Page 1

QD141X1LH03A2 Page

These specification sheets are the proprietary product of Quanta Display Inc. (”QDI”)

and include materials protected under copyright of QDI. Do not reproduce or cause any third

party to reproduce them in any form or by any means, electronic or mechanical, for any

purpose, in whole or in part, without the express written permission of QDI.

The device listed in these technical literature sheets w as designed and manufactured

for use in OA equipment.

In case of using the device for applications such as control and safety equipment for

transportation (aircraft, trains, automobiles, etc. ), rescue and security equipment and

various safety related equipment which require higher reliability and safety, take into

consideration that appropriate measures such as fail-safe functions and redundant system

design should be taken.

1

Do not use the device for equipment that requires an extreme level of reliability, such as

aerospace applications, telecommunication equipment (trunk lines), nuclear power control

equipment and medical or other equipment for life support.

QDI assumes no responsibility for any damage resulting from the use of the device

which does not comply with the instructions and the precautions specified in these

technical literature sheets.

Contact and consult with a QDI sales representative for any questions about this device.

Page 2

QD141X1LH03A2 Page

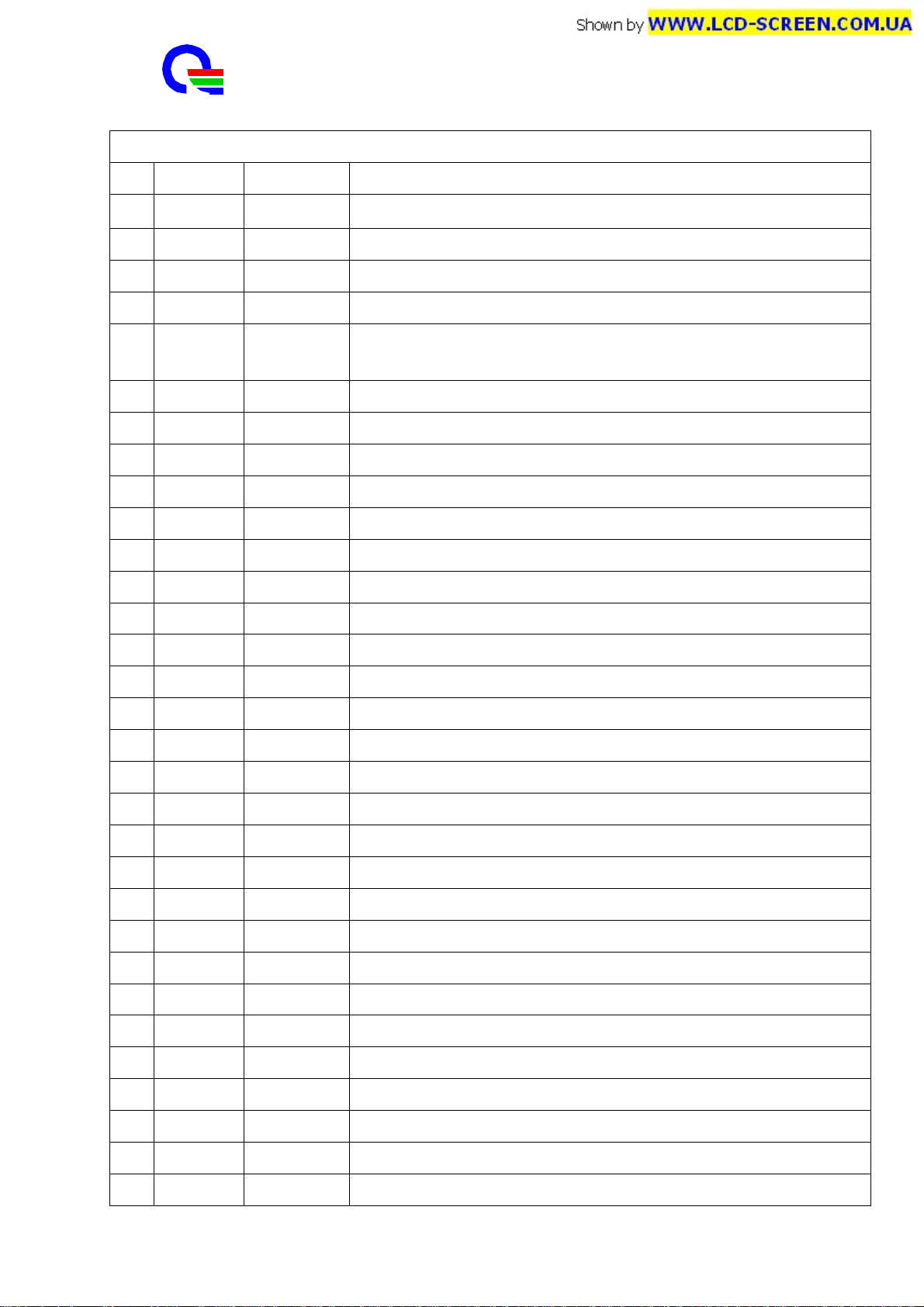

Revision History

REV. Date ECN NO. Change Content

0 3/12/2001 N/A Preliminary specification Initiate

1 4/10/2001 N/A Outline dimension drawing format changed

2 6/1/2001 N/A Page 14 add tolerance to x, y value

3 8/22/2001 N/A Mass 525g change to 530 +/- 10 g, Adding cosmetic critera

2

10/5/2001 N/A

4

in page 23

10/8/2001 N/A Page 21 Major defects AQL=0.4 , Minor defects AQL=1.0

5

Remove “ The inspection standards are in accordance with ……”

Page 3

QD141X1LH03A2 Page

Content List

Page

1. Application 4

2. Overview 4

3. Mechanical Specifications 4

4. Input Terminals 5

5. Absolute Maximum Ratings 7

6. Electrical Characteristics 8

7. Timing Characteristics 10

8. Input Signals, Basic Display Colors and Gray

Scale of Each Color 13

9. Optical Characterics 14

10. Display Quality 17

11. Handling Precautions 17

12. Reliability Test Items 18

3

13. Others 18

14. Attachment 19

Page 4

QD141X1LH03A2 Page

1. Application

This specification applies to a color TFT-LCD module, QD141X1LH03.

