Qualstar 1260 User Manual

Corporation

1260

User's

Guide

500250 Rev. K

Caution!

ii

Copyright

Notice

Information contained

in

this

document is copyrighted by

Qualstar

Corporation.

It

is

intended

for

use

by

Qualstar's

customers

and

prospective customers to

evaluate,

inte-

grate, operate

and

maintain

Qualstar

products. Customers

and

prospective customers

may

reproduce

this

document

as

needed for

these

uses. Reproduction

in

whole

or

in

part

for

any

other

use

or

by

any

other

party

is

prohibited

without

prior

written

permis-

sion from

Qualstar

Corporation.

Every effort

has

been

made

to

keep

the

information contained

in

this

document

cur-

rent

and

accurate

as

of

the

date

of

publication or revision. However, no

guarantee

is

given

or

implied

that

the

document

is

error-free

or

that

it

is

accurate

with

regard

to

any

specification.

Qualstar

reserves

the

right

to modify product designs

and

specifica-

tions

without

notice.

• Qualstar® is a registered

trademark

of

Qualstar

Corporation.

• Cipher® is a registered

trademark

of

Archive Corporation.

• Pertec®

is

a registered

trademark

ofDDC Pertec

..

•

IB~

is

a registered

trademark

of

International

Business Machines, Incorpo-

rated.

References contained in this manual to

DIP

switch settings,

jumper

loca-

tions, primary voltages and other options are for reference only.

Access

to the interior

of

this equipment

is

restricted

to

dealers and qualified

service technicians, and only in accordance with published service

manu-

als and bulletins.

For

service information

or

help

with

installation,

please

write

or

call

Qualstar

Customer Support:

Qualstar

Corporation

6709

Independence

Avenue

Canoga

Park,

CA 91303

FAX:

(818) 592-0116

Phone:

(818) 592-0061

500250K

Important

-

Read

This

Before

Opening

the

Package

Qualstar

merchandise arrives

pany

these

If

or

If

•

•

• Call

• Clearly identify

• Return

Corporation

immediately.

instructions.

this

merchandise was

reseller for

this

Treat

Retain

shipped to

packing

chandise Authorization (RMA) number.

cepted

ments to:

return

merchandise was

the

merchandise carefully to

all shipping

Qualstar

material

Qualstar

without

the

merchandise, including cables, manuals, software

has

made

every effort to provide

damaged

If

the

instructions.

and

in

or carton

Customer Service

this

number.

the

outside of

or

has

merchandise

purchased

purchased

packing materials.

the

original packing

has

the

been

at

carton and

been mishandled,

is

defective

from a

dealer

or

directly from

assure

damaged, a new

(818) 592-0061 to

Qualstar,

its

suitability

Returned

material

Returned

the

packing list with

quality

in

any

other

and

merchandise will

merchandise.

please

notify

other

way, please follow

reseller, contact

please do

for

return.

merchandise

carton.

set

may

request a Return

and

the

delivery com-

that

the

following:

must

be

If

the

original

be

requested.

Mer-

not

be ac-

the

RMA

number.

all related docu-

If

the

dealer

QUALSTAR

6709

Federal

This

equipment

puting

provide reasonable protection

cial environment. Operation

ceptable interference to radio

expense will be required to

Communications

has

been

device

pursuant

to

tested

Subpart

take

CORPORATION

Independence

Canoga

Attn:

Phone:

Park,

Customer

FAX: (818) 592-0116

(818) 592-0061

Commission

and

found to comply

J of

Part

15 of FCC Rules, which

against

of

and

such interference

this

equipment

TV reception,

whatever steps

Avenue

CA

91303

Service

with

the

when

in a residential

in

which case

are

necessary to correct

Requirements

limits for a Class A com-

are

designed to

operated

area

the

may

user

the

in

a commer-

cause unac-

at

his

own

interference.

500250 K

iii

iv

Limited

Warranty

QUALSTAR SHALL NOT BE RESPONSIBLE OR LIABLE FOR

AA"Y

SPECIAL, IN-

CIDENTAL

OR CONSEQUENTIAL DAMAGES OR LOSS

L~~ISING

FROM

THE

USE

OF

THIS

PRODUCT.

THIS

WARRANTY IS

IN

LIEU OF, AND BUYER WAIVES, ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, ARISING BY LAW OR OTHERWISE, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTY

OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

THE

REME-

DIES STATED

IN

THIS WARRANTY ARE EXCLUSIVE.

Qualstar

Corporation

warrants

this

Magnetic Tape

Transport

or Tape Subsystem to

be free from defects

in

materials

and

workmanship

under

normal

use

and

service for a

period

of

one

year

from

the

date

of

shipment

from

the

factory to

the

buyer, provided

however

that

goods

or

parts

which

are

replaced

or

repaired

under

this

warranty

are

warranted

only for

the

remaining unexpired portion of

the

original

warranty

period

applicable to

the

goods

in

which

they

are

installed. This

warranty

does

not

apply

to ac-

cessories such

as

tape, carrying cases,

or

manuals.

Qualstar's

sole

and

exclusive obligation

under

this

limited

warranty

is

to

repair

or re-

place

at

Qualstar's

option all products

that

are

returned

to

Qualstar

within

the

appli-

cable

warranty

period

and

found

by

Qualstar

to

be

defective. Replacement

parts

may

be

either

new

or

reconditioned

at

Qualstar's

option. The Buyer is responsible for prop-

erly packing

the

unit

to be returned

in

accordance with applicable user's guide instruc-

tions,

and

the

Buyer shall ship

the

unit

prepaid

at

Buyer's expense.

Qualstar

will

return

the

unit

to

the

Buyer prepaid

at

Qualstar's expense via surface transportation. Air trans-

portation, customs charges, and other special charges are

the

responsibility of

the

Buyer.

This

warranty

shall

immediately be

null

and

void if,

in

Qualstar's

sole judgement,

the

unit

has

been

altered

or repaired

other

than

with

authorization from

Qualstar

and

by

its

approved procedures,

has

been

subject to misuse, abuse, negligence

or

accident,

damaged

by

excessive voltage, damaged

in

shipment, subjected to

improper

environ-

mental

conditions

or

had

its

serial

numbers

and/or

other

product

markings

altered,

de-

faced

or

removed. Normal

user

preventive

maintenance

such

as

tape

path

cleaning

as

set

forth

in

Qualstar's

User's Guides is

the

responsibility of

the

Buyer

and

is excluded

from

this

warranty.

This

warranty

will

remain

in

effect

notwithstanding

Buyer's

shipment

to

third

par-

ties,

but

warranty

remedies defined

herein

are

applicable only to

Buyer

and

are

not

transferable.

Buyer

shall disclose to

third

parties

the

terms

of

this

warranty

and

shall

indemnify

Qualstar

from

any

failure to

make

such disclosure

and

from

any

warranties

made

by

the

Buyer beyond those

set

forth herein.

Qualstar

makes

no representations

as

to

the

suitability

of

Software supplied for

use

in

any

application,

and

the

Buyer agrees to accept all such Software on

an

"as is" basis.

Furthermore, Qualstar does not

warrant

Software to be free from defects,

and

assumes

no

responsibility for damages of

any

kind,

either

actual

or consequential, for

such

Soft-

ware

failing to perform

as

documented

or

in

any

other

manner.

In

no

event

will Qual-

star

be liable for damages, including

any

lost profits, lost savings

or

other

incidental

500250 K

500250 K

or

consequential

damages

arising

out

of

the

use

or

inability

to

use

such

software, even

if

Qualstar

has

been

advised

of

the

possibility

of

such

damages,

or

for

any

claim by

any

other

party.

Qualstar

Service

Policy

Service

is

provided

at

the

Qualstar

factory

in

Canoga

Park,

California, USA. Addition-

ally, service

may

be available on

site

or

in

selected locations from a

Qualstar

factory-

authorized

service organization. Consult a

Qualstar

sales

representative

for

further

information.

All

material

returned

to

the

Qualstar

factory for

any

reason

must

be

authorized

prior

to

shipment. Write or Call

Qualstar

Customer

Service to

obtain

an

RMA

number.

This

number

must

appear

on all boxes

and

packing slips.

Qualstar

will refuse delivery

ofma-

terial without proper

RMA

identification.

Units

being

returned

must

be

shipped

in

the

original packing

material

and

shipping

carton. Any

damage

or

expenses

resulting

from

shipping

in a non-authorized

shipping

carton

will be

the

responsibility

of

the

Buyer.

If

the

original

carton

and

packing

are

not

available,

they

may

be

purchased

from

Qualstar.

In-Warranty

Service

If

this

merchandise

was

purchased

from a dealer/reseller, consult

that

dealer/reseller

for instructions.

Qualstar's

warranty

obligation

is

to

the

original

purchaser

(dealer/re-

seller) only.

If

this

merchandise

was

purchased

directly from

Qualstar,

in-warranty

service will be

provided

at

the

Qualstar

factory

in

Canoga

Park,

California, USA.

The

Buyer

is re-

sponsible for all freight charges

incurred

in

returning

the

merchandise

to

the

factory.

