Page 1

8VHU·V*XLGH8VHU·V*XLGH8VHU·V*XLGH8VHU·V*XLGH8VHU·V*XLGH

70

70

4XDQWXP6XSHU/RDGHU

4XDQWXP6XSHU/RDGHU

6XSHU/RDGHU

70

$

Page 2

Quantum SuperLoader Automated Tape Library User’s Guide, 81-60226-02 01, August 2004, Made in USA.

Quantum Corporation provides this publication “as is” without warranty of any kind, either express or

implied, including but not limited to the implied warranties of merchantability or fitness for a particular

purpose. Quantum Corporation may revise this publication from time to time without notice.

COPYRIGHT STATEMENT

Copyright 2004 by Quantum Corporation. All rights reserved.

Your right to copy this manual is limited by copyright law. Making copies or adaptations without prior

written authorization of Quantum Corporation is prohibited by law and constitutes a punishable violation of

the law.

TRADEMARK STATEMENT

Quantum and the Quantum logo are trademarks of Quantum Corporation, registered in the U.S.A. and other

countries. SuperLoader, DLTtape, and Super DLTtape are trademarks of Quantum Corporation. Products

mentioned herein are for identification purposes only and may be trademarks or registered trademarks of

their respective companies. All other trademarks are the property of their respective owners.

6207947-00cP 153

Page 3

Contents

Preface xix

Chapter 1 Introduction 1

General Description........................................................................................... 1

Front View........................................................................................................... 3

Mailslot......................................................................................................... 3

LCD............................................................................................................... 4

Function Keys..............................................................................................4

Status LEDs.................................................................................................. 5

Power Switch...............................................................................................5

Magazines ....................................................................................................5

Rear View ............................................................................................................ 7

Cooling Fans................................................................................................ 8

AC Power.....................................................................................................8

Ethernet Connection................................................................................... 8

SCSI Connection.......................................................................................... 9

Internal View ...................................................................................................... 9

Picker ..........................................................................................................11

Drive Carrier Assembly (DCA) .............................................................. 11

Bar Code Reader ....................................................................................... 11

Supported Software......................................................................................... 12

SuperLoader User’s Guide iii

Page 4

Contents

Chapter 2 Installation and Configuration 13

Preparation........................................................................................................13

SCSI Bus Requirements ............................................................................14

Accessories .................................................................................................14

Installation Location Requirements........................................................15

Rack Mounting the SuperLoader...................................................................16

General Preparation for Rack Mount Installation................................19

Stationary Rack Mount Installation........................................................19

Making the SCSI Connection..........................................................................26

Powering On the SuperLoader.......................................................................28

Configuration....................................................................................................30

Setting SCSI ID..................................................................................................32

Setting Ethernet ................................................................................................34

IP Address..................................................................................................34

Subnet Mask...............................................................................................37

IP Gateway .................................................................................................38

Setting the SNMP Server..........................................................................39

Setting the Time Server ............................................................................40

Setting the Time................................................................................................42

Setting the Change Mode ................................................................................46

Sequential Mode Operations ...................................................................47

Setting Security .................................................................................................49

Security Option..........................................................................................49

Setting Magazines ............................................................................................50

v20 Firmware and the SuperLoader LTO..............................................51

v45 Firmware and the SuperLoader DLT (excludes DLT1)................51

v45 Firmware and the SuperLoader DLT1............................................51

Passwords..........................................................................................................52

Getting Lost Passwords............................................................................53

Chapter 3 Tape Cartridge Use 55

Tape Cartridges Defined .................................................................................56

Tape Maintenance ............................................................................................59

The Write-Protect Switch ................................................................................59

Tape Drive Cleaning ........................................................................................60

Insert the Cleaning Tape ..........................................................................61

Storing the Cleaning Tape (DLT/SDLT Only) in a Magazine............63

Eject the Cleaning Tape............................................................................64

iv SuperLoader User’s Guide

Page 5

Contents

Tape Drive Cleaning Methods ....................................................................... 65

Manual Cleaning (DLT/SDLT Only)..................................................... 65

Auto Clean................................................................................................. 66

Software...................................................................................................... 67

Chapter 4 SuperLoader Operation 69

Front Panel Components ................................................................................70

Function Keys............................................................................................70

LEDs............................................................................................................ 70

LCD............................................................................................................. 71

Front Panel Menus........................................................................................... 71

Commands Menu ..................................................................................... 74

Status Menu............................................................................................... 74

Configuration Menu................................................................................. 75

Diagnostics Menu ..................................................................................... 75

Front Panel Functionality ............................................................................... 75

Enter Passwords........................................................................................ 75

Logout......................................................................................................... 77

Set Change Mode Settings....................................................................... 77

Using Data Cartridges.............................................................................. 77

Insert a Single Cartridge .......................................................................... 78

Move a Single Cartridge .......................................................................... 80

Eject a Single Cartridge............................................................................80

Use of Magazines and Magazine Blanks ...................................................... 82

Eject a Magazine .......................................................................................82

Install a Magazine..................................................................................... 83

Manually Operate the Magazine............................................................ 84

View Status Information................................................................................. 90

View SuperLoader Status ........................................................................ 90

View Firmware Version........................................................................... 92

View Element Status................................................................................. 92

View Tape Drive Status ........................................................................... 94

View Tape Drive Version ........................................................................95

View Ethernet Information...................................................................... 96

View Flex I/O Information ..................................................................... 97

Run Inventory................................................................................................... 98

Set Data Compression ..................................................................................... 98

Updating the System ....................................................................................... 99

SuperLoader User’s Guide v

Page 6

Contents

On-board Remote Management...................................................................102

Open On-board Remote Management.................................................102

Status Information...................................................................................103

Default Username and Password .........................................................103

Time Display............................................................................................104

Feedback on Pages ..................................................................................104

Commands Page.............................................................................................105

Moving Tapes ..........................................................................................106

Inventory ..................................................................................................106

Set to Home..............................................................................................106

Sequential Operations ............................................................................107

Configurations Page.......................................................................................108

System Operations Options...................................................................109

SCSI ID......................................................................................................109

Set the Mode ............................................................................................111

View the Compression Setting..............................................................112

Set the Cleaning Mode............................................................................113

Set the Magazines....................................................................................113

Set the System Time................................................................................114

Set Networking Options.........................................................................117

Set Security Options................................................................................118

Diagnostics Page.............................................................................................124

Run Diagnostic Tests ..............................................................................124

Identify SuperLoader..............................................................................126

Perform a System Reset..........................................................................127

System Updates Page.....................................................................................127

Perform System Updates .......................................................................127

Chapter 5 Troubleshooting 129

Before Contacting Quantum Support..........................................................129

Contacting Quantum Technical Support....................................................134

Returning Units for Repair............................................................................135

Return Authorization Process ...............................................................135

Policies and Procedures .........................................................................136

Repair Process..........................................................................................138

How to Return the SuperLoader for Service..............................................139

To Pack the SuperLoader ..............................................................................142

Check for Errors..............................................................................................144

vi SuperLoader User’s Guide

Page 7

Contents

SuperLoader Error Logs................................................................................ 146

Screen Display of Hard Error Logs ...................................................... 146

Hard Error Log Display ........................................................................153

Hard Error Log Fields ............................................................................ 155

Error Code Field Description................................................................ 155

Error Code Listing .................................................................................. 158

Tape Drive Error Logs...................................................................................165

Error Log Display ................................................................................... 165

