Page 1

Instructions for the

Assembly and Safe Use of

FramePro Products Multi-Functional Scaffold

Prefabricated Mobile Interior Scaffolds

FramePro Product LLC.

900 Business Park Dr., Suite D

Dixon, Calif. 95620

phone: 707-678-9496

fax: 707-678-9497

© 2007

WHERE TO BEGIN

Page 2

Worksite Inspection

Users of FramePro Scaffolding must walk the area in which they will work, to remove any materials that may be a in the way of the

scaffold setup. Particular care must be taken to note floor hazards such as construction debris, holes in the floor, etc. FramePro

Scaffolds must be used on solid flat surfaces.

Equipment Inspection Prior to use

FramePro Scaffold users must thoroughly inspect the scaffold prior to use. All components must be complete, functioning properly

and correctly assembled. Any incomplete part, missing part, or ill-fitting part should be replaced prior to use. Never use a FramePro

Scaffold without first completely inspecting the unit.

During Use

Keep the platform free from trip hazards. Do not allow loose objects and debris to accumulate on the platform. Make sure the unit is

free from paint, mud, grease or any other hazardous material that may cause you to slip. Never leave the scaffolding unattended.

Following Use

When finished with scaffolding inspect for any damage, deterioration, and any missing parts.

Equipment Maintenance Platforms

Platforms must be checked for loose or missing edge banding, large holes or thin spots where the plywood has been worn. Worn or

damaged boards must be replaced with new boards.

Trusses and Guardrail Sides

Trusses and Guardrail sides must be checked to make sure locking pins are working correctly. Any bent pins or guardrails should not

be used.

Ladders

End Frame Ladders must be inspected for loose or missing caster bushings and stack pins. Casters should be lubricated and checked

before every use.

Casters

Casters should be checked for worn or damaged wheels, and missing bearings. Wheels should spin freely and bearing races should

turn freely and smoothly. Axle, bearing should be lubricated often.

