Page 1

WORK BENCH • GUARDRAIL COMBINATION

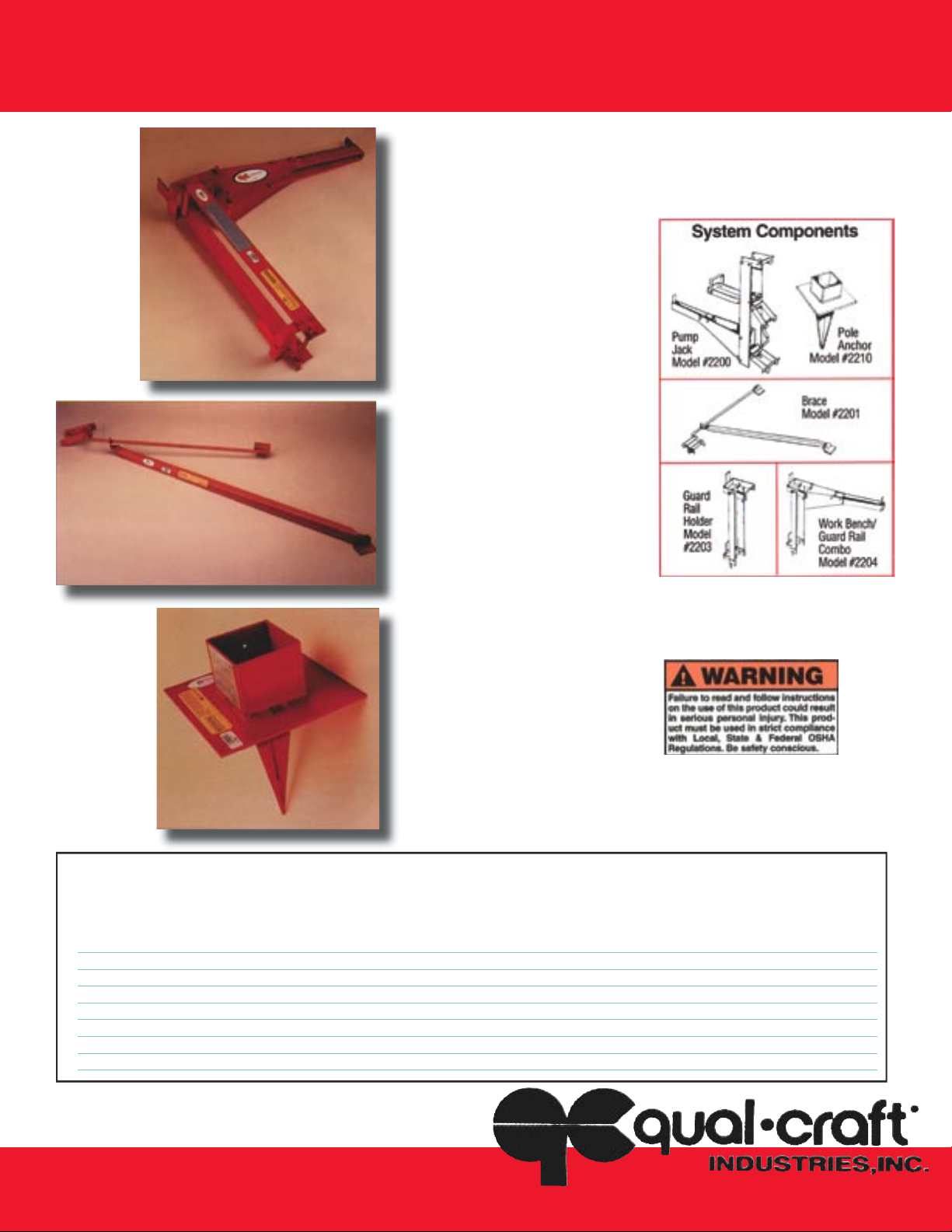

PUMP JACK BRACE

PUMP JACK ANCHOR

Workbench and Guardrail

Holder Combo

Model #2204

Substantially cut work time with a

workbench attached to the pump

jack scaffold. Guardrail holder included.

Components below can be purchased separately.

Workbench Nose Section

Model #2202

Guardrail Holder

Model #2203

Pump Jack Brace

Model #2201

PUMP JACK

SYSTEMS

Provides rigid steel triangular bracing as required by OSHA. Used as

bracing for wood pump jack poles.

(Poles to be constructed in accordance with operating instructions).

Pump Jack Pole Anchor

Model #2210

Pole anchor provides additional

margin of safety and security when

used in accordance with instructions. Provides a mud sill in loose

soil conditions.

Product Speci cations

Pump Jack & System Components

Model # 2200 2201 2213 2202 2203 2204

Description: Pump Jack Brace H.D. Swivel Brace Work Bench Nose Guard Rail Guard Rail / Work Bench Comb.

Unit Pack: 1 1 1 / Carton 1 1 1

Weight per Pack: 19.4 lbs. 5.2 lbs. 7 lbs. 5 lbs. 5 lbs. 10 lbs.

