Page 1

User’s Manual

2U 2-Way x86 Server

QSSC-S99K 2U

Page 2

铅

Lead

(Pb)

○

○

○

Preface

Regional EMC Compliance Information

FCC Verification Notice (USA only)

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause undesired operation.

Class

A

This equipment has been tested and found to comply with the limits for a Class A digital device pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the manufacturer’s instruction manual, may cause harmful interference with radio

communications. Operation of this equipment in a residential area is likely to cause harmful interference, in which

case you will be required to correct the interference at your own expense.

INDUSTRY CANADA (Canada only)

This Class B (or Class A, if so indicated on the registration label) digital apparatus meets the requirements of the

Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la Classe B (ou Classe A, si ainsi indiqué sur l’étiquette d’enregistration) respecte

toutes les exigences du Reglement sur le Materiel Brouilleur du Canada.

CE Declaration of Conformity (EUROPE only)

This product has been tested in accordance to, and complies with the European Low Voltage Directive

(73/23/EEC) and European EMC Directive (89/336/EEC).

The product has been marked with the CE Mark to illustrate its compliance.

China RoHS Declaration Table

部件名称

(Component Name)

有毒有害物质或元素(Hazardous Substance)

铅

Lead

(Pb)

汞

Mercury

(Hg)

镉

Cadmium

(Cd)

六价铬

Chromium VI

Compounds

(Cr6+)

多溴联苯

Polybrominated

Biphenyls

(PBB)

多溴二苯醚

Polybrominated

Diphenyl Ethers

(PBDE)

机箱子组件

Chassis Subassembly

电源

Power Supply

印刷版组件

Printed Board

A

ssemblies (PBA)

○: 表示该有毒有害物质在该部件所有均质材料中的含量均在 SJ/T 11363-2006 标准规定的限量要求以下.

○

○

○

○: Indicates that this hazardous substance contained in all homogeneous materials of this part is below the limit requirement in SJ/T 11363-2006.

ii

○

○

○

○

○

○

○

○

○

○

○

○

Page 3

Preface

Copyright

This publication, including all photographs, illustrations and software, is protected under international copyright

laws, with all rights reserved. Neither this manual, nor any of the material contained herein, may be reproduced

without the express written consent of the manufacturer.

Version 1.0, September, 2010

Disclaime

r

The information in this document is subject to change without notice. The manufacturer makes no representations

or warranties with respect to the contents hereof and specifically disclaims any implied warranties of

merchantability or fitness for any particular purpose. Furthermore, the manufacturer reserves the right to revise

this publication and to make changes from time to time in the content hereof without obligation of the manufacturer

to notify any person of such revision or changes.

For the latest information and updates please refer to www.qsscit.com.

iii

Page 4

Preface

Safety Information

READ THIS IMPORTANT SAFETY INFORMATION SECTION. RETAIN THIS MANUAL FOR REFERENCE.

READ THIS SECTION BEFORE SERVICING.

CAUTION!

TO REDUCE THE RISK OF ELECTRIC SHOCK, THIS SERVER SHOULD ONLY BE SER-

VICED BY QUALIFIED SERVICE PERSONNEL.

RTC Battery

CAUTION!

TO REDUCE THE RISK OF ELECTRIC SHOCK, THIS SERVER SHOULD ONLY BE SER-

VICED BY QUALIFIED SERVICE PERSONNEL.

Power Supply

CAUTION!

THE POWER SUPPLIES IN YOUR SYSTEM MAY PRODUCE HIGH VOLTAGES AND

ENERGY HAZARDS, WHICH CAN CAUSE BODILY HARM. UNLESS YOU ARE INSTRUCTED OTHERWISE, ONLY TRAINED SERVICE TECHNICIANS ARE AUTHORIZED

TO REMOVE THE COVERS AND ACCESS ANY OF THE COMPONENTS INSIDE THE

SYSTEM.

Power Supply Cord

CAUTION!

THIS SYSTEM MAY HAVE MORE THAN ONE POWER SUPPLY CABLE. TO REDUCE

THE RISK OF ELECTRICAL SHOCK, A TRAINED SERVICE TECHNICIAN MAY NEED TO

DISCONNECT ALL POWER SUPPLY CABLES BEFORE SERVICING THE SYSTEM.

Laser Drive Equipment

The optical transceiver module in this server is a laser Class 1 product.

Ambient Operation

This equipment cannot be operated above an ambient operation temperature of 40 degrees centigrade.

Equipment Location

This equipment can only be accessed by SERVICE PERSONNEL or by USERS who have been instructed about

the reasons for the restrictions applied to the location. Access is through the use of a TOOL or lock and key, or

other means of security, and is controlled by the authority responsible for the location.

CAUTION!

REGARDING THE STANDARDS OF WORKSTATIONS REGULATIONS, DO NOT PLACE

THE MODEL IN THE VISUAL FIELD OF THE USER, BECAUSE OF THE GLOSSY FRONT

OF THE CASE.

Rack Mounting of Systems

CAUTION!

BEFORE WORKING ON THE RACK, MAKE SURE THAT THE STABILIZERS ARE SECURED TO THE RACK, EXTENDED TO THE FLOOR, AND THAT THE FULL WEIGHT OF

THE RACK RESTS ON THE FLOOR. INSTALL FRONT AND SIDE STABILIZERS ON A

SINGLE RACK OR FRONT STABILIZERS FOR JOINED MULTIPLE RACKS BEFORE

WORKING ON THE RACK.

CAUTION!

A

LWAYS LOAD THE RACK FROM THE BOTTOM UP, AND LOAD THE HEAVIEST ITEM

IN THE RACK FIRST. MAKE SURE THAT THE RACK IS LEVEL AND STABLE BEFORE

EXTENDING A COMPONENT FROM THE RACK.

iv

Page 5

Preface

CAUTION!

DO NOT OVERLOAD THE AC SUPPLY BRANCH CIRCUIT THAT PROVIDES POWER TO

THE RACK. THE TOTAL RACK LOAD SHOULD NOT EXCEED 80 PERCENT OF THE

BRANCH CIRCUIT RATING.

CAUTION!

ENSURE THAT PROPER AIRFLOW IS PROVIDED TO COMPONENTS IN THE RACK. DO

NOT STEP ON OR STAND ON ANY COMPONENT WHEN SERVICING OTHER COMPONENTS IN A RACK.

Typographic Conventions

Several different typographic conventions are used throughout this manual. Refer to the following examples for

common usage.

Bold type face denotes menu items, buttons and application names.

Italic type face denotes references to other sections.

Note:

Highlights general or useful information and tips.

WARNING!

Warning information appears before the text it references and should not be ig-nored as the

content may prevent damage to the device.

CAUTION!

CAUTIONS APPEAR BEFORE THE TEXT IT REFERENCES, SIMILAR TO NOTES AND

WARNINGS. CAUTIONS, HOWEVER, APPEAR IN CAPITAL LET-TERS AND CONTAIN

VITAL HEALTH AND SAFETY INFORMATION.

Personal Inventory

This Computer system is designed for years of productive computing. Use this section to keep notes about details

of your purchase. Update this section when you add new options.

Date of Purchase:

Dealer’s Name:

Phone:

A

ddress:

E-mail Address:

WWW Site:

Serial Number:

CPU Type:

Hard Disk Capacity:

Memory Capacity:

A

ccessories

(check the accessories that shipped with your model):

CPU heat sink x 2

Utility CD ROM with support software driver and

user's manual x 1

Rail slide kit x 1 set

Others________________

v

Page 6

CHAPTER 1 1

Introduction 1

Checklist 1

A Tour of the System 2

Front View 2

Rear View 4

System Controls and LEDs Description 6

CHAPTER 2 7

Installing Hardware 7

Safety Measures 7

S99K 2U Mainboard Components 8

Installing Hard Drives 9

Removing the Chassis Cover 11

Removing the Fan Duct 12

Installing CPUs 13

Installing Heat Sinks 15

Installing the Fan Duct 16

Installing an Expansion Card 17

Installing Memory 18

Supported DIMM Configuration 19

Replacing the Fan Assembly 20

Installing the LSI/PERC 6i card and Battery 21

Installing a Redundant Power Supply Unit 23

Replacing a Power Supply Unit 24

Replacing the Riser Card 25

Replacing the Expander Backplane 26

Replacing the Motherboard 27

Replacing the Chassis Cover 28

CHAPTER 3 29

BIOS 29

BIOS System Support 29

BIOS Features 29

BIOS POST 29

PCI Sub-System Sub Device ID 29

Hotkeys 29

LEDs 30

Boot Device Sequence Selection 30

Eventlog 30

System Management BIOS (SMBIOS) 31

ACPI BIOS 31

RAID 31

Console Redirection 31

Processor Configuration 32

Memory Configuration 33

Setup Function 36

Summary Screen 36

BIOS Setup Options at Boot 36

Access Level 36

Setup submenu: Main 37

Setup submenu: Advance 37

Setup submenu: Boot 44

Setup submenu: Server 46

Setup submenu: Security 49

Setup submenu: Exit 49

Preface

T

ABLE OF CONTENTS

vi

Page 7

ACPI BIOS Specification 51

System States 51

Query System Address Map 52

BIOS and BMC Communication 55

Overview 55

KCS 55

CHAPTER 4 56

BMC 56

Introduction 56

Order of Precedence 56

Intended Audience 56

Reference Documents 56

Acronyms 57

Server System Overview 60

BMC Hardware Architecture Overview 60

BMC Key Features and Functions 62

Power System 62

Front Panel User Interface 64

Host Interface 69

IPMB Interface 69

LAN Interface 69

NMI 70

Serial Over LAN 70

Channel Number Assignment 70

Time Sync 71

SEL 71

SDR 71

FRU and Device ID Map 72

Platform Event 72

AST2050 Firmware Update 74

Temperature Monitoring 74

Voltage Monitoring 74

FAN Control and Monitoring 75

Bus Error Detection 75

Processor Error Detection 75

Watchdog 76

BIOS BMC Interface 77

RMCPOEM Command Packet Format 77

IPMI 1.5/2.0 Command Support List 78

GUID Flow Chart 78

IPMI Device Global Commands 78

BMC Device and Messaging Command 79

BMC Watchdog Timer Commands 80

Chassis Commands 80

Event Commands 81

SEL Commands 81

SDR Repository Commands 81

FRU Inventory Device Commands 82

Sensor Device Commands 82

LAN Commands 82

PEF/PET Alerting Commands 85

OEM Command 87

Sensor and SDR Definition 89

Sensor Relate SDR Format 89

SDR Type 11h—FRU Device (M/B) 106

SDR Type 12h—BMC Device Locator Record 106

Preface

vii

Page 8

FRU Format 107

MB FRU 107

Front Panel FRU 109

WEB GUI 113

Web GUI Requirements 113

KVM Session 113

Virtual Media Session 114

CHAPTER 5 115

ESMS 115

Introduction 115

Acronyms 115

WEB Interface 116

Login 116

System Information 117

Server Health 120

Configuration 123

Remote Control 137

Language 140

User Privilege for WEB 141

KVM Interface 142

Setting up Internet Explorer 142

Console Redirection Window 145

APPENDIX A 153

Support 153

Before you Begin 153

Installing the Rack Brackets 154

Troubleshooting Sequence 156

Server Boot Issues 156

Installation Problems 158

Troubleshooting External Connections 158

Status LED Descriptions 159

AMI POST Errors and Beep Codes 161

POST Code Checkpoints 162

Beep Codes 164

POST Error Messages and Handling 165

Preface

viii

Page 9

Chapter 1 — Introduction

Chapter 1

Introduction

The QSSC-S99K 2U server system features a motherboard with two FC-LGA1366 socket that accommodate single or dual

Intel® Xeon Nehalem-EP processors, and features the Tylersburg-EP-2S/ICH10R chipsets.

Eighteen DDR3 registered DIMM slots enable you to add up to 144 GB of total memory. ECC support provides extra

security against system failure. Six Serial ATA II (SATAII) ports and four optional Serial Attached SCSI 6Gbp/s ports

provide maximum flexibility in installing hard drives.

The QSSC-S99K 2U has a full range of I/O ports, including two USB ports, two 10/100/1000 Gigabit Ethernet LAN ports, one

link from ICH10R+82576, one 10/100M LAN port from AST2050, one 9-pin serial port, and one 15-pin VGA port.

ASPEED 2050 server management firmware enables the administrator to monitor the QSSC-S99K 2U status through a typical

web browser.

Checklist

Carefully unpack the QSSC-S99K 2U and check that the following items are included.

One QSSC-S99K 2U chassis

One single power supply or a set of redundant power supplies

One CPU heat sink for a single CPU order, two CPU heat sinks for a dual CPU order

One set of rack mount rails

User manual

One utility CD with support software drivers

Contact your vendor if some items are missing or appear damaged.

1

Page 10

Chapter 1 — Introduction

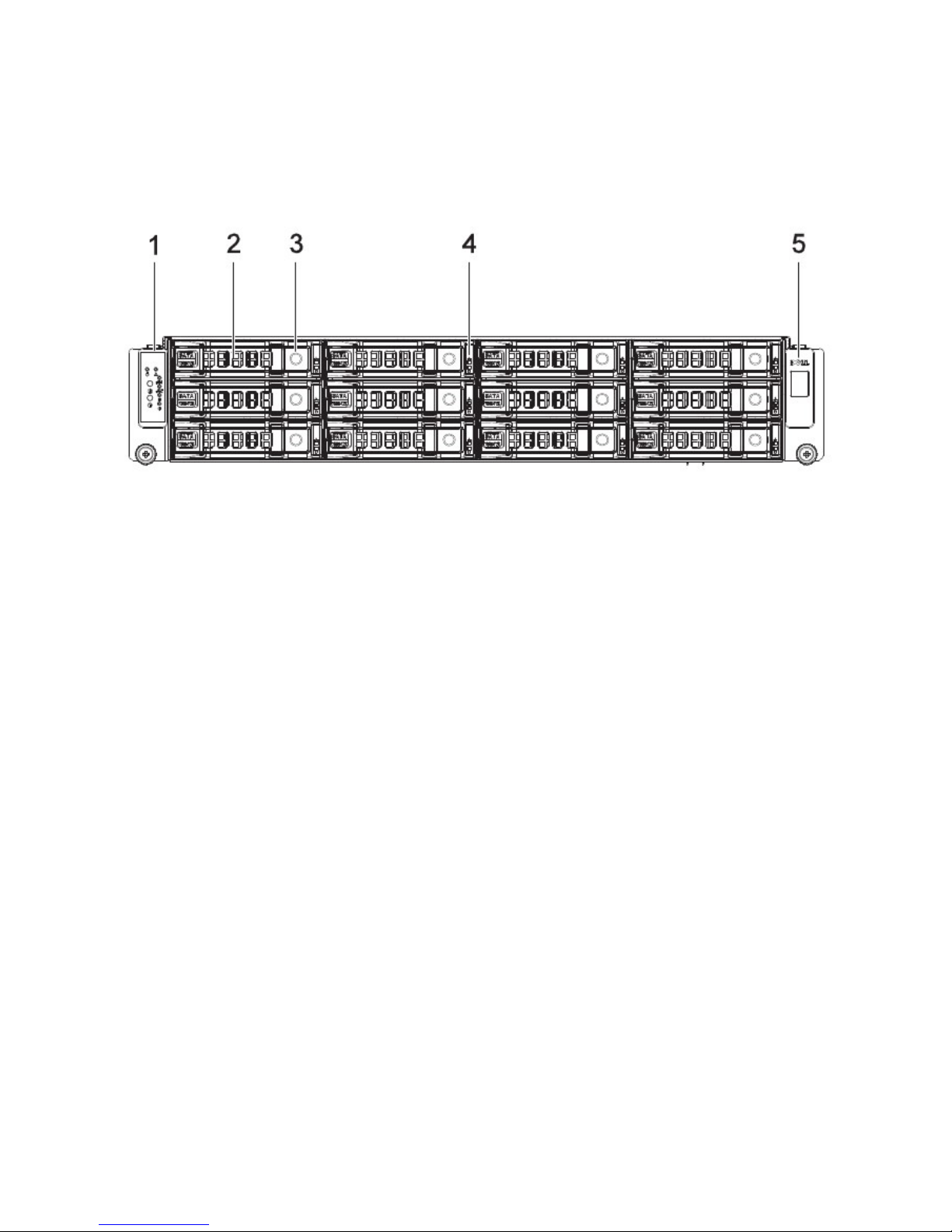

A Tour of the System

The following sections describe the external features for the hot swap version of the QSSC-S99K 2U.

Front View

1.

2.

3.

4.

Front control panel (left)

HDD bay

HDD release lever/ button

HDD status LEDs

See Front Control Panel on page 3.

HDD bay

Use this lever/button to remove the hard drive in HDD bay 1.

Display HDD status:

Active/Present: Green

Fault: Red

5.

