Qualstar RLS-5244, RLS-4124, RLS-6227, RLS-8116, RLS-8202 Technical & Service Manual

...

RLS-8000

Tape Library

Technical

Service Manual

501510 Rev. S

501510 Rev. S iii

Firmwarethe firmwarethe RLS firmwaredifferent part numbers or firmwareQualstarTechnical Supportfirmware

Copyright Notice

Copyright© 2011 by Qualstar Corporation — All Rights Reserved

Information contained in this document is copyrighted by Qualstar Corporation. It is

intended for use by Qualstar’s customers and prospective customers to evaluate, integrate, operate and maintain Qualstar products. Customers and prospective customers

may reproduce this document as needed for these uses. Reproduction in whole or in

part for any other use or by any other party is prohibited without prior written permission from Qualstar Corporation.

Every effort has been made to keep the information contained in this document current and accurate as of the date of publication or revision. However, no guarantee is

given or implied that the document is error-free or that it is accurate with regard to

any specification. Qualstar reserves the right to modify product designs and specifications without notice.

Qualstar and the Qualstar logo are registered trademarks of Qualstar Corporation.

Other trademarks are the property of their respective owners.

iv 501510 Rev. S

Notices

Qualstar products are covered by one or more of the following patents:

6,163,139 and 6,560,061. Other patents pending.

Qualstar equipment is manufactured from new parts, or new and used parts. In some

cases, Qualstar equipment may not be new and may have been previously installed.

Regardless, Qualstar’s warranty terms apply unless the equipment is specifically

identified by Qualstar as “used” or “refurbished”.

This equipment has been tested and found to comply with the limits for a Class A di gital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is ope rated in a commercial environment. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of

this equipment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own expense. Shielded

cables are required for this device to comply with FCC Rules. Use shielded cables

when connecting this device to others.

European Union Directive 89/336/EEC and Standard EN55022

(Electromagnetic Compatibility)

Warning

This is a Class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

European Directive on Waste Electrical and Electronic Equipment (WEEE)

Qualstar encourages its customers to use current recycling practices in order to reduce the burden that waste electronic products place on the environment.

If you are retiring a fully functional tape library, you are encouraged to transfer the

functional unit to a new user, thereby extending the useful life of the tape library.

The manufacture of all products requires the consumption of energy. By extending

the life of the tape library, energy is conserved.

In accordance with environmental directives that are being implemented in many

countries (refer to the European Directive on Waste Electrical and Electronic Equipment - WEEE) Qualstar provides customers with “End of Life Instructions” that iden-

501510 Rev. S v

tify the process for recycling the materials and components that make up a Qualstar

tape library.

End of Life Instructions

Tools required

• P1 and P2 Phillips head screwdrivers

• T20 Torx head screwdriver

• Hex head (Allen) wrench/driver set

• 1/4-inch hex nut driver

Disassembly procedure

1. Remove door.

2. Remove top panel.

3. Remove side external panels.

4. Remove internal subassemblies.

Items recyclable using conventional methods

• Aluminum: Door, exterior panels, frame, robotics

• Stainless steel: Robot guides

• Steel: Some frames, fasteners

• Plastic: Window, cartridge magazines, tape cassettes

• Copper: Internal wiring, motors, SCSI cables

• Paper: Manuals

Items requiring special disposal due to lead-based solder

• Printed Circuit Boards: Controller, miscellaneous small printed circuit

boards

Items that may have salvage or resale value

• Tape drives

• EMI line power filter

Reduction of Hazardous Substances (RoHS)

Qualstar is committed to the implementation of RoHS (Restriction of the use of certain hazardous substances in electrical and electronic equipment) in accordance with

vi 501510 Rev. S

the European Directive. The effectivity date for compliance is July 1, 2006, at which

time Qualstar will certify that its Tape Library products are compliant with the RoHS

standard. With the exception of Lead Based Solder, Qualstar will certify that its

products are free of all other substances listed in the Directive.

Qualstar Tape Libraries fall under the category of “Information Technology Storage

Array Systems” for which the RoHS Directive provides for a lead solder exemption.

Insofar as lead free solders are new to the electronics industry and no quality or reliability data is available, Qualstar will invoke the lead based solder exemption until

such time as industry data verifies that lead free solders are capable of meeting or e xceeding the documented reliability and quality standards achieved with lead based

solders.

Until such time as Qualstar replaces lead based solder with lead free solder, effected

subassemblies must be disposed of appropriately.

Technical Support Information

The best source for service-related information is your system reseller. Alternately,

the Qualstar Technical Support Department can be reached Monday through Friday,

between the hours of 6:30 A.M. and 5:00 P.M. Pacific Time, at:

Qualstar Corporation

130 W. Cochran St; Suite C

Simi Valley, CA 93065

Attn: Technical Support

Phone: (877) 444-1744, (805) 583-7744

Monday – Friday 7:00 A.M.. to 4:00 P.M. PST

E-Mail support@qualstar.com

E-Mail: sales@qualstar.com

Web: www.qualstar.com

501510 Rev. S vii

Table of Contents

1. Introduction ................................................................................................................... 1-1

1.1 Who Should Read This Manual ................................................................................... 1-1

1.2 Important Safety Information ..................................................................................... 1-3

1.3 Lithium Battery ............................................................................................................ 1-4

2. Description and Theory of Operation ..................................................................... 2-1

2.1 Models ........................................................................................................................... 2-1

2.2 General Description ...................................................................................................... 2-6

2.2.1 Motion Systems ..................................................................................................... 2-6

2.2.2 Sensors ................................................................................................................... 2-7

2.2.3 Barcode Reader .................................................................................................... 2-10

2.2.4 Barcode Labels ..................................................................................................... 2-10

2.2.5 Capacity on Demand (COD) ............................................................................... 2-10

2.3 Component Identification .......................................................................................... 2-11

2.3.1 RLS Models .......................................................................................................... 2-11

2.3.2 Handler ................................................................................................................ 2-12

2.3.3 Field-Replaceable Units (FRUs) ......................................................................... 2-13

3. The Operator Interface ............................................................................................... 3-1

3.1 The Door Lock ............................................................................................................... 3-1

3.2 Using the Menu System ............................................................................................... 3-1

3.2.1 The MENU Control Key ........................................................................................ 3-2

3.2.2 The (UP) and (DOWN) Control Keys............................................................. 3-2

3.2.3 The ENTER Control Key ...................................................................................... 3-3

3.2.4 The EXIT Control Key........................................................................................... 3-3

3.2.5 The (Daisy) Key ................................................................................................ 3-4

3.3 Quick Operation Menu ................................................................................................. 3-4

3.3.1 OPEN & PARK LEFT command .......................................................................... 3-4

3.3.2 OPEN & PARK RIGHT command........................................................................ 3-5

3.3.3 OPEN VIOP (n) command .................................................................................... 3-5

3.3.4 PARK LEFT command .......................................................................................... 3-5

3.3.5 PARK RIGHT command ....................................................................................... 3-5

3.3.6 (UN)LOAD LIBRARY command .......................................................................... 3-6

3.3.7 The Status LEDs ................................................................................................... 3-7

3.4 The Top Menu ............................................................................................................... 3-7

3.5 Menu Elements ............................................................................................................. 3-8

3.5.1 Menu Items ............................................................................................................ 3-8

3.5.2 Values ..................................................................................................................... 3-9

viii 501510 Rev. S

3.5.3 Location Designators ........................................................................................... 3-10

3.5.4 Editing Values ..................................................................................................... 3-11

3.6 The Menu Hierarchy .................................................................................................. 3-13

3.7 Displaying the RLS Firmware Revision .................................................................... 3-14

3.8 Alerts/Faults ............................................................................................................... 3-14

3.9 Dynamic Menus and Menu Items.............................................................................. 3-15

4. The Maintenance Menu ............................................................................................... 4-1

4.1 The Maintenance menu ................................................................................................ 4-3

4.2 The Maintenance\Display Prevents status screen .................................................... 4-3

4.3 The Maintenance\Display Revision status screen ..................................................... 4-4

4.4 The Maintenance\Display Stats. status screen ......................................................... 4-4

4.5 The Maintenance\Display Voltage status screen ...................................................... 4-5

4.6 The Maintenance\Fibre Channel menu ..................................................................... 4-6

4.7 The Maintenance\Fibre Channel\Info status screen ................................................ 4-6

4.8 The Maintenance\Log menu ....................................................................................... 4-8

4.8.1 Introduction ........................................................................................................... 4-8