2. Overview

This module is a color active matrix LCD module incorporating amorphous silicon TFT

(Thin Film Transistor). It is composed of a color TFT-LCD panel, driver ICs, control circuit

and power supply circuit and a backlight unit. Graphics and texts can be displayed on a

4

1024×3×768 dots panel with 262,144 colors by using LVDS (L

ignaling) to interface and supplying +3.3V DC supply voltage for TFT-LCD panel driving

S

and supply voltage for backlight.

The TFT-LCD panel used for this module has very high aperture ratio. A low-reflection and

higher-color-saturation type color filter is also used for this panel. Therefore, highbrightness and high-contrast image, which is suitable for the multimedia use, can be

obtained by using this module.

Optimum viewing direction is 6 o'clock.

[Features]

1) High aperture panel; high-brightness or low power consumption.

2) Brilliant and high contrast image.

3) Small footprint and thin shape.

4) Light weight.

3. Mechanical Specifications

Parameter Specifications Unit

ow Voltage Differential

Display size 36 (14.1") Diagonal cm

Active area 285.7 (H)×214.3 (V) mm

Pixel format 1024 (H)×768 (V) Pixel

(1 pixel = R+G+B dots)

Pixel pitch 0.279 (H) × 0.279 (V) mm

Pixel configuration R,G,B vertical stripe

Display mode Normally white

Unit outline dimensions (typ.)*1 298.5(W)×226.5 (H)×6.0typ(D)*

(Special location 6.4mm)*

Mass 530 +/- 10 g

Surface treatment Anti-glare and hard-coating 2H

Low reflection (~5%)

*1.Note : excluding backlight cables.

Outline dimensions is shown outline dimension.

mm

Page 5

QD141X1LH03A2 Page

4. Input Terminals

4-1. TFT-LCD panel driving

CN1 (LVDS signals and +3.3V DC power supply)

Using connector: FI-SEB20P-HF10 (JAE)

Corresponding connector: FI-SE20M (JAE), or FI-S20S(JAE)

Pin No. Symbol Function Remark

1 Vcc +3.3V power supply

2 Vcc +3.3V power supply

3 GND

4 GND

5 RXIN0- Receiver signal (-) LVDS

6 RXIN0+ Receiver signal (+) LVDS

7 GND

8 RXIN1- Receiver signal (-) LVDS

9 RXIN1+ Receiver signal (+) LVDS

10 GND

11 RXIN2- Receiver signal (-) LVDS

12 RXIN2+ Receiver signal (+) LVDS

13 GND

14 RXCLK IN- Clock signal (-) LVDS

15 RXCLK IN+ Clock signal (+) LVDS

16 GND

17 RESERVED This should be electrically opened during

operation.

18 RESERVED This should be electrically opened during

operation.

19 GND

20 GND

5

【

Note 1】Relation between LVDS signals and actual data shows below section (4-2).

【Note 2】The shielding case is connected with signal GND.