Logo panel (right) Right panel

2

Page 11

Chapter 1 — Introduction

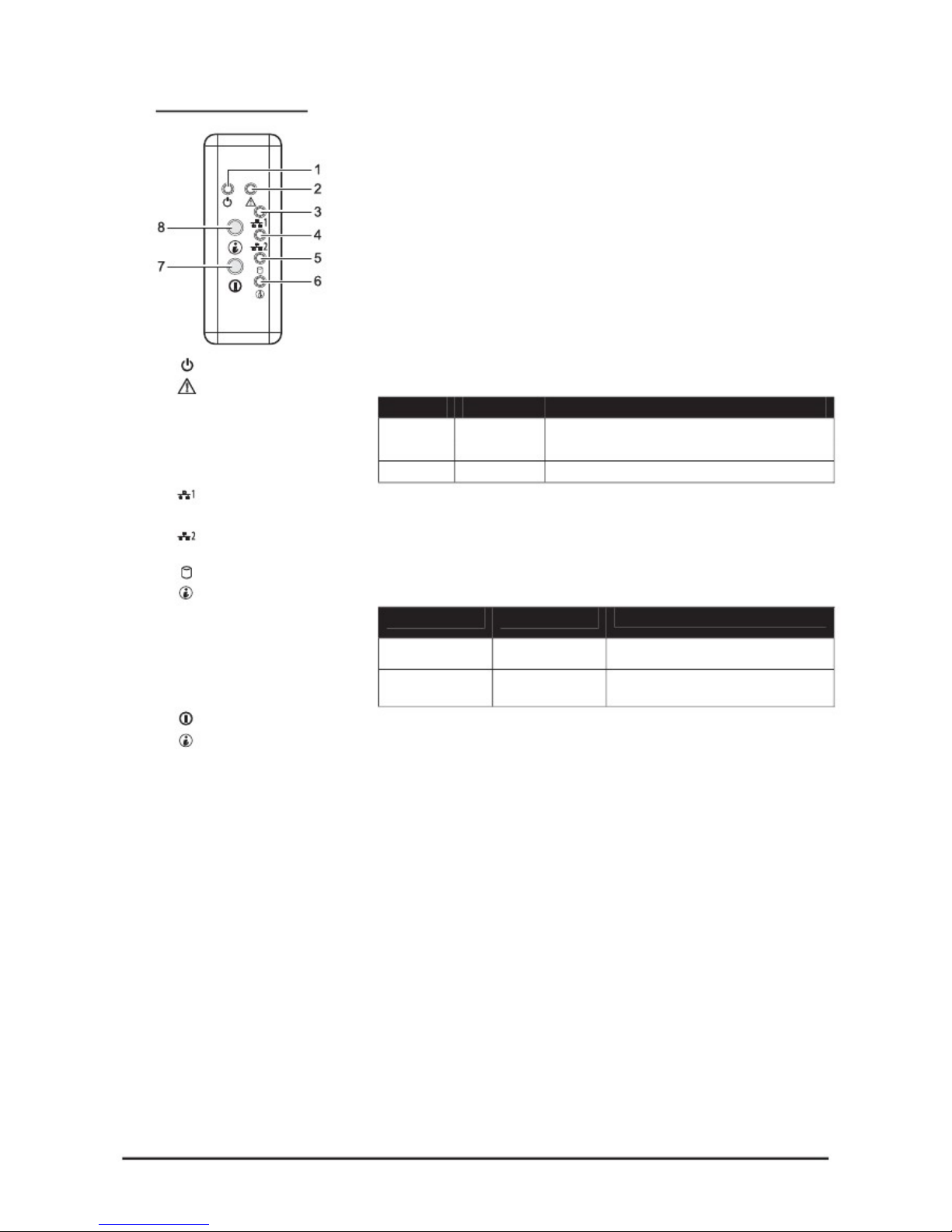

Front Control Panel

1.

2.

Power LED

Status LED

Lights Green when server is powered on.

Displays status/errors and is controlled by BMC

Color

A

mber

A

mber

Condition

Blinking

Off

Occurrence

Non-critical failure: Fan voltage temperature

state.

3.

4.

5.

6.

NIC1 LED

NIC2 LED

HDD active LED

System D LED

Lights green when a connection is made to the NIC1 port, blinks when

NIC1 port is active (access).

Lights green when a connection is made to the NIC2 port, blinks when

NIC2 port is active (access).

Lights Green for hard drive operation.

See table below for behavior.

Color

Blue Off

Blinking

Condition

Occurrence

No identification

Indicate, ID button pressed on chassis

7.

8.

Power button

System D button

Press this button to turn on the QSSC-S99K 2U.

Press to light ID LED.

3

Page 12

Chapter 1 — Introduction

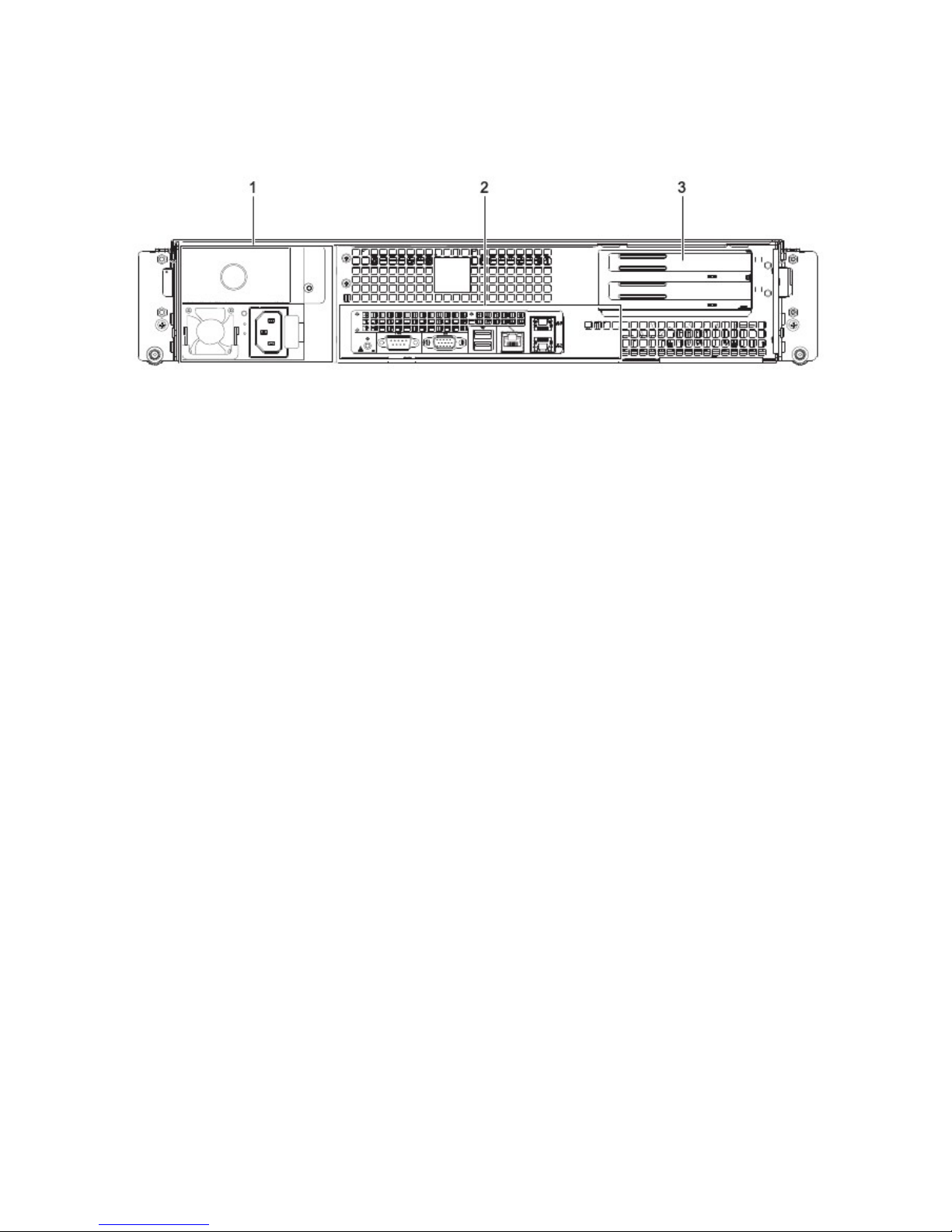

Rear View

1.

2.

3.

Power module

I/O ports

A

dd-on card covers

Connect the power cable to the socket. An optional power module can be installed

for backup power support.

Connect I/O devices to these ports. See QSSC-S99K 2U I/O Ports on page 5.

Remove these covers before installing any PCI-e card.

4

Page 13

Chapter 1 — Introduction

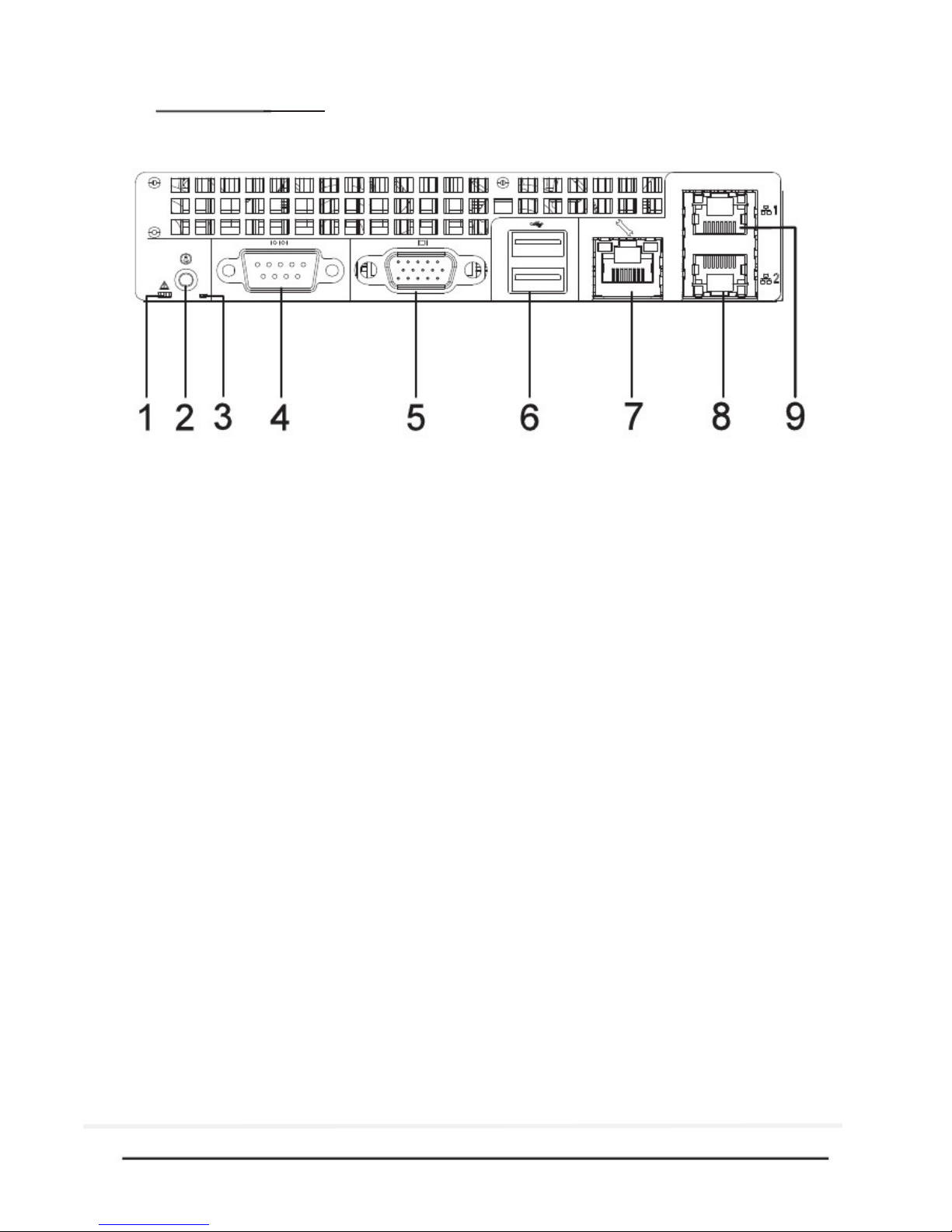

QSSC-S99K 2U I/O Ports

The QSSC-S99K 2U has the following I/O port configuration.

1.

2.

3.

4.

5.

6.

7.

8.

9.

Status LED

ID button

Rear ID LED

Serial port

VGA port

USB ports

Remote monitoring and

management (RMM)

NIC1

NIC2

Behavior is controlled by BMC (see System Controls and LEDs Description on

page 6).

Press to light front and rear ID LEDs (see table below for behavior).

Lights when the system has been selected for identification

Connect serial devices to this port.

Connect a monitor to this port.

Connect USB devices to these two ports.

Connect a RJ-45 jack to this port to link to a 10/100M LAN from AST2000.

Connect a RJ-45 jack to this port to link to a 10/100/1000 Megabit Ethernet

LAN.

Connect a RJ-45 jack to this port to link to a 10/100/1000 Megabit Ethernet

LAN.

5

Page 14

Chapter 1 — Introduction

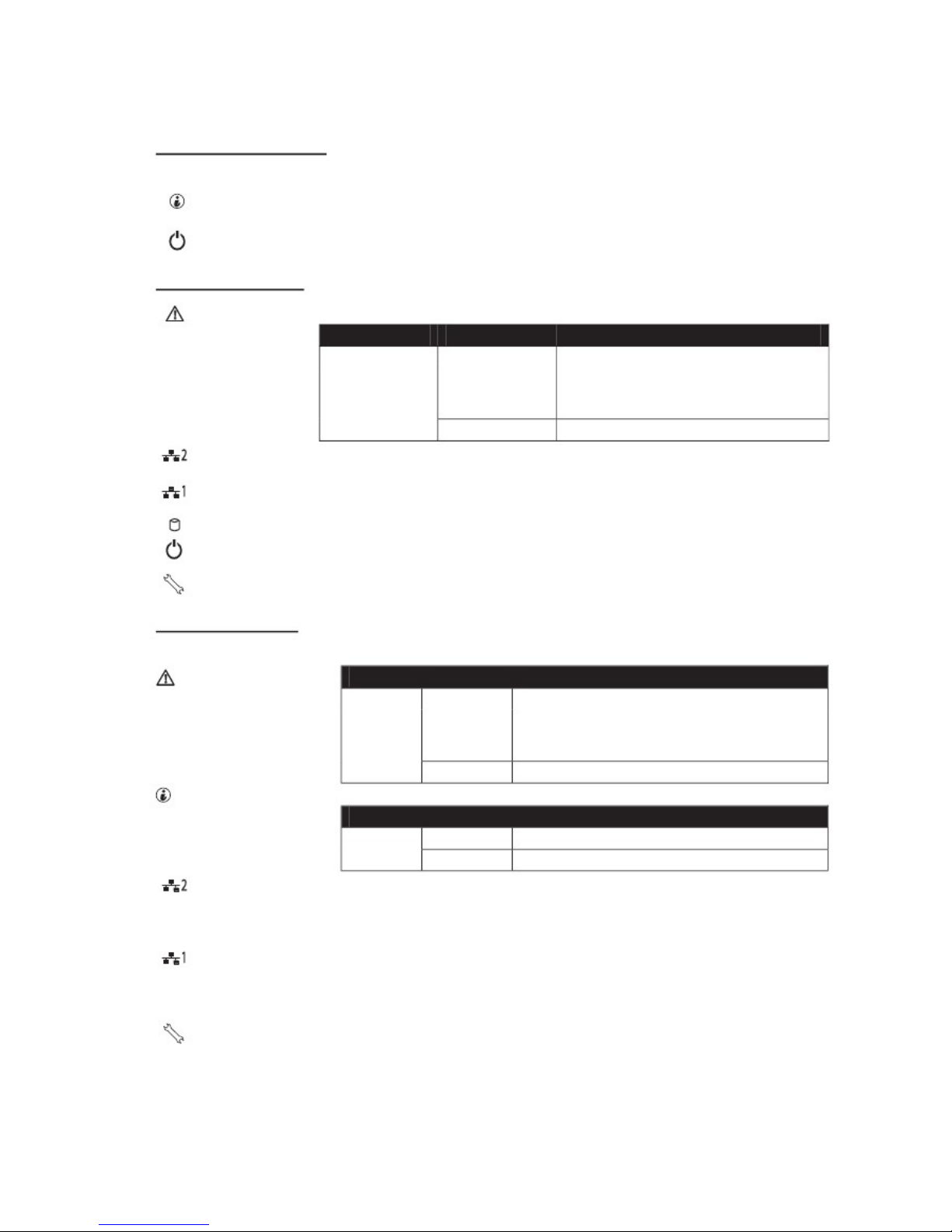

System Controls and LEDs Description

Front System Controls

RESET

Reset Button

Identification

Button

Power button

Push to restart the system when the system is powered on.

Push to clear the ID LED

Toggles system power. When system is off, push briefly to power on the PSU and

the system. When power is on, push briefly to turn off.

Front System LEDs

Fault LED Displays status/errors and is controlled by BMC.

Color

A

mbe

r

Condition

Blinking

Occurrence

Critical Failure: critical Fan, Voltage, Temperature state

Non-Critical Failure: non-critical Fan, Voltage, Temperature state, CPU Thermal Trip.

Off

NIC2 LED

NIC1 LED

HDD Active LED

Power LED

Service LED

OK

Lights green when a connection is made to the NIC2 port, blinks off when there is

traffic on the NIC2 port.

Lights green when a connection is made to the NIC1 port, blinks off when there is

traffic on the NIC1 port.

Lights for hard drive operation.

Lights when server is powered on. (This LED is inside the button on the 2.5” option)

Lights when the BMC port is on, blinks off when there is traffic on the BMC port.

Rear System LEDs

Status System Status LED Displays status/errors and is controlled by BMC.

Color

A

mbe

r

Condition

Blinking

Occurrence

Critical Failure: critical Fan, Voltage, Temperature

state

Non-Critical Failure: non-critical Fan, Voltage,

Temperature state, CPU Thermal Trip

Off

System ID LED

Color

Blue

LAN2 LED

Condition

Off

On

OK

Occurrence

No Identification requested

Unit selected for identification

Lights when front or rear ID button is pressed.

Link/Act: Lights green when a connection is made to the NIC2 port, blinks off

when there is traffic on the NIC2 port.

Speed: Lights green when speed is 100 Mbits/sec, Lights Amber when speed is

1000Mbits/sec

LAN1 LED

Link/Act: Lights green when a connection is made to the NIC1 port, blinks off

when there is traffic on the NIC1 port.

Speed: Lights green when speed is 100 Mbits/sec, Lights Amber when speed is

1000 Mbits/sec

Service Port

Lights when the BMC port is on, blinks off when there is traffic on the BMC port.

6

Page 15

Chapter 2 — Installing Hardware

Chapter 2

Installing Hardware

Safety Measures

Computer components and electronic circuit boards can be damaged by discharges of static electricity. Working

on computers that are still connected to a power supply can be extremely dangerous. Follow the simple guidelines

below to avoid damage to your computer or injury to yourself.

