Page 1

SIDE WALL STAGING BRACKET

MODEL #2300, #2301

CONSTRUCTION

PRODUCTS

Side Wall

Staging Bracket

Model # 2300

This sturdy, steel con struct ed

brack et bolts through walls with

ad just ment for wall thickness.

Supports a 36” plat form con struct ed of 2” thick planks. Holds

two work ers plus 75lbs. per 8

foot stag ing, no more than 8 foot

span be tween brack ets. Must use

guardrails when in stalled over 6

feet above ground. Folds for compact storage and trans por ta tion.

Staging Bracket Guard Rail

Model # 2301

You must use guardrails when

in stalling staging over 6 feet above

ground.

Product Speci cations

Model # 2300 2301

Description: Staging Bracket Staging Bracket/Guardrail

Unit Pack: 1 1

Weight per Pack: 10.5 Pounds 7 Pounds

Cu. Ft. per Pack: .31 cu. ft. .31 cu. ft.

Customer Supprt and Ordering In for ma tion

781-344-1000 • www.qualcraft.com

Page 2

CONSTRUCTION

PRODUCTS

SIDE WALL STAGING BRACKET

MODEL #2300, #2301

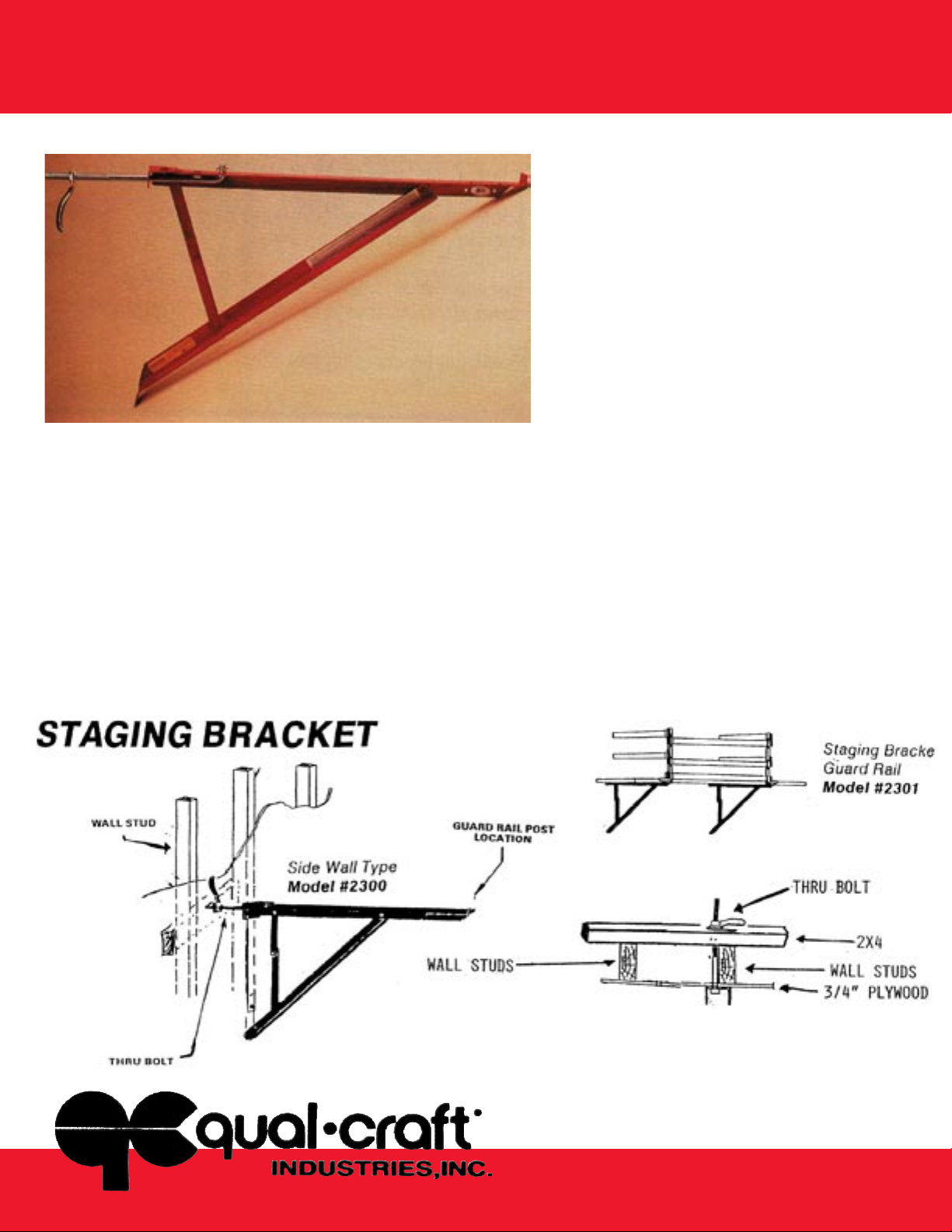

INSTRUCTIONS FOR INSTALLATION

AND USE OF STAGING BRACKET

MODEL #2300

CAPACITY: Capacity of the Model #2300

Staging Bracket is two men per staging plus

75 lbs.

