Each device connected to a SCSI bus must have a unique

SCSI ID number. The factory preset SCSI ID is 3 for the

3

tabletop tape drive and 5 for the internal tape drive. Ensure

that your tape drive’s SCSI ID is unique on your SCSI bus.

Y ou can change the SCSI ID using the push-button switch on

the back of the tape drive. Use the point of a pencil to press

the buttons above or below the number display to increase or

decrease the ID number.

! If the tape drive is the only SCSI device, leave the SCSI ID

set to 3, the default setting.

! Do not use a SCSI ID of 7. This setting is typica lly

reserved for the SCSI controller.

Page 16

Connecting the SCSI Model as a Single Device | C4

C4 Connecting the SCSI

Mode l as a Si ngl e Devi ce

The SDLT 600 tape drive performs best when it is the only

device connected to the SCSI bus. If the SDLT 600 tape

drive is the only SCSI device you intend to connect to the

SCSI bus, follow these steps:

Terminate upper

SCSI port.

1. Make sure the host computer and all peripheral devices

are powered off.

! Never connect the tape drive while the host system or

peripheral devices are powe red on .

2. Connect a terminator to the upper SCSI connector on the

3

back of the tape drive.

! Yo u mus t terminate the SCS I bus. The SCSI contr oller

terminates one end, while a terminator on the tape drive

terminates the other end.

3. Connect one end of the SCSI cable to the lower

connector on the back of the tape drive.

4. Connect the other end of the SCSI cable to the SCSI

connector on the host computer.

For more information about connecting the SDLT 600 tape

drive, refer to th e SDL T 600 Pr oduct Manual.

Page 17

C5 | Connecting the SCSI Model in a Daisy Chain

C5 Connecting the SCSI

Model in a Daisy Chain

If you are adding your SDLT 600 tape drive to a SCSI daisy

chain, follow these steps:

T erminate upper

SCSI port.

3

3

1. Ensure that all devices have unique SCSI IDs. C3

2. Make sure the host computer and all peripheral devices

are powered off.

! Never connect the tape drive while the host system or

peripheral devices are powe red on .

3. Connect the SCSI cable from the host computer to the

lower SCSI connector on the back of the tape drive.

4. Continue the SCSI chain using the upper SCSI

connector.

5. If the SDLT 600 tape drive is the last device in the

chain, connect a terminator to the upper SCSI connector.

! Yo u mus t terminate the SCS I bus. The SCSI contr oller

terminates one end, while a terminator on the last device

in the chain terminates the other end.

For more information about connecting the SDLT 600 tape

drive, refer to th e SDL T 600 Pr oduct Manual.

Page 18

Connecting the Fibre Channel Model | C6

C6 Connecting the Fibre

Channel Model

The Fibre Channel protocol and the SCSI protocol rely on

different methods of addressing devices. Unlike the SCSI

protocol, which uses fixed SCSI IDs , the Fibre Channel

protocol uses different addressing depending on the type of

topology used for the network: point-to-point, arbitrated

loop, or fabric. The addresses are set dynamically (in real

time) at the time the device attaches to the network.

Follow these steps to connect a Fibre Channel SDLT 600

tape drive:

1. Insert a fiber optic cable into the Fibre Channel port on

the back of the tape drive.

The connector is fully seated when it snaps into the port.

! Y ou can connect a Fibre Channel connector while the tape

drive is still powered on; this capability is known as “hotswappable” or hot-pluggable.”

2. Optional step (for this step, rely on your judgement

based on your knowledge of the host bus adapter that

you are currently using): Attach an SFP connector

C2) to the other end of the fiber optic cable before

(

connecting it to the host device.

For more information about c onnecting a Fibre Channel tape

drive, refer to th e SDL T 600 Pr oduct Manual.

Page 19

D1 | Using the Power-On Self-Test

D Troubleshooting Tape Drive Pr oblems

D1 Using the Power-On

Self-Test

The SDLT 600 tape drive performs a self-diagnostic test,

called a Power-On Self-Test (POST), each time you power it

on. This test helps you detect problems with your tape drive.

