Page 1

p

PART NUMBERS:

______ 10910/10912/10915 20ft., 25ft., and 30ft. Galvanized Cable SRL

______ 10906 20ft. Web Retractable

______ 10930/10932/10935 20ft., 25ft., and 30ft Stainless Steel SRL

______ 10911/10913/10916 20ft., 25ft., and 30ft With Boot

______ 10921/10922/10925 20ft., 25ft., and 30ft Heavey Duty

______ 10940/10941/10942 20ft., 25ft., and 30ft None Indicating

GGuuaarrddiiaann FFaallll PPrrootteeccttiioonn KKeenntt,, WWAA

880000--446666--66338855 wwwwww..gguuaarrddiiaannffaallll..ccoomm

GGEENNEERRAALL SSYYSSTTEEMM SSEELLEECCTTIIOONN CCRRIITTEERRIIAA::

fall protection shall be made by a Competent Person. All fall protection

equipment shall be purchased new and unused.

The equipment is designed for use as a part of a personal fall protection system.

Components shall not be used for any other operation other than that which it has

been designed and approved.

Fall Arrest Systems shall be designed to comply with OSHA or applicable state

regulatory limitations. Systems must be used in a compliant manner.

Fall Restraint systems shall be designed by a Qualified Person, and must be

installed and used under the supervision of a competent person.

Consult a doctor if there is any reason to doubt a user’s ability to withstand and

safely absorb fall arrest forces. Age, fitness, and health conditions can seriously

affect the worker should a fall occur. Pregnant women and minors should

use this equipment.

Selection of

not

RReettrraaccttaabbllee LLiiffeelliinneess

DO NOT THROW AWAY THESE INSTRUCTIONS!

READ AND UNDERSTAND BEFORE USING EQUIPMENT!

This manual

training program as required by OSHA or any applicable state regulatory agency.

This and any other included instructions must be provided to the users of the

equipment. The user must understand the proper equipment use and limitations.

This

should be read and understood in its entirety, and used as part of a

User must keep a copy of these instructions for reference and training.

roduct meets all applicable OSHA and ANSI standards for fall protection.

DDOO NNOOTT::

• Do not alter or misuse this equipment.

• Do not use combinations of components or subsystems

that may affect or interfere with the safe, compatible

function of each other.

• Do not expose the equipment to chemicals which may

produce a harmful effect or degrade the equipment.

Consult manufacturer in cases where doubt exists.

• Do not use the equipment around moving machinery or

electrical hazards unless specifically designed for such

use.

• Do not use the equipment around sharp edges or

abrasive surfaces unless intended for such use.

WARNING!

The employer shall provide a training program for each employee who might be exposed to fall hazards. The

TTRRAAIINNIINNGG RREEQQUUIIRREEMMEENNTTSS:

:

program shall enable each employee to recognize the hazards of falling and shall train each employee in the procedures to be followed in order to

minimize these hazards. Relevant Federal, State, and local regulatory requirements, procedures, and standards shall also be a part of training.

The employer shall ensure that each employee has been trained, as necessary, by a Competent or Qualified Person in the nature of fall hazards in the

work area, the correct erecting, maintaining, disassembling, and inspection of the fall protection systems being used, and the use of personal fall

arrest systems.

The user is required to have a rescue plan and the means at hand to implement it when using the equipment. The plan shall be

RREESSCCUUEE PPLLAANN:

project specific. Employees shall be trained in self-rescue or alternate means shall be provided for prompt rescue in t

:

he event of a fall.

Remove the equipment from service immediately if it has been subjected to the forces of a

IIFF EEQQUUIIPPMMEENNTT IISS SSUUBBJJEECCTTEEDD TTOO AA FFAALLLL:

fall arrest. Contact your distributor or Guardian about policies regarding replacement of Guardian components involved in a fall.

:

IINNSSPPEECCTTIIOONN::

• Only the manufacturer of this equipment or persons or entities authorized in writing by the manufacturer shall make repairs to fall

protection equipment.

• The date of first inspection

should be recorded by the employer on the equipment, and any serial numbers shall be recorded on the

Inspection Log.

• Formal inspections shall be made by either a Competent or Qualified Person on at least a semi-annual basis.

PPRRIIOORR TTOO EEAACCHH UUSSEE::

• Fall protection equipment shall be inspected by the user for defects, damage, or deterioration.

• Any suspected defective equipment shall be removed from service.

• If the manufacturer’s label is not legible or is missing, the equipment shall be removed from service. Fall protection equipment shall

be removed from service upon evidence of defects, damage, or deterioration, or upon expiration of the manufacturer’s specified

service limits, whichever comes first.

