Page 1

ACL 4/52 Automated Tape Library

for DLT Cartridges

Software Interface Guide

6211225-03

Version 3.0

Page 2

Page 3

6211225-03, Version 3.0, October 25, 1996, Made in USA.

© Copyright 1996, ATL Products, Inc. All rights reserved.

Your right to copy this manual is limited by copyright law. Making copies or adaptations without prior written authorization of

ATL Products, Inc. is prohibited by law and constitutes a punishable violation of the law.

ATL Products, Inc. provides this publication “as is” without warranty of any kind, either express or implied, including but not

limited to the implied warranties of merchantability or fitness for a particular purpose. ATL Products, Inc. may revise this

publication from time to time without notice.

FCC STATEMENT

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated

in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful interference to radio communications.

Any changes or modifications made to this equipment may void the user's authority to operate this equipment.

Operation of this equipment in a residential area may cause interference in which case the user at his own expense will be

required to take whatever measures may be required to correct the interference.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following conditions: (1) this device may not

cause harmful interference, and (2) this device must accept any interference received, including interference that may cause

undesired operation.

CISPR-22 WARNING!

This is a Class A product. In a domestic environment this product may cause radio interference in which case the user may be

required to take adequate measures.

ACHTUNG!

Dieses ist ein Gerät der Funkstörgrenzwertklasse A. In Wohnbereichen können bei Betrieb dieses Gerätes Rundfunkstörungen

auftreten, in welchen Fällen der Benutzer für entsprechende Gegenmassnahmen verantwortlich ist.

ATTENTION!

Ceci est un produit de classe A. Dans un environment domestique, ce produit peat causer des interférences radio lectriques. Il

appartienl alors a l'utilisateur de prendre les mesures appropriées.

NOTICE FOR USA AND CANADA ONLY

If shipped to USA, use the UL LISTED power cord specified below for 100-120 V operation. If shipped to CANADA, use the

CSA CERTIFIED power cord specified below for 100-120V operation.

Plug Cap Parallel blade with ground pin (NEMA 5-15P Configuration)

Cord Type: SJT, three 16 or 18 AWG wires

Length Maximum 15 feet

Rating Minimum 10 A, 125 V

LIRE LA REMARQUE DANS LE MODE D'EMPLOI

ATTENTION

Page 4

REMARQUE

CETTE REMARQUE NE CONCERNE QUE LES ÉTATS-UNIS ET LE CANADA.

En cas d'envoi aux États-Unis, utiliser le cordon d'alimentation certifié UL et convenant pour 100-120 V.

En cas d'envoi au CANADA, utiliser le cordon d'alimentation CERTIFIÉ CSA et convenant pour 100-120 V.

Fiche Broches paralléus avec une broche de mise à la terre (configuration NEMA 5-15P)

Cordon Type: SJT, trifilaire 16 ou 18 AWG

Longeur Maximum 15 pieds

Capacité Minimum 10 A, 125 V

ZU IHRER SICHERHEIT

Vorsicht

Um Feuergefahr und die Gefahr eines elektrischen Schlages zu vermeiden. darf das Gerät weder Regen noch Feuchtigkeit

ausgesetzt werden.

Um einen elektrischen Schlag zu vormeiden, darf das Gehäuse nicht geöffnet werden. Überlassen Sie Wartungsarbeiten stets

nur einem Fachmann.

Achtung

Da der interne Laserstrahl in lhre Augen eindringen und Verletzungen verursachen kann, darf das Gehäuse nicht selbst geöffnet

werden. Überlassen Sie Wartungearbeiten stets nur einem Fachmann.

Die Verwendung von Brillen, Kontaktlinsen usw.vergrössert die Gefahr.

Zur besonderen Beachtung

Zur Sicherheit

Sollte ein fester Gegenstand oder Flüssigkeit in das Geräteinnere gelangen, trennen Sie das Gerät von der Wandsteckdose ab und

lassen Sie es von einem Fachmann überprufen, bevor Sie es weiter verwenden.

Zum Abziehen des Kabels fassen Sie stets am Stecker und niemals am Kabel selbst an.

Zur Aufstellung

Stellen Sie das Gerät weder auf einer weichen Unterlage (z. B. Decke, T eppich) noch in der Nahe von Vorhangen, Tapeten usw,

auf, da hierdurch die Ventilationsöffnungen blockiert werden können.

Zur Reiningung

Verwenden Sie zur Reiningung des Gehäuses, des Bedienungspultes und der Bedienungselemente ein trockenes, weiches Tuch

oder ein weiches, leicht mit mildem Haushaltsreiniger angefeuchtetes Tuch. Lösemittel wie Alkohol oder Benzin dürfen nicht

verwendet werden, da diese die Gehäuseoberfläche ungreifen.

Page 5

Table of Contents

Introduction

Purpose.......................................................................................................................1-3

Conventions Used in this Guide ................................................................................1-3

Related Documentation..............................................................................................1-4

ATL Products Technical Publications.................................................................1-5

ATL Products BBS..............................................................................................1-5

ATL Products Internet Web Site.........................................................................1-5

Theory of Operation

Chapter Overview......................................................................................................2-3

Library Description....................................................................................................2-3

SCSI Implementation Philosophy..............................................................................2-4

Medium Changer Elements........................................................................................2-4

Medium Transport Element.................................................................................2-5

Storage Elements.................................................................................................2-5

Import/Export (Load Port) Elements...................................................................2-5

Data Transfer Elements.......................................................................................2-5

Events.........................................................................................................................2-6

Power Cycle ........................................................................................................2-7

Library Unit Off-line/Standby.............................................................................2-7

Library Unit On-line Initialization Failure..........................................................2-7

Library Unit Door Opened..................................................................................2-7

Library Unit Stopped...........................................................................................2-7

Accessed Load Port.............................................................................................2-7

Maximum Temperature Exceeded ......................................................................2-7

Operational Sequences........................................................................................2-8

Power-On Sequence......................................................................................2-8

Door Opened Sequence ................................................................................2-8

System Stopped Sequence............................................................................2-9

On-line Initialization Sequence ....................................................................2-9

Library Unit Inventory Sequence ...............................................................2-10

Off-line Sequence.......................................................................................2-11

Automatic Drive Cleaning Sequence..........................................................2-11

Configuration Procedures ........................................................................................2-12

“DIAG” Interface..............................................................................................2-12

ACL 4/52 Software Interface Guide

Document 6211225-03

Version 3.0

Table of Contents v

Page 6

ACL 4/52 Software Interface Guide

Document 6211225-03

Version 3.0

Control Panel Menu Mode ............................................................................... 2-13

Error Recovery Procedures..................................................................................... 2-14

Internal Error Recovery.................................................................................... 2-14

Operator Recovery............................................................................................ 2-14

System Performance ............................................................................................... 2-15

Key Performance Items.................................................................................... 2-15

Typical Application Enhancements.................................................................. 2-15

System Diagnostic Support..................................................................................... 2-16

Host Interface Diagnostic Error Codes............................................................. 2-16

Off-line Diagnostics via the “DIAG” Port ....................................................... 2-16

Software Interfaces

Chapter Overview ..................................................................................................... 3-3

SCSI Interface........................................................................................................... 3-3

Reset Sequence................................................................................................... 3-4

Supported Messages........................................................................................... 3-4

Abort ............................................................................................................ 3-5

Bus Device Reset......................................................................................... 3-5

Command Complete .................................................................................... 3-5

Disconnect (from Target to Initiator)........................................................... 3-5

Identify (Initiator to Target)......................................................................... 3-6

Identify (Target to Initiator)......................................................................... 3-6

Save Data Pointer......................................................................................... 3-6

Supported Operational Commands..................................................................... 3-7

Initialize Element Status (07h)..................................................................... 3-9

Initialize Element Status with Range (E7h)............................................... 3-10

Inquiry (12h).............................................................................................. 3-12

Log Sense Command (4Dh)....................................................................... 3-15

Mode Select Command (15h).................................................................... 3-19

Mode Sense (1Ah) ..................................................................................... 3-25

Move Medium (A5h)................................................................................. 3-35

Position To Element (2Bh) ........................................................................ 3-37

Prevent/Allow Medium Removal (1Eh).................................................... 3-38

Read Element Status (B8h)........................................................................ 3-40

Ready Inport (DEh).................................................................................... 3-53

Release (17h) ............................................................................................. 3-54

Reserve (16h)............................................................................................. 3-55

Request Sense (03h)................................................................................... 3-58

Request Volume Element Address (B5h).................................................. 3-61

Rezero Unit (01h) ...................................................................................... 3-75

Send Diagnostic (1Dh)............................................................................... 3-76

vi Table of Contents

Page 7

ACL 4/52 Software Interface Guide

Document 6211225-03

Send Volume Tag (B6h)............................................................................ 3-78

Test Unit Ready (00h)................................................................................ 3-80

Sense Data Values

Introduction...............................................................................................................A-1

Control Panel Messages

Introduction...............................................................................................................B-1

System States ............................................................................................................B-2

Operator Messages....................................................................................................B-4

Menu Mode Messages ..............................................................................................B-5

Automatic Drive Cleaning Discussion

Purpose and Scope ....................................................................................................C-3

Drive Cleaning Modes ..............................................................................................C-3

Host Initiated Cleaning Mode ............................................................................C-3

Fully Automatic Cleaning Mode........................................................................C-3

Selection of Cleaning Mode......................................................................................C-4

Diagnostic Software ...........................................................................................C-4

Control Panel......................................................................................................C-4

Mode Select Command (Host Initiated).............................................................C-4

Reporting of Cleaning Mode.....................................................................................C-5

Diagnostic Software ...........................................................................................C-5

Mode Sense Command (Host Initiated) .............................................................C-5

Cleaning Cartridges...................................................................................................C-5

Capacity..............................................................................................................C-5

Identification.......................................................................................................C-6

Storage and Tracking..........................................................................................C-6

Monitoring Usage...............................................................................................C-7

Element Status Information................................................................................C-7

Monitoring Drives.....................................................................................................C-8

Drive Interface....................................................................................................C-8

Drive Monitoring................................................................................................C-8

Initiating Drive Cleaning Operations........................................................................C-8

Selection of Cleaning Cartridges ..............................................................................C-9

Media Movement to the Drive..................................................................................C-9

Supervising the Drive Cleaning Operation.............................................................C-10

Media Movement from the Drive ...........................................................................C-10

Unloading Cleaning Cartridges...............................................................................C-11

Version 3.0

Table of Contents vii

Page 8

ACL 4/52 Software Interface Guide

Document 6211225-03

Version 3.0

Exabyte EXB-120 Emulation Discussion

Purpose and Scope ....................................................................................................D-3

Host Interface Modes................................................................................................D-3

Standard Interface Mode ....................................................................................D-3

Exabyte EXB-120 Interface Mode.....................................................................D-3

Selection of Host Interface Mode .............................................................................D-4

Diagnostic Software ...........................................................................................D-4

Control Panel......................................................................................................D-4

Mode Select Command (Host Initiated).............................................................D-4

Reporting of Host Interface Mode ............................................................................D-5

Diagnostic Software ...........................................................................................D-5

Mode Sense Command (Host Initiated) .............................................................D-5

SCSI Command Differences.....................................................................................D-6

Inquiry (12h).......................................................................................................D-6

Move Medium (A5h)..........................................................................................D-6

Read Element Status (B8h) ................................................................................D-6

Receive Diagnostic Results (1Ch)......................................................................D-7

Request Sense (03h) ...........................................................................................D-7

Send Diagnostic (1Dh) .......................................................................................D-7

Write Firmware (C1h)........................................................................................D-7

Unsolicited Message Differences.......................................................................D-7

Exabyte Emulation Design Philosophy.....................................................................D-8

Glossary

Index

viii Table of Contents

Page 9

List of Figures

Figure 1: Control Panel .........................................................................................2-6