POST completes in approximately 10 seconds. While POST

is in progress, the tape drive re sponds BUSY to SCSI

commands.

If the host computer attempts to negotiate synchronous or

wide transfers, the tape drive negotiates to asynchronous or

narrow. It may take longer than the duration of POST for the

tape drive to become ready.

During POST, each LED lights in sequence. When POST is

complete, the green Drive Status LED lights steadily.

If the tape drive fails POST, check for the following possible

problems:

There is no cartridge in the tape drive .

The tape drive is not receiving adequate power (try a new

cord or different outlet).

The tape drive is not properly connected to the host

computer and other SCSI devices.

If any of these problems exist, correct the problem, power

off the tape drive and power it back on to restart POST. If

none of these problems exists or the tape drive fails POST

after you have corrected them, refer to additional

troubleshooting information in the SDLT 600 Product

Manual available on the product CD-ROM.

! Do not attempt to open the tape drive enclosure. Only a

qualified Quantum technician should perfo rm servi ce.

Page 20

General Troubleshooting | D2

D2 General Troubleshooting

Troubleshoot problems with your S DLT 600 tape drive using

the following steps:

1. Visua lly inspect the cartridge for damage, and try a new

cartridge if necessary. B4

2. Make sure the cables and connectors are in good

condition. For example, check that they are not worn

or broken, and there are no mis sing or bent pins.

3. Make sure the connector on each end of the cable is fully

seated.

4. Disconnect the tape drive from the host system, power

off the tape drive, and power it on again to perform a

POST. D1

5. If you have a SCSI tape drive, remove all devices f rom

the SCSI bus. Connect the tape drive directly to the host

computer and terminate it ( C4). Confirm that the tape

drive and host computer are communicating proper ly

before adding other devices.

6. If you have a Fibre Channel tape drive, look at the back

panel to see if the green LED (the “link light”) there is

illuminated ( C6). If the link light is illuminated, you

have a working connection with the Fibre Channel

network.

7. Ensure that your operating system (modules, patches,

and drivers), backup software, and tape drive are

compatible. Visit www.quantum.com/sdlt for the most

current compatibility information.

If you cannot identify or correct the problem, call Quantum

Technical Support at 1-888-827-3378. Have your model and

serial number available when you call. Find thes e numbers

on the bottom of the ta pe drive.

Page 21

D3 | SCSI Troubleshooting

D3 SCSI Troubleshooting

If the tape drive passes POST with no power or data

cartridge problems, but is still performing poorly, check for

the following SCSI issues.

SCSI Troubleshooting

Possible Problem Solution

Your system is not configured to “see”

the tape drive.

The SCSI ID is not unique. Change the SCSI ID. The new ID takes effect the

The parameters for your SCSI adapter

are incorrect.

The SCSI bus is not terminated cor rec tly. Confirm that a terminator is installed on the last

The SCSI bus is too long. For single-ended mode, limit the length of the

T oo many devices are connected to the

SCSI bu s.

The tape drive is operating more slowly

than indicat ed i n its perfo rm an c e

specifications.

Check your system and SCSI bus settings.

Configure your system to recognize the tape

drive.

next time you power on the tape drive. C3

Check your SCSI controller card. Ensure that it is

LVD for the optimal tape drive performance, or

SE for slower performance. C1

device in the SCSI chain and that it is fully

seated. C4, C5

SCSI bus to 3 m eters. For LVD mode, limit the

length to 25 meters.

Limit the number of external devices. Try using

the tape drive as a stand-alone device.

For the best performance, make sure your SCSI

controller card can operat e at 160 M B/second.

C1

For information about possible Fibre Channe l problems,

refer to the next section.

D4.