4.8.2 Data Logging – General Description .................................................................... 4-9

4.9 The Maintenance\Log\Display\Entry menu .......................................................... 4-10

4.10 The Maintenance\Test Inventory menu ................................................................... 4-11

4.11 The Maintenance\Test Keyboard status screen ...................................................... 4-11

4.12 The Maintenance\Test LC Display status screen .................................................... 4-13

5. The Private Menu ......................................................................................................... 5-1

5.1 Introduction .................................................................................................................. 5-3

5.2 Security Locks ............................................................................................................... 5-3

5.2.1 Door Lock ............................................................................................................... 5-3

5.2.2 Master Lock ........................................................................................................... 5-4

5.2.3 Disabling the Master Security Lock ..................................................................... 5-4

5.3 Enabling the Private Menu .......................................................................................... 5-6

5.3.1 Access ..................................................................................................................... 5-6

5.3.2 Setting a Password ................................................................................................ 5-6

5.3.3 Clearing the Password .......................................................................................... 5-9

5.4 The Private Menu ....................................................................................................... 5-10

5.4.1 The Private\CALIBRATE command ................................................................. 5-10

5.4.2 The Private\CLEAR ACCESS command .......................................................... 5-12

5.4.3 The OPEN VIOP WINDOW command .............................................................. 5-12

5.4.4 The REBOOT command ...................................................................................... 5-12

5.4.5 The RESET SCSI BUS command ....................................................................... 5-12

5.4.6 The Private\Cabling status screen .................................................................... 5-13

5.4.7 The Private\Calibration status screen .............................................................. 5-13

5.4.8 The Private\Configuration menu ...................................................................... 5-14

501510 Rev. S ix

5.4.9 The Private\Control Panel status screen .......................................................... 5-17

5.4.10 The Private\Display A/D status screen ............................................................. 5-17

5.4.11 The Private\Display Locations Menu ................................................................ 5-18

5.4.12 The Private\Display Positions status screen .................................................... 5-19

5.4.13 The Private\DriveBay status screen ................................................................. 5-20

5.4.14 The Private\Drive Bay\Alarm Limits status screen ........................................ 5-21

5.4.15 The Private\Drive Bay\C? menu ...................................................................... 5-21

5.4.16 The Private\Drive Bay\C?\Carrier status screen ........................................... 5-23

5.4.17 The Private\Drive Bay\C?\DIA status screen ................................................. 5-24

5.4.18 The Private\Drive Bay\Power ? status screen ................................................. 5-25

5.4.19 The Private\Executive status screen ................................................................. 5-26

5.4.20 The Private\Magazine menu.............................................................................. 5-27

5.4.21 The Private\ Sensors status screen ................................................................... 5-28

6. Troubleshooting ............................................................................................................ 6-1

6.1 Faults without Fault Messages ................................................................................... 6-1

6.1.1 When the power is turned on: no motion occurs, the LCD does not illuminate,

the three power-indicating LEDs on the IPM (rear of RLS) are dark. ............................. 6-1

6.1.2 When the power is turned on: no motion occurs, the LCD does not illuminate,

the +24V LED on the IPM (rear of RLS) blinks. ................................................................ 6-1

6.1.3 When the power is turned on: the LCD is illuminated and shows the library

model number, no errors messages are displayed, and nothing moves. .......................... 6-1

6.1.4 When the power is turned on: the Handler moves normally and the LCD is

illuminated, but it does not show text. ............................................................................... 6-2

6.1.5 The Barcode Reader does not read barcode labels reliably. ............................... 6-2

6.1.6 After Installing a Tape Drive, it Fails to Appear in the Menu System. ............. 6-2

6.2 POST (Power On Self Test) Fault Messages ............................................................... 6-2

6.2.1 BCR Failed (BCR is the Barcode Reader) ............................................................ 6-3

6.2.2 BCR Misconfigured (BCR is the Barcode Reader) .............................................. 6-3

6.2.3 Calibration Req’d ................................................................................................... 6-3

6.2.4 Not Configured ...................................................................................................... 6-3

6.2.5 Carousel Failed, Carousel Jammed...................................................................... 6-3

6.2.6 Array Failed, Array Jammed ................................................................................ 6-3

6.2.7 Gripper Homing Failed ......................................................................................... 6-3

6.2.8 X Failed to Home ................................................................................................... 6-3

6.2.9 Z Failed to Home ................................................................................................... 6-4

6.2.10 No Drivebay Found ............................................................................................... 6-4

6.2.11 No Carriage Found ................................................................................................ 6-4

6.2.12 No Sensor Pcb Found ............................................................................................ 6-4

6.2.13 No Carousel Found ................................................................................................ 6-4

6.2.14 No Storage Array ................................................................................................... 6-4

6.3 Operating Fault Messages ........................................................................................... 6-6

x 501510 Rev. S

6.3.1 Pick Failed ............................................................................................................. 6-6

6.3.2 Place Failed ............................................................................................................ 6-6

6.3.3 Carousel Failed, Carousel Jammed...................................................................... 6-6

6.3.4 Array Failed, Array Jammed ................................................................................ 6-6

6.3.5 X Axis Jammed ...................................................................................................... 6-6

6.3.6 X-Axis Obstructed ................................................................................................. 6-6

6.3.7 Z-Axis Jammed ...................................................................................................... 6-7

6.3.8 Z-Axis Obstructed .................................................................................................. 6-7

6.3.9 Handler Fault ........................................................................................................ 6-7

6.3.10 Left Fan Failed or Right Fan Failed .................................................................... 6-7

6.3.11 Left Supply Fail or Right Supply Fail .................................................................. 6-7

6.3.12 Fan Failed .............................................................................................................. 6-8

6.3.13 Supply Failed ......................................................................................................... 6-8

6.4 Operating Error Messages ........................................................................................... 6-8

6.4.1 Gripper Full ........................................................................................................... 6-8

6.4.2 No Target Magazine .............................................................................................. 6-8

6.4.3 No Target Drive ..................................................................................................... 6-8

6.4.4 Target Full ............................................................................................................. 6-8

6.4.5 Source Empty ......................................................................................................... 6-8

6.4.6 No Source Magazine .............................................................................................. 6-8

6.4.7 No Source Drive ..................................................................................................... 6-9

6.4.8 Tape Not Ejected ................................................................................................... 6-9

6.4.9 The Door is Locked ................................................................................................ 6-9

6.4.10 The Door is Open ................................................................................................... 6-9

6.5 Calibration Fault Messages ......................................................................................... 6-9

6.5.1 Calibration Fault ................................................................................................... 6-9

6.5.2 Failed No Magazine ............................................................................................... 6-9

6.5.3 Failed, Remove Cart .............................................................................................. 6-9

6.5.4 Failed Gripper Full ................................................................................................ 6-9

6.5.5 Calibration Failed ................................................................................................ 6-10

6.5.6 Opto Cal Failed .................................................................................................... 6-10

7. Field–Replaceable Units (FRUs) ............................................................................... 7-1

7.1 Introduction .................................................................................................................. 7-1

7.2 Field Upgrades .............................................................................................................. 7-5

7.3 Required Tools and Materials ...................................................................................... 7-7

7.4 Opening the Front Panel/Door..................................................................................... 7-8

7.5 Rack-Mounted Libraries .............................................................................................. 7-9

7.5.1 Extending the RLS from the Rack ..................................................................... 7-10

7.5.2 Retracting the RLS into the Rack ...................................................................... 7-10

7.6 Top Cover .................................................................................................................... 7-11

501510 Rev. S xi

7.6.1 Opening the Top Cover ....................................................................................... 7-11

7.6.2 Closing the Top Cover ......................................................................................... 7-11

7.7 Carriage Assembly...................................................................................................... 7-12

7.7.1 Carriage Assembly Removal Procedure ............................................................. 7-13

7.7.2 Carriage Assembly Replacement ........................................................................ 7-14

7.8 Carousel Assembly ..................................................................................................... 7-15

7.8.1 Carousel Removal ................................................................................................ 7-15

7.8.2 Carousel Replacement ......................................................................................... 7-17

7.9 Storage Array .............................................................................................................. 7-18

7.9.1 Style A Chassis Storage Array Removal ............................................................ 7-19

7.9.2 Style A Chassis Storage Array Replacement ..................................................... 7-24

7.9.3 Style B Chassis Storage Array Removal ............................................................ 7-25

7.9.4 Style B Chassis Storage Array Replacement ..................................................... 7-28

7.10 Front Panel/Door Assembly (Bezel) ........................................................................... 7-29

7.10.1 Front Panel/Door Assembly Removal ................................................................ 7-29

7.10.2 Front Panel/Door Assembly Replacement ......................................................... 7-30

7.11 Tape Drive Assembly .................................................................................................. 7-33

