Page 1

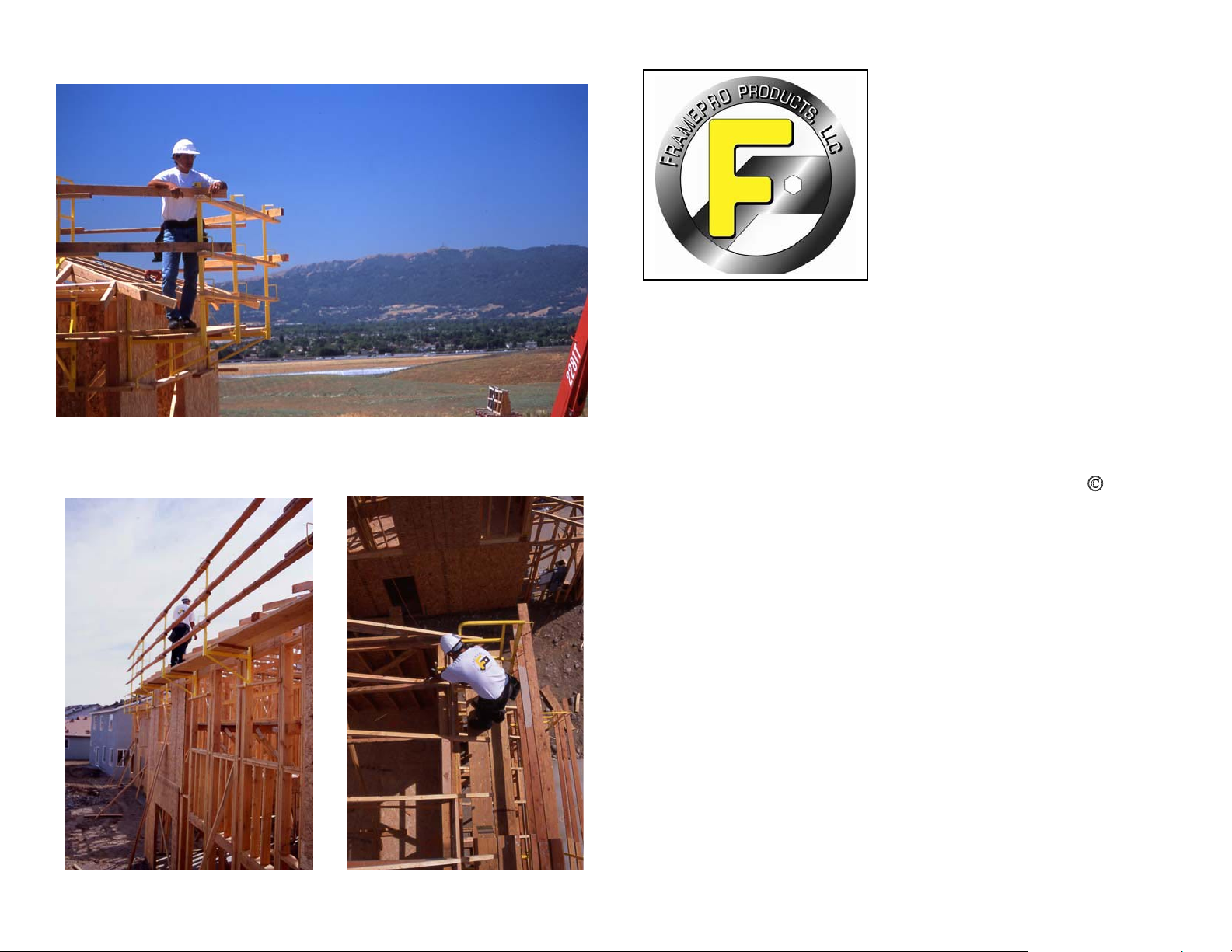

FRAMEPRO

PRODUCTS, LLC

Guide for Installation

Of

STACKER-BRACKET �

(Fall Protection System)

“It is easier to accept the responsibility of a safe

Work Attitude, than to live with the consequence

of a thoughtless procedure”