Page 22

Checking for Tape Drive Errors | D4

D4 Checking for Tape Drive

Errors

The SDLT 600 tape drive (SCSI version) provides status and

event information about the SCSI controller, devices, data

transfer, and errors. The Fibre Channel version of the tape

drive also indicates whether a signal is present and provides

the Fibre Channel address, speed, topology, and node and

port information.

You can use iTalk to access this information through the tape

drive’s infrared port located on the front of the tape drive.

You can find iTalk on the CD-ROM that accompanies the

tape drive, or you can download it from

www.quantum.com/sdlt

(you must first register your tape drive on the web site). See

iTalk’s online help for inf orma tion about using the software.

Page 23

D5 | Optimizing the Tape Drive

D5 Optimizing the Tape

Drive

Many factors contribute to SDLT 600 tape drive

performance. Host system considerations include processor

speed, block size, SCSI adapter performance, bus

configurations, and software.

If you are concerned about the performance of your

SDLT 600 tape drive, check the following:

1. Ensure that your tape drive is properly defined for the

host system. If the tape drive is not defined within the

system, the SCSI adapte r does not inte ra ct we ll with the

tape drive.

2. Make sure your controller card and the SCSI bus are

operating in LVD. If the controller card or the SCSI bus

are operating in SE, the tape drive switches to SE.

3. De-fragment your hard disk on a regular basis.

Fragmented disks and files take much longer to back up.

4. Check your host block size. The SDL T 600 tape drive

supports block sizes up to 16 MB. In general, the larger

the block size, the better the throughput. Many older

software applications default to a 512-byte block s i ze,

which results in poor performance.

5. Make sure you are using a data cartridge that is

compatible with the tape drive. B1

Page 24

Specifications | E1

E Tape Drive Information

E1 Specifications

This section lists maximum data transfer rates, physical

specifications, functional specifications, dimensions, and

weight for the SDLT 600 tape drive.

Maximum Data Transfer Rate

The following table shows the maximum and burst data

transfer rates for the SDLT 600 tape drive.

Configuration Native

SCSI Ultra 160 (LVD mode) 36 MB/sec 72 MB/sec 160 MB/sec

SCSI Ultra 160 (MSE L VD mode) 36 MB/sec 72 MB/sec 160 MB/sec

SCSI Ultra 160 (SE mode) 36 MB/sec 40 MB/sec 40 MB/se c

Fibre Channel (1 Gb/s) 36 MB/sec 72 MB/sec 100 MB/se c

Fibre Channel (2 Gb/s) 36 MB/sec 72 MB/sec 200 MB/se c

* The compression rates shown assume an ind us try s tandard 2:1 compression rat io.

Actual compressi on ratios achieve d depend on the redundancy of data files being

recorded.

† Burst speeds are l imited by t he SCSI bus it self , or by the Fib re Ch annel t ransc ei ver , not

the design of the SDLT 600 tape drive or the Super DLTtape II data cartridge.

Compressed

*

Burst Max

†

Page 25

E1 | Specifications

Physical Specifications

The following table lis ts environmental operating limits and

accuracy for the SDLT 600 tape drive.

Data I nte g r ity

Error Type Frequency

Dete cted, Recoverable

(ECC) Read

Detected, Unrecoverable

Read

Undetected Re ad

Rewrite of Data

< 1 error in 106 bytes read

< 1 error in 1017 bits read

< 1 error in 1027 bits read

< 1 per 106 bytes written

Tem perature

Operating 10 °C to 40 °C (50 °F to 104 °F)

Storage -40 °C to 66 °C (-40 °F to 150 °F)

Humidity

Operating 20% to 80% non-condensing

Storage 10% to 95% non-condensing

Safety Certifications

Meets UL 60950, GS mark, and EN60950/IEC 950 standards

(EN60825-1: Information Technology Equipment)

Air Fl ow

10.4 CFM minimum with 0.09 in H2O pressure drop

Note: Allow at least 100 mm of unobstructed space behind the

tape drive for pro per ai r fl ow.