Page 2

CCoonnssuulltt wwiitthh yyoouurr ddooccttoorr iiff tthheerree iiss rreeaassoonn ttoo ddoouubbtt yyoouurr ffiittnneessss ttoo ssaaffeellyy aabbssoorrbb tthhee sshhoocckk ffrroomm aa ffaallll aarrrreesstt.. AAggee,,

ffiittnneessss,, aanndd hheeaalltthh ccoonnddiittiioonnss ccaann sseerriioouussllyy aaffffeecctt aa wwoorrkkeerr’’ss aabbiilliittyy ttoo wwiitthhssttaanndd ffaallllss.. PPrreeggnnaanntt wwoommeenn oorr mmiinnoorrss

mmuusstt nnoott uussee aannyy GGuuaarrddiiaann FFaallll PPrrootteeccttiioonn eeqquuiippmmeenntt..

WARNING!

:

MMAAIINNTTEENNAANNCCEE,, CCLLEEAANNIINNGG,, AANNDD SSTTOORRAAGGEE:

authorized by Guardian. Contact Guardian for maintenance and repair. Cleaning after use is important for maintaining the safety and life of the

equipment. Cleanse the equipment of all dirt, corrosives, and contaminants. If the equipment cannot simply be wiped clean use a mild soap and

water. Rinse, wipe, and hang to dry. Store equipment where it cannot be affected by heat, light, excessive moisture, oil, chemicals, or other

degrading elements. This device, unless otherwise indicated, must be returned for factory servicing every two years from the date of first use. This

device must also be returned if the product fails any daily inspection, load indicator has been activated, or a competent person has deemed the

equipment unsafe.

Repairs to equipment can be made only by a Guardian representative or person or entity

DESCRIPTION OF PRODUCT:

Retractable: All Guardian Retractables are to be considered a mechanical device or a“Self-Locking Anchorage Device”, or a Self Retracting Lifeline

(SRL). This device is used to safely expand the working area where a harness with a 6ft. lanyard is not adequate. Also, a SRL is designed to reduce

the shock loading to the body of a worker by limiting the distance of a fall. The device allows for complete freedom of movement. The SRL is to

be considered part of a personal fall arrest system. The SRL is to be used as part of a complete fall arrest system. PFAS most commonally include

the use of a full body harnees, anchorage connector such as a carabiner and the SRL.

GUARDIAN PREMIUM EDGE SERIES 11FT. WEBBED SELF RETRACTING LIFELINE:

point. SRL also includes a double locking snap hook. All 11ft. retractables include a shock absorbing pack as a part of the 1-inch wide nylon web

lifeline. Additonal option may include a swivel snap hook with an impact load indicator.

GUARDIAN PREMIUM EDGE SERIES 20FT. WEBBED SELF RETRACTING LIFELINE

hook with impact indicator, and 1-inch wide nylon web in the length of 20ft. SRL also comes with a carabineer and tag line to be used with the

device to avoid improper use.

GUARDIAN PREMIUM EDGE SERIES 20FT., 25FT., and 30FT., GALVANIZED SELF RETRACTING LIFELINE:

self-locking swivel snap hook with impact indicator, and 3/16

the device to avoid improper use.

th

galvanized wire cable. SRL also comes with a carabineer and tag line to be used with

Includes a carabineer for attachment to an approved anchor

: Includes a swivel eye anchorage, self-locking swivel snap

Includes a swivel eye anchorage,

PRODUCT APPLICATION INFORMATION:

The SRL is used in a stationary or mobile manner. As a stationary device, the SRL would be mounted to an approved fixed anchorage connector

directly overhead. The SRL would extend as the user moves away from the anchorage point and retracts as the user moves back towards the

anchorage point. As the SRL is used in a mobile manner, the device would be traveling on a steel cable, rope, or fixed rail traveling from one

anchorage connector to the other.

LIMITATIONS:

Consider the following application limitations before using this equipment.

• Capacity: The SRL is to be used by an individual with a combined weight (person, clothing, tools, etc.) of 90 pounds

minimum and no more than 310lbs maximum. No more than one person may be connected at one time.

• Corrosion: Leaving the SRL in an environment for long periods of time that could cause corrosion of metal parts is not

warranted in any way and must not be done. Use caution when working around corrosive compounds such as ammonia,

sewage, fertilizers, seawater or other corrosive environments, may require more frequent inspections or servicing. These

increased inspections and servicing are required to ensure corrosive damage is not impacting the performance of the SRL.

• Chemical Hazards and Heat: Extreme caution must be taken when working in or around environments containing acid or

caustic chemicals, particularly at elevated temperatures. Damage will result to GFP SRL’s in this environment. Chemical

damage is difficult to detect and it is recommended that the lifeline be replaced periodically to ensure safety of the workers.

Additionally, this SRL is not to be used in high temperature environments. The SRL must be protected when using near

welding, metal cutting, or similar activities. Hot sparks and slag can damage this equipment. Users must inspect SRL prior

to each use.

• Electrical Hazards: For web and wire rope models, there is a possibility of an electric current flowing through the lifeline.

Moisture absorbed by the lifeline may provide a path for electrical current to flow, resulting in electrical shock. Use caution

where the lifeline may contact high voltage power lines.

