Page 1

HitchClip™

Part #: 10560, 10561, 10562,10563, 10564, 10566, 10567, 10568

Prior to use, read and understand all manufacturer’s instructions provided with equipment at time

of shipment.

DO NOT THROW AWAY THESE INSTRUCTIONS!

Compliant with all OSHA 1910, OSHA 1926 Subpart M, ANSI Z359.1-2007, and ANSI A10.32-2012 regulations.

HitchClip™ is compatible with the following applications:

WARNING

!

WARNING

!

Maintenance, Cleaning, and Storage

Use of equipment in unintended applications may result in serious

injury or death. Maximum 1 attachment per connection point.

Personal Fall Arrest: HitchClips™ may be used to support a MAXIMUM 1 Personal Fall Arrest System (PFAS) for use in Fall Arrest applications.

Structure must withstand loads applied in the directions permitted by the system of at least 5,000 lbs. Maximum free fall is 6‘, or up to 12’ if

used in combination with equipment explicitly certified for such use. Applicable D-ring: Dorsal.

Restraint: HitchClips™ may be used in Restraint applications. Restraint systems prevent workers from reaching the leading edge of a fall

hazard. Always account for fully deployed length of lanyard/SRL. Structure must withstand loads applied in the directions permitted by the

system of at least 1,000 lbs. No free fall is permitted. Restraint systems may only be used on surfaces with slopes up to 4/12

(vertical/horizontal). Applicable D-rings: Dorsal, Chest, Side, Shoulder.

Work Positioning: HitchClips™ may be used in Work Positioning applications. Work Positioning systems allow a worker to be supported while

in suspension and work freely with both hands. Structure must withstand loads applied in the directions permitted by the system of at least

3,000 lbs. Maximum allowable free fall is 2’. Applicable D-rings: Side, Shoulder.

Rescue/Confined Space: HitchClips™ may be used in Rescue/Confined Space applications. Rescue systems function to safely recover a worker

from a confined location or after exposed to a fall. There are various configurations of Rescue systems depending on the type of rescue.

Structure must withstand loads applied in the directions permitted by the system of at least 3,000 lbs. No free fall is permitted. Applicable

D-rings: Dorsal, Chest, Shoulder.

IMMEDIATELY remove from service if exposed to forces of fall arrest.

Capacity range (including all equipment): 130 - 310 lbs., or up to 420 lbs.

if used in combination with equipment explicity certified for such use.

For use by trained personnel only.

Qualcraft Industries 60 Maple St., P.O. Box 36, Mansfield, MA 02048 phone: (800) 231-5647 www.qualcraft.com

Repairs to HitchClips™ can only be made by a Guardian Fall Protection representative or an entity authorized by Guardian. Contact Guardian for all

maintenance and repair needs at: 1-800-466-6385. If a HitchClip™ fails inspection in any way, immediately remove it from service, and contact Guardian to

inquire about its return or repair.

Proper care is important for maintaining the safety and longevity of HitchClips™. Remove all dirt, corrosives, and contaminants from HitchClip™ before and

after each use. If HitchClip™ cannot be cleaned with plain water, use mild soap and water, then rinse and wipe dry. NEVER clean HitchClip™ with corrosive

substances. When not in use, store equipment where it will not be affected by heat, light, excessive moisture, chemicals, or other degrading elements.

Inspection

User must inspect prior to EACH use. Competent Person other than user must complete

formal inspection at least every 6 months. Competent Person to inspect and initial.

Date of First Use: __________________. Product lifetime is indefinite as long as it

passes pre-use and Competent Person inspections.

This inspection log must be specific to one HitchClip™. Separate inspection logs must be

used for each HitchClip™. All inspection records must be made visible and available to all

users at all times.

If equipment fails inspection IMMEDIATELY REMOVE FROM SERVICE.