Error Log Information............................................................................ 166

SCSI Check Condition Error Logs ....................................................... 167

Bugcheck Error Logs .............................................................................. 173

Event Error Logs ..................................................................................... 174

A400: Read Error............................................................................................ 176

Cause ........................................................................................................ 178

Suggested Actions ..................................................................................178

A401: Write Error........................................................................................... 179

Cause ........................................................................................................ 181

Suggested Actions ..................................................................................181

A402: Drive Error........................................................................................... 182

Cause ........................................................................................................ 185

Suggested Actions ..................................................................................186

A403: Loader Log........................................................................................... 186

Cause ........................................................................................................ 187

Suggested Actions ..................................................................................187

A404/A405: Calibration................................................................................ 188

Cause ........................................................................................................ 190

Suggested Actions ..................................................................................191

A407: Directory Read .................................................................................... 191

Cause ........................................................................................................ 196

Suggested Actions ..................................................................................196

A408: Directory Write.................................................................................... 197

A500: SDLT Hard Read Error....................................................................... 201

Cause ........................................................................................................ 202

Suggested Actions ..................................................................................203

A501: SDLT Hard Write Error......................................................................203

Cause ........................................................................................................ 205

Suggested Actions ..................................................................................205

A502: SDLT Loader Communication Error................................................ 205

Cause ........................................................................................................ 206

Suggested Actions ..................................................................................206

A503: SDLT Drive-Servo Error..................................................................... 206

Cause ........................................................................................................ 211

Suggested Actions ..................................................................................211

SuperLoader User’s Guide vii

Page 8

Contents

A507/A508: Directory Read Failure/Directory Write Failure ................212

Cause.........................................................................................................218

Suggested Actions...................................................................................219

Chapter 6 Diagnostics 221

POST.................................................................................................................221

POST Descriptions ..................................................................................222

Perform a POST.......................................................................................222

Interpret the POST Results ....................................................................223

Diagnostic Tests..............................................................................................223

Set the Security ........................................................................................223

Stop a Diagnostic Test ............................................................................224

Front Panel Diagnostic Tests .................................................................225

On-board Remote Management Diagnostic Tests.....................................226

Diagnostics Using On-board Remote Management ..........................227

Appendix A Basic Information Logs 229

Log Descriptions......................................................................................229

SuperLoader Logs ..........................................................................................230

Common Information.............................................................................231

Log Display ..............................................................................................231

Log Fields .................................................................................................231

Error Codes ..............................................................................................232

Soft Logs ...................................................................................................236

Update Logs.............................................................................................236

Shadow Event Log ..................................................................................236

Boot Logs..................................................................................................237

OEM Logs.................................................................................................237

ID Logs......................................................................................................237

Tape Drive Logs..............................................................................................238

Common Information.............................................................................238

Log Display ..............................................................................................238

Log Fields .................................................................................................238

POST Failure Logs...................................................................................239

DLT Drive Diagnostic Results Logs .....................................................240

DLT Firmware Changes ........................................................................241

viii SuperLoader User’s Guide

Page 9

Contents

Appendix B Specifications 243

SuperLoader Physical Specifications .......................................................... 244

SuperLoader Performance Specifications................................................... 244

SuperLoader Power Specifications.............................................................. 246

SuperLoader Environmental Specifications............................................... 247

SuperLoader Vibration Specifications ........................................................ 248

SuperLoader Shock Specifications...............................................................248

SuperLoader Product Safety/Compliance................................................. 249

SuperLoader Acoustic and Noise Limits.................................................... 249

SCSI Specifications......................................................................................... 250

SCSI Cable and Terminator Requirements ......................................... 250

SCSI Cable Length .................................................................................. 250

Ethernet ........................................................................................................... 250

Appendix C Time Zones 251

Appendix D Regulatory Statements 255

Taiwan Statement ..........................................................................................256

Japan Notice.................................................................................................... 257

Canadian Notice (Avis Canadien)...............................................................257

European Union Notice ................................................................................257

Product Safety Electrostatic Discharge .......................................................258

Grounding Methods ...................................................................................... 259

Laser Safety..................................................................................................... 259

Taiwan Battery Recycling Label .................................................................. 259

Glossary 261

Index 273

SuperLoader User’s Guide ix

Page 10

Contents

x SuperLoader User’s Guide

Page 11

Figures

Figure 1 LCD Front Panel Screen ..........................................................xxii

Figure 2 On-board Remote Management Screen ...............................xxiii

Figure 3 SuperLoader Front View............................................................. 3

Figure 4 Function Keys ............................................................................... 4

Figure 5 Magazine (left and right sides)...................................................6

Figure 6 Magazine Blank ............................................................................7

Figure 7 SuperLoader DLT Rear View ..................................................... 7

Figure 8 SuperLoader LTO Rear View ..................................................... 8

Figure 9 Internal View of the SuperLoader............................................ 10

Figure 10 Clearance Requirements for Rack Mounting ......................... 18

Figure 11 Required Parts for Installation .................................................20

Figure 12 Installing Two Clip Nuts...........................................................21

Figure 13 Attaching SuperLoader Brackets ............................................. 22

Figure 14 Attaching Support Brackets......................................................23

Figure 15 Sliding SuperLoader into Rack.................................................24

Figure 16 Front Alignment ......................................................................... 25

Figure 17 Connecting Support Brackets ................................................... 25

SuperLoader User’s Guide xi

Page 12

Figures

Figure 18 Making the SCSI Connection ....................................................27

Figure 19 Sample Idle Screen Display (SuperLoader LTO

illustrated) 29

Figure 20 LCD Front Panel .........................................................................30

Figure 21 Submenu for Configuration ......................................................31

Figure 22 Main Menu (LCD).......................................................................33

Figure 23 Configuration Menu (LCD).......................................................33

Figure 24 Main Menu (LCD).......................................................................34

Figure 25 Main Menu (LCD).......................................................................35

Figure 26 Static IP Selection........................................................................36

Figure 27 Main Menu (LCD).......................................................................37

Figure 28 Set Subnet Mask..........................................................................37

Figure 29 Main Menu (LCD).......................................................................38

Figure 30 IP Gateway...................................................................................38

Figure 31 Main Menu (LCD).......................................................................39

Figure 32 Set IP Server.................................................................................40

Figure 33 Main Menu (LCD).......................................................................41

Figure 34 Setting a Time Server..................................................................41

Figure 35 Main Menu (LCD).......................................................................43

Figure 36 Setting a Time Zone (Hours).....................................................43

Figure 37 Setting a Time Zone (Minutes) .................................................44

Figure 38 Main Menu (LCD).......................................................................44

Figure 39 Setting the Date and Time .........................................................45

Figure 40 Main Menu (LCD).......................................................................46

Figure 41 Main Menu (LCD).......................................................................48

Figure 42 Main Menu (LCD).......................................................................48

Figure 43 Main Menu (LCD).......................................................................49

Figure 44 Main Menu (LCD).......................................................................50

Figure 45 Main Menu (LCD).......................................................................52

xii SuperLoader User’s Guide

Page 13

Figures

Figure 46 Password Screen......................................................................... 53

Figure 47 DLTtape IV and Super DLTtape I Cartridges ........................ 57

Figure 48 SDLT II Cartridge ....................................................................... 58

Figure 49 Ultrium Format Tape Cartridge...............................................58

Figure 50 Write-Protect Switch (SDLT Shown) ....................................... 59

Figure 51 Magazine Map ............................................................................ 62