Qualstar

will

return

the

merchandise

to

the

Buyer

prepaid

at

Qualstar's

expense

by

surface

transportation.

The expense

of

air

transportation,

if

requested,

is

the

responsi-

bility

of

the

buyer.

In-warranty

service

may

also

be

available on-site

or

at

selected

Qualstar

factory-

authorized

service

centers

for

an

additional charge. Consult a

Qualstar

sales

repre-

sentative

for

further

information.

Out-Of-Warranty

Service

Should service

be

required

after

the

warranty

period

has

expired,

Qualstar

will

repair

and

test

the

tape

drive

or

tape

subsystem

for a flat fee

as

shown

in

the

current

price

list. Service charges, freight

and

customs charges will

be

billed to

the

Buyer.

An

Extended

Service Agreement, available for

units

located

within

the

United

States,

may

be

purchased

which

extends

the

warranty

period for one year.

Units

covered un-

der

the

Extended

Service Agreement

may

be

serviced

as

often

as

required

during

the

contract

period. Prices

are

shown

in

the

Factory Service Price

List

and

include

return

freight

by

surface

transportation.

Qualstar

customer service

representatives

can

pro-

vide details on

the

Extended Service Agreement.

v

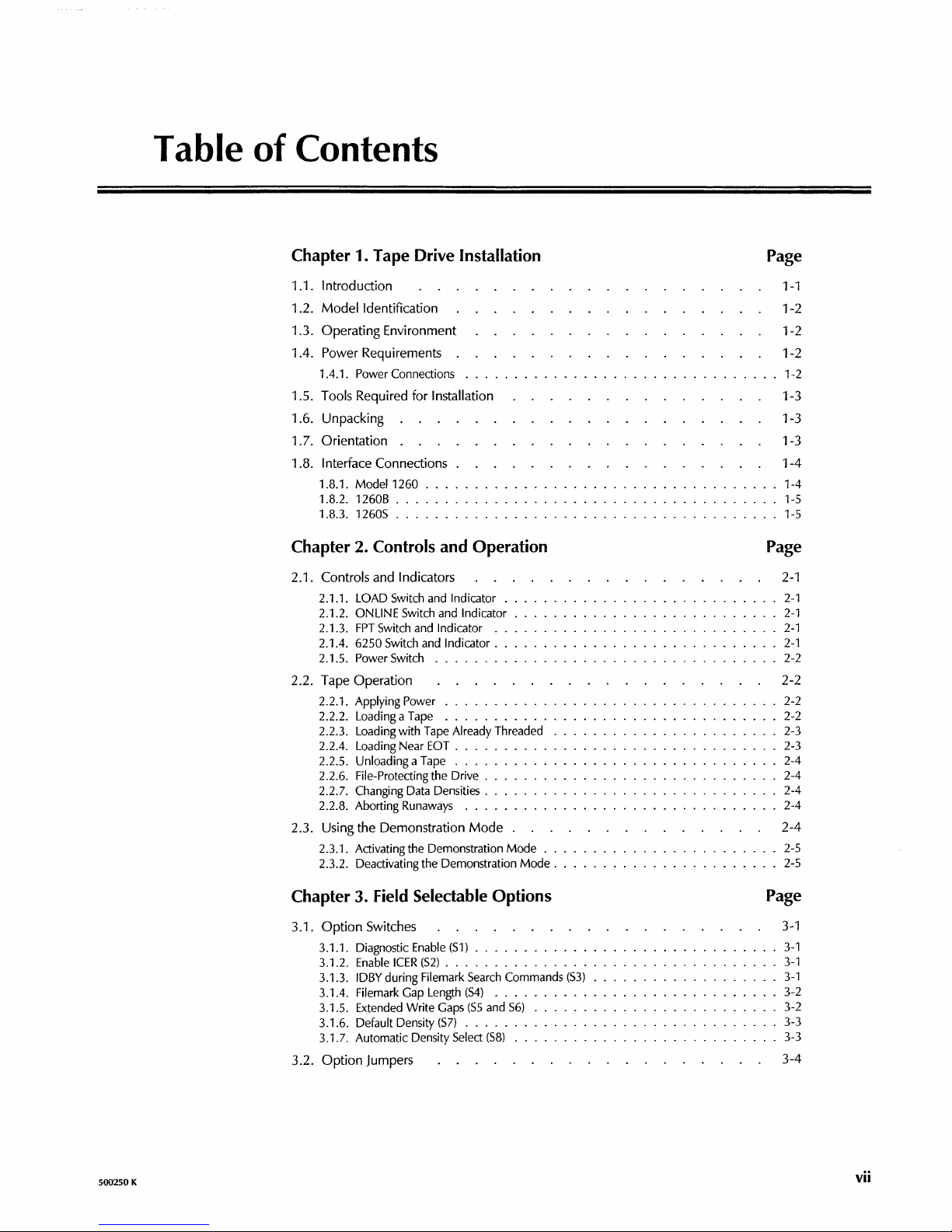

500250

Revision Table

CHAPTER

TITLE

REVISION

LETTER

Title

Page

and

Contents

K

1

Installation

K

!

2 Controls

and

Operation

K

3

I Options

K

I

4 Preventive

Maintenance

K

I

I

!

I I

5

I Specifications K

i

I

6

Error

Codes K

I

r

I

I

7

I SCSI Information

K

!

8

K

AC

Power

vi

500250 K

500250 K

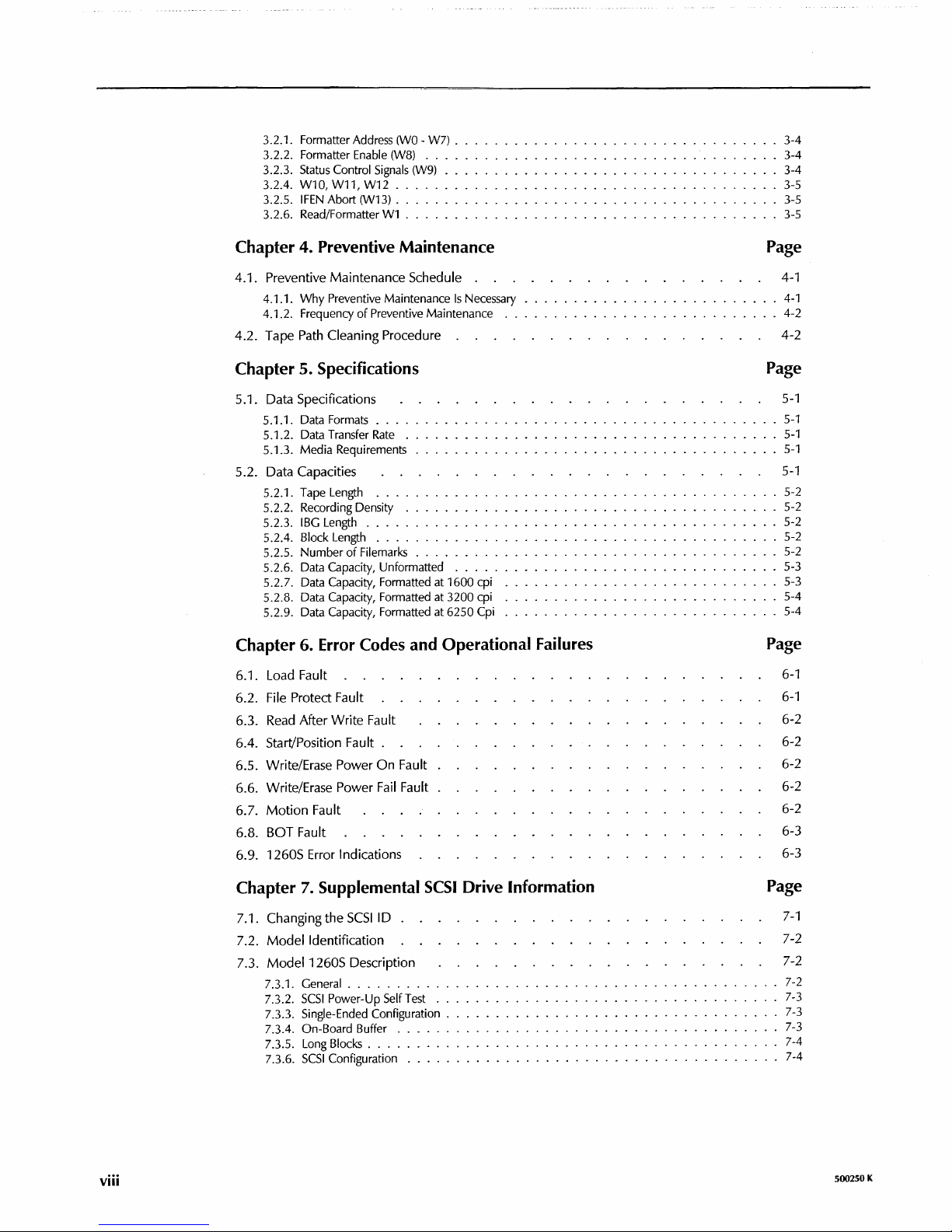

Table

of

Contents

Chapter 1. Tape Drive Installation

1.1. Introduction

1.2. Model Identification

1.3.

