Page 1

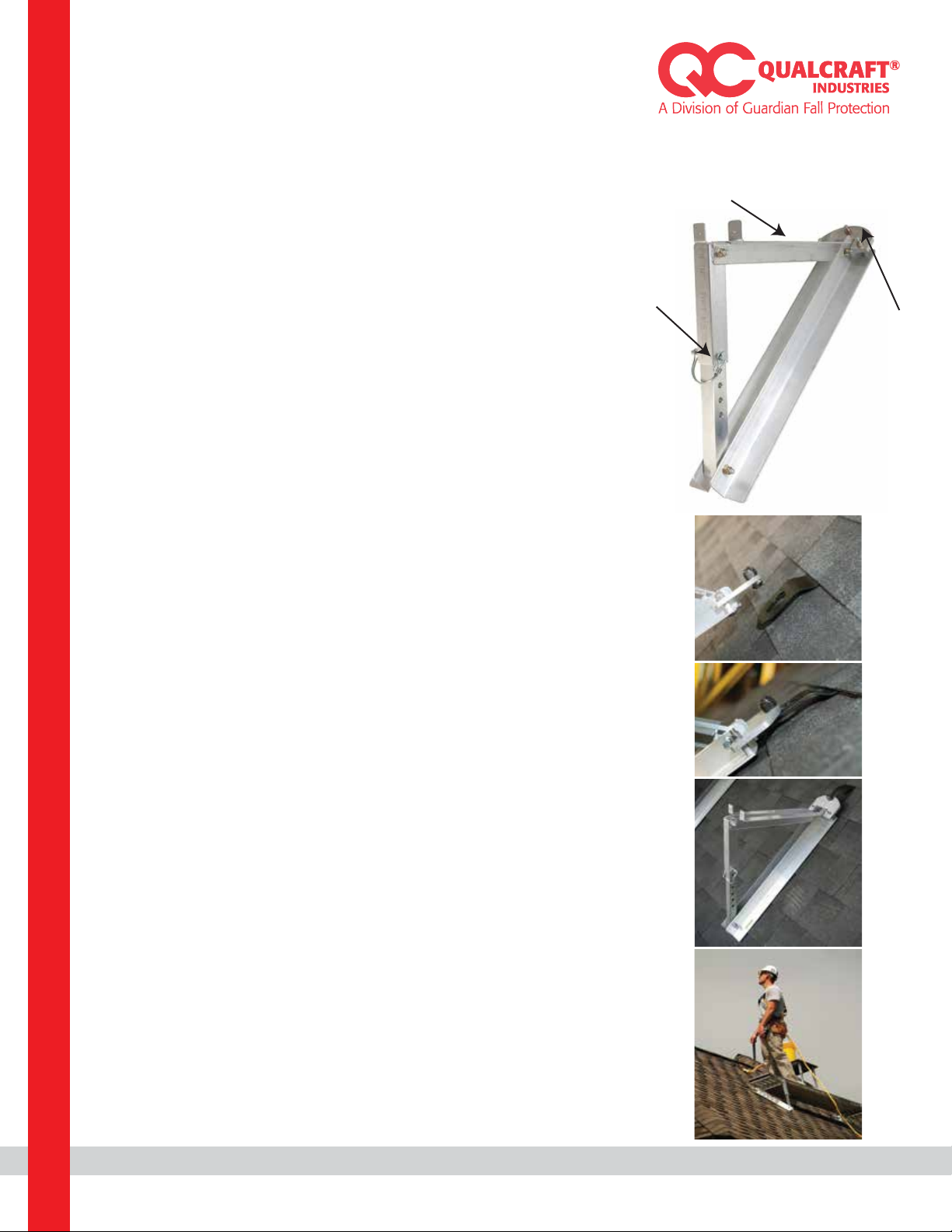

Roof Jack

Part #: 10572

Instructions

Compliant with all applicable OSHA 1910 and 1926 regulations.

Custom configurations not available. Not repairable.

Contact customer service for details.

(2) Roof Jacks required to set up a complete platform stage.

(1) HitchClip™ required per (1) Roof Jack.

Roof Jacks are specially designed to be utilized during

construction as a staging area for workers, tools, materials,

and debris, and can be adjusted to fit a 6/12-12/12 pitch.

ALWAYS use a complete and compatible PFAS, as determined

by a Competent Person, when working at heights 6’ or above.

NEVER make connections to Roof Jack.

Maximum weight per pair of Roof Jacks: 2,600 lbs.

(including all workers, tools, and equipment).

Staging Installation

Location

Locking Pin

Headpin

Installation and Use:

1. Install all necessary HitchClips™ according to manufacturer’s

instructions. For use with Roof Jacks, recommended spacing

between HitchClips™ is 8’.

2. Insert Roof Jack Headpin into HitchClip™ key hole attachment

point from top to bottom, and ensure Roof Jack fully locks into

place. HitchClip™ and Roof Jack must be perpendicular to leading

edge of fall hazard.

3. Adjust Roof Jack so that platform staging will lie flat when

installed. Secure and lock Roof Jack with provided Locking Pin.

4. Place platform staging across Roof Jacks. Platform must be

construction grade lumber or better. Platform width must not

exceed 14”. Platform length must span across pair of Roof

Jacks + 2’, so that platform will overhang 1’ on each end. During

work, only work between Roof Jacks.

Materials: aluminum.

Qualcraft Industries 60 Maple St., P.O. Box 36, Mansfield, MA 02048 phone: (800) 231-5647 www.qualcraft.com

UPC-A Code: 672421105727

Loading...

Loading...