Figure 2: Read Element Status Data General Structure ......................................3-42

Figure 3: Request Volume Element Address Data General Structure ................3-63

ACL 4/52 Software Interface Guide

Document 6211225-03

Version 3.0

List of Figures ix

Page 10

x

Page 11

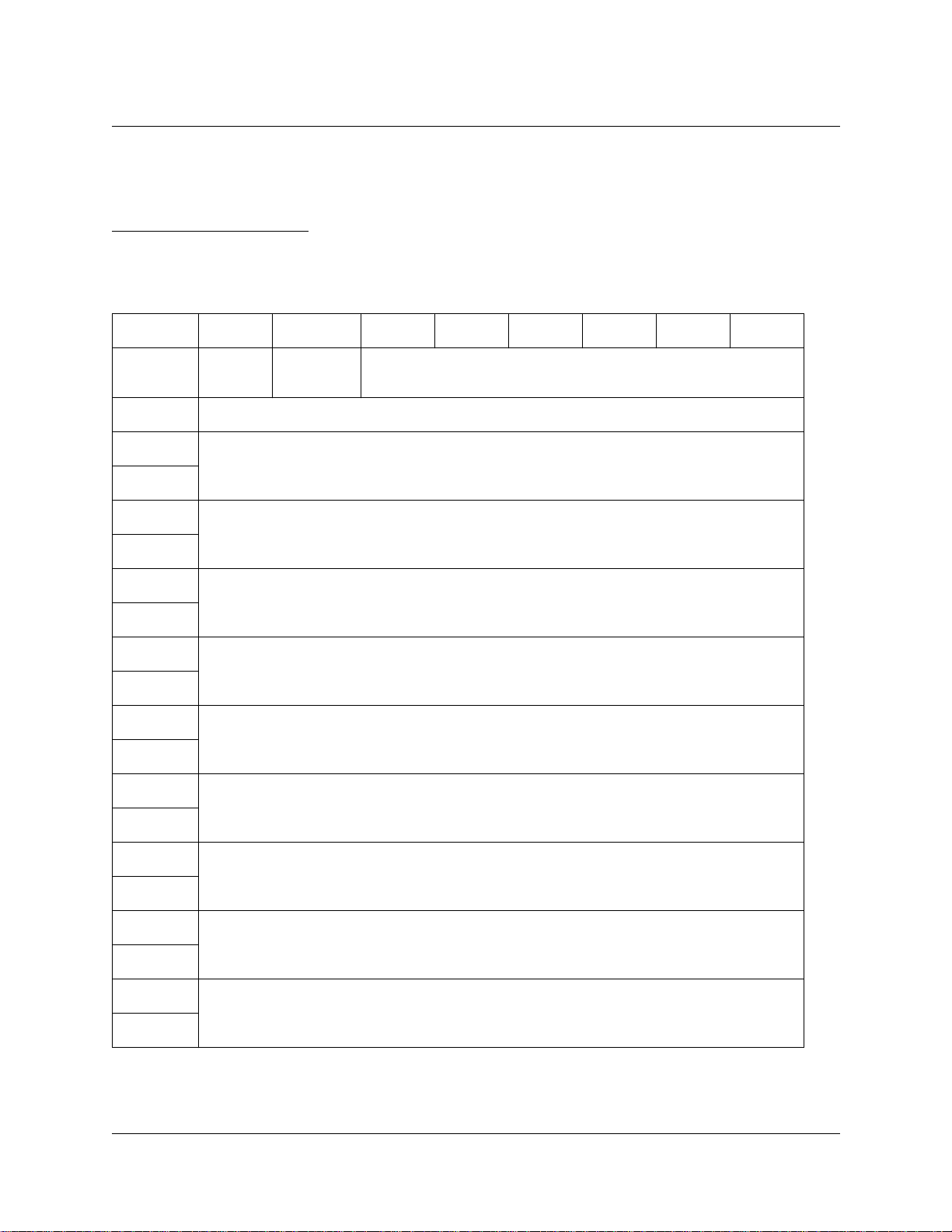

List of Tables

Table 1: Related Documentation .......................................................................... 1-4

Table 2: Supported Operational Commands......................................................... 3-8

Table 3: Initialize Element Status Cmd................................................................ 3-9

Table 4: Initialize Element Status with Range Command.................................. 3-10

Table 5: Inquiry Command................................................................................. 3-12

Table 6: Standard Inquiry Data........................................................................... 3-13

Table 7: Log Sense Command............................................................................ 3-15

Table 8: Supported Log Pages............................................................................ 3-16

Table 9: Medium Changer Statistics Page.......................................................... 3-17

Table 10: Log Parameter....................................................................................... 3-17

Table 11: Supported Log Parameter Codes.......................................................... 3-18

Table 12: Mode Select Command ........................................................................ 3-19

Table 13: Mode Select Data - Vendor Unique Page 20h...................................... 3-20

Table 14: Mode Select Data - Vendor Unique Page 00h...................................... 3-21

Table 15: Mode Select Data - Element Address Assignment Page...................... 3-23

Table 16: Mode Sense Command......................................................................... 3-25

Table 17: Mode Sense Data Header ..................................................................... 3-27

Table 18: Mode Sense Data - Vendor Unique Page 00h...................................... 3-28

Table 19: Mode Sense Data - Element Address Assignment Page ...................... 3-30

Table 20: Mode Sense Data - Transport Geometry Parameters Page................... 3-32

Table 21: Mode Sense Data - Device Capabilities Data....................................... 3-33

Table 22: Mode Sense Data - Vendor Unique Page 20h...................................... 3-34

Table 23: Move Medium Command..................................................................... 3-36

Table 24: Position To Element Command............................................................ 3-37

Table 25: Prevent/Allow Medium Removal Command....................................... 3-39

Table 26: Read Element Status Command........................................................... 3-40

Table 27: Element Status Data.............................................................................. 3-43

Table 28: Element Status Page ............................................................................. 3-44

Table 29: Medium Transport Element Descriptor................................................ 3-45

Table 30: Primary Volume Tag Information........................................................ 3-46

Table 31: Storage Element Descriptor.................................................................. 3-47

Table 32: Import/Export Element Descriptor....................................................... 3-49

Table 33: Data Transfer Element Descriptor........................................................ 3-51

ACL 4/52 Software Interface Guide

Document 6211225-03

Version 3.0

List of Tables xi

Page 12

ACL 4/52 Software Interface Guide

Document 6211225-03

Version 3.0

Table 34: Ready Inport Command....................................................................... 3-53

Table 35: Release Command ............................................................................... 3-54

Table 36: Reserve Command............................................................................... 3-56

Table 37: Element List Descriptor....................................................................... 3-57

Table 38: Request Sense Command .................................................................... 3-58

Table 39: Request Sense Data.............................................................................. 3-59

Table 40: Request Volume Element Address Command .................................... 3-61

Table 41: Volume Element Address Header ....................................................... 3-64

Table 42: Element Status Page ............................................................................ 3-65

Table 43: Medium Transport Element Descriptor............................................... 3-66

Table 44: Primary Volume Tag Information ....................................................... 3-68

Table 45: Storage Element Descriptor................................................................. 3-68

Table 46: Import/Export Element Descriptor ...................................................... 3-71

Table 47: Data Transfer Element Descriptor....................................................... 3-73

Table 48: Rezero Unit Command ........................................................................ 3-75

Table 49: Send Diagnostic Command ................................................................. 3-76

Table 50: Selftest Bit Definitions ........................................................................ 3-77

Table 51: Send Volume Tag Command............................................................... 3-78

Table 52: Send Volume Tag Parameters ............................................................. 3-79

Table 53: Test Unit Ready Command ................................................................. 3-80

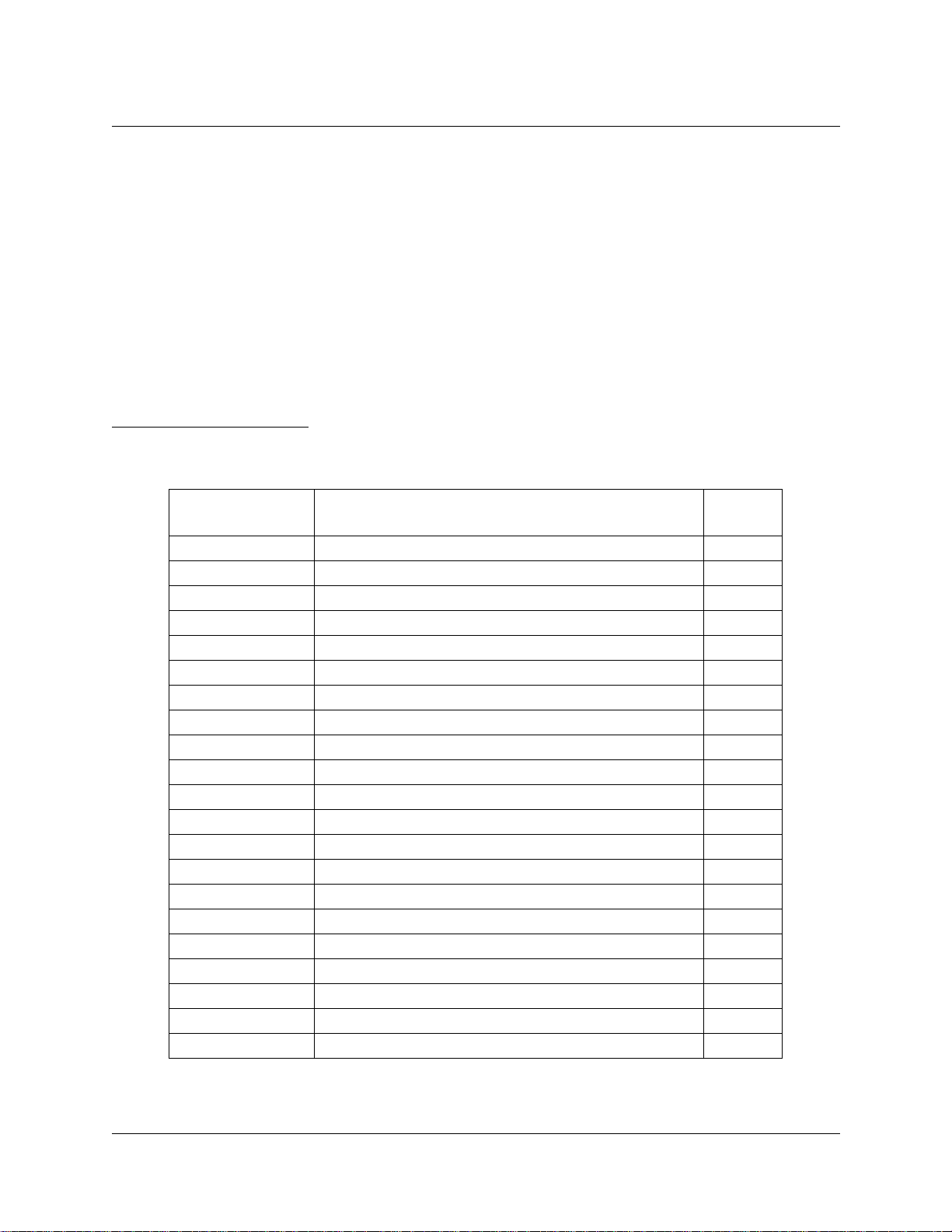

Table A-1: Sense Data Values (Hexadecimal)......................................................... A-2

Table B-1: System States......................................................................................... B-2

Table B-2: Operator Messages................................................................................. B-4

xii List of Tables

Page 13

ACL 4/52 Software Interface Guide

Document 6211225-03

Version 3.0

Introduction

Purpose...................................................................................................................... 1-3

Conventions Used in this Guide................................................................................ 1-3

Related Documentation............................................................................................. 1-4

ATL Products Technical Publications................................................................ 1-5

ATL Products BBS............................................................................................. 1-5

ATL Products Internet Web Site........................................................................ 1-5

1

1-1

Page 14

1-2

Page 15

Purpose

ACL 4/52 Software Interface Guide

Document 6211225-03

Version 3.0

This guide was written for software engineers developing the

application and hierarchical mass storage software that accesses the

ACL 4/52 Automated T ape Library (library). The manual describes the

SCSI-2 software interfaces, discusses performance issues as well as

error handling. The document is divided into the following sections:

• Section 1, “Introduction,” describes the purpose of this manual,

provides a list of its contents and a list of related documentation.