Operating Environment

1.4.

Power Requirements .

1.4.1. Power Connections .

1.5. Tools Required for Installation

1.6. Unpacking

1.7.

Orientation

1.8. Interface Connections

1.8.1. Model 1260 .

1.8.2.

1260B .

1.8.3.

12605 . . . .

Chapter 2. Controls and Operation

2.1. Controls

and

Indicators

2.1.1. LOAD Switch and Indicator

2.1.2. ONLINE Switch and Indicator

2.1.3.

FPT

Switch and Indicator .

2.1.4.

6250 Switch and

Indicator.

2.1.5. Power Switch

2.2 . Tape Operation

2.2.1. Applying Power .

2.2.2. Loading a Tape .

2.2.3. Loading with Tape

Already Threaded

2.2.4. Loading Near

EOT

...

.

2.2.5.

Unloading a Tape

...

.

2.2.6.

File-Protecting the Drive .

2.2.7. Changing Data Densities.

2.2.8. Aborting

Runaways

...

2.3. Using the Demonstration Mode .

2.3.1. Activating the Demonstration Mode

2.3.2. Deactivating the Demonstration

Mode.

Chapter 3. Field Selectable Options

3.1. Option Switches

3.1.1. Diagnostic

Enable

(Sl) .

3.1.2.

Enable

ICER

(52)

.....

.

3.1.3.

IDBY during Filemark

Search

Commands

(S3)

3.1.4. Filemark Gap Length

(54)

....

3.1.5. Extended Write Gaps

(S5

and

56)

3.1.6. Default Density

(57)

......

.

3.1

.7. Automatic Density Select

(58)

3.2. Option Jumpers

Page

1-1

1-2

1-2

1-2

. 1-2

1-3

1-3

1-3

1-4

1-4

1-5

1-5

Page

2-1

2-1

2-1

2-1

2-1

2-2

2-2

2-2

2-2

2-3

2-3

2-4

2-4

2-4

2-4

2-4

2-5

. 2-5

Page

3-1

3-1

3-1

3-1

3-2

3-2

3-3

3-3

3-4

vii

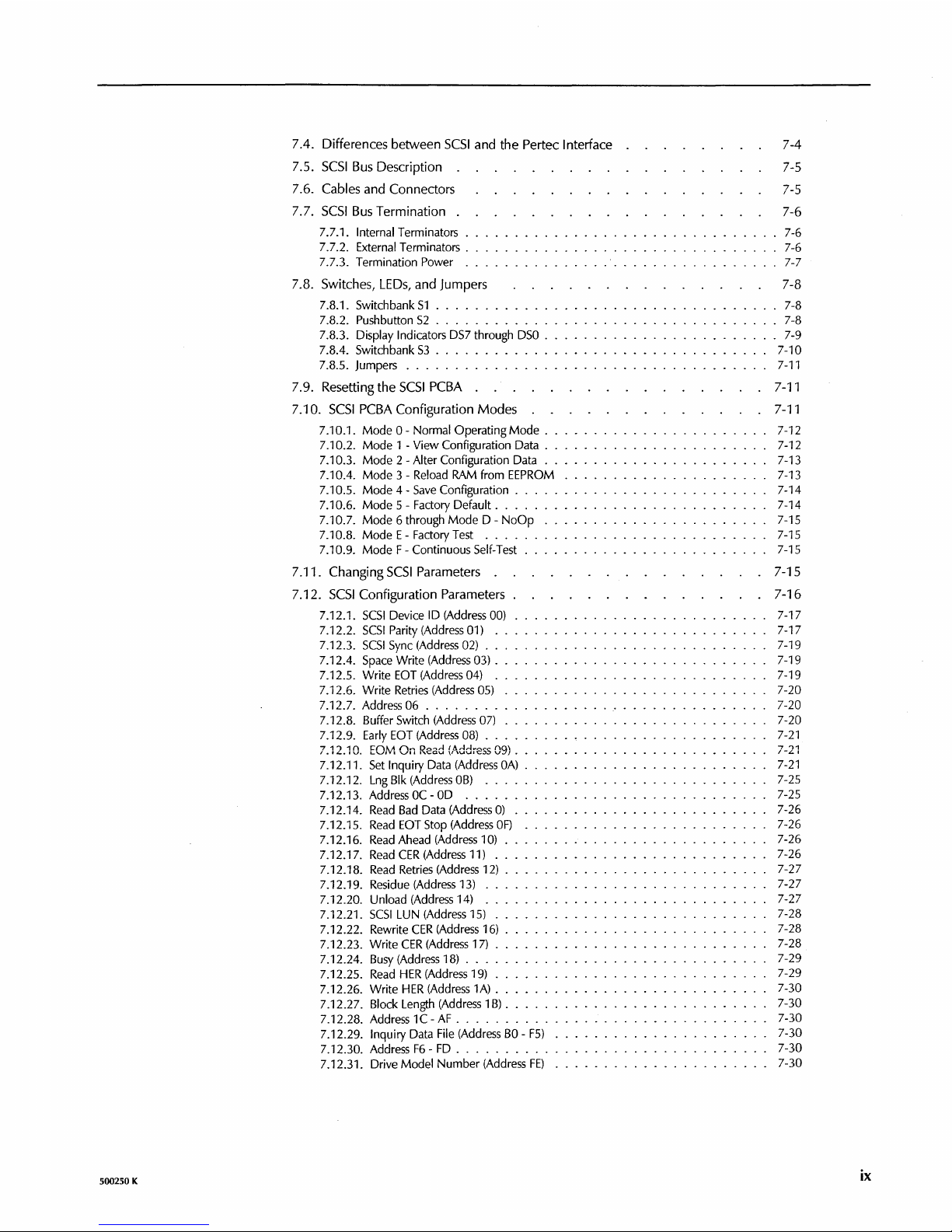

3.2.1. Formatter Address

3.2.2. Formatter

Status

3.2.3.

W10, W11, W12

3.2.4.

IFEN

3.2.5.

3.2.6. Read/Formatter

Enable

Control

Signals

Abort (W13)

Wl

(WO

- W7)

(WS)

......................

............................

. . . . . . . .

.........................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(W9) . . . . . . . . . . . . . . . .

..............

.. . ......

.

.

.

.

.

3-4

3-4

3-4

3-5

3-5

3-5

Chapter 4. Preventive Maintenance

4.1. Preventive Maintenance Schedule .

4.1.1.

Why

4.1.2. Frequency

4.2. Tape

Preventive Maintenance

of

Preventive Maintenance

Path

Cleaning Procedure

Is

Necessary

Chapter 5. Specifications

5.1. Data Specifications

5.1.1. Data Formats

5.1.2. Data Transfer

5.1.3. Media Requirements

....

Rate

...............

.

5.2. Data Capacities

5.2.1. Tape Length

5.2.2. Recording Density

IBG

5.2.3.

5.2.4.

5.2.5. Number

5.2.6. Data Capacity, Unformatted

5.2.7. Data Capacity, Formatted at

5.2.S. Data Capacity, Formatted at 3200 cpi

5.2.9. Data Capacity, Formatted at

Length . . . . . . .

Block Length

........

.........................

of

Filemarks

.....

..

.....................

.........................

1600 cpi

6250 Cpi

. . . . . . .

. . . . . . . . .

.

..............

.................

.........................

Chapter 6. Error Codes and Operational Failures

6.1.

Load

Fault

6.2.

File

Protect Fault

Read

6.3.

6.4.

6.5. Write/Erase

6.6. Write/Erase

6.7. Motion Fault

6.8.

6.9.

After Write Fault

Start/Position Fault .

Power On Fault

Power

Fail

BOT Fault

1260S

Error

Indications

Fault

........

........

Page

4-1

.

4-1

...

4-2

4-2

Page

5-1

.

......

.....

5-1

5-1

5-1

5-1

.

.

.

.

.

......

.

.

.

5-2

5-2

5-2

5-2

5-2

5-3

5-3

5-4

5-4

.

Page

6-1

6-1

6-2

6-2

6-2

6-2

6-2

6-3

6-3

Chapter 7. Supplemental

7.1. Changing the

7.2. Model

Identification

7.3. Model 1260S Description

7.3.1. General

7.3.2.

SCSI

7.3.3.

Single-Ended Configuration

7.3.4. On-Board Buffer .

7.3.5.

Long

7.3.6.

SCSI

viii

SCSI

ID.

...........

Power-Up Self

Blocks

....

Configuration

Test

SCSI

Drive Information

.

.

..

.

..

................................

.

Page

7-1

7-2

7-2

7-2

7-3

7-3

7-3

7-4

7-4

500250 K

500250 K

7.4. Differences between

SCSI

and the Pertec Interface

7.5.

SCSI

Bus

Description .

7.6. Cables and Connectors

7.7.

SCSI

Bus

Termination .

7.7.1. Internal Terminators .

7.7.2. External

Terminators.

7.7.3. Termination Power

..

7.B.

Switches,

LEOs,

and Jumpers

7.8.1. SwitchbankS1

.....