Page 6

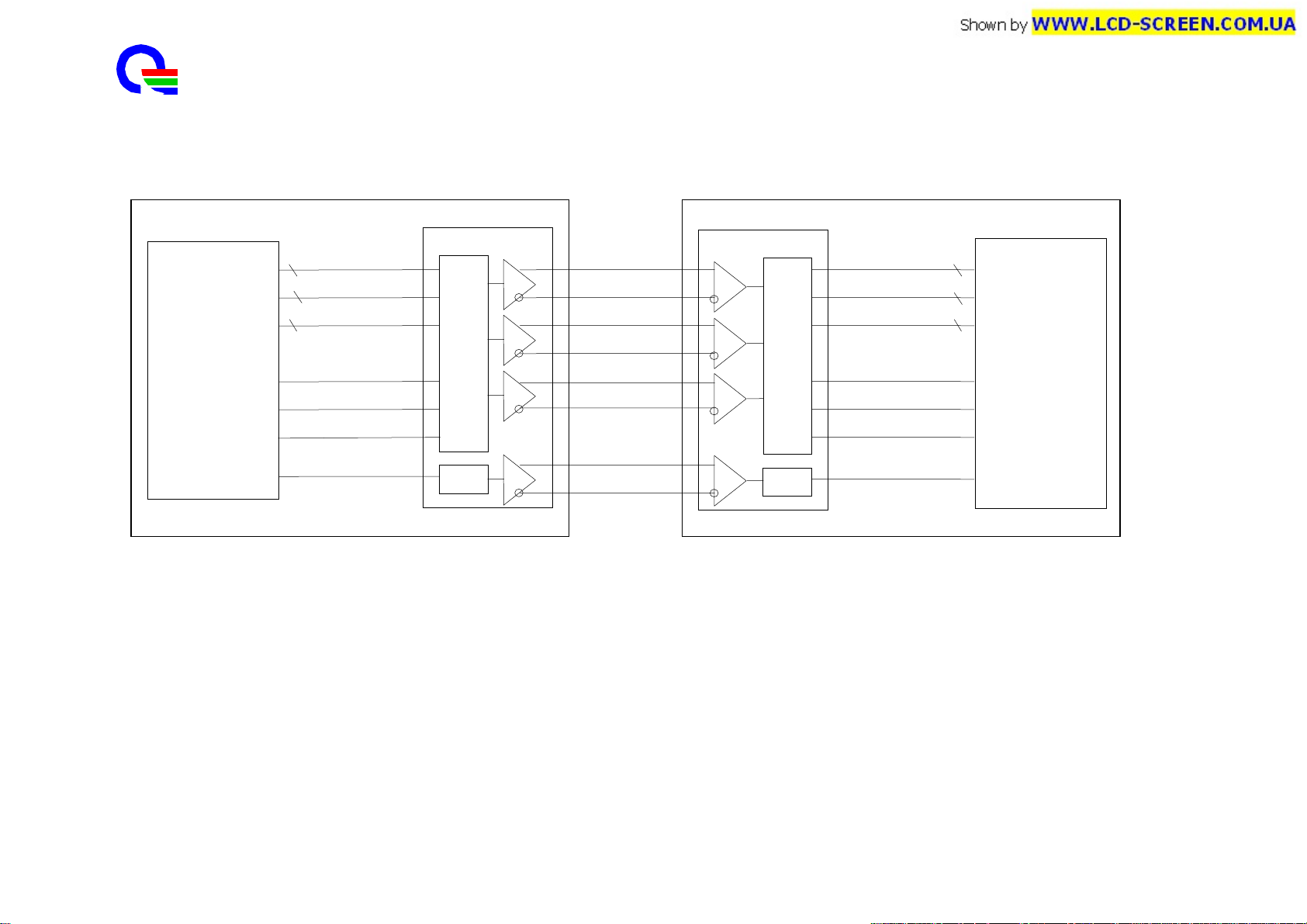

4-2 Interface block diagram

K

QD141X1LH03A2 Page

6

Using receiver:DS90CF364(National semiconductor) Corresponding Transmitter:DS90C363,DS90C383(National semiconductor

(Computer side)

(TFT-LCD side)

)

R0~R5

G0~G5

B0~B5

Hsync

Vsync

Controller

ENAB

CLK

TxIN 0~ 5

6

6

TxIN 6~11

6

TxIN12~17

TxCLK IN

TxIN18

TxIN19

TxIN20

TTL PARALLEL-TO-LVDS

PLL

RXIN0+(6)

RXIN0-(5)

RXIN1+(9)

RXIN1-(8)

RXIN2+(12)

RXIN2-(11)

RXCLKIN+(1

RXCLKIN-

DS90C*363

DS90CF364

PLL

RxOUT0~5

RxOUT6~11

RxOUT12~17

RxOUT18

RxOUT19

LVDS-TO-PARALLEL TTL

RxOUT20

RxCLK OUT

6

R0~R5

6

G0~G5

6

B0~B5

Hsync

Vsync

ENAB

C

Internal circuits

Page 7

4-3. Backlight driving

CN2: BHSR-02VS-1(JST)

Mating connector: SM02B-BHSS-1(JST)

Pin No. Symbol Function

1

V

Power supply for lamp

HIGH

(High voltage side)

2

V

Power supply for lamp

LOW

(Low voltage side)