• Section 2, “Theory of Operation,” contains detailed discussions of

the Medium Changer Elements, Events, Operational Sequences,

Configuration and Error Recovery Procedures as well as System

Performance and Diagnostic Support issues.

• Section 3, “Softwar e Interfaces,” describes the specific terminology

of the Small Computer Systems Interface (SCSI-2).

Conventions Used in this Guide

The following conventions are used in this guide:

All binary numbers are succeeded by “b”.

All hexadecimal numbers are succeeded by “h”.

Error or attention conditions are represented in parenthesis that

translate as follows:

(SK=S ASC=AA ASCQ=QQ)

where:

S = hexadecimal sense key value

AA = hexadecimal additional sense code

QQ = hexadecimal additional sense code qualifier

Definitions of these values are located in Appendix A.

Purpose 1-3

Page 16

ACL 4/52 Software Interface Guide

Document 6211225-03

Version 3.0

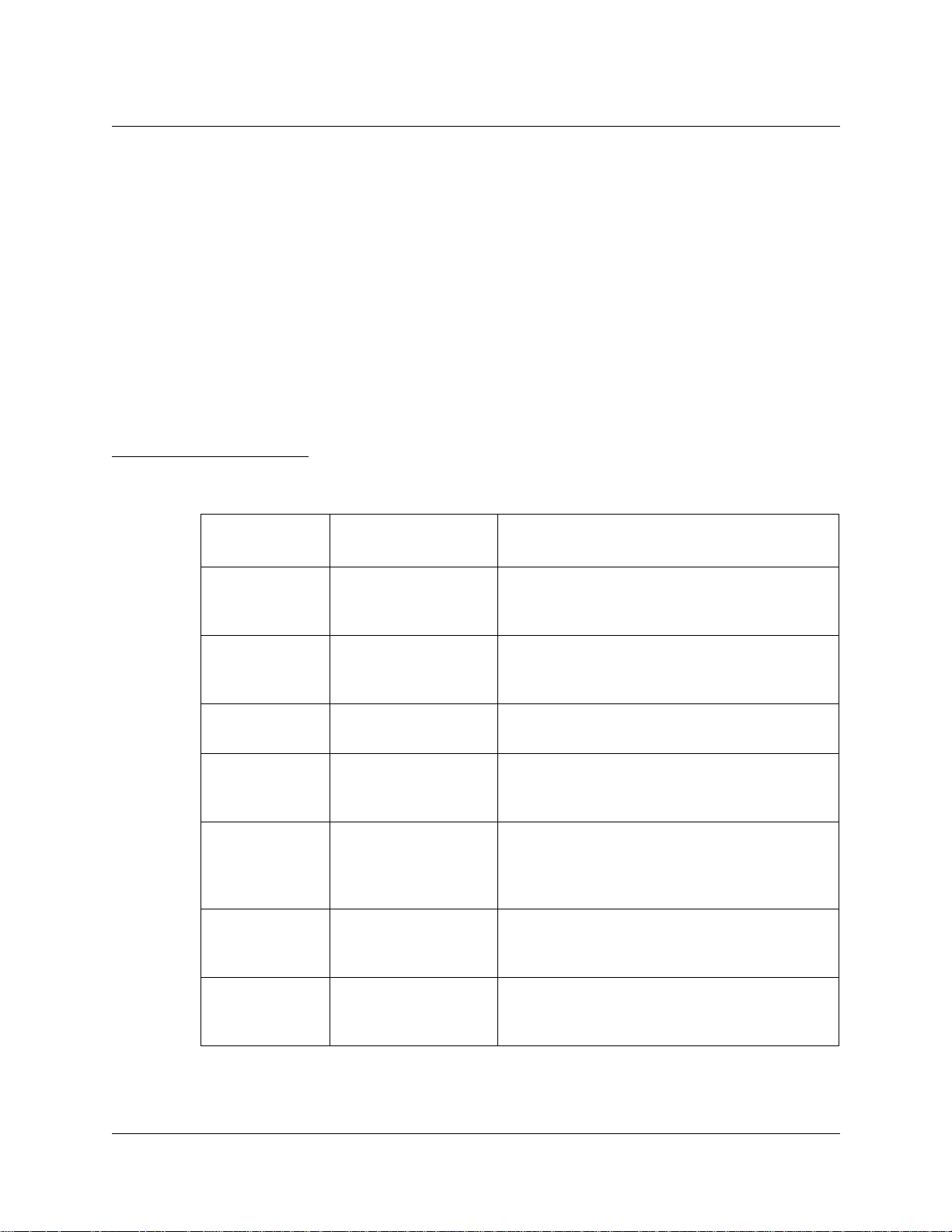

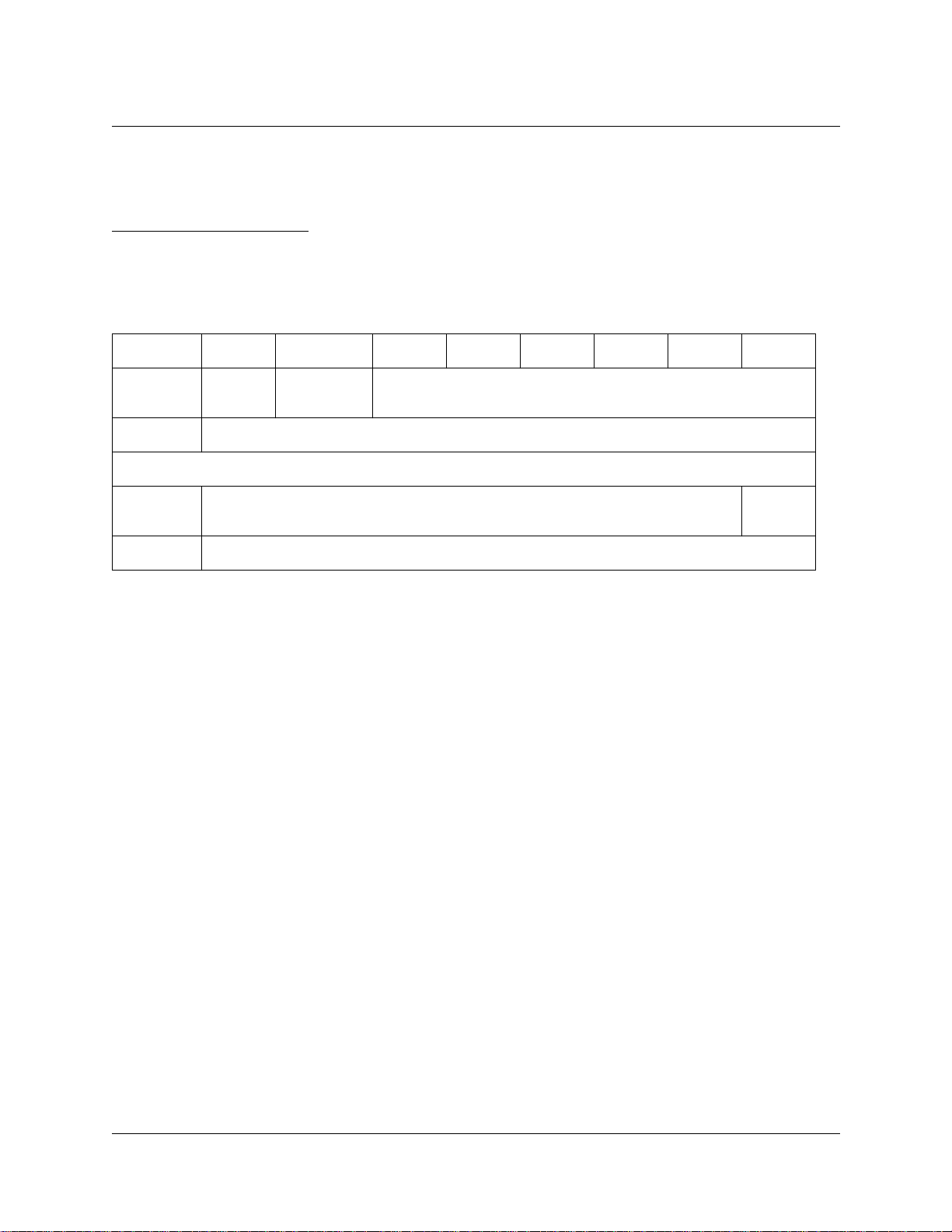

Related Documentation

Table 1 is a list of all manuals associated with the ACL 4/52

Automated Tape Library. To obtain further information and/or copies

of documentation on this product, contact:

ATL Products, Inc.

1515 South Manchester Avenue

Anaheim, California 92802-2907

(714)774-6900

The part number of each document will be required at the time of

order.

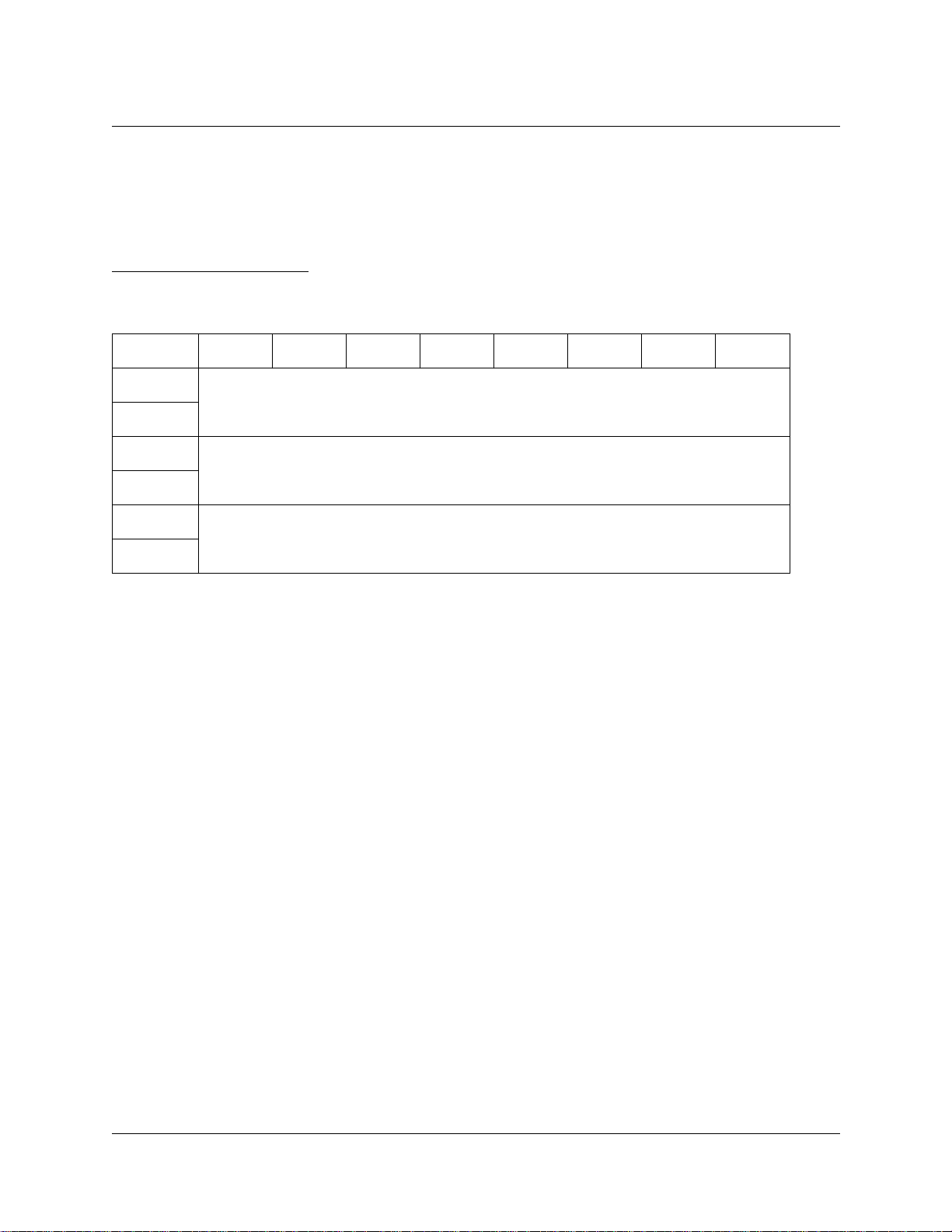

Table 1: Related Documentation

Document

Number

6211221 ACL 4/52 Facilities

6211222 ACL 4/52 Operator’s

6211223 ACL 4/52 Field Service

6211224 ACL 4/52 Diagnostic

EK-TH4XX-1M DLT™2000 Series

81-108336-01 DLT™4000 Cartridge

Document Title Document Description

Planning and

Installation Guide

Guide

Manual

Software User’s

Manual

Cartridge Tape

Subsystem Owner’s

Manual

Tape Drive Product

Manual

This guide describes facility preparation and

provides the procedures for first-time installation of

the library.