900 Business Park Drive, Suite D

Dixon, Ca. 95620

Toll Free Tel: (888) 813-8880 / Fax: (707) 678-9497

Page 2

TABLE OF CONTENTS

Introduction…………………………………………………….2

Material identification and inspection………………………….3

Installation

Stage #1: Planning…………………………………………....4

Stage #2: Lay-out…………………………………………….5

Stage #3: Installation……………………………………...5 - 8

Stage #4: Removal……………………………………………9

Special Conditions

a. Balloon Walls…………………………………………..10

b. Openings at bracket locations…………………………..10

c. Shear Walls……………………………………………..10

d. Moving an installed bracket………………………….....10

Ladder Safety……………………………………………………11

Access zones……………………………………………………..11

Safety Monitor…………………………………………………...12

Summary…………………………………………………………12

Notes……………………………………………………………..13

WARNING

Read complete instruction manual prior to installation.

Failure to follow instructions could result in serious injury

Page 1

or death!

Page 1

Page 3

INTRODUCTION

In the construction industry, falls are the leading cause of worker

fatalities. Each year, on the average, between 150 and 200 workers are

killed and more than 100,000 are injured as a result of falls at

construction sites. The standard for fall protection deals with both the

human and equipment-related issues in

protecting workers from fall

hazards. The unique feature of our product is the way it attaches and

detaches to the top plate. After the entire roof is completed, you simply

remove the safety pin and the top clamp bolt, and then let the bracket

slip away from behind the frieze block.

OBJECTIVE

The objective of this booklet is to supplement the “Hands on” training

class provided by FRAME PRO PRODUCTS, LLC. The Stacker

Bracket System

is a safety tool designed for protecting workers who

perform stacking, fascia, sheathing, nailing, and any other roof edge

operations on construction sites. The Stacker Bracket has been

designed and engineered to meet OSHA requirements for scaffolding

and fall protection.

In general the employers must ensure that:

� Safe work procedures are used.

� Workers are trained in the proper use and maintenance of

all

aspects of your protection systems.

� System is inspected daily for modifications or any unsafe

condition.

� Daily inspections are documented and corrective actions

taken.

� Those erecting, dismantling or modifying the system are

under the direct supervision of a qualified person.