Electrical Rating (numbers describe the Ultra 160 m odel)

Tabletop 85 to 264 VAC, 63 W typical,

100 W (power supply rating)

maximum, 47 to 63 Hz

Internal +5V , 4.9 A RMS, 6.2 A Peak,

typical

+12V, 0.7 A RMS, 2.7 A Peak,

typical

Page 26

Specifications | E1

Functional Specifications

The following table lists capac ity and life expe cta ncy for the

SuperDLTtape II cartridge, as well as tape drive performance

characteristics.

Super DLTtape II Cartridge Capacity

Native 300 GB

Compressed (2:1) 600 GB

Super DLTtape II Life Expectancy

Cartridge load/unload cycles

Media insertions

†

Full media uses (end-to-end)

Media passes

Tape Drive Performance Characteristics

**

*

‡

5,000

20,000

250

1,000,000

Load to BOT 18 s (typical),

63 s (unformatted tape)

Unload fro m BO T 19 s

Average access time 79 s (from BOT)

Maxim um access time 190 s (from BOT)

Average rewind time 77 s

Maximum rewind time 156 s

Read/write tape speed 108 ips

Rewind tape speed 160 ips

Linear search tap e speed 160 ips

Linear density 233 Kbpi

Track densit y 1502 tpi

Number of tracks 640 physical tracks

* A load/u n load cycle i s when the the data cartridge is inserted

into the receiver, loaded to BOT, calibrated, and then

unloaded.

† An insertion is when a data cartridge is inserted into the

receiver and then unloaded.

‡ A full media use is an operati on that reads or writes (with

verify off) the full capacity of the data cartridge.

** A media pass occ urs with any movement (in either direction)

of the surface of the media over the tape head.

Page 27

E1 | Specifications

Dimensions , Pa rt I

The following table lis ts the dimensions for the internal and

the tabletop tape drive.

Dimension Internal Version Tabletop

Version

Height 82.55 mm (3.25 in.) without front bezel;

85.73 mm (3.38 in.) with front bezel

164.46 mm

(6.48 in.)

Width 146.05 mm (5.75 in.) behind front bezel;

148.59 mm (5.85 in.) with front bezel

Depth 203.20 mm (8.00 in.) measur ed from back

of front bezel;

215.40 mm (8.48 in.) including front bezel

174.75 mm

(6.88 in.)

320.04 mm

(12.60 in.)

Dimensions , Pa rt II

The following table lis ts the library tape drive’s dimensions.

Dimension Librar y Version

Height 82.55 mm (3.25 in.) without front bezel;

85.73 mm (3.38 in.) with front bezel

Width 146.05 mm (5.75 in.) behind front bezel;

148.59 mm (5.85 in.) with front bezel

Depth 203.20 mm (8.00 in.) measured from back of front bezel;

212.22 mm (8.36 in.) including front bezel

Page 28

Specifications | E1

Weight

The following table lists the tape drive’ s unpackaged weight

and shipping weight.

Weight

Unpackaged

Weight

Shipping

Weight

*

* W eights depend on configuration. The packaging used may change the

shipping weight.

Internal and Library Version Tabletop Version

2.38 kg (5 lbs 4 oz) 6.27 kg

(13 lbs 13 oz)

3.77 kg (8 lbs 5 oz) 9.90 kg

(21 lbs 13 oz)

Page 29

E2 | Regulatory Information

E2 Regulatory Information

This section lists regulatory information for the SDLT 600

tape drive.

Safety Certific ations

The SDLT 600 tape drive meets or exceeds the following

safety requirements:

UL 60950 (USA): Information Technology Including

Electrical Business Equipment

EN60950/IEC 950 (Europe): Information Technology

Including Electrical Business Equipment

• EN60825-1 Information Technology Equipment

The SDLT 600 tape drive is certified to bear the GS mark

and TUV identification markings.

The SDLT 600 tape drive is a Class I laser product that

complies with 21 CFR 1040.10 as applicable on the date of

manufacture.