Page 3

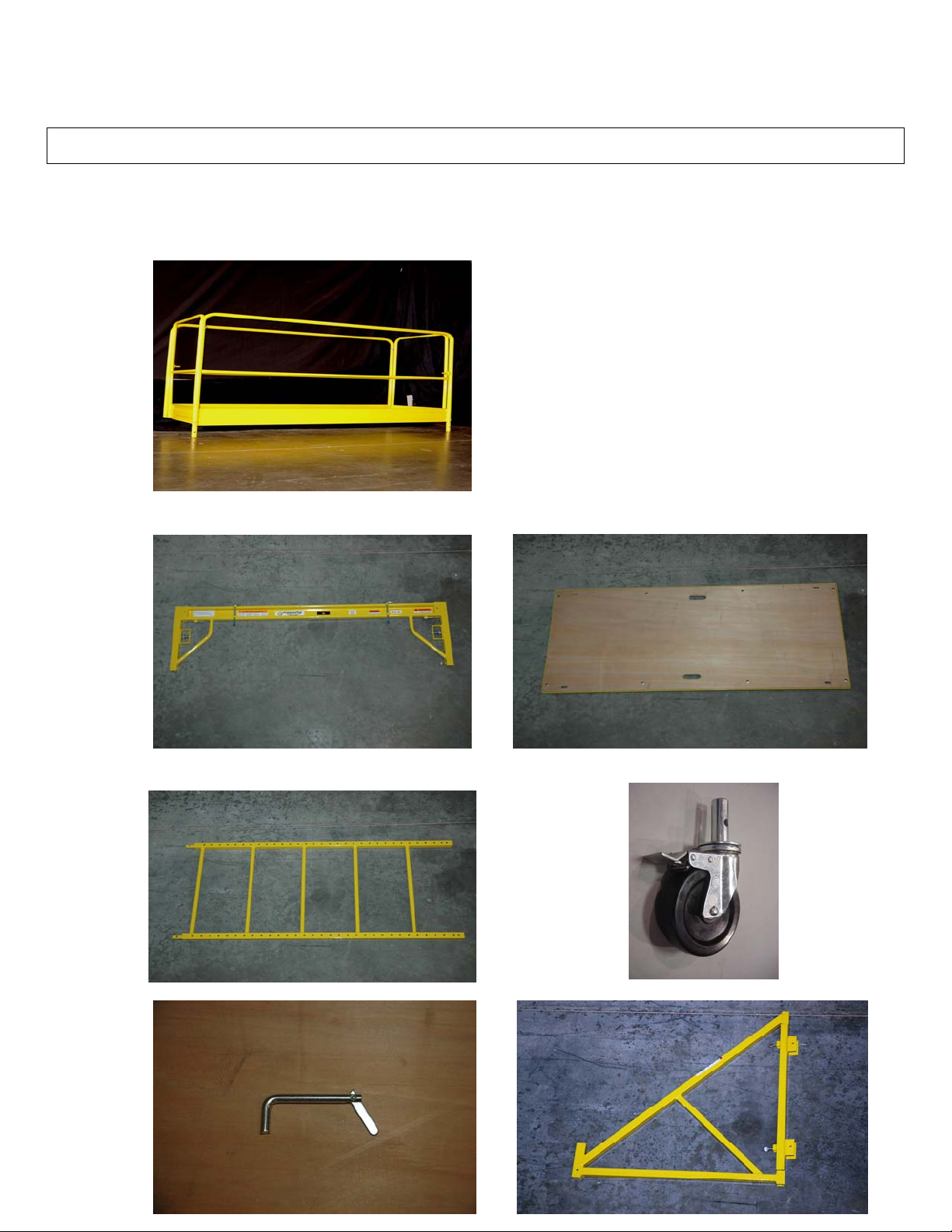

ACCESSORIES

The FramePro Products Multi-Functional

Scaffold is available in Steel and Aluminum

GUARDRAIL SET

MFS TRUSS MFS PLATFORM

MFS LADDERS MFS CASTERS/ PINS

Page 4

MFS GUARDRAIL SAFETY PIN MFS OUTRIGGERS

DANGER

This metal equipment is conductive. Do not use near electrical circuits. Serious injury or death could result.

WARNING

Do not use this equipment if you are in poor health, taking medications, drugs, or drinking alcoholic beverages, all of which may impair

your ability to work safely on this product.

Do not mix platforms, casters, trusses, end frame access ladders or other components from other manufacturers with FramePro

scaffolding. Component dimensions differ enough to be hazardous when mixed. Use only authorized FramePro parts and components.

Discard the scaffold if it has been exposed to fire or corrosive chemical.

Do not overreach. Keep your body within the boundaries of the guardrail and scaffold section.

Do not stand on guardrail or use any components of the guardrail to gain additional standing height.

Do not place ladders, chairs, boxes or any other such object or device on the platform to gain addition a l standing height.

Do not try to pull or “scoot” yourself from one location to another while standing on platform. Climb down from the platform to the

floor. Mount and dismount the platform from the top center of the End Frame Access Ladder. Do not swing around the side of the

ladder. Unlock the casters and move the scaffold in a safe manner. Relock the casters before climbing to the working platform. For

easier locking and unlocking of the casters, turn the brake levers outward.

Do not subject the FramePro scaffold to any side-load forces or im pact s.

Do not place a FramePro on the deck of a scissor-lift or any other type of access equipment in order to gain additional standing

height.

Guardrails must be used at working platform heights of 6 ft. or higher.

(Refer to OSHA 1910.28, 1910.29, and ANSI A10.8) Check with state and local codes and regulations for variance from federal

standards.

Before units are to be stacked, a set of four (4 ) Outriggers ( PN MFS-NOR , MFS-WOR )

Must be installed on the base section of scaffolding. Insert casters form a section of scaffolding to be stacked into the outriggers prior

to installation. Do not stack more than three (3) sections high (18 ft./ 5.5 m). Once the scaffold is in the desired position on the jobsite

floor, lock the casters on the scaffold tower and all four outriggers.

All lock pins must be engaged before using scaffold. Lock nut screws onto threaded nipple after scaffold assembly and platform height

adjustment. DO NOT HAMMER LOCK PINS. If locks stick, clean and grease lightly. Move back and forth to free movement.

CAUTION

-The truss channels within which the platforms are secured in place, should be inspected prior to use. Any debris, accumulation of

drywall mud, etc. must be removed prior to use. After placing the platform within the truss channels, always inspect to see that the

platform is properly seated into place.

Page 5

-Always lock the brakes on scaffold casters before climbing the End Frame Access Ladders. For easier locking and unlocking of the

casters, turn the brake lever outward. The lever on the casters is to be pressed down until it locks the wheel

-The maximum Distributed Load of a FramePro Scaffold Tower decreases with the number of sections that are stacked.

Base Only 1,000 lbs.

2 Sections 850 lbs.

3 sections 700 lbs.

1. Invert an End Frame Access Ladder. Insert

the casters into the ladder leg bushings, pressing the casters into the bushing by hand

until the hole in the caster stem lines up

with the hole in the scaffold ladder- attach

with safety pins. Repeat this process

for the second End Frame Access Ladder.

ASSEMBLY INSTRUCTIONS

` 2. Turn the End Frame Access Ladder over so that it rests on its casters. Holding an End Frame

Access Ladder with one hand, engage one truss to the ladder leg. Note: The locking pin on

the truss should be disengaged and free to be pushed back and forth. Depress the thumb plate

of the truss lock and align the pin to a predetermined hole in the ladder leg. Release the thumb

plate to engage the spring- loaded Positive Engagement Lock.

3. Hold the second End Frame Access Ladder

with one hand. Repeat Step 2 to attach the

other end of the truss to the second End Frame

Access Ladder.

4. Attach the second truss to the partially

assembled scaffold. Make sure both trusses

are the same height and parallel to the floor.

Do not screw the knurled thumb plate onto

the threaded nipple of the Positive Engagement Lock yet. The spring-loaded pin, when

properly positioned in the ladder leg holes,

will hold the truss in place.