This guide describes the operator accessible

components of the library and provides both

operating and troubleshooting procedures.

This document contains periodic maintenance, fault

isolation and removal/replacement procedures.

This manual provides procedures for installing and

using the ACL 4/52 Diagnostic Software.

This document describes the DLT™2000 Tape

Drive and provides operating instructions and

troubleshooting procedures.

This document describes the DLT™4000 Tape

Drive and provides operating instructions and

troubleshooting procedures.

81-60000-01 DLT™7000 Tape

Drive Product Manual

1-4 Related Documentation

This document describes the DLT™7000 Tape

Drive and provides operating instructions and

troubleshooting procedures.

Page 17

ATL Products Technical Publications

Comments or questions regarding this or any ATL Products’

documentation can be directed to the address listed on page 1-4 or by

sending email directly to the ATL Products, Inc. technical publications

group. Send all documentation related email comments and questions

to:

atl-docs@odetics.com

ATL Products BBS

The ATL Products, Inc. Bulletin Board Service (BBS) provides a

customer service conference, product support conference,

documentation conference and public-domain software conference.

product manuals, utility software, firmware updates, and other

product information may be obtained in soft copy. BBS. The BBS is

available 24 hours a day, 7 days a week at 714-780-7736.

ACL 4/52 Software Interface Guide

Document 6211225-03

Version 3.0

Modem settings for the ATL BBS are:

• 8 bits, 1 stop bit, no parity.

• support for up to 28.8 Kbps.

• modems that are also capable of V.34, V.FC

TM

V.32 bis

.

ATL Products Internet Web Site

If you are on the Internet, you may prefer to access our home page.

Documents, utility software, firmware updates, and product

information may be obtained in soft copy. You will also find Sales &

Marketing contacts along with e-mail address for customer

information and feedback. A TL Products, Inc. can be reached 24 hours

a day, 7 days a week on the internet at:

http://www.atlp.com/

TM

, V.32 terboTM, and

Related Documentation 1-5

Page 18

1-6

Page 19

ACL 4/52 Software Interface Guide

Document 6211225-03

Version 3.0

Theory of Operation

Chapter Overview.................................................................................................. 2-3

Library Description ................................................................................................2-3

SCSI Implementation Philosophy ........................................................................2-4

Medium Changer Elements...................................................................................2-4

Medium Transport Element............................................................................2-5

Storage Elements .............................................................................................2-5

Import/Export (Load Port) Elements ...........................................................2-5

Data Transfer Elements ..................................................................................2-5

Events........................................................................................................................2-6

Power Cycle ......................................................................................................2-7

Library Unit Off-line/Standby.......................................................................2-7

Library Unit On-line Initialization Failure ...................................................2-7

Library Unit Door Opened .............................................................................2-7

Library Unit Stopped.......................................................................................2-7

Accessed Load Port..........................................................................................2-7

Maximum Temperature Exceeded.................................................................2-7

Operational Sequences ....................................................................................2-8

Power-On Sequence...................................................................................2-8

Door Opened Sequence.............................................................................2-8

System Stopped Sequence ........................................................................2-9

On-line Initialization Sequence................................................................2-9

Library Unit Inventory Sequence..........................................................2-10

Off-line Sequence ....................................................................................2-11

Automatic Drive Cleaning Sequence....................................................2-11

Configuration Procedures....................................................................................2-12

“DIAG” Interface............................................................................................2-12

2

2-1

Page 20

ACL 4/52 Software Interface Guide

Document 6211225-03

Version 3.0

Control Panel Menu Mode........................................................................... 2-13

Error Recovery Procedures................................................................................. 2-14

Internal Error Recovery ................................................................................ 2-14

Operator Recovery ........................................................................................ 2-14

System Performance ............................................................................................ 2-15

Key Performance Items................................................................................. 2-15

Typical Application Enhancements............................................................ 2-15

System Diagnostic Support................................................................................. 2-16

Host Interface Diagnostic Error Codes....................................................... 2-16

Off-line Diagnostics via the “DIAG” Port.................................................. 2-16

2-2

Page 21

Chapter Overview

This chapter contains detailed discussions of the Medium Changer

Elements, Events, Operational Sequences, Configuration and Error

Recovery Procedures as well as System Performance and Diagnostic

Support issues.

Library Description

The ACL 4/52 library is the automated storage and retrieval

component of an automated tape library system. It is capable of

storing a maximum of 48 Digital Linear Tapes (DLT™) in a Fixed

Storage Array (FSA) within the library cabinet. An operator accessible

Load Port at the front of the cabinet can hold an additional four

DLT™s for a total of 52. A host computer communicates with the

library via a SCSI interface. The host controls the robotic equipment

using the SCSI-2 Medium Changer Command Set.

ACL 4/52 Software Interface Guide

Document 6211225-03

Version 3.0

In a typical operation, the host commands the robotics to transfer

DL T™s between storage bins (in the FSA), one of the four (DLT™2000,

DLT™4000, or DLT™7000) tape drives or the Load Port. Each time a

DLT™ is transferred, a gripping mechanism is moved to the DLT™s

location where it “picks” the tape, moves it to the designated (new)

location and then “places” it.

The library has fully functional media changer capability as defined by

the SCSI-2 specification. The library robotics control is directed by the

host computer. The SCSI interface enables the robotics to be driven by

the same SCSI bus as the tape drives. By providing a standard control

interface and supporting standard tape drives, the ACL 4/52 enables

host software developers to adapt their software to drive the ACL

4/52.

The ACL 4/52 has a minimal connection to any installed tape drives.

The library knows the number of drives installed and the SCSI

addresses for the tape drives. The library does not know if the drives

are on the same SCSI bus or not. This information is only relevant to

the host computer.

Chapter Overview 2-3

Page 22

ACL 4/52 Software Interface Guide

Document 6211225-03

Version 3.0

SCSI Implementation Philosophy

Using the SCSI-2 standard, the tape library has been designed so that

the host can adapt to changes in the tape library configuration.

Changes in the number of tape drives can be detected by the host.

The tape library uses the SCSI-2 Medium Changer Command Set. No

attempt is made to add complex commands to the tape library

command set. The tape library command set is complete and includes

all primitive (elemental) commands required by a host to carry out any

required complex operations.

Even though the tape library relies on the host computer to issue a

sequence of elemental commands in the correct order to complete

complex operations, it has been designed to be forgiving of system

integration errors. The tape library monitors the status of all

mechanisms and does not execute operations that could result in

damage to the library or an installed tape drive.

Medium Changer Elements

The Medium Changer Command Set accesses the address space for

the set of physical locations and mechanisms within the library unit.

The SCSI-2 term “element” is used throughout this document to refer

to one member of the tape library address space. Each “element” is a

discrete physical entity that can hold a DLT™ cartridge.

Each element within a library is represented by a unique 16 bit element

address. Each library consists of the following medium changer

elements:

• Medium Transport Element

• Storage Elements

• Data Transfer Elements

• Import/Export Elements

The Mode Sense Command can be issued to determine each library’s

configuration. The first address and number of elements for each type

(medium transport, storage, import/export or data transfer) can also

be determined using this command.

2-4 SCSI Implementation Philosophy

Page 23

Medium Transport Element

The library has a transport mechanism. This mechanism consists of the

horizontal, vertical and extension axes and a gripper.

The transport mechanism can hold a single cartridge using the gripper

and is considered one medium transport element. The transport

mechanism is used to move media between elements within the

library unit.

Storage Elements

Each library unit contains up to 48 storage elements, which correspond

to the bins in the FSA. One storage element exists per bin.

Import/Export (Load Port) Elements

ACL 4/52 Software Interface Guide

Document 6211225-03

Version 3.0

The import/export mechanism consists of a four-bin, rotating Load

Port. Each of the four bins in the Load Port has a unique element

address.

When the door is open the elements still exist, but are not “accessible”

to the medium transport.

Data Transfer Elements

A data transfer element is associated with every tape drive installed in

a library unit since each tape drive can store a single tape cartridge.

The medium transport mechanism is able to load or unload tape

cartridges into or from each tape drive.