Page 2

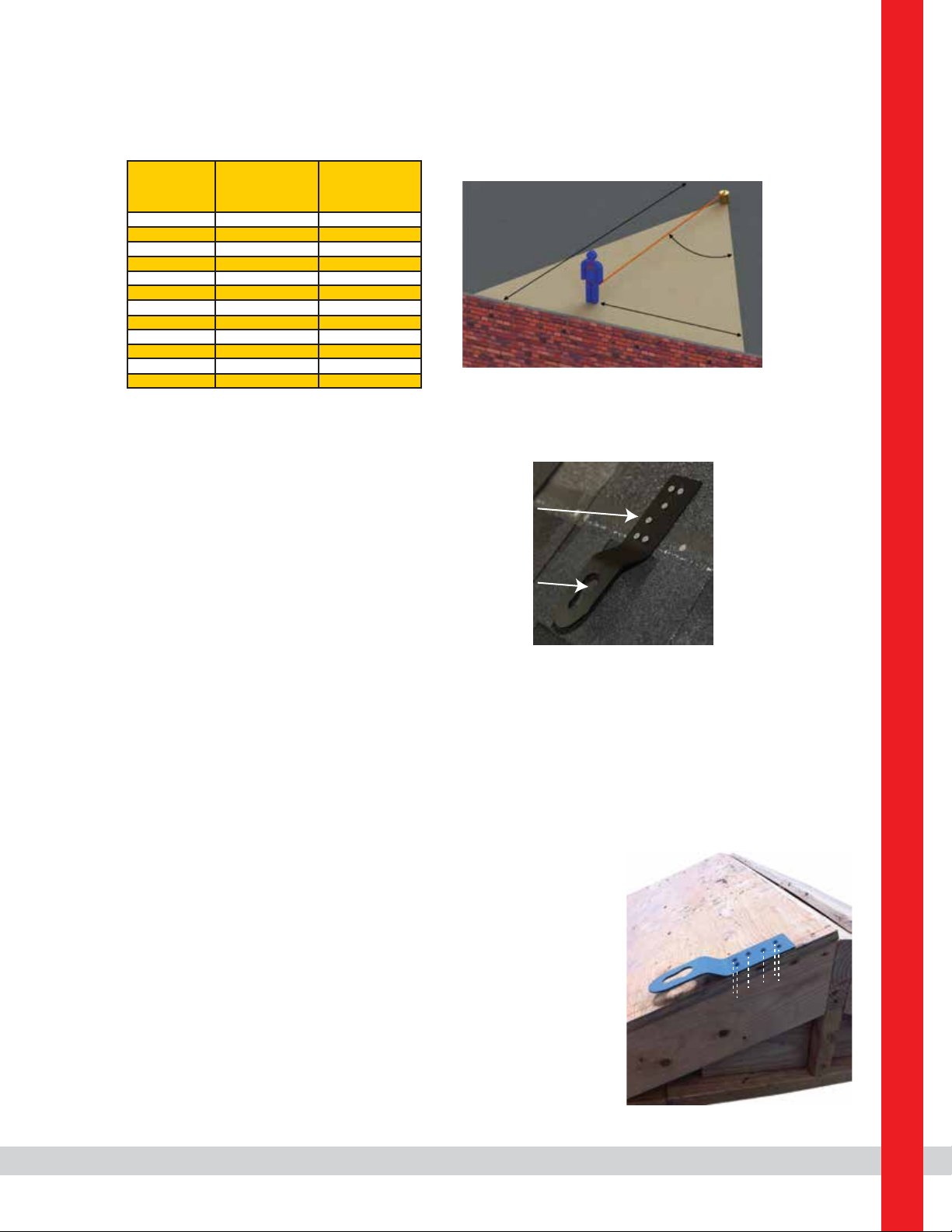

The below charts detail allowable working zones required to reduce risk of swing falls and improper side loading.

ALWAYS adhere to information specified by charts.