• Locking Speed: Extreme caution should be taken when using this device whereas an obstructed fall could occur as well as

when someone must perform work in a confined or cramped space. Working in these types of environments could limit the

speed at which the locking mechanisms engage. Extreme caution should be taken when working on low pitched roofs, where

a worker may slide instead of fall. A clear path is required to ensure positive locking of the SRL.

Page 3

• Capacity: The SRL is for use by one person with a combined weight (person, clothing, tools, etc.) of 95lbs. minimum and

310lbs. maximum.

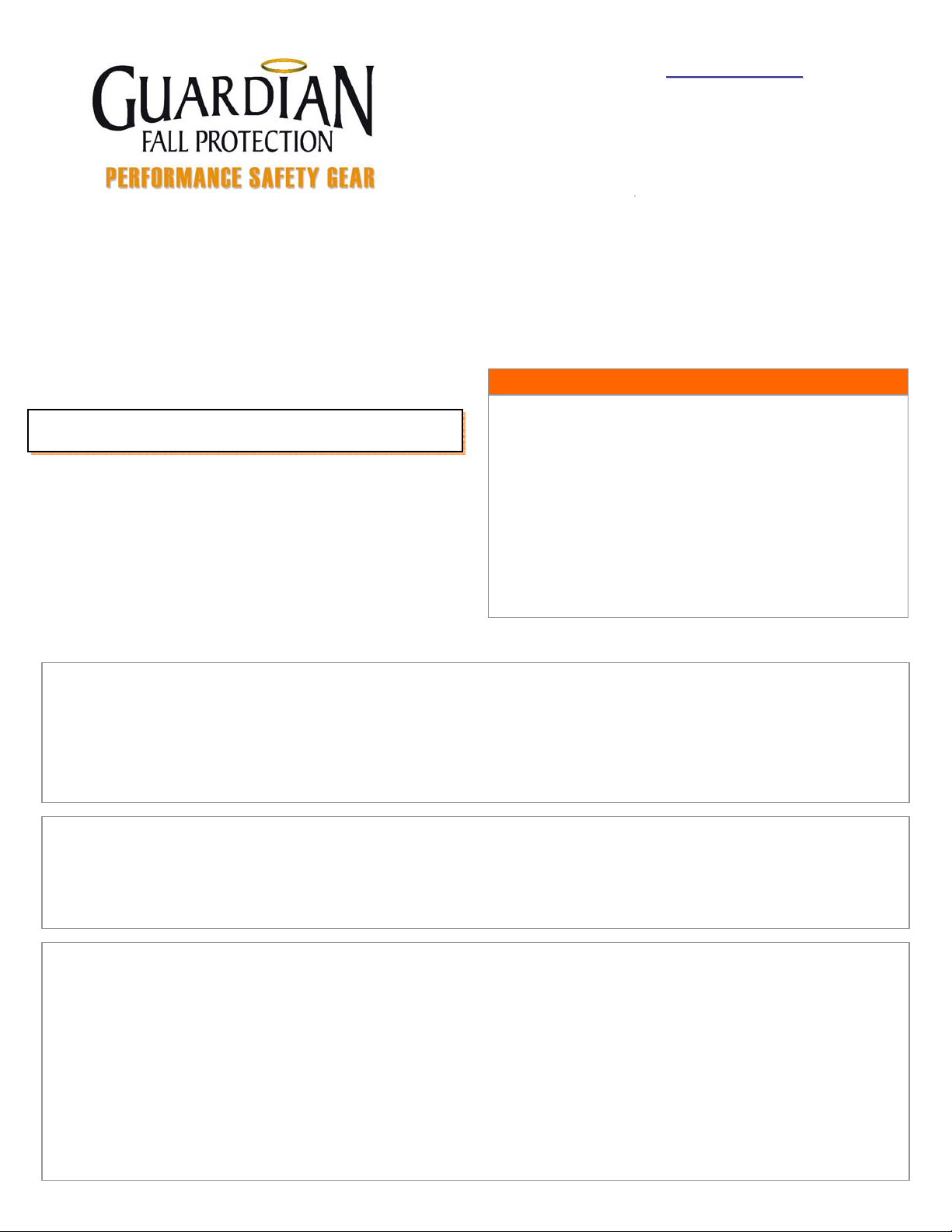

Consider When Calculating Distance:

• Deceleration Distance

• Movement of harness attachment

element (D-ring)

• Free Fall Distance

• Worker Height (how tall the worker is

6 Feet Max

Free Fall

Total Fall Distance

(Free Fall + Deceleration Distance)

could affect the free fall distance)

• Elevation of Anchorage Connector

• Connecting Subsystems Length

APPLICABLE STANDARDS:

Refer to potential applicable standards. Standards might include OSHA regulations depending on the type of work, and also might include state regulations if

applicable. Consult regulatory agencies for more information on personal fall arrest systems and associated components. This product is designed to comply with

OSHA and ANSIZ359.1 standards when used properly, and in accordance with manufacturer’s instructions.