Figure 52 Media Compatibility Chart....................................................... 68

Figure 53 SuperLoader DLT Menu Tree Structure ................................. 72

Figure 54 SuperLoader LTO Menu Tree Structure................................. 73

Figure 55 Log In Sample .............................................................................76

Figure 56 Loading a Cartridge (SDLT Tape Shown) .............................. 79

Figure 57 Installing a Magazine................................................................. 83

Figure 58 Installing a Magazine (continued) ...........................................84

Figure 59 View of Magazines.....................................................................85

Figure 60 Cartridge Orientation (SDLT Shown) ..................................... 86

Figure 61 Upper Slot of Magazine (SDLT Shown).................................. 87

Figure 62 Top of Magazine.........................................................................88

Figure 63 Identifying a Magazine Slot (SDLT Shown)...........................89

Figure 64 LCD Messages............................................................................. 91

Figure 65 Firmware Version Display........................................................ 92

Figure 66 Element Status ............................................................................ 93

Figure 67 Magazine Slot Map .................................................................... 93

Figure 68 Element Status ............................................................................ 94

Figure 69 Tape Drive Status (DLT/SDLT Shown).................................. 94

Figure 70 Tape Drive Version .................................................................... 95

Figure 71 View Ethernet Information ....................................................... 96

Figure 72 View Flex I/O Information (Scrolled Down) ......................... 97

Figure 73 Accessing the Backup Copy of Firmware (SuperLoader

DLT Shown) .............................................................................. 101

Figure 74 On-board Remote Management Home Page ....................... 103

SuperLoader User’s Guide xiii

Page 14

Figures

Figure 75 Feedback in On-board Remote Management Screen ..........104

Figure 76 Commands Page .......................................................................105

Figure 77 Screen for Configurations Page ..............................................108

Figure 78 Systems Operations Page.........................................................109

Figure 79 Screen for Configurations........................................................110

Figure 80 Setting the Mode .......................................................................111

Figure 81 Viewing the Compression Setting..........................................112

Figure 82 Setting the System Time...........................................................116

Figure 83 Setting Network Options.........................................................117

Figure 84 Setting Security Options ..........................................................119

Figure 85 Setting Authorized Client List ................................................121

Figure 86 Disabling Sets ............................................................................122

Figure 87 Setting Client Overlap Control ...............................................123

Figure 88 Diagnostics Page .......................................................................124

Figure 89 View Test Status........................................................................125

Figure 90 Viewing Error or History Logs ...............................................126

Figure 91 System Updates.........................................................................127

Figure 92 Removing the SuperLoader from the Rack...........................140

Figure 93 Loosening the Support Brackets.............................................140

Figure 94 Connecting Support Brackets..................................................141

Figure 95 Removing the Brackets ............................................................142

Figure 96 Shipping Materials....................................................................143

Figure 97 Error Flowchart.........................................................................145

Figure 98 Hard Error Log as Displayed via FTP and On-board

Remote Management ...............................................................153

Figure 99 Hard Error Log as Displayed on Front Panel and SCSI

Formats.......................................................................................154

Figure 100 Error Code Block Descriptor for Hard and Soft Event

Logs.............................................................................................156

Figure 101 Example Tape Drive Error Log...............................................166

xiv SuperLoader User’s Guide

Page 15

Figures

Figure 102 Example DLT1 Tape Drive Error Log ...................................166

Figure 103 SCSI Check Condition Error Log ...........................................168

Figure 104 Bugcheck Error Log..................................................................173

Figure 105 Event Error Log ........................................................................ 175

Figure 106 Read Error Block Descriptor...................................................176

Figure 107 Write Error Block Descriptor.................................................. 179

Figure 108 Drive Error Block Descriptor .................................................. 182

Figure 109 32-Bit Register ........................................................................... 185

Figure 110 Loader Error Field Descriptions............................................. 186

Figure 111 Calibration Block Descriptor .................................................. 188

Figure 112 Directory Read Block Descriptor............................................ 192

Figure 113 Directory Write Block Descriptor........................................... 197

Figure 114 Hard Read Error/Hard Write Error Block Descriptor ....... 201

Figure 115 Hard Read Error/Hard Write Error Block Descriptor ....... 203

Figure 116 Loader Communication Error Block Description................ 205

Figure 117 Drive Servo Error Block Descriptor....................................... 206

Figure 118 Directory Read Failure/Write Failure Block

Descriptor .................................................................................. 212

Figure 119 Log Display ............................................................................... 231

Figure 120 Error Code Block Descriptor for Hard and Soft Event

Logs ............................................................................................ 232

Figure 121 Shadow Event Log ...................................................................237

Figure 122 Example Tape Drive Log......................................................... 238

Figure 123 POST Failures Event Log ........................................................240

Figure 124 DLT Drive Diagnostics Event Log .........................................241

SuperLoader User’s Guide xv

Page 16

Figures

xvi SuperLoader User’s Guide

Page 17

Tables

Table 1 LCD Panel Function Keys ........................................................... 5

Table 2 Location Criteria......................................................................... 15

Table 3 UL Criteria................................................................................... 16

Table 4 Write-Protect Switch Positions.................................................60

Table 5 LED Display ................................................................................ 70

Table 6 SuperLoader Status .................................................................... 91

Table 7 Firmware Version Description ................................................. 92

Table 8 Tape Drive Status ....................................................................... 95

Table 9 Tape Drive Version .................................................................... 96

Table 10 Ethernet Information Messages................................................ 97

Table 11 Flex I/O Information .................................................................97

Table 12 Suggested Actions for Performance Problems..................... 130

Table 13 Screen Display of Hard Error Logs........................................ 146

Table 14 Hard Error Log Fields.............................................................. 155

Table 15 Error Code Field Descriptions................................................ 156

Table 16 Error Code Listing.................................................................... 158

Table 17 Tape Drive Field Descriptions................................................ 167

SuperLoader User’s Guide xvii

Page 18

Tables

Table 18 SCSI Check Condition Error Log Field Descriptions ..........168

Table 19 Sense Key Field Definitions.....................................................169

Table 20 ASC/ASCQ Field Description ................................................171

Table 21 Bugcheck Log Field Descriptions...........................................174

Table 22 Event Error Log Field Descriptions........................................175

Table 23 Read Error Field Descriptions.................................................177

Table 24 Write Error Field Descriptor ...................................................180

Table 25 Drive Error Log Field Descriptions........................................183

Table 26 Loader Error Field Descriptions .............................................187

Table 27 Calibration Field Descriptions................................................188

Table 28 Directory Read Field Descriptions .........................................193

Table 29 Directory Write Field Descriptions ........................................198

Table 30 Hard Read Error/Hard Write Error Field Descriptions .....202

Table 31 Hard Read Error/Hard Write Error Field Descriptions .....204

Table 32 Loader Communication Error Field Description.................205

Table 33 Drive Servo Error Field Descriptions.....................................207

Table 34 Directory Read Failure/Write Failure Field Descriptions..213

Table 35 POST Descriptions....................................................................222

Table 36 Log Retrieval Methods.............................................................230

Table 37 Basic Information (SuperLoader) Log Fields........................232

Table 38 Error Code Field Descriptions ................................................233

Table 39 Tape Drive Field Descriptions ................................................239

Table 40 POST Failures Event Log Field Description .........................240

Table 41 DLT Drive Diagnostics Field Descriptions ...........................241

Table 42 Times and Time Zones.............................................................252

xviii SuperLoader User’s Guide

Page 19

Preface

This chapter describes this guide’s audience, purpose, organization,

document conventions, and product safety.