Anchor Distance

From

Leading Edge (Y)

6’

10’

15’

20’

25’

30’

35’

40’

45’

50’

55’

60’

Working Distance

Along Roof Edge

(Either Direction) (X)

For example, if the anchorage connector is 6’ from the leading edge (Y), the working distance (X)

is 8’ in each direction from the perpendicular, which translates to a 53° working angle.

Components and Specifications

Materials: aluminum.

Minimum breaking strength: 5,000 lbs.

8’

9’ - 9”

11’ - 7”

13’ - 3”

14’ - 6”

16’

17’ - 2”

18’ - 3”

19’ - 4”

19’ - 10”

21’ - 4”

22’ - 3”

Working Angle

From

Perpendicular (Ø)

53°

45°

38°

33°

30°

28°

26°

24°

23°

21°

21°

21°

Key:

X: Working Distance

Along Roof Edge

Y: Distance From

Leading Edge

Ø: Total Working

Angle

Fastener installation

location (6)

Connection point

Y

Ø

X

Installation and Use

Prior to installation:

Ensure minimum substrate thickness requirement is met, ensure all obstructions/debris are removed from substrate, and eliminate/minimize all swing fall

hazards. HitchClip™ may be used in multiple installation applications. ALWAYS use new fasteners for each new installation application. All connections must

be selected and deemed compatible with HitchClips™ by a Competent Person. Read and understand all instructions provided with accessories to be used in

combination with HitchClip™.

Minimum substrate thickness requirements:

• Wood: 1/2” CDX plywood sheathing and 3“ support beam.

• Metal: HitchClip™ may be installed onto metal substrates, providing there is a sufficient framing member beneath, as determined by a Competent Person.

• Compatible pitch range: flat - vertical/sheer.

Recommended fasteners (Not included. Use either screws OR nails):

• (6) 2½” #10 Grip-Rite exterior screws, or equivalent, as determined by Competent Person.

• (6) 16d galvanized framing nails.

Installation:

1. Installation location must be selected and deemed compatible with HitchClip™ by a Competent Person.

2. Place HitchClip™ at selected installation location and install all fasteners. HitchClip™ must lie flush

against substrate. Fasteners must be installed through roof sheathing and into truss or compatible

support beam. Minimum fastener embedment in support beam is 2”.

3. All (6) nails OR all (6) screws must be used, and must by fully embedded through sheathing and

into truss or compatible support beam.

4. Connect complete and compatible PFAS to HitchClip™ connection point OR install compatible HitchClip™

accessory according to instructions provided with accessory. When used with compatible accessory,

NEVER make any other connections to HitchClip™.

85144 (Rev. E)

Qualcraft Industries 60 Maple St., P.O. Box 36, Mansfield, MA 02048 phone: (800) 231-5647 www.qualcraft.com

Page 3

HitchClip™

# de pieza: 10560, 10561, 10562,10563, 10564, 10566, 10567, 10568

Antes de usar, lea y comprenda todas las instrucciones del fabricante que se proporcionan con el equipo

en el momento del envío.

¡NO DESECHE ESTAS INSTRUCCIONES!

Obediente con todas las normas OSHA 1910, OSHA 1926 Subparte M, ANSI Z359.1-2007, y ANSI A10.32-2012 pertinentes.

HitchClip™ es compatible con las siguientes aplicaciones:

ADVERTENCIA

!

Para evitar caídas personales: los HitchClip™ pueden usarse para sostener como MÁXIMO 1 sistema personal para evitar caídas (PFAS, por sus

siglas en inglés) para el uso en aplicaciones para evitar caídas. La estructura debe soportar cargas aplicadas en las direcciones permitidas por

el sistema de por lo menos 5,000 lb. La caída libre máxima es de 6 pies o hasta 12 pies si se usa en combinación con equipos certificados

explícitamente para dicho uso. Anillo D aplicable: Dorsal.