Always disconnect the computer from the power outlet whenever you are working inside the computer case.

If possible, wear a grounded wrist strap when you are working inside the computer case. Alternatively,

discharge any static electricity by touching the bare metal chassis of the computer case, or the bare metal body

of any other grounded appliance.

Hold electronic circuit boards by the edges only. Do not touch the components on the board unless it is

necessary to do so. Do not flex or stress the circuit board.

Leave all components inside the static-proof packaging until you are ready to use the component for the

installation.

7

Page 16

Chapter 2 — Installing Hardware

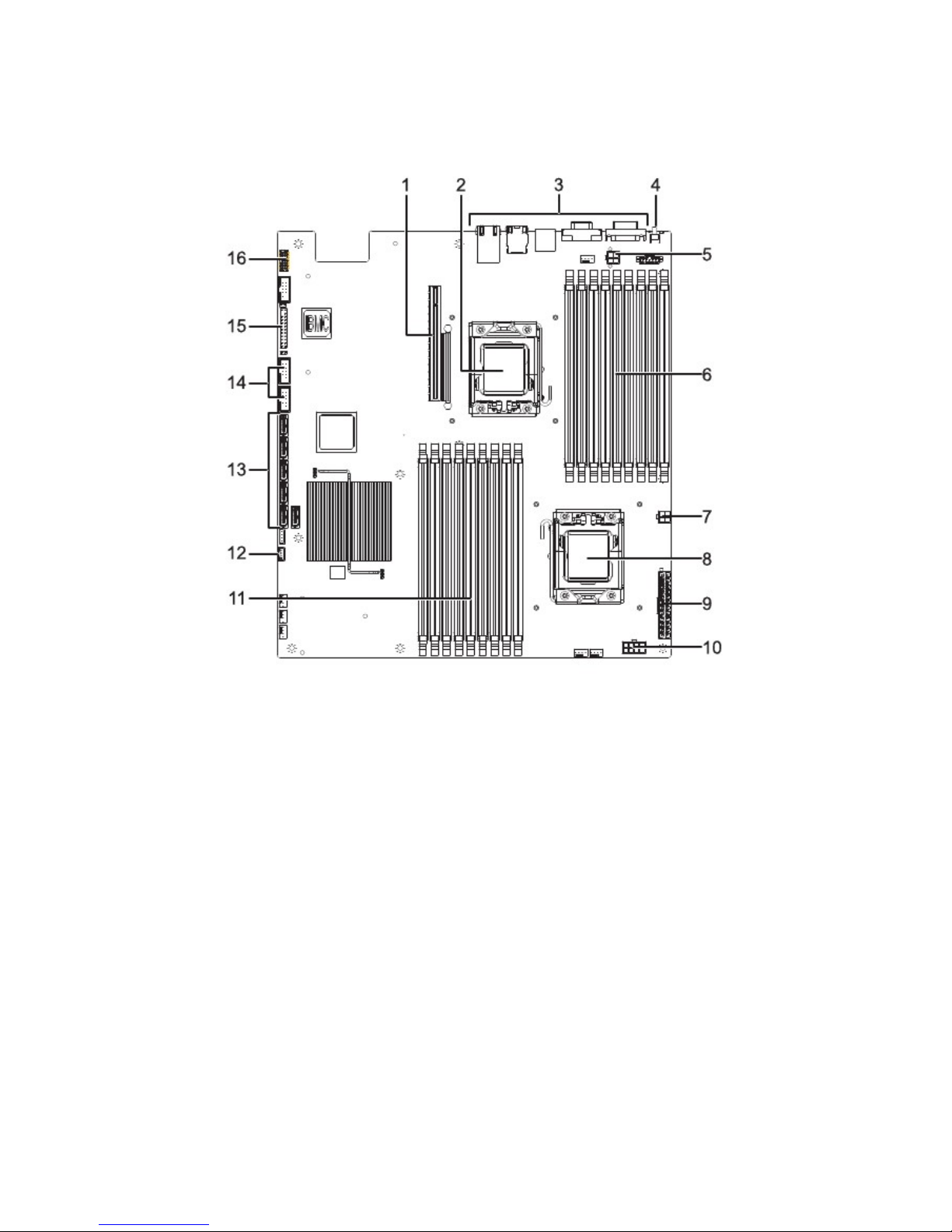

QSSC-S99K 2U Mainboard Components

The following illustration displays the most important mainboard components.

Figure 1 – Mainboard diagram

Item Component

PCI-E Slot for riser card

CPU0 socket

I/O ports (see Rear View on page 4)

ID LED button

CPU0 power connector

DDR3 DIMM slots x9 (CPU0)

CPU0 power connector

CPU1 socket

Mainboard power connector

CPU1 power connector

DDR3 DIMM slots x9 (CPU1)

IPMB connector

SATA II connectors x 6

Front USB connectors x2

Front panel connectors

Port 80

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

8

Page 17

Chapter 2 — Installing Hardware

Installing Hard Drives

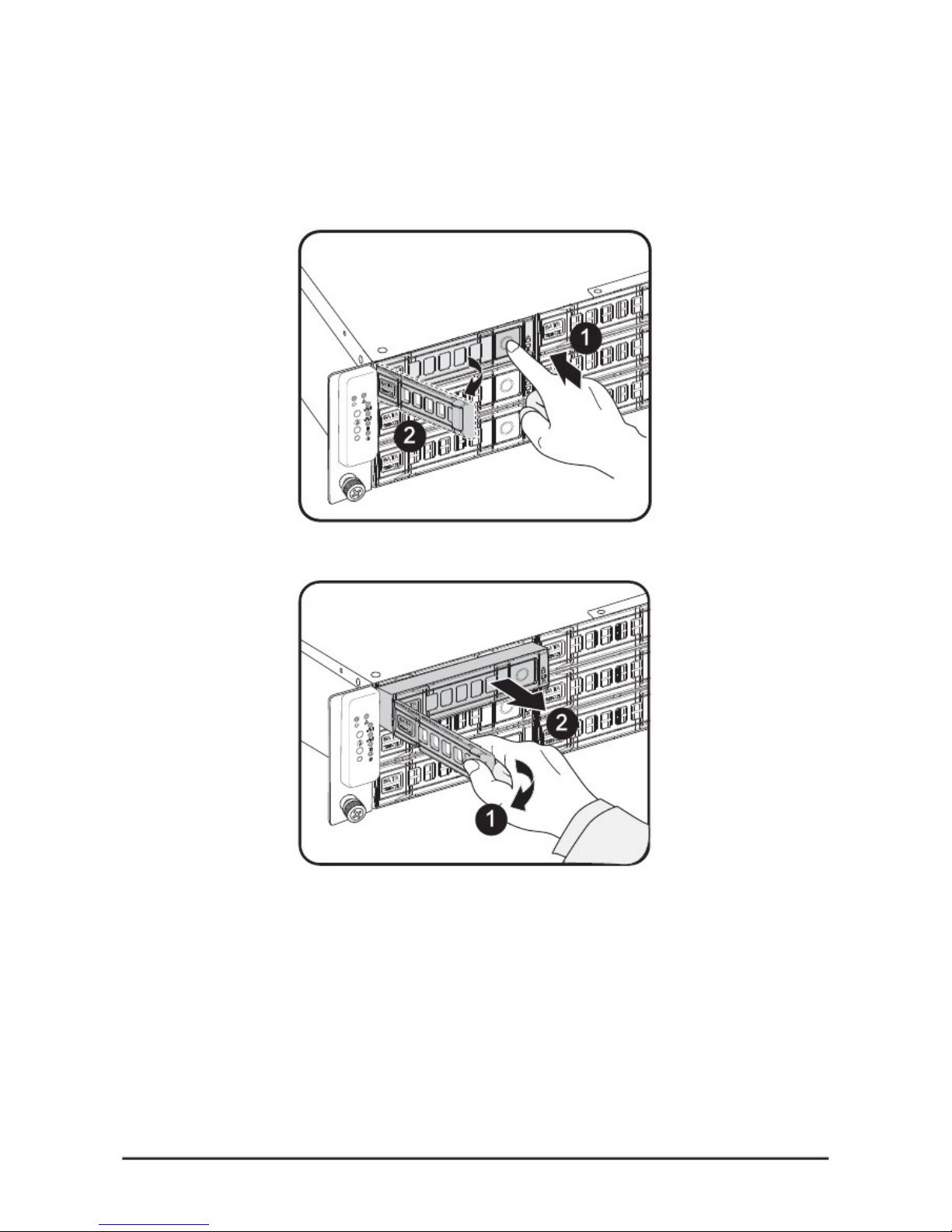

Follow these instructions to install an HDD:

1.

Push the release button in the direction of the arrow .

The HDD tray-locking handle springs open

.

2.

Open the locking handle and pull to remove the HDD tray .

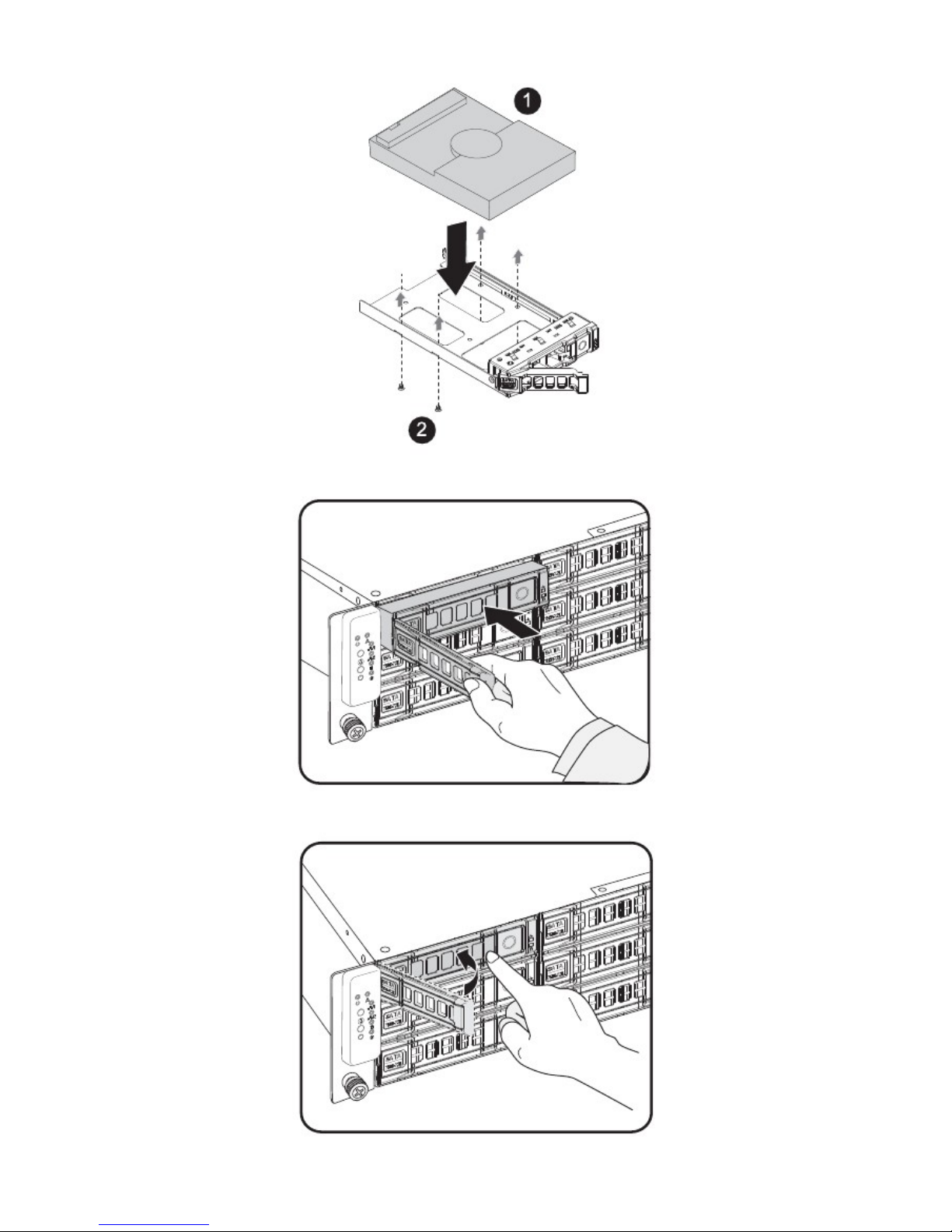

3.

Place the hard drive on the HDD tray and secure with the four screws. Do not over tighten the

screws.

9

Page 18

Chapter 2 — Installing Hardware

4. Replace the HDD tray and push firmly until the sits flush in the HDD bay.

5.

Close the locking handle by pushing it in the direction shown until it clicks.

10

Page 19

Chapter 2 — Installing Hardware

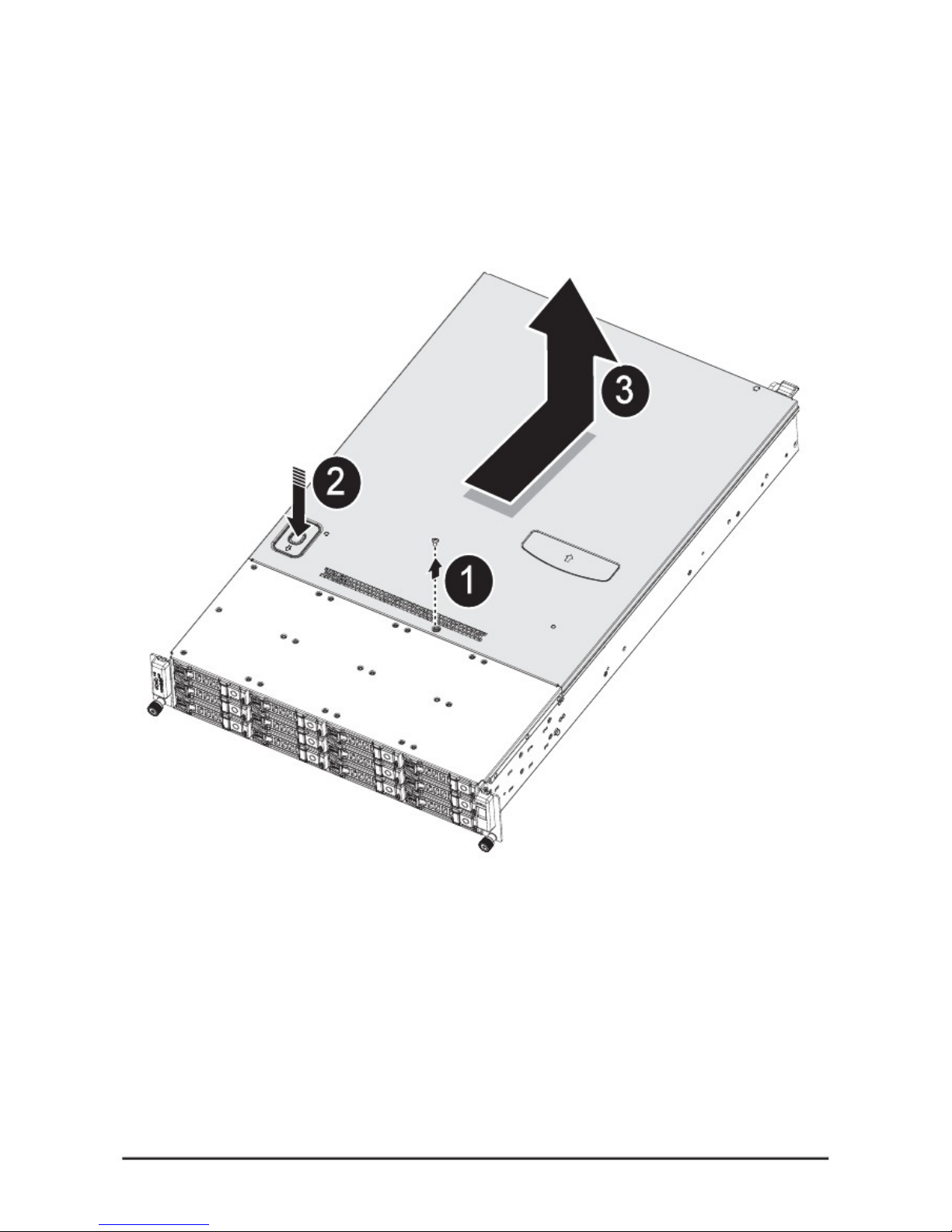

Removing the Chassis Cover

Refer to the following illustrations for instructions on removing the chassis cover:

1.

2.

3.