Page 2

Page 4

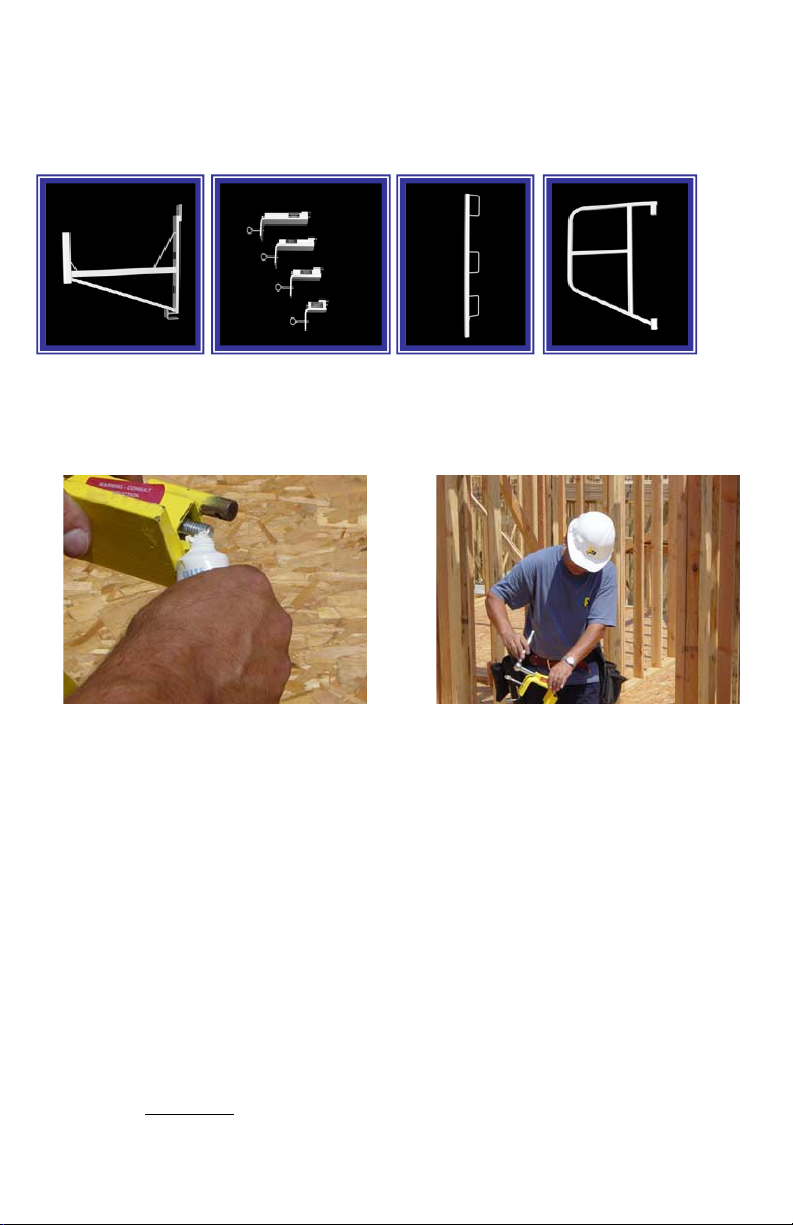

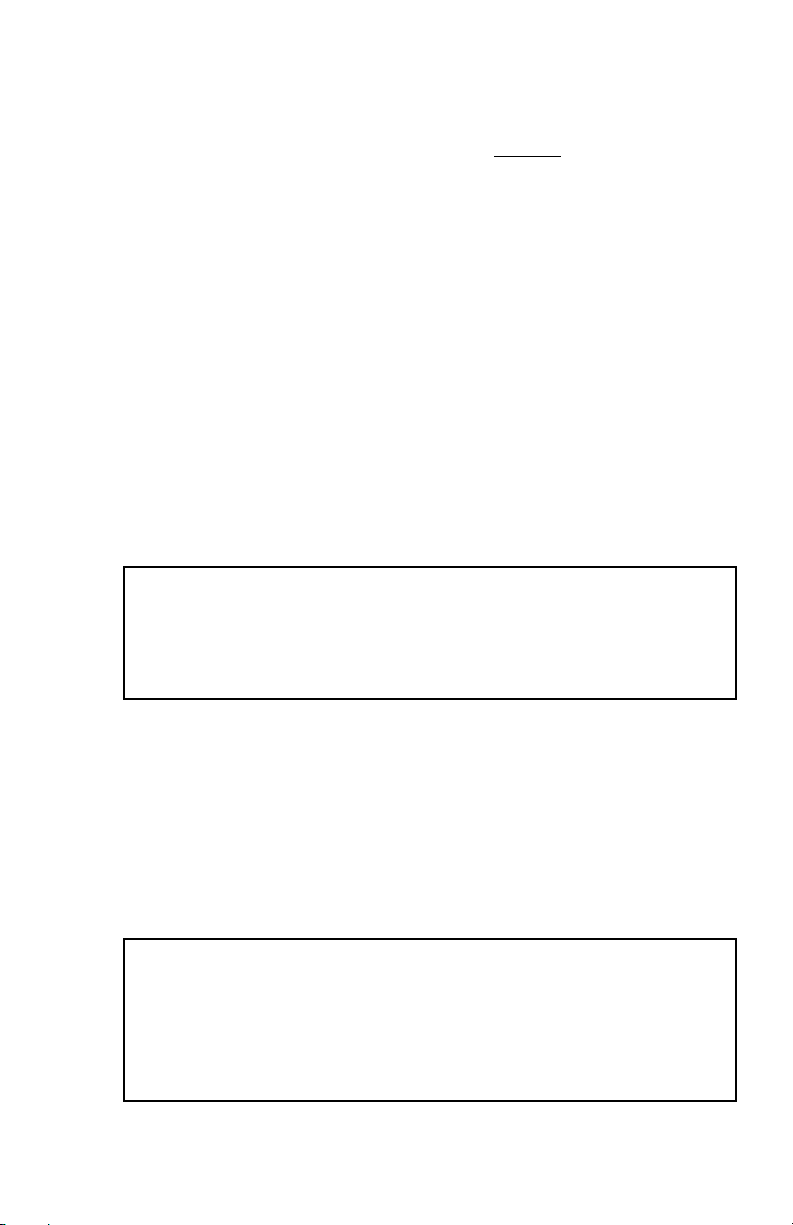

MATERIAL IDENTIFICATION AND INSPECTION

There are 4 basic parts to the Stacker-Bracket system

.