LIMITATIONS CONTINUED:

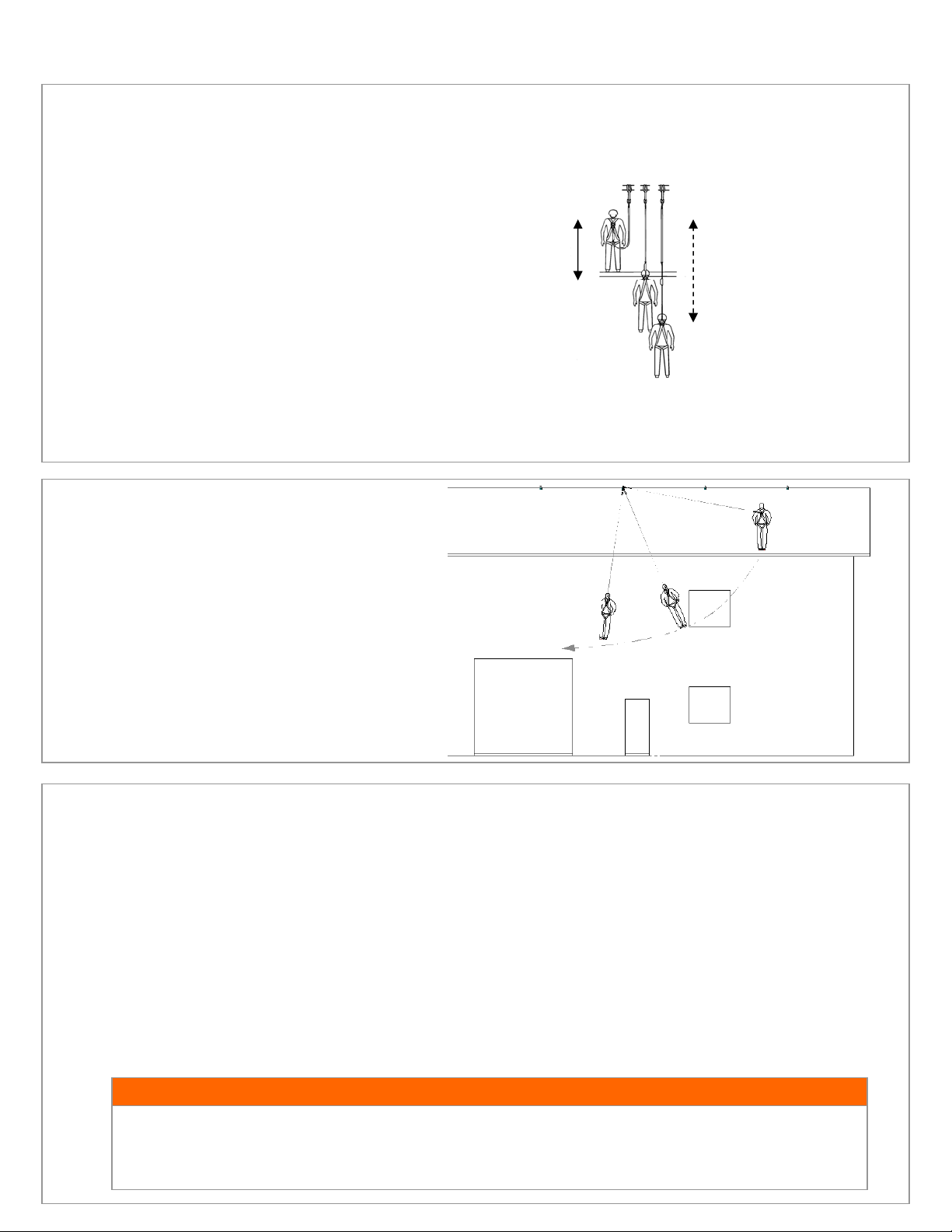

• Swing Falls: Swing falls occur when the anchorage point is not

directly above the point where a fall occurs. The force of striking an

object in a swing fall may cause serious injury or death. Minimize

the risk of swing falls by working as close to the

anchorage point as possible. Do not permit a swing fall if

injury could occur. Swing falls will significantly

increase the clearance required when a self retracting

lifeline or other variable length connecting system is

used.

• Potential Environmental Hazards: Use of fall protection

equipment in areas with environmental hazards may require

additional precautions to prevent injury to the user or damage to the

equipment. Hazards may include but are not limited to: chemicals,

corrosive environments, high voltage power lines, gases, moving

machinery, and sharp edges.

ATTACH TO OVERHEAD

ANCHORS!

SWING FALLS INCREASE

FALL ARREST DISTANCE.