GENERAL REQUIREMENTS: The brackets

may be spaced no more than 8 ft. apart. The

platform shall consist of not less than 2 inch

x 10-inch planks extending not more than

10 inches or less than 6 inches beyond each

staging bracket. The platform of each staging

bracket must be fully planked. Do not nail stag-

ing brackets onto the wall for support. Guardrails

and toe boards must be used on all staging 6 ft. or more above the ground.

Always use a Qual-Craft Model #2301 Guardrail Holder with the installation

of each staging bracket.

INSTALLATION INSTRUCTIONS: WARNING: Do not install staging bracket

scaffolding directly onto walls constructed of sheathing materials other than

inch thick exterior grade plywood. To install rst bracket choose a location

between two interior studs that is no more than 2 inches from one of the studs

and drill a 5/8 inch clearance hole. Prepare a 2”x 4” plank (clear - no knots or

cracks) long enough to span the interior studs and drill a 5/8” clearance hole

in the center of the 4” face in a location corresponding to the exterior hole

previously drilled. Place the staging bracket against the work wall so that the

bolt protrudes through both the surface hole and the corresponding hole of

Customer Supprt and Ordering Information

781-344-1000 • www.qualcraft.com

Page 3

SIDE WALL STAGING BRACKET

MODEL #2300, #2301

Staging Bracket Guardrail

Holder Model # 2301

Th e Qual-C raft Model # 2301 Stag ing

Bracket Guardrail Holder should be installed

prior to mounting the model #2300 Staging

Bracket to the work wall. Lay the base of

the guardrail holder up under the end of the

staging bracket platform so that the guardrail

holder is at right angle to the platform arm.

Line up the holes in the base of the guardrail

with the corresponding holes in the staging

bracket. Secure in place with four 3/8”-16

x ” hex bolts and four 3/8”-16 reversible

lock nuts. Repeat installation procedure with

each of the staging brackets that will form the

completed scaffold. Install all staging brackets

(with guardrail holder attached) to the work wall

in accordance with the instructions af xed to

the Model #2300 Staging Bracket. Fully deck

the scaffold and secure in place. Install 2” x

4” wooden guardrails, mid-rails and 1” x 3”

wooden toe boards. Guardrails, mid-rails and

toe boards must run the complete perimeter

of the deck and must be secured to the work

wall. To insure a ridged guardrail system it is

important to use all nail holes provided at each

receptacle.

CONSTRUCTION

PRODUCTS

the 2x4 that spans the interior studs. With the cross brace securely spanning the two interior studs attach the handle to the bolt and tighten until

bracket is rmly in place. Be sure that the staging bracket is in a vertical

position to ensure proper bracing. Nail brace at base into the work wall.

Install guardrail holder to end of platform. Choose location for next staging

bracket that is no more than 8 feet from previously installed bracket and

repeat installation procedures for bracket. Fully plank the work platform

and install all guardrails. When installing staging on sheathing that is less

than inch in thickness provide a 5/8 inch plywood sheet large enough

to span two studs and high enough to encompass both the bolt at the top

of the bracket and the brace at the bottom of the bracket and secure to

the exterior sheathing prior to the installation of the bracket.

CARE & MAINTENANCE: Inspect staging brackets, guardrails and walk

planks before and after each use to be sure there is no damage or deformation of any of the scaffold components. Also inspect to be sure there

is no deterioration as a result of rusting. Discard if necessary. Always

handle staging brackets and guardrails with care to ensure safe and lasting use of the equipment. Do not throw or drop from a building or onto a

truck. Always handle with care. If staging or guardrail equipment has been

exposed to extreme heat or cold, discard equipment. Use this product

in strict compliance with all State, Local and Federal OSHA Regulations.

Federal Regulations require that your employer provide training in the use

and care of this product.

To prevent an unstable scaffold that could lead to serious personal injury:

•Do not install directly onto walls constructed of sheathing materials other than ” thick

exterior grade plywood.

•When used on sheathing material other than ” thick exterior grade plywood read and

follow instructions.

Care & Maintenance

Inspect staging brackets, guardrails and walk

platforms before and after each use to be sure

there is no damage or deformation to any of

the scaffold components. Also inspect to be

sure there is no deterioration as a result of

rusting. Discard if necessary. Always handle

staging brackets and guardrails with care to

insure safe and lasting use of this equipment.

Do not throw or drop from a building or onto a

truck. If staging bracket or guardrail equipment

has been exposed to extreme heat or cold

discard equipment. Use this product in strict

compliance with all State, Local and Federal

OSHA Regulations. Federal regulations require

that your employer provide training in the use

and care of this product.

Customer Supprt and Ordering In for ma tion

Failure to read and follow instructions on the use of this product could result in serious

personal injury. This product must be used in strict compliance with Local, State & Federal

OSHA Regulations. Be safety conscious.

© Copyright 2001 QUAL-CRAFT INDUSTRIES, INC. Stoughton, MA 02072

781-344-1000 • www.qualcraft.com

Loading...

Loading...