Support Bracket Top Clamp Guard Rail Post End Rail

Part #SBBF Part # SBTC4,6,8,12 Part # SBGP Part # SBER

INSPECTION

Visually inspect all parts: brackets, clamps, guard-rail posts, and end

rails, for broken welds, bent components, or stripped threads. Inspect

planks and 2 x 4 rails for cracks and splits.

PRE-INSTALLATION

In the event that the parts aren’t pre-assembled, you’ll need to attach

the Top Clamp to the support bracket. (Be sure to match correct Top

Clamp with top plate size)

Using a small amount of thread lube, attach the Top Clamp to the

Support Bracket. Start the hex bolt by hand and then use the ratchet to

finish tightening approx. ¼ turn past snug. To avoid damaging the

threads, DO NOT

use an impact wrench with this system at any time.

Page 3

Safety Monitor

The employer shall designate a competent person to monitor the safety

of other employees, and:

Summary

The most effective way to prevent job-related injuries is to implement

and maintain a proactive safety program. A proactive safety program

is one in which safety is a part of every decision made and activity

performed during the course of the workday. The skill level of

employees is such that it matches the job assignment, and appropriate

training is provided to maintain such skills. A proactive safety

program not only helps keep the workplace safe, but includes:

Since safety awareness is not instilled in all people, it must be taught.

However, all the training in the world cannot help those who cannot,

or will not, master a safe mental attitude. So be willing to learn and

enhance your safety skills in order to minimize the misery of accidents

or death.

Page 5

Stage #1: Planning

A. Manpower:

1. Minimum of two (2) people trained

on installation

Procedures

B. Tools

1. Roof layout diagram

2. Spray paint or keel (layout)

3. 9/16” deep socket with 3/8” ratchet

4. Spray lubricant or lithium grease

5. Extension ladder with hook

C. Stacker Bracket� System

1. One bracket with support brace

2. One top clamp (4” for 2x4 wall – 6” for 2x6 wall,

Etc.)

3. One guard rail post per bracket

4. End Rail at end of scaffold run

5. One lowering strap per bracket at sheer wall

locations

6.

D. Planking Material

1. Two (2) 2x10 – 10’ Scaffold Planks or

equivalent per section (OSHA approved)

2. Three (3) 2x4 – 10’ DF#1 Hand Rail per section

(OSHA approved metal rails are also acceptable)

Page 4

WARNING

This system is engineered for use with 2x4 DF #1 handrails

or approved metal rails and scaffold grade planks. Failure to

use designated materials may result in bodily injury or

death.

INFORMATIONAL NOTE

With full hip roofs, brackets are placed all the way around

the top plate with corners connected on a 45. End rails are

not necessary on hip roofs.

Page 6

Stage #2: Layout

A. Roof Plan Diagram

1. The first step is to use a roof plan and layout the bracket

location.

2. Place a mark on the floor 1’-0” from the outside corner

of the building and continue marking the rest of the wall

on 8’-0” centers at all eaves.

3. When you get to the end of the wall, place a mark

on the floor at 1 foot back from the end.

4. Continue around the house until all eave areas are

laid out and marked on the floor.

5. Distribute the proper material to each mark on the

floor.

a. One Stacker Bracket

with Top Clamp attached.

(Be sure to match clamp size with wall thickness)

b. One Guard Rail Post

c. One 36” Support Brace

d. Two 2x10x10’-0” scaffold planks

e. Three 2x4x10’-0” rails or approved metal rails.

f. End rails where necessary.

g. One optional lowering strap per sheer area.

Stage #3: Installation

1. Mark bracket location on 36” 2x4 making sure 2x4

crosses three studs, even at sheer areas

.

2. Nail 2x4 to bracket at layout mark (NOTE! The

bracket is not always in the middle of the 36” 2x4) DO

NOT drive nail flush, as it must be removed later.

Page 5

Special Conditions

A. Balloon walls

O.S.H.A, requires interior fall protection at certain working heights.

Since trigger heights vary from state to state, be sure to check local

and state requirements. Below is an example of a variable height

scaffold for use at interior locations of balloon walls. If you build or

erect this first, it makes a good platform to work from while installing

the bracket system.

b. Sole plate allows for ease

of assembly/removal

B. Openings At Bracket Locations

When a Stacker Bracket

doorway, you must install a double trimmer at that location, with three

16d nails at the top and bottom, along with the proper line brace.