SYSTEM REQUIREMENTS:

• Compatibility of Components: Guardian Fall Protection equipment is designed to be used with Guardian approved

components. Please contact Guardian if you have a question regarding compatibility. Making substitutions without approval

from Guardian Fall Protection may lead to injuries and or death by compromising the safety and reliability of the complete

system. A Qualified person can make a determination on compatibility of equipment from different manufacturers. If in

doubt, please contact Guardian Fall Protection for clarification.

• Compatibility of Connectors: Connectors (D-rings, hooks, carabiners) must be capable of supporting at least 5,000 lbs.

(22kN). Do not use equipment that is not compatible. Non-compatible connectors may unintentionally disengage. Self

locking snap hooks and carabiners are required by ANSI and OSHA. Connectors must be compatible in size, shape, and

strength.

• Making Connections: Only use self-locking snap hooks and carabiners with any Guardian Fall Protection equipment. Do not

use equipment that is not compatible. If you have any questions on compatibility, please call Guardian Fall Protection at

800.466.6385.

LLaarrggee tthhrrooaatt ooppeenniinngg ssnnaapp hhooookkss sshhoouulldd nnoott bbee ccoonnnneecctteedd ttoo ssttaannddaarrdd ssiizzee DD--rriinnggss oorr ssiimmiillaarr oobbjjeeccttss wwhhiicchh wwiillll rreessuulltt

iinn aa llooaadd oonn tthhee ggaattee iiff tthhee hhooookk oorr DD--rriinngg ttwwiissttss oorr rroottaatteess.. LLaarrggee tthhrrooaatt ssnnaapp hhooookkss aarree ddeessiiggnneedd ffoorr uussee oonn ffiixxeedd

ssttrruuccttuurraall eelleemmeennttss ssuucchh aass rreebbaarr oorr ccrroossss mmeemmbbeerrss tthhaatt aarree nnoott sshhaappeedd iinn aa wwaayy tthhaatt ccaann ccaappttuurree tthhee ggaattee ooff tthhee hhooookk..

WARNING!

Page 4

PERSONAL FALL ARREST INFORMATION:

• Personal Fall Arrest System (PFAS): Personal fall arrest systems used with this equipment must meet applicable state,

federal, OSHA, and ANSI requirements. A full body harness must be worn when this equipment is used as a component of a

personal fall arrest system. As required by OSHA, the personal fall arrest system must be capable of arresting the user’s fall

with a maximum arresting force of 1,800 lbs., and limit the free fall to six feet or less.

Do not alter or intentionally misuse this equipment. Consult with GFP when using this equipment in

combination with components or susbsystems other than those described here in this manual and or other

information. Use caution when using this equipment around moving machinery, electrical and chemical

hazards, and sharp edges.

WARNING!

OPERATION, USE and PLAN:

• Anchorage: The anchorage to which the SRL is attached must sustain static loads applied in the directions permitted by the

fall arrest system of at least 3,600lbs. with certification of a qualified person, or 5,000lbs. without certification. Refer to

OSHA and ANSI for specific definition. This device is to only be used by one person. When more than one personal fall

arrest system is attached to the same structure, the strength requirements stated above must be multiplied by the number of

personal fall arrest systems attached to the structure.

• Horizontal Systems and Tripods: In applications where an SRL is used in conjunction with a horizontal system or with a

tripod or davit arm, ensure the support structure and or the horizontal system components are compatible. Horizontal systems

must be designed and installed under the supervision of a qualified engineer.

• Anchorage Selection: Select a anchorage point capable of support at least 5,000 lbs. Additionally, select a location for

anchorage of the SRL that will avoid a free fall and swing fall hazards. To prevent an increased free fall distance, do not

work above the anchorage location.

• Free Fall: Personal fall arrest systems must be rigged so the potential free fall is never greater than six feet. Avoid slack in

the line and do not lengthen the SRL by connecting a lanyard or other snap hooks directly to the retractable. Do not use this

device at or below your feet. This will increase your free fall distance beyond the allowable limits set by OSHA and exceed

the capabilities of the SRL to safely arrest a free fall.

• Swing Falls: Swing fall will occur when the anchorage point is not directly over the head of the worker or directly above the

point where a fall occurs. The force of striking an object in a swing fall may cause serious injury up to and including death.

Minimize swing falls by working as directly below the anchorage point as possible. In all situations where a swing fall can

occur, the likelihood of an injury can occur. Please contact Guardian Fall Protection if you have questions on a particular

application involving one of our retractables.

• Fall Clearance: Ensure that there is always adequate clearance in the path of a fall to avoid striking an object or lower level.

A minimum of six feet from the working level to the lower level or nearest obstruction is recommended as long as the SRL is

attached directly over head of the worker and the worker is not in danger of injury as a result of a swing fall hazard.

• Sharp Edges: Unprotected and sharp edges can damage the lifeline. Please make sure to avoid working where this can

occur and provide protection where possible. A Guardian manufactured energy absorbing device can be added to aid in

reducing the impact forces on the entire device. For more information on this product, please contact Guardian Fall

Protection directly. No alterations to Guardian products is allowed.