5. Complete the assembly by laying the platform

in place, resting it securely within the platform

ledges of each truss channel. No metal platform

banding should be visible above the vertical lip

Page 6

of the truss channel. Make sure the platform ledges on the truss channel are thoroughly cleaned

and free of debris that would prevent the platform

form seating properly into the trusses.

6. To adjust the platform height move to one end of the scaffold and grasp both Positive

Engagement Locks on the trusses. Depress both thumb plates, pushing the pins out of

the holes in the ladder legs. The trusses are now free to move either up or down on the

ladder frame to the desired platform height. Following height adjustment, release the

thumb plates and allow the spring-loaded pins to engage the nearest ladder leg hole. For

added security tighten pin as shown in picture above.

7. Screw the knurled thumb plate onto the threaded nipple

of the Positive Engagement Lock to positively prevent

the pin from backing out of the hole. Repeat Steps 6-7

at the opposite end of the scaffold making sure the tru sses are at the same height and parallel to the floor. Check

again to see that the platform is properly secured within

the truss channels.

Assembly of the Guardrails

WARNING

Guardrails shall be used at working platform heights of 6 foot

or higher. ( OSHA 1910.28, 1910.29, AND ANSI A10.8 )

Check with state and local codes or private company directives for

variances which may be more restrictive than federal codes.

1.) Install guardrails by inserting four corner pegs in their corresponding receivers. Insert safety pins to

keep it in place. Make sure end gates are ALWAYS closed and locked when not being actively used.

Page 7

2.)Rail will feel “loose” this is normal. Pull gently up to ensure proper locking.

Assembly of the Outriggers

WARNING

Before scaffold units are to be stacked, a set of (4) Outriggers (MFS-

NOR, MFS-WOR) with casters shall be installed on the base section

of scaffolding. (OSHA 1910.29) The casters must be the same size as

the casters in the base scaffold

.

1. Insert a caster into each 2. Attach one Outrigger (with caster) 3. Lock the casters on the

Outrigger. Casters used in to each of the four (4) ladder legs Outriggers each time

the Outriggers must be the of the base scaffold section. you lock the casters on

same size as the casters used Lock them into place by using the base scaffold. This

in the base scaffold. (2) safety snap pins. is to be done prior to

the same size as the ca- to climbing the tower.

sters used in the base For easier locking and

scaffold. unlocking of the casters,

turn the brake lever outward.

Assembly of a FramePro Scaffold Tower

CAUTION

Do not erect a free-standing FramePro Scaffold Tower more than three

(3) Sections high. Use a team of at least two (2) persons to erect a

FramePro Scaffold Tower – one on the ground handing up components

and a second person on the tower installing the components.

1. Assemble a Basic FramePro Scaffold base by following

the instructions in this booklet

.

2. Install a set of four (4) outriggers on the base section if

3. you are planning on stacking the MFS more than its

single height. by following the instruction in this booklet.

4. Lock the casters on the scaffold and four (4) outriggers

Page 8

before proceeding. For easier locking and unlocking

of the casters, turn the brake levers outward.

5. One person climbs onto the platform of the

Base scaffold. From the ground, the second

person hands up components of the first stacked section

.

6. Install the two (2) End Frame Access Ladder. First, then install the two (2) side Trusses at the desired platform height. Lock

all four (4) Positive Engagement Locks on the Trusses

7. Install the platform securely within the platform Ledges of the truss channels.

.

8. While moving from one platform to another, it is

neccessary, to carefully step around the End Frame

Access Ladder, to the outside of the ladder. Keep

your body close to the ladder at all times during

this move.

scaffold section and the four outriggers must be locked

prior to this movement. For easier locking and

unlocking of the casters, turn the brake levers outward.

REMEMBER: All casters in the base

9. Repeat Steps 4-8 if another section is to

be stacked ( not to exceed 3 high ). When

necessary, use a rope to bring up components

from the person on the ground

.

Page 9

Complete sections with platforms should be stacked. Each stacked section includes two ( 2 ) End Frame

Access Ladders two ( 2 ) adjustable trusses, and one ( 1 ) platform.

To get maximum height from a FramePro Products Multi-Functional Scaffold set trusses just below the

top of the ladders.

DO NOT roll a FramePro Scaffold tower when workers is on the platform

Climbing A FramePro Mobile Scaffold

Lock All Casters before Climbing The Scaffold

Before climbing the scaffold, lock all four (4) casters on the base section of the scaffold. Also lock all outrigger casters if outriggers

have been installed on the base section. DO NOT CLIMB a FramePro Mobile Scaffold when the casters are unlocked. For easier

locking and unlocking of the casters, turn the brake levers outward.

Keep Your Body Close to the Scaffold As You Climb

Page 10

Mount and dismount the platform from the top center of the End Frame Access Ladder. Do not swing around the scaffold. Do

not try to pull or “scoot” yourself from one location to another while standing on the platform. Climb down from platform to

the floor. Unlock the casters and move the scaffold in a safe manner. Relock the casters before climbing up to the working

platform. For easier locking and unlocking of the casters, turn the brake lever outward.

Loading...

Loading...