.

7.8.2. Pushbutton

S2

......

.

7.8.3. Display

Indicators DS7 through

DSO

.

7.8.4. Switchbank

S3

...

.

7.8.5. Jumpers

...........

.

7.9. Resetting the

SCSI

PCBA .

7.10.

SCSI

PCBA Configuration Modes

7.10.1.

Mode

0 - Normal

Operating

Mode

. .

7.10.2.

Mode

1 -

View

Configuration Data

..

7.10.3.

Mode

2 - Alter Configuration Data

..

7.10.4.

Mode

3 - Reload RAM from EEPROM

7.10.5.

Mode

4 -

Save

Configuration

..

.

7.10.6.

Mode

5 - Factory Default

....

.

7.10.7.

Mode

6 through

Mode

0 -

NoOp

7.10.8.

ModeE-FactoryTest

....

7.10.9.

Mode

F - Continuous Self-Test

7.11. Changing

SCSI

Parameters .

7.12.

SCSI

Configuration Parameters

7.12.1.

SCSI

Device 10 (Address 00)

7.12.2.

SCSI

Parity (Address 01) .

7.12.3.

SCSI

Sync (Address 02)

..

7.12.4. Space

Write

(Address 03) .

7.12.5.

Write

EOT (Address 04) .

7.12.6.

Write

Retries (Address 05)

7.12.7. Address 06

.......

.

7.12.8. Buffer Switch (Address

07)

7.12.9. Early EOT (Address 08)

..

7.12.10. EOM

On

Read

(Address 09) .

7.12.11.

Set

Inquiry Data (Address

OA)

.

7.12.12. Lng

Blk (Address

OB)

...

.

7.12.13.

AddressOC-OD

.....

.

7.12.14.

Read

Bad Data (Address

0)

.

7.12.15.

Read

EOT Stop (Address

OF)

7.12.16.

Read

Ahead (Address 10) .

7.12.17.

Read

CER

(Address 11)

..

7.12.18.

Read

Retries (Address 12) .

7.12.19. Residue (Address 13) .

7.12.20. Unload (Address 14)

...

7.12.21.

SCSI

LUN (Address 15)

..

7.12.22. Rewrite

CER

(Address 16) .

7.12.23.

Write

CER

(Address 17)

7.12.24. Busy (Address 18) . . . . .

7.12.25.

Read

HER

(Address 19)

..

7.12.26.

Write

HER

(Address 1A)

..

7.12.27. Block Length (Address 1B)

..

7.12.28. Address 1 C -

AF

. . . . . . .

7.12.29.

Inquiry Data File (Address

BO -F5)

7.12.30. Address

F6 -FD

.........

.

7.12.31. Drive

Model

Number

(Address

FE)

7-4

7-5

7-5

7-6

7-6

· 7-6

· 7-7

7-B

7-8

· 7-8

· 7-9

7-10

7-11

7-11

7-11

7-12

7-12

7-13

7-13

7-14

7-14

7-15

7-15

7-15

7-15

7-16

7-17

7-17

7-19

7-19

7-19

7-20

7-20

7-20

7-21

7-21

7-21

7-25

7-25

7-26

7-26

7-26

7-26

7-27

7-27

7-27

7-28

7-28

7-28

7-29

7-29

7-30

7-30

7-30

7-30

7-30

7-30

ix

x

7.12.32. Checksum (Address

FF)

..................

.

7.13. Drive Configuration Requirements

7.13.1. Formatter Address

(WO

- W7)

...........................

.

7.13.2.

IFEN

(W8)

.....................................

.

7.13.3.

Status

Control

Signals

(W9)

............................

.

7.13.4.

IFEN

Abort (W13)

..............................

.

7.13.5. Read/Formatter

PCBA

W1

.............................

.

Chapter 8. AC Power Configuration

8.1. Tools Required to Change

AC

Power Configuration

8.2.

Opening the Drive

8.3. Closing the Drive

8.4. Configuring the Drive for

Available Power

7-31

7-31

7-31

7-31

7-31

7-31

7-31

Page

8-2

8-2

8-2

8-2

500250 K

500250 K

Tape

Drive

Installation

1.1

Introduction

This guide provides

installation

instructions

and

techniques for

operating

the

Qual-

star

1260 series

tape

drives.

In

order

for

the

tape

drive to operate,

it

must

be

con-

nected to a

tape

coupler

card

within

your

computer. Refer to

the

specific coupler

manual

for

the

installation

and

configuration

of

the

tape

coupler before

installing

your

tape

drive.

1

The

software provided

with

the

coupler controls

the

transfer

of

data

to

and

from

the

tape

drive.

The

wide

variety

of options which

Qualstar

offers allows

the

tape

drive to

operate

with a number

of

different coupler packages.

The

best

choice

of

couplers de-

pends

upon

your

particular

application

and

computer

system.

Figure 1-1

The

Qualstar

1260

Series

Tape Drive

Tape

Drive Installation

1-1

1-2

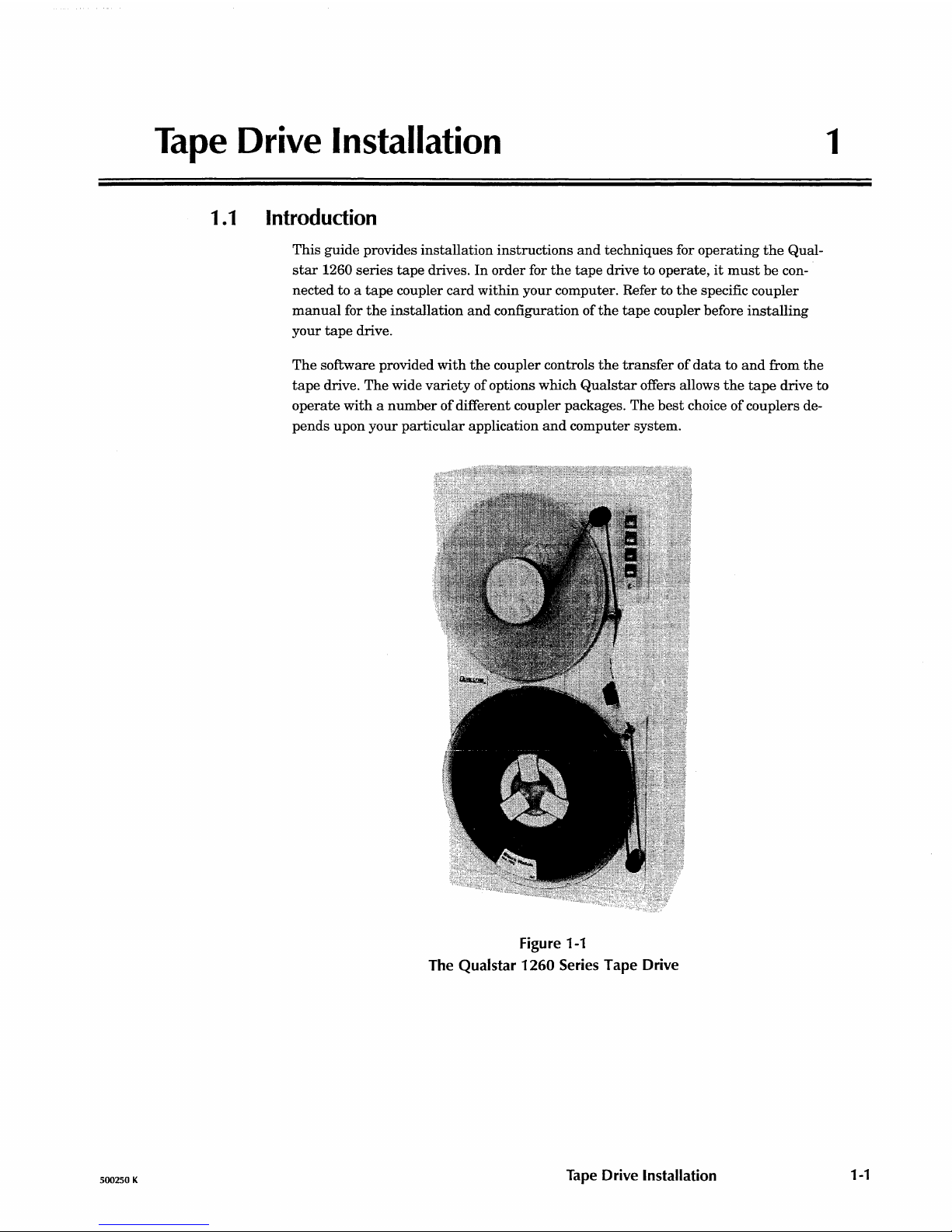

1.2 Modelldentification

Figure

1-2 shows

the

breakdown

of

the

1260 Series model

numbers.

This

guide ap-

plies

to

all models.

The

basic

tape

drive

in

each

of

the

models covered

by

this

guide

is

the

same. Differences

among

models is

noted

when

required.

From

an

operator's

point

of

view, all models function similarly.