Note: Due to the nature of their similarities, this manual is for the

SuperLoader™ DLT™, the SuperLoader SDLT™, the

SuperLoader LTO-1, and the SuperLoader LTO-2. Many

component parts are not interchangeable. These include the

magazines, cartridges, drive carrier assembly, magazine blank,

magazine handle, and the bar code scanner. Please order the

appropriate part numbers when replacing these items.

Refer to the appropriate Quick Start reference guide for

instructions on Customer-Replaceable Units (see Related

Quantum Documentation on page xxi).

Audience This user manual is designed and written for end users and field service

engineers.

SuperLoader User’s Guide xix

Page 20

Preface

Purpose The purpose of this manual is to provide end users with the following

information:

• SuperLoader description and specifications

• SuperLoader installation and configuration

• Tape cartridge description and general overview

• SuperLoader operation

• Troubleshooting

Document

Organization

This manual is organized as follows:

• Chapter 1, Introduction

- This chapter provides a general overview of

the SuperLoader’s components and functionality.

• Chapter 2, Installation and Configuration

- This chapter describes

how to unpack, install, configure, remove, and repack the

SuperLoader.

• Chapter 3, Tape Cartridge Use

- This chapter describes tape cartridge

care and usage.

• Chapter 4, SuperLoader Operation

- This chapter describes the

components of the SuperLoader, setting passwords, setting modes,

loading cartridges, installing magazines, and testing the

SuperLoader’s functionality.

• Chapter 5, Troubleshooting

- This chapter describes how to

determine and repair minor and major problems that may occur in

the SuperLoader. It also contains information relating to the error and

event logs.

• Chapter 6, Diagnostics

- This chapter describes the Power-On Self

Test (POST) and diagnostic tests for testing the SuperLoader’s

functionality and for troubleshooting errors.

• Appendix A, Basic Information Logs

- This appendix describes the

logs for the SuperLoader and tape drives. It contains a description of

each log type including log block descriptor and field descriptions.

• Appendix B, Specifications

- This appendix describes the

SuperLoader’s specifications.

• Appendix C, Time Zones

- This appendix provides a listing of Time

Zones for setting the time on the SuperLoader.

xx SuperLoader User’s Guide

Page 21

• Appendix D, Regulatory Statements - This appendix provides

required regulatory statements for the SuperLoader.

Preface

Related

Documentation

Documents related to the Quantum SuperLoader are shown below:

Related Quantum Documentation

Document No. Document Title Document Description

81-81263

Quantum

SuperLoader Quick

Start Guide

This guide contains a

sequence of steps

recommended for unpacking,

installing, and setting up

your SuperLoader.

81-81264

81-81265

81-81266

Quantum

SuperLoader Drive

Carrier Assembly

(DCA) Quick Start

Guide

Quantum

SuperLoader

Magazine Quick

Start Guide

Quantum

SuperLoader Bar

Code Reader Quick

Start Guide

This guide contains a

sequence of steps

recommended for unpacking

and installing a DCA.

This guide contains a

sequence of steps

recommended for unpacking

and installing a magazine.

This guide contains a

sequence of steps

recommended for unpacking

and installing a bar code

reader.

0

81-81267

81-81237

Quantum

SuperLoader Slide

Rail Kit Quick Start

Guide

How to Ship the

SuperLoader

This guide contains a

sequence of steps

recommended for unpacking

and installing a slide rail kit.

This guide provides

information on the proper

packing for returning the

SuperLoader for repair.

SuperLoader User’s Guide xxi

Page 22

Preface

Notational

Conventions

LCD Screen Shots Screen shots for the front panel LCD appear as follows:

Figure 1 LCD Front

Panel Screen

This manual uses the following conventions to designate specific

elements:

Note: Notes emphasize important information related to the main

topic.

Caution: Cautions indicate potential hazards to equipment and are

included to prevent damage to equipment.

Warning: Warnings indicate potential hazards to personal safety

and are included to prevent injury.

Status

Commands

Configuration

Diagnostics

xxii SuperLoader User’s Guide

Page 23

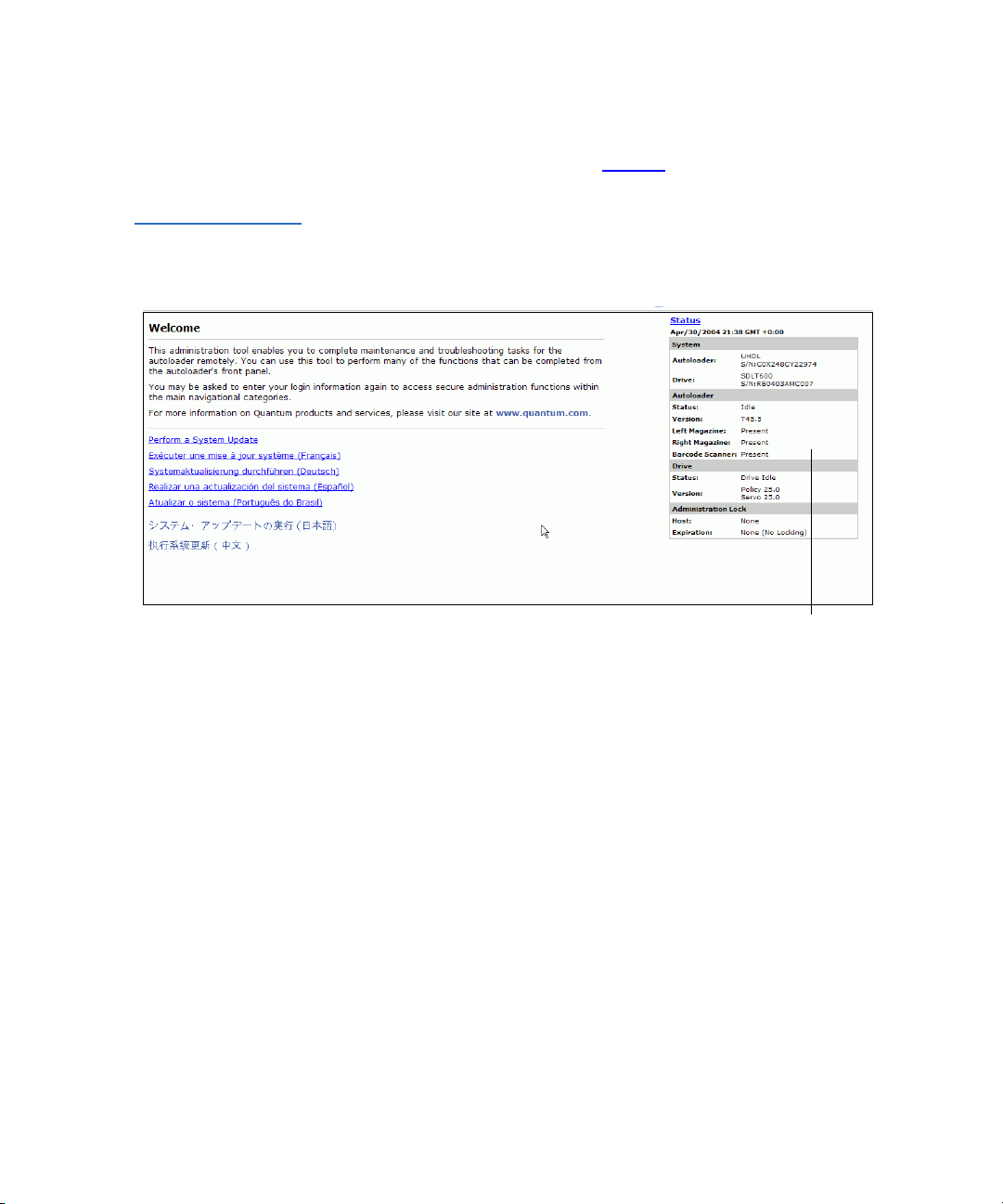

Figure 2 On-board

Remote Management

Screen

Screen shots for On-board Remote Management sometimes contain

callouts and appear as shown in figure 2

.