Remove the securing screw

Press the top cover release button

Slide the cover back and then remove

11

Page 20

Chapter 2 — Installing Hardware

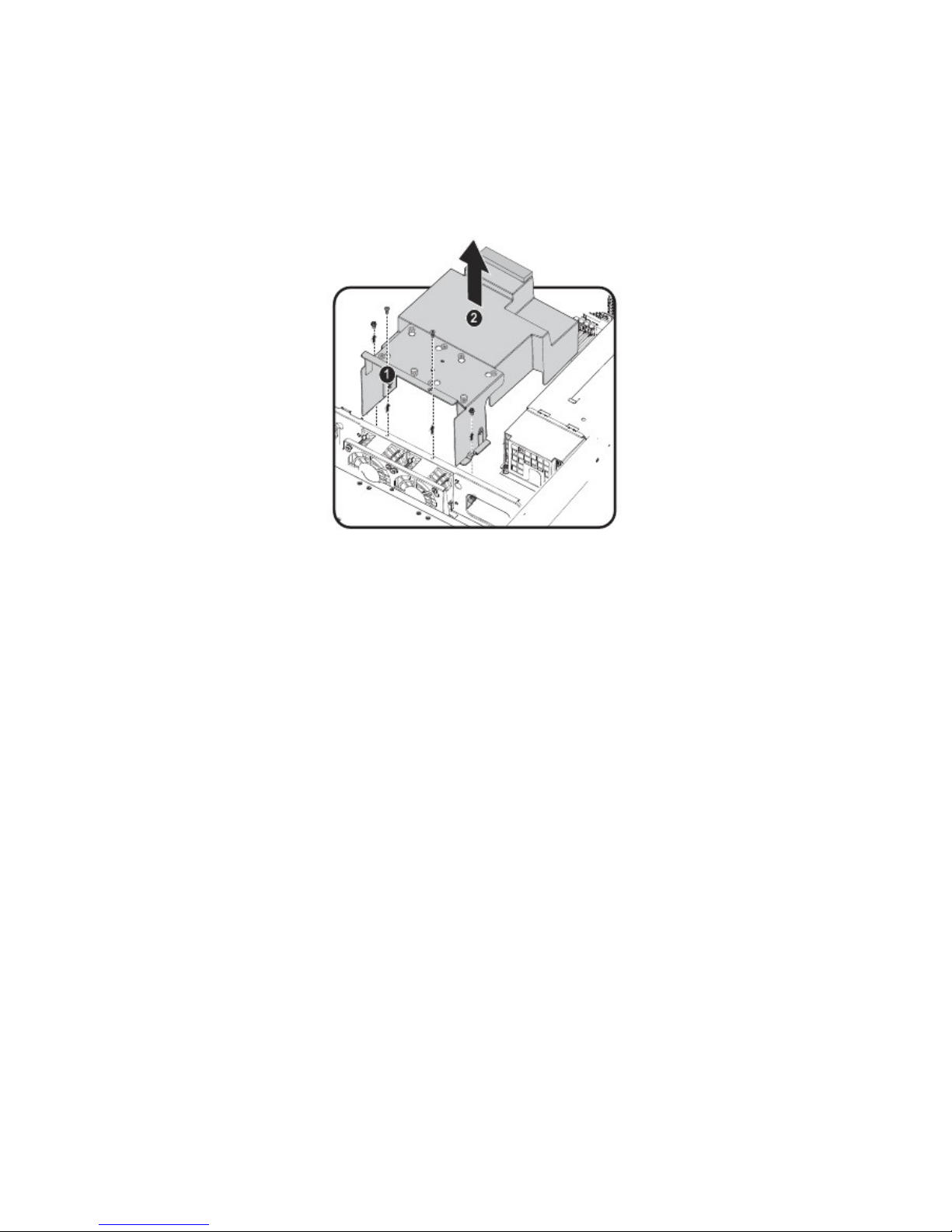

Removing the Fan Duct

Refer to the following instructions to remove the fan duct assembly.

1.

2.

Locate the fan duct cover and remove the four (4) securing screws

Carefully lift up the fan duct cover as shown

12

Page 21

Chapter 2 — Installing Hardware

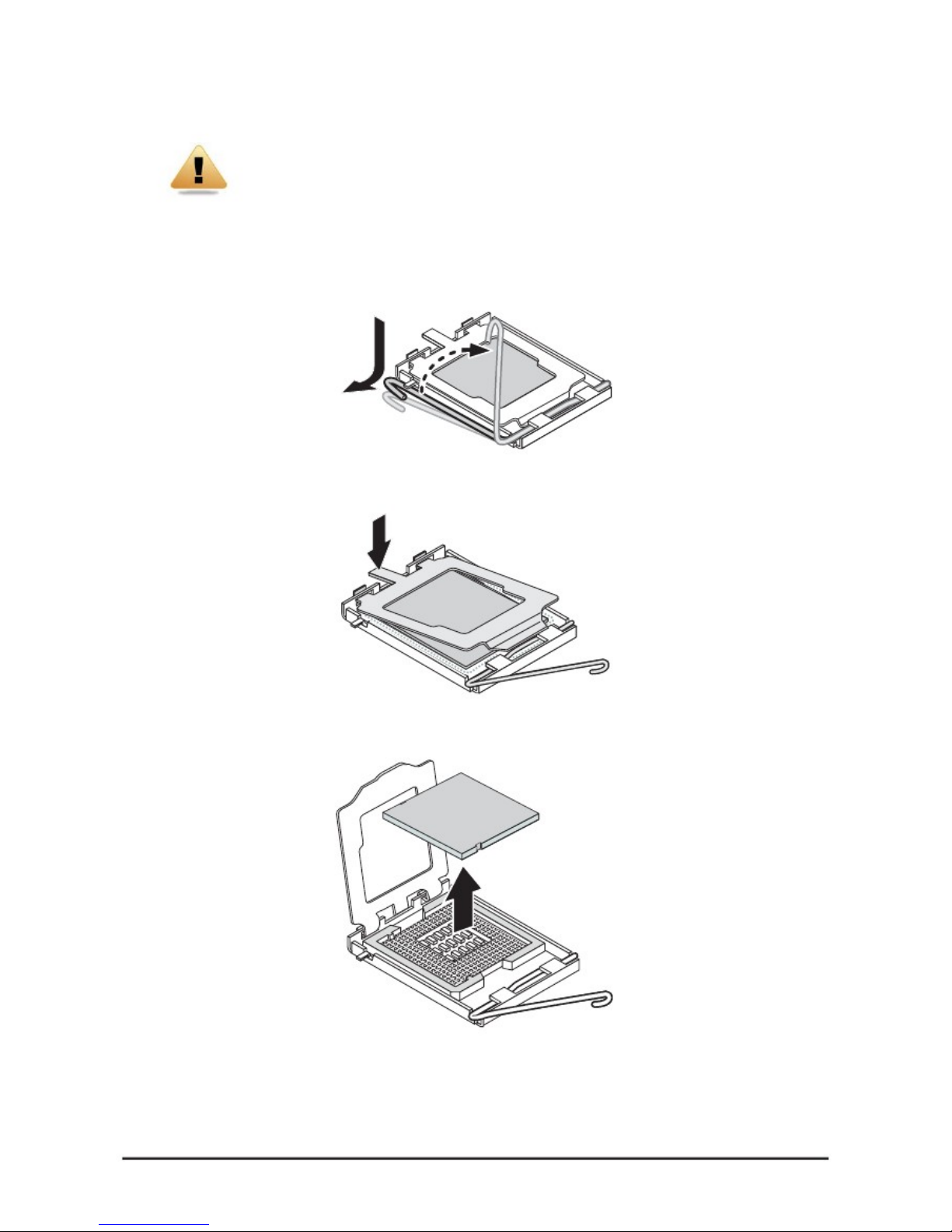

Installing CPUs

WARNING!

In a single CPU configuration, the single processor must be installed in the CPU_1 socket

(see QSSC-S99K 2U Mainboard Components on page 2 for location).

Refer to the following instructions to install CPUs:

Follow these instructions to install the CPU:

1. Pull the locking lever of the CPU socket out and up as shown.

2.

Push down as demonstrated to lift the CPU bracket.

3.

Remove the CPU dust cover by lifting the tab marked Remove.

4.

Locate the pin-1 corner of the CPU (marked by a small triangle) and the pin-1 corner of the socket; note

that the CPU has notches that fit into the socket.

13

Page 22

Chapter 2 — Installing Hardware

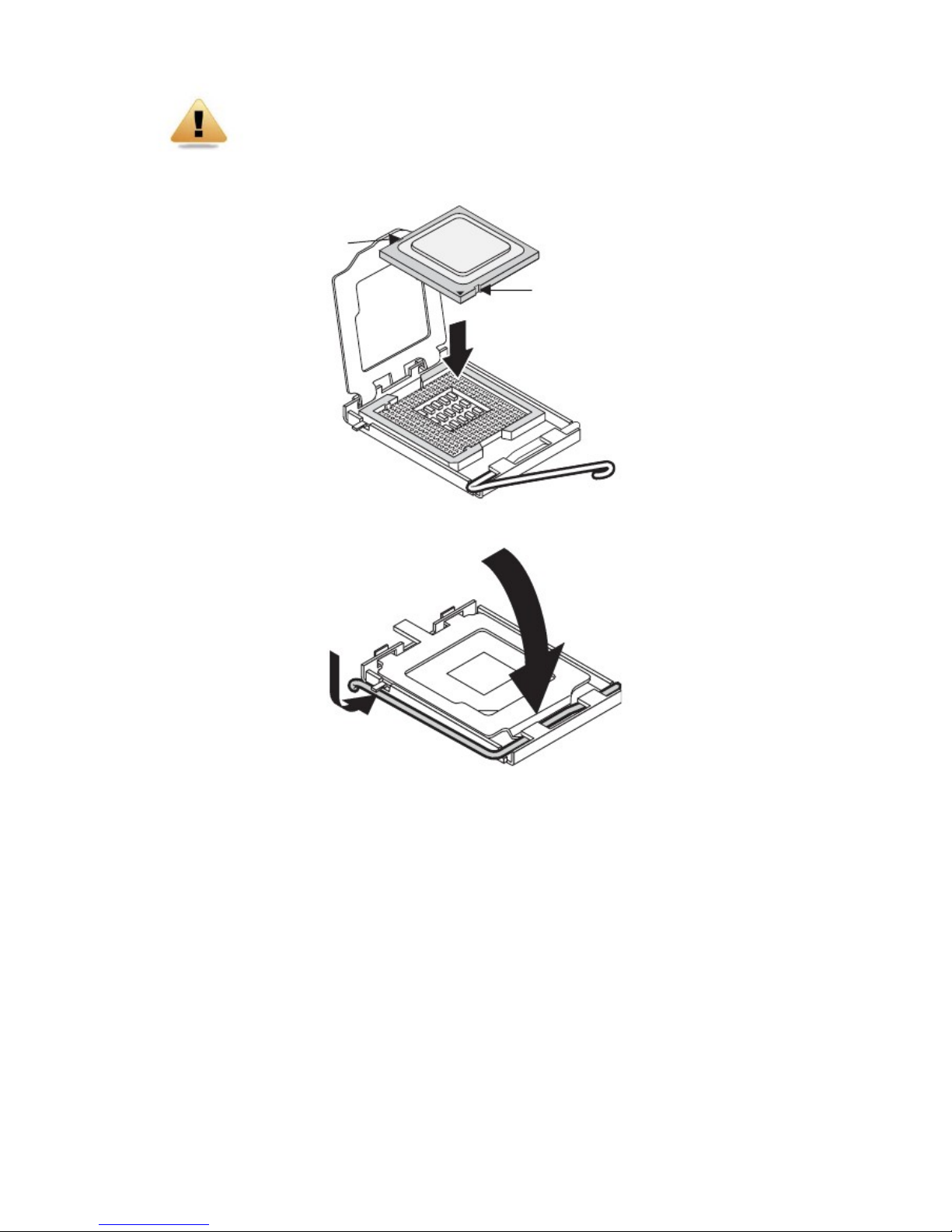

WARNING!

The QSSC-S99K 2U uses LGA 1366 sockets, which are designed for trouble free insertion of the CPU.

A

fter placing a CPU into the socket, press the lever down and lock in place. If you notice any

resistance when inserting the CPU, ensure that it is aligned correctly.

5.

Align the pin-1 corner (▼) and the notches and drop the processor into the socket.

N

otch

N

otch

6.

Replace the CPU bracket and locking lever to lock the processor in place.

7. Repeat steps 1 through 9 for the second CPU.

14

Page 23

Chapter 2 — Installing Hardware

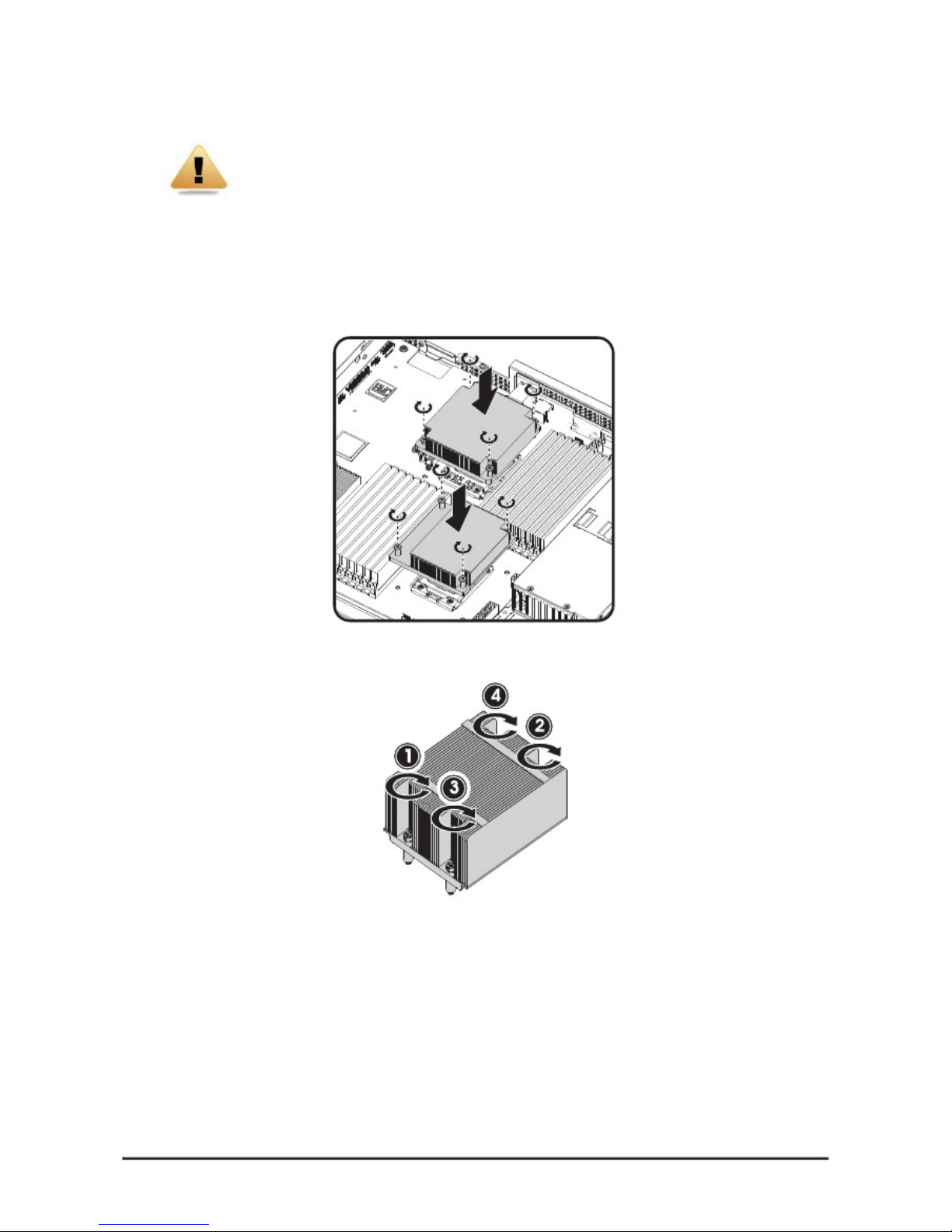

Installing Heat Sinks

WARNING!

If the server board is to be operated with only a single processor, both heat sinks must be

installed to insure proper cooling.

Refer to the following instructions to install heat sinks:

1.

2.

3.

Apply thermal compound evenly on the top of the CPU.

Remove the protective cover from the underside of the heat sink.

Place the heat sink(s) on top of the CPU and tighten the four (per heat sink) captive screws.

4. Tighten the four retaining screws clockwise, in the order shown, to secure the heat sink.

5. Repeat steps 1 through 4 for the second heat sink.

15

Page 24

Chapter 2 — Installing Hardware

Installing the Fan Duct

Refer to the following instruction to install the fan duct:

1.

2.

Insert the fan duct into place as shown .Ensure it is flush with the fan assembly and the screw holes are

aligned.

Replace the four (4) securing screws .

WARNING!

Fan ducts are situated over and around the DIMM modules. Ensure that all edges are not

lodged inside the memory banks.

16

Page 25

Chapter 2 — Installing Hardware

Installing an Expansion Card

CAUTION!

VOLTAGES CAN BE PRESENT WITHIN THE SERVER WHENEVER AN AC POWER

SOURCE IS CONNECTED. THIS VOLTAGE IS PRESENT EVEN WHEN THE MAIN

POWER SWITCH IS IN THE OFF POSITION. ENSURE THAT THE SYSTEM IS POWERED-DOWN AND ALL POWER SOURCES HAVE BEEN DIS-CONNECTED FROM THE

SERVER PRIOR TO INSTALLING A PCI CARD. USE ONLY A S99Q SPECIFIC PCI RISER

CARDS WHEN INSTALLING A PCI CARD.FAILURE TO OBSERVE THESE WARNINGS

COULD RESULT IN PER-SONAL INJURY OR DAMAGE TO EQUIPMENT.

You can install expansion cards on the system's riser board. The riser board plugs into the riser connector on the

system board.

A second PCI card can be installed. Because the lower and upper PCI cards are installed in the same manner, both

use the following procedure.

Note:

The PCI riser assembly does not include a riser card or any cabling as standard. To install a

PCI card, a riser card must be installed. Refer to riser card user manual for installation pro-

cedures.

1.

2.

3.

Remove the riser card. See Replacing the Riser Card on page 19.

Remove the PCI dummy cover on the riser assembly.

Orient the PCI card with the riser guide slot and push in the direction of the arrow until the PCI card sits

in the PCI card connector . Secure the PCI card with the screw as shown .

4.

Repeat Step 3 for a second PCI card.

5. Turn the riser assembly over and insert in the chassis.

See Replacing the Riser Card on page 19.