7.11.1 Tape Drive Assembly Removal ........................................................................... 7-35

7.11.2 Tape Drive Assembly Replacement .................................................................... 7-35

7.11.3 Verifying a Tape Drive Assembly Installation .................................................. 7-37

7.11.4 Drive Fillers ......................................................................................................... 7-37

7.12 Serial Control Panel PCBA ........................................................................................ 7-38

7.12.1 Serial Control Panel PCBA Removal ................................................................. 7-39

7.12.2 Serial Control Panel PCBA Replacement .......................................................... 7-39

7.13 Drive Bay PCBA Assembly ........................................................................................ 7-41

7.13.1 Drive Bay PCBA Assembly Removal ................................................................. 7-42

7.13.2 Drive Bay Assembly Replacement ..................................................................... 7-49

7.14 Executive-XI PCBA .................................................................................................... 7-51

7.14.1 Executive-XI PCBA Removal .............................................................................. 7-51

7.14.2 Executive-XI PCBA Replacement ...................................................................... 7-53

7.15 Door Lock PCBA ......................................................................................................... 7-54

7.15.1 Door Lock PCBA Removal .................................................................................. 7-54

7.15.2 Door Lock PCBA Replacement ........................................................................... 7-55

7.16 X-Clear Emitter PCBA ............................................................................................... 7-55

7.16.1 X-Clear Emitter PCBA Removal ........................................................................ 7-55

7.16.2 X-Clear Emitter PCBA Replacement ................................................................. 7-56

7.17 Sensor Master and Slave Assemblies ........................................................................ 7-57

7.17.1 Sensor Master Assembly Removal ..................................................................... 7-58

7.17.2 Sensor Slave Assembly Removal ........................................................................ 7-59

7.17.3 Sensor Slave Assembly Replacement ................................................................. 7-60

xii 501510 Rev. S

7.17.4 Sensor Master Assembly Replacement .............................................................. 7-60

7.18 Drive Interface Adapter (DIA) ................................................................................... 7-61

7.18.1 Drive Interface Adapter Removal ...................................................................... 7-61

7.18.2 Drive Interface Adapter (DIA) Replacement ..................................................... 7-62

7.19 DFA (Direct Fibre Attach) Duplex Cable .................................................................. 7-63

7.19.1 DFA Duplex Cable Removal ............................................................................... 7-63

7.19.2 DFA Duplex Cable Replacement ........................................................................ 7-65

7.20 Interface Personality Module (IPM) .......................................................................... 7-65

7.20.1 IPM Removal ....................................................................................................... 7-66

7.20.2 IPM Replacement ................................................................................................ 7-66

7.21 Power Supplies ........................................................................................................... 7-67

7.21.1 Removal of a Single Power Supply Module ....................................................... 7-68

7.21.2 Replacement of a Single Power Supply Module ................................................ 7-68

7.21.3 Hot Removal of a Dual-Redundant Power Supply Module ............................... 7-68

7.21.4 Hot Replacement of a Dual-Redundant Power Supply Module ....................... 7-69

7.22 Fixed Slots ................................................................................................................... 7-69

7.22.1 Fixed Slot Removal .............................................................................................. 7-70

7.22.2 Fixed Slot Replacement ...................................................................................... 7-70

7.23 Air Filter ..................................................................................................................... 7-70

7.23.1 Air Filter Inspection ............................................................................................ 7-71

7.23.2 Air Filter Replacement ........................................................................................ 7-72

7.24 Calibration .................................................................................................................. 7-72

7.24.1 Calibration Setup ................................................................................................ 7-72

7.24.2 Calibration Initialization .................................................................................... 7-74

7.24.3 Calibration Completion ....................................................................................... 7-74

8. Firmware Updating ...................................................................................................... 8-1

8.1 Firmware Replacement ................................................................................................ 8-1

8.2 Determining the Current Firmware Revision ............................................................ 8-1

8.3 Firmware Update via the SCSI or Fibre Channel Interface ..................................... 8-2

8.4 Firmware Update via Q-Link ...................................................................................... 8-4

8.5 Firmware Update via Q-Conn ..................................................................................... 8-8

8.5.1 RS-232 Cable Wiring ............................................................................................. 8-8

8.5.2 RS-232 Serial Communications Parameters ....................................................... 8-8

8.5.3 User Terminal Software Setup Example ............................................................. 8-9

8.5.4 VT100 Terminal Emulation ................................................................................ 8-11

8.5.5 Remote Library Command Mode ....................................................................... 8-13

8.5.6 Xmodem Firmware Download <xdl> .................................................................. 8-13

9. RLS Expansions ............................................................................................................ 9-1

9.1 Introduction .................................................................................................................. 9-1

9.2 Model Expansions ......................................................................................................... 9-2

501510 Rev. S xiii

9.2.1 Installing a Model Expansion Kit ......................................................................... 9-2

9.2.2 Style A Chassis Storage Array Removal .............................................................. 9-3

9.2.3 Style A Chassis Storage Array Expansion Kit Installation ................................ 9-6

9.2.4 Style B Chassis Storage Array Removal .............................................................. 9-7

9.2.5 Style B Chassis Storage Array Expansion Kit Installation ................................ 9-9

9.2.6 Entering the Update Password .......................................................................... 9-11

9.2.7 Reconfiguring the Model Number ...................................................................... 9-11

9.2.8 Recalibrating the Unit ........................................................................................ 9-12

9.2.9 Clearing the Password ........................................................................................ 9-12

xiv 501510 Rev. S

This page left blank intentionally.

501510 Rev. S Introduction 1-1

1. Introduction

1.1 Who Should Read This Manual

This Technical Service Manual is for RLS service personnel. It describes the Maintenance Menu, the Private Menu and instructions for removing and replacing Field Replacement Units (FRU's). It also contains troubleshooting procedures and after–

maintenance testing procedures.

The following topics are covered in the RLS-8000 Tape Library Installation and Operation manual (Qualstar document number 501500):

• Unpacking Instructions

• Control Panel

• Menu System

• System Configuration

• System Operation

• Preventative Maintenance

• Repacking Instructions

For information about the SCSI interface, or other information outside the scope of

this manual, please refer to the appropriate documents listed below.