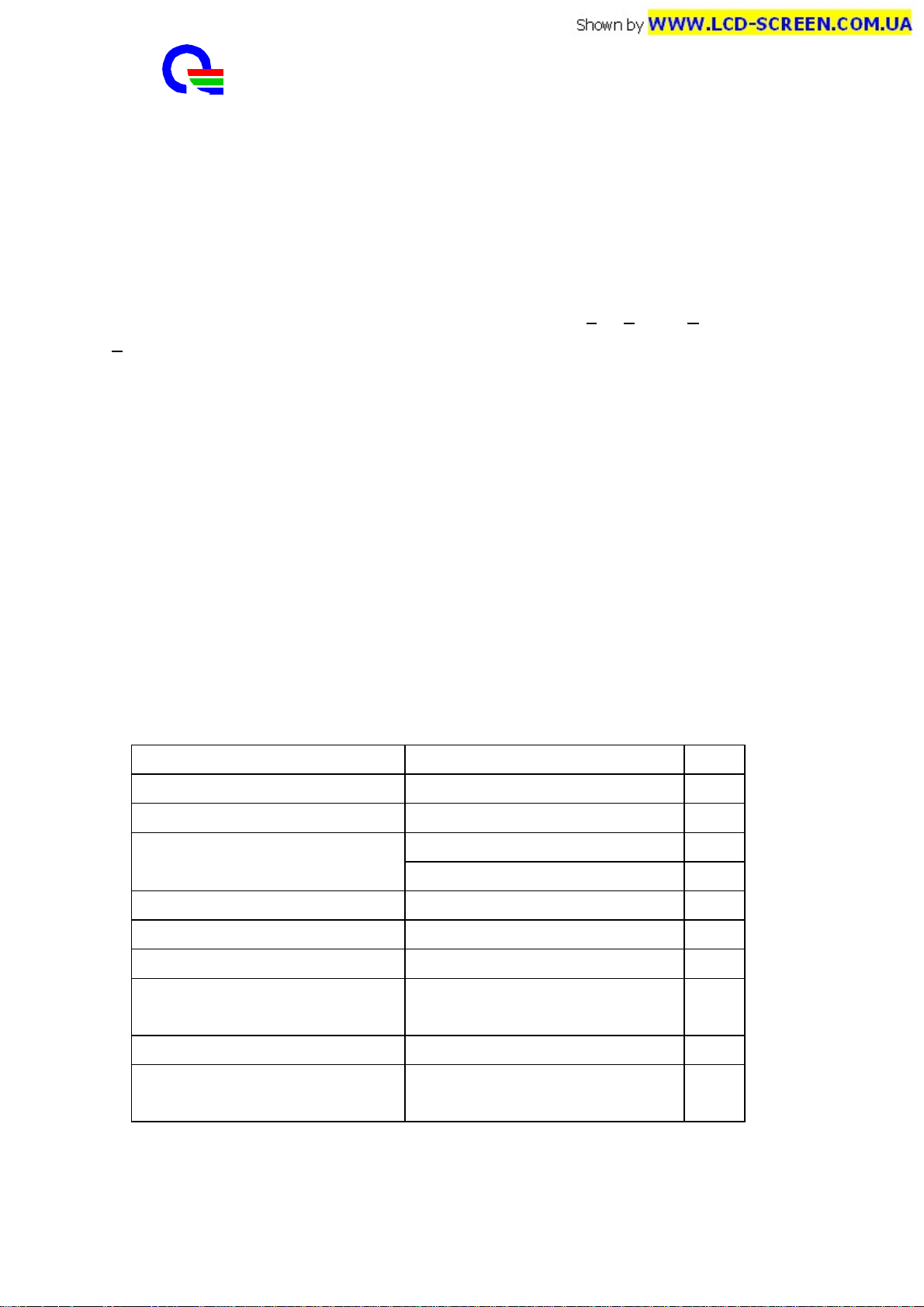

5. Absolute Maximum Ratings

5-1 LCD module

Parameter Symbol Condition Ratings Unit Remark

Input voltage

VI

Ta=25

0.3 ~ Vcc+0.3

℃ -

QD141X1LH03A2 Page

Note1】

【

V

7

+3.3V supply voltage Vcc Ta=25℃ 0 ~ + 4

Storage temperature Tstg

Operating temperature (Ambient) Topa

-

-

-25 ~ +60

0 ~ +50

V

℃

℃

【Note1】LVDS signals

【Note2】Humidity:95%RH Max. at Ta≦40℃.

Maximum wet-bulb temperature at 39℃ or less at Ta>40℃.

No condensation.

【

Note2】

Page 8

QD141X1LH03A2 Page

6. Electrical Characteristics

6-1.TFT-LCD panel driving Ta=25℃

Parameter Symbol Min. Typ. Max. Unit Remark

Vcc Supply voltage Vcc +3.0 +3.3 +3.6 V

Current dissipation Icc -

Permissive input ripple

V

RP

-

420 TBD mA

-

100 mV p-p Vcc=+3.3V

【

Note2】

【

Note3】

voltage

Differential input High

threshold voltage Low

Input current (High)

Input current (Low)

Terminal resistor

V

TH

V

TL

I

OH

I

OL

R

T

–100 -

-

-

-

-

-

+100 mV V

-

±

-

±

-

100 -

10

10

=+1.2V

CM

mV

μ

A

【

Note1】

VI=2.4V

Vcc=3.6V

A

VI=0V

μ

Vcc=3.6V

Ω

Differential

input

Rush current I

1.5 A Rise time

RUSH

470uS

8

【

Note1】 V

: Common mode voltage

CM

of LVDS driver.

【

Note2】

On-off conditions for supply voltage

0<t1≦10 ms

0<t2≦50 ms

0<t3≦1 s

t4>1 s

Vcc

data

2.8V 2.8V

0.3V 0.3V

t4

t1

Vcc

Vcc

data

t2t3

Vcc-dip conditions

1) 2.5 V≦Vcc<3.0 V

td

V

0

V

5

2

.

3

.

td≦10 ms

2) Vcc<2.5 V

Vcc-dip conditions should also follow the On-off conditions for supply voltage

【

Note3】 Typical current situation : 16-gray-bar pattern.

Vcc=+3.3V

RGB

GS0

RGB

GS4

RGB

GS8

....

RGB

GS56

RGB

GS60

Page 9

QD141X1LH03A2 Page

V

W

6-2. Backlight driving

The backlight system is an edge-lighting type with single CCFT (Cold Cathode

Fluorescent Tube).

The characteristics of the lamp are shown in the following table.

Parameter Symbol Min. Typ. Max. Unit Remark

Lamp current range IL 2.0 4.0 6.0 mArms【Note1】

Lamp voltage V L 660 Vrms

Lamp power

consumption

Lamp frequency FL 30 60 70 kHz

Kick-off voltage Vs

Lamp life time LL 10000

【Note1】 Lamp current is measured with current meter for high frequency as shown

below.

PL

-

-

-

2.7

-

-

-

-

1500 Vrms Ta=25℃

1500 Vrms Ta=0℃ 【Note4】

-

W

hour 【Note5】

【Note2】

【

Note3】

9

1

Module

Inverter

2

A

~

* 2pin is

【

Note2】Calculated Value for reference ( I

【

Note3】Lamp frequency may produce interference with horizontal synchronous

frequency, and this may cause beat on the display. Therefore lamp frequency

shall be detached as much as possible from the horizontal synchronous

frequency and from the harmonics of horizontal synchronous to avoid

interference.