Medium Changer Elements 2-5

Page 24

ACL 4/52 Software Interface Guide

Document 6211225-03

Version 3.0

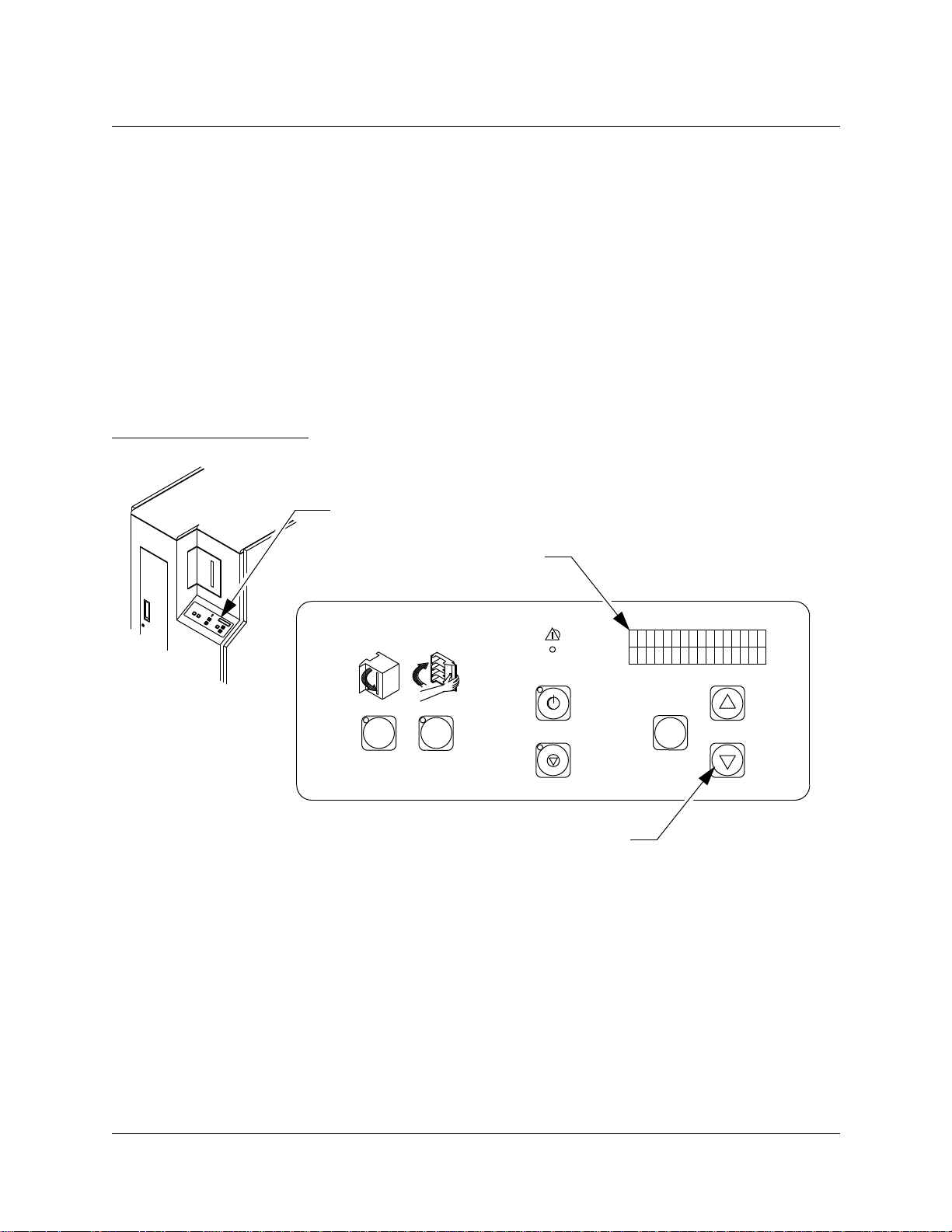

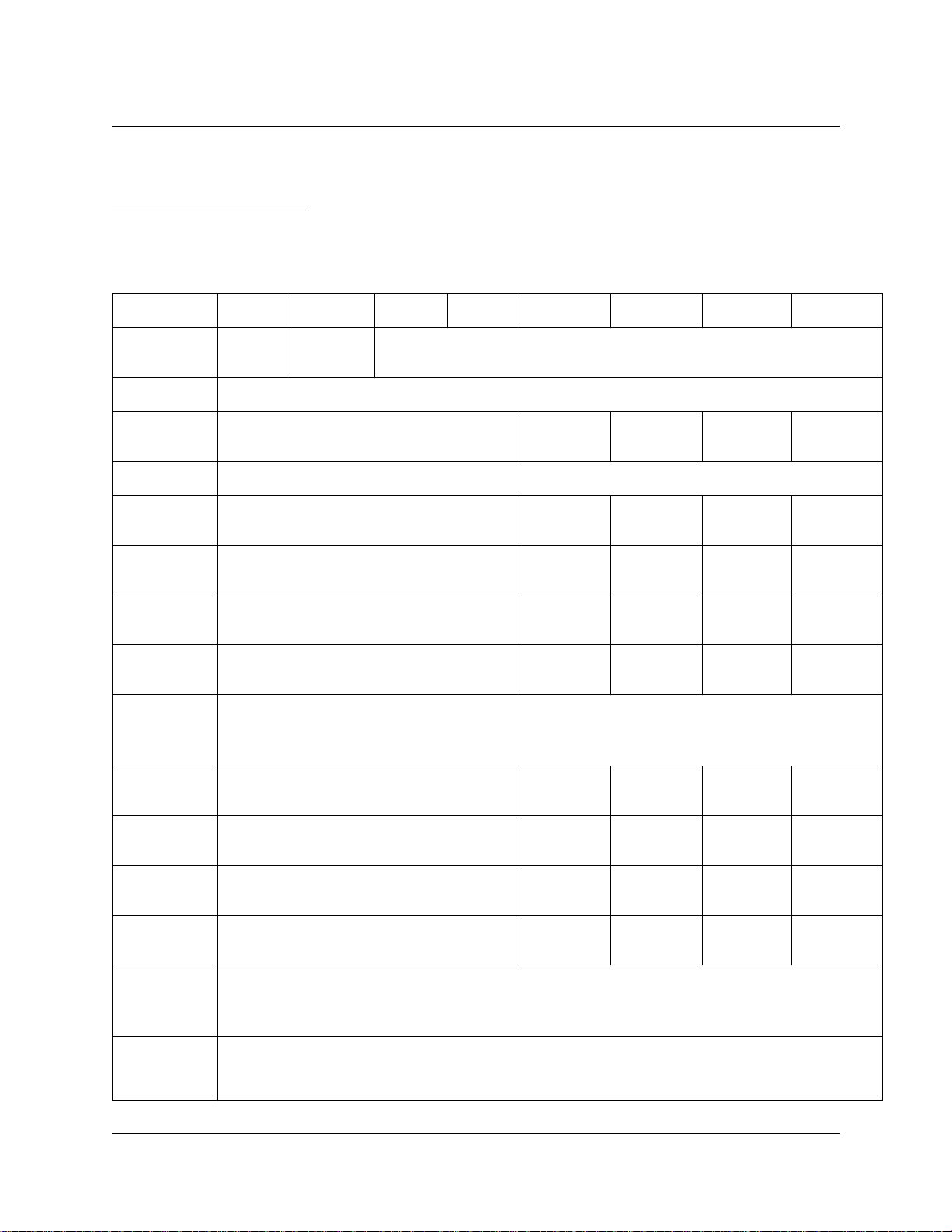

Events

Events are system conditions created by failures or operator actions

such as opening the door or pressing the STOP switch.

Some of these events appear as states on the control panel. For a list of

event states, see Appendix B. (The control panel does not queue these

states.)

Events are recorded in sense data. Depending on the interface, the host

can obtain the sense data either in response to a Request Sense

Command or as an Unsolicited Message.

Figure 1: Control Panel

Control Panel

Status Display Area

(16 Characters/2 Lines)

FAULT

STANDBY

OPEN CLOSE

STOP

Scrolling Buttons

(Up {↑} and Down{↓})

SELECT

TA00003b/15b

The library does not support asynchronous event notification. This

simplifies the host/library interface and is acceptable since the events

happen infrequently and do not require an immediate host response.

The SCSI host can check for library events by issuing the Request

Sense command to the library. The event sense data is transmitted in

response to a Request Sense command. The library queues event

conditions for the library. The host can repeatedly issue the Request

Sense command to obtain each queued condition.

The most significant events are described in the sections that follow.

2-6 Events

Page 25

Power Cycle

When the library is powered on it generates a “Power On/Reset

Occurred” event (SK=6 ASC=29 ASCQ=00).

Library Unit Off-line/Standby

When a library is placed into the off-line/standby state, it generates a

“Logical Unit Standby Button Was Pressed” event (SK=6 ASC=80

ASCQ=09).

Library Unit On-line Initialization Failure

When a library is placed into the on-line state and the on-line

initialization fails, the library generates an event for the specific error

condition that caused the failure. The control panel indicates which

state of the initialization failed (see Appendix B for more information).

ACL 4/52 Software Interface Guide

Document 6211225-03

Version 3.0

Library Unit Door Opened

When the front door of a library is opened, the library disables all

actuators and generates a “Door Was Opened” event (SK=6 ASC=80

ASCQ=00).

Library Unit Stopped

When the library is stopped by pressing the STOP switch on the

control panel, the library disables all actuators and generates a

“System Stop Button Was Pressed” event (SK=6 ASC=80 ASCQ=07).

Accessed Load Port

When the Load Port door is closed, the library generates an “Import or

Export Element Accessed” event (SK=6 ASC=28 ASCQ=01).

Maximum Temperature Exceeded

The library monitors the ambient temperature within the system. If the

temperature exceeds 91.4

to the medium, the library generates a “Warning Safe Temperature

Exceeded” event (SK=6 ASC=88 ASCQ=00) and continues operations.

If the temperature exceeds 96.8

until the temperature decreases and generates a “Maximum

Temperature Exceeded” event (SK=4 ASC=88 ASCQ=01).

ο

F, there is a possibility for potential damage

ο

F, the library disables all actuators

Events 2-7

Page 26

ACL 4/52 Software Interface Guide

Document 6211225-03

Version 3.0

Operational Sequences

A description of operational sequences follow. They are listed in or der

of precedence. For example, if the door is opened and the STOP switch

was pressed, the door open sequence will override the system stop

sequence until it is complete.

Power-On Sequence

The following actions occur when the library is powered-on:

• The local controller for the library resets and initializes all

hardware.

• The control panel is blank.

• During this time, the library responds to the Inquiry, Request

Sense, Log Sense, and Mode Sense commands. Check Condition is

set for all other commands and the “Logical Unit is Not Ready”

condition (SK=2 ASC=04 ASCQ=00) is set in the sense data.

• When the power -on initialization is complete, the library generates

a “Power On/Reset Occurred” event (SK=6 ASC=29 ASCQ=00).

• The library sets the tape drive SCSI IDs and then resets the tape

drives

The system then moves into one of the following sequences depending

on the condition of the system.

Door Opened Sequence

Before entering the library, take the unit off-line. After the off-line

sequence is complete, it is recommended that you press the STOP

switch before opening the doors. When the door is opened, the library

is no longer operational (as viewed by the host). The following actions

occur when the door is opened:

• The control panel indicates that the door is opened.

• The library generates a “Door Was Opened” event (SK=6 ASC=80

ASCQ=00).

• If the door is opened without performing the of f-line sequence, the

system halts all library motion. Any motion command currently in

progress is aborted and Check Condition is returned to the host.

The “Door is Opened” condition (SK=2 ASC=80 ASCQ=00) is set

in the sense data.

2-8 Events

Page 27

ACL 4/52 Software Interface Guide

Document 6211225-03

Version 3.0

• While the door is opened, the library responds to the Inquiry,

Request Sense, Log Sense, and Mode Sense commands. Check

Condition is set for all other commands issued during this time

and the “Door is Opened” condition (SK=2 ASC=80 ASCQ=00) is

set in the sense data.

System Stopped Sequence

The STOP switch allows the operator to stop all power to the

actuators. The following actions occur when the system is stopped:

• The control panel indicates that the system is stopped.

• The library generates a “System Stop Button Was Pressed” event

(SK=6 ASC=80 ASCQ=07).

• The system halts all library motion. Any motion command

currently in progress is aborted and Check Condition status is

returned to host. The “System is Stopped” condition (SK=2

ASC=80 ASCQ=07) is set in the sense data.

• While the system is stopped, the library responds to the Inquiry,

Request Sense, Log Sense, and Mode Sense commands. Check

Condition status is set for all other commands issued during this

time, and the “System is Stopped” condition (SK=2 ASC=80

ASCQ=07) is set in the sense data.

On-line Initialization Sequence

The STANDBY switch allows the library to be placed on-line. The

on-line initialization sequence occurs only after the door is shut, the

system is not stopped and the library does not have the STANDBY

button pressed. The following actions occur during the on-line

initialization sequence:

• The control panel indicates that the library is performing the

on-line initialization sequence.

• The local controller for the library performs a test to check the

operation of the library unit mechanisms.

• The mechanisms are then homed.

• During this time, the library responds to the Inquiry, Request

Sense, Log Sense, and Mode Sense commands. Check Condition

status is set for all other commands, and the “Logical Unit in

Process of Becoming Ready” condition (SK=2 ASC=04 ASCQ=01)

is set in the sense data.

Events 2-9

Page 28

ACL 4/52 Software Interface Guide

Document 6211225-03

Version 3.0

• When the mechanisms are successfully tested and homed, the

library performs an inventory of its elements. (See Library Unit

Inventory Sequence).

• When initialization successfully completes, the control panel

changes to “System On-line” and the library is fully operational.