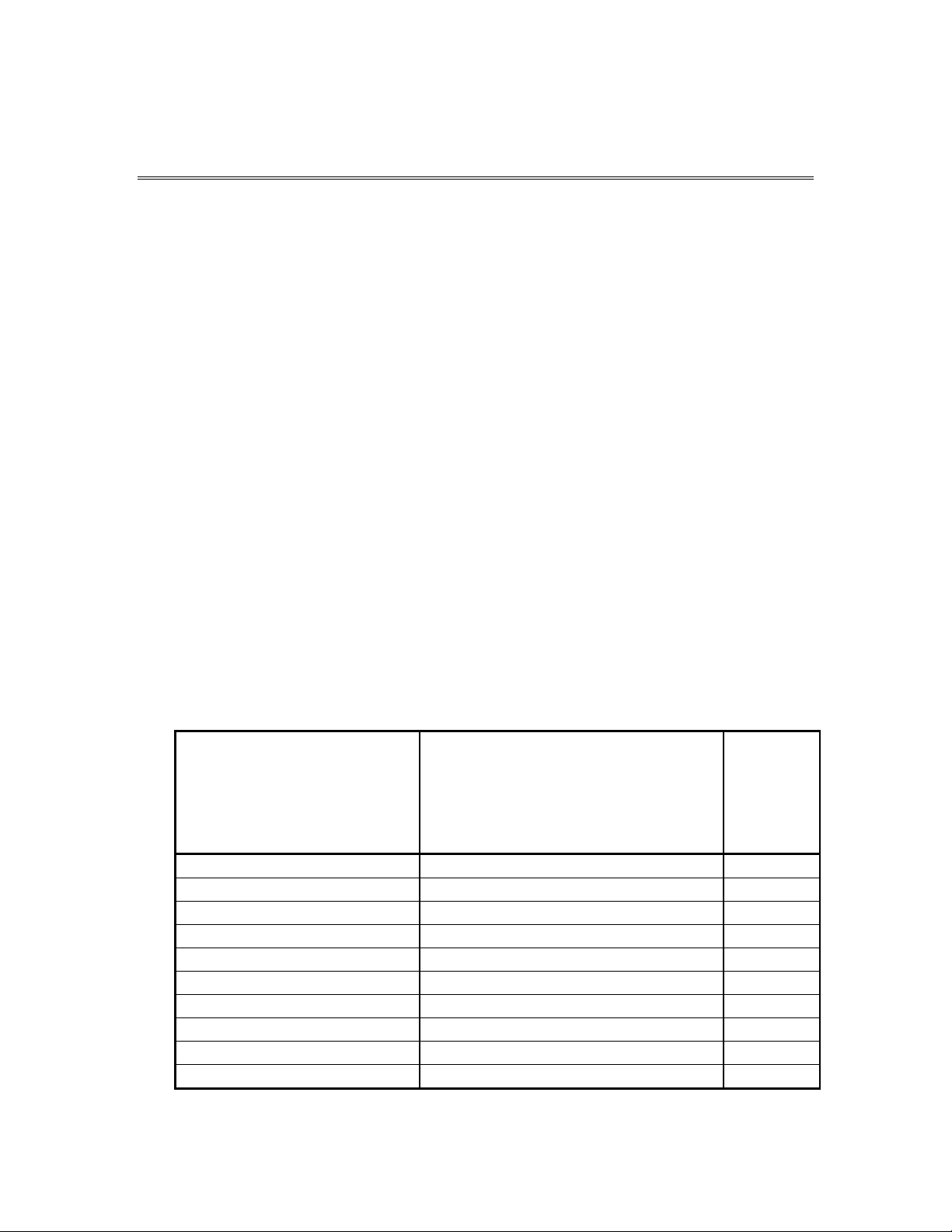

Subject

Document

Qualstar

Documen

t

Number

Specifications

RLS-8000 Product Specification

501490

Installation and Operation

RLS-8000 Installation and Operation Manual

501500

ADI Interface Quick Start

Product Application Note

PAN-025

Approved Data Cartridges

Product Information Note

PIN-038

Barcode Label Specifications

Product Information Note

PIN-040

Capacity on Demand

Ordering & Installing Capacity on Demand

PIN-044

SAS Cable and HBA Considerations

Product Information Note

PIN-046

SCSI Medium-changer Information

RLS SCSI-2 Interface Reference

501551

SCSI-2 Specification

ANSI X3.131-1994

N/A

SCSI SPI-3 Specification

NCITS T10 Project 1302D

N/A

1-2 Introduction 501510 Rev. S

Table 1-1 Applicable Documents

501510 Rev. S Introduction 1-3

Although Qualstar has made every effort to insure the accuracy of the information

contained in this manual, no guarantee is expressed or implied that the manual is

error-free. Qualstar reserves the right to make changes at any time without prior notification.

The Qualstar RLS is a sophisticated, state-of-the-art computer peripheral. It may only be serviced by an authorized service technician who is experienced with the operation and maintenance of tape libraries, and only after reading and understanding this

manual and the RLS Installation and Operation Manual.

1.2 Important Safety Information

All of the operating instructions and maintenance procedures in Qualstar manuals

must be followed to prevent personal injury or damage to the equipment. In the interests of safety, there are two kinds of warnings used in Qualstar documents, as shown

below.

DANGER

PERSONAL INJURY MAY RESULT IF YOU DO NOT FULLY COMPLY WITH THE

HANDLING, OPERATING, OR SERVICE INSTRUCTIONS FOUND IN A DANGER

PARAGRAPH.

GEFAHR

UNSACHGEMAESSE BENUTZUNG, BEDLENUNG ODER RAPARATUR

AUFGRUND VON NICHTBEGEFAHR DER SICHERHEITSANWEISUNG KANN ZU

VERIET-ZUNGEN FUEHREN.

CAUTION

EQUIPMENT DAMAGE OR LOSS OF DATA may result if you do not fully comply with the handling, operating, or service instructions found in a CAUTION

paragraph.

1-4 Introduction 501510 Rev. S

In addition, useful information and tips may be found throughout the document in

the following formats:

NOTE

SPECIAL ATTENTION to explanatory statements found in a NOTE paragraph will help

you avoid mistakes and/or save time.

NOTICE

A NOTICE box contains additional important information not covered by the

other three types of special text: DANGER, CAUTION, or NOTE.

1.3 Lithium Battery

Please observe the following information when repairing the unit.

DANGER

U9, A DALLAS SEMICONDUCTOR CORPORATION DS1225AB OR A SGSTHOMPSON MICROELECTRONICS M48258X IC ON THE EXECUTIVE PCBA

CONTAINS AN INTEGRAL LITHIUM BATTERY. AN EXPLOSION DANGER

EXISTS IF THE IC IS INCORRECTLY REPLACED. REPLACE THE IC ONLY WITH

THE SAME PART NUMBER, OR AN EQUIVALENT DESIGNATED BY THE

MANUFACTURER. DISPOSE OF THE USED IC ACCORDING TO THE

MANUFACTURER'S INSTRUCTIONS.

GEFAHR

DER U9, EIN DALLAS SEMICONDUCTOR CORPORATION DS1225AB ODER

EIN A SGS-THOMPSON MICROELECTRONICS M48258X IC AUF DEM

EXECUTIVE BOARD ENTHAELT EINE INTEGRIERTE LITHIUM BATTERIE. WENN

DIESE UNSACHGEMAESS AUSGETAUSCHT WIRD, BESTEHT EXPLOSIONS

GEFAHR. DER IC DARF NUR DURCH EINEN ARTIKEL MIT DER SELBEN

ARTIKELNUMMER, BZW, MIT EINEM VERGLEICHBAREN ARTIKEL LAUT

501510 Rev. S Introduction 1-5

HERSTELLER ANGABE ERSETZT WERDEN. DIE ENTSORGUNG DES ALTEN IC’S

DARF NUR GEMAESS HERSTELLERANGABEN ERFOLGEN.

1-6 Introduction 501510 Rev. S

This page left blank intentionally.