【

Note4】 It is defined at 22pF for the ballast capacitor of a DC/AC inverter.

L × V L)

LO

The voltage above this value should be applied to the lamp for more than 1

second to start-up. Otherwise the lamp may not be turned on.

【

Note5】 Lamp life time is defined as the time when either ① or ② occurs in the

continuous operation under the condition of Ta = 25℃ and I

① Brightness becomes 50 % of the original value under standard condition.

② Kick-off voltage at Ta = 0℃ exceeds maximum value, 1500V rms.

Note) The performance of the backlight, for example life time or brightness, is much

influenced by the characteristics of the DC-AC inverter for the lamp. When you design or

= 6.0 mArms.

L

Page 10

QD141X1LH03A2 Page

order the inverter, please make sure that a poor lighting caused by the mismatch of the

backlight and the inverter (miss-lighting, flicker, etc.) never occur. When you confirm it, the

module should be operated in the same condition as it is installed in your instrument.

7. Timing characteristics of LCD module input signals

7-1. Timing characteristics (This is specified at digital outputs of LVDS driver.)

Data

B

ENAB

Sync

C

D E F

10

A

(Vertical)

Item(symbol)

Vsync cycle (TVA)

Min. Typ. Max. Unit Remark

-

16.667

-

ms Negative

803 806 line

Blanking period(TVB) 35 38

Sync pulse width (TVC) 4 6

-

-

line

line

Back porch (TVD) 0 29 line

Sync pulse width + Back

porch

35 35 35 line

(TVC+TVD)

Active display area (TVE) 768 768 768 line

Front porch (TVF) 0 3

-

line

(Horizontal)

Item(symbol)

Hsync cycle (THA) 19.2 20.677

Min. Typ. Max. Unit Remark

- μs

1260 1344 1408 clock

Blanking period (THB) 236 320

Sync pulse width (THC) 8 136

-

-

clock

clock

Back porch (THD) 0 160 312 clock

Sync pulse width + Back

porch (T

+THD)

HC

1500 - T

HA

296 THA -

1024

clock

Active display area (THE) 1024 1024 1024 clock

Front porch (THF) 8 24

-

clock

Negative

(Clock)

Item Min. Typ. Max. Unit Remark

Frequency

-

65.0 65.0 MHz

【Note1】

Note) In case of lower frequency, the deterioration of display quality, flicker etc., may be

occurred.

Page 11

(Hsync-Vsync Phase difference)

y

y

Vsync

nc

Hs

QD141X1LH03A2 Page

11

Item(symbol) Min. Typ. Max. Unit Remark

Hsync-Vsync Phase difference

)

(T

HV

(Hsync-ENAB Phase difference)

ENAB

nc

Hs

THN

Item Min. Typ. Max. Unit Remark

(THN)

7-2 Display position

Item Standards Beginning Ending Unit Remark

T

HV

1

0

- T

-

HA-THC

312 clock

clock

Horizontal rising edge of ENAB 0 1024 clock

rising edge of Hsync 296 1320 clock

【Note1】

Vertical rising edge of Vsync 35 803 clock

【Note1】 ENAB signal must be fixed to low.

[

Note]

(Horizontal display direction)

When ENAB is fixed low, 296 clock are counted from Hsync negative edge and data from

after are available . If you need other timing, please use ENAB signal.

(Vertical display direction)

35 lines are counted from Vsync negative edge and data from next line are available.

(Note of ENAB signal)

ENAB could not be used for the purpose of the vertical display start timing.

Caution

Image will not be displayed on the right position otherwise.

Page 12

7-3. Input Data Signals and Display Position on the screen

Display position of input data

(H,V)

QD141X1LH03A2 Page

UP

12

D1,DH1

D1,DH2

D1,DH3

D1,DH768

D2,DH1 D3,DH1

D2,DH2

R

G

D1024,DH1

B

D1024,

DH768

Page 13

8. Input Signals, Basic Display Colors and Gray Scale of Each Color

QD141X1LH03A2 Page

13

Colors &

Gray scale Gray

Scale

Black -

Blue -

Basic Color Gray Scale of Red Gray Scale of Green Gray Scale of Blue

Green -

Cyan -

Red -

Magenta -

Yellow -

White -

R0 R1 R2 R3 R4 R5 G0 G1 G2 G3 G4 G5 B0 B1 B2 B3 B4 B5

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1

0 0 0 0 0 0 1 1 1 1 1 1 0 0 0 0 0 0

0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1 1 1

1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0

1 1 1 1 1 1 0 0 0 0 0 0 1 1 1 1 1 1

1 1 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

Data signal

Black GS0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

×

GS1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Darker GS2 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

×

Ø

È

È

È

È

È

È

È

È

Brighter GS61 1 0 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0

Ø

GS62 0 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0

Red GS63 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0

Black GS0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

×

GS1 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0

Darker GS2 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0

×

Ø

È

È

È

È

È

È

È

È

Brighter GS61 0 0 0 0 0 0 1 0 1 1 1 1 0 0 0 0 0 0

Ø

GS62 0 0 0 0 0 0 0 1 1 1 1 1 0 0 0 0 0 0

Green GS63 0 0 0 0 0 0 1 1 1 1 1 1 0 0 0 0 0 0

Black GS0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

×

GS1 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0

Darker GS2 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0

×

Ø

È

È

È

È

È

È

È

È

Brighter GS61 0 0 0 0 0 0 0 0 0 0 0 0 1 0 1 1 1 1

Ø

GS62 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1

Blue GS63 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1

0 : Low level voltage, 1 : High level voltage

Each basic color can be displayed in 64 gray scales from 6 bit data signals. According to the

Page 14

QD141X1LH03A2 Page

14

combination of total 18 bit data signals, the 262,144-color display can be achieved on the screen.