Library Unit Inventory Sequence

The library inventories its storage elements after power-up (if on-line),

upon receipt of an Initialize Element Status Command or after the

door is closed and the library is placed on-line.

• The local controller for the library checks the state of the medium

transport element (gripper). The inventory cannot be performed if

there is a DLT™ in the medium transport element. In this case, if

the inventory is host commanded, then Check Condition is set, and

the “Transfer Full” condition (SK=5 ASC=80 ASCQ=01) is set in

the sense data. Otherwise, the library generates a “Transfer Full”

(SK=5 ASC=80 ASCQ=01) on-line initialization failure event.

• If a tape drive handle is not closed, the gripper is extended to sense

the presence of a cartridge with the Cartridge-in-Gripper (CIG)

Sensor. If a cartridge is found, the gripper is used to push the

cartridge into the tape drive and the handle is closed. If no

cartridge is found, the tape drive handle is closed.

• If this is the first inventory since power-on, an inventory was

commanded using Initialize Element Status or an inventory was

initiated by opening and closing the front door , each element of the

FSA will be inventoried. Otherwise if an inventory was previously

commanded, only those elements who’s status is unknown will be

inventoried.

• First, the FSA is scanned for bar codes. If the library determines

that a bin contains an invalid bar code (or no bar code), it uses the

gripper to sense whether or not there is a DLT™ present.

• After the FSA is scanned, Load Port bins are scanned in the same

manner.

• An inventory is attempted for each tape drive present. If the

interface reports that a cartridge is present, the controller scans for

a valid bar code.

• The inventory time varies depending on the number of DLT™

cartridges with valid bar codes. A fully populated FSA with valid

bar codes takes much less time than a partially populated FSA.

2-10 Events

Page 29

ACL 4/52 Software Interface Guide

Document 6211225-03

Version 3.0

• Results of the inventory ar e returned with the Read Element Status

Command.

Off-line Sequence

The STANDBY switch allows the library to be taken off-line. The

off-line sequence can only occur when the door is shut, the system is

not stopped and the STANDBY button is pressed. When a library is

placed off-line, the following sequence is performed:

• The local controller for the library completes any currently

processing command. The STANDBY LED will flash during this

time.

• When all commands are complete, the control panel changes to

“System Off-line” and the STANDBY LED will become solid to

indicate that the unit is off-line.

• The library generates a “Unit Standby Button Was Pressed” event

(SK=6 ASC=80 ASCQ=09).

• When the library is off-line, it responds to the Inquiry, Request

Sense, Log Sense, and Mode Sense commands. Check Condition is

set for all other commands issued during this time, and the “Unit

Is Turned Off-line” (SK=2 ASC=80 ASCQ=09) condition is set in

the sense data.

• Field Service Engineer (FSE) level diagnostic commands can be

executed via the diagnostic port or control panel.

The library remains off-line until one of the other operational

sequences occur.

Automatic Drive Cleaning Sequence

The default state of automatic drive cleaning is “disabled.” For a

detailed discussion of the automatic drive cleaning features, see

Appendix C.

Events 2-11

Page 30

ACL 4/52 Software Interface Guide

Document 6211225-03

Version 3.0

Configuration Procedures

The library can be configured using either the EIA/TIA-574 (DIAG)

interface (refer to Document 6211224, ACL 4/52 Diagnostic Software

User’s Manual) or through the Control Panel Menu Mode (refer to

Document 6211222, ACL 4/52 Operator’s Guide).

“DIAG” Interface

The following configuration functions are available using the

Diagnostic Software Program via the “DIAG” port:

• Horizontal, vertical and extension positions of the data transfer

elements of the: FSA, load port and tape drives

• Set SCSI address of the: library and tape drives

• Set power-up state (on-line/off-line)

• Enable/Disable the Auto Clean option

• Enable/Disable the Auto Load option

• Select the language to be displayed in the Status Display Area

(English/Francais/Deutsch/Espanol/Italiano)

• Initialize Inventory

• Initialize non-volatile RAM

• Enable/Disable Recovery

• Report Recovery status

• Enable/Disable the Tape Drive Cleaning feature

• Initialize Auto Cleaning default values

• Report the Tape Drive Cleaning status

• Download firmware revisions

2-12 Configuration Procedures

Page 31

Control Panel Menu Mode

The following configuration functions are available using the Control

Panel Menu Mode:

• Horizontal, vertical and extension positions of the data transfer

elements of the: FSA, load port and tape drives

• Set SCSI address of the: library and tape drives

• Set power-up state (on-line/off-line)

• Enable/Disable the Auto Clean option

• Enable/Disable Recovery

• Enable/Disable the Auto Load option

• Select the language to be displayed in the Status Display Area

(English/Francais/Deutsch/Espanol/Italiano)

ACL 4/52 Software Interface Guide

Document 6211225-03

Version 3.0

• Operate System Test

• Enable/Disable temperature sensor

Configuration Procedures 2-13

Page 32

ACL 4/52 Software Interface Guide

Document 6211225-03

Version 3.0

Error Recovery Procedures

Internal Error Recovery

If a failure occurs during a movement command, the software

attempts to recover. The following are types of retries and recovery

efforts:

• If an actuator is not in a valid starting position at the start of any

movement command, the software attempts to home the actuator

before starting the command. If the home is successful, the

command is continued. (SK=B ASC=81 ASCQ=10, SK=B ASC=83

ASCQ=10, SK=B ASC=84 ASCQ=10, SK=B ASC=86 ASCQ=10)

• If an actuator movement fails because of a current feedback,

actuator timeout or mechanical position error, the actuator move is

retried. If the retry is successful, the command is continued. (SK=B

ASC=81 ASCQ=00-05, SK=B ASC=83 ASCQ=01-03, SK=B ASC=84

ASCQ=01, SK=B ASC=84 ASCQ=03, SK=B ASC=86 ASCQ=01,

SK=B ASC=86 ASCQ=03, SK=B ASC=86 ASCQ=07)

• If a drive does not eject a DLT™ far enough for it to be fully

• If the pick portion of a move command fails and the DLT™

• If a place into a drive fails because of an extension axis current

Operator Recovery

Refer to Document 6211222, ACL 4/52 Operator’s Guide, for suggested

operator recovery procedures.

gripped, the software will make several attempts to pull the DLT™

out of the drive. It closes the gripper on the DLT™, pulls it out

slightly and then attempts again to pull it out of the drive. (SK=B

ASC=81 ASCQ=51)

appears to be in the gripper, the command is continued and the

place completed if possible. If the place fails as well, only the

original pick error code is returned.

feedback error, the extension axis is retracted and the “place” is

attempted one additional time before the error is reported. (SK=B

ASC=83 ASCQ=02)

2-14 Error Recovery Procedures

Page 33

System Performance

Key Performance Items

The actuator move times are the key performance items. The internal

software attempts to maximize the library’s performance by allowing

multiple actuators to move simultaneously. For example, the vertical

and horizontal axes are moved to the appropriate position at the same

time when moving toward a storage element, i.e., diagonally. Also, the

extension and gripper actuators are moved to a ready position after

the completion of a move to prepare for the next move.

The host can increase performance by minimizing the distance of the

actuator moves. It can do this by using the time when the tape drives

are busy (or when no commands are being issued) to sort the storage

elements to better suit the application.

ACL 4/52 Software Interface Guide

Document 6211225-03

Version 3.0

Typical Application Enhancements

The host should check for any attention or error conditions that the

tape library may have buffered by issuing Request Sense Commands

until no conditions exist.

The SCSI interface allows the host to enable the “disconnect from bus”

option. This allows the target to disconnect from the bus while

processing a command from the host application and reconnect when

the command is complete. Disconnecting allows access to the drives or

other logical units while the command is being performed.

The internal software does not support command queueing. It is up to

the host application to queue commands to the unit. It may also be

advantageous for the application to group queued commands to

require the least amount of actuator motion.

The Position To Element command allows the application to move the

robotics to a more advantageous position while the tape drives are

busy. For example, if a DLT™ is about to be ejected from the drive, the

robotics can be positioned in front of a drive to pick up the DLT™

when ejected. (The host should verify that a tape is present before

attempting a “pick” operation. If the tape drive is not unloaded, the

error “MEDIUM NOT PRESENT” {SK=5 ASC=3A ASCQ=00} is

returned and the host should attempt to retry.)

System Performance 2-15

Page 34

ACL 4/52 Software Interface Guide

Document 6211225-03

Version 3.0

System Diagnostic Support

The library unit has a layered self diagnostic capability. Each layer

addresses a specific type of diagnostic need. The layers provide a basic

go/no-go capability as-well-as complete fault isolation capability.

Host Interface Diagnostic Error Codes

This lowest layer consists of the tests that are performed when the

library unit is placed on-line. These tests are designed to catch all

major system failures and give the host computer a high degree of

confidence that the library is operational. This layer has been kept as

simple as possible to minimize the amount of support software

required at the host.

The next layer allows isolation of faults that occur during operation.

Error definitions and recovery procedures, provided in Appendix A,

are designed to be descriptive enough to quickly test failed operations

and correct any conditions that would have resulted in an unnecessary

service call.

Off-line Diagnostics via the “DIAG” Port

The top level of diagnostic commands are available through the use of

the Diagnostic Software Program (DSP) interfacing to the library over

the “DIAG” Port on the rear of the library. The commands are

designed for use by an authorized Field Service Engineer and are

intended for use with the fault isolation procedures described in

Document 6211223, ACL 4/52 Field Service Manual. Use of the DSP is

described in Document 6211224, ACL 4/52 Diagnostic Software User’s

Manual.

2-16 System Diagnostic Support

Page 35

ACL 4/52 Software Interface Guide

Software Interfaces

Chapter Overview.................................................................................................. 3-3

SCSI Interface...........................................................................................................3-3

Reset Sequence..................................................................................................3-4

Supported Messages ........................................................................................3-4

Abort............................................................................................................3-5

Bus Device Reset........................................................................................3-5

Command Complete .................................................................................3-5

Disconnect (from Target to Initiator)......................................................3-5

Identify (Initiator to Target) .....................................................................3-6

Identify (Target to Initiator) .....................................................................3-6

Save Data Pointer.......................................................................................3-6

Supported Operational Commands ..............................................................3-7

Initialize Element Status (07h) .................................................................3-9

Initialize Element Status with Range (E7h)..........................................3-10

Inquiry (12h).............................................................................................3-12

Log Sense Command (4Dh)....................................................................3-15

Mode Select Command (15h).................................................................3-19

Mode Sense (1Ah)....................................................................................3-25

Move Medium (A5h)...............................................................................3-35

Position To Element (2Bh) ......................................................................3-37

Prevent/Allow Medium Removal (1Eh)..............................................3-38

Read Element Status (B8h)......................................................................3-40

Ready Inport (DEh) .................................................................................3-53

Release (17h).............................................................................................3-54

Reserve (16h) ............................................................................................3-55

Request Sense (03h) .................................................................................3-58

Request Volume Element Address (B5h).............................................3-61

Rezero Unit (01h) .....................................................................................3-75

Send Diagnostic (1Dh).............................................................................3-76

Send Volume Tag (B6h) ..........................................................................3-78

Test Unit Ready (00h)..............................................................................3-80

Document 6211225-03

Version 3.0

3

3-1

Page 36

3-2

Page 37

Chapter Overview

This chapter describes the specific terminology of the Small Computer

Systems Interface (SCSI-2) in relation to the ACL 4/52.

SCSI Interface

Note SCSI-2 terminology is listed below with its ACL 4/52 equivalent:

• Logical Unit is the Library.

• Initiator is the Host Computer.

• Data Transfer Element is the Tape Drive.

• Medium Transport Element is the Gripper Mechanism.

ACL 4/52 Software Interface Guide

Document 6211225-03

Version 3.0

• Storage Element is a Bin in the Fixed Storage Array.