Preface

Status Information

SCSI-2 Specification 0

The SCSI-2 communications specification is the proposed American

National Standard for information systems, dated March 9, 1990. Copies

may be obtained from:

Global Engineering Documents

15 Inverness Way, East

Englewood, CO 80112

(800) 854-7179 or (303) 397-2740

SuperLoader User’s Guide xxiii

Page 24

Preface

Contact Information

This section provides contact information for worldwide customer

support.

Quantum

To order documentation for the Quantum SuperLoader or other products

contact:

Quantum Corporation

P.O. Box 57100

Irvine, CA 92619-7100

(949) 856-7800

(800) 284-5101

Technical Publications 0

To comment on existing documentation, send e-mail to:

doc-comments@quantum.com

Visit the Quantum home p age at: 0

http://www.Quantum.com

Customer Support 0

0

The Quantum Customer Support Department provides a 24-hour help

desk that can be reached at:

North/South America (949) 725-2100 or

Asia/Pacific Rim (International Code)

Europe/Middle East/Africa: (International Code)

xxiv SuperLoader User’s Guide

(800) 284-5101

+61 7 3839 0988

+44 (0) 1256 848748

Page 25

Send faxes for the Customer Support Department to:

North/South America (949) 725-2176

Asia/Pacific Rim (International Code)

+61 7 3839 0955

Europe/Middle East/Africa: (International Code)

+44 (0) 1256 848777

Send e-mail for the Customer Support Department to:

North/South America www.quantum.com/askaquestion

Asia/Pacific Rim apachelp@quantum.com

Europe/Middle East/Africa: eurohelp@quantum.com

Preface

SuperLoader User’s Guide xxv

Page 26

Preface

xxvi SuperLoader User’s Guide

Page 27

Chapter 1

1Introduction

This chapter describes the SuperLoader components and functionality.

General Description 1

Data backup is essential to protect irreplaceable information. Backing up

data to magnetic tape is an easy, cost-efficient method used by many

small and medium sized businesses. However, most enterprises have so

much data that a single backup tape is not enough; the information has to

be spread across numerous tapes. To avoid constantly changing tapes

manually, many tape backup systems include a SuperLoader.

Each SuperLoader is a robot that includes a tape drive and one or two

magazines for tape cartridges. The user’s application can automatically

load and unload tape cartridges as required for data backup or data

retrieval. SuperLoaders provide compact, high capacity, but low cost

method for simple, unattended data backup.

SuperLoader User’s Guide 1

Page 28

Chapter 1 Introduction

General Description

The SuperLoader contains either the DLT1, SDLT 220, SDLT 320,

SDLT 600, HP LTO-1, or HP LTO-2 tape drive, and one or two magazines

containing up to eight cartridges each. A single cartridge can be inserted

directly via a password-protected mailslot. The cartridge inserts directly

into the tape drive provided there is no cartridge already in the drive, or

you can load the cartridge into a magazine slot provided there is no

cartridge already in the slot.

Note: Throughout this manual, SuperLoaders containing the DLT1,

SDLT 220, SDLT 320, or SDLT 600 tape drives are referred to

as

SuperLoader DLT

. For those SuperLoaders containing

HP LTO-1 or HP LTO-2 tape drives, they are referred to as

SuperLoader LT O

common to all variants, the reference will be

. In instances where the information is

SuperLoader

.

The front panel on the SuperLoader includes a liquid crystal display

(LCD) screen and four function keys. A scrolling menu on the LCD screen

allows you to obtain information from the SuperLoader and enter

commands. The front panel also includes two light emitting diodes

(LEDs) indicating the SuperLoader’s ready status and error status.

The SuperLoader connects to your host server via a SCSI connection

allowing the host to send data and commands automatically. You can

also connect to the SuperLoader using an Ethernet connection to perform

administrative functions and download system updates.