Ta=25

9. Optical Characteristics

℃

, Vcc=+3.3V

Parameter Symbol Condition Min. Typ. Max. Unit Remark

Viewing

angle

Horizontal

Vertical

range

Contrast ratio

Response Rise

time Decay

Chromaticity of x

white y

Luminance of

white

【

Note4】 Y

θ21,θ22 CR>10 45 -

θ

11 10 -

θ

12 30 -

CR

n

CR

o

τ

r

τ

d -

Y

L1

L2

θ=0°

Optimum

viewing

θ=0°

150 -

-

angle

-

0.273 0.313 0.354

0.289 0.329 0.369

120 - Cd/m

120 150 - Cd/m

-

-

-

-

300 -

15 ms

Deg.

Deg.

Deg.

Note1,4

【

Note2,4

【

Note3,4

【

30 ms

Note4】

【

2

IL = 4

FL=60kHz

2

IL =

6.0mArms

】

】

】

.0mArms

FL=60kHz

White Uniformity δ

The measurement shall be executed 30 minutes after lighting at rating. (typical condition :

※

W

-

-

1.45

【

Note5

】

IL = 4.0 mArms)

The optical characteristics shall be measured in a dark room or equivalent state with the

method shown below.

Page 15

Photodetector (BM-5A:TOPCON)

QD141X1LH03A2 Page

15

TFT-LCD

module

Field=

Fig.3 Optical characteristics measurement method

2°

400

Center of the screen

mm

LCD

panel

Page 16

【

Note1】Definitions of viewing angle range:

【

Note2】Definition of contrast ratio:

The contrast ratio is defined as the following.

QD141X1LH03A2 Page

16

Luminance (brightness) with all pixels white

Contrast Ratio (CR)=

Luminance (brightness) with all pixels black

【

Note3】Definition of response time:

The response time is defined as the following figure and shall be measured by

switching the input signal for "black" and "white" .

【

Note4】This shall be measured at center of the screen.

【

Note5】Definition of white uniformity:

White uniformity is defined as the

following with five measurements

(A~E).

Maximum Luminance of five points (brightness)

δw=

Minimum Luminance of five points (brightness)

768 pixel 512256

D A

C

E B

192

384

576

Pixel

Page 17

QD141X1LH03A2 Page

10. Display Quality

The display quality of the color TFT-LCD module shall be in compliance with the Incoming

Inspection Standard.

11.Handling Precautions

a) Be sure to turn off the power supply when inserting or disconnecting the cable.

b) Be sure to design the cabinet so that the module can be installed without any extra

stress such as warp or twist.

c) Since the front polarizer is easily damaged, pay attention not to scratch it.

d) Wipe off water drop immediately. Long contact with water may cause discoloration or

spots.

e) When the panel surface is soiled, wipe it with absorbent cotton or other soft cloth.

f) Since the panel is made of glass, it may break or crack if dropped or bumped on hard

surface. Handle with care.

g) Since CMOS LSI is used in this module, take care of static electricity and injure the

17

human earth when handling.

h) Observe all other precautionary requirements in handling components.

i) This module has its circuitry PCBs on the rear side and should be handled carefully in

order not to be stressed.

j) Laminated film is attached to the module surface to prevent it from being scratched .

Peel the film off slowly just before the use with strict attention to electrostatic charges.

Ionized air shall be blown over during the action. Blow off the 'dust' on the polarizer by

using an ionized nitrogen gun, etc..

K) Black PET sheet covers some electric components and handle with special care to

avoid mechanical stress and shock on this PET surface.

L) Mounting screw hole can stand torque 1.3~1.5 Kgf-cm.