1 2 6 0 X

1

.3

Operating

Environment

BASIC SERIES

SPECIAL CONFIGURATION

B = 256K Buffer

E = Extended

Chassis

S = SCSI

Device

Figure 1-2

Model Number Identification

The

tape

drive is designed to

operate

in

an

environment

between

400 F to 1040 F (4.4

0

C to 400 C), 20% to 85% relative humidity,

and

at

altitudes

from 0 to +8000 feet. Mois-

ture

must

not

be

allowed to condense inside

the

drive

or

in

the

tape

path

area.

Note

that

the

humidity

specification

of

the

drive exceeds

that

of

the

media.

1 .4

Power

Requirements

The

tape

drive

requires

100,

120,220,

or

240 volts AC, +10%/-15%,

at

48 to 62

Hertz

primary

power.

Peak

power

requirements

for model 1260

is

195

watts,

and

211

watts

for models 1260B

and

1260S.

DANGER!

IF

THE

LINE

VOLTAGE

DIFFERS

FROM

THAT

SPECIFIED

ON

THE

NAME-

PLATE,

DO NOT

APPLY

POWER.

THE

POWER

TRANSFORMER

TAPS

INSIDE

THE

DRIVE

AND

THE

FUSE

MUST

FIRST

BE

CHANGED

BY

A QUALIFIED

SERVICE

PERSON

TO

MATCH

THE

LINE

VOLTAGE.

REFER

TO

CHAPTER

8.

1.4.1 Power Connections

The

power connection to

the

drive is

by

means

of

a detachable power cord which com-

plies

with

the

following specifications.

• 100/120

volt

applications

-

U.L.listed

and

CSA certified

three

conductor, 18

AWG, SVT vinyl

jacketed

cord. One

end

is

terminated

with

an

lEC

320, C13

style connector (CEE-22

standard

sheet

VI).

The

remaining

end

is

terminated

with

plug type NEMA 5-15P.

Tape

Drive Installation

500250 K

500250 K

• 220/240

volt

applications

-

D.L.listed

and

CSA certified

three

conductor, 18

AWG, SVT vinyl

jacketed

cord. One

end

is

terminated

with

an

IEC

320, C13

style connector (CEE-22

standard

sheet

VI).

The

other

end

is

not

terminated.

The

conductors

are

to

be

connected to a customer-supplied plug

as

follows:

Black

or

brown

wire to

AC

hot

(Live);

white

or

blue

wire to

AC

return

(neutral

or

common);

green

or

green

with

yellow

strips

to

chassis

(ground).

The

following

statement

is

included for compliance

with

German

safety

regulations:

Die

Verbindung

ziir Steckdose sollte moglich

kurz

sein,

und

die Steckdose sollte frei

zuganglich bleiben.

(English

translation:

The

connection to

the

power receptacle should be

as

short

as

pos-

sible,

and

the

receptacle should

be

readily accessible.)

1.5

Tools

Required

for

Installation

A #2 Phillips screwdriver

is

required to

install

the

drive.

1.6

Unpacking

Caution! Model

1260

tape drives weigh between

36

and

44

pounds, depending

upon the configuration.

Use caution in lifting.

The

tape

drive

is

shipped

in a specially

designed

double-walled

carton

with

energy-

absorbing

end

caps. The packaging should be stored for possible

future

transportation

purposes.

The

carton

contains

the

following items:

• Tape Drive

• Power Cord

• User's Guide

• Interface Cable(s) (optional)

Remove

the

drive together

with

its

end-caps from

the

carton

and

place

it

on a table.

Then

remove

the

end-caps

and

the

polyethylene bag.

Remove all

other

materials

from

the

carton

and

store

the

end-caps

and

bag

in

the

car-

ton

for

the

possibility

of

future

shipment.

1 .7 Orientation

The

drive

must

be

placed on a

hard

surface; do

not

place

it

on a

typewriter

pad

or

simi-

lar

surface.

It

may

rest

on

its

bottom,

back

or

side.

There

must

be

no obstructions

which would

prevent

air

from freely flowing

into

the

fan inlet(s)

or

exiting

from

the

ventilation slots.

Tape Drive Installation

1-3

1-4

Fanlnleffi

UW

Power

'\~

Switch

roolU

~II

AC

Plug

and

Fuseholder

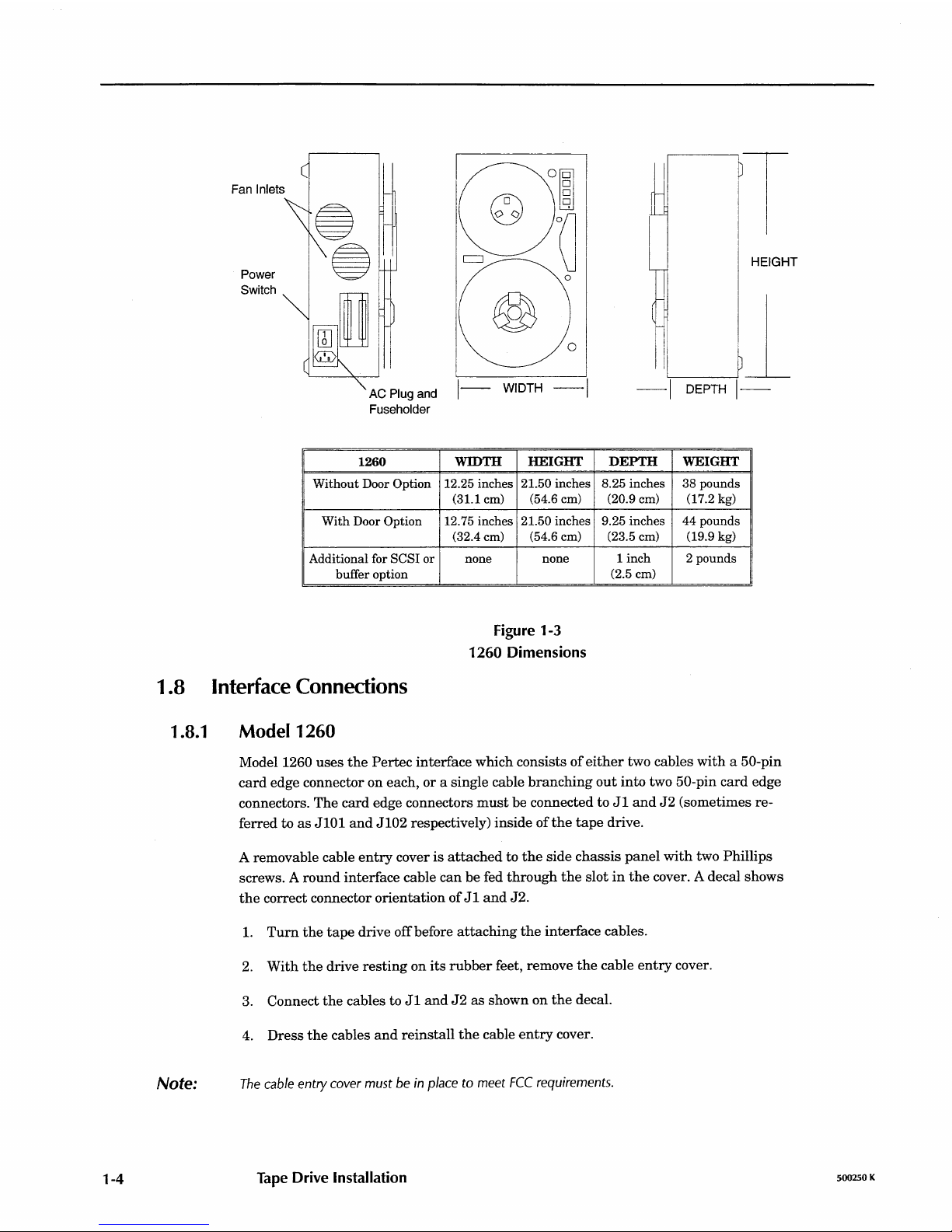

1260

Without Door Option

With

Door Option

Additional for

SCSI

or

buffer option

o

WIDTH

-I

WIDTH

HEIGHT

12.25 inches 21.50 inches

(31.1 cm)

(54.6 cm)

12.75 inches

21.50 inches

(32.4 cm) (54.6 em)

none none

Figure 1-3

1260 Dimensions

~nT

~

I 1

I I I

HEIGHT

II~~

-I

DEPTH

1-

DEPTH

WEIGHT

8.25 inches

38

pounds

(20.9 cm)

(17.2 kg)

9.25 inches

44

pounds

(23.5 cm)

(19.9 kg)

1 inch 2 pounds

(2.5 cm)

1.8 Interface Connections

1.8.1 Model 1260

Note:

Model 1260

uses

the

Pertec

interface

which

consists

of

either

two

cables

with a 50-pin

card

edge

connector on

each,

or a single

cable

branching

out

into

two 50-pin

card

edge

connectors.

The

card

edge connectors

must

be

connected

to

Jl

and

J2

(sometimes

re-

ferred

to

as

JI0l

and

JI02

respectively)

inside

of

the

tape

drive.

A removable cable

entry

cover

is

attached

to

the

side

chassis

panel

with

two

Phillips

screws. A

round

interface

cable

can

be

fed

through

the

slot

in

the

cover. A decal

shows

the

correct

connector

orientation

of

Jl

and

J2.