2 SuperLoader User’s Guide

Page 29

Chapter 1 Introduction

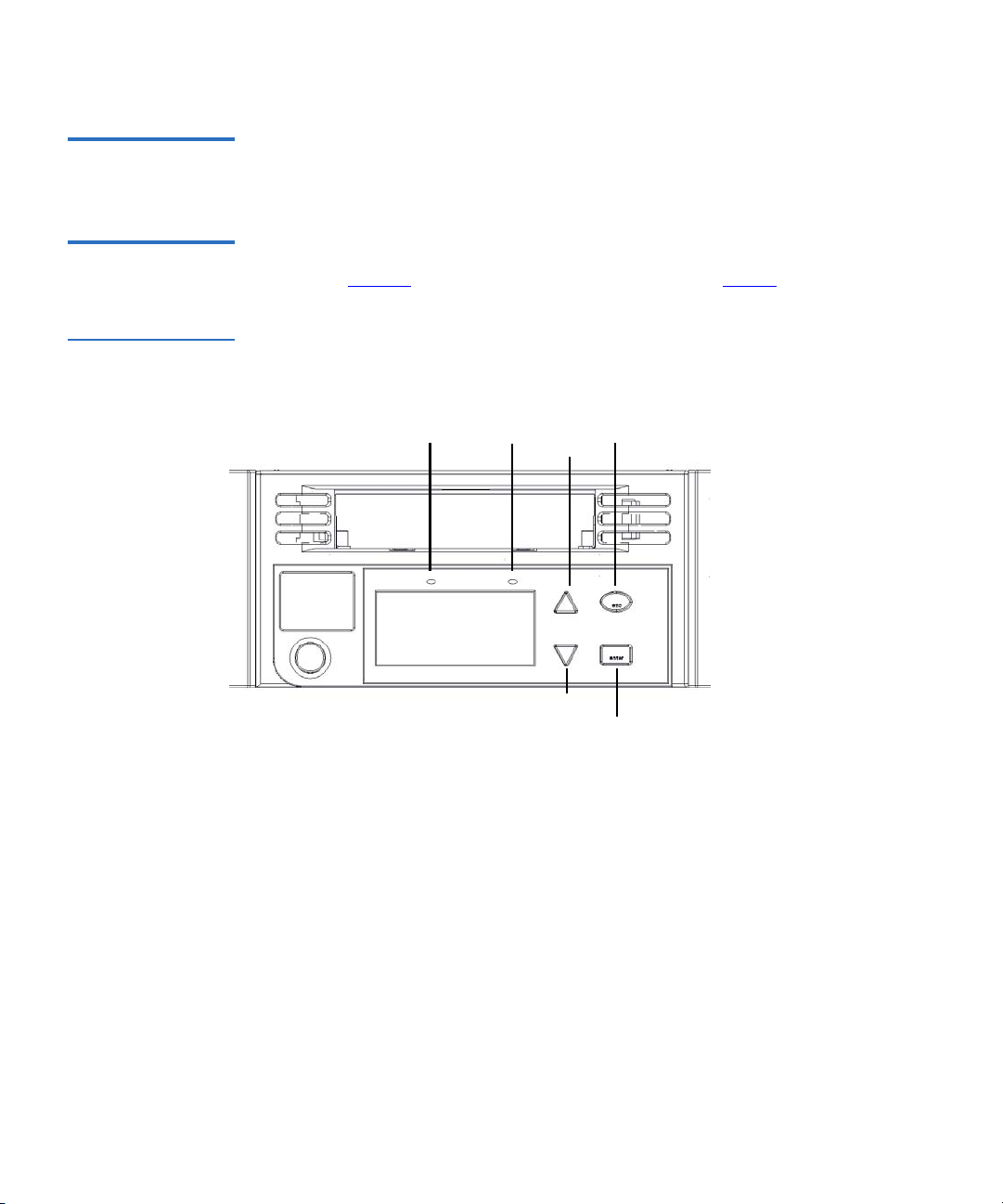

Front View

Front View 1

The mailslot, LCD, function keys, status LEDs, power switch, and left and

right magazines are visible on the front panel of the SuperLoader (see

figure 3

Figure 3 SuperLoader

Front View

).

Mailslot

Left magazine/blank

Power switch

Status LEDs

LCD 4 Function keys

Right magazine/blank

Mailslot 1 The SuperLoader has a manual entry port, the mailslot, which you can

use to load or unload a single cartridge. To maintain security, the mailslot

can be password protected. You can insert a cartridge in the mailslot even

if both magazines are completely filled, so long as the tape drive itself is

empty. You can also pass a tape cartridge from the mailslot to the

magazine if the drive is full but the magazine is not.

Note: You should run an inventory from the host application after

using the mailslot. The mailslot is not directly available from

the host application.

SuperLoader User’s Guide 3

Page 30

Chapter 1 Introduction

Front View

LCD 1 The LCD allows you to use the scrolling menu to perform diagnostics and

to enter commands.

Function Keys 1 The function keys allow scrolling through menus to make selections as

shown in figure 4

Figure 4 Function

Keys

. These function keys are described in table 1.

Ready LED

Fault LED

Scroll down

Escape

Scroll up

Enter

4 SuperLoader User’s Guide

Page 31

Chapter 1 Introduction

Front View

Table 1 LCD Panel

Function Keys

Status LEDs 1 The status LEDs show SuperLoader and drive status information. The

Power Switch 1 The power switch is a soft key, which means that if the SuperLoader is

Function Key Description

Enter

Escape

(Scroll Up)

(Scroll Down)

green

Ready LED shows ready status information, and the amber Fault

LED shows fault status information. A solid

and a blinking

moving any cartridges when you press the power switch, it finishes

moving them before powering off. Any other functions, such as writing

to a tape or performing a diagnostic, are interrupted and terminated

when you press the power switch. However, the SuperLoader attempts to

write cached data to tape before the unit powers down.

Fault LED indicates a need for attention.

Press to select an option

Press to return to the previous

menu, to move backwards on a

screen, or to abort an operation

Press to move up through a menu

or through the menu settings

Press to move down through a

menu or through the menu

settings

Fault LED indicates an error,

Magazines 1 The SuperLoader is equipped with one or two cartridge magazines (see

figure 5

accommodates up to eight cartridges. If your SuperLoader contains only

one magazine, a magazine blank is installed in the other magazine bay.

The handles on magazines and magazine blanks are removable and allow

you to configure any magazine or magazine blank to fit in either the left

or the right magazine bay.

The magazines store the tape cartridges and can also store the cleaning

cartridge. The magazines also contain the part of the robotics that moves

the cartridges inside the SuperLoader.

). The magazines are removable and each magazine

SuperLoader User’s Guide 5

Page 32

Chapter 1 Introduction

Front View

Figure 5 Magazine

(left and right sides)

Use one of these knobs to

manually rotate the magazine

when you load and unload

cartridges.

The SuperLoader DLT and

SuperLoader LTO

magazines, magazine

blanks, and magazine

handles are not

interchangeable. The

SuperLoader LTO magazine

displays the LTO Ultrium

logo on the handle.

6 SuperLoader User’s Guide

Page 33

Chapter 1 Introduction

Rear View

Figure 6 Magazine

Blank

Rear View 1

The fans and connection ports are visible on the back of the SuperLoader

as illustrated in figure 7

SuperLoader LTO.

for SuperLoader DLT, and in figure 8 for

Figure 7 SuperLoader

DL T Rear View

Power supply

cooling fan

AC power System cooling fan

Ethernet connection

SCSI connector

SuperLoader User’s Guide 7

AC power

switch

Page 34

Chapter 1 Introduction

Rear View

Figure 8 SuperLoader

LTO Rear View

Power supply

cooling fan

connection

AC Power

AC power switch

System cooling fan

EthernetSCSI

connection

Cooling Fans 1 The SuperLoader has a system cooling fan, plus a second fan to cool the

power supply. These fans maintain the acceptable temperature range for

the tape drive path and all internal electronics. See appendix B

on

page 243 for details about required specifications.

AC Power 1 The SuperLoader requires a nominal voltage in the range of 110 volts AC

to 220 volts AC to operate.

Ethernet Connection 1

The SuperLoader’s Ethernet connection allows you to connect the

SuperLoader to a network, enabling remote administration. The

SuperLoader can also connect to an Simple Network Management

Protocol (SNMP) server and a time server.

The Ethernet connection supports HyperText Transfer Protocol (http).

You can download system updates and perform administrative tasks,

including diagnostics, using http, such as with a Web browser.

8 SuperLoader User’s Guide

Page 35

Chapter 1 Introduction

Internal View

SCSI Connection 1 A low-voltage differential (LVD) SCSI connection links the SuperLoader

to the external host server. LVD connections allow you to have more

devices and longer cable lengths than single ended (SE) SCSI connections.

The LVD SCSI connection uses an 0.8 mm offset Very High Density

(VHD) connector.

Internal View 1

Figure 9

picker sits behind the front panel and mailslot, and can “put” and “get”

cartridges to/from the mailslot, magazines, and tape drive. The drive

carrier assembly (DCA) contains the tape drive, internal power supply,

and cooling fan, and can be removed and replaced as a single component.

shows how the components of the SuperLoader fit together. The

SuperLoader User’s Guide 9

Page 36

Chapter 1 Introduction

Internal View

Figure 9 Internal View

of the SuperLoader

Picker with

misinsertion feature

and turret spreader

Bar code reader bay

DCA

Magazine

Mailslot

Picker Magazine blank

Note: Due to the nature of their similarities, unless noted otherwise,

these illustrations are for the SuperLoader DLT and the

SuperLoader LTO. Many component parts are not

interchangeable. These include the magazines, cartridges,

drive carrier assembly, magazine blank, magazine handle, and

the bar code scanner. Please order the appropriate part

numbers when replacing these items.

10 SuperLoader User’s Guide

Page 37

Chapter 1 Introduction

Internal View

Picker 1 The picker is the component of the SuperLoader that shuttles cartridges

between the drive, both magazines, and the mailslot. It has two degrees

of freedom: rotation and translation. The rotation axis positions the

picker platform in front of each location while the translation axis moves

cartridges on and off of the picker platform. By combining these two

degrees of freedom, a pin on the translation axis engages and disengages

a notch on the right side of the cartridge for pushing and pulling the

cartridge on and off of the platform.