INSPECTION OF SELF RETRACTING LIFELINES:

IIff iinnssppeeccttiioonn rreevveeaallss aann uunnssaaffee oorr ddeeffeeccttiivvee ccoonnddiittiioonn,, rreemmoovvee tthhee pprroodduucctt ffrroomm sseerrvviiccee aanndd sseenndd pprroodduucctt bbaacckk ttoo

GGuuaarrddiiaann FFaallll PPrrootteeccttiioonn oorr aa GGFFPP aauutthhoorriizzeedd sseerrvviiccee cceenntteerr..

WARNING!

• Before each use of this equipment inspect it according to the following guidelines:

A formal inspection of fall protection products/components must be performed at least every six months by a competent

person other than the user. The frequency of formal inspections should be based on conditions of use or exposure. Record

Page 5

the inspection results in the inspection and maintenance log at the end of this manual. OSHA 1910.66, OSHA 1926.502 and

ANSI Z359.1 requires an inspection of equipment before each use.

• Annually: ANSI requires a formal inspection of the SRL be completed by a competent person other than the user at least

twice a year. More formal and frequent inspections maybe required based upon the severity and environmental conditions of

the workplace. Guardian Fall Protection Retractables, unless otherwise marked, are required to be recertified every two years

from the date of first use.

• After a Fall Arrest: Inspect the impact indicator on the snap hook of the SRL and look for an exposed red color band. Do

not attempt to reset the impact indicator. Remove the retractable from service immediately and return to Guardian or an

authorized repair center. If using a retractable with a webbed lifeline, then inspection of the shock pack is required. Remove

retractable from service if there are any deformation, elongation or other signs of the shock pack being torn or deployed. If

inspection reveals an unsafe condition, remove unit from service immediately and destroy, or contact an authorized service

center for repair.

Inspecting the SELF RETRACTING LIFELINES:

Step 1. Inspect for loose screws and bent or damaged parts.

Step 2. Inspect housing for distortion, cracks or other damage. Ensure the swivel eye is not damaged or distorted in

anyway. Make sure the swivel eye turns freely.

Step 3. The lifeline must fully extend and retract without hesitation or creating a slack line condition.

Step 4. Ensure the device locks up when lifeline is jerked sharply.

Step 5. The labels must be present and fully legible with inspection log information completed.

Step 6. Look for signs of corrosion on the entire unit.

Step 7. Wire rope inspection must include identifying cuts, kinks, broken wires, bird-caging, corrosion, welding splatter,

chemical damage, or severely abraded areas. Check all thimbles etc…for excessive wear including cracks or

separation of metal components.

Step 8. Webbed lifeline inspection must include identifying frayed strands, broken webbing, burns, cuts, and abrasions.

Inspect for excessive heat, paint build-up, soiling, rust, or chemical damage indicated by brown or discolored areas.

Step 9. Inspect connecting hooks or carabiners for signs of damage, corrosion or excessive wear.

Step 10. Record inspection results in the inspection and maintenance log found in this manual. Clearly check off month the

SRL was inspected on the label of the housing.

CABLE INSPECTION:

When inspecting SRL’s that utilize cable lifelines, it is critical to look for the following damages and deterioration that will result

in malfunction of the unit and potentially unsafe conditions.

Crushing: The cable will often get crushed or bent while being used on a job site. Cable that is crushed or bent will damage

the retractable and thus the unit should be immediately taken out of service and returned to Guardian or an authorized repair

center.

Cutting: Movement over sharp edges or other objects while the cable is under tension can result in damaged strands and

broken wires. If, through inspection of the retractable lifeline prior to each use, it is found to have any broken strands,

immediately remove from service and return to Guardian or an authorized repair center.

Abrasion: Abrasion can result from normal wear. Particular attention must be paid to the outer wire strands as they will

appear to be flattened and or shiner than other parts of the cable. If, through inspection of the retractable lifeline prior to each

use, it is found have damage or deterioration from abrasion, immediately remove from service and return to Guardian or an

authorized repair center.

Kinking: Any deformation in the cable whereas the lifeline appears to be bent, requires the retractable to be immediately

removed from service and returned to Guardian or an authorized repair center.

Corrosion, Arc or Heat Damage: Extreme caution must be taken to avoid any potential damage as a result of using a

retractable within an environment where corrosive compounds, welding, or high heat may exist. Corrosive damage could

cause the cable to crack. Welding damage would result in fused wires and thus change the characteristics of the strength with

regards to the wire. If the retractable is used in these environments, the retractable lifeline needs to be closely examined for

damage. If you have any questions in terms of damage to the retractable or further explanation of the above information is

needed, please call 1-800-466-6385.

WARNING!