1.

Turn

the

tape

drive

offbefore

attaching

the

interface

cables.

2.

With

the

drive

resting

on

its

rubber

feet, remove

the

cable

entry

cover.

3.

Connect

the

cables to

Jl

and

J2

as

shown

on

the

decal.

4.

Dress

the

cables

and

reinstall

the

cable

entry

cover.

The

cable

entry

cover

must be

in

place

to

meet

FCC

requirements.

Tape Drive Installation

500250 K

1.8.2

1.8.3

500250 K

12608

This model contains a Buffer PCBA. Refer to

the

Buffered Interface

Supplement

(docu-

ment

500200) for instructions.

1260S

This

model connects to a SCSI bus. Refer to

Chapter

7 for

further

information.

Tape Drive Installation

1-5

500250 K

Controls and Operation

2

2.1

Controls

and

Indicators

2.1.1 LOAD Switch and Indicator

2.1.2

2.1.3

2.1.4

Use

the

LOAD switch to load, rewind

and

unload tapes.

The

LOAD indicator

is

illuminated

when

the

tape

is

at

Beginning

of

Tape

(BOT.)

\Vhen

the

tape

is unloaded (no tension,)

the

LOAD indicator will flash rapidly

when

a

BOT

marker

is

sensed, providing a

means

of

testing

the

BOT

sensing

circuits.

ONLINE Switch and Indicator

Use

the

ONLINE switch to place

the

drive online

and

offline.

The

drive will only re-

spond to

the

host

ifit

is online. You

may

place

the

drive online

whenever

tape

is

loaded

and

tensioned

and

may

take

the

drive offline

at

any

time.

Pressing

the

switch while a command or rewind operation is

in

progress will abort

the

command

and

place

the

drive offline. All

tape

motion, except for rewind, will halt. You

can

also

use

this

switch to

take

the

drive offline to

abort a runaway

operation.

When

the

Online indicator

is

illuminated,

the

drive

is

online

and

ready

for operation.

When

it

is

not

illuminated,

the

drive is offline

and

will

not

accept

any

commands from

the

host.

FPT

Switch and Indicator

If

the

drive detects

the

presence of a write enable ring on

the

bottom side

of

the

supply

reel,

the

drive will initially be write-enabled. You

can

override

this

condition

and

manually

protect

the

tape

by pressing

the

FPT

switch while

the

LOAD indicator is il-

luminated

and

the

tape

is

at

BOT. The

FPT

switch

has

no effect

when

no

write

ring

is

present.

When

the

drive

is

write-enabled,

it

can

write

on

and

erase

tape. When

the

drive is file-

protected,

its

write

and

erase

circuits

are

disabled. The

FPT

indicator will be illumi-

nated

when

the

drive is

in

the

file-protected

state,

and

will

not

be

illuminated

when

the

drive

is

in

the

write-enabled

state.

The

FPT

indicator serves

as

a power indicator

when a tape

is

not

tensioned.

When

the

tape

is

threaded

but

not

tensioned,

the

FPT

indicator will flash rapidly

when

an

End-Of-

Tape

(EOT)

marker

is sensed, providing a

means

of

testing

the

EOT

sensing

circuits.

6250

Switch

and Indicator

When

the

tape

is unloaded, or

when

it

is

tensioned

and

at

BOT

and

the

drive is

off-

line, you can select

an

operating

density of

either

6250

characters

per

inch (cpi) or

Controls and Operation

2-1

2-2

2.1.5

1600 cpi

by

pressing

the

switch.

When

the

drive

is

online

and

the

tape

is

tensioned

and

at

BOT,

the

host

may

also select

either

density.

The

data

density

for

both

writing

and

reading

is

indicated

by

the

6250

indicator.

When

illuminated,

the

drive

reads

and

writes

at

6250 cpi

and

when

extinguished,

at

1600 cpi.

Either

1600

or

6250 cpi

may

be

selected for a

default

density

upon

power-up

according

to

an

option

switch

setting.

This

should

not

be

confused

with

Automatic

Density

Se-

lect,

which

is

determined

after

the

first

read

operation. Refer

to

Chapter

3 for

more

in-

formation.

Power Switch

The

POWER

switch

is

located on

the

side

of

the

drive

near

the

AC

line

receptacle.

2.2

Tape

Operation

2.2.1 Applying Power

Caution!

It

is

possible to create an undesired flux transition on a tape

if

the tape

is

touching the head when power

is

applied. This

is

not normally a prob-

lem, since the tape

is

not generally loaded when power

is

applied.

If

the

tape

is

threaded past the

BOT

tab, make certain that there

is

at least 1/8

inch gap between the tape and the head before applying power.

2.2.2

Press

the

side

of

the

switch

with

the

"I" to

apply

power.

Listen

for

the

fans.

If

they

do

not

operate,

the

drive

is

not

operational.

Turn

the

power

off, verify

the

power

source

and

then

turn

the

drive

back

on

again.

If

this

fails,

the

drive will

require

service.

After

a

normal

power-up sequence,

the

FPT

indicator

should

be

illuminated.

The

6250 indi-

cator

mayor

may

not

be

illuminated.

Loading a Tape

1.

To

load a reel

of

tape,

unlock

the

supply

hub

by

pressing

the

inside

of

its

three

reel

clamps.

2.

Place

the

tape

reel

over

the

hub

with

the

label

facing out.

3. Lock

the

reel

to

the

hub

by

pressing

the

outside

of

all

three

reel

clamps.

4.

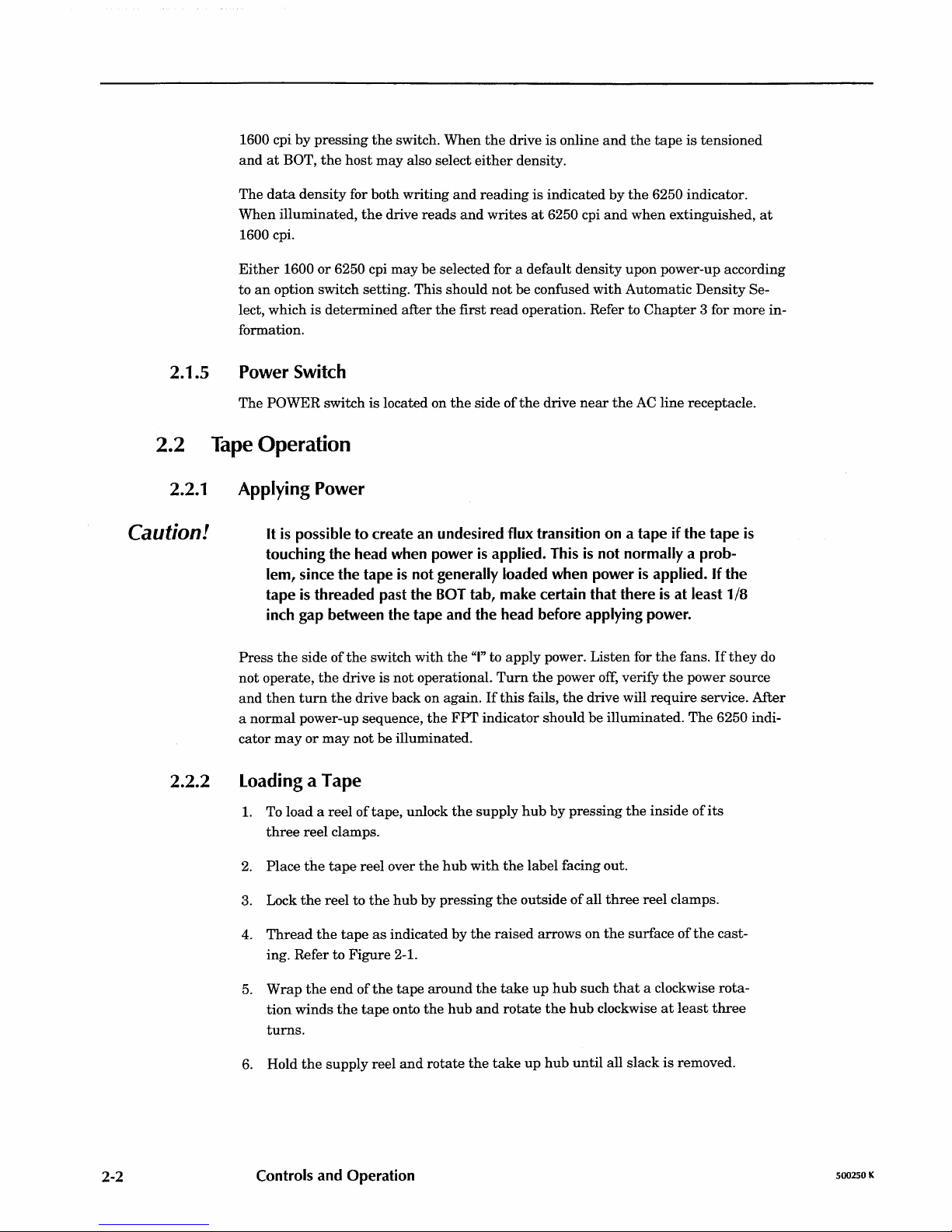

Thread

the

tape

as

indicated

by

the

raised

arrows

on

the

surface

of

the

cast-

ing. Refer

to

Figure

2-1.