Page 18

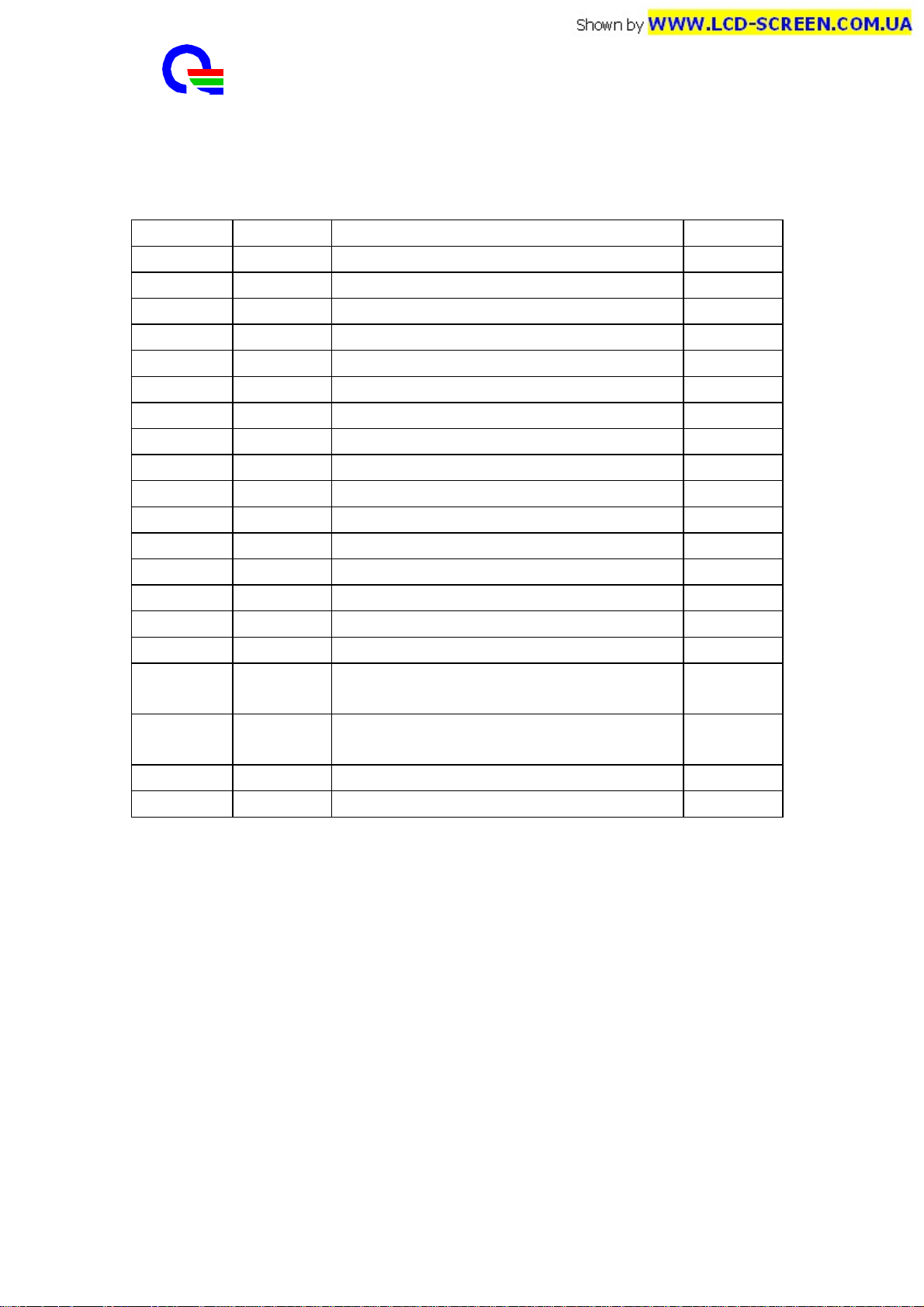

12. Reliability test items

Test item Conditions

No.

1 High temperature storage test Ta = 60℃ 240h

2 Low temperature storage test Ta = -25℃ 240h

QD141X1LH03A2 Page

18

3 High temperature

& high humidity operation test

Ta = 40℃ ; 95 %RH 240h

(No condensation)

4 High temperature operation test Ta = 50℃ 240h

(The panel temp. must be less than 60℃)

5 Low temperature operation test Ta = 0℃ 240h

6 Vibration test

(non- operating)

Frequency: 1. 10~57Hz/Vibration width (one

side) 0.075mm

2. 58~500Hz/Gravity 9.8m/s

Sweep time : 11 minutes

Test period : 3 hours

(1 hour for each direction of X,Y,Z)

7 Shock test

(non- operating)

Max. gravity : 490 m/s2

Pulse width : 11 ms, sine wave

Direction : ±X,±Y,±Z

once for each direction.

2

13.Others

1) Lot No. Label:

Serial number Product Name

HFC1171000001 QD141X1LH03 Rev.A

Ver.: xxxx

QDI internal

control version No.

Serial Number Bar Code

2) Adjusting volume has been set optimally before shipment, so do not change any

adjusted value. If adjusted value is changed, the specification may not be satisfied.

3) Disassembling the module can cause permanent damage and should be strictly

avoided.

4) Please be careful since image retention may occur when a fixed pattern is displayed

for a long time.

5) If any problem occurs in relation to the description of this specification, it shall be

resolved through discussion with spirit of cooperation.

Page 19

QD141X1LH03A2 Page

14. Attachment

Incoming Inspection Standards for TFT-LCD Modules

1) Scope

These incoming inspection standards shall apply to TFT-LCD modules (hereinafter called

“Module”) supplied by QDI Corporation (hereinafter called “Seller”) to Quanta

(hereinafter called the “Buyer”).

2) Incoming inspection

The Buyer shall have the right to conduct at its own cost and expense, an incoming

inspection of the Module’s at the destination specified in the relevant bills of landing in

accordance with the Module’s specifications separately agreed upon and the inspection

standard set forth in this Article. The Buyer shall notify the Seller writing of a result of

such inspection judgment (acceptance or rejection) in accordance with the said

19

inspection standard within 40 days after the date of the bills of landing. Should the Buyer

fail to so notify the seller within the said 40 days period, the Buyer’s right to reject the

Module’s shall then lapse, and the said Module’s shall be deemed to have been accepted

by the Buyer.

3) Method of incoming inspection

Unless otherwise agreed in writing, the method of incoming inspection shall be in

accordance with a sampling inspection based on MIL-STD-105E.

4) Classification of defects

Defects are classified as major defect and a minor defect according to the degree of

defect defined herein.

a) major defect

A major defect is a defect that is likely to result in failure, or to reduce materially

the usability of the product for its intended purpose.

b) Minor defect

A minor defect either is a defect that is not likely to reduce materially the usability

of the product for its intended purpose, or is a departure from an established

having little bearing on the effective use or operation of the product.