17

Page 26

Chapter 2 — Installing Hardware

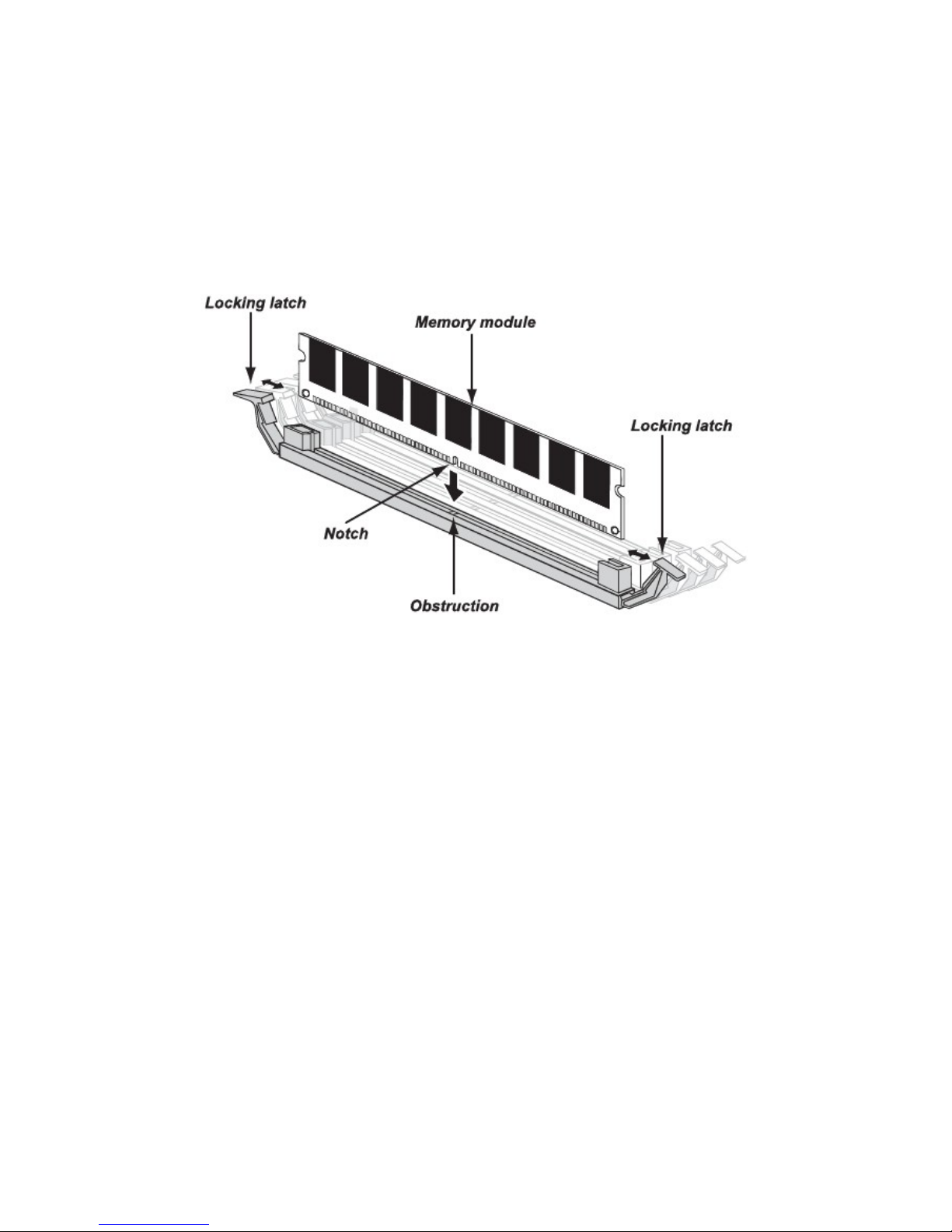

Installing Memory

The mainboard has eighteen DDR3-DIMM slots for the installation of up to twelve un-buffered DIMMs @ DDR3

800/1066/1333 MHz or eighteen registered DIMM memory sockets with ECC. Refer to QSSC-S99K 2U Mainboard Com-

ponents on page 2 for the location of the memory modules.

Refer to the following instructions to install memory modules:

1.

2.

Pull the locking latches of the DIMM slot outwards.

Align the memory module correctly. Note the notch and obstruction in the following illustration.

3. Press the edge connector of the memory module into the slot. Press down firmly so that the locking

latches of the DIMM slot are levered upwards to secure the memory module in place.

18

Page 27

Chapter 2 — Installing Hardware

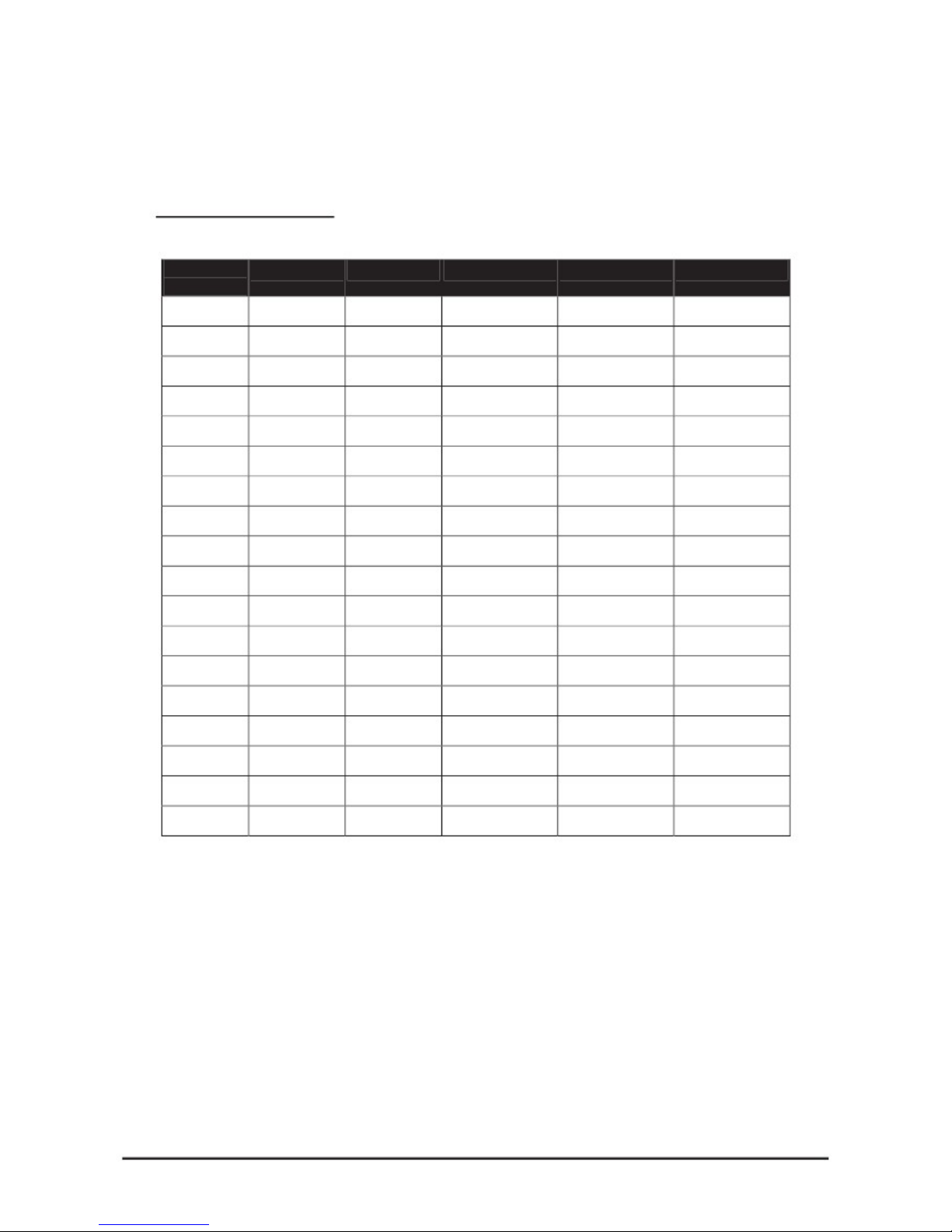

Supported DIMM Configuration

The following DIMM configurations are supported by the QSSC-S99K 2U server. DIMM slots are numbered 0 to 1 and

designated by 3 channels. Populate DIMM slots starting with slot 0: channel 0. See the following for possible

memory configurations.

DIMM Population Rule

RDIMM population configuration within a channel for three slots per channel.

No. of

DIMMs

POR Speed

DDR3-1333

DDR3-1333

DDR3-1066

DDR3-1333

DDR3-1333

DDR3-1333

DDR3-1333

DDR3-800

DDR3-800

DDR3-800

DDR3-800

DDR3-800

DDR3-800

DDR3-800

DDR3-800

DDR3-800

DDR3-800

DDR3-800

1N or 2N

1N

1N

1N

1N

1N

1N

1N

1N

1N

1N

1N

1N

1N

1N

1N

1N

1N

1N

DIMM 2

Empty

Empty

Empty

Empty

Empty

Empty

Empty

Empty

Empty

Empty

Single-rank

Single-rank

Single-rank

Dual-rank

Single-rank

Dual-rank

Dual-rank

Dual-rank

DIMM 1

Empty

Empty

Empty

Single-rank

Single-rank

Dual-rank

Dual-rank

Single-rank

Dual-rank

Quad-rank

Single-rank

Single-rank

Dual-rank

Single-rank

Dual-rank

Single-rank

Dual-rank

Dual-rank

DIMM 0

Single-rank

Dual-rank

Quad-rank

Single-rank

Dual-rank

Single-rank

Dual-rank

Quad-rank

Quad-rank

Quad-rank

Single-rank

Dual-rank

Single-rank

Single-rank

Dual-rank

Dual-rank

Single-rank

Dual-rank

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19

Page 28

Chapter 2 — Installing Hardware

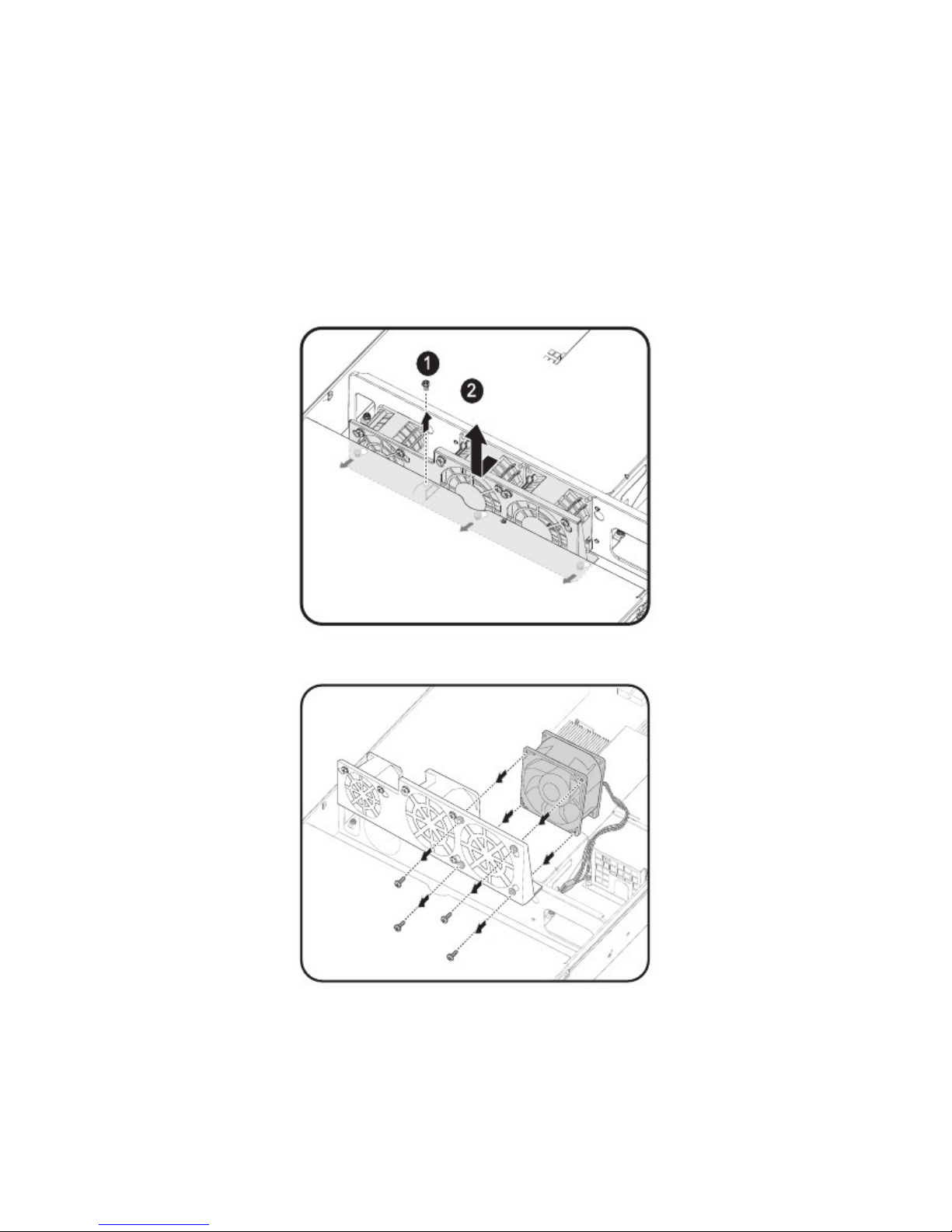

Replacing the Fan Assembly

In case of fan failure, you can quickly replace the fan assembly.

Follow these instructions to replace the fan assembly:

1.

2.

3.

4.

Remove the chassis cover. See Removing the Chassis Cover on page 5.

Disconnect the three (3) power cables from the backplane.

Remove the single securing screw from the chassis as shown.

Slide the assembly to clear the securing pins, and pull up as shown .

5.

Select the fan module to replace and remove the screws from the assembly carrier.

6.

Replace the fan and reverse steps 5 to 1 to connect the fan assembly.