Page 6

PLAN THE FALL PROTECTION SYSTEM:

Before installation plan your system. Consider all factors that will affect your safety during use of this equipment. The following

list gives important points to consider when planning your system:

Anchorage: Select a rigid anchorage capable of supporting the loads no less than 5,000 lbs. per worker attached.

Sharp Edges: Avoid working where system components may be in contact with, or abrade against, unprotected sharp edges.

After a Fall: Components which have been subjected to the forces of arresting a fall must be removed from service and

destroyed. Retractable must be returned for servicing to GFP or an authorized repair center.

Rescue: The employer must have a rescue plan when using this equipment. The employer must have the ability to perform a

rescue quickly and safely.

WARNING!

INSTALLATION REQUIREMENTS:

The following requirements outline the proper installation procedures to be followed.

Location:

Select a location on an appropriate strength anchorage that will provide overall safety and proper loading. The anchorage

must be free of deformities or defects that may weaken the structure. The anchorage to which the SRL is attached must be

capable of sustaining static loads in the directions applied by the personal fall arrest systems of at least 3,600lbs with

certification of a qualified person, or 5,000lbs without certification.

When more than one person is attached to the same structure, the strength requirements stated above must be multiplied by

the number of personal fall arrest systems.

Do not work above the anchorage point. While using an SRL, always ensure that there is constant tension on the cable.

Slack in the cable could result in an increase in fall distance. Move normally as sudden jerky movements will allow the

locking mechanism to engage.

Do not install in an area where a swing fall hazard potentially could exist. Failure to do so could result in injury or

possibly death.

Keep these instructions for reference.

IIff iinnssppeeccttiioonn rreevveeaallss aann uunnssaaffee oorr ddeeffeeccttiivvee ccoonnddiittiioonn,, rreemmoovvee tthhee SSeellff RReettrraaccttiinngg LLiiffeelliinnee ffrroomm sseerrvviiccee aanndd sseenndd bbaacckk

ttoo GGuuaarrddiiaann FFaallll PPrrootteeccttiioonn oorr aann aauutthhoorriizzeedd rreeppaaiirr cceenntteerr..

WARNING!

TRAINING:

It is the responsibility of the user and the purchaser of this equipment to assure that they are familiar with these instructions,

trained in the correct care and use of, and are aware of the operating characteristics, application limits, and the consequences of

improper use of this equipment.

TTrraaiinniinngg sshhoouulldd bbee ccoonndduucctteedd wwiitthhoouutt eexxppoossiinngg aannyyoonnee ttoo aa ffaallll hhaazzaarrdd.. TTrraaiinniinngg sshhoouulldd bbee rreeppeeaatteedd oonn aa ppeerriiooddiicc

bbaassiiss iinn aaccccoorrddaannccee wwiitthh yyoouurr oorrggaanniizzaattiioonnss ppoolliiccyy aanndd ccoommpplliiaannccee wwiitthh OOSSHHAA rreegguullaattiioonnss..

WARNING!

Page 7

20ft Web Retractable (

10906)

Page 8

20ft. to 30ft. Galvanized/Stainless Steel Cable Retractable (10910/10912/10915/10930/10932/10935)

Page 9

INSPECTION AND MAINTENANCE LOG:

*ALL EDGE RETRACTABLES, EXCLUDING THE 11FT. WEB UNIT, MUST BE SERVICED EVERY

TWO YEARS FROM DATE OF FIRST USE. 11FT. WEB RETRACTABLE MUST BE INSPECTED

EVERYDAY AS ANY OTHER RETRACTABLE DEVICE.

SERIAL NUMBER:______________________(Log unit serial number found on backside of label)

MODEL NUMBER:______________________(Model number found on backside of label)

DATE PUCHASED:______________________ DATE OF FIRST USE:____________________

INSPECTION DATE:____________ (Mark date of inspection)

INSPECTION ITEMS NOTED: (Refer to inspection guidelines in this manual)

1. Example: Cable lifeline frayed.

2.

3.

4.

5.

CORRECTIVE ACTION TAKEN: _________________________________________

Example: Retractable taken out of service and returned to Guardian Fall Protection

APPROVED BY:____________________________ DATE: ____________ (Who approved inspection and

corrective action taken)

INSPECTION DATE:____________ (Mark date of inspection)

INSPECTION ITEMS NOTED: (Refer to inspection guidelines in this manual)

1. Example: Cable lifeline frayed.

2.

3.

4.

5.

CORRECTIVE ACTION TAKEN: _________________________________________

Example: Retractable taken out of service and returned to Guardian Fall Protection

APPROVED BY:____________________________ DATE: ____________ (Who approved inspection and

corrective action taken)

INSPECTION DATE:____________ (Mark date of inspection)

Page 10

INSPECTION ITEMS NOTED: (Refer to inspection guidelines in this manual)

1. Example: Cable lifeline frayed.

2.

3.

4.

5.