5.

Wrap

the

end

of

the

tape

around

the

take

up

hub

such

that

a clockwise

rota-

tion

winds

the

tape

onto

the

hub

and

rotate

the

hub

clockwise

at

least

three

turns.

6. Hold

the

supply

reel

and

rotate

the

take

up

hub

until

all

slack

is

removed.

Controls and Operation

500250 K

2.2.3

2.2.4

500250 K

Supply Hub

Figure

2-1

Threading the Tape

7.

Turn

on

the

power

and

press

the

LOAD switch to

initiate

the

load sequence.

a. After a

short

pause,

the

tape

will move forward.

b. After

the

BOT

marker

passes

the

head,

the

tape

will be moved

in

reverse

until

the

BOT

marker

is

in

front of

the

head.

c.

The

LOAD indicator will

then

illuminate, indicating

the

tape

is

at

load

point, or

BOT.

d.

The

drive automatically

sends

the

ONLINE

and

READY signals to

the

interface, indicating

that

the

drive

is

ready

to operate. The ONLINE indi-

cator

will be illuminated.

Should

the

tape

fail to load properly due to

an

operator

error,

the

drive will normally

terminate

the

load sequence

and

display a load

fault

by flashing

the

LOAD indicator.

Thread

the

tape

properly

and

press

the

LOAD switch to

restart

the

load sequence.

Loading with Tape Already Threaded

If

the

tape

is

threaded

but

not tensioned,

turn

on

the

power, remove

the

slack,

and

press

the

Load switch.

Loading

Near

EDT

To

tension

the

tape

when

most

of

it

is

on

the

take

up

reel:

1.

Make

certain

the

EOT

marker

is

on

the

supply reel.

2.

Remove all slack.

3.

Press

LOAD while holding

the

FPT

switch to compensate for

the

large

amount

of

tape on

the

take

up

reel.

Controls and Operation

2-3

2-4

2.2.5

2.2.6

2.2.7

2.2.8

If

the

tape

comes off

the

supply reel, moisten

the

last

two inches

and

lay

it

over

the

top

of

the

supply reel.

Turn

the

reel counter-clockwise so

that

the

tape

winds onto

the

reel. Continue winding

the

tape

onto

the

reel for five

turns

past

the

EOT

marker.

Hold

the

FPT

switch before pressing

the

LOAD switch

and

then

hold

both

for one sec-

ond to

initiate

the

load sequence.

The

drive will tension

and

rewind

the

tape

to BOT.

Unloading a Tape

1.

If

the

tape

is

stopped

and

not

at

BOT,

take

the

drive offline

and

press

the

LOAD switch to rewind

the

tape.

2.

When

the

tape

is

at

BOT

and

the

drive

is

offline, pressing

the

LOAD switch

initiates

an

unload sequence.

The

drive will wind

the

tape

onto

the

supply

reel

until

the

leader

comes off

the

take

up

hub.

3.

Press

the

inside

of

the

three

supply reel clamps,

and

then

remove

the

reel

from

the

supply hub.

The

drive will also respond to a combination rewind-unload signal from

the

host.

File-Protecting the Drive

You

may

place

the

drive into

and

out

of

the

file-protected

state

when

the

tape

is

at

BOT by toggling

the

FPT

switch until

the

FPT

indicator illuminates.

Changing Data Densities

To

read

prerecorded tapes, you

must

first configure

the

drive to operate

at

the

density

of

the

tape

to be read. 1600 cpi

is

the

most commonly

used

density. You

can

also en-

able

the

Automatic Density Select option described

in

Section 3.1.7.

When

writing on a

tape

from BOT, you

must

choose

the

operating density.

When

ap-

pending

data

to a prerecorded tape, you

must

first configure

the

drive to

operate

at

the

density

at

which

the

tape

was

originally written.

Aborting Runaways

Occasionally

it

may

be

necessary to

abort a tape

operation. This is preferably done

by

the

application program.

If

the

application program is unable to abort a

read

or

write,

you

may

place

the

drive offline

manually

by

pressing

and

holding

the

ONLINE switch

until

the

tape

stops completely. This should also

terminate

the

application program.

Caution! Taking the drive offline while writing can result in an incomplete block be-

ing recorded on the tape, with subsequent

loss

of

data.

2.3

Using

the Demonstration Mode

When

the

drive is

in

the

demonstration mode,

it

will

shuttle

the

tape

at

both

low

and

high speeds, gradually moving

the

tape

towards

EaT.

When

the

tape

reaches EOT,

the

drive will rewind

the

tape

reenter

the

shuttle

mode. This provides

an

effective

Controls and Operation

500250 K

2.3.1

2.3.2

500250 K

means

of

demonstrating

the

drive's

tape

handling

ability. Any size

reel

may

be

used,

and

the

demonstration mode will continue

until

deactivated.

Activating the Demonstration Mode

1.

Thread a tape

and

remove all slack.

2.

Apply power to

the

drive.

3. Perform

the

following sequence;

a.

Press

and

hold

the

ONLINE switch.

b.

Press

and

hold

the

LOAD switch.

c.

Release

the

ONLINE switch.

d. Release

the

LOAD switch. The drive will

enter

the

demonstration

mode.

Deactivating the Demonstration Mode

To

deactivate

the

demonstration mode, press

the

ONLINE switch.

The

drive will re-

wind

the

tape

and

place

itself

online.

Controls and Operation

2-5

500250 K

Field

Selectable

Options

3

DANGER!

Several

operating

configurations

may

be

selected

by

the

dealer

or

qualified personnel.

Options

are

changed

with

push-on

jumpers

or

DIP

switches

on

the

Write/Controller

PCBA which is located on

the

hinged chassis

of

the

drive.

ACCESSING

THE

JUMPERS

AND

DIP

SWITCHES

REQUIRES

THAT

THE

DRIVE

BE

OPENED

BY A QUALIFIED

SERVICE

PERSON.

REFER

TO

CHAPTER

8.

3.1

Option

Switches

3.1.1

3.1.2

3.1.3

An

eight

position

DIP

switchbank

(SW

A)

is

located

on

the

upper

part

of

the

Write/Controller PCBA

with

switches

numbered

Sl

through

S8.

Diagnostic Enable

(Sl)

When

Sl

is

on,

the

drive

is

in

the

offline diagnostic mode;

when

Sl

is

off,

the

drive

is

in

the

normal

mode

of

operation. Information

about

the

offline diagnostic mode

is

given

in

the

1260 Technical Service

Manual

(document

number

500244.)

The

drive is

shipped

with

Sl

off.

Enable ICER (S2)

S2

is

used to control correctable

error

reporting. A correctable

error

(CER)

is a data

er-

ror

which

the

tape

drive

can

detect

and

correct "on-the-fly"

and

is

therefore

transpar-

ent

to

the

host. The drive

can

correct a single-track

error

in

the

PE

and

GCR modes,

and

a two-track

error

in

the

GCR mode.

When

an

error

is corrected,

the

data

sent

to

the

host

is good.

The

drive

is

shipped

with

S2

off.

S2

is

also

used

during

the

diagnostic mode

as

explained

in

the

1260 Technical Service

Manual.

·

82

ON - The

tape

drive

reports

all detected correctable

errors

and

sends

cor-

rected

data

to

the

host.

82

off

- The

tape

drive does

not

report

any

correctable

errors

during

read

op-

erations,

but

will still

send

corrected

data

to

the

host.

During

write

operations,

the

drive will

report

only two-track correctable errors.