C. Shear Walls

Where shear–walls occur, the optional strap should be looped through

the bracket with the free end laid over the wall for future use.

D. Moving Installed Brackets

If a bracket needs to be moved for the framer/stacker, simply loosen

the eye-bolt and move the bracket over a few inches. (Never loosen

the hex bolt until you are ready to remove the entire system.)

WARNING

Never use #1 D. F. 2 x 4’s for spans greater than 8’-0”.

SAFETY NOTE

Prior to installation of the Stacker Bracket system, you must

use a barricade to define a perimeter around the building to

prevent injury from falling objects. Be sure to consult your

local and state regulations for specific requirements.

Page 7

Working from secured ladder (See page 11 for “Ladder Safety”)

3. Hang bracket over top plate at layout location

4. Using a ratchet handle, tighten the eyebolt at least 2 full turns

past finger tight.

5. Install attached safety pin EVERY

TIME.

6. Install guard rail post, with loops to the

outside

7. Complete installing all brackets from a

ladder, adding end rails as necessary.

8. At sheer wall areas, the optional strap should be looped through

the bracket with the free end over the top of the wall for future

use.

SAFETY NOTE

Each Stacker Bracket� must have a plumb and line brace within one foot of

bracket. (Please note that perpendicular walls are acceptable as a brace.)

Page 6

Page 8

Installing Planks and Rails

1. Spread Trus Joist Scaffold Planks, 2x4 D.F #1 handrails, to

each bracket.

2. Always install first section of planks and rails, from an

extension ladder.

3. From there, complete the entire run of planks and rails from

either the scaffold or a ladder.

Page 7

CARPENTRY INSTRUCTIONS

Before removing the Stacker Bracket

carpentry, including the following.

Page 8

SAFETY NOTE

Do not use a stepladder as a lean-to ladder.

Page 9

4. Continue lapping planks in one direction for consistent overlap.

(This simplifies the removal process. )

CARPENTRY INSTRUCTIONS

Before removing the Stacker Bracket

system, complete all roof

carpentry, including the following.

� Install all roof vents and frieze blocks

� All hardware required by engineer. (L50, A35, H1, etc.)

� Complete all fascia

� Complete all roof sheeting and nailing

� All roof carpentry

� Nailing inspection approved and signed off

� Fireplace stacks, pop-outs, skylights, dormers, etc.

� Chevrons at gable ends w / OSHA approved harness.

� Holes cut for heat

� Tile kick at the eve installed

Page 8

Page 10

Stage #4: Removal

Note: Before removal, verify that caution tape is still in place around

the entire building and have a Safety Monitor present at all times.

Safety Equipment Required (Must meet OSHA regs.)

� Full body safety harness (follow mfg. Instructions)

� Self-retracting life line (follow mfg. Instructions)

� Nail on roof anchors

Removal of Bracket System

1. Remove rails, uprights, and planks while working in reverse

direction of installation.

2. Stack material on roof jacks, or lower to the ground.

Dismantling Bracket System

1. At shear wall areas, attach the previously installed lowering

strap to a rope or strap. While your assistant holds the strap,

loosen the eyebolt and remove the top clamp. Then lower the

bracket down using the strap or rope.

2. On walls without shear, remove the 36” 2x4, loosen the hex

bolt, remove the top clamp, and bring bracket in between the

studs.

3. Use a Safety Monitor to assure that lowering material does not

injure someone.

Page 9

Working from secured ladder (See page 11 for “Ladder Safety”)

3. Hang bracket over top plate at layout location

SAFETY NOTE

Each Stacker Bracket� must have a plumb and line brace within one foot of

Page 6

SAFETY NOTE

Roof jacks must be properly made and secured

.

CAUTION ! DO NOT overload jacks.

Page 11

Special Conditions

A. Balloon walls

O.S.H.A, requires interior fall protection at certain working heights.

Since trigger heights vary from state to state, be sure to check local

and state requirements. Below is an example of a variable height

scaffold for use at interior locations of balloon walls. If you build or

erect this first, it makes a good platform to work from while installing

the bracket system.