20

Page 29

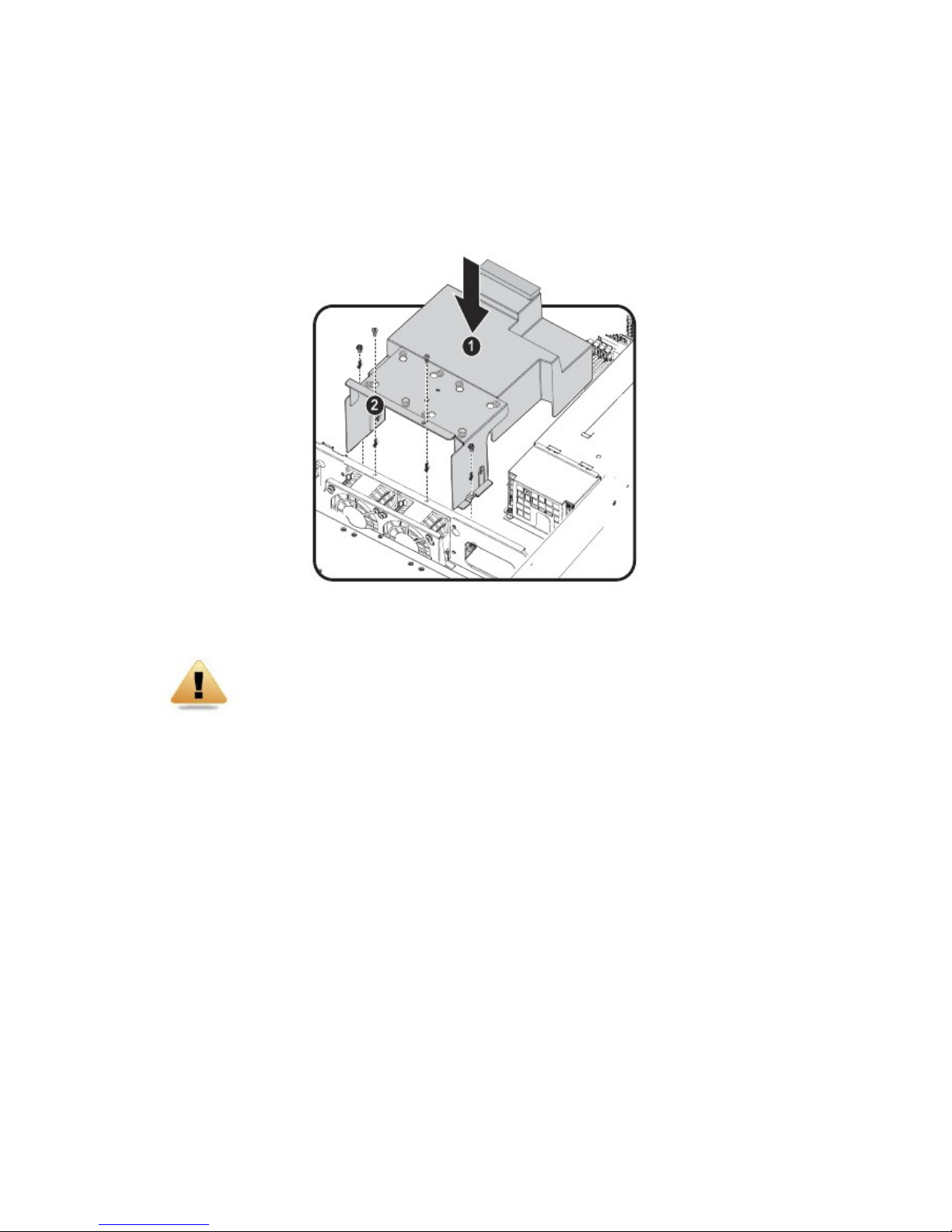

Chapter 2 — Installing Hardware

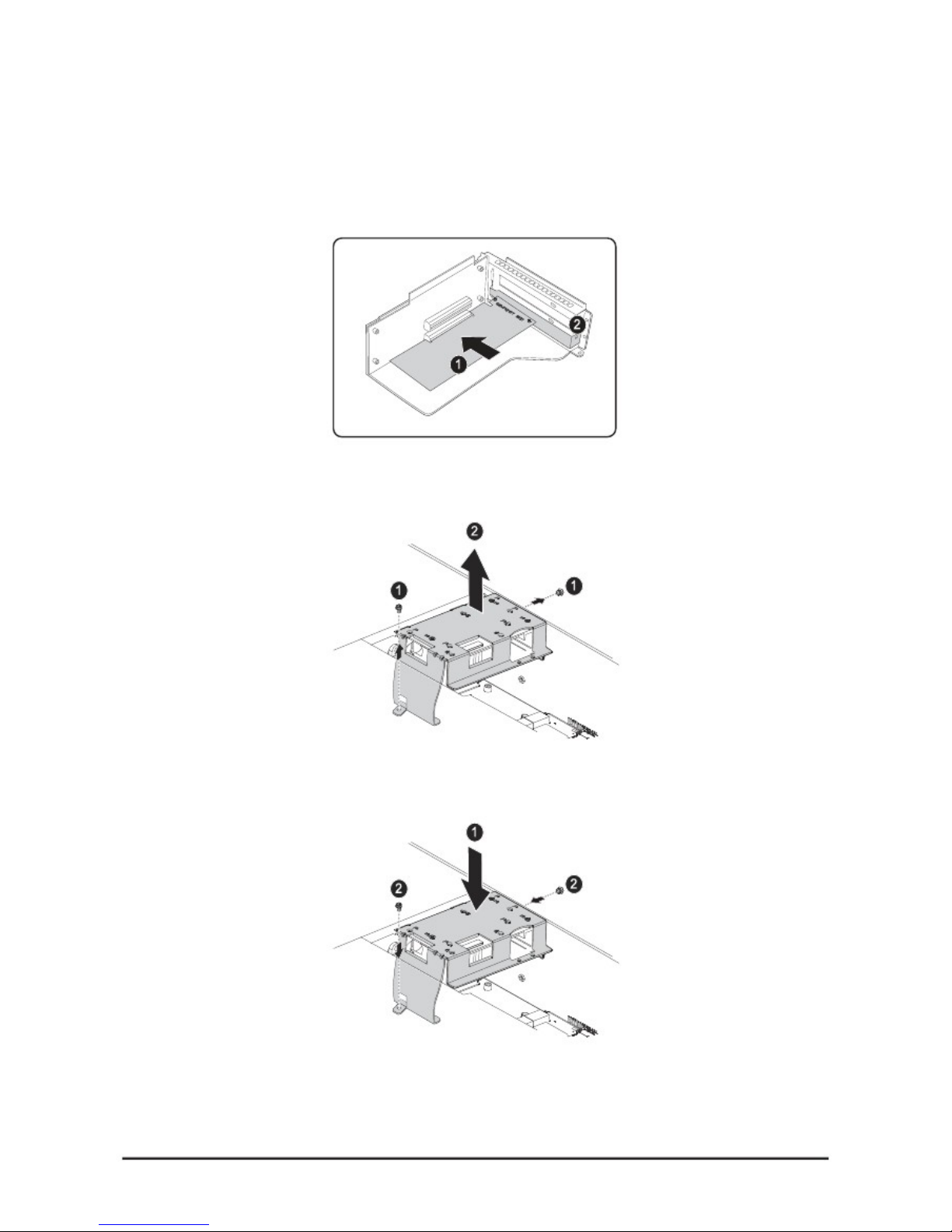

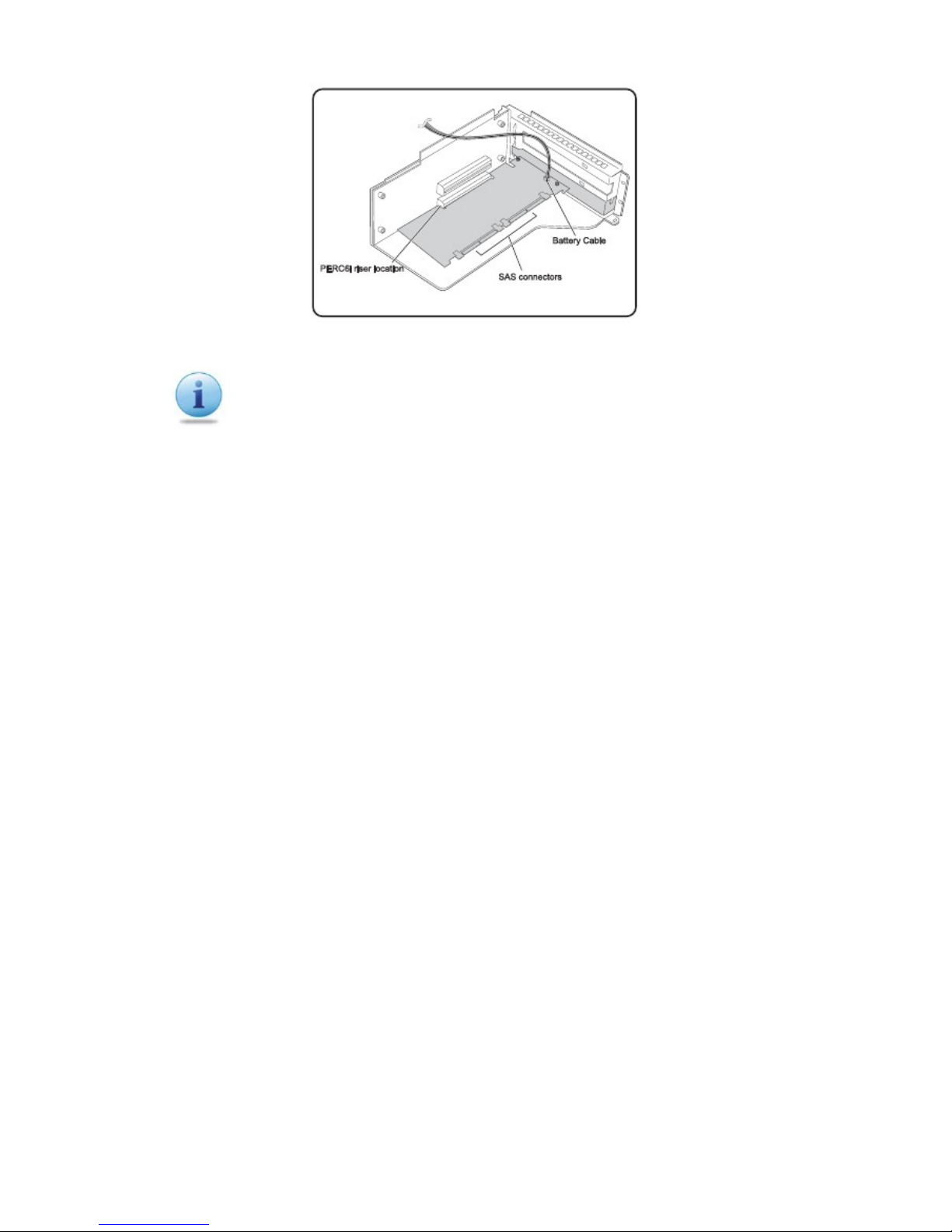

Installing the LSI SAS Raid Card and Battery

To install the LSI SAS Raid Card

1.

2.

Remove the Riser Card from the motherboard as described in Replacing the Riser Card on page 19.

Insert the LSI SAS Raid Card into the riser card as shown.

3.

4.

Locate the battery carrier and remove the two (2) securing screws .

Lift the battery carrier up to remove .

5.

6.

Turn the battery carrier over and affix the battery in place.

Replace the battery and carrier assembly , and secure in place with the two (2) screws .

7. Connect the battery leads into the indicated location on the LSI SAS Raid Card.

21

Page 30

Chapter 2 — Installing Hardware

8. Replace the Riser assembly. See Replacing the Riser Card on page 19.

Note:

The PCI riser assembly does not include a riser card or any cabling as standard. To install a

PCI card, a riser card must be installed. Refer to riser card user manual for installation pro-

cedures.

22

Page 31

Chapter 2 — Installing Hardware

Installing a Redundant Power Supply Unit

Follow the instructions as provided in the following guide to install a redundant power supply unit (PSU).

Note:

You can also install an optional backup power supply. Contact your dealer for details.

1.

2.

Remove the single securing screw from the PSU bracket .

Remove the blank bracket .

3. Insert the new power supply unit it locks in place.

23

Page 32

Chapter 2 — Installing Hardware

Replacing a Power Supply Unit

In case of a power supply failure, you can quickly replace the power supply unit (PSU).

Note:

You can also install an optional backup power supply. Contact your dealer for details.

Follow these instructions to install the redundant power supply:

1.

2.

3.

Lift the PSU handle to grasp it.

Push the locking lever in to release the PSU .

Pull the PSU by the handle to remove .

4. Insert the new power supply unit it locks in place.

24

Page 33

Chapter 2 — Installing Hardware

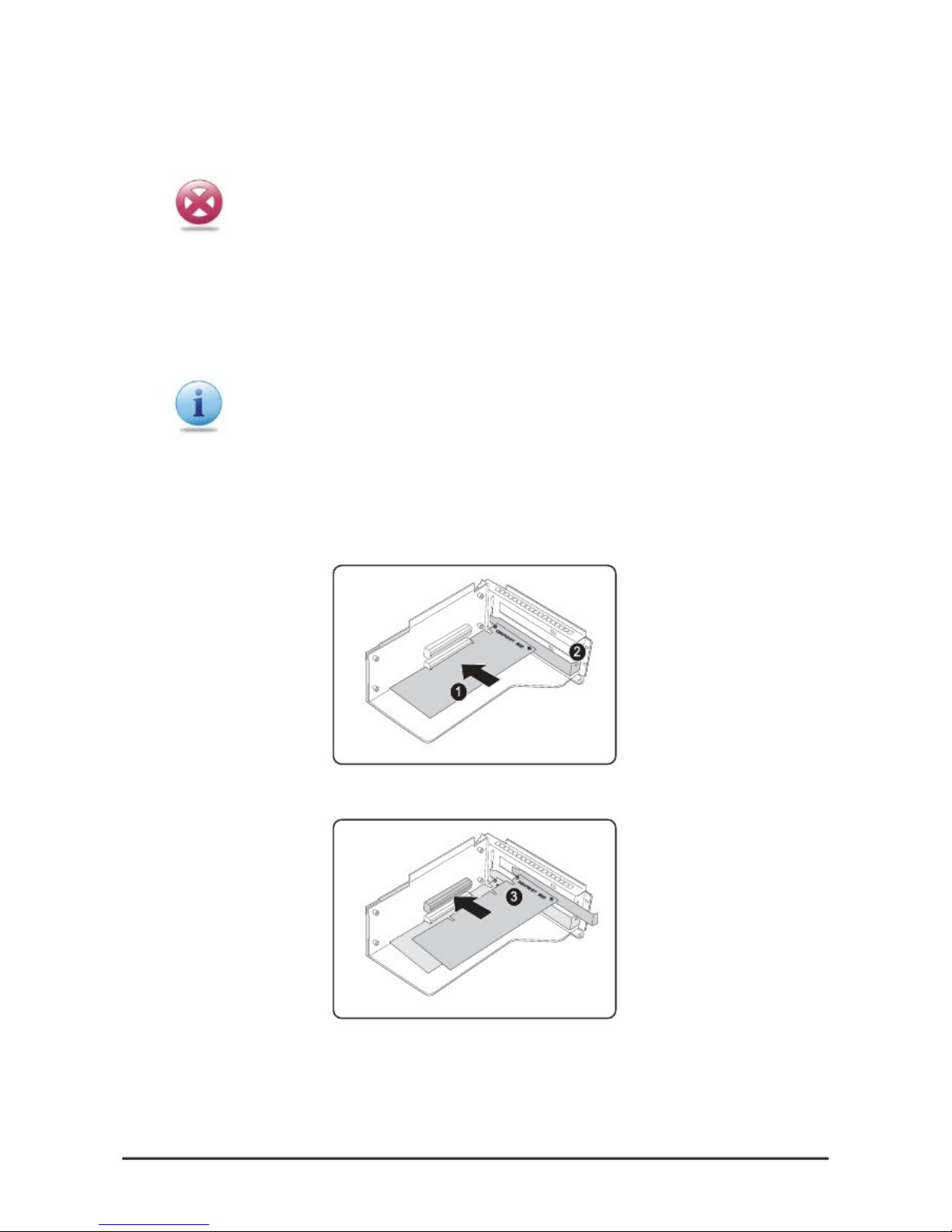

Replacing the Riser Card

Refer to the following illustrations for instructions on replacing the riser card:

1.

2.

Remove the top cover. See Removing the Chassis Cover on page 5.

Firmly grasp the riser assembly and lift up and away. See the following image.

3.

4.

5.

Turn the assembly over and place on a clean static mat.

Remove the securing screw (1) and slide the riser card as shown (2).

Pull out the riser card as shown in the following figure.

6.

To replace the riser card, reverse steps 5 to 1.

25

Page 34

Chapter 2 — Installing Hardware

Replacing the Expander Backplane

WARNING!

A

lways disconnect power cables before installing or removing any components from the

computer, including the expander backplane.

Disconnect the power cable before installing or removing any cables from the backplane.

Make sure that the backplane is securely installed to prevent damage to the system.

To remove the backplane board, perform the following steps:

1.

2.

3.

4.

5.

6.

7.

8.

9.

Remove the chassis cover. See Removing the Chassis Cover on page 5.

Remove the Fan Duct. See Removing the Fan Duct on page 6.

Remove the Fan Assembly. See Replacing the Fan Assembly on page 14.

Locate and disconnect the fan and the power cables from the backplane board.

Remove the two securing screws from the backplane board.

Grasp the backplane and gently remove the board from the chassis.

Place the new board in the chassis. Ensure that the board is right side up and the twelve hard-disk driver

connectors face outward.

Secure the board with the two screws.

Connect the fan and power cables.

10. Replace the Fan Assembly. See Replacing the Fan Assembly on page 14.

11. Replace the Fan Duct. See Removing the Fan Duct on page 6.

12. Replace the Chassis Cover. See Replacing the Chassis Cover on page 22.

26

Page 35

Chapter 2 — Installing Hardware

Replacing the Motherboard

In order to remove the motherboard, you need to disconnect all connections between the motherboard and compo-

nents in the case and any cables that are simply in the way.

Important!

When removing any component, wear a properly grounded static strap to prevent static discharge.

Follow these instructions to replace the motherboard:

1.

2.

3.

4.

5.

6.

7.

8.

9.

Unplug the power supply.

Remove the chassis cover. See Removing the Chassis Cover on page 5.

Remove all installed memory. See Installing Memory on page 12.

Remove the PCI riser card assembly. See Replacing the Riser Card on page 19.

Remove the heat sinks from the chassis. See Installing Heat Sinks on page 9.

Remove the CPU(s) from the chassis. See Installing CPUs on page 7.

Disconnect the power, IPMB, SATA, front panel, and mainboard cable connectors from the motherboard.

See QSSC-S99K 2U Mainboard Components on page 2.

Remove the ten (10) screws securing the mainboard in place.

Lift the mainboard out of the chassis in the direction of the arrow, front edge first, to clear the I/O ports.

10. When replacing the mainboard, align holes A and B to position the mainboard correctly in the chassis.

11. Replace the ten (10) screws to secure the motherboard in place.

12. Reconnect the power, IPMB, SATA, front panel, and mainboard connectors to the mainboard. See QSSC-S99K

2U

Mainboard Components on page 2.

13. Replace all removed components.

14. Replace the chassis cover. See Replacing the Chassis Cover on page 22.

27

Page 36

Chapter 2 — Installing Hardware

Replacing the Chassis Cover

Refer to the following instructions to replace the chassis cover:

1.

2.

Replace cover and slide in the direction shown (1).

Replace the securing screw (2).

28

Page 37

BIOS

BIOS System Support

BIOS Features

AMI Core 08.00.16

OEM Special Functions

Boot-Device Sequence Selection

OEM Logo Screen

Shadow RAM BIOS feature

Boot Block Feature

SMBIOS 2.5

ACPI 2.0

PXE 2.1

IPMI 2.0

4MB Flash EPROM

AC Power Loss handling

BIOS POST

At the system boot, BIOS should perform initial diagnostic test of hardware (CPU, Memory, PCI …etc). If "BIOS

Detected Error", BIOS stops the system. In any case, display an error message with POST Code. Some of the event will

be logged to BMC (e.g. CMOS checksum error, Memory ECC error, PCI error…), in any POST stop case, BMC will

timeout with a POST code event log.

BIOS stratagem is to stop the POST and display error message only when the error is detect by BIOS during POST. The

error detected by BMC or MMB during POST will handle and react by BMC or MMB, these errors are unaware for

BIOS, so BIOS will not stop the POST and not display error message to screen. For example CPU temp is monitored by

BMC to log the event, but no reaction by BMC, the CPU will do TM2 (Thermal Monitor 2) to reduce the CPU’s speed

and the temp, the worst case is, if CPU’s temp go more higher, the CPU’s Thermtrip output pin will assert to ICH10 and

make a system shut down by H/W (not by BMC). CPU’s voltage is also monitored by BMC with event log,

If error is detected, POST Code is displayed on Screen.

PCI Sub-System Sub-Device ID

SVID: 152Dh

SDID: 8981h

Hotkeys

The BIOS provides the hot keys during POST or BIOS Setup as following:

Chapter 3 — BIOS

Chapter 3

29

Page 38

Key or Key Sequence Function Availability

F2

Enter BIOS Setup During POST

F7

Discard Changes In BIOS Setup

F9

Load Optimal (e.g. CMOS) Defaults In BIOS Setup

F10

Save Settings and Exit In BIOS Setup

F11

BBS POPUP During POST

F12

PXE Boot During POST

ESC

Skip Memory Test During POST

Tab

Skip Logo During POST

Ctrl + HOME

BIOS Recovery During Boot Block

Note:

When populate an add-on card, please don’t press the add-on card option ROM control key and “F2” (Enter

BIOS setup) at the same POST. Because some add on card may need to be modified first and the information

will be show in bios setup menu at next boot (for example: SAS Raid card HDD information).

LEDs

Power LED will be turned on when system is in power on state.

Power LED Status Function description

OFF Shutdown

ON Power ON

Blink at 50% Duty Cycle Sleep/Suspend

Boot Device Sequence Selection

S99K 2U BIOS support BBS Ver.1.01.

Eventlog

S99K 2U BIOS will log POST errors and ECC/PCI/IOH/QPI errors, and eventlog can be seen from BIOS Setup. BMC

will record other system events, like FAN speed, Thermal…etc, the user can get the information through BIOS Setup and

AST2050 UI-WEB.

ECC Eventlog

S99K 2U will log two ECC events.