Specific criteria of judgment on major and/or minor defects or otherwise shall be in

accordance with the attached “Classification of Defect.”

5) Acceptable quality level (“AQL”)

The AQL for major and minor defects shall be respectively set forth below.

a) Major defects : AQL :0.4

Page 20

QD141X1LH03A2 Page

b) Minor defects : AQL:1 Based on overall evaluation

6) Method of sampling inspection

a) Lot size : Quantity per shipment lot per mode

b) Sampling type : Normal inspection, Single sampling

c) Inspection level : II

d) Sampling table : Table in MIL-STD-105E

e) Inspection conditions : The inspection conditions shall be as in the LCD

specifications. The environmental conditions and the visual inspection shall be as

follows:

(i) The environmental conditions

Room temperature: 20-25°C

Humidity: 65±20%RH

(ii) The external visual inspection: The inspection shall be conducted by using a

20

single 20W fluorescent lamp for illumination and the distance between the

MODULE and the eyes of the inspection shall be 35CM±5CM.

7) Determination of acceptability and subsequent disposal

If the number of defects found in the sample Module’s from the lot is equal to or less

than the applicable acceptance level, the lot shall be accepted.

If the number of defects is greater than the applicable acceptance level, the lot shall be

rejected. The Buyer shall inform the Seller of detailed result of such inspection within the

time period stipulated in Article 2.

The disposal is as follows:

a) Accepted lot

An acceptance under the above incoming inspection shall constitute an acceptance

by the Buyer of such lot of the Module’s in terms of the landed quality thereof.

b) Rejected lot

If a lot of PRODUCTS is rejected under the above incoming inspection due to any

defects for which the Seller is responsible and such a fact is clearly confirmed by

the Sellers, the Seller shall exercise one of the following three options. This must

be determined with mutual consent and shall be confirmed by the Seller. The best

choice of the options shall be left to the Seller’s discretion and the Seller shall

advise the Buyer of its choice not later than two weeks of receipt of the Buyer’s

advance:

(1) The Buyer shall return the defective lot to the place to be designated by the Seller

and Seller shall screen all of the PRODUCTS in the lot and repair defective

PRODUCTS.

(2) The Seller shall screen all of the PRODUCTS in the lot and repair defective products

Page 21

QD141X1LH03A2 Page

within a reasonable time period at the Buyer’s facility.

(3) The Buyer shall screen the entire lot for the good modules at the expense of the

Seller to be separately agreed upon. The rejected PRODUCTS shall be returned to

the place to be designated buy the Seller.

8) External inspection

Inspection item Criteria Reject count(N)

21

Black spot ,White spot,

Foreign circular

Material Dent &bubble

L:length; W:width(mm)

Average Diameter:D

a+b

D =

2

a

b

D>0.35mm N>1

D>0.15mm N>4

D<0.15mm Don’t care

Minimum distance between defects :10mm

L>2.0 N>1 Scratches ,lint

N>

0.01<W<0.05 L≦2.0

3

Length:L

L =Lon

est

oint

W

L

*1 The external visual inspection: The inspection shall be conducted by using a single

20W fluorescent lamp for illumination and the distance between the MODULE and the

eyes of the inspector shall be 35 ㎝ or more.

* The area for external inspection is active area plus 1.0mm width. (Upper, Low er, Left

and Right)

Page 22

QD141X1LH03A2 Page

9) Dot defect

(1) Inspection Conditions [Visual inspection]

Viewing distance : 35 ㎝

Ambient illumination : 300 to 700Lux ( Standard 500Lux )

Ambient temperature : 20-25℃

Light source condition : Based on the specification

Note: Viewing angle : The surface of the MODULE and the eyes of the inspector

shall be 90 degrees.

(2) Definition

a) Bright dot

The sub-pixel can been seen when using the 5% ND-Filter

22

b) Scratches on the color filter (Bright dot count)

Count: defect area > 1/4 dot

No count: defect area < 1/4 dot

(3) Bright dots (Acceptable)

Green/Red/Blue dots:When the MODULE lights, dots appear bright in display at

black picture position.(V0)

Check pattern Total Quantity

Black picture

Position

2 adjacent ….. 1 pair MAX

Green Bright dots 2 adjacent ….. Nothing

Defect distance ….. more than 15mm

(4) Black dots (Acceptable)

Black dots : When the MODULE lights, dots appear black in display at

≦4

Green+Blue+Red picture position.

Check pattern Total

Green+Blue+Red

Picture position

Two joined dots ….. 2 pair MAX

Defect distance ….. more than 5mm

Three joined bright dots must be nil

Three picture position total

8 MAX

Page 23

QD141X1LH03A2 Page

(5) Total dot defect ( Black & Bright )

Total dot defects:It is possible if accept count is the counts of Bright and Dark

dots at V24 gray screen

23

Check pattern Total Quantity

V24

8 MAX

gray screen

10) Display non-uniformity

There should be no distinct non-uniformity visible through 5﹪transparency of filter.

Viewing distance :35cm

Ambient illumination :300 to 700 Lux(standard 500Lux)

Ambient temperature :20-25℃

Light source condition :Based on the specification.

Note : Viewing angle : The surface of the Module and the eyes of the inspector shall be

90 degrees.

11) Others

If some problems arise about mentioned items in this document and other items, the

user of the TFT-LCD module and QDI will cooperate and make efforts to solve the

problems with mutual respect and good will.

Loading...

Loading...