• Import Export Element is a Bin in the Load Port.

The ACL 4/52 is a SCSI-2 medium change device. The host computer

serves as the SCSI initiator and issues commands to the library and

tape drives which act as SCSI targets.

The library provides only SCSI target support. It does not perform any

of the initiator functions. The library has its own SCSI address separate

from any other SCSI devices including the tape drives.

The library does not support SCSI queuing or linked commands. All

element addresses must be specified absolutely; no relative addressing

is permitted.

The amount of data transferred between the host and the library is

minimal. For this reason, the library does not support either

synchronous or wide data transfers.

The library is intended for use with SCSI-2 initiators. It cannot be used

with a SCSI-I initiator.

The library does not support the Change Definition Command,

Asynchronous Event Notification or extended contingent allegiance.

Note The message and command sections of this chapter assume that you

have significant knowledge of the SCSI Specification.

Chapter Overview 3-3

Page 38

ACL 4/52 Software Interface Guide

Document 6211225-03

Version 3.0

Reset Sequence

The ACL 4/52 library supports the SCSI-2 soft reset option. When a

SCSI bus reset occurs, the library clears the SCSI bus as described in

the SCSI-2 Standard.

Supported Messages

This section describes the required messages and supported optional

messages and their use in coordinating the host and library. The

messages that the host (a SCSI initiator) can send to the library (a SCSI

target) are described along with the library response when the

message is received. The messages sent by the library to the host are

described along with why they are sent.

These descriptions are not meant as a supplement to the information

provided in the SCSI-2 standard. These descriptions are intended to

document how these messages have been adapted for use with the

library.

The library supports all messages indicated as mandatory for target

support by the SCSI-2 specification. The mandatory messages are:

• Abort

• Bus Device Reset

• Command Complete

• Identify (initiator to target)

• Initiator Detected Error

• Message Parity Error

• Message Reject

• No Operation

The library also supports several messages indicated as optional for

SCSI targets by the SCSI-2 specification. Most of the library operations

are slow in relation to the other operations being controlled using the

SCSI bus. By using these optional messages, the library can make the

bus available for other operations while completing a library

operation. These messages are:

• Disconnect (Direction is from target to initiator)

• Identify

• Save Data Pointer

3-4 SCSI Interface

Page 39

ACL 4/52 Software Interface Guide

Document 6211225-03

Version 3.0

Abort

The Abort message allows the host to clear the present operation on

the library. Abort can be used as follows with the library:

• The initiator of an operation can abort that pr ocess by sending this

message to the library. This stops the operation of the library at its

next “safe” position. Since only one operation is supported per

library at a time, this message effectively stops all processing.

• If any other initiators send this message, the library accepts the

message but does not abort any of the operations.

Bus Device Reset

The Bus Device Reset message from a host to the library causes the

library to clear all I/O processes. The Unit Attention condition is set to

indicate that the device has been reset.

Command Complete

The library sends this message to the host after the library has

completed the command operation and sent valid status information

to the host. This message does not indicate that the operation was

completed successfully. Successful completion must be determined by

examining the status information. After sending this message, the

library is ready to accept another command.

Disconnect (from Target to Initiator)

The Identify message from the host indicates if the library can

disconnect during the execution of an operation. When the library

receives a command which cannot be immediately completed and a

disconnect has been allowed, then the library disconnects from the

host while performing the operation. This frees the SCSI bus for other

uses while the operation is in progress.

The library disconnects from the host by sending the host the Save

Data Pointer message (if necessary) just before the Disconnect

message.

Given the nature of the host and library interface it is not expected that

a data pointer will be used by the host. Only data transfers which are

broken into multiple connections will end each successful connection

with a Save Data Pointer and Disconnect message sequence. This

conforms to SCSI-2 standard section 5.6.6.

The SCSI-2 standard also allows an optional host-to-target disconnect

message. The library does not support this option and responds with a

Message Reject if a Disconnect message is received.

SCSI Interface 3-5

Page 40

ACL 4/52 Software Interface Guide

Document 6211225-03

Version 3.0

Identify (Initiator to Target)

The host sends this message to the library to identify the library to

which the command is being sent. This message also indicates whether

the library may disconnect during the command.

The Identify message from the host overrides the unit number in the

command descriptor block. If the library receives an Identify message

from the host, the library ignores the unit number in the command

descriptor block. If an Identify message is not received, the library uses

the unit number in the command descriptor block. The library does not

disconnect during an operation under these circumstances.

Identify (Target to Initiator)

When the library uses the Disconnect message to disconnect from the

host, the library sends an Identify message to the host after completing

the operation and reselecting the host. The library number in this

Identify message is the same as the library number in the Identify

message the host sent to the library at the start of the operation.

The library does not support any target routines.

The host does an implied Resume Pointers when the Identify message

is received from the library.

Save Data Pointer

The library sends this message to the host, when data transfers are

broken into multiple connections, before disconnection using the

Disconnect message.

3-6 SCSI Interface

Page 41

Supported Operational Commands

The library supports all commands that the SCSI-2 Specification

indicates are required by all devices:

• Inquiry (12h)

• Request Sense (03h)

• Send Disagnostic (1Dh)

• Test Unit Ready (00h)

The library also supports all of the commands which the SCSI-2

Specification indicates are required by media change devices:

• Move Medium (A5h)

In addition, the library supports the following optional commands:

ACL 4/52 Software Interface Guide

Document 6211225-03

Version 3.0

• Initialize Element Status (07h)

• Log Sense (4Dh)

• Mode Select (15h)

• Mode Sense (1Ah)

• Position to Element (2Bh)

• Read Element Status (B8h)

• Request Volume Element Address (B5h)

• Rezero Unit (01h)

• Prevent/Allow Medium Removal (1Eh)

• Release (17h)

• Reserve (16h)

• Send Volume Tag (B6h)

Finally, the library supports the following vendor specific commands:

• Initialize Element Status with Range(E7h)

• Ready Import (DEh)

SCSI Interface 3-7

Page 42

ACL 4/52 Software Interface Guide

Document 6211225-03

Version 3.0

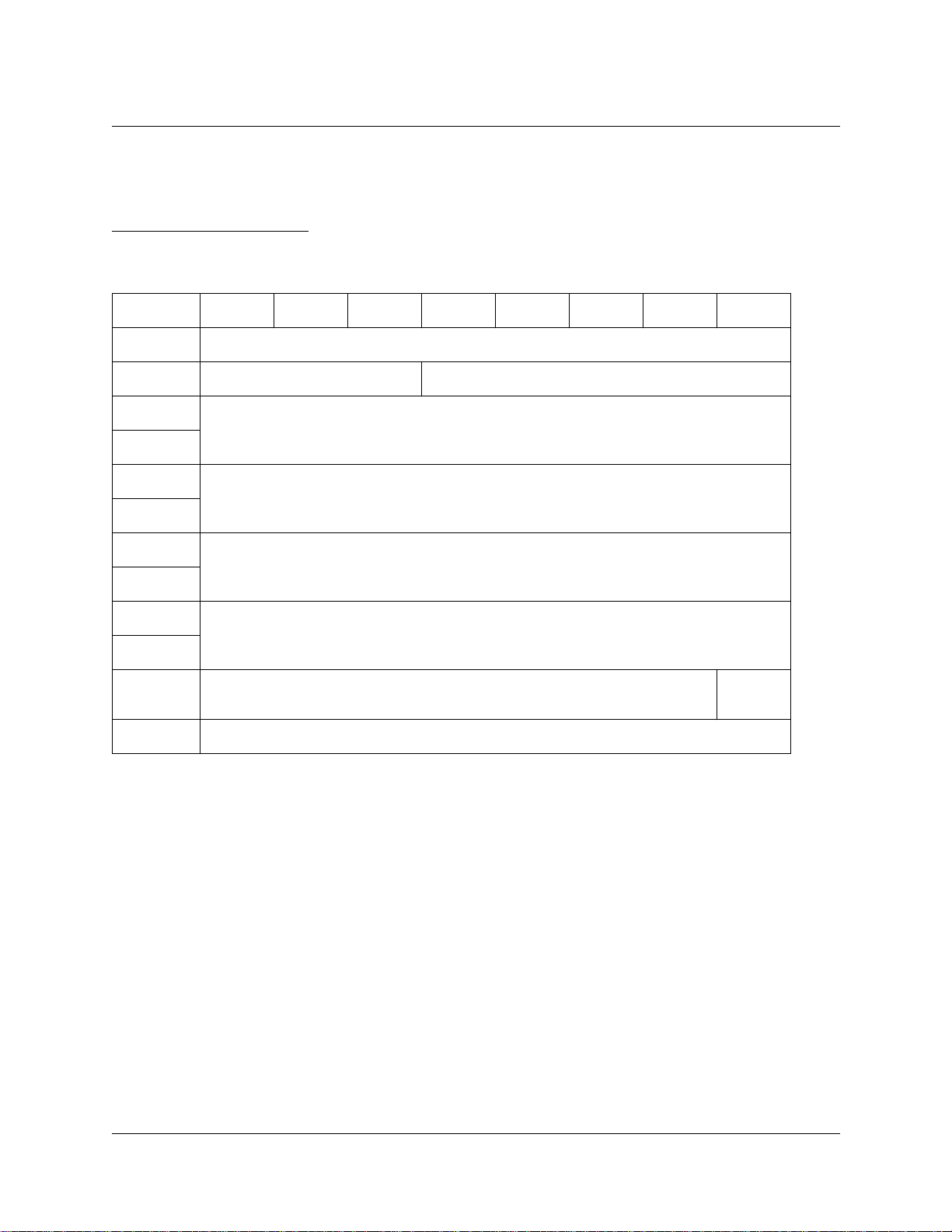

Note This section describes the commands, command format and data

format. For the most part, these formats are taken directly from the

SCSI-2 Specification. Only the fields and values supported by the ACL

4/52 are described in this guide. The commands, their operation code

and type are shown in Table 2.