Electromagnetic Interference

Certifications

The internal version of the SDLT 600 tape drive complies

with FCC Class A limits in a standard enclosure. The

tabletop tape drive complies with FCC Class B limits. The

following table lists Electromagnetic Interf e renc e (EMI )

certifications.

Type Regulation/Certification

EEC Directive 89/336 CE EN55022 (EU)

EN55024 (EU)

CFR 47, 1995 FCC Rules Part 15B Class B

(MDOC)

IECS-003 Canada

V-3/97.04 VCCI Clas s B (Japan)

CNS 13438 BSMI Class A (Taiwan)

AS/NZS 3548 Australia/New Zealand

Page 30

Regulatory Information | E2

Immunity a nd ESD Limits

The following table lists the immunity and ESD failure level

limits to which the SDLT 600 tape drive has been tested.

Test Name Test Specification Required

EN55022: 1998 Radiated and Conducted Emissions

Radiated Electromagne tic Emissions

Conducted Electromagnetic Emissions

Current Harmonics and Flicker Emissions Tests

AC Power Supply Harmonic Emissions EN61000-3-2 As per the standard

AC Power Supply Voltage Flicker EN61000-3-3 As per the standard

EN55024: 1998 Immunity Tests

Electrostatic Discharge Immunity EN61000-4-2 Criteria A

Radiated Electromagne tic Immunity EN61000-4-3 Criteria A

Electrical Fast Transient / Burst Immunity EN61000-4-4 Criteria B

Electrica l Surge Immunity EN61000-4-5 Criteria B

Conducted Electromagnetic Immunity EN61000-4-6 Criteria A

Power Frequency Magnetic Fiel d Immunity EN61000-4-8 Criteria A

AC Voltage Dips and Interrupts Immunity EN61000-4-11 Criteria B

EN55022: 1998 Class B

Performance

Page 31

E2 | Regulatory Information

Acoustic Noise Emissions

The following table lists acous tic noise emission levels, both

as noise power and sound pressure, for the SDLT 600 tape

drive. The table provides the preliminary declared values per

ISO 9296 and ISO 7779/EN27779.

Mode Noise Power Emiss ion Leve l

(LNPEc)

Internal Tabletop Internal Tabletop

Idle Not applicable 5.4 Bel Not applicabl e 42 dB

Streaming 5.9 Bel 5.9 Bel 47 dB 53 dB

* Sound pressure level m ea sured at front of drive.

Sound Pressure Level

(LPA c)

*

Page 32

Copyright

Copyright © 2004 by Quantum Corporation. All rights reserved .

Document Origination: Boulder, Colorado, USA.

Trademarks

Quantum, the Quantum logo, and the DLTtape logo are trademarks of

Quantum Corporation, registered in the U.S.A. and other countries. DLT tape,

DLTSage, Val u e D LTtape, and S uper DLTtape are tradem ar k s of Qu an tu m

Corporation.

Other company and product names used in this document are trademarks,

registered trademarks, or service marks of their respective owners.

Legal Disclaimers

The information cont ained in this document is the exclusive prope rty of

Quantum Corporation. Quantum retains its copyright on the information

contained herein in al l ca ses and situations of usage, includi ng derivative

works.

The possessor agrees to safeguard this in form ation and to maintain it in

confidence and not re-publish it in whole or in part without Quantum’s prior

written consent.

Quantum reserves the rig ht to make chan ges and im provement s to its pro ducts,

without incurring any obligation to incorporate such changes or improvements

in units previously sold or shipped.

It is the responsibility of the user to carefully read and understa nd the User

Manual statements for Class A Equipment and Class B Equipment that appear

on the insi de of the front c over.

Contact Information

Telephone numbers and street addresses change fre quently; for the latest,

up-to-date contact information, visit www.quantum.com .

Telephone numbers, street addresses, time zones, and other pertine nt facts are

listed in the Support section of the web s ite.

February 2004

Quantum Publication Num ber: 81-81220-01 REV A02

*81-81220-01 A02*

Loading...

Loading...