Important !

a. Notice both platforms

and their heights.

b. Sole plate allows for ease

of assembly/removal

c. Adequate bracing

d. Maximum 8’-0” spans

B. Openings At Bracket Locations

When a Stacker Bracket

falls in an opening such as a window or

doorway, you must install a double trimmer at that location, with three

16d nails at the top and bottom, along with the proper line brace.

C. Shear Walls

Where shear–walls occur, the optional strap should be looped through

the bracket with the free end laid over the wall for future use.

D. Moving Installed Brackets

If a bracket needs to be moved for the framer/stacker, simply loosen

the eye-bolt and move the bracket over a few inches. (Never loosen

the hex bolt until you are ready to remove the entire system.)

Page 10

SAFETY NOTE

Do not create a hazard at the

bal- loon wall by having a

platform at a high window

without putting hand rails thru

such openings.

Page 12

Ladder Safety

Stairways and ladders are a major source of injuries and fatalities

among construction workers. Below are some basic requirements from

O.S.H.A. regarding ladder safety. Be sure to check with your local

state for any special requirements.

� When portable ladders are used for access to an upper

landing surface, the side rails MUST extend at least 3’

above the upper landing surface.

� Ladders must be used ONLY for the purpose for which

they were designed.

� Ladders must not be used on slippery surfaces unless

secured or provided with slip-resistant feet to prevent

movement.

� When ascending or descending a ladder, the worker must

face the ladder.

� Each worker must use at least one hand to grasp the ladder

when moving up or down the ladder.

� A worker on a ladder must not carry any object or load that

could cause the worker to lose balance and fall.

Access Zones

Any employee working in a controlled area shall be under the direct

supervision of a safety monitor, and shall comply with all safety

regulations

Toe Boards

Regulations concerning toe boards include the following:

� Toe boards must be provided on all open sides and ends of

railed scaffolds at locations where persons are required to

work or pass under.

� A toe board must be securely fastened at a minimum of 4”

(nominal) in height from its top edge to the level of the

floor or platform. A toe board must have no more than 1/4

inch clearance above the floor level

Page 11

Stage #1: Planning

Page 4

Page 13

Safety Monitor

The employer shall designate a competent person to monitor the safety

of other employees, and:

� Shall be competent to recognize fall hazards

� Shall warn an employee when it appears that the employee is

unaware of a fall hazard or is acting in an unsafe manner.

� Shall be on the same walking/working surface and within

visual sighting distance of the employee being monitored.

� Shall be close enough to communicate orally with the

employee.

� Shall have NO OTHER responsibilities which could take the

monitor’s attention from the monitoring function.

Summary

The most effective way to prevent job-related injuries is to implement

and maintain a proactive safety program. A proactive safety program

is one in which safety is a part of every decision made and activity

performed during the course of the workday. The skill level of

employees is such that it matches the job assignment, and appropriate

training is provided to maintain such skills. A proactive safety

program not only helps keep the workplace safe, but includes:

� Fewer work injuries

� Lower compensation insurance

� Lower absenteeism

� Lower employee turnover

� Higher job efficiency

� Higher employee morale

� Higher quality of work

Since safety awareness is not instilled in all people, it must be taught.

However, all the training in the world cannot help those who cannot,

or will not, master a safe mental attitude. So be willing to learn and

enhance your safety skills in order to minimize the misery of accidents

or death.

Page 12

Page 14

NOTES

Page 13

INTRODUCTION

In the construction industry, falls are the leading cause of worker

fatalities. Each year, on the average, between 150 and 200 workers are

killed and more than 100,000 are injured as a result of falls at

construction sites. The standard for fall protection deals with both the

human and equipment-related issues in

hazards. The unique feature of our product is the way it attaches and

detaches to the top plate. After the entire roof is completed, you simply

remove the safety pin and the top clamp bolt, and then let the bracket

slip away from behind the frieze block.

OBJECTIVE

The objective of this booklet is to supplement the “Hands on” training

class provided by FRAME PRO PRODUCTS, LLC. The Stacker

Bracket System

perform stacking, fascia, sheathing, nailing, and any other roof edge

operations on construction sites. The Stacker Bracket has been

designed and engineered to meet OSHA requirements for scaffolding

and fall protection.

Loading...

Loading...