Cu. Ft. per Pack: 2.55 .61 1.05 .63 .55 1.33

Customer Support and Ordering In for ma tion

781-344-1000 • www.qualcraft.com

Page 2

ROOFING

Model 2210 Pole Anchor

center when using 2 inch undressed lumber or 11 feet on center when using aluminum walk planks. Always sup-

so that the pole’s seam faces the carriage bolt. Then tighten at the desired height. Nail clamp to pole. 3) Position

the poles along the work wall and secure in place.

PRODUCTS

Model 2201 Triangular Pump Jack

Brace

WORK BENCH • GUARDRAIL COMBINATION

PUMP JACK BRACE

PUMP JACK ANCHOR

Always use triangular steel pump jack braces. The round

brace is then fastened to the right or left as desired. Space between the brace arms is 32 inches, enabling

installation on studs 16 inches apart. The seam of the pole must face the work wall. 4) All poles must bear

on a rm foundation or mudsill. Install a pole anchor, then insert pole and secure in place. Or, using a 2”x10”

square piece of lumber remove enough dirt to insert board creating a rm level foundation. Secure pole in place

by blocking all four sides with 2x4’s and nailing in place. 5) Install triangular steel bracing at the bottom of the

pole to prevent movement. 6) Additional pump jack braces must be installed vertically along each pole no

more than 10 feet apart.

Mo de l # 2204 Workbench/

Guardrail Combo

1) Remove the round pin connecting the Nose Section of the Combo.

2) Remove the round pin from the

bottom of the guardrail. 3) From

the platform side of the pump jack,

place the guardrail over the pump

jack pole such that the Guardrail

retainers are on the platform side of

the poles and are pointed towards

the sky. 4) Re-install the bottom

pin connecting the guardrail to the

pump jack using the holes provided

in the connector plate at the top of

the pump jack and the holes at the

bottom of the guardrail. Ensure that

the Guardrail rests on the outside

of the connector plates. Secure in

place by inserting a cotter pin into

the hole at the end of the pin and

bending it over. 5) Place the second

pin through the holes provided at the

top of the guardrail installing the

nose section, so that the guardrail/

workbench combo will ride up and

down with the pump jack and secure

with a cotter pin. Ensure that the

nose section rests on the inside of

the guardrail. 6) Place a single length

2x4 across the scaffold connecting

two pump jacks at both the middle

and the top of the guardrail in the

space provided and secure with #6d

common nails. Install a toe board

as required onto the scaffold plank.

CAUTION: Always install guardrails

when using pump jack scaffolding.

The workbench should be fully

decked when in use and should be

used only as a work surface for

tools and materials. Never stand on

workbench. Spacing between poles

should not exceed 7 feet on center

when using 2 inch thick nominal walk

planks, 9 feet on center when using

2 inch undresses lumber, or 11 feet

on center when using aluminum walk

planks. Poles must not exceed 30

ft. in height and must be secured

using rigid triangular steel bracing

at the top, bottom and at 10-foot

intervals. Mending plates must be

must be installed at all splices. Care

& Maintenance: Inspect all pump

jack equipment including the pump

jack pole before and after each use

to be sure that there is no damage,

deformation or deterioration due to

rusting or extensive use to any of the

equipment’s components. Read and

follow the instructions and warnings

on the Qual-Craft Pump Jack before

installation and use of this product.

General Requirements: Qual-Craft’s

Pump Jack Scaffolding products

are intended for use by qualified

professional contractors. Prior to

installation, the user should review

all instructions for the installation,

use and care of these products. All

scaffolding and accessories must

be used in strict compliance with

Local, State and Federa l OSHA

regulations.

Installation: The pump jack pole

an ch or ha s be en de si gn ed to

provide an additional method of

securing the bottom of the Pump

Jack pole and should be used in

conjunction with the pump jack pole

brace. After determining the location, care should be taken to insure

that the ground is rm and free of

small rocks or other objects. The

presence of rocks or other objects

could prevent the anchor from being

fully seated into the ground. Soft

or muddy surface areas may cause

the pole to be unstable and would

constitute an unsafe condition. With

a small block of wood placed into the

shoe, the anchor should be driven

into the ground using a hammer.

Care should be taken to insure that

the 8”x 8” plate is resting completely

on the ground and that the spike has

been fully seated into the ground.

The nail holes provided in the shoe

should be used to secure the wood

pole to the anchor after the anchor

has been placed into the ground.

Care & Maintenance: Inspect the

Pump Jack Pole Anchor and all

other pump jac k equipment in cluding the pump jack pole before

and after each use to be sure that

there is no damage, deformation or

deterioration due to rusting or extensive use to any of the equipment’s

components. Always handle pump

jack sc affolding equipment with

care to insure safe and lasting use.

Do not throw or drop this product.

Do not use this equipment if it has

been exposed to extreme heat or

cold. Discard at once. Do not use

if wet or frozen. Read and follow

the instructions and warnings on

the Qual-Craft Pump Jack before

installation and use of this product.

Customer Support and Ordering In for ma tion

781-344-1000 • www.qualcraft.com

Loading...

Loading...