PCIE Eventlog

S99K 2U will log three kinds of error, correctable, uncorrectable and fatal error, for PCI-Express.

Chapter 3 — BIOS

30

Page 39

System Management BIOS (SMBIOS)

System Management BIOS Ver. 2.5 is supported.

ACPI BIOS

S99K 2U BIOS supports ACPI BIOS with system state S0, S1, S4, S5.

RAID

S99K 2U platform support RAID0, RAID1, and RAID0+1.

Console redirection

S99K 2U BIOS supports console redirection to a serial port.

If serial port based headless server support is provided by the system, the system must provide support for redirection of

all BIOS driven console I/O to the serial port .The driver for the serial console must be capable of supporting the

capabilities documented in Extensions to the ANSI Terminal Definition.

Configuring Special Keys

Console redirection used ANSI terminal emulation, which is limited to basic ASCII characters. There are no function

keys, arrow keys, or control keys in this character set. However, S99K 2U BIOS software requires the use of function

keys and control keys for ordinary functions. You can emulate a function key or control key by using a special key

sequence, call on escape sequence, to represent a specific key.

For console redirection, an escape sequence starts with an escape character. This character can be entered in a number of

different ways, depending on the requirements of your terminal emulation software. For example, 0x1b, ^[, and <Esc> all

refer to the same escape character.

Following table list the escaped sequence that must be sent to represent a special key or command.

Structure Name and Type Supported

BIOS INFORMATION (TYPE 00) Yes

SYSTEM INFORMATION (TYPE 01) Yes

BASE BOARD INFORMATION (TYPE 02) Yes

SYSTEM ENCLOSURE OR CHASSIS (TYPE 03) Yes

PROCESSOR INFORMATION (TYPE 04) Yes

CACHE INFORMATION (TYPE 07) Yes

PORT CONNECTOR INFORMATION (TYPE 08) Yes

SYSTEM SLOTS (TYPE 09) Yes

ONBOARD DEVICES INFORMATION (TYPE 10) Yes

OEM STRINGS (TYPE 11) Yes

BIOS LANGUAGE INFORMATION (TYPE 13) Yes

PHYSICAL MEMORY ARRAY (TYPE 16) Yes

MEMORY DEVICE (TYPE 17) Yes

SYSTEM BOOT INFORMATION(TYPE 32) Yes

IPMI DEVICE INFORMATION (TYPE 38) Yes

End of Table (Type 127) Yes

Chapter 3 — BIOS

31

Page 40

VT100 Supported Escape Sequences

UTF8/ANSI Supported Escape Sequences

Note: Reset key function need to press “Ctrl”, “Shift” and “–“ at the same time.

Processor Configuration

For S99K 2U, only identical processors should be installed in system. S99K 2U is 2-socket boards which may have 1 or 2

processors installed. When a single processor is installed, it must be installed into CPU Socket 0, and only DIMM sockets

on memory channels corresponding to CPU Socket 0 may be used.

Chapter 3 — BIOS

Key Escape Sequence

Up <ESC> [<Shift>a

Down <ESC> [<Shift>b

Right <ESC> [<Shift>c

Left <ESC> [<Shift>d

Home <ESC> [<Shift>h

End <ESC> [<Shift>k

F1 <ESC><Shift>op

F2 <ESC><Shift>oq

F3 <ESC><Shift>or

F4 <ESC><Shift>os

Key Escape Sequence

F1 <ESC>1

F2 <ESC>2

F3 <ESC>3

F4 <ESC>4

F5 <ESC>5

F6 <ESC>6

F7 <ESC>7

F8 <ESC>8

F9 <ESC>9

F10 <ESC>0

F11 <ESC>!

F12 <ESC>@

Home <ESC>h

End <ESC>k

Ins <ESC>+

Del <ESC>-

Alt <ESC>^A

Ctrl <ESC>^C

Page Up <ESC>?

Page Down <ESC>/

Reset <Ctrl> <Shift> -

32

Page 41

Memory Configuration

DIMM population

For three slots per channel configuration, the Tylersburg-EP platform require s DIMMs within a channel to be populated

starting with the DIMMs farthest from the processor in a “fill-farthest” approach. In addition, when populating a

quad-rank DIMM with a Single- or Dual-rank DIMM in the same channel, the Quad-rank DIMM must be populated

farthest from the processor. Note that Quad-rank DIMMs are not allowed in three slots populated configurations. All

allowed DIMM population configurations for three slots per channel are shown in below tables.

Chapter 3 — BIOS

33

Page 42

Memory RAS

1. Independent Channel Mode

Channels can be populated in any order in Independent Channel Mode. All three channels may be populated in any order

and have no matching requirements. All channels must run at the same interface frequency, but individual channels may

run at different DIMM timings (RAS latency, CAS latency, etc.).

2. Mirrored Channel Mode

In Mirrored Channel Mode, the memory contents are mirrored between Channel 0 and Channel 1. As a result of the

mirroring, the total physical memory available to the system is half of what is populated. Mirrored Channel Mode

requires that Channel 0 and Channel 1 must be populated identically. DIMM slot populations within a channel do not

have to be identical but the same DIMM slot location across Channel 0 and Channel 1 must be populated the same.

Channel 2 is unused in Mirrored Channel Mode.

3. Mirrored Channel Mode

In Lockstep Channel Mode, each memory access is a 128-bit data access that spans

Channel 0 and Channel 1. This is done to support SDDC for DRAM devices with 8-bit wide data ports. The same address

is used on both channels such that an address error on any channel is detectable by bad ECC. Lockstep Channel mode is

the only RAS mode that supports x8 SDDC. Lockstep Channel Mode requires that Channel 0 and Channel 1 must be

populated identically. That is, each DIMM in one channel must have a corresponding DIMM of identical organization

such as number of ranks, banks, rows, and/or columns. DIMMs may be of different speed grades, but the Integrated

Memory Controller will be configured to operate all DIMMs according to the slowest parameters present. DIMM slot

populations within a channel do not have to be identical but the same DIMM slot location across Channel 0 and Channel

1 must be populated the same. Channel 2 is unused in Lockstep Channel Mode.

34

Chapter 3 — BIOS

Page 43

LV DIMM support

35

Chapter 3 — BIOS

Page 44

Setup Function

Summary Screen

Summary Screen is shown prior to booting Operating System. Example:

BIOS Setup Options at Boot

The user will be able to initiate BIOS SETUP by pressing the respective keys.

<F2> Enter the BIOS Setup

Access Level

The Access Level property controls who has access to the control (supervisor, user, etc.). The following table summarizes

the effect of Access Level on a control.

Chapter 3 — BIOS Chapter 3 — BIOS Chapter 3 — BIOS

36

System Configuration, AMI BIOS Version 08.00.16

Main Processor(s) : Inter® CPU @2.40GHz

Math Processor : Built-In Base Memory Size : 640KB

Extd Memory Size : 2040MB Serial Port(s) : 3F8, 2F8

Display Type : VGA/EGA BIOS Built Date : 11/24/09

ACPI v2.0 : Enabled BMC Interface : KCS

Page 45

SETUP submenu: Main

NOTE 1: *N (N is 1, 2, 3 ….) lists the possible selection items for each SETUP ITEM.

NOTE 2: The default value for each SETUP ITEM is marked with bold and shadow.

SETUP submenu: Advance

37

Chapter 3 — BIOS

Control Group User Access Level

System Date Access Level 2

System Time Access Level 2

BIOS Setup Utility

Main Advanced Boot Server Security Exit

Use [ENTER], [TAB]

Or [SHIFT-TAB] to

Select a field.

Use [+] or [-] to

Configure system Time.

← Select Screen

↑↓ Select Item

-+ Change Field

Tab Select Field

F1 General Help

F10 Save and Exit

ESC Exit

System Overview

----------------------------------------------------

AMIBIOS

Version : S99_2A01

Build Date : 07/30/10

Product : QSSC

Processor

Genuine Intel® CPU 000 @ 2.40GHz

Speed : 2400MHz

Counte : 2

System Memory

Size : 2048MB

System Date [Fri/30/2010]

System Time [09:40:55]

v02.66 © Copyright 1985-2009, American Megatrends, Inc.

Main Advanced Boot Server Security Exit

Configure CPU.

← Select Screen

↑↓ Select Item

Enter Go to Sub Screen

F1 General Help

F10 Save and Exit

ESC Exit

BIOS Setup Utility

Advanced Settings

----------------------------------------------------

WARMING: Setting wrong values in below section

may cause system to malfunction.

► CPU Configuration

► Memory Configuration

► IDE Configuration*1

► SuperIO Configuration

► USB Configuration

► PCI Configuration

v02.66 © Copyright 1985-2009, American Megatrends, Inc.

Page 46

Control Group User Access Level

CPU Configuration Access Level 3

Memory Configuration Access Level 3

IDE Configuration Access Level 3

SuperIO Configuration Access Level 3

USB Configuration Access Level 3

PCI Configuration Access Level 3

*1: Only for SATA SKU.

CPU Configuration

*1: Disabled/Enabled (Only for CPUs that support this feature.)

*2: Disabled/Enabled (Only for CPUs that support this feature.)

*3: All/1/2

*4: Disabled/ACPI C2/ACPI C3

*5: Disabled/Enabled (NUMA for SLES 11 )

*6: Compute/IO

Control Group User Access Level

Hardware Prefetcher Access Level 1

Adjacent Cache Line Prefetch Access Level 1

L1 Data Prefectcher Access Level 1

Data Reuse Optimization Access Level 1

QPI Bandwidth Priority Access Level 1

Max CPUID Value Limit Access Level 1

Chapter 3 — BIOS

38

Advanced

Disabled for WindowsXP

← Select Screen

↑↓ Select Item

-+ Change Option

F1 General Help

F10 Save and Exit

ESC Exit

Configure advanced CPU settings

----------------------------------------------------

Intel® Xeon® CPU X5560 @ 2.80GHz

CPUID : 206C0

Frequency : 2.40GHz

BCLK Speed : 133MHz

Cache L1 : 384KB

Cache L2 : 1536 KB

Cache L3 : 12288 KB

Ratio Status : Unlocked (Min:12, Max:18)

Ratio Actual Value:18

Hardware Prefetcher [Enabled] *2

Adjacent Cache Line Prefetch [Enabled] *2

L1 Data Prefectcher [Enabled] *2

Data Reuse Optimization [Enabled] *2

QPI Bandwidth Priority [Compute] *6

Max CPUID Value Limit [Disabled] *1

Intel® Virtualization Tech [Enabled] *2

Execute-Disable Bit Capability [Enabled] *2

Intel® HT Technology [Enabled] *2

Active Processor Cores [All] *3

Intel® SpeedStep(tm) tech [Enabled] *2

Intel® Turbo mode tech [Enabled] *2

Intel® C-STATE tech [Enabled] *2

C3 State [Disabled] *4

C6 State [Enabled] *2

NUMA Support [Disabled] *5

BIOS Setup Utility

v02.66 © Copyright 1985-2009, American Megatrends, Inc.

Page 47

Intel® Virtualization Tech Access Level 1

Execute-Disable Bit Capability Access Level 1

Intel® HT Technology Access Level 1

Active Processor Cores Access Level 1

Intel® SpeedStep™ tech Access Level 1

Intel® TurboMode tech Access Level 1

Intel® C-STATE tech Access Level 1

C3 State Access Level 1

C6 State Access Level 1

NUMA Support Access Level 1

S99K 2U supports Nehalem-EP and Westmere-EP processors.

For detail description about hardware support, please refer to HW SPEC.

Memory Configuration

*1: Auto/ 800 Mhz/ 1066 Mhz

*2: Independent/Channel Mirroring/Lockstep

*3: Disable/Enabled

Control Group User Access Level

Memory Frequency Access Level 1

Memory Mode Access Level 1

Throttling - Closed Loop Access Level 1

Throttling - Open Loop Access Level 1

Chapter 3 — BIOS

39

Advanced

BIOS Setup Utility

pppppppOptionspppppp

Forces a DDR3

Frequency slower than

the common tCK

detected via SPD

← Select Screen

↑↓ Select Item

-+ Change Option

F1 General Help

F10 Save and Exit

ESC Exit

System Memory Settings

----------------------------------------------------

Current Memeory Frequency 1066MHz

Memory Frequency [Auto]*1

Memory Mode [Independent]*2

Throttling – Closed Loop [Enabled]*3

Throttling – Open Loop [Enabled]*3

v02.66 © Copyright 1985-2009, American Megatrends, Inc.

Page 48

IDE Configuration

*1: Disabled/Compatible/Enhanced

*2: IDE/RAID/AHCI

*3: Disabled/Enabled

*4: 0/5/10/15/20/25/30/35

Control Group User Access Level

SATA Configuration Access Level 1

Configure SATA#1 as Access Level 1

SATA Port0 Access Level 3

SATA Port1 Access Level 3

SATA Port2 Access Level 3

SATA Port3 Access Level 3

SATA Port4 Access Level 3

SATA Port5 Access Level 3

Hard Disk Write Protect Access Level 1

IDE Detect Time Out (Sec) Access Level 1

HDD Security Erase Support Access Level 1

Chapter 3 — BIOS

40

Advanced

BIOS Setup Utility

pppppppOptionspppppp

Disabled

Compatible

Enhanced

← Select Screen

↑↓ Select Item

-+ Change Option

F1 General Help

F10 Save and Exit

ESC Exit

IDE Configuration

----------------------------------------------------

SATA Configuration [Enhanced]*1

Configure SATA#1 as [IDE]*2

► SATA Port0 : [Hard Disk]

► SATA Port1 : [Not Detected]

► SATA Port2 : [Not Detected]

► SATA Port3 : [Not Detected]

► SATA Port4 : [Not Detected]

► SATA Port5 : [Not Detected]

Hard Disk Write Protect [Disabled]*3

IDE Detect Time Out (Sec) [35]*4

HDD Security Erase Support [Disabled]*3

Advanced

BIOS Setup Utility

Disabled: Disables LBA

Mode.

Auto: Enables LBA Mode if

the device supports it and

the device is not already

formatted with LBA Mode

disabled.

← Select Screen

↑↓ Select Item

-+ Change Option

F1 General Help

F10 Save and Exit

ESC Exit

SATA Port1

----------------------------------------------------

Device : Hard Disk

Vendor : ST320410A

Size : 20.0GB

LBA Mode : Supported

Block Mode : 16Sectors

PIO Mode : 4

Async DMA : MultiWord DMA-2

Ultra DMA : Ultra DMA-2

S.M.A.R.T : Supported

----------------------------------------------------

Type [Auto]*1

LBA/Large Mode [Auto]*2

Block (Multi-Sector Transfer) [Auto]*2

PIO Mode [Auto]*3

DMA Mode [Auto]*4

S.M.A.R.T. [Auto]*5

32Bit Data Transfer [Enabled]*6

v02.66 © Copyright 1985-2009, American Megatrends, Inc.

v02.66 © Copyright 1985-2009, American Megatrends, Inc.

Page 49

*1: Not Installed/Auto/CD/DVD/ARMD

*2: Disabled/Auto

*3: Auto/0/1/2/3/4

*4: Auto/SWDMA0/SWDMA1/SWDMA2/MWDMA0/MWDMA1/MWDMA2

/UDMA0/UDMA1/UDMA2/UDMA3/UDMA4/UDMA5/UDMA6

*5: Auto/Disabled/Enabled

*6: Disabled/Enabled

Control Group User Access Level

Type Access Level 1

LBA/Large Mode Access Level 1

Block (Multi-Sector Transfer) Mode Access Level 1

PIO Mode Access Level 1

DMA Mode Access Level 1

S.M.A.R.T. Access Level 1

32Bit Data Transfer Access Level 1

SuperIO Configuration

*1: Disabled/[3F8/IRQ4]/[3E8/IRQ4]/[2E8/IRQ3]

*2: Disabled/[2F8/IRQ3]/[3E8/IRQ4]/[2E8/IRQ3]

Control Group User Access Level

Serial Port1 Address Access Level 1

Serial Port2 Address Access Level 1

Chapter 3 — BIOS

41

Advanced

BIOS Setup Utility

A

llows BIOS to Select

Serial Port1 Base

Addresses.

← Select Screen

↑↓ Select Item

-+ Change Option

F1 General Help

F10 Save and Exit

ESC Exit

Configure Win627DHG Super IO Chipset

---------------------------------------------------Serial Port1 Address [3F8/IRQ4]*1

Serial Port2 Address [2F8/IRQ3]*2

v02.66 © Copyright 1985-2009, American Megatrends, Inc.

Page 50

USB Configuration

*1: Disabled/Auto

Control Group User Access Level

Legacy USB Support Access Level 1

USB Mass Storage Device Configuration Access Level 3

*1:10 Sec / 20 Sec / 30 Sec / 40 Sec

*2: Auto / Floppy / Forced FDD / Hard Disk / CDROM

Control Group User Access Level

USB Mass Storage Reset Delay Access Level 1

Emulation Type Access Level 1

42

Chapter 3 — BIOS

A

uto option disables

Legacy support if no

USB devices are

connected.

← Select Screen

↑↓ Select Item

-+ Change Option

F1 General Help

F10 Save and Exit

ESC Exit

USB Configuration

----------------------------------------------------

USB Devices Enabled :

3 Keyboard, 3 Mice, 1 Drive

Legacy USB Support [Auto]*1

USB 2.0 Controller [Enabled]

► USB Mass Storage Device Configuration

Advanced

BIOS Setup Utility

v02.66 © Copyright 1985-2009, American Megatrends, Inc.

Advanced

BIOS Setup Utility

Number of seconds POST

waits for the USB mass

storage Devices after start

Unit command.

← Select Screen

↑↓ Select Item

-+ Change Option

F1 General Help

F10 Save and Exit

ESC Exit

USB Mass Stroage Device Configuration

----------------------------------------------------

USB Mass Stroage Reset Delay [20 Sec] *1

Device#1 USB Flash Disk

Emulation Type [Auto]*2

v02.66 © Copyright 1985-2009, American Megatrends, Inc.