Control de caídas: los HitchClip™ pueden usarse en aplicaciones para evitar caídas. Los sistemas para evitar caídas evitan que los trabajadores

lleguen al borde de un peligro de caída. Siempre tenga en cuenta el largo totalmente extendido de la cuerda/SRL (cuerda de seguridad

retráctil). La estructura debe soportar cargas aplicadas en las direcciones permitidas por el sistema de por lo menos 1,000 lb. No se permite

caída libre. Los sistemas de control de caídas solo pueden usarse en superficies con inclinaciones de hasta 4/12 (vertical/horizontal). Anillos

D aplicables: Dorsal, pecho, lateral, hombro.

Posicionamiento para el trabajo: los HitchClip™ pueden usarse en aplicaciones de posicionamiento para el trabajo. Los sistemas de

posicionamiento para el trabajo permiten que un trabajador tenga soporte mientras está en suspensión y que funcione libremente con

ambas manos. La estructura debe soportar cargas aplicadas en las direcciones permitidas por el sistema de por lo menos 3,000 lb. La caída

libre máxima permisible es de 2 pies. Anillos D aplicables: Lateral, hombro.

Rescate/espacios confinados: Los HitchClip™ pueden usarse en aplicaciones de rescate/espacios confinados. Los sistemas de rescate

funcionan para recuperar de forma segura a un trabajador de una ubicación confinada o después de estar expuesto a una caída. Existen

varias configuraciones de sistemas de rescate, dependiendo del tipo de rescate. La estructura debe soportar cargas aplicadas en las

direcciones permitidas por el sistema de por lo menos 3,000 lb. No se permite caída libre. Anillos D aplicables: Dorsal, pecho, hombro.

ADVERTENCIA

!

El uso del equipo en aplicaciones no previstas puede provocar lesiones

graves o la muerte. Como máximo, 1 accesorio por punto de conexión.

Rango de capacidad (incluido todo el equipo): 130-310 lbs., o hasta 420 lbs.

si se usa en combinación con equipo explícitamente certificado para dicho uso.

Si es expuesto a fuerzas de detención de caídas deje de usarlo de INMEDIATO.

Para uso por personal capacitado únicamente.

Qualcraft Industries 60 Maple St., P.O. Box 36, Mansfield, MA 02048 phone: (800) 231-5647 www.qualcraft.com

Mantenimiento, limpieza y almacenamiento

Las reparaciones a los HitchClips™ solo pueden ser realizadas por un representante de Guardian Fall Protection o una entidad autorizada por Guardian.

Póngase en contacto con Guardian para todas las necesidades de mantenimiento y reparación al: 1-800-466-6385. Si un HitchClip™ no pasa la inspección por

algún motivo, retírelo de servicio inmediatamente y contacte a Guardian para consultar sobre su devolución o reparación.

El cuidado adecuado es importante para mantener la seguridad y longevidad de los HitchClips™. Elimine toda la suciedad, corrosivos y contaminantes del

HitchClip™ antes y después de cada uso. Si el HitchClip™ no se puede limpiar con agua sola, use agua y jabón suave, luego enjuague y seque con un trapo.

NUNCA limpie el HitchClip™ con sustancias corrosivas. Cuando no esté en uso, guarde el equipo en donde no será afectado por el calor, la luz, la humedad

excesiva, productos químicos u otros elementos corrosivos.

Inspección

El usuario debe inspeccionarlo antes de CADA uso. Una persona competente, además

del usuario debe realizar una inspección formal por lo menos cada 6 meses. Persona

competente para inspeccionar y colocar sus iniciales.

Fecha del primer uso: __________________. La vida útil del producto es indefinida

siempre que pase las inspecciones previas al uso y por una persona competente.

Este registro de inspección debe ser específico para un HitchClip™. Se deben usar

registros de inspección independientes para cada HitchClip™. Todos los registros de

inspección deben estar visibles y disponibles para todos los usuarios en todo momento.

Si el equipo no aprueba la inspección RETÍRELO INMEDIATAMENTE DEL SERVICIO.