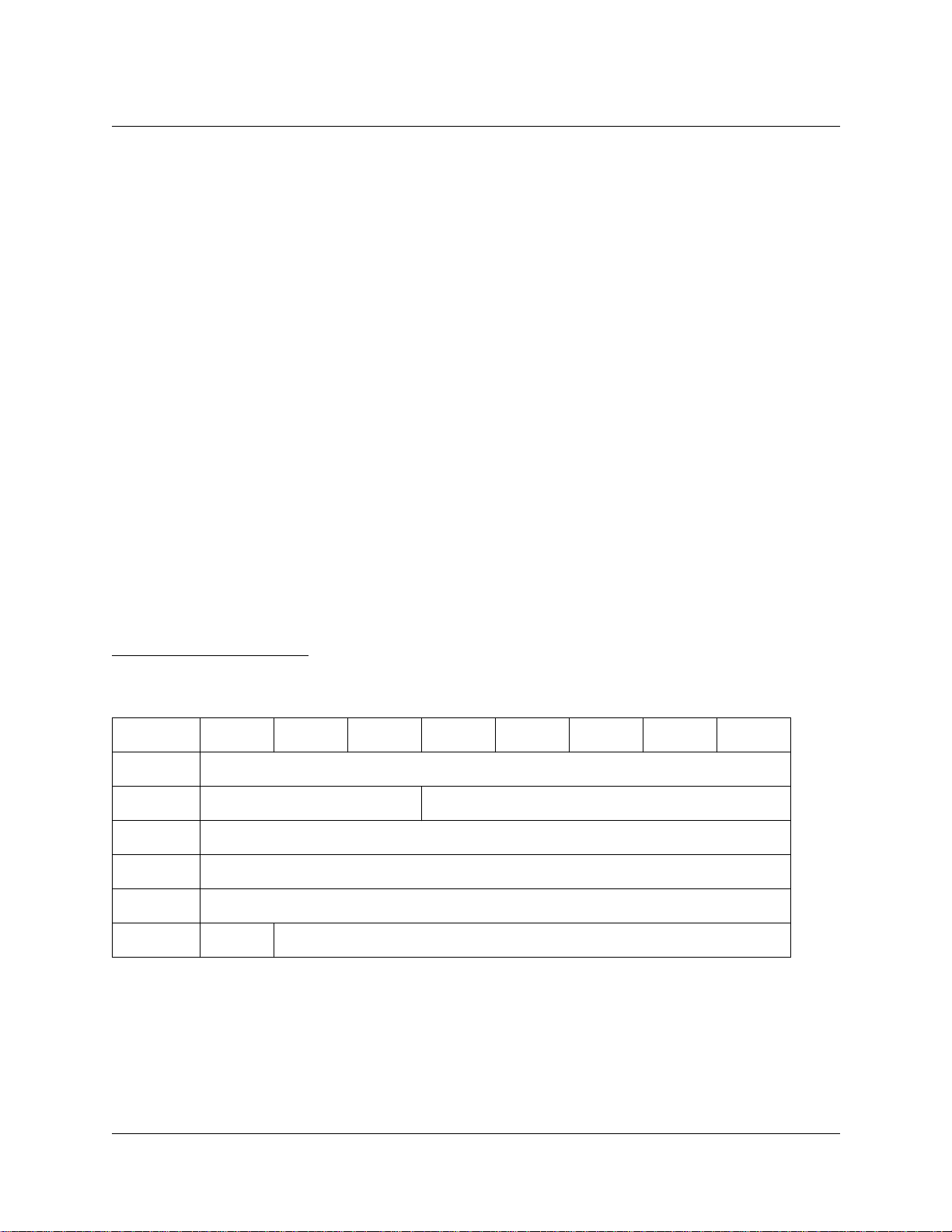

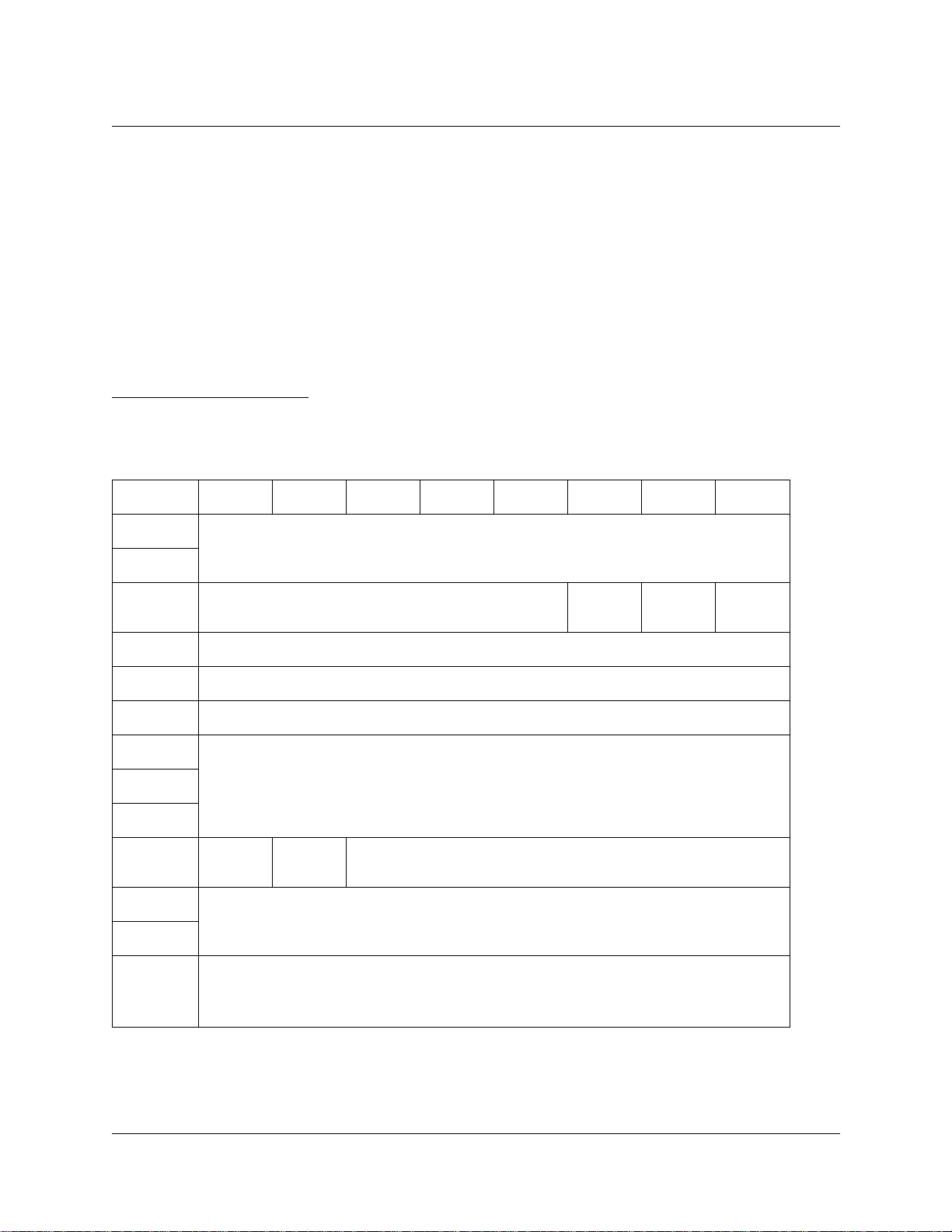

Table 2: Supported Operational Commands

Initialize Element Status 07h Optional

Initialize Element Status with Range E7h Vendor

Inquiry 12h Mandatory

Log Sense 4Dh Optional

Command Name Operation Code Type

Mode Select 15h Optional

Mode Sense 1Ah Optional

Move Medium A5h Mandatory

Position to Element 2Bh Optional

Prevent/Allow Medium Removal 1Eh Optional

Read Element Status B8h Optional

Ready Inport DEh Vendor

Release 17h Optional

Request Sense 03h Mandatory

Request Volume Element Address B5h Optional

Reserve 16h Optional

Rezero Unit 01h Optional

Send Diagnostic 1Dh Mandatory

Send Volume Tag B6h Optional

Test Unit Ready 00h Mandatory

3-8 SCSI Interface

Page 43

ACL 4/52 Software Interface Guide

Document 6211225-03

Version 3.0

Initialize Element Status (07h)

The Initialize Element Status Command allows the host to request an

inventory of the tape cartridges held in a library. The library conducts

an inventory and determines whether each element contains a tape

cartridge. The inventory will read the bar code of each tape (unless

commanded not to). If no bar code is read, the library will use sensors

to determine whether each element contains a tape.

Inventory information is returned to the host only if requested using

the Read Element Status command.

The library does not accept any other commands from the host during

the inventory process.

The host can issue an Abort of the inventory for the library. If another

Initialize Element Status command is then issued, the inventory

process is restarted from the beginning.

If the gripper contains a tape cartridge, the inventory procedure

cannot be conducted. In this case a Transfer Full error (SK=5 ASC=80

ASCQ=01) is returned. The cartridge should be moved to an available

bin, and the command retried.

The format for this command data block is shown in Table 3.

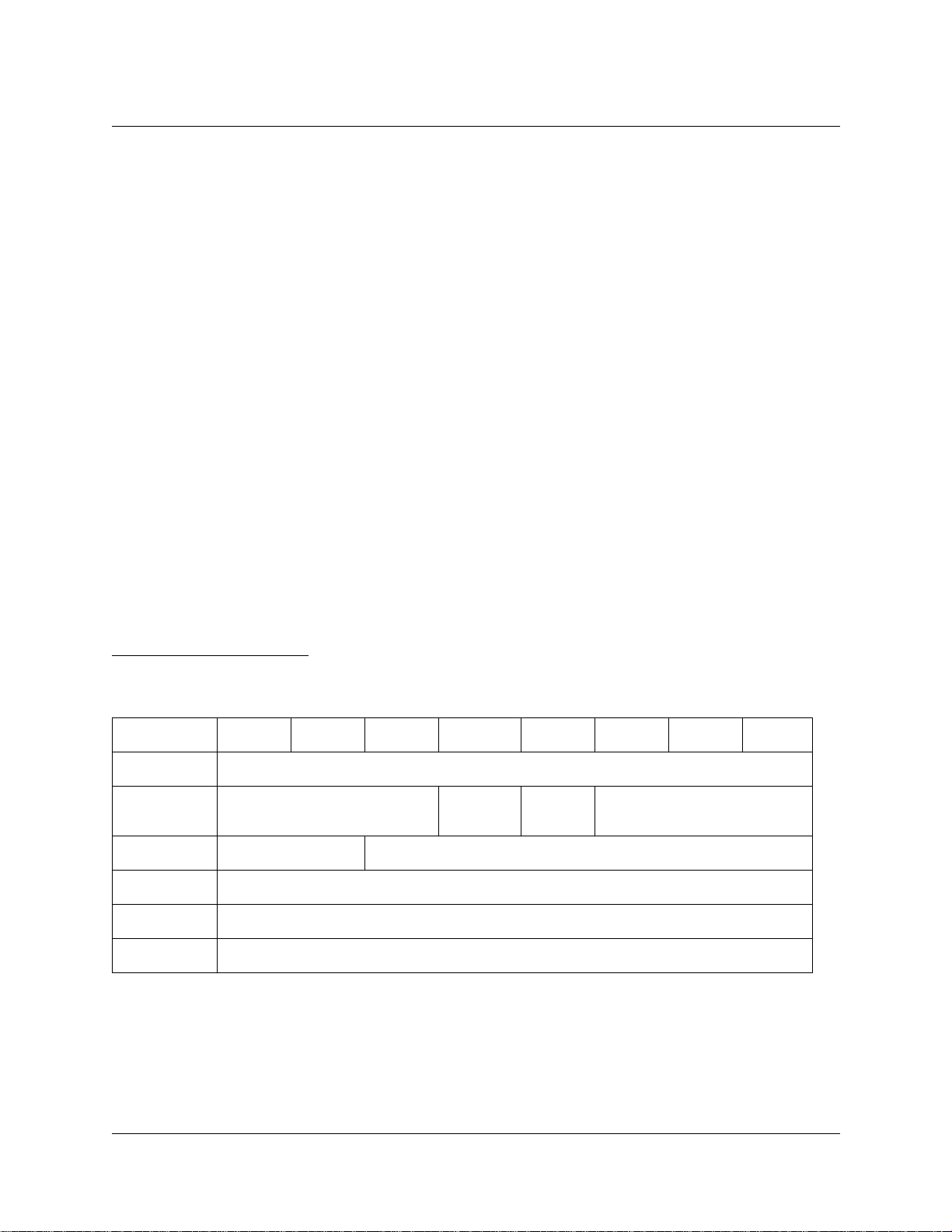

Table 3: Initialize Element Status Cmd

Bit/Byte 76543210

0

1

2

3

4

5

Logical Unit Number Reserved (00h)

NBL Reserved (00h)

Operation Code (07h)

Reserved (00h)

Reserved (00h)

Reserved (00h)

Logical Unit Number The Logical Unit Number must be set to 0. This field indicates

which logical unit the command should be sent to.

NBL A

No Bar-code Labels field of 1 specifies the inventory to not scan

the bar codes of the elements and set the corresponding primary

volume tags to empty. A value of 0 specifies element bar code

labels are to be scanned and placed in the primary volume tags.

SCSI Interface 3-9

Page 44

ACL 4/52 Software Interface Guide

Document 6211225-03

Version 3.0

Initialize Element Status with Range (E7h)

The Initialize Element Status with Range Command allows the host to