Page 51

PCI Configuration

*1: Disabled/Enable with PXE/Enable without PXE

*2: Slow-Mode/Full-Speed

*3: Auto/4.800GT/5.866GT/6.400GT

*4: Disabled/Enabled

*5: Disabled/Enabled

*6: Auto/128 Bytes/256 Bytes

NOTE: If “iSCSI Remote Boot” be enabled, then both NIC1 and NIC2 will not be displayed.

Control Group User Access Level

Maximum Payload Size Access Level 2

iSCSI Remote Boot Access Level 1

NIC1 – KAWELA Access Level 1

NIC2 - KAWELA Access Level 1

PCI-E SLOT Option ROM Access Level 2

PCI-E Connector Option ROM Access Level 2

QPI Links Speed Access Level 1

QPI Frequency Access Level 1

QPI L0s and L1 Access Level 1

Crystal Beach / DMA Access Level 1

Intel VT-d Access Level 1

SR-IOV Supported Access Level 1

Active State Power Management Access Level 2

ME Support Access Level 1

Chapter 3 — BIOS

43

Advanced

BIOS Setup Utility

pppppppOptionspppppp

Disabled

Enable with PXE

Enabled without PXE

iSCSI Remote Boot.

← Select Screen

↑↓ Select Item

-+ Change Option

F1 General Help

F10 Save and Exit

ESC Exit

PCI Configuration

----------------------------------------------------

Maximum Payload Size [Auto]*6

iSCSI Remote Boot [Disabled] *4

NIC1 - KAWELA [Enable with PXE]*1

NIC2 - KAWELA [Enable with PXE]*1

PCI-E SLOT Option Rom [Enabled] *5

PCI-E Connector Option Rom [Enabled] *5

NIC1 Mac Address [00-23-8B-64-8E-EC-CD]

NIC2 Mac Address [00-23-8B-64-8E-EC-CE]

Current QPI Frequency 6.400GT

QPI Links Speed [Full-Speed]*2

QPI Frequency [Auto]*3

QPI L0s and L1 [Enabled] *5

Crystal Beach/DMA [Disabled]*4

Intel VT-d [Disabled]*4

SR-IOV Supported [Disabled]*4

Active State Power-Management [Disabled]*4

ME Support [Enabled] *5

v02.66 © Copyright 1985-2009, American Megatrends, Inc.

Page 52

SETUP submenu: Boot

Boot Settings Configuration

44

Control Group User Access Level

Boot Settings Configuration Access Level 3

Boot Device Priority Access Level 3

Hard Disk Drives Access Level 3

CD/DVD Device Access Level 3

Network Device Access Level 3

USB Drives Access Level 3

Chapter 3 — BIOS

Main Advanced Boot Server Security Exit

Configure Settings during

System Boots.

← Select Screen

↑↓ Select Item

-+ Change Option

F1 General Help

F10 Save and Exit

ESC Exit

Boot Settings

----------------------------------------------------

► Boot Settings Configuration

► Boot Device Priority

► Hard Disk Drives

► CD/DVD Device

► Network Device

► USB Drives

BIOS Setup Utility

v02.66 © Copyright 1985-2009, American Megatrends, Inc.

Boot

A

llow BIOS to skip certain

tests while booting. This

will decrease the time

needed to boot the system.

← Select Screen

↑↓ Select Item

-+ Change Option

F1 General Help

F10 Save and Exit

ESC Exit

Boot Settings Configuration

----------------------------------------------------

Quick Boot [Enabled]*1

Quiet Boot [Disabled]*2

AddOn ROM Display Mode [Force BIOS]*3

Bootup Num-Lock [On]*4

Wait For ‘F1’ If Error [Disabled]*2 *5

Hit ‘F2’ Message Display [Enabled]*1

BIOS Setup Utility

v02.66 © Copyright 1985-2009, American Megatrends, Inc.

Page 53

*1: Disabled/Enabled

*2: Disabled/Enabled

*3: Force BIOS/Keep Current

*4: Off/On

*5: Only for POST error event

Boot Device Priority

Control Group User Access Level

1st Boot Device Access Level 1

2nd Boot Device Access Level 1

Control Group User Access Level

Quick Boot Access Level 2

Quiet Boot Access Level 2

AddOn ROM Display Mode Access Level 1

Bootup Num-Lock Access Level 1

Wait For 'F1' If Error Access Level 1

Hit 'F2' Message Display Access Level 1

Chapter 3 — BIOS

45

Specifies the boot

sequence from the

available devices.

A device enclosed in

parenthesis has been

disabled in the

corresponding type menu.

← Select Screen

↑↓ Select Item

-+ Change Option

F1 General Help

F10 Save and Exit

ESC Exit

Boot Device Priority

----------------------------------------------------

1st Boot Device [USB:USB Flash Disk]

2nd Boot Device [Network: IBA GB Slo]

Boot

BIOS Setup Utility

v02.66 © Copyright 1985-2009, American Megatrends, Inc.

Page 54

SETUP submenu: Server

*1: Disabled/Enabled

*2: Disabled/Enabled

*3: Power Off/Power On/Last State

*4: Disabled/Correctable/Uncorrectable/Fatal

Control Group User Access Level

Set BMC LAN Configuration Access Level 3

Remote Access Configuration Access Level 3

Restore on AC Power Loss Access Level 1

View BMC System Event Log Access Level 3

Clear BMC System Event Log Access Level 1

Event Logging Access Level 1

ECC Event Logging Access Level 1

PCI Error Logging Access Level 1

QPI Error Logging Access Level 1

IOH Internal Error Logging Access Level 1

NMI on Error Access Level 1

46

Chapter 3 — BIOS

Main Advanced Boot Server Security Exit

Configure Remote Access.

←→ Select Screen

↑↓ Select Item

Enter Go to Sub Screen

F1 General Help

F10 Save and Exit

ESC Exit

IPMI Configuration

----------------------------------------------------

Status Of BMC Working

IPMI Specification Version 2.0

BMC Firmware Version 00 00.01

► Set BMC LAN Configuration

► Remote Access Configuration

Restore on AC Power Loss [Power On]*3

Event Control Interface

----------------------------------------------------

►View BMC System Event Log

Clear BMC System Event Log

Event Logging [Enabled] *1

ECC Event Logging [Enabled] *1

PCI Error Logging [Enabled] *1

QPI Error Logging [Enabled] *1

IOH Internal Error Logging [Enabled] *1

NMI on Error [Fatal]*4

BIOS Setup Utility

v02.66 © Copyright 1985-2009, American Megatrends, Inc.

Page 55

Set BMC LAN Configuration

*1: Dedicated -NIC/ Shared-NIC

*2: Disabled/ Enabled

*3: Input By User

*4: Don’t set Lan in BIOS menu and BMC web at the same time

Control Group User Access Level

BMC LAN Port Configuration Access Level 1

DHCP Enabled Access Level 1

IP Address Access Level 1

Subnet Mask Access Level 1

GateWay Address Access Level 1

Chapter 3 — BIOS

47

Server

Select BMC LAN port

to dedicated-NIC or

shared-NIC

← Select Screen

↑↓ Select Item

-+ Change Option

F1 General Help

F10 Save and Exit

ESC Exit

Lan Configuration

----------------------------------------------------

Channel Number [01]

Channel Number Status : Status is OK

BMC LAN Port Configuration [Shared-NIC]*1

DHCP Enabled [Disabled]*2

IP Address [192.168.001.002]*3

Subnet Mask [255.255.255.000]*3

GateWay Address [192.168.001.001]*3

Current Mac address in BMC: 00.00.64.3D.30.78

BIOS Setup Utility

v02.66 © Copyright 1985-2009, American Megatrends, Inc.

Page 56

Remote Access Configuration

*1: Disabled/Enabled

*2: COM1/COM2

*3: 115200 8,n,1/57600 8,n,1/38400 8,n,1/19200 8,n,1/09600 8,n,1

*4: None/Hardware/Software

*5: Disabled/Enabled

*6: ANSI/VT100/VT-UTF8

Limitation: When populate serial device, the remote access function must be disabled.

Control Group User Access Level

Remote Access Access Level 2

Serial port number Access Level 2

Serial Port Mode Access Level 2

Flow Control Access Level 2

Redirection After BIOS POST Access Level 2

Terminal Type Access Level 2

View BMC System Event Log

Chapter 3 — BIOS

48

Select Remote Access

type.

← Select Screen

↑↓ Select Item

-+ Change Option

F1 General Help

F10 Save and Exit

ESC Exit

Configure Remote Access type and parameters

----------------------------------------------------

Remote Access [Enabled]*1

Serial port number [COM1]*2

Current SOL Baud Rate 115200 bps

Serial Port Mode [115200 8,n,1]*3

Flow Control [None]*4

Redirection After BIOS POST [Enabled]*5

Terminal Type [ANSI]*6

Server

BIOS Setup Utility

v02.66 © Copyright 1985-2009, American Megatrends, Inc.

Use +/- to traverse

The event log.

← Select Screen

↑↓ Select Item

-+ Change Option

F1 General Help

F10 Save and Exit

ESC Exit

Total Number Of Entries: 84

----------------------------------------------------

SEL Entry Number [1]

SEL Record ID: 0001

SEL Record Type 02(System Event)

Event Timestamp: 48s from SEL init

Generator ID: 0020

Event Message Format Ver: 04 (IPMI ver 2.0)

Event Sensor Type 14 (Button)

Event Sensor Number: D3

Event Dir Type: 6F

Event Data: 00 00 00

- Power Button pressed

- N/A

- N/A

Server

BIOS Setup Utility

v02.66 © Copyright 1985-2009, American Megatrends, Inc.

Page 57

SETUP submenu: Security

*1: No Access/View Only/Limited/Full Access

*2: Setup/Always

Control Group User Access Level

Change Supervisor Password Access Level 0

User Access Level Access Level 0

Change User Password Access Level 1

Clear User Password Access Level 1

Password Check Access Level 1

SETUP submenu: Exit

Chapter 3 — BIOS

49

Main Advanced Boot Server Security Exit

Install or Change the

Password

← Select Screen

↑↓ Select Item

-+ Change Option

F1 General Help

F10 Save and Exit

ESC Exit

Security Settings

----------------------------------------------------

Supervisor Password : Not Installed

User Password : Not Installed

Change Supervisor Password

User Access Level [Full Access] *1

Change User Password

Clear User Password

Password Check [Setup] *2

Main Advanced Boot Server Security Exit

Exit system setup

after saving the

changes.

F10 key can be used

for this operation.

← Select Screen

↑↓ Select Item

-+ Change Option

F1 General Help

F10 Save and Exit

ESC Exit

Exit Options

----------------------------------------------------

Save Changes and Exit

Discard Changes and Exit

Discard Changes

Load Optimal Defaults

BIOS Setup Utility

v02.66 © Copyright 1985-2009, American Megatrends, Inc.

BIOS Setup Utility

v02.66 © Copyright 1985-2009, American Megatrends, Inc.

Page 58

ControlGroup UserAccessLevel

SaveChangesandExit AccessLevel2

DiscardChangesandExit AccessLevel3

DiscardChanges AccessLevel3

LoadOptimalDefaults AccessLevel1

Save Changes and Exit

Highlight this item and press Enter to save any changes that you have made in the Setup utility and exit the Setup utility.

When the Save Settings and Exit dialog box appears, select [OK] item to save the changes and exit, or press [Cancel] to

return to the setup main menu. [F10] key can be used for this operation.

Discard Changes and Exit

Highlight this item and press Enter to discard any changes that you have made in the Setup utility and exit the Setup utility.

When the Exit Discarding Changes dialog box appears, press [OK] to discard changes and exit, or press [Cancel] to return to

the setup main menu. [ESC] key can be used for this operation.

Discard Changes

If you highlight this item and press Enter, a dialog box asks if you want to discard the settings changes for all the items in the

Setup utility. Select the [OK] item to indicate Yes, and then press Enter to bypass the optimal settings changes.

Load Optimal Defaults

If you highlight this item and press Enter, a dialog box asks if you want to install optimal settings for all the items in the

Setup utility. Select the [OK] item to indicate Yes, and then press Enter to install the optimal settings. [F9] key can be used

for this operation.

Chapter 3 — BIOS

50

Page 59

ACPI BIOS Specification

System States

The S99K 2U hardware supports these ACPI states as followings. The S99K 2U could wake up from S0, S1 and S4.

G0, System in working mode

While the system is in the S0 state, it is in the system working state. The behavior of this state is defined as:

The processors are in the C0, C1, C2, or C3 states. The processor complex context is maintained and instructions are

executed as defined by any of these processor states.

Dynamic RAM context is maintain ed and is read/write by the processors.

Devices states are individually managed by the operating software and can be in any device state (D0, D1, D2 or D3).

Power Resources are in a state compatible with the current device states.

Transition into the S0 state from some system sleeping state is automatic, and by virtue that instructions are being executed

the OS assumes the system to be in the S0 state.

G1, System in Suspend to Memory

While the system is in this state, it is in the system S4 sleeping state. The state is logically lower than the S1 state and is

assumed to conserve more power. The behavior of this state is defined as follows:

The processors are not executing instructions. The processor complex context is not maintained.

Dynamic RAM context is maintain ed.

Power Resources are in a state compatible with the system S4 state. All Power Resources that supply a System Level

reference of S0 or S1 are in the OFF state.

Device states are compatible with the current Power Resource states. Only devices that solely reference Power

Resource that are in the On state for a given device state can be in that device state.

Devices that are enabled to wake the system and that can do so from their current device state can initiate a hardware

event that transitions the system state to S0.

Resume events are: Power button.

G1, System in Suspend to Disk mode (S4 is done by OS)

While the system is in this state, it is in the system S4 sleeping state. The state is logically lower than the S1 state and is

assumed to conserve more power. The behavior of this state is defined as follows:

The processors are not executing instructions. The processor complex context is not maintained.

Dynamic RAM context is not maintained.

Power Resources are in a state compatible with the system S4 state. All Power Resources that supply a System Level

reference of S0 or S1 are in the OFF state.

Device states are compatible with the current Power Resource states. In other words, all devices are in the D3 state

when the system state is S4.

Devices that are enabled to wake the system and that can do so from their D3 device state can initiate a hardware event

which transitions the system state to S0. This transition causes the processor to begin execution at its boot location.

Resume events are: Power button.

Chapter 3 — BIOS

51

Page 60

G2, System Soft Off

Power is removed from most of system components, Suspend Well logic in ICH10, SIO.

G3, Mechanical off

Kinds of computer state that system entered and only left mechanical means. It is implied by the entry of this off state

through a mechanical means that the no electrical current is running through the circuitry and it can be worked on without

damaging the hardware or endangering the service personnel. No hardware context is retained. Except for the real time clock,

power consumption is zero. No power source is attached to the system (AC or battery). Pushing the Power button will be no

function in state at all.

Resume events are: Power Button

Query System Address Map

INT 15H, E820H - Query System Address Map

This call can be used in real mode only.

This call returns a memory map of the entire installed RAM, and of physical memory ranges reserved by the BIOS. Making

successive calls to this API, each returning one run of physical address information, returns the address map. Each run has a

type that dictates how this run of physical address range is to be treated by the operating system.

If the information returned from E820 in some way differs from INT-15 88 or INT-15 E801, the information returned from

E820 supersedes the information returned from INT-15 88 or INT-15 E801. This replacement allows the BIOS to return any

information that it requires from INT-15 88 or INT-15 E801 for compatibility reasons. For compatibility reasons, if E820

returns any AddressRangeACPI or AddressRangeNVS memory ranges below 16Mb, the INT-15 88 and INT-15 E801

functions must return the top of memory below the AddressRangeACPI and AddressRangeNVS memory ranges.

Input

EAX Function Code E820h

EBX Continuation

Contains the continuation value to get the next run of physical memory. This is

the value returned by a previous call to this routine. If this is the first call, EBX

must contain zero.

ES:DI Buffer Pointer Pointer to an Address Range Descriptor structure that the BIOS fills in.

ECX Buffer Size

The length in bytes of the structure passed to the BIOS. The BIOS fills in the

number of bytes of the structure indicated in the ECX register, maximum, or

whatever amount of the structure the BIOS implements. The minimum size that

must be supported by both the BIOS and the caller is 20 bytes. Future

implementations might extend this structure.

EDX Signature

'SMAP' – Used by the BIOS to verify the caller is requesting the system map

information to be returned in ES:DI.

Chapter 3 — BIOS

52

Page 61

Output

CF Carry Flag Non-Carry – Indicates No Error

EAX Signature 'SMAP' – Signature to verify correct BIOS revision.

ES:DI Buffer Pointer Returned Address Range Descriptor pointer. Same value as on input.

ECX Buffer Size

Number of bytes returned by the BIOS in the address range descriptor. The

minimum size structure returned by the BIOS is 20 bytes.

EBX Continuation

Contains the continuation value to get the next address descriptor. The actual

significance of the continuation value is up to the discretion of the BIOS. The

caller must pass the continuation value unchanged as input to the next iteration of

the E820 call in order to get the next Address Range Descriptor. A return value of

zero means that this is the last descriptor.

NOTE: The BIOS can also indicate that the last descriptor has already been

returned during previous iterations by returning a carry. The caller will ignore any

other information returned by the BIOS when the carry flag is set.

Address Range Descriptor Structure

Offset in Bytes Name Description

0 BaseAddrLow Low 32 Bits of Base Address

4 BaseAddrHigh High 32 Bits of Base Address

8 LengthLow Low 32 Bits of Length in Bytes

12 LengthHigh High 32 Bits of Length in Bytes

16 Type Address type of this range

The BaseAddrLow and BaseAddrHigh together are the 64-bit base address of this range. The base address is the physical

address of the start of the range being specified.

The LengthLow and LengthHigh together are the 64-bit length of this range. The length is the physical contiguous length in

bytes of a range being specified.

The Type field describes the usage of the described address range as defined in the following table.

Address Ranges in the Type Field

Valu

e

Mnemonic Description

1 AddressRangeMemory This run is available RAM usable by the operating system.