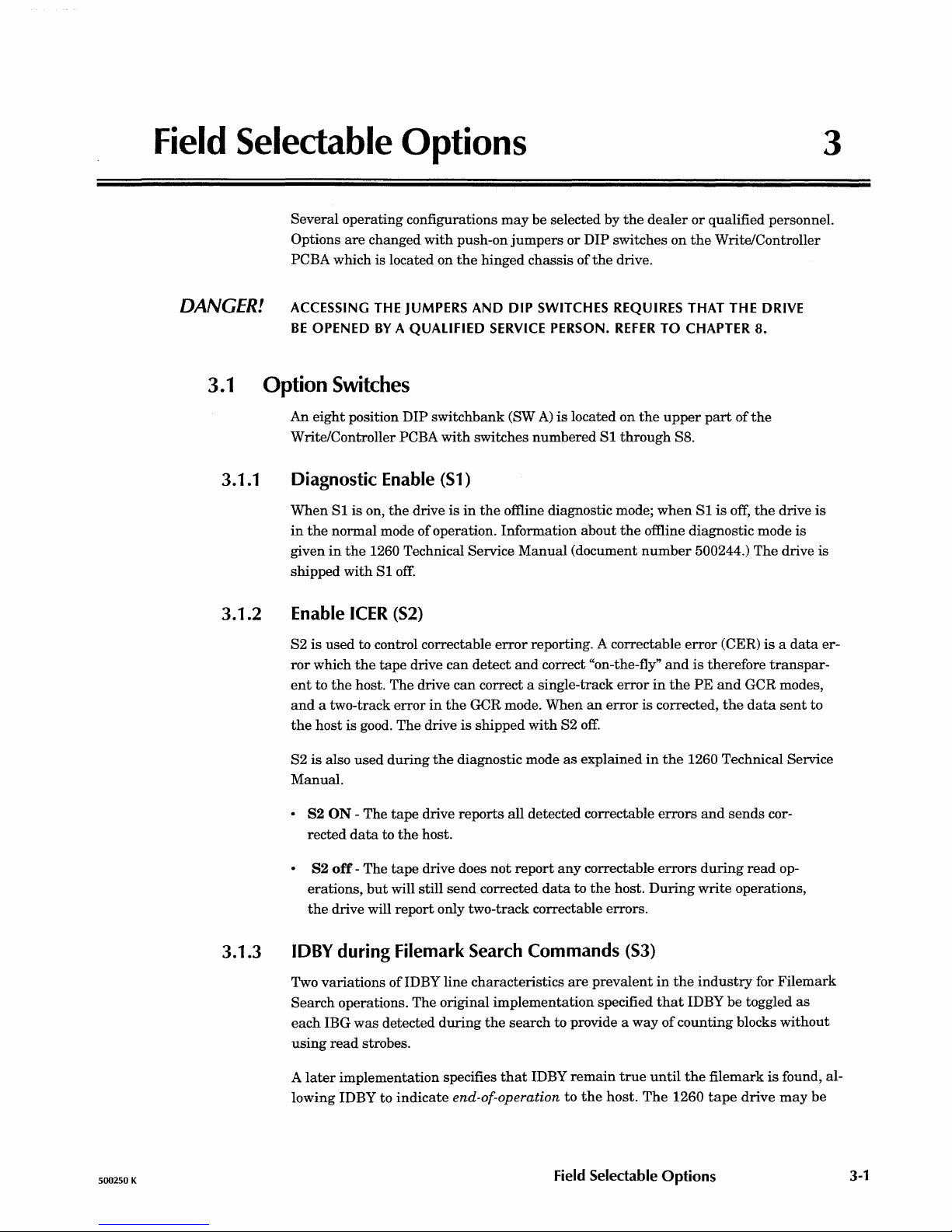

IDBY during Filemark Search Commands (S3)

Two

variations

of

IDBY line characteristics

are

prevalent

in

the

industry

for

Filemark

Search

operations. The original

implementation

specified

that

IDBY

be

toggled

as

each

IBG

was

detected

during

the

search

to provide a

way

of

counting

blocks

without

using

read

strobes.

A

later

implementation

specifies

that

IDBY

remain

true

until

the

filemark

is

found, al-

lowing IDBY

to

indicate

end-or-operation

to

the

host.

The

1260

tape

drive

may

be

Field

Selectable

Options

3-1

3.1.4

3.1.5

3-2

configured

by

S3

to

provide

either

implementation

(see Table 3-1.)

The

drive

is

shipped

with

S3 off.

I

S3

I

On

Off

(Factory default)

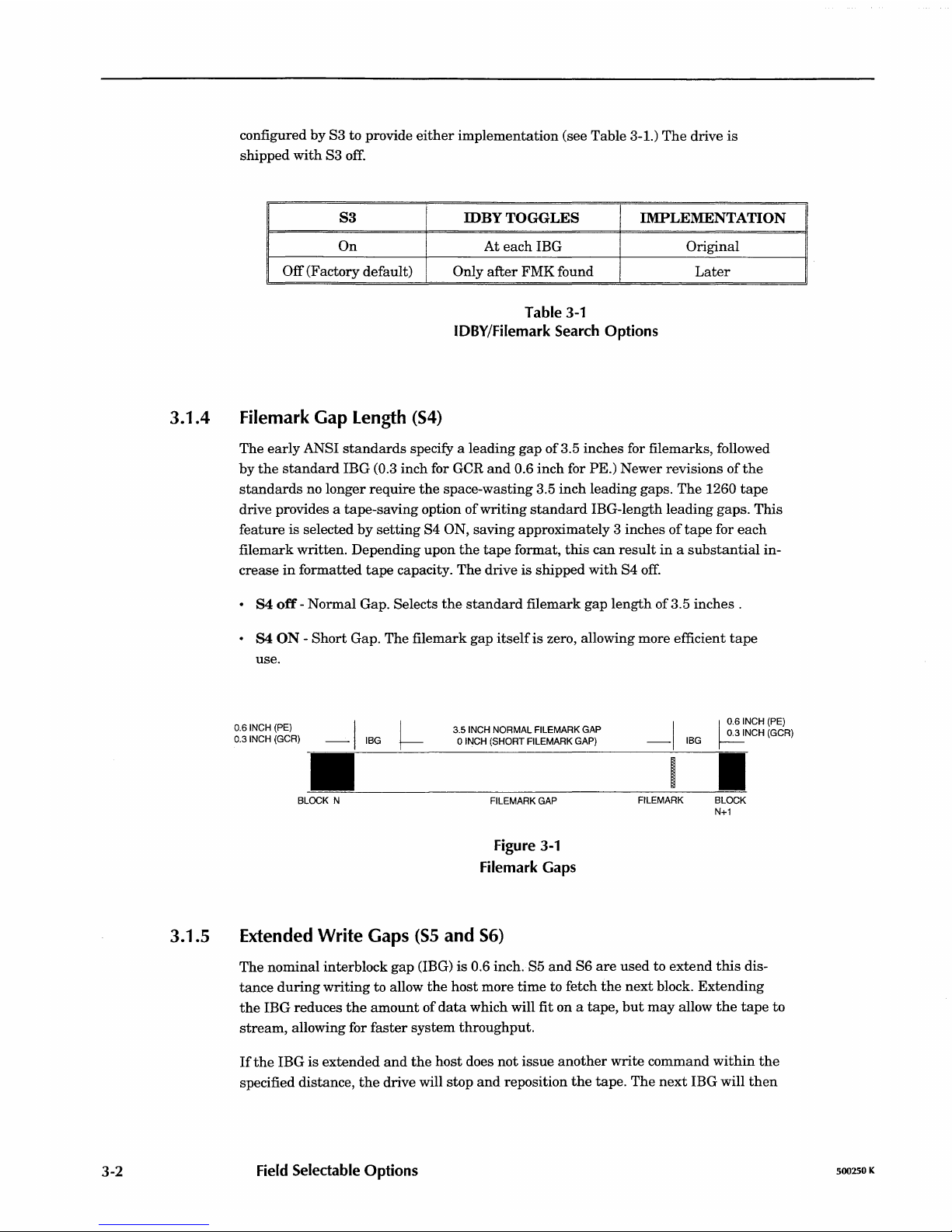

Filemark Gap Length (S4)

IDBY TOGGLES IMPLEMENTATION

At

each

IBG

Only

after

FMK

found

Table

3-1

IDBY/Filemark

Search

Options

Original

Later

The

early

ANSI

standards

specify a leading

gap

of

3.5 inches for filemarks, followed

by

the

standard

IBG

CO.3

inch for GCR

and

0.6 inch for PE.)

Newer

revisions

of

the

standards

no longer

require

the

space-wasting 3.5

inch

leading gaps.

The

1260

tape

drive provides a

tape-saving

option

of

writing

standard

IBG-Iength

leading

gaps.

This

feature

is

selected

by

setting

S4 ON,

saving

approximately 3 inches

of

tape

for

each

file

mark

written.

Depending upon

the

tape

format,

this

can

result

in a substantial

in-

crease

in

formatted

tape

capacity.

The

drive is shipped

with

S4

off.

·

S4

off

-

Normal

Gap. Selects

the

standard

filemark

gap

length

of

3.5

inches.

• S4 ON -

Short

Gap. The filemark

gap

itself

is zero, allowing more efficient

tape

use.

0.6

INCH

(PE)

0.3

INCH

(GCR)

3.5

INCH

NORMAL FILEMARK

GAP

03

INCH

(GCR)

I

~

I

~

.6INCH

(PE)

-

IBG

0

INCH

(SHORT FILEMARK

GAP)

-

IBG

.

~--~------------------------------~-----

BLOCK

N

FILEMARK

GAP

Figure

3-1

Filemark

Gaps

Extended

Write

Gaps

(S5

and

S6)

I

FILEMARK

BLOCK

N+1

The

nominal interblock

gap

(IBG) is 0.6 inch. S5

and

S6

are

used

to

extend

this

dis-

tance

during

writing

to allow

the

host

more

time

to fetch

the

next

block.

Extending

the

IBG reduces

the

amount

of

data

which will fit on a tape,

but

may

allow

the

tape

to

stream,

allowing for

faster

system

throughput.

If

the

IBG is

extended

and

the

host

does

not

issue

another

write

command

within

the

specified distance,

the

drive will

stop

and

reposition

the

tape.

The

next

IBG will

then

Field

Selectable

Options

500250 K

Loading...

Loading...