Drive Carrier Assembly (DCA) 1

The DCA is configured with either a DLT1, SDLT 220, SDLT 320,

SDLT 600, HP LTO-1, or HP LTO-2 tape drive. The DCA facilitates easy

removal of the drive. To change tape drives, you can replace the DCA

without having to remove the top cover of the SuperLoader. The

SuperLoader LTO DCA is not interchangeable with the SuperLoader DLT

or SDLT DCA. For further information, refer to the

Carrier Assembly (DCA) Quick Start Guide

.

SuperLoader Drive

Bar Code Reader 1 Since the bar code reader is optional, your SuperLoader may be equipped

with a bar code reader when you receive it, or you may decide to install

one later. The bar code reader provides inventory feedback to the host

application and/or LCD panel/On-board Remote Manager by reading

the cartridge bar code labels. A full 16-cartridge inventory scan may take

up to 90 seconds. The SuperLoader DLT bar code reader and the

SuperLoader LTO bar code reader are

information, refer to the

SuperLoader Bar Code Reader Quick Start Guide

not interchangeable. For further

.

SuperLoader User’s Guide 11

Page 38

Chapter 1 Introduction

Supported Software

Supported Software 1

The SuperLoader is compatible with most operating systems such as:

•NetWare

•Windows® 2000

•Windows

•Windows

• Windows Server™ 2003

•Novell

• Solaris™

•HP-UX

•Linux® (Red Hat®, SuSe®, Caldera™, and TurboLinux®)

•AIX™

The SuperLoader is also compatible with most popular backup software

applications, including:

• CAI ARCserve

®

®

2003

®

XP

®

®

®

•VERITAS™ NetBackup™

• VERITAS BackupExec™

•IBM

•LEGATO Networker

®

Tivoli® Storage Manager

®

Note: Please check with your operating system supplier and your

backup software vendor to verify which version is required for

this SuperLoader.

12 SuperLoader User’s Guide

Page 39

Chapter 2

2Installation and Configuration

This chapter describes how to rack mount and configure the

SuperLoader.

Preparation 2

Before you install your new SuperLoader, unpack it carefully and inspect

it for any damage that might have occurred during shipping. The

SuperLoader Quick Start Guide

necessary information to unpack and inspect your SuperLoader correctly.

Please locate the

SuperLoader Quick Start Guide

included in the packaging describes all the

and follow the directions.

Ensure that the work area is free from conditions that could cause

electrostatic discharge (ESD). Discharge static electricity from your body

by touching a known grounded surface, such as your computer’s metal

chassis.

SuperLoader User’s Guide 13

Page 40

Chapter 2 Installation and Configuration

Preparation

SCSI Bus Requirements 2

You must connect the SuperLoader to one of the following SCSI bus

types:

•Wide, SCSI-2, LVD

•SE SCSI bus

Note: The SuperLoader is not compatible with a High-Voltage

Differential (HVD) SCSI bus.

Your SCSI host adapter card must also support the SCSI bus type used to

connect the SuperLoader. If you use a LVD SCSI bus, use a host adapter

card with a connection for the VHDCI cable.

Note: If you use an SE SCSI bus, the tape drive’s performance is

limited to the maximum data transfer speed of the bus.

Note: The maximum number of SuperLoaders supported per SCSI

bus is four.

Note: The SuperLoader may not work with multiple SCSI LUNS

when attached to a RAID controller. The SuperLoader is not

recommended for use with a RAID controller. If this problem

occurs, it is recommended that the SuperLoader be attached to

a separate SCSI bus controller on the host or server.

Accessories 2 The following accessories are shipped with each SuperLoader:

• Quick Start Guide

• SCSI host cable

•SCSI terminator

• Hardware to rack mount the SuperLoader

• One magazine blank

•Power cable

• Documentation CD containing all of the documentation in Adobe

Portable Document Format (PDF)

14 SuperLoader User’s Guide

®

Page 41

•Bar code labels

Chapter 2 Installation and Configuration

Preparation

Installation Location Requirements 2

Table 2 Location

Criteria

The SuperLoader is designed to fit in a standard 19-inch rack using either

the long or short brackets (depending on the depth of the rack) or the

optional slide rail kit. When choosing an installation location, make sure

that it meets the criteria found in table 2

and table 3.

Requirement Description

Rack Size Standard 19 inch

Room Temperature 10 to 35 degrees C

(50 to 95 degrees F)

Power Source Line frequency: 50 to 60 Hz

Air Quality Good air quality with minimal sources of particulate

contamination. Avoid placing the SuperLoader near

cooling or exhaust vents, printing machines, frequently

used doors and walkways, stacks of supplies that collect

dust, and smoke-filled rooms.

Caution: Excessive dust or other debris in the tape path

can damage tape and tape drives.

Humidity 20% to 80% relative humidity (non-condensing)

Minimum Clearance (to Facilitate

Component Removal and

Installation)

Front:

27.0 in. (686 mm), including 2.0 in. (51 mm) from the

front mounting rail to the inside of the front door.

Rear:

17.0 in. (432 mm). Using the appropriate

SuperLoader bracket, ensure the rear door closes (see

figure 10

).

Proximity to the Host Computer The SCSI bus maximum length is 39.37 ft. (12 m) including

all SCSI bus lengths within the SuperLoader. The SCSI bus

lengths are 16 in. (406.4 mm) per SuperLoader DLT/SDLT

or 23.5 in. (596.9 mm) per SuperLoader LTO.

SuperLoader User’s Guide 15

Page 42

Chapter 2 Installation and Configuration

Rack Mounting the SuperLoader

Table 3 UL Criteria

General Hazards

Elevated Operating Ambient

Temperature

Reduced Air Flow Installation of the equipment in a rack should be such that

Mechanical Loading Mounting of the equipment in a rack should be such that a

Circuit Overloading Consideration should be given to the connection of the

Reliable Earthing (Grounding) Reliable earthing of rack-mounted equipment should be

When installed in a closed or multi-unit rack assembly, the

operating ambient temperature of the rack environment

may be greater than the room ambient. Therefore,

consideration should be given to installing the equipment in

an environment compatible with the manufacturer’s

maximum recommended ambient (TMRA).

the amount of air flow required for safe operation of the

equipment is not compromised.

hazardous condition is not achieved due to uneven

mechanical loading.

equipment to the supply circuit and the effect that

overloading of circuits might have on overcurrent

protection and supply wiring. Appropriate consideration of

equipment nameplate ratings should be used when

addressing the concern.

maintained. Particular attention should be given to supply

connections other than direct connections to the branch

circuit, such as use of power strips.

Rack Mounting the SuperLoader 2

The SuperLoader can be rack mounted in two ways:

• Attached directly to the cabinet rails (stationary)

• Attached to an optional slide rail kit (removable)

16 SuperLoader User’s Guide

Page 43

Chapter 2 Installation and Configuration

Rack Mounting the SuperLoader

Only the stationary installation is included in this manual.

Note: To mount the SuperLoader on the slide rail, refer to the

SuperLoader Slide Rail Kit Installation Quick Start Guide

with the optional shelf assembly. The

Installation Quick Start Guide

Documentation CD or at

is also available on the

www.Quantum.com.