CORRECTIVE ACTION TAKEN: _________________________________________

Example: Retractable taken out of service and returned to Guardian Fall Protection

APPROVED BY:____________________________ DATE: ____________ (Who approved inspection and

corrective action taken)

INSPECTION DATE:____________ (Mark date of inspection)

INSPECTION ITEMS NOTED: (Refer to inspection guidelines in this manual)

1. Example: Cable lifeline frayed.

2.

3.

4.

5.

CORRECTIVE ACTION TAKEN: _________________________________________

Example: Retractable taken out of service and returned to Guardian Fall Protection

APPROVED BY:____________________________ DATE: ____________ (Who approved inspection and

corrective action taken)

INSPECTION DATE:____________ (Mark date of inspection)

INSPECTION ITEMS NOTED: (Refer to inspection guidelines in this manual)

1. Example: Cable lifeline frayed.

2.

3.

4.

5.

CORRECTIVE ACTION TAKEN: _________________________________________

Example: Retractable taken out of service and returned to Guardian Fall Protection

APPROVED BY:____________________________ DATE: ____________ (Who approved inspection and

corrective action taken)

Page 11

INSPECTION DATE:____________ (Mark date of inspection)

INSPECTION ITEMS NOTED: (Refer to inspection guidelines in this manual)

1. Example: Cable lifeline frayed.

2.

3.

4.

5.

CORRECTIVE ACTION TAKEN: _________________________________________

Example: Retractable taken out of service and returned to Guardian Fall Protection

APPROVED BY:____________________________ DATE: ____________ (Who approved inspection and

corrective action taken)

INSPECTION DATE:____________ (Mark date of inspection)

INSPECTION ITEMS NOTED: (Refer to inspection guidelines in this manual)

1. Example: Cable lifeline frayed.

2.

3.

4.

5.

CORRECTIVE ACTION TAKEN: _________________________________________

Example: Retractable taken out of service and returned to Guardian Fall Protection

APPROVED BY:____________________________ DATE: ____________ (Who approved inspection and

corrective action taken)

INSPECTION DATE:____________ (Mark date of inspection)

INSPECTION ITEMS NOTED: (Refer to inspection guidelines in this manual)

1. Example: Cable lifeline frayed.

2.

3.

4.

5.

CORRECTIVE ACTION TAKEN: _________________________________________

Example: Retractable taken out of service and returned to Guardian Fall Protection

APPROVED BY:____________________________ DATE: ____________ (Who approved inspection and

corrective action taken)

Page 12

INSPECTION DATE:____________ (Mark date of inspection)

INSPECTION ITEMS NOTED: (Refer to inspection guidelines in this manual)

1. Example: Cable lifeline frayed.

2.

3.

4.

5.

CORRECTIVE ACTION TAKEN: _________________________________________

Example: Retractable taken out of service and returned to Guardian Fall Protection

APPROVED BY:____________________________ DATE: ____________ (Who approved inspection and

corrective action taken)

INSPECTION DATE:____________ (Mark date of inspection)

INSPECTION ITEMS NOTED: (Refer to inspection guidelines in this manual)

1. Example: Cable lifeline frayed.

2.

3.

4.

5.

CORRECTIVE ACTION TAKEN: _________________________________________

Example: Retractable taken out of service and returned to Guardian Fall Protection

APPROVED BY:____________________________ DATE: ____________ (Who approved inspection and

corrective action taken)

INSPECTION DATE:____________ (Mark date of inspection)

INSPECTION ITEMS NOTED: (Refer to inspection guidelines in this manual)

1. Example: Cable lifeline frayed.

2.

3.

4.

5.

CORRECTIVE ACTION TAKEN: _________________________________________

Example: Retractable taken out of service and returned to Guardian Fall Protection

APPROVED BY:____________________________ DATE: ____________ (Who approved inspection and

corrective action taken)

Page 13

do so voids warranty of product.

INSPECTION DATE:____________ (Mark date of inspection)

INSPECTION ITEMS NOTED: (Refer to inspection guidelines in this manual)

1. Example: Cable lifeline frayed.

2.

3.

4.

5.

CORRECTIVE ACTION TAKEN: _________________________________________

Example: Retractable taken out of service and returned to Guardian Fall Protection

APPROVED BY:____________________________ DATE: ____________ (Who approved inspection and

corrective action taken)

INSPECTION DATE:____________ (Mark date of inspection)

INSPECTION ITEMS NOTED: (Refer to inspection guidelines in this manual)

1. Example: Cable lifeline frayed.

2.

3.

4.

5.

CORRECTIVE ACTION TAKEN: _________________________________________

Example: Retractable taken out of service and returned to Guardian Fall Protection

APPROVED BY:____________________________ DATE: ____________ (Who approved inspection and

corrective action taken)

Mark on the retractable label that the

device has been inspected. Failure to

GGuuaarrddiiaann FFaallll PPrrootteeccttiioonn,, IInncc..

800-466-6385

26513 79th Ave. S.

Kent, WA 98032

www.guardianfall.com

Loading...

Loading...