501510 Rev. S Description and Theory of Operation 2-1

2. Description and Theory of Operation

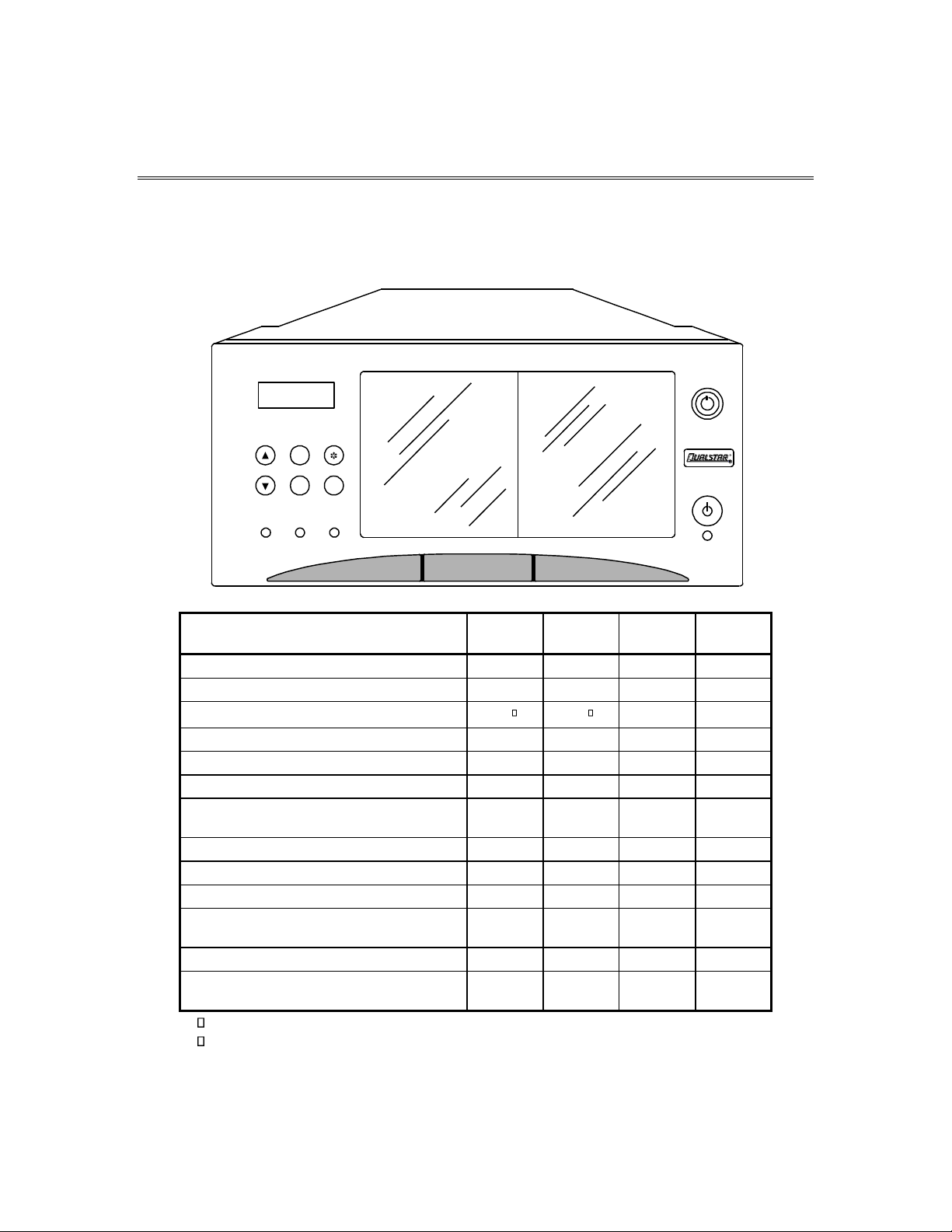

2.1 Models

EXIT

ENTER

MENU

READY

FAULT

BUSY

R

FEATURE/MODEL

4124

4221

4445

4470

Tape Technology

AIT

AIT

AIT

AIT

Maximum No. of Drives

1 2 4

4

Total Cartridge Capacity

24

22

45

70

Number of Magazines

4 4 9

14

Cartridges per Magazine

5 5 5

5

Barcode Reader

Optional

Optional

Optional

Optional

LVD/SE SCSI

Interface Personality Module (IPM)

N/A

Standard

Standard

Standard

2-GB Fibre Channel Interface (IPM)

N/A

Optional

Optional

Optional

Q-Link Remote Manager

Standard

Standard

Standard

Standard

Quick swap tape drive carriers

N/A

Standard

Standard

Standard

Buffered Drive Interface Adapters (BDIAs)

for Hot Swappable Tape Drives

N/A

Optional

Optional

Optional

Standard Power Module Output (watts)

125

125

250

250

Redundant, Hot-Swappable Power Modules

(Dual 250-watt modules)

N/A

N/A

Optional

Optional

Includes 4 fixed cartridge storage locations

Includes 2 fixed cartridge storage locations

Table 2-1 RLS-4000 Models, Features and Options

2-2 Description and Theory of Operation 501510 Rev. S

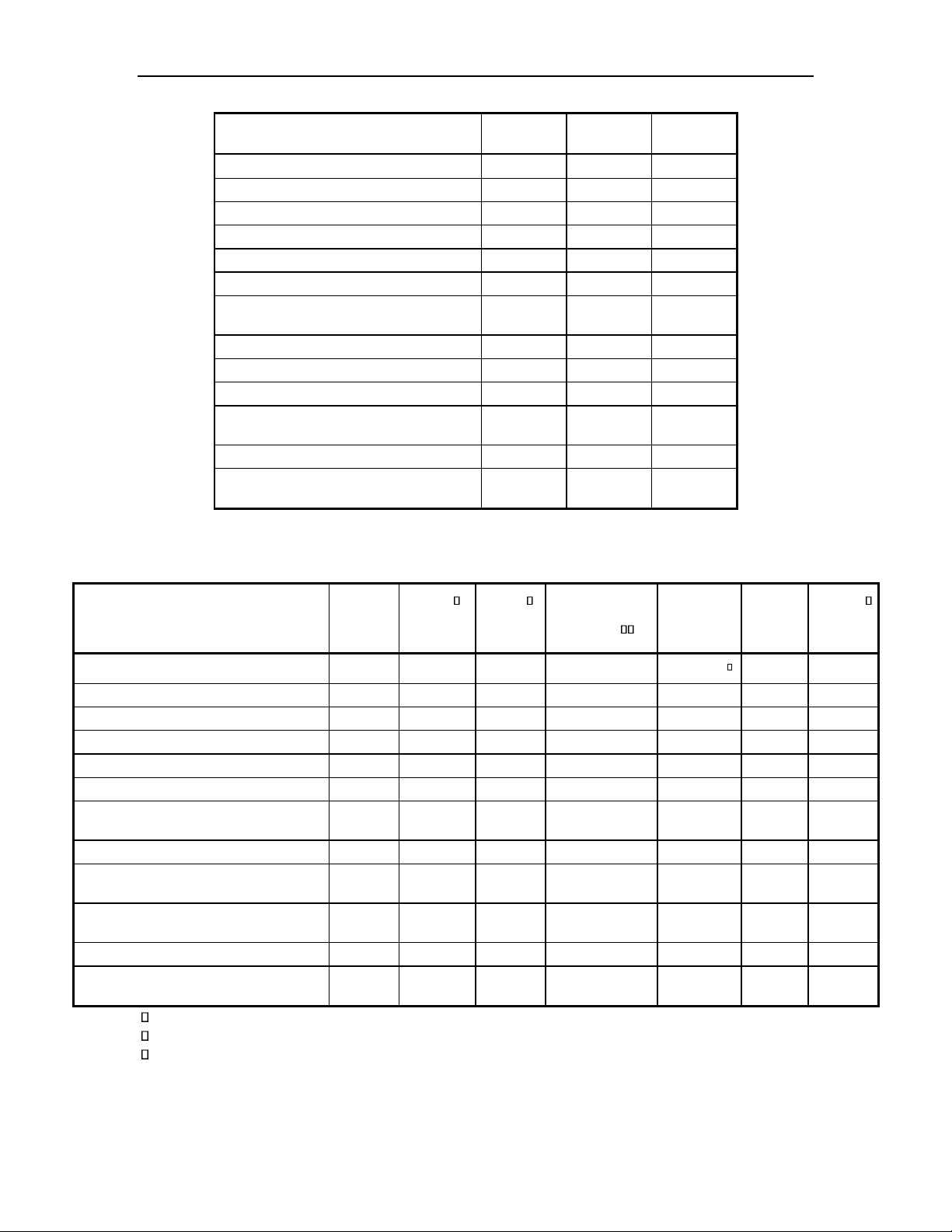

FEATURE/MODEL

5116

5244

6227

Tape Technology

SAIT

SAIT

Super DLT

Maximum No. of Drives

1 2 2

Total Cartridge Capacity

16

44

27

Number of Magazines

4

11

9

Cartridges per Magazine

4 4 3

Barcode Reader

Optional

Optional

Optional

LVD/SE SCSI

Interface Personality Module (IPM)

N/A

Standard

Standard

2-GB Fibre Channel Interface (IPM)

N/A

Optional

Optional

Q-Link Remote Manager

Standard

Standard

Standard

Quick swap tape drive carriers

N/A

Standard

Standard

Buffered Drive Interface Adapters (BDIAs) for Hot Swappable Tape Drives

N/A

Optional

Optional

Standard Power Module Output (watts)

125

250

250

Redundant, Hot-Swappable Power Modules (Dual 250-watt modules)

N/A

Optional

Optional

Table 2-2 RLS-5/6000 Models, Features and Options

FEATURE/MODEL

8116

8202

8204

RLS-

8204D

8216H

8236

8236D

Tape Technology

LTO

LTO

LTO

LTO

LTO (HH)

LTO

LTO

Maximum No. of Drives

1 2 2 2 2 2 2

Total Cartridge Capacity

1

12-36

12-44

12-44

16

36

36

Number of Magazines

16

3-9

3-11

3-11

4 9 9

Cartridges per Magazine

4 4 4 4 4 4 4

Barcode Reader

Optional

Optional

Optional

Standard

Optional

Optional

Optional

LVD/SE SCSI

Interface Personality Module (IPM)

N/A

Standard

Standard

Standard

Standard

Stand-

ard

Standard

2-GB Fibre Channel Interface (IPM)

N/A

Optional

Optional

Optional

Optional

Optional

Optional

Q-Link Remote Manager

Standard

Standard

Standard

Standard

Standard

Stand-

ard

Standard

Quick swap tape drive carriers

N/A

Standard

Standard

Standard

Standard

Stand-

ard

Standard

Standard Power Module Output (watts)

125

250

250

250

160

250

250

Redundant, Hot-Swappable Power

Modules (Dual 250-watt modules)

N/A

Optional

Optional

Optional

N/A

Optional

Optional

Features field-upgradeable Capacity on Demand

“D” models support LTO DFA fibre channel tape drives

HH = Half-High tape drives

Table 2-3 RLS-8000 Models, Features and Options (continued below)