SuperLoader Slide Rail Kit

shipped

SuperLoader User’s Guide 17

Page 44

Chapter 2 Installation and Configuration

Rack Mounting the SuperLoader

Figure 10 Clearance

Requirements for

Rack Mounting

Minimum clearance to load

or unload a magazine from

the system

27.0” [686 mm]

Minimum clearance to load

a tape via the mailslot

Clearance to door inside a rack

2.0” [51 mm]

Minimum side

clearance (both

sides)

1.0” [25 mm]

FRONT

REAR

6.0” [152 mm]

Minimum clearance

between the rear of the

SuperLoader and the

inside of the rack (using

standard mounting

brackets adjusted to their

closest setting)

3.4” [86 mm]

18 SuperLoader User’s Guide

Page 45

Chapter 2 Installation and Configuration

Rack Mounting the SuperLoader

General Preparation for Rack Mount Installation 2

Take the following general safety steps before beginning either rack

mount installation.

1 Lower the cabinet feet.

2 Extend the cabinet anti-tip device, if available.

3 Ensure that the cabinet and all rack mounted equipment have a

reliable ground connection.

4 Verify that the total current of all rack mounted components

(including the SuperLoader) will not exceed the current rating of the

power distribution unit or outlet receptacles.

5 Secure the help of at least one other person. At least two people are

required to safely install the SuperLoader into a rack cabinet.

Warning: Failure to take these safety steps may result in

personal injury or equipment damage.

Caution: Do not remove the top cover of the SuperLoader

during the installation process. Removing the top

cover could result in damage to the SuperLoader.

Stationary Rack Mount Installation 2

This section describes the steps for attaching the SuperLoader directly to

the rails of a rack.

1 Make sure you have the following tools and parts:

• #2 PHILLIPS

®

screwdriver

• Level

• The following SuperLoader accessory kit parts (see figure 11

):

• Four SuperLoader brackets (two long and two short to

accommodate different rack depths)

Use the short SuperLoader brackets (74-60604-03) unless the

distance from the front mounting rail to the rear mounting

rail is less than 30.25 in. (76.84 cm).

• Two support brackets (74-60605-01)

• Eight 10-32 x 1/4 inch button head screws for the support

brackets (four per support bracket)

SuperLoader User’s Guide 19

Page 46

Chapter 2 Installation and Configuration

Rack Mounting the SuperLoader

• The following parts shipped with the rack:

• Eight clip nuts

•Eight screws

Figure 11 Required

Parts for Installation

Short SuperLoader

brackets (74-60604-03)

Support brackets

(74-60605-01)

Long SuperLoader

brackets (74-60604-01)

Support bracket screws

2 Install two clip nuts, 1.75 in. (44.45 mm) apart, onto each of the four

rails of the rack, making sure that you install each pair of clip nuts at

exactly the same level (see figure 12

).

20 SuperLoader User’s Guide

Page 47

Figure 12 Installing

Two Clip Nuts

Chapter 2 Installation and Configuration

Rack Mounting the SuperLoader

Rail

Outer covers

of the rack

Rail

Clip nut

1.75 in

(44.45 mm)

Rail

Clip nut

3 Select the long or short SuperLoader brackets (depending on the

depth of the rack), and then attach them to the rear of the

SuperLoader (see figure 13

).

SuperLoader User’s Guide 21

Page 48

Chapter 2 Installation and Configuration

Rack Mounting the SuperLoader

Figure 13 Attaching

SuperLoader Brackets

SuperLoader

(SuperLoader DLT illustrated)

Screws (10-32 x 1/4 only)

22 SuperLoader User’s Guide

SuperLoader bracket

Page 49

Figure 14 Attaching

Support Brackets

Chapter 2 Installation and Configuration

Rack Mounting the SuperLoader

4 Using rack screws, attach a support bracket to the clip nuts on each

rear rail (see figure 14

.)

Note: Be sure to attach the support brackets correctly; the side of

the bracket with only two holes should be secured to the

rail.

Tighten the screws just enough to hold the support brackets firmly

against the rail while still allowing the support bracket to be slightly

shifted by hand. This shifting will help facilitate the engagement of

SuperLoader brackets as the SuperLoader is installed in the rack. You

will fully tighten the screws in step 8

.

Support bracket

Clip nuts

Outer cover of rack

Rack

screws

Rear rail in rack

SuperLoader User’s Guide 23

Page 50

Chapter 2 Installation and Configuration

Rack Mounting the SuperLoader

5 With the help of a second installer, insert the SuperLoader into the

rack so that the SuperLoader brackets slide into corresponding

support brackets on the rear rails and the tabs at the front of the

SuperLoader align flush with the clip nuts on the front rails (see

figure 15

Caution: Do not release the front end of the SuperLoader until

Figure 15 Sliding

SuperLoader into

Rack

).

it can be secured to the rack.

SuperLoader bracket

(SuperLoader DLT illustrated)

24 SuperLoader User’s Guide

Support bracket

Page 51

Figure 16 Front

Alignment

Chapter 2 Installation and Configuration

Rack Mounting the SuperLoader

6 While the other installer holds the front end of the SuperLoader,

secure the SuperLoader in the rack by doing the following:

a Secure the front end of the SuperLoader to the rack using four

rack screws (two per tab) as shown in figure 16

. Tighten the

screws just enough to secure the SuperLoader to the front rails.

Front rail

Rack

screws

Tab (one

per side)

SuperLoader (front)

Figure 17 Connecting

Support Brackets

b Install four screws (two per side) to secure the support brackets

to the SuperLoader brackets (see figure 17

Support bracket

SuperLoader

bracket

Screws

).

7 Verify that the SuperLoader is level. Adjust as needed.

SuperLoader User’s Guide 25

Page 52

Chapter 2 Installation and Configuration

Making the SCSI Connection

8 When the SuperLoader is level, tighten all screws securing the

SuperLoader to the rack. This includes the following:

• Four screws securing the SuperLoader tabs to the front rails.

• Four screws securing the support brackets to the rear rails.

• Four screws securing the SuperLoader brackets to the support

brackets.

Making the SCSI Connection 2

The SCSI connection allows the host computer to communicate with the

SuperLoader.

Note: You must have already installed a SCSI host adapter card in

the host computer. The adapter card must be LVD or SE

compatible.

Before you start, make sure that your cable is long enough to reach from

the SuperLoader to the host computer. Remember, the SCSI bus

maximum length is 39.37 ft. (12 m) including all SCSI bus lengths within

the SuperLoader. The SCSI bus lengths are 16 in. (406.4 mm) per

SuperLoader DLT/SDLT or 23.5 in. (596.9 mm) per SuperLoader LTO.

Caution: When installing cables, be careful not to damage the SCSI

pins on the connectors. Damaged pins will cause the

connection to fail.

To Make the SCSI Connection: 2

1 If the host computer is connected to a network, check with the system

administrator before turning off power.

2 Properly power off all peripheral devices connected to the host

computer.

3 Power off the host computer and any peripheral devices.

26 SuperLoader User’s Guide

Page 53

Figure 18 Making the

SCSI Connection

Chapter 2 Installation and Configuration

Making the SCSI Connection

4 Install the supplied VHDCI SCSI cable to the double-stacked SCSI

connector on the back of the SuperLoader/DCA and tighten the

screws. You can install the SCSI cable in either port.

Double-stacked SCSI connector

(SuperLoader DLT)

Note: Notice that the connector on the end of the cable is offset.

5 If the SuperLoader is the last device on the SCSI bus, install the

supplied SCSI terminator to the remaining port that is on the

SuperLoader/DCA, and then tighten the screws.

Note: On all SuperLoaders, SCSI terminators must be used for