Page 4

En este cuadro se detallan las zonas de trabajo permitidas necesarias para reducir el riesgo de caídas pendulares y carga lateral inadecuada.

SIEMPRE siga la información que se especifica en el cuadro.

Distancia de

anclaje desde

el borde

progresivo (Y)

6’

10’

15’

20’

25’

30’

35’

40’

45’

50’

55’

60’

Distancia de trabajo a

lo largo del borde del

techo (en cualquier

dirección) (X)

8’

9’ - 9”

11’ - 7”

13’ - 3”

14’ - 6”

16’

17’ - 2”

18’ - 3”

19’ - 4”

19’ - 10”

21’ - 4”

22’ - 3”

Por ejemplo, si el conector de anclaje está a 6’ del borde progresivo (Y), la distancia de trabajo (X)

es de 8’ en cada dirección desde la perpendicular, lo que implica un ángulo de trabajo de 53°.

Componentes y especificaciones

Materiales: aluminio.

Fuerza de tensión mínima tolerable: 5,000 lb.

Ángulo de trabajo

desde la

perpendicular (Ø)

53°

45°

38°

33°

30°

28°

26°

24°

23°

21°

21°

21°

Ubicación de la instalación

del sujetador (6)

Referencia:

X: distancia de trabajo a lo

largo del borde del techo

Y: distancia desde

el borde progresivo

Ø: ángulo total de

trabajo

Punto de conexión

Y

Ø

X

Instalación y uso

Antes de la instalación:

Asegure que se cumpla el requisito de espesor mínimo de sustrato, asegúrese de haber retirado todas las obstrucciones/residuos del sustrato y

elimine/minimice todos los riesgos de caída por balanceo. Se puede usar HitchClip™ en diversas aplicaciones de instalación. SIEMPRE use sujetadores nuevos

para cada instalación. Todas las conexiones deben seleccionarse y ser consideradas como compatibles con el dispositivo de anclaje HitchClip™ por una

persona competente. Lea y comprenda todas las instrucciones proporcionadas con los accesorios para ser utilizados con HitchClip™.

Requisitos mínimos de espesor de sustrato:

• Madera: 1/2 pulg. de contrachapado CDX revestimiento y 3” barras de soporte.

• Metal: El HitchClip™ se puede instalar en sustratos de metal, siempre que existan suficientes barras de soporte por debajo, según lo determinado por una

persona competente.

• Compatible rango de la inclinación: plano - vertical/perpendicularmente.

Sujetadores recomendados (No incluido. Use tornillos o clavos):

• (6) tornillos exteriores Grip-Rite de 2½ pulg. #10, o equivalente, según lo determine una persona competente.

• (6) clavos galvanizados de encuadre 16d.

Instalación:

1. La instalación debe seleccionarse y ser considerada como compatible con el dispositivo de anclaje

HitchClip™ por una persona competente.

2. Coloque el HitchClip™ en el lugar de instalación seleccionado e instale todos los sujetadores. El

dispositivo de anclaje HitchClip™ DEBE quedar al ras contra el sustrato.. El dispositivo de anclaje HitchClip™

debe quedar al ras contra el sustrato. Los sujetadores deben instalarse a través de las tejas del techo y

el entramado o viga de soporte compatible. Empotramiento sujetador en mínimo en viga de apoyo es de 2”.

3. Deben utilizarse todos (6) los clavos o todos (6) los tornillos y deben estar bien colocados a través

de las tejas y en el entramado o viga de soporte compatible.

4. Conecte los PFAS completos y compatibles al punto de conexión de HitchClip™ o instale el accesorio

de HitchClip™ compatible según las instrucciones proporcionadas con el accesorio. Cuando se utilicen con

accesorios compatibles, NUNCA haga ninguna otra conexión a un HitchClip™.

85144 (Rev. E)

Qualcraft Industries 60 Maple St., P.O. Box 36, Mansfield, MA 02048 phone: (800) 231-5647 www.qualcraft.com

Loading...

Loading...