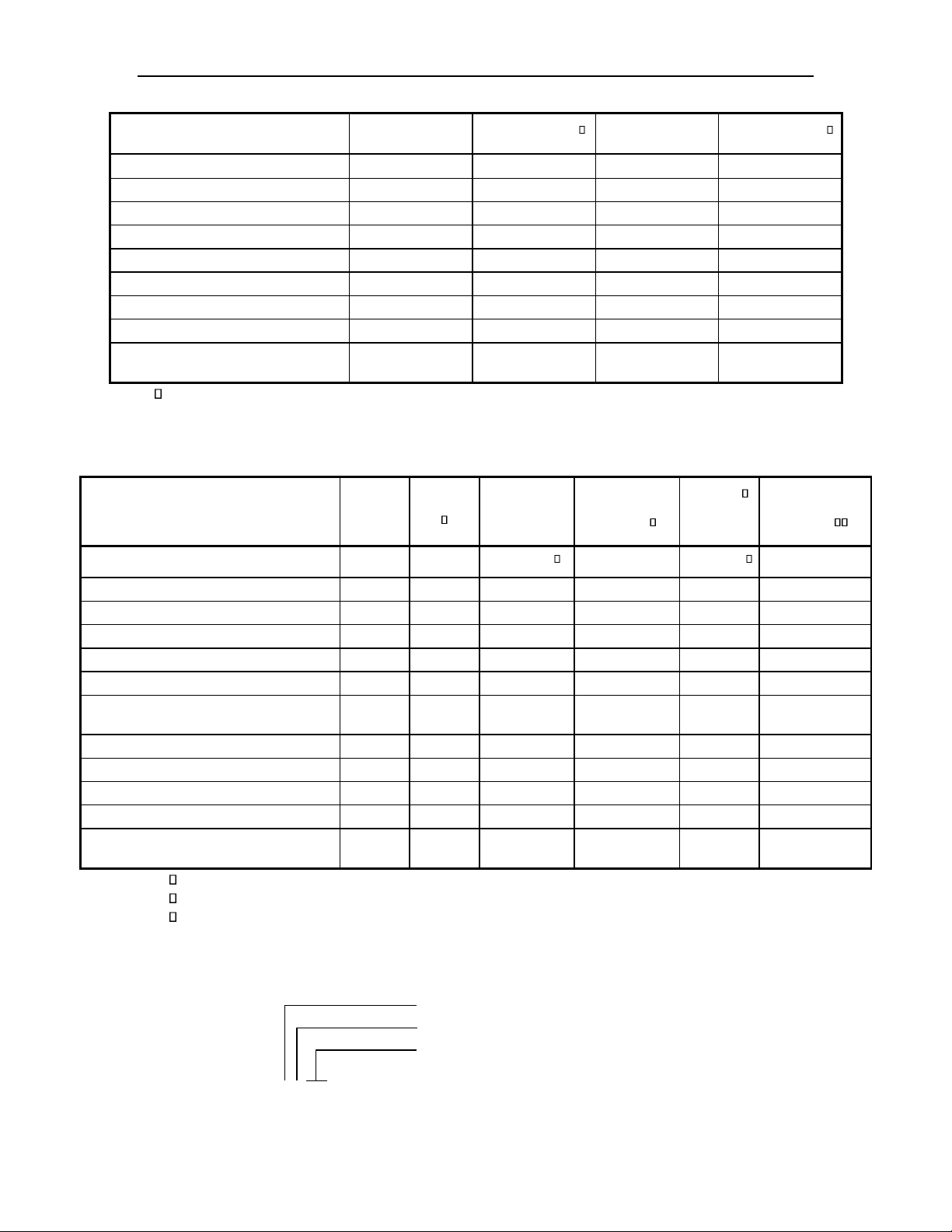

501510 Rev. S Description and Theory of Operation 2-3

2-4 Description and Theory of Operation 501510 Rev. S

FEATURE/MODEL

RLS-8216C

RLS-8216CD

RLS-8236C

RLS-8236CD

Tape Technology

LTO

LTO

LTO

LTO

Maximum No. of Drives

2 2 2

2

Total Cartridge Capacity

16

16

36

36

Number of Magazines

4 4 9

9

Cartridges per Magazine

4 4 4

4

Barcode Reader

Standard

Standard

Standard

Standard

Q-Link Remote Manager

Standard

Standard

Standard

Standard

Quick swap tape drive carriers

Standard

Standard

Standard

Standard

Standard Power Module Output

(watts)

160

160

160

160

“D” models support LTO DFA fibre channel tape drives

Table 2-4 RLS-8000 Models, Features and Options (continued below)

FEATURE/MODEL

8244

8244D

RLS-

8444H

RLS-

8444D

8404H

RLS-

8404D

Tape Technology

LTO

LTO

LTO (HH)

LTO

LTO (HH)

LTO

Maximum No. of Drives

2 2 4 4 4

4

Total Cartridge Capacity

44

44

44

44

12-44

12-44

Number of Magazines

11

11

11

11

3-11

11

Cartridges per Magazine

4 4 4 4 4

4

Barcode Reader

Optional

Optional

Standard

Standard

Optional

Standard

LVD/SE SCSI

Interface Personality Module (IPM)

Standard

Standard

Standard

Standard

Standard

Standard

2-GB Fibre Channel Interface (IPM)

Optional

Optional

Optional

Optional

Optional

Optional

Q-Link Remote Manager

Standard

Standard

Standard

Standard

Standard

Standard

Quick swap tape drive carriers

Standard

Standard

Standard

Standard

Standard

Standard

Standard Power Module Output (watts)

250

250

250

250

250

250

Redundant, Hot-Swappable Power

Modules (Dual 250-watt modules)

Optional

Optional

Optional

Optional

Optional

Optional

Features field-upgradeable Capacity on Demand

“D” models support LTO DFA fibre channel tape drives

HH = Half-High tape drives

Table 2-5 RLS-8000 Models, Features and Options

RLS-0000

Series Identifier

Maximum Number of Drives

Maximum Number of Cartridges in Magazines

501510 Rev. S Description and Theory of Operation 2-5

Figure 2-1 Model Number Identification Scheme

This manual applies to all models. The installation and operation of the various models is virtually identical. Differences among the models are noted where required.

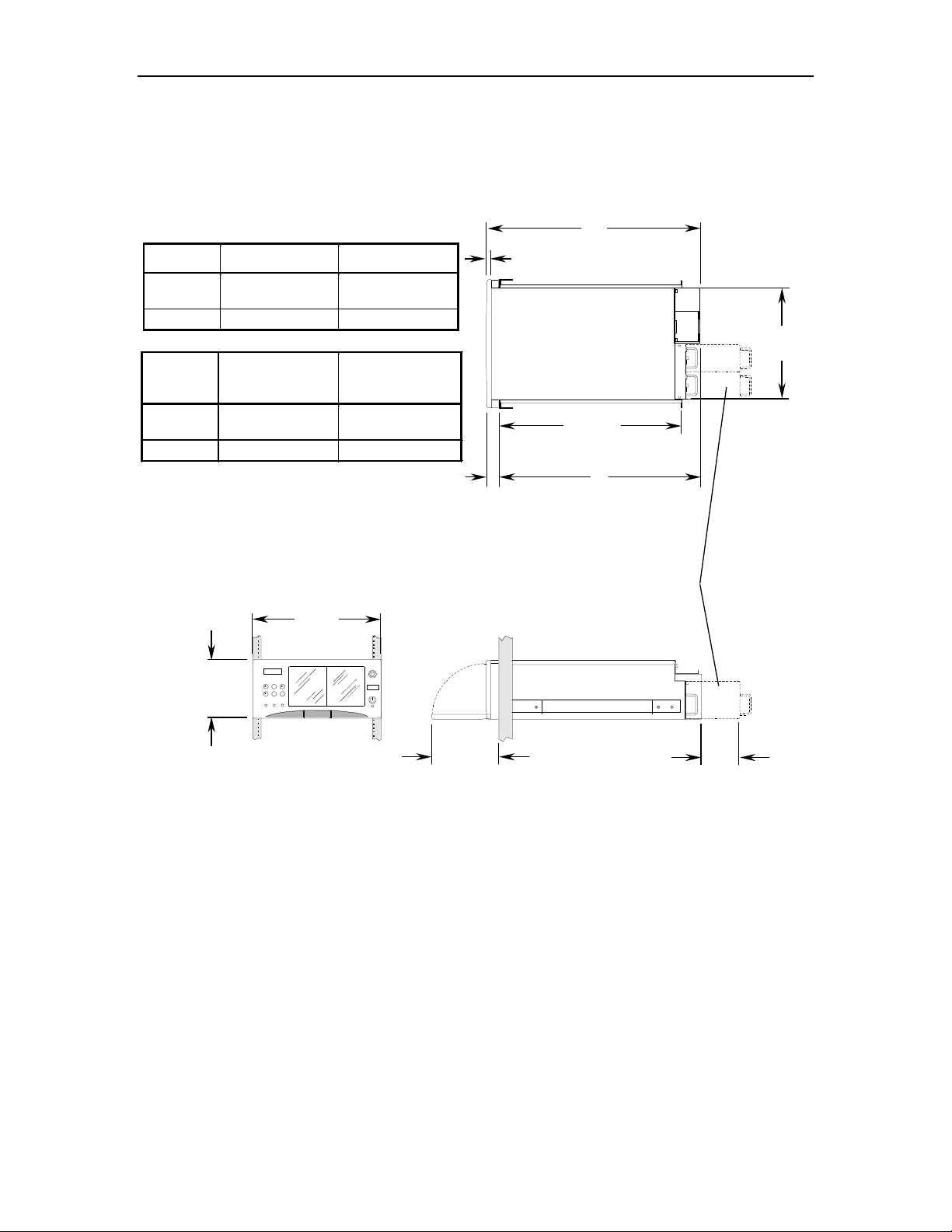

EXIT

ENTER

MENU

READY

FAULT

BUSY

19.0”

48.3 cm

8.75”

22.2 cm

10.0”

25.4 cm

8.0”

20.3 cm

Dual-Redundant, Hot-Swappable

Power Supply Option

.7”

1.8 cm

A

B

16.6”

42.2 cm

2.0”

5.1 cm

C

(Rail Spacing)

Model

“A” Dimension

“B” Dimension

5116 &

XXX4

36.9” / 93.7 cm

34.9” / 88.6 cm

All Others

32.1” / 81.5 cm

30.1” / 76.4 cm

Model

“C” Dimension

Minimum

“C” Dimension

Maximum

5116 &

XXX4

27.5” / 69.9 cm

36.2” / 92.0 cm

All Others

22.0” / 55.9 cm

30.6” / 77.7 cm

Figure 2-2 RLS External Dimensions

These tape libraries are not intended for use in mobile applications. They were designed for use in an office environment.

2-6 Description and Theory of Operation 501510 Rev. S

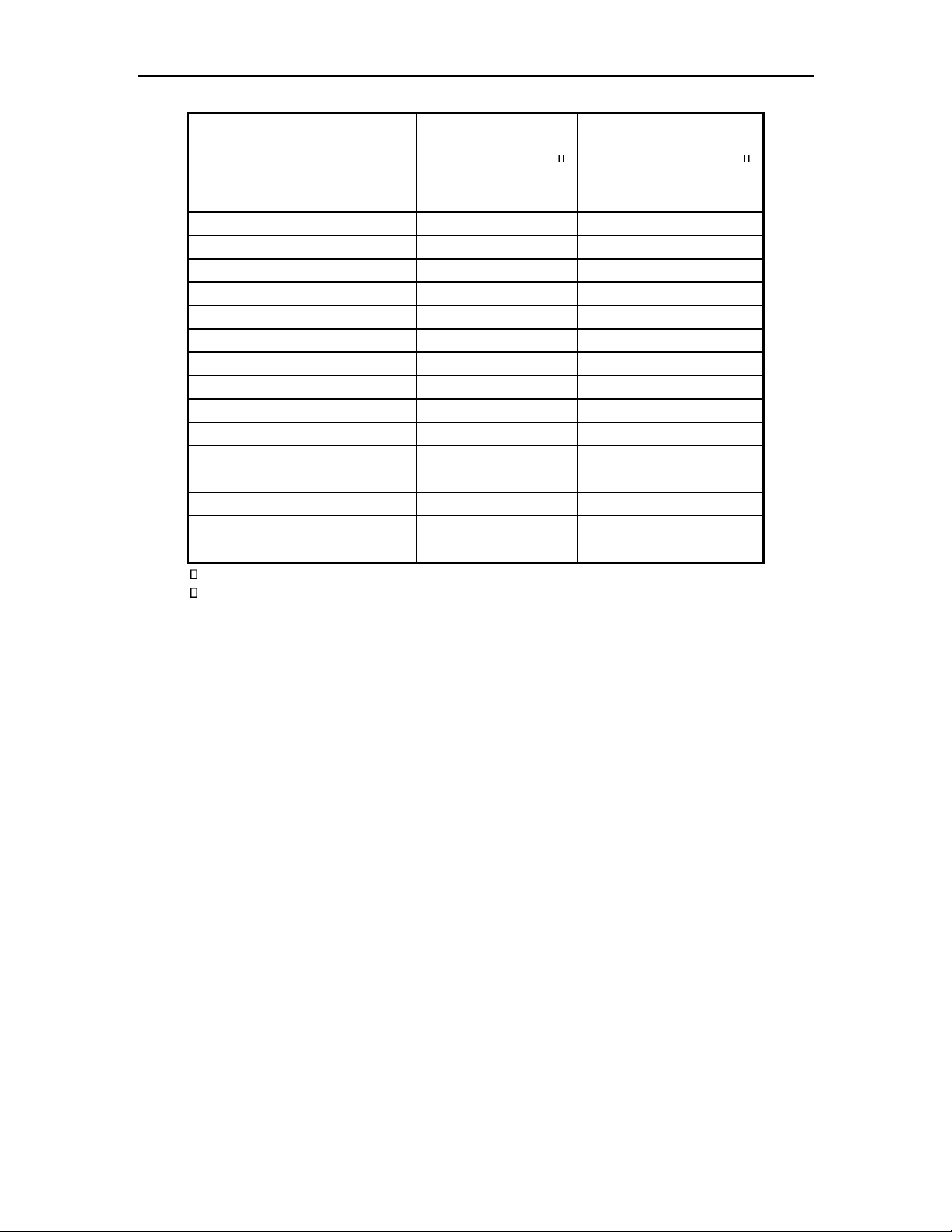

MODEL

NET WEIGHT

FULLY LOADED

(LBS / KG)

COMBINED

SHIPPING WEIGHT

(LBS / KG)

RLS-4124

61 / 28

81 / 37

RLS-4221

67 / 30

87 / 39

RLS-4445

87 / 39

107 / 49

RLS-4470

92 / 42

112 / 51

RLS-5116

108 / 49

138 / 63

RLS-5244

151 / 68

181 / 82

RLS-6227

97 / 44

119 / 54

RLS-8116

69 / 31

97 / 44

RLS-8202/8216C/8216CD

104 / 47

132 / 60

RLS-8236/8236C/8236CD/8236D

114 / 52

142 / 64

RLS-8204/8204D

147 / 67

177 / 80

RLS-8216H

70 / 32

98 / 44

RLS-8244/8244D

147 / 67

177 / 80

RLS-8404H/8404D

151 / 69

181 / 82

RLS-8444H/8444D

151 / 69

181 / 82

Includes a full complement of Tape Drives, magazines and tape cartridges

Not including tape cartridges

Table 2-6 RLS Weights

2.2 General Description

Models accommodate one or four tape drives and have removable magazines for tape

cartridge storage. There are models that utilize AIT, LTO, SDLT and SAIT tape technology. All units operate on internationally available AC power. Brushless motors are

used exclusively. All digital closed-loop servo systems use magnetic and optical position sensors. The servos automatically calibrate themselves, thus eliminating all electrical adjustments. Preventive maintenance is reduced to replacing the Air Filter,

when so prompted by the control panel display and removing debris inside the RLS.

2.2.1 Motion Systems

• On the RLS-4124, 4221, 5116, 8116 and 8216H a rotating carousel is utilized

to hold four magazines containing tape cartridges. The carousel rotates in

90-degree increments to present one magazine (or 5 tape cartridge slots)

to the robotic handler. The carousel rotates in either direction to minimize the access time to any data cartridge.

• All other models utilize a patented storage array that holds 9 magazines in

a rectangular array that is 2 magazines wide and 5 magazines deep. One of

501510 Rev. S Description and Theory of Operation 2-7

the possible 10 magazines is missing in order to facilitate movement of the

other 9. Due to its increased depth, the RLS-5244, 8204, 8204D, 8244, 8244D,

8404, 8404D, 8444 and 8444D have two more magazines (11 magazines out

of 12 positions). The magazines are identified MA through MI or MK and

the magazine in the right front corner is accessible by the Handler.

The RLS-4470 utilizes a patented storage array that holds 14 magazines in

a rectangular array that is 2 magazines wide and 8 magazines deep. Two

of the possible 16 magazines are missing in order to facilitate movement of

the other 14. The 14 magazines are identified MA through MN and the

magazine in the right front corner is accessible by the Handler.

The magazines in the storage arrays are shuffled around the racetracklike array in either direction. The direction of movement is chosen to minimize the time to access the desired magazine.

• The RLS utilizes a two-axis robotic cartridge handling mechanism that

moves cartridges between the storage slots and the Tape Drives. In the

unlikely event this assembly ever needs replacing, it can be accomplished

in less than 5-minutes.

All motion is powered by brushless DC motors turning precision leadscrews and drive shafts. Magnetic sensors provide position and velocity

feedback to the motors, while optical sensors provide absolute positional

information. This unique design produces optimum positioning accuracy,

reliability and long life. The servo systems are digital, self-calibrating and

never require mechanical adjustments.

2.2.2 Sensors

Optoelectronic Interrupters Sensors

These consist of an LED emitter and a Schmidt trigger optoelectronic sensor, which

produces a digital output indicating if it is blocked or not. Some consist of two loose

parts, and others have both parts integrated into one housing. These can only be used

at very short ranges, and must either be protected from ambient light, or be designed

to be fail-safe.

• X Home

This is an Opto switch pair located on the Carriage Emitter PCBA. The

signal feeds back to the Sensor Master PCBA. It is blocked when the carriage is far enough to the right of its travel to be in danger of actuating

the door-opening device. It is used for homing the X-axis during POST

(Power On Self Test), self-diagnostics, or calibration.

• Door Latched

This indicates that the front door is closed and latched. The sensor is located on and read by the front panel PCBA.

• IO Port Door Latched

This indicates that the IO Port door is closed and latched. The sensor is

located on and read by the front panel PCBA.

2-8 Description and Theory of Operation 501510 Rev. S

• Door Locked

This indicates that the door lock is fully turned to the locked position. The

sensor is located on the Door Lock Sensor PCBA and feeds back to the

Sensor Master PCBA.

• Carousel on Face

This indicates that the carousel is aligned on a face. The sensor is located

on the Carousel PCBA and it feeds back directly to the Executive PCBA.

• Drive Locked1 and 2

Located on the Drive Bay PCBA, it is used to sense that a drive is installed. These devices do not have Schmidt triggers as the others do, but

rather they have a phototransistor output.

Hall Effect Sensors

These are simple three-lead devices, which indicate the presence or direction of a local

magnetic field.

• Carousel Home

This sensor gives a once-around indication for the carousel, and is used to

find the home face of the carousel. It is located on the carousel PCBA, and

feeds back to the Executive PCBA. It looks for a magnet buried in the carousel platform.

• X Motor Phase A, B & C

These sensors are integral to the Brushless DC motors, and provide the

Executive PCBA with feedback for both commutation and position. They

route through the Carriage PCBA, the Interconnect PCBA, and finally to

the Executive PCBA. These sensors provide continuous incremental position feedback so the library always knows where its carriage is.

• Z Motor Phase A, B & C

These sensors are integral to the Brushless DC motors, and provide the

Executive PCBA with feedback for both commutation and position. They

route through the Carriage PCBA, the Interconnect PCBA, and finally to

the Executive PCBA.

• Storage Array Index Sensor

This sensor is located on the Storage Array PCBA and senses a magnet

embedded in a cam to provide phasing information for the control system.

• Storage Array Home Sensor

These two sensors are located on the Storage Array PCBA and sense a

magnet on the bottom of car “A”, so the control system can identify which

car is the first one.

Modulated Optoelectronic Sensors

These are used where the range is greater that allowed by simple optoelectronic sensor pairs. These sensors consist of an LED emitter, which is modulated, and a detector, which was designed for remote control of consumer products. The detector looks

for a particular carrier frequency, which is modulated by a sub-carrier that would

normally carry data. In our application, we use it to detect the presence of the modulated signal, but impose no data on it. The part features an infrared filter, carrier and

501510 Rev. S Description and Theory of Operation 2-9

sub-carrier band selection, automatic gain control, and signal detection, which allow

it to run directly off a processor.

• Z Home

The detector is located on the Interconnect PCBA, and the emitter is located on the X Clear PCBA. Both devices are operated by the Sensor Master PCBA. The principle function is to detect when the Z axis of the carriage is back far enough to operate the door-opening mechanism, which is

very nearly all the way towards the front of the library. It is used for homing the Z-axis during POST (Power On Self Test), self-diagnostics, or calibration.

• Gripper Home

The detector is located on the Interconnect PCBA, and the emitter is located on the X Clear PCBA. Both devices are operated by the Sensor Master PCBA. The principle function is to detect when the grippers are all the

way open while the carriage is at the back of its travel. It is used for homing the gripper during POST (Power On Self Test), self-diagnostics, or calibration, and various times during fault recovery and in normal operation.

The grippers are driven by a step-motor, and there is no feedback to determine their position except this sensor.

• X Clear

The detector is located on the Interconnect PCBA, and the emitter is located on the X Clear PCBA. Both are operated by the Sensor Master PCBA.

The principle function is to detect an object unexpectedly obstructing the

“no man’s land” between the carriage and the cartridges. It is also used to

detect the presence of magazines in the carousel during inventory. The

other function is to sense if someone may have modified the inventory of

the library. If the front door or the IO Port access door is open, and the

beam becomes blocked, then the library assumes that the inventory information may have been compromised, so it will rescan the affected elements.

• Magazine Cartridge 1, 2, 3, 4 & 5

The emitters are located on the Sensor Slave PCBA, and the detectors are

located on the Sensor Master PCBA. These are operated by the Sensor

Master PCBA. They are used to detect cartridges in the magazine facing

the front door. During inventory, each face is turned to the front to present its cartridges to these sensors for detection. If a cartridge is present,

then the corresponding sensor beam will be blocked, and the library will

mark the location as occupied in its inventory data base.

• Fixed Cartridge 1, 2, 3 & 4

The emitters are located on the Sensor Slave PCBA, and the detectors are

located on the Sensor Master PCBA. These are operated by the Sensor

Master PCBA. They are used to detect cartridges in the fixed cartridge

storage slots. During inventory, if a cartridge is present, then the corresponding sensor beam will be blocked, and the library will mark the location as occupied in its inventory data base.

2-10 Description and Theory of Operation 501510 Rev. S

• Drive Cartridge 1 & 2

The emitters are located on the Sensor Slave PCBA, and the detectors are

located on the Sensor Master PCBA. These are operated by the Sensor

Master PCBA. They are used to detect cartridges in the Tape Drives. During inventory, if a cartridge is present, then the corresponding sensor

beam will be blocked, and the library will mark the location as occupied

in its inventory data base.

2.2.3 Barcode Reader

An integrated Barcode Reader (BCR) is optional on all RLS models. The BCR can

uniquely identify each barcode labeled cartridge, thus saving the system from reading

each cartridge in a Tape Drive. Preprinted barcode labels, which are both human- and

machine-readable, are available from a number of sources including Qualstar.

The Barcode Reader consists of an LED light source and a Charge-Coupled Device

(CCD) sensor (similar to that used in a video camera) and associated electronics. It is

mounted on the carriage and contains no moving parts. The Barcode Reader can scan

all cartridges within the RLS (except those loaded inside Tape Drives). Barcode data

is stored internally in the changer’s non-volatile RAM (the internal inventory database) and is available to the host computer upon request.

2.2.4 Barcode Labels

Pre-printed barcode labels, which are both human- and machine-readable, are available from a number of sources including Qualstar.

Barcode labels must conform to ANSI/AIM BCI-1995, Uniform Symbology Specification Code 39. Please refer to PIN-040 at www.qualstar.com (click on Support tab) for

more information.

By default, the RLS expects a modulus 43 check character at the end of each label.

The use of a check character helps assure that labels are read error-free. The RLS

configuration must be changed before using barcode labels without a check character.

All of the labels within the RLS must match the check character configuration: either

all with or all without a check character.

2.2.5 Capacity on Demand (COD)

The Capacity on Demand (COD) feature allows the storage capacity of RLS-8204,

8204D, 8404 and 8404D models to be field expanded from 12 tape cartridges up to 44

in increments of eight. The RLS-8202 may be expanded from 12 tape cartridges up to

36 in increments of eight. To order an upgrade kit, contact an authorized Reseller, or

Qualstar Sales at 805-583-7744 x 773. Necessary information about ordering and installing COD can be found in PIN-044 available at www.qualstar.com (click on the

Support